Page 1

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC Ident

RFID systems

SIMATIC RF185C, RF186C,

RF188C

Operating Instructions

10/2018

C79000

Introduction

1

Security recommendations

2

Description

3

Mounting

4

Connection

5

Configuring

6

Configuring with the WBM

7

Programming via SIMATIC

controller

8

Programming via the OPC

UA interface

9

Service and maintenance

10

Technical data

11

Dimension drawings

12

Appendix

A

Service & Support

B

-G8976-C512-01

Page 2

Siemens AG

Division Process Industries and Drives

Postfach 48 48

9

GERMANY

C79000-G8976-C512-01

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

0026 NÜRNBERG

09/2018 Subject to change

Page 3

Table of contents

1 Introduction ............................................................................................................................................. 7

2 Security recommendations ...................................................................................................................... 9

3 Description ............................................................................................................................................ 13

4 Mounting ............................................................................................................................................... 19

5 Connection ........................................................................................................................................... 23

6 Configuring ........................................................................................................................................... 43

7 Configuring with the WBM ..................................................................................................................... 53

3.1 Properties of the communications modules ............................................................................ 13

3.2 User-specific procedure .......................................................................................................... 15

3.3 Design ..................................................................................................................................... 17

4.1 Installation dimensions and position ....................................................................................... 19

4.2 Mounting the communications module ................................................................................... 20

5.1 Operation of the CM on grounded/ungrounded power supply ............................................... 26

5.2 Electrical design of the CM ..................................................................................................... 29

5.3 Connect CM to functional ground (PE) ................................................................................... 31

5.3.1 Mounting the CM on a conductive base ................................................................................. 31

5.3.2 Mounting the CM on a non-conductive base .......................................................................... 33

5.4 Connecting the communications module ................................................................................ 35

5.5 Supply voltage and PROFINET IO loop-through .................................................................... 39

5.6 Connecting cables for the CMs ............................................................................................... 40

6.1 Assign the IP address / device name ..................................................................................... 43

6.1.1 Assigning the IP address / device name with STEP 7 ............................................................ 43

6.1.2 Assigning the IP address / device name with the PST ........................................................... 45

6.2 Configuration via PROFINET IO ............................................................................................. 47

6.3 Configuration via OPC UA ...................................................................................................... 51

7.1 Starting WBM .......................................................................................................................... 53

7.2 The WBM ................................................................................................................................ 55

7.3 The menu items of the WBM .................................................................................................. 59

7.3.1 The "Start page" menu item .................................................................................................... 59

7.3.2 The "Settings - General" menu item ....................................................................................... 62

7.3.3 The "Settings - Reader Interface" menu item ......................................................................... 63

7.3.4 The "Settings - Communication" menu item ........................................................................... 66

7.3.5 The "Diagnostics - Log" menu item ........................................................................................ 74

7.3.6 The "Diagnostics - Service Log" menu item ........................................................................... 75

7.3.7 The "Edit transponder" menu item .......................................................................................... 78

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

3

Page 4

Table of contents

8 Programming via SIMATIC controller .................................................................................................... 87

9 Programming via the OPC UA interface ................................................................................................ 89

10 Service and maintenance ..................................................................................................................... 113

11 Technical data ..................................................................................................................................... 147

12 Dimension drawings ............................................................................................................................. 149

7.3.8 The "User management" menu item ...................................................................................... 80

7.3.9 The "System" menu item ....................................................................................................... 83

7.3.10 The "Help" menu item ............................................................................................................ 85

9.1 Supported methods/functions ................................................................................................ 90

9.2 OPC UA variables .................................................................................................................. 94

9.2.1 Description of the variables .................................................................................................... 94

9.2.2 ExecuteScan .......................................................................................................................... 95

9.2.3 CommonSettings.................................................................................................................... 95

9.2.4 RfidSettings ............................................................................................................................ 96

9.2.5 Diagnosis ............................................................................................................................... 97

9.2.6 DigitalIOPorts ....................................................................................................................... 103

9.3 OPC UA events .................................................................................................................... 105

9.3.1 Description of the events ..................................................................................................... 105

9.3.2 AutoIdPresenceEvent .......................................................................................................... 106

9.3.3 RfidLastAccessEvent ........................................................................................................... 106

9.3.4 AutoIdLastLogEntryEvent .................................................................................................... 111

10.1 Diagnostics ........................................................................................................................... 113

10.1.1 Diagnostics via the LED display ........................................................................................... 114

10.1.2 Diagnostics via SNMP ......................................................................................................... 117

10.1.3 Diagnostics using the WBM ................................................................................................. 117

10.1.4 Diagnostics over OPC UA .................................................................................................... 118

10.1.5 Diagnostics using the TIA Portal (STEP 7 Basic / Professional) ......................................... 118

10.1.6 Parameterization of the diagnostics ..................................................................................... 121

10.2 Error messages .................................................................................................................... 123

10.2.1 Error messages of the communications module .................................................................. 123

10.2.2 OPC UA error messages ..................................................................................................... 131

10.2.3 Reading out error messages using the WBM ...................................................................... 134

10.3 Firmware update .................................................................................................................. 134

10.3.1 Updating the firmware via WBM .......................................................................................... 135

10.3.2 Update firmware via TIA Portal (STEP 7 Basic / Professional) ........................................... 136

10.3.3 Updating firmware of the readers using the TIA Portal (STEP 7 Basic / Professional) ....... 137

10.4 Factory defaults.................................................................................................................... 139

10.4.1 Restoring the factory settings via WBM ............................................................................... 139

10.4.2 Restoring the factory settings manually ............................................................................... 140

10.5 Module replacement ............................................................................................................ 141

10.5.1 Backup configuration data ................................................................................................... 142

10.5.2 Replacing a module ............................................................................................................. 144

SIMATIC RF185C, RF186C, RF188C

4 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 5

Table of contents

A Appendix............................................................................................................................................. 151

B Service & Support ............................................................................................................................... 157

A.1 System planning ................................................................................................................... 151

A.2 Connecting cables ................................................................................................................ 152

A.2.1 Standard cables .................................................................................................................... 152

A.2.2 Custom assembled cables .................................................................................................... 153

A.3 Ordering data ........................................................................................................................ 154

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

5

Page 6

Table of contents

SIMATIC RF185C, RF186C, RF188C

6 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 7

1

Purpose of these operating instructions

Basic knowledge required

Scope of validity of this documentation

Trademarks

Orientation in the documentation

Abbreviations and naming conventions

Reader

Write/read device (SLG)

Transponder, tag

Data medium, mobile data storage (MDS)

Communications module (CM)

Interface module (ASM)

The information provided in these operating instructions enables you to commission the

RF18xC communications module on a PROFINET IO controller.

These operating instructions assume general knowledge of automation engineering and

identification systems.

These operating instructions are valid for the RF185C, RF186C and RF188C

communications modules as of product version "01" and delivery date as of 10/2018.

The following and possibly other names not identified by the registered trademark sign ® are

registered trademarks of Siemens AG:

SIMATIC ®, SIMATIC RF ®, MOBY ®, RF MANAGER ®, SIMATIC Sensors ®

In addition to these operating instructions, you require the operating instructions for the S7300, S7-400, S7-1200 or S7-1500 controller used.

If you are using SIMATIC S7, you can find information on programming the module as well

as a complete error description in the description of the FB 45 function block, RFID standard

profile and Ident profile.

You can find information on the readers and optical readers to be connected in the intrinsic

safety manual of the respective product family (RF200, RF300, RF600, MV400 and MV500).

You can find the current versions of the various manuals on the pages of the Siemens

Industry Online Support (https://support.industry.siemens.com/cs/ww/en/ps/14970/man

The following terms/abbreviations are used synonymously in this document:

).

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

7

Page 8

Introduction

Recycling and disposal

The products are low in harmful substances, can be recycled and meet the requirements of

the Directive 2012/19/EU for disposal of waste electrical and electronic equipment (WEEE).

Do not dispose of the products at public disposal sites.

For environmentally compliant recycling and disposal of your electronic waste, please

contact a company certified for the disposal of electronic waste or your Siemens

representative.

Adhere to the various country-specific regulations.

SIMATIC RF185C, RF186C, RF188C

8 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 9

2

General

Physical access

Software (security functions)

Passwords

To prevent unauthorized access, observe the following security recommendations when

working with the communications module and WBM (Web Based Management).

● Check regularly that the device complies with these recommendations and/or other

internal security policies.

● Evaluate your plant as a whole in terms of security. Use a cell protection concept with

suitable products.

● Do not connect the device directly to the Internet. Operate the device within a protected

network area.

● Restrict physical access to the device to qualified personnel.

● Lock unused physical ports (e.g. Ethernet ports) on the device. Unused ports can be used

to access the system without authorization.

● Keep the software up to date. Keep yourself informed regularly about safety updates for

the product.

You can find information about this at Link (http://www.siemens.com/industrialsecurity

● Activate only protocols that you actually need to use the device.

● Limit access to the device using a firewall or rules in an access control list (ACL).

● The configuration files are available in XML format for simple use. Make sure that the

configuration files outside the device are suitably protected. You can, for example,

encrypt the files, store them at a safe location and transfer them only via secure

communications channels.

● Activate user management and create new user profiles.

● Change all default passwords for users before operating the device.

).

● Only use passwords with high password strength. Avoid weak passwords, e.g.

password1, 123456789, abcdefgh.

● Define rules for using devices and assigning passwords.

● Make sure that all passwords are protected and inaccessible to unauthorized personnel.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

9

Page 10

Security recommendations

Keys and certificates

Firmware encryption

Secure/non-secure protocols

● Do not use the same password for different users and systems.

