Siemens SIMATIC RF185C, SIMATIC RF186C, SIMATIC RF188C Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC Ident

RFID systems

SIMATIC RF185C, RF186C,

RF188C

Operating Instructions

10/2018

C79000

Introduction

1

Security recommendations

2

Description

3

Mounting

4

Connection

5

Configuring

6

Configuring with the WBM

7

Programming via SIMATIC

controller

8

Programming via the OPC

UA interface

9

Service and maintenance

10

Technical data

11

Dimension drawings

12

Appendix

A

Service & Support

B

-G8976-C512-01

Siemens AG

Division Process Industries and Drives

Postfach 48 48

9

GERMANY

C79000-G8976-C512-01

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

0026 NÜRNBERG

09/2018 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 7

2 Security recommendations ...................................................................................................................... 9

3 Description ............................................................................................................................................ 13

4 Mounting ............................................................................................................................................... 19

5 Connection ........................................................................................................................................... 23

6 Configuring ........................................................................................................................................... 43

7 Configuring with the WBM ..................................................................................................................... 53

3.1 Properties of the communications modules ............................................................................ 13

3.2 User-specific procedure .......................................................................................................... 15

3.3 Design ..................................................................................................................................... 17

4.1 Installation dimensions and position ....................................................................................... 19

4.2 Mounting the communications module ................................................................................... 20

5.1 Operation of the CM on grounded/ungrounded power supply ............................................... 26

5.2 Electrical design of the CM ..................................................................................................... 29

5.3 Connect CM to functional ground (PE) ................................................................................... 31

5.3.1 Mounting the CM on a conductive base ................................................................................. 31

5.3.2 Mounting the CM on a non-conductive base .......................................................................... 33

5.4 Connecting the communications module ................................................................................ 35

5.5 Supply voltage and PROFINET IO loop-through .................................................................... 39

5.6 Connecting cables for the CMs ............................................................................................... 40

6.1 Assign the IP address / device name ..................................................................................... 43

6.1.1 Assigning the IP address / device name with STEP 7 ............................................................ 43

6.1.2 Assigning the IP address / device name with the PST ........................................................... 45

6.2 Configuration via PROFINET IO ............................................................................................. 47

6.3 Configuration via OPC UA ...................................................................................................... 51

7.1 Starting WBM .......................................................................................................................... 53

7.2 The WBM ................................................................................................................................ 55

7.3 The menu items of the WBM .................................................................................................. 59

7.3.1 The "Start page" menu item .................................................................................................... 59

7.3.2 The "Settings - General" menu item ....................................................................................... 62

7.3.3 The "Settings - Reader Interface" menu item ......................................................................... 63

7.3.4 The "Settings - Communication" menu item ........................................................................... 66

7.3.5 The "Diagnostics - Log" menu item ........................................................................................ 74

7.3.6 The "Diagnostics - Service Log" menu item ........................................................................... 75

7.3.7 The "Edit transponder" menu item .......................................................................................... 78

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

3

Table of contents

8 Programming via SIMATIC controller .................................................................................................... 87

9 Programming via the OPC UA interface ................................................................................................ 89

10 Service and maintenance ..................................................................................................................... 113

11 Technical data ..................................................................................................................................... 147

12 Dimension drawings ............................................................................................................................. 149

7.3.8 The "User management" menu item ...................................................................................... 80

7.3.9 The "System" menu item ....................................................................................................... 83

7.3.10 The "Help" menu item ............................................................................................................ 85

9.1 Supported methods/functions ................................................................................................ 90

9.2 OPC UA variables .................................................................................................................. 94

9.2.1 Description of the variables .................................................................................................... 94

9.2.2 ExecuteScan .......................................................................................................................... 95

9.2.3 CommonSettings.................................................................................................................... 95

9.2.4 RfidSettings ............................................................................................................................ 96

9.2.5 Diagnosis ............................................................................................................................... 97

9.2.6 DigitalIOPorts ....................................................................................................................... 103

9.3 OPC UA events .................................................................................................................... 105

9.3.1 Description of the events ..................................................................................................... 105

9.3.2 AutoIdPresenceEvent .......................................................................................................... 106

9.3.3 RfidLastAccessEvent ........................................................................................................... 106

9.3.4 AutoIdLastLogEntryEvent .................................................................................................... 111

10.1 Diagnostics ........................................................................................................................... 113

10.1.1 Diagnostics via the LED display ........................................................................................... 114

10.1.2 Diagnostics via SNMP ......................................................................................................... 117

10.1.3 Diagnostics using the WBM ................................................................................................. 117

10.1.4 Diagnostics over OPC UA .................................................................................................... 118

10.1.5 Diagnostics using the TIA Portal (STEP 7 Basic / Professional) ......................................... 118

10.1.6 Parameterization of the diagnostics ..................................................................................... 121

10.2 Error messages .................................................................................................................... 123

10.2.1 Error messages of the communications module .................................................................. 123

10.2.2 OPC UA error messages ..................................................................................................... 131

10.2.3 Reading out error messages using the WBM ...................................................................... 134

10.3 Firmware update .................................................................................................................. 134

10.3.1 Updating the firmware via WBM .......................................................................................... 135

10.3.2 Update firmware via TIA Portal (STEP 7 Basic / Professional) ........................................... 136

10.3.3 Updating firmware of the readers using the TIA Portal (STEP 7 Basic / Professional) ....... 137

10.4 Factory defaults.................................................................................................................... 139

10.4.1 Restoring the factory settings via WBM ............................................................................... 139

10.4.2 Restoring the factory settings manually ............................................................................... 140

10.5 Module replacement ............................................................................................................ 141

10.5.1 Backup configuration data ................................................................................................... 142

10.5.2 Replacing a module ............................................................................................................. 144

SIMATIC RF185C, RF186C, RF188C

4 Operating Instructions, 10/2018, C79000-G8976-C512-01

Table of contents

A Appendix............................................................................................................................................. 151

B Service & Support ............................................................................................................................... 157

A.1 System planning ................................................................................................................... 151

A.2 Connecting cables ................................................................................................................ 152

A.2.1 Standard cables .................................................................................................................... 152

A.2.2 Custom assembled cables .................................................................................................... 153

A.3 Ordering data ........................................................................................................................ 154

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

5

Table of contents

SIMATIC RF185C, RF186C, RF188C

6 Operating Instructions, 10/2018, C79000-G8976-C512-01

1

Purpose of these operating instructions

Basic knowledge required

Scope of validity of this documentation

Trademarks

Orientation in the documentation

Abbreviations and naming conventions

Reader

Write/read device (SLG)

Transponder, tag

Data medium, mobile data storage (MDS)

Communications module (CM)

Interface module (ASM)

The information provided in these operating instructions enables you to commission the

RF18xC communications module on a PROFINET IO controller.

These operating instructions assume general knowledge of automation engineering and

identification systems.

These operating instructions are valid for the RF185C, RF186C and RF188C

communications modules as of product version "01" and delivery date as of 10/2018.

The following and possibly other names not identified by the registered trademark sign ® are

registered trademarks of Siemens AG:

SIMATIC ®, SIMATIC RF ®, MOBY ®, RF MANAGER ®, SIMATIC Sensors ®

In addition to these operating instructions, you require the operating instructions for the S7300, S7-400, S7-1200 or S7-1500 controller used.

If you are using SIMATIC S7, you can find information on programming the module as well

as a complete error description in the description of the FB 45 function block, RFID standard

profile and Ident profile.

You can find information on the readers and optical readers to be connected in the intrinsic

safety manual of the respective product family (RF200, RF300, RF600, MV400 and MV500).

You can find the current versions of the various manuals on the pages of the Siemens

Industry Online Support (https://support.industry.siemens.com/cs/ww/en/ps/14970/man

The following terms/abbreviations are used synonymously in this document:

).

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

7

Introduction

Recycling and disposal

The products are low in harmful substances, can be recycled and meet the requirements of

the Directive 2012/19/EU for disposal of waste electrical and electronic equipment (WEEE).

Do not dispose of the products at public disposal sites.

For environmentally compliant recycling and disposal of your electronic waste, please

contact a company certified for the disposal of electronic waste or your Siemens

representative.

Adhere to the various country-specific regulations.

SIMATIC RF185C, RF186C, RF188C

8 Operating Instructions, 10/2018, C79000-G8976-C512-01

2

General

Physical access

Software (security functions)

Passwords

To prevent unauthorized access, observe the following security recommendations when

working with the communications module and WBM (Web Based Management).

● Check regularly that the device complies with these recommendations and/or other

internal security policies.

● Evaluate your plant as a whole in terms of security. Use a cell protection concept with

suitable products.

● Do not connect the device directly to the Internet. Operate the device within a protected

network area.

● Restrict physical access to the device to qualified personnel.

● Lock unused physical ports (e.g. Ethernet ports) on the device. Unused ports can be used

to access the system without authorization.

● Keep the software up to date. Keep yourself informed regularly about safety updates for

the product.

You can find information about this at Link (http://www.siemens.com/industrialsecurity

● Activate only protocols that you actually need to use the device.

● Limit access to the device using a firewall or rules in an access control list (ACL).

