Siemens SIMATIC S7-400H User Manual

Important Notes, Contents

SIMATIC

S7-400H Programmable

Controller

Fault-Tolerant Systems

Manual

This manual has the order number:

6ES7988-8HA10-8BA0

Fault-Tolerant Systems in

Automation Engineering

S7-400H Installation Options

Getting Started

System and Operating Modes of

the S7-400H

Link-up and Update

Using I/O on the S7-400H

Communications

Configuring with STEP 7

Failure and Replacement of

Components During Operation

1

2

3

4

5

6

7

8

9

Edition 07/2000

A5E00068197-04

Modifications to the System while

in Operation

Appendices

Characteristic Values of

Redundant Programmable Logic

Controllers

Separate Operation

Converting from S5-H to S7-400H

Differences between

Fault-Tolerant Systems and

Standard Systems

Function Modules and

Communication Processors Used

on the S7-400H

Glossary, Index

10

A

B

C

D

E

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

!

!

!

Danger

indicates that death, severe personal injury or substantial property damage will result if proper precautions are not taken.

Warning

indicates that death, severe personal injury or substantial property damage can result if proper precautions are not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

Warning

!

Trademarks

Copyright Siemens AG 1998 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created b y patent grant or registration of a utility model or design, are

reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschaeftsgebiet Industrie-Automatisierungssysteme

Postfach 4848, D- 90327 Nuernberg

Siemens Aktiengesellschaft A5E00068197

Index-2

This device and its components may only be used for the applications described in the catalog or the

technical descriptions, and only in connection with devices or components from other manufacturers

which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and operated and maintained as recommended.

SIMATIC, SIMATIC HMI and SIMATIC NET are registered trademarks of SIEMENS AG.

Some of other designations used in these documents are also registered trademarks; the owner’s rights

may be violated if they are used by third parties for their own purposes.

Disclaimer of Liability

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be precluded entirely, we cannot guarantee full agreement. However, the

data in this manual are reviewed regularly and any necessary corrections included in subsequent editions. Suggestions for improvement are welcomed.

Siemens AG 1998

Technical data subject to change.

S7-400H Programmable Controller Fault-Tolerant Systems

07/2000

Important Notes

Purpose of the manual

The present manual is intended for persons involved in the areas of configuration,

commissioning and servicing of programmable logic control systems.

To help you get familiar with the product, we recommend that you start with the

example in Chapter 3. It shows you an easy method of getting started on the subject

of fault-tolerant systems.

Basic knowledge required

In order to understand the manual, you will need to be familiar with the general

principles of automation technology.

Knowledge of S7 programs is also a prerequisite; you can read more about S7

programs in the

standard software while you are configuring, you should also be familiar with running

the standard software, as explained in the STEP 7 User Manual.

Programming with STEP 7

manual. As you need the STEP 7

Validity of the manual

The manual is valid for CPU 417-4H firmware version V2.1.0 or higher and option

package S7 H Systems, version V5.1 or higher.

S7-400H Programmable Controllers, Fault-Tolerant Systems

A5E00068197-04

iii

Important Notes

Online Help

In addition to the manual, detailed support on how to use the software is provided by

the online Help system integrated in the software.

The Help system can be accessed using a number of interfaces:

In the Help menu are a number of commands: Contents opens the Help index.

How to Use Help provides detailed instructions on how to use online Help.

Context-sensitive Help provides information on the current context – for

Another form of context-sensitive Help is the status bar. A brief explanation of

A brief explanation of the toolbar buttons is also shown when the mouse pointer

You will find help on fault-tolerant systems at Call Help on options packages,

configuring fault-tolerant systems.

example, on an open dialog box or an active window. It is accessed by means

of the “Help” button or F1.

each menu command is displayed here when you point the mouse pointer at

the menu command.

comes to rest for a short time on the buttons.

If you would like to read information from online Help in printed form, you can print

individual topics, books or the entire Help.

Feedback on documentation

We need your help to enable us to provide you and future users with optimum

documentation. Should you have any remarks on this

fill out the remarks form at the end of the manual and return it to the address shown

on the form. Please also indicate your personal opinion of the manual.

SIMATIC Training Center

We offer a number of courses to help you become familiar with the SIMATIC S7

programmable logic controller. Please contact your regional training center or the

central training center in D-90327 Nuremberg.

Phone: +49 (911) 895-3200.

Further support

The Nuremberg H/F Competence Center holds a special workshop on fault-tolerant

SIMATIC S7 programmable logic controllers. In addition, the H/F Competence Center

will provide on-site assistance with configuration, commissioning and other problems.

manual or online Help

, please

Further information can be obtained as follows:

Phone: +49 (911) 895-4759

Fax: +49 (911) 895-4519

iv

S7-400H Programmable Controllers, Fault-Tolerant Systems

A5E00068197-04

SIMATIC Customer Support Hotline

Available 24 hours a day, worldwide:

Nuremberg

Johnson City

SIMATIC Hotline

Important Notes

Singapore

Worldwide (Nuremberg)

T echnical Support

(FreeContact)

Local tim e : Mon. through

Fri. 7.00 a.m. to 5.00 p.m.

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

E-mail: techsupport@

ad.siemens.de

GMT: +1:00

Europe / Africa (Nuremberg)

Authorization

Local time: Mon. through

Fri. 7.00 a.m. to 5.00 p.m.

Phone: +49 (911) 895-7200

Fax: +49 (911) 895-7201

E-mail: authorization@

nbgm.siemens.de

GMT: +1:00

The SIMATIC Hotline languages are normally German and English; French, Italian and Spanish are also spoken on

the Authorization Hotline.

Worldwide (Nuremberg)

T echnical Support

(subject to charge, with SIMATIC Card

only)

Local time: Mon. through

Fri. 0.00 a.m. to 12.00 p.m.

Phone: +49 (911) 895-7777

Fax: +49 (911) 895-7001

GMT: +01.00

America (Johnson City)

T echnical Support and

Authorization

Local time: Mon. through

Fri. 8 a.m. to 5.00 p.m.

Phone: +1 423 461-2522

Fax: +1 423 461-2289

E-mail: simatic.hotline@

sea.siemens.com

GMT: –5:00

Asia/Australia (Singapore)

T echnical Support and

Authorization

Local time: Mon. through

Fri. 8.30 a.m. to 5.30 p.m.

Phone: +65 740-7000

Fax: +65 740-7001

E-mail: simatic.hotline@

sae.siemens.com.sg

GMT: +8:00

S7-400H Programmable Controllers, Fault-Tolerant Systems

A5E00068197-04

v

Important Notes

SIMATIC Customer Support Online Services

SIMATIC Customer Support provides you with comprehensive additional information

in SIMATIC products by means of its online services:

You can obtain up–to–date information

– on the Internet at http://www.ad.siemens.de/simatic

Current product information leaflets and downloads which you may find useful

for your product:

– on the Internet at http://www.ad.siemens.de/simatic–cs

– From our Bulletin Board System (BBS) in Nuremberg (

Support Mailbox)

by dialing +49 (911) 895-7100.

SIMATIC Customer

To dial the mailbox, use a modem having up to V.34 (28.8 kbps) and set its

parameters as follows: 8, N, 1, ANSI, or dial in using ISDN (x.75, 64 kbps).

