Siemens SIMATIC S7-300 Series, CPU 314 IFM, CPU 315, CPU 315-2 DP, CPU 316-2 DP Reference Manual

...

DATASHEET

6ES7314-5AE03-0AB0

SIEMENS

OTHER SYMBOLS:

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

www.rgbelektronika.pl

www.rgbautomatyka.pl

YOUR

PARTNER IN

MAINTENANCE

Repair this product with RGB ELEKTRONIKA

LINEAR

ENCODERS

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

OUR SERVICES

PLC

SYSTEMS

CNC

CONTROLS

ORDER A DIAGNOSIS

INDUSTRIAL

COMPUTERS

POWER

SUPPLIERS

∠

MOTORS

SERVO

DRIVERS

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

Buy this product at RGB AUTOMATYKA

OPERATOR

PANELS

BUY

∠

Preface, Contents

SIMATIC

PLC S7-300,

CPU Specifications CPU 312 IFM

to CPU 318-2 DP

Reference Manual

CPUs

CPU 31x-2 as DP Master/DP

Slave and Direct Communication

Cycle and Reaction times

CPU Function, depending on

CPU and STEP 7 Version

Tips and Tricks

Appendix

Standards, Certificates and

Approvals

Dimensioned Drawings

List of Abbreviations

1

2

3

4

5

A

B

C

This manual is part of the documentation

package with the order number

6ES7398-8FA10-8BA0

Edition 10/2001

A5E00111190-01

This documentation can no longer be ordered under

the given number!

Glossary, Index

Safety Guidelines

This manual contains notices intended to ensure personal safety, as well as to protect the products and

connected equipment against damage. These notices are highlighted by the symbols shown below and

graded according to severity by the following texts:

Danger

!

indicates that death, severe personal injury or substantial property damage will result if proper precautions

are not taken.

Warning

!

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

!

indicates that minor personal injury can result if proper precautions are not taken.

Caution

indicates that property damage can result if proper precautions are not taken.

Notice

draws your attention to particularly important information on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground and to tag circuits, equipment, and

systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

Warning

!

Trademarks

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or

design, are reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschaeftsgebiet Industrie-Automatisierungssysteme

Postfach 4848, D- 90327 Nuernberg

Index-2

Siemens Aktiengesellschaft A5E00111190

This device and its components may only be used for the applications described in the catalog or the

technical description, and only in connection with devices or components from other manufacturers which

have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed

correctly, and operated and maintained as recommended.

SIMATIC, SIMA TIC HMI and SIMATIC NET are registered trademarks of SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to trademarks

might infringe upon the rights of the trademark owners.

Disclaim of LiabilityCopyright W Siemens AG 2001 All rights reserved

We have checked the contents of this manual for agreement

with the hardware and software described. Since deviations

cannot be precluded entirely, we cannot guarantee full

agreement. However, the data in this manual are reviewed

regularly and any necessary corrections included in

subsequent editions. Suggestions for improvement are

welcomed.

Siemens AG 2001

Technical data subject to change.

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

Preface

Purpose of the Manual

This manual gives you a brief overview of 312 IFM to 318-2 CPUS in an S7-300.

You can look up information on how to operate the system, its functions and

technical data of the CPUs.

Essential know-how

General knowledge of automation technology is required for comprehension of this

Manual. You should also be acquainted with basic STEP 7 software as described

in your Programming with STEP 7 V 5.1 Manual.

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

iii

Preface

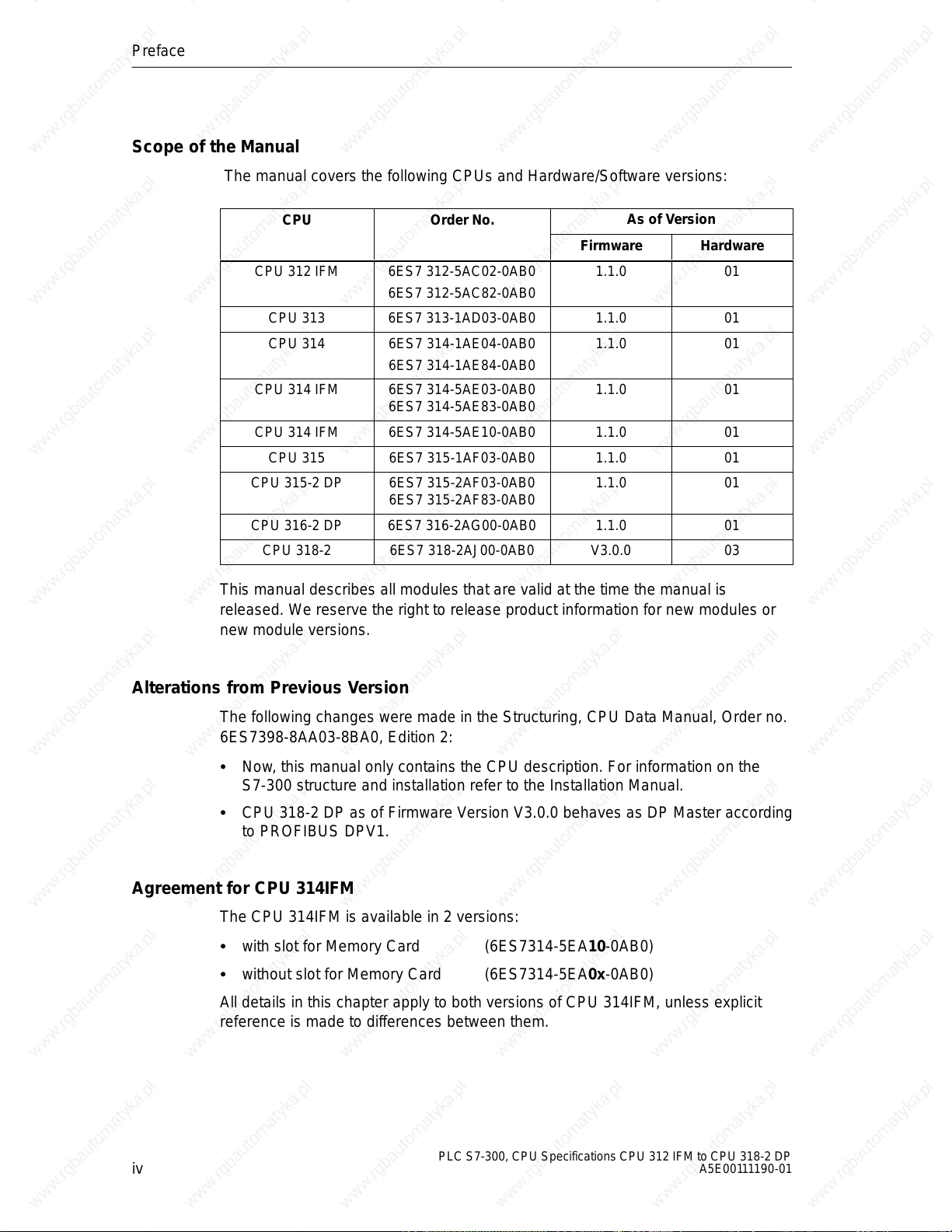

Scope of the Manual

The manual covers the following CPUs and Hardware/Software versions:

CPU Order No.

CPU 312 IFM 6ES7 312-5AC02-0AB0

6ES7 312-5AC82-0AB0

CPU 313 6ES7 313-1AD03-0AB0 1.1.0 01

CPU 314 6ES7 314-1AE04-0AB0

6ES7 314-1AE84-0AB0

CPU 314 IFM 6ES7 314-5AE03-0AB0

6ES7 314-5AE83-0AB0

CPU 314 IFM 6ES7 314-5AE10-0AB0 1.1.0 01

CPU 315 6ES7 315-1AF03-0AB0 1.1.0 01

CPU 315-2 DP 6ES7 315-2AF03-0AB0

6ES7 315-2AF83-0AB0

CPU 316-2 DP 6ES7 316-2AG00-0AB0 1.1.0 01

CPU 318-2 6ES7 318-2AJ00-0AB0 V3.0.0 03

As of Version

Firmware Hardware

1.1.0 01

1.1.0 01

1.1.0 01

1.1.0 01

This manual describes all modules that are valid at the time the manual is

released. We reserve the right to release product information for new modules or

new module versions.

Alterations from Previous Version

The following changes were made in the Structuring, CPU Data Manual, Order no.

6ES7398-8AA03-8BA0, Edition 2:

Now, this manual only contains the CPU description. For information on the

S7-300 structure and installation refer to the Installation Manual.

CPU 318-2 DP as of Firmware Version V3.0.0 behaves as DP Master according

to PROFIBUS DPV1.

Agreement for CPU 314IFM

The CPU 314IFM is available in 2 versions:

with slot for Memory Card (6ES7314-5EA10-0AB0)

without slot for Memory Card (6ES7314-5EA0x-0AB0)

All details in this chapter apply to both versions of CPU 314IFM, unless explicit

reference is made to differences between them.

iv

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

Approbation, Standards and Approvals

The SIMATIC S7-300 series conforms to:

Requirements and criteria to IEC 61131, Part 2

CE labeling

– EC Guideline 73/23/EEC on Low Voltages

– EC Guideline 89/336/EEC on electromagnetic compatibility (EMC)

Canadian Standards Association: CSA C22.2 Number 142, tested (Process

Control Equipment)

Underwriters Laboratories, Inc.: UL 508 registered (Industrial Control

Equipment)

Underwriters Laboratories, Inc.: UL 508 (Industrial Control Equipment)