● The configuration files are available in XML format for simple use. Make sure that the

configuration files outside the device are suitably protected. You can, for example,

encrypt the files, store them at a safe location and transfer them only via secure

communications channels.

● Activate user management and create new user profiles.

● Change all default passwords for users before operating the device.

).

● Only use passwords with high password strength. Avoid weak passwords, e.g.

password1, 123456789, abcdefgh.

● Define rules for using devices and assigning passwords.

● Make sure that all passwords are protected and inaccessible to unauthorized personnel.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

9

Security recommendations

Keys and certificates

Firmware encryption

Secure/non-secure protocols

● Do not use the same password for different users and systems.

● Update passwords and keys regularly to improve security.

This section deals with the security keys and certificates that you need to set up SSL.

● We urgently recommend creating your own SSL certificates and making them available.

Preset certificates and keys are present in the device.

The preset and automatically created SSL certificates are self-signed. We recommend

using certificates signed either by a reliable external certification authority or an internal

certification authority.

The device has an interface via which you can import certificates and keys.

● We recommend using certificates with a key length of at least 2048 bits.

● If protocols support both certificates and keys, you should favor certificates.

The firmware itself is signed and encrypted. This ensures that only authentic firmware can be

downloaded to the device.

● Check whether it is necessary to use SNMPv1. SNMPv1 is classified as non-secure.

Make use of the possibility to prevent write access. The product offers corresponding

settings for this.

● If SNMP is activated, change the community names. If unrestricted access is not

necessary, limit access via SNMP.

● Use secure protocols if access to the device is not protected by means of physical

safeguards.

The following protocols provide secure alternatives:

HTTP → HTTPS

● To prevent unauthorized access to the device or network, set up appropriate safeguards

against non-secure protocols.

● Enable only the services (protocols) that will actually be used on the device. The same

applies to the installed interfaces/ports. Unused ports could be used to access the

network downstream from the device.

SIMATIC RF185C, RF186C, RF188C

10 Operating Instructions, 10/2018, C79000-G8976-C512-01

Security recommendations

List of available protocols

Protocol

Port number

Default

protocol status

Protocol status

configurable

Port number

configurable

Authentication

Encryption

DHCP

UDP/68

Open

✓

--

No

No

HTTP

TCP/80

Open

--

--

No

No

HTTPS

TCP/443

Open

--

--

Yes

Yes

NTP

UDP/123

Closed

✓

--

No

No

SNMP

UDP/161

Closed

✓

--

No

No

ured)

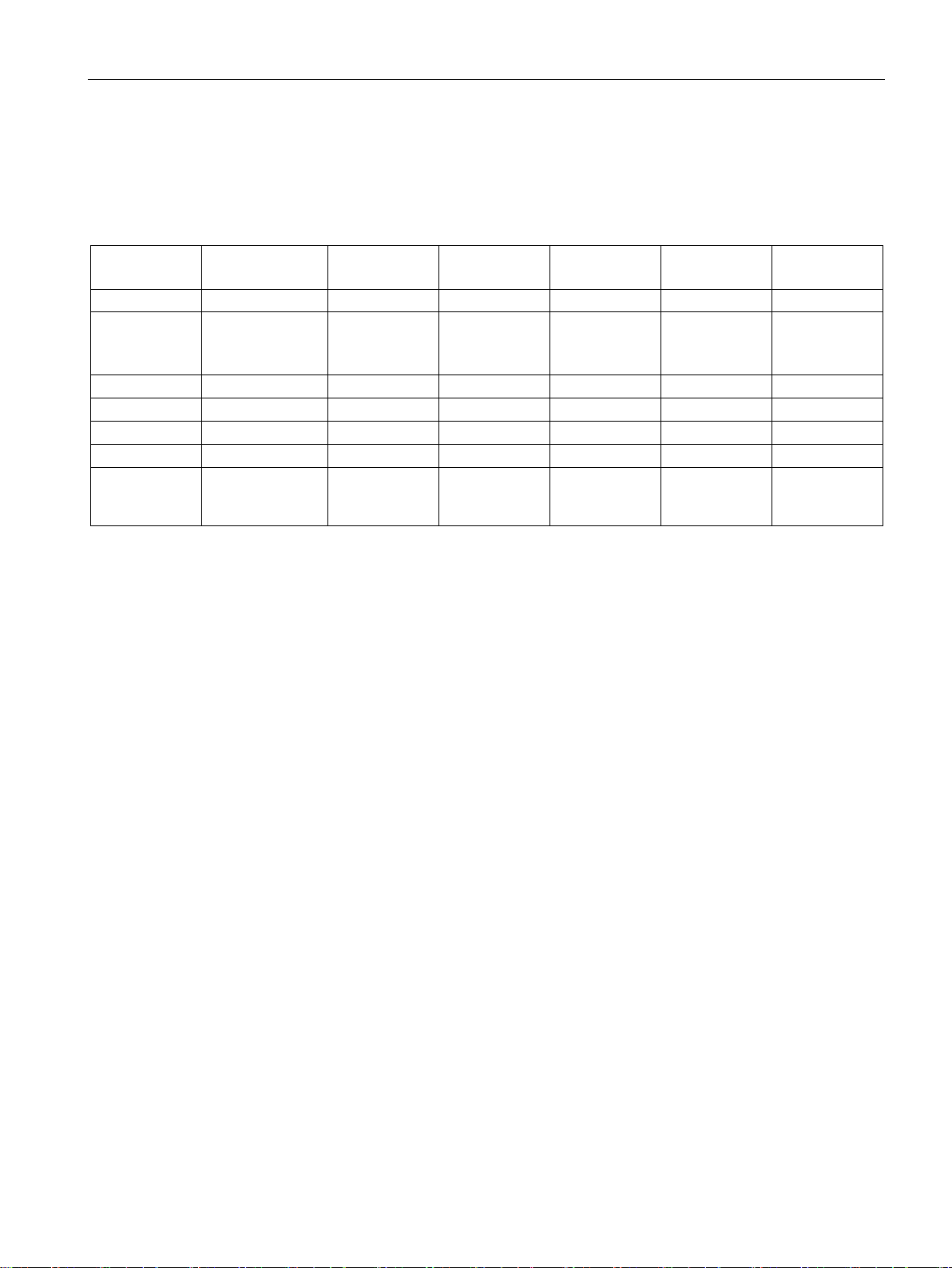

All available protocols and their ports that are used with SIMATIC RF18xC are listed below.

Table 2- 1 List of available protocols

PROFINET UDP/34964

UDP/4915265535

OPC UA TCP/4840 Open ✓ ✓ Yes (simple,

Open ✓ -- No No

when config-

Explanation of the table:

● Authentication

Specifies whether authentication of the communication partner takes place.

● Encryption

Specifies whether the transfer is encrypted.

Yes (when

configured)

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

11

Security recommendations

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For additional information on industrial security measures that may be

implemented, please visit

Link: (http://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers’ exposure

to cyber threats.

)

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Link: (http://www.siemens.com/industrialsecurity

)

SIMATIC RF185C, RF186C, RF188C

12 Operating Instructions, 10/2018, C79000-G8976-C512-01

3

3.1

Properties of the communications modules

Area of application

The SIMATIC RF185C, RF186C and RF188C communications modules are designed for

use in all areas of automation. It covers all areas in which SIMATIC Ident RFID readers and

optical readers are operated. The application can run at the field level on a controller, on a

PC or at the IT level. For example, RFID data can be transmitted via the standardized OPC

UA interface to higher-level systems - even parallel to communication with a controller if

required.

