Page 1

RFID SYSTEMS

Mobile Reader

Function Manual · 02/2009

Valid for the following products:

SIMATIC RF310M

SIMATIC RF610M

SIMATIC Sensors

Page 2

Page 3

SIMATIC Sensors

RFID Systems

Mobile Reader

Function Manual

Introduction

RFID Reader Interface

User's Guide

RFID Reader Interface

Reference

1

2

3

Valid for the following products:

SIMATIC RF310M

SIMATIC RF610M

02/2009

J31069-D0198-U001-A1-0076

Page 4

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

J31069-D0198-U001-A1-0076

Ⓟ 02/2009

Copyright © Siemens AG 2007, 2009.

Technical data subject to change

Page 5

Table of contents

1 Introduction................................................................................................................................................ 7

2 RFID Reader Interface User's Guide......................................................................................................... 9

2.1 RFID Reader Interface...................................................................................................................9

2.2 How Do I Use the Reader Interface?...........................................................................................10

2.2.1 Tools Needed...............................................................................................................................10

2.2.2 Creating the Application...............................................................................................................11

2.2.3 Starting the RFID reader..............................................................................................................12

2.2.4 Compile and Run .........................................................................................................................15

2.2.5 I Want To See Tags… .................................................................................................................18

2.2.6 Know More about the Tags … .....................................................................................................19

2.2.7 Change the Tags' Data ................................................................................................................20

2.2.8 Summary......................................................................................................................................21

2.3 Extending the Reach....................................................................................................................22

2.3.1 Being Part of a Larger Family ......................................................................................................22

2.3.2 Entering the system .....................................................................................................................24

2.3.3 Wake me up before you go… ......................................................................................................25

2.3.4 We are started: What to make out of it? ......................................................................................29

2.3.5 Jerry’s tag monitoring scenario revisited .....................................................................................30

2.3.6 I’m all ears....................................................................................................................................31

2.3.7 Not without my approval ..............................................................................................................34

2.3.8 Make it fun: Working keys............................................................................................................36

2.3.9 Summary......................................................................................................................................39

3 RFID Reader Interface Reference ........................................................................................................... 41

3.1 The Interface................................................................................................................................41

3.2 RfReaderApi.Current ...................................................................................................................42

3.3 RfReaderApiException.................................................................................................................42

3.4 IRfReaderApi................................................................................................................................43

3.4.1 Version.........................................................................................................................................43

3.4.2 StartReader..................................................................................................................................44

3.4.3 StopReader..................................................................................................................................45

3.4.4 ReaderStatus ...............................................................................................................................46

3.4.5 AirProtocol....................................................................................................................................47

3.4.6 SetAirProtocol ..............................................................................................................................47

3.4.7 SetTagID......................................................................................................................................49

3.4.8 GetTagIDs....................................................................................................................................50

3.4.9 GetTagMemory ............................................................................................................................51

3.4.10 SetTagMemory.............................................................................................................................53

3.4.11 .....................................................................................................................................................55

3.4.14 LockEPCGen2Tag .......................................................................................................................59

3.4.15 LockIsoTag...................................................................................................................................62

3.4.16 SetTrigger ....................................................................................................................................63

3.4.17 SubscribeForNotifications ............................................................................................................64

3.4.18 UnsubscribeForNotifications ........................................................................................................65

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

5

Page 6

Table of contents

3.4.19 SetTagEvents.............................................................................................................................. 66

3.4.20 SubscribeForAlarms.................................................................................................................... 67

3.4.21 UnsubscribeForAlarms................................................................................................................ 68

3.4.22 GetConfigParameter ................................................................................................................... 69

3.4.23 TagEventNotification ................................................................................................................... 71

3.4.24 Alarms ......................................................................................................................................... 73

3.4.25 Information .................................................................................................................................. 74

3.5 References.................................................................................................................................. 75

Mobile Reader

6 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 7

Introduction

This document describes the RFID Reader Interface for the SIMATIC handheld systems

RF610M and RF310M and how this interface can be utilized.

The document consists of two parts. The first part gives you an overview of how the RFID

Reader Interface can be used and the second part contains a detailed reference description

of the RFID Reader Interface.

While this document describes the usage of the RFID module within the handheld device it

neither includes nor describes how other features of the device such as barcode detection,

WLAN or updates of the operating system itself are used. You have to directly contact the

device vendor PSION in order to get software and support for these features.

With the version V1.1 of the RF610M device and the RFID Reader Interface some of the

topics above will be covered. You get an overview regarding topics such as WLAN and

barcode by consulting the RF610M device manual. Detailed developer information, however,

is still to be retrieved from the device vendor PSION directly.

This new version of RF610M will also be integrated in the SIMATIC RF-MANAGER 2008

product which allows you to configure RF610M devices to work in integrated scenarios. As

far as these scenarios deal with issues such as barcode handling, these issues will be

covered in this document either at least from a functional perspective.

This document will use the short form RF-MANAGER as an abbreviation for convenience

when speaking of SIMATIC RF-MANAGER 2008.

1

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

7

Page 8

Introduction

Mobile Reader

8 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 9

RFID Reader Interface User's Guide

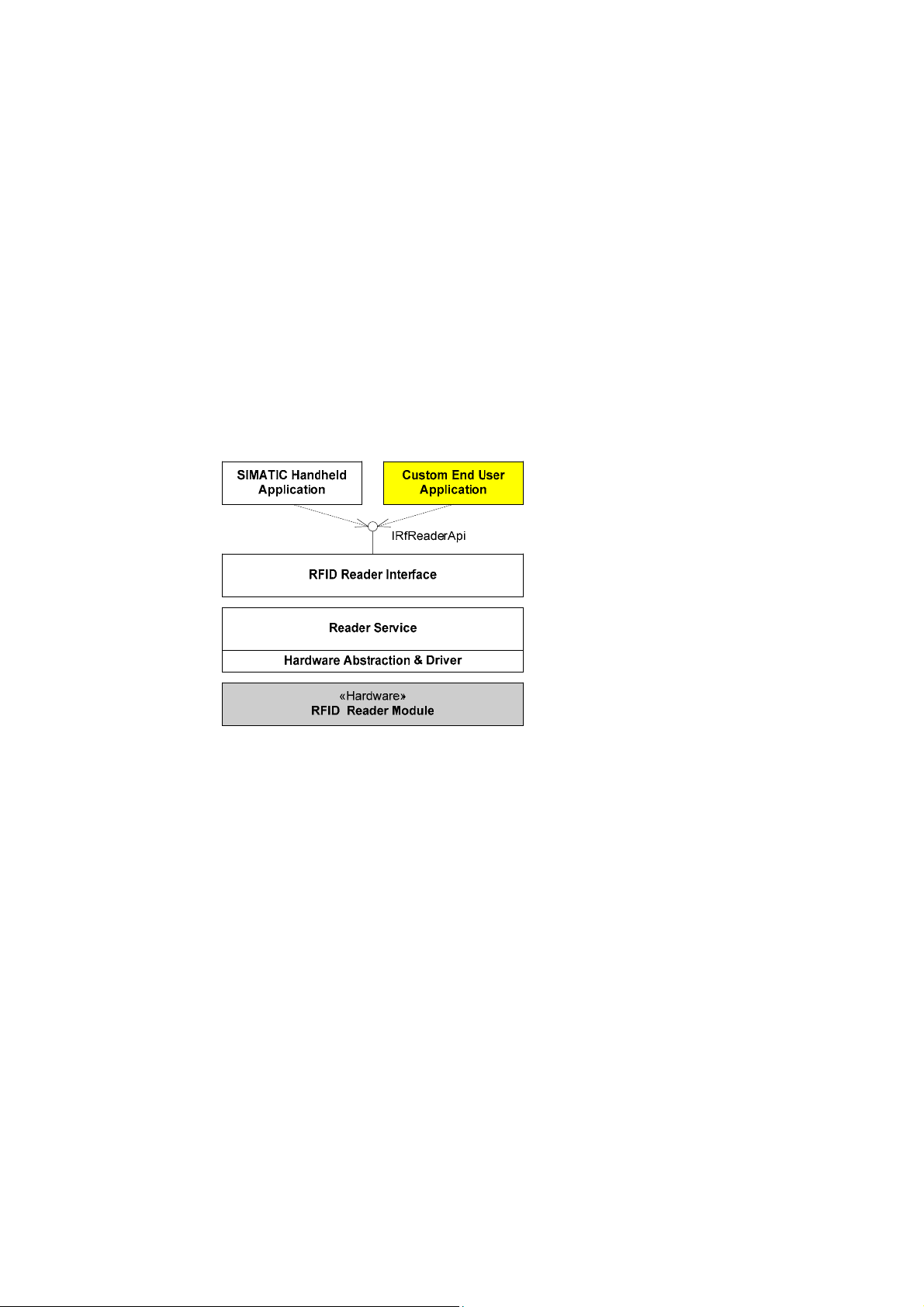

2.1 RFID Reader Interface

Simatic Handheld devices enable end users to acquire tag data from any place without the

limitations of a cable-bound system. It provides the hardware as well as a software

application to use the features of the mobile reader.

Figure 2-1 Software system structure on a SIMATIC Handheld device.

2

The Figure above shows the main components of a SIMATIC Handheld device. Obviously, a

piece of hardware is necessary – the RFID Reader Module – to acquire RFID information.

The capabilities of this hardware are accessed by a driver that is also used by the reader

service which is the software component that controls all RFID features.

The Simatic Handheld application utilizes the reader service's features and provides

customers with a user interface that can trigger all RFID features made available by the

reader service (IRfReaderApi). However, the application has no information on the special

requirements or the business processes of end customers.

Since a single application can almost never meet every need of every customer, another

approach is used. Instead of inflating the application with a large number of possible options

while still missing others, only the basic features are supported.