You can find your local point–of–contact for Automation & Drives in our contacts

database

– on the Internet at

http://www3.ad.siemens.de/partner/search.asp

vi

S7-400H Programmable Controllers, Fault-T olerant Systems

A5E00068197-04

Contents

1 Fault-Tolerant Systems in Automation Engineering 1-1. . . . . . . . . . . . . . . . . . . . . . .

1.1 Redundant Programmable Logic Controllers in the SIMATIC Series 1-2. . . .

1.2 Increasing System Availability 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 S7-400H Installation Options 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Base System of the S7-400H 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 I/O for the S7-400H 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Communication 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Configuration and Programming Applications 2-7. . . . . . . . . . . . . . . . . . . . . . . .

2.5 User Program 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Documentation 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Getting Started 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Requirements 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Configuring Hardware and Starting Up the S7-400H 3-3. . . . . . . . . . . . . . . . . .

3.3 Examples of Fault-Tolerant System Response in the Event of Faults 3-5. . .

4 System and Operating Modes of the S7-400H 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Introduction 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 System Modes of the S7-400H 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Operating Modes of the CPUs 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 STOP Operating Mode 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 STARTUP Operating Mode 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 LINK-UP and UPDATE Operating Modes 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 RUN Operating Mode 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 HOLD Operating Mode 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.6 ERROR-SEARCH Operating mode 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Time Response 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Link-up and Update 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Effects of Link-up and Update 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Functional Sequence of Link-up and Update 5-3. . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Process of Link-up 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Process of Updating 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Switch to CPU with modified configuration 5-12. . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Block Link-up and Update 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Time Monitoring 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Time Behavior 5-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Determination of the Monitoring Times 5-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Influences on the Time Behavior 5-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Performance Values for Link-up and Update 5-26. . . . . . . . . . . . . . . . . . . . . . . .

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

vii

Contents

5.4 Special Features during Link-up and Update 5-28. . . . . . . . . . . . . . . . . . . . . . . .

6 Using I/O on the S7-400H 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Introduction 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Using a Single-Channel, One-Sided I/O 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Using Single-Channel, Switched I/O 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Connecting a Redundant I/O 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Communications 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Fundamentals and Basic Concepts 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Suitable Networks 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Industrial Ethernet 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 PROFIBUS 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Supported Communication Services 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Communications via Fault-Tolerant S7 Connections 7-7. . . . . . . . . . . . . . . . . .

7.4.1 Communications between Fault-Tolerant Systems 7-9. . . . . . . . . . . . . . . . . . .

7.4.2 Communications between Fault-Tolerant Systems and a

Fault-Tolerant CPU 7-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.3 Communications between Fault-Tolerant Systems and PCs 7-12. . . . . . . . . . .

7.5 Communications via S7 Connections 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Communications via S7 Connections – One-Sided Mode 7-13. . . . . . . . . . . . .

7.5.2 Communications over Redundant S7 Connections 7-15. . . . . . . . . . . . . . . . . . .

7.5.3 Communications via a Point-to-Point CP on the ET200M 7-16. . . . . . . . . . . . .

7.5.4 Random Connection with Single-channel Systems 7-17. . . . . . . . . . . . . . . . . . .

8 Configuring with STEP 7 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Installing the Options Package 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Configuring with STEP 7 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Rules for H Station Equipment 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Configuring Hardware 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Configuring Networks 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Programming Device Functions in STEP 7 8-6. . . . . . . . . . . . . . . . . . . . . . . . . .

9 Failure and Replacement of Components During Operation 9-1. . . . . . . . . . . . . . .

9.1 Failure and Replacement of Components in Central Racks

and Expansion Racks 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1 Failure and Replacement of a Central Processing Unit CPU 417-4H 9-3. . . .

9.1.2 Failure and Replacement of a Power Supply Module 9-5. . . . . . . . . . . . . . . . .

9.1.3 Failure and Replacement of an Input/Output or Function Module 9-6. . . . . . .

9.1.4 Failure and Replacement of a Communication Processor 9-7. . . . . . . . . . . . .

9.1.5 Failure and Replacement of a Synchronization Submodule

or Fiber-Optic Cable 9-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.6 Failure and Replacement of an IM 460 and IM 461 Interface Module 9-11. . .

9.2 Failure and Replacement of Components of the Distributed I/O 9-12. . . . . . . .

9.2.1 Failure and Replacement of a PROFIBUS-DP Master 9-13. . . . . . . . . . . . . . . .

9.2.2 Failure and Replacement of a redundant PROFIBUS-DP

Interface Module 9-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S7-400H Programmable Controller Fault-Tolerant Systems

viii

A5E00068197-04

Contents

9.2.3 Failure and Replacement of a PROFIBUS-DP Slave 9-15. . . . . . . . . . . . . . . . .

9.2.4 Failure and Replacement of PROFIBUS-DP Cables 9-16. . . . . . . . . . . . . . . . . .

10 Modifications to the System while in Operation 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Possible Hardware Modifications 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Adding Components in PCS7 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 PCS7, Step 1: Modification of Hardware 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 PCS7, Step 2: Offline Modification of the Hardware Configuration 10-8. . . . . .

10.2.3 PCS7, Step 3: Stopping the Standby CPU 10-9. . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.4 PCS7, Step 4: Loading new Hardware Configuration in

the Standby CPU 10-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.5 PCS7, Step 5: Switch to CPU with modified configuration 10-11. . . . . . . . . . . . .

10.2.6 PCS7, Step 6: Transition to the Redundant System Mode 10-13. . . . . . . . . . . . .

10.2.7 PCS7, Step 7: Changing and Loading User Program 10-14. . . . . . . . . . . . . . . . .

10.2.8 Use of free channels on an existing module 10-15. . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Removing Components in PCS7 10-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.1 PCS7, Step I: Offline Modification of the Hardware Configuration 10-17. . . . . .

10.3.2 PCS7, Step II: Changing and Loading User Program 10-18. . . . . . . . . . . . . . . . .

10.3.3 PCS7, Step III: Stopping the Standby CPU 10-19. . . . . . . . . . . . . . . . . . . . . . . . .

10.3.4 PCS7, Step IV: Loading new Hardware Configuration in

the Standby CPU 10-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.5 PCS7, Step V: Switch to CPU with modified configuration 10-20. . . . . . . . . . . . .

10.3.6 PCS7, Step VI: Transition to the Redundant System Mode 10-22. . . . . . . . . . . .

10.3.7 PCS7, Step VII: Modification of Hardware 10-23. . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Adding Components in STEP 7 10-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.1 STEP 7, Step 1: Modification of Hardware 10-25. . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.2 STEP 7, Step 2: Offline Modification of the Hardware Configuration 10-26. . . .

10.4.3 STEP 7, Step 3: Expanding and Loading Organization Blocks 10-26. . . . . . . . .

10.4.4 STEP 7, Step 4: Stopping the Standby CPU 10-27. . . . . . . . . . . . . . . . . . . . . . . .

10.4.5 STEP 7, Step 5: Loading new Hardware Configuration in

the Standby CPU 10-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.6 STEP 7, Step 6: Switch to CPU with modified configuration 10-28. . . . . . . . . . .

10.4.7 STEP 7, Step 7: Transition to the Redundant System Mode 10-30. . . . . . . . . . .

10.4.8 STEP 7, Step 8: Changing and Loading User Program 10-31. . . . . . . . . . . . . . .

10.4.9 Use of free channels on an existing module 10-32. . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Removing Components in STEP 7 10-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.1 STEP 7, Step I: Offline Modification of the Hardware Configuration 10-34. . . . .

10.5.2 STEP 7, Step II: Changing and Loading User Program 10-35. . . . . . . . . . . . . . .

10.5.3 STEP 7, Step III: Stopping the Standby CPU 10-36. . . . . . . . . . . . . . . . . . . . . . . .

10.5.4 STEP 7, Step IV: Loading new Hardware Configuration

in the Standby CPU 10-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.5 STEP 7, Step V: Switch to CPU with modified configuration 10-37. . . . . . . . . . .

