Siemens SIMATIC S7, SIMATIC S7-200 SMART System Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

S7

S7-200 SMART

System Manual

V2.3, 07/2017

A5E03822230

Preface

Product overview

1

Getting started

2

Installation

3

PLC concepts

4

Programming concepts

5

PLC device configuration

6

Program instructions

7

Communication

8

Libraries

9

Debugging and

troubleshooting

10

PID loops and tuning

11

Open loop motion control

12

Technical specifications

A

Calculating a power budget

B

Error codes

C

Special memory (SM) and

system symbol names

D

References

E

Ordering information

F

-AF

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E03822230-AF

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

06/2017 Subject to change

Preface

Purpose of the manual

Required basic knowledge

Scope of the manual

Certification, CE label and other standards

Service and support

The S7-200 SMART series is a line of micro-programmable logic controllers (Micro PLCs)

that can control a variety of automation applications. Compact design, low cost, and a

powerful instruction set make the S7-200 SMART a perfect solution for controlling small

applications. The wide variety of S7-200 SMART models and the Windows-based

programming tool give you the flexibility you need to solve your automation problems.

This manual provides information about installing and programming the S7-200 SMART

CPUs and is designed for engineers, programmers, installers, and electricians who have a

general knowledge of programmable logic controllers.

To understand this manual, it is necessary to have a general knowledge of automation and

programmable logic controllers.

This manual describes the following products:

● STEP 7-Micro/WIN SMART V2.3

● S7-200 SMART CPU firmware release V2.3

For a complete list of the S7-200 SMART products and article numbers described in this

manual, see Technical Specifications (Page 679).

Refer to the technical specifications for more information.

In addition to our documentation, we offer our technical expertise on the Internet on the

customer support web site (http://www.siemens.com/automation/).

Contact your Siemens distributor or sales office for assistance in answering any technical

questions, for training, or for ordering S7 products. Because your sales representatives are

technically trained and have the most specific knowledge about your operations, process

and industry, as well as about the individual Siemens products that you are using, they can

provide the fastest and most efficient answers to any problems you might encounter.

S7-200 SMART

System Manual, V2.3, 07/2017, A5E03822230-AF

3

Preface

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

S7-200 SMART

4 System Manual, V2.3, 07/2017, A5E03822230-AF

Table of contents

Preface ................................................................................................................................................... 3

1 Product overview .................................................................................................................................. 17

2 Getting started ...................................................................................................................................... 31

3 Installation ............................................................................................................................................ 47

1.1 S7-200 SMART CPU .............................................................................................................. 18

1.2 New features ........................................................................................................................... 21

1.3 CPU feature differences.......................................................................................................... 23

1.4 S7-200 SMART expansion modules ....................................................................................... 26

1.5 HMI devices for S7-200 SMART ............................................................................................. 27

1.6 Communications options ........................................................................................................ 28

1.7 Programming software ............................................................................................................ 29

2.1 Connecting to the CPU ........................................................................................................... 31

2.1.1 Configuring the CPU for communication ................................................................................ 32

2.1.1.1 Overview ................................................................................................................................. 32

2.1.1.2 Establishing the Ethernet hardware communication connection ............................................ 33

2.1.1.3 Setting up Ethernet communication with the CPU .................................................................. 34

2.1.1.4 Establishing the RS485 hardware communication connection............................................... 36

2.1.1.5 Setting up RS485 communication with the CPU .................................................................... 37

2.2 Creating the sample program ................................................................................................. 39

2.2.1 Network 1: Starting the timer .................................................................................................. 40

2.2.2 Network 2: Turning the output on ........................................................................................... 41

2.2.3 Network 3: Resetting the timer ............................................................................................... 42

2.2.4 Setting the CPU type and version for your project ................................................................. 43

2.2.5 Saving the sample project ...................................................................................................... 44

2.3 Downloading the sample program .......................................................................................... 45

2.4 Changing the operating mode of the CPU .............................................................................. 46

3.1 Guidelines for installing S7-200 SMART devices ................................................................... 47

3.2 Power budget .......................................................................................................................... 49

3.3 Installation and removal procedures ....................................................................................... 51

3.3.1 Mounting dimensions for the S7-200 SMART devices ........................................................... 51

3.3.2 Installing and removing the CPU ............................................................................................ 52

3.3.3 Installing and removing a signal board or battery board ......................................................... 55

3.3.4 Removing and reinstalling the terminal block connector ........................................................ 57

3.3.5 Installing and removing an expansion module ....................................................................... 58

3.3.6 Installing and removing the expansion cable .......................................................................... 60

3.4 Wiring guidelines ..................................................................................................................... 62

S7-200 SMART

System Manual, V2.3, 07/2017, A5E03822230-AF

5

Table of contents

4 PLC concepts ....................................................................................................................................... 69

5 Programming concepts ........................................................................................................................ 103

4.1 Execution of the control logic ................................................................................................. 69

4.1.1 Reading the inputs and writing to the outputs ........................................................................ 71

4.1.2 Immediately reading or writing the I/O ................................................................................... 71

4.1.3 Executing the user program ................................................................................................... 72

4.2 Accessing data ....................................................................................................................... 74

4.2.1 Accessing memory areas ....................................................................................................... 75

4.2.2 Format for Real numbers ....................................................................................................... 82

4.2.3 Format for strings ................................................................................................................... 82

4.2.4 Assigning a constant value for instructions ............................................................................ 83

4.2.5 Addressing the local and expansion I/O ................................................................................ 83

4.2.6 Using pointers for indirect addressing.................................................................................... 84

4.2.7 Pointer examples ................................................................................................................... 87

4.3 Saving and restoring data ...................................................................................................... 89

4.3.1 Downloading project components .......................................................................................... 89

4.3.2 Uploading project components .............................................................................................. 92

4.3.3 Types of storage .................................................................................................................... 93

4.3.4 Using a memory card ............................................................................................................. 94

4.3.5 Inserting a memory card in a standard CPU .......................................................................... 96

4.3.6 Transferring your program with a memory card ..................................................................... 97

4.3.7 Restoring data after power on ................................................................................................ 99

4.4 Changing the operating mode of the CPU ........................................................................... 100

4.5 Status LEDs ......................................................................................................................... 101

5.1 Guidelines for designing a PLC system ............................................................................... 103

5.2 Elements of the user program .............................................................................................. 105

5.3 Creating your user program ................................................................................................. 108

5.3.1 Earlier versions of STEP 7-Micro/WIN projects ................................................................... 108