To facilitate the end user's needs, these basic functions are provided by an interface that

allows custom applications to fully exploit all RFID features with programming and to add the

customer's own workflows and relationships to suit his needs.

It would have been possible to directly access the reader service component via an interface

that extends the EPC standards. However, these standards are complicated and use many

internal concepts and entities. You do neither need nor probably want to know these details

if your only objective is to simply access and write data to RFID tags. That is why all this

complexity is hidden behind a simple interface - the RFID Reader Interface.

The following sections will explain how to use this interface in your work. Detailed

information about all the functions provided by this interface is given in the next chapter.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

9

Page 10

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

2.2 How Do I Use the Reader Interface?

So far, so good. We have learned that there is an easy way to access the RFID features of a

handheld device. But how do we do this?

2.2.1 Tools Needed

First, we will create a small sample application that only reads tags.

What tools will you need?

The interface is a .Net CompactFramework 2.0 SP2 assembly. Logically this requires a

derivate of the Microsoft Visual Studio 2005 as its starting point. Remember that the Express

versions will not be sufficient because they do not allow the installation of additional device

packages. You will need at least the Standard or Professional version of Visual Studio 2005.

Next comes the installation of the software development kit (SDK) from PSION Teklogix.

This software kit is available from developer resources on the PSION TEKLOGIX website

www.psionteklogix.com) after registration.

(

These are all the development tools you need to get started. Although you can now create

applications targeting a handheld device such as the RF610M, you will also need to transfer

the developed software to the handheld device. This means that Microsoft ActiveSync must

also be installed.

Moreover, in order to utilize the RFID features you will also need to reference the RFID

Reader Interface assembly within your applications. This assembly is available on your

handheld device. You can retrieve the file Siemens.Simatic.RfReaderApi.dll via

ActiveSync from the handheld device (\Flash Disk\SIMATIC

xxx\Support\RFID_AP\RFID_API.ZIP) and store it to reference the assembly.

You should now be able to create, deploy and run your custom applications.

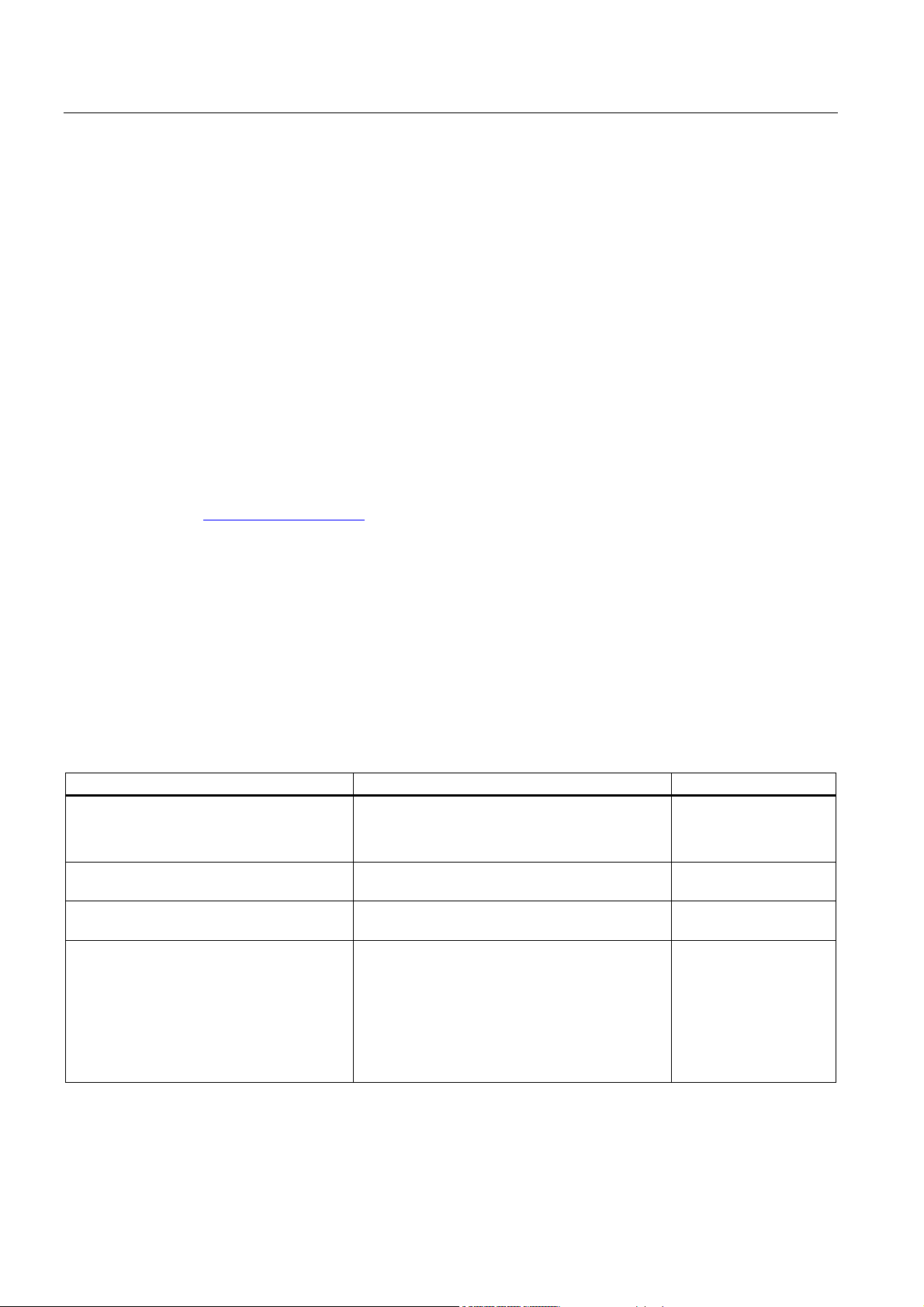

The table below summarizes the required components.

Tool / Component Description Vendor

Microsoft Visual Studio 2005

(at least Standard edition)

(at least CompactFramework 2.0 SP2)

PSION TEKLOGIX Software Development

Kit (SDK)

Microsoft ActiveSync Enables communication between your

Siemens.Simatic.RfReaderApi.dll

rfid_power_commutation.dll

PsionTeklogixRFID.dll

PsionTeklogicNet.dll

PtxSdkCommon.dll

Siemens.Simatic.RfReaderApi.dll.config

The basic development environment Microsoft

Enables creation of applications for Windows CE

devices

development PC and a handheld device

The RFID Reader Interface assembly

Even if this assembly is enough to compile, don’t

forget to provide rfid_power_commutation.dll,

PsionTeklogixRFID.dll, PsionTeklogicNet.dll

PtxSdkCommon.dll and

Siemens.Simatic.RfReaderApi.dll.config for

executing your own application.

PSION

Microsoft

All of these components

are provided on the

device’s flash memory

within a compressed

archive.

Moreover, the sample code of the small demo application developed within the following

chapters is also available on the device’s flash disk.

Mobile Reader

10 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 11

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

2.2.2 Creating the Application

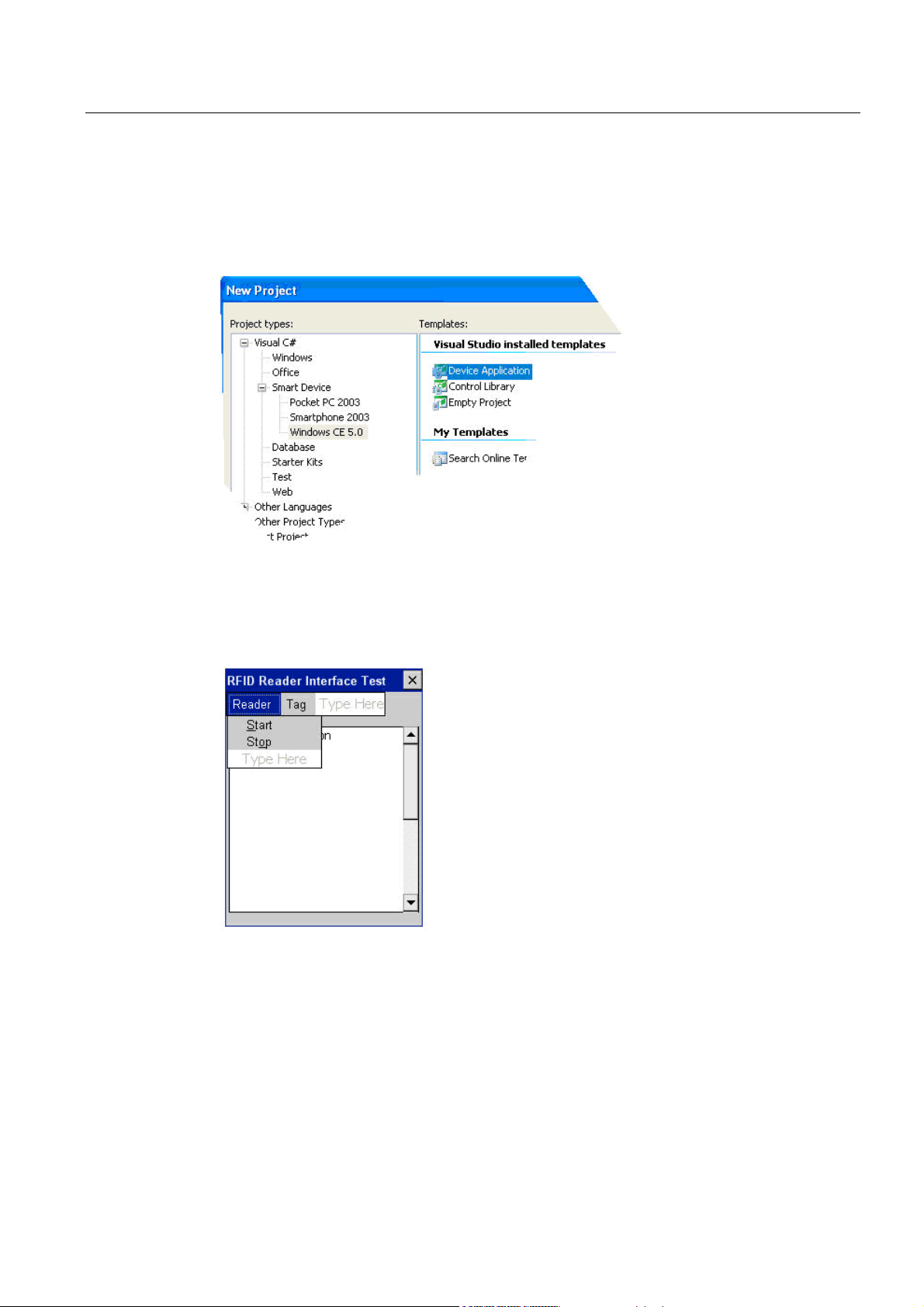

To start a new application for a handheld device, create a new project of type 'Visual

C#\Smart Device\Windows CE 5.0\DeviceApplication' since handheld devices currently run

under Windows CE 5.0.