10.5.6 STEP 7, Step VI: Transition to the Redundant System Mode 10-39. . . . . . . . . .

10.5.7 STEP 7, Step VII: Modification of Hardware 10-40. . . . . . . . . . . . . . . . . . . . . . . . .

10.5.8 STEP 7, Step VIII: Modifying and loading organization blocks 10-41. . . . . . . . .

10.6 Changing the CPU Parameters 10-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.1 Step A: Changing the CPU Parameters Offline 10-43. . . . . . . . . . . . . . . . . . . . . .

10.6.2 Step B: Stopping the Standby CPU 10-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.3 Step C: Loading new Hardware Configuration in the Standby CPU 10-44. . . . .

10.6.4 Step D: Switch to CPU with modified configuration 10-45. . . . . . . . . . . . . . . . . . .

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

ix

Contents

10.6.5 Step E: Transition to the Redundant System Mode 10-46. . . . . . . . . . . . . . . . . . .

10.7 Changing the Memory Components of the CPU 10-47. . . . . . . . . . . . . . . . . . . . .

10.7.1 Expand the main and/or load memory 10-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.2 Changing the type of load memory 10-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8 Perform operating system update 10-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Characteristic Values of Redundant Programmable Logic Controllers A-1. . . . . .

A.1 Basic Concepts A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Comparison of MTBFs for Selected Configurations A-4. . . . . . . . . . . . . . . . . .

A.2.1 System Configurations With Central I/O A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2 System Configurations With Distributed I/O A-6. . . . . . . . . . . . . . . . . . . . . . . . .

A.2.3 Comparison of System Configurations With Standard and

Fault-Tolerant Communications A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Separate Operation B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Converting from S5-H to S7-400H C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 General Information C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 Configuration, Programming and Diagnostics C-2. . . . . . . . . . . . . . . . . . . . . . .

D Differences between Fault-Tolerant Systems and Standard Systems D-1. . . . . . .

E Function Modules and Communication Processors Used on the S7-400H E-1. .

Glossary Glossary-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

Fault-Tolerant Systems in Automation Engineering

This chapter contains an introduction to redundant and fault-tolerant programmable

logic controllers.

In Section You Will Find On Page

1.1 Redundant Programmable Logic Controllers in the SIMATIC

1.2 Increasing System Availability 1-4

1

1-2

Series

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

1-1

Fault-Tolerant Systems in Automation Engineering

1.1 Redundant Programmable Logic Controllers in the SIMATIC Series

Economic, and thus resource-sparing and low-pollution production can be

achieved nowadays in all branches of industry only by employing a high degree of

automation. At the same time there is a demand for fail-safe programmable logic

controllers with the greatest degree of distribution possible.

Redundant programmable logic controllers from Siemens have proved themselves

in operation and thousands are in service.

Perhaps you are already familiar with one of the fault-tolerant systems such as the

SIMATIC S5-115H and S5-155H, or the fail-safe S5-95F and S5-115F systems.

The S7-400H is the latest fault-tolerant PLC and we will be presenting it on the

pages that follow. It is a member of the SIMATIC S7 system family, meaning that

you can fully avail yourself of all the advantages of the SIMATIC S7.

Operating objectives of Redundant PLCs

Redundant programmable logic controllers are used in practice with the aim of

achieving a higher degree of availability or fault tolerance.

Redundant programmable logic

controllers, for example:

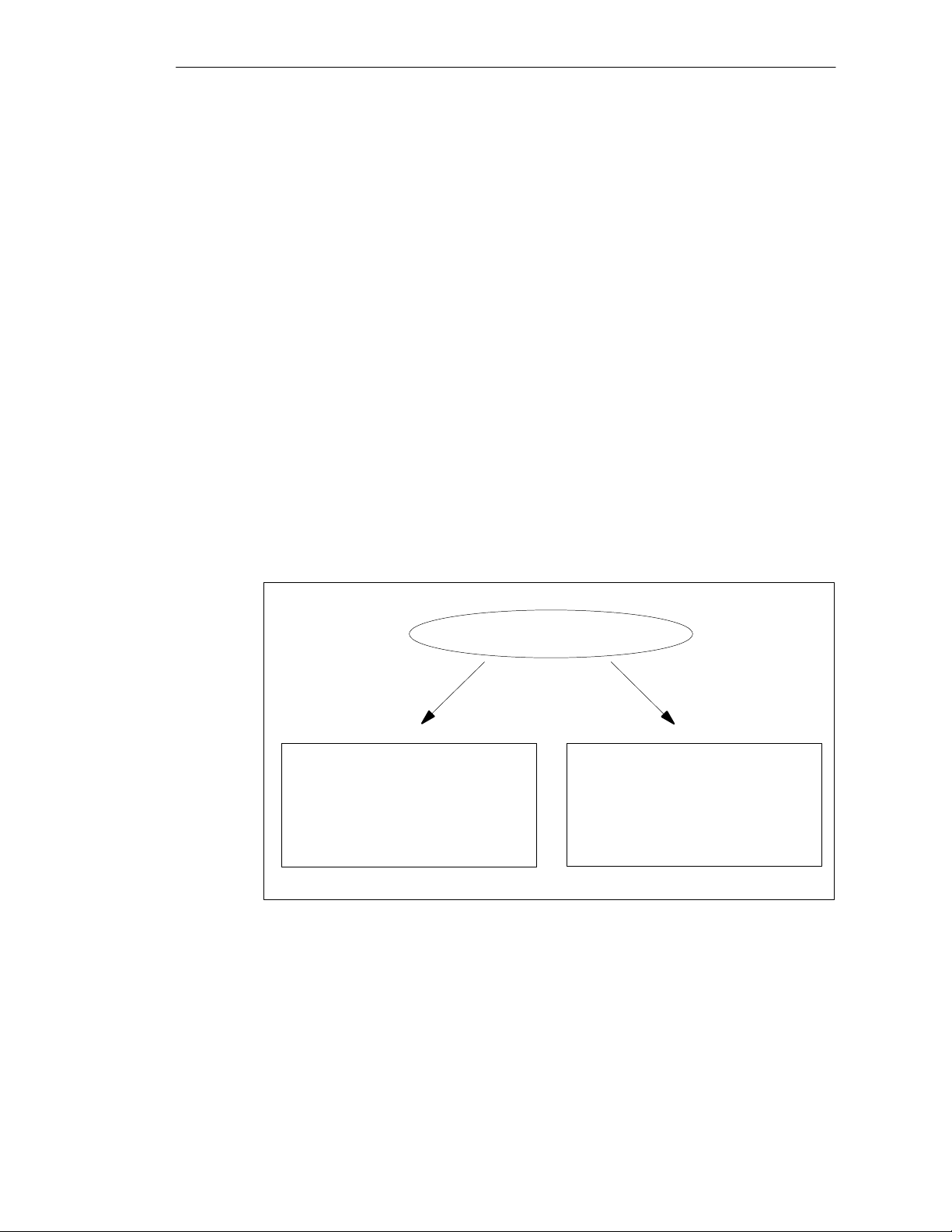

Fault-tolerant 1-out-of-2 systems

Objective:

Reduce the probability of losses of

production by switching to a standby

system

Figure 1-1 Operating Objectives of Redundant Programmable Logic Controllers

Fail-safe 2-out-of-2-systems

Objective:

Protect life, the environment and

investments by safely

disconnecting to a secure ”off”

position

Note the difference between fault-tolerant systems and fail-safe systems. The

S7-400H is a fault-tolerant programmable logic controller that can be used only

with additional means for controlling processes relevant to safety.