Factory Mutual Research: Approval Standard Class Number 3611

C-Tick Australia

Preface

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

v

Preface

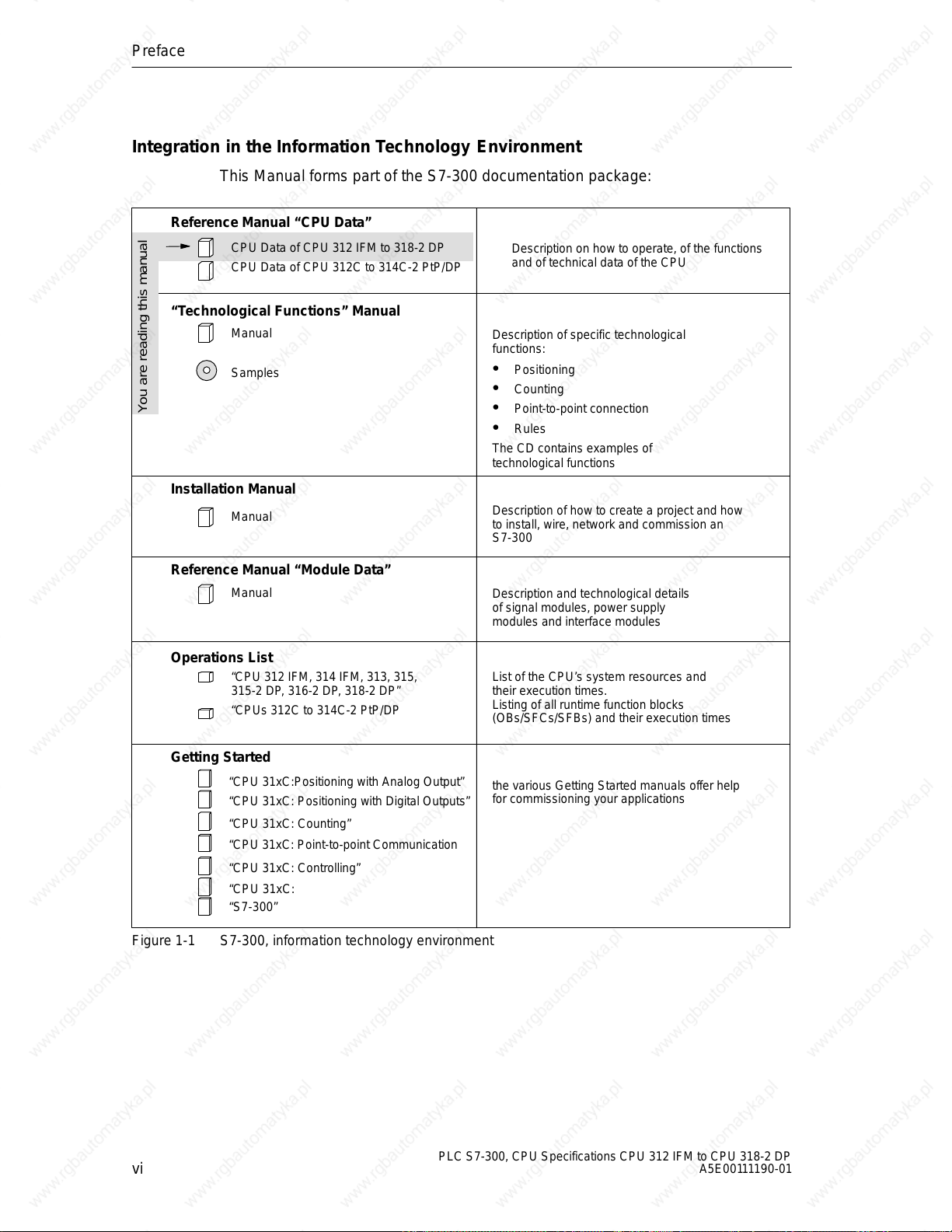

Integration in the Information Technology Environment

This Manual forms part of the S7-300 documentation package:

Reference Manual “CPU Data”

CPU Data of CPU 312 IFM to 318-2 DP

CPU Data of CPU 312C to 314C-2 PtP/DP

“Technological Functions” Manual

Manual

Samples

Description on how to operate, of the functions

and of technical data of the CPU

Description of specific technological

functions:

Positioning

Counting

You are reading this manual

Point-to-point connection

Rules

The CD contains examples of

technological functions

Installation Manual

Manual

Description of how to create a project and how

to install, wire, network and commission an

S7-300

Reference Manual “Module Data”

Manual

Operations List

“CPU 312 IFM, 314 IFM, 313, 315,

315-2 DP, 316-2 DP, 318-2 DP”

“CPUs 312C to 314C-2 PtP/DP

Getting Started

“CPU 31xC:Positioning with Analog Output”

“CPU 31xC: Positioning with Digital Outputs”

“CPU 31xC: Counting”

“CPU 31xC: Point-to-point Communication

“CPU 31xC: Controlling”

“CPU 31xC:

“S7-300”

Figure 1-1 S7-300, information technology environment

Description and technological details

of signal modules, power supply

modules and interface modules

List of the CPU’s system resources and

their execution times.

Listing of all runtime function blocks

(OBs/SFCs/SFBs) and their execution times

the various Getting Started manuals offer help

for commissioning your applications

vi

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

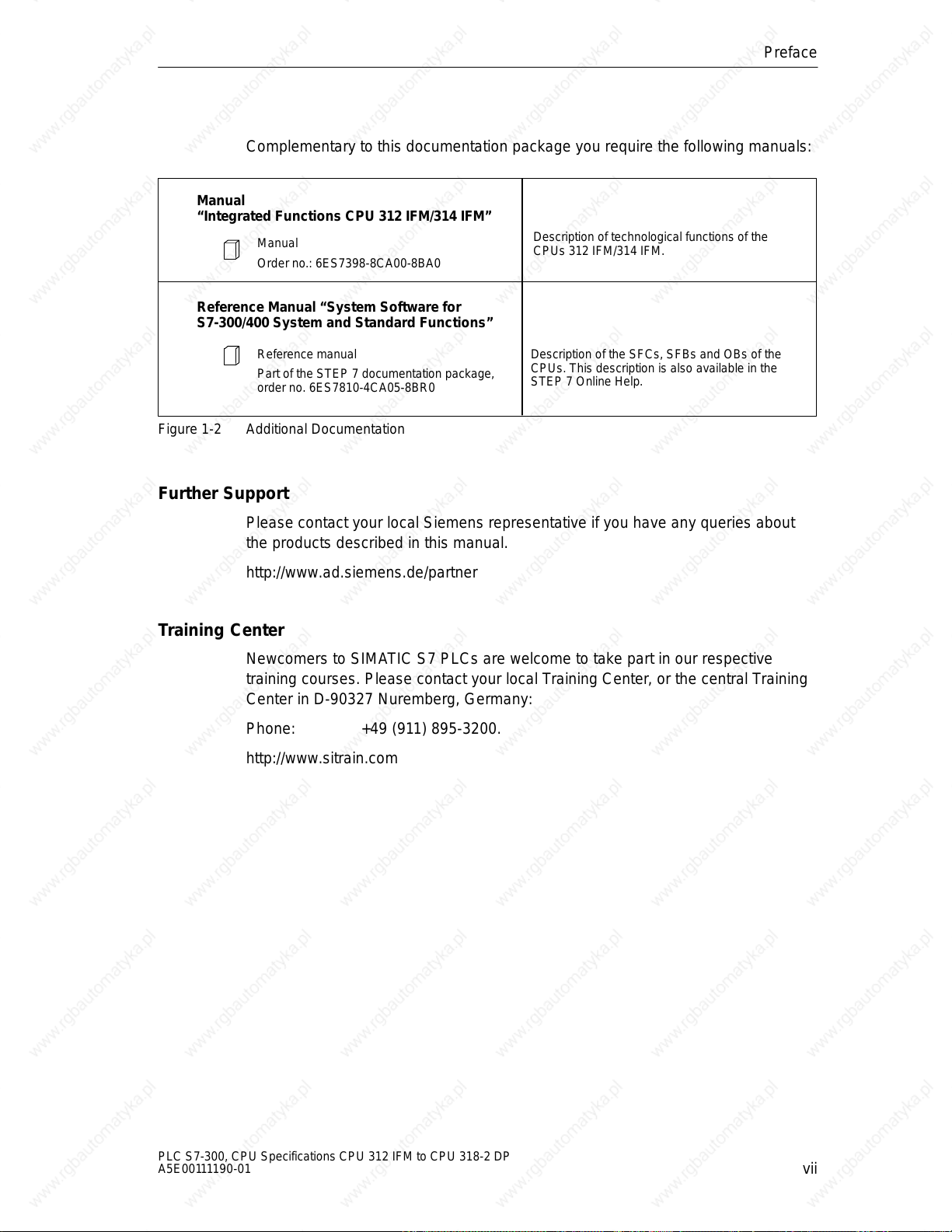

Complementary to this documentation package you require the following manuals:

Manual

“Integrated Functions CPU 312 IFM/314 IFM”

Manual

Order no.: 6ES7398-8CA00-8BA0

Reference Manual “System Software for

S7-300/400 System and Standard Functions”

Preface

Description of technological functions of the

CPUs 312 IFM/314 IFM.

Reference manual

Part of the STEP 7 documentation package,

order no. 6ES7810-4CA05-8BR0

Figure 1-2 Additional Documentation

Further Support

Please contact your local Siemens representative if you have any queries about

the products described in this manual.

http://www.ad.siemens.de/partner

Training Center

Newcomers to SIMATIC S7 PLCs are welcome to take part in our respective

training courses. Please contact your local Training Center, or the central Training

Center in D-90327 Nuremberg, Germany:

Phone: +49 (911) 895-3200.

http://www.sitrain.com

Description of the SFCs, SFBs and OBs of the

CPUs. This description is also available in the

STEP 7 Online Help.

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

vii

Preface

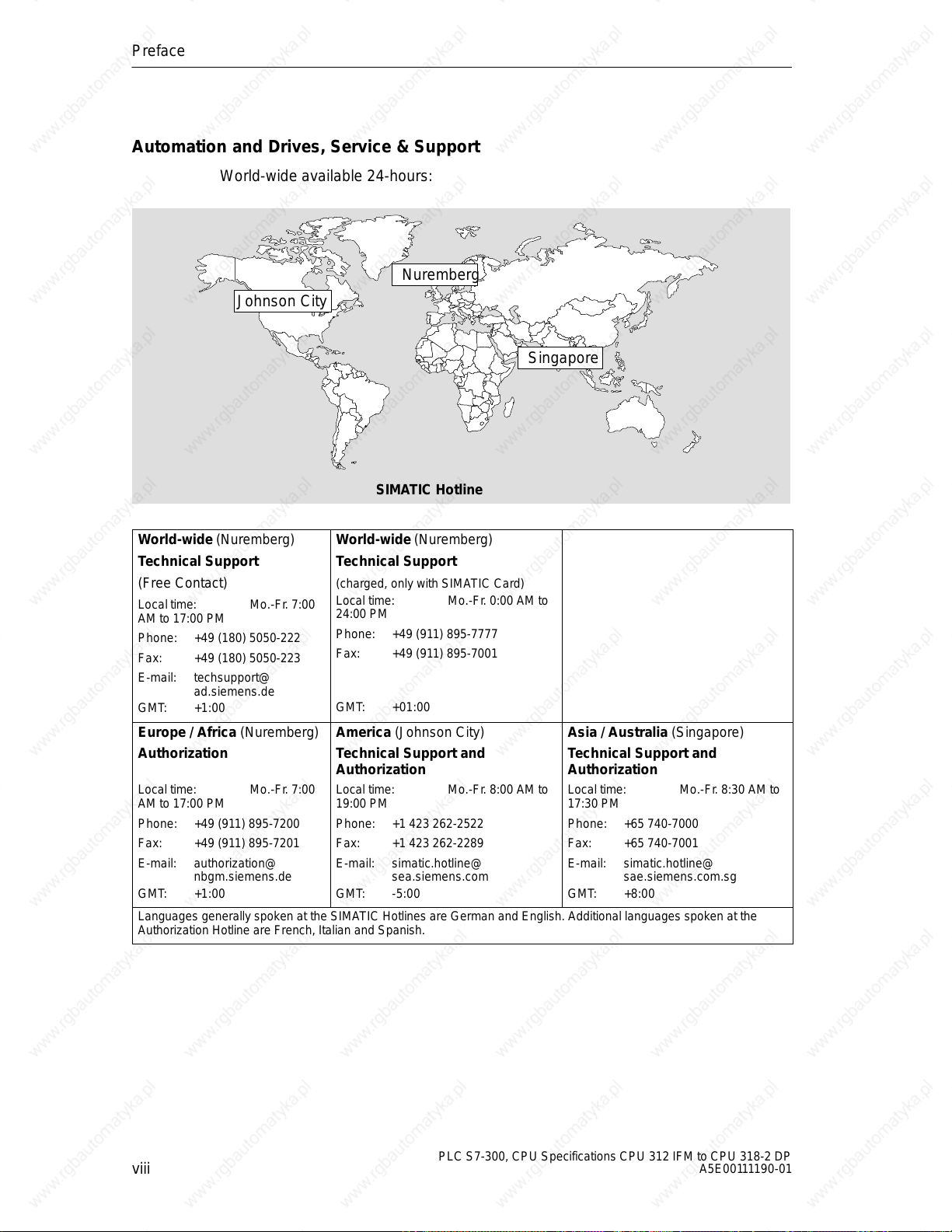

Automation and Drives, Service & Support

World-wide available 24-hours:

Nuremberg

Johnson City

SIMATIC Hotline

Singapore

World-wide (Nuremberg)

T echnical Support

(Free Contact)

Local time: Mo.-Fr. 7:00

AM to 17:00 PM

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

E-mail: techsupport@

ad.siemens.de

GMT: +1:00

Europe / Africa (Nuremberg)

Authorization

Local time: Mo.-Fr. 7:00

AM to 17:00 PM

Phone: +49 (911) 895-7200

Fax: +49 (911) 895-7201

E-mail: authorization@

nbgm.siemens.de

GMT: +1:00

Languages generally spoken at the SIMATIC Hotlines are German and English. Additional languages spoken at the

Authorization Hotline are French, Italian and Spanish.