Figure 2-2 Type of application to create for a handheld device

You will need menu items to start and stop the reader and to trigger a read command.

Moreover, you will provide a textbox to display the results. This gives you a simple GUI as

shown in the following figure.

Figure 2-3 Our simple test application

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

11

Page 12

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

2.2.3 Starting the RFID reader

So far this application has nothing unusual about it. It is not yet connected to RFID. This is

done by coding the event handler for the menu items. The code is provided below. It will be

discussed in detail.

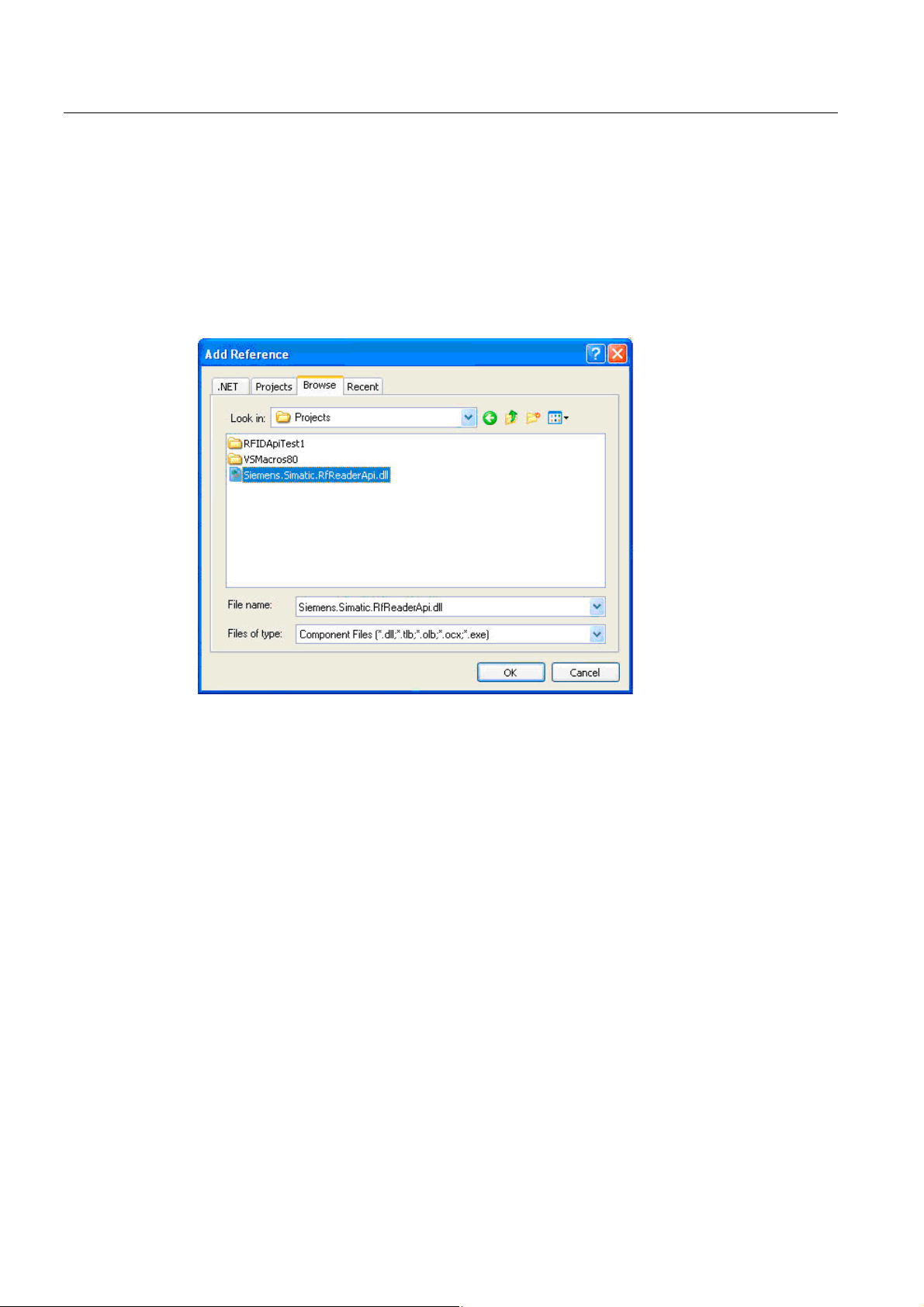

To simplify development, first add a reference to the RFID Reader Interface assembly and a

directive for the namespace Siemens.Simatic.RfReader which enables you to use 'intellisense' on the types provided by the RFID Reader Interface.

Figure 2-4 Adding a reference to the reader interface: Go to where you filed the interface assembly

which you retrieved from the handheld device.

Your first job is to start the reader service (see the RFID management component reader

service in

RFID Reader Interface (Page 9) )

The interface IRfReaderApi provides a method StartReader to accomplish that. Using the

function, however, poses two new questions:

● First, you will need a parameter to provide initialization data. This is done by creating an

object of type RfReaderInitData. The only parameters necessary is the reader type and

the reader mode, which we set to standalone for now. For all other members of

RfReaderInitData we accept the defaults.

● The StartReader function also offers other options that allow you to specify other instance

names or IP Addresses, but, for the time being, you can use the defaults.Now that you

know which function to call, the second task is – where do you obtain an object that

implements the IRfReaderApi interface.

A public static property called RfReaderApi.Current exists that always returns the current

instance of the object which implements the RFID Reader Interface.

What if you start again and no current instance is available? The Current property is

designed to return the current instance of the RFID Reader Interface if one exists or to

create a new one if none exists. If processing is correct, RfReaderApi.Current will always

return a valid instance be it a new one or an existing one. Null is only returned when

internal errors occur. Since this may cause exceptions, you must put a try catch frame

around your calls.

Mobile Reader

12 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 13

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

Another look at our code shows that only four lines of code are needed to start up the reader

service. The code for starting the RFID Reader Interface:

private void menuReaderStart_Click(object sender, EventArgs e)

{

try

{

// We want to create and start an instance of the RFID

// reader interface for a handheld device with a default name.

RfReaderInitData initData = new RfReaderInitData();

// Initialize the appropriate reader type (RF610M, RF310M)

// and reader mode

initData.Type = „RF610M“;

initData.Mode = RfReaderInitData.ReaderMode.Standalone;

// With RfReaderApi.Current we address the current

// RFID reader interface instance

// or initiate the creation of a new instance.

// StartReader connects to an existing reader service

// or creates a new reader service.

RfReaderApi.Current.StartReader(initData);

}

catch (RfReaderApiException rfidException)

{

// Something went wrong while starting the reader.

// More information is available by inspecting the

// RfReaderApiException's members ResultCode, Error,

// Cause and Description.

...

}

}

Stopping a running reader only requires a single call that terminates the connection to the

underlying reader service and shuts it down; The code for stopping the RFID Reader

Interface:

private void menuReaderStop_Click(object sender, EventArgs e)

{

try

{

// Use the current reader interface instance and tell

// it to shut down.

RfReaderApi.Current.StopReader();

}

catch (RfReaderApiException rfidException)

{

// Something went wrong while stopping the reader.

// More information is available by inspecting the

// RfReaderApiException's members ResultCode, Error,

// Cause and Description.

...

}

}

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

13

Page 14

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

A last issue we have to consider is that the RFID reader service needs time to initialize his

internal states. The good news is that after initialization the reader service will use its Alarm

event mechanism to notify clients when it is ready to start work. In order to catch this

information, we have to implement an alarm handler.

The alarm handler function has to comply with the following prototype that defines the

special RfAlarmArgs parameters.

public void AlarmHandler(object sender, RfAlarmArgs alarmArgs)

Before starting the reader we add the alarm handler:

RfReaderApi.Current.Alarms += new RfAlarmHandler(this.AlarmHandler);

Once installed, our AlarmHandler function gives us a chance to notice a successful startup

or restart by catching the ‘Reconfiguration’ and ‘Initial’ alarms:

public void AlarmHandler(object sender, RfAlarmArgs alarmArgs)

{

if (alarmArgs.InfoItems != null)

{

// Configuration has finished

if (alarmArgs.InfoItems[0].Name == "Reconfiguration" &&

alarmArgs.InfoItems[0].Value == "Initial")

{

// This is the very first startup of the application

// Now we can access RFID reader

…

}

}

}

Mobile Reader

14 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 15

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

2.2.4 Compile and Run

Even if tags cannot be read yet, you can create an application to prove that it can at least

start up and shut down. You can improve the visual appearance by indicating the status of

the functions which you called in the results window of your application; The code for starting

the RFID Reader Interface:

private void menuReaderStart_Click(object sender, EventArgs e)

{

try

{

// First, we add an event handler to catch alarm notifications

RfReaderApi.Current.Alarms +=

new RfAlarmHandler(rfmIntegration.AlarmHandler);

// We want to create and start an instance of the RFID

// reader interface for a handheld device with a default name.