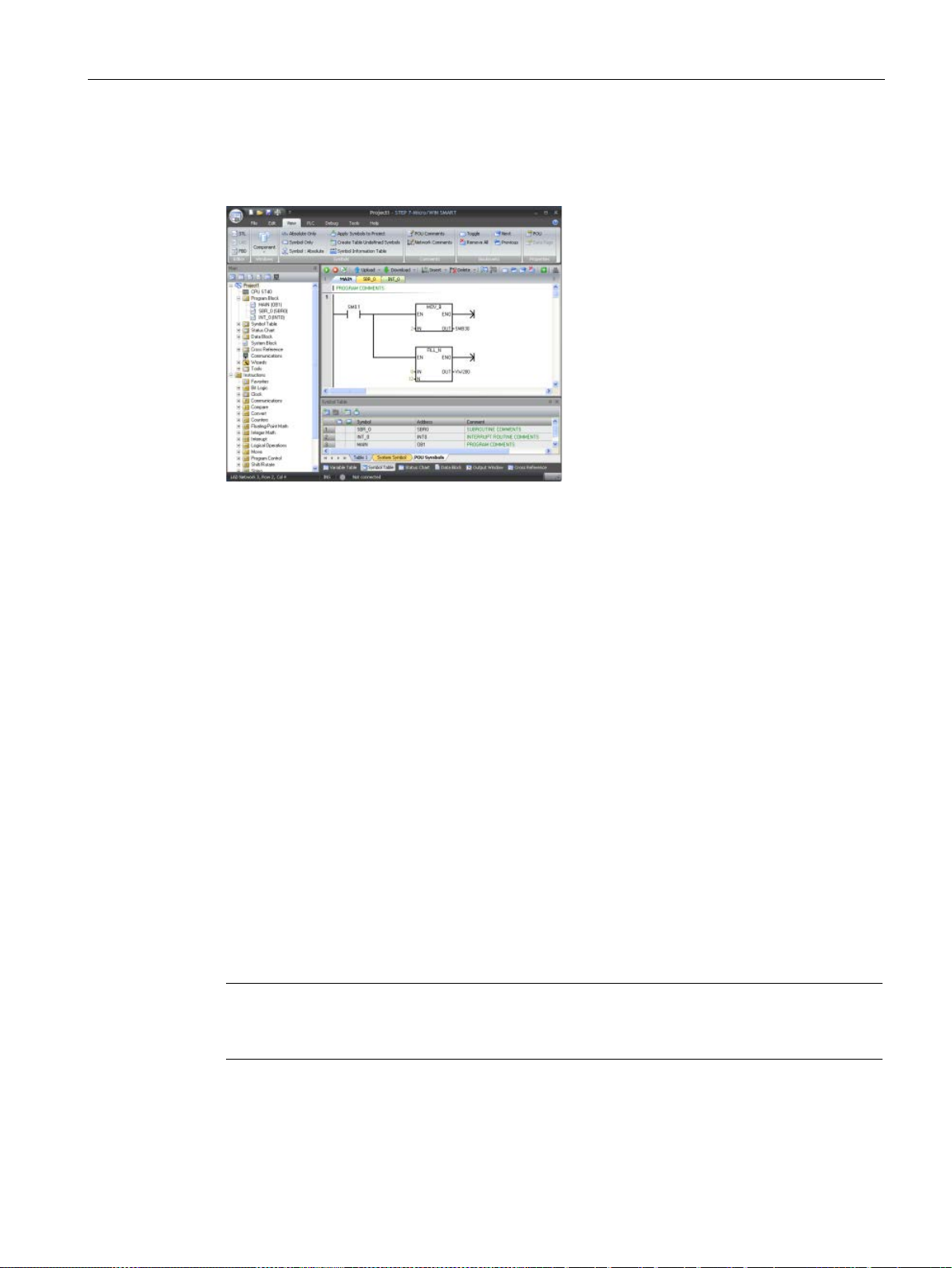

5.3.2 Using STEP 7-Micro/WIN SMART user interface ................................................................ 110

5.3.3 Using STEP 7-Micro/WIN SMART to create your programs ............................................... 111

5.3.4 Using wizards to help you create your control program....................................................... 112

5.3.5 Features of the LAD editor ................................................................................................... 113

5.3.6 Features of the FBD editor ................................................................................................... 114

5.3.7 Features of the STL editor ................................................................................................... 114

5.4 Data block (DB) editor .......................................................................................................... 115

5.5 Symbol table ........................................................................................................................ 118

5.6 Variable table ....................................................................................................................... 121

5.7 PLC error reaction ................................................................................................................ 127

5.7.1 Non-fatal errors and I/O errors ............................................................................................. 128

5.7.2 Fatal errors ........................................................................................................................... 129

5.8 Program edit in RUN mode .................................................................................................. 130

5.9 Features for debugging your program ................................................................................. 132

S7-200 SMART

6 System Manual, V2.3, 07/2017, A5E03822230-AF

Table of contents

6 PLC device configuration .................................................................................................................... 133

7 Program instructions ........................................................................................................................... 169

6.1 Configuring the operation of the PLC system ....................................................................... 133

6.1.1 System block ......................................................................................................................... 133

6.1.2 Configuring communication .................................................................................................. 135

6.1.3 Configuring the digital inputs ................................................................................................ 138

6.1.4 Configuring the digital outputs .............................................................................................. 140

6.1.5 Configuring the retentive ranges ........................................................................................... 141

6.1.6 Configuring system security .................................................................................................. 143

6.1.7 Configuring the startup options ............................................................................................. 147

6.1.8 Configuring the analog inputs ............................................................................................... 148

6.1.9 Reference to the analog inputs technical specifications ....................................................... 150

6.1.10 Configuring the analog outputs ............................................................................................. 151

6.1.11 Reference to the analog outputs technical specifications..................................................... 152

6.1.12 Configuring the RTD analog inputs ....................................................................................... 153

6.1.13 Configuring the TC analog inputs ......................................................................................... 158

6.1.14 Configuring the RS485/RS232 CM01 communications signal board ................................... 162

6.1.15 Configuring the BA01 battery signal board ........................................................................... 163

6.1.16 Clearing PLC memory........................................................................................................... 164

6.1.17 Creating a reset-to-factory-defaults memory card ................................................................ 167

6.2 High-speed I/O ...................................................................................................................... 168

7.1 Bit logic ................................................................................................................................. 169

7.1.1 Standard inputs ..................................................................................................................... 169

7.1.2 Immediate inputs ................................................................................................................... 171

7.1.3 Logic stack overview ............................................................................................................. 172

7.1.4 STL logic stack instructions .................................................................................................. 174

7.1.5 NOT....................................................................................................................................... 176

7.1.6 Positive and negative transition detectors ............................................................................ 177

7.1.7 Coils: output and output immediate instructions ................................................................... 178

7.1.8 Set, reset, set immediate, and reset immediate functions .................................................... 179

7.1.9 Set and reset dominant bistable ........................................................................................... 180

7.1.10 NOP (No operation) instruction ............................................................................................. 181

7.1.11 Bit logic input examples ........................................................................................................ 182

7.1.12 Bit logic output examples ...................................................................................................... 183

7.2 Clock ..................................................................................................................................... 185

7.2.1 Read and set real-time clock ................................................................................................ 185

7.2.2 Read and set real-time clock extended ................................................................................ 187

7.3 Communication ..................................................................................................................... 191

7.3.1 GET and PUT (Ethernet) ...................................................................................................... 191

7.3.2 Transmit and receive (Freeport on RS485/RS232) .............................................................. 199

7.3.3 Get port address and set port address (PPI protocol on RS485/RS232) ............................. 213

7.3.4 Get IP address and set IP address (Ethernet) ...................................................................... 214

7.3.5 Open user communication .................................................................................................... 217

7.3.5.1 OUC instructions ................................................................................................................... 217

7.3.5.2 OUC instruction error codes ................................................................................................. 228

7.4 Compare ............................................................................................................................... 230

7.4.1 Compare number values ...................................................................................................... 230

7.4.2 Compare character strings ................................................................................................... 234

S7-200 SMART

System Manual, V2.3, 07/2017, A5E03822230-AF

7

Table of contents

7.5 Convert ................................................................................................................................. 236

7.5.1 Standard conversion instructions ......................................................................................... 236

7.5.2 ASCII character array conversion ........................................................................................ 240

7.5.3 Number value to ASCII string conversion ............................................................................ 245

7.5.4 ASCII sub-string to number value conversion ..................................................................... 249

7.5.5 Encode and decode ............................................................................................................. 252

7.6 Counters ............................................................................................................................... 253

7.6.1 Counter instructions ............................................................................................................. 253

7.6.2 High-speed counter instructions .......................................................................................... 257

7.6.3 High-speed counter summary .............................................................................................. 260

7.6.4 Noise reduction for high-speed inputs ................................................................................. 261

7.6.5 High-speed counter programming ....................................................................................... 264

7.6.6 Example initialization sequences for high-speed counters .................................................. 277

7.7 Pulse output ......................................................................................................................... 285

7.7.1 Pulse output instruction (PLS) ............................................................................................. 285

7.7.2 Pulse train output (PTO) ...................................................................................................... 287

7.7.3 Pulse width modulation (PWM) ............................................................................................ 289

7.7.4 Using SM locations to configure and control the PTO/PWM operation ............................... 290

7.7.5 Calculating the profile table values ...................................................................................... 294

7.8 Math ..................................................................................................................................... 297

7.8.1 Add, subtract, multiply, and divide ....................................................................................... 297