● Update passwords and keys regularly to improve security.

This section deals with the security keys and certificates that you need to set up SSL.

● We urgently recommend creating your own SSL certificates and making them available.

Preset certificates and keys are present in the device.

The preset and automatically created SSL certificates are self-signed. We recommend

using certificates signed either by a reliable external certification authority or an internal

certification authority.

The device has an interface via which you can import certificates and keys.

● We recommend using certificates with a key length of at least 2048 bits.

● If protocols support both certificates and keys, you should favor certificates.

The firmware itself is signed and encrypted. This ensures that only authentic firmware can be

downloaded to the device.

● Check whether it is necessary to use SNMPv1. SNMPv1 is classified as non-secure.

Make use of the possibility to prevent write access. The product offers corresponding

settings for this.

● If SNMP is activated, change the community names. If unrestricted access is not

necessary, limit access via SNMP.

● Use secure protocols if access to the device is not protected by means of physical

safeguards.

The following protocols provide secure alternatives:

HTTP → HTTPS

● To prevent unauthorized access to the device or network, set up appropriate safeguards

against non-secure protocols.

● Enable only the services (protocols) that will actually be used on the device. The same

applies to the installed interfaces/ports. Unused ports could be used to access the

network downstream from the device.

SIMATIC RF185C, RF186C, RF188C

10 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 11

Security recommendations

List of available protocols

Protocol

Port number

Default

protocol status

Protocol status

configurable

Port number

configurable

Authentication

Encryption

DHCP

UDP/68

Open

✓

--

No

No

HTTP

TCP/80

Open

--

--

No

No

HTTPS

TCP/443

Open

--

--

Yes

Yes

NTP

UDP/123

Closed

✓

--

No

No

SNMP

UDP/161

Closed

✓

--

No

No

ured)

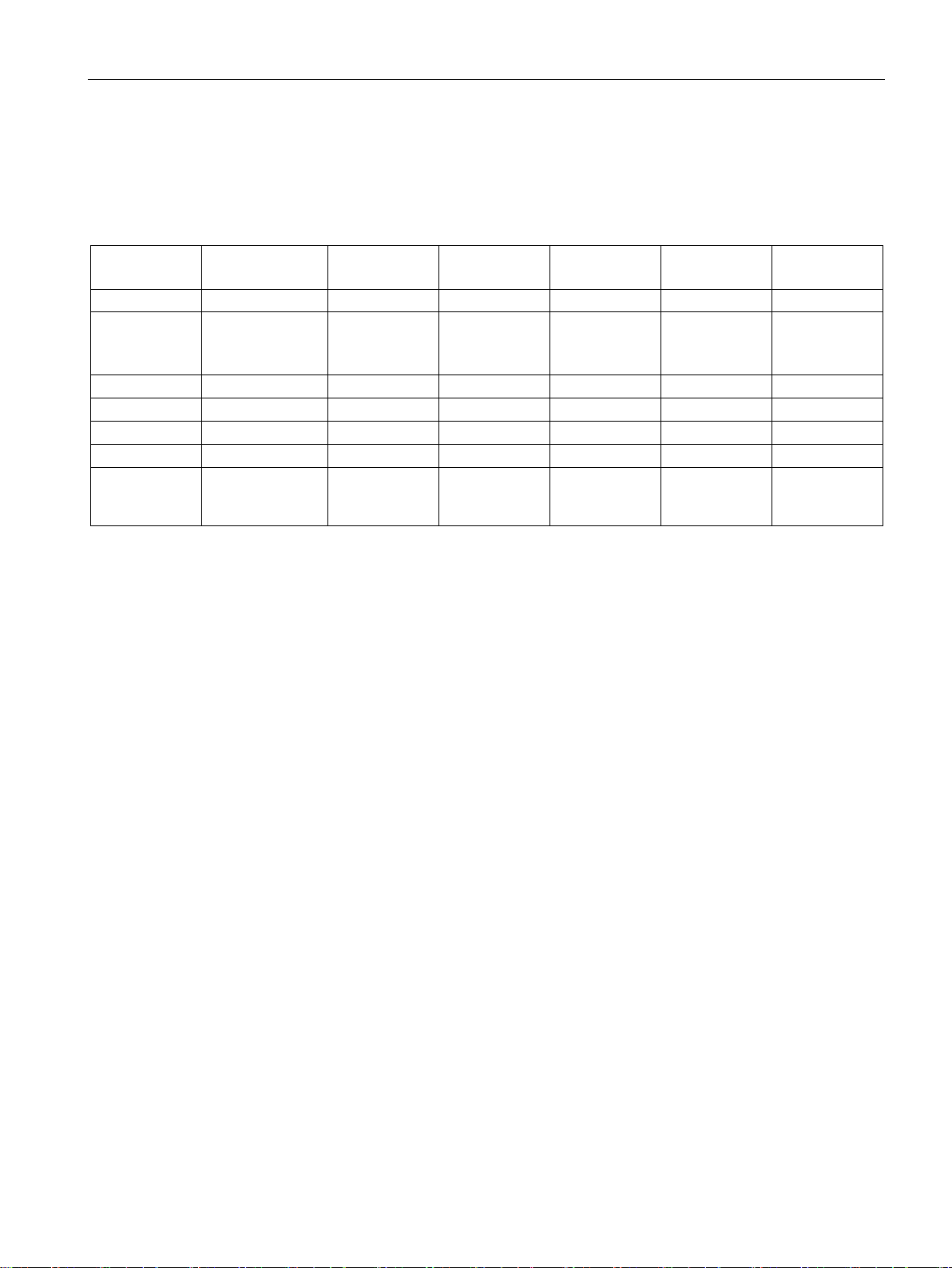

All available protocols and their ports that are used with SIMATIC RF18xC are listed below.

Table 2- 1 List of available protocols

PROFINET UDP/34964

UDP/4915265535

OPC UA TCP/4840 Open ✓ ✓ Yes (simple,

Open ✓ -- No No

when config-

Explanation of the table:

● Authentication

Specifies whether authentication of the communication partner takes place.

● Encryption

Specifies whether the transfer is encrypted.

Yes (when

configured)

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

11

Page 12

Security recommendations

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For additional information on industrial security measures that may be

implemented, please visit

Link: (http://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers’ exposure

to cyber threats.

)

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Link: (http://www.siemens.com/industrialsecurity

)

SIMATIC RF185C, RF186C, RF188C

12 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 13

3

3.1

Properties of the communications modules

Area of application

The SIMATIC RF185C, RF186C and RF188C communications modules are designed for

use in all areas of automation. It covers all areas in which SIMATIC Ident RFID readers and

optical readers are operated. The application can run at the field level on a controller, on a

PC or at the IT level. For example, RFID data can be transmitted via the standardized OPC

UA interface to higher-level systems - even parallel to communication with a controller if

required.

Figure 3-1 Communications modules RF185C, RF186C and RF188C

Due to the high degree of protection, mounting without a protective enclosure is possible

directly near the RFID read points. The small mounting surface of the communications

module facilitates installation in confined spaces.

Two connectors each for Ethernet and power supply allow configuration in a line structure in

addition to a star structure. The innovative L-coded M12 connectors for the power supply

allow a high feed-through current in a line structure. In addition to the familiar configuration

types via TIA Portal and GSDML, these communications modules also feature integrated

Web Based Management (WBM), which enables devices to be set via a standard browser.

During commissioning, diagnostics and maintenance, WBM is a very convenient tool and

displays the status of the connected readers and the data of the recorded transponders.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

13

Page 14

Description

Features

Features

RF185C

RF186C

RF188C

devices

Transfer speed: 19.2 ... 115.2 KB

Transmission speed: 100 Mbps

Degree of protection

IP67

Application protocols

PROFINET IO, OPC UA

diagnostic options

Function blocks

Ident profile, FB 45, faceplate for PCS 7

controllers

controllers

and IEC61131 programming are supported.

NOTICE

Operation in VLANs

3.1 Properties of the communications modules

You can find additional information on the various RFID devices and optical readers on the

Internet on the "Siemens Industry Online Support

(https://support.industry.siemens.com/cs/ww/en/ps/14970/man

)" page.

