Siemens Simatic S7-300 CPU 31xC, Simatic S7-300 CPU 312C, Simatic S7-300 CPU 314C-2 DP, Simatic S7-300 CPU 313C-2 DP, Simatic S7-300 CPU 314C-2 PtP Installation And Operating Instructions Manual

...

SIMATIC

S7-300, CPU 31xC and CPU 31x:

Installation

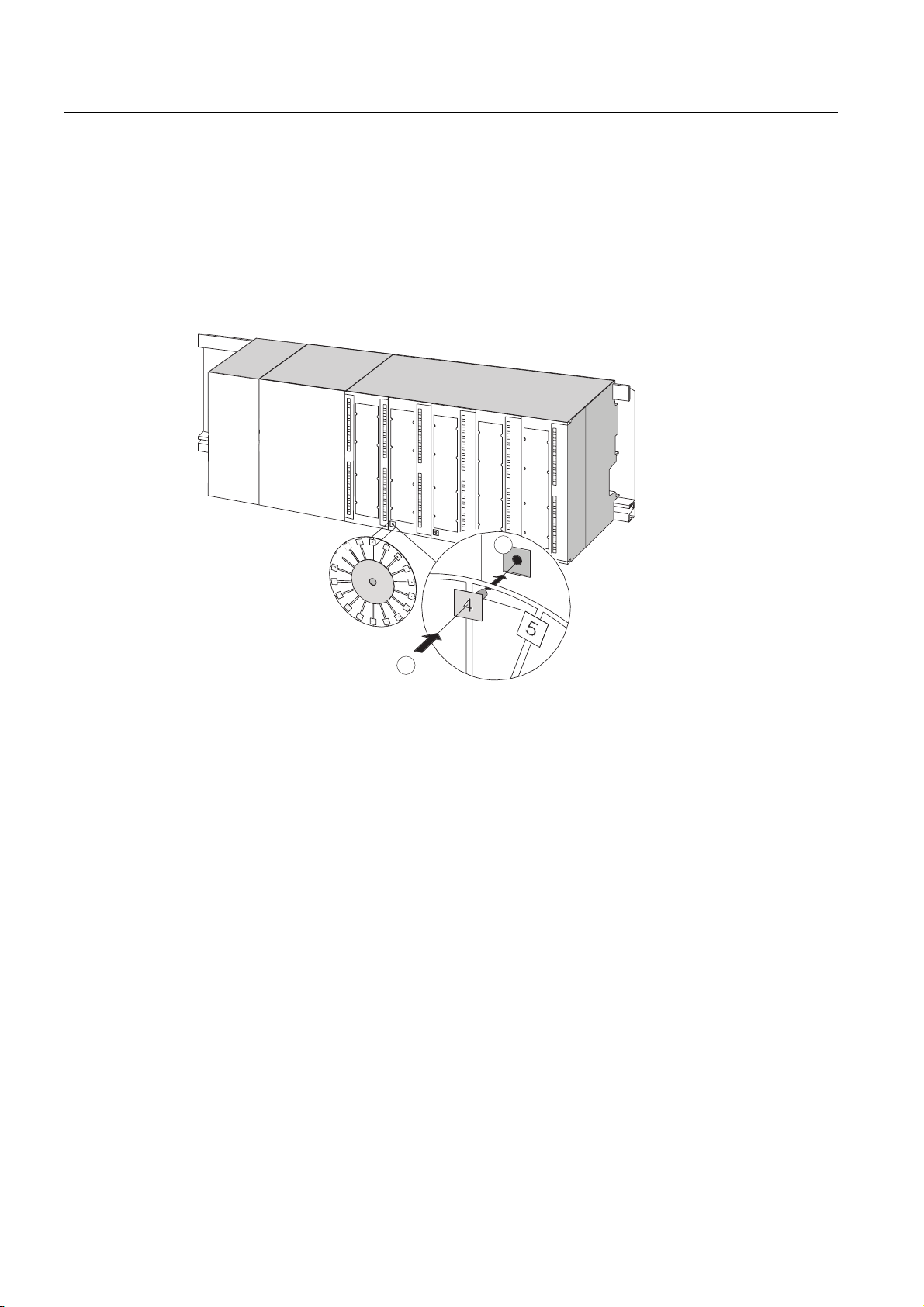

Operating Instructions

Preface

Guide to the S7-300

documentation

Installation Order

S7-300 components

Configuring

Installing

Wiring

1

2

3

4

5

6

Addressing

Commissioning

Maintenance

Debugging functions, diagnostics and troubleshooting

Appendix

7

8

9

10

A

This manual is part of the documentation package

with the order number: 6ES7398-8FA10-8BA0

Edition 08/2004

A5E00105492-05

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety as well as to avoid

property damage. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring to property damage only have no safety alert symbol.

Danger

indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Warning

indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Caution

used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Caution

used without safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

Notice

used without the safety alert symbol indicates a potential situation which, if not avoided, may result in

an undesirable result or state.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and operated in conjunction with this documentation. Only qualified

personnel should be allowed to install and work on the equipment. Qualified persons are defined as persons who

are authorized to commission, to earth, and to tag circuits, equipment and systems in accordance with

established safety practices and standards.

Intended Use

Please note the following:

Warning

This device and its components may only be used for the applications described in the catalog or

technical description, and only in connection with devices or components from other manufacturers

approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up and installed

correctly, and operated and maintained as recommended.

Trademarks

All designations marked with ® are registered trademarks of Siemens AG. Other designations in this

documentation might be trademarks which, if used by third parties for their purposes, might infringe upon the

rights of the proprietors.

Copyright Siemens AG ,2004.All rights reserved

Reproduction, transmission or use of this document or its contents is not permitted without

express written authority. Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design, are reserved.

Siemens AG

Automation and Drives Group

P.O. Box 4848, D-90327 Nuremberg (Germany)

Siemens Aktiengesellschaft Order No. A5E00105492-05

Disclaimer of Liability

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in the manual are reviewed regularly, and any

necessary corrections will be included in subsequent editions. Suggestions for

improvement are welcomed.

Siemens AG 2004

Technical data subject to change

Preface

Purpose of the manual

This manual contains all the information you need to configure, install, wire, address and

commission an S7-300.

In addition, you will become familiar with the tools you can use to diagnose and eliminate

errors in hardware and software.

Basic knowledge

To understand this manual, you require a general knowledge of automation engineering. You

should also be accustomed to working with STEP 7 basic software. For further information,

refer to the Programming with STEP 7 V5.3 manual.

Area of application

Note

The special features of the 315F-2 DP and CPU 317F-2 DP CPUs are described in their

Product Information, available on the Internet at

http://www.siemens.com/automation/service&support, article ID 17015818.

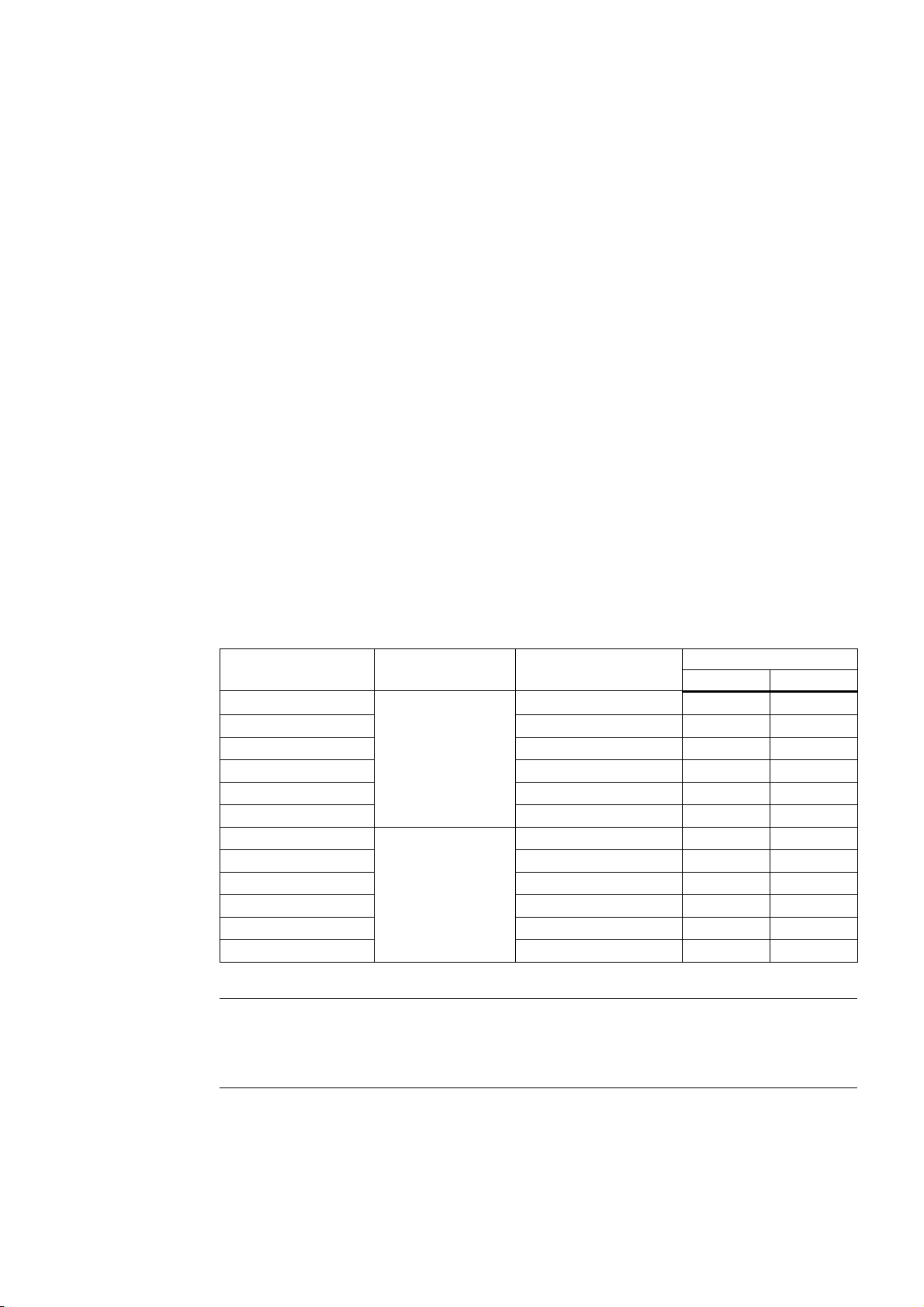

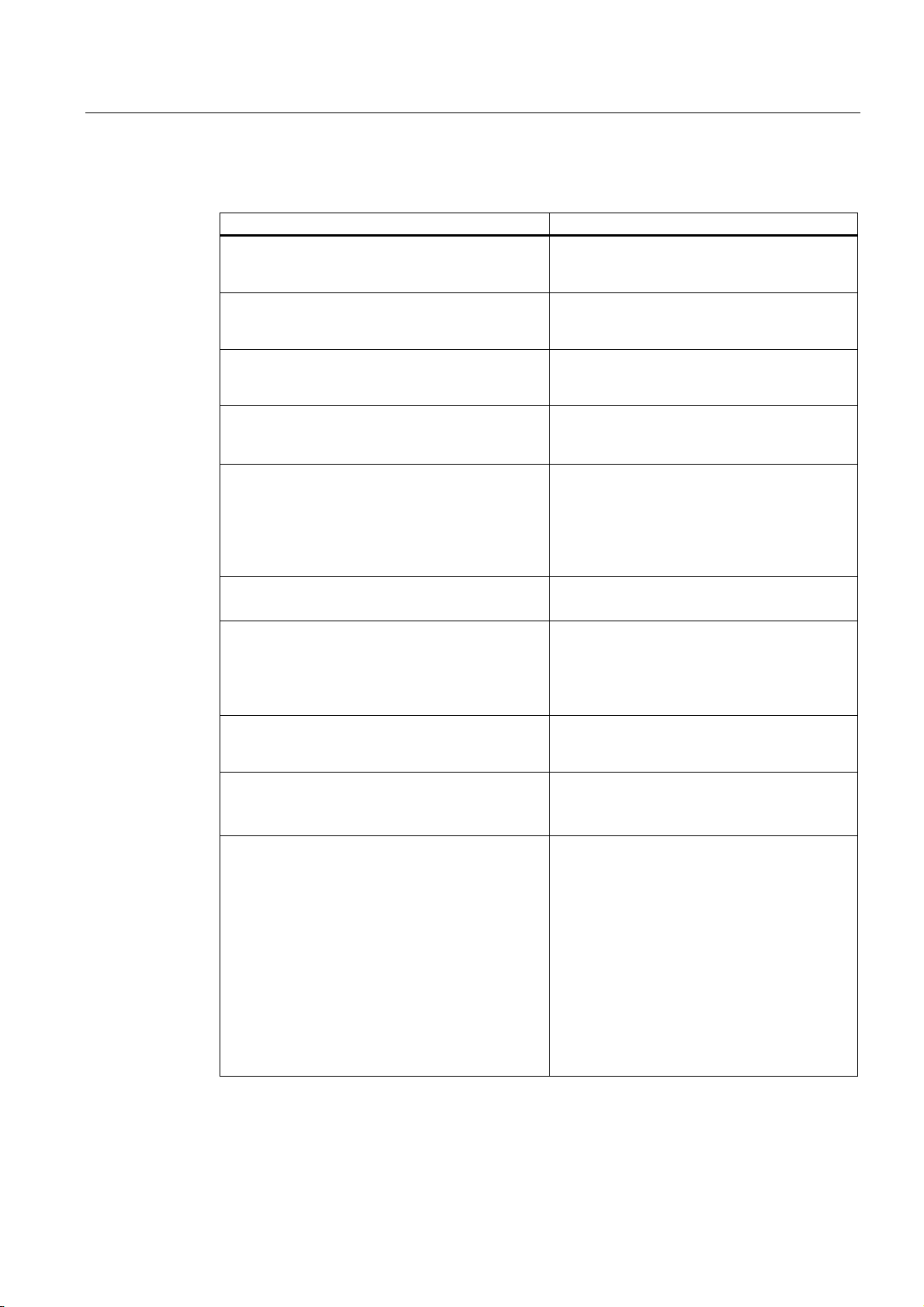

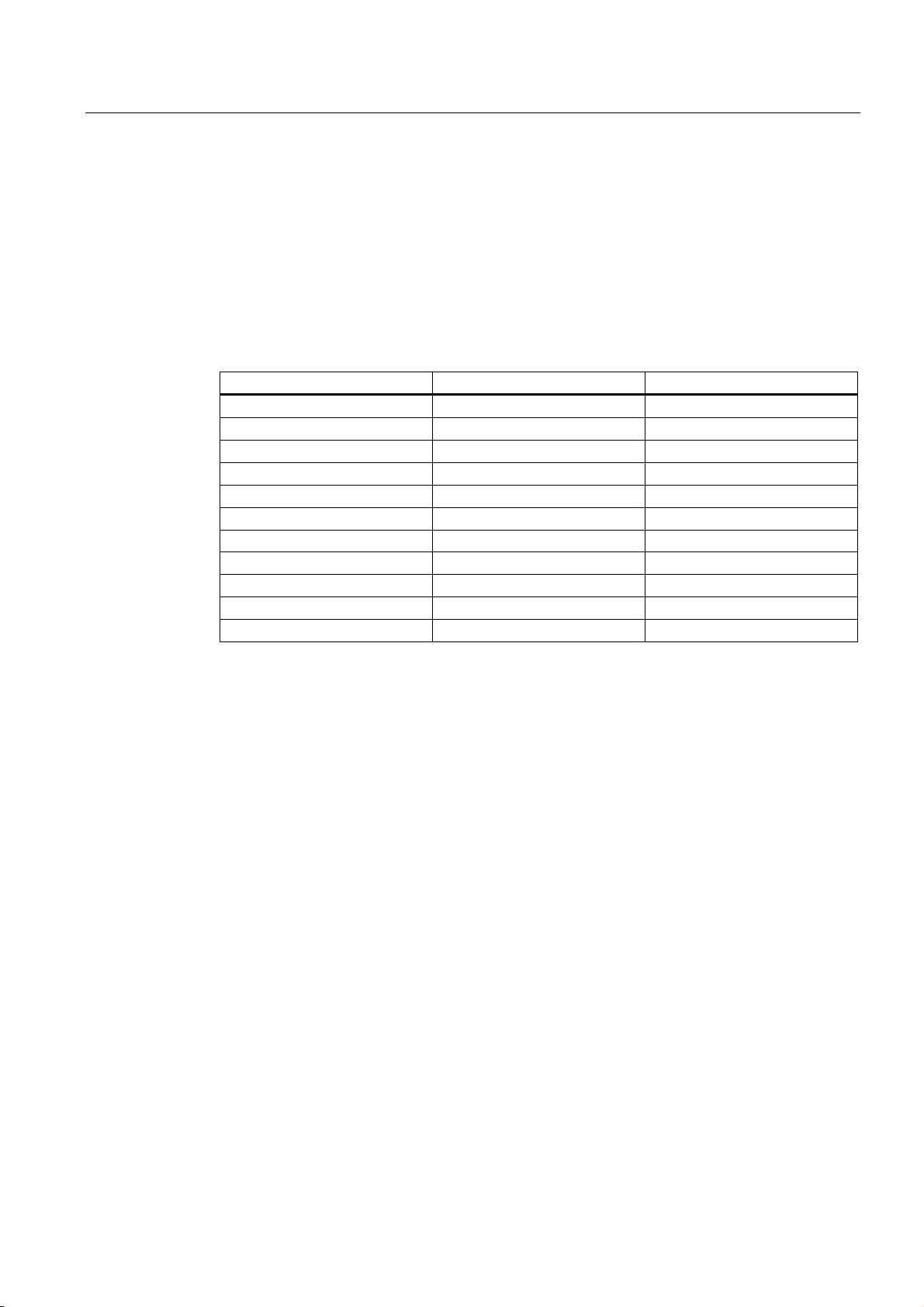

Order number

CPU designation

CPU 312C 6ES7312-5BD01-0AB0 V2.0.0 01

CPU 313C 6ES7313-5BE01-0AB0 V2.0.0 01

CPU 313C-2 PtP 6ES7313-6BE01-0AB0 V2.0.0 01

CPU 313C-2 DP 6ES7313-6CE01-0AB0 V2.0.0 01

CPU 314C-2 PtP 6ES7314-6BF01-0AB0 V2.0.0 01

CPU 314C-2 DP

CPU 312 6ES7312-1AD10-0AB0 V2.0.0 01

CPU 314 6ES7314-1AF10-0AB0 V2.0.0 01

CPU 315-2 DP 6ES7315-2AG10-0AB0 V2.0.0 01

CPU 315-2-PN/DP 6ES7315-2EG10-0AB0 V2.3.0 01

CPU 317-2 DP 6ES7317-2AJ10-0AB0 V2.1.0 01

CPU 317-2 PN/DP

CPU 31xC

6ES7314-6CF01-0AB0 V2.0.0 01

CPU 31x

6ES7317-2EJ10-0AB0 V2.3.0 01

as of version CPU Convention:

Firmware Hardware

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

iii

Preface

Approvals

CE label

Note

There you can obtain the descriptions of all current modules.