7.8.2 Multiply integer to double integer and divide integer with remainder................................... 300

7.8.3 Trigonometry, natural logarithm/exponential, and square root ............................................ 302

7.8.4 Increment and decrement .................................................................................................... 305

7.9 PID ....................................................................................................................................... 307

7.9.1 Using the PID wizard ........................................................................................................... 308

7.9.2 PID algorithm ....................................................................................................................... 313

7.9.3 Converting and normalizing the loop inputs ......................................................................... 317

7.9.4 Converting the loop output to a scaled integer value........................................................... 318

7.9.5 Forward- or reverse-acting loops ......................................................................................... 319

7.10 Interrupt ................................................................................................................................ 322

7.10.1 Interrupt instructions ............................................................................................................ 322

7.10.2 Interrupt routine overview and CPU model event support ................................................... 324

7.10.3 Interrupt programming guidelines ........................................................................................ 326

7.10.4 Types of interrupt events that the S7-200 SMART CPU supports ...................................... 328

7.10.5

Interrupt priority, queuing, and example program ................................................................ 330

7.11 Logical operations ................................................................................................................ 335

7.11.1 Invert .................................................................................................................................... 335

7.11.2 AND, OR, and exclusive OR ................................................................................................ 336

7.12 Move .................................................................................................................................... 338

7.12.1 Move byte, word, double word, or real ................................................................................. 338

7.12.2 Block move ........................................................................................................................... 339

7.12.3 Swap bytes ........................................................................................................................... 340

7.12.4 Move byte immediate (read and write) ................................................................................ 341

7.13 Program control.................................................................................................................... 342

7.13.1 FOR-NEXT loop ................................................................................................................... 342

7.13.2 JMP (jump to label) .............................................................................................................. 344

7.13.3 SCR (sequence control relay) .............................................................................................. 345

S7-200 SMART

8 System Manual, V2.3, 07/2017, A5E03822230-AF

Table of contents

8 Communication ................................................................................................................................... 395

7.13.4 END, STOP, and WDR (watchdog timer reset) .................................................................... 354

7.13.5 GET_ERROR (Get non-fatal error code) .............................................................................. 356

7.14 Shift and rotate ...................................................................................................................... 357

7.14.1 Shift and rotate ...................................................................................................................... 357

7.14.2 Shift register bit ..................................................................................................................... 360

7.15 String ..................................................................................................................................... 362

7.15.1 String (Get length, copy, and concatenate) .......................................................................... 362

7.15.2 Copy substring from string .................................................................................................... 364

7.15.3 Find string and first character within string ........................................................................... 365

7.16 Table ..................................................................................................................................... 368

7.16.1 Add to table ........................................................................................................................... 368

7.16.2 First-in-first-out and last-in-first-out ....................................................................................... 370

7.16.3 Memory fill ............................................................................................................................. 372

7.16.4 Table find .............................................................................................................................. 373

7.17 Timer ..................................................................................................................................... 377

7.17.1 Timer instructions .................................................................................................................. 377

7.17.2 Timer programming tips and examples ................................................................................ 380

7.17.3 Interval timers ....................................................................................................................... 386

7.18 Subroutine ............................................................................................................................. 388

7.18.1 CALL (subroutine) and RET (conditional return) .................................................................. 388

8.1 CPU communication connections ......................................................................................... 396

8.2 CPU communication ports .................................................................................................... 397

8.3 HMIs and communication drivers ......................................................................................... 398

8.4 Ethernet ................................................................................................................................ 400

8.4.1 Overview ............................................................................................................................... 400

8.4.2 Local/partner connection ...................................................................................................... 400

8.4.3 Sample Ethernet network configurations .............................................................................. 401

8.4.4 Assigning Internet Protocol (IP) addresses .......................................................................... 402

8.4.4.1 Assigning IP addresses to programming and network devices ............................................ 402

8.4.4.2 Configuring or changing an IP address for a CPU or device in your project ........................ 404

8.4.4.3 Searching for CPUs and devices on your Ethernet network ................................................ 412

8.4.5 Locating the Ethernet (MAC) address on the CPU ............................................................... 413

8.4.6 HMI-to-CPU communication ................................................................................................. 415

8.4.7 Open user communication .................................................................................................... 417

8.4.7.1 Protocols ............................................................................................................................... 417

8.4.7.2 Connections .......................................................................................................................... 418

8.4.7.3 Ports and TSAPs .................................................................................................................. 419

8.5 PROFIBUS ............................................................................................................................ 421

8.5.1 EM DP01 PROFIBUS DP module ........................................................................................ 423

8.5.1.1 Distributed Peripheral (DP) standard communications ......................................................... 423

8.5.1.2 Using the EM DP01 to connect an S7-200 SMART as a DP device .................................... 424

8.5.1.3 Configuring the EM DP01 ..................................................................................................... 426

8.5.1.4 Data consistency ................................................................................................................... 427

8.5.1.5 Supported configurations ...................................................................................................... 428

8.5.1.6 Installing the EM DP01 GSD file ........................................................................................... 429

8.5.1.7 Configuring the EM DP01 I/O ............................................................................................... 431

S7-200 SMART

System Manual, V2.3, 07/2017, A5E03822230-AF

9

Table of contents

9 Libraries ............................................................................................................................................... 471

8.5.1.8 Example of V memory and I/O address area ....................................................................... 433

8.5.1.9 User program considerations ............................................................................................... 435

8.5.1.10 LED status indicators for the EM DP01 PROFIBUS DP ...................................................... 437

8.5.1.11 Using HMIs and S7-CPUs with the EM DP01 ..................................................................... 439

8.5.1.12 Device database file: GSD ................................................................................................... 440

8.5.1.13 PROFIBUS DP communications to a CPU example program ............................................. 444

8.5.1.14 Reference to the EM DP01 PROFIBUS DP module technical specifications ..................... 446

8.6 RS485 .................................................................................................................................. 446

8.6.1 PPI protocol .......................................................................................................................... 447

8.6.2 Baud rate and network address ........................................................................................... 448

8.6.2.1 Definition of baud rate and network address ....................................................................... 448

8.6.2.2 Setting the baud rate and network address for the S7-200 SMART CPU ........................... 449

8.6.3 Sample RS485 network configurations ................................................................................ 451

8.6.3.1 Single-master PPI networks ................................................................................................. 451

8.6.3.2 Multi-master and multi-slave PPI networks .......................................................................... 451

8.6.4 Assigning RS485 addresses ................................................................................................ 452

8.6.4.1 Configuring or changing an RS485 address for a CPU or device in your project ............... 452

8.6.4.2 Searching for CPUs and devices on your RS485 network .................................................. 457

8.6.5 Building your network ........................................................................................................... 458

8.6.5.1 General guidelines ............................................................................................................... 458

8.6.5.2 Determining the distances, transmission rates, and cable lengths for your network ........... 459

8.6.5.3 Repeaters on the network .................................................................................................... 459

8.6.5.4 Specifications for RS485 cable ............................................................................................ 460

8.6.5.5 Connector pin assignments ................................................................................................. 460

8.6.5.6 Biasing and terminating the network cable .......................................................................... 462

8.6.5.7 Biasing and terminating the CM01 signal board .................................................................. 463

8.6.5.8 Using HMI devices on your RS485 network ........................................................................ 464

8.6.6 Freeport mode...................................................................................................................... 465

8.6.6.1 Creating user-defined protocols with Freeport mode........................................................... 465

8.6.6.2 Using the RS232/PPI Multi-Master cable and Freeport mode with RS232 devices ............ 468

8.7 RS232 .................................................................................................................................. 470

9.1 Library types (Siemens and user-defined) ........................................................................... 471

9.2 Overview of Modbus communication ................................................................................... 473

9.2.1 Modbus addressing .............................................................................................................. 473

9.2.2 Modbus read and write functions ......................................................................................... 475

9.3 Modbus RTU library ............................................................................................................. 476

9.3.1 Modbus communication overview ........................................................................................ 476

9.3.1.1 Modbus RTU library features ............................................................................................... 476