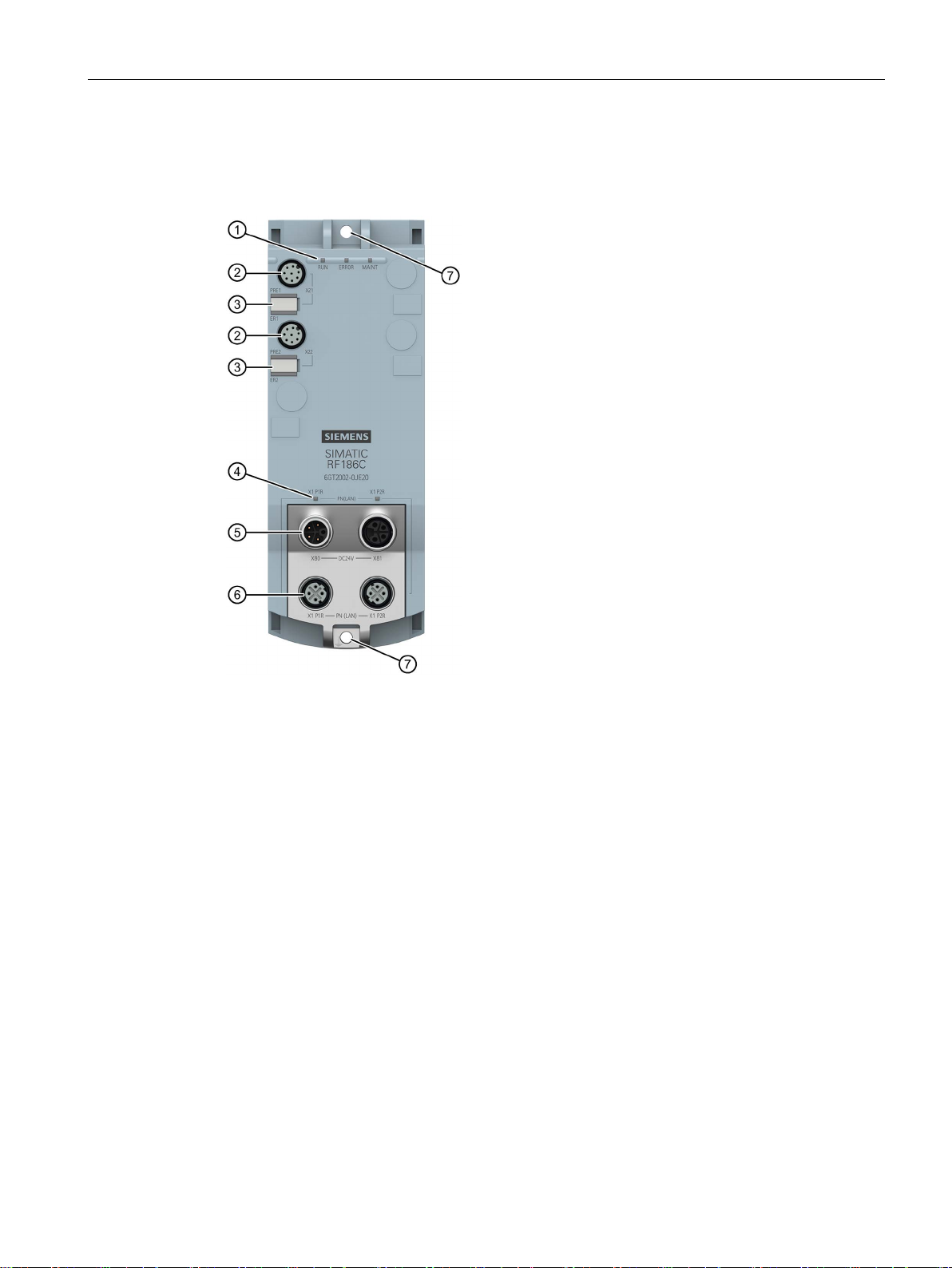

Figure 3-1 Communications modules RF185C, RF186C and RF188C

Due to the high degree of protection, mounting without a protective enclosure is possible

directly near the RFID read points. The small mounting surface of the communications

module facilitates installation in confined spaces.

Two connectors each for Ethernet and power supply allow configuration in a line structure in

addition to a star structure. The innovative L-coded M12 connectors for the power supply

allow a high feed-through current in a line structure. In addition to the familiar configuration

types via TIA Portal and GSDML, these communications modules also feature integrated

Web Based Management (WBM), which enables devices to be set via a standard browser.

During commissioning, diagnostics and maintenance, WBM is a very convenient tool and

displays the status of the connected readers and the data of the recorded transponders.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

13

Description

Features

Features

RF185C

RF186C

RF188C

devices

Transfer speed: 19.2 ... 115.2 KB

Transmission speed: 100 Mbps

Degree of protection

IP67

Application protocols

PROFINET IO, OPC UA

diagnostic options

Function blocks

Ident profile, FB 45, faceplate for PCS 7

controllers

controllers

and IEC61131 programming are supported.

NOTICE

Operation in VLANs

3.1 Properties of the communications modules

You can find additional information on the various RFID devices and optical readers on the

Internet on the "Siemens Industry Online Support

(https://support.industry.siemens.com/cs/ww/en/ps/14970/man

)" page.

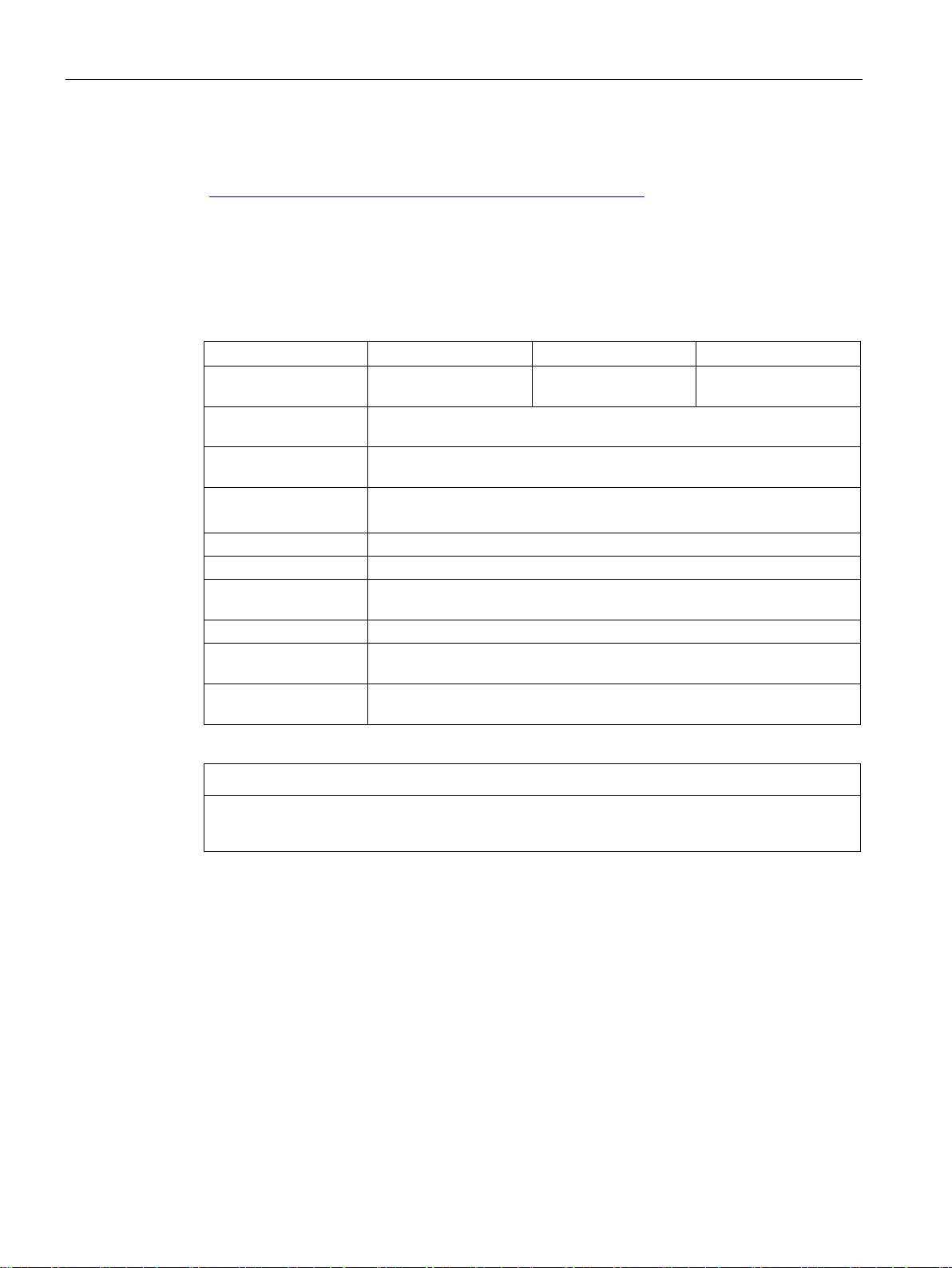

The following features characterize the RF18xC communications modules:

Table 3- 1 Features of the communications modules

Number of connectable

Supported product

families

Interfaces RS422

Ethernet interface 2x M12, switch integrated

Configuration/

Supported SIMATIC

Supported third-party

Source code of the Ident profile available. All controllers with PROFINET

1 2 4

RF200, RF300, MV400, MV500

STEP 7 (TIA Portal), GSDML, WBM (browser)

S7-300, S7-400, S7-1200, S7-1500

Note that the communications modules cannot be operated in VLANs whose ID is ≠ 0.

SIMATIC RF185C, RF186C, RF188C

14 Operating Instructions, 10/2018, C79000-G8976-C512-01

Description

3.2

User-specific procedure

Procedure as S7 user

Procedure as an OPC UA user

3.2 User-specific procedure

As described in the previous section, the communications modules are designed for different

environments and requirements.

If you operate the communications modules in an automation environment, they are

configured and programmed from the perspective of an S7 user. If you operate the

communications modules in an OPC UA environment, they are configured and programmed

from the perspective of an OPC UA user.

If you want to adapt the communications modules to your requirements, we recommend the

following user-specific procedure:

1. Connect the hardware

You can find information on this in the section "Connection (Page 23)".

2. Assign the IP address / device name

You can find information on this in the section "Assign the IP address / device name

(Page 43)".

3. Configure communications module

You can find information on this in the section "Configuration via PROFINET IO

(Page 47)" or "Configuring with the WBM (Page 53)".

4. Program reader commands

You can find information on this in the section "Programming via SIMATIC controller

(Page 87)".

1. Connect the hardware

You can find information on this in the section "Connection (Page 23)".

2. Assign the IP address / device name

You can find information on this in the section "Assigning the IP address / device name

with the PST (Page 45)".

3. Configure the communications module

You can find information on this in the section "Configuring with the WBM (Page 53)".

