Siemens SIMATIC S7-300,SIMATIC S7-300 CPU Data: CPU 315-T-2 DP User Manual

_

_

_

_

_

_

_

_

_

_

SIMATIC S7-300 S7-300 CPU Data: CPU 315T-2 DP

Preface

_____________

Product Overview

_____________

1

2

SIMATIC

S7-300

S7-300 CPU Data: CPU 315T-2 DP

Manual

Operator controls and

indicators

_____________

Setting up an S7-300 with a

Technology CPU

_____________

Communication with the

S7-300

_____________

Memory concept

_____________

Cycle and response times

_____________

Technical data

_____________

Information for the

Changeover to the

_____________

Technology CPU

3

4

5

6

7

8

9

Appendix A

_____________

A

12/2005

A5E00427933-02

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury

Warning

indicates that death or severe personal injury

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

will result if proper precautions are not taken.

may result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended

by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: A5E00427933-02

Edition 12/2005

Copyright © Siemens AG .

Technical data subject to change

Table of contents

1 Preface ................................................................................................................................................... 1-1

2 Product Overview ................................................................................................................................... 2-1

3 Operator controls and indicators............................................................................................................. 3-1

4 Setting up an S7-300 with a Technology CPU........................................................................................ 4-1

4.1 Overview .................................................................................................................................... 4-1

4.2 S7-300 components................................................................................................................... 4-1

4.3 Configuring................................................................................................................................. 4-2

4.4 Subnets...................................................................................................................................... 4-2

4.4.1 Expanding and Networking Subnets.......................................................................................... 4-2

4.4.2 Interfaces ................................................................................................................................... 4-3

4.5 Addressing ................................................................................................................................. 4-4

4.6 Commissioning........................................................................................................................... 4-5

4.7 Operating system....................................................................................................................... 4-6

4.8 Status and error displays of the Technology CPU..................................................................... 4-6

5 Communication with the S7-300............................................................................................................. 5-1

5.1 Interfaces ................................................................................................................................... 5-1

5.1.1 Overview .................................................................................................................................... 5-1

5.1.2 MPI/DP interface (X1) ................................................................................................................ 5-1

5.1.3 PROFIBUS DP(DRIVE) interface (X3) ...................................................................................... 5-3

5.2 DPV1 (X1 only as PROFIBUS DP interface)............................................................................. 5-4

5.3 Communication services on the MPI/DP interface (X1)............................................................. 5-6

5.3.1 Overview of communication services ........................................................................................ 5-6

5.3.2 PG communication..................................................................................................................... 5-7

5.3.3 OP communication..................................................................................................................... 5-7

5.3.4 S7 basic communication ............................................................................................................ 5-8

5.3.5 S7 communication ..................................................................................................................... 5-8

5.3.6 Global data communication ....................................................................................................... 5-9

5.3.7 Routing..................................................................................................................................... 5-10

5.3.8 Data consistency...................................................................................................................... 5-13

5.4 S7 communication structure .................................................................................................... 5-13

5.4.1 Communication path of an S7 connection ............................................................................... 5-13

5.4.2 Assignment of S7 connections................................................................................................. 5-14

5.4.3 Distribution and availability of S7 connection resources ......................................................... 5-16

6 Memory concept ..................................................................................................................................... 6-1

6.1 Memory areas and retentive address areas .............................................................................. 6-1

6.1.1 Technology CPU memory areas................................................................................................ 6-1

6.1.2 Retentive address areas of the load memory, system memory and technology system data .. 6-2

6.1.3 Retentive behavior of the memory objects ................................................................................ 6-3

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

iii

Table of contents

6.1.4 Address areas of system memory ............................................................................................. 6-4

6.1.5 Properties of the Micro Memory Card (MMC)............................................................................ 6-7

6.1.6 Saving/retrieving whole projects to/from the Micro Memory Card ............................................. 6-8

6.2 Memory functions..................................................................................................................... 6-10

6.2.1 Downloading the user program................................................................................................ 6-10

6.2.2 Downloading a user program (enhanced handling)................................................................. 6-11

6.2.3 CPU memory reset and restart ................................................................................................ 6-12

6.3 Recipes .................................................................................................................................... 6-13

6.4 Measured value log files .......................................................................................................... 6-15

6.5 Technology data blocks ........................................................................................................... 6-17

6.6 Memory of the integrated technology of the CPU.................................................................... 6-17

7 Cycle and response times....................................................................................................................... 7-1

7.1 Overview .................................................................................................................................... 7-1

7.2 Cycle time................................................................................................................................... 7-2

7.2.1 Overview .................................................................................................................................... 7-2

7.2.2 Calculating the cycle time .......................................................................................................... 7-4

7.2.3 Different cycle times................................................................................................................... 7-5

7.2.4 Communication Load ................................................................................................................. 7-6

7.2.5 Cycle time extension as a result of testing and commissioning functions ................................. 7-8

7.3 Response time ........................................................................................................................... 7-8

7.3.1 Overview .................................................................................................................................... 7-8

7.3.2 Shortest response time ............................................................................................................ 7-10

7.3.3 Longest response time............................................................................................................. 7-11

7.3.4 Reducing the response time with direct I/O access................................................................. 7-13

7.4 Calculating method for calculating the cycle/response time.................................................... 7-13

7.5 Interrupt response time ............................................................................................................ 7-14

7.5.1 Overview .................................................................................................................................. 7-14

7.5.2 Reproducibility of Time-Delay and Watchdog Interrupts ......................................................... 7-16

7.6 Sample calculations ................................................................................................................. 7-16

7.6.1 Calculation example for the cycle time of the CPU 315T-2 DP ............................................... 7-16

7.6.2 Calculation example for the response time of the CPU 315T-2 DP ........................................ 7-17

7.6.3 Calculation example for the interrupt response time of the CPU 315T-2 DP .......................... 7-19

8 Technical data ........................................................................................................................................ 8-1

8.1 General technical data ............................................................................................................... 8-1

8.1.1 Dimension drawing..................................................................................................................... 8-1

8.1.2 Technical specifications of the Micro Memory Card (MMC) ...................................................... 8-2

8.1.3 Clock .......................................................................................................................................... 8-2

8.2 CPU 315T-2 DP ......................................................................................................................... 8-3

8.3 Integrated Inputs/Outputs for Technology.................................................................................. 8-9

8.3.1 Arrangement of integrated inputs/outputs for integrated technology......................................... 8-9

8.3.2 Technical specifications of digital inputs.................................................................................. 8-10

8.3.3 Technical specifications of digital outputs................................................................................ 8-12

9 Information for the Changeover to the Technology CPU......................................................................... 9-1

9.1 Scope ......................................................................................................................................... 9-1

9.2 Changed behavior of certain SFCs............................................................................................ 9-2

9.3 Interrupt events from distributed I/Os while the CPU status is in STOP.................................... 9-3

S7-300 CPU Data: CPU 315T-2 DP

iv Manual, 12/2005, A5E00427933-02

Table of contents

9.4 Runtimes that change while the program is running ................................................................. 9-4

9.5 Converting the diagnostic addresses of DP slaves ................................................................... 9-4

9.6 Reusing existing hardware configurations ................................................................................. 9-5

9.7 Replacement of a Technology CPU .......................................................................................... 9-5

9.8 Using consistent data areas in the process image for DP slaves.............................................. 9-5

9.9 Load memory design for the Technology CPU.......................................................................... 9-5

9.10 Altered retentive response with a Technology CPU .................................................................. 9-6

9.11 FMs/CPs with their own MPI address in a Technology CPU rack............................................. 9-6

9.12 Information about interface X3 DP(DRIVE) ............................................................................... 9-7

A Appendix A .............................................................................................................................................A-1

A.1 List of abbreviations ................................................................................................................... A-1

Glossary ..................................................................................................................................... Glossary-1

Index................................................................................................................................................ Index-1

Tables

Table 1-1 Scope of this manual .................................................................................................................

1-1

Table 1-2 Documentation for the Technology CPU ................................................................................... 1-2

Table 1-3 Additional documentation for the Technology CPU................................................................... 1-3

Table 3-1 Operator controls and indicators of the Technology CPU ......................................................... 3-1

Table 3-2 Integrated technology inputs and outputs on the Technology CPU .......................................... 3-2

Table 3-3 Switch positions of the mode selector switch ............................................................................ 3-3

Table 3-4 Status and error displays of the CPU ........................................................................................ 3-3

Table 4-1 S7-300 components................................................................................................................... 4-2

Table 4-2 Subnet nodes............................................................................................................................. 4-3

Table 4-3 Possible operating modes of interfaces on the Technology CPU ............................................. 4-4

Table 4-4 Connectable devices.................................................................................................................. 4-4

Table 4-5 Status and error displays of the Technology CPU..................................................................... 4-6

Table 4-6 LEDs BF1 and BF3 .................................................................................................................... 4-7

Table 4-7 LED BF1 illuminated .................................................................................................................. 4-8

Table 4-8 ED BF1 flashes .......................................................................................................................... 4-8

Table 4-9 LED BF3 illuminated .................................................................................................................. 4-8

Table 4-10 LED BF3 flashes ........................................................................................................................ 4-8

Table 5-1 Interrupt blocks with DPV1 functionality .................................................................................... 5-5

Table 5-2 System function blocks with DPV1 functionality ........................................................................ 5-5

Table 5-3 CPU communication services .................................................................................................... 5-6

Table 5-4 GD resources of the CPU .......................................................................................................... 5-9

Table 5-5 Distribution of the S7 connections ........................................................................................... 5-16

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

v

Table of contents

Table 5-6 Availability of the S7 connections for the CPU 315T-2 DP ...................................................... 5-16

Table 6-1 Retentive behavior of the memory objects................................................................................. 6-3

Table 6-2 Retentive behavior of the DBs for the Technology CPU............................................................ 6-4

Table 6-3 Address areas of system memory ............................................................................................. 6-4

Table 6-4 Plug-in MMCs............................................................................................................................. 6-7

Table 7-1 Cyclic program processing......................................................................................................... 7-2

Table 7-2 Data for calculating the process image (PI) transfer time.......................................................... 7-4

Table 7-3 Increase in cycle time by nesting interrupts ............................................................................... 7-5

Table 7-4 Cycle time extension as a result of errors.................................................................................. 7-5

Table 7-5 Cycle time extension as a result of testing and commissioning functions ................................. 7-8

Table 7-6 Calculating the response time.................................................................................................. 7-14

Table 7-7 Process/diagnostic interrupt response times ........................................................................... 7-14

Table 7-8 Process/diagnostic interrupt response times ........................................................................... 7-15

Table 8-1 Available MMCs ......................................................................................................................... 8-2

Table 8-2 Features and functions of the clock ........................................................................................... 8-2

Table 8-3 Technical data for the CPU 315T-2 DP ..................................................................................... 8-3

Table 8-4 Technical specifications of the integrated inputs for integrated technology ............................ 8-10

Table 8-5 Technical specifications of the integrated outputs for integrated technology .......................... 8-12

Table 9-1 CPUs previously used................................................................................................................ 9-1

Table 9-2 Behavior of FMs/CPs with their own MPI address..................................................................... 9-6

Table A-1 List of abbreviations ................................................................................................................... A-1

S7-300 CPU Data: CPU 315T-2 DP

vi Manual, 12/2005, A5E00427933-02

Preface

Purpose of this manual

This manual contains all the necessary information for the installation, the communication

functions, the memory concept, the cycle and response times as well as the technical

specifications of the Technology CPU. You will then learn the points to consider when

upgrading to the CPU discussed in this manual.