9.3.1.2 Requirements for using Modbus instructions ....................................................................... 477

9.3.1.3 Initialization and execution time for Modbus protocol .......................................................... 478

9.3.2 Modbus RTU master ............................................................................................................ 479

9.3.2.1 Using the Modbus RTU master instructions ........................................................................ 479

9.3.2.2 MBUS_CTRL / MB_CTRL2 instruction (initialize master) .................................................... 481

9.3.2.3 MBUS_MSG / MB_MSG2 instruction ................................................................................... 483

9.3.2.4 Modbus RTU master execution error codes ........................................................................ 487

9.3.3 Modbus RTU slave .............................................................................................................. 489

9.3.3.1 Using the Modbus RTU slave instructions ........................................................................... 489

9.3.3.2 MBUS_INIT instruction (initialize slave) ............................................................................... 491

S7-200 SMART

10 System Manual, V2.3, 07/2017, A5E03822230-AF

Table of contents

10 Debugging and troubleshooting ........................................................................................................... 565

9.3.3.3 MBUS_SLAVE instruction ..................................................................................................... 492

9.3.3.4 Modbus RTU slave execution error codes............................................................................ 493

9.3.4 Modbus RTU master example program................................................................................ 494

9.3.5 Modbus RTU advanced user information ............................................................................. 496

9.4 Open user communication library ......................................................................................... 498

9.4.1 Parameters common to the OUC library instructions ........................................................... 499

9.4.2 Open user communication library instructions ...................................................................... 501

9.4.2.1 TCP_CONNECT instruction .................................................................................................. 501

9.4.2.2 ISO_CONNECT instruction ................................................................................................... 504

9.4.2.3 UDP_CONNECT instruction ................................................................................................. 508

9.4.2.4 TCP_SEND instruction.......................................................................................................... 510

9.4.2.5 TCP_RECV instruction.......................................................................................................... 513

9.4.2.6 UDP_SEND instruction ......................................................................................................... 516

9.4.2.7 UDP_RECV instruction ......................................................................................................... 519

9.4.2.8 DISCONNECT instruction ..................................................................................................... 522

9.4.3 Open user communication library instruction error codes .................................................... 524

9.4.4 Open user communication library example .......................................................................... 525

9.4.4.1 Active partner (client) ............................................................................................................ 526

9.4.4.2 CheckErrors subroutine ........................................................................................................ 535

9.4.4.3 Active partner symbol table .................................................................................................. 536

9.4.4.4 Passive partner (server)........................................................................................................ 537

9.4.4.5 CheckErrors subroutine ........................................................................................................ 543

9.4.4.6 Passive partner symbol table ................................................................................................ 544

9.5 USS library ............................................................................................................................ 545

9.5.1 USS communication overview .............................................................................................. 545

9.5.1.1 USS protocol overview.......................................................................................................... 545

9.5.1.2 Requirements for using the USS protocol ............................................................................ 546

9.5.1.3 Calculating the time required for communicating with the drive ........................................... 547

9.5.2 USS program instructions ..................................................................................................... 548

9.5.2.1 Using the USS protocol instructions ..................................................................................... 548

9.5.2.2 USS_INIT instruction ............................................................................................................. 549

9.5.2.3 USS_CTRL instruction .......................................................................................................... 551

9.5.2.4 USS_RPM_x instruction ........................................................................................................ 554

9.5.2.5 USS_WPM_x instruction ....................................................................................................... 557

9.5.2.6 USS protocol execution error codes ..................................................................................... 560

9.5.2.7 USS protocol example program ............................................................................................ 561

9.6 Creating a user-defined library of instructions ................................................................

...... 563

10.1 Debugging your program ...................................................................................................... 565

10.1.1 Bookmark functions .............................................................................................................. 565

10.1.2 Cross reference table............................................................................................................ 566

10.2 Displaying program status .................................................................................................... 568

10.2.1 Displaying status in the program editor ................................................................................ 568

10.2.2 Configuring the STL status options ....................................................................................... 571

10.3 Using a status chart to monitor your program ...................................................................... 572

10.4 Forcing specific values.......................................................................................................... 574

10.5 Writing and forcing outputs in STOP mode .......................................................................... 575

S7-200 SMART

System Manual, V2.3, 07/2017, A5E03822230-AF

11

Table of contents

11 PID loops and tuning ............................................................................................................................ 581

12 Open loop motion control ..................................................................................................................... 595

10.6 How to execute a limited number of scans .......................................................................... 576

10.7 Hardware troubleshooting guide .......................................................................................... 578

11.1 PID loop definition table ....................................................................................................... 582

11.2 Prerequisites ........................................................................................................................ 586

11.3 Auto-hysteresis and auto-deviation...................................................................................... 586

11.4 Auto-tune sequence ............................................................................................................. 587

11.5 Exception conditions ............................................................................................................ 589

11.6 Notes concerning PV out-of-range (result code 3) .............................................................. 590

11.7 PID Tune control panel ........................................................................................................ 590

12.1 Using the PWM output ......................................................................................................... 596

12.1.1 Configuring the PWM output ................................................................................................ 596

12.1.2 PWMx_RUN subroutine ....................................................................................................... 598

12.2 Using motion control ............................................................................................................ 599

12.2.1 Maximum and start/stop speeds .......................................................................................... 599

12.2.2 Entering the acceleration and deceleration times ................................................................ 600

12.2.3 Configuring the motion profiles ............................................................................................ 601

12.3 Features of motion control ................................................................................................... 604

12.4 Programming an Axis of Motion ........................................................................................... 606

12.5 Configuring an Axis of Motion .............................................................................................. 607

12.6 Subroutines created by the Motion wizard for the Axis of Motion ........................................ 620

12.6.1 Guidelines for using the Motion subroutines ........................................................................ 621

12.6.2 AXISx_CTRL subroutine ...................................................................................................... 622

12.6.3 AXISx_MAN subroutine ....................................................................................................... 623

12.6.4 AXISx_GOTO subroutine ..................................................................................................... 625

12.6.5 AXISx_RUN subroutine ........................................................................................................ 626

12.6.6 AXISx_RSEEK subroutine ................................................................................................... 627

12.6.7 AXISx_LDOFF subroutine .................................................................................................... 628

12.6.8 AXISx_LDPOS subroutine ................................................................................................... 629

12.6.9 AXISx_SRATE subroutine ................................................................................................... 630

12.6.10 AXISx_DIS subroutine ......................................................................................................... 631

12.6.11 AXISx_CFG subroutine ........................................................................................................ 632

12.6.12 AXISx_CACHE subroutine ................................................................................................... 633

12.6.13 AXISx_RDPOS subroutine ................................................................................................... 634

12.6.14 AXISx_ABSPOS subroutine ................................................................................................. 635

12.7 Using the AXISx_ABSPOS subroutine to read the absolute position from a SINAMICS

servo drive ............................................................................................................................ 637

12.7.1 AXISx_ABSPOS and AXISx_LDPOS subroutines usage examples ................................... 637

12.7.2 Interconnections ................................................................................................................... 638

12.7.3 Commissioning..................................................................................................................... 639

12.7.3.1 Control mode ........................................................................................................................ 639

12.7.3.2 Setpoint pulse input channel ................................................................................................ 639

12.7.3.3 Setpoint pulse train input format .......................................................................................... 639

S7-200 SMART

12 System Manual, V2.3, 07/2017, A5E03822230-AF

Table of contents

A Technical specifications ...................................................................................................................... 679

12.7.3.4 Common engineering units basis ......................................................................................... 639

12.7.4 Important facts to know ......................................................................................................... 642

12.8 Axis of Motion example programs ........................................................................................ 643

12.8.1 Axis of Motion simple relative move (cut-to-length application) example ............................. 643

12.8.2 Axis of Motion AXISx_CTRL, AXISx_RUN, AXISx_SEEK, and AXISx_MAN example ........ 645

12.9 Monitoring the Axis of Motion ............................................................................................... 649