For new modules, or modules of a more recent version, we reserve the right to include a

Product Information containing latest information.

The SIMATIC S7-300 product series has the following approvals:

• Underwriters Laboratories, Inc.: UL 508 (Industrial Control Equipment)

• Canadian Standards Association: CSA C22.2 No. 142, (Process Control Equipment)

• Factory Mutual Research: Approval Standard Class Number 3611

The SIMATIC S7-300 product series satisfies the requirements and safety specifications of

the following EU Directives:

• EU Directive 73/23/EC "Low-voltage directive"

• EU Directive 89/336/EWE "EMC directive"

C tick mark

Standards

The SIMATIC S7-300 product series is compliant with AS/NZS 2064 (Australia).

The SIMATIC S7-300 product series is compliant with IEC 61131-2.

S7-300, CPU 31xC and CPU 31x: Installation

iv Operating Instructions, Edition 08/2004, A5E00105492-05

Preface

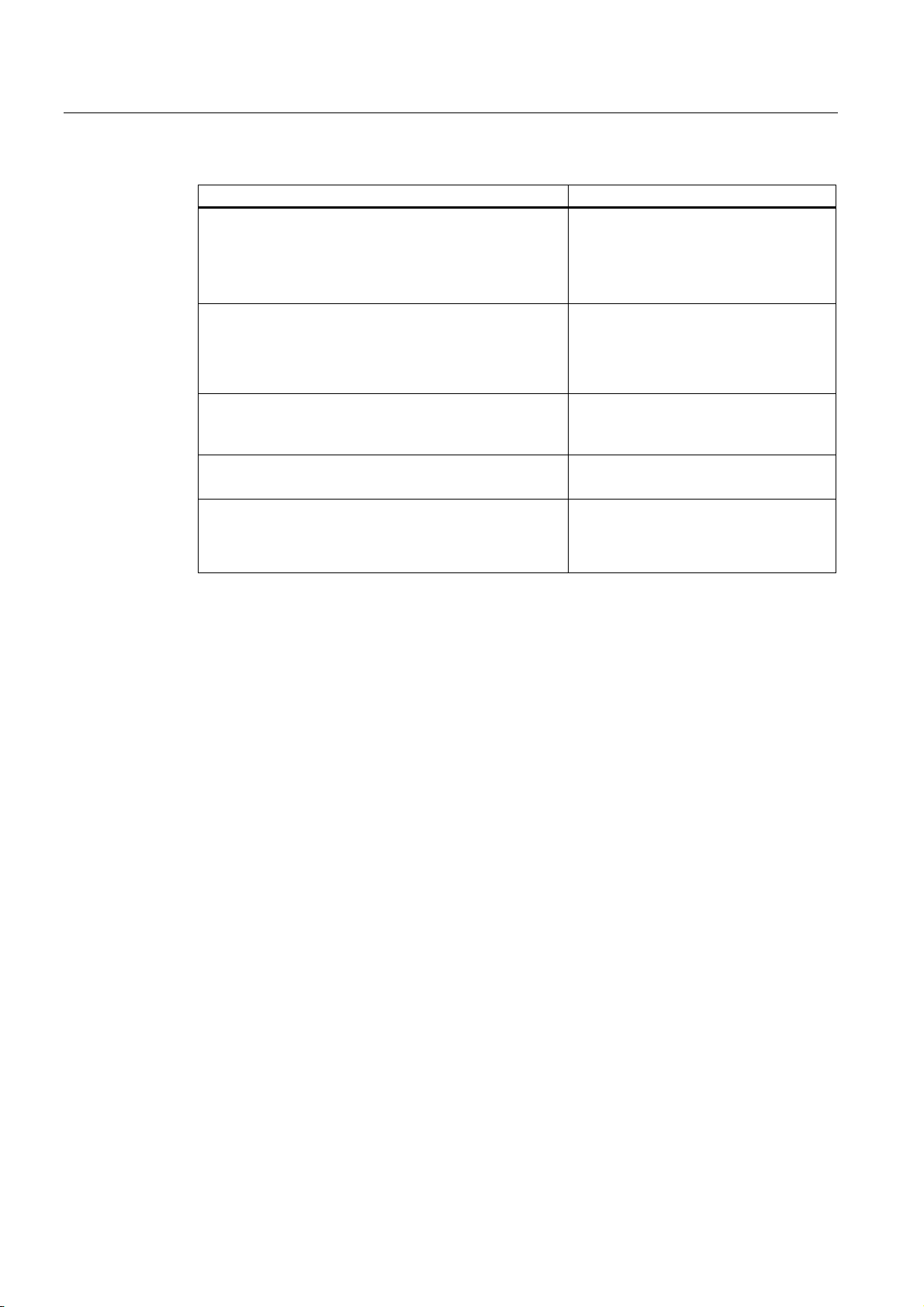

Documentation classification

This manual is part of the S7-300 documentation package.

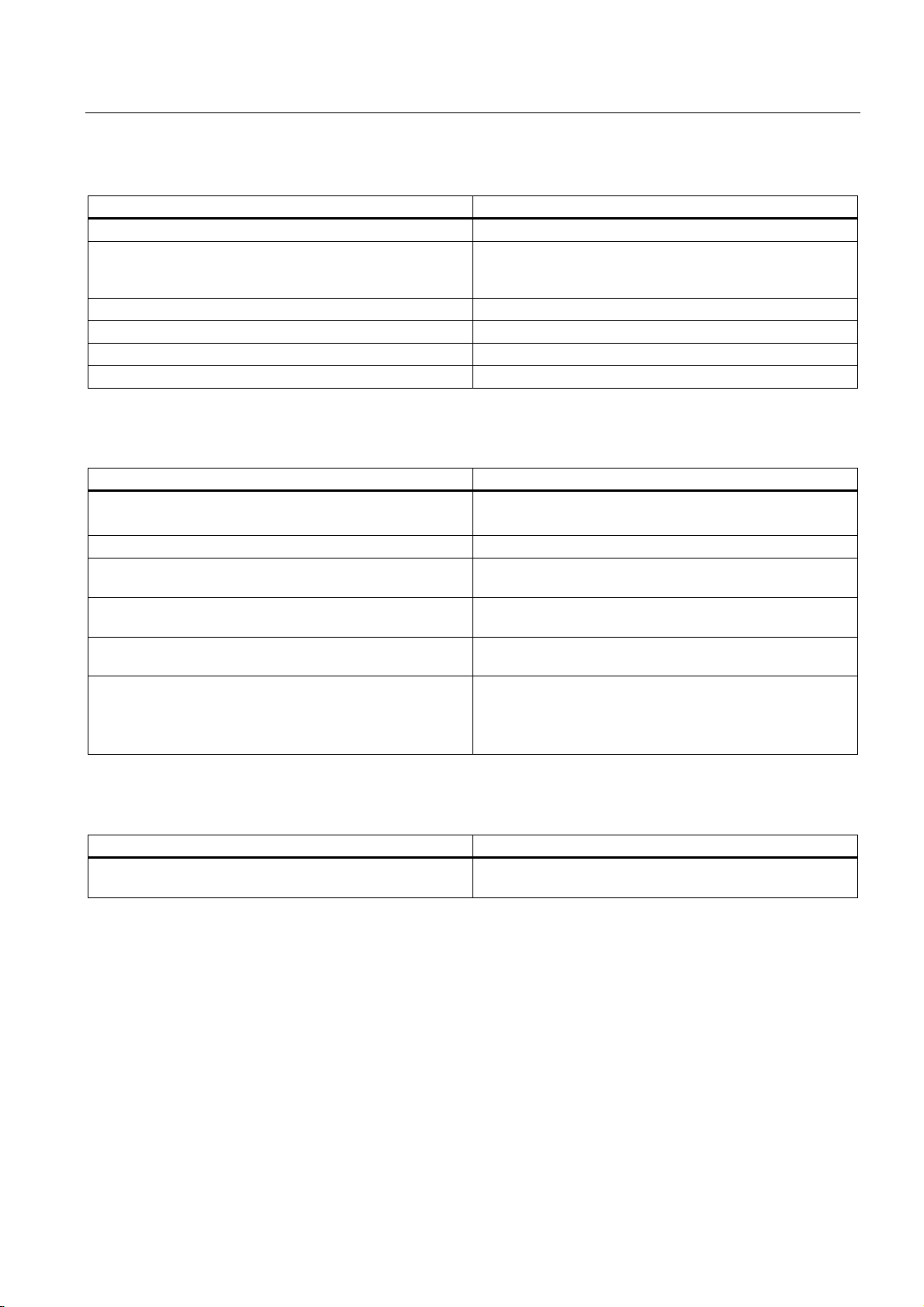

Name of the manual Description

Manual

• 31xC and 31x CPUs, technical data

Reference Manual

• CPU data: CPU 312 IFM – 318-2 DP

YOU ARE READING the Manual

• S7-300, CPU 31xC and CPU 31x: Installation

Installation Manual

• S7-300 Automation System: Installation: CPU

312 IFM – 318-2 DP

System Manual

PROFINET System Overview

Programming Manual

From PROFIBUS DP to PROFINET I/O

Manual

• CPU 31xC: Technological functions

• Examples

Reference Manual

• S7-300 Automation System: Module data

Instruction List

• CPU 312 IFM – 318-2 DP

• CPU 31xC and CPU 31x

Getting Started

The following Getting Started editions are available

as a collective volume:

• CPU 31x: Commissioning

• CPU 31xC: Commissioning

• CPU 31xC: Positioning with analog output

• CPU 31xC: Positioning with digital output

• CPU 31xC: Counting

• CPU 31xC: Rules

• CPU 31xC: PtP communication

• CPU 31x-2 PN/DP: Commissioning a

PROFINET I/O subnet

Control and display elements, communication,

memory concept, cycle and response times,

technical data

Control and display elements, communication,

memory concept, cycle and response times,

technical data

Configuration, installation, wiring, addressing,

commissioning, maintenance and the test

functions, diagnostics and troubleshooting.

Configuration, installation, wiring, addressing,

commissioning, maintenance and the test

functions, diagnostics and troubleshooting.

Basic information on PROFINET:

Network components, data exchange and

communication, PROFINET I/O, Component

based Automation, application example of

PROFINET I/O and Component based

Automation

Guideline for the migration from PROFIBUS DP

to PROFINET I/O.

Description of the various technological

functions of positioning and counting. PtP

communication, rules

The CD contains examples of the technological

functions

Descriptions of the functions and technical data

of signal modules, power supply modules and

interface modules.

List of CPU instruction resources and the

relevant execution times. List of executable

blocks.

The example used in this Getting Started

guides you through the various steps in

commissioning required to obtain a fully

functional application.

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

v

Preface

Additional information required:

Name of the manual Description

Reference Manual

System software for S7-300/400 system and standard

functions

Manual

SIMATIC NET: Twisted Pair and Fiber-Optic Networks

Manual

Component-based Automation: Configuring systems with

SIMATIC iMap

Manual

Programming with STEP 7 V5.3

Manual

SIMATIC communication

Description of the SFCs, SFBs and OBs.

This manual is part of the STEP 7

documentation package. For further

information, refer to the STEP 7 Online

Help.

Description of Industrial Ethernet

networks, network configuration,

components, installation guidelines for

networked automation systems in

buildings, etc.

Description of the engineering software

iMAP

Programming with STEP 7

Basics, services, networks,

communication functions, connecting

PGs/OPs, engineering and configuring in

STEP 7.

S7-300 documentation package: Additional documentation

Recycling and Disposal

The devices described in this manual can be recycled, because their components contain a

minimum of harmful substances. For environment-friendly recycling and disposal of your old

equipment, contact a certified disposal facility for electronic scrap.

S7-300, CPU 31xC and CPU 31x: Installation

vi Operating Instructions, Edition 08/2004, A5E00105492-05

Table of contents

Preface ......................................................................................................................................................iii

1 Guide to the S7-300 documentation ....................................................................................................... 1-1

2 Installation Order .................................................................................................................................... 2-1

3 S7-300 components................................................................................................................................ 3-1

3.1 Example of an S7-300 configuration..........................................................................................3-1

3.2 Overview of the vital modules of an S7-300 .............................................................................. 3-2

4 Configuring ............................................................................................................................................. 4-1

4.1 Overview .................................................................................................................................... 4-1

4.2 Basic engineering principles ...................................................................................................... 4-1

4.3 Component dimensions ............................................................................................................. 4-4

4.4 Required clearances .................................................................................................................. 4-6

4.5 Arrangement of modules on a single rack ................................................................................. 4-7

4.6 Distribution of modules to several racks ....................................................................................4-8

4.7 Selection and installation of cabinets....................................................................................... 4-11

4.8 Example: Selecting a cabinet................................................................................................... 4-14

4.9 Electrical assembly, protective measures and grounding ....................................................... 4-15

4.9.1 Grounding concept and overall structure................................................................................. 4-15

4.9.2 Installing an S7-300 with grounded reference potential .......................................................... 4-16

4.9.3 Configuring an S7-300 with ungrounded reference potential (not CPU 31xC)........................ 4-17

4.9.4 Modules with isolated or common potential?........................................................................... 4-19

4.9.5 Grounding measures ............................................................................................................... 4-21

4.9.6 Overview: Grounding ............................................................................................................... 4-24

4.10 Selecting the Load Power Supply............................................................................................ 4-26

4.11 Planning subnets ..................................................................................................................... 4-28

4.11.1 Overview .................................................................................................................................. 4-28

4.11.2 Configuring MPI and PROFIBUS subnets ............................................................................... 4-30

4.11.2.1 Overview .................................................................................................................................. 4-30

4.11.2.2 Basic principles of MPI and PROFIBUS subnets .................................................................... 4-30

4.11.2.3 Multi-Point Interface (MPI) ....................................................................................................... 4-33

4.11.2.4 PROFIBUS DP interface.......................................................................................................... 4-34

4.11.2.5 Network components of MPI/DP and cable lengths ................................................................ 4-35

4.11.2.6 Cable lengths of MPI and PROFIBUS subnets ....................................................................... 4-40

4.11.3 Configuring PROFINET subnets.............................................................................................. 4-45

4.11.3.1 Overview .................................................................................................................................. 4-45

4.11.3.2 PROFINET nodes .................................................................................................................... 4-45

4.11.3.3 Integration of field bus systems in PROFINET ........................................................................ 4-48

4.11.3.4 PROFINET IO and PROFINET CBA ....................................................................................... 4-49

4.11.3.5 PROFINET cable lengths and network expansion .................................................................. 4-54

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

vii

Table of contents

4.11.3.6 Connectors and other components for Ethernet...................................................................... 4-56

4.11.3.7 Example of a PROFINET Subnet ............................................................................................4-57

4.11.3.8 Example of a PROFINET IO system........................................................................................ 4-59

4.11.4 Routed network transitions....................................................................................................... 4-60

4.11.5 Point-to-point (PtP)................................................................................................................... 4-62

4.11.6 Actuator/sensor interface (ASI) ................................................................................................ 4-63