Required basic knowledge

Knowledge required to understand this manual:

• General knowledge of automation

• Knowledge of motion control

• Knowledge of the STEP 7 basic software.

For further information, refer to the

Scope of this manual

This manual is valid for the following CPU with the following firmware and hardware

versions:

Programming with STEP 7 V5.3

1

manual.

Table 1-1 Scope of this manual

CPU Order number

CPU 315T-2 DP 6ES7 315-6TG10-0AB0 V2.4/V3.2 02

This manual describes the properties and differences of the Technology CPU compared with

the installation manual,

and CPU 31x

Note

This manual contains the descriptions of all current modules.

For new modules, or modules of a more recent version, we reserve the right to include a

Product Information containing latest information.

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

As of version

Firmware Hardware

S7-300 Automation Systems: Hardware and Installation: CPU 31xC

.

1-1

Preface

Approvals

The SIMATIC S7-300 product series has the following approvals:

• Underwriters Laboratories, Inc.: UL 508 (Industrial Control Equipment)

• Canadian Standards Association: CSA C22.2 No. 142 (Process Control Equipment)

• Factory Mutual Research: Approval Standard Class Number 3611

CE marking

The SIMATIC S7-300 product series satisfies the requirements and safety specifications of

the following EC directives:

• EC Directive 73/23/EEC "Low-voltage directive"

• EC Directive 89/336/EEC "EMC Directive"

C-tick mark

The SIMATIC S7-300 product series is compliant with AS/NZS 2064 (Australia and New

Zealand).

Standards

The SIMATIC S7-300 product series is compliant with IEC 61131-2.

The Technology CPU is oriented to the planned standards for PLCopen V2.0 and

PROFIdrive V3.0.

Documentation classification

This manual is part of the Technology CPU documentation package.

All of these manuals are available as electronic manuals on the CD-ROM of the

Technology

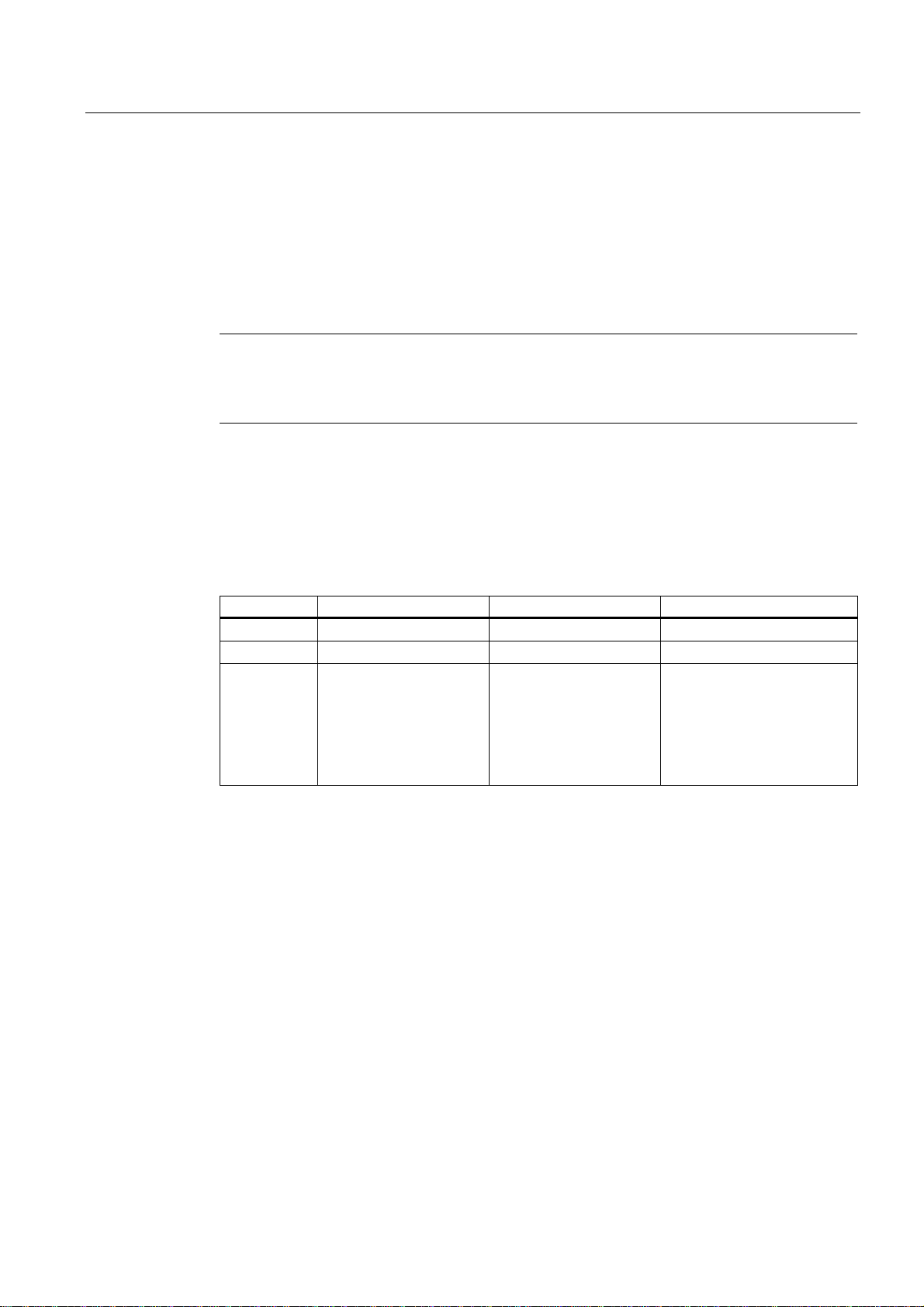

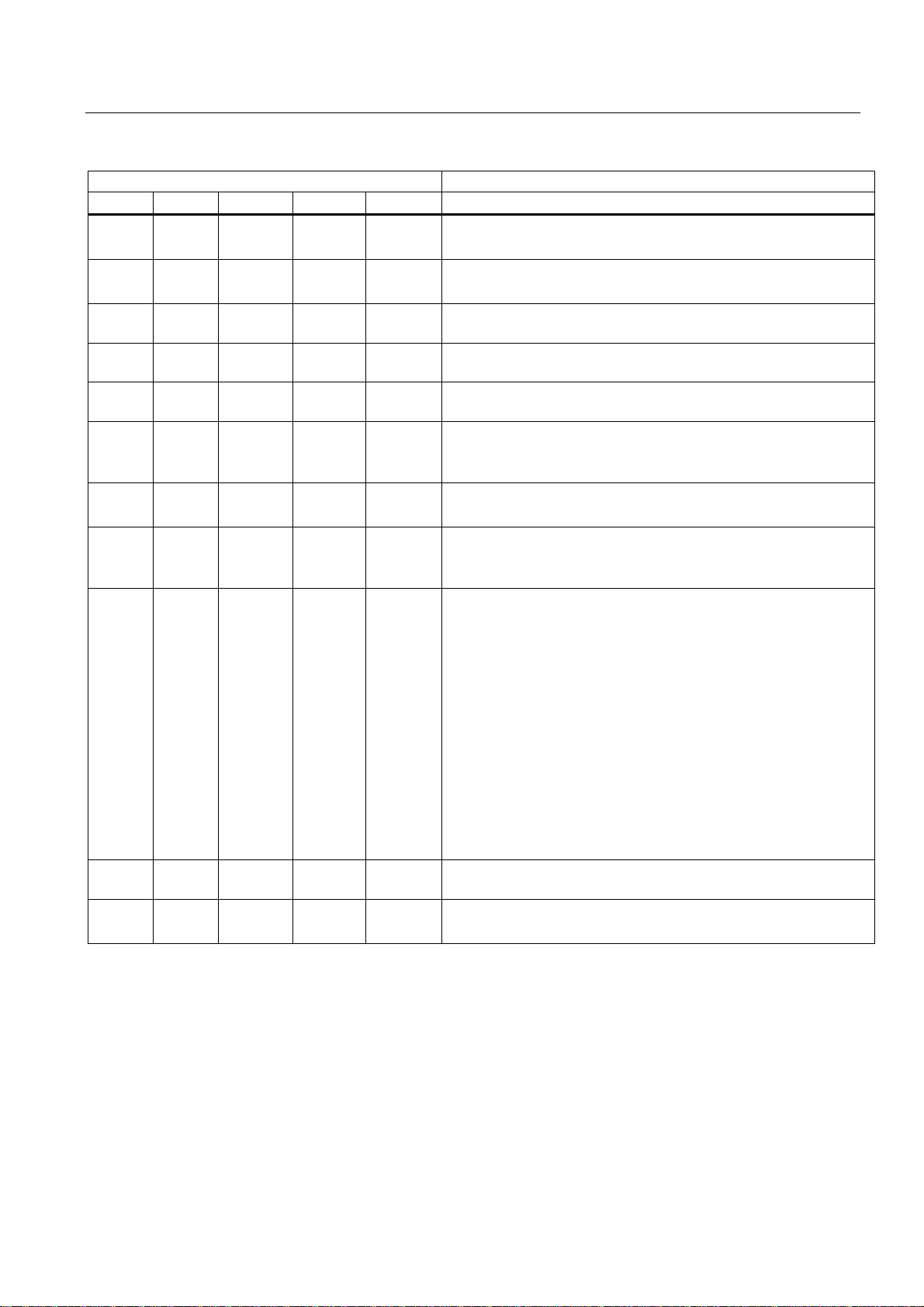

Table 1-2 Documentation for the Technology CPU

Title Contents

Getting Started

CPU 317T-2 DP: Controlling a SINAMICS S120

CPU 317T-2 DP: Controlling a physical axis

CPU 317T-2 DP: Controlling a virtual axis

CPU Data Reference Manual

→

CPU data: CPU 315T-2 DP

(you are reading this manual)

CPU data:CPU 317T-2 DP

Manual

S7-Technology

option package.