12.9.1 Displaying and controlling the operation of the Axis of Motion ............................................. 651

12.9.2 Displaying and modifying the configuration of the Axis of Motion ........................................ 656

12.9.3 Displaying the profile configuration for the Axis of Motion .................................................... 656

12.9.4 Error codes for the Axis of Motion (WORD at SMW620, SMW670, or SMW720)................ 658

12.9.5 Error codes for the Motion instruction (seven LS bits of SMB634, SMB684, or

SMB734) ............................................................................................................................... 659

12.10 Advanced topics .................................................................................................................... 661

12.10.1 Understanding the configuration/profile table for the Axis of Motion .................................... 661

12.10.2 Special memory (SM) locations for the Axis of Motion ......................................................... 670

12.11 Understanding the RP Seek modes of the Axis of Motion .................................................... 673

12.11.1 Selecting the work zone location to eliminate backlash ....................................................... 678

A.1 General specifications........................................................................................................... 679

A.1.1 General technical specifications ........................................................................................... 679

A.2 S7-200 SMART CPUs .......................................................................................................... 685

A.2.1 CPU ST20, CPU SR20, and CPU CR20s ............................................................................ 685

A.2.1.1 General specifications and features ..................................................................................... 685

A.2.1.2 Digital inputs and outputs ..................................................................................................... 689

A.2.1.3 Wiring diagrams .................................................................................................................... 692

A.2.2 CPU ST30, CPU SR30, and CPU CR30s ............................................................................ 695

A.2.2.1 General specifications and features ..................................................................................... 695

A.2.2.2 Digital inputs and outputs ..................................................................................................... 698

A.2.2.3 Wiring diagrams .................................................................................................................... 701

A.2.3 CPU ST40, CPU SR40, and CPU CR40s ............................................................................ 704

A.2.3.1 General specifications and features ..................................................................................... 704

A.2.3.2 Digital inputs and outputs ..................................................................................................... 708

A.2.3.3 Wiring diagrams .................................................................................................................... 711

A.2.4 CPU ST60, CPU SR60, and CPU CR60s ............................................................................ 714

A.2.4.1 General specifications and features ..................................................................................... 714

A.2.4.2 Digital inputs and outputs ..................................................................................................... 718

A.2.4.3 Wiring diagrams .................................................................................................................... 721

A.2.5 Wiring diagrams for sink and source input, and relay output................................................ 724

A.3 Digital inputs and outputs expansion modules (EMs) ........................................................... 725

A.3.1 EM DE08 and EM DE16 digital input specifications ............................................................. 725

A.3.2 EM DT08, EM DR08, EM QR16, and EM QT16 digital output specifications ...................... 727

A.3.3 EM DT16, EM DR16, EM DT32, and EM DR32 digital input/output specifications .............. 732

A.4 Analog inputs and outputs expansion modules (EMs) ......................................................... 738

A.4.1 EM AE04 and EM AE08 analog input specifications ............................................................ 738

A.4.2 EM AQ02 and EM AQ04 analog output module specifications ............................................ 741

A.4.3 EM AM03 and EM AM06 analog input/output module specifications ................................... 744

A.4.4 Step response of the analog inputs ...................................................................................... 748

A.4.5 Sample time and update times for the analog inputs ........................................................... 749

S7-200 SMART

System Manual, V2.3, 07/2017, A5E03822230-AF

13

Table of contents

B Calculating a power budget .................................................................................................................. 787

C Error codes .......................................................................................................................................... 791

A.4.6 Measurement ranges of the analog inputs for voltage and current (SB and EM) ............... 749

A.4.7 Measurement ranges of the analog outputs for voltage and current (SB and EM) ............. 750

A.5 Thermocouple and RTD expansion modules (EMs) ............................................................ 752

A.5.1 Thermocouple expansion modules (EMs) ........................................................................... 752

A.5.1.1 EM AT04 thermocouple specifications ................................................................................ 752

A.5.2 RTD expansion modules (EMs) ........................................................................................... 758

A.6 Digital signal boards ............................................................................................................. 763

A.6.1 SB DT04 digital input/output specifications ......................................................................... 763

A.7 Analog signal boards ........................................................................................................... 767

A.7.1 SB AE01 analog input specifications ................................................................................... 767

A.7.2 SB AQ01 analog output specifications ................................................................................ 769

A.8 RS485/RS232 signal boards ................................................................................................ 771

A.8.1 SB RS485/RS232 specifications.......................................................................................... 771

A.9 Battery board signal boards (SBs) ....................................................................................... 773

A.9.1 SB BA01 Battery board ........................................................................................................ 773

A.10 EM DP01 PROFIBUS DP module ....................................................................................... 775

A.10.1 S7-200 SMART CPUs that support the EM DP01 PROFIBUS DP module ........................ 776

A.10.2 Connector pin assignments for EM DP01 ............................................................................ 777

A.10.3 EM DP01 PROFIBUS DP module wiring diagram ............................................................... 778

A.11 S7-200 SMART cables ........................................................................................................ 779

A.11.1 S7-200 SMART I/O expansion cable ................................................................................... 779

A.11.2 RS-232/PPI Multi-Master Cable and USB/PPI Multi-Master Cable ..................................... 780

A.11.2.1 Overview .............................................................................................................................. 780

A.11.2.2 RS-232/PPI Multi-Master Cable ........................................................................................... 781

A.11.2.3 USB/PPI Multi-Master Cable ................................................................................................ 784

B.1 Power budget ....................................................................................................................... 787

B.2 Calculating a sample power requirement ............................................................................ 789

B.3 Calculating your power requirement .................................................................................... 790

C.1 Timestamp mismatch ........................................................................................................... 791

C.2 PLC non-fatal error codes .................................................................................................... 792

C.3 PLC non-fatal error SM flags ............................................................................................... 795

C.4 PLC fatal error codes ........................................................................................................... 796

S7-200 SMART

14 System Manual, V2.3, 07/2017, A5E03822230-AF

Table of contents

D Special memory (SM) and system symbol names................................................................................ 799

D.1 SM (Special Memory) overview ............................................................................................ 799

D.2 SMB0: System status............................................................................................................ 802

D.3 SMB1: Instruction execution status ...................................................................................... 803

D.4 SMB2: Freeport receive character ........................................................................................ 804

D.5 SMB3: Freeport character error ............................................................................................ 804

D.6 SMB4: Interrupt queue overflow, run-time program error, interrupts enabled, freeport

transmitter idle, and value forced .......................................................................................... 805

D.7 SMB5: I/O error status .......................................................................................................... 805

D.8 SMB6-SMB7: CPU ID, error status, and digital I/O points.................................................... 806

D.9 SMB8-SMB19: I/O module ID and errors ............................................................................. 807

D.10 SMW22-SMW26: Scan times ............................................................................................... 808

D.11 SMB28-SMB29: Signal board ID and errors ......................................................................... 808

D.12 SMB30: (Port 0) and SMB130: (Port 1) ................................................................................ 809

D.13 SMB34-SMB35: Time intervals for timed interrupts ............................................................. 809

D.14 SMB36-SMB45 (HSC0), SMB46-SMB55 (HSC1), SMB56-SM65 (HSC2), SMB136-

SMB145 (HSC3), SMB146-SMB155 (HSC4), SMB156-SMB165 (HSC5): high-speed

counters ................................................................................................................................ 810

D.15 SMB66-SMB85 (PTO0/PWM0, PTO1/PWM1), SMB166-SMB169 (PTO0), SMB176-

SMB179 (PTO1), and SMB566-SMB579 (PTO2/PWM2): high-speed outputs .................... 816

D.16 SMB86-SMB94 and SMB186-SMB194: Receive message control ..................................... 819

D.17 SMW98: Expansion I/O bus communication errors .............................................................. 821

D.18 SMW100-SMW114 System alarms ...................................................................................... 822

D.19 SMB130: Freeport control for port 1 (See SMB30) .............................................................. 823

D.20 SMB146-SMB155 (HSC4) and SMB156-SMB165 (HSC5) .................................................. 823

D.21 SMB186-SMB194: Receive message control (See SMB86-SMB94) ................................... 823

