Siemens SIMATIC S7-200 System Manual

Preface, Contents

Product Overview

1

Getting Started

2

Installing the S7-200

3

PLC Concepts

4

Programming Concepts,

Conventions and Features

5

S7-200 Instruction Set

6

Communicating over a Network

7

Hardware Troubleshooting Guide

and Software Debugging Tools

8

Open Loop Motion Control with

the S7-200

9

Creating a Program for the

Modem Module

10

Using the USS Protocol Library to

Control a MicroMaster Drive

11

Using the Modbus Protocol

Library

12

Using Recipes

13

Using Data Logs

14

PID Auto-Tune and the PID

Tuning Control Panel

15

Appendices

Index

S7-200

Programmable Controller

System Manual

SIMATIC

Edition 08/2008

A5E00307987--04

This manual has the order number:

6ES7298-8FA24--8BH0

ii

Safety Guidelines

This manual contains noticeswhichyou should observe to ensure your own personalsafety,as

well as to protecttheproductandconnectedequipment. These notices are highlighted in the

manual by a warning triangleand aremarkedas follows according tothelevelofdanger:

Danger

Danger indicates an imminently hazardous situation which, if not avoided,will result in death or

serious injury.

Warning

Warningindicates a potentially hazardous situation which,ifnotavoided, could result in death or

serious injury.

Caution

Caution used with the safetyalert symbol indicates a potentially hazardous situation which, if not

avoided, may resultinminoror moderate injury.

Caution

Caution used withoutthesafety alertsymbolindicates a potentially hazardous situation which, if

not avoided, may resultinproperty damage.

Notice

Notice indicatesa potential situation which,ifnotavoided, may resultin an undesirableresult or

state.

QualifiedPersonnel

Only qualified personnelshould be allowed to installand work on this equipment.Qualified

persons are defined as persons who are authorized to commission, to ground, and to tag circuits,

equipment,and systems inaccordancewith established safety practicesand standards.

Correct Usage

Note the following:

Warning

This device and its components may only be used for the applicationsdescribed in the catalog

or the technicaldescriptions, and only in connectionwith devices or components from other

manufacturers which have been approved or recommended by Siemens.

This product can only functioncorrectly and safely if it is transported,stored, set up, and

installedcorrectly,and operatedand maintained as recommended.

Trademarks

SIMATICR,SIMATIC HMIR and SIMATICNETR are registered trademarks of SIEMENS AG.

Some of other designations used in these documents are also registered trademarks; the owner’s rights may be

violated if they are used by third parties for their own purposes.

Wehave checkedthe contentsof this manual fo r agreement with th e hardware and

software described. Since deviations cannot be precluded entirely, we cannot

guarantee fullagreement. However,thedata inthis manualare reviewed regularly

and any necessary corrections included in subsequent editions. Suggestions for

improvementare welcomed.

Disclaimer of LiabilityCopyright Siemens AG 2008All rights reserved

The reproduction, transmission or use of this document or its contents is not

permitted without express writtenauthority.Offenders will be liable fordamages.

Allrights,including rightscreated by patentgrantor registration ofa utilitymodel

or design, arereserved.

Siemens AG

Bereich Automation and Drives

Geschaeftsgebiet Industrial AutomationSystems

Postfach 4848, D- 90327Nuernberg

E SiemensAG 2008

Technicaldata subject tochange.

Siemens Aktiengesellschaft 6ES7298-8FA24-8BH0

iii

Preface

Purpose of the manual

The S7-200 series is a line of micro-programmable logic controllers(Micro PLCs) that can control

a variety of automation applications. Compact design, low cost, and a powerful instruction set

make the S7-200 a perfect solution for controlling smallapplications. The wide variety of S7-200

models and the Windows-based programming tool give you the flexibility you need to solve your

automationproblems.

This manual provides information about installing and programming the S7-200 Micro PLCs and

is designed for engineers,programmers,installers, and electricians who have a general

knowledge of programmablelogic controllers.

Required Basic Knowledge

To understand this manual, it is necessary to have a general knowledge of automationand

programmablelogic controllers.

Scope of the Manual

This manual is valid forSTEP 7--Micro/WIN,version 4.0 and the S7-200 CPU product family. For

a complete listoftheS7-200products and order numbersdescribed in this manual, see

AppendixA.

Changes compared to the previous version

This manual has been revised to include two new analog expansion modules and one additional

appendix.

- EM 231 Analog Input RTD, 4 Inputs

- EM 231 Analog Input Thermocouple 8 Inputs

- Appendix H, S7-200CN Products

Certification

The SIMATIC S7-200 products have the following certification:

- Underwriters Laboratories, Inc.UL508 Listed(Industrial Control Equipment),

Registration number E75310

- Canadian Standards Association:CSA C22.2 Number 142 (Process Control Equipment)

- Factory MutualResearch:Class Number 3600, Class Number3611, FM Class I, Division 2,

Groups A, B, C, & D Hazardous Locations, T4A and Class I, Zone 2, IIC, T4

Tip

The SIMATIC S7-200 series meets the CSA standard.

The cULus logo indicates that the S7-200 has been examined and certified by Underwriters

Laboratories(UL)to standards UL 508 and CSA 22.2 No. 142.

S7-200 Programmable Controller System Manual

iv

CE Labeling

Refer to the GeneralTechnical Specifications in Appendix A formoreinformation.

C-Tick

The SIMATIC S7-200 products are compliant with requirements of the AS/NZS 2064 (Australian)

standard.

Standards:

The SIMATIC S7-200 products fulfilltherequirement and criteria of IEC 61131 -- 2, Programmable

controllers -- Equipment requirements.

Refer to Appendix A for additional compliance information.

Place of this Documentation in the Information Environment

Product

Family

Documentation Order Number

S7-200 S7-200 Point-to-Point Interface Communication Manual (English/German) 6ES7298--8GA00--8XH0

SIMATIC Text Display User Manual (included on the STEP 7--Micro/WIN

documentation CD)

none

HMI device OP 73micro, TP 177micro (WinCC Flexible) Operating

Instructions (English)

6AV6 691--1DF01--0AB0

SIMATIC HMI WinCC flexible 2005 Micro User’s Manual (English) 6AV6691--1AA01--0AB0

SIMATIC NET CP 243--2 AS-Interface Master Manual (English) 6GK7 243--2AX00--8BA0

SIMATIC NET CP 243--1 Communications processor of Industrial Ethernet

Technical Manual (English)

J31069--D0428--U001--A2--7618

SIMATIC NET CP 243--1 IT Communications Processor of Industrial

Ethernet and Information T echnology Technical Manual (English)

J31069--D0429--U001--A2--7618

SIMATIC NET S7Beans / Applets for IT--CPs Programming Tips (English) C79000--G8976--C180--02

SIMATIC NET GPRS/GSM--Modem SINAUT MD720--3 System manual

(English)

C79000--G8976--C211

SIMATIC NET SINAUT MICRO SC System manual (English) C79000--G8900--C210

SIWAREX MS Device Manual (English) (included with device) none

S7-200 Programmable Controller System Manual (English) 6ES7 298--8FA24--8BH0

Preface

v

Finding Your Way

If you are a first-time user of S7-200 Micro PLCs, you should read the entireS7-200

ProgrammableController System Manual. If you are an experienced user, refer to the table of

contents or index to findspecific information.

The S7-200 Programmable Controller SystemManualisorganized according to the following

topics:

- Chapter 1 (ProductOverview) provides an overview of some of the features of the S7-200

familyofMicro PLC products.

- Chapter 2 (Getting Started)provides a tutorial for creating and downloading a sample

control program to an S7-200.

- Chapter 3 (Installing the S7-200) provides the dimensions and basic guidelines for installing

the S7-200 CPU modules and expansion I/O modules.

- Chapter 4 (PLC Concepts) providesinformation about the operation of the S7-200.

- Chapter 5 (Programming Concepts, Conventions,andFeatures) provides information about

the featuresofSTEP7--Micro/WIN, the program editors and types of instructions

(IEC 1131-3 or SIMATIC), S7-200 data types,and guidelines forcreating programs.

- Chapter 6 (S7-200 Instruction Set) provides descriptionsand examples of programming

instructions supportedby the S7-200.

- Chapter 7 (Communicating over a Network)provides information forsetting up the different

network configurations supported by the S7-200.

- Chapter 8 (HardwareTroubleshooting Guide and Software Debugging Tools) provides

information for troubleshooting problems with the S7-200 hardware and about the

STEP 7--Micro/WINfeatures that help you debug your program.

- Chapter 9 (Open Loop Motion Controlwith the S7-200) provides informationaboutthree

methods of open loop motion control:Pulse Width Modulation, Pulse Train Output, and the

EM 253 Position ControlModule.

- Chapter 10 (Creating a Program fortheModemModule) provides information about the

instructions and wizard used to create a programforthe EM 241 Modem module.

- Chapter 11 (Using the USS Protocol Library to ControlaMicroMaster Drive) provides

information about the instructions used to create a controlprogram foraMicroMaster drive.

It also providesinformationabouthowtoconfigure the MicroMaster 3 and MicroMaster4

drives.

- Chapter 12 (Using the Modbus ProtocolLibrary)provides information about the instructions

used to create a program thatuses the Modbus protocolfor communications.

- Chapter 13 (Using Recipes)provides information about organizing and loading automation

program recipesinthememory cartridge.

- Chapter 14 (Using Data Logs) providesinformation about storing process measurement

data in the memory cartridge.

- Chapter 15 (PID Auto-Tune and the PID TuningControl Panel)providesinformation about

using these featurestogreatly enhance the utility and ease of use of the PID function

provided by the S7-200.

- Appendix A (Technical Specifications)provides the technicalinformation and data sheets

about the S7-200 hardware.

The other appendices provide additional referenceinformation,suchas descriptions of the error

codes, descriptionsofthe Special Memory (SM)area,part numbers for ordering S7-200

equipment,STL instruction execution times, and S7-200CN product information.

In addition tothis manual, STEP 7--Micro/WINprovides extensive online help forgetting started

with programming the S7-200.Included with the purchase of the STEP 7--Micro/WIN software is a

free documentation CD. On this CD you can find application tips,anelectronic version of this

manual and other information.

S7-200 Programmable Controller System Manual

vi

Online Help

Help is only a keystroke away! Pressing F1 accesses the extensive onlinehelpfor

STEP 7--Micro/WIN.Theonline help includes useful information about gettingstarted with

programmingtheS7-200, as well as many other topics.

Electronic Manual

An electronic versionofthis S7-200 System Manual is availableon the documentation CD. You

can installtheelectronic manual onto your computer so that you can easily access the information

in the manual while you are working withtheSTEP7--Micro/WIN software.

Programming Tips

The documentation CD includes Programming Tips,asetofapplic ation examples with sample

programs.Reviewing or modifying these examplescan help you find efficient or innovative

solutions foryourownapplication. You can also findthemostcurrent version of Programming Tips

on the S7-200 Internetsite.

Recycling and Disposal

Please contact a company certified in the disposalofelectronic scrap for environmentallysafe

recyclingand disposalofyourdevice.