5 Installing .................................................................................................................................................5-1

5.1 Installing an S7-300 ................................................................................................................... 5-1

5.2 Installing the mounting rail ......................................................................................................... 5-3

5.3 Mounting modules onto the rail.................................................................................................. 5-7

5.4 Labeling the modules................................................................................................................. 5-9

6 Wiring ..................................................................................................................................................... 6-1

6.1 Requirements for wiring the S7-300 ..........................................................................................6-1

6.2 Bonding the Protective Conductor to the Mounting Rail ............................................................ 6-3

6.3 Adjusting the Power Supply Module to local Mains Voltage...................................................... 6-4

6.4 Wiring the Power Supply Module and the CPU ......................................................................... 6-5

6.5 Wiring Front Connectors ............................................................................................................ 6-7

6.6 Plugging the front connectors into modules............................................................................. 6-10

6.7 Labeling the module I/O........................................................................................................... 6-11

6.8 Connecting shielded cables to the shielding contact element ................................................. 6-12

6.9 Wiring the MPI / PROFIBUS DP bus connectors..................................................................... 6-15

6.9.1 Wiring the bus connector ......................................................................................................... 6-15

6.9.2 Setting the terminating resistor on the bus connector ............................................................. 6-16

6.10 RJ45 Ethernet connector ......................................................................................................... 6-17

7 Addressing.............................................................................................................................................. 7-1

7.1 Slot-specific addressing of modules .......................................................................................... 7-1

7.2 User-specific addressing of modules.........................................................................................7-3

7.2.1 User-specific addressing of modules ......................................................................................... 7-3

7.2.2 Addressing digital modules ........................................................................................................ 7-3

7.2.3 Addressing analog modules....................................................................................................... 7-5

7.2.4 Addressing the integrated I/Os of CPU 31xC ............................................................................ 7-6

7.3 Consistent data .......................................................................................................................... 7-8

8 Commissioning ....................................................................................................................................... 8-1

8.1 Overview .................................................................................................................................... 8-1

8.2 Commissioning procedure ......................................................................................................... 8-1

8.2.1 Procedure: Commissioning the hardware.................................................................................. 8-1

8.2.2 Procedure: Software commissioning .........................................................................................8-3

8.3 Commissioning check list........................................................................................................... 8-5

8.4 Commissioning the Modules...................................................................................................... 8-7

8.4.1 Inserting/Replacing a Micro Memory Card (MMC)..................................................................... 8-7

8.4.2 Initial power on ........................................................................................................................... 8-9

8.4.3 CPU memory reset by means of mode selector switch ............................................................. 8-9

8.4.4 Formatting the Micro Memory Card (MMC) ............................................................................. 8-12

8.4.5 Connecting the programming device (PG)............................................................................... 8-13

S7-300, CPU 31xC and CPU 31x: Installation

viii Operating Instructions, Edition 08/2004, A5E00105492-05

Table of contents

8.4.5.1 Connecting a PG/PC to the integrated PROFINET interface of the CPU 31x-2 PN/DP ......... 8-13

8.4.5.2 Connecting the PG to a node................................................................................................... 8-14

8.4.5.3 Connecting the PG to several nodes ....................................................................................... 8-15

8.4.5.4 Using the PG for commissioning or maintenance.................................................................... 8-16

8.4.5.5 Connecting a PG to ungrounded MPI nodes (not CPU 31xC) ................................................ 8-17

8.4.6 Starting SIMATIC Manager...................................................................................................... 8-18

8.4.7 Monitoring and modifying I/Os ................................................................................................. 8-19

8.5 Commissioning PROFIBUS DP............................................................................................... 8-23

8.5.1 Commissioning PROFIBUS DP............................................................................................... 8-23

8.5.2 Commissioning the CPU as DP master................................................................................... 8-24

8.5.3 Commissioning the CPU as DP Slave..................................................................................... 8-27

8.5.4 Direct data exchange ............................................................................................................... 8-33

8.6 Commissioning PROFINET IO ................................................................................................ 8-34

8.6.1 Requirements........................................................................................................................... 8-34

8.6.2 Configuring and commissioning the PROFINET IO system .................................................... 8-35

9 Maintenance ........................................................................................................................................... 9-1

9.1 Overview .................................................................................................................................... 9-1

9.2 Backup of firmware to Micro Memory Card (MMC) ................................................................... 9-1

9.3 Updating the firmware from MMC..............................................................................................9-3

9.4 Online (via networks) update of CPU FW V2.2.0 or higher. ...................................................... 9-4

9.5 Backup of project data to a Micro Memory Card (MMC) ........................................................... 9-5

9.6 Module installation / removal ..................................................................................................... 9-6

9.7 Digital output module AC 120/230 V: Changing fuses ............................................................ 9-11

10 Debugging functions, diagnostics and troubleshooting......................................................................... 10-1

10.1 Overview .................................................................................................................................. 10-1

10.2 Overview: Debugging functions ............................................................................................... 10-1

10.3 Overview: Diagnostics ............................................................................................................. 10-4

10.4 Diagnostic Options with STEP 7.............................................................................................. 10-7

10.5 Network Infrastructure Diagnostics (SNMP) ............................................................................ 10-8

10.6 Diagnostics using status and error LEDs................................................................................. 10-9

10.6.1 Introduction .............................................................................................................................. 10-9

10.6.2 Status and error displays of all CPUs .................................................................................... 10-10

10.6.3 Evaluating the SF LED in case of software errors ................................................................. 10-11

10.6.4 Evaluating the SF LED in case of hardware errors................................................................ 10-13

10.6.5 Status and Error Indicators: CPUs with DP Interface ............................................................ 10-14

10.6.6 Status displays: CPUs with PN Interface............................................................................... 10-16

10.7 Diagnostics of DP CPUs ........................................................................................................ 10-18

10.7.1 Diagnostics of DP CPUs operating as DP Master ................................................................. 10-18

10.7.2 Reading out slave diagnostic data......................................................................................... 10-21

10.7.3 Interrupts on the DP Master................................................................................................... 10-25

10.7.4 Structure of slave diagnostic data when the CPU is operated as Intelligent Slave............... 10-27

10.8 Diagnostics of PN CPUs ........................................................................................................ 10-34

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

ix

Table of contents

A Appendix.................................................................................................................................................A-1

A.1 General Rules and Regulations for S7-300 Operation ..............................................................A-1

A.2 Protection against electromagnetic interference........................................................................ A-3

A.2.1 Basic Points for EMC-compliant system installations ................................................................A-3

A.2.2 Five basic rules for securing EMC .............................................................................................A-5

A.2.2.1 1. Basic rule for ensuring EMC ..................................................................................................A-5

A.2.2.2 2. Basic rule for ensuring EMC ..................................................................................................A-5

A.2.2.3 3. Basic rule for ensuring EMC ..................................................................................................A-6

A.2.2.4 4. Basic rule for ensuring EMC ..................................................................................................A-6

A.2.2.5 5. Basic rule for ensuring EMC ..................................................................................................A-7

A.2.3 EMC-compliant installation of PLCs...........................................................................................A-7

A.2.4 Examples of an EMC-compliant installation: Cabinet installation.............................................. A-9

A.2.5 Examples of an EMC-compliant installation: Wall mounting....................................................A-10

A.2.6 Cable shielding.........................................................................................................................A-12

A.2.7 Equipotential bonding...............................................................................................................A-14

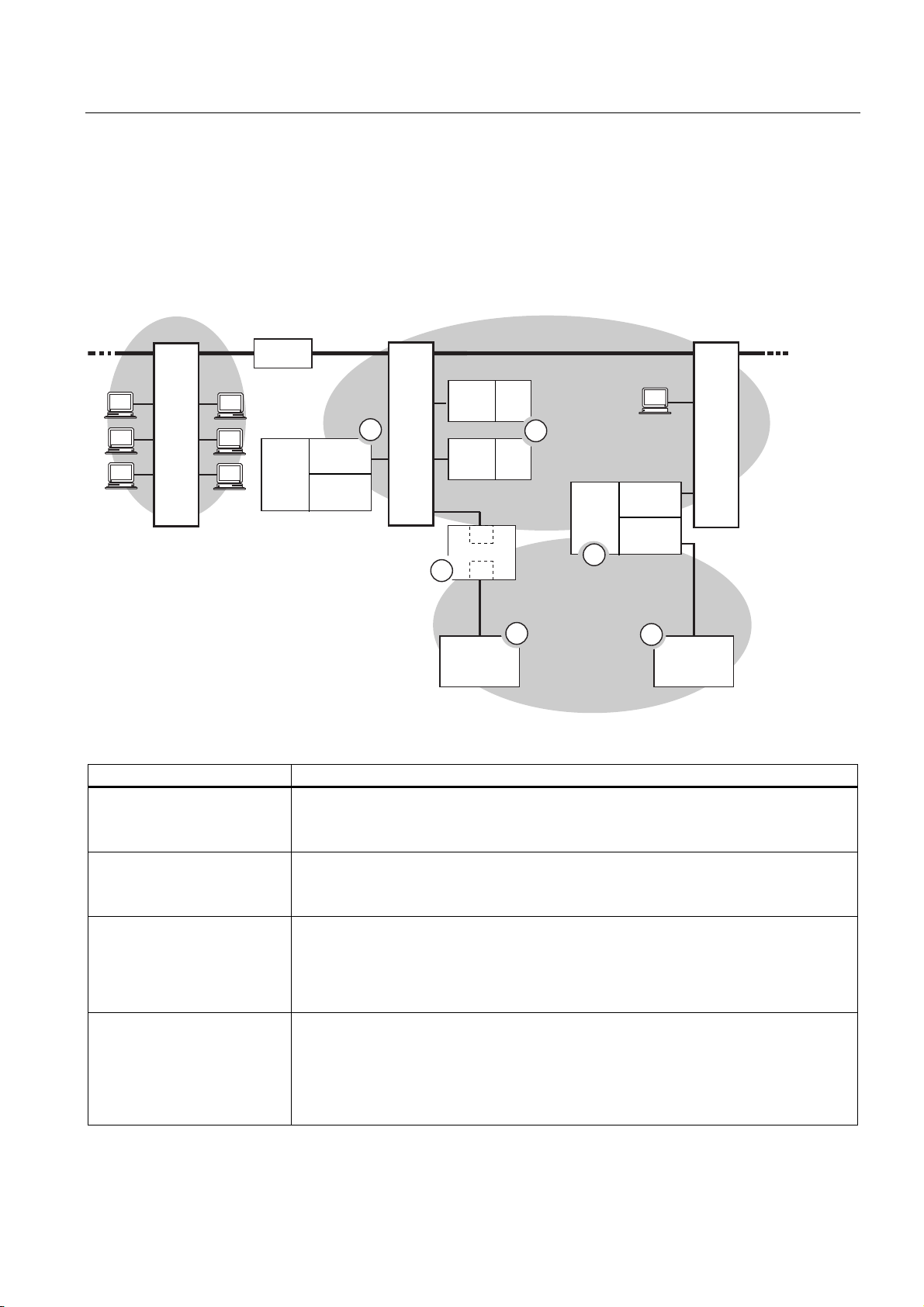

A.2.8 Cable routing inside buildings ..................................................................................................A-16

A.2.9 Outdoor routing of cables.........................................................................................................A-18

A.3 Lightning and Surge Voltage Protection ..................................................................................A-18

A.3.1 Overview ..................................................................................................................................A-18

A.3.2 Lightning protection zone concept ...........................................................................................A-19

A.3.3 Rules for the transition point between lightning protection zones 0 <-> 1 ...............................A-21

A.3.4 Rules for the transition point between lightning protection zones 1 <-> 2 and higher.............A-22

A.3.5 Example: Surge protection circuit for networked S7-300 PLCs...............................................A-26

A.3.6 How to Protect Digital Output Modules against Inductive Surge Voltage................................A-28

A.4 Safety of Electronic Control Equipment ...................................................................................A-30

Glossary ..................................................................................................................................... Glossary-1

Index................................................................................................................................................ Index-1

S7-300, CPU 31xC and CPU 31x: Installation

x Operating Instructions, Edition 08/2004, A5E00105492-05

Table of contents

Tables

Table 1-1

Ambient influence on the automation system (AS).................................................................... 1-1

Table 1-2 Galvanic isolation....................................................................................................................... 1-1

Table 1-3 Communication between sensors/actuators and the PLC......................................................... 1-2

Table 1-4 The use of local and distributed I/O ........................................................................................... 1-2

Table 1-5 Configuration consisting of the Central Unit (CU) and Expansion Modules (EMs) ................... 1-2

Table 1-6 CPU performance ...................................................................................................................... 1-3

Table 1-7 Communication .......................................................................................................................... 1-3

Table 1-8 Software..................................................................................................................................... 1-3

Table 1-9 Supplementary features............................................................................................................. 1-4

Table 3-1 S7-300 components:.................................................................................................................. 3-2

Table 4-1 Mounting rails - Overview .......................................................................................................... 4-4

Table 4-2 Module width.............................................................................................................................. 4-4

Table 4-3 Shielding terminals - Overview ..................................................................................................4-5

Table 4-4 Interface modules - Overview ....................................................................................................4-8

Table 4-5 Cabinet types ........................................................................................................................... 4-13

Table 4-6 Cabinet selection ..................................................................................................................... 4-15

Table 4-7 VDE specifications for the installation of a PLC system .......................................................... 4-16

Table 4-8 Measures for protective grounding .......................................................................................... 4-22

Table 4-9 Connecting the load voltage reference potential ..................................................................... 4-23

Table 4-10 Connecting the load voltage reference potential ..................................................................... 4-24

Table 4-11 Connecting the load voltage reference potential ..................................................................... 4-25

Table 4-12 Features of load power supply units ........................................................................................ 4-26

Table 4-13 Subnet nodes........................................................................................................................... 4-31

Table 4-14 MPI/PROFIBUS DP addresses................................................................................................ 4-31

Table 4-15 MPI addresses of CPs/FMs in an S7-300 system ................................................................... 4-32

Table 4-16 Operating modes for CPUs with two DP interfaces................................................................. 4-34

Table 4-17 Permissible cable length of a segment on the MPI subnet...................................................... 4-35

Table 4-18 Permissible cable length of a segment on the PROFIBUS subnet.......................................... 4-35

Table 4-19 Lengths of stub cables per segment........................................................................................ 4-36

Table 4-20 PG patch cord .......................................................................................................................... 4-36

Table 4-21 Available bus cables ................................................................................................................ 4-37

Table 4-22 Properties of PROFIBUS cables.............................................................................................. 4-37

Table 4-23 Marginal conditions for wiring interior bus cables.................................................................... 4-38

Table 4-24 Bus connector .......................................................................................................................... 4-38

Table 4-25 Data for twisted-pair patch cables............................................................................................ 4-55

Table 5-1 Module accessories ................................................................................................................... 5-2

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

xi

Table of contents

Table 5-2 Installation tools and materials................................................................................................... 5-3

Table 5-3 Mounting holes for rails.............................................................................................................. 5-5

Table 5-4 Slot numbers for S7 modules.....................................................................................................5-9

Table 6-1 Wiring accessories..................................................................................................................... 6-1

Table 6-2 Tools and material for wiring...................................................................................................... 6-1

Table 6-3 Wiring conditions for PS and CPU ............................................................................................. 6-2

Table 6-4 Wiring conditions for front connectors........................................................................................ 6-2

Table 6-5 Assignment of front connectors to modules............................................................................... 6-7

Table 6-6 Wiring front connectors .............................................................................................................. 6-9

Table 6-7 Inserting the front connector .................................................................................................... 6-10

Table 6-8 Labeling strip assignment to modules...................................................................................... 6-11

Table 6-9 Shielding diameter assignment to shielding terminals............................................................. 6-12

Table 7-1 Integrated I/Os of CPU 312C .....................................................................................................7-6

Table 7-2 Integrated I/Os of CPU 313C .....................................................................................................7-6

Table 7-3 Integrated I/Os of CPU 313C-2 PtP/DP..................................................................................... 7-7

Table 7-4 Integrated I/Os of CPU 314C-2 PtP/DP..................................................................................... 7-7

Table 8-1 Recommended commissioning procedure: Hardware............................................................... 8-2

Table 8-2 Recommended commissioning procedure - Part II: Software ................................................... 8-4

Table 8-3 Possible reasons of a CPU request to reset memory................................................................ 8-9

Table 8-4 Procedure for CPU memory reset............................................................................................ 8-10

Table 8-5 Internal CPU events on memory reset..................................................................................... 8-11

Table 8-6 Software requirements............................................................................................................. 8-23

Table 8-7 DP address areas of the CPUs................................................................................................ 8-23

Table 8-8 Event recognition by CPUs 31x-2 DP/31xC-2 DP operating as DP master ............................ 8-25

Table 8-9 Event recognition by CPUs 31x-2 DP/31xC-2 DP as DP slave............................................... 8-28

Table 8-10 Configuration example for the address areas of transfer memory........................................... 8-30

Table 8-11 PROFINET IO address areas of the CPUs.............................................................................. 8-35

Table 8-12 CPU startup for operation as IO controller............................................................................... 8-39