RfReaderInitData initData = new RfReaderInitData();

// Initialize the appropriate reader type (RF610M, RF310M)

// and reader mode

initData.Type = „RF610M“;

initData.Mode = RfReaderInitData.ReaderMode.Standalone;

// With RfReaderApi.Current we address the current

// RFID reader interface instance

// or initiate the creation of a new instance.

// StartReader connects to an existing reader service

// or creates a new reader service.

RfReaderApi.Current.StartReader(initData);

WriteInformationLine("Reader started successfully");

}

catch (RfReaderApiException rfidException)

{

// Something went wrong while starting the reader.

// More information is available by inspecting the

// RfReaderApiException's members ResultCode, Error,

// Cause and Description.

WriteInformationLine(string.Format("ERROR: {0} - {1}, cause:

{2}, desc: {3}\r\n",

rfidException.ResultCode, rfidException.Error,

rfidException.Cause, rfidException.Description));

}

}

...

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

15

Page 16

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

public void AlarmHandler(object sender, RfAlarmArgs alarmArgs)

{

if (alarmArgs.InfoItems != null)

{

// Configuration has finished

if (alarmArgs.InfoItems[0].Name == "Reconfiguration" &&

alarmArgs.InfoItems[0].Value == "Initial")

{

// This is the very first startup of the application

// Now we can access RFID reader

reconfiguration");

}

}

}

...

private void WriteInformationLine(string message)

{

WriteInformation(message + "\r\n");

}

private void WriteInformation(string message)

{

// Add the information to the existing text

this.textBoxInfo.Text = this. textBoxInfo.Text + message;

this. textBoxInfo.SelectionStart = this. textBoxInfo.Text.Length;

this. textBoxInfo.ScrollToCaret();

}

WriteInformationLine("INFO: Initial

Compilation should be successful unless you forgot to add the reference to the interface

assembly and the corresponding directive using Siemens.Simatic.RfReader.

Mobile Reader

16 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 17

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

When you deploy your application, there are two things to consider.

● When using Visual Studio to deploy your application, make sure you selected

"PtxPxa27x: ARMV4I_Release as a target device.

● Regardless of how you deploy your application, ensure that all needed system

components are located beneath your application.

This means you must provide the RFID Reader Interface assembly

Siemens.Simatic.RfReaderApi.dll and its configuration file

Siemens.Simatic.RfReaderApi.dll.config.

You also must provide the following Psion-specific files

rfid_power_commutation.dll

PsionTeklogixRFID.dll

PsionTeklogicNet.dll

PtxSdkCommon.dll

All of these are provided on the device’s flash memory within a compressed archive.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

17

Page 18

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

2.2.5 I Want To See Tags…

You are able to start and stop the RFID reader service and would now like to see tags.

Another look at the RfReaderApi interface reveals a member called GetTagIDs. Checking

the return value’s type indicates that you will receive an array of strings containing the read

tag IDs.

You already know how to obtain an instance of an object providing the IRfReaderApi

interface. The code is shown below; The code for reading tag IDs:

private void menuItemReadIDs_Click(object sender, EventArgs e)

{

string[] tagIDs = null;

try

{

// Request all tags that are currently within reach

tagIDs = RfReaderApi.Current.GetTagIDs();

}

catch (RfReaderApiException rfidException)

{

// Something went wrong while reading tags.

// More information is available by inspecting the

// RfReaderApiException's members ResultCode, Error,

// Cause and Description.

WriteInformationLine(string.Format("ERROR: {0} - {1}, cause:

{2}, desc: {3}\r\n",

rfidException.ResultCode, rfidException.Error,

rfidException.Cause, rfidException.Description));

}

// Display read tags ...

if (null != tagIDs && tagIDs.Length > 0)

{

for (int index = 0; index < tagIDs.Length; index++)

{

WriteInformationLine(" > tagID " + index.ToString() + ": " +

tagIDs[index]);

}

}

else

{

// or a message telling us there were no tags

WriteInformationLine(" > No tags in field");

}

}

As you can see, it is easy to read tag IDs.

Mobile Reader

18 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 19

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

2.2.6 Know More about the Tags …

You can learn more about tags in the same way that you can access additional data on tags

or write data to tags.

Some additional data must be specified. For our test scenario the most flexible way to

provide these data is to enter them with the user interface as shown below:

Figure 2-5 A dialog for entering the address of the additional tag data to be read

Once you have acquired the address of the data, accessing the data is easy. The code for

acquiring data is given in the Figure below.

Note how the specified data is returned as an array of bytes with the requested length. Be

sure to check for a null reference which is returned if no data could be read.

When you request additional data from EPC Gen2 tags, the tag to be addressed must

always be specified by giving its tag ID. Only if a EPC Gen2 tag with a matching ID is

detected will the operation succeed.

Reading additional tag data:

byte[] buffer = null;

try

{

// Code for invoking a dialog and retrieving the data entered

left out for brevity -> check sample code for details

...

// Request all tags that are currently within reach

buffer = RfReaderApi.Current.GetTagMemory(

currentTagID, memoryBank,

startAddress, dataLength,

accessPassword);

...

// Code to show the resulting buffer left out for brevity ->

check sample code for details

}

catch (RfReaderApiException rfidException)

{

// Something went wrong while reading additional data

WriteInformationLine(string.Format("ERROR: {0} - {1}, cause:

{2}, desc: {3}\r\n",

rfidException.ResultCode, rfidException.Error,

rfidException.Cause, rfidException.Description));

}

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

19

Page 20

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

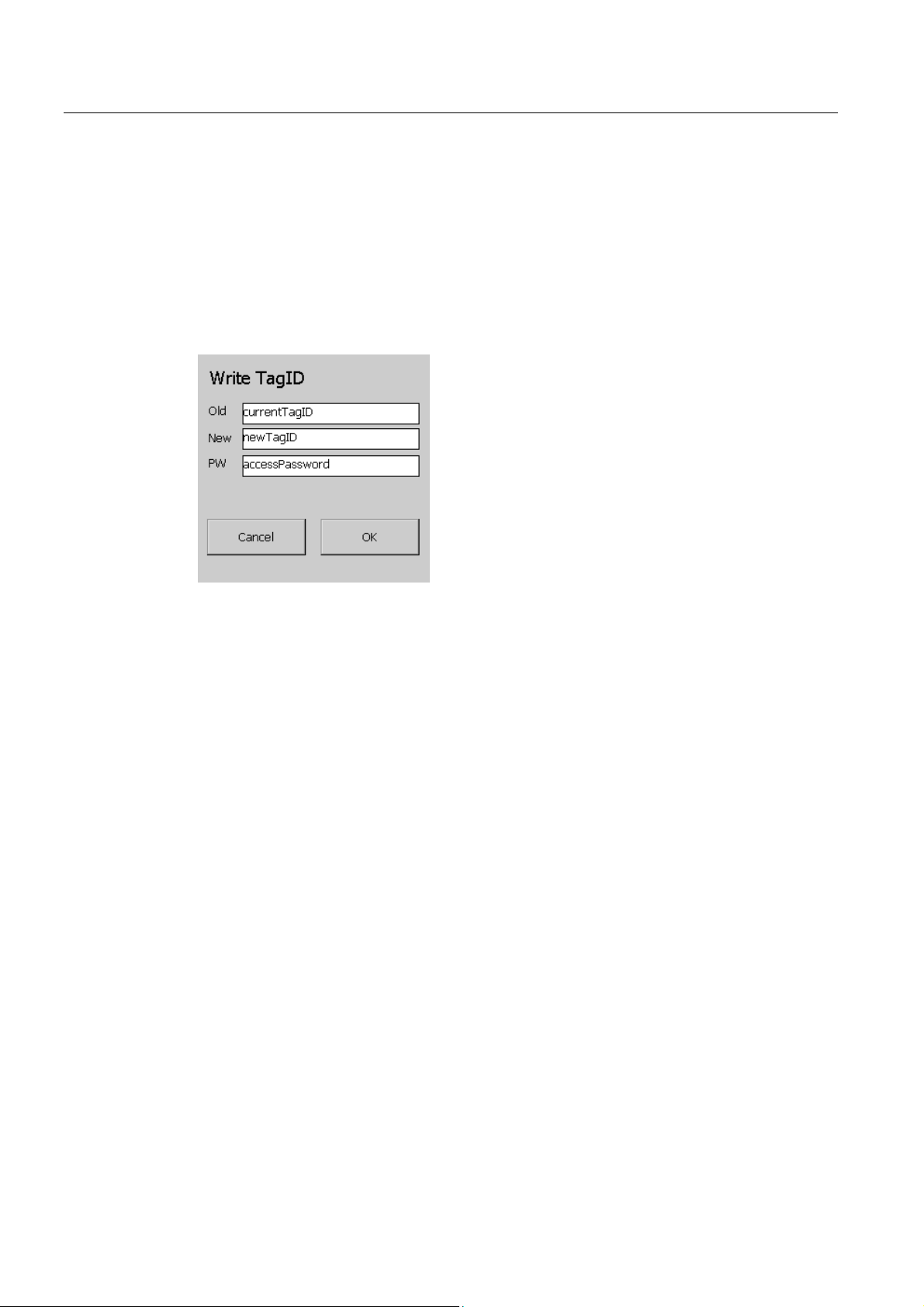

2.2.7 Change the Tags' Data

When the data on a tag must be changed, the same restriction applies on EPC Gen2 tags as

with obtaining additional data. The EPC Gen2 tag that you want to change must be specified

by supplying its ID. Only if a matching tag is detected will the operation succeed.