4. Program reader commands

You can find information on this in the section "Programming via the OPC UA interface

(Page 89)".

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

15

Description

Note

Synchronize device time

Note that the time of the device clock corresponds to UTC time and cannot be adj

time zones. Clicking the button transfers the local time stored in your operating system to the

communications module. Because the time synchronized with the PC is lost when the power

supply is terminated, we recommend synchronizing the time with

3.3 Design

usted to

an NTP server.

Later in the document, these symbols will help your orientation and will show you whether

the section is of interest to you or not. Only the sections with user-specific content, in other

words content that is tool/interface-specific, contain these symbols. Sections without these

symbols are general and relevant for both areas of application.

SIMATIC RF185C, RF186C, RF188C

16 Operating Instructions, 10/2018, C79000-G8976-C512-01

Description

3.3

Design

①

⑤

(M12, 4-pin, L-coded)

②

(M12, 8-pin, A-coded)

⑥

(M12, 4-pin, D-coded)

③

Reader LEDs

⑦

Mounting holes and functional ground (PE)

④

PROFINET/Ethernet LEDs

3.3 Design

The following figure shows the basic design of the RF18xC.

Status LEDs

Reader interfaces

Figure 3-2 Design of the communications module

Interface for the power supply

Interface for PROFINET IO

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

17

Description

Integration

3.3 Design

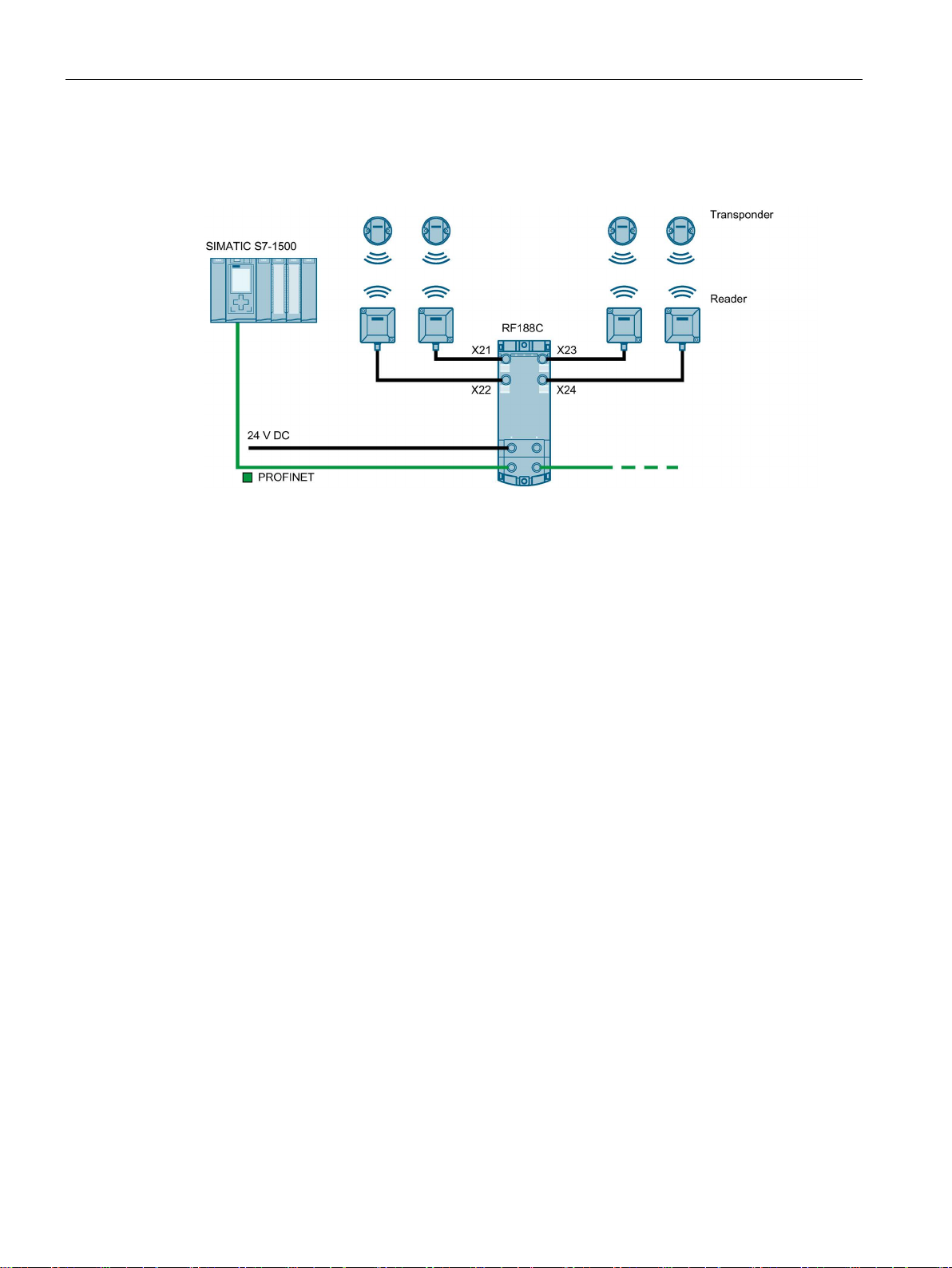

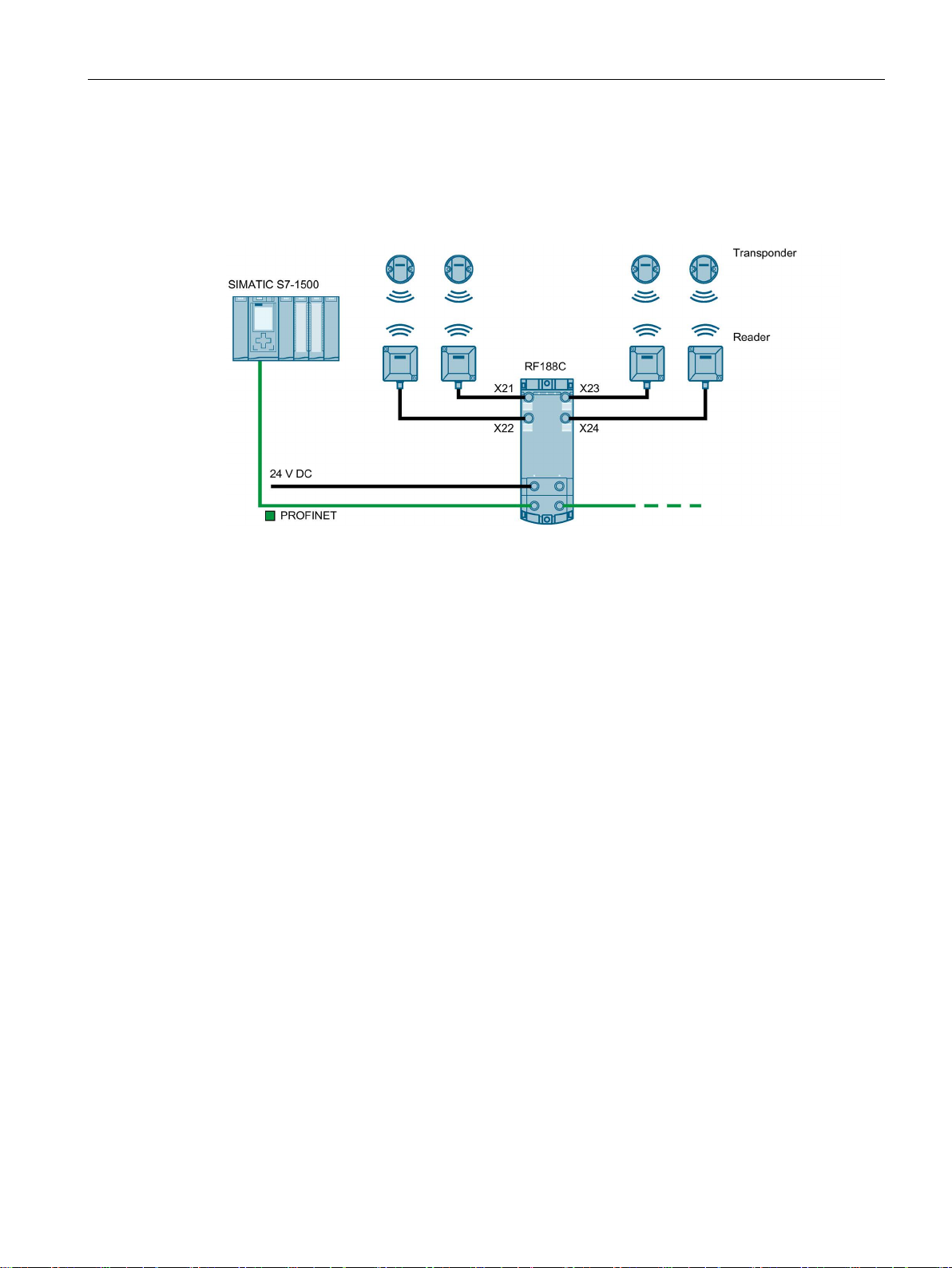

The following figure shows an example of an RF188C connection to an automation system.