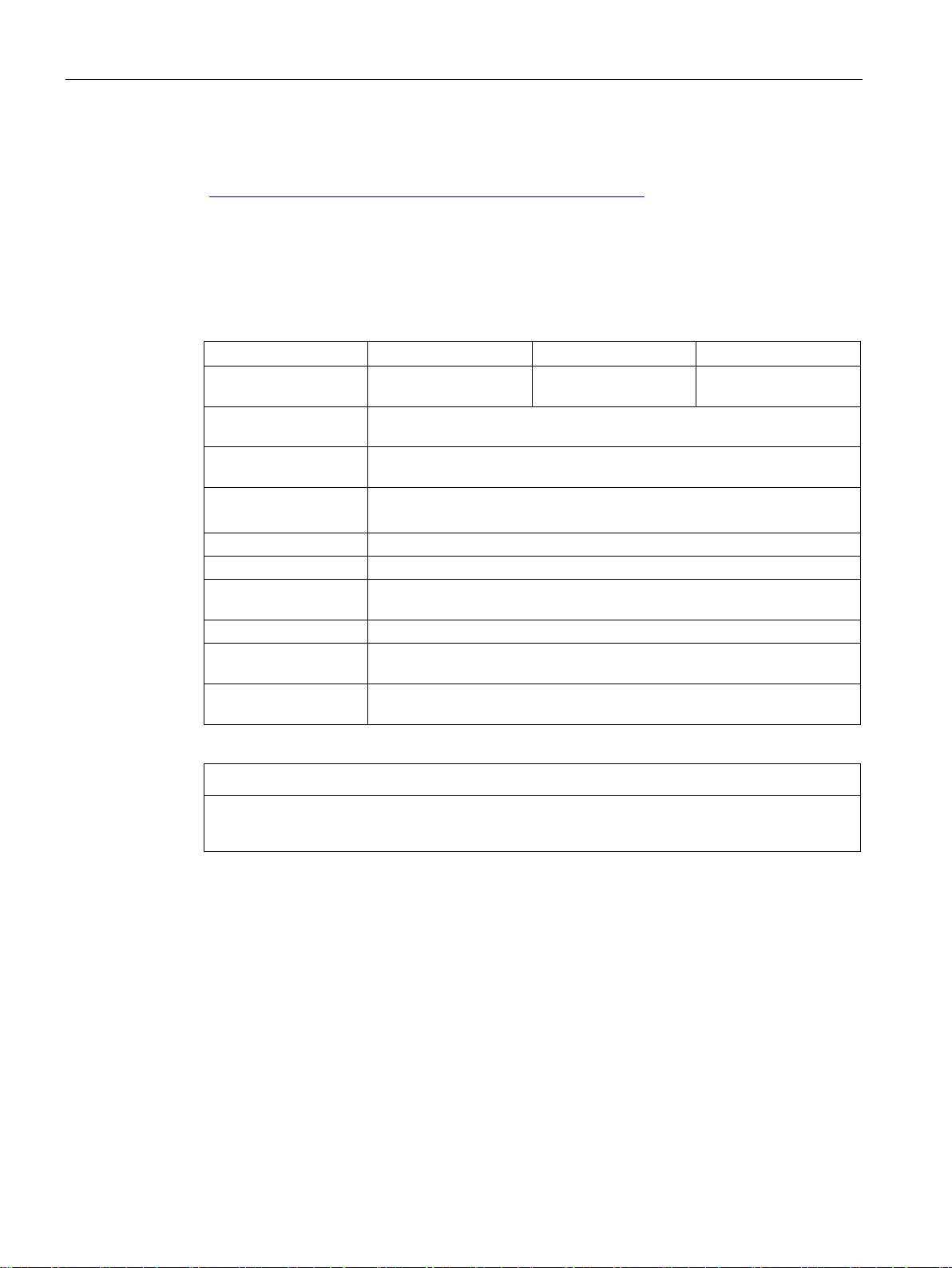

The following features characterize the RF18xC communications modules:

Table 3- 1 Features of the communications modules

Number of connectable

Supported product

families

Interfaces RS422

Ethernet interface 2x M12, switch integrated

Configuration/

Supported SIMATIC

Supported third-party

Source code of the Ident profile available. All controllers with PROFINET

1 2 4

RF200, RF300, MV400, MV500

STEP 7 (TIA Portal), GSDML, WBM (browser)

S7-300, S7-400, S7-1200, S7-1500

Note that the communications modules cannot be operated in VLANs whose ID is ≠ 0.

SIMATIC RF185C, RF186C, RF188C

14 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 15

Description

3.2

User-specific procedure

Procedure as S7 user

Procedure as an OPC UA user

3.2 User-specific procedure

As described in the previous section, the communications modules are designed for different

environments and requirements.

If you operate the communications modules in an automation environment, they are

configured and programmed from the perspective of an S7 user. If you operate the

communications modules in an OPC UA environment, they are configured and programmed

from the perspective of an OPC UA user.

If you want to adapt the communications modules to your requirements, we recommend the

following user-specific procedure:

1. Connect the hardware

You can find information on this in the section "Connection (Page 23)".

2. Assign the IP address / device name

You can find information on this in the section "Assign the IP address / device name

(Page 43)".

3. Configure communications module

You can find information on this in the section "Configuration via PROFINET IO

(Page 47)" or "Configuring with the WBM (Page 53)".

4. Program reader commands

You can find information on this in the section "Programming via SIMATIC controller

(Page 87)".

1. Connect the hardware

You can find information on this in the section "Connection (Page 23)".

2. Assign the IP address / device name

You can find information on this in the section "Assigning the IP address / device name

with the PST (Page 45)".

3. Configure the communications module

You can find information on this in the section "Configuring with the WBM (Page 53)".

4. Program reader commands

You can find information on this in the section "Programming via the OPC UA interface

(Page 89)".

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

15

Page 16

Description

Note

Synchronize device time

Note that the time of the device clock corresponds to UTC time and cannot be adj

time zones. Clicking the button transfers the local time stored in your operating system to the

communications module. Because the time synchronized with the PC is lost when the power

supply is terminated, we recommend synchronizing the time with

3.3 Design

usted to

an NTP server.

Later in the document, these symbols will help your orientation and will show you whether

the section is of interest to you or not. Only the sections with user-specific content, in other

words content that is tool/interface-specific, contain these symbols. Sections without these

symbols are general and relevant for both areas of application.

SIMATIC RF185C, RF186C, RF188C

16 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 17

Description

3.3

Design

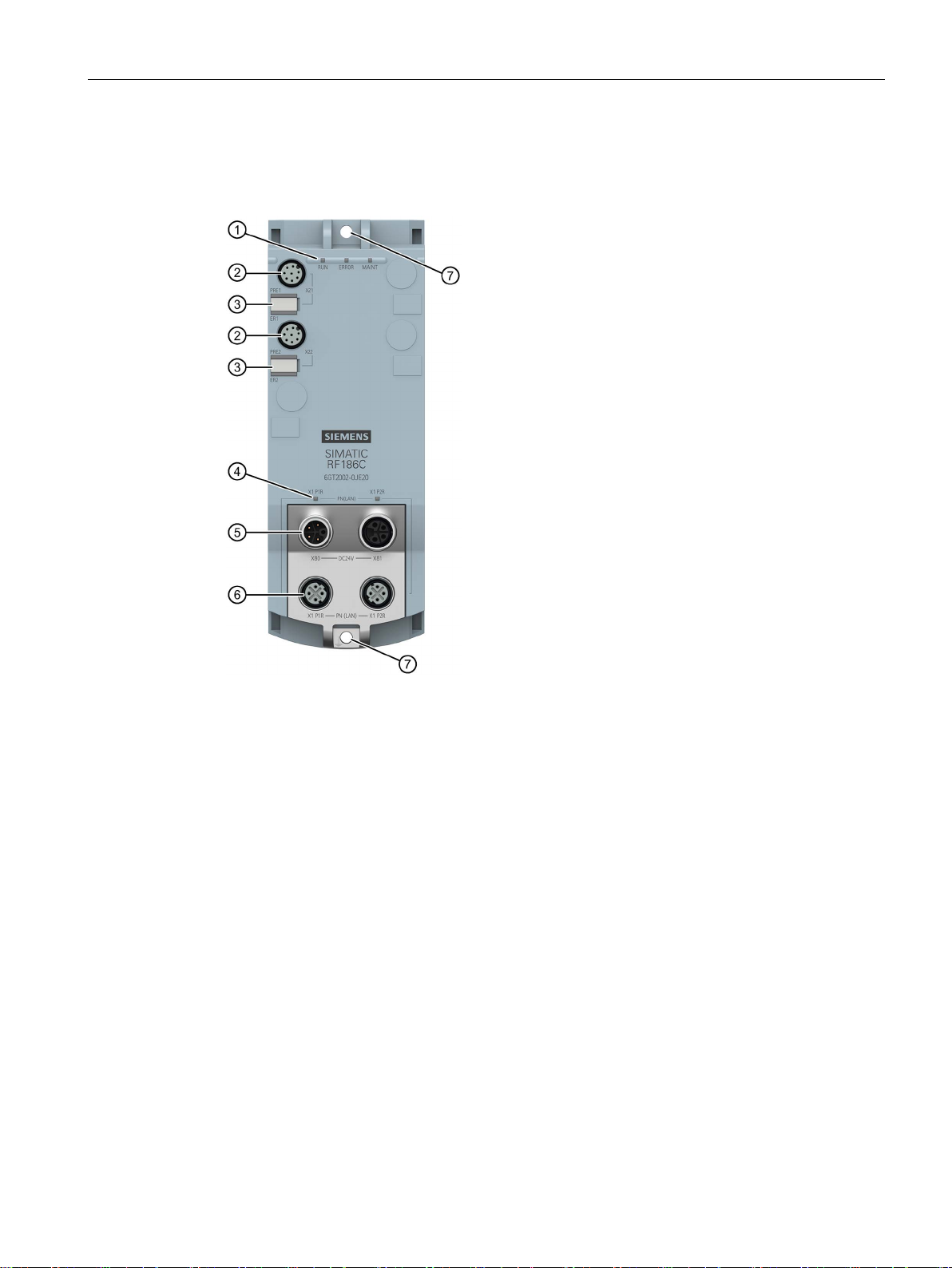

①

⑤

(M12, 4-pin, L-coded)

②

(M12, 8-pin, A-coded)

⑥

(M12, 4-pin, D-coded)

③

Reader LEDs

⑦

Mounting holes and functional ground (PE)

④

PROFINET/Ethernet LEDs

3.3 Design

The following figure shows the basic design of the RF18xC.