How to write a new ID to an existing tag for a data-change function (for EPC GEN2 only):

The tag's current ID must be supplied together with the new ID and a password (if needed)

and an instance of an object must be used that implements the IRfReaderApi which is

always available via RfReaderApi.Current.

Figure 2-6 Write TagID

Below is the code for accomplishing this; writing a new tag ID to a tag:

try

{

// Code for invoking a dialog and retrieving the data entered

left out for brevity -> check sample code for details

...

// Request all tags that are currently within reach

RfReaderApi.Current.SetTagID(

currentTagID, newTagID,

accessPassword);

}

catch (RfReaderApiException rfidException)

{

// Something went wrong while writing data

AddInformation(string.Format("ERROR: {0} - {1}, cause: {2},

desc: {3}\r\n",

rfidException.ResultCode, rfidException.Error,

rfidException.Cause, rfidException.Description));

}

Mobile Reader

20 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 21

RFID Reader Interface User's Guide

2.2 How Do I Use the Reader Interface?

2.2.8 Summary

Using the RFID Reader Interface is easy if you keep the few important points below in mind.

● Be sure to reference the Siemens.Simatic.RfReaderApi.dll assembly, use its namespace

and place the assembly beneath your application on the target device.

● Access the member RfReaderApi.Current whenever you want to use the RFID Reader

Interface.

● Remember that member functions which return data may also return null if no data are

found.

● Don't forget to check RfReaderApiExceptions that indicate malfunctions and errors.

● And please make sure you always place the following files beneath your application so

that it is able to run.

Siemens.Simatic.RfReaderApi.dll

Siemens.Simatic.RfReaderApi.dll.config

rfid_power_commutation.dll

PsionTeklogixRFID.dll

PsionTeklogicNet.dll

PtxSdkCommon.dll

With these simple guidelines and the description of the RFID Reader Interface's member

functions you should be able to implement your own business logic for a standalone RFID

client application without having to bother too much with the details of RFID processing.

See the sample code provided that shows the RFID Reader Interface functions in use.

If you are intending to use the barcode feature of the RF610M device within your standalone

applications, remember to consult the device vendor’s documentation about it. When

working integrated in a SIMATIC RF-MANAGER configured environment, barcode scanning

is a by-product gained automatically as you will see below.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

21

Page 22

RFID Reader Interface User's Guide

2.3 Extending the Reach

2.3 Extending the Reach

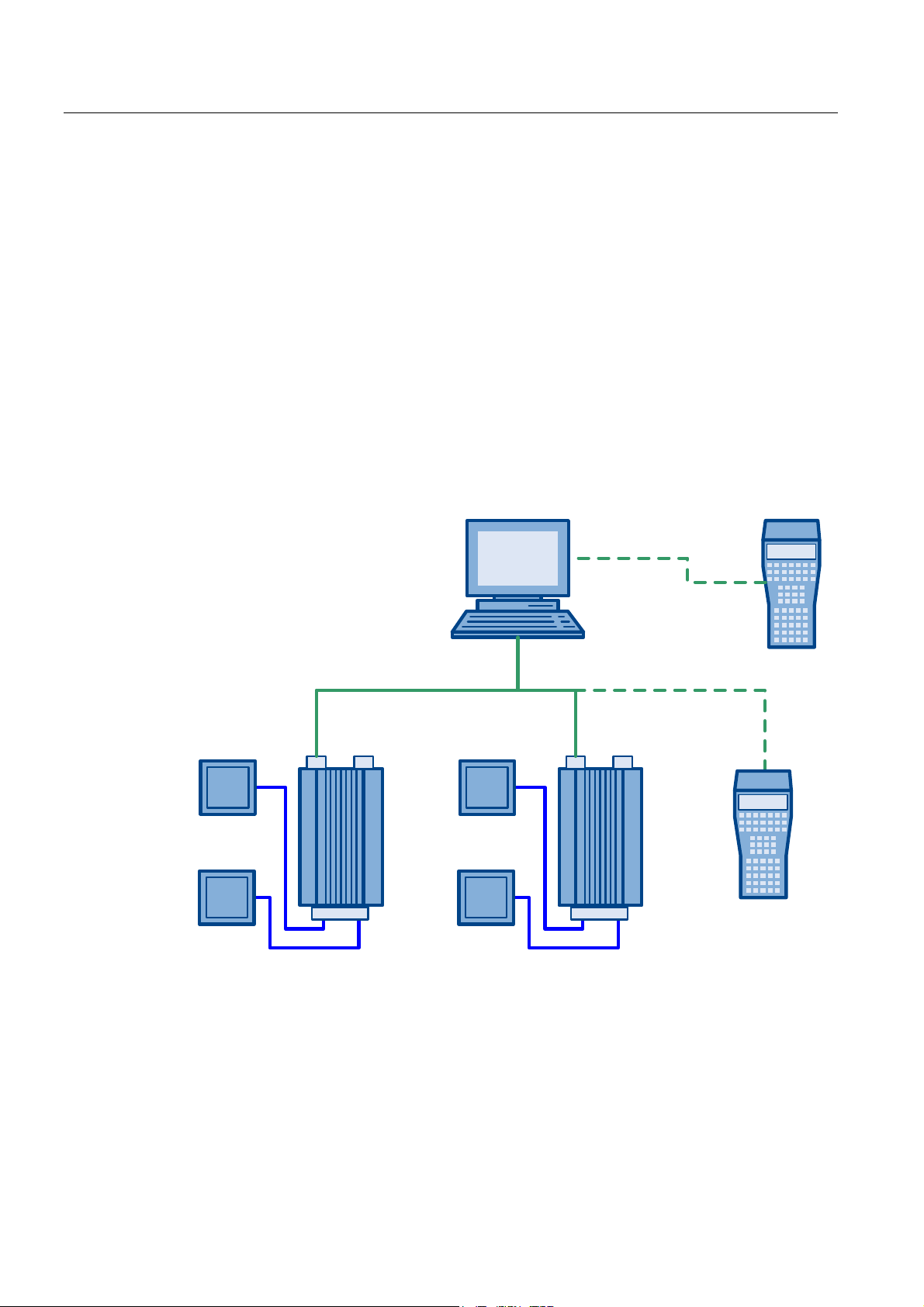

2.3.1 Being Part of a Larger Family

The last chapter discussed using the handheld RFID reader interface in a standalone

scenario. However, even RFID reader are not always alone in this world but have to interact

– or want to interact – with other components in larger systems.

Being aware of this fact, the RFID reader interface now supports ( RF610M only) integrating

into SIMATIC RF-MANAGER configured environments. Please bear in mind that both the

communication and synchronization among devices and usage of configuration data relies

on a working RF-MANAGER infrastructure. More precisely we are talking of integrating into a

SIMATIC RF-MANAGER system only.

Consider an integration scenario as given in the figure below.

5)5

*DWH

Figure 2-7 Larger Infrastructures

5)0$1$*(55XQWLPH

5)5

*DWH

2IILFH

5)0

:/$1

:/$1(WKHUQHW

5)0

:DUHKRXVH

)ORRU

There are some stationary RF660R readers which are controlled by an RF-MANAGER

runtime. Let’s say, they check incoming and outgoing goods at warehouse gates. The whole

system is set up using a configuration created with RF-MANAGER.

Mobile Reader

22 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 23

RFID Reader Interface User's Guide

2.3 Extending the Reach

Now, Jerry – the guy working at the warehouse – wants to check if all the goods having been

unloaded at the gate are still within the package now stored in aisle three of the warehouse.

So he takes his RF610M device with him, walks up to the package in aisle three and scans

the package again just for monitoring purposes.

Since Jerry realized there were some parts missing in the package, the supplier sent the

missing parts right away in a second delivery by a parcel service. This second parcel,

however, did not pass the gates but arrived directly at the office counter. There, Molly – the

soul of the office – used another RF610M device to scan the ID of the delivered goods.

Contrary to Jerry’s scanning, the data she acquired was not only used for monitoring but as

additional input to the system just as it would be a third gate.

However, Molly’s desk is crowded as always and thus her scanning detects not only the tags

of the new parcel but some others from nearby as well. She wants to forward only the new

product IDs and skip the remaining known IDs that where scanned accidentally.

The story above shows two new use cases for the RF610M. We will go through both of them

and discuss the implications to the usage of the RFID reader interface.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

23

Page 24

RFID Reader Interface User's Guide

2.3 Extending the Reach

2.3.2 Entering the system

How do we achieve to be part of a larger system with an RF610M?

The good news is that starting with RF-MANAGER 2008 the RF610M can be configured

within a project as just another reader. All you have to do is, setting the reader type to

‘RF610M’ and setting the IP address accordingly so that the RF610M can be reached via

Ethernet. Of course you have to set up a WLAN connection to the device first.

Afterwards, you start the RFID reader using the already familiar interface member

StartReader but specifying the RF-MANAGER mode as shown in the code snippet below.

private void menuReaderStart_Click(object sender, EventArgs e)

{

try

{

// We want to create and start an instance of the RFID

// reader interface for an RF610M device that interacts with

// an RF-MANAGER runtime.

RfReaderInitData initData = new(RfReaderInitData();

initData.Type = „RF610M“;

initData.Mode = RfReaderInitData.ReaderMode.RfMananger;

// With RfReaderApi.Current we address the current

// RFID reader interface instance

// or initiate the creation of a new instance.

// StartReader connects to an existing reader service

// or creates a new reader service.

RfReaderApi.Current.StartReader(initData);

}

catch (RfReaderApiException rfidException)

{

// Something went wrong while starting the reader.