World-wide (Nuremberg)

T echnical Support

(charged, only with SIMATIC Card)

Local time: Mo.-Fr. 0:00 AM to

24:00 PM

Phone: +49 (911) 895-7777

Fax: +49 (911) 895-7001

GMT: +01:00

America (Johnson City)

Technical Support and

Authorization

Local time: Mo.-Fr. 8:00 AM to

19:00 PM

Phone: +1 423 262-2522

Fax: +1 423 262-2289

E-mail: simatic.hotline@

sea.siemens.com

GMT: -5:00

Asia / Australia (Singapore)

Technical Support and

Authorization

Local time: Mo.-Fr. 8:30 AM to

17:30 PM

Phone: +65 740-7000

Fax: +65 740-7001

E-mail: simatic.hotline@

sae.siemens.com.sg

GMT: +8:00

viii

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

SIMATIC Documentation on the Internet

Documentation is available free of charge on the Internet under:

http://www.ad.siemens.de/support

Please use the Knowledge Manager offered at these locations for quick location of

your required documentation. Our Internet Forum offers a “Documentation”

conferencing room for your questions and solution proposals.

http://www.ad.siemens.de/support

Service & Support on the Internet

As a supplement to our provided documentation we offer our complete know-how

base on the Internet.

http://www.ad.siemens.de/support

There you will find:

Up-to-date product information (News), FAQs (Frequently Asked Questions),

Downloads, Tips and Tricks.

Preface

Our Newsletter always offers you the most up-to-date information on your

products.

The Knowledge Manager finds the right documents for you.

Users and specialists across the globe share their experiences in our Forum.

Your local service partner for Automation & Drives is found in our Service

Partner Database.

Information relating to on–site Service, repairs, spare parts and lots more is

available to you under the topic “Service”.

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

ix

Preface

x

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

Contents

1 CPUs

1.1 Control and Display Elements 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Status and Fault Displays 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Mode Selector Switch 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Backup battery/accumulator 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Memory card 1-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5 MPI and PROFIBUS-DP Interface 1-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.6 Clock and Runtime Meter 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Communication Options of the CPU 1-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Test Functions and Diagnostics 1-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Testing Functions 1-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Diagnostics with LED Display 1-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Diagnostics with STEP 7 1-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 CPUs - Technical Specifications 1-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 CPU 312 IFM 1-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 CPU 313 1-37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3 CPU 314 1-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.4 CPU 314IFM 1-43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.5 CPU 315 1-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.6 CPU 315-2 DP 1-63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.7 CPU 316-2 DP 1-66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.8 CPU 318-2 1-69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 CPU 31x-2 as DP Master/DP Slave and Direct Communication

2.1 Information on DPV1 Functionality 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 DP Address Areas of the CPUs 31x-2 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 CPU 31x-2 as DP Master 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Diagnostics of the CPU 31x-2 as DP Master 2-6 . . . . . . . . . . . . . . . . . . . . . . . .

2.5 CPU 31x-2 as DP-Slave 2-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

xi

Contents

2.6 Diagnosis of the CPU 31x-2 operating as DP-Slave 2-18 . . . . . . . . . . . . . . . . . .

2.6.1 Diagnosis with LEDs 2-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Diagnostics with STEP 5 or STEP 7 2-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Reading Out the Diagnostic Data 2-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.4 Format of the Slave Diagnostic Data 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.5 Station Status 1 to 3 2-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.6 Master PROFIBUS Address 2-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.7 Manufacturer ID 2-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.8 Module Diagnostics 2-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.9 Station Diagnostics 2-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.10 Interrupts 2-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Direct Data Exchange 2-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Diagnosis with Direct Communication 2-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Cycle and Reaction times

3.1 Cycle time 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Response Time 3-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Calculation Examples for Cycle Time and Response Time 3-10 . . . . . . . . . . . .

3.4 Interrupt response time 3-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Calculation Example for the Interrupt Response Time 3-16 . . . . . . . . . . . . . . . .

3.6 Reproducibility of Delay and Watchdog Interrupts 3-16 . . . . . . . . . . . . . . . . . . . .

4 CPU Function, depending on CPU and STEP 7 Version

4.1 Differences between CPU 3182 and CPUs 312 IFM to 3162 DP 4-2 . . . . . . .

4.2 The Differences Between the CPUs 312 IFM to 318 and

Their Previous Versions 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Tips and Tricks

A Standards, Certificates and Approvals

B Dimensioned Drawings

C List of Abbreviations

Glossary

Index

xii

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

Figures

1-1 Control and Display Elements of the CPUs 1-2 . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Status and Fault Displays of the CPUs 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Principle of Connection Resource Allocation for CPU 318-2 1-15 . . . . . . . . . . .

1-4 The Principle of Forcing with S7-300 CPUs (CPU 312IFM to 316-2DP) 1-21 .

1-5 Display of the States of the Interrupt Inputs of the CPU 312 IFM 1-26 . . . . . . .

1-6 Front View of the CPU 312 IFM 1-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Wiring diagram of the CPU 312 IFM 1-34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 Basic Circuit Diagram of the CPU 312 IFM 1-36 . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9 Display of the States of the Interrupt Inputs of the CPU 314 IFM 1-45 . . . . . . .

1-10 Front View of the CPU 314 IFM 1-46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-11 Wiring diagram of the CPU 314 IFM 1-56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12 Basic Circuit Diagram of the CPU 314 IFM (Special Inputs

and Analog Inputs/Outputs) 1-57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-13 Basic Circuit Diagram of the CPU 314 IFM (Digital Inputs/Outputs) 1-58 . . . . .

1-14 Connecting 2-wire measurement transducers to the analog inputs

of CPU 314 IFM 1-59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-15 Wiring of 4-wire measurement transducers to the analog inputs

of CPU 314 IFM 1-59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Diagnostics with CPU 315-2DP < 315-2AF03 2-8 . . . . . . . . . . . . . . . . . . . . . . .

2-2 Diagnostics with CPU 31x-2 (315-2DP as of 315-2AF03) 2-9 . . . . . . . . . . . . .

2-3 Diagnostic Addresses for DP Master and DP Slave 2-10 . . . . . . . . . . . . . . . . . .

2-4 Transfer Memory in a CPU 31x-2 operating as DP Slave 2-14 . . . . . . . . . . . . .

2-5 Diagnostic Addresses for DP Master and DP Slave 2-22 . . . . . . . . . . . . . . . . . .

2-6 Format of the Slave Diagnostic Data 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Structure of the Module Diagnosis of the CPU 31x-2 2-28 . . . . . . . . . . . . . . . . .

2-8 Structure of the Station Diagnosis 2-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 Byte x +4 to x +7 for Diagnostic and Hardware interrupt 2-30 . . . . . . . . . . . . . .

2-10 Direct Communication using CPU 31x-2 2-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11 Diagnostic address for receiver with direct communication 2-33 . . . . . . . . . . . .

3-1 Component Parts of the Cycle Time 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Shortest Response Time 3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Longest Response Time 3-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Overview of the Bus Runtime on PROFIBUS-DP at 1.5 Mbps

and 12Mbps 3-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Sample Configuration 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1 Dimensioned Drawing of the CPU 312 IFM B-1 . . . . . . . . . . . . . . . . . . . . . . . . .

B-2 Dimensioned Drawing of the CPU 313/314/315/315-2 DP/316-2DP B-2 . . . .

B-3 Dimensioned Drawing of the CPU 318-2 B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-4 Dimensioned Drawing of the CPU 314 IFM, Front View B-4 . . . . . . . . . . . . . . .

B-5 Dimensioned Drawing of the CPU 314 IFM, Side View B-5 . . . . . . . . . . . . . . .

Contents

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

xiii

Contents

Tables

1-1 The Differences in Control and Display Elements Between CPUs 1-2 . . . . . .

1-2 Using a Backup Battery or Accumulator 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Memory Cards 1-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 CPU Interfaces 1-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Characteristics of the Clock of the CPUs 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 CPU Communication Options 1-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Connection Resources for CPUs 312 IFM to 316-2 DP 1-14 . . . . . . . . . . . . . . .

1-8 Communication Resources for CPU 318-2 1-15 . . . . . . . . . . . . . . . . . . . . . . . . .

1-9 Diagnostic LEDs of the CPU 1-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-10 Start Information for OB 40 for the Interrupt Inputs

of the Integrated I/Os 1-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-11 Start Information for OB 40 for the Interrupt Inputs

of the Integrated I/Os 1-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12 Characteristic Features of the Integrated Inputs and Outputs

of the CPU 314 IFM 1-50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Meaning of the BUSF LED of the CPU 31x-2 as DP Master 2-6 . . . . . . . . . . .

2-2 Reading Diagnostic Data with STEP 7 2-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Event Detection of the CPU 31x-2 as DP Master 2-11 . . . . . . . . . . . . . . . . . . . .

2-4 Evaluating RUN-STOP Transitions of the DP Slaves in the DP Master 2-12 . .

2-5 Example of an address area configuration for transfer memory 2-15 . . . . . . . .

2-6 Meaning of the BUSF LEDs in the CPU 31x-2 as DP Slave 2-19 . . . . . . . . . . .

2-7 Fetching diagnostic data with STEP 5 and STEP 7

in the master system 2-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Event Detection of the CPU 31x-2 as DP Slave 2-23 . . . . . . . . . . . . . . . . . . . . .

2-9 Evaluating RUN-STOP Transitions in the DP Master/DP Slave 2-23 . . . . . . . .

2-10 Structure of Station Status 1 (Byte 0) 2-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11 Structure of Station Status 2 (Byte 1) 2-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12 Structure of Station Status 3 (Byte 2) 2-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-13 Structure of the Master PROFIBUS Address (Byte 3) 2-27 . . . . . . . . . . . . . . . .

2-14 Structure of the Manufacturer Identification (Bytes 4 and 5) 2-27 . . . . . . . . . . .