D.22 SMB480-SMB515: Data log status ....................................................................................... 823

D.23 SMB600-SMB749: Axis (0, 1, and 2) open loop motion control ........................................... 824

D.24 SMB650-SMB699: Axis 1 open loop motion control (See SMB600-SMB740) ..................... 825

D.25 SMB700-SMB749: Axis 2 open loop motion control (See SMB600-SMB740) ..................... 825

D.26 SMB1000-SMB1049: CPU hardware/firmware ID ................................................................ 826

D.27 SMB1050-SMB1099: SB (signal board) hardware/firmware ID ........................................... 826

D.28 SMB1100-SMB1399: EM (expansion module) hardware/firmware ID ................................. 827

D.29 SMB1400-SMB1699: EM (expansion module) module-specific data ................................... 830

S7-200 SMART

System Manual, V2.3, 07/2017, A5E03822230-AF

15

Table of contents

E References .......................................................................................................................................... 831

F Ordering information ............................................................................................................................ 843

Index ................................................................................................................................................... 849

E.1 Often-used special memory bits .......................................................................................... 831

E.2 Interrupt events in priority order ........................................................................................... 832

E.3 High-speed counter summary .............................................................................................. 833

E.4 STL instructions ................................................................................................................... 834

E.5 Memory ranges and features ............................................................................................... 841

F.1 CPU modules ....................................................................................................................... 843

F.2 Expansion modules (EMs) and signal boards (SBs) ........................................................... 844

F.3 Programming software ......................................................................................................... 844

F.4 Communication .................................................................................................................... 845

F.5 Spare parts and other hardware .......................................................................................... 845

F.6 Human Machine Interface devices....................................................................................... 847

S7-200 SMART

16 System Manual, V2.3, 07/2017, A5E03822230-AF

1

The S7-200 SMART series of micro-programmable logic controllers (Micro PLCs) can control

a wide variety of devices to support your automation needs.

The CPU monitors inputs and changes outputs as controlled by the user program, which can

include Boolean logic, counting, timing, complex math operations, and communications with

other intelligent devices. The compact design, flexible configuration, and powerful instruction

set combine to make the S7-200 SMART a perfect solution for controlling a wide variety of

applications.

S7-200 SMART

System Manual, V2.3, 07/2017, A5E03822230-AF

17

Product overview

1.1

S7-200 SMART CPU

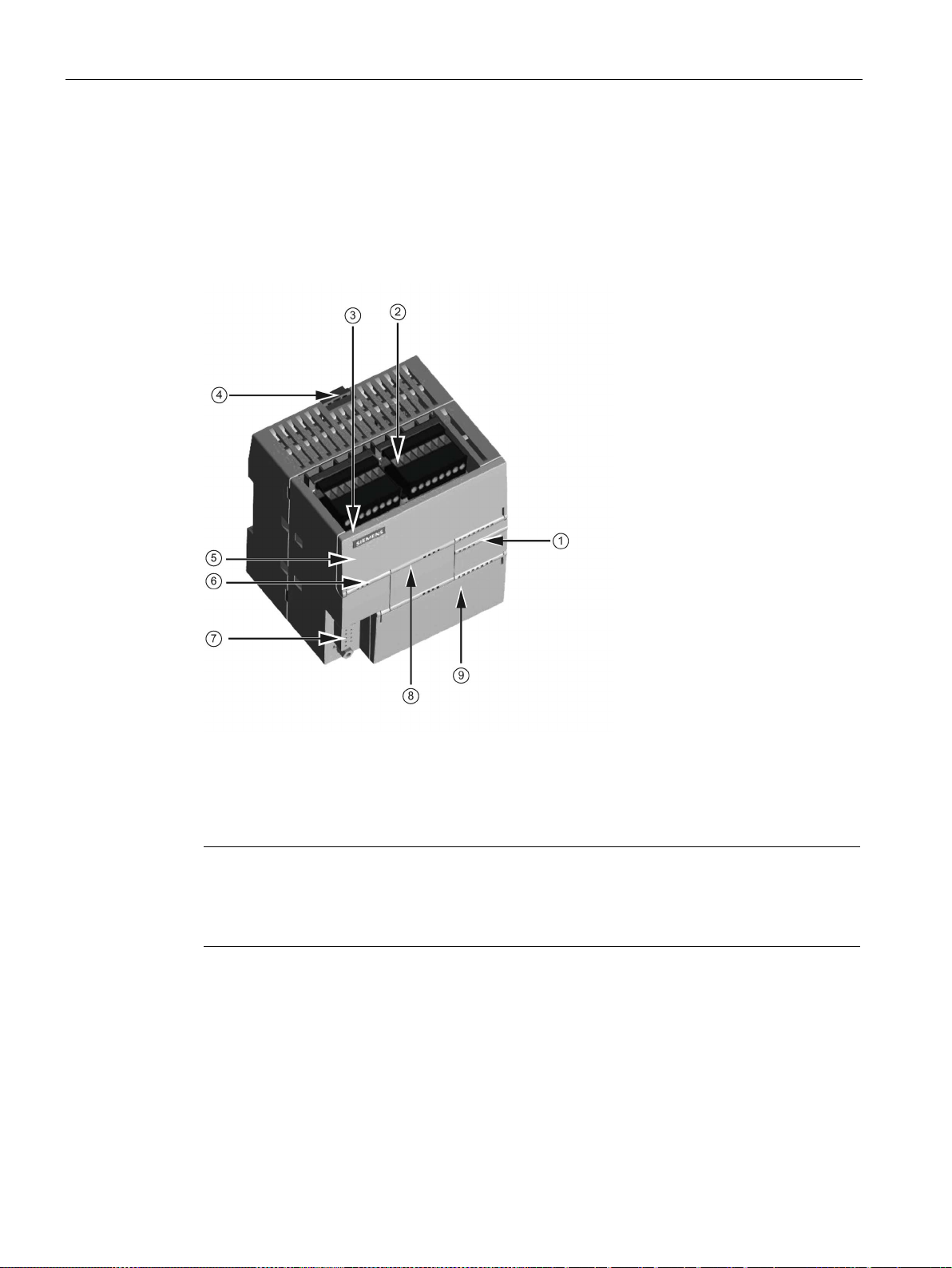

①

LEDs for the I/O

②

Terminal connectors

③

Ethernet

④

Clip for installation on a

standard (DIN) rail

⑤

Ethernet status LEDs

(under door): LINK, Rx/Tx

⑥

Status LEDs: RUN, STOP and

ERROR

⑦

RS485 Communication port

⑧

Optional signal board

(Standard models only)

⑨

Memory card r

door)

(Standard models only)

Note

CPU CR40 and CPU CR60

S7

CR60 models.

1.1 S7-200 SMART CPU

The CPU combines a microprocessor, an integrated power supply, input circuits, and output

circuits in a compact housing to create a powerful Micro PLC. After you have downloaded

your program, the CPU contains the logic required to monitor and control the input and

output devices in your application.