// More information is available by inspecting the

// RfReaderApiException's members ResultCode, Error,

// Cause and Description.

...

}

}

As a result, the RFID reader interface starts the underlying reader service in such a way that

it waits for a connection with an RF-MANAGER runtime. As long as no connection to an RFMANAGER runtime has happened, you will not be able to perform any operations on the

interface successfully apart from stopping, getting the version or adding an event handler.

Any try to call an API function while the connection to the RF-MANAGER is still pending will

result in an RfReaderApiInvalidModeException exception.

Hold on a second! You won’t tell me that after starting a reader the only thing that happens is

that the interface is blocked, will you? That’s crazy.

Well, actually it is not. And here is why: When working in RF-MANAGER integrated mode

the reader service needs initialization data configured with RF-MANAGER in order to know

for example if it has to scan only for RFID data or for barcodes and how the keys on the

device trigger reading and whether the device is used for monitoring or for control. As long

as this information is not available, the behavior of the RFID reader interface would be

somehow random. To prevent clients from being confused by such indiscriminate behavior,

the best way is to allow operation only, if system configuration has been finished.

Mobile Reader

24 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 25

RFID Reader Interface User's Guide

2.3 Extending the Reach

2.3.3 Wake me up before you go…

So far, so good – we will wait until the configuration has been finished. But how do we know

it has finished?

Luckily the RFID reader interface provides a notification mechanism which enables us as a

client of the API to know what is going on. Let’s have a closer look at what happens when a

new configuration from RF-MANAGER arrives:

ಭ5HFRQILJXUDWLRQಫ

ಭ6WDUWHGಫHYHQW

5),'UHDGHU$3,

YDOLG

LQYDOLG

5)0$1$*(5

FRQILJXUDWLRQ

QHZ

DEVHQW

NQRZQ

5HDGHU6HUYLFH

UXQQLQJ

LQDFWLYH

Figure 2-8 RFID Reader Interface

Whenever the reader service receives configuration data from a connected RF-MANAGER

runtime it sends a "Reconfiguration:Started" notification telling you that it will now start

reconfiguration (t1 , t3). At this point in time the interfaces changes to the invalid state and

disables access. For you as a client this means, you should disable functions that use the

interface until reconfiguration has finished.

&KDQJHGFRQILJ

HOHPHQWVHYHQW

W

W

ಭ5HFRQILJXUDWLRQಫ

ಭ6WDUWHGಫHYHQW

W

&KDQJHGFRQILJ

HOHPHQWVHYHQW

W

WLPHW

W

After the reconfiguration of the system has finished, the RFID reader interface changes its

state to valid and a second notification – containing either the changed configuration items

as parameters or just "Reconfiguraiton: Nochange" – is sent (t2 , t4). Now, that is the trigger

for an API client to start working with the RFID reader interface.

You can easily follow those conclusions, can’t you? But what happens if no new

configuration arrives because either a configuration is already available on the device or

there has not been a connection to an RF-MANAGER runtime yet? Do we have to wait

forever to detect these cases?

No, you don’t. The reader service and as a consequence the RFID reader interface will

always send a notification on startup as well. If there is

device the "Reconfiguration: Initial" event is sent. If a configuration is available you will either

get the changed items or the "Reconfiguration: Nochange" event.

Bear in mind, however, that in those cases no "Reconfiguration:Start" event will be issued

contrary to the arrival of new configuration data.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

no

configuration available on the

25

Page 26

RFID Reader Interface User's Guide

2.3 Extending the Reach

Nevertheless, this means, we can always rely on getting an event during startup – no matter

what.

Great, we now know when we are started. Normally, you start an underlying reader service

during startup of your client via StartReader() and you stop it again during shutdown of your

client with the StopReader() function of the RFID reader interface causing the reader service

to terminate as well.

If you shut down your client application without calling StopReader() first, the underlying

reader service keeps running. The next time you start up your client and call StartReader(),

no startup sequence of the reader service will occur because it is still running.

The downside of this behavior would be that you are again without a trigger to start working.

The good news is that the RFID reader interface knows that a reader service was already

running before and initiates a "Reconfiguration : Reconnect" notification. So, you as a client

can react and reinitialize your application.

And again, you can rely on always receiving an event during the RFID reader interface

startup.

Back to practice

So much for the theory, now back to practice. The notification means of the RFID reader

interface is its Alarms event. As a client you have to add an event handler best before you do

anything else with the interface.

The alarm handler function has to comply with the following prototype that defines the

special RfAlarmArgs parameters.

public void AlarmHandler(object sender, RfAlarmArgs alarmArgs)

Before starting the reader we add the alarm handler:

RfReaderApi.Current.Alarms += new RfAlarmHandler(this.AlarmHandler);

Now we are ready for take-off. We compile, deploy and run our test application to the

RF610M and use our new "Start RF-MANAGER" menu item.

Mobile Reader

26 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 27

RFID Reader Interface User's Guide

2.3 Extending the Reach

On a connected host PC we start a RF-MANAGER runtime with an RF610M device

configured as follows. Notice that the reader type and the application mode have to be set

accordingly.

Figure 2-9 RF610M Properties

As a side node, please bear in mind to set the network address for your runtime under

‘Device Settings, RFID/Network Settings’. This is needed as a ‘callback’ so that your

RF610M devices is able to pass read tag data on to the RF-MANAGER runtime.

Figure 2-10 RF610M Network Settings

When starting up our application on the RF610M and the RF-MANAGER runtime on the host

PC our AlarmHandler is called three times. Fine!

Wait: Did you say three times?

Ok, when the RF-MANAGER configuration is transmitted to the RF610M device there will be

the start reconfiguration event, which is signaled by the Boolean RfAlarmArgs member

IsConfigStart as well.

And when reconfiguration is finished there will be another event containing a list of changed

configuration items, which we deal with in a minute.

But what is the third time we are called? Just keep in mind the initial startup event that is

created in all cases telling you if it was an initial startup or a reconnect and whether there is

configuration data available.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

27

Page 28

RFID Reader Interface User's Guide

2.3 Extending the Reach

Here is a skeleton alarm handler body that shows the different events:

public void AlarmHandler(object sender, RfAlarmArgs alarmArgs)

{

if (alarmArgs.IsConfigStart)

{

// Reconfiguration has started

// => disable UI

}

else if (alarmArgs.InfoItems != null)

{

// Reconfiguration has finished

if (alarmArgs.InfoItems[0].Name == "Reconfiguration" &&

alarmArgs.InfoItems[0].Value == "Initial")

{

// This is the very first startup of the application

// where no configuration data is available

}

else if (alarmArgs.InfoItems[0].Name == "Reconfiguration"

&& alarmArgs.InfoItems[0].Value == "Reconnect")

{

// The reader service was already running and we

// only reconnected => reinitialize, e.g by rereading

// configuration data

}

else

{

// A configuration was received from RF-MANAGER and

// has been activated.

// => The list of RfInfoItems contains the changed

// configuration items

}

}

…

}

Mobile Reader

28 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 29

RFID Reader Interface User's Guide

2.3 Extending the Reach

2.3.4 We are started: What to make out of it?

Now the system is up and running and with the reconfiguration end event we got a list of

changed configuration items. You missed them? No problem, because there is another

possibility to query the configuration items. It’s the RFID reader interface’s

GetConfigParameter member which allows you to ask the current value for any known

parameter. In order to make it easier for you, the sample application implements a dialog for

showing you the values of the configuration parameters.

Figure 2-11 Configuration Parameter

In essence it uses a code sequence such as the following to ask for parameter values

whereas parameterName is a string giving the parameter’s id.

RfInfoItem infoItem =

RfReaderApi.Current.GetConfigParameter(parameterName);Here is a list

of parameters that you can query:

Configuration Parameter Name Possible Values / Description

MobileOperatingModeEnabled This parameter tells you if the device is working in remote

EditTagEnable This parameter could be used by your applications.

ScanBeepEnable Produce a sound on valid reads (if true).

ScanResultTime The configured time

All of the following configuration parameters give information

PistolGrip Information about the pistol grip button

Scan Key Left Information about the scan key button on the left of the device

Scan Key Right Information about the scan key button on the right of the

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

mode (FALSE) or mobile mode (TRUE).

Whenever this parameter is false, you may only monitor tag

events. Only if this parameter is true, filtering is enabled and

tag events might be changed and can be fed in again with the

SetTagEvents API function.

It signals that changing of tags is allowed inside your

application.

on how certain triggers are configured. On the one hand they

specify whether a configured trigger is only valid as long as

the associated key is pressed (KEY_PRESSED) or whether

the trigger implements an ON/OFF toggling (START_STOP).

Moreover, depending on the configuration, each trigger is

associated with either RFID scanning or barcode scanning or

with both.

device

29

Page 30

RFID Reader Interface User's Guide

2.3 Extending the Reach

Configuration Parameter Name Possible Values / Description

Scan Key Top Information about the scan key button on top of the device

Application Information about the virtual software trigger

Checking the parameter values from our default RF-MANAGER configuration, we find the

following setup:

We are running in RF-MANAGER mode and we are only allowed to monitor tags but not to

change them. All keys trigger as long as pressed and trigger RFID reading except for the

pistol grip which is associated with barcode. And there is a software trigger available as well

that we can use.

Comparing this setup with our introductory scenario it looks like it suffices to fulfill Jerry’s

requirements.

2.3.5 Jerry’s tag monitoring scenario revisited

Let’s start out by making our life easy: Before we deal with key handling we first explore the

possibilities for software triggering. We now know that there is an application trigger

connected with the internal RFID data source. So we start reading tags by just telling this

trigger to work and here is how:

We add a new menu item that uses the RFID reader interface’s function SetTrigger to

change the state of the application trigger. As we learned from the configuration parameter

settings this trigger acts as a on/off button and we take that into account by toggling the

trigger’s state with every invocation of the menu item (that is what our internal Boolean flag

fAppTriggerState is for).

private void menuItemAppTrigger_Click(object sender, EventArgs e)

private void menuItemAppTrigger_Click(object sender, EventArgs e)

{

...