2-15 Event Detection by CPU 31x-2 Acting as Receiver in

Direct Communication 2-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-16 Evaluation of the Station Failure of the Sender During

Direct Communication 2-34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Operating System Processing Times of the CPUs 3-6 . . . . . . . . . . . . . . . . . . .

3-2 Process image update of the CPUs 3-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 CPU-specific Factors for the User Program Processing Time 3-7 . . . . . . . . . .

3-4 Updating the S7 Timers 3-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Update Time and SFB Runtimes 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Extending the Cycle by Nesting Interrupts 3-10 . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Response time of the CPUs to process interrupts 3-14 . . . . . . . . . . . . . . . . . . .

3-8 Diagnostic Interrupt Response Times of the CPUs 3-15 . . . . . . . . . . . . . . . . . .

3-9 Reproducibility of the Delay and Watchdog Interrupts of the CPUs 3-17 . . . . .

xiv

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

CPUs

In This Section

Section Contents Page

1.1 Control and Display Elements 1-2

1.2 CPU Communication Options 1-11

1.3 Test Functions and Diagnostics 1-19

1.4 CPUs - Technical Specifications 1-24

Agreement for CPU 314IFM

The CPU 314IFM is available in 2 versions:

with slot for memory card (6ES7314-5EA10-0AB0)

without slot for memory card (6ES7314-5EA0x-0AB0/

6314ES7314-5EA8x-0AB0)

All details in this chapter apply to both versions of the CPU314IFM unless explicit

reference is made to differences between them.

1

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

1-1

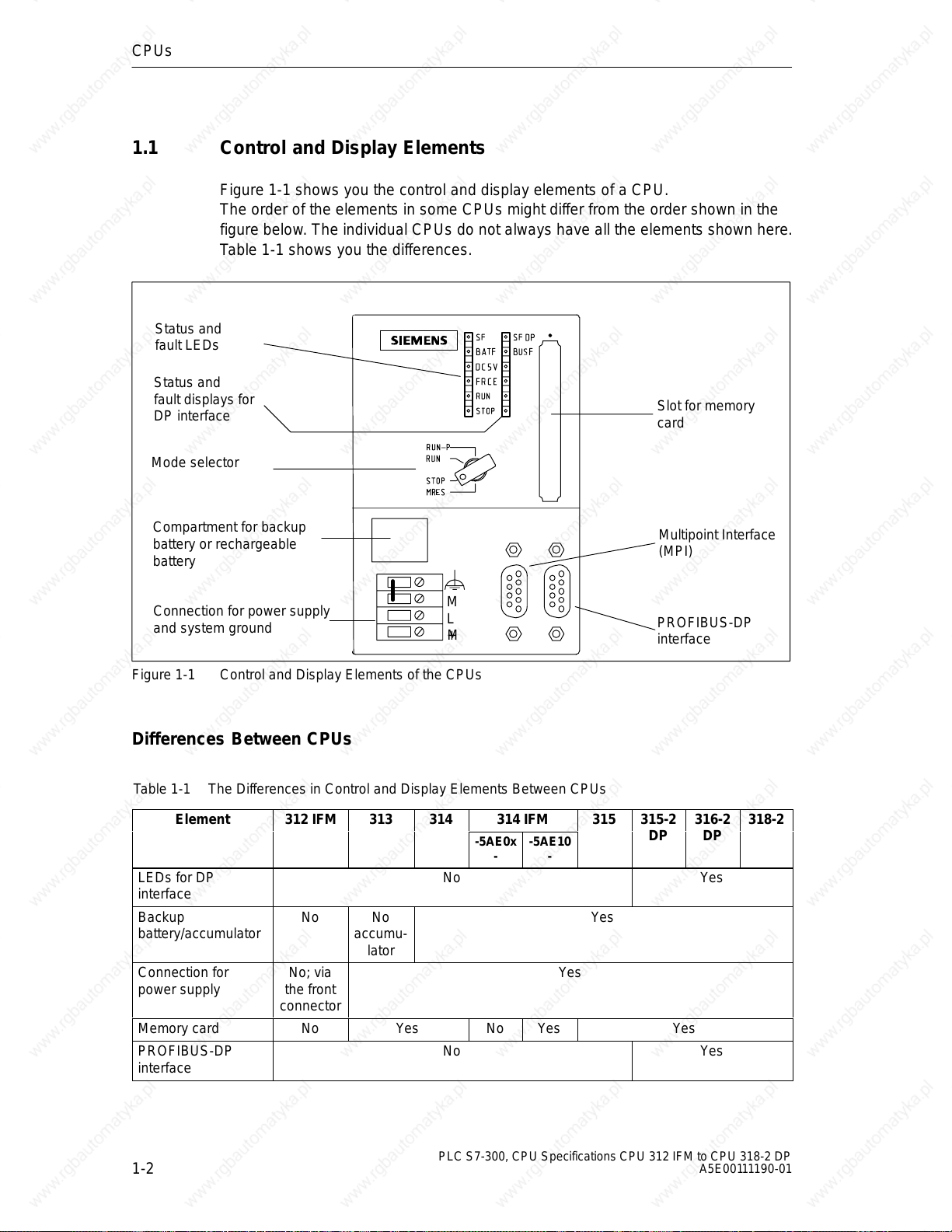

CPUs

1.1 Control and Display Elements

Figure 1-1 shows you the control and display elements of a CPU.

The order of the elements in some CPUs might differ from the order shown in the

figure below. The individual CPUs do not always have all the elements shown here.

Table 1-1 shows you the differences.

Status and

fault LEDs

Status and

fault displays for

DP interface

Mode selector

Slot for memory

card

Compartment for backup

battery or rechargeable

battery

Connection for power supply

and system ground

Figure 1-1 Control and Display Elements of the CPUs

M

L

+M

Multipoint Interface

(MPI)

PROFIBUS-DP

interface

Differences Between CPUs

Table 1-1 The Differences in Control and Display Elements Between CPUs

Element 312 IFM 313 314

LEDs for DP

interface

Backup

battery/accumulator

Connection for

power supply

Memory card No Yes No Yes Yes

PROFIBUS-DP

interface

No No

accumu-

lator

No; via

the front

connector

No Yes

No Yes

314 IFM

-5AE0x--5AE10

315 315-2 316-2 318-2

DP DP

-

Yes

Yes

1-2

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

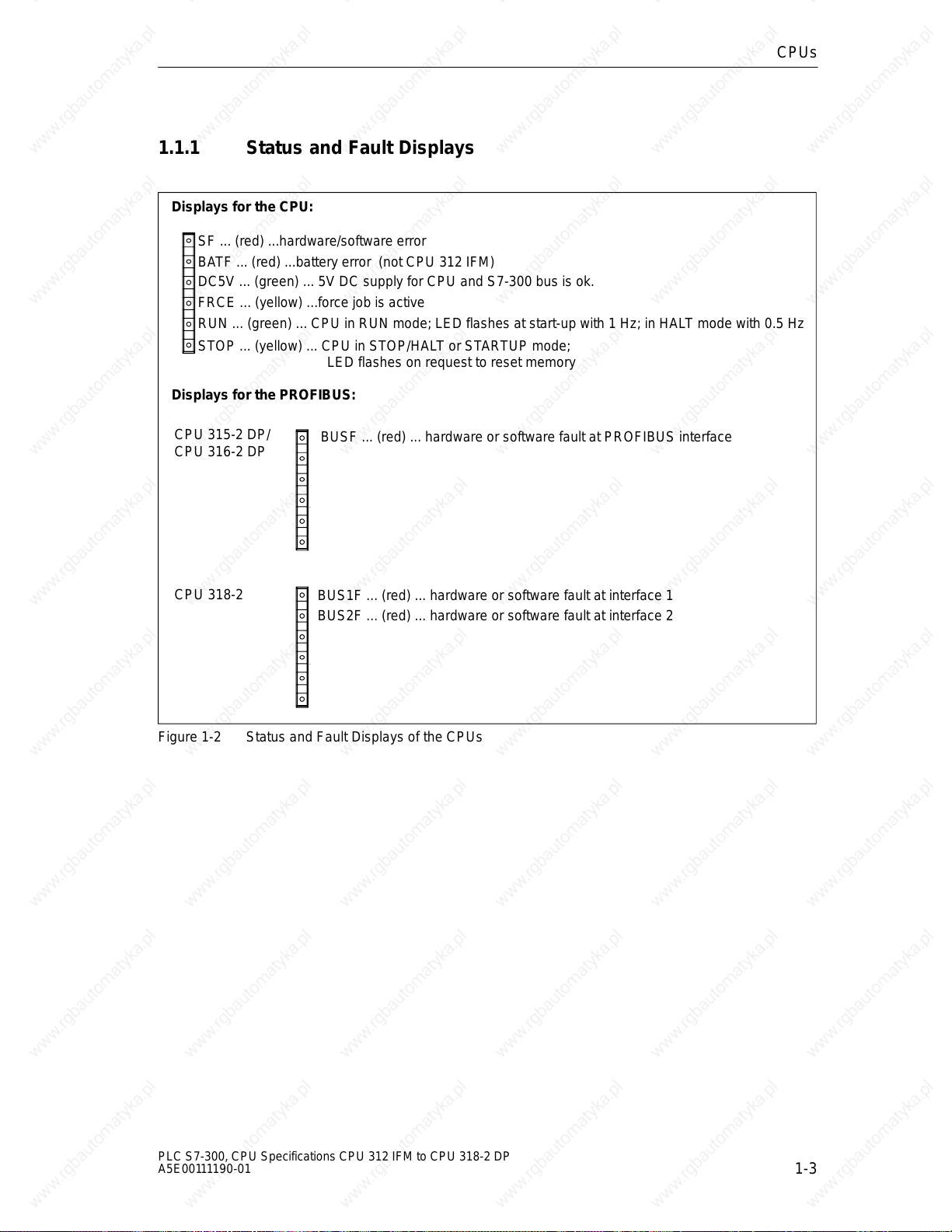

1.1.1 Status and Fault Displays

Displays for the CPU:

SF ... (red) ...hardware/software error

BATF ... (red) ...battery error (not CPU 312 IFM)

DC5V ... (green) ... 5V DC supply for CPU and S7-300 bus is ok.