Additional Support

Local Siemens Sales Office or Distributor

For assistance in answeringany technicalquestions, for training on the S7-200 products,orfor

ordering S7-200products , contact your Siemens distributororsales office.Becauseyoursales

representatives are technically trained and have the most specificknowledgeaboutyour

operations,process and industry, as wellas about the individual Siemens products that you are

using, they can provide the fastestandmostefficient answers to any problems thatyou might

encounter.

Service & Support on the Internet

In addition to ourdocumentation, we offer our Know-how online on the Internetat:

http://www

.siemens.com/automation/service&support

where you will find the following:

- www.siemens.com/S7--200 for S7-200 productinformation

The S7-200 Internetsite includes frequently asked questions(FAQs), ProgrammingTips

(application examples and sample programs), information about newly released products,

and product updates or downloads.

- The newsletter, which constantly provides you with up-to-date information on your products.

- The right documents via our Search function in Service& Support.

- A forum, whereusersand expertsfrom allovertheworld exchange theirexperiences.

- Your local representative for Automation & Drives.

- Information on field service,repairs, spareparts and more under “Services”.

Techn ical Services

The highly trainedstaff of the S7-200 Technical Services centerisalsoavailable to help you solve

any problems that you mightencounter. You can call on them 24 hours a day, 7 days a week.

Preface

vii

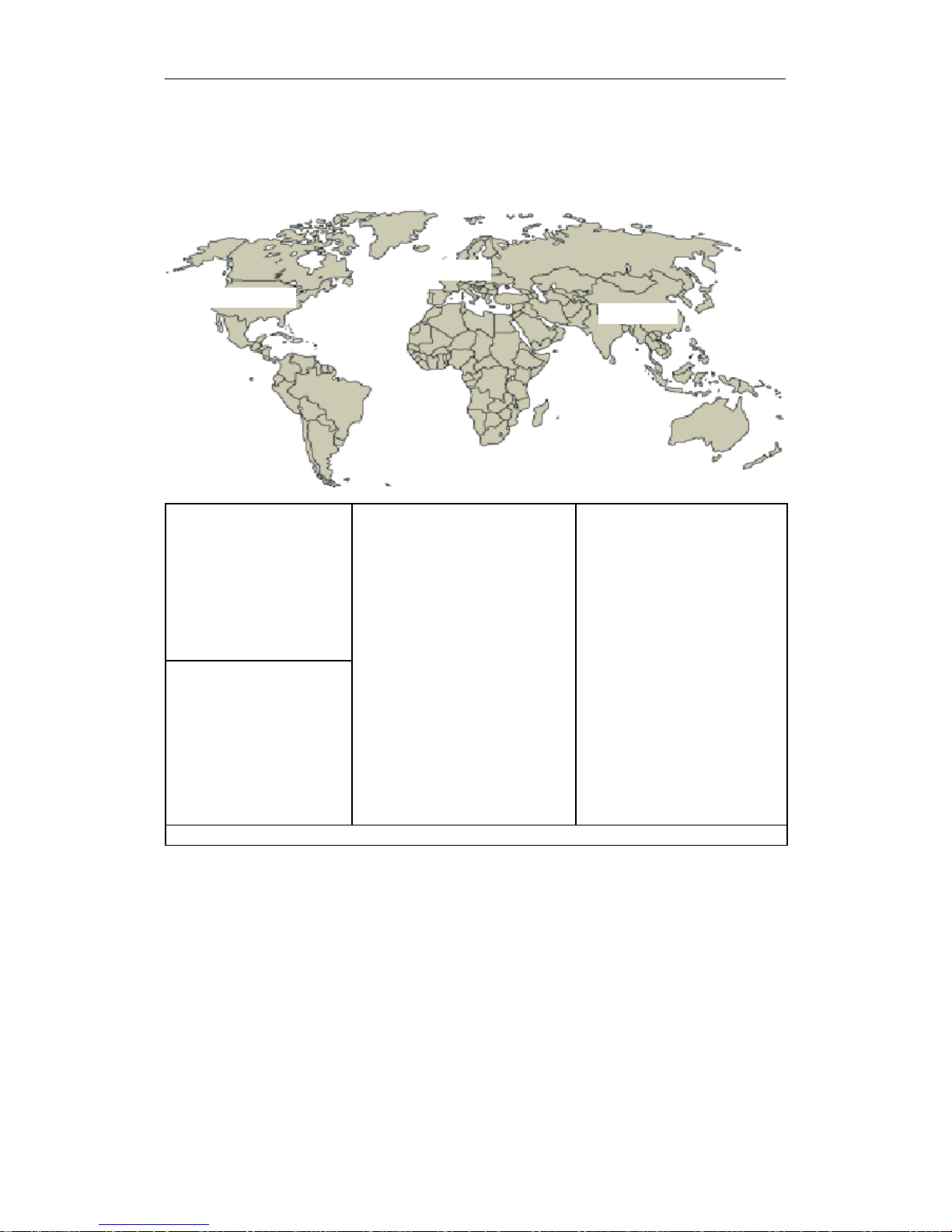

A&D Technical Support

Worldwide, available 24 hours a day:

Johnson City

Nuernberg

Beijing

Technical Support

Worldwide (Nuernberg)

Technical Support

24 hours a day, 365 days a year

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

mailto:adsupport@siemens.com

GMT: +1:00

United States (Johnson City)

Technical Support and

Authorization

Local time: Mon.-Fri.

8:00 AM to 5:00 PM

Phone: +1 (423) 262 2522

+1 (800) 333--7421 (USA only)

Fax: +1 (423) 262 2289

mailto:simatic.hotline

@

sea.siemens.com

Asia / Australia (Beijing)

Technical Support and

Authorization

Local time: Mon.-Fri.

8:00 AM to 5:00 PM

Phone: +86 10 64 75 75 75

Fax: +861064747474

mailto:adsupport.asia@siemens.com

GMT: +8:00

Europe / Africa (Nuernberg)

Authorization

Local time: Mon.-Fri.

8:00 AM to 5:00 PM

Phone: +49 (180) 5050--222

Fax: +49 (180) 5050-223

mailto:adsupport@siemens.com

GMT: +1:00

mailto:simati

c.hotline@sea.siemens.com

GMT : --5:00

The languages of the SIMATIC Hotlines and the authorization hotline are generally German and English.

S7-200 Programmable Controller System Manual

viii

ix

Contents

1 Product Overview 1.......................................................

What’sNew? 2....................................................................

S7-200 CPU 2....................................................................

S7-200 Expansion Modules 4.......................................................

STEP 7--Micro/WIN ProgrammingPackage 5..........................................

CommunicationsOptions 5.........................................................

Display Panels 6..................................................................

2 Getting Started 7..........................................................

Connecting the S7-200 CPU 8......................................................

Creating a Sample Program 10.......................................................

Downloading the Sample Program 14.................................................

Placing the S7-200 in RUN Mode 14..................................................

3 Installing the S7-200 15.....................................................

Guidelines for Installing S7-200 Devices 16............................................

Installing and Removing the S7-200 Modules 17........................................

Guidelines forGrounding and Wiring 20...............................................

4 PLC Concepts 23...........................................................

Understanding How the S7-200 Executes Your Control Logic 24..........................

Accessing the Data of the S7-200 27..................................................

Understanding How the S7-200 Saves and Restores Data 36.............................

Selecting the Operating Mode for the S7-200 CPU 40....................................

Using the S7-200 Explorer 41........................................................

Features of the S7-200 41...........................................................

5 Programming Concepts, Conventions, and Features 51.......................

Guidelines forDesigning a MicroPLC System 52.......................................

Basic Elements of a Program 53......................................................

Using STEP 7--Micro/WINtoCreate Your Programs 55..................................

Choosing Between the SIMATIC and IEC 1131--3 Instruction Sets 57......................

Understanding theConventions Used by the Program Editors 58..........................

Using Wizards To Help You Create Your Control Program 60..............................

Handling ErrorsintheS7-200 60.....................................................

Assigning Addresses and Initial Values in the Data Block Editor 62........................

Using the Symbol Table for Symbolic Addressing of Variables 62..........................

Using Local Variables 63............................................................

Using the Status Chart to Monitor Your Program 63......................................

Creating an Instruction Library 64.....................................................

Features forDebuggingYour Program 64..............................................

S7-200 Programmable Controller System Manual

x

6 S7-200 Instruction Set 65...................................................

Conventions Used to Describe the Instructions 67.......................................

S7-200 Memory Ranges and Features 68..............................................

Bit Logic Instructions 70.............................................................

Contacts 70...................................................................

Coils 73.......................................................................

Logic Stack Instructions 75......................................................

Set and Reset Dominant BistableInstructions 77....................................

Clock Instructions 78................................................................

CommunicationsInstructions 81......................................................

Network Read and Network Write Instructions 81....................................

Transmitand Receive Instructions (Freeport) 86....................................

Get Port Address and Set PortAddressInstructions 95..............................

Compare Instructions 96............................................................

Comparing NumericalValues 96..................................................

Compare String 98.............................................................

Conversion Instructions 99...........................................................

Standard ConversionInstructions 99..............................................

ASCII ConversionInstructions 103.................................................

String ConversionInstructions 107.................................................

Encode and Decode Instructions 112...............................................

Counter Instructions 113..............................................................

SIMATIC Counter Instructions 113.................................................

IEC Counter Instructions 116......................................................

High-Speed CounterInstructions 118...................................................

Pulse Output Instruction 133..........................................................

Math Instructions 140................................................................

Add, Subtract,Multiply,andDivideInstructions 140...................................

MultiplyInteger to Double Integer and Divide Integer with Remainder 142................

Numeric FunctionsInstructions 143................................................

Incrementand DecrementInstructions 144..........................................

Proportional/Integral/Derivative (PID)Loop Instruction 145.................................

Interrupt Instructions 153.............................................................

Logical Operations Instructions 161....................................................

InvertInstructions 161............................................................

AND, OR, and Exclusive OR Instructions 162........................................

Move Instructions 164................................................................

Move Byte, Word,Double Word,or Real 164........................................

Move Byte Immediate(Readand Write) 165.........................................

Block Move Instructions 166......................................................

Program ControlInstructions 167......................................................

ConditionalEnd 167.............................................................

Stop 167.......................................................................

Watchdog Reset 167.............................................................

For--Next Loop Instructions 169....................................................

Jum

p Instructions 171............................................................

Sequence Control Relay (SCR)Instructions 172.....................................

Diagnostic LED Instruction 178....................................................

Contents

xi

Shift and RotateInstructions 179.......................................................

Shift RightandShift Left Instructions 179............................................

Rotate Right and RotateLeftInstructions 179........................................

Shift RegisterBit Instruction 181...................................................

Swap Bytes Instruction 183.......................................................

String Instructions 184...............................................................

Table Instructions 189................................................................

AddToTable 189................................................................

First-In-First-Outand Last-In-First-Out 190..........................................

Memory Fill 192.................................................................

Table Find 193..................................................................

TimerInstructions 196................................................................

SIMATIC Timer Instructions 196...................................................

IEC TimerInstructions 201........................................................

Interval Timers 203..............................................................

Subroutine Instructions 204...........................................................

7 Communicating over a Network 209..........................................

Understanding theBasicsofS7-200Network Communications 210.........................

Selecting the Communications Protocolfor Your Network 214..............................

Installing and Removing Communications Interfaces 220..................................

Building Your Network 221............................................................