Table 8-13 Event detection by the CPU 31x-2 PN/DP operating as IO controller ..................................... 8-39

Table 9-1 Firmware backup to MMC..........................................................................................................9-2

Table 9-2 Updating the firmware from MMC.............................................................................................. 9-3

Table 10-1 The differences between forcing and modifying variables....................................................... 10-4

Table 10-2 Status and error displays ....................................................................................................... 10-10

Table 10-3 Evaluation of the SF LED (software error) ............................................................................. 10-11

Table 10-4 Evaluation of the SF LED (Hardware error)........................................................................... 10-13

Table 10-5 BUSF, BUSF1 and BUSF2 LEDs .......................................................................................... 10-14

Table 10-6 BUSF LED is lit ...................................................................................................................... 10-14

Table 10-7 BUSF LED flashes ................................................................................................................. 10-15

S7-300, CPU 31xC and CPU 31x: Installation

xii Operating Instructions, Edition 08/2004, A5E00105492-05

Table of contents

Table 10-8 BF2/ BUSF LED is lit.............................................................................................................. 10-17

Table 10-9 BF2/ BUSF LED flashes on a PROFINET IO controller ........................................................ 10-17

Table 10-10 Event detection of CPU 31x#2 operating as DP master ........................................................ 10-20

Table 10-11 Evaluating RUN to STOP transitions of the DP slave in the DP master................................ 10-20

Table 10-12 Reading out diagnostic data in the master system, using STEP 5 and STEP 7 ................... 10-21

Table 10-13 Event recognition of CPUs 31x-2 operating in DP slave mode ............................................. 10-24

Table 10-14 Evaluating RUN#STOP transitions in the DP Master/DP Slave............................................. 10-25

Table 10-15 Structure of Station Status 1 (Byte 0) .................................................................................... 10-28

Table 10-16 Structure of Station Status 2 (Byte 1) .................................................................................... 10-28

Table 10-17 Structure of Station Status 3 (Byte 2) .................................................................................... 10-29

Table 10-18 Structure of the Master PROFIBUS address (byte 3)............................................................ 10-29

Table 10-19 Structure of the manufacturer ID (byte 4 and 5).................................................................... 10-29

Table A-1 System startup after specific events .......................................................................................... A-1

Table A-2 Mains voltage............................................................................................................................. A-2

Table A-3 Protection against external electrical interference..................................................................... A-2

Table A-4 Protection against external electrical interference..................................................................... A-2

Table A-5 Coupling mechanisms................................................................................................................A-4

Table A-1 Key to example 1 ..................................................................................................................... A-10

Table A-2 Cable routing inside buildings..................................................................................................A-16

Table A-3 High#voltage protection of cables with the help of surge protection equipment ......................A-21

Table A-4 Surge-protection components for lightning protection zones 1 <-> 2...................................... A-24

Table A-5 Surge-protection components for lightning protection zones 2 <-> 3...................................... A-25

Table A-6 Example of a circuit conforming to lightning protection requirements (legend to previous figure)

.................................................................................................................................................A-27

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

xiii

Table of contents

S7-300, CPU 31xC and CPU 31x: Installation

xiv Operating Instructions, Edition 08/2004, A5E00105492-05

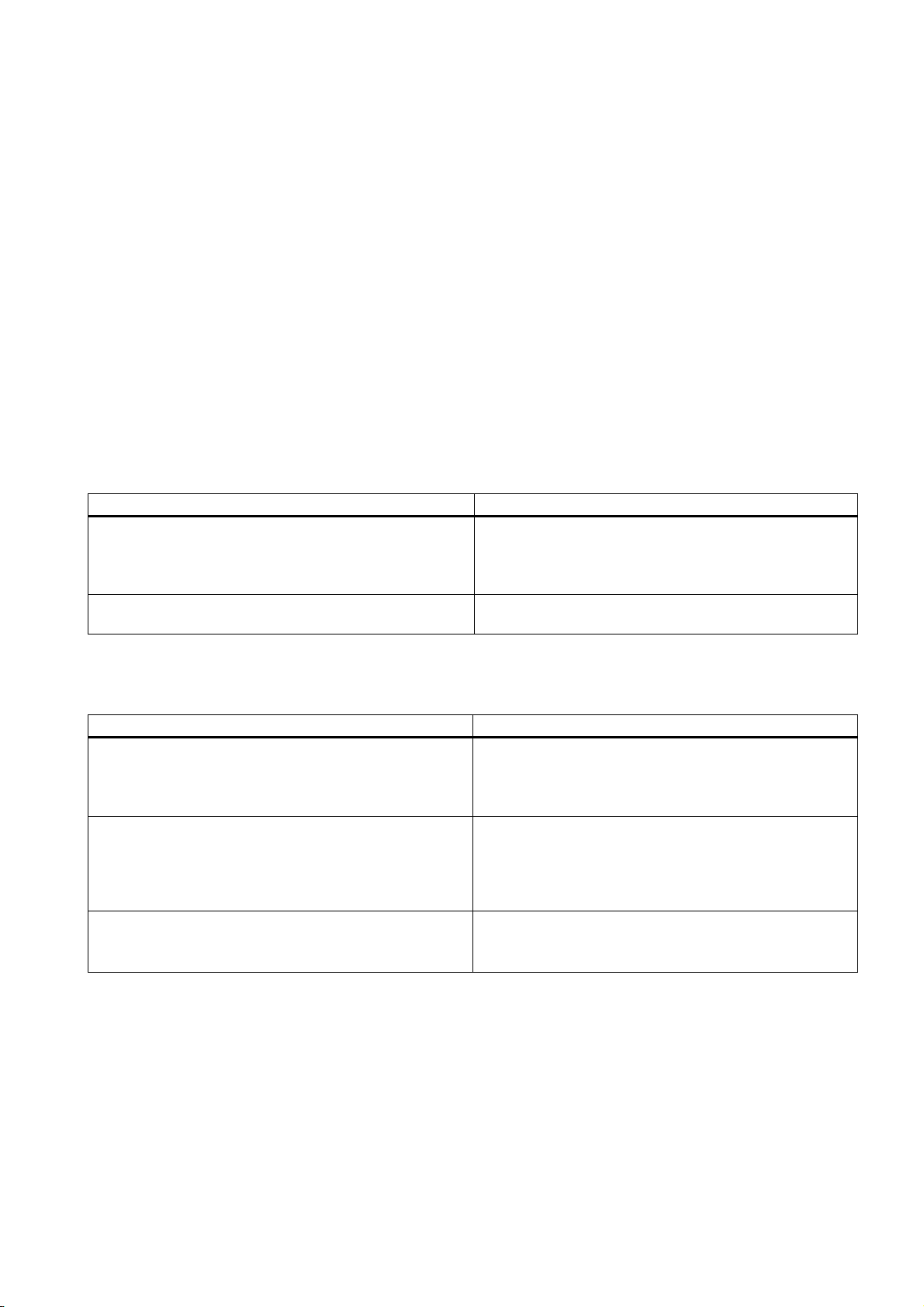

Guide to the S7-300 documentation

Overview

This guide leads you through the S7-300 documentation.

Selecting and configuring

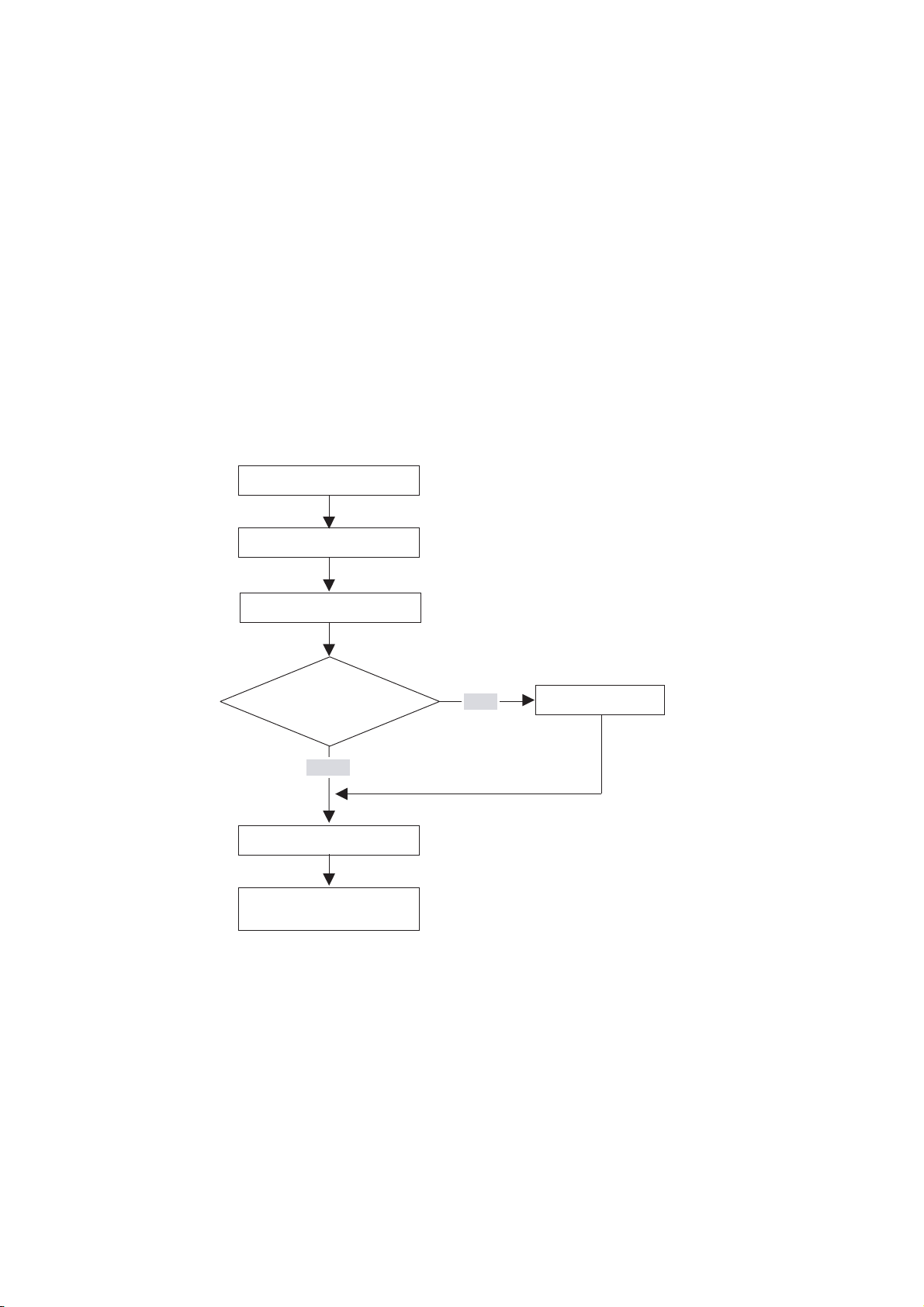

Table 1-1 Ambient influence on the PLC

Information on.. is available in ...

What provisions do I have to make for PLC installation

space?

How do environmental conditions influence the PLC? S7-300, CPU 31xC and CPU 31x Manual: Installation:

Table 1-2 Galvanic isolation

Information on.. is available in ...

Which modules can I use if electrical isolation is required

between sensors/actuators?

Under what conditions do I have to isolate the modules

electrically?

How do I wire it?

Under which conditions do I have to isolate stations

electrically?

How do I wire it?

S7-300, CPU 31xC and CPU 31x Manual: Installation:

Configuring - Component dimensions

S7-300, CPU 31xC and CPU 31x Manual: Installation:

Mounting - Installing the mounting rail

Appendix

S7-300, CPU 31xC and CPU 31x Operating Instructions:

Installation: Configuring – Electrical assembly, protective

measures and grounding

Module data Manual

S7-300, CPU 31xC and CPU 31x operating instructions:

Installation: Configuring – Electrical assembly, protective

measures and grounding

CPU 31xC and CPU 31x operating instructions: Installation:

Wiring

S7-300, CPU 31xC and CPU 31x operating instructions:

Installation – Configuring – Configuring subnets

1

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

1-1

Guide to the S7-300 documentation

Table 1-3 Communication between sensors/actuators and the PLC

Information on.. is available in ...

Which module is suitable for my sensor/actuator? For CPU: CPU 31xC and CPU 31x Manual, Technical Data

For signal modules: Reference manual of your signal

module

How many sensors/actuators can I connect to the module? For CPU: CPU 31xC and CPU 31x Manual, technical data

of signal modules: Reference manual of your signal module

To connect my sensors/actuators to the PLC, how do I wire

the front connector?

When do I need expansion modules (EM) and how do I

connect them?

How to mount modules on racks / mounting rails S7-300, CPU 31xC and CPU 31x operating instructions:

S7-300, CPU 31xC and CPU 31x operating instructions:

Installation: Wiring – Wiring the front connector

S7-300, CPU 31xC and CPU 31x operating instructions:

Installation: Configuring – Distribution of modules to several

racks

Installation: Assembly – Installing modules on the mounting

rail

Table 1-4 The use of local and distributed I/O

Information on.. is available in ...

Which range of modules do I want to use? For local I/O and expansion devices: Module Data reference

manual

For distributed I/O and PROFIBUS DP: Manual of the

relevant I/O device

Table 1-5 Configuration consisting of the Central Unit (CU) and Expansion Modules (EMs)

Information on.. is available in ...

Which rack / mounting rail is most suitable for my

application?

Which interface modules (IM) do I need to connect the EMs

to the CU?

What is the right power supply (PS) for my application? S7-300, CPU 31xC and CPU 31x operating instructions:

S7-300, CPU 31xC and CPU 31x operating instructions:

Installation: Configuring

S7-300, CPU 31xC and CPU 31x operating instructions:

Installation: Configuring – Distribution of modules to several

racks

Installation: Configuring

S7-300, CPU 31xC and CPU 31x: Installation

1-2 Operating Instructions, Edition 08/2004, A5E00105492-05

Guide to the S7-300 documentation

Table 1-6 CPU performance

Information on.. is available in ...

Which memory concept is best suited to my application? CPU 31xC and CPU 31x Manual, Technical Data

How do I insert and remove Micro Memory Cards? S7-300, CPU 31xC and CPU 31x operating instructions:

Installation: Commissioning – Commissioning modules –

Removing / inserting a Micro Memory Card (MMC)

Which CPU meets my demands on performance? S7-300 instruction list: CPU 31xC and CPU 31x

Length of the CPU response / execution times CPU 31xC and CPU 31x Manual, Technical Data

Which technological functions are implemented? Technological Functions Manual

How can I use these technological functions? Technological Functions Manual

Table 1-7 Communication

Information on.. is available in ...

Which principles do I have to take into account? Communication with SIMATIC Manual

PROFINET System Manual, System Description

Options and resources of the CPU CPU 31xC and CPU 31x Manual, Technical Data

How to use communication processors (CPs) to optimize

communication

Which type of communication network is best suited to my

application?

How to network the various components S7-300, CPU 31xC and CPU 31x operating instructions:

What to take into account when configuring PROFInet

networks

CP Manual

S7-300, CPU 31xC and CPU 31x operating instructions:

Installation: Configuring – Configuring subnets

Installation: Configuring – Configuring subnets

SIMATIC NET Manual, Twisted-Pair and Fiber Optic

Networks (6GK1970-1BA10-0AA0) – Network Configuration

PROFINET System Manual, System Description –

Installation and Commissioning

Table 1-8 Software

Information on.. is available in ...

Software requirements of my S7-300 system CPU 31xC and CPU 31x Manual, Technical Data –

Technical Data

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

1-3

Guide to the S7-300 documentation

Table 1-9 Supplementary features

Information on.. is available in ...