1-2

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

Fault-Tolerant Systems in Automation Engineering

Why do we have fault-tolerant programmable logic controllers?

The objective of using high-availabilty programmable logic controllers is a reduction

of losses of production. It does not matter whether the losses are caused by an

error or as a result of maintenance work.

The higher the costs of a stoppage, the more worthwhile it is to use a fault-tolerant

system. The generally higher investment costs of fault-tolerant systems are quickly

compensated by the avoidance of losses of production.

Software redundancy

In a large number of applications, requirements in respect of the quality of

redundancy or the number of system sections that necessitate redundant PLCs

are not high enough to warrant the use of a specific fault-tolerant system.

Frequently, simple software mechanisms are sufficient to allow continuation of a

failed control task on a substitute system in the event of an error.

The “SIMATIC S7 Software Redundancy” options software can run on S7-300 and

S7-400 standard systems to control processes that tolerate transfer times to a

substitute system within seconds, such as water works, water treatment systems

or traffic flows.

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

1-3

Fault-Tolerant Systems in Automation Engineering

1.2 Increasing System Availability

The S7-400H programmable logic controller meets these high requirements for

availability, intelligence and distribution that are required of state-of-the-art

programmable logic controllers. Further, it features all the functions for acquiring

and preparing process data and for controlling, regulating and monitoring units and

systems.

System-wide universality

The S7-400H programmable logic controller and all other SIMATIC components,

such as the SIMATIC PCS7 control system, are harmonized. Total system

universality, from the supervisory console to the sensors and actuators, is a matter

of course and guarantees maximum system performance.

Single-user

OS

*) not possible with firmware version 2.0.0

S7-300

ET 200B

Report printer

ET 200L

Server Server

S7-400

Client Client

S7-400H

system

ET 200M

ET 200X

Figure 1-2 Universal Automation Solutions with SIMATIC

Engineering

system

S7-400 with

CPU 417-4H *)

Bus link DP/PA

Supervisory console

LAN (redundant)

Programmable logic

controllers

PROFIBUS DP (redundant)

Distributed I/O

Sensors/

actuators

Graduated availability by duplicating components

The S7-400H is designed with redundancy so that it remains available at all

events. This means that all major components are duplicated.

The components that are duplicated as a matter of policy are the central

processing unit (CPU), the power supply and the hardware for interconnecting the

two central processing units.

You can decide for yourself whether you wish to duplicate more components for

the process you are going to automate and thus enhance their availability.

S7-400H Programmable Controller Fault-T olerant Systems

1-4

A5E00068197-04

Redundant nodes

Redundant nodes represent the fault tolerance of systems with redundant

components. The independence of a redundant node is given when the failure of a

component within the node does not result in reliability constraints in other nodes

or in the entire system.

The availability of the entire system can be illustrated in a simple manner by

means of a block diagram. With a 1-out-of-2 system, one component of the

redundant node may fail without impairing the operability of the overall system. The

weakest link in the chain of redundant nodes determines the availability of the

overall system.

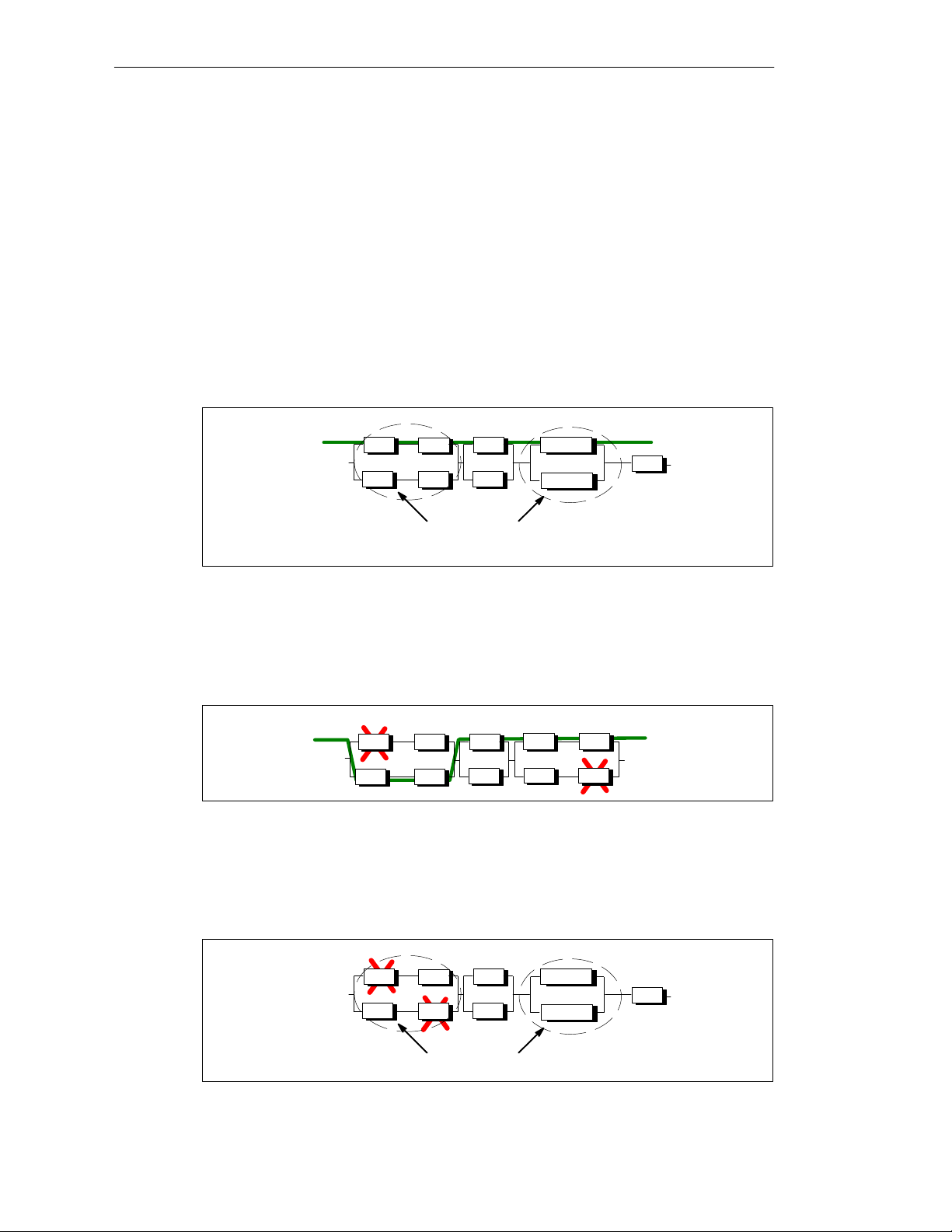

Without malfunction (Figure 1-3).

Fault-Tolerant Systems in Automation Engineering

PS CPU

PS

CPU

Redundant nodes with 1-out-of-2 redundancy

Bus

Bus

IM 153-2

SM

IM 153-2

Figure 1-3 Example of Redundancy in a Network without Malfunction

With malfunction

In Figure 1-4, one component may fail per redundant node without the functionality

of the overall system being impaired.

Bus

Bus

CPU

CP

CP

Figure 1-4 Example of Redundancy in a 1-out-of-2 System with Malfunction

CP

CP

CPUCPU

CPU

Failure of a redundant node (total failure)

In Figure 1-5, the entire system is no longer operable since both subcomponents

have failed in a 1-out-of-2 redundant node (total failure).