The example used in these Getting Started manuals guides

you through the various steps in commissioning required to

obtain a fully functional application.

Description of the operation, functions and technical

specifications of the CPU 315T-2 DP and CPU 317T-2 DP

Description of the individual technological functions:

• Application and benefits

• Fundamentals and configuration

• Loading, testing and diagnostics

• PLCopen functions

S7-

S7-300 CPU Data: CPU 315T-2 DP

1-2 Manual, 12/2005, A5E00427933-02

Preface

Title Contents

Software Installation Manual

S7-300 Automation Systems:

Installation: CPU 31xC and CPU 31x

Module Data Reference Manual

S7-300 Automation Systems:Module Data

Instruction List

CPU 31xC, CPU 31x

IM 151-7 CPU, BM 147-1 CPU, BM 147-2 CPU

Description of the configuration, installation, wiring,

networking and commissioning of an S7-300

Technical data and descriptions of the functions of signal

modules, power supply modules and interface modules

List of the CPU operation set and their execution times. List

of the executable blocks (OBs/SFCs/SFBs) and their

execution times

In addition to this documentation package, you require the following manual:

Table 1-3 Additional documentation for the Technology CPU

System Software for S7-300/400, System and Standard

Functions reference manual

The reference manual is part of the STEP 7

documentation package

Further support

Do you have more questions about using the products described in the manual? Then

contact the Siemens representative or office nearest you.

http://www.siemens.com/automation/partner

Training center

SIEMENS offers a range of courses to help you to get started with your S7-300 automation

system. Please contact your regional Training Center, or the central Training Center in D90327 Nuremberg.

Telephone:+49 (911) 895-3200

http://www.sitrain.com

SIMATIC documentation on the Internet:

You can find the documentation free of charge on the Internet at:

Description of the SFCs, SFBs and OBs of the CPUs.

You can also find the description in the online help for

STEP 7.

http://www.ad.siemens.de/support

Use the Knowledge Manager provided there to quickly find the required documentation. You

can enter any questions or suggestions for the documentation in the forum. You will receive

a quick reply.

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

1-3

Preface

Technical support

You can reach the technical support team for all A&D projects

• Using the support request web form:

http://www.siemens.de/automation/support-request

• Telephone: + 49 180 5050 222

• Fax: + 49 180 5050 223

Further information about SIEMENS technical support is available on the Internet at

http://www.siemens.com/automation/service

Service & Support on the Internet

In addition to our documentation, we offer a comprehensive knowledge base online on the

Internet at:

http://www.siemens.com/automation/service&support

There you will find:

• The latest product information, FAQs (Frequently Asked Questions), downloads, tips and

tricks.

• Our newsletter, providing you with the latest information about your products.

• A Knowledge Manager to find the right documents for you.

• Our bulletin board, where users and specialists share their knowledge worldwide.

• Your local contact partner for Automation & Drives in our Partner Database.

• Information about field service, repairs, spare parts and lots more under "Services."

S7-300 CPU Data: CPU 315T-2 DP

1-4 Manual, 12/2005, A5E00427933-02

Product Overview

Introduction

The current trend in the field of automation is toward PLC-integrated solutions. This also

applies to technology and motion control applications.

Integrated technology of Technology CPU

With the Technology CPU, technology and motion control functions are integrated in one

SIMATIC CPU.

The Technology CPU incorporates:

• SIMATIC CPU 31x-2 DP

• PLCopen-compliant motion control functions

• Technological configurations (technology objects, axis configurations, tools)

The Technology CPU is completely integrated in the SIMATIC family and thus in the TIA

environment.

Field of application

The Technology CPU is especially suited to solving the following control tasks:

2

• Control tasks and technology requirements primarily relating to motion control in the

SIMATIC S7-300

• Motion tasks for up to eight coupled axes or single axes

• Technological tasks, e.g. gearing and camming, position-controlled positioning (operating

modes: absolute, relative, additive and superimposed), travel to fixed stop, probe-based

print mark correction, position- or time-dependent cam control).

The Technology CPU is designed for use with flow machines, processing/assembly lines,

flying shears, labeling equipment, drum feeds or simple gantries (without interpolation).

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

2-1

Product Overview

SIEMENS

Interfaces

The Technology CPU has two interfaces:

• One MPI/DP interface, parameterizable as an MPI or DP interface (master or slave).

• one DP (DRIVE) interface for connection of drive systems

MPI/DP interface

03,'3

(70 (76

(76

0,&520$67(5

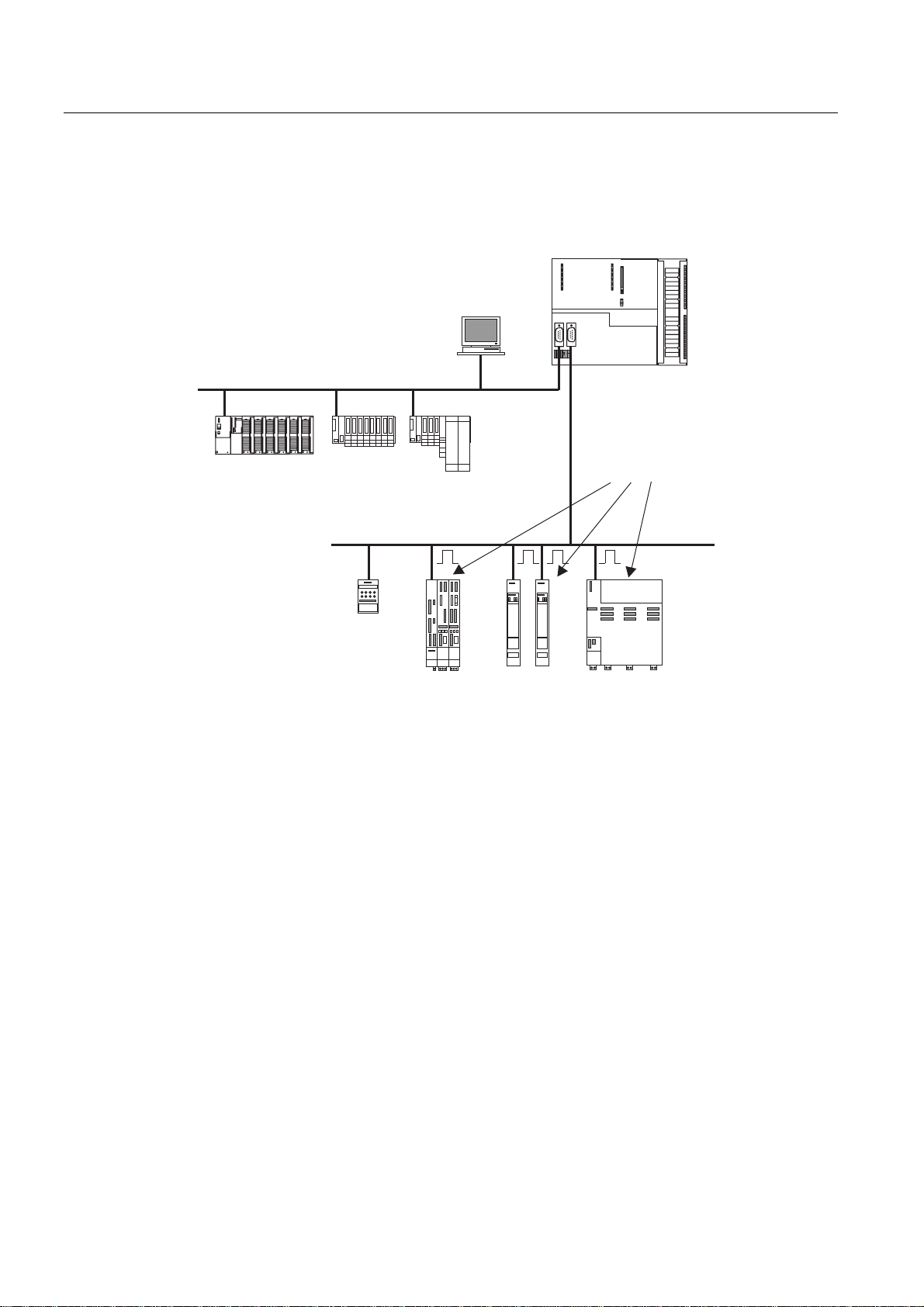

Figure 2-1 Typical configuration with the Technology CPU

&38[7'3

LVRFKURQRXV

'3GULYH

6,1$0,&60$67(5'5,9(66,02'5,9(

The MPI/DP interface is used to connect additional SIMATIC components, such as PG, OP,

S7 controllers and distributed I/O. Extensive networks can be built up in DP interface mode.

DP(DRIVE) interface

The DP(DRIVE) interface is optimized for the connection of drives. It supports all the major

SIEMENS drive types:

• MICROMASTER 420/430/440 and COMBIMASTER 411

• SIMODRIVE 611 universal

• SIMODRIVE POSMO CD/SI/CA

S7-300 CPU Data: CPU 315T-2 DP

2-2 Manual, 12/2005, A5E00427933-02

• MASTERDRIVES MC/VC

• ET 200M with IM 153-2 (isochronous!) and SM 322 for additional cam output

• ET 200S with IM 151-1 high feature

• SINAMICS S120 (optional with TM15 or TM17 high feature for high-speed cams)

• Analog drive interface ADI4

Product Overview

• Isochronous PROFIBUS encoder "SIMODRIVE sensor isochronous"

The components configured in HW Config are displayed in the "Hardware Catalog" window

in HW Config. To show the screen, select profile "SIMATIC Technology CPU" in HW Config.

To ensure that the profile's selection list is complete, you must have installed the most recent

version of S7-Technology.

The isochronous capability means that even high-speed processes can be controlled with

excellent precision.