Figure 3-3 Configuration graphic RF188C

As of STEP 7 Basic / Professional V15.1, the RF18xC communications modules are

integrated in the TIA Portal. Integration into 3rd-party systems is performed via a GSDML

file. The RF18xC can then be configured via the TIA Portal or another engineering system.

The GSDML file is stored on the communications module and can be downloaded from it

using a Web browser.

SIMATIC RF185C, RF186C, RF188C

18 Operating Instructions, 10/2018, C79000-G8976-C512-01

4

NOTICE

Installation outdoors

irect sunlight,

4.1

Installation dimensions and position

Minimum clearances

Mounting rules

Note

Mounting the communications modules

Only install the communications module when supply voltage

The RF18xC communications modules are designed for easy installation.

Please note that the communications module needs to be installed in a protected area. In

the case of installation outdoors, make sure that the device is protected from d

precipitation and wind.

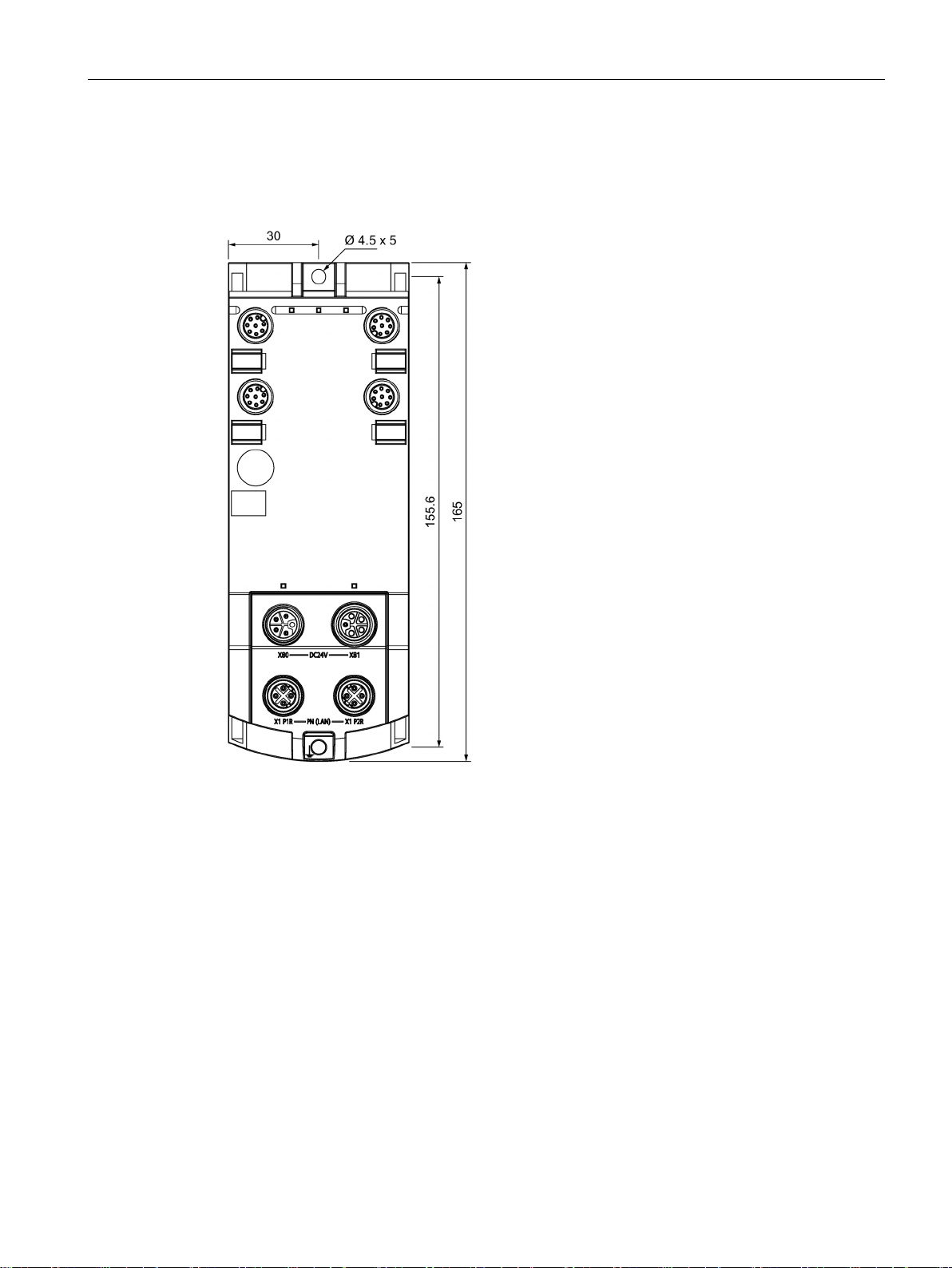

The RF18xC communications modules have the following installation dimensions (W × H ×

D): 60 × 165 × 45 mm.

You can mount the communications modules in any mounting position.

When installing the communications modules, keep a minimum distance of 1 cm from an

adjacent device or another device.

You do not have to observe any special rules when installing the communications modules.

s are switched off.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

19

Mounting

4.2

Mounting the communications module

Introduction

Note

Functional ground (PE)

If a grounded metal mounting surface is used, the bottom mounting screw of the RF18xC

module already e

separate ground conductor. If you use the fixing screw as grounding connection, the thread

of the fixing screw or the contact facing of the fastening nut on the base must be unpainted.

This ensures a low

Requirements

Screw type

Description

ISO 1207 / DIN EN ISO 1580

ing to DIN EN ISO 4762

4.2 Mounting the communications module

The communications modules are designed for mounting on a flat, solid surface.

Alternatively, you can use the axially symmetrical drill holes of the modules to fasten them to

an aluminum profile using sliding blocks.

stablishes a reliable ground connection. This eliminates the need for a

-resistance connection.

The following table shows and explains the types of screws you need to mount the modules.

Table 4- 1 Recommended screw types

Cylinder head screw M4 according to DIN EN

Cylinder head screw with M4 hex socket accord-

The minimum screw length should be 35 mm.

If you need washers, use washers conforming to

DIN EN ISO 7089 / DIN EN ISO 7090.

SIMATIC RF185C, RF186C, RF188C

20 Operating Instructions, 10/2018, C79000-G8976-C512-01

Mounting

Procedure

4.2 Mounting the communications module

Fasten the communications module with the screws on a solid level surface. The device

must be screwed (≤ 3 Nm) onto the panel at both fastening points (front top and bottom).

Figure 4-1 Mounting the RF18xC communications module

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

21

Mounting

Fastener for cable ties

4.2 Mounting the communications module

All communications modules have integrated fastening points for cable ties. The fastening

points are located at all four corners of the modules.

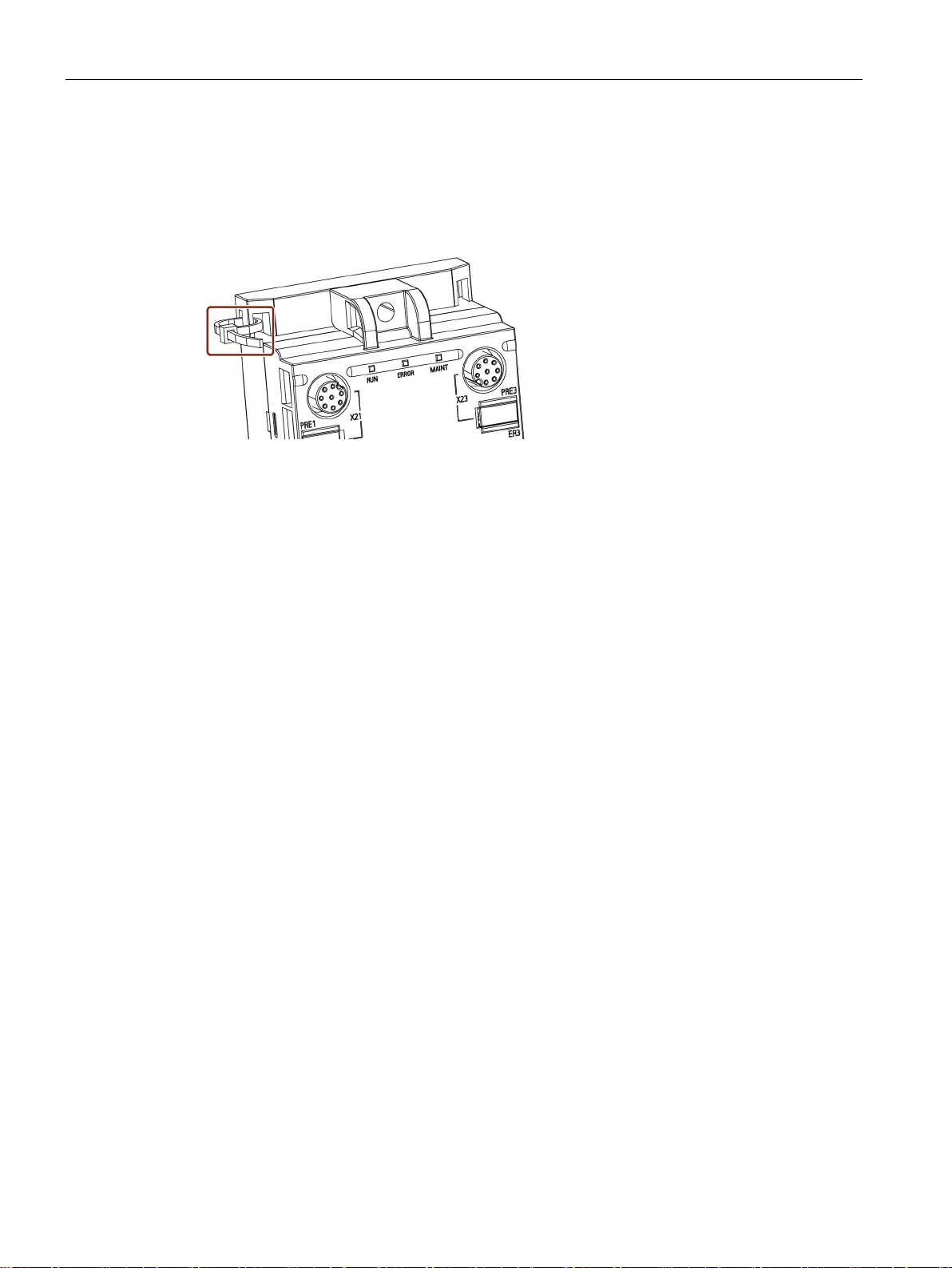

The following figure shows the upper left fastening point for 2.5 mm wide cable ties.