Creating User-Defined Protocolswith Freeport Mode 226.................................

Using Modems and STEP 7--Micro/WIN with Your Network 228............................

Advanced Topics 233................................................................

ConfiguringtheRS-232/PPI Multi-Master Cable forRemoteOperation 239...................

8 Hardware Troubleshooting Guide and Software Debugging Tools 243...........

Features forDebuggingYour Program 244..............................................

Displaying the ProgramStatus 246.....................................................

Using a Status Chart to Monitorand ModifytheDataintheS7-200 247......................

Forcing SpecificValues 248...........................................................

Running Your Program fora Specified Number of Scans 248..............................

Hardware Troubleshooting Guide 249..................................................

9 Open Loop Motion Control with the S7-200 251................................

Overview 252.......................................................................

Using the PWM (Pulse WidthModulation) Output 253.....................................

Basic Information for Open Loop Position ControlUsing SteppersorServos 255..............

Instructions Createdby the Position ControlWizard 260...................................

ErrorCodes forthePTO Instructions 264...............................................

Features of the Position Module 265...................................................

ConfiguringthePosition Module 267...................................................

Instructions Createdby the Position ControlWizard for the Position Module 273..............

Sample Programs forthePosition Module 285...........................................

Monitoringthe Position Module withtheEM253 ControlPanel 290.........................

ErrorCodes forthePosition Module and the Position Instructions 292.......................

Advanced Topics 294................................................................

Understanding theRP Seek Modes Supported by the PositionModule 303..................

S7-200 Programmable Controller System Manual

xii

10 Creating a Program for the Modem Module 307................................

Features of the Modem Module 308....................................................

Using the Modem Expansion Wizard to Configure the Modem Module 314...................

Overview of Modem Instructions and Restrictions 318....................................

Instructions fortheModemModule 319.................................................

Sample Program fortheModemModule 323............................................

S7-200 CPUs that Support Intelligent Modules 323.......................................

Special Memory Locationforthe Modem Module 323.....................................

Advanced Topics 325................................................................

Messaging Telephone Number Format 327..............................................

Text Message Format 328............................................................

CPU Data TransferMessageFormat 329...............................................

11 Using the USS Protocol Library to Control a MicroMaster Drive 331.............

RequirementsforUsing the USS Protocol 332...........................................

CalculatingtheTime Required forCommunicating with the Drive 332.......................

Using the USS Instructions 333........................................................

Instructions fortheUSS Protocol 334...................................................

Sample Programs fortheUSS Protocol 341.............................................

USS Execution ErrorCodes 342.......................................................

Connecting and SettingUp the MicroMaster Series 3 Drive 342............................

Connecting and SettingUp the MicroMaster Series 4 Drive 345............................

12 Using the Modbus Protocol Library 347.......................................

Overview 348.......................................................................

RequirementsforUsing Modbus Protocol 348...........................................

Initialization and Execution Time for Modbus Protocol 349.................................

Modbus Addressing 350..............................................................

Using the Modbus Master Instructions 351..............................................

Using the Modbus Slave Instructions 352...............................................

Instructions fortheModbus Protocol 353................................................

Advanced Topics 362................................................................

13 Using Recipes 365...........................................................

Overview 366.......................................................................

Recipe Definition and Terminology 367.................................................

Using the Recipe Wizard 367..........................................................

Instructions Createdby the Recipe Wizard 371..........................................

14 Using Data Logs 373........................................................

Overview 374.......................................................................

Using the Data Log Wizard 375........................................................

Instruction Created by the Data Log Wizard 379..........................................

15 PID Auto-Tune and the PID Tuning Control Panel 381..........................

Understanding thePIDAuto-Tune 382..................................................

Expanded Loop Table 382............................................................

Prerequisites 385....................................................................

Auto-Hysteresis and Auto-Deviation 385................................................

Auto-TuneSequence 386.............................................................

Contents

xiii

Exception Conditions 387.............................................................

Notes Concerning PV Out-of-Range (ResultCode3) 387..................................

PID Tuning ControlPanel 388.........................................................

A Technical Specifications 391.................................................

General Technical Specifications 392...................................................

CPU Specifications 396..............................................................

DigitalExpansionModules Specifications 405...........................................

Analog Expansion Modules Specifications 412...........................................

Thermocouple and RTD Expansion ModulesSpecifications 424............................

EM 277 PROFIBUS--DP Module Specifications 438......................................

EM 241 Modem Module Specifications 450..............................................

EM 253 Position Module Specifications 452.............................................

(CP 243--1) Ethernet Module Specifications 458.........................................

(CP 243--1 IT) Internet Module Specifications 460........................................

(CP 243--2) AS--Interface Module Specifications 463......................................

Optional Cartridges 465..............................................................

I/O Expansion Cable 466.............................................................

RS-232/PPI Multi-Master Cable and USB/PPI Multi-MasterCable 467......................

Input Simulators 471.................................................................

B Calculating a Power Budget 473..............................................

C Error Codes 477.............................................................

Fatal ErrorCodesand Messages 478..................................................

Run-TimeProgramming Problems 479.................................................

Compile Rule Violations 480..........................................................

D Special Memory (SM) Bits 481................................................

SMB0: Status Bits 482...............................................................

SMB1: Status Bits 482...............................................................

SMB2: FreeportReceiveCharacter 483................................................

SMB3: FreeportParity Error 483.......................................................

SMB4: Queue Overflow 483...........................................................

SMB5: I/O Status 484................................................................

SMB6: CPU ID Register 484..........................................................

SMB7: Reserved 484................................................................

SMB8 to SMB21: I/O Module ID and ErrorRegisters 485..................................

SMW22 to SMW26: Scan Times 486...................................................

SMB28 and SMB29: Analog Adjustment 486............................................

SMB30 and SMB130: Freeport ControlRegisters 486.....................................

SMB31 and SMW32: Permanent Memory (EEPROM) Write Control 487.....................

SMB34 and SMB35: Time IntervalRegisters forTimed Interrupts 487.......................

SMB36 to SMB65: HSC0, HSC1, and HSC2 Register 487.................................

SMB66 to SMB85: PTO/PWMRegisters 489............................................

SMB86 to SMB94, and SMB186 to SMB194: Receive Message Control 490.................

SMW98: Errorson theExpansionI/O Bus 491...........................................

SMB130: FreeportControl Register (see SMB30) 491....................................

SMB131 to SMB165: HSC3, HSC4, and HSC5 Register 491...............................

SMB166 to SMB185: PTO0, PTO1Profile Definition Table 492.............................

S7-200 Programmable Controller System Manual

xiv

SMB186 to SMB194: Receive Message Control (see SMB86 to SMB94) 492.................

SMB200 to SMB549: Intelligent Module Status 493.......................................

E S7-200 Order Numbers 495...................................................

F Execution Times for STL Instructions 499.....................................

G S7-200 Quick Reference Information 505......................................

H S7-200CN Products 511......................................................

Certifications and Approvals for S7-200CN Products 512..................................

S7-200CN Products 513..............................................................

1

Product Overview

The S7-200 series of micro-programmable logic controllers(Micro PLCs) can controla wide

variety of devices tosupportyourautomation needs.

The S7-200 monitors inputsand changes outputs as controlled by the user program,which can

include Boolean logic,counting, timing,complex math operations, and communications withother

intelligent devices. The compact design, flexible configuration, and powerful instructionset

combine to make the S7-200 a perfect solution forcontrolling a wide variety of applications.

In This Chapter

What’sNew? 2....................................................................

S7-200 CPU 2....................................................................

S7-200 Expansion Modules 4.......................................................

STEP 7--Micro/WIN ProgrammingPackage 5..........................................

CommunicationsOptions 5.........................................................

Display Panels 6..................................................................

S7-200 Programmable Controller System Manual

2

What’s New?

The new features of the SIMATIC S7-200 include two new analog expansion modules:

- EM 231 Analog Input RTD, 4 Inputs

- EM 231 Analog Input Thermocouple 8 Inputs

- Appendix H, S7-200CN Products

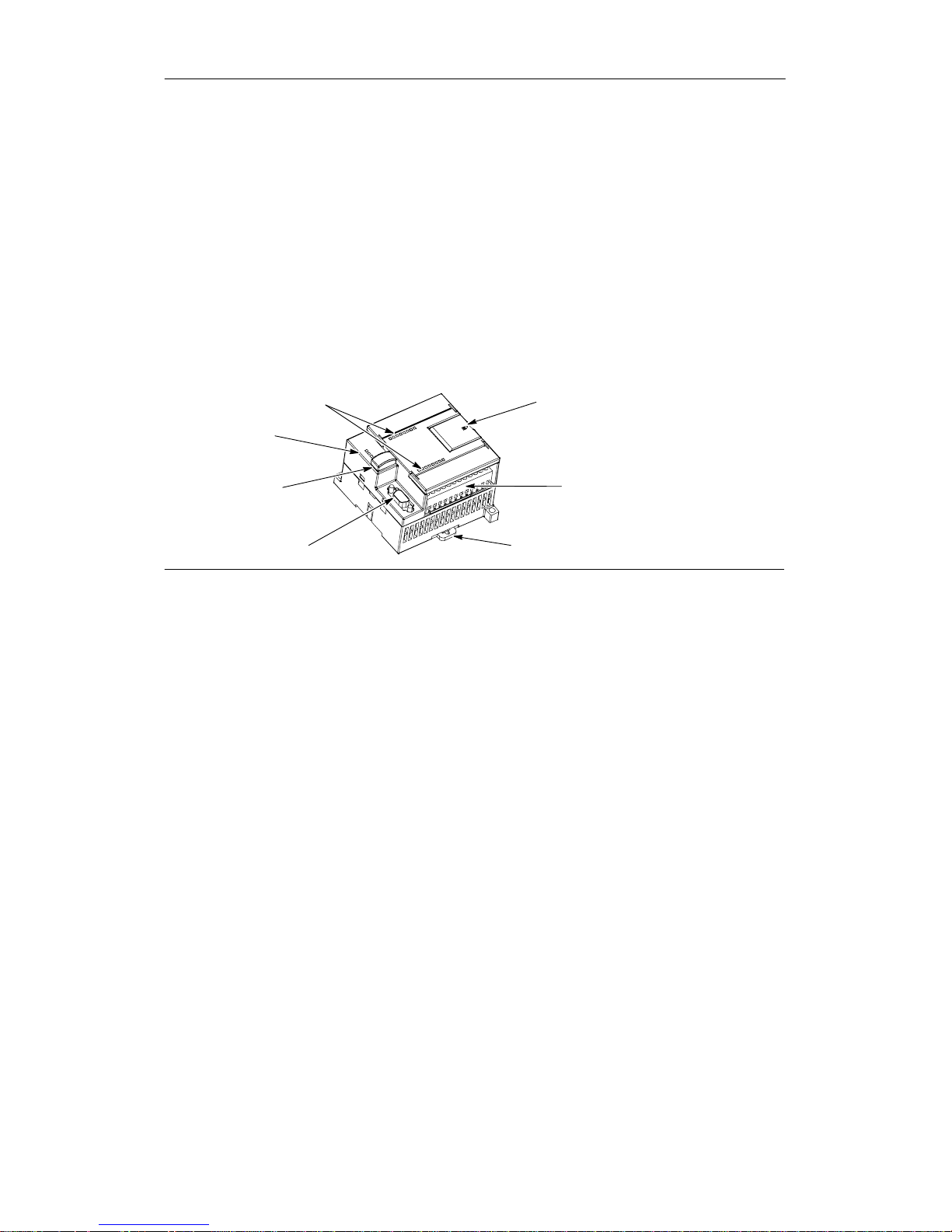

S7-200 CPU

The S7-200 CPU combines a microprocessor, an integrated power supply, input circuits, and

output circuits in a compact housing to create a powerfulMic ro PLC. See Figure 1-1. After you

have downloaded your program, the S7-200contains the logic required tomonitor and control the

input and output devices in your application.

