Page 1

_

_

_

_

SIMATIC S7 300 PLC CPU 317T-2 DP: Controlling a SINAMICS S120

SIMATIC

S7 300 PLC

CPU 317T-2 DP: Controlling a

SINAMICS S120

Getting Started

Introduction

_____________

Preparation

_____________

Learning units

_____________

Further information

_____________

1

2

3

4

12/2005

A5E00480391-01

Page 2

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

will result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended

by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: A5E00480391-01

Edition 12/2005

Copyright © Siemens AG .

Technical data subject to change

Page 3

Table of contents

1 Introduction............................................................................................................................................. 1-1

1.1 Introduction ................................................................................................................................ 1-1

2 Preparation............................................................................................................................................. 2-1

2.1 Requirements............................................................................................................................. 2-1

3 Learning units ......................................................................................................................................... 3-1

3.1 1. Step: Wiring............................................................................................................................ 3-1

3.2 2. Step: Configuring CPU 317T-2 DP with HW Config .............................................................. 3-2

3.3 3. Step: Changing the transmission rate at the MPI/DP interface ............................................. 3-4

3.4 4. Step: Vital settings in your DP (DRIVE) configuration ........................................................... 3-5

3.5 5. Step: Generating technology system data............................................................................. 3-6

3.6 6. Step: Configuring the drive in HW Config .............................................................................. 3-7

3.7 7. Step: Configuration of the PG/PC interface......................................................................... 3-10

3.8 8. Step: Downloading the hardware configuration to the target hardware .............................. 3-18

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config .............................................. 3-21

3.10 10. Step: Configuring the axes with S7T Config ...................................................................... 3-59

3.11 11. Step: Creating the technology DBs.................................................................................... 3-70

3.12 12. Step: Controlling the axis with the STEP 7 user program ................................................. 3-71

3.13 13. Step: Trial run .................................................................................................................... 3-72

4 Further information ................................................................................................................................. 4-1

4.1 Further information..................................................................................................................... 4-1

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

iii

Page 4

Table of contents

CPU 317T-2 DP: Controlling a SINAMICS S120

iv Getting Started, 12/2005, A5E00480391-01

Page 5

Introduction

1.1 1.1 Introduction

Introduction

This Getting Started contains a practical example guiding you through thirteen steps in

commissioning a fully functional application, and showing you how to carry out motion

commands. It is thus a valuable help in getting started with the basic functions of a CPU

317T-2 DP.

Depending on your degree of experience, working through the sample will take between two

and three hours.

Note

This Getting Started presumes that you have connected a SINAMICS

the DP (DRIVE) interface of the CPU 317T-2 DP In case you do not have a drive, we

recommend you refer to the Getting started documentation "CPU 317T-2 DP: Controlling a

virtual axis".

SINAMICS

1

S120 drive to

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

1-1

Page 6

Introduction

1.1 Introduction

CPU 317T-2 DP: Controlling a SINAMICS S120

1-2 Getting Started, 12/2005, A5E00480391-01

Page 7

Preparation

2.1 2.1 Requirements

Requirements

The following requirements must be fulfilled:

• An S7-300 station, consisting of:

– Power supply module (PS), for example, 6ES7 307-1EA00-0AA0

– CPU 317T-2 DP with inserted MMC (4 MB or more).

– Optional digital input module (DI) with bus connector, for example,

6ES7 321-1BH02-0AA0

– Optional digital output module (DO) with bus connector, for example,

6ES7 322-1BH01-0AA0

– Two optional front connectors for the digital modules

• A PG with MPI interface and properly installed software packages and commissioning

tools as listed below:

– STEP 7 V5.3 SP3 and higher

2

– S7-Technology V3.0

• The PG is connected to the CPU via the MPI/DP interface (transmission rate up to 12

Mbps; default 187.5 kbps).

• A SINAMICS

• The SINAMICS

– CU320 control unit with TB30 terminal board (6SL3040-0MA00-0AA1)

– Smart line module, 5 kW (6SL3130-6AE15-0AA0-Z)

– Single/double motor module, 3 A (6SL3120-2TE13-0AA0-Z)

– 1 synchronous motor 1FK7022-5AK71-1AG3 with incremental encoder sin/cos 1 Vpp

via SMC20 sensor module cabinet (6SL3055-0AA00-5BA1)

– 1 synchronous motor 1FK7022-5AK71-1LG3 with DRIVE-CLiQ interface: Absolute

encoder EnDat 512 pulses/revolution

– Reference loops for position monitoring

– Control box for setpoint/actual-value linkage via terminals

• You know the firmware version of your SINAMICS S120.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

®

S120 is connected to the CPU 317T-2 DP via the DP (DRIVE) interface.

®

S120 comprises the following modules:

2-1

Page 8

Preparation

2.1 Requirements

If you do not know the firmware version, then you can find the version on the supplied

certificate. Alternatively, you can open the "content.txt" file on the CF card. The firmware

version is in the "Internal Version" entry. You can find more detailed information on

reading the firmware version in the SINAMICS S120 product information.

Note

For the example of a drive in Getting Started, we use a SINAMICS® S120 training case.

The training case is available under the following order number:

• Axis version with 1FK7 motor

6ZB2480-0AA00

• Axis version with 1FK7 motors

6ZB2480-0BA00

• The system is completely installed and wired. For information, refer to

CPU 31x: Commissioning

• You provided hardware limit switches and EMERGENCY-OFF switches for safe and

reliable operation of the system.

.

Getting Started

Warning

Operation of an S7-300 as part of plants or systems is subject to special rules and

regulations, based on its field of application. Please note the current safety regulations for

the prevention of accidents, e.g. IEC 204 (EMERGENCY-OFF equipment). You risk

severe injury, or damage to machines and equipment if you ignore these directives.

CPU 317T-2 DP: Controlling a SINAMICS S120

2-2 Getting Started, 12/2005, A5E00480391-01

Page 9

Preparation

2.1 Requirements

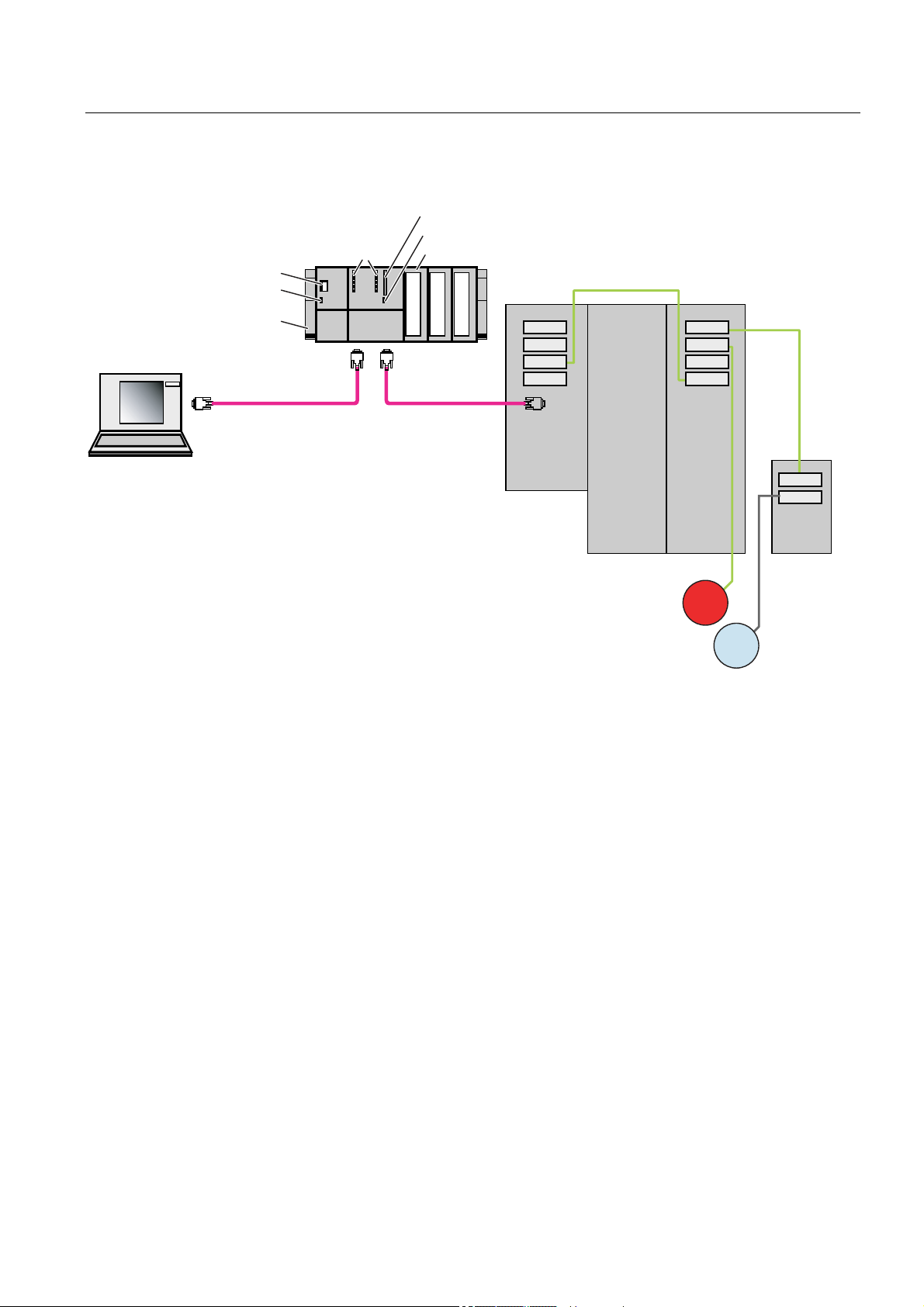

Example configuration

00&

/('V

6HWWLQJRIVXSSO\YROWDJH

3RZHUVXSSO\212))

0RGHVHOHFWRU

,QWHJUDWHGLQSXWVRXWSXWVIRUWHFKQRORJ\

'5,9(&/,4

3URJUDPPLQJ

GHYLFH3*ZLWK

67(3

67HFKQRORJ\

Task

0RXQWLQJUDLO

352),%86FDEOHIRU

FRQQHFWLRQWRWKH03,

LQWHUIDFH

36

&38

'2

',

352),%86

'3'5,9(

;

;

;

;

&8

1R'5,9(

&/,4

LQWHUIDFH

6PDUW/LQH

0RGXOH

;

;

;

;

'RXEOH0RWRU

0RGXOH

0RWRU

(QFR

GHU

0RWRU

(QFR

GHU

;

;

60&

0RGXOH

Configuration of an axis using HW Config and S7T Config. You then operate this axis with

the help of a STEP 7 user program.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

2-3

Page 10

Preparation

2.1 Requirements

CPU 317T-2 DP: Controlling a SINAMICS S120

2-4 Getting Started, 12/2005, A5E00480391-01

Page 11

Learning units

3.1 3.1 1. Step: Wiring

Warning

You may come into contact with live wires. Always switch off power before you start wiring

the S7-300.

Procedure

A description of the installation and wiring of your 317T-2DP CPU is found in the

Started Collection S7-300 PLC: CPU 31x: Commissioning

Set the PROFIBUS address of the SINAMICS

PROFIBUS address on the CU230 directly via the hardware DIP switch, is performed in the

following way:

&RQWURO8QLW

3

Getting

.