RfTriggerState newTriggerState = RfTriggerState.On;

if (this.fAppTriggerState)

{

newTriggerState = RfTriggerState.Off;

}

RfReaderApi.Current.SetTrigger(RfTriggerType.Application,

newTriggerState);

this.fAppTriggerState = !this.fAppTriggerState;

...

}

If we now start our test application, start the reader service in RF-MANAGER mode, wait

until we got the ‘API valid’ event and then toggle our trigger while an RFID tag is within reach

we can now see read tags.

You don’t see them? Well, to be honest, so far you won’t see any tags within our test

application but you will see them within the connected RF-MANAGER runtime if you open a

screen at runtime that shows an RFID view. This view shows the tag events we want to

monitor.

While this is great for the guys in front of the RF-MANAGER runtime PC, it won’t help our

poor plant floor guy Jerry with its RF610M device because he still does not know whether the

tags have been read or not.

So, next let’s make sure that poor Jerry sees the read tags on his device as well.

Mobile Reader

30 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 31

RFID Reader Interface User's Guide

2.3 Extending the Reach

2.3.6 I’m all ears

Scanning the RFID reader interface members, the most promising one for our purpose is the

TagEventNotifications event. We add a handler to this event when starting the reader

private void menuReaderStartRfm_Click(object sender, EventArgs e)

{ ...

RfReaderApi.Current.TagEventNotifications +=

new

RfNotificationHandler(rfmIntegration.NotificationHandler);

...

}

And we implement the handler after a quick look at the reference section on how to

interprete the delivered data. For a starter we look at the tag ID, the event type and the time

of occurrence.

public void NotificationHandler(object sender, RfNotificationArgs notificationArgs)

{

if (null != notificationArgs.TagEvents)

{

foreach (RfTagEvent tagEvent in notificationArgs.TagEvents)

{

this.mainFormRef.WriteInformationLine("Tag Event: " +

tagEvent.EventTimeUTC);

this.mainFormRef.WriteInformationLine(" > ID : " +

tagEvent.TagID);

this.mainFormRef.WriteInformationLine(" > Type: " +

tagEvent.EventType);

}

}

else

{

this.mainFormRef.WriteInformationLine("Tag Event: No tags");

}

}

Let’s give it a try and run the code, start the reader service and the trigger.

Did you see any tags within your test application?

No?

You might ask yourself ‘Why not? I used the very same code as with alarms and there it

worked’. What is so different here?

The difference is that contrary to alarms, notifications about tag events are only delivered if a

client subscribes at the reader service. Since such a subscription might cause heavy data

traffic, this subscription is not done automatically- Only if a client requests the data it will be

delivered.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

31

Page 32

RFID Reader Interface User's Guide

2.3 Extending the Reach

OK, we know for sure, we need the data, so we add a subscribe menu item and as we are

add it an unsubscribe item as well.

private void menuItemSubscribeMonitor_Click(

object sender, EventArgs e)

{

// Subscribe is only valid if we run in RF-MANAGER mode

if (this.fRfmIntegrated)

{

// It does not make sense to subscribe twice

if (!this.fSubscriptionActive)

{

try

{

// Subscribe for all possible data sources

bool fResult = RfReaderApi.Current.SubscribeForNotifications

(RfReaderApi.NC_ALL, false);

if (fResult)

this.fSubscriptionActive = true;

}

catch(RfReaderApiException rfidException)

...

}

}

}

private void menuItemUnsubscribeMonitor_Click(

object sender, EventArgs e)

{

...

if(this.SubscriptionActive)

{

// Subscribe for all possible data sources

RfReaderApi.Current.UnsubscribeForNotifications(

RfReaderApi.NC_ALL);

this.fSubscriptionActive = false;

}

...

}

As you can see by looking at the code snippets above, there is an SubscribeForNotifications

member within the RFID reader interface.

It needs two parameter, the first one specifying the data source and the second whether we

only want to monitor or to filter the tag event data. As we are still on the way to let Jerry

monitor the tags, the second paramter is set to false.

For the first parameter we would have to know which data sources are configured within a

project. Luckily, configurations for a RF610M do not allow too much variation on the data

sources. They normally include an RFID and/or a barcode source only. Moreover, these data

sources have fixed names which are provided via constants within the RFID reader interface.

The following table lists possible values.

RfReaderApi.NC_RFID

RfReaderApi.NC_BARCODE

RfReaderApi.NC_ALL

Mobile Reader

32 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

This is the data source name if you want to target the RFID

component

This is the data source name if you want to target the barcode

component

This is a generic name that subscribes for all configured data

sources within a project.

Page 33

RFID Reader Interface User's Guide

2.3 Extending the Reach

Most interesting here is the last constant which ensures that all available data sources are

subscribed. Most often ‘NC_ALL’ is the safest option.

Running the application again now gives us what we wanted. Whenever we are not

subscribed, toggling the trigger will show tag events only at the RF-MANAGER runtime.

As soon as we subscribe, tag events are also shown within our test application directly on

the RF610M device. After unsubscribing tag events are still shown within the RF-MANAGER

runtime but no longer within our test application.

We got it! Jerry can now monitor his tags.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

33

Page 34

RFID Reader Interface User's Guide

2.3 Extending the Reach

2.3.7 Not without my approval

Now back to the office where Molly still wants to add the missing parcel to the original

delivery. Using the device with an application such as that we created above doesn’t really

help. While it would be possible to scan new IDs and to forward them to a connected RFMANAGER runtime there is no way of intercepting the data before it is delivered to the RFMANAGER.

Here is where the second parameter of the SubscribeForTagNotifications function of the

RFID reader interface comes to play. Whenever this parameter is set to true, scanned

information is delivered to the subscribed client (i.e. our application) but not yet to a

connected RF-MANAGER.

Forwarding of the data to the RF-MANAGER runtime will not occur until the RFID reader

interface member SetTagEvents is called with a list of tag events to be passed on.

Having the said facts about filtering in mind, subscribing and unsubscribing for our Molly

scenario is just a duplicate of what we already have whereas only the filtering parameter is

changed.

private void menuItemSubscribeFilter_Click(

object sender, EventArgs e)

{

...

// Subscribe for all data sources with filtering (!)

bool fResult = RfReaderApi.Current.SubscribeForNotifications(

RfReaderApi.NC_ALL, true);

...

}

In order to make it easier for us to test our code we introduce another new function that

allows us to simulate the pressing of a key where acquiring data only happens as long as the

key is pressed.

This is achieved by setting a corresponding trigger to ON, waiting for a second and setting

the trigger to OFF again. Here is the code for our new ‘simulate key’ function

private void menuItemSimulateKey_Click(

object sender, EventArgs e)

{

...

// Pretend we pressed the top key

RfReaderApi.Current.SetTrigger(RfTriggerType.ScanTop,

RfTriggerState.On);

// Hold the key for a second

Thread.Sleep(1000);

// 'Release' the key again

RfReaderApi.Current.SetTrigger(RfTriggerType.ScanTop,

RfTriggerState.Off);

...

}

Starting our application, starting the reader, subscribing as mentioned above and using our

new trigger method will result in the scanned tag data to appear within our notification

handler.

Mobile Reader

34 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 35

RFID Reader Interface User's Guide

2.3 Extending the Reach

We store incoming tag events in a list of tag events for later delivery

public void NotificationHandler(object sender, RfNotificationArgs

notificationArgs)

{

...

if (null != notificationArgs.TagEvents)

{

foreach (RfTagEvent tagEvent in notificationArgs.TagEvents)

{

// Remember this tag event when filtering for later

// confirmation

this.bufferedTagEvents.Add(tagEvent);

}

}

...

}

// This is our internal list to store tag events

private List<RfTagEvent> bufferedTagEvents = new List<RfTagEvent>();

Remember that as long as we are scanning, all acquired data is only stored locally on your

RF610M device. A connected RF-MANAGER runtime will not see a single one of the

scanned tags.

Now we can present the buffered tags to an end user such as Molly. If she confirms that all

shown tag events are valid, we can forward them to the RF-MANAGER runtime by calling

the SetTagEvents function as shown below:

public void ConfirmTagEvents()

{

...

if (this.bufferedTagEvents.Count > 0)

{

RfReaderApi.Current.SetTagEvents(RfReaderApi.NC_RFID,

this.bufferedTagEvents.ToArray());

}

...

}

Notice that the second parameter for the SetTagEvents function is just a list of tag events. In

the code above, simply all buffered tag event items are passed on to the function. The only

other information needed is the name of the data source within our reader service that will

receive the tag events. Again, we can safely rely on the system’s default component names

and use the given constant RfReaderApi.NC_RFID.

Contrary to subscribing for tag event notifications – where we simply used NC_ALL – we are

not allowed to use a generic name such as ‘all’ here but we have to address a specific data

source.

Running the code above now passes on the read tag events to the connected RFMANAGER runtime.

As said in our case the whole list of tag events. However, nothing prevents you from

selecting only some of the tag events, deleting events, adding your own tag events or

changing the values of a tag event before handing it over to the SetTagEvents function.

That way you can allow ‘Molly-like’ filtering for example by providing all tag events in a list

and letting the user select those events to be passed on.

And voila! We are able to make both Jerry and Molly happy again.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

35

Page 36

RFID Reader Interface User's Guide

2.3 Extending the Reach

2.3.8 Make it fun: Working keys

Finally, let’s get back to the trigger keys – remember your RF610M device has plenty of it, on

the left on the right, a big one on top and a pistol grip trigger (if you have a device equipped

with a barcode unit).