I/OLEDs

Status LEDs:

System Fault/Diagnostic

(SF/DIAG)

RUN

STOP

Optional cartridge:

Memory Cartridge

Real-time Clock

Battery

Communications port

Terminal connector

(removable on CPU 224, CPU 224XP

and CPU 226)

Clip for installation on a standard (DIN) rail

A

ccess door:

Modeselector switch(RUN/STOP)

Analog adjustment potentiometer(s)

Expansion port (for most CPUs)

Figure 1-1 S7-200 Micro PLC

Product Overview Chapter 1

3

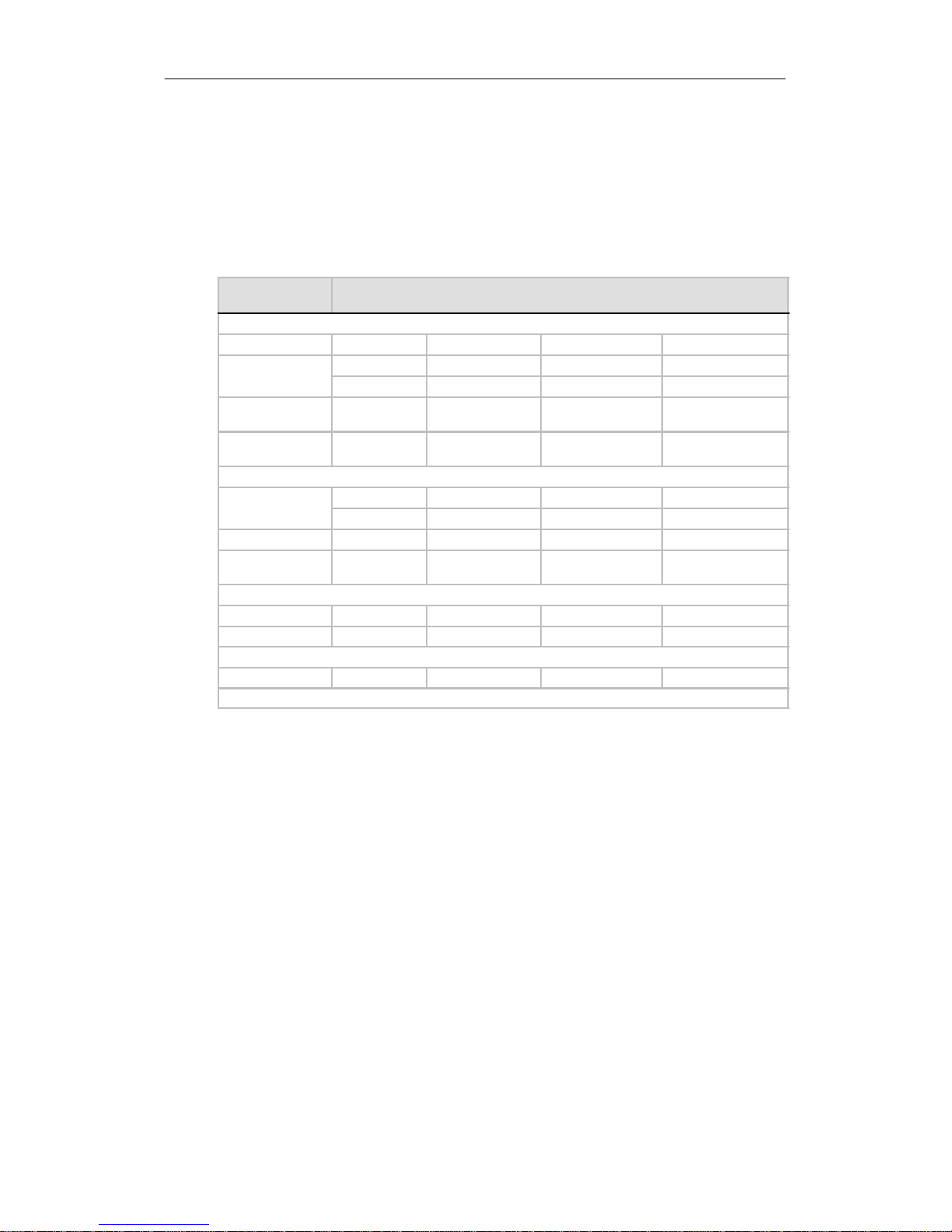

Siemens provides different S7-200 CPU models with a diversity of features and capabilities that

help you create effective solutions for your varied applications. Table 1-1 briefly compares some of

the features oftheCPU.Fordetailed information about a specific CPU, see Appendix A.

Table 1-1 Comparison of the S7-200 CPU Models

Feature CPU 221 CPU 222 CPU 224

CPU 224XP

CPU 224XPsi

CPU 226

Physical size(mm) 90 x 80 x 62 90 x 80 x 62 120.5 x 80 x 62 140x 80 x 62 190 x 80 x 62

Program memory:

with run mode edit

without run mode edit

4096 bytes

4096 bytes

4096 bytes

4096 bytes

8192 bytes

12288 bytes

12288 bytes

16384 bytes

16384 bytes

24576 bytes

Data memory 2048 bytes 2048 bytes 8192 bytes 10240 bytes 10240 bytes

Memory backup 50 hours

typical

50 hours

typical

100 hours

typical

100 hours

typical

100 hours

typical

Local on-board I/O

Digital

Analog

6In/4Out--8In/6Out

--

14 In/10 Out--14 In/10 Out

2In/1Out

24 In/16 Out

--

Expansion modules 0 modules 2 modules

1

7 modules

1

7 modules

1

7 modules

1

High-speed counters

Single phase

Two phase

4at30kHz

2at20kHz

4at30kHz

2at20kHz

6at30kHz

4at20kHz

4at30kHz

2 at 200 kHz

3at20kHz

1 at 100 kHz

6at30kHz

4at20kHz

Pulse outputs (DC) 2at20kHz 2at20kHz 2at20kHz 2 at 100 kHz 2at20kHz

Analog adjustments 1 1 2 2 2

Real-time clock Cartridge Cartridge Built-in Built-in Built-in

Communications ports 1 RS--485 1 RS--485 1 RS--485 2 RS--485 2 RS--485

Floating-point math Yes

Digital I/O image size 256 (128 in, 128 out)

Boolean execution

speed

0.22 microseconds/instruction

1 Youmust calculateyourpower budget todetermine howmuchpower (or c urrent) the S7-200CPU canprovide foryour configuration.If theCPU

powerbudget is exceeded,you may notbeable to connectthe maximum numberof modules.See Appendix Afor CPU andexpansion module

power requirements, and Appendix B to calculate your power budget.

S7-200 Programmable Controller System Manual

4

S7-200 Expansion Modules

To better solve your application requirements, the S7-200 family includes a wide varietyof

expansion modules. You can use these expansion modules to add additionalfunctionality to the

S7-200 CPU. Table 1-2 provides a list of the expansion modules that are currently available.For

detailed information about a specific module, see Appendix A.

Table 1-2 S7-200 Expansion Modules

Expansion

Modules

Type

Discrete modules

Input 8xDCIn 8xACIn 16 x DC In

Output

4xDCOut 4xRelays 8xRelay

8xDCOut 8xACOut

Combination 4xDCIn/

4xDCOut

8xDCIn/

8xDCOut

16 x DC In/

16 x DC Out

32 x DC In/

32 x DC Out

4xDCIn/

4xRelay

8xDCIn/

8xRelay

16 x DC In/

16 x Relay

32 x DC In/

32 x Relay

Analog modules

Input

4 x Analog In 8 x Analog In 4 x Thermocouple In 8 x Thermocouple In

2xRTDIn 4xRTDIn

Output 2 x Analog Out 4 x Analog Out

Combination 4x Analog In

4 x Analog Out

Intelligent modules

Position Modem PROFIBUS--DP

Ethernet Ethernet IT

Other modules

AS--Interface SIWAREX MS

1

1

Detailed information not included in Appendix A. Please refer to your module documentation.

Product Overview Chapter 1

5

STEP 7--Micro/WIN Programming Package

The STEP 7--Micro/WIN programming package provides a user-friendly environment to develop,

edit, and monitorthe logic needed to controlyourapplication.STEP7--Micro/WIN providesthree

program editors for convenience and efficiency in developing the control program foryour

application.To help you find the information you need, STEP 7--Micro/WIN providesan extensive

online help system and a documentationCD thatcontains an electronic versionofthis manual,

applicationtips, and otherusefulinformation.

Computer Requirements

STEP 7--Micro/WINrunson eitherapersonalcomputer or a Siemens programming device, such

as a PG 760. Yourcomputeror programming device should meet the followingminimum

requirements:

- Operatingsystem:

Windows 2000, Windows XP, Vista

- At least 350M bytes of free hard

disk space

- Mouse (recommended)

Figure 1-2 STEP 7--Micro/WIN

Installing STEP 7--Micro/WIN

Insert theSTEP 7--Micro/WINCD intothe CD-ROM drive of your computer. The installation wizard

starts automatically and promptsyou throughtheinstallation process. Refer to the Readme file for

more information about installing STEP 7--Micro/WIN.

Tip

To install STEP 7--Micro/WIN on a Windows 2000, Windows XP, or Windows Vistaoperating

system, you must log in withAdministratorprivileges.

Communications Options

Siemens provides two programming options forconnecting your computer to your S7-200:a direct

connection with a PPI Multi-Mastercable,oraCommunications Processor(CP)card with an MPI

cable.

The PPI Multi-Master programming cable is the most common and economical method of

connecting your computertotheS7-200. This cable connects the communicationsportof the

S7-200 to the serialcommunications of your computer. The PPI Multi-Masterprogramming cable

can also be used to connect other communications devices to the S7-200.