How to implement operating and monitoring functions

(Human Machine Interface)

How to integrate process control modules For PCS7: The relevant Manual

Options of redundant and fail-safe systems S7-400H Manual – Redundant Systems

Information to be observed when migrating from PROFIBUS

DP to PROFINET IO

For text-based displays: The relevant Manual

For Operator Panels: The relevant Manual

For WinCC: The relevant Manual

Fail-Safe Systems Manual

Programming Manual: From PROFIBUS DP to PROFINET

IO

S7-300, CPU 31xC and CPU 31x: Installation

1-4 Operating Instructions, Edition 08/2004, A5E00105492-05

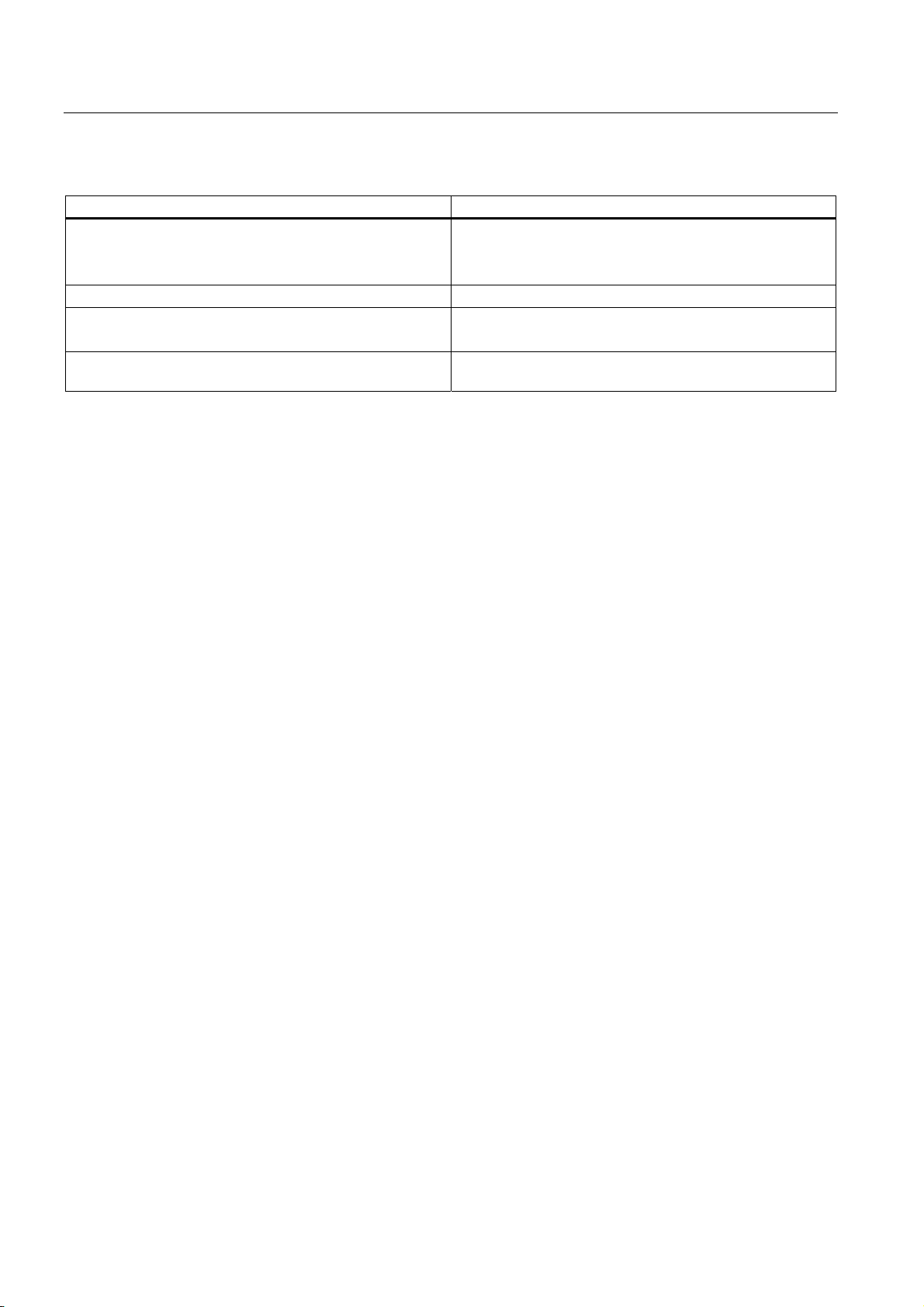

Installation Order

We will start by showing you the sequence of steps you have to follow to install your system.

Then we will go on to explain the basic rules that you should follow, and how you can modify

an existing system.

Installation procedure

Configuring

Do you want to

set up a subnet?

Mounting

Wiring

YES

2

Networking

NO

Addressing

Installation completed,

continue with commissioning

Basic rules for trouble-free operation of the S7 system

In view of the many and versatile applications, we can only provide basic rules for the

electrical and mechanical installation in this section.

You have to at least keep to these basic rules in order to obtain a fully functional SIMATICS7 system.

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

2-1

Installation Order

Modifying the existing S7 system structure

To modify the configuration of an existing system, proceed as described earlier.

Reference

Note

When adding a new signal module, always refer to the relevant module information.

Also refer to the description of the various modules in the manual:

Automation Systems, Module Data Reference Manual

.

SIMATIC S7-300

S7-300, CPU 31xC and CPU 31x: Installation

2-2 Operating Instructions, Edition 08/2004, A5E00105492-05

S7-300 components

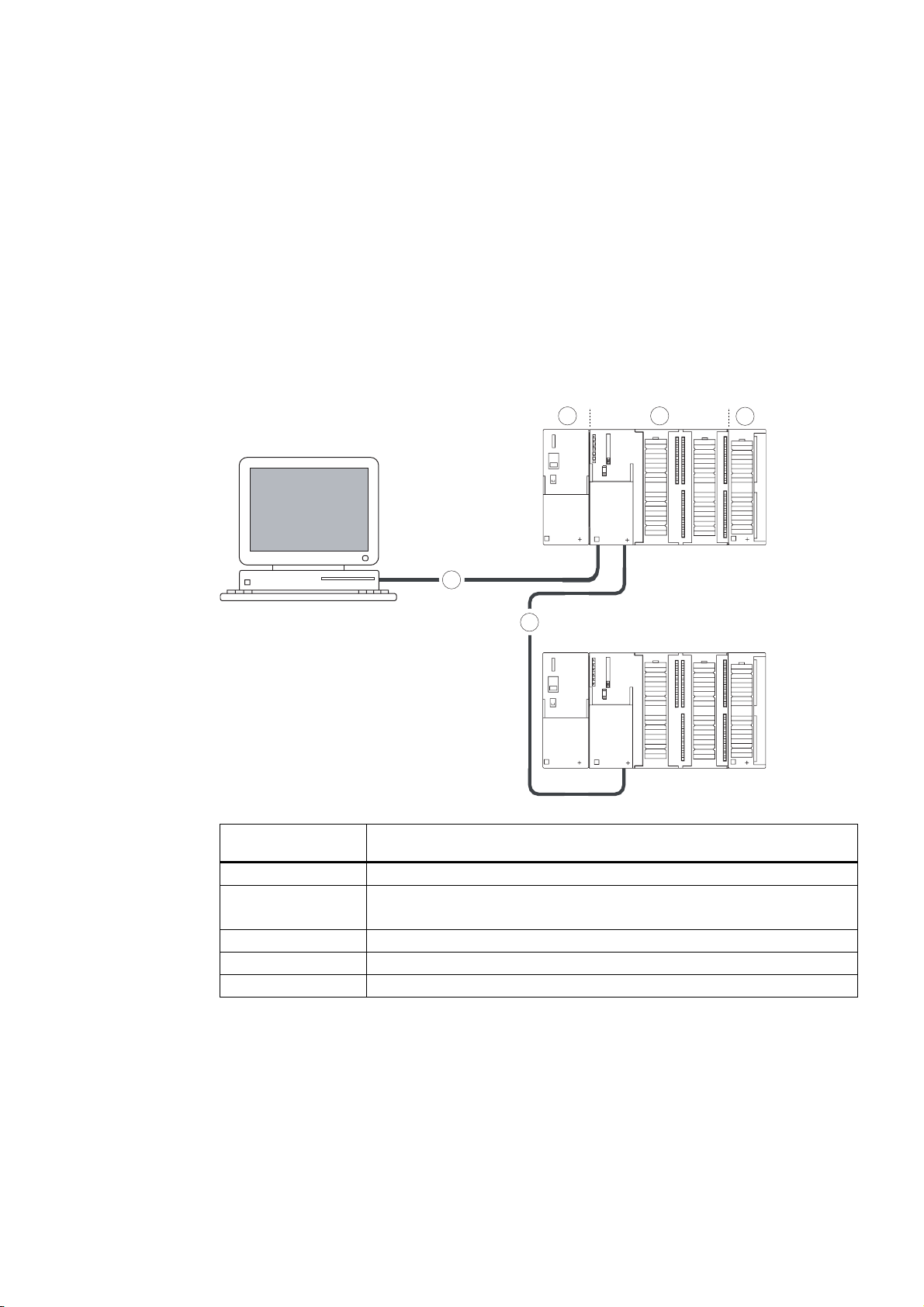

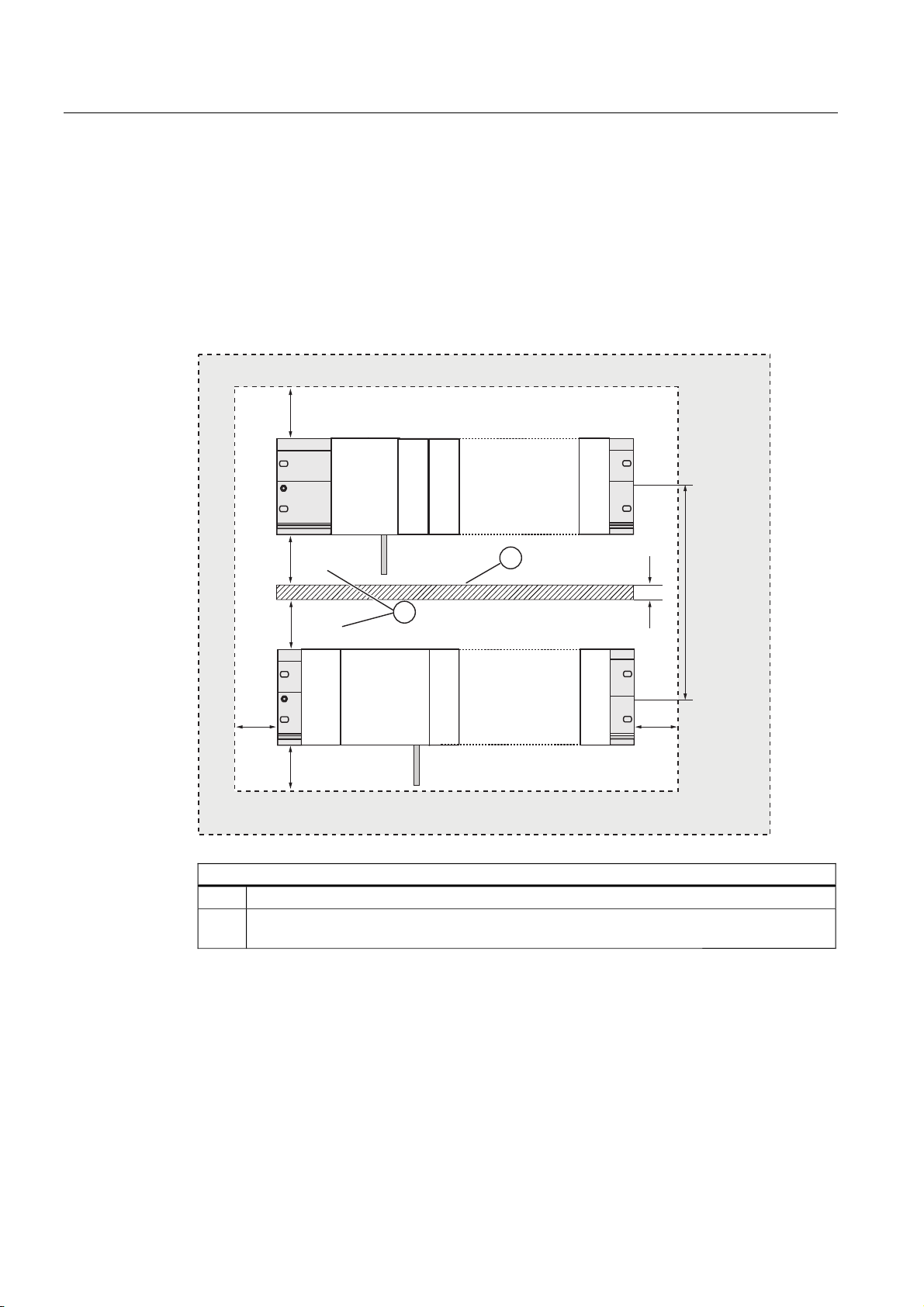

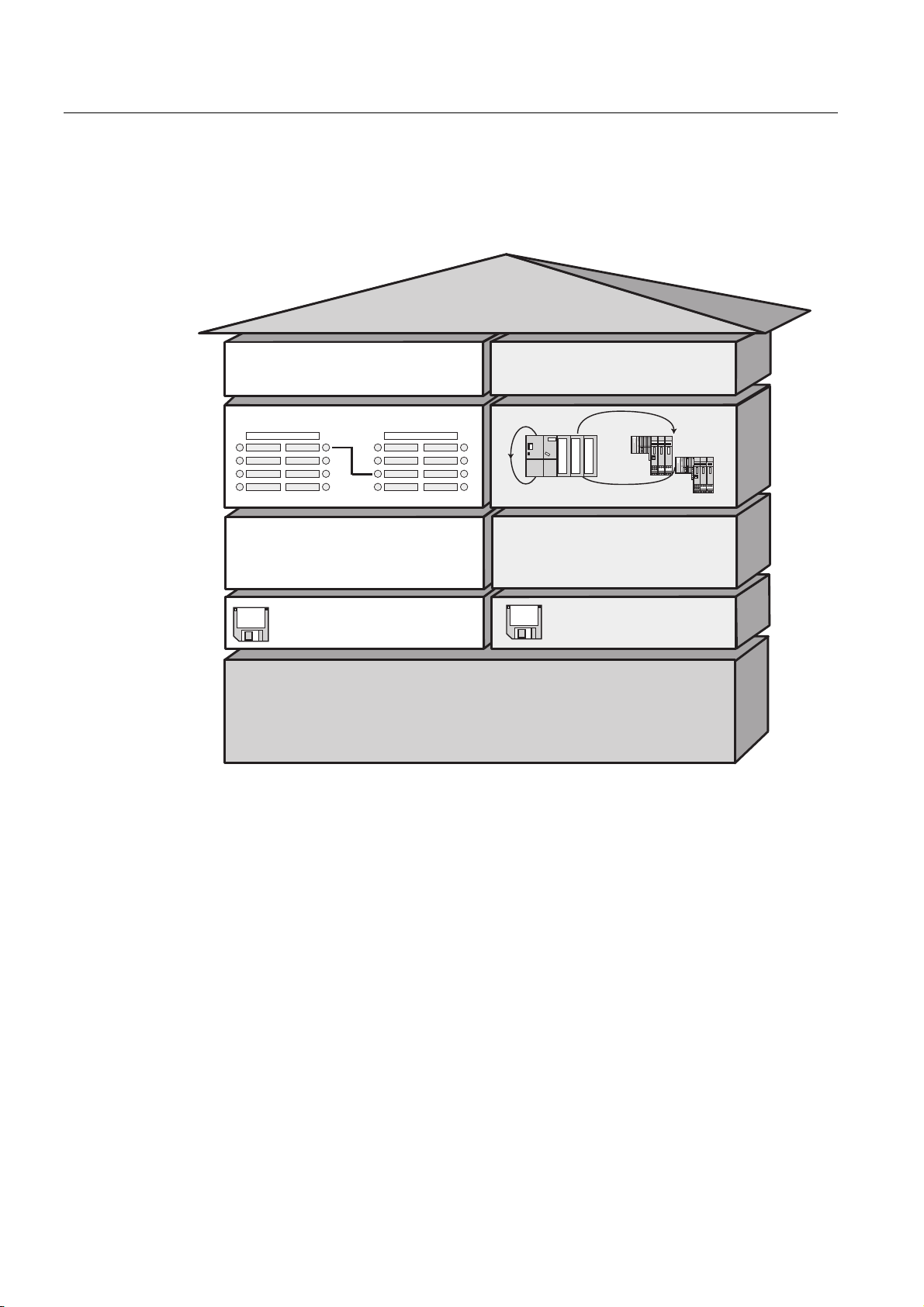

3.1 Example of an S7-300 configuration

5

123

SF

BUSF

DC5V

FRCE

RUN

STOP

4

SF

BUSF

DC5V

FRCE

RUN

STOP

3

The figure illustrates

the following

(1) Power supply (PS) module

(2) Central processing unit (CPU)

(3) Signal module (SM)

(4) PROFIBUS bus cable

(5) Cable for connecting a programming device (PG)

You use a programming device (PG) to program the S7300 PLC. Use the PG cable to

interconnect the PG with the CPU.

To commission or program a CPU with PROFINET interface, you may also use an Ethernet

cable to interconnect the PG with the PROFINET connector of the CPU. Please note that

you need to adjust the Ethernet interface on your PG.

Several S7-300 CPUs communicate with one another and with other SIMATIC S7 PLCs via

the PROFIBUS cable. Several S7-300 are connected via the PROFIBUS bus cable.

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

the following S7-300 components

The example in the figure shows a CPU 31xC with integrated I/O.