Capturing keyboard input as such is easy: We only have to add an event handler to the main

form’s keydown event. And since we want to know when the key is released again we also

add an event handler to the keyup event. The simple code is shown below.

...

// Main Form initialization code

this.KeyDown += new System.Windows.Forms.KeyEventHandler(

this.KeyDownHandler);

this.KeyUp += new System.Windows.Forms.KeyUpHandler(

this.KeyDownHandler);

...

However, this code will only work as long as the main form has the focus. Whenever a

control residing on this main form has the focus, we will not get the key events. Therefore,

our demo application uses a simply ‘intercept all controls’ mechanism starting at the main

form. The main form’s constructor invokes CaptureKeys(this).

protected void CaptureKeys(Control control)

{

for (int i = control.Controls.Count - 1; i >= 0; i--)

{

Control c = control.Controls[i] as Control;

if (c != null)

{

c.KeyDown += new System.Windows.Forms.KeyEventHandler(

this.KeyDownHandler);

c.KeyUp += new System.Windows.Forms.KeyEventHandler(

this.KeyUpHandler);

CaptureKeys(c);

}

}

}

Now, we only have to check for the right keycode and invoke the correct trigger function.

Mobile Reader

36 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 37

RFID Reader Interface User's Guide

2.3 Extending the Reach

Initially, all of the special keys produce the same keycode 0xEF or 239 decimal. So,

whenever such a code arrives with a key down event, we set our trigger to active. And if the

key is released again, we reset the trigger. That way we implemented a simple ‘scan as long

as key is pressed’ behavior.

protected void KeyDownHandler(object sender, KeyEventArgs e)

{

if (e.KeyValue == 0xEF)

{

...

// (Error handling code omitted for the sake of clarity

RfReaderApi.Current.SetTrigger(RfTriggerType.Application,

RfTriggerState.On);

...

}

}protected void KeyUpHandler(object sender, KeyEventArgs e)

{

if (e.KeyValue == 0xEF)

{

...

// (Error handling code omitted for the sake of clarity

RfReaderApi.Current.SetTrigger(RfTriggerType.Application,

RfTriggerState.Off);

...

}

}

That is all you need to attach keys to function. Piece of cake, isn’t it?

Let’s add some cream on top of it. What if you do want to distinguish among all of those scan

keys. It is not always desireable using the same function for all keys. But if they all send the

same keycode it is impossible.

Luckily, PSION provides a way to change this. There is an interface assembly

PsionTeklogixNet.dll that offers you a PsionTeklogix.Keyboard namespace containing a

KeyRemapper class. This class allows redefining the keycodes. So we add some

initialization code in our main form’s constructor as shown below

...

// Initialize key mapping

PsionTeklogix.Keyboard.KeyRemapper Rf610MKeyRemapper =

new KeyRemapper();

// left scan key

Rf610MKeyRemapper.Add(0x38, null,

PsionTeklogix.Keyboard.Function.SendCode,

(int)PsionTeklogix.Keyboard.VirtualKey.VK_F27);

// right scan key

Rf610MKeyRemapper.Add(0x39, null,

PsionTeklogix.Keyboard.Function.SendCode,

(int)PsionTeklogix.Keyboard.VirtualKey.VK_F25);

// Pistol Grip

Rf610MKeyRemapper.Add(0x3A, null,

PsionTeklogix.Keyboard.Function.SendCode,

(int)PsionTeklogix.Keyboard.VirtualKey.VK_F26);

// top scan key

Rf610MKeyRemapper.Add(0x01, null,

PsionTeklogix.Keyboard.Function.SendCode,

(int)PsionTeklogix.Keyboard.VirtualKey.VK_F28);

...

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

37

Page 38

RFID Reader Interface User's Guide

2.3 Extending the Reach

These calls to PsionTeklogix.Keyboard.KeyRemapper select the key in question with the first

parameter and provide new keycodes wih the last parameter. After this initialization we can

rewrite our keyhandler as follows:

protected void KeyDownHandler(object sender, KeyEventArgs e)

{

switch (e.KeyValue)

{

...

case (int)PsionTeklogix.Keyboard.VirtualKey.VK_F25:

// right scan key pressed

...

break;

case (int)PsionTeklogix.Keyboard.VirtualKey.VK_F26:

// pistol grip key pressed

...

break;

case (int)PsionTeklogix.Keyboard.VirtualKey.VK_F27:

// left scan key pressed

...

break;

case (int)PsionTeklogix.Keyboard.VirtualKey.VK_F28:

// top scan key pressed

... break;

...

}

}

Now we know which key was pressed and can implement a different behavior for each of

them if wanted.

The key mapping stays active until a cold reset, a redefinition or if we manually remove the

key mapping again. As we want to leave the system as clean as we found it, we undo our

key mapping before exiting:

...

// Make our key mapping undone again

PsionTeklogix.Keyboard.KeyRemapper Rf610MKeyRemapper =

new KeyRemapper();

Rf610MKeyRemapper.Remove(0x38, null);

Rf610MKeyRemapper.Remove(0x39, null);

Rf610MKeyRemapper.Remove(0x3A, null);

Rf610MKeyRemapper.Remove(0x01, null);

...

Mobile Reader

38 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 39

RFID Reader Interface User's Guide

2.3 Extending the Reach

2.3.9 Summary

This chapter provided a short overview of the possibilities that the RFID reader interface

offers when working in integrated scenarios where most of the configuration is done with RFMANAGER and custom applications on a mobile device such as the RF610M need to tweak

the system behavior a little.

You are now familiar with the basics of monitoring and filtering of tag events. You know how

to eliminate unwanted data or even create data artificially.

You learned about the possibilities to find out what is configured under the hood by exploring

the configuration parameters and about the considerations necessary when starting up or

shutting down.

This manual can in no way cover all aspects and details of creating client applications. It is

intended as a jump start into the realm of tag event processing.

Additional topics such as connecting keys to triggers or something similar are left for your

own exploration.

Build on the basics you learned and adjust them to fit your needs to ‘Extend your Reach’.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

39

Page 40

RFID Reader Interface User's Guide

2.3 Extending the Reach

Mobile Reader

40 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 41

RFID Reader Interface Reference

The RFID Reader Interface provides a way to access the RFID features that the handheld

device provides. End users can utilize these features by using the DLL interface which is

provided as a .Net assembly within own client applications.

This chapter provides a detailed description of all available functions and their parameters.

3.1 The Interface

The programming interface is contained in a .Net assembly with the name

Siemens.Simatic.RfReaderApi.dll. Whenever clients want to use the interface, they must

reference this assembly in their applications.

This assembly contains the defining and implementing classes in a namespace

Siemens.Simatic.RfReader.

There are a few helper classes, the interface itself and a static function to instantiate an

instance of the RFID Reader Interface.

Starting with RFID Reader Interface V1.1 notifications and alarms are supported which led to

some new helper classes

Supported in RFID reader interface: since v1.0

RfReaderApiException Helper class to wrap exception information

RfReaderInitData Helper class for initialization purposes

IRfReaderApi The interface class

RfReaderApi Creation of an RFID Reader Interface instance

3

Supported in RFID reader interface: since V1.1

RfNotificationArgs Helper class that wraps arguments for notification events

RfTagEvent Helper class that contains all data of a single tag event

RfAlarmArgs Helper class that wraps argument for alarm events

RfAlarm Helper class that contains all data of a single alarm

RfInfoItem Helper class that contains information about configuration or state

RF310M device is supported with reader interface V1.2

The following chapters describe each member of the interface in detail including its

parameters and return.

Mobile Reader

Function Manual, 02/2009, J31069-D0198-U001-A1-0076

changes

41

Page 42

RFID Reader Interface Reference

3.2 RfReaderApi.Current

3.2 RfReaderApi.Current

RfReaderApi.Current : IRfReaderApi {get}

Parameters:

None (.Net Property)

Return value(s):

This function returns the current instance of an RFID Reader interface or null.

Note:

If no instance has been created before, a call for this function will create a new RFID Reader

Interface instance.

If there is already an instance of the RFID Reader Interface running, it will be returned.

Should it not be possible to create an instance of the RFID Reader Interface, null will be

returned.

3.3 RfReaderApiException

Whenever RFID reader API related exceptions occur either internally or by calling the

underlying reader service or the physical RFID reader device, these exceptions are wrapped

within an instance of the RfReaderApiException class.

However, this does not prevent general exceptions such as ‘out of memory’ or ‘out of range’

to occur either. So, be prepared to catch those kind of exceptions as well.

This class provides additional information about the source or cause of an exception via the

following members:

● ResultCode : int

The ResultCode specifies the source location of an exception.

ResultCode_System specifies error conditions which occurred internally.

ResultCode_Reader specifies error conditions arising from within an underlying reader

service.

● Error : string

Error is a short description of the error that occurred.

● Cause : string

Cause gives additional information if the cause of an error is known.

● Description : string

Additional extra description of the error. May be left blank if not applicable.

Mobile Reader

42 Function Manual, 02/2009, J31069-D0198-U001-A1-0076

Page 43

RFID Reader Interface Reference

3.4 IRfReaderApi

3.4 IRfReaderApi

3.4.1 Version

IRfReaderApiVersion : string {get}

Parameters

None (.Net Property)

Return value(s)

The current version of the interface and its implementation as a string formatted as 'V

mj.mn.sp.hf_i1.i2.i3.i4' whereby mj and mn are the major and minor version of the product,

sp specifies a service pack number and hf a hotfix number.

All of the four following numbers (i1, i2, i3, i4) are internal identifiers qualifying a special

release or build of the RFID reader interface assembly.

Note

This information can be used to determine which features are supported by a certain version