S7-200 Programmable Controller System Manual

6

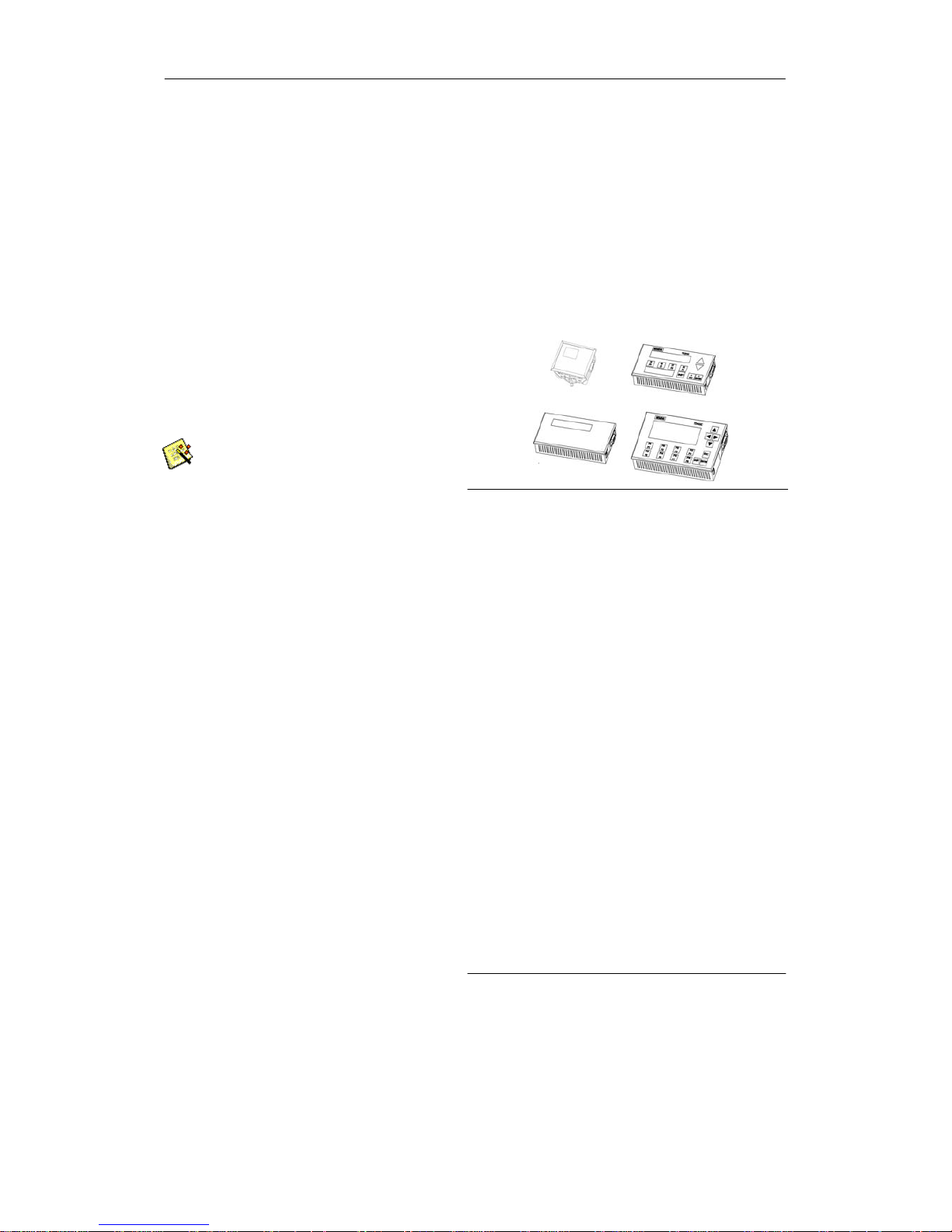

Display Panels

Text Display Units

The Text Display (TD) is a display device that can be connected to the S7-200. Using the Text

Display wizard,youcan easilyprogram your S7-200 to display text messages and other data

pertainingtoyourapplication.

The TD device provides a low cost interfacetoyourapplic ation by allowing you to view, monitor,

and change the process variables pertaining to your application.

The S7-200 product familyprovides fourTD devices:

- The TD100C has a 4-line text

display with2 fontchoices.

- The TD 200C has a 2-line text

display with20 characters per line

for a total of 40 characters.

- The TD 200 has a faceplate which

provides four keys withpredefined,

set-bitfunctions and allowsup to

eight set-bitfunctions.

- The TD400C can have a 2- or

TD 100C

TD 200C

TD 200

TD400C

-

TheTD400Ccanhavea2o

r

4-line textdisplay depending on

your font and characterchoice.

Figure 1-3 Text Display Units

For more information about the TextDisplay Units,refer to the SIMATICText Display (TD) User

Manual on the STEP 7--Micro/WIN docuCD.

The Text Display wizard in STEP 7--Micro/WINhelpsyou configure Text Display messages

quickly and easily. Tostart the Text Display wizard, select the Tools > Text Display Wizardmenu

command.

Operator and To u ch Panel Displays

The OP 73micro and TP 177micro

panels are tailoredtoapplications with

SIMATIC S7-200 Micro PLC and provide

operating and monitoring functions for

small-scale machines and plants. Short

configuration and commissioning times,

and their configuration in WinCC flexible

form the highlights of these panels. In

addition,thesepanelssupportup to 32

configuration languages and five online

languages, includingtheAsian and

Cyrillic charactersets.

The mounting dimensions of the

OperatorPanelOP 73microwith its

graphical 3”displayunitare compatible

with OP3 and TD 200.

Touch Panel TP 177microreplaces the

Touch Panel TP 070/TP 170micro.It can

be mounted vertically to accommodate

additionalapplication

s.Thisfeature

enables its use even when space is

restricted.

Figure 1-4 Operator and TouchPanelDisplays

Text Display

7

Getting Started

STEP 7--Micro/WINmakes iteasy foryoutoprogram your S7-200.Injusta few shortstepsusing

a simple example, you can learn how to connect, program, and run your S7-200.

All you need for this example is a PPI Multi-Master cable, an S7-200 CPU, and a programming

device running the STEP 7--Micro/WINprogramming software.

In This Chapter

Connecting the S7-200 CPU 8......................................................

Creating a Sample Program 10.......................................................

Downloading the Sample Program 14.................................................

Placing the S7-200 in RUN Mode 14..................................................

S7-200 Programmable Controller System Manual

8

Connecting the S7-200 CPU

Connecting your S7-200 is easy. For this example, you only need to connect power to your

S7-200 CPU and then connect the communications cable between your programming device and

the S7-200 CPU.

Connecting Power to the S7-200 CPU

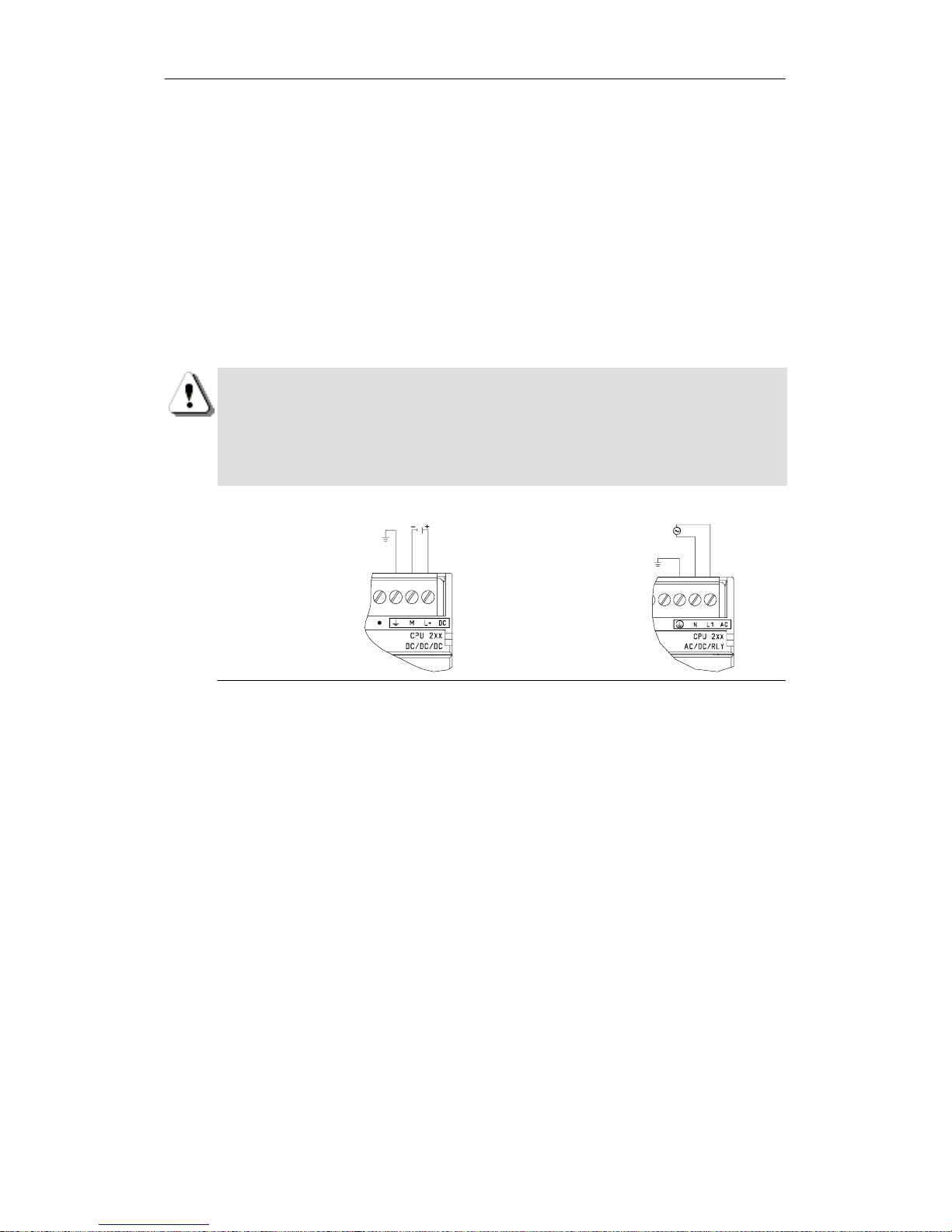

The firststepistoconnecttheS7-200toapowersource.Figure 2-1 shows the wiring

connections for eithera DC or an AC model of the S7-200 CPU.

Before you installorremove any electrical device, ensure thatthepowertothatequipment has

been turned off.Always followappropriate safetyprecautions and ensure thatpowertothe

S7-200 is disabled beforeattempting to install or remove the S7-200.

Warning

Attemptstoinstall or wiretheS7-200orrelated equipment with power applied could cause

electricshock or faulty operation of equipment. Failure to disableallpowerto the S7-200 and

related equipmentduring installation or removalprocedures could resultin death or serious

injury to personnel,and/or damage to equipment.

Always follow appropriate safety precautions and ensure that power to theS7-200isdisabled

before attempting to install or remove the S7-200 or relatedequipment.