Integrated inputs and outputs for integrated technology

The Technology CPU has 4 digital inputs and 8 digital outputs integrated. You use these

inputs and outputs for technology functions, e.g. reference point acquisition (reference cams)

or high-speed output cam switching signals. The inputs and outputs can also be used with

technology functions in the

STEP 7

user program.

Configuring and programming

The Technology CPU is configured and programmed completely in

and later) and optional package

is integrated after installation in

S7-Technology V3.0

STEP 7

).

(the

S7-Technology

STEP 7

(Version 5.3 SP3

optional package

STEP 7

(e.g. to create subnets on the two interfaces MPI/DP and DP(DRIVE)) including the drive

equipment.

You will need optional package

objects", e.g. axes, cams, output cams and probes.

The objects are parameterized in specially provided screens. The technology object data are

stored in data blocks for use by the

S7-Technology

blocks which are used to program the motion control tasks themselves. You call these

standard FBs in your

STEP 7

S7-GRAPH are provided to enable you to create the

control tasks).

Single-tier configuration

The Technology CPU supports only single-tier configurations.

HW Config

languages LAD, CSF and STL and all the required engineering tools, e.g. S7-SCL or

is the tool used to configure all hardware components of the system

S7-Technology

STEP 7

also includes a library containing PLCopen-compliant standard function

STEP 7

user program.

to parameterize the so-called "technology

user program.

STEP 7

user program (incl. motion

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

2-3

Product Overview

S7-300 CPU Data: CPU 315T-2 DP

2-4 Manual, 12/2005, A5E00427933-02

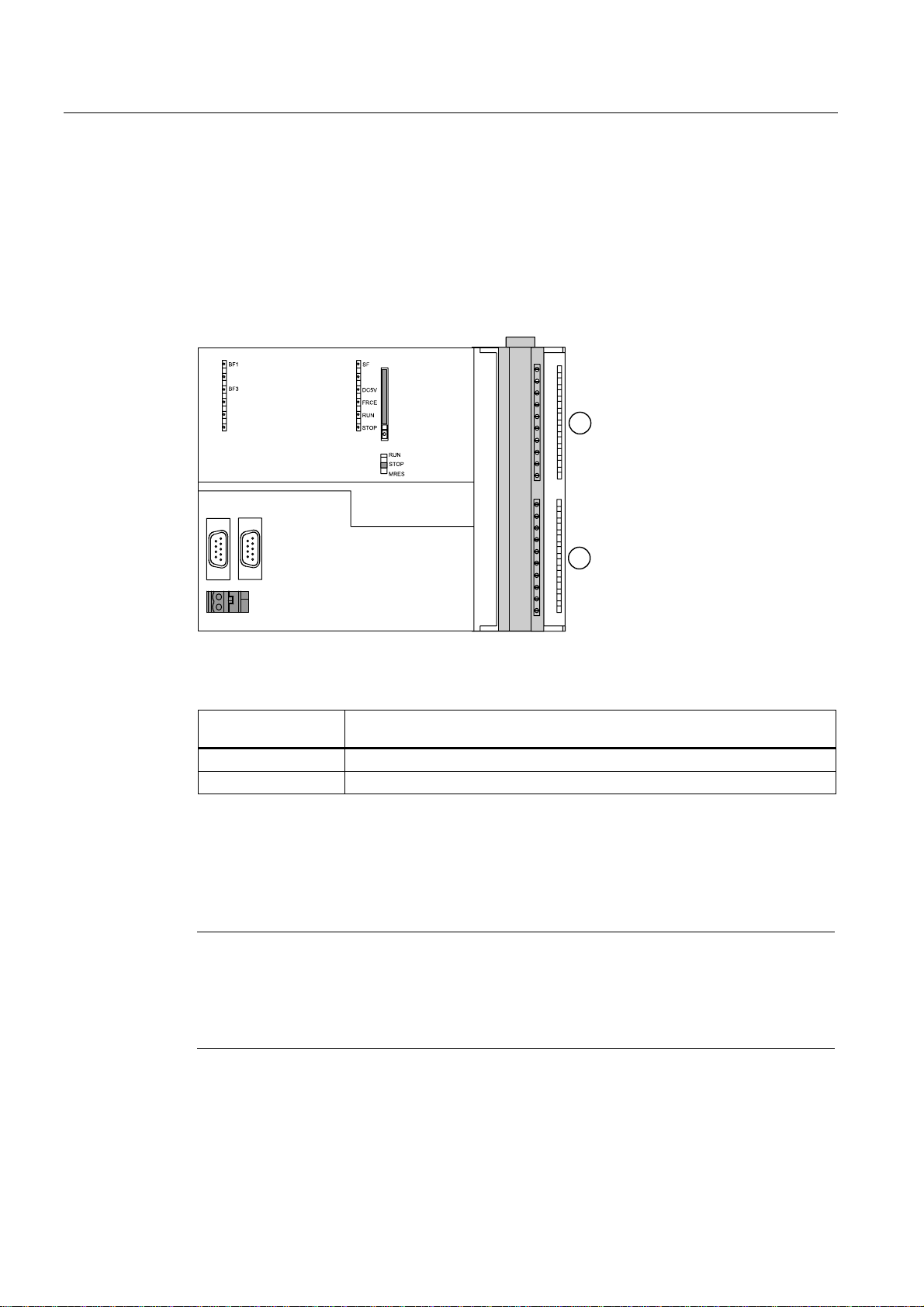

Operator controls and indicators

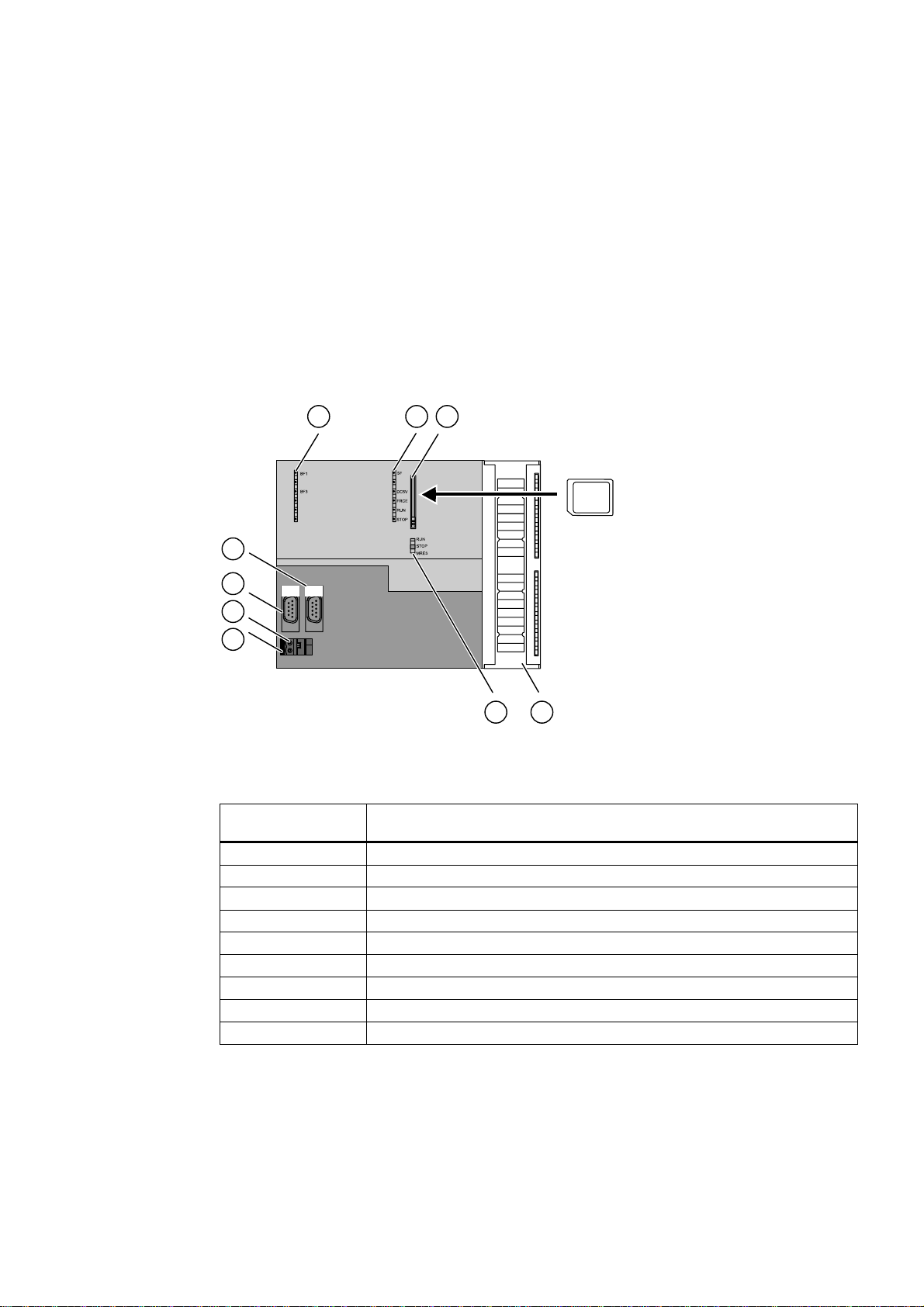

Operator controls and indicators of the CPU

The following diagram shows the operator controls and indicators on the Technology CPU.

Figure 3-1 Operator controls and indicators of the Technology CPU

;

;

;

3

00&

Table 3-1 Operator controls and indicators of the Technology CPU

The number in the

diagram

1 Bus error indicators

2 Status and error displays

3 Slot for the Micro Memory Card (MMC), incl. the ejector

4 Connection of the integrated I/Os

5 Mode selector switch

6 Power supply connection

7 Grounding slide

8 Interface X1 MPI/DP

9 Interface X3 DP(DRIVE)

points to the following element on the Technology CPU

Integrated inputs and outputs for integrated technology

You can use the integrated technology inputs and outputs for technology functions and

configure them using

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

S7T Config

(included in the optional package

S7-Technology

).