PS CPU

PS

Redundant nodes with 1-out-of-2 redundancy

Figure 1-5 Example of Redundancy in a 1-out-of-2 System with Total Failure

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

CPU

Bus

Bus

IM 153-2

SM

IM 153-2

1-5

Fault-Tolerant Systems in Automation Engineering

1-6

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

S7-400H Installation Options

The first part of the description starts with the basic configuration of the

fault-tolerant S7-400H programmable controller and the components making up

the S7-400H base system. We then describe the hardware components with which

you can expand this base system.

The second part describes the software applications with which you can configure

and program the S7-400H. In addition, a description is given of the additions and

extensions, compared to the S7-400 standard system, that you will require for

programming your user program in order to be able to react specifically to the

properties of the S7-400H that enhance availability.

In Section You Will Find On Page

2.1 Base System of the S7-400H 2-3

2.2 I/O for the S7-400H 2-5

2.3 Communications 2-6

2.4 Configuration and Programming Applications 2-7

2.5 User Program 2-8

2.6 Documentation 2-9

2

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

2-1

S7-400H Installation Options

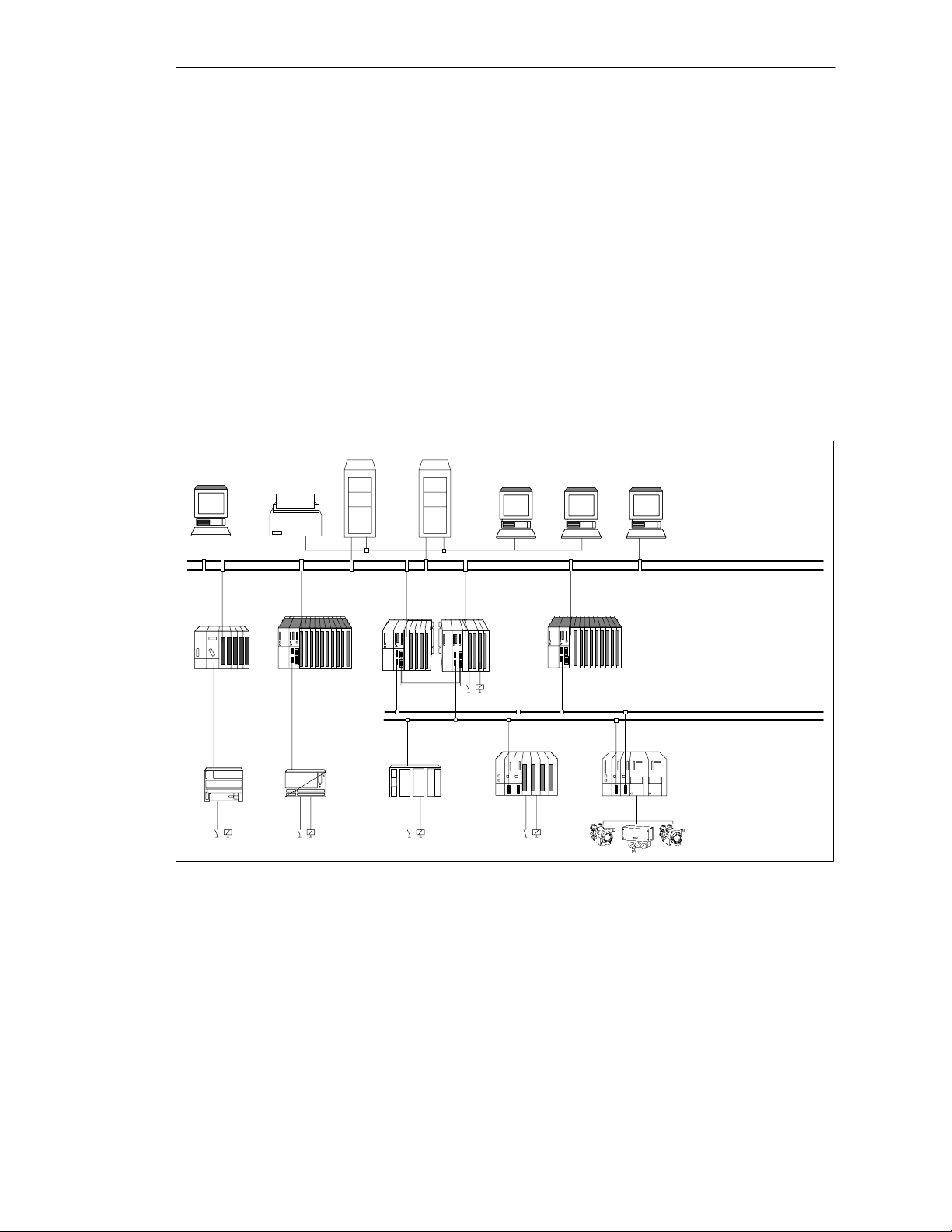

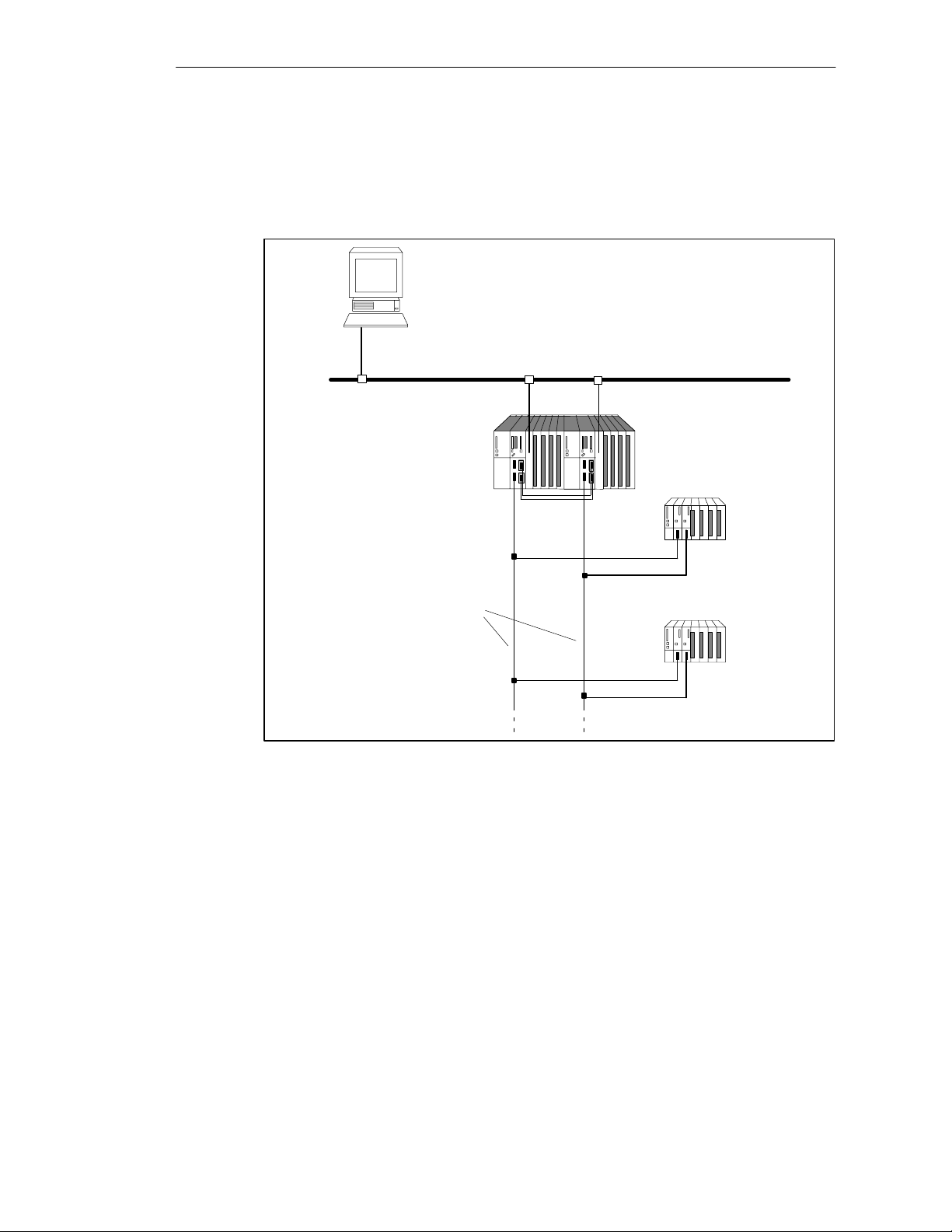

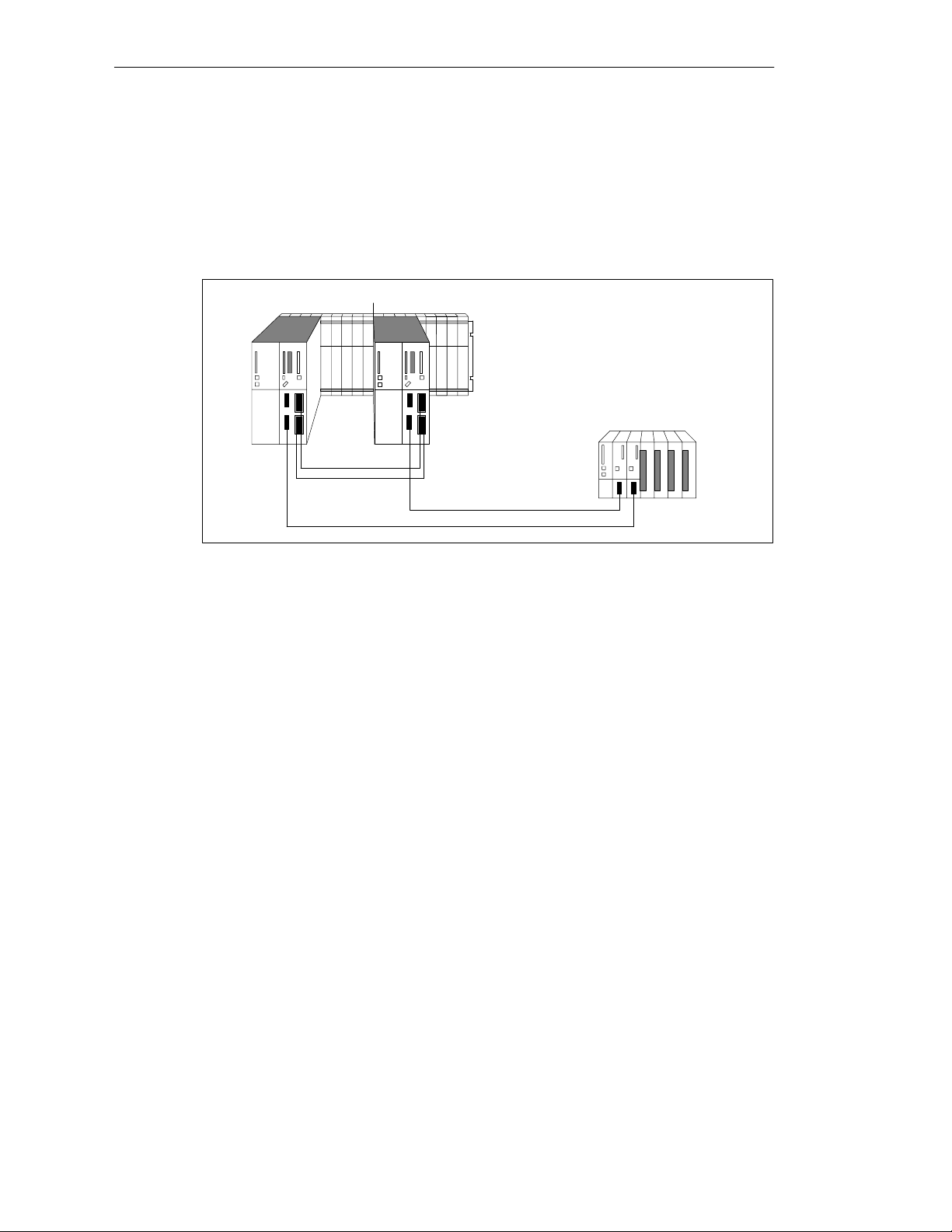

Figure 2-1 shows an example of the configuration of an S7-400H with common

distributed I/O and a connection to a redundant system bus. On the next few

pages we will describe step by step the hardware and software components

necessary for configuring and operating the S7-400H.

Operator station

(system visualization)

redundant system bus (PROFIBUS or Ethernet)

S7-400H PLC

ET 200M distributed I/O

redundant PROFIBUS-DP

Figure 2-1 Overview

Further information

The components of the S7-400 standard system are also used in the fault-tolerant

S7-400H programmable logic controller. A detailed description of all the hardware

components of the S7-400 and S7-400H may be found in the Reference Manual

S7-400, M7-400 Programmable Controllers, Module Specifications

The same rules as for a standard S7-400 system apply to designing the user

program and the usage of blocks for the fault-tolerant S7-400H programmable

logic controller. Please take note of the descriptions in the

STEP 7

Functions

manual and in the

ET 200M distributed I/O

.

Programming with

System Software for S7-300/400, System and Standard

Reference Manual.