®

to PROFIBUS address 4. The setting of the

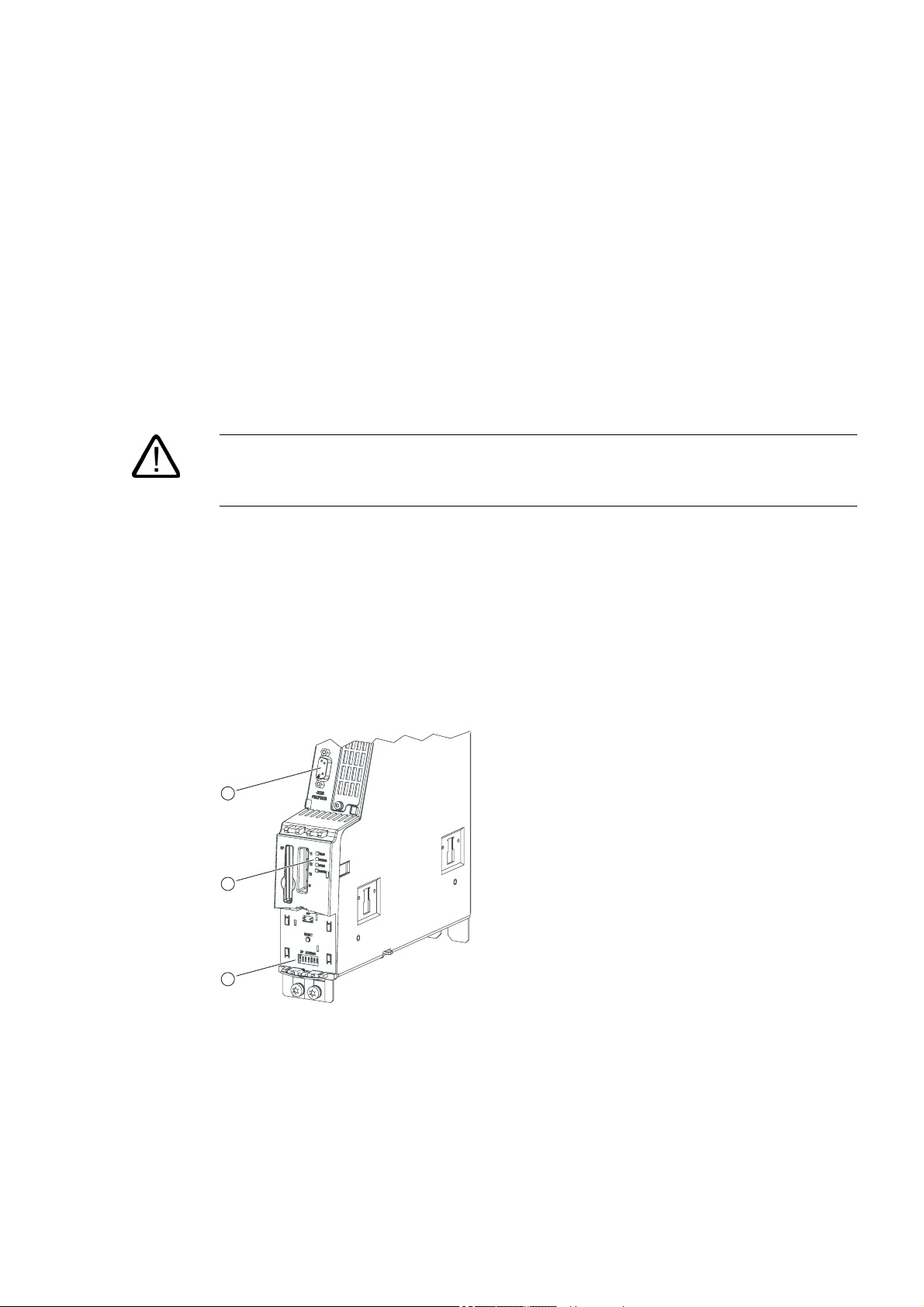

Figure 3-1 Schematic representation of the CU320 control unit

① PROFIBUS interface

② PROFIBUS diagnostics LED "DP1"

③ PROFIBUS address switch

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-1

Page 12

Learning units

3.2 2. Step: Configuring CPU 317T-2 DP with HW Config

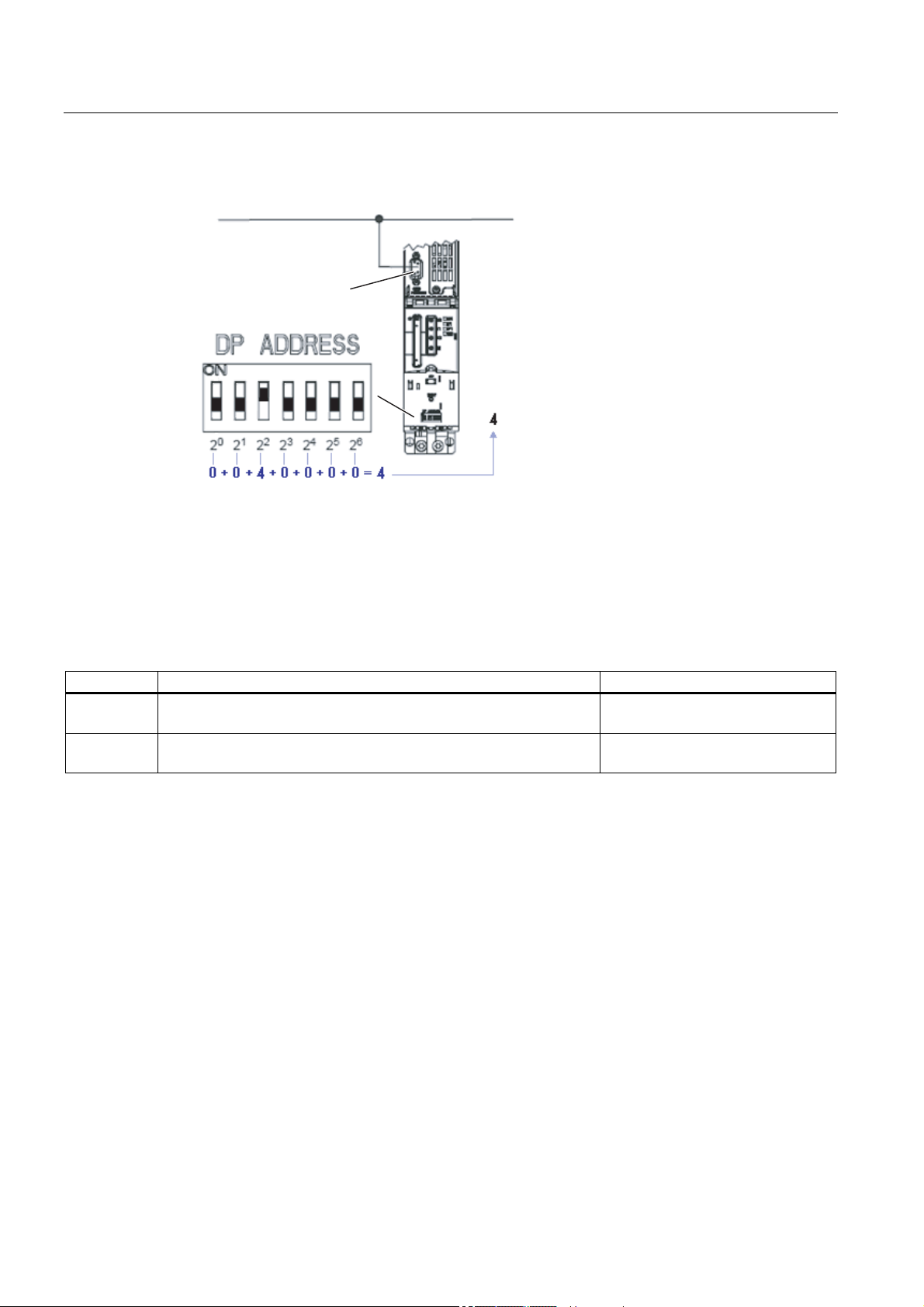

352),%86

LQWHUIDFH

$GGUHVV

3.2 3.2 2. Step: Configuring CPU 317T-2 DP with HW Config

Procedure

Sequence Activity Result

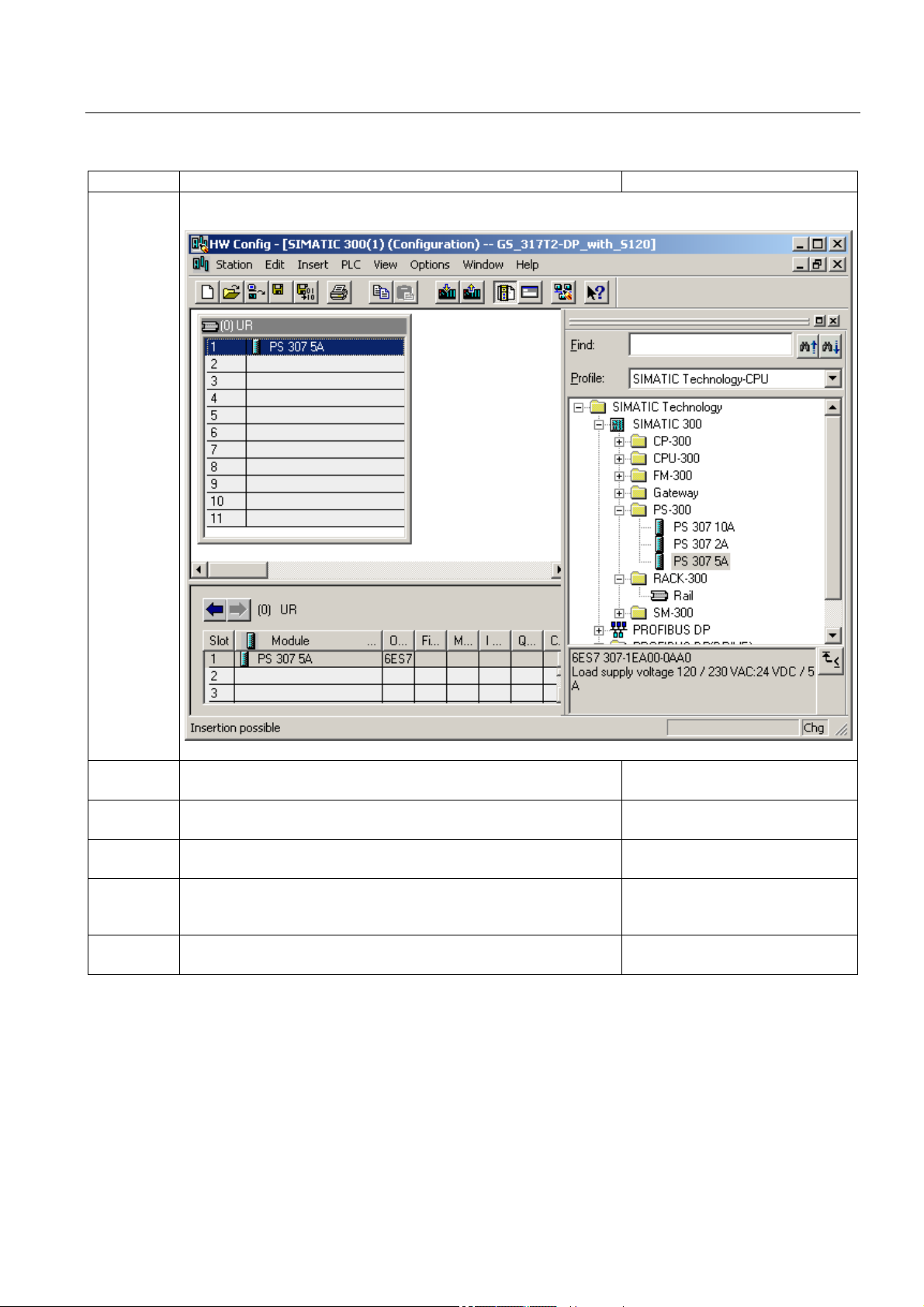

1 Create a new project in the SIMATIC Manager (for example,

"GS_317T2-DP_with_S120") and add a SIMATIC 300 station.

2 Open HW Config by selecting the "SIMATIC 300" station and double-

clicking "Hardware".

The SIMATIC 300 station appears

in the SIMATIC Manager.

HW Config opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-2 Getting Started, 12/2005, A5E00480391-01

Page 13

Learning units

3.2 2. Step: Configuring CPU 317T-2 DP with HW Config

Sequence Activity Result

3 Open the "Hardware Catalog" and select the "SIMATIC Technology CPU" hardware profile in the "Profile"

drop-down list.