3-1

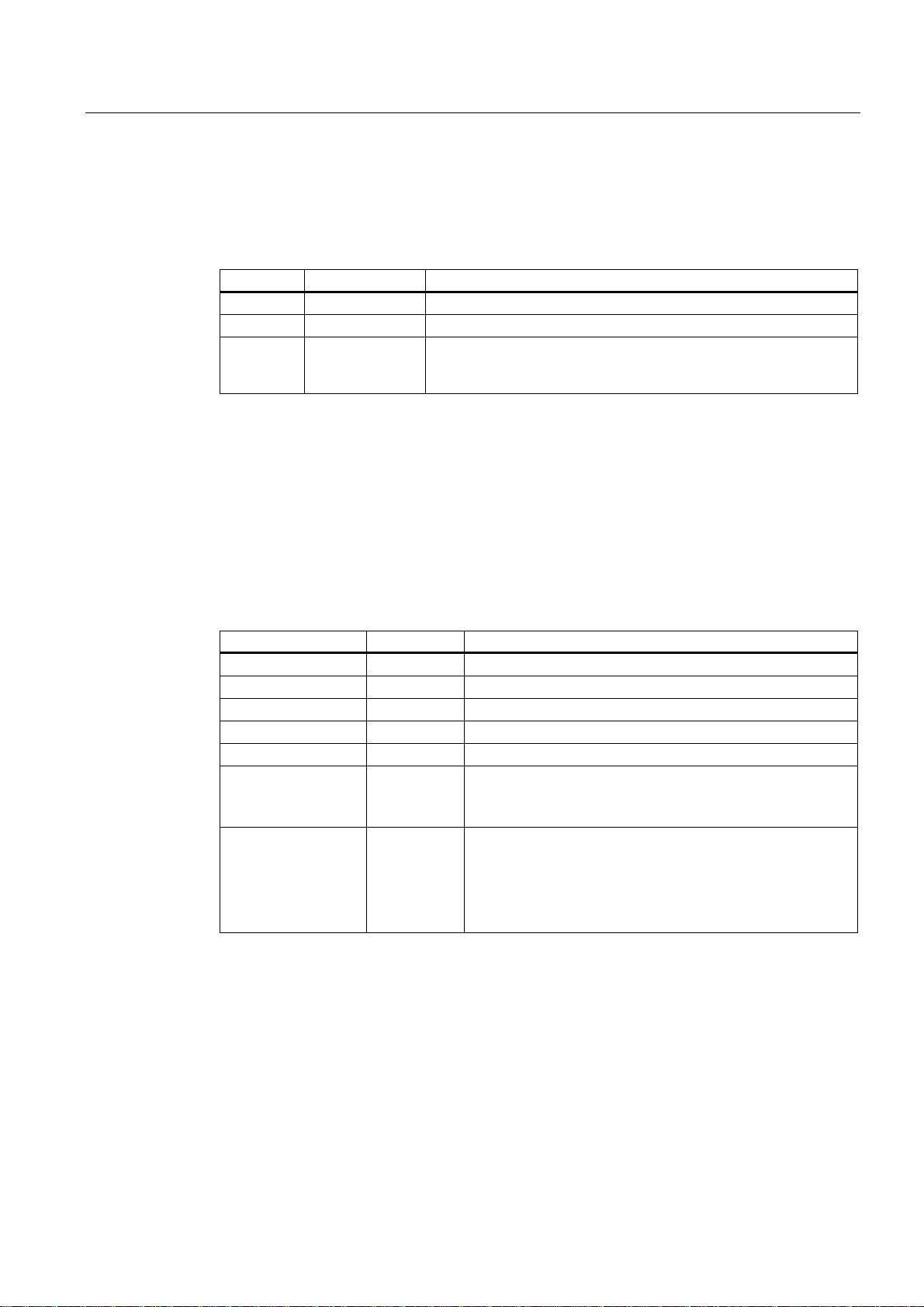

Operator controls and indicators

The digital outputs are provided for high-speed camming functions. They can be

programmed with technology functions in the STEP 7 user program. Digital inputs can be

used with technology functions such as reference point acquisition (reference cam) as well

as with technology functions in the STEP 7 user program.

You use the integrated inputs and outputs for applications in which rapid technological

processing is of prime importance.

If you wish to evaluate other inputs and outputs in the STEP 7 user program, they can be

interconnected in the usual way by means of supplementary input/output modules.

;

;

;

Figure 3-2 Integrated technology inputs and outputs on the Technology CPU with open front door

Table 3-2 Integrated technology inputs and outputs on the Technology CPU

The number in the

diagram

1 4 digital inputs

2 8 digital outputs

points to the following integrated I/Os

Slot for the SIMATIC Micro Memory Card (MMC)

A SIMATIC Micro Memory Card (MMC) is used as memory module. The MMC is used as

load memory and as a transportable data medium.

Note

Because the Technology CPU does not have an integrated load memory, you must plug in

an MMC to operate it.

You require an MMC, 4 MB and larger; for an operating system update you require an MMC

with 8 MB.

S7-300 CPU Data: CPU 315T-2 DP

3-2 Manual, 12/2005, A5E00427933-02

Operator controls and indicators

Mode selector switch

The mode selector switch is used to set the current CPU operating mode.

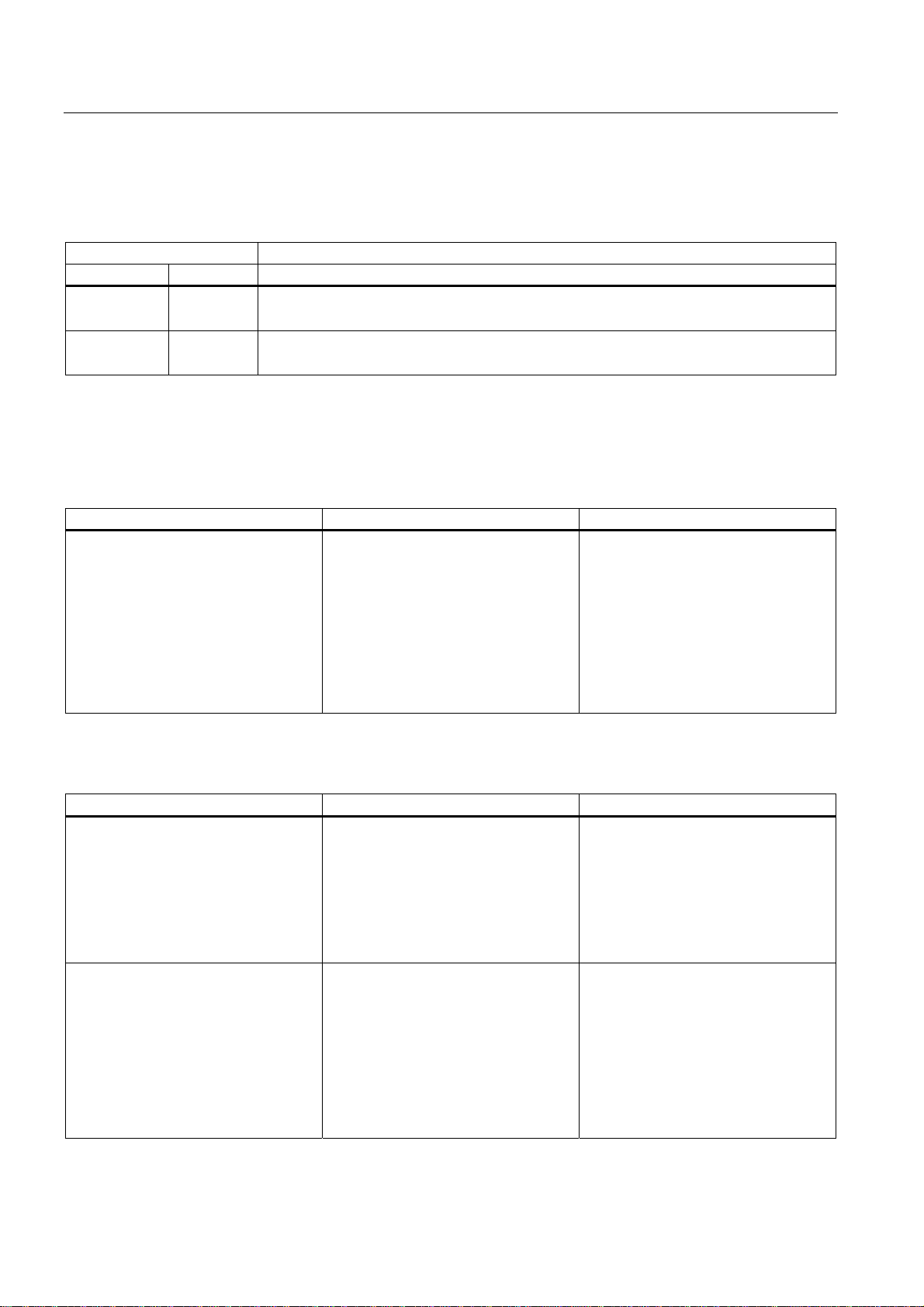

Table 3-3 Switch positions of the mode selector switch

Position Meaning Description

RUN RUN mode The CPU executes the user program.

STOP STOP mode The CPU does not execute a user program.

MRES CPU memory

reset

Mode selector switch position with pushbutton function for CPU

memory reset. A general CPU reset by means of a mode selector

switch requires a specific sequence of operation.

Power supply connection

Each CPU is equipped with a double-pole power supply socket. The connector with screw

terminals is inserted into this socket when the CPU is delivered.

Status and error displays

The CPU is equipped with the following LEDs:

Table 3-4 Status and error displays of the CPU

LED Color Meaning

SF red Hardware or software error

BF1 red Bus errors (MPI/DP)

BF3 red Bus error on DP(DRIVE)

5 VDC green 5V power supply for the CPU and the S7-300 bus

FRCE yellow Active force job

RUN green CPU in RUN

The LED flashes during STARTUP at a rate of 2 Hz, and in

HOLD state at 0.5 Hz.

STOP yellow CPU in STOP, or HOLD, or STARTUP

The LED flashes

• At 0.5 Hz on general reset request

• At 2 Hz during general reset

• At 2 Hz during shutdown (LED RUN lit).

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

3-3

Operator controls and indicators

Shutdown

What happens during shutdown?

1. The control of the Technology CPU is already in STOP mode during "shutdown". The

outputs of the centralized and distributed I/Os on the MPI/DP are deactivated. The

"STOP" LED flashes at 2 Hz. The "RUN" LED lights up.

2. The integrated inputs/outputs for integrated technology and the distributed I/Os on

DP(DRIVE) are still active during shutdown.

3. The integrated technology of the Technology CPU shuts down the drives on PROFIBUS

DP(DRIVE) in a controlled manner.