DC Installation AC Installation

24VDC 85to 265 VAC

Figure 2-1 Connecting Power to the S7-200 CPU

Getting Started Chapter 2

9

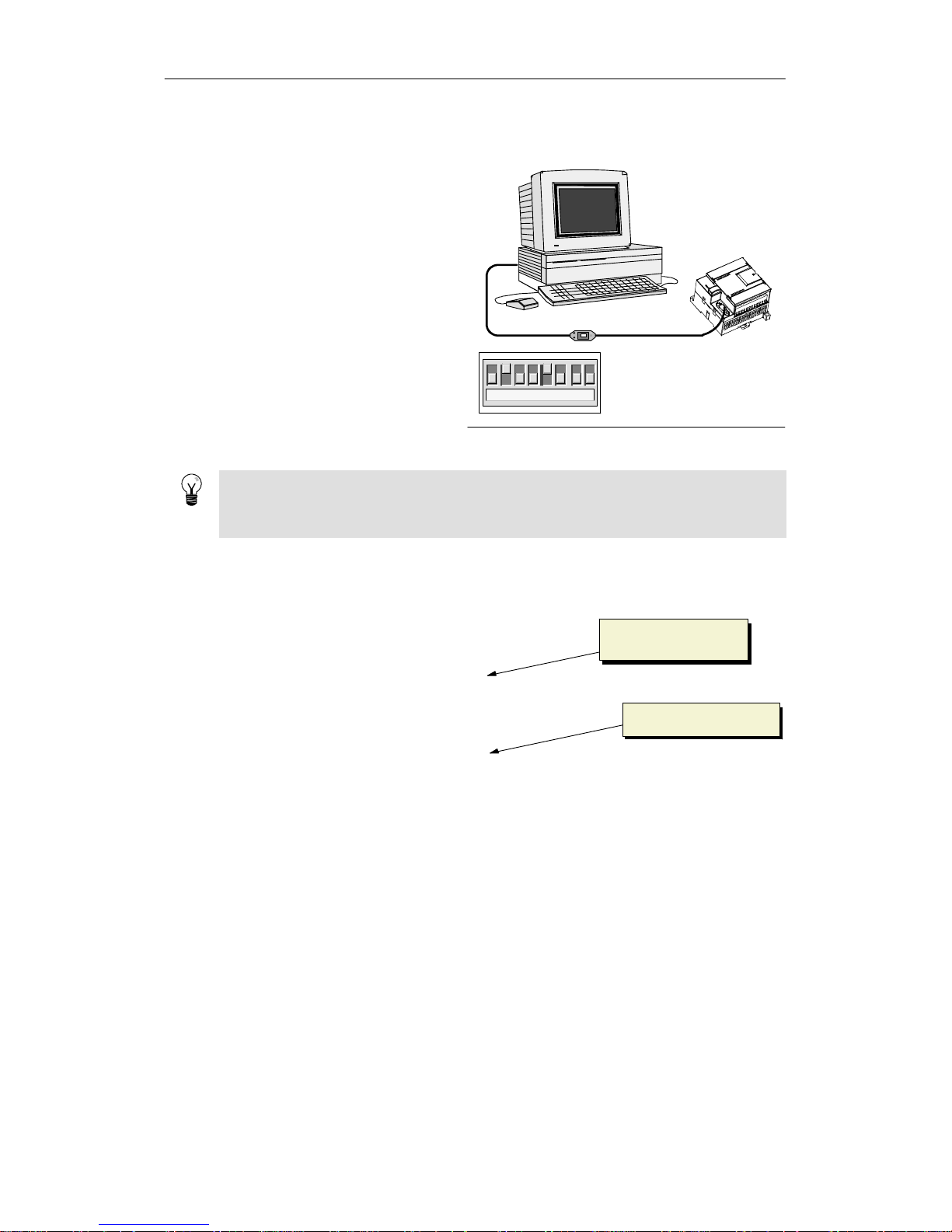

Connecting the RS-232/PPI Multi-Master Cable

Figure 2-2 shows an RS-232/PPI

Multi-Master cable connectingthe

S7-200 to the programming device. To

connect the cable:

1. Connect the RS-232 connector

(marked “PC”)ofthe RS-232/PPI

Multi-Master cable to the

communicationsportofthe

programmingdevice.(For this

example, connect to COM 1.)

2. Connect the RS-485 connector

(marked “PPI”) of the RS-232/PPI

Multi-Master cable to Port0or

Port 1 of the S7-200.

3. Ensure that the DIP switchesof

-

-

12345678

RS-232/PPI

Multi-Master Cable

S7-200

Programming

Device

↑1--On

↓0--Off

theRS-232/PPIMult

i-Mastercable

are set as shown in Figure 2-2.

Figure 2-2 Connecting the RS-232/PPI Multi-Master Cable

Tip

Examples in this manual use the RS-232/PPIMulti-Master cable. The RS-232/PPIMulti-Master

cable replaces the previous PC/PPIcable. A USB/PPIMulti-Master cable is also available.

Refer to Appendix E for ordernumbers.

Starting STEP 7--Micro/WIN

Click on the STEP 7--Micro/WIN icon to

open a new project. Figure 2-3 shows a

new project.

Notice the navigation bar.You can use

the icons on the navigation bar to open

elements of the STEP 7--Micro/WIN

project.

Click on the Communications icon in the

navigation bartodisplay the

Communicationsdialog box. Youuse

this dialog box to set up the

communicationsforSTEP7--Micro/WIN.

Navigation bar

Communications icon

Figure 2-3 New STEP 7--Micro/WIN Project

S7-200 Programmable Controller System Manual

10

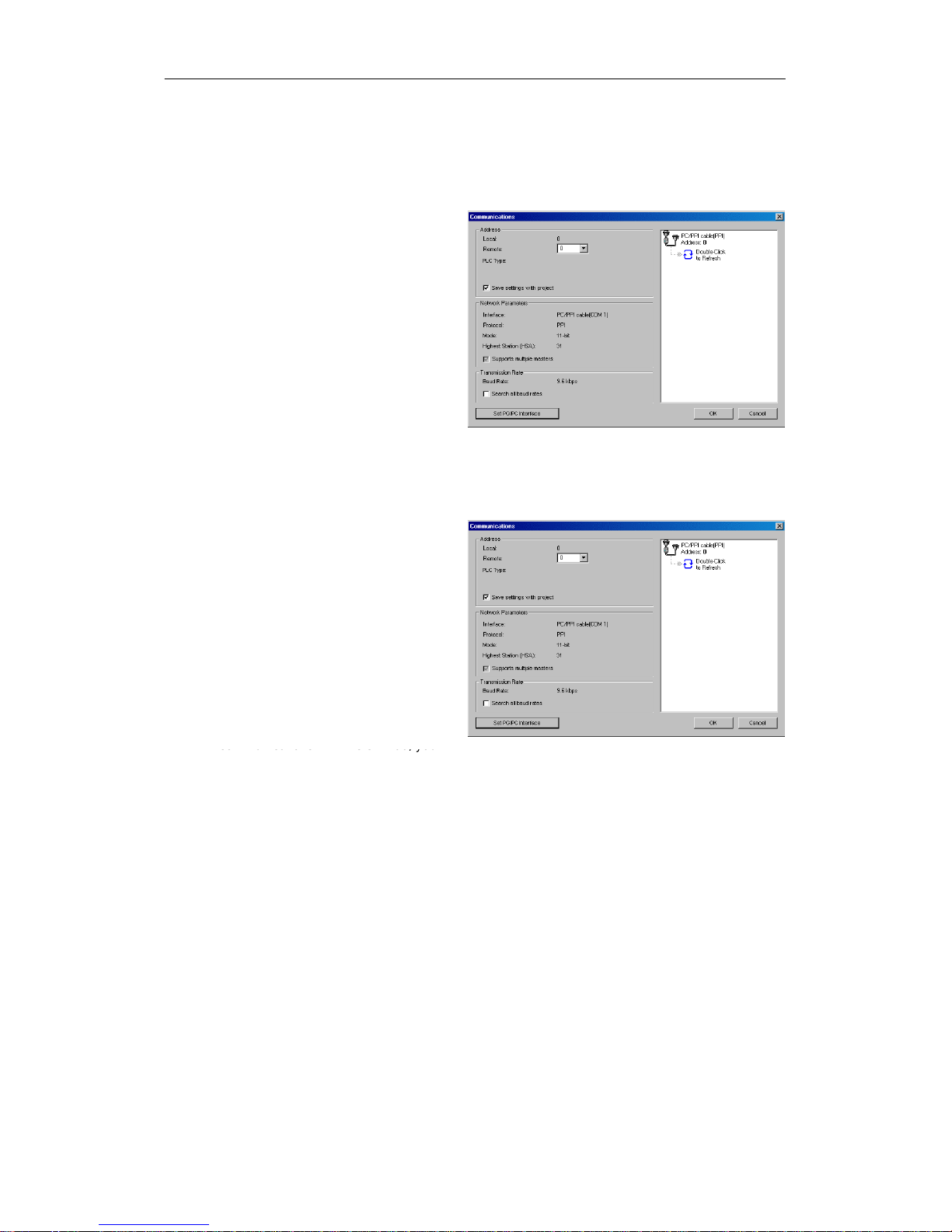

Verifying the Communications Parameters for STEP 7--Micro/WIN

The example project uses the defaultsettings for STEP 7-- Micro/WIN and the RS-232/PPI

Multi-Master cable.To verify these settings:

1. Verify that the address of the

PC/PPI cable in the

Communicationsdialog box is set

to 0.

2. Verify that the interface for the

network parameteris set for

PC/PPI cable(COM1).

3. Verify that the transmission rateis

set to 9.6 kbps.

If you need to change your

communicationsparameter settings, see

Chapter 7.

Figure 2-4 Verifying the Communications Parameters

Establishing Communications with the S7 -200

Use the Communications dialogbox to connect withyourS7-200CPU:

1. Double-clicktherefresh icon in the

Communicationsdialog box.

STEP 7--Micro/WINsearchesfor

the S7-200 stationand displaysa

CPU icon fortheconnected

S7-200 station.

2. Select the S7-200 and click OK.

If STEP 7--Micro/WINdoes not findyour

S7-200 CPU, check the settings forthe

communicationsparameters and repeat

these steps.

After you have established

communicationswith the S7-200, you

coucatostteS00,yo

u

are ready to create and download the

example program.