FRCE ... (yellow) ...force job is active

RUN ... (green) ... CPU in RUN mode; LED flashes at start-up with 1 Hz; in HALT mode with 0.5 Hz

STOP ... (yellow) ... CPU in STOP/HALT or STARTUP mode;

LED flashes on request to reset memory

Displays for the PROFIBUS:

CPUs

CPU 315-2 DP/

CPU 316-2 DP

CPU 318-2

Figure 1-2 Status and Fault Displays of the CPUs

BUSF ... (red) ... hardware or software fault at PROFIBUS interface

BUS1F ... (red) ... hardware or software fault at interface 1

BUS2F ... (red) ... hardware or software fault at interface 2

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

1-3

CPUs

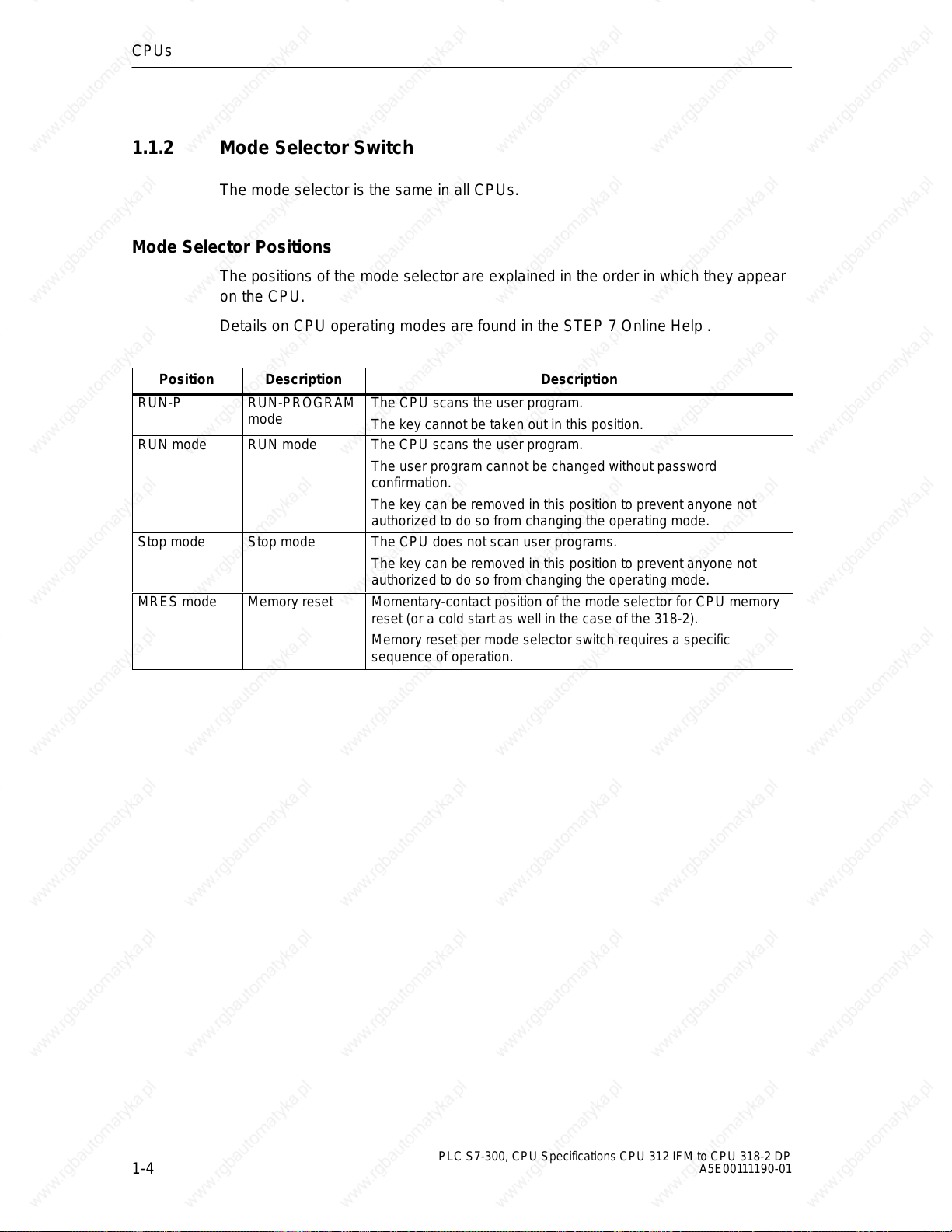

1.1.2 Mode Selector Switch

The mode selector is the same in all CPUs.

Mode Selector Positions

The positions of the mode selector are explained in the order in which they appear

on the CPU.

Details on CPU operating modes are found in the STEP 7 Online Help .

Position Description Description

RUN-P RUN-PROGRAM

mode

RUN mode RUN mode The CPU scans the user program.

Stop mode Stop mode The CPU does not scan user programs.

MRES mode Memory reset Momentary-contact position of the mode selector for CPU memory

The CPU scans the user program.

The key cannot be taken out in this position.

The user program cannot be changed without password

confirmation.

The key can be removed in this position to prevent anyone not

authorized to do so from changing the operating mode.

The key can be removed in this position to prevent anyone not

authorized to do so from changing the operating mode.

reset (or a cold start as well in the case of the 318-2).

Memory reset per mode selector switch requires a specific

sequence of operation.

1-4

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

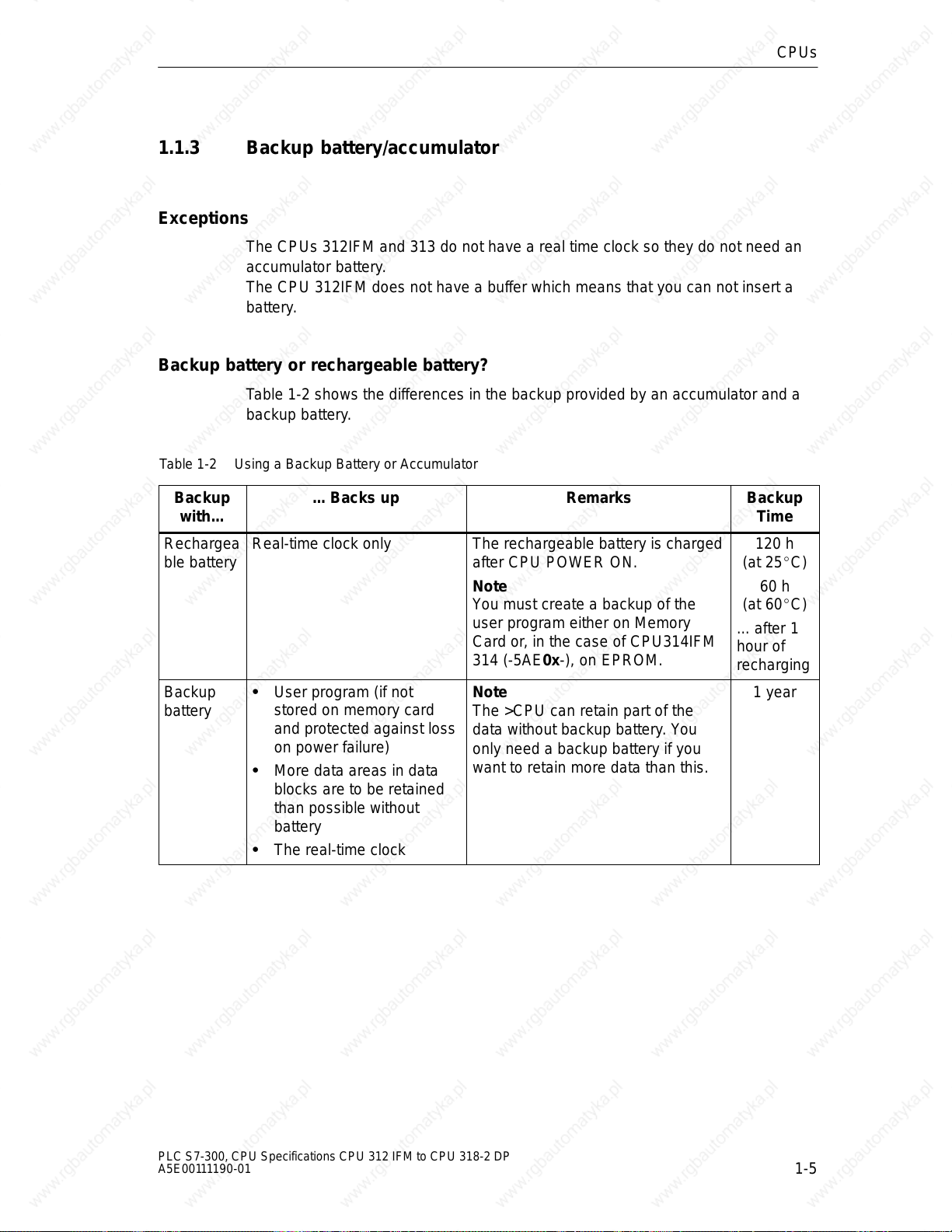

1.1.3 Backup battery/accumulator

Exceptions

The CPUs 312IFM and 313 do not have a real time clock so they do not need an

accumulator battery.

The CPU 312IFM does not have a buffer which means that you can not insert a

battery.

Backup battery or rechargeable battery?

Table 1-2 shows the differences in the backup provided by an accumulator and a

backup battery.

Table 1-2 Using a Backup Battery or Accumulator

CPUs

Backup

with...

Rechargea

ble battery

Backup

battery

... Backs up Remarks Backup

Real-time clock only The rechargeable battery is charged

after CPU POWER ON.

Note

You must create a backup of the

user program either on Memory

Card or, in the case of CPU314IFM

314 (-5AE0x-), on EPROM.

User program (if not

stored on memory card

and protected against loss

on power failure)

More data areas in data

blocks are to be retained

than possible without

battery

Note

The >CPU can retain part of the

data without backup battery. You

only need a backup battery if you

want to retain more data than this.

The real-time clock

Time

120 h

(at 25C)

60 h

(at 60C)

... after 1

hour of

recharging

1 year

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

1-5

CPUs

then uploaded from the memory card to

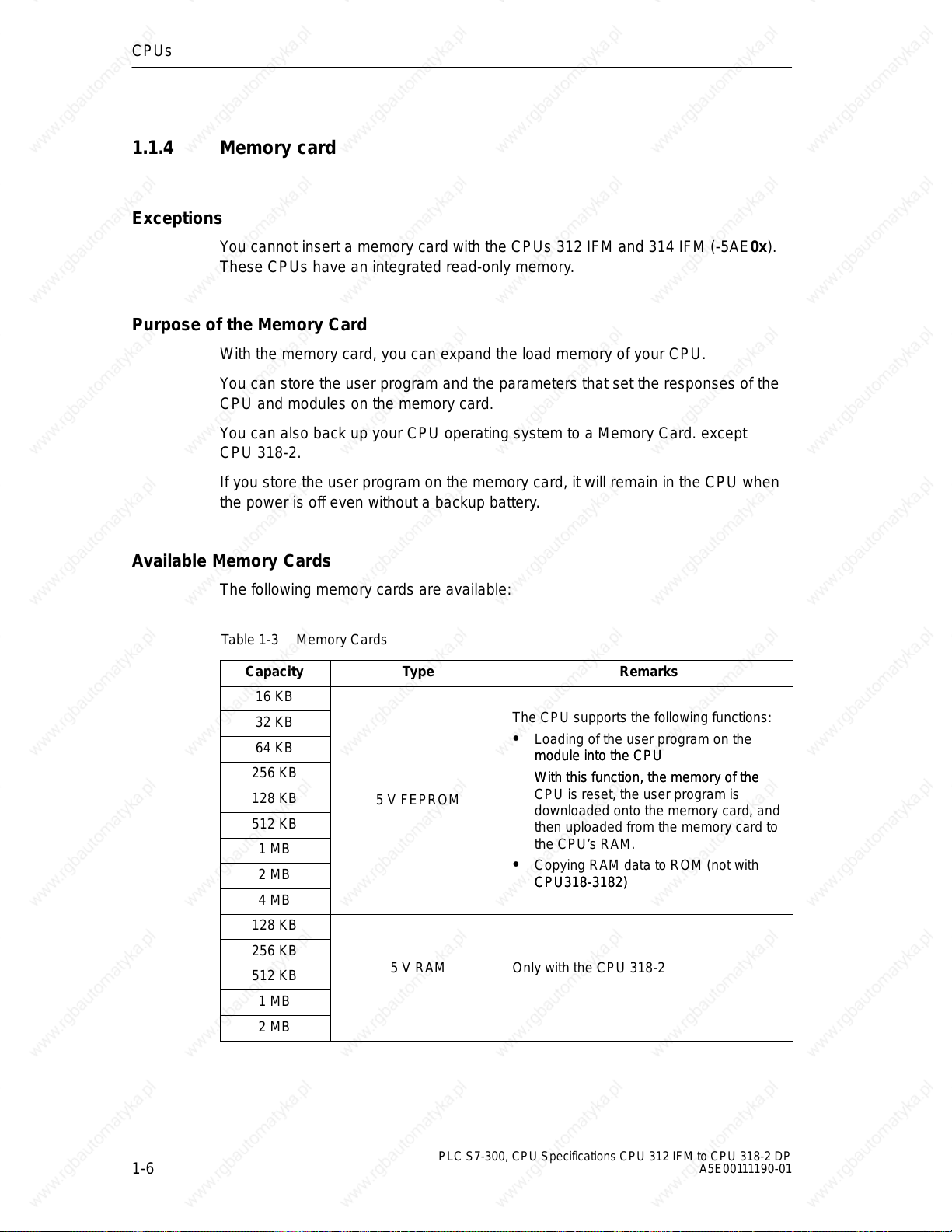

1.1.4 Memory card

Exceptions

You cannot insert a memory card with the CPUs 312 IFM and 314 IFM (-5AE0x).