4. The integrated technology then also switches to STOP. The integrated inputs/outputs for

integrated technology and the distributed I/Os on DP(DRIVE) are deactivated. The

"STOP" LED lights up.

The maximum duration of shutdown depends on your configuration in S7T Config.

Caution

The distributed I/Os on DP(DRIVE) cannot be controlled from the user program during

"shutdown". The outputs which can be controlled with technology function

"MC_WritePeripherie" retain their last current setting.

Reference

Further information

• about CPU operating modes can be found in the

• about operating the mode selector switch for a general CPU reset can be found in the

installation manual, chapter

• about understanding LED displays in event of faults/trouble shooting can be found in the

installation manual, chapter

• about operating MMCs and the memory concept can be found in chapter

Concept.

Commissioning

Test Functions, Diagnostics and Fault Correction

STEP 7 Online Help

.

.

.

Memory

S7-300 CPU Data: CPU 315T-2 DP

3-4 Manual, 12/2005, A5E00427933-02

Setting up an S7-300 with a Technology CPU

4.1 4.1 Overview

This section

contains the information which differs from the content of installation manual

Programmable Controller, Assembly: CPU 31xc and CPU 31x

information.

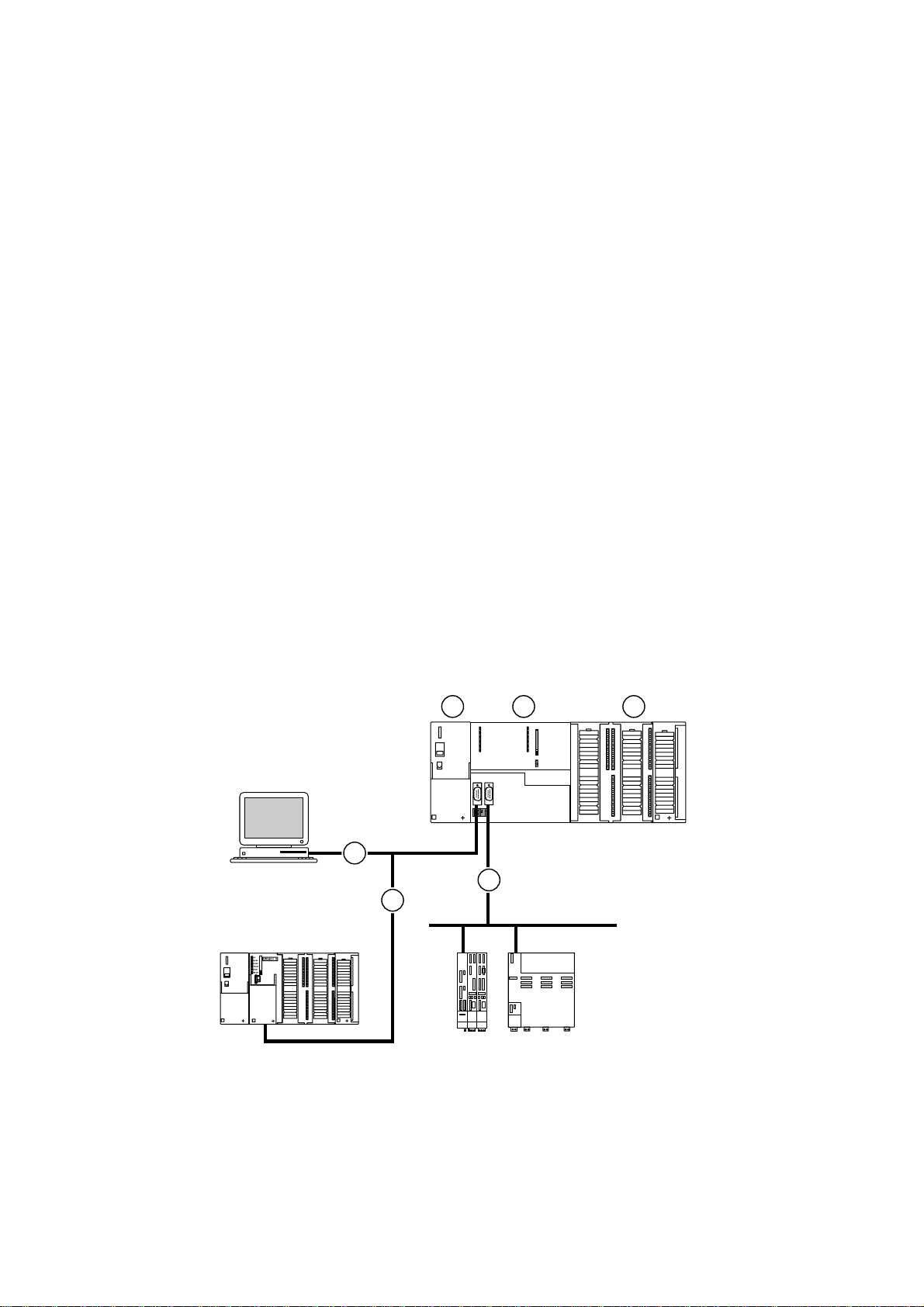

4.2 4.2 S7-300 components

Which components do you need to build an S7-300 with Technology CPU?

The following diagram shows one possible configuration:

or useful supplementary

4

S7-300

Figure 4-1 S7-300 components

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

03,'3

'3'5,9(

4-1

Setting up an S7-300 with a Technology CPU

4.3 Configuring

Table 4-1 S7-300 components

The number in the

diagram

(1) Power supply (PS) module

(2) Central processor unit (CPU)

(3) Signal module (SM)

(4) PROFIBUS cable

(5) Cable for connecting a programming device (PG) or for networking with other

You use a programming device (PG) to program the S7300. You connect the PG to the CPU

by means of a PG cable.

Using the PROFIBUS bus cable, you connect the CPU

• to other SIMATIC controls via the MPI/DP interface

• to the drives via the DP(DRIVE) interface.

No PG/OP on DP(DRIVE)

We do not recommend that you connect a PG/OP to DP(DRIVE).

Reason: If you connect a PG/OP to DP(DRIVE), the properties of DP(DRIVE) change (e.g.

isochronism), and the synchronism between drives may be lost as a result. Always therefore

connect a PG/OP to the MPI/DP interface and access the DP(DRIVE) via the "Routing"

function.

points for the following component of an S7-300 system

SIMATIC controls

4.3 4.3 Configuring

Single-tier configuration

The Technology CPU supports only single-tier configurations.

4.4 4.4 Subnets

4.4.1 Expanding and Networking Subnets

Overview: Subnets with the Technology CPU

The Technology CPU provides the following subnets:

• Multi Point Interface (MPI) or PROFIBUS DP

• DP(DRIVE): Optimized for drives

S7-300 CPU Data: CPU 315T-2 DP

4-2 Manual, 12/2005, A5E00427933-02

Setting up an S7-300 with a Technology CPU

4.4 Subnets

Transmission rate

Maximum transmission rates:

• MPI/PROFIBUS DP: 12 Mbaud

We recommend that you set 12 Mbaud for the Technology CPU

• DP(DRIVE): 12 Mbaud

Number of nodes

Note

Before you transfer projects to the Technology CPU via the MPI/DP interface, you should

increase the baud rate to at least 1.5 Mbaud or else the data transmission can take a very

long time (up to 15 minutes at 187.5 kbaud).

Maximum number of nodes per subnet:

Table 4-2 Subnet nodes

Parameters MPI PROFIBUS DP PROFIBUS DP (DRIVE)

Number 127 126 33

Addresses 0 to 126 0 to 125 1 to 125

Comments Default: 32 addresses

Reserved addresses:

• Address 0 for PG

• Address 1 for OP

of which:

1 master (reserved)

1 PG connection

(address 0 reserved)

124 slaves or other

masters

of which:

• 1 master (reserved) and

32 slaves or drives

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

4-3

Setting up an S7-300 with a Technology CPU

4.4 Subnets

4.4.2 Interfaces

MPI/DP interface

You can reconfigure this interface in STEP 7 as a PROFIBUS DP interface.

The MPI (Multi-Point Interface) represents the CPU interface for PG/OP connections, or for

communication on an MPI subnet.

The PROFIBUS DP interface is mainly used to connect distributed I/O. PROFIBUS DP

allows you to create large subnets, for example.