Result: The "SIMATIC Technology" directory is displayed.

4 Insert a mounting rail using drag-and-drop in the station window of

HW Config.

5 Drag-and-drop the "PS 307 5A" power supply module onto the

mounting rail.

6 Add the Technology CPU to the mounting rail by means of drag-and-

drop.

7 You change the transmission rate in the next step.

Confirm the message box with "OK.“

8 Confirm the default settings of the PROFIBUS configuration with

"OK".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

This creates a mounting rail.

The power supply module appears

on the mounting rail.

A message box appears.

In the next dialog box, you can set

the PROFIBUS properties of the DP

(DRIVE).

3-3

Page 14

Learning units

3.3 3. Step: Changing the transmission rate at the MPI/DP interface

Sequence Activity Result

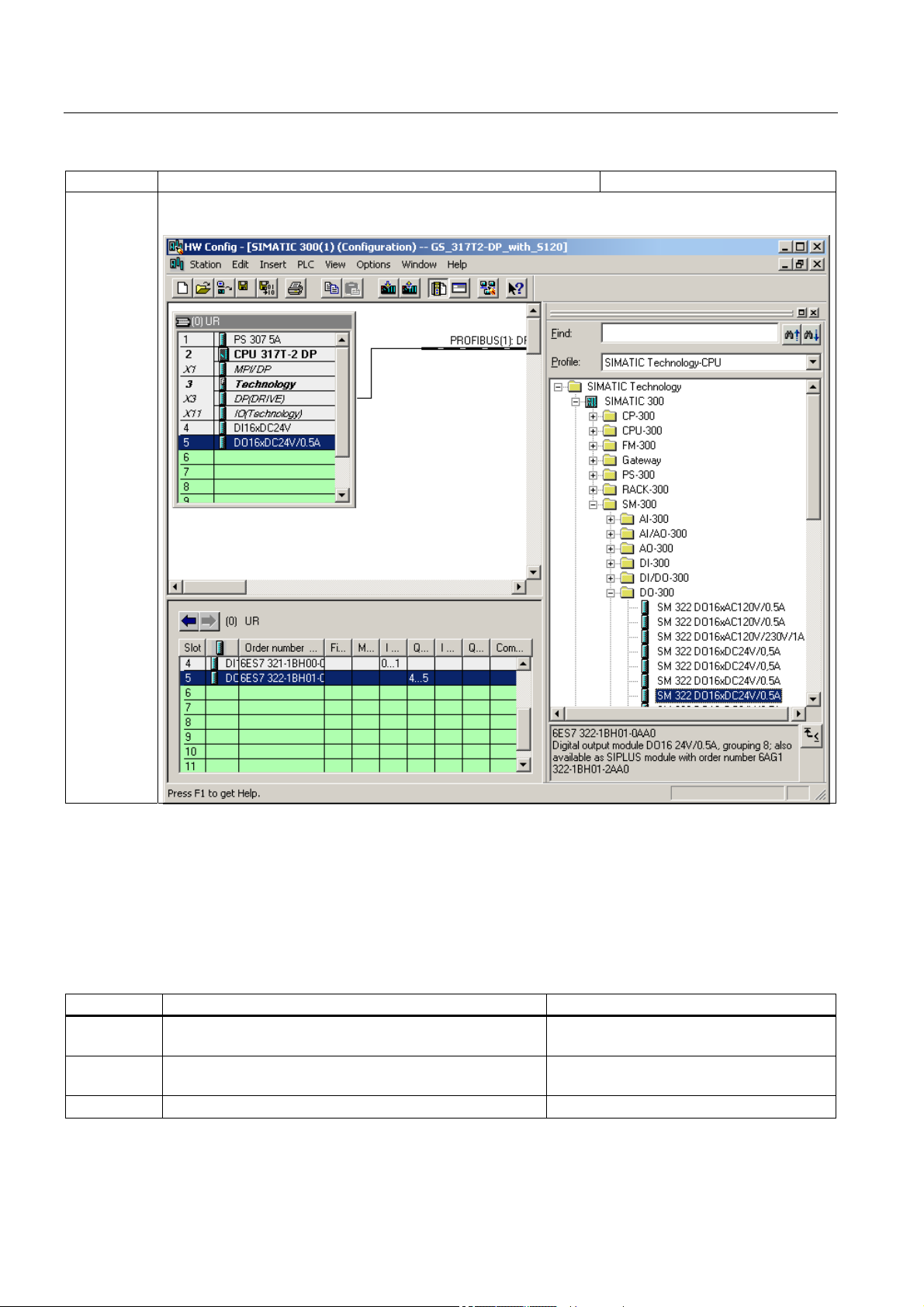

9 Add a digital input module and a digital output module.

You now have this layout:

3.3 3.3 3. Step: Changing the transmission rate at the MPI/DP interface

Procedure

Sequence Activity Result

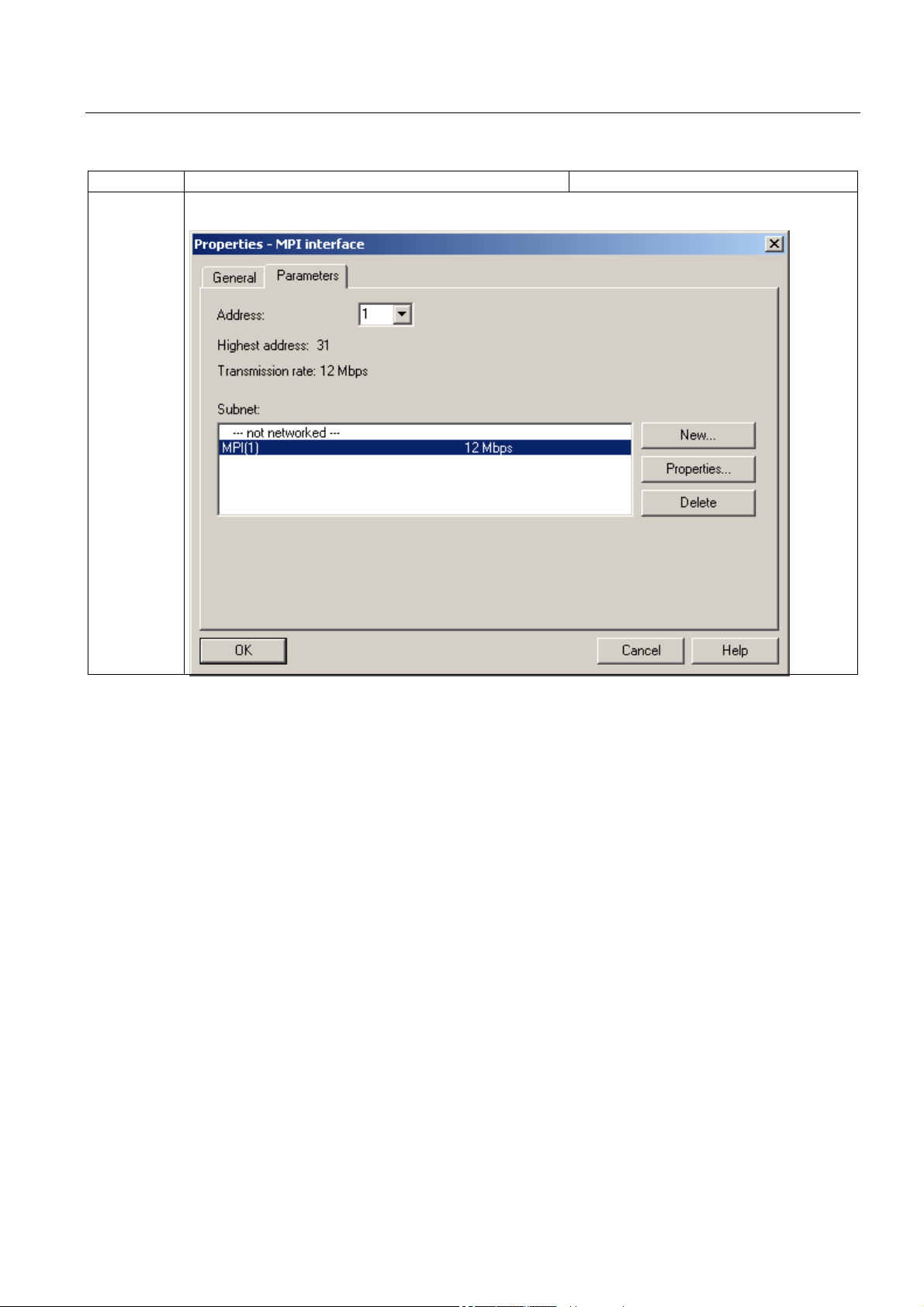

1 Open the MPI/DP interface (X1) in HW Config with double-

click.

2 Click "Properties". The "Properties – MPI interface MPI/DP"

3 Click MPI(1), then click "Properties". The "Properties - MPI" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-4 Getting Started, 12/2005, A5E00480391-01

The "Properties - MPI/DP" dialog box opens.

dialog box opens.

Page 15

Learning units

3.4 4. Step: Vital settings in your DP (DRIVE) configuration

Sequence Activity Result

4 Select the "Network settings" tab and select a transmission

speed of "1.5 Mbps".

5 Confirm all open dialog boxes with "OK". You have now increased the configured

6 When the CPU is in STOP, select PLC > Download to

download the configuration. Select the CPU and confirm

with "OK".

7 Confirm with "OK". The data are now downloaded from the

transmission speed of the MPI interface at

the CPU in order to accelerate data transfer.

The "Select node address" dialog box

opens.

The default transmission rate of the MPI

interface is 187 kbps, i.e. the PG/PC

interfaces must be set up as described

earlier in the requirements section.

PG/PC to the CPU.

3.4 3.4 4. Step: Vital settings in your DP (DRIVE) configuration

Procedure

Sequence Activity Result

1 In HW Config, double-click X3 DP (DRIVE). The "Properties – DP (DRIVE)" dialog box

opens.

2 Click the "Properties" button. The "Properties – PROFIBUS interface DP

(DRIVE)" dialog box opens.

3 Enter PROFIBUS address "2".

4 Click "New" to create a new PROFIBUS subnet. The "Properties – New subnet PROFIBUS"

dialog box opens.

5 In the "Network settings" tab of the next dialog box, set the

transmission rate of the PROFIBUS network. Enter a rate of

12 Mbps.

Maintain the "DP" profile setting of the subnet.