These CPUs have an integrated read-only memory.

Purpose of the Memory Card

With the memory card, you can expand the load memory of your CPU.

You can store the user program and the parameters that set the responses of the

CPU and modules on the memory card.

You can also back up your CPU operating system to a Memory Card. except

CPU 318-2.

If you store the user program on the memory card, it will remain in the CPU when

the power is off even without a backup battery.

Available Memory Cards

The following memory cards are available:

Table 1-3 Memory Cards

Capacity

16 KB

32 KB

64 KB

256 KB

128 KB

512 KB

1 MB

2 MB

4 MB

128 KB

256 KB

512 KB

1 MB

2 MB

Type Remarks

The CPU supports the following functions:

Loading of the user program on the

module into the CPU

module into the CPU

With this function, the memory of the

With this function, the memory of the

5 V FEPROM

CPU is reset, the user program is

downloaded onto the memory card, and

then uploaded from the memory card to

the CPU’s RAM.

Copying RAM data to ROM (not with

CPU318-3182)

CPU318-3182)

5 V RAM Only with the CPU 318-2

1-6

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

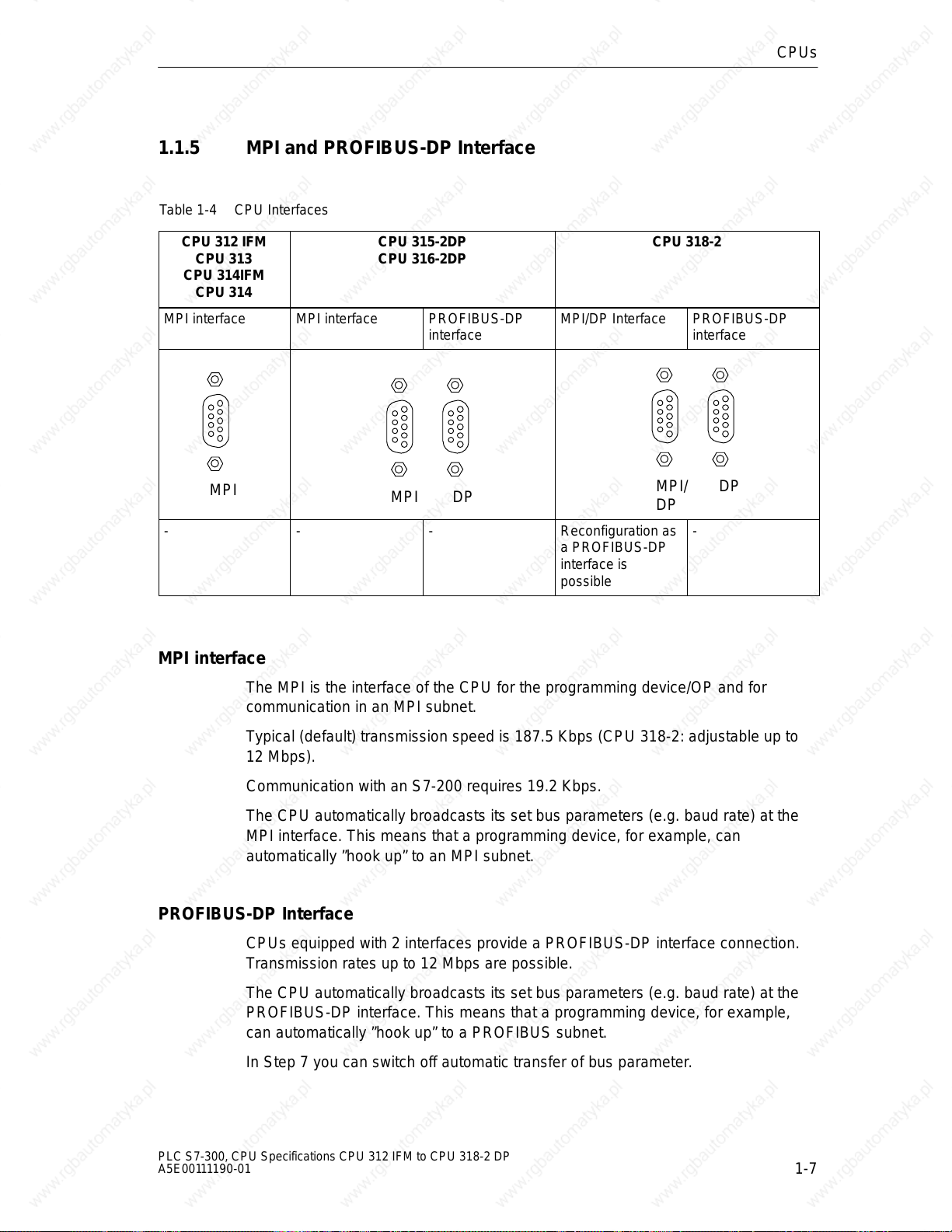

1.1.5 MPI and PROFIBUS-DP Interface

Table 1-4 CPU Interfaces

CPUs

CPU 312 IFM

CPU 313

CPU 314IFM

CPU 314

MPI interface MPI interface PROFIBUS-DP

MPI

- - - Reconfiguration as

CPU 315-2DP

CPU 316-2DP

MPI/DP Interface PROFIBUS-DP

interface

MPI DP

a PROFIBUS-DP

interface is

possible

CPU 318-2

MPI interface

The MPI is the interface of the CPU for the programming device/OP and for

communication in an MPI subnet.

MPI/

DP

interface

DP

-

Typical (default) transmission speed is 187.5 Kbps (CPU 318-2: adjustable up to

12 Mbps).

Communication with an S7-200 requires 19.2 Kbps.

The CPU automatically broadcasts its set bus parameters (e.g. baud rate) at the

MPI interface. This means that a programming device, for example, can

automatically ”hook up” to an MPI subnet.

PROFIBUS-DP Interface

CPUs equipped with 2 interfaces provide a PROFIBUS-DP interface connection.

Transmission rates up to 12 Mbps are possible.

The CPU automatically broadcasts its set bus parameters (e.g. baud rate) at the

PROFIBUS-DP interface. This means that a programming device, for example,

can automatically ”hook up” to a PROFIBUS subnet.

In Step 7 you can switch off automatic transfer of bus parameter.

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

1-7

CPUs

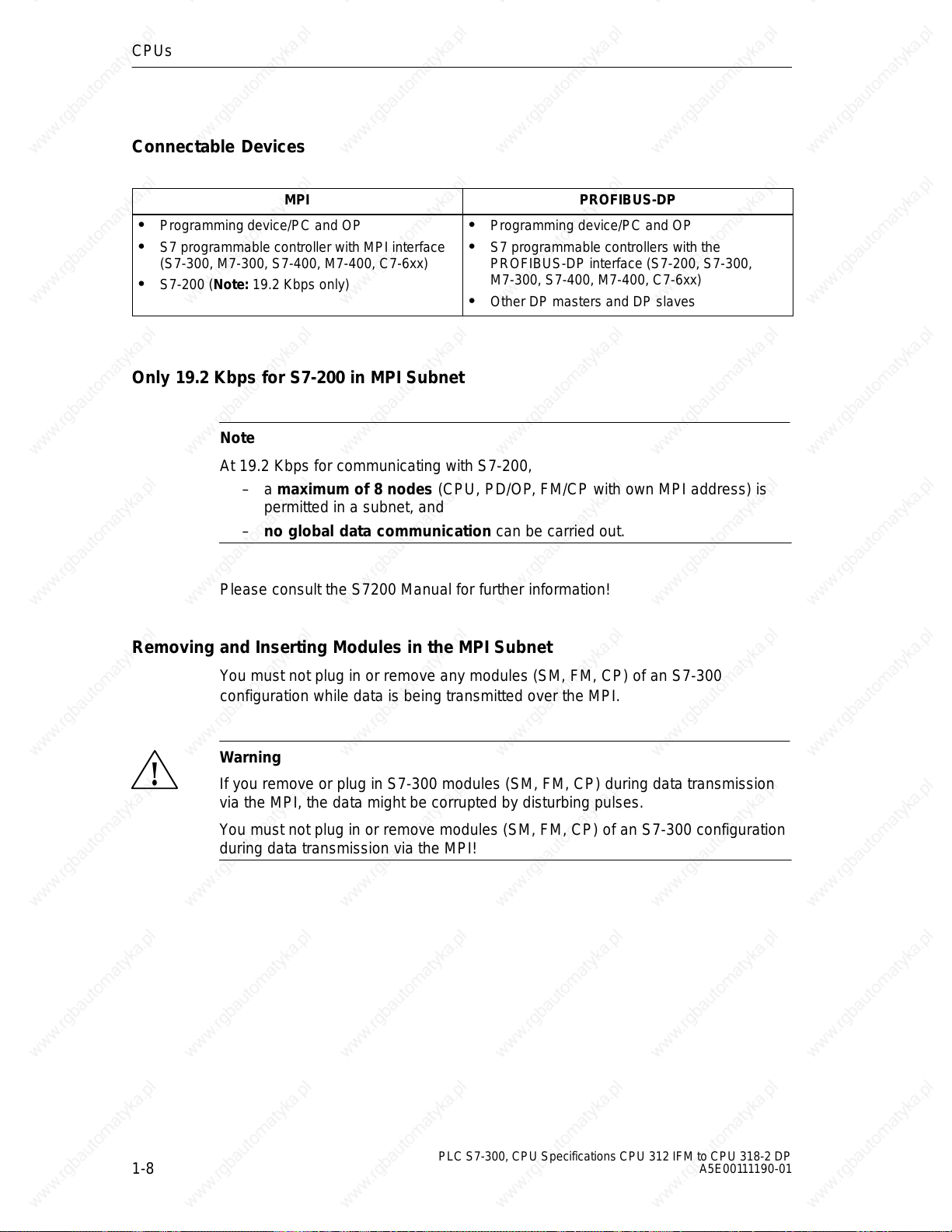

Connectable Devices

MPI PROFIBUS-DP

Programming device/PC and OP

S7 programmable controller with MPI interface

(S7-300, M7-300, S7-400, M7-400, C7-6xx)

S7-200 (Note: 19.2 Kbps only)

Only 19.2 Kbps for S7-200 in MPI Subnet

Note

At 19.2 Kbps for communicating with S7-200,

– a maximum of 8 nodes (CPU, PD/OP, FM/CP with own MPI address) is

permitted in a subnet, and

– no global data communication can be carried out.