Figure 4-2 Mounting the RF18xC communications module

SIMATIC RF185C, RF186C, RF188C

22 Operating Instructions, 10/2018, C79000-G8976-C512-01

5

Proper use

PROFINET IO connection system

CAUTION

Power supply for devices with PROFINET interfaces

Only use the device for its intended purpose. If unspecified devices are connected to the

RF18xC, the connected device may be destroyed.

You can find detailed information on connecting the RF18xC on PROFINET IO in the

"SIMATIC PROFINET system description

(https://support.industry.siemens.com/cs/ww/en/view/19292127

)".

Modules with PROFINET interfaces may only be operated in LANs (Local Area Networks)

in which all connected devices are equipped with SELV/PELV power supplies (or have

equivalent protection).

A data transfer terminal (modem, for example) is required to access the WAN (Wide Area

Network) in order to ensure compliance with this safety standard.

All supply and signal voltages must be safety extra low voltage (SELV/PELV according to

IEC 61140).

DC 24 V supply: safe (electrical) isolation of extra-low voltage (SELV/PELV according to

EN 61140).

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

23

Connection

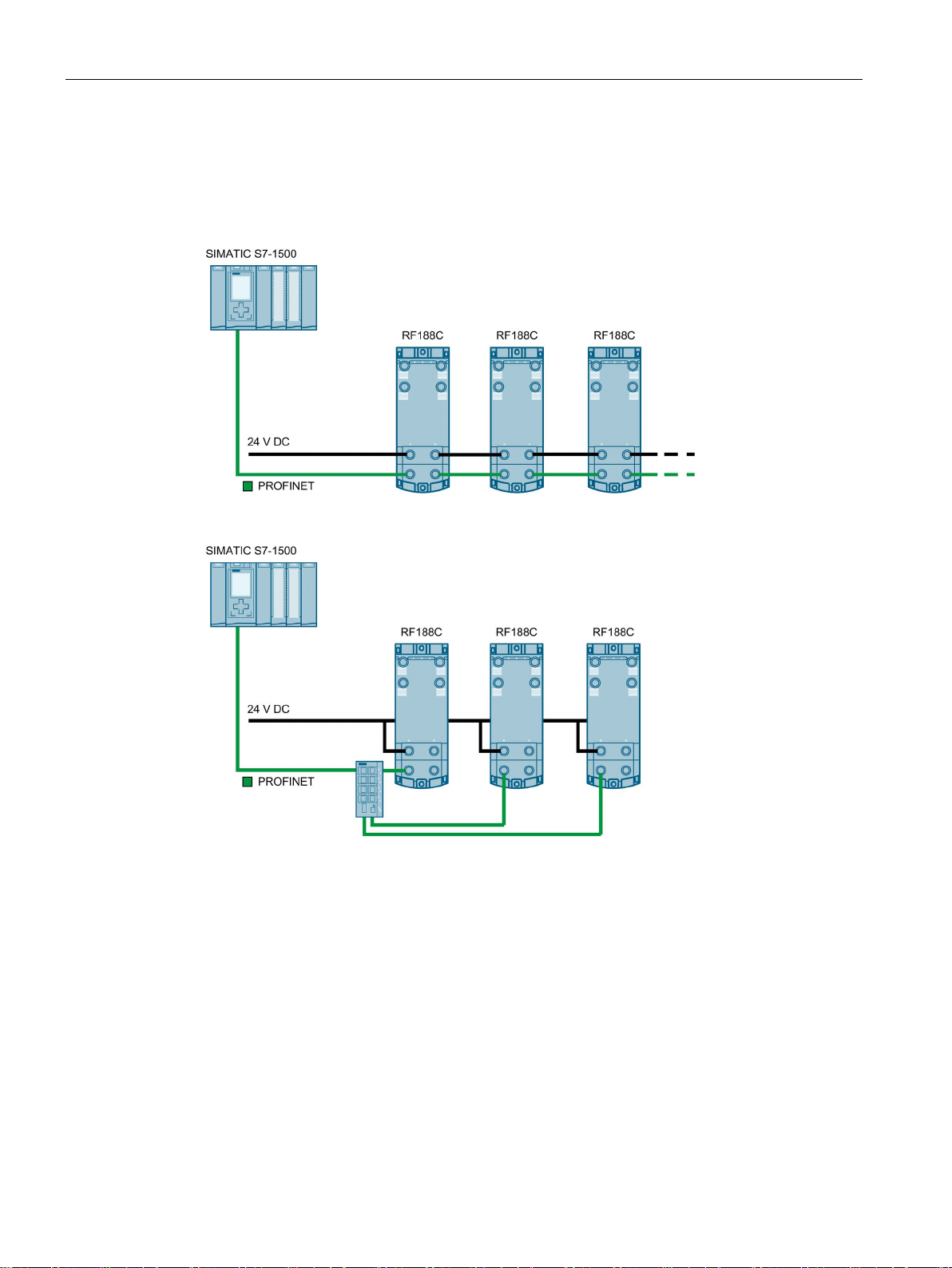

PROFINET IO topology

PROFINET IO communication can be structured as a line topology or star topology. Also

note the information in the section "Supply voltage and PROFINET IO loop-through

(Page 39)".

Figure 5-1 Configuration graphic of a line topology

Figure 5-2 Configuration graphic of a star topology

SIMATIC RF185C, RF186C, RF188C

24 Operating Instructions, 10/2018, C79000-G8976-C512-01

Connection

Reader connector system

A reader always occupies one M12 socket on the RF18xC. You can connect the reader to

the communications module using a preassembled cable. The connection cable is available

in lengths of 2, 5, 10, 20 and 50 m as standard. If necessary, these can be extended.

Figure 5-3 Overview of connections

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

25

Connection

5.1

Operation of the CM on grounded/ungrounded power supply

Grounded power supply

Supply voltages

Safe electrical isolation (SELV/PELV according to IEC 60364-4-41)

Setting up RF18xC with grounded reference potential

Setting up RF18xC with ungrounded reference potential

5.1 Operation of the CM on grounded/ungrounded power supply

Below, you can find information on the overall configuration of an RF18xC communications

module on a grounded power supply (TN-S network). The specific subjects discussed here

are:

● Supply voltages of the communications module

● Disconnecting devices, short-circuit and overload protection according to IEC 60364

(corresponds to DIN VDE 0100) and IEC 60204 (corresponds to DIN VDE 0113)

● Load voltage supplies and load circuits

For grounded power supplies, the neutral conductor of the supply system is grounded. A

short-circuit to ground of a live conductor, or of a grounded part of the system, trips the

protective devices.

Two supply voltages are available for the communications module:

● 1L+: Power supply

● 2L+: Load voltage

Note that the power supply (1L+) supplies the communications module and the readers with

power. Load voltage (2L+) has no direct effect on the communications module. This voltage

is looped through to further consumers via the plug-in connectors.

Power supply units/power supply modules with safe electrical isolation are required for

operation of the communications module. This protection is referred to as SELV (Safety

Extra Low Voltage) / PELV (Protective Extra Low Voltage) according to IEC 60364-4-41.

When the communications module is set up with grounded reference potential, any

interference currents that occur are diverted to functional ground. The connections must be

connected externally (connection between 1M and FE).

When the communications module is set up with ungrounded reference potential, any

interference currents occurring are conducted to functional ground via an internal RC

network (no external connection between 1M and FE).