6 Click "OK" to confirm all open dialog boxes of HW Config.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-5

Page 16

Learning units

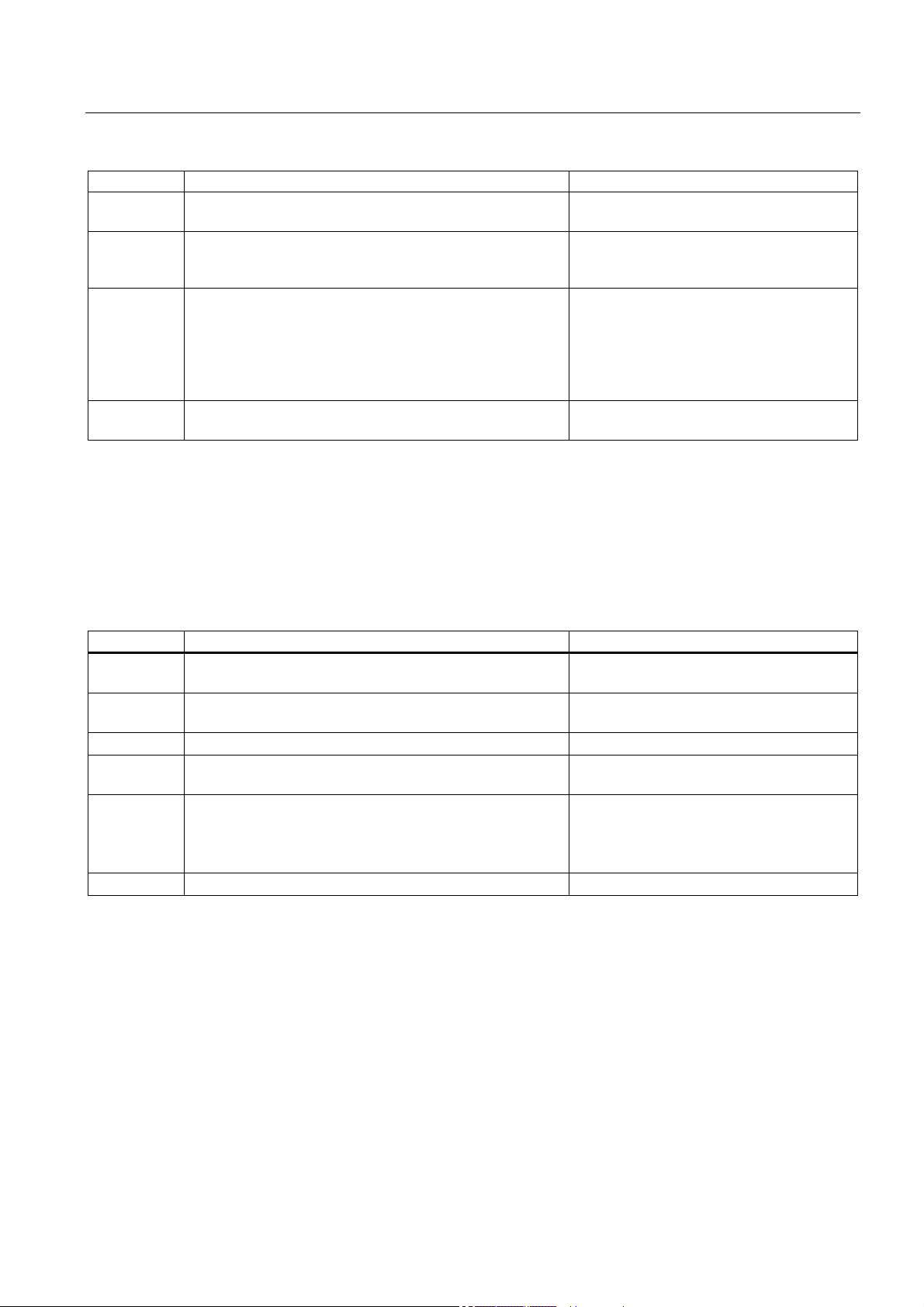

3.5 5. Step: Generating technology system data

3.5 3.5 5. Step: Generating technology system data

Procedure

Sequence Activity Result

1 Double-click "Technology" on the mounting rail. The "Properties - Technology" dialog box

opens.

2 Select the "Technology system data" tab, then set the "Generate technology system data" check box.

Confirm with "OK".

Result: When you download these data to the PLC later on in this Getting Started, the system also

generates the technology system data and includes these in the download to your CPU 317T-2 DP.

Note: If you do not activate the check box, then the technology system data is also not generated.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-6 Getting Started, 12/2005, A5E00480391-01

Page 17

Learning units

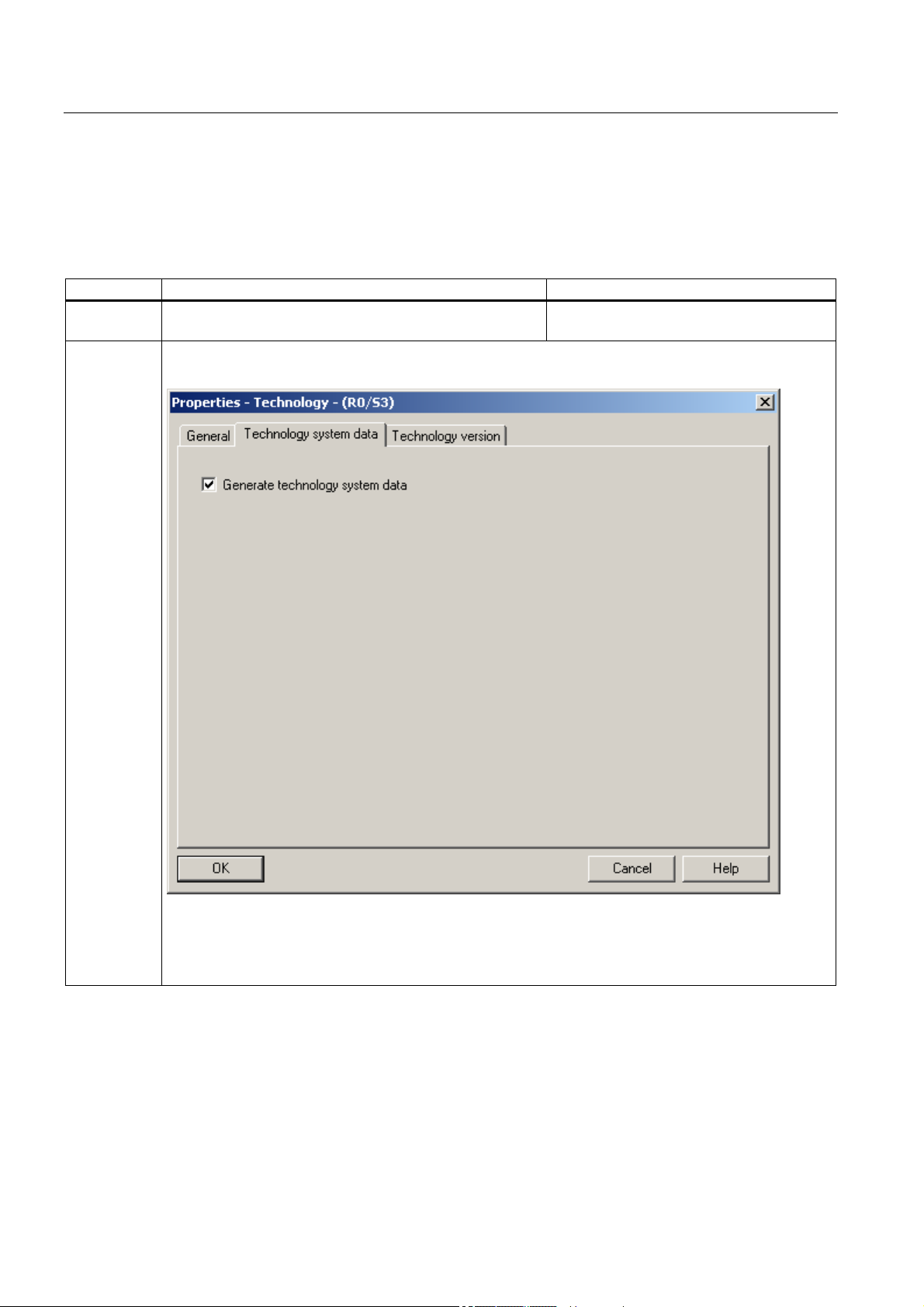

3.6 6. Step: Configuring the drive in HW Config

3.6 3.6 6. Step: Configuring the drive in HW Config

Procedure

Sequence Activity Result

1 In the HW catalog, open the tree structure

SIMATIC Technology > PROFIBUS DP (DRIVE) > Drives >

SINAMICS.

2 Select the drive component "SINAMICS S120" from the tree structure of the HW catalog.

3 Drag-and-drop this component to the master system of the

DP (DRIVE).

4 Enter PROFIBUS address "4", then confirm with "OK". The "Properties - SIMOTION Drive" dialog

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

The "Properties – PROFIBUS interface

SINAMICS" dialog box opens.

box opens.