Programming device/PC and OP

S7 programmable controllers with the

PROFIBUS-DP interface (S7-200, S7-300,

M7-300, S7-400, M7-400, C7-6xx)

Other DP masters and DP slaves

Please consult the S7200 Manual for further information!

Removing and Inserting Modules in the MPI Subnet

You must not plug in or remove any modules (SM, FM, CP) of an S7-300

configuration while data is being transmitted over the MPI.

Warning

!

If you remove or plug in S7-300 modules (SM, FM, CP) during data transmission

via the MPI, the data might be corrupted by disturbing pulses.

You must not plug in or remove modules (SM, FM, CP) of an S7-300 configuration

during data transmission via the MPI!

1-8

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

Loss of GD packets Following Change in the MPI Subnet During Operation

Warning

!

Loss of data packets in the MPI subnet:

Connecting an additional CPU to the MPI subnet during operation can lead to loss

of GD packets and to an increase in cycle time.

Remedy:

1. Disconnect the node to be connected from the supply.

2. Connect the node to the MPI subnet.

3. Switch the node on.

CPUs

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

1-9

CPUs

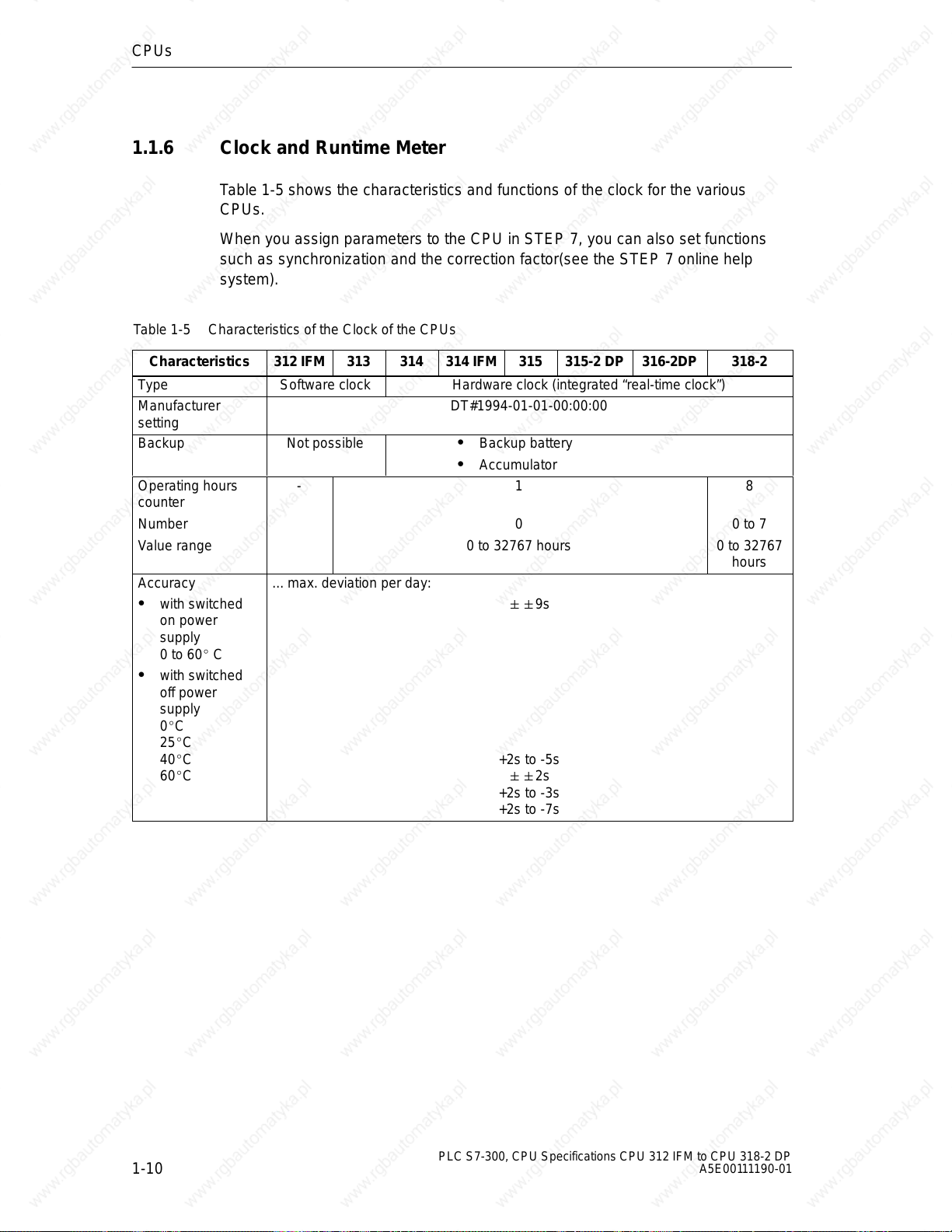

1.1.6 Clock and Runtime Meter

Table 1-5 shows the characteristics and functions of the clock for the various

CPUs.

When you assign parameters to the CPU in STEP 7, you can also set functions

such as synchronization and the correction factor(see the STEP 7 online help

system).

Table 1-5 Characteristics of the Clock of the CPUs

Characteristics

Type Software clock Hardware clock (integrated “real-time clock”)

Manufacturer

setting

Backup Not possible Backup battery

312 IFM 313 314 314 IFM 315 315-2 DP 316-2DP 318-2

DT#1994-01-01-00:00:00

Accumulator

Operating hours

counter

Number

Value range

Accuracy

with switched

on power

supply

0 to 60 C

with switched

off power

supply

0C

25C

40C

60C

- 1

0

0 to 32767 hours

... max. deviation per day:

9s

+2s to -5s

2s

+2s to -3s

+2s to -7s

8

0 to 7

0 to 32767

hours

1-10

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

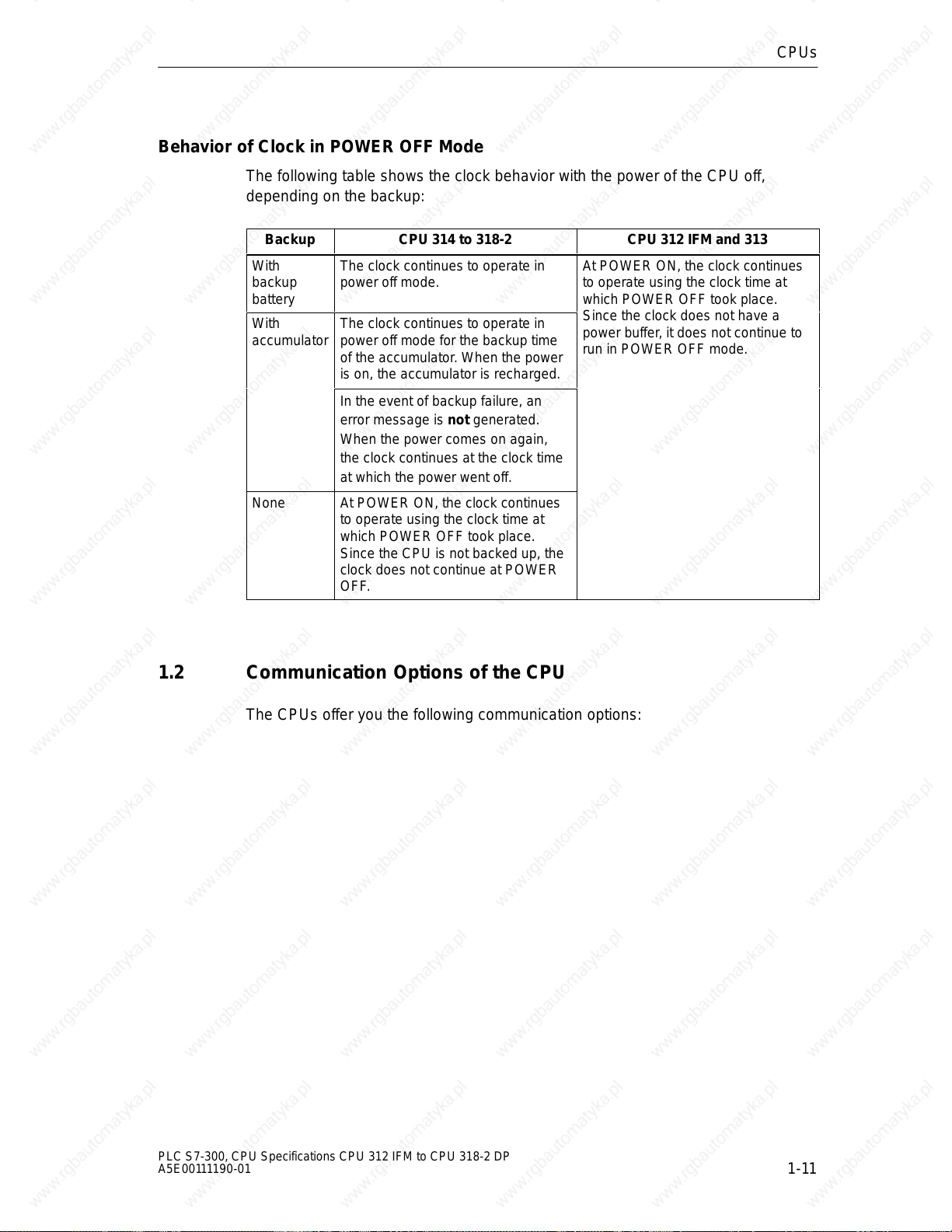

Behavior of Clock in POWER OFF Mode

The following table shows the clock behavior with the power of the CPU off,

depending on the backup:

Backup CPU 314 to 318-2 CPU 312 IFM and 313

With

backup

battery

With

accumulator

None At POWER ON, the clock continues

The clock continues to operate in

power off mode.

The clock continues to operate in

power off mode for the backup time

of the accumulator. When the power

is on, the accumulator is recharged.

In the event of backup failure, an

error message is not generated.

When the power comes on again,

the clock continues at the clock time

at which the power went off.

to operate using the clock time at

which POWER OFF took place.

Since the CPU is not backed up, the

clock does not continue at POWER

OFF.

CPUs

At POWER ON, the clock continues

to operate using the clock time at

which POWER OFF took place.

Since the clock does not have a

power buffer, it does not continue to

run in POWER OFF mode.