Status LEDs

Reader interfaces

Figure 3-2 Design of the communications module

Interface for the power supply

Interface for PROFINET IO

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

17

Page 18

Description

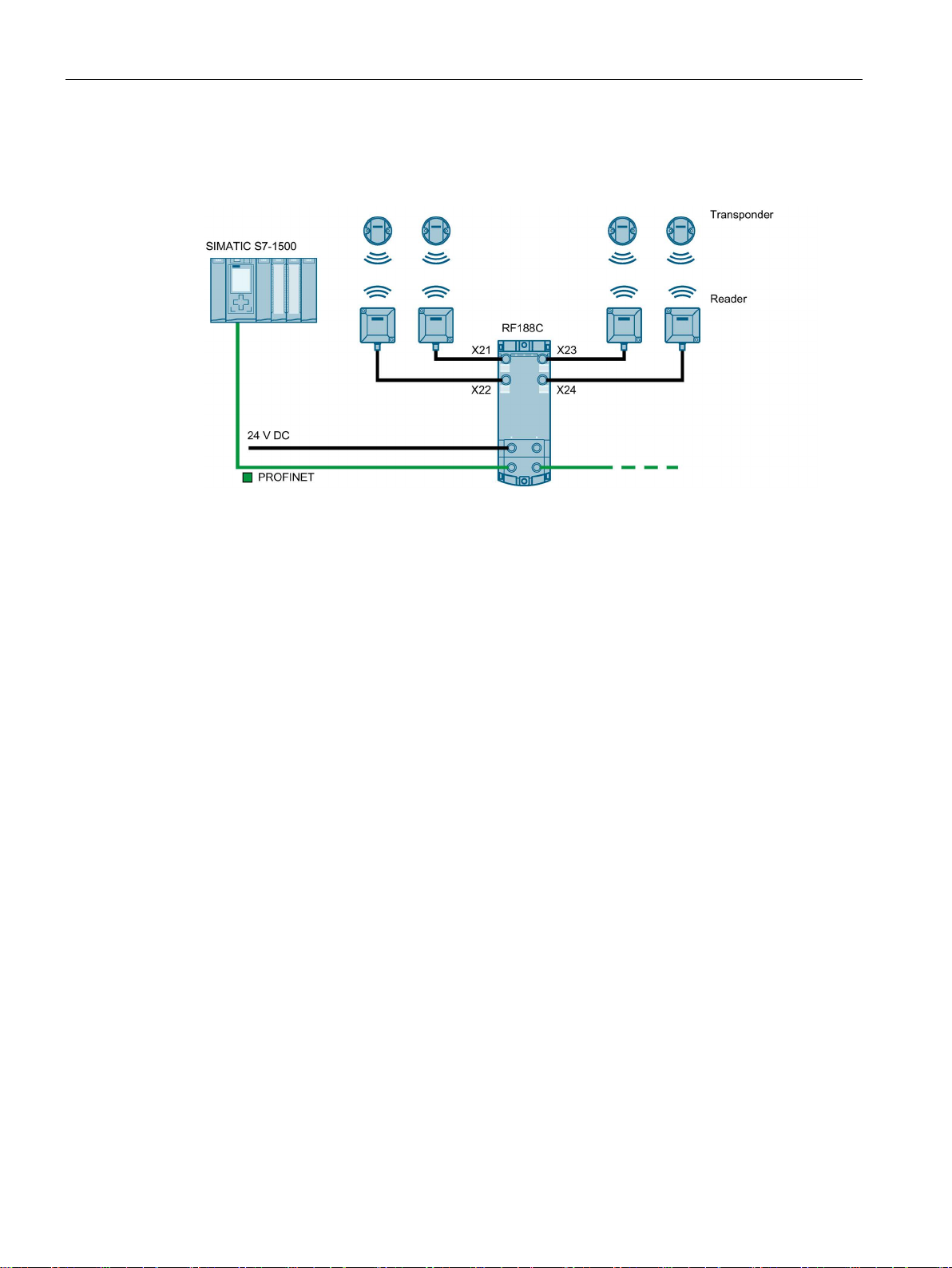

Integration

3.3 Design

The following figure shows an example of an RF188C connection to an automation system.

Figure 3-3 Configuration graphic RF188C

As of STEP 7 Basic / Professional V15.1, the RF18xC communications modules are

integrated in the TIA Portal. Integration into 3rd-party systems is performed via a GSDML

file. The RF18xC can then be configured via the TIA Portal or another engineering system.

The GSDML file is stored on the communications module and can be downloaded from it

using a Web browser.

SIMATIC RF185C, RF186C, RF188C

18 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 19

4

NOTICE

Installation outdoors

irect sunlight,

4.1

Installation dimensions and position

Minimum clearances

Mounting rules

Note

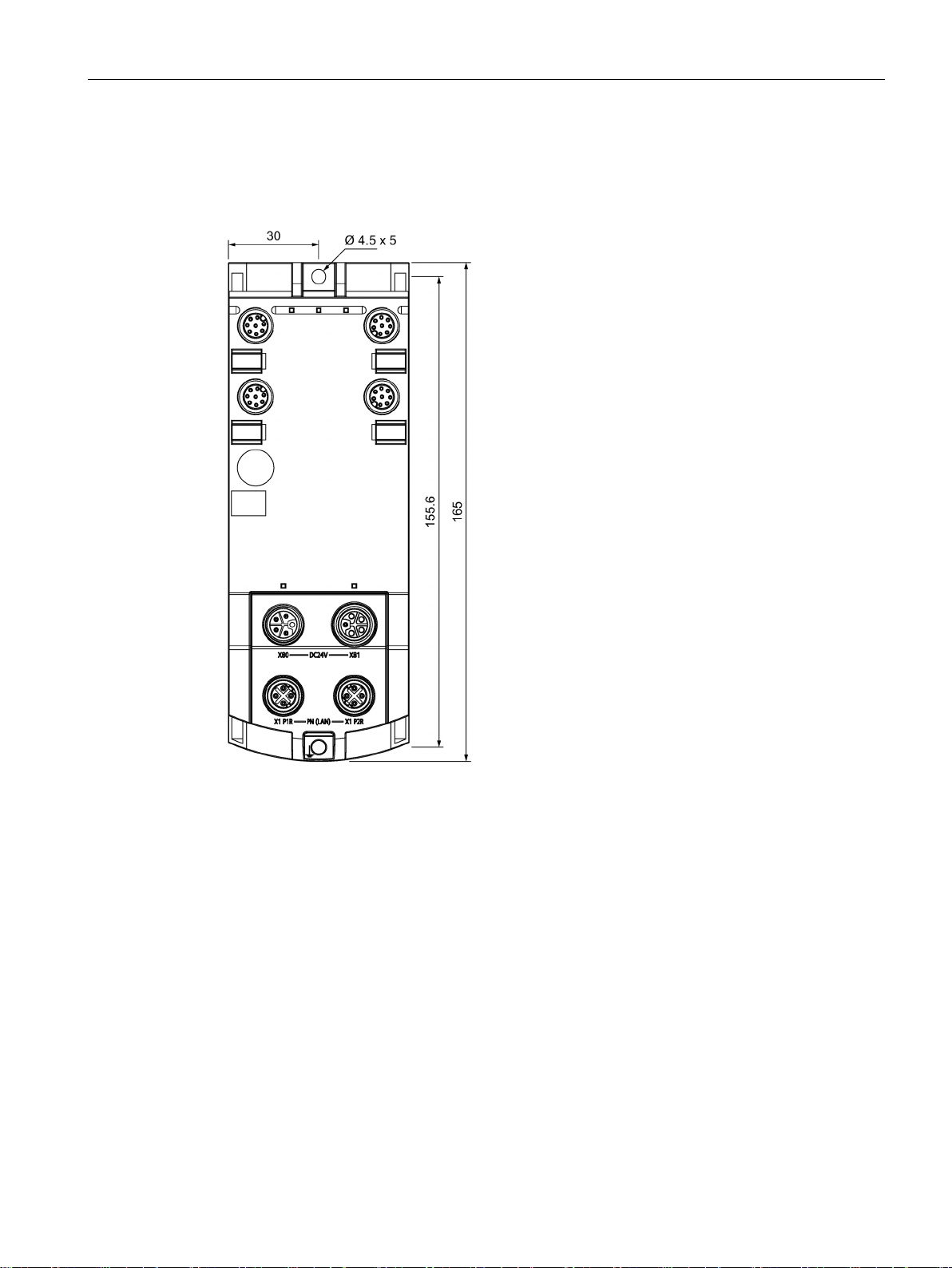

Mounting the communications modules

Only install the communications module when supply voltage

The RF18xC communications modules are designed for easy installation.

Please note that the communications module needs to be installed in a protected area. In

the case of installation outdoors, make sure that the device is protected from d

precipitation and wind.

The RF18xC communications modules have the following installation dimensions (W × H ×

D): 60 × 165 × 45 mm.

You can mount the communications modules in any mounting position.

When installing the communications modules, keep a minimum distance of 1 cm from an

adjacent device or another device.

You do not have to observe any special rules when installing the communications modules.

s are switched off.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

19

Page 20

Mounting

4.2

Mounting the communications module

Introduction

Note

Functional ground (PE)

If a grounded metal mounting surface is used, the bottom mounting screw of the RF18xC

module already e

separate ground conductor. If you use the fixing screw as grounding connection, the thread

of the fixing screw or the contact facing of the fastening nut on the base must be unpainted.

This ensures a low

Requirements

Screw type

Description

ISO 1207 / DIN EN ISO 1580

ing to DIN EN ISO 4762

4.2 Mounting the communications module

The communications modules are designed for mounting on a flat, solid surface.

Alternatively, you can use the axially symmetrical drill holes of the modules to fasten them to

an aluminum profile using sliding blocks.

stablishes a reliable ground connection. This eliminates the need for a

-resistance connection.

The following table shows and explains the types of screws you need to mount the modules.

Table 4- 1 Recommended screw types

Cylinder head screw M4 according to DIN EN

Cylinder head screw with M4 hex socket accord-

The minimum screw length should be 35 mm.

If you need washers, use washers conforming to

DIN EN ISO 7089 / DIN EN ISO 7090.