3-7

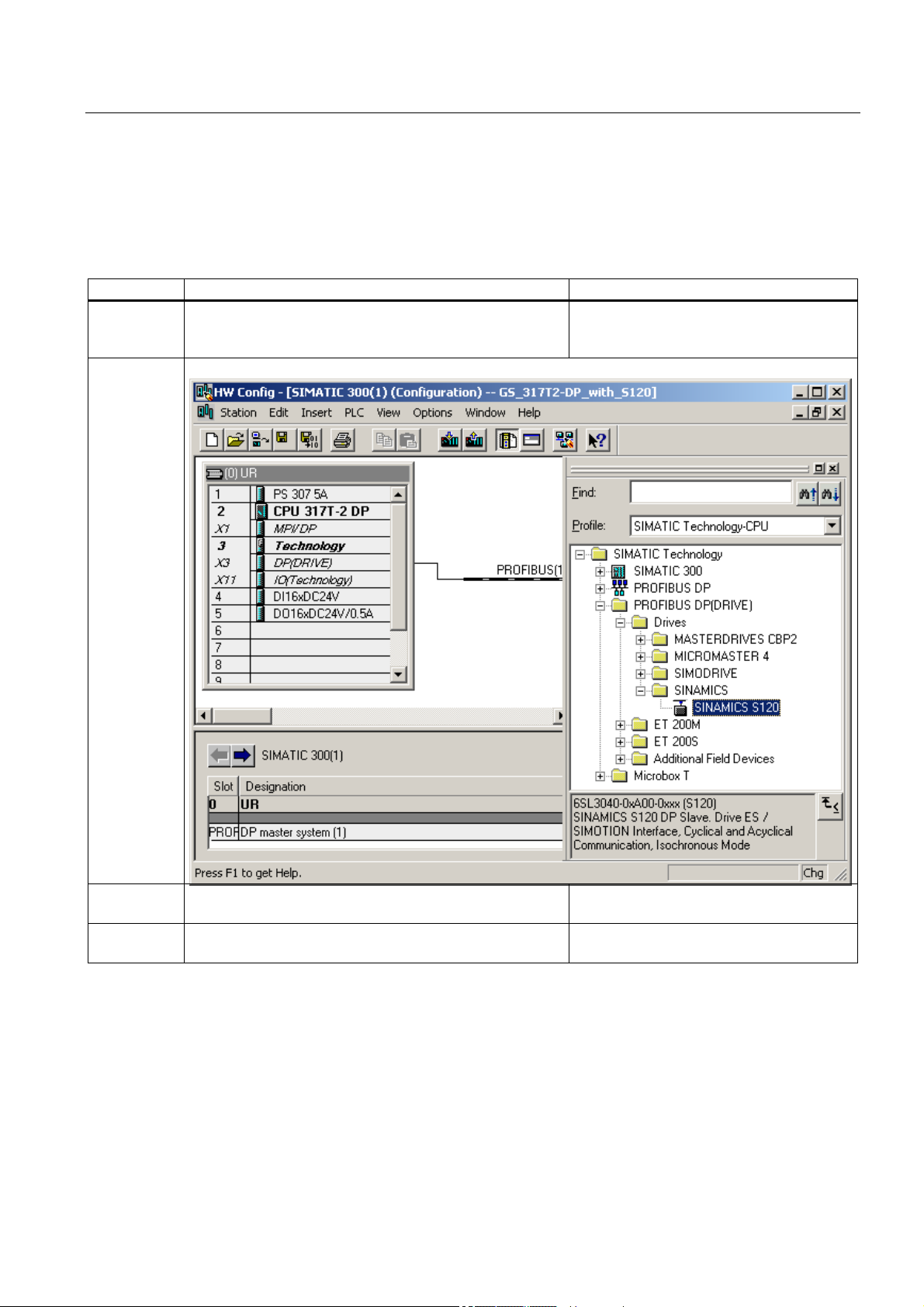

Page 18

Learning units

3.6 6. Step: Configuring the drive in HW Config

Sequence Activity Result

5 Select the appropriate drive version for your SINAMICS® and confirm with "OK".

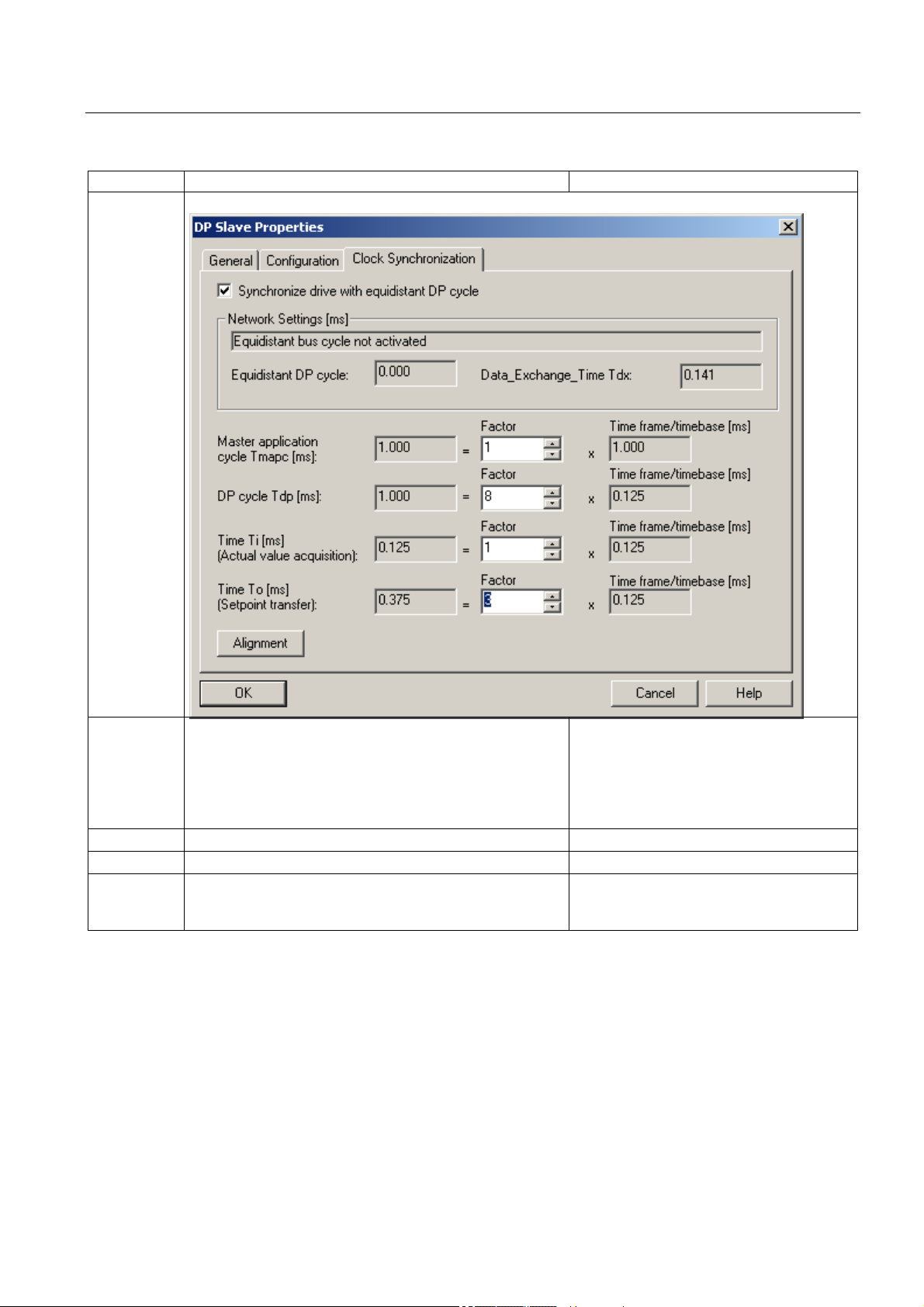

6 The "DP Slave Properties" dialog box opens. Select the

"Clock Synchronization" tab.

The "Clock Synchronization" dialog box

opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-8 Getting Started, 12/2005, A5E00480391-01

Page 19

Learning units

3.6 6. Step: Configuring the drive in HW Config

Sequence Activity Result

7 Set the "Synchronize drive with equidistant DP cycle", then set the time coefficients as shown below.

8 Click "Alignment". The following components are aligned to the

set values:

• DP cycle in the DP master system

9 Confirm with "OK".

10 Confirm the possible warning with "OK".

11 Finalize your HW configuration by calling the Station > Save

and compile

command.

• All drive components of the same family

(here SINAMICS

values.

The system compiles your project, and adds

the "Technology Objects" object to the

project window in SIMATIC Manager.

®

) are aligned to the set

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-9

Page 20

Learning units

3.7 7. Step: Configuration of the PG/PC interface

3.7 3.7 7. Step: Configuration of the PG/PC interface

Procedure

Sequence Activity Result

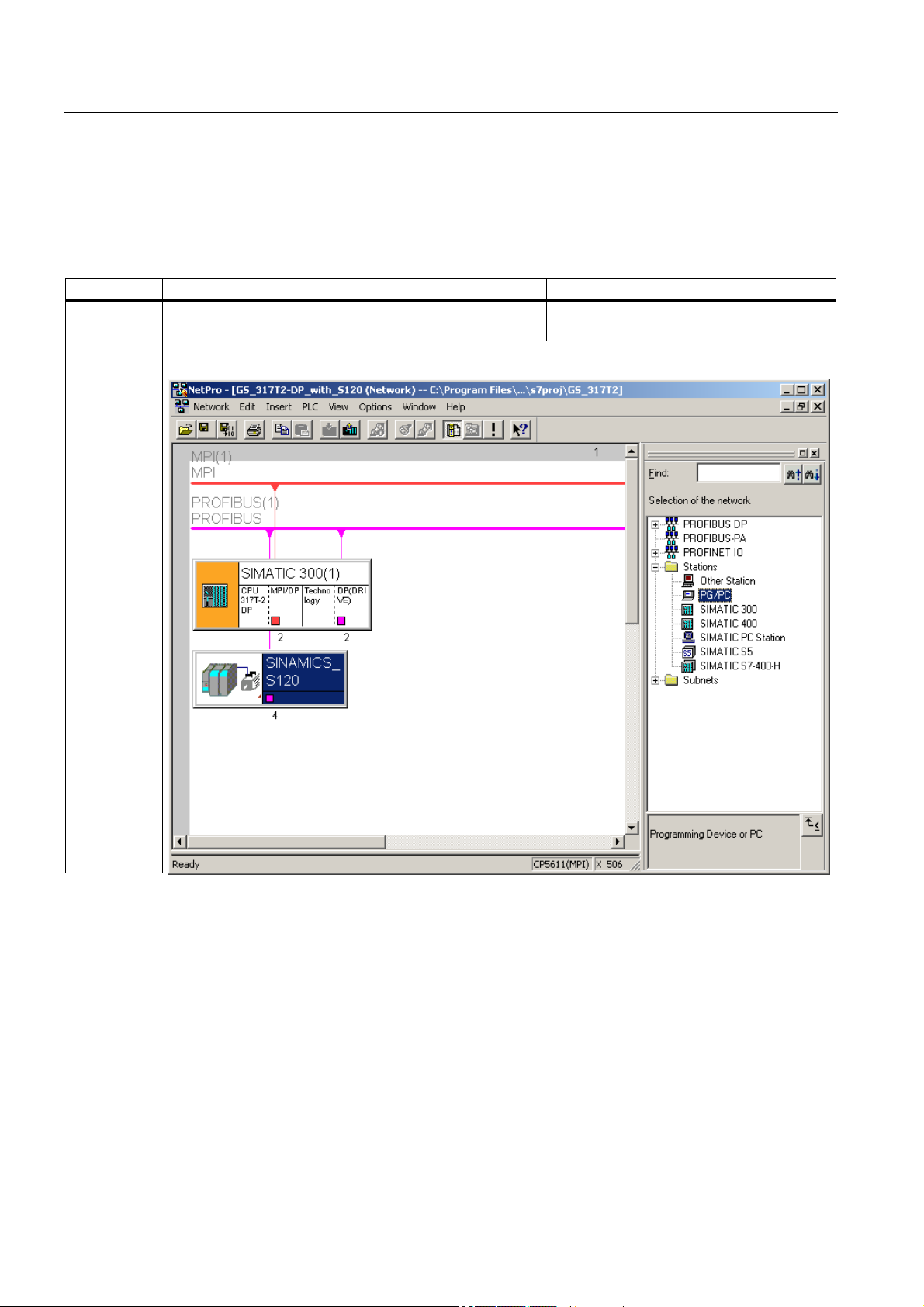

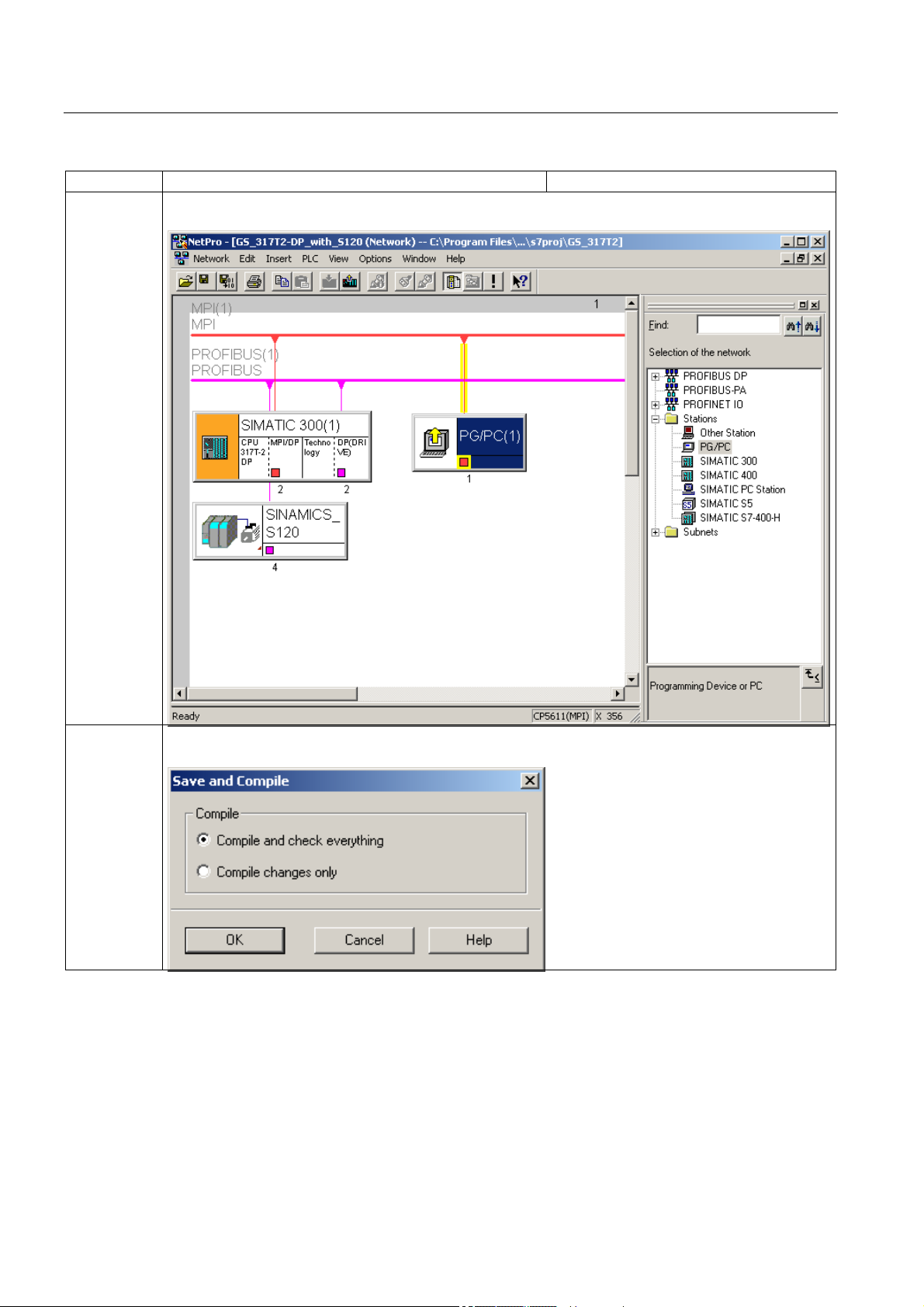

1 Start the NetPro network configuration program in HW

Config with

2 In the HW catalog, open the tree structure

Stations > PG/PC and drag-and-drop a PG/PC station into the "Network View" window.

