Siemens SIMATIC S7-1500,SIMATIC ET 200SP Configuration Manual

https://support.industry.siemens.com/cs/ww/de/view/109741600

Application Example 11/2016

Configuration manual

“Shared Device”

SIMATIC S7-1500 / ET 200SP

Warranty and Liability

SharedDeviceKonfig

Entry ID: 109741600, V1.0, 11/2016

2

Siemens AG 2016 All rights reserved

Warranty and Liability

Note

The Application Examples are not binding and do not claim to be complete with

regard to configuration, equipment or any contingencies. The Application

Examples do not represent customer-specific solutions. They are only intended

to provide support for typical applications. You are responsible for the correct

operation of the described products. These Application Examples do not relieve

you of the responsibility of safely and professionally using, installing, operating

and servicing equipment. When using these Application Examples, you

recognize that we cannot be made liable for any damage/claims beyond the

liability clause described. We reserve the right to make changes to these

Application Examples at any time and without prior notice. If there are any

deviations between the recommendations provided in this Application Example

and other Siemens publications – e. g. catalogs – the contents of the other

documents shall have priority.

We do not accept any liability for the information contained in this document.

Any claims against us – based on whatever legal reason – resulting from the use of

the examples, information, programs, engineering and performance data etc.,

described in this Application Example shall be excluded. Such an exclusion shall

not apply in the case of mandatory liability, e.g. under the German Product Liability

Act (“Produkthaftungsgesetz”), in case of intent, gross negligence, or injury of life,

body or health, guarantee for the quality of a product, fraudulent concealment of a

deficiency or breach of fundamental contractual obligations (“wesentliche

Vertragspflichten”). The compensation for damages due to a breach of a

fundamental contractual obligation is, however, limited to the foreseeable damage,

typical for the type of contract, except in the event of intent or gross negligence or

injury to life, body or health. The above provisions do not imply a change of the

burden of proof to your detriment.

Any form of duplication or distribution of these Application Examples or excerpts

hereof is prohibited without the expressed consent of Siemens AG.

Security

informati

on

Siemens provides products and solutions with Industrial Security functions that

support the secure operation of plants, solutions, machines, equipment and/or

networks. They are important components in a holistic Industrial Security

concept. With this in mind, Siemens’ products and solutions undergo continuous

development. Siemens recommends strongly that you regularly check for

product updates.

For the secure operation of Siemens products and solutions, it is necessary to

take suitable preventive action (e.g. cell protection concept) and integrate each

component into a holistic, state-of-the-art Industrial Security concept. Third-party

products that may be in use should also be considered. For more information

about Industrial Security, visit http://www.siemens.com/industrialsecurity.

To stay informed about product updates as they occur, sign up for a productspecific newsletter. For more information, visit

http://support.industry.siemens.com..

Table of Contents

SharedDeviceKonfig

Entry ID: 109741600, V1.0, 11/2016

3

Siemens AG 2016 All rights reserved

Table of Contents

Warranty and Liability ................................................................................................. 2

1 Task and Solution .............................................................................................. 4

1.1 Task description ................................................................................... 4

1.2 Possible solutions ................................................................................. 4

2 Fundamentals on “Shared Device” ................................................................. 6

3 Configuration ..................................................................................................... 8

3.1 Infrastructure information ..................................................................... 8

3.2 Configuring a “Shared Device” ............................................................. 9

3.2.1 Configuration of project 1 ..................................................................... 9

3.2.2 Configuration of project 2 ................................................................... 12

3.2.3 Adjusting the real time settings .......................................................... 15

3.2.4 Compiling and loading ........................................................................ 17

3.3 Diagnostics with “Shared Device” ...................................................... 18

4 References ....................................................................................................... 20

5 History............................................................................................................... 20

1 Task and Solution

SharedDeviceKonfig

Entry ID: 109741600, V1.0, 11/2016

4

Siemens AG 2016 All rights reserved

1 Task and Solution

1.1 Task description

Description

For bigger or widely dispersed plants, multiple IO controllers are frequently used.

Every peripheral module of an IO device is assigned to a particular IO controller. If

sensors spatially close to one another must send data to different IO controllers,

multiple IO devices are required.

In this configuration description, an IO device shall be assigned to multiple IO

controllers.