SIMATIC RF185C, RF186C, RF188C

20 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 21

Mounting

Procedure

4.2 Mounting the communications module

Fasten the communications module with the screws on a solid level surface. The device

must be screwed (≤ 3 Nm) onto the panel at both fastening points (front top and bottom).

Figure 4-1 Mounting the RF18xC communications module

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

21

Page 22

Mounting

Fastener for cable ties

4.2 Mounting the communications module

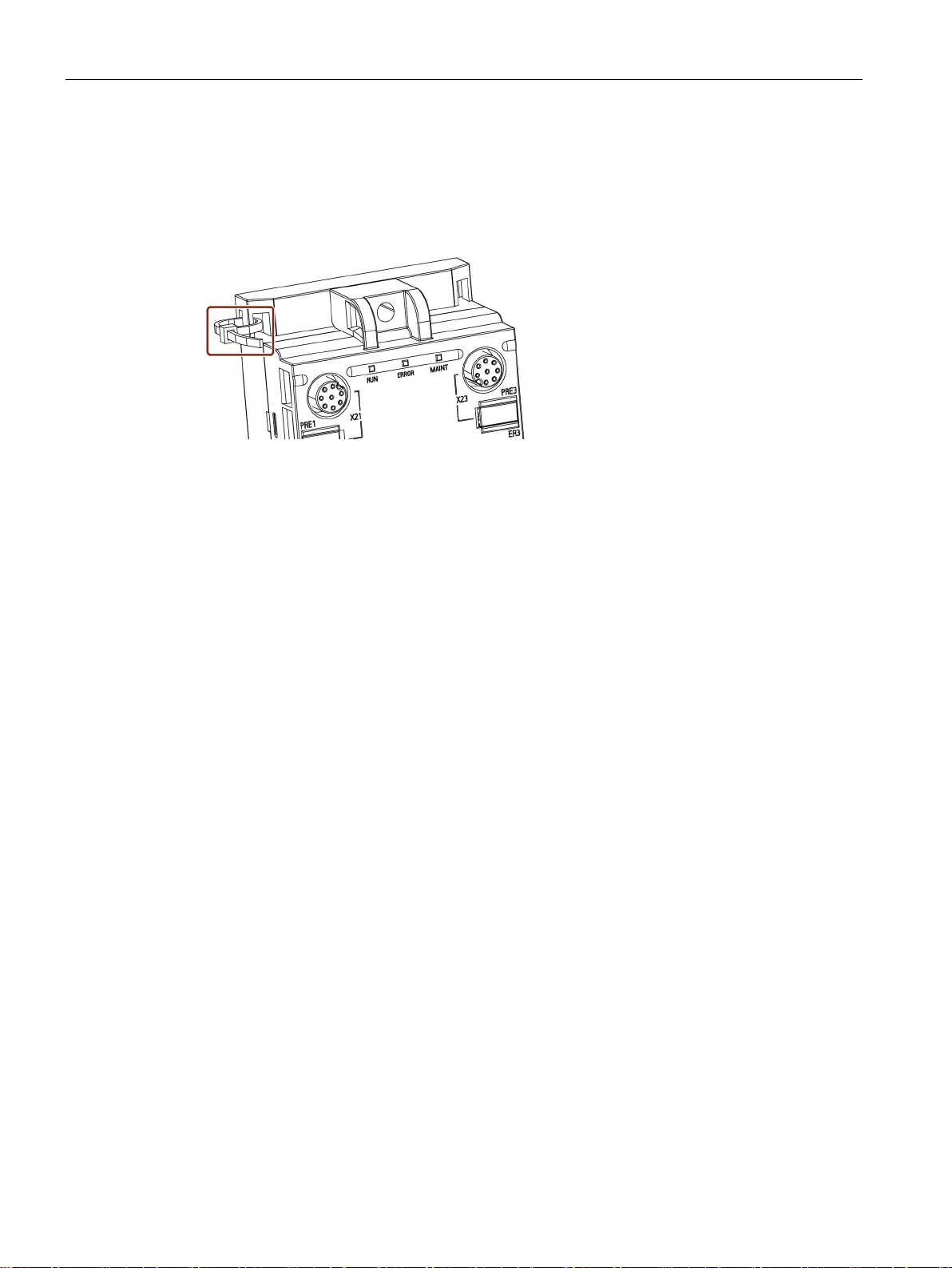

All communications modules have integrated fastening points for cable ties. The fastening

points are located at all four corners of the modules.

The following figure shows the upper left fastening point for 2.5 mm wide cable ties.

Figure 4-2 Mounting the RF18xC communications module

SIMATIC RF185C, RF186C, RF188C

22 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 23

5

Proper use

PROFINET IO connection system

CAUTION

Power supply for devices with PROFINET interfaces

Only use the device for its intended purpose. If unspecified devices are connected to the

RF18xC, the connected device may be destroyed.

You can find detailed information on connecting the RF18xC on PROFINET IO in the

"SIMATIC PROFINET system description

(https://support.industry.siemens.com/cs/ww/en/view/19292127

)".

Modules with PROFINET interfaces may only be operated in LANs (Local Area Networks)

in which all connected devices are equipped with SELV/PELV power supplies (or have

equivalent protection).

A data transfer terminal (modem, for example) is required to access the WAN (Wide Area

Network) in order to ensure compliance with this safety standard.

All supply and signal voltages must be safety extra low voltage (SELV/PELV according to

IEC 61140).

DC 24 V supply: safe (electrical) isolation of extra-low voltage (SELV/PELV according to

EN 61140).