Options > Configure network.

NetPro is started

CPU 317T-2 DP: Controlling a SINAMICS S120

3-10 Getting Started, 12/2005, A5E00480391-01

Page 21

Learning units

3.7 7. Step: Configuration of the PG/PC interface

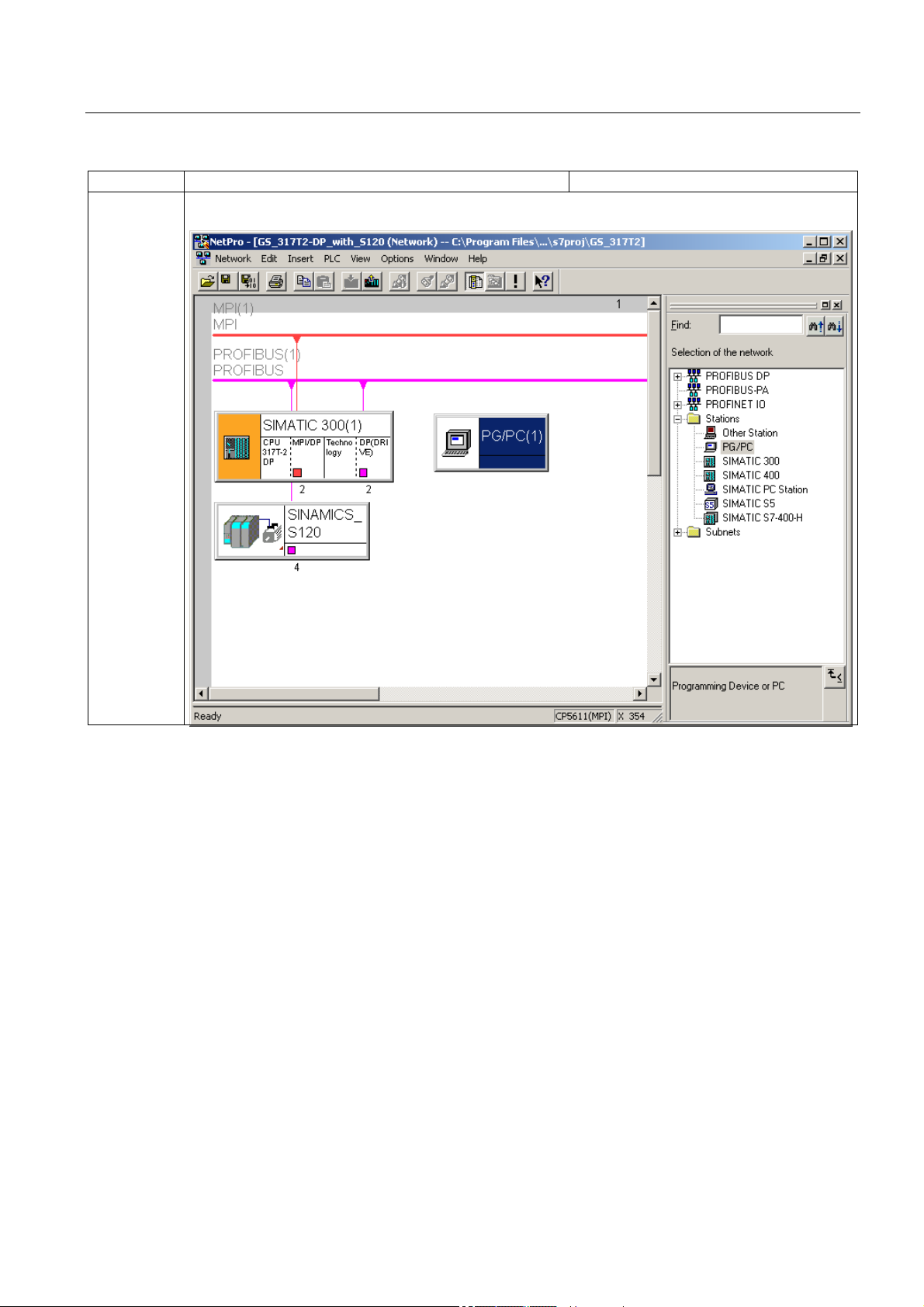

Sequence Activity Result

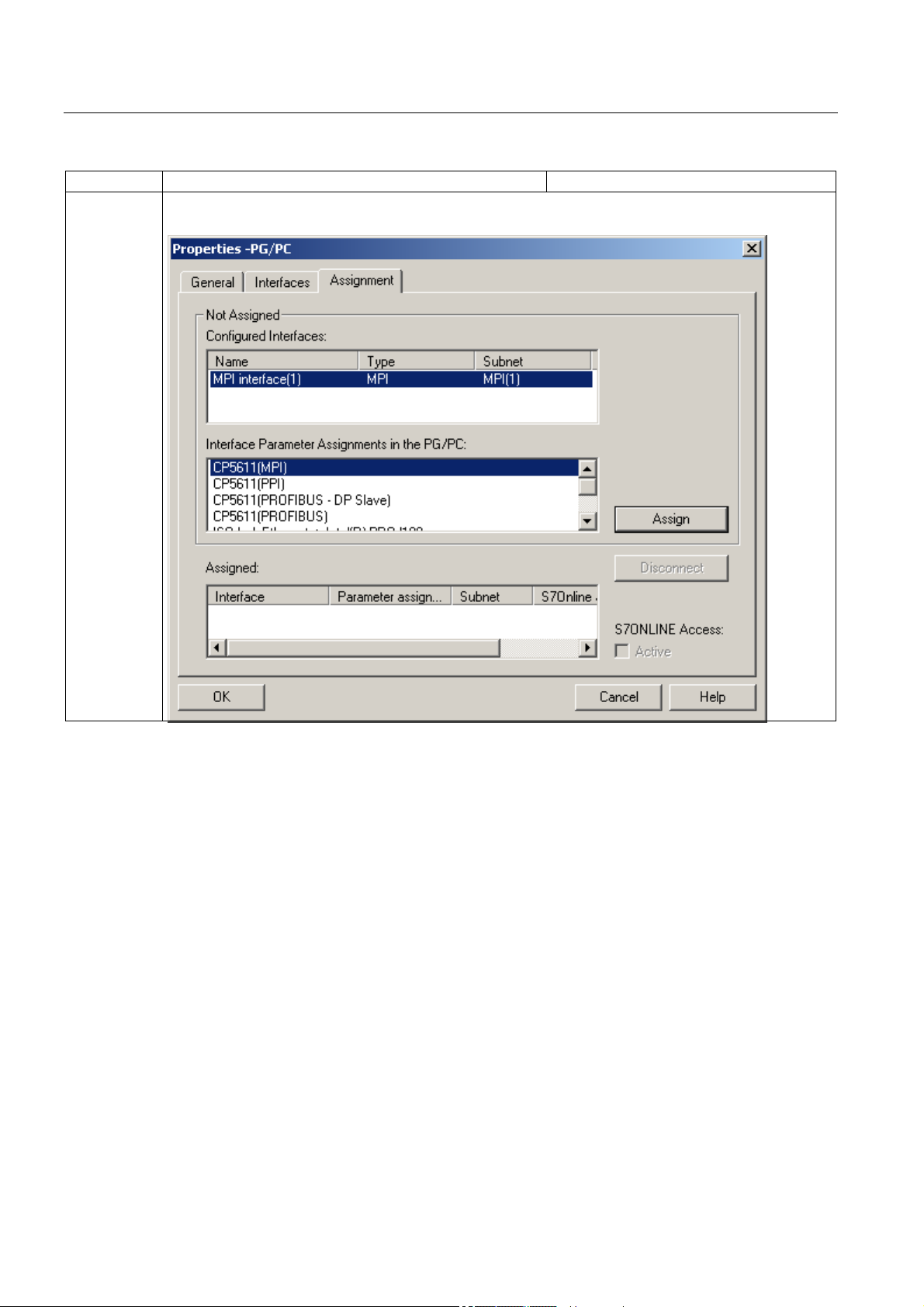

3 Select the newly inserted PG/PC component and open the "Properties – PG/PC" dialog box with Edit >

Object properties….

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-11

Page 22

Learning units

3.7 7. Step: Configuration of the PG/PC interface

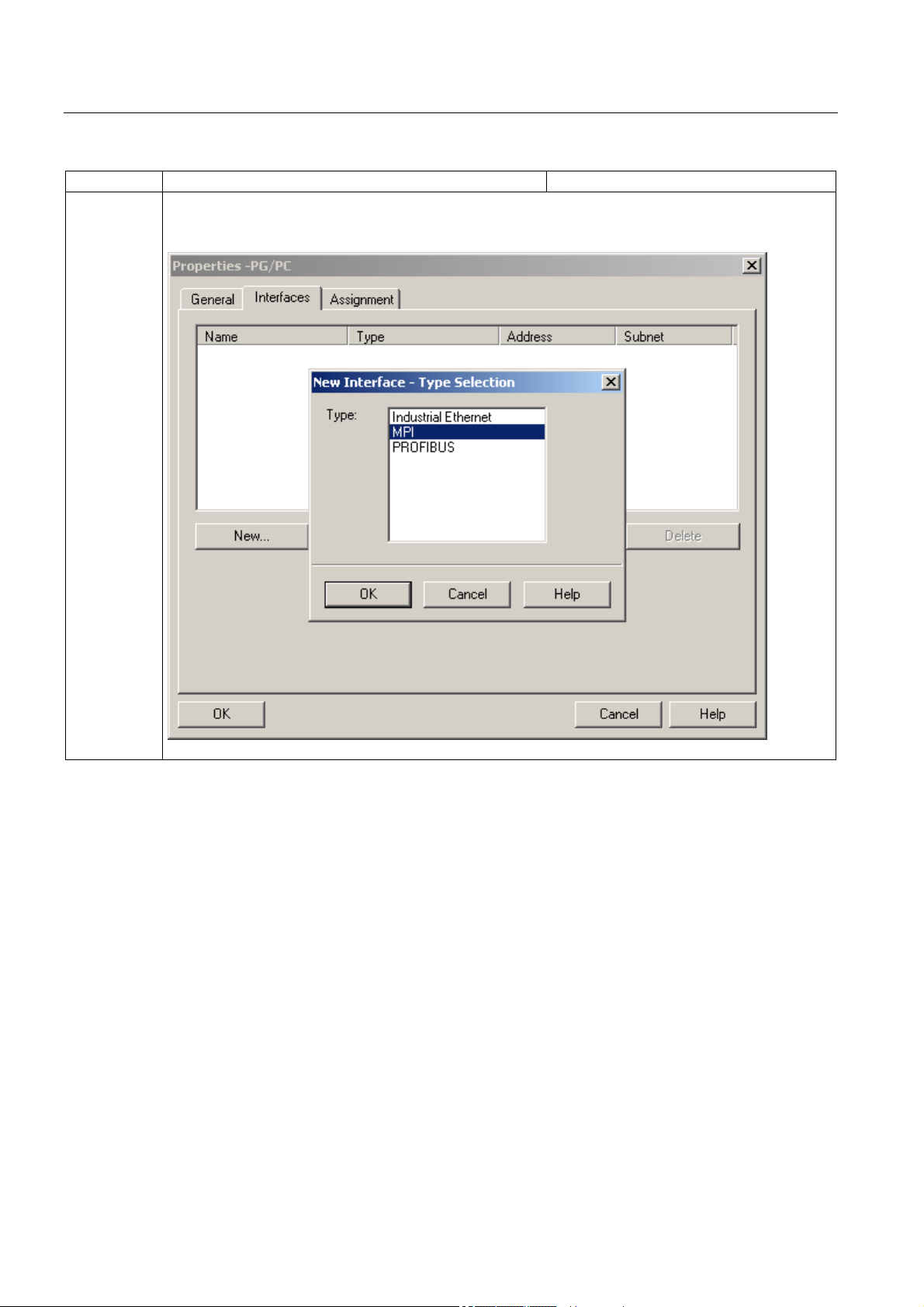

Sequence Activity Result

4 Select the "Interfaces" tab in the "Properties – PG/PC" dialog box.

Click the "New…" button to open the "New Interface – Type Selection" dialog box. Select "MPI" and confirm

with "OK".