SIMATIC RF185C, RF186C, RF188C

26 Operating Instructions, 10/2018, C79000-G8976-C512-01

Connection

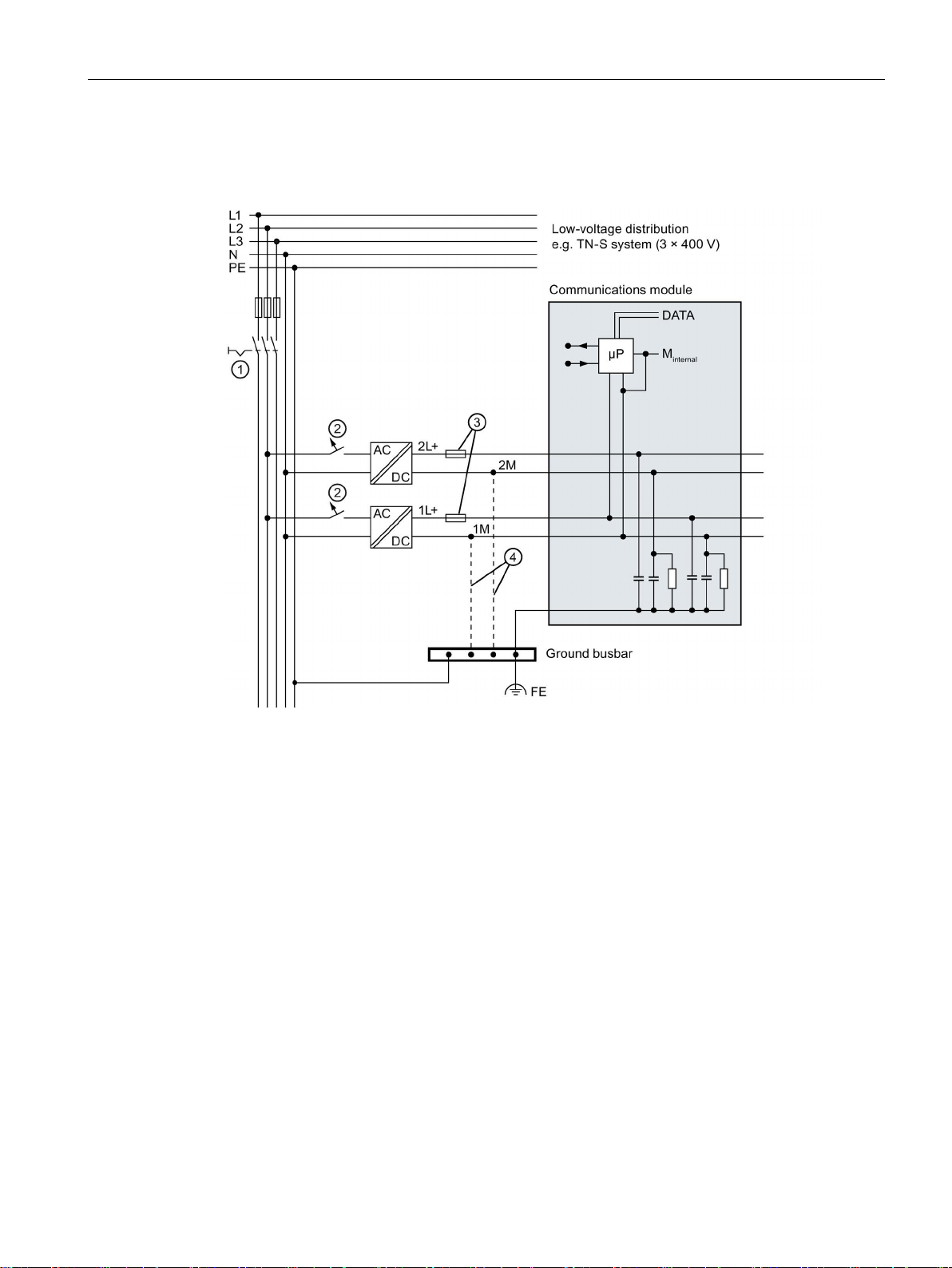

RF18xC in overall configuration

①

Main switch

②

Short-circuit and overvoltage protection

③

Fuses for line protection (automatic circuit breaker for 16 A)

④

connection between 1M, 2M and FE

5.1 Operation of the CM on grounded/ungrounded power supply

The following figure shows the communications module in its overall electrical design.

When setting up the communications module with ungrounded reference potential, there is no

Figure 5-4 Electrical design

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

27

Connection

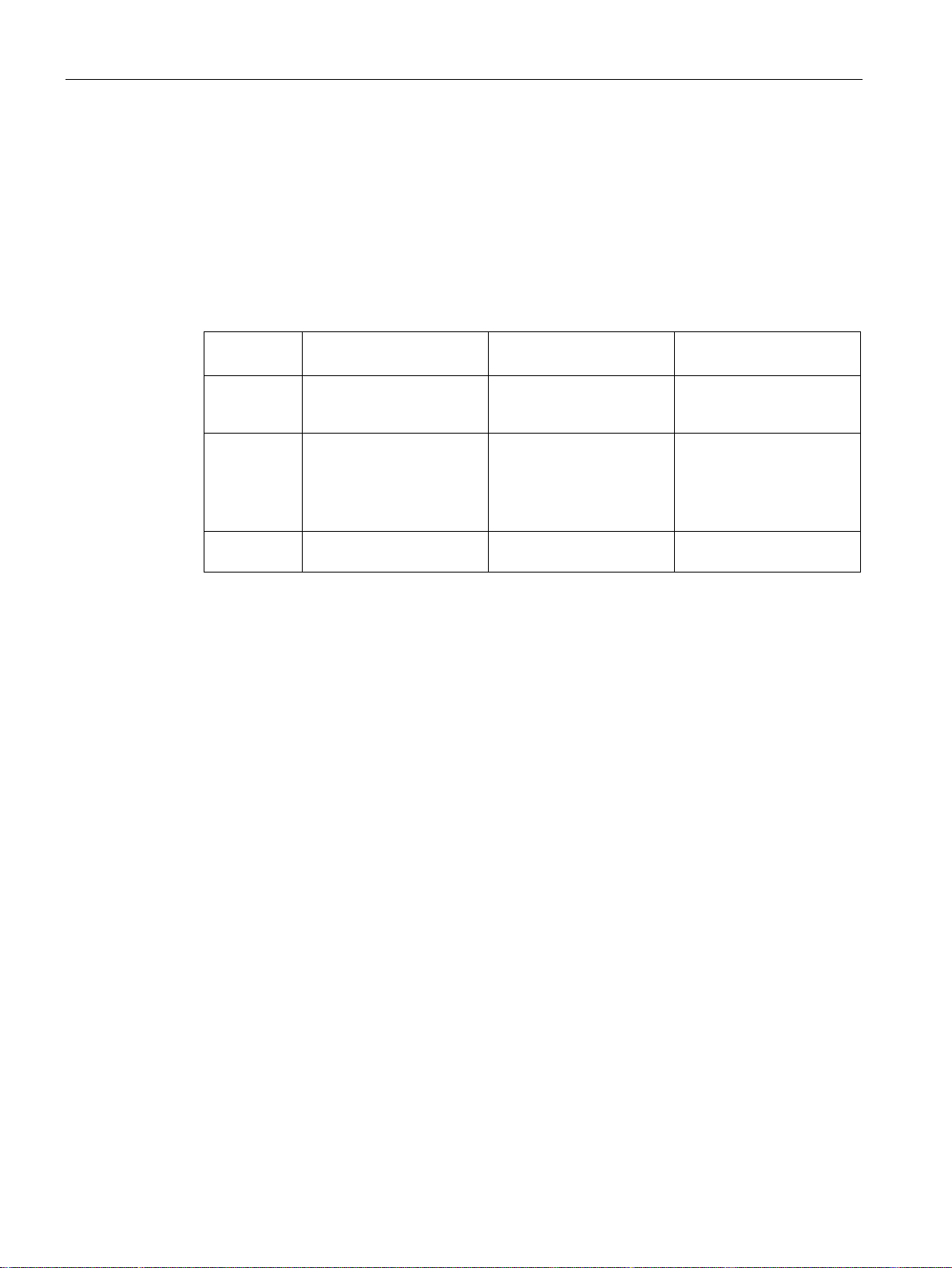

Components and protective measures

Screen number

Components

IEC 60364

IEC 60204

actuators

②

circuit breaker.

lines against overcurrent

Insulation monitoring

5.1 Operation of the CM on grounded/ungrounded power supply

A number of components and protective measures are prescribed for plant installations. The

types of components and the degree to which the protective measures are mandatory

depend on the IEC regulation that applies to your plant setup.

The following table shows the components of the electrical design with reference to the

previous figure and compares the IEC regulations.

Table 5- 1 Components of the electrical design

①

③

Isolation monitoring must be provided in the following cases:

● Design of the communications module with ungrounded reference potential

● If hazardous plant states can be expected as a result of faults.

Disconnecting device for

controller, sensors, and

Short-circuit and overload

protection

Circuit breaker

Main switch Disconnector

Single-pole protection of

circuits.

Protect all power supply

lines with a 24 V DC / 16 A

Protection of cables and

Single-pole protection must

be used for a grounded

secondary circuit.