Requirements

The following requirements have to be considered:

Reduction of the required network and system components

Sustained reduction of engineering costs and commissioning time

Easy communication between multiple IO controllers and an IO device.

1.2 Possible solutions

Description

The function “Shared Device” allows splitting up the modules of an IO device

between different IO controllers. This distribution allows flexible automation

concepts. You have the possibility, for example, to summarize peripheral modules

spatially close to one another into one IO device.

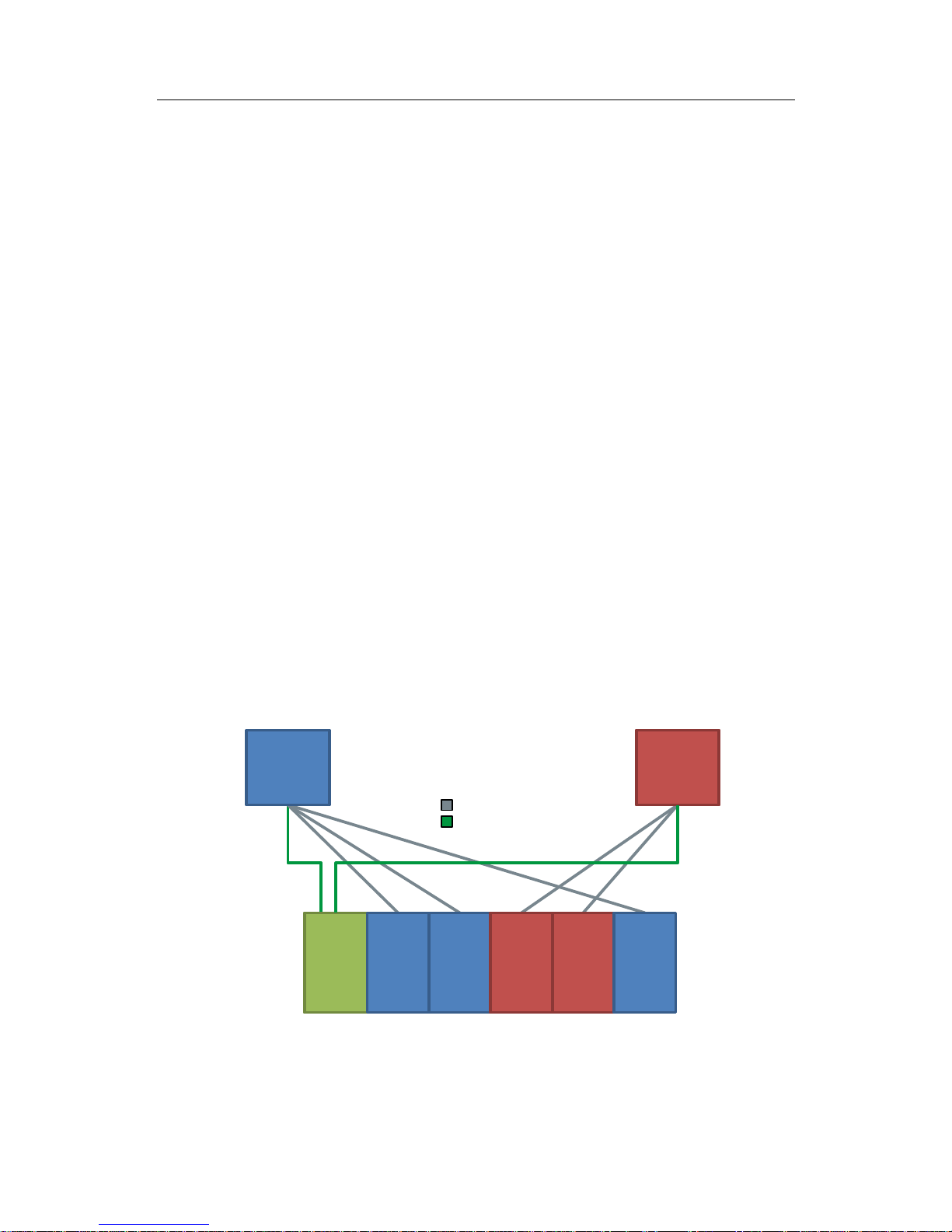

Diagrammatic representation

The following figure schematically shows the function “Shared Device”:

Figure 1-1

IO

Controller

1

IO

Controller

2

IO

Device

Module 1Module 2Module

3

Module

4

Module

5

PROFINET

Logical Assignment

Shared Device allows a shared use of IO devices via multiple IO controllers without

additional CPU-CPU communication.