Result: The "Properties - MPI Interface" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-12 Getting Started, 12/2005, A5E00480391-01

Page 23

Learning units

3.7 7. Step: Configuration of the PG/PC interface

Sequence Activity Result

5 In the "Properties - MPI Interface" dialog box, select address "1" and the "MPI network". Confirm your input

with "OK".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-13

Page 24

Learning units

3.7 7. Step: Configuration of the PG/PC interface

Sequence Activity Result

6 Select the "Assignment" tab in the "Properties – PG/PC" dialog box.

Assign the MPI interface parameterization in the PG/PC to the configured interface by clicking "Assign".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-14 Getting Started, 12/2005, A5E00480391-01

Page 25

Learning units

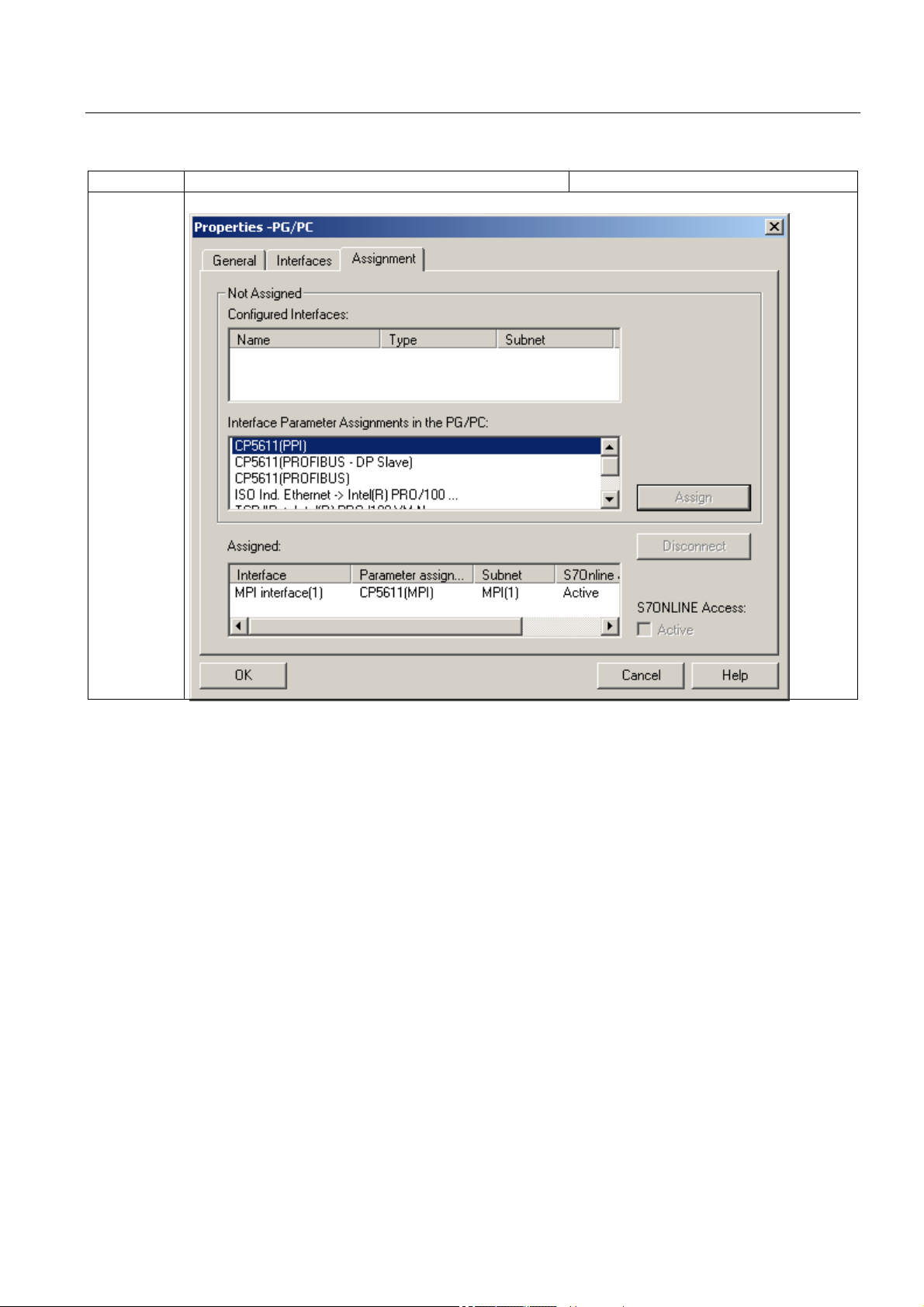

3.7 7. Step: Configuration of the PG/PC interface

Sequence Activity Result

7 Complete the configuration by clicking "OK".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-15

Page 26

Learning units

3.7 7. Step: Configuration of the PG/PC interface

Sequence Activity Result

8 You have now inserted your PG/PC in the MPI network and established the condition to exchange data

with the SINAMICS® control.

9 Complete the network configuration by calling the Network > Save and compile command.

Select "Compile and check everything" and confirm with "OK".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-16 Getting Started, 12/2005, A5E00480391-01

Page 27

Learning units

3.7 7. Step: Configuration of the PG/PC interface

Sequence Activity Result

10 Close the output window with File > Close.

11 Close the NetPro configuration program by calling the Network > Exit command.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-17

Page 28

Learning units

3.8 8. Step: Downloading the hardware configuration to the target hardware

3.8 3.8 8. Step: Downloading the hardware configuration to the target

hardware

Procedure

Sequence Activity Result

1 Switch back to HW Config

Download the hardware configuration to the CPU by calling the

PLC > Download … command.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-18 Getting Started, 12/2005, A5E00480391-01

Page 29

Learning units

3.8 8. Step: Downloading the hardware configuration to the target hardware

Sequence Activity Result

2 Select the "CPU317T-2DP" and confirm with "OK".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-19

Page 30

Learning units

3.8 8. Step: Downloading the hardware configuration to the target hardware

Sequence Activity Result

3 Enter the MPI address of your destination address and confirm with "OK".

Result: The data are now downloaded from the PG to the CPU.

4 Also close the HW Config by calling the Station > Exit command.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-20 Getting Started, 12/2005, A5E00480391-01

Page 31

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

3.9 3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Procedure

Sequence Activity Result

1 In SIMATIC Manager, double-click "Technological Objects“ to open S7T Config.

Result: "Technological Objects Management" opens. The system automatically runs S7T Config if you

have not configured any technological objects yet, as in this example.

You may also run S7T Config without using "Technological Objects Management". Select the

"Technological Objects" object and then select the

2 Save the current project data by selecting the Project > Save and recompile all command.

Options > Configure the technology command.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-21

Page 32

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

3 Change to the online mode by selecting the Project > Connect to target system command.

4 In the project navigator, open the tree structure SIMATIC 300(1) > Technology > SINAMICS_S120 >

Automatic configuration. Open the automatic configuration by double-clicking "Automatic configuration".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-22 Getting Started, 12/2005, A5E00480391-01

Page 33

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

5 Start the automatic configuration in the "Automatic Configuration" dialog box by clicking the "Start

automatic configuration" button.

6 Set the drive object type for both motors to "Servo" and exit the dialog box with "Finish".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-23

Page 34

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

7 The SINAMICS® training case on which this document is based has two different motor types. One of the

two motor types has DRIVE-CLIQ technology. The second motor/encoder is connected via SMC20, which

is why DRIVE-CLiQ recognizes that a second motor/encoder is present and creates this, but cannot

automatically configure it. Therefore, not all drive information can be completely configured automatically.

Confirm the warning with "OK".

8 Close the "Automatic Configuration" dialog box by clicking "Close".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-24 Getting Started, 12/2005, A5E00480391-01

Page 35

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

9 Change to the offline mode by selecting the Project > Disconnect from target system command.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-25

Page 36

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

10 In the project navigator, open the tree structure SIMATIC 300(1) > Technology > SINAMICS_S120 >

Drives > Servo_03 > Configuration. Open the offline drive configuration by double-clicking "Configuration".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-26 Getting Started, 12/2005, A5E00480391-01

Page 37

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

11 Click the "Configure DDS..." button to start the configuration.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-27

Page 38

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

12 Accept the default settings and click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-28 Getting Started, 12/2005, A5E00480391-01

Page 39

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

13 The power section has DRIVE-CLIQ technology and has already been correctly configured. Check the

order number and click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-29

Page 40

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

14 The SINAMICS® training case on which this document is based does not have an active infeed module.

Confirm the warning with "OK".

15 Click the blue button and in the TB30_04 context menu, select digital input 0, which corresponds to

parameter r4022, bit 0. Then click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-30 Getting Started, 12/2005, A5E00480391-01

Page 41

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

16 The motor without complete DRIVE-CLIQ technology is connected to terminal X2 of the power section.

Click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-31

Page 42

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

17 Select the correct motor from the list. To activate the selection option, you must select the "Select standard

motor from list" box.

The motor used in the SINAMICS

supplied documents or the motor type plate (lower motor - blue gear wheel). Select the appropriate motor

and click "Continue >".

®

training case is the 1FK7022-xAK7x-xxxx. Check this against the

CPU 317T-2 DP: Controlling a SINAMICS S120

3-32 Getting Started, 12/2005, A5E00480391-01

Page 43

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

18 Select "Without holding brake" and click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-33

Page 44

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

19 Select 1FK7xxx-xxxxx-xAxx. Check this against the supplied documents and click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-34 Getting Started, 12/2005, A5E00480391-01

Page 45

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

20 Set the PROFIBUS message frame to "SIEMENS telegram 105 (105)" and click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-35

Page 46

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

21 Click the "Finish" button to exit the offline configuration of the drive.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-36 Getting Started, 12/2005, A5E00480391-01

Page 47

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

22 The offline configuration of the drive is completed. Close the dialog box with the "Close" button.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-37

Page 48

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

23 In the project navigator, open the tree structure SIMATIC 300(1) > Technology > SINAMICS_S120 >

Drives > Servo_03.

Right-click to open the context menu and select

Expert > Expert list.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-38 Getting Started, 12/2005, A5E00480391-01

Page 49

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

24 Select parameter "p210" and enter "345".

The smart line module and the motor module of the SINAMICS S120 training case have been especially

equipped for operation on a 230 V system. For this reason, "Parameter p210" of the connected drives must

be set to the following value, which differs from the factory settings:

p210 = 345 V device connection voltage SERVO/VECTOR

The setting of "parameter p210 = 345 V"

pre-assigned for the error-free operation of the SINAMICS S120 training case on the 230 V system.

cannot be calculated by the SINAMICS operating system and is

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-39

Page 50

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

25 In the project navigator, open the tree structure SIMATIC 300(1) > Technology > SINAMICS_S120 >

Drives > Servo_02 > Configuration. Double-click "Configuration" to open the offline drive configuration.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-40 Getting Started, 12/2005, A5E00480391-01

Page 51

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

26 Start the configuration by clicking the "Configure DDS…" button.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-41

Page 52

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

27 Accept the default settings and click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-42 Getting Started, 12/2005, A5E00480391-01

Page 53

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

28 The power section has DRIVE-CLIQ technology and has already been correctly configured. Check the

order number and click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-43

Page 54

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

29 The SINAMICS® training case on which this document is based does not have an active infeed module.

Confirm the warning with "OK".