Figure 2-5 Establishing Communications to the S7-200

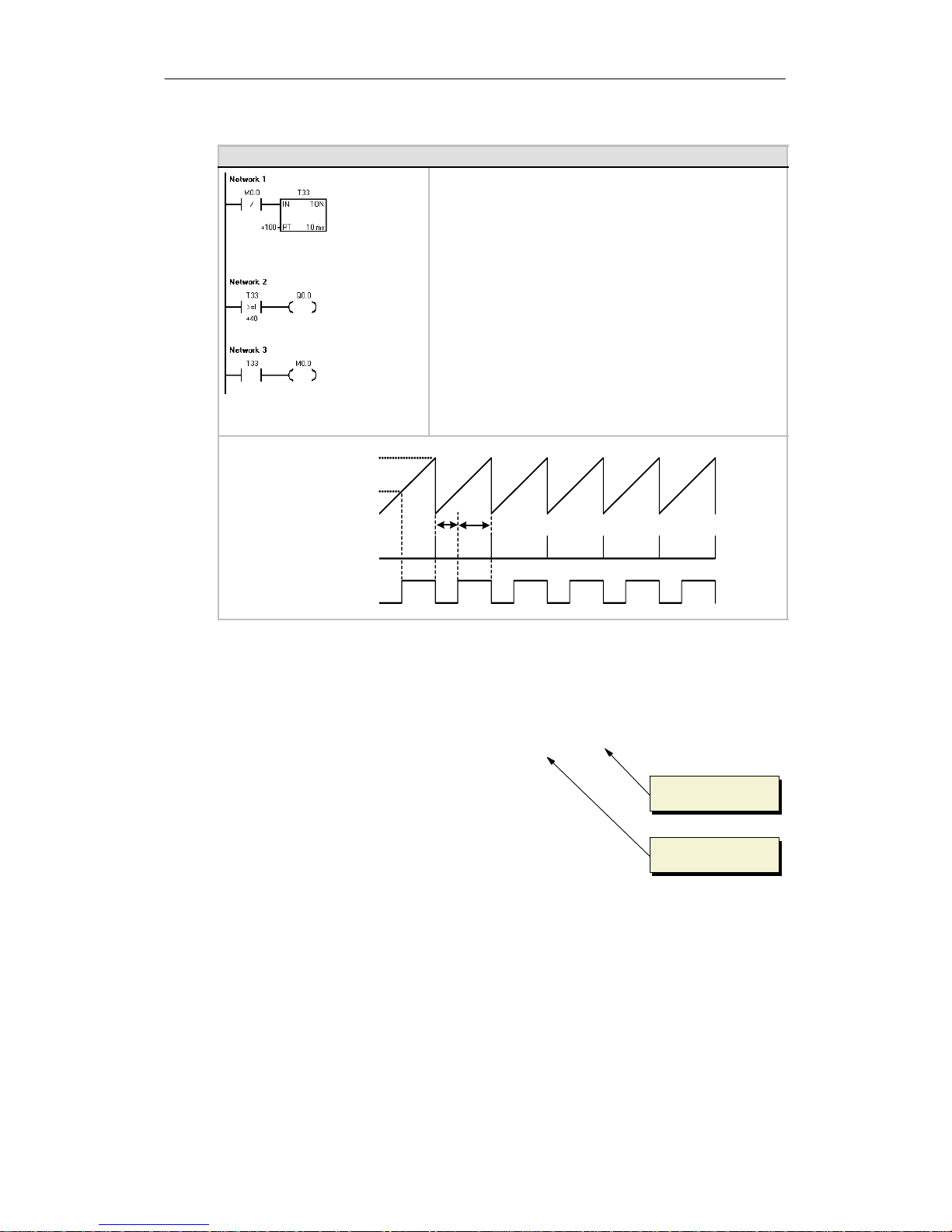

Creating a Sample Program

Entering thisexample of a control programwillhelp you understandhow easy it is to use

STEP 7--Micro/WIN.This program uses six instructions in three networks to createa very simple,

self-starting timer that resets itself.

For this example,you use the Ladder (LAD)editor to enter the instructions for the program. The

followingexampleshows the complete program in both LAD and Statement List(STL). The

network comments in the STL programexplain the logic foreachnetwork. The timing diagram

shows the operation of the program.

Getting Started Chapter 2

11

Example: Sample Program for getting started with STEP 7--Micro/WIN

Network 1 //10 ms timer T33 times out after

//(100 x 10 ms = 1 s) M0.0 pulse is

// too fast to monitorwithStatusview.

LDN M0.0

TON T33, +100

Network 2 //Comparison becomes true at a

//rate that is visible with

//Status view. Turnon Q0.0 after

//(40 x 10 ms = 0.4s), fora

// 40% OFF/60% ON waveform.

LDW>= T33, +40

=Q0.0

Network 3 //T33 (bit) pulse too fast to monitor with

//Status view. Reset the timer through

//M0.0 after the (100 x 10 ms = 1 s) period.

LD T33

=M0.0

0.4s

0.6s

Timing Diagram

current = 100

current = 40

T33 (current)

T33 (bit)

M0.0

Q0.0

Opening the Program Editor

Click on the Program Block icon to open

the program editor. See Figure 2-6.

Notice the instruction tree and the

program editor. Youuse theinstruction

tree to insert the LAD instructions into

the networks of the programeditor by

dragging and dropping the instructions

from the instruction tree to the networks.

The toolbar icons provideshortcuts to

the menu commands.

After you enterand save the program,

you can download the program to the

S7-200.

Instruction tree

Program editor

Figure 2-6 STEP 7--Micro/WIN Window

S7-200 Programmable Controller System Manual

12

Entering Network 1: Starting the Timer

When M0.0 is off(0), this contact turns on and provides power flow to startthetimer. To enter the

contact forM0.0:

1. Either double-click the Bit Logic

icon or click on the plus sign (+) to

display the bitlogic instructions.

2. Select the Normally Closed

contact.

3. Hold down the left mouse button

and drag the contact onto the first

network.

4. Click on the “???” above the

contact and enter the following

address: M0.0

5. Press the Return key to enter the

address for the contact.

Figure 2-7 Network 1

To enter the timer instruction for T33:

1. Double-clicktheTimers icon to displaythetimer instructions.

2. Select the TON (On-Delay Timer).

3. Hold down the left mouse button and drag the timeronto the first network.

4. Click on the “???” above the timerbox and enter thefollowing timernumber: T33

5. Press the Return key to enter the timernumber and to move the focus to the presettime

(PT) parameter.

6. Enter the following value forthepresettime: 100

7. Press the Return key to enter the value.

Entering Network 2: Turning the Output On

When the timervalueforT33isgreater than or equal to 40 (40 times 10 milliseconds, or 0.4

seconds), the contactprovides power flow to turn on outputQ0.0oftheS7-200. To enter the

Compare instruction:

1. Double-clicktheCompareicon to display the compare instructions. Select the >=I

instruction (Greater-Than-Or-Equal-To-Integer ).

2. Hold down the left mouse button

and drag the compare instruction

onto the second network.

3. Click on the “???” above the

contact and enter the address for

the timervalue:T33

4. Press the Return key to enter the

timernumberandtomove the

focus to the other value to be

compared with the timervalue.

5. Enter the following value to be

compared with the timervalue: 40

p

6. Press the Return key to enter the

value.

Figure 2-8 Network 2

To enter the instruction forturning on outputQ0.0:

1. Double-clicktheBitLogic icon to displaythebitlogic instructions and select the outputcoil.

2. Hold down the left mouse button and drag the coilontothesecond network.

3. Click on the “???” above the coil and enter the following address: Q0.0

4. Press the Return key to enter the address forthecoil.

Getting Started Chapter 2

13

Entering Network 3: Resetting the Timer

When the timerreachesthepresetvalue (100)and turnsthetimer bit on, the contact for T33 turns

on. Power flow fromthis contactturns on the M0.0 memory location.Because the timer is enabled

by a Normally Closed contact forM0.0, changing the state of M0.0 fromoff (0) to on (1) resets the

timer.

To enter the contact for the timerbitof

T33:

1. Select the Normally Open contact

from the bitlogic instructions.

2. Hold down the left mouse button

and drag the contact onto the third

network.

3. Click on the “???” above the

contact and enter the address of

the timerbit: T33

4.PresstheReturnkeytoenterthe

address for the contact.

Figure 2-9 Network 3

To enter the coil for turning on M0.0:

1. Select the outputcoilfrom the bit logicinstructions.

2. Hold down the left mouse button and drag the outputcoilonto the third network.

3. Double-clickthe“???”above the coil and enterthefollowing address: M0.0

4. Press the Return key to enter the address forthecoil.

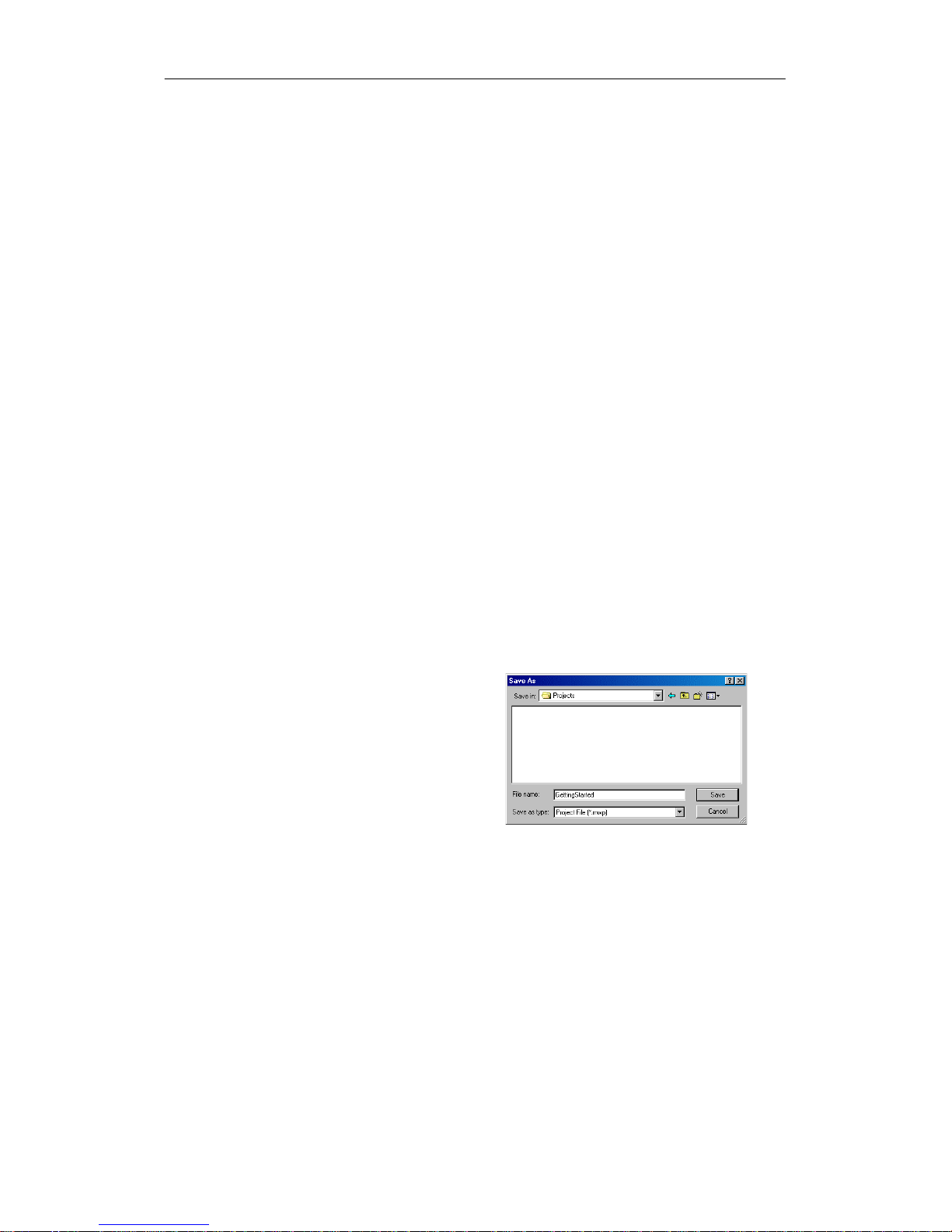

Saving the Sample Project

After entering the three networksofinstructions,you have finishedentering the program. When

you save the program, you create a projectthatincludes the S7-200 CPU type and other

parameters.To save the project:

1. Select the File > Save As menu

command from the menu bar.

2. Enter a name for the projectinthe

Save As dialog box.

3. Click OK to save the project.

After saving theproject, you can

download the program to the S7-200.

Figure 2-10 Saving the Example Program

S7-200 Programmable Controller System Manual

14

Downloading the Sample Program

Tip

Each STEP 7--Micro/WIN projectisassociated with a CPU type (CPU 221, CPU 222, CPU 224,

CPU 224XP, or CPU 226). If the project type does not match the CPU to which you are

connected, STEP 7--Micro/WINindicates a mismatchandprompts you to take an action. Ifthis

occurs, choose “ContinueDownload”for this example.

1. Click the Download icon on the

toolbar orselectthe

File > Download menu command

to download the program.See

Figure 2-11.