--

SIMATIC RF185C, RF186C, RF188C

28 Operating Instructions, 10/2018, C79000-G8976-C512-01

Connection

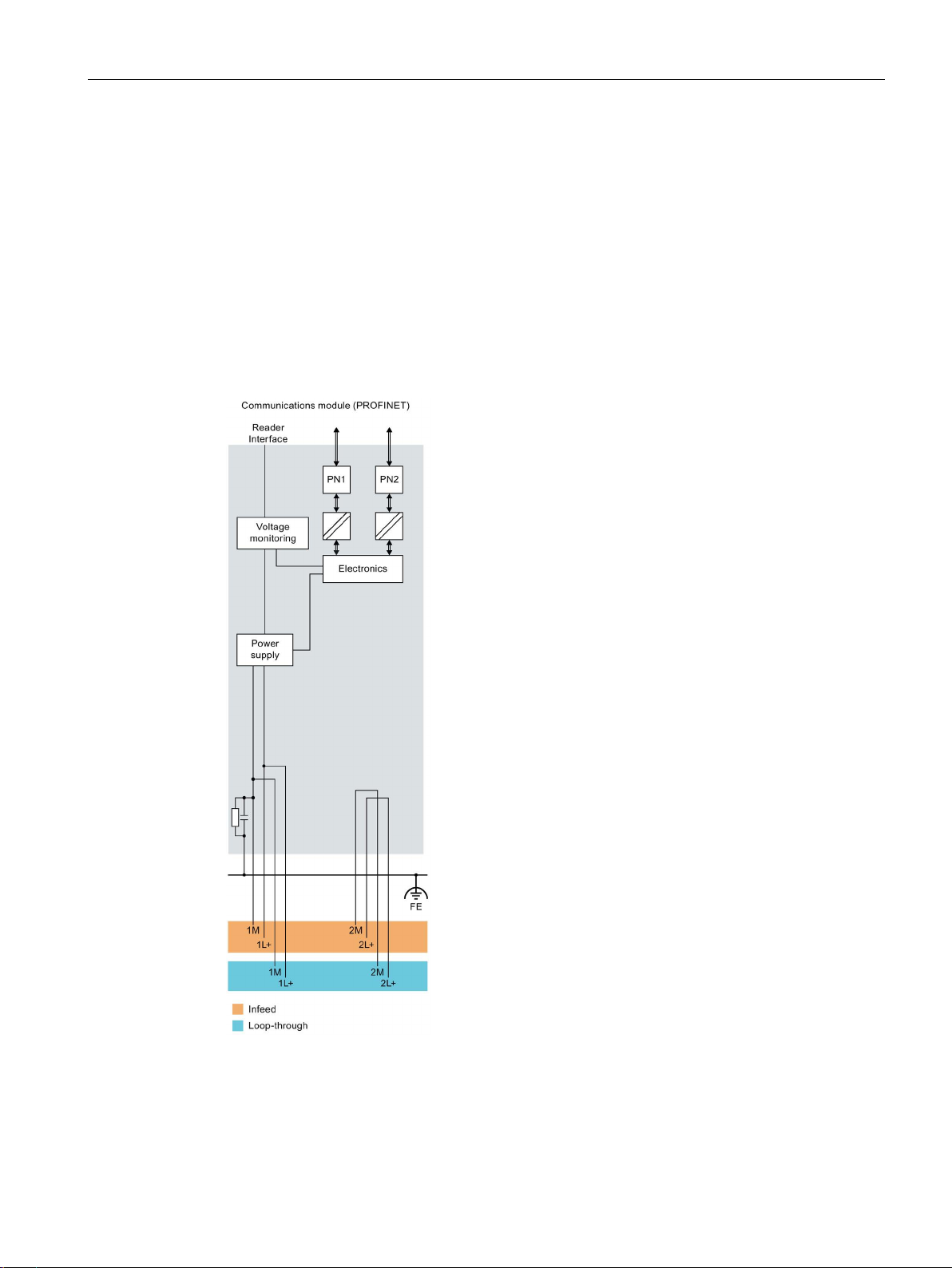

5.2

Electrical design of the CM

Electrical isolation

5.2 Electrical design of the CM

In the electrical design of the communications module, electrical isolation is provided

between:

● Load voltage 2L+ and all other circuit components

● Communication interfaces (PROFINET) of the communications module and all other

circuit components

The following figure shows the potential ratios of the communications module.

Figure 5-5 Potential ratios of the communications module

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

29

Connection

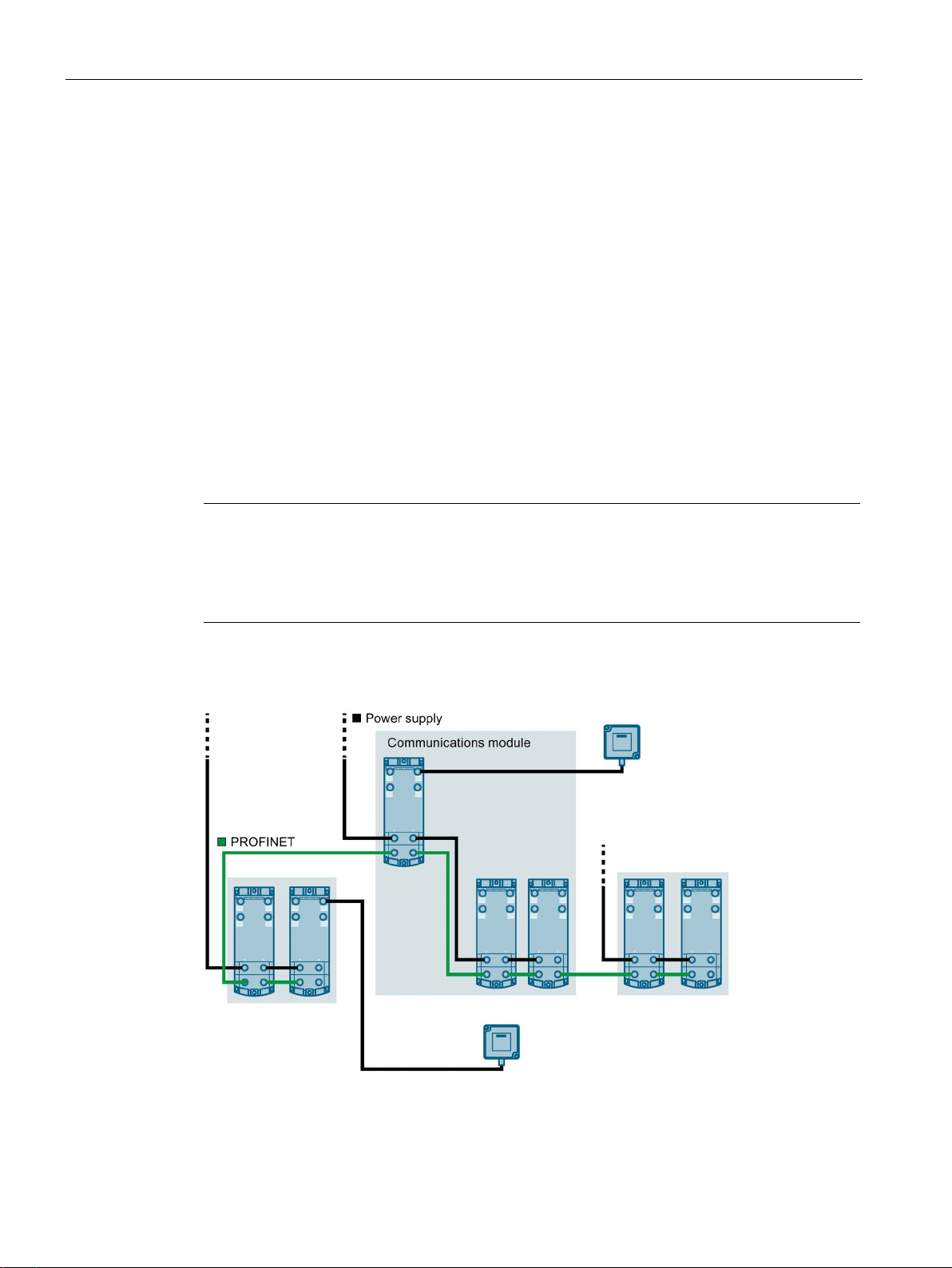

Circuit breaker

Power supply of the assembly

Note

Switching 1L+ and 2L+ on and off

Note that the power supply (1L+) supplies the communications module and the readers with

power. Load voltage (2L+)

is looped through to further consumers via the plug

5.2 Electrical design of the CM

According to IEC 60364, line protection is required, i.e. the supply lines must always be

protected externally.

All supply voltages must be protected with a UL/IEC approved fuse 24 V DC / 16 A (tripping

characteristic type B or C). At ambient temperatures of 40 °C to 55 °C, the power supplies

must be protected with a UL/IEC approved fuse 24 V DC / 12 A.

Two voltage groups are available for the communications module, 1L+ (supply voltage) and

2L+ (load voltage).

Another power supply may be required in order to supply all communications modules of an

assembly with the required voltage. Another voltage supply of 1L+ and 2L+ may be needed

to form different potential groups, or because the voltage is insufficient for all

communications modules due to the voltage drop. Create a power budget for the selection of

the supply point of the voltage.

has no direct effect on the communications module. This voltage

-in connectors.

The following figure shows a configuration with another voltage supply for the

communications modules. The different potential groups are highlighted in gray.

Figure 5-6 Wiring of the power supply

SIMATIC RF185C, RF186C, RF188C

30 Operating Instructions, 10/2018, C79000-G8976-C512-01

Loading...

Loading...