3-1

S7-300 components

SIEMENS

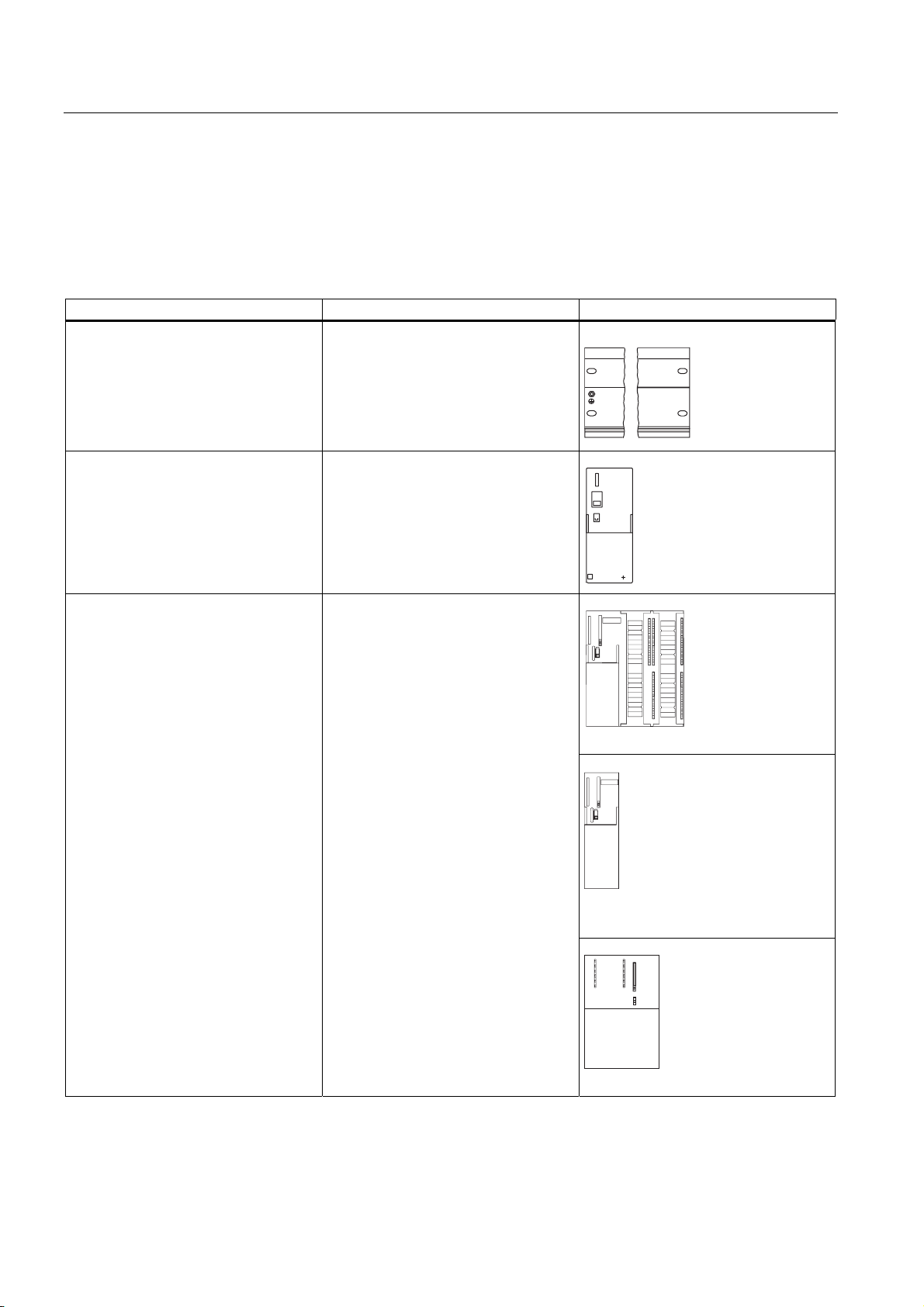

3.2 Overview of the vital modules of an S7-300

3.2 Overview of the vital modules of an S7-300

You can choose from a number of modules for installing and commissioning the S7-300. The

most important modules and their functions are shown below.

Table 3-1 S7-300 components:

Component Function Illustration

Mounting rail

Accessories:

• Shielding terminal

Power supply (PS) module The PS converts the line voltage

S7-300 racks

(120/230 VAC) into a 24 VDC operating

voltage, and supplies the S7-300 and

its 24 VDC load circuits.

CPU

Accessories:

• Front connectors (CPU 31xC only)

The CPU executes the user program,

supplies 5 V to the S7-300 backplane

bus, and communicates with other

nodes of an MPI network via the MPI

interface.

Additional features of specific CPUs:

• DP master or DP slave on a

PROFIBUS subnet

• Technological functions

• PtP communication

• Ethernet communication via

integrated PROFINET interface

SIEMENS

A CPU 31xC, for example

A CPU 312, 314, or 315-2 DP, for

example

A CPU 317, for example

S7-300, CPU 31xC and CPU 31x: Installation

3-2 Operating Instructions, Edition 08/2004, A5E00105492-05

S7-300 components

3.2 Overview of the vital modules of an S7-300

Component Function Illustration

Signal modules (SM)

• Digital input modules

• Digital output modules

• Digital I/O modules,

• Analog input modules

• Analog output modules

• Analog I/O modules

Accessories:

• Front connectors

Function modules (FM)

Accessories:

• Front connectors

The SM matches different process

signal levels to the S7-300.

The FM performs time-critical and

memory-intensive process signal

processing tasks.

Positioning or controlling, for example

Communication processor (CP)

Accessories: Connecting cable

SIMATIC TOP connect

Accessories:

• Front connector module with ribbon

cable terminals

Interface module (IM)

Accessories:

• Connecting cable

PROFIBUS cable with bus connector Interconnect the nodes of an MPI or

The CP relieves the CPU of

communication tasks.

Example: CP 342-5 DP for connecting

to PROFIBUS DP

Wiring of digital modules

The IM interconnects the various rows

in an S7-300

PROFIBUS subnet

PG cable Connects a PG/PC to a CPU

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

3-3

S7-300 components

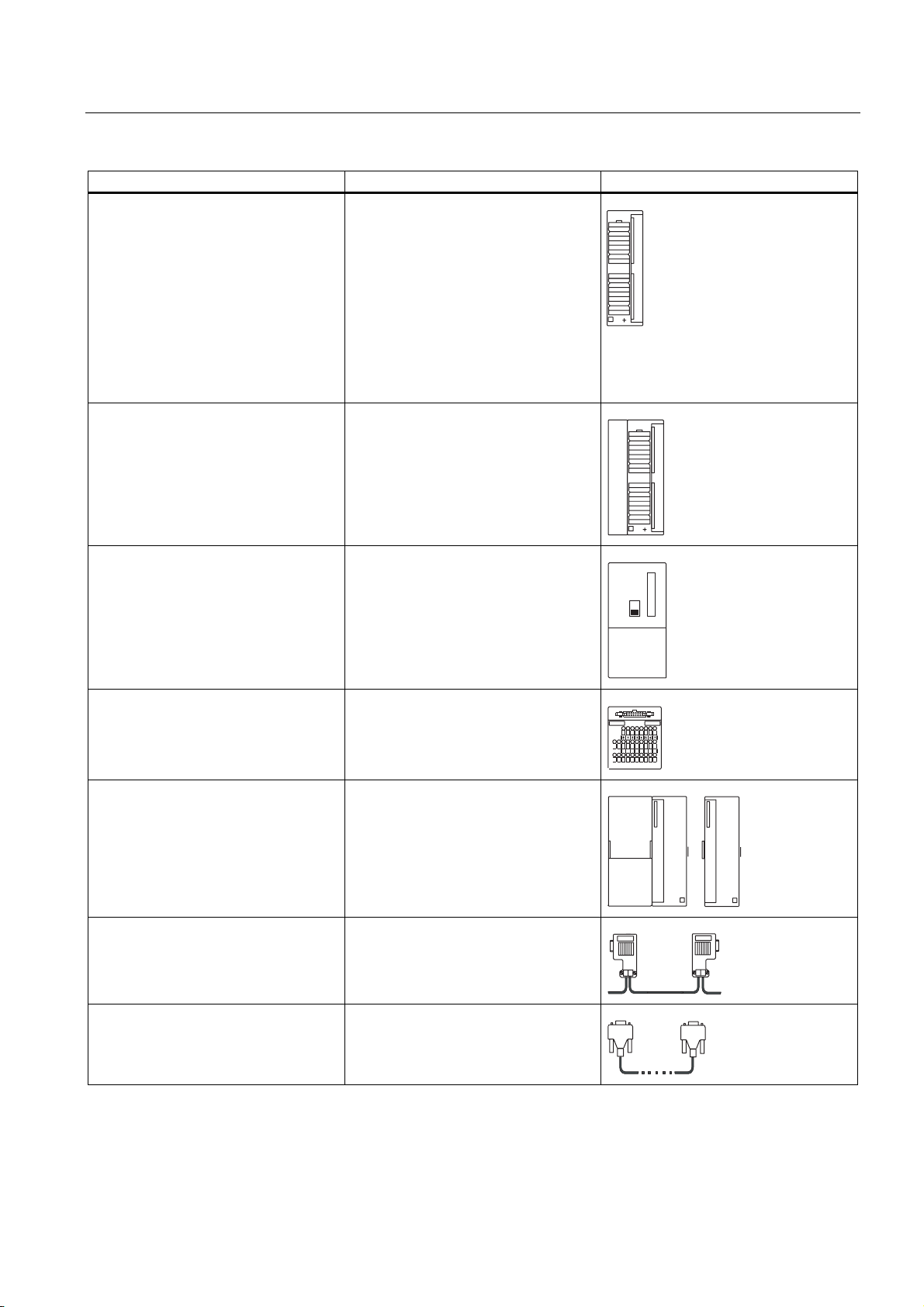

3.2 Overview of the vital modules of an S7-300

Component Function Illustration

RS 485 repeater The repeater is used to amplify the

signals and to couple segments of an

MPI or PROFIBUS subnet.

Switch A switch is used to interconnect the

Twisted-pair cables with RJ45

connectors.

Ethernet nodes.

Interconects devices with Ethernet

interface (a switch with a

CPU 317-2 PN/DP, for example)

Programming device (PG) or PC with

the STEP 7 software package

You need a PG to configure, set

parameters, program and test your

S7-300

S7-300, CPU 31xC and CPU 31x: Installation

3-4 Operating Instructions, Edition 08/2004, A5E00105492-05

Configuring

4.1 Overview

There, you can find all the necessary information

• for the mechanical configuration of an S7-300,

• for the electrical configuration of an S7-300,

• that has to be observed in networking.

Reference

• For further information, refer to the

(6ES7398-8EA00-8AA0), or

• the

4.2 Basic engineering principles

SIMATIC NET Twisted-Pair and Fiber-Optic Networks

(6GK1970-1BA10-0AA0)

Communication with SIMATIC

Manual

4

manual

Important information for engineering

Warning

Open equipment

S7-300 modules are open equipment. That is, the S7-300 must be installed in a cubicle,

cabinet or electrical control room which can only be accessed using a key or tool. Only

trained or authorized personnel are allowed access to such cubicles, cabinets or electrical

operating rooms.

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

4-1

Configuring

n

4.2 Basic engineering principles

Caution

Operation of an S7-300 in plants or systems is defined by special set of rules and

regulations, based on the relevant field of application. Observe the safety and accident

prevention regulations for specific applications, for example, the machine protection

directives. This chapter and the appendix

provide an overview of the most important rules you need to observe when integrating an

S7-300 into a plant or a system.

General rules and regulations on S7-300 operatio

Central unit (CU) and expansion module (EM)

An S7-300 PLC consists of a central unit (CU) and of one or multiple expansion modules.

The rack containing the CPU is the central unit (CU). Racks equipped with modules and

connected to the CU form the expansion modules (EMs) of the system.

Use of an expansion module (EM)

You can use EMs if the CU runs out of slots for your application.

When using EMs, you might require further power supply modules in addition to the extra

racks and interface modules (IM). When using interface modules you must ensure

compatibility of the partner stations.

Racks

The rack for your S7-300 is a mounting rail. You can use this rail to mount all modules of

your S7-300 system.

S7-300, CPU 31xC and CPU 31x: Installation

4-2 Operating Instructions, Edition 08/2004, A5E00105492-05

Configuring

DC5V

FRCE

RUN

STOP

4.2 Basic engineering principles

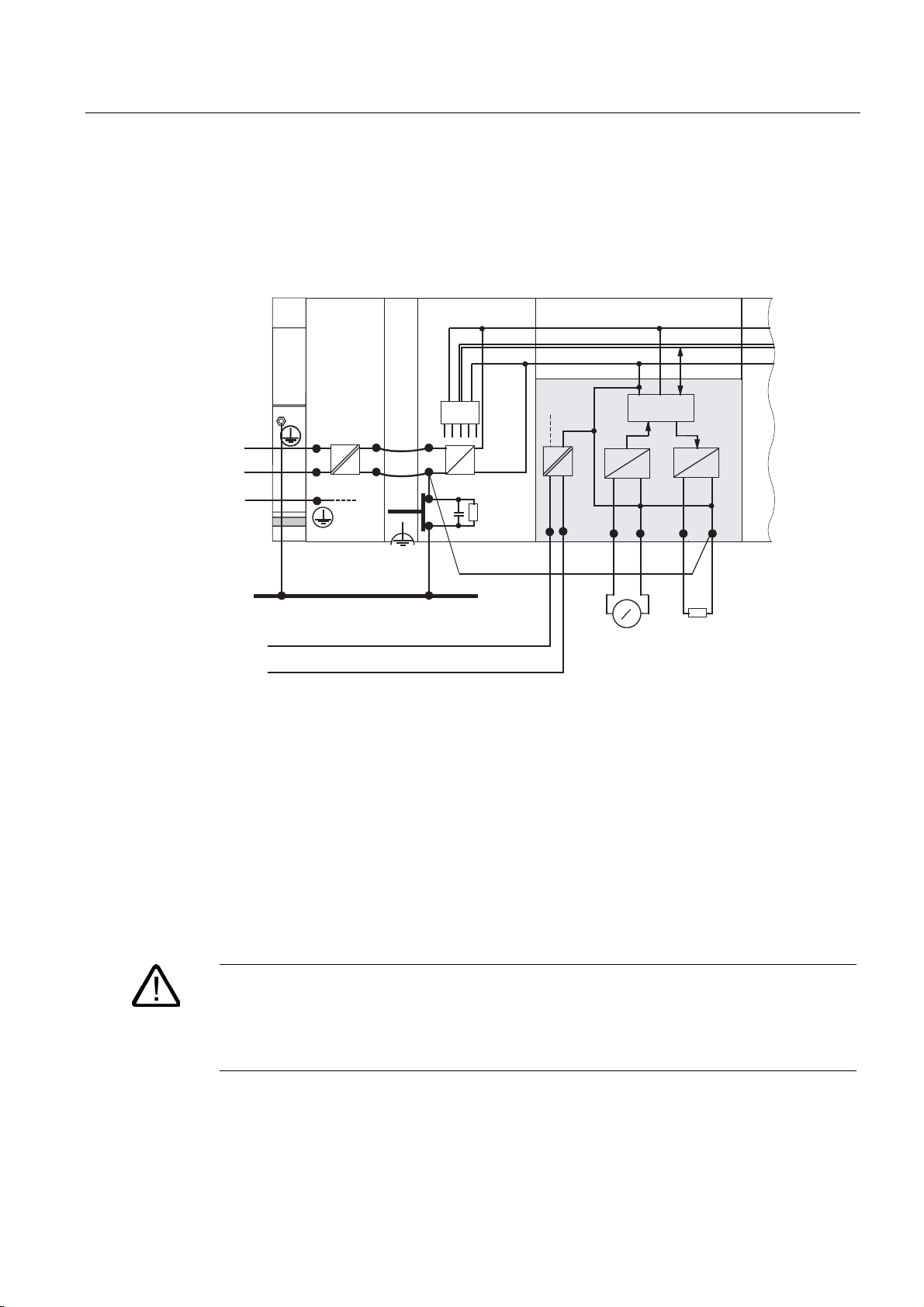

Horizontal and vertical installation

You can mount an S7-300 either vertically or horizontally. The following ambient air

temperatures are permitted:

• Vertical assembly: 0 °C to 40 °C

• Horizontal assembly: 0 °C to 60 °C

Always install the CPU and power supply modules on the left or at the bottom.