2. Click OK to download the elements

of the program to the S7-200.

If your S7-200 is in RUN mode, a dialog

box prompts you to place the S7-200 in

STOP mode. ClickYes to place the

S7-200 into STOP mode.

Figure 2-11 Downloading the Program

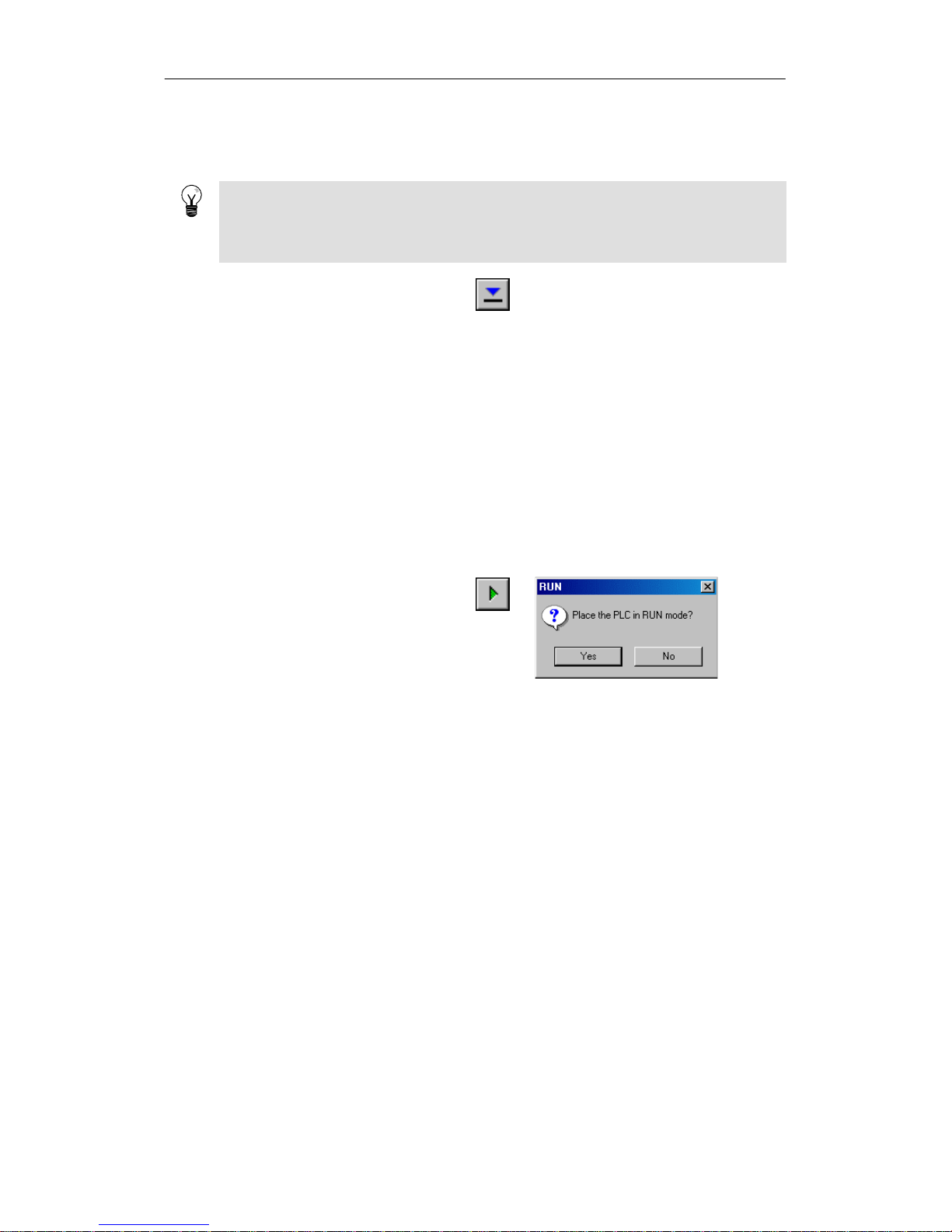

Placing the S7-200 in RUN Mode

For STEP 7--Micro/WIN to place the S7-200CPU in RUN mode, the mode switch of the S7-200

must be set to TERM or RUN. When you place the S7-200 in RUN mode, the S7-200 executes

the program:

1. Click the RUN icon on the toolbar

or select the PLC > RUN menu

command.

2. Click OK to change the operating

mode of the S7-200.

When the S7-200 goes to RUN mode,

g

the outputLED for Q0.0 turns on and o

f

f

as the S7-200 executes the program.

Figure 2-12 Placing the S7-200 in RUN Mode

Congratulations! You have just completed your first S7-200 program.

You can monitor the programby selecting the Debug > Program Status menu command.

STEP 7--Micro/WINdisplays the values for the instructions. To stop the program, place the S7-200

in STOP mode by clicking the STOPiconorbyselecting the PLC > STOP menu command.

15

Installing the S7-200

The S7-200 equipment is designed to be easy to install.You can use the mounting holes to attach

the modules to a panel, or you can use the built-inclips to mount the modules onto a standard

(DIN)rail. The small size of the S7-200 allows you to make efficientuseofspace.

This chapter providesguidelines forinstalling and wiring your S7-200 system.

In This Chapter

Guidelines for Installing S7-200 Devices 16............................................

Installing and Removing the S7-200 Modules 17........................................

Guidelines forGrounding and Wiring 20...............................................

S7-200 Programmable Controller System Manual

16

Guidelines for Installing S7-200 Devices

You can install an S7-200 eitheron a panel or on a standard rail,andyou can orientthe S7-200

either horizontally or vertically.

Warning

The SIMATIC S7-200 PLCs are Open TypeControllers. It is requiredthatyouinstall the S7-200

in a housing, cabinet,orelectric control room. Entry to thehousing,cabinet, or electric control

room should be limitedto authorized personnel.

Failure tofollow these installation requirements could result in deathorserious injury to

personnel, and/ordamagetoequipment.

Always followtheserequirements when installing S7-200 PLCs.

Separate the S7-200 Devices from Heat, High Voltage, and Electrical

Noise

As a general rule for layingoutthedevicesofyoursystem, always separate the devices that

generate high voltageand high electrical noise from the low-voltage,logic-type devices such as

the S7-200.

When configuringthelayoutof the S7-200 inside your panel, consider the heat-generating

devices and locate the electronic-type devices in the cooler areasofyourcabinet. Operating any

electronicdeviceinahigh-temperature environment willreduce the timetofailure.

Consider also the routing of the wiring forthedevicesinthepanel.Avoid placing low voltage

signal wires and communications cables in the same tray with AC power wiringand high-energy,

rapidly-switched DC wiring.

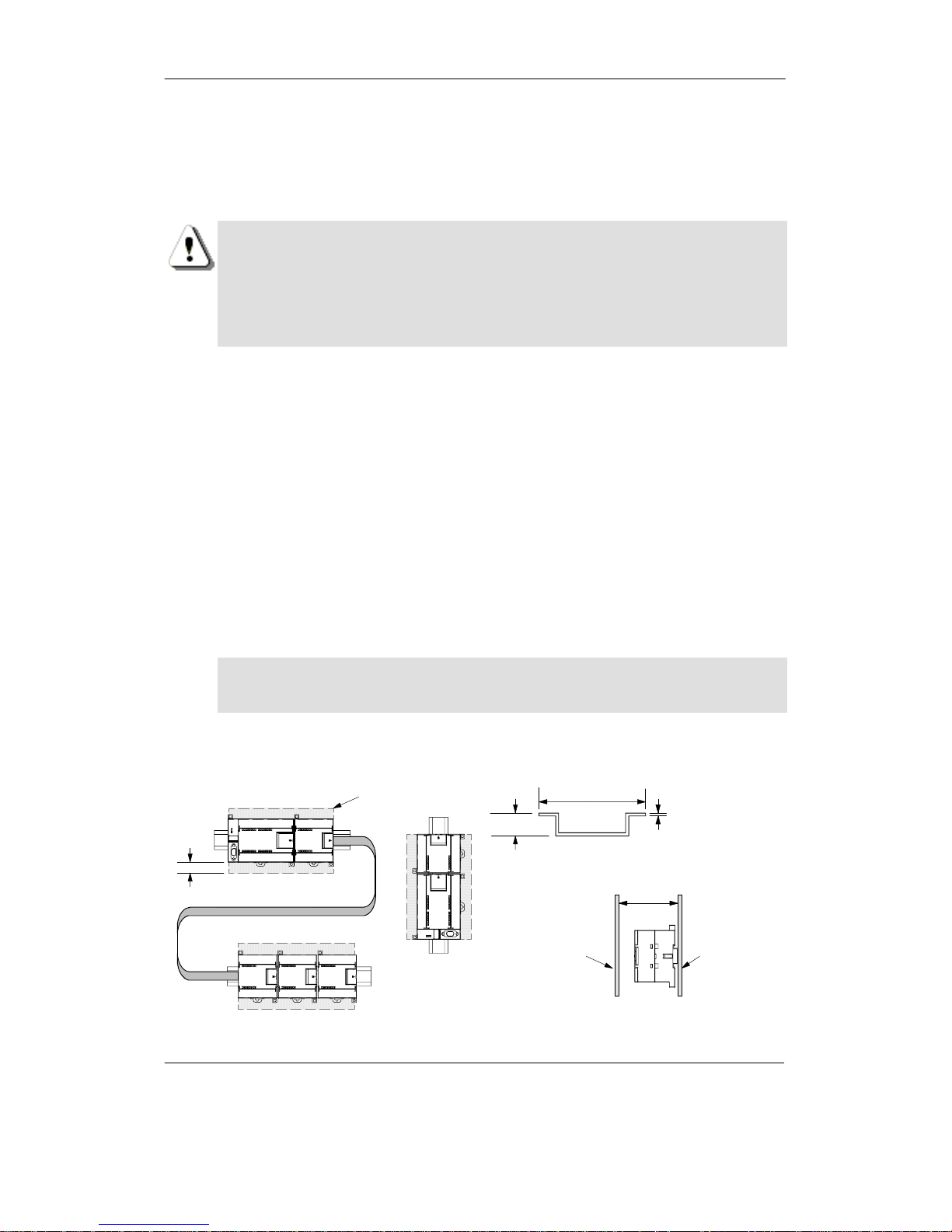

Provide Adequate Clearance for Cooling and Wiring

S7-200 devices are designed for naturalconvection cooling. For proper cooling, you must provide

a clearance of at least 25 mm above and below the devices. Also, allowatleast75 mm of depth.

Caution

For verticalmounting, the maximumallowable ambienttemperature is reducedby

10 degrees C. Mount the S7-200 CPU below any expansion modules.

When planning your layout forthe S7-200 system, allow enough clearanceforthe wiring and

communicationscableconnections. For additional flexibility in configuring the layout of the S7-200

system, use the I/Oexpansioncable.

75 mm

Frontofthe

enclosure

Side View

Mounting

surface

35 mm

7.5 mm

1mm

DIN Rail

25 mm

Clearance

Horizontal DIN Rail Mounting with Optional

Expansion Cable (limit one per system)

Vertical Panel

Mounting

Figure 3-1 Mounting Methods, Orientation, and Clearance

Loading...

Loading...