The CPU provides different models with a diversity of features and capabilities that help you

create effective solutions for your varied applications. The different models of CPUs are

shown below. For detailed information about a specific CPU, see the technical specifications

(Page 685).

communication port

eader (under

S7-200 SMART

18 System Manual, V2.3, 07/2017, A5E03822230-AF

-200 SMART CPU firmware release V2.3 does not apply to the CPU CR40 and CPU

Product overview

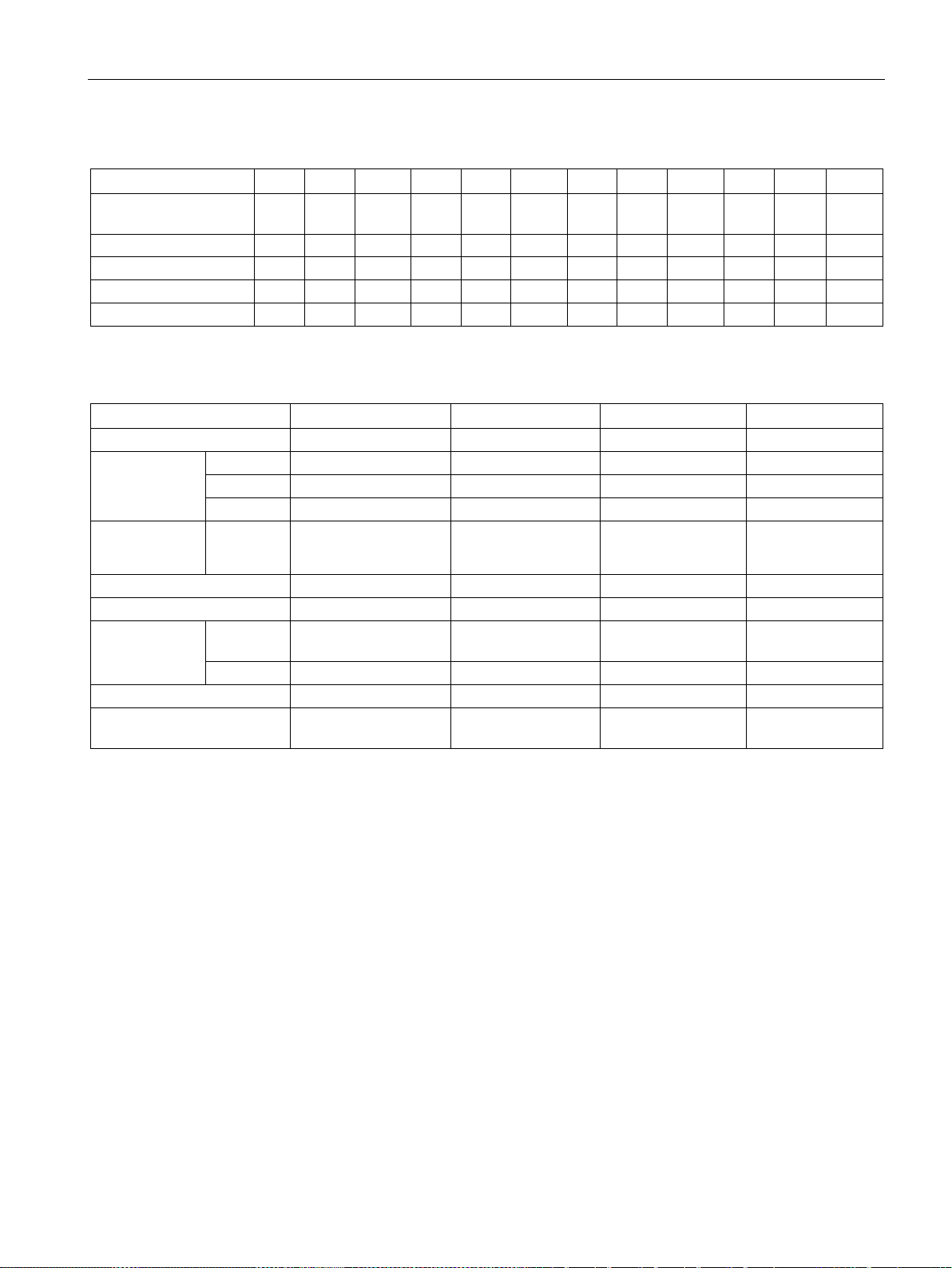

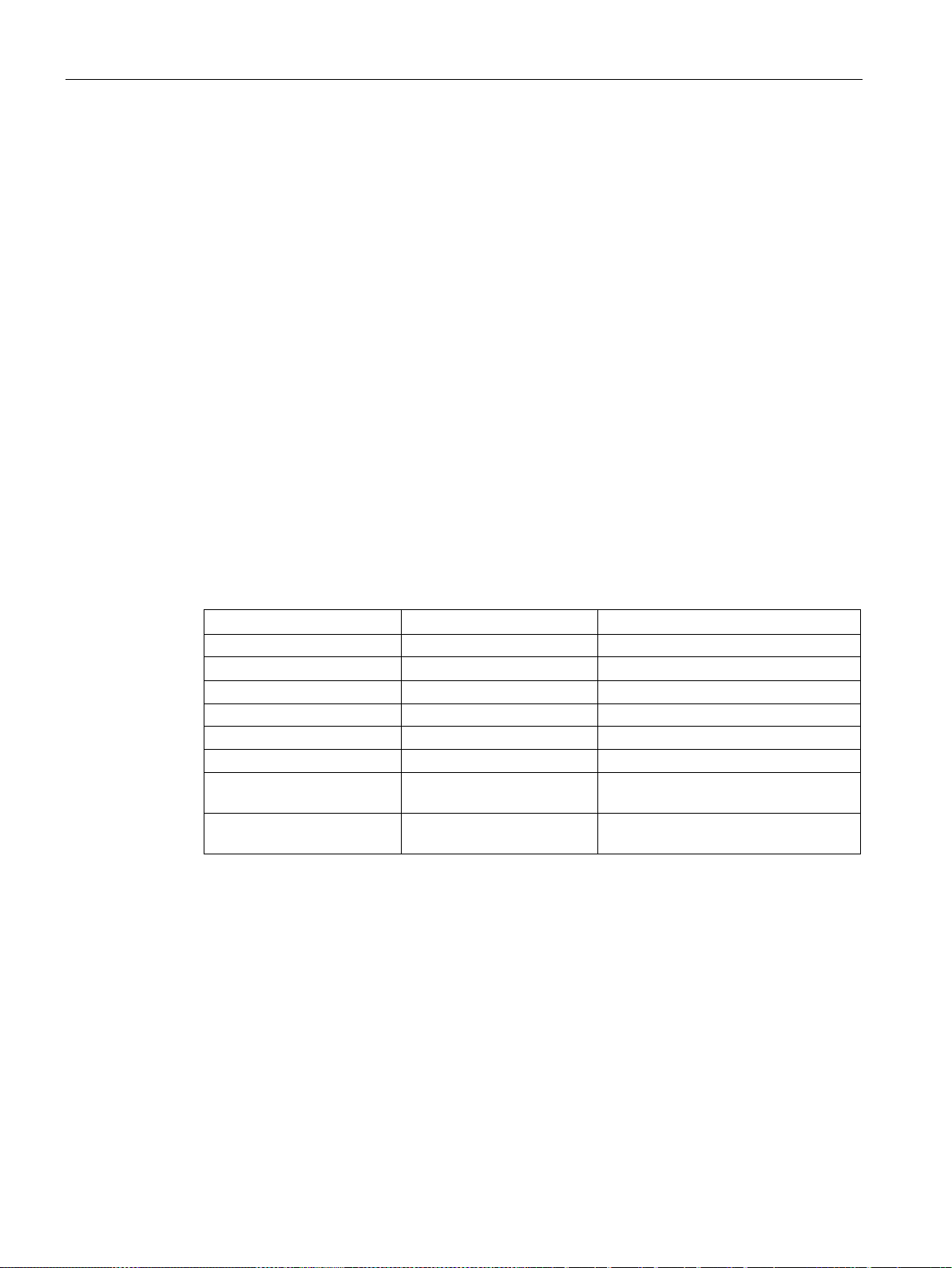

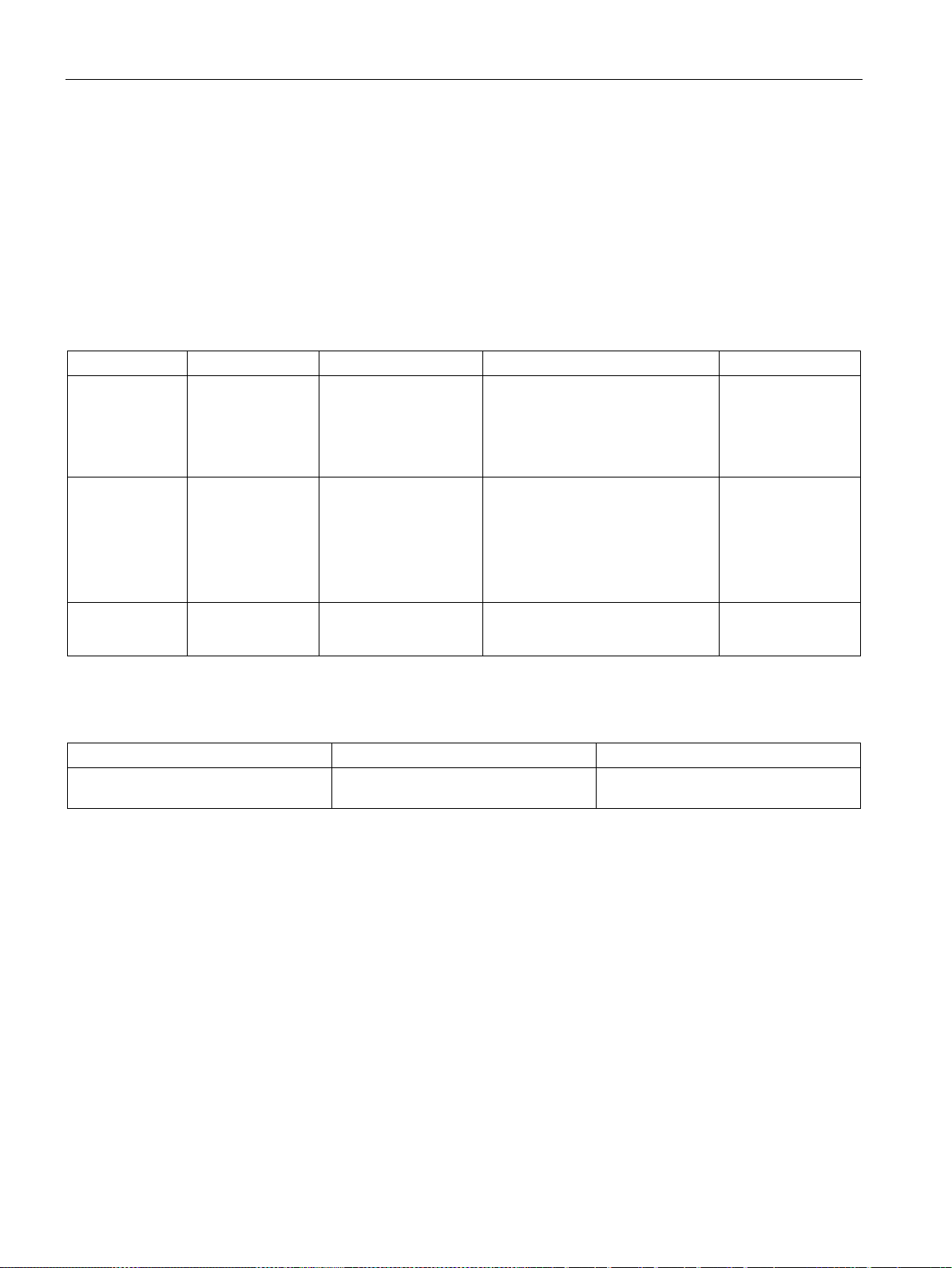

SR20

ST20

CR20s

SR30

ST30

CR30s

SR40

ST40

CR40s

SR60

ST60

CR60s

expandable

Relay output