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

23

Page 24

Connection

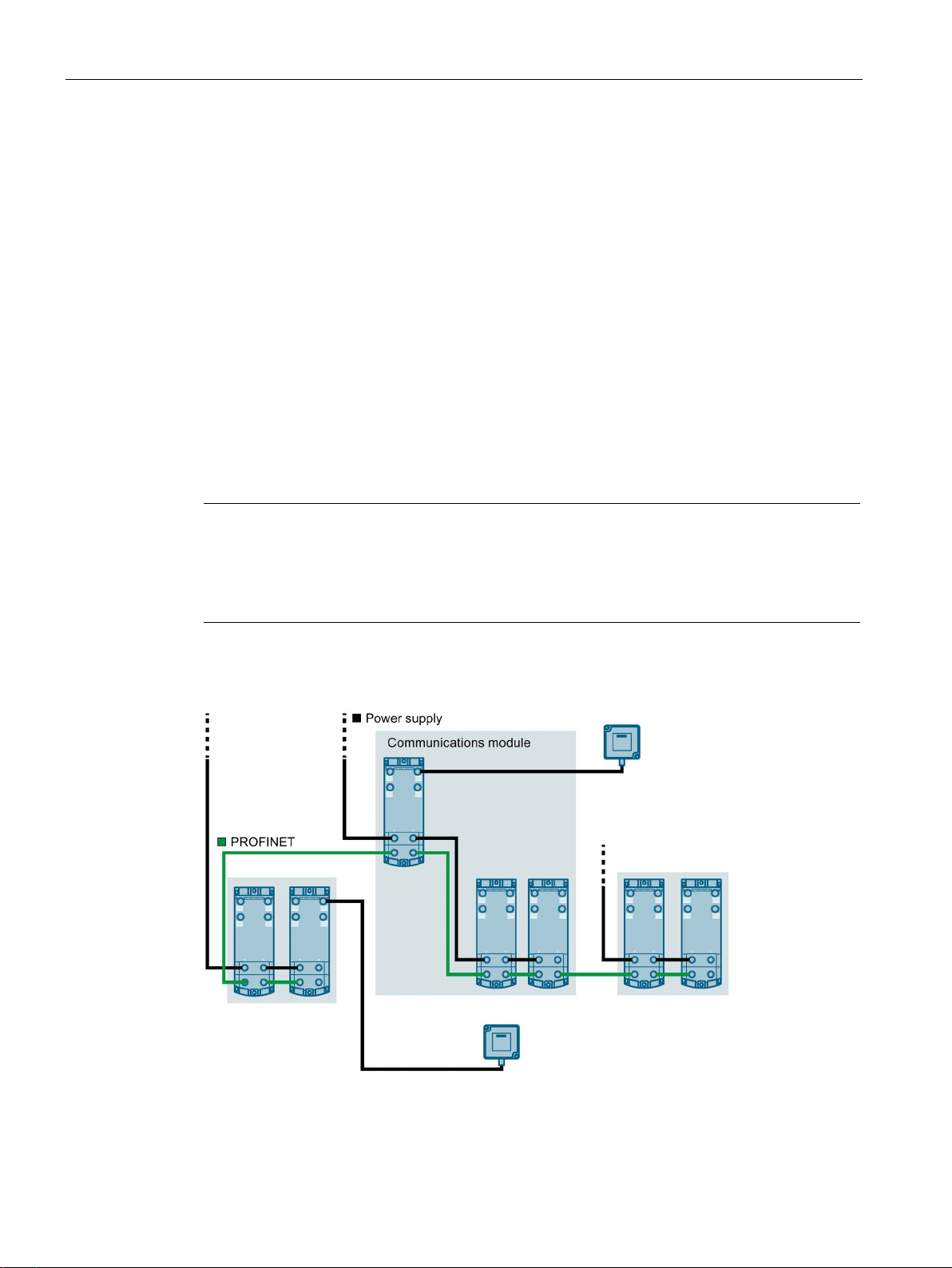

PROFINET IO topology

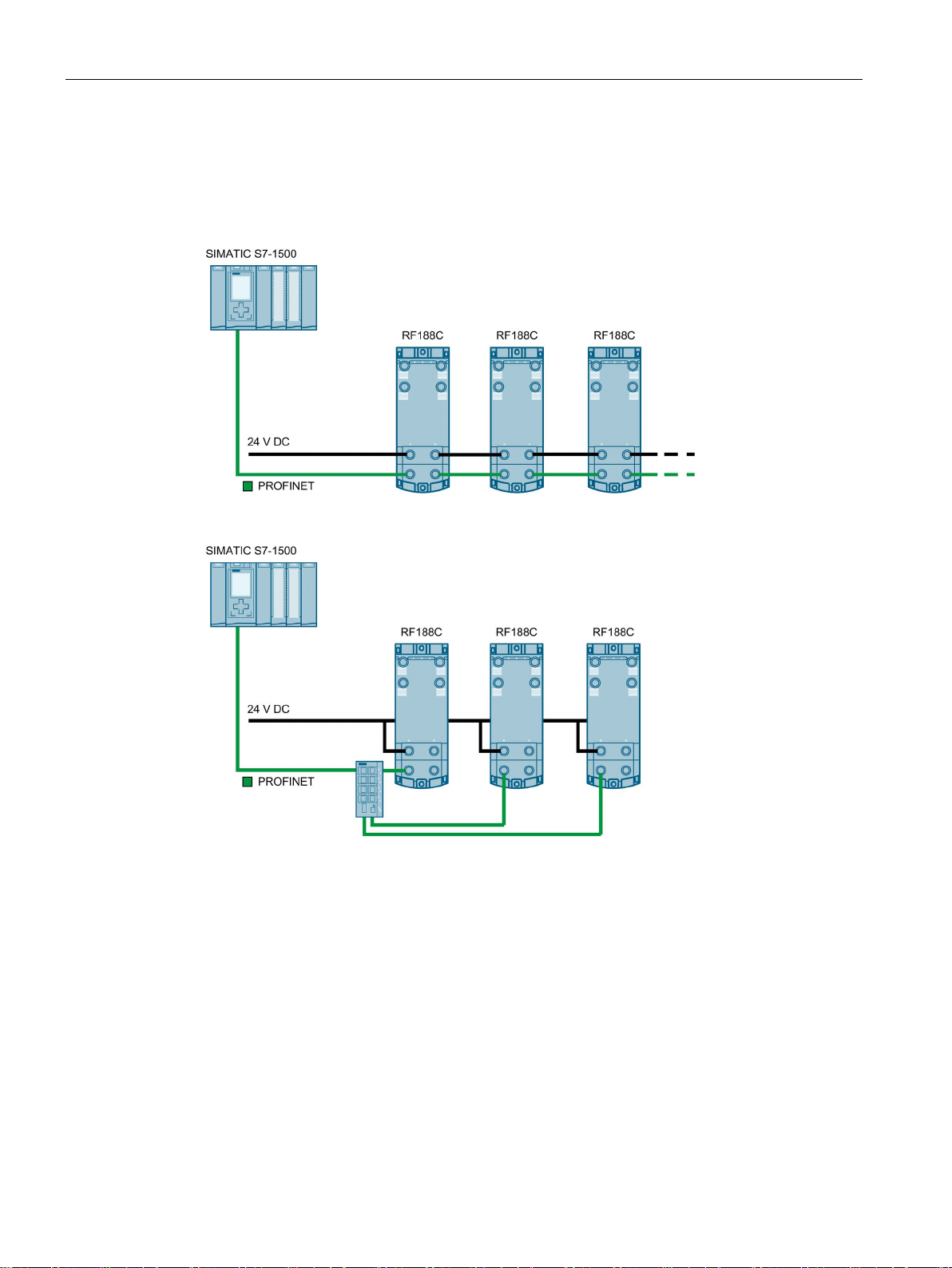

PROFINET IO communication can be structured as a line topology or star topology. Also

note the information in the section "Supply voltage and PROFINET IO loop-through

(Page 39)".

Figure 5-1 Configuration graphic of a line topology

Figure 5-2 Configuration graphic of a star topology

SIMATIC RF185C, RF186C, RF188C

24 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 25

Connection

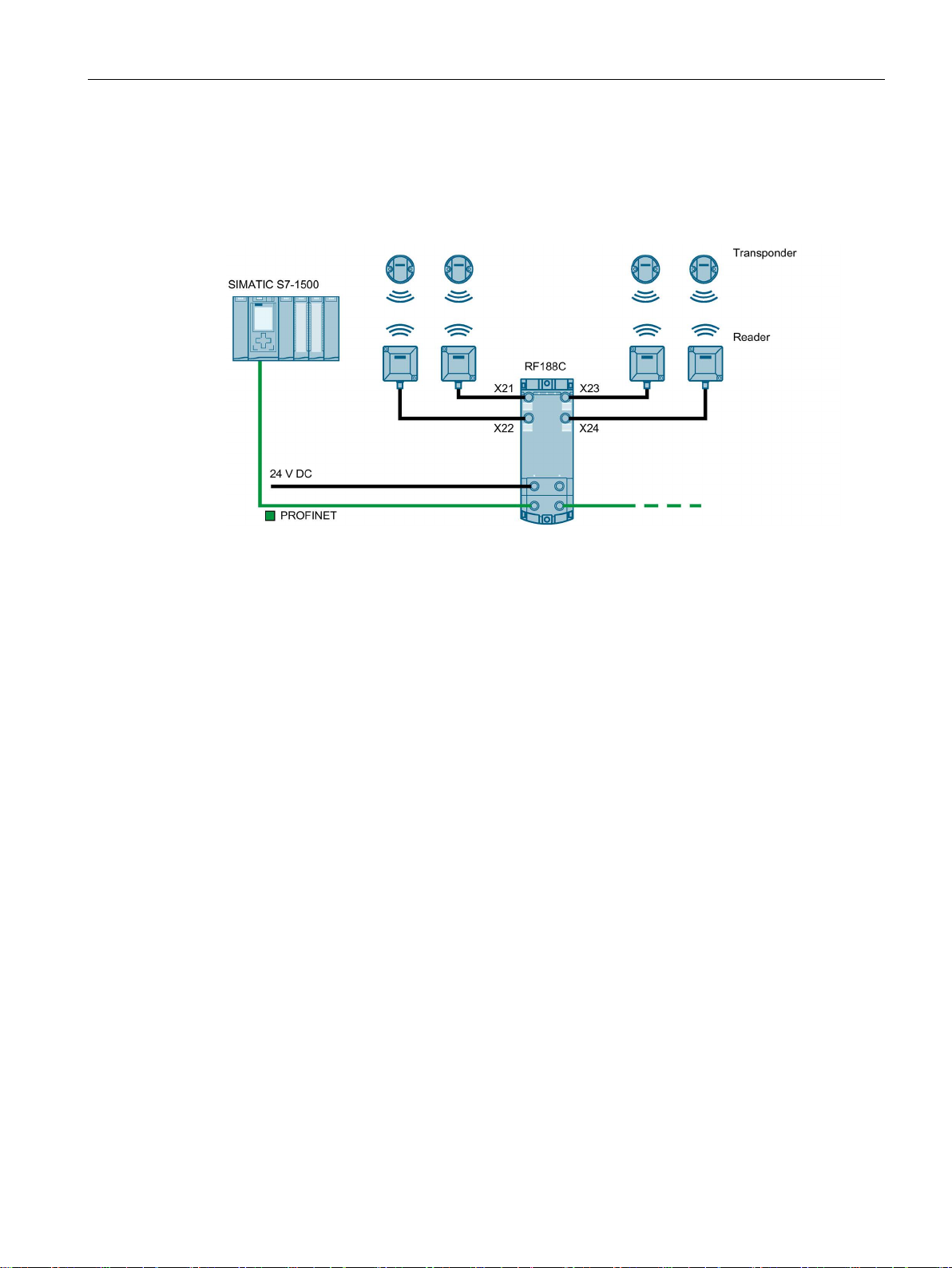

Reader connector system

A reader always occupies one M12 socket on the RF18xC. You can connect the reader to

the communications module using a preassembled cable. The connection cable is available

in lengths of 2, 5, 10, 20 and 50 m as standard. If necessary, these can be extended.

Figure 5-3 Overview of connections

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

25

Page 26

Connection

5.1

Operation of the CM on grounded/ungrounded power supply

Grounded power supply

Supply voltages

Safe electrical isolation (SELV/PELV according to IEC 60364-4-41)

Setting up RF18xC with grounded reference potential

Setting up RF18xC with ungrounded reference potential

5.1 Operation of the CM on grounded/ungrounded power supply

Below, you can find information on the overall configuration of an RF18xC communications

module on a grounded power supply (TN-S network). The specific subjects discussed here

are:

● Supply voltages of the communications module

● Disconnecting devices, short-circuit and overload protection according to IEC 60364

(corresponds to DIN VDE 0100) and IEC 60204 (corresponds to DIN VDE 0113)

● Load voltage supplies and load circuits

For grounded power supplies, the neutral conductor of the supply system is grounded. A

short-circuit to ground of a live conductor, or of a grounded part of the system, trips the

protective devices.

Two supply voltages are available for the communications module:

● 1L+: Power supply

● 2L+: Load voltage

Note that the power supply (1L+) supplies the communications module and the readers with

power. Load voltage (2L+) has no direct effect on the communications module. This voltage

is looped through to further consumers via the plug-in connectors.

Power supply units/power supply modules with safe electrical isolation are required for

operation of the communications module. This protection is referred to as SELV (Safety

Extra Low Voltage) / PELV (Protective Extra Low Voltage) according to IEC 60364-4-41.

When the communications module is set up with grounded reference potential, any

interference currents that occur are diverted to functional ground. The connections must be

connected externally (connection between 1M and FE).

