Siemens SIMATIC RF300 USE CASE

SIMATIC RF300 USE CASE

Electric engine production

in the automotive industry

Task

The trend toward electric engine technology

continues apace. To meet it, the automotive

industry must successfully manufacture energy-

efficient electric motors as quickly, efficiently, and

flexibly as possible. In the process, the traceability

of all quality-relevant materials and components

must be ensured at all times.

Benefits

• Facilitating flexible manufacturing with

the high-performance SIMATIC RF300

RFID system.

• SIMATIC RF360R combines the functions

of the CM (communication module) and

reader in one device, enabling space-

savings and cost-efficient installation

Solution

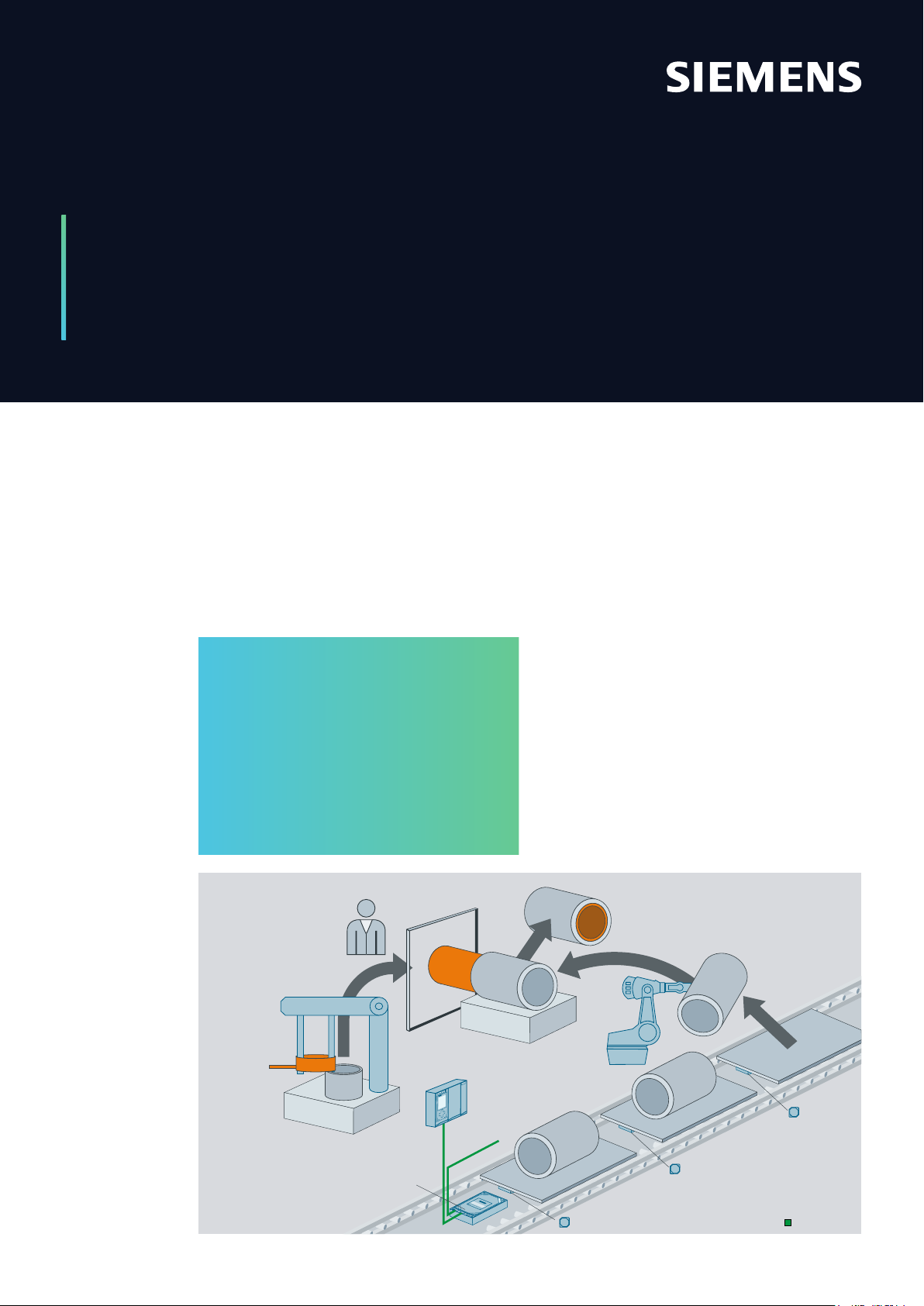

In electric engine production, especially for the

stator component, individual copper wire wind-

ings are drawn into the stator housing with

specialized machines. The finished stator is then

assembled together with other components (e.g.

anchor, rotor) to a complete, ready-to-install

electric engine. After completion, the components

are assembled on a track-guided assembly line on

workpiece carriers. Each workpiece carrier is

equipped with a SIMATIC RF350T transponder, on

which all production-relevant information is

stored. With the help of the SIMATIC RF360R

reader, this data is read and written at individual

and manual workstations.

SIMATIC

RF360R

SIMATIC

S7-1500

SIMATIC RF350T

SIMATIC

RF350T

SIMATIC

RF350T

PROFINET

siemens.com/rf300

G_FS10_XX_01383

Loading...

Loading...