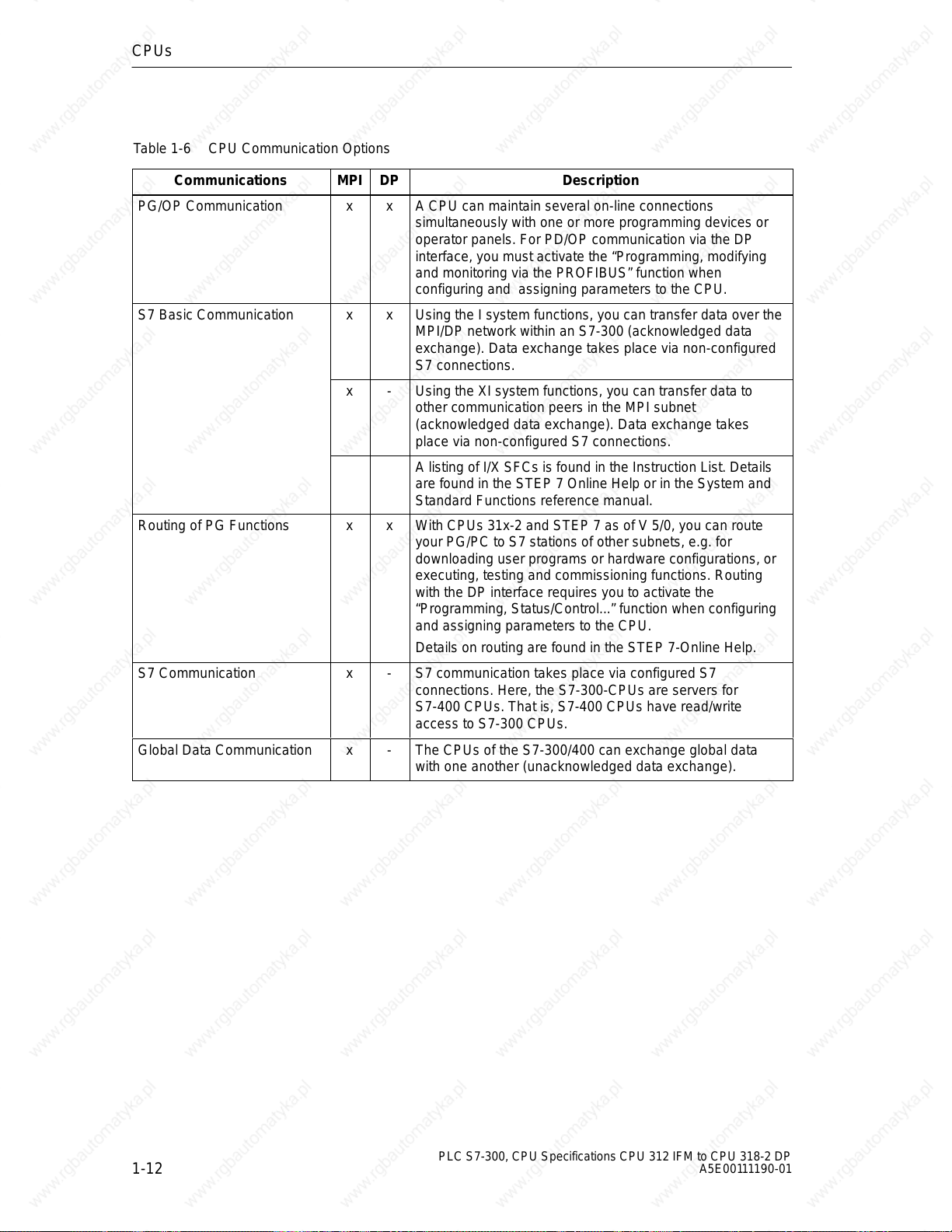

1.2 Communication Options of the CPU

The CPUs offer you the following communication options:

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

1-11

CPUs

Table 1-6 CPU Communication Options

Communications

PG/OP Communication x x A CPU can maintain several on-line connections

S7 Basic Communication x x Using the I system functions, you can transfer data over the

Routing of PG Functions x x With CPUs 31x-2 and STEP 7 as of V 5/0, you can route

S7 Communication x - S7 communication takes place via configured S7

Global Data Communication x - The CPUs of the S7-300/400 can exchange global data

MPI DP Description

simultaneously with one or more programming devices or

operator panels. For PD/OP communication via the DP

interface, you must activate the “Programming, modifying

and monitoring via the PROFIBUS” function when

configuring and assigning parameters to the CPU.

MPI/DP network within an S7-300 (acknowledged data

exchange). Data exchange takes place via non-configured

S7 connections.

x - Using the XI system functions, you can transfer data to

other communication peers in the MPI subnet

(acknowledged data exchange). Data exchange takes

place via non-configured S7 connections.

A listing of I/X SFCs is found in the Instruction List. Details

are found in the STEP 7 Online Help or in the System and

Standard Functions reference manual.

your PG/PC to S7 stations of other subnets, e.g. for

downloading user programs or hardware configurations, or

executing, testing and commissioning functions. Routing

with the DP interface requires you to activate the

“Programming, Status/Control...” function when configuring

and assigning parameters to the CPU.

Details on routing are found in the STEP 7-Online Help.

connections. Here, the S7-300-CPUs are servers for

S7-400 CPUs. That is, S7-400 CPUs have read/write

access to S7-300 CPUs.

with one another (unacknowledged data exchange).

1-12

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

Connection Resources

Every communication connection requires a communication resource on the

S7 CPU as a management unit for the duration of the communication. Every

S7 CPU has a certain number of connection resources available to it according to

its technical specifications which can be assigned to various communication

services (PD/OP communication, S7 communication or S7 basic communication).

The distribution of connection resources differs between CPUs 312 IFM to 316-2

DP (see the table 3-6) and the CPU 318-2 (see Table 1-8):

CPUs

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

1-13

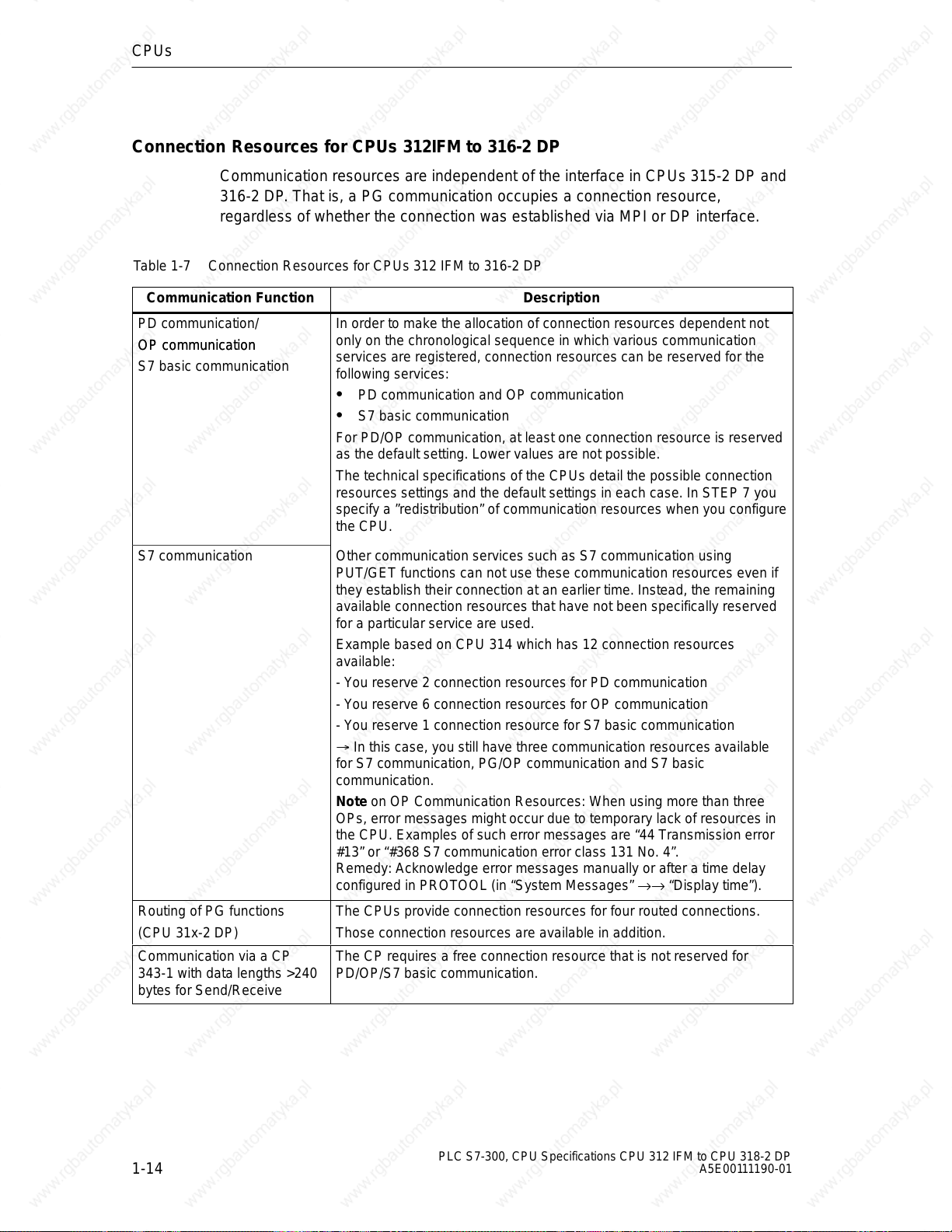

CPUs

Connection Resources for CPUs 312IFM to 316-2 DP

Communication resources are independent of the interface in CPUs 315-2 DP and

316-2 DP. That is, a PG communication occupies a connection resource,

regardless of whether the connection was established via MPI or DP interface.

Table 1-7 Connection Resources for CPUs 312 IFM to 316-2 DP

Communication Function

PD communication/

OP communication

OP communication

S7 basic communication

In order to make the allocation of connection resources dependent not

only on the chronological sequence in which various communication

services are registered, connection resources can be reserved for the

following services:

Description

PD communication and OP communication

S7 basic communication

For PD/OP communication, at least one connection resource is reserved

as the default setting. Lower values are not possible.

The technical specifications of the CPUs detail the possible connection

resources settings and the default settings in each case. In STEP 7 you

specify a ”redistribution” of communication resources when you configure

the CPU.

S7 communication Other communication services such as S7 communication using

PUT/GET functions can not use these communication resources even if

they establish their connection at an earlier time. Instead, the remaining

available connection resources that have not been specifically reserved

for a particular service are used.

Example based on CPU 314 which has 12 connection resources

available:

- You reserve 2 connection resources for PD communication

- You reserve 6 connection resources for OP communication

- You reserve 1 connection resource for S7 basic communication

In this case, you still have three communication resources available

for S7 communication, PG/OP communication and S7 basic

communication.

Note on OP Communication Resources: When using more than three

OPs, error messages might occur due to temporary lack of resources in

the CPU. Examples of such error messages are “44 Transmission error

#13” or “#368 S7 communication error class 131 No. 4”.

Remedy: Acknowledge error messages manually or after a time delay

configured in PROTOOL (in “System Messages” →→ “Display time”).

Routing of PG functions The CPUs provide connection resources for four routed connections.

(CPU 31x-2 DP) Those connection resources are available in addition.

Communication via a CP

343-1 with data lengths >240

bytes for Send/Receive

The CP requires a free connection resource that is not reserved for

PD/OP/S7 basic communication.

1-14

PLC S7-300, CPU Specifications CPU 312 IFM to CPU 318-2 DP

A5E00111190-01

Loading...

Loading...