When the communications module is set up with ungrounded reference potential, any

interference currents occurring are conducted to functional ground via an internal RC

network (no external connection between 1M and FE).

SIMATIC RF185C, RF186C, RF188C

26 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 27

Connection

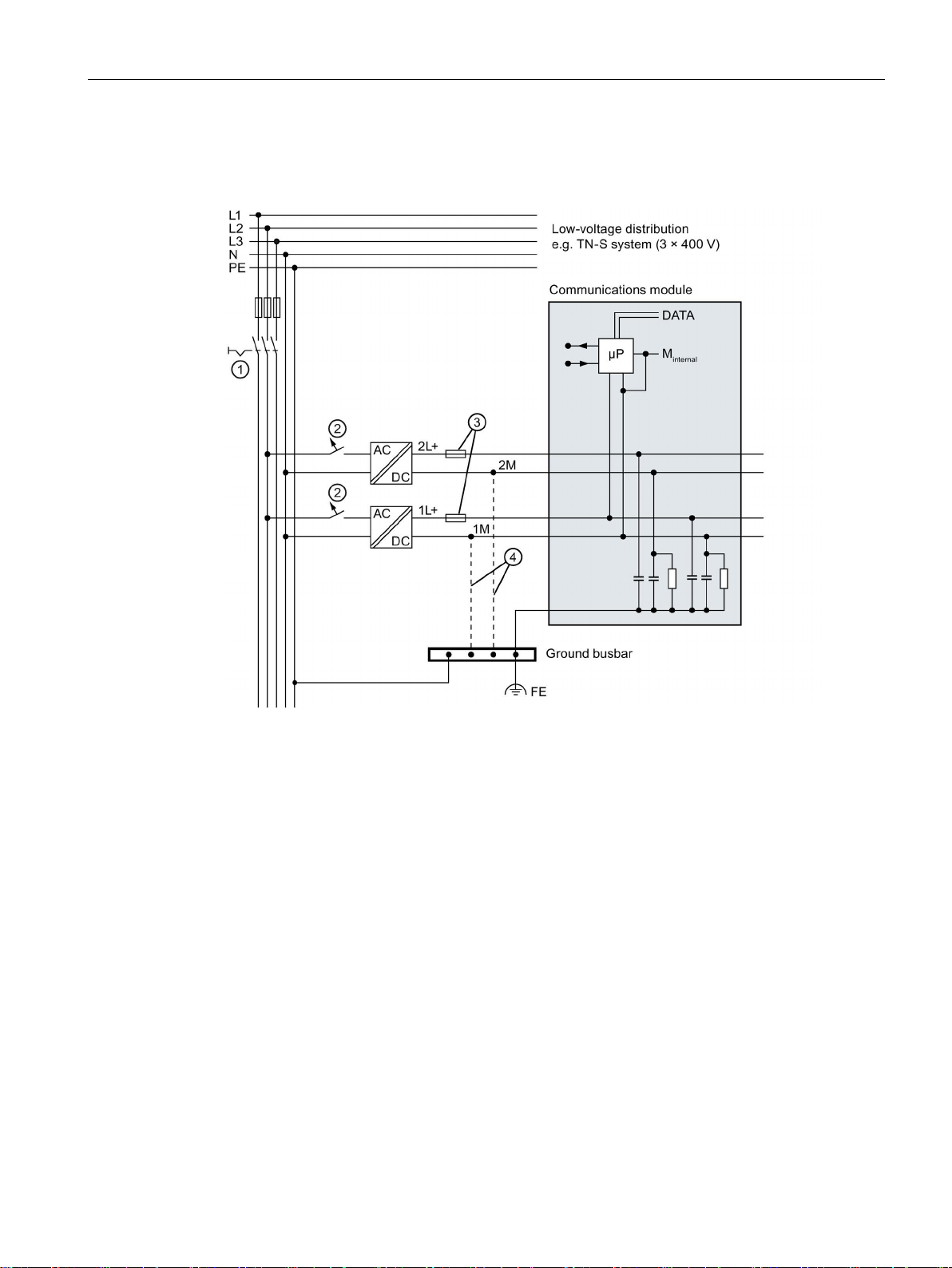

RF18xC in overall configuration

①

Main switch

②

Short-circuit and overvoltage protection

③

Fuses for line protection (automatic circuit breaker for 16 A)

④

connection between 1M, 2M and FE

5.1 Operation of the CM on grounded/ungrounded power supply

The following figure shows the communications module in its overall electrical design.

When setting up the communications module with ungrounded reference potential, there is no

Figure 5-4 Electrical design

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

27

Page 28

Connection

Components and protective measures

Screen number

Components

IEC 60364

IEC 60204

actuators

②

circuit breaker.

lines against overcurrent

Insulation monitoring

5.1 Operation of the CM on grounded/ungrounded power supply

A number of components and protective measures are prescribed for plant installations. The

types of components and the degree to which the protective measures are mandatory

depend on the IEC regulation that applies to your plant setup.

The following table shows the components of the electrical design with reference to the

previous figure and compares the IEC regulations.

Table 5- 1 Components of the electrical design

①

③

Isolation monitoring must be provided in the following cases:

● Design of the communications module with ungrounded reference potential

● If hazardous plant states can be expected as a result of faults.

Disconnecting device for

controller, sensors, and

Short-circuit and overload

protection

Circuit breaker

Main switch Disconnector

Single-pole protection of

circuits.

Protect all power supply

lines with a 24 V DC / 16 A

Protection of cables and

Single-pole protection must

be used for a grounded

secondary circuit.

--

SIMATIC RF185C, RF186C, RF188C

28 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 29

Connection

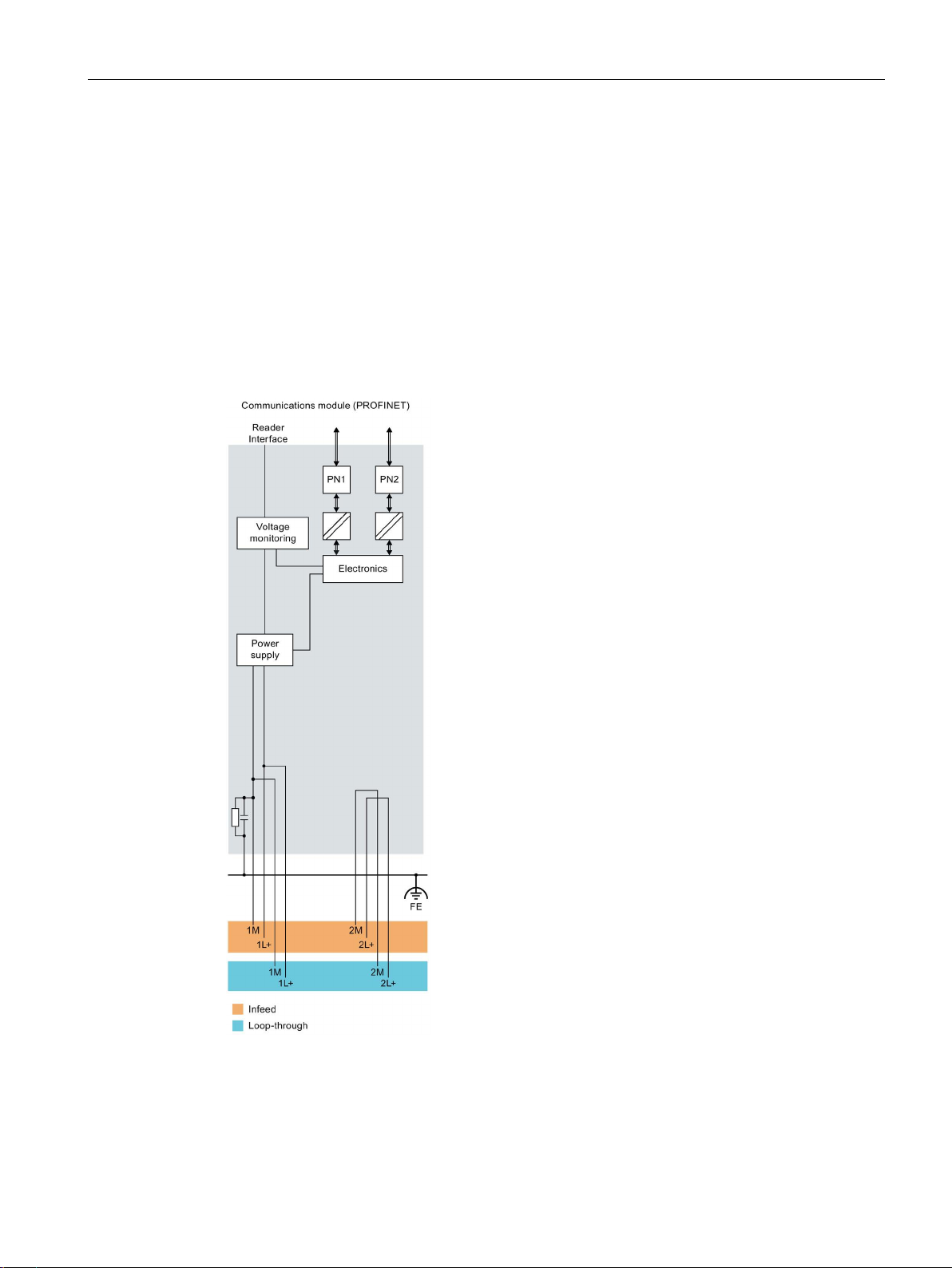

5.2

Electrical design of the CM

Electrical isolation

5.2 Electrical design of the CM

In the electrical design of the communications module, electrical isolation is provided

between:

● Load voltage 2L+ and all other circuit components

● Communication interfaces (PROFINET) of the communications module and all other

circuit components

The following figure shows the potential ratios of the communications module.