Interfaces

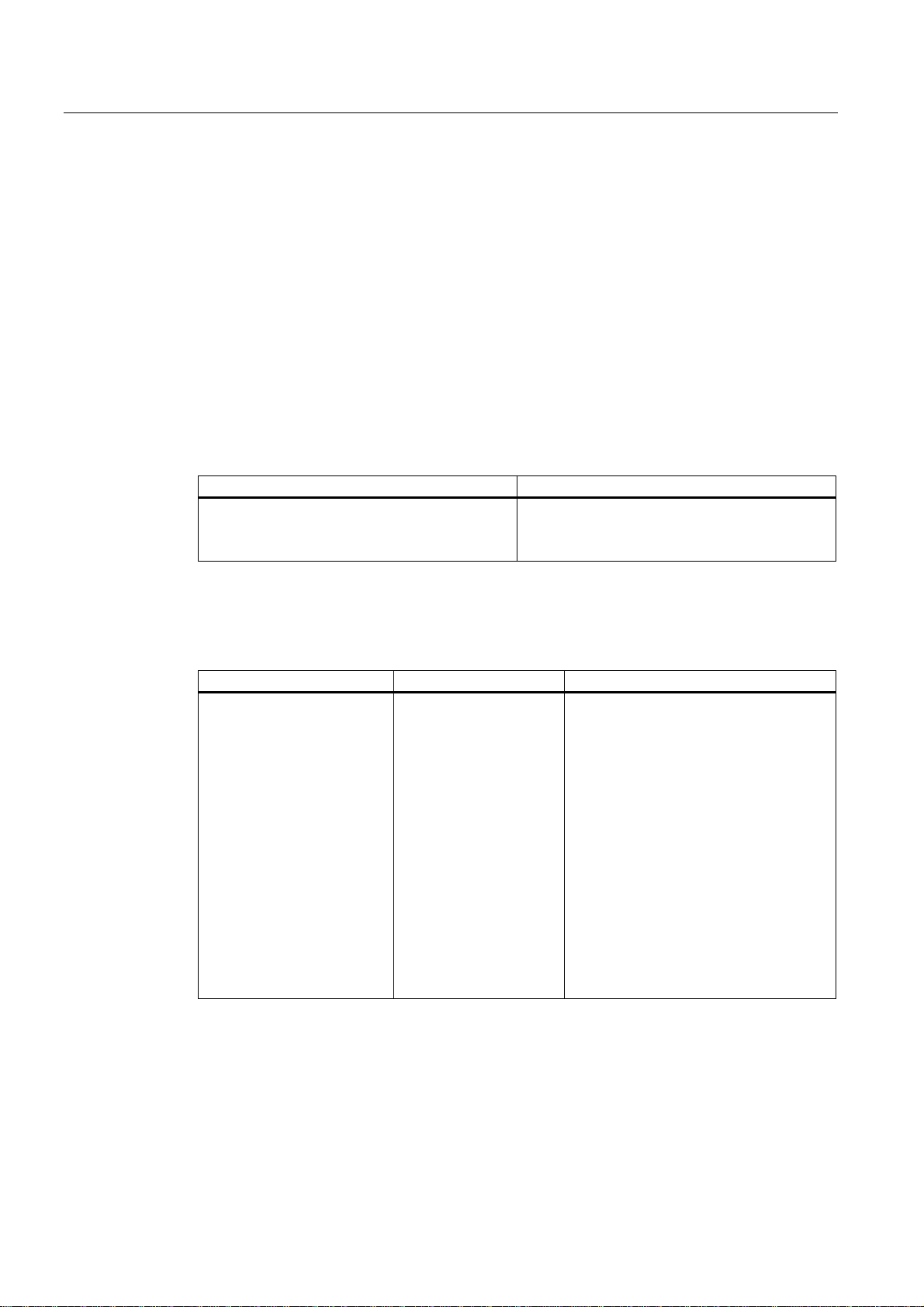

Table 4-3 Possible operating modes of interfaces on the Technology CPU

MPI/DP interface (X1) DP(DRIVE) interface (X3)

• MPI

• DP master

• DP slave

• DP master for DP(DRIVE)

Which devices can you connect to which interface?

Table 4-4 Connectable devices

MPI PROFIBUS DP DP (drive)

• PG/PC

• OP/TD

• S7-300/400 with

MPI interface

• S7-200

(with 19.2 kbaud only)

• PG/PC

• OP/TD

• DP slaves

• DP master

• Actuators/sensors

• S7-300/400 with

PROFIBUS

DP interface

• MICROMASTER 420/430/440 and

COMBIMASTER 411

• SIMODRIVE 611 universal

• SIMODRIVE POSMO CD/SI/CA

• MASTERDRIVES MC/VC

• ET 200M with IM 153-2 (isochronous!)

• ET 200S with IM 151-1

• SINAMICS S120 (optional with TM15

or TM17 high feature for high-speed

cams)

• SIMODRIVE sensor isochronous

• Analog drive interface ADI4

Tip: You will find a list of connectable

devices in STEP 7 under the "SIMATIC

Technology CPU" profile in the hardware

catalog.

S7-300 CPU Data: CPU 315T-2 DP

4-4 Manual, 12/2005, A5E00427933-02

Setting up an S7-300 with a Technology CPU

4.5 Addressing

4.5 4.5 Addressing

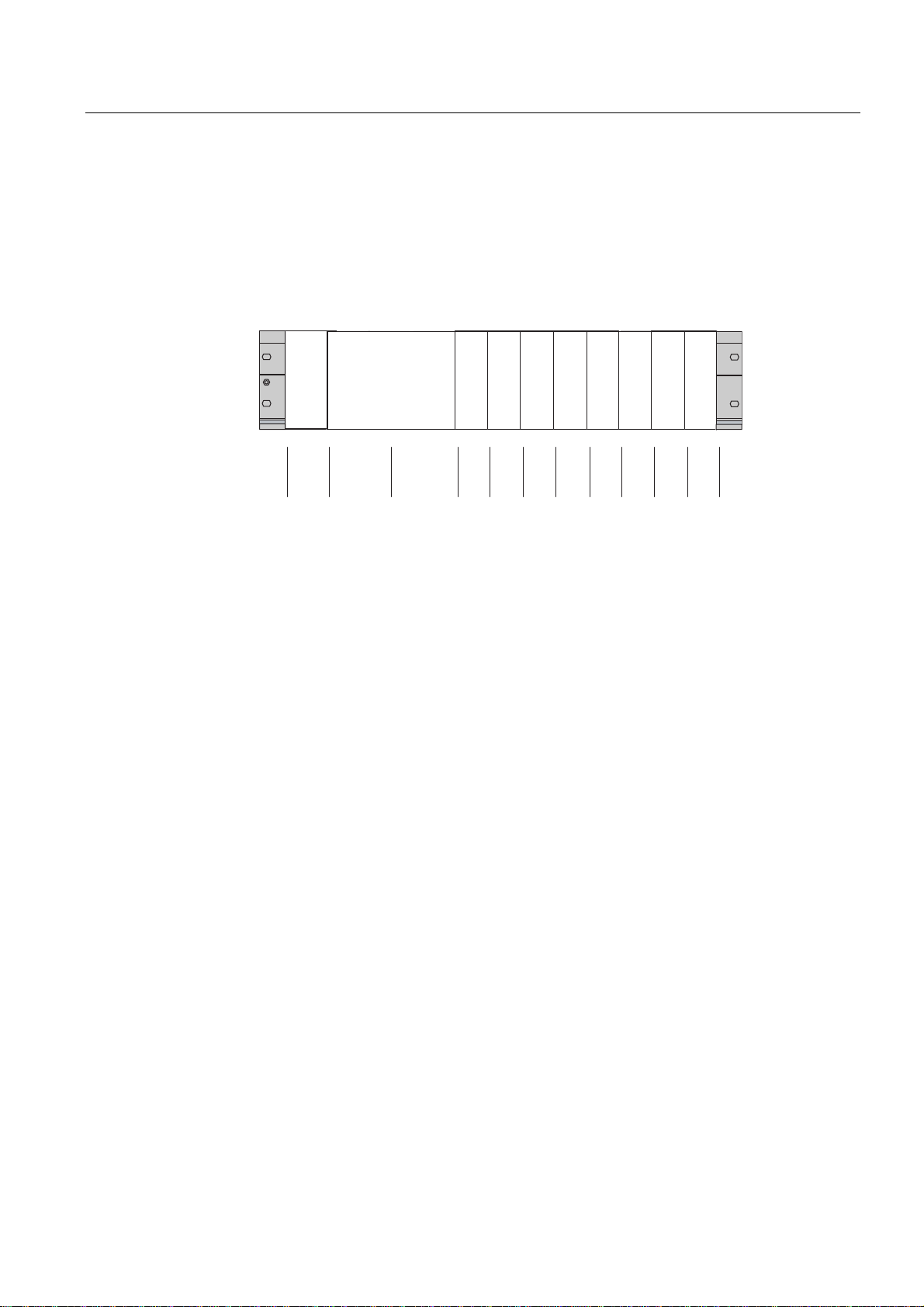

Slots of the S7-300 and associated module start addresses

The Technology CPU is assigned to two slot numbers: 2 and 3.

The input and output addresses for I/O modules begin at the same module start address.

0RGXOHUDFN

&5

&3836

60 60 60

60 60

60

60

60

6ORWQXPEHU

0'LQLWLDODGGUHVVGLJLWDO

0'LQLWLDODGGUHVVDQDORJ

3/&VHFWLRQ

7HFKQRORJ\VHFWLRQ

Figure 4-2 Slots of the S7-300 with Technology CPU and associated module start addresses

Integrated inputs and outputs for integrated technology

The Technology CPU has 4 integrated digital iputs and 8 integrated digital outputs for

integrated technology. You use these integrated inputs and outputs for technology functions,

e.g. reference point acquisition (reference cams) or high-speed output cam switching

signals.

The integrated inputs and outputs can also be used with technology function in the STEP 7

user program.

You use the integrated inputs and outputs for applications in which rapid technological

processing is of prime importance.

DP address areas

The CPU 315T-2 DP has the following address areas:

• For inputs and outputs respectively: 2048 bytes

• Of which in the process image, for inputs and outputs respectively: Bytes 0 to 127

DP (DRIVE) address areas

The CPU 315T-2 DP has the following DP(DRIVE) address areas:

• For inputs and outputs respectively: 1024 bytes

• Of which in the I/O image, for inputs and outputs respectively: Bytes 0 to 63

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

4-5

Setting up an S7-300 with a Technology CPU

4.6 Commissioning

4.6 4.6 Commissioning

Conditions

If you wish to utilize the full scope of CPU functions, you will require

• STEP 7 as of V 5.3 + SP 3 and option package

• S7-300 is installed

• S7-300 is wired

• For a networked S7-300:

– MPI/PROFIBUS addresses are set

– Terminating resistors on the segments are enabled

4.7 4.7 Operating system

Technology CPU operating system

To meet the requirements of the integrated technology, technology functions have been

added to the standard CPU operating system to obtain the technology operating system.

The technology operating system is included in the project and the configuration. In other

words, if you load a project created with S7-Technology to the Technology CPU, the

technology operating system is automatically transferred at the same time.

Updating the operating system

You can order the latest operating system versions from your Siemens contact or download

it from the Internet at (Siemens Homepage; Industrial Automation, Customer Support).

S7-Technology V3.0

4.8 4.8 Status and error displays of the Technology CPU

Status and error displays of the Technology CPU

Table 4-5 Status and error displays of the Technology CPU

LED Meaning

SF 5 VDC FRCE RUN STOP

Off Off Off Off Off CPU power supply missing.

Remedy:

Check whether the power supply module is connected to mains and

switched on.

Check whether the CPU is connected to the power supply and switched on.

S7-300 CPU Data: CPU 315T-2 DP

4-6 Manual, 12/2005, A5E00427933-02

Setting up an S7-300 with a Technology CPU

4.8 Status and error displays of the Technology CPU

LED Meaning

SF 5 VDC FRCE RUN STOP

Off On

On On X Off On The CPU is in STOP mode as a result of error.

X On X Off Flashes

X On X Off Flashes

X On X Flashes

X On X Flashes

On On X X X Hardware or software error

X X On X X You enabled the Force function

X X X On Flashes

X X X Flashes

Flashes Flashes Flashes Flashes Flashes Internal errors in Technology CPU.

X (see the

description)

Off On The CPU is in STOP mode.

Remedy: Start the CPU.

Remedy: refer to the tables below, evaluation of the SF LED

The CPU requests memory reset.