1

1

SM

SM

SM

1

SM

2

SM

SM

SM

SM

SM

SM

SM

1

3

SM

SM

SM

SM

SM

PS

DC5V

FRCE

RUN

STOP

CPU

CPU

DC5

FRCE

RUN

STOP

PS

3

The figure illustrates the following

(1) the vertical installation of an S7-300

(2) the horizontal installation of an S7-300

(3) the mounting rail

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

4-3

Configuring

4.3 Component dimensions

4.3 Component dimensions

Length of the mounting rails

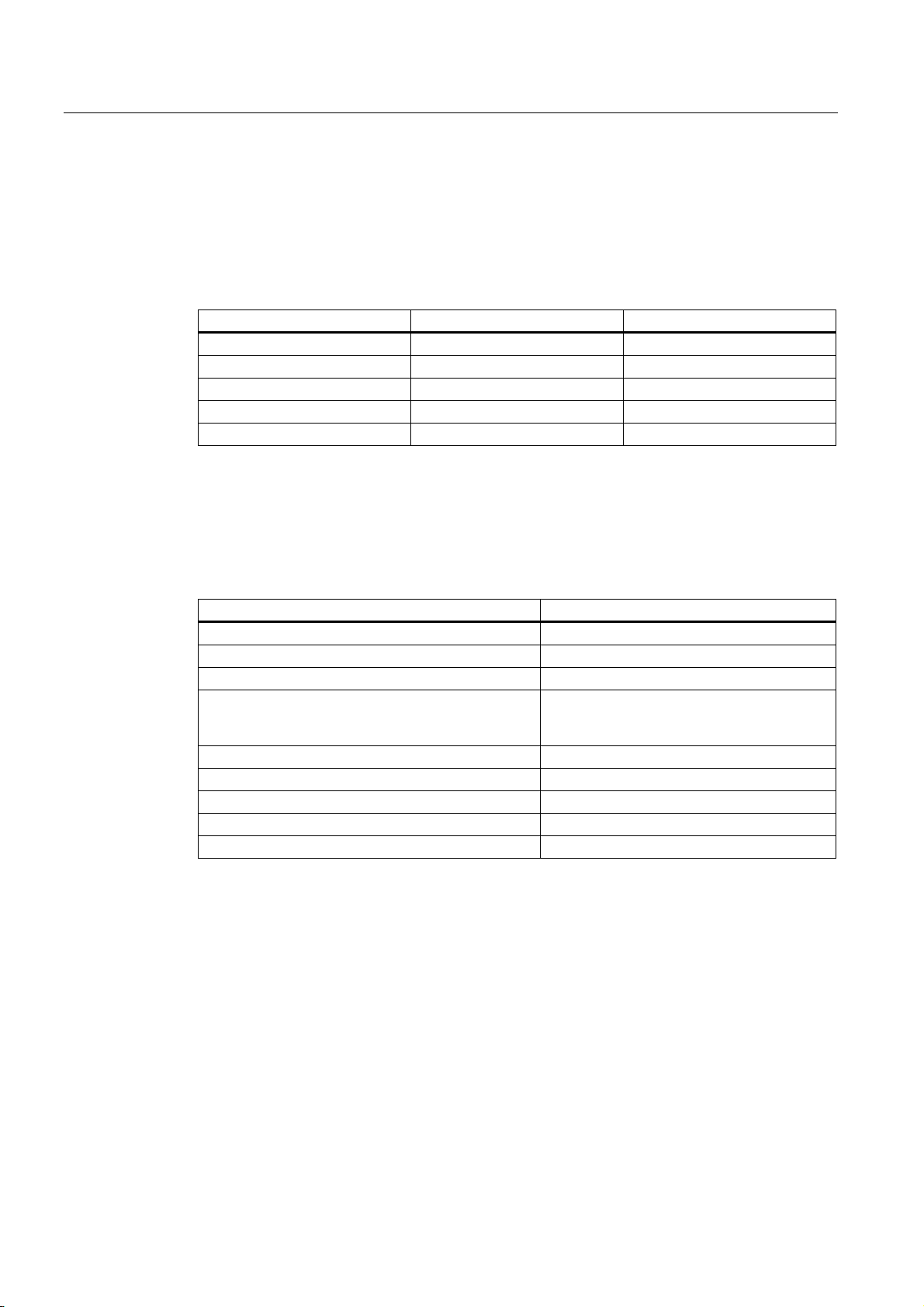

Table 4-1 Mounting rails - Overview

Mounting rail length Usable length for modules Order number

160 mm 120 mm 6ES7 390-1AB60-0AA0

482.6 mm 450 mm 6ES7 390-1AE80-0AA0

530 mm 480 mm 6ES7 390-1AF30-0AA0

830 mm 780 mm 6ES7 390-1AJ30-0AA0

2000 mm cut to length as required 6ES7 390-1BC00-0AA0

In contrast to other rails, the 2 m mounting rail is not equipped with any fixing holes. These

must be drilled, allowing optimal adaptation of the 2 m rail to your application.

Dimensions of modules

Table 4-2 Module width

Module Width

Power supply module PS 307, 2 A 50 mm

Power supply module PS 307, 5 A 80 mm

Power supply module PS 307, 10 A 200 mm

CPU For information on assembly dimensions,

refer to the Technical Data in

CPU 31x Manual, Technical Data

Analog I/O modules 40 mm

Digital I/O modules 40 mm

Simulator module SM 374 40 mm

Interface modules IM 360 and IM 365 40 mm

Interface module IM 361 80 mm

CPU 31xC and

.

• Module height: 125 mm

• Module height with shielding contact element: 185 mm

• Maximum assembly depth: 130 mm

• Maximum assembly depth of a CPU with an inserted DP connector with angled cable

feed: 140 mm

• Maximum assembly depth with open front panel (CPU): 180 mm

Dimensions of other modules such as CPs, FMs etc. are found in the relevant manuals.

S7-300, CPU 31xC and CPU 31x: Installation

4-4 Operating Instructions, Edition 08/2004, A5E00105492-05

Configuring

4.3 Component dimensions

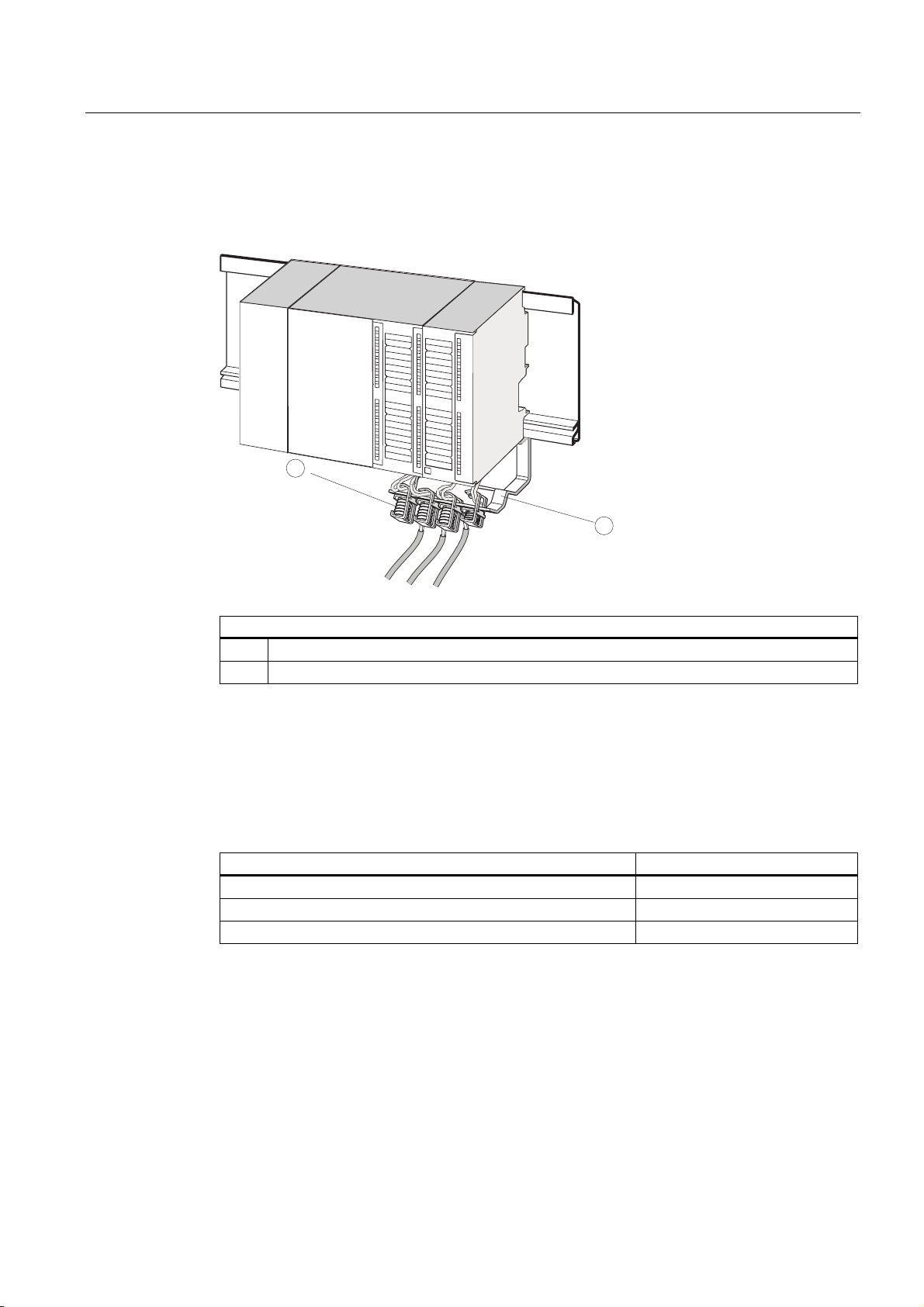

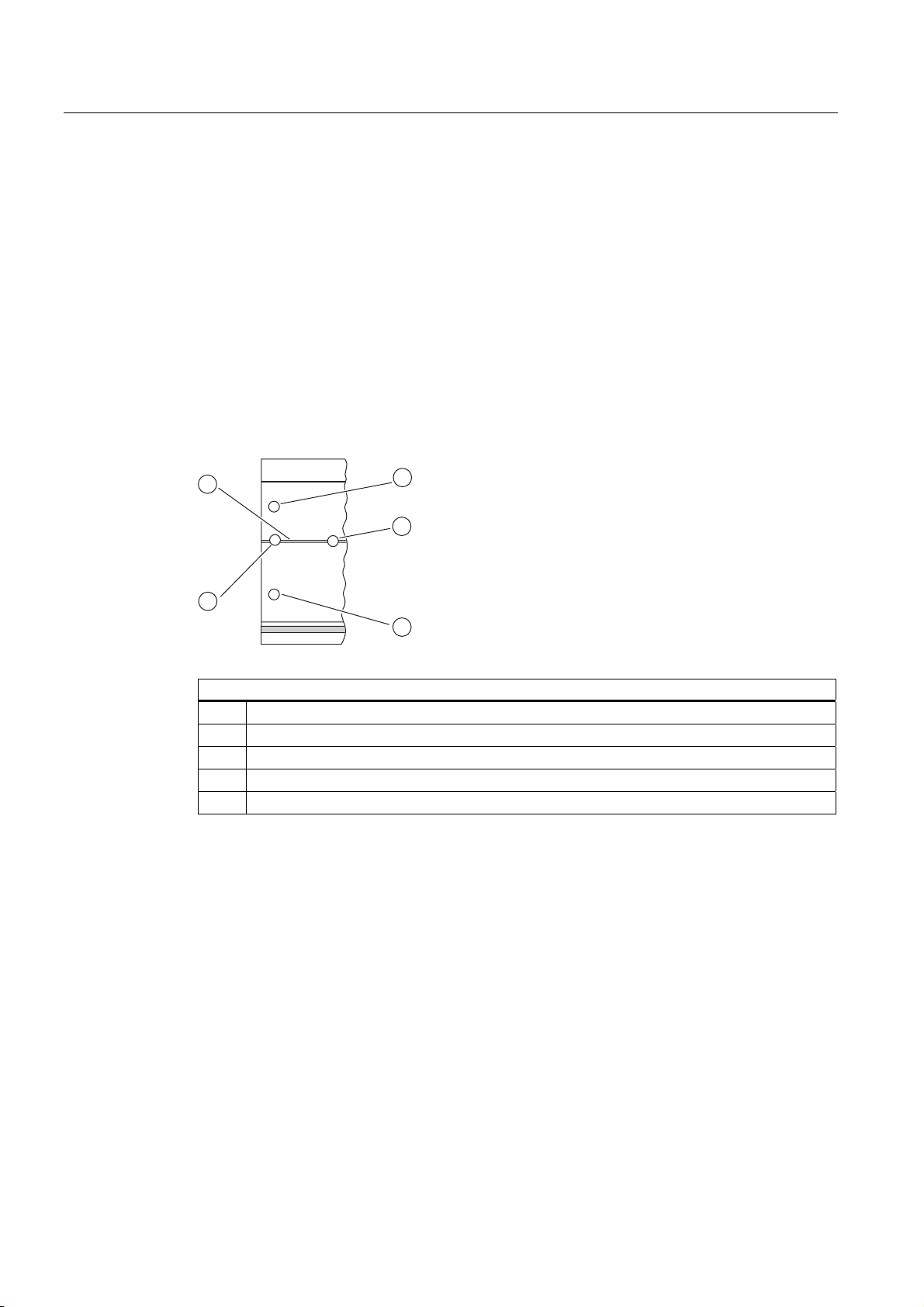

Shielding contact element

The direct contact between the shielding contact element and the mounting rail makes it

easy for you to connect all shielded cables of your S7 modules to ground.

PS

CPU

1

2

The figure illustrates the following

(1) Shielding terminals

(2) The bracket.

Mount the bracket (order no. 6ES5 390-5AA0-0AA0) to the rail using the two screw bolts. If

you use a shielding contact element, the specified dimensions are measured from the base

of the element.

• Width of the shielding contact element: 80 mm

• Mountable shielding terminals per shielding contact element max. 4

Table 4-3 Shielding terminals - Overview

Cable with shielding diameter Shielding terminal order no.

Cable with 2 mm to 6 mm shielding diameter 6ES7 390–5AB00–0AA0

Cable with 3 mm to 8 mm shielding diameter 6ES7 390–5BA00–0AA0

Cable with 4 mm to 13 mm shielding diameter 6ES7 390–5CA00–0AA0

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

4-5

Configuring

4.4 Required clearances

4.4 Required clearances

You must maintain the clearance shown in the figure in order to provide sufficient space for

installing the modules, and to allow the dissipation of heat generated by the modules.

The S7-300 assembly on multiple racks shown in the figure below shows the clearance

between racks and adjacent components, cable ducts, cabinet walls etc.

For example, when routing your module wiring through cable duct, the minimum clearance

between the bottom of the shielding contact element and the cable duct is 40 mm.

PP

PP

PP

PP

36

PP

&38

&38

60

60

60

60

PPD

D

60

PP

The figure illustrates the following

(1) Wiring with cable duct

(2) Minimum clearance between the cable duct and the bottom edge of the shielding contact

element is 40 mm

S7-300, CPU 31xC and CPU 31x: Installation

4-6 Operating Instructions, Edition 08/2004, A5E00105492-05

Configuring

4.5 Arrangement of modules on a single rack

4.5 Arrangement of modules on a single rack

Reasons for using one or multiple racks

The number of racks you need will depend on your application.

Reasons for using a single rack: Reasons for distributing modules between

several racks

• Compact, space-saving use of all your

modules

• Local use of all modules

• Fewer signals to be processed

• More signals to be processed

• Insufficient number of slots

Note

If you opt for the installation on a single rack, insert a dummy module to the right of the CPU

(order no.: 6ES7 370-0AA01-0AA0). This gives you the option of adding a second rack for

your application, simply by replacing the dummy module with an interface module, and

without having to reinstall and rewire the first rack.

Rules: Layout of modules on a single module rack

The following rules apply to module installations on a single rack:

• No more than eight modules (SM, FM, CP) may be installed to the right of the CPU.

• The accumulated power consumption of modules mounted on a rack may not exceed

1.2 A on the S7-300 backplane bus.

Reference

For further information, refer to the technical data, for example, in the

Specifications Reference Manual

Example

The figure below shows a layout with eight signal modules in an S7-300 assembly.

or in the

Reference Manual

S7-300 Module

for your CPU.

PS

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

CPU

SM1

SM2

SM3

SM4

SM5

SM6

SM7

SM8

4-7

Configuring

4.6 Distribution of modules to several racks

4.6 Distribution of modules to several racks

Exceptions

With CPU 312 and CPU 312C, only a single-row configuration on a rack is possible.

Using interface modules

If you are planning an assembly in multiple racks, then you will need interface modules (IM).

Interface modules route the backplane bus of an S7-300 to the next rack.

The CPU is always located on rack 0.

Table 4-4 Interface modules - Overview

Properties Two or more rows Cost-effective 2-row configuration

Send IM in rack 0 IM 360

order no..: 6ES7 360-3AA01-0AA0

Receiver IM in racks 1 to 3 IM 361

order no..: 6ES7 361-3CA01-0AA0

Maximum number of expansion

modules

Length of connecting cables 1 m (6ES7 368-3BB01-0AA0)

Remarks - Rack 1 can only receive signal modules;

3 1

2.5 m (6ES7 368-3BC51-0AA0)

5 m (6ES7 368-3BF01-0AA0)

10 m (6ES7 368-3CB01-0AA0)

IM 365

order no..: 6ES7 365-0AB00-0AA0

IM 365 (hard-wired to send IM 365)

1 m (hard-wired)

the accumulated current load is limited to

1.2 A, whereby the maximum for rack 1 is

0.8 A

These restrictions do not apply to operation

with interface modules IM 360/IM 361

S7-300, CPU 31xC and CPU 31x: Installation

4-8 Operating Instructions, Edition 08/2004, A5E00105492-05

Configuring

4.6 Distribution of modules to several racks

Rules: arrangement of the modules on several racks

Please note the following points if you wish to arrange your modules on multiple racks:

• The IM always uses slot 3 (slot 1: power supply module; slot 2: CPU, slot 3: Interface

module)

• It is always on the left before the first signal module.

• No more than 8 modules (SM, FM, CP) are permitted per rack.