2-2

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

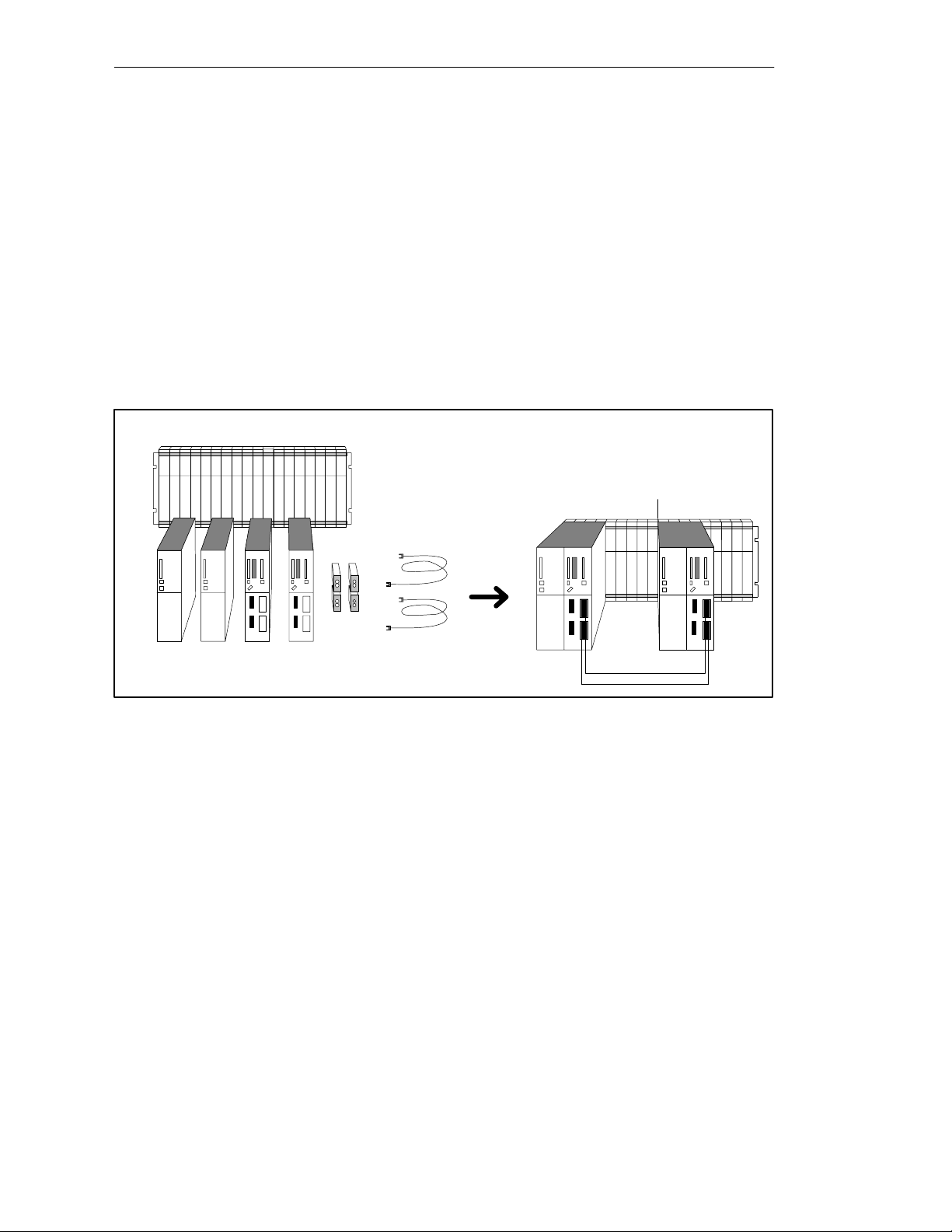

2.1 Base System of the S7-400H

Hardware of the Base System

By base system of the S7-400H we mean the minimum configuration of the

S7-400H. The base system consists of all the requisite hardware components that

make up the fault-tolerant control system. Figure 2-2 shows the components in the

installation.

You can upgrade the base system by means of standard modules from the

S7-400. There are restrictions in the case of the function and communication

processors (see appendix E).

S7-400H Installation Options

Rack UR2H

2 PS 2 CPUs 2 fiber-optic cables

Figure 2-2 Hardware of the S7-400H Base System

4 synchronization

submodules

CPU 417-4 H central processing unit

At the heart of the S7-400H are the two central processing units CPU 417-4H.

Setting of the synchronization submodules, which have to be plugged into the

CPU, defines the rack numbers. In the following we will refer to the CPU in rack 0

as CPU 0,and to the CPU in rack 1 as CPU 1.

S7-400H base system

Rack 0

Rack 1

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

2-3

S7-400H Installation Options

Mounting rack for S7-400H

We recommend you the UR2-H mounting rack for the S7-400H. The mounting rack

makes it possible to configure two separate subsystems, each containing nine

slots, and is suitable for installation in 19” cabinets.

Alternatively, you can also configure the S7-400H on two separate mounting racks.

Two mounting racks, the UR1 and UR2, are available for this purpose.

Power supply

As a power supply, you will require for each CPU 417-4 H – or, to be more precise,

for each of the two subsystems of the S7-400H – a power supply module from the

standard range of the S7-400.

Power supply modules for rated input voltages of 24 V DC and 120/230 V AC are

available with input powers of 4, 10 and 20 A.

To enhance the availability of the power supply, you can also use two redundant

power supplies in each subsystem. In this case you should use the PS 407 10 A R

power supply module for rated voltages of 120/230 V AC with an output power of

10 A.

Synchronization submodules

The synchronization submodules are used to connect the two central processing

units. They are installed in the central processing units and interconnected by

means of fiber-optic cables.

Two synchronization submodules have to be inserted in each CPU.

Fiber-optic cables

The fiber-optic cables are inserted into the synchronization submodules and form

the physical connection (redundant link) between the two central processing units.

You will find further information on handling and adjusting the synchronization

submodules and the fiber-optic cables in the

Controllers, Module Specifications

Programmable Controllers, Hardware and Installation

S7-400, M7-400 Programmable

Reference Manual and in the

Manual.

S7-400, M7-400

2-4

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

2.2 I/O for the S7-400H

For the S7-400H you can use virtually any of the input/output modules featured in

the SIMATIC S7 system range. The I/O can be used in

• central racks

• expansion units

• distributed over PROFIBUS DP.

The function modules (FMs) and communication processors (CPs) that can be

used in the S7-400H will be found in Appendix E.

I/O configuration versions

In addition to the power supplies and central processing units that are always used

as redundant modules, there are the following configuration versions for the

input/output modules:

• Single-channel, one-sided configuration with normal availability

S7-400H Installation Options

With the single-channel, one-sided configuration single input/output modules

are present (single-channel). The input/output modules are located in just one

of the subsystems and are only addressed by that subsystem.

• Single-channel, switched configuration with enhanced availability

With the single-channel switched (distributed) configuration single input/output

modules are present (single-channel) but can be addressed by either

subsystem.

Further information

You will find detailed information on the usage of I/O in Chapter 6.

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

2-5

S7-400H Installation Options

2.3 Communication

For communication tasks on the S7-400H you can use almost any communications

components offered in the SIMATIC system range.

This applies to communication components used either with central I/O or

distributed I/O such as

• system buses (Industrial Ethernet, PROFIBUS)

• point-to-point connection

Availability of communications

You can vary the availability of communications with the S7-400H. There are

different solutions for the S7-400H in keeping with your communication

requirements. They range from a simple linear network structure to a redundant

optical two-fiber loop.

Fault-tolerant communication over PROFIBUS or Industrial Ethernet is supported

entirely with S7 communication functions.

Programming and configuration

Apart from the use of additional hardware components, there are basically no

differences with regard to configuration and programming compared to standard

systems. Fault-tolerant connections have to be configured only; specific

programming is not necessary.

All communication functions required for operating fault-tolerant communications

have been integrated in the operating system of CPU 417-4H and run

automatically and in the background – for example, monitoring of the

communication connection or automatic switching to a redundant connection in the

event of a malfunction.

Further information

You will find detailed information on the subject of communications with the

S7-400H in Chapter 7.

2-6

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

S7-400H Installation Options

2.4 Configuration and Programming Applications

The S7-400H is configured and programmed with STEP 7 just like any other

SIMATIC S7 programmable logic controller.

After configuration with STEP 7, you treat the S7-400H as a normal S7-400

system.

For you this means that you can use your full knowledge of the SIMATIC S7 and,

for example, only have to take minor constraints into account when writing your

user program. However, there are also H-specific additions to the configuration.

Redundant components are monitored by the operating system, which

independently performs switching in the event of a fault. You have already

configured the information required for this in STEP 7 and it is known to the

system.

You will find detailed information on this subject in online Help and in Chapter 8.

Requisite software

The software components specified in Section 8.1 are required for configuration

and programming.

Optional software

All standard tools, engineering tools and runtime software that can be used on the

S7-400 can, of course, also be used on the S7-400H.

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

2-7

S7-400H Installation Options

2.5 User Program

The rules applicable to the design and programming of the standard S7-400

system apply similarly to the S7-400H.

The user programs are stored in an identical form in the two central processing

units and are executed simultaneously (event-synchronous).

From the viewpoint of user program execution, the S7-400H behaves in exactly the

same manner as a standard system. The synchronization functions are integrated

in the operating system and run automatically and totally in the background. There

is no need to take these functions into account in the user program.