1 Task and Solution

SharedDeviceKonfig

Entry ID: 109741600, V1.0, 11/2016

5

Siemens AG 2016 All rights reserved

Advantages

The solution presented here offers you the following advantages:

Lower costs through the reduction of additional IO devices and modules.

Real time capture in several CPUs.

Lower space requirements through the reduction of additional IO devices and

modules.

Lower communications burden through the suspension of CPU-CPU

communication.

No additional programming work for CPU-CPU communication.

Prerequisite

The following prerequisites must be met in order to use the “Shared Device”

function:

STEP 7 V12 SP 1 or higher

CPU as of FW 1.1 or higher as IO controller

IO device supports the “Shared Device” function

Note

IO controllers that use the “Shared Device” function, are created in different

projects.

In every project, you must ensure that the “Shared Device” is configured the

same at every station.

Characteristics with I-Device

If you use “I-Device” and the “Shared Device” function in parallel, please bear the

following conditions in mind:

A S7-1500-CPU configured as I-Device supports the “Shared Device” function

from firmware V1.5 or higher. The I-Device needs to be integrated into the IO

controller’s IO system via a GSD import.

A S7-300-CPU or a S7-400-CPU configured as I-Device supports the “Shared

Device” function. You need to export the PROFINET-GSD file for the I-Device

from STEP 7 (from V5.5 or higher) and then import it in STEP 7 (TIA Portal).

A ET 200SP-CPU configured as I-Device supports the “Shared Device”

function from firmware V1.6 or higher. The I-Device needs to be integrated into

the IO controller’s IO system via a GSD import.

2 Fundamentals on “Shared Device”

SharedDeviceKonfig

Entry ID: 109741600, V1.0, 11/2016

6

Siemens AG 2016 All rights reserved

2 Fundamentals on “Shared Device”

Explanation of terms

An IO device whose modules are used by different IO controllers is referred to as

“Shared Device”.

The access to the modules of the “Shared Device” is split up between the different

IO controllers. Every module of the “Shared Device” is exclusively assigned to a

particular IO controller.

Functionality “Shared Device”

The function “Shared Device” allows splitting up the modules of an IO device

between different IO controllers. Thereby, several IO controllers can access the

same IO device without CPU-CPU communication. You have the possibility, for

example, to summarize peripheral modules spatially close to one another into one

IO device.

Note

The “Shared Device” allows you to build up an IO device from F- and default

modules and assign each module according to the F-CPU or default CPU.

Thus, the F-CPU can control a safe F-Power module for a failsafe F-shutdown

and a robot can use the default inputs/outputs in the same station.

Access of IO controllers to “Shared Device”

In the Engineering Tool via the “Shared Device” parameter of the interface module,

it can be determined to which modules the IO controller has access to:

If the local IO controller has access to the configured module, select the IO

controller’s name from the list.

If not the local IO controller but the IO controller from another project shall have

access to the configured module, select the entry “---”. If every module in just

one project is assigned to one IO controller, then access-wise, the

configuration is consistent.

If an IO controller does not have access to a module (entry “--”), the following

consequences apply:

A data exchange with the module is not possible.

Alarms and diagnostics cannot be received, meaning that in the online view,

the diagnostic status will not be displayed.

Configuring the module is not possible.

Setting the real-time properties

STEP 7 calculates the communications burden and the resulting update times. In

order to allow a calculation for “Shared Device” configurations, you need to enter

the number of project-external IO controllers into the project where the PROFINET

interface of the “Shared Device” is assigned to the IO controller. The maximum

possible number of IO controllers for the “Shared Device” is device-dependent.

This number is stored in the GSD file of the “Shared Device”. If the IO controller is

a CPU, you can set a very short send clock. The send clock can be shorter than

the shortest sending rate supported by the “Shared Device”. In this case, the

“Shared Device” will be operated by the IO controller with a send clock that it

supports (send clock adaption).

Loading...

Loading...