• The number of modules (SM, FM, CP) is limited by the permitted current consumption on

the S7-300 backplane bus. The accumulated power consumption may not exceed 1.2 A

per row.

Note

For information on the power consumption of the various modules, refer to the

Specifications Reference Manual.

Module

Rules: Interference-proof interfacing

Special shielding and grounding measures are not required if you interconnect the CU and

EM using suitable interface modules (Send IM and Receive IM).

However, you must ensure

• a low impedance interconnection of all racks,

• that the racks of a grounded assembly are grounded in a star pattern,

• that the contact springs on the racks are clean and not bent, thus ensuring that

interference currents are properly discharged to ground.

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

4-9

Configuring

4.6 Distribution of modules to several racks

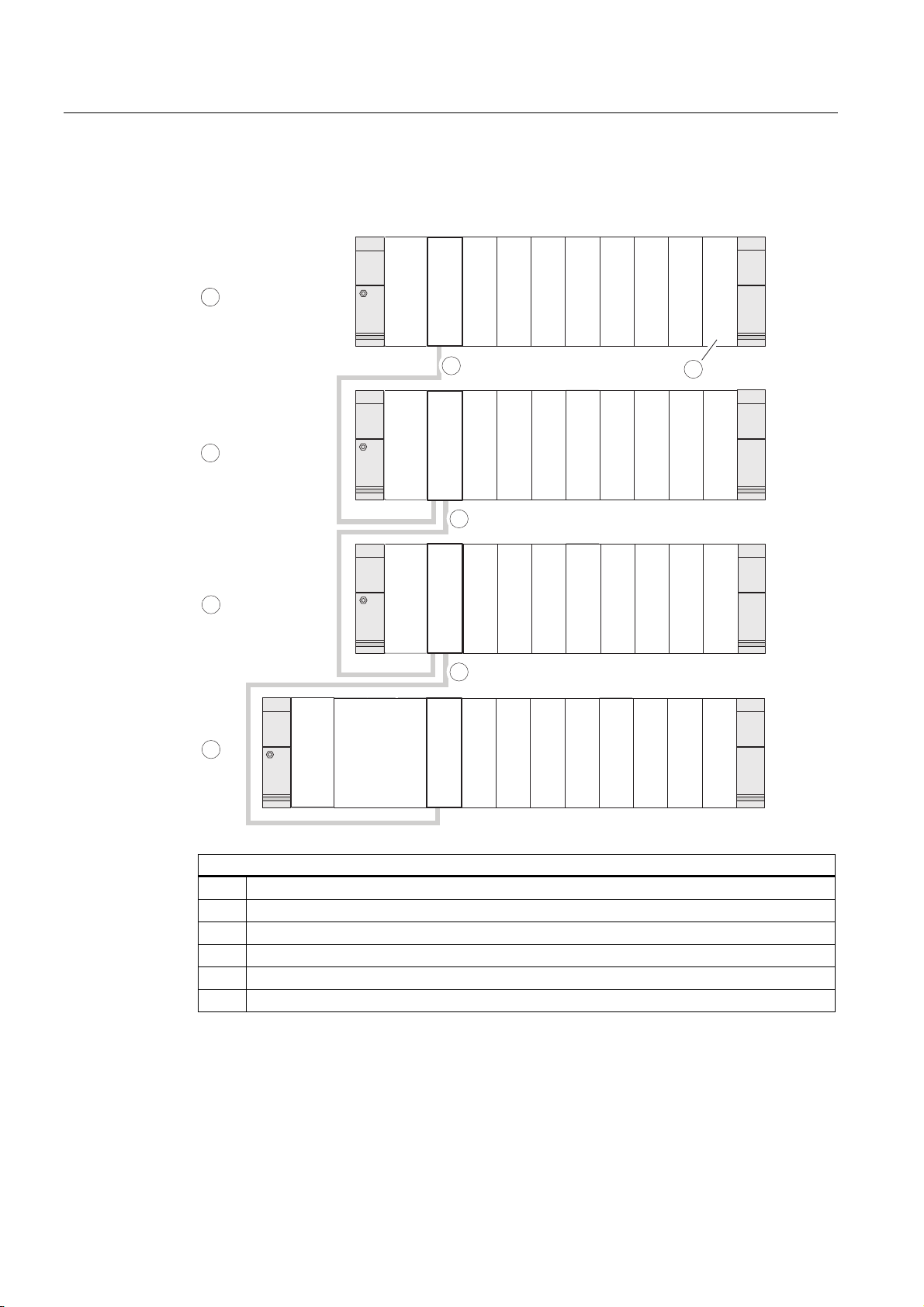

Example: Full assembly using four racks

The figure shows the arrangement of modules in an S7-300 assembly on 4 racks.

SM4

SM4

SM4

SM5

SM5

SM5

SM6

SM6

SM6

SM7

6

SM7

SM7

SM8

SM8

SM8

SM3

SM2

SM1

PS

PS

IM

IM

IM

IM

5

SM3

SM2

SM1

5

SM3

SM2

SM1

5

4

4

3

2

1

PS

CPU

IM

IM

SM1

SM2

SM3

SM4

SM5

SM6

SM7

SM8

The figure illustrates the following

(1) Rack 0 (central unit)

(2) Rack 1 (expansion module)

(3) Rack 2 (expansion module)

(4) Rack 3 (expansion module)

(5) The connecting cable 368

(6) Restriction for CPU 31xC. When this CPU is used, do not insert SM 8 into Rack 4.

S7-300, CPU 31xC and CPU 31x: Installation

4-10 Operating Instructions, Edition 08/2004, A5E00105492-05

Configuring

4.7 Selection and installation of cabinets

4.7 Selection and installation of cabinets

Reasons for installing an S7-300 in a cabinet

Your S7-300 should be installed in a cabinet,

• if you plan a larger system,

• if you are using your S7-300 systems in an environment subject to interference or

contamination, and

• to meet UL/CSA requirements for cabinet installation.

Selecting and dimensioning cabinets

Take the following criteria into account:

• ambient conditions at the cabinet's place of installation

• the specified mounting clearance for racks (mounting rails)

• accumulated power loss of all components in the cabinet.

The ambient conditions (temperature, humidity, dust, chemical influence, explosion hazard)

at the cabinet's place of installation determine the degree of protection (IP xx) required for

the cabinet.

Reference for degrees of protection

For further information on the degrees of protection, refer to IEC 529 and DIN 40050.

The power dissipation capability of cabinets

The power dissipation capability of a cabinet depends on its type, ambient temperature and

on the internal arrangement of devices.

Reference for power loss

For detailed information on power dissipation, refer to the Siemens catalogs NV21 and ET1.

Specification of cabinet dimensions

Note the following specifications when you determine the dimensions of a cabinet for your

S7-300 installation:

• Space required for racks (mounting rails)

• Minimum clearance between the racks and cabinet walls

• Minimum clearance between the racks

• Space required for cable ducts or fan assemblies

• Position of the stays

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

4-11

Configuring

4.7 Selection and installation of cabinets

Warning

Modules may get damaged if exposed to excess ambient temperatures.

Reference for ambient temperatures

For information on permitted ambient temperatures, refer to the

Module data

Reference Manual.

S7-300 Automation System,

S7-300, CPU 31xC and CPU 31x: Installation

4-12 Operating Instructions, Edition 08/2004, A5E00105492-05

Configuring

4.7 Selection and installation of cabinets

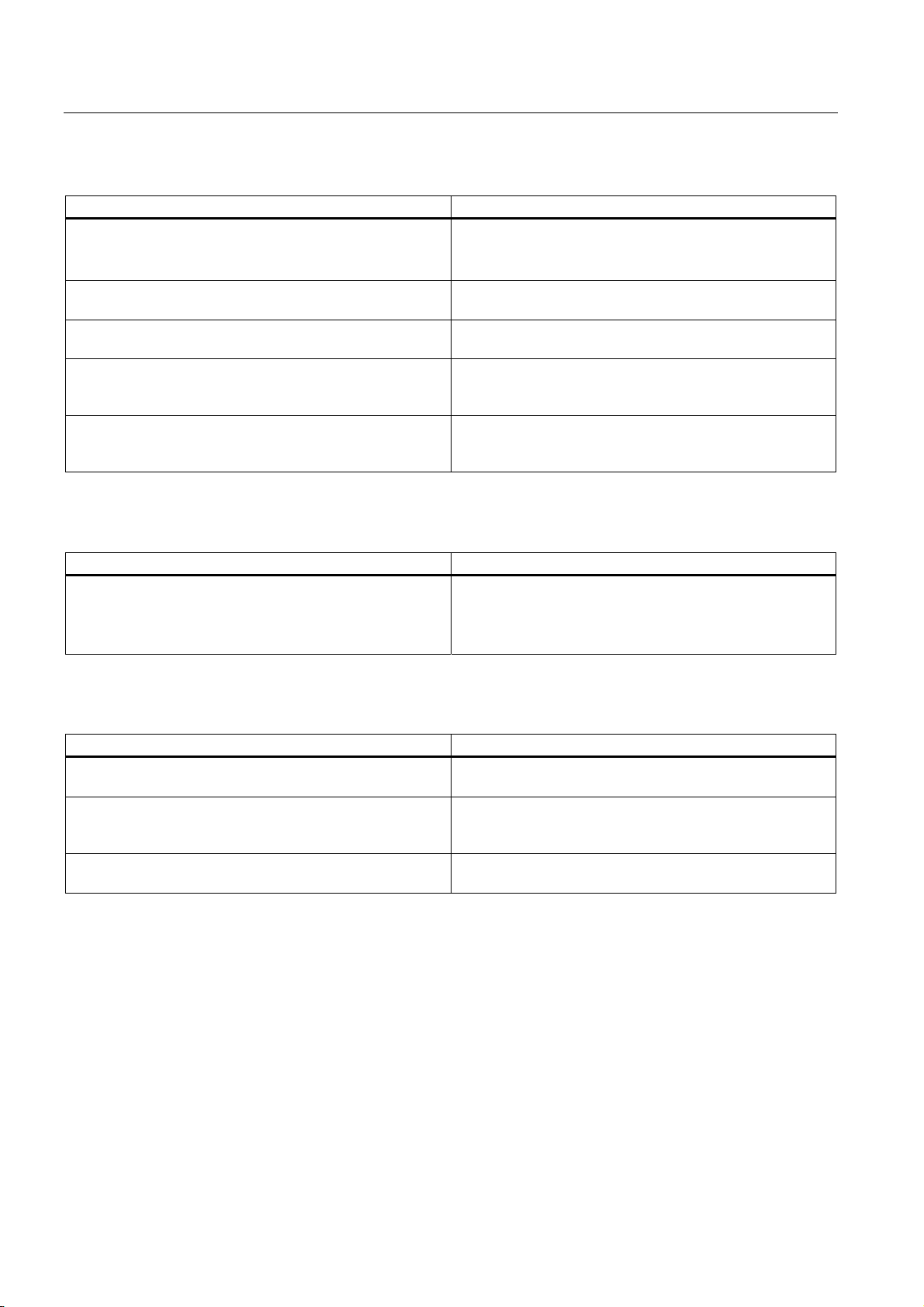

Overview of typical cabinet types

The table below gives you an overview of commonly used cabinet types. It shows you the

applied principle of heat dissipation, the calculated maximum power loss and the degree of

protection.

Table 4-5 Cabinet types

Open cabinets Closed cabinets

Enclosed ventilation by

means of natural

convection

Increased enclosed

ventilation

Natural convection Forced convection with

rack fan, improvement

of natural convection

Forced convection with

heat exchanger,

internal and external

auxiliary ventilation

Mainly inherent heat

dissipation, with a

small portion across

the cabinet wall.

Degree of protection

IP 20

Typical power dissipation under following marginal conditions:

• Cabinet size: 600 mm x 600 mm x 2,200 mm

• Difference between the outer and inner temperature of the cabinet is 20 °C (for other temperature differences refer to

the temperature charts of the cabinet manufacturer)

up to 700 W up to 2,700 W (with

Higher heat dissipation

with increased air

movement.

Degree of protection

IP 20

fine filter up to

1,400 W)

Heat dissipation only

across the cabinet

wall; only low power

losses permitted. In

most cases, the heat

accumulates at the top

of the cabinet interior.

Degree of protection

IP 54

up to 260 W up to 360 W up to 1,700 W

Heat dissipation only

across the cabinet

wall. Forced

convection of the

interior air improves

heat dissipation and

prevents heat

accumulation.

Degree of protection

IP 54

Heat dissipation by

heat exchange

between heated

internal air and cool

external air. The

increased surface of

the pleated profile of

the heat exchanger

wall and forced

convection of internal

and external air

provide good heat

dissipation.

Degree of protection

IP 54

S7-300, CPU 31xC and CPU 31x: Installation

Operating Instructions, Edition 08/2004, A5E00105492-05

4-13

Configuring

4.8 Example: Selecting a cabinet

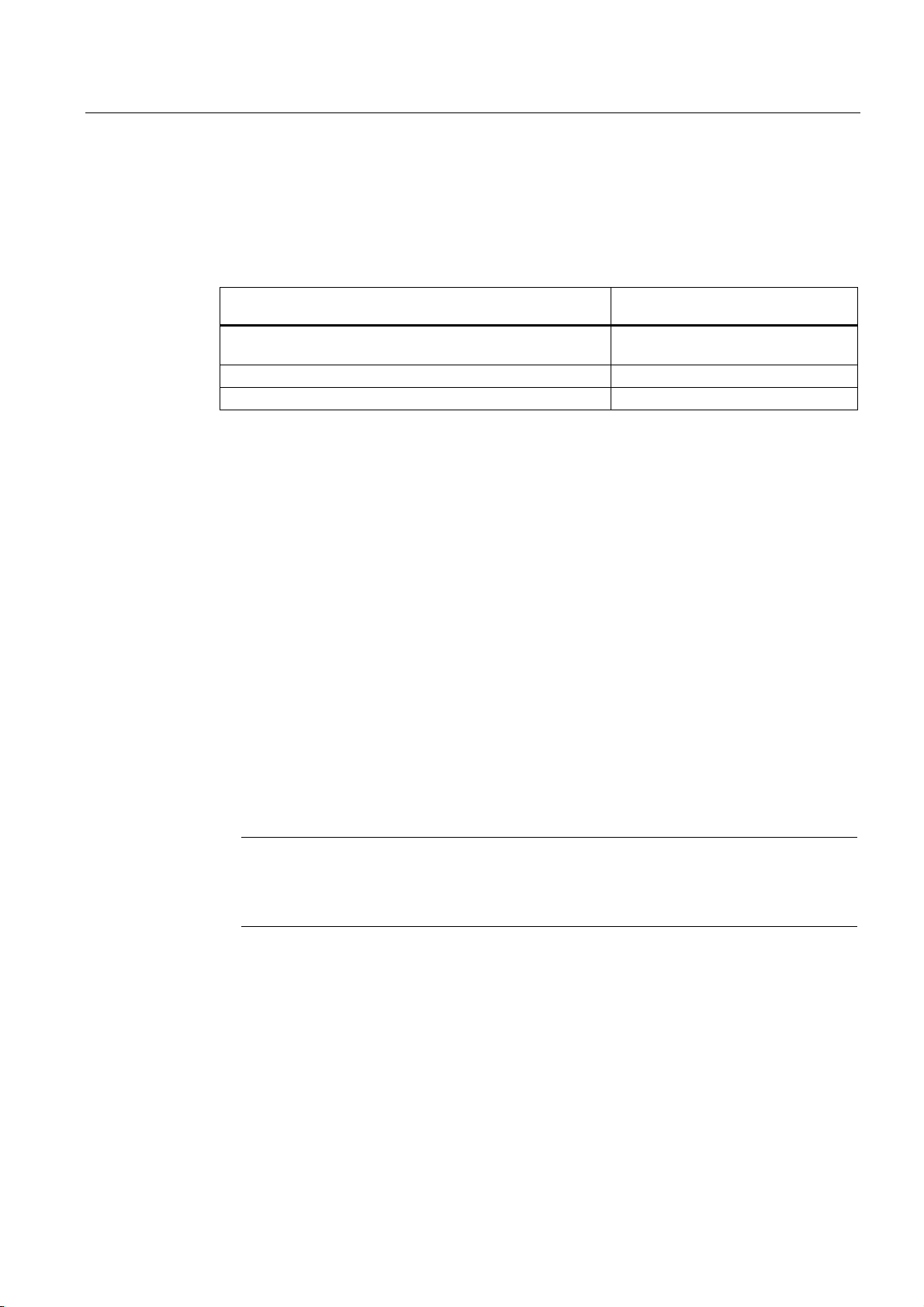

4.8 Example: Selecting a cabinet

Introduction

The sample below clearly shows the maximum permitted ambient temperature at a specific

power loss for different cabinet designs.

Installation

The following device configuration should be installed in a cabinet:

• Central unit, 150 W

• Expansion modules, each with 150 W

• Load power supply under full load, 200 W

This results in an accumulated power loss of 650 W.

Power loss dissipated

The diagram in the figure below shows guide values for the permitted ambient temperature

of a cabinet with the dimensions 600 mm x 600 mm x 2,000 mm, based on the accumulated