X X X X X X X

X

I/O points (built-in)

20

20

20

30

30

30

40

40

40

60

60

60

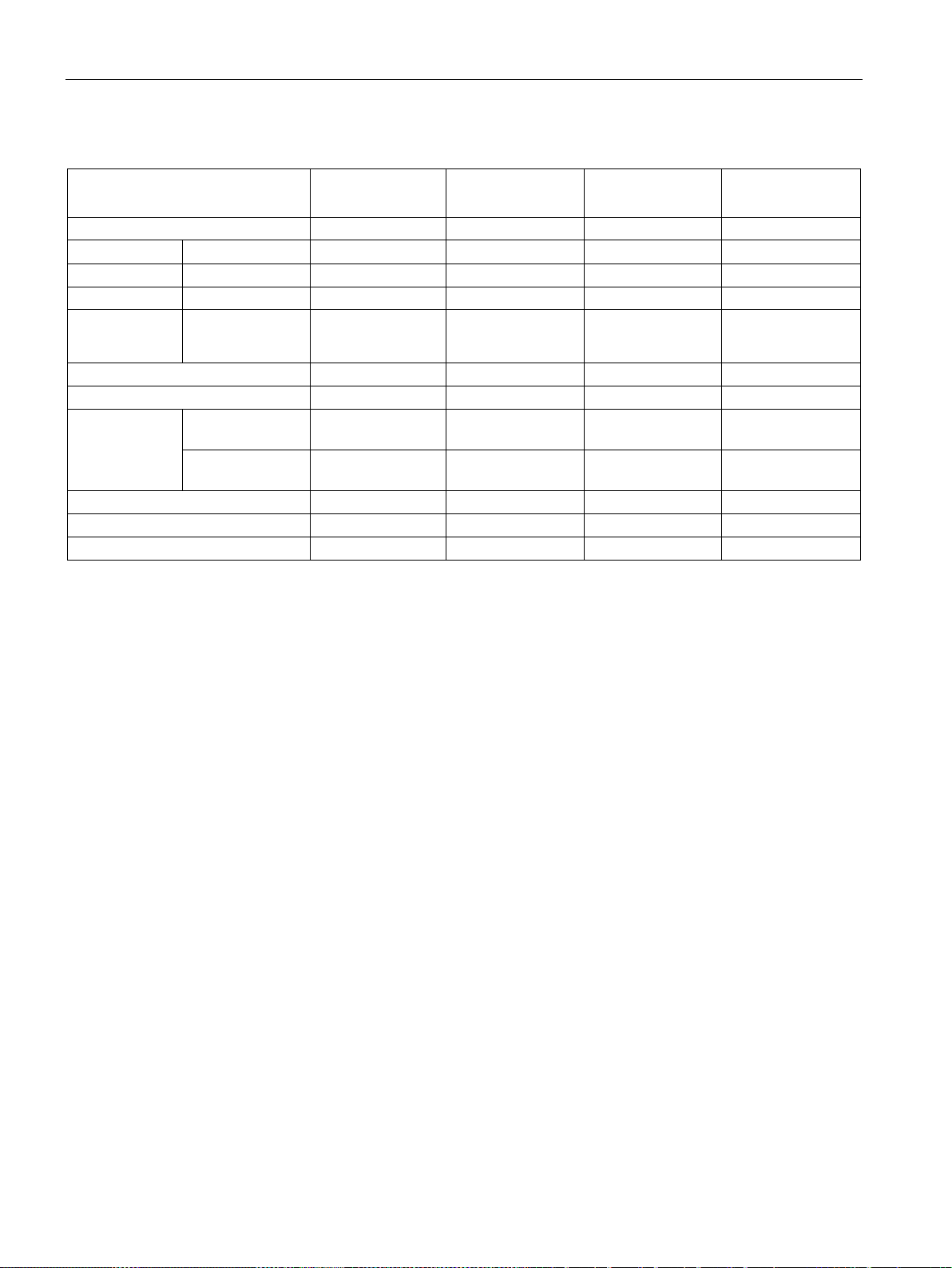

Features

CPU CR20s

CPU CR30s

CPU CR40s

CPU CR60s

Dimensions: W x H x D (mm)

90 x 100 x 81

110 x 100 x 81

125 x 100 x 81

175 x 100 x 81

Program

12 Kbytes

12 Kbytes

12 Kbytes

12 Kbytes

User data

8 Kbytes

8 Kbytes

8 Kbytes

8 Kbytes

Retentive

2 Kbytes max.1

2 Kbytes max.1

2 Kbytes max.1

2 Kbytes max.1

Expansion modules

None

None

None

None

Signal board

None

None

None

None

phase

A/B phase

2 at 50 kHz

2 at 50 kHz

2 at 50 kHz

2 at 50 kHz

PID loops

8 8 8

8

back-up

1

ues on retentive timers) to be retentive, up to the specified maximum amount.