In order to be able to react to the lengthening of the cycle time due to updating, for

example, a few specific blocks allow you to optimize your user program in this

respect.

Specific organization blocks and system functions for the S7-400H

Apart from the blocks that can be used on both the S7-400 and the S7-400H, there

are further additional blocks for the S7-400H with which you can influence the

redundancy functions.

You can react to redundancy errors of the S7-400H with the following organization

blocks:

• OB 70, I/O redundancy errors

• OB 72, CPU redundancy errors

Using system function SFC 90 “H_CTRL” you can inhibit and re-enable link-up and

updates of the 417-4H CPUs. You can also affect the scope and execution of the

cyclical self-test.

Note

With a fail-safe system, the periodic self-tests must not be inhibited and then

enabled again.

For more details refer to the manual

Controllers; Fail-Safe Systems.

Further information

S7-400F and S7-400FH Programmable

2-8

You will find detailed information on the programming of the above-mentioned

blocks in the manual called

Manual called

System Software for S7-300/400, System and Standard Functions

Programming with STEP 7

S7-400H Programmable Controller Fault-T olerant Systems

and in the Reference

A5E00068197-04

.

2.6 Documentation

The following illustration presents an overview of the description of the different

components and possibilities presented by the S7-400H PLC.

Subject Documentation

S7-400H Installation Options

Hardware:

CPU 417-4H

Redundancy-capable power supply

synchronization submodule

rack UR2-H

IM 153-2

H-specific programming:

S7-400H-specific OBs, SFC

S7-400H-specific expansion of the SSL,

events and help on error

Specifically for fault-tolerant systems:

Fault-tolerant Systems

Configuration Options for S7-400H

Getting Started

System Modes for S7-400H

Link-up and Update

I/O, Communications

Configuration with the STEP 7 Option Pack

Failure and Replacement, System Modification

Figure 2-3 User Documentation for Fault-Tolerant Systems

S7/M7-400 standard documentation

Installation

Module Specifications

Instruction List

ET 200M Distributed I/O

STEP 7 documentation

Programming with STEP 7 V5.0

System and Standard Functions

(manual and online Help)

S7-400H PLC

Fault-Tolerant Systems

(manual and online Help)

Note

You will find the manuals listed in Figure 2-3 on the S7-400H product CD.

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

2-9

S7-400H Installation Options

2-10

S7-400H Programmable Controller Fault-T olerant Systems

A5E00068197-04

Getting Started

This guide walks you through the steps that have to be performed to commission

the system by means of a specific example and results in a working application.

You will learn how an S7-400H programmable logic controller operates and

become familiar with its response in the event of a fault.

It takes about one to two hours to work through this example, depending on your

previous experience.

In Section You Will Find On Page

3.1 Requirements 3-2

3.2 Configuring Hardware and Starting Up the S7-400H 3-3

3.3 Examples of Fault-Tolerant System Response in the Event of

Faults

3

3-5

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

3-1

Getting Started

3.1 Requirements

The following requirements must be met:

A permitted version of the STEP 7 standard software and the ”S7 Fault-Tolerant

System” option pack are correctly installed on your programming device (refer to

Section 8.1).

You must have the modules required for the hardware configuration:

• an S7-400H PLC consisting of:

– 1 mounting rack, UR2-H

– 2 power supplies, PS 407 10A

– 2 CPU 417-4 H

– 4 synchronization submodules

– 2 fiber-optic cables

• an ET 200M distributed I/O device having an active backplane bus with

– 2 IM 153-2

– 1 digital input module, SM321 DI 16 x DC24V

– 1 digital output module, SM322 DO 16 x DC24V

• the necessary accessories such as PROFIBUS shielded cables, etc.

3-2

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

3.2 Configuring Hardware and Starting Up the S7-400H

Installing Hardware

To configure the S7-400H as illustrated in Figure 3-1, perform the following steps:

Rack 0 Rack 1

S7-400H PLC

ET 200M

distributed I/O

Getting Started

Figure 3-1 Hardware Configuration

1. Configure the two subunits of the S7-400H PLC as described in the

M7-400 Programmable Controllers, Hardware and Installation/Module

Specifications

manuals. In addition, you must:

– Set the mounting rack number by means of the switches on the

synchronization submodules. The setting is applied by the CPU after

POWER ON and a subsequent memory reset by means of the mode

selector. If the mounting rack number is not set correctly you will not have

online access and the CPU will not run in certain circumstances.

– Insert the synchronization submodules into the CPUs. Then screw up the

additional front bezels to activate them (refer to

Programmable Controllers, Hardware and Installation

S7-400, M7-400

).

– Connect the fiber-optic cables (always connect the two upper

synchronization submodules and the two lower synchronization submodules

of the CPUs). Lay the fiber-optic cable so that it is protected from any

damage.

Make sure with the route wires in addition that the two fiber-optic cables are

always laid so that they are isolated from each other. Laying them

separately enhances their availability and protects then from potential dual

faults in the event, say, of simultaneous interruption of the fiber-optic cables.

In addition, make sure that the fiber -opt ic cables are plugged into the two CPUs

before turning on the power supply or turning on the system. If they are not, the

two CPUs might bot h process the user program as master CPUs.

S7-400,

2. Configure the distributed I/O as described in the

Device

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

manual.

ET 200M Distributed I/O

3-3

Getting Started

3. Connect the programming device to the first CPU 417-4 H (CPU0). This CPU

4. A high-quality RAM test is performed after power on. It requires approximately

5. Perform a memory reset for both CPUs using the mode selector. This applies

should be the master CPU of the S7-400H.

8 seconds per megabyte of RAM. During this time the CPU cannot be

addressed via the multipoint interface and the STOP LED flashes. If there is a

backup battery, the test will not be performed on further POWER ONs.

the set mounting rack numbers of the synchronization modules to the

operating system of the CPU.

6. Perform commissioning individually for each CPU as described in the

M7-400 Programmable Controllers, Hardware and Installation

loading the program carry out a warm restart: first for the CPU you want as

the master CPU, and then for the standby CPU.

7. Switch the two CPUs of the S7-400H to STOP.

Starting up the S7-400H

To start up the S7-400H, perform the following steps:

1. Open the “HProject” in SIMATIC Manager. The configuration is the same as

the hardware configuration described in “Requirements”.

2. Open the hardware configuration of the project by selecting the “Hardware”

object and execute the pop-up menu command Object > Open with the right

mouse button. When you have an identical configuration, you can proceed

with step 6.

3. If your hardware configuration is different from that of the project – for

example, the module types, MPI addresses or DP address – you must adjust

and save the project accordingly. You will find descriptions in the basic help for

SIMATIC Manager.

4. Open the user program in the “S7 program” folder.

The “S7 program” folder is assigned only to CPU0 in the offline view. The user

program can run on the hardware configuration described. It makes the LEDs

on the digital output module light up in the form of a running light.

S7-400,

manual. After

3-4

5. If necessary, modify the user program – to adapt it to your hardware

configuration, for example – and save it.

6. Load the user program into CPU0 with the menu command PLC > Load.

7. Start the S7-400H PLC by switching the mode selector, first for CPU0 and

then for CPU1, to RUN-P.

Result: CPU0 starts up as the master CPU and CPU1 as the standby CPU.

After the link-up and update of the standby CPU the S7-400H switches to the

Redundant system mode and executes the user program (run light on digital

output module).

S7-400H Programmable Controller Fault-Tolerant Systems

A5E00068197-04

Loading...

Loading...