30 Click the blue button and in the TB30_04 context menu, select digital input 0, which corresponds to

parameter r4022, bit 0. Then click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-44 Getting Started, 12/2005, A5E00480391-01

Page 55

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

31 The motor with complete DRIVE-CLIQ technology is connected to terminal X1 of the power section. Click

"Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-45

Page 56

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

32 The motor with complete DRIVE-CLIQ technology has already been correctly configured. Click

"Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-46 Getting Started, 12/2005, A5E00480391-01

Page 57

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

33 Click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-47

Page 58

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

34 The correct encoder has already been correctly configured by means of DRIVE-CLIQ technology. Click

"Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-48 Getting Started, 12/2005, A5E00480391-01

Page 59

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

35 Set the PROFIBUS message frame to "SIEMENS telegram 105 (105)" and click "Continue >".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-49

Page 60

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

36 Click the "Finish" button to exit the offline configuration of the drive.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-50 Getting Started, 12/2005, A5E00480391-01

Page 61

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

37 The offline configuration of the drive is completed. Close the dialog box with the "Close" button.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-51

Page 62

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

38 In the project navigator, open the tree structure SIMATIC 300(1) > Technology > SINAMICS_S120 >

Drives > Servo_02.

Right-click to open the context menu and select

Expert > Expert list.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-52 Getting Started, 12/2005, A5E00480391-01

Page 63

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

39 Select parameter "p210" and enter "345".

The smart line module and the motor module of the SINAMICS S120 training case have been especially

equipped for operation on a 230 V system. For this reason, "Parameter p210" of the connected drives must

be set to the following value, which differs from the factory settings:

p210 = 345 V device connection voltage SERVO/VECTOR

The setting of "parameter p210 = 345 V" cannot be calculated by the SINAMICS operating system and is

pre-assigned for the error-free operation of the SINAMICS S120 training case on the 230 V system.

40 In the project navigator, open the tree structure SIMATIC 300(1) > Technology > SINAMICS_S120 >

Configuration. Double-click "Configuration" to start the SINAMICS® configuration.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-53

Page 64

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

41 In the "SINAMICS_S120 – Configuration" dialog box, set both message frame types to "SIEMENS telegram

105" and then click the "Align with HW Config" button.

42 Close the "SINAMICS_S120 – Configuration" dialog box by clicking "Close".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-54 Getting Started, 12/2005, A5E00480391-01

Page 65

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

43 Select the Project > Save and recompile all menu command to save and compile the entire technology

project.

44 Select the Project > Connect to target system menu command to switch to online mode.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-55

Page 66

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

45 The desired configuration is on the PG/PC. Click the "<== Download" button to transfer the configuration to

the drive.

46 Confirm the safety query with "Yes".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-56 Getting Started, 12/2005, A5E00480391-01

Page 67

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

47 Close the dialog message with "OK".

48 Close the dialog box with "Close".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-57

Page 68

Learning units

3.9 9. Step: Configuration of the SINAMICS drive with S7T Config

Sequence Activity Result

49 Select the Project > Disconnect from target system menu command to switch to offline mode.

50 Activate the check boxes "Copy RAM to ROM" and "Load changes to PG/PC". Then confirm with "OK".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-58 Getting Started, 12/2005, A5E00480391-01

Page 69

Learning units

3.10 10. Step: Configuring the axes with S7T Config

3.10 3.10 10. Step: Configuring the axes with S7T Config

Important information

In this step, you create your technology objects (e.g. axes) with S7T Config. Use

"Technology Objects Management“ to generate a technology DB for each TO. Do not copy

the technology DBs in order to ensure a defined assignment between the technology DB and

its TO.

Procedure

Sequence Activity Result

1 In the project navigator, open the tree structure SIMATIC 300(1) > Technology > AXES. Double-click

"Insert axis" to start the axis wizard:

Result: The “Insert Axis" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-59

Page 70

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

2 Confirm the default technology selection (speed control, positioning) with "OK".

Result: The "Axis Configuration - Axis_1 – Axis Type" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-60 Getting Started, 12/2005, A5E00480391-01

Page 71

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

3 Accept the "Axis type: Linear, electric" and "Motor type: standard motor". Confirm with "Continue".

Result: The "Axis configuration - Axis_1 - Units" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-61

Page 72

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

4 Confirm with "Continue".

Result: The "Axis configuration Axis_1 - Modulo" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-62 Getting Started, 12/2005, A5E00480391-01

Page 73

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

5 Confirm with "Continue".

Result: The "Axis Configuration - Axis_1 Drive Assignment" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-63

Page 74

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

6 Click the "Align Sinamics devices..." button.

7 Select the "SINAMICS_S120" device and click "Align".

Result: The "Axis Configuration - Axis_1 Drive Assignment" dialog box opens again.

8 Select your "actual drive unit (SINAMICS_S120)".

CPU 317T-2 DP: Controlling a SINAMICS S120

3-64 Getting Started, 12/2005, A5E00480391-01

Page 75

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

9 The configured message frame is taken over from the drive configuration and must be confirmed in this

dialog box. Enter the maximum motor speed as "Rated speed“ (see motor type plate). Set a maximum

motor speed of 6000 rpm for our example. Confirm your settings with "Continue".

Result: A message box appears.

9 Close the message box with "OK". The "S7T Config Help" online help opens.

10 Close the online help. The "Axis configuration - Axis_1 – Encoder

assignment" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-65

Page 76

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

11 Select the encoder type and mode, and the measuring system. Settings for the first axis in our example:

• "Encoder type" is an "Absolute encoder"

• "Encoder mode" is "Endat"

• "Measuring system" is "Rotary encoder system"

Confirm with "Continue".

Result: The "Axis Configuration - Axis_1 - Encoder - Data" dialog box opens.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-66 Getting Started, 12/2005, A5E00480391-01

Page 77

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

12 Enter the resolution specified on your motor rating plate as well as the number of data bits. In our example,

the number of encoder pulses is "512" and the number of data bits is "21".

Accept the settings with "Continue".

If you use another encoder type, you can find appropriate examples for the encoder configuration in the

online help of S7T Config.

Result: The "Axis Configuration - Axis_1 - Completion" dialog box opens, showing the data you configured.

13 Complete the axis configuration with "Finish". A message box appears.

14 Close the message box with "OK". The "S7T Config Help" online help opens.

15 Close the online help. The axis configuration with S7T Config is

completed.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-67

Page 78

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

16 Select Project > Save and recompile all to save the

configuration in S7T Config.

Note:

Repeat sequence 1 to 16 in step number 10 if you are using a double axis module.

The SINAMICS

incremental encoder. Make sure that you make the correct settings during the configuration of the second

axis.

The second drive has an incremental encoder with 2048 encoder lines.

®

demonstration case has a motor module with absolute encoder and a motor module with

The system now compiles the axis

configuration data.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-68 Getting Started, 12/2005, A5E00480391-01

Page 79

Learning units

3.10 10. Step: Configuring the axes with S7T Config

Sequence Activity Result

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-69

Page 80

Learning units

3.11 11. Step: Creating the technology DBs

3.11 3.11 11. Step: Creating the technology DBs

Procedure

Sequence Activity Result

1 Change to "Technological Objects Management". Confirm the first message box with "OK", and the second

with "Yes".

If you are not running the "Technological Objects Management“ application yet, you can open it by double-

clicking "Technological Objects“ in the "Technology“ folder in SIMATIC Manager (see also step:

"Configuring the axes with S7T Config").

Result: The "Technological Objects Management" opens.

Edit the DB numbers as shown in the figure in order to adapt these for use in our example.

2 Create the technology DBs listed below by clicking "Create":

• Axis_1

• Axis_2 (if this exists)

• Trace

• MCDevice

3 Close the "Technological Objects Management" via the

Technological objects > Exit menu command.

The system generates the technology data

blocks DB1, DB2, DB3 or DB4.

CPU 317T-2 DP: Controlling a SINAMICS S120

3-70 Getting Started, 12/2005, A5E00480391-01

Page 81

Learning units

3.12 12. Step: Controlling the axis with the STEP 7 user program

3.12 3.12 12. Step: Controlling the axis with the STEP 7 user program

Procedure

Sequence Activity Result

1 In SIMATIC Manager, open the sample project

"\Examples\PROJECT-CPU317T". Copy the blocks listed

below to your project:

• OB1

• FB 100 (SimplePositioning)

• FB401 (MC_Power)

• FB402 (MC_Power)

• FB405 (MC_Halt)

• FB410 (MC_MoveAbsolute)

• DB 100 (IDB_SimplePositioning)

• AxisData (variable table for axis control)

Confirm the message "The object 'OB1' already exists. Do

you want to overwrite it?” with "Yes".

Also copy the inputs, outputs and flags from the example

symbol table to the project, so that the symbols are

displayed completely in the variable table.

Important: The sample program does not contain DB1 to

DB4! Create these technology DBs in STEP 7 (see the step

"Creating the technology DBs"), in order to maintain

consistency between the user program and the technology

objects.

2 You can edit the sample program in the LAD/STL/FBD

Editor. To do so, click FB 100, then right-click to select

"Open object".

3 Select these settings:

• View > LAD,

• View > Overviews, and

• View > Details.

4 In SIMATIC Manager, load the entire user program to the

CPU with

card

5 Confirm the message box with "Yes". The STEP 7 user program is now stored in

PLC > Download user program to memory

.

The sample program is copied to the project.

The LAD/STL/FBD editor opens.

You have now opened an extended and

clear view for editing the STEP 7 user

program.

the CPU. This download of your SDBs may

take longer (up to a few minutes), because

of their larger data volume.

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

3-71

Page 82

Learning units

3.13 13. Step: Trial run

3.13 3.13 13. Step: Trial run

Procedure

Sequence Activity Result

1 In the "Blocks" folder of your project, double-click the

"AxisData" variable table.

2 Select PLC > Connect to > Configured CPU to go online. The CPU "STOP" status is indicated on the

3 Select Variable > Monitor to set monitoring mode. The "Status value" column shows the actual

Caution

You start the drive in the next two steps.

To stop the drive again:

Set input I0.2 (Stop) to "1"

Switch the CPU to STOP.

4 Switch the CPU to RUN. The CPU "RUN" status is indicated on the

5 Perform the following trials: Monitor the relevant output values.

• Enable the axis by setting I0.0 = "1" (DriveEnable)

• Move the axis into position 2 (500 mm) by setting I0.4 (StartPosition2)

• Move the axis into position 1 (0 mm) by setting I0.3 (StartPosition1)

• Stop the moving axis with a signal at I0.2 (Stop)

• Acknowledge all queued errors of the axis with I0.1 (Reset)

Terminal strip:

The variable table is opened for monitoring.

bottom right.

values of the addresses.

Use the variable table to monitor the control

and status bits of the application, and the

status of the axis.

bottom right.

'ULYH(QDEOH

5HVHW

6WRS

6WDUWB3RVLWLRQ

6WDUWB3RVLWLRQ

3RVLWLRQ 3RVLWLRQ

PP

9HORFLW\

$[LV

Y PPV

PP

$[LV

CPU 317T-2 DP: Controlling a SINAMICS S120

3-72 Getting Started, 12/2005, A5E00480391-01

Page 83

Further information

4.1 4.1 Further information

Diagnostics / correction of errors

Incorrect operator input, faulty wiring or inconsistent configuration data may lead to errors.

For information on how to analyze such errors and messages, refer to the

manual.

Service and support on the Internet

In addition to our documentation, we offer a comprehensive online knowledge base on the

Internet at:

http://www.siemens.com/automation/service&support

There you will find:

• The newsletter that provides you with latest information relating to your product

• Your appropriate documentation, using our Service & Support search engine

4

S7-Technology

• A bulletin board in which users and specialists worldwide exchange their know-how

• Your local Siemens partner for Automation & Drives in our Partner database

• Information about local service, repairs, and spare parts. You will find much more under

"Services".

CPU 317T-2 DP: Controlling a SINAMICS S120

Getting Started, 12/2005, A5E00480391-01

4-1

Page 84

4 Further information

4.1 4.1 Further information

•

CPU 317T-2 DP: Controlling a SINAMICS S120

4-2 Getting Started, 12/2005, A5E00480391-01

Loading...

Loading...