(0.5 Hz)

The CPU executes memory reset.

(2 Hz)

On The CPU is in startup mode.

(2 Hz)

On The CPU was halted by a programmed break point.

(0.5 Hz)

(0.5 Hz)

(2 Hz)

Flashes

(2 Hz)

For details, refer to the Programming Manual

STEP 7

Remedy: refer to the tables below, evaluation of the SF LED

For details refer to the Programming Manual

STEP 7

STOP/shutdown

What happens during shutdown?

The control of the Technology CPU is already in STOP mode during

"shutdown". The outputs of the centralized and distributed I/Os are

deactivated.

The integrated inputs/outputs for integrated technology and the

ET 200M on the DP(DRIVE) are still active during shutdown.

The integrated technology of the Technology CPU shuts down the

drives on PROFIBUS DP(DRIVE) in a controlled manner.

The integrated technology of the CPU then also goes into STOP.

The integrated inputs/outputs for integrated technology and the

ET 200M on the DP(DRIVE) are deactivated.

The maximum duration of shutdown depends on your configuration

in S7TConfig.

HOLD/shutdown

Contact your local SIEMENS partner.

.

.

Programming with

Programming with

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

4-7

Setting up an S7-300 with a Technology CPU

4.8 Status and error displays of the Technology CPU

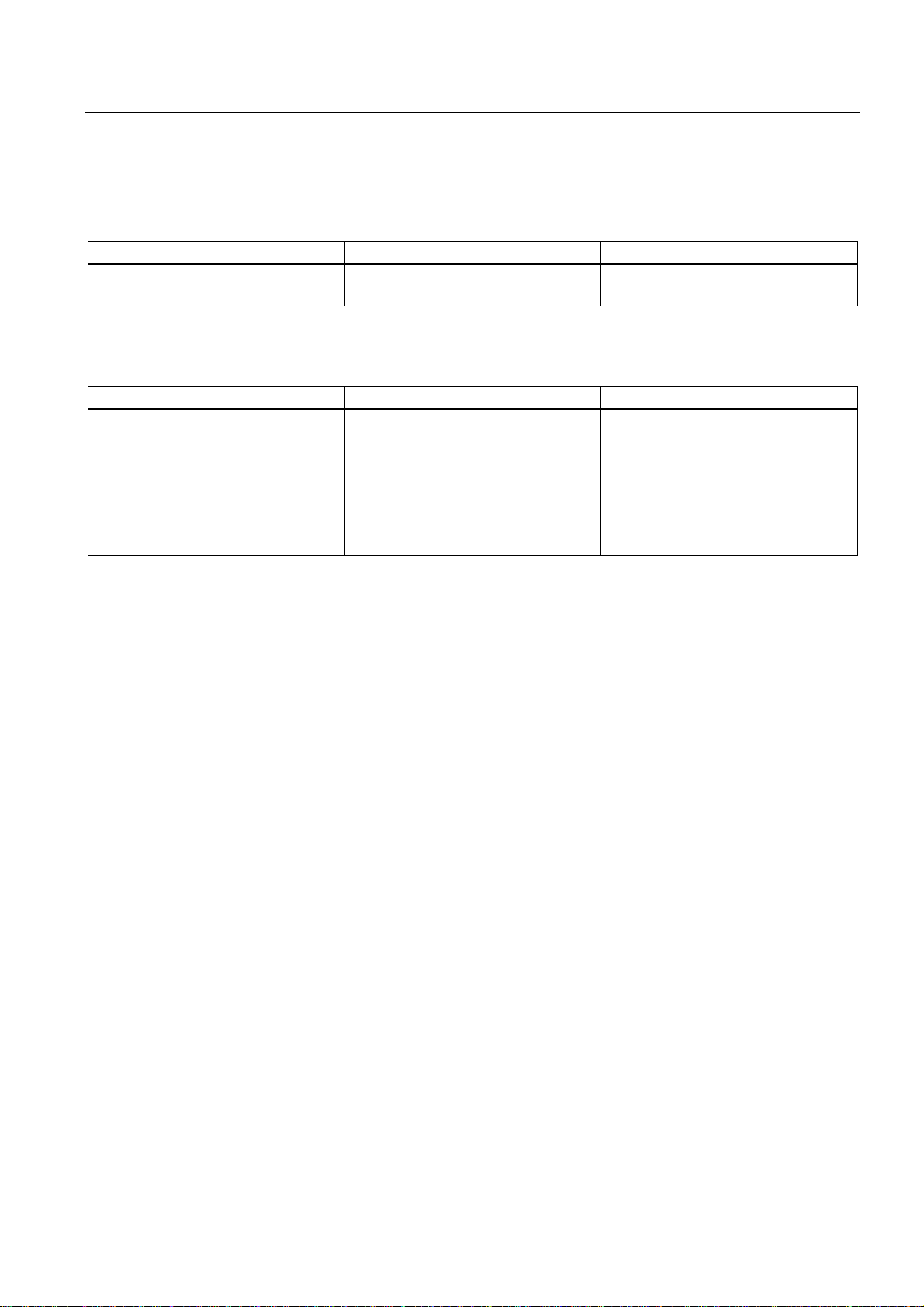

Status and error displays for DP or DP(DRIVE)

Table 4-6 LEDs BF1 and BF3

LED Meaning

BF1 BF3

On/ flashes X Error on the PROFIBUS DP interface of the Technology CPU.

Remedy: See table LED BF1 illuminated

X On/ flashes Error on the DP(DRIVE) interface

Remedy: See table

Description of status X:

The LED can assume the On or Off state. This status, however, is irrelevant for the current

CPU function. For example, the states Force On or Off do not influence the CPU STOP

status

Table 4-7 LED BF1 illuminated

Possible Errors CPU reaction Possible Remedies

• Bus fault (physical fault)

• DP interface error

• Different transmission rates in

multiple DP master mode.

• If the DP slave / master interface is

active: Short-circuit on the bus.

• With passive DP slave interface:

transmission rate search, i.e. there

are no other active nodes on the

bus (a master, for example)

Call of OB 86 (when CPU is in RUN

mode). CPU switches to STOP if OB

86 is not loaded.

LED BF1 flashing

• Check the bus cable for short-circuit

or breaks.

• Evaluate the diagnostics.

Reconfigure or correct the

configuration.

Table 4-8 ED BF1 flashes

Possible Errors CPU reaction Possible Remedies

The CPU is DP master / active slave:

• Failure of a connected station

• At least one of the configured

slaves cannot be accessed.

• Incorrect configuration

The CPU is a DP slave

The CPU parameters are incorrectly

set. Possible causes:

• The response monitoring period has

elapsed.

• PROFIBUS DP communication is

down.

• Wrong PROFIBUS address.

• Incorrect configuration

Call of OB 86 (when CPU is in RUN

mode). CPU switches to STOP if OB

86 is not loaded.

Call of OB 86

(if CPU is in RUN mode).

CPU switches to STOP if OB 86 is not

loaded.

Verify that the bus cable is connected

to the CPU, or that the bus is not

interrupted.

Wait until the CPU has completed its

startup. If the LED does not stop

flashing, check the DP slaves or

analyze the diagnostic data of the DP

slaves.

• Check the CPU.

• Verify that the bus connector is

properly seated.

• Check whether the bus cable to the

DP master has been disconnected.

• Check the configuration and

parameter assignment.

S7-300 CPU Data: CPU 315T-2 DP

4-8 Manual, 12/2005, A5E00427933-02

Setting up an S7-300 with a Technology CPU

4.8 Status and error displays of the Technology CPU

Table 4-9 LED BF3 illuminated

Possible Errors CPU reaction Possible Remedies

• Bus fault (physical fault)

• DP interface error

Error message in the technology DB

configured by you.

Check for short-circuit or interruption in

the bus cable.

Table 4-10 LED BF3 flashes

Possible Errors CPU reaction Possible Remedies

• Failure of a connected station

• At least one of the configured

slaves cannot be accessed.

• Incorrect configuration

Error message in the technology DB

configured by you.

Verify that the bus cable is connected

to the CPU, or that the bus is not

interrupted.

Wait until the CPU has completed its

startup. If the LED does not stop

flashing, check the DP slaves or

analyze the diagnostic data of the DP

slaves.

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

4-9

Setting up an S7-300 with a Technology CPU

4.8 Status and error displays of the Technology CPU

S7-300 CPU Data: CPU 315T-2 DP

4-10 Manual, 12/2005, A5E00427933-02

Communication with the S7-300

5.1 5.1 Interfaces

5.1.1 Overview

Overview

The Technology CPU has two interfaces:

• MPI/DP interface (X1)

• PROFIBUS DP(DRIVE) interface (X3)

&38[7'3

5

03,'3

Figure 5-1 Technology CPU interfaces

S7-300 CPU Data: CPU 315T-2 DP

Manual, 12/2005, A5E00427933-02

'3'5,9(

5-1

Communication with the S7-300

5.1 Interfaces

5.1.2 MPI/DP interface (X1)

Availability

The Technology CPU features an MPI/DP interface (X1). A CPU with MPI/DP interface is

supplied with default MPI parameter settings. Depending on your requirements, you may

need to reconfigure the interface as a DP interface in STEP 7.

MPI properties

The MPI (Multi-Point Interface) represents the CPU interface for PG/OP connections, or for

communication on an MPI subnet.

The typical (default) transmission rate of all CPUs is 187.5 kbaud. You can also set 19.2

kbps for communication with an S7-200. You can set baud rates of up to 12 Mbaud.

The CPU automatically broadcasts its bus configuration via the MPI interface (the

transmission rate, for example). A PG, for example, can thus receive the correct parameters

and automatically connect to a MPI subnet.

Note

You may only connect PGs to an MPI subnet which is in RUN.

Other stations (for example, OP, TD, ...) should not be connected to the MPI subnet while

the system is in RUN. Otherwise, transferred data might be corrupted as a result

interference, or global data packages may be lost.

Note

Before you transfer data to the CPU via the MPI interface, you should increase the baud rate

to 1.5 Mbaud or else the data transmission can take a very long time (up to 15 minutes at

187.5 kbaud)!

Operating modes of the MPI/DP interface

Operating modes for MPI/DP interface (X1):

• MPI

• DP master

• DP slave

• I slave

S7-300 CPU Data: CPU 315T-2 DP

5-2 Manual, 12/2005, A5E00427933-02

Loading...

Loading...