Figure 5-5 Potential ratios of the communications module

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

29

Page 30

Connection

Circuit breaker

Power supply of the assembly

Note

Switching 1L+ and 2L+ on and off

Note that the power supply (1L+) supplies the communications module and the readers with

power. Load voltage (2L+)

is looped through to further consumers via the plug

5.2 Electrical design of the CM

According to IEC 60364, line protection is required, i.e. the supply lines must always be

protected externally.

All supply voltages must be protected with a UL/IEC approved fuse 24 V DC / 16 A (tripping

characteristic type B or C). At ambient temperatures of 40 °C to 55 °C, the power supplies

must be protected with a UL/IEC approved fuse 24 V DC / 12 A.

Two voltage groups are available for the communications module, 1L+ (supply voltage) and

2L+ (load voltage).

Another power supply may be required in order to supply all communications modules of an

assembly with the required voltage. Another voltage supply of 1L+ and 2L+ may be needed

to form different potential groups, or because the voltage is insufficient for all

communications modules due to the voltage drop. Create a power budget for the selection of

the supply point of the voltage.

has no direct effect on the communications module. This voltage

-in connectors.

The following figure shows a configuration with another voltage supply for the

communications modules. The different potential groups are highlighted in gray.

Figure 5-6 Wiring of the power supply

SIMATIC RF185C, RF186C, RF188C

30 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 31

Connection

5.3

Connect CM to functional ground (PE)

Protection against external electrical influences

5.3.1

Mounting the CM on a conductive base

Requirement

Required tools

Accessories required

5.3 Connect CM to functional ground (PE)

You need to connect the RF18xC communications module to functional ground (PE). For this

purpose, a grounding screw for one ground conductor is provided on the communications

module.

If a grounded metal mounting surface is used, the bottom mounting screw of the RF18xC

module already establishes a reliable ground connection. This eliminates the need for a

separate ground conductor.

The connection to functional ground (PE) is also required to deflect the interference currents

and for electromagnetic compatibility.

Below is a description of what you must pay attention to in terms of protection against

electrical impacts and/or faults:

● In all plants or systems in which the communications module is installed, you must ensure

that the plant or the system for dissipating electromagnetic interference is connected to

functional ground.

● For supply, signal and bus lines, you must ensure that the laying of the lines and the

installation is correct.

● For signal and bus lines, you must ensure that a wire/cable breakage or a cross-circuit

does not lead to undefined states of the plant or system.

Conductive base for mounting the module.

You need the following tool to connect to the functional ground:

● Screwdriver

You need the following accessories to connect to the functional ground:

● Fastening screw (M4) and washer

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

31

Page 32

Connection

Mounting

NOTICE

Grounding with a conductive mounting base

①

Grounded, metallic base

②

Unpainted thread or nut support

5.3 Connect CM to functional ground (PE)

Proceed as follows to connect the communications module to functional ground via a

conductive mounting base:

1. Drill 2 mounting holes with a distance of 155.6 mm.

2. Screw the module together with the M4 fastening screws with a torque of 1.2 Nm.

If you fasten the communications module to a conductive, grounded base, the lower

fastening screw provides a conductive connection to the ground potential.

Ensure there is a low-impedance connection between the communications module and the

conductive base and between the conductive base and functional ground.

Figure 5-7 Mounting the CM on a conductive base

SIMATIC RF185C, RF186C, RF188C

32 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 33

Connection

5.3.2

Mounting the CM on a non-conductive base

Requirement

Required tools

Accessories required

5.3 Connect CM to functional ground (PE)

Non-conductive base for mounting the module.

You need the following tools to connect to the functional ground:

● Screwdriver

● Stripping tool

● Crimp tool

To connect to functional ground with a non-conductive mounting base, you can need the

following accessories:

● Fastening screw (M4) and washer

● Cable lug suitable for M4 screws

● Ground conductor cable (copper braid) with a minimum cross-section of 4 mm

2

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

33

Page 34

Connection

Mounting

NOTICE

Grounding with non-conductive mounting base

5.3 Connect CM to functional ground (PE)

Proceed as follows to connect the communications module to functional ground via a ground

conductor:

1. Drill 2 mounting holes with a distance of 155.6 mm.

2. Insulate the ground conductor.

3. Attach the cable lug to the ground conductor.

4. Screw the module and the cable lug together with the M4 fastening screws with a torque

of 1.2 Nm.

Ensure a low impedance connection between the communications module and functional

ground.

Figure 5-8 Mounting the CM on a non-conductive base / connection to functional ground

SIMATIC RF185C, RF186C, RF188C

34 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 35

Connection

5.4

Connecting the communications module

Interfaces

①

⑤

(M12, 4-pin, L-coded)

②

(M12, 8-pin, A-coded)

⑥

(M12, 4-pin, D-coded)

③

Reader LEDs

⑦

Mounting holes and functional ground (PE)

④

PROFINET/Ethernet LEDs

Requirement

5.4 Connecting the communications module

Status LEDs

Reader interfaces

X21-X24

Figure 5-9 Design of the communications module

You can loop the supply voltages and PROFINET IO via the M12 round sockets ⑤ + ⑥.

The pin assignments of the various interfaces are lasered on the side of each

communications module at the factory.

Only wire the communications module when the supply voltage is switched off.

Interface for the power supply

X80, X81

Interface for PROFINET IO

X1 P1R, X1 P2R

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

35

Page 36

Connection

Required tools

Note

Using preassembled cables

When connecting the supply voltage, we recommend the cables specified in section

"

If you want to make the cable yourself, ensure that the cable has a conductor cross

of 1.5

Accessories required

Wiring interfaces/connectors

Pin

Assignment

View of M12 socket, 4-pin

1

Data line TxP

2

Data line RxP

3

Data line TxN

5.4 Connecting the communications module

When using preassembled cables, you need the following tool:

● Torque wrench set (e.g. from Peres; M12/M8, can be set; PER091) for wiring the reader

connections

Ordering data (Page 154)" (5 x 1.5 mm2 preassembled).

-section

mm2.

When using cables that are not preassembled, you need the following tool:

● Stripping tool

● Screwdriver for wiring M12 connectors

You need the following accessories:

● PROFINET IO connection

M12 plug (4-pin, D-coded) and 4-wire Ethernet cable (Twisted Pair, shielded)

● Connection: Power supply

M12 plug (4-pin, L-coded) and 4-wire cable (4 x 1.5 mm

● Reader connection

M12 plug (8-pin, A-coded) and 8-wire cable (8 x 24 AWG)

You can find the associated article numbers in the section "Ordering data (Page 154)".

The following tables show the pin assignment for the M12 interface/connector.

Table 5- 2 Pin assignment PROFINET IO; M12 socket (4-pin, D-coded)

2

or 4 x 2 mm2)

4 Data line RxN

SIMATIC RF185C, RF186C, RF188C

36 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 37

Connection

Pin

Assignment

View of M12 socket, 4-pin

1

L1: +24 V (brown)

3

N1: 0 V (blue)

Pin

Assignment

View of M12 socket, 8-pin

RS422

RS232

1

+24 V

+24 V

2

-RxD

--

3

0 V

0 V 4 +RxD

RxD

5

+TxD

+5 V

7

--

TxD

5.4 Connecting the communications module

Table 5- 3 Pin assignment power supply; M12 socket (4-pin, L-coded)

2 N2: 0 V load supply (white)

4 L2: +24 V (black)

Table 5- 4 Pin assignment reader interface; M12 socket (8-pin, A-coded)

6 -TxD --

8 Functional ground

(PE) / shield

Functional ground

(PE) / shield

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

37

Page 38

Connection

Connect the plug

NOTICE

Ensuring the degree of protection

①

Connector for the reader connection (M12, 8-pin, A-coded)

②

Connector for the power supply (M12, 5-pin, L-coded)

③

Connector for PROFINET IO connection (M12, 4-pin, D-coded)

5.4 Connecting the communications module

Proceed as follows to connect the device:

1. Push the respective plug into the corresponding round socket on the communications

module.

Ensure that the correct stop is provided between the connector and bush (groove and

spring).

2. Fasten the connector by tightening the knurled locking ring.

To guarantee the degree of protection, all connectors need to be tightened with ≃ 1.0 Nm.

You need to close all unused sockets with M12 sealing caps to ensure IP65 or IP67

degree of protection. You can find the order data of the sealing caps in the section

"Ordering data (Page 154)".

Figure 5-10 Connect the plug

SIMATIC RF185C, RF186C, RF188C

38 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 39

Connection

5.5

Supply voltage and PROFINET IO loop-through

Notes for wiring

NOTICE

Damage to the device

5.5 Supply voltage and PROFINET IO loop-through

The RF18xC communications modules each have two M12 connections for the supply

voltage and PROFINET IO. Supply takes place via the 1st connection, the supply voltage

and PROFINET IO can be forwarded to another device via the 2nd connection.

Figure 5-11 Supply voltage and PROFINET IO loop-through

● When wiring your assembly, you need to take into account the effect of the cable length

on the supply voltage at the RF18xC.

● The maximum supply current of the communications module is 16 A at 1L+ and 2L+ for a

maximum ambient temperature of 40 °C. At ambient temperatures of 40 °C to 55 °C, the

maximum supply current is 12 A. These values must not be exceeded.

● Adhere to the current carrying capacity of the connected cables, which depends on the

conductor material, the conductor cross-section and the ambient temperature.

Make sure to use a conductor cross-section of at least 1.5 mm².

If you do not observe the maximum permissible supply current and the cable crosssection required, this may result in the cable isolation and contacts overheating and in

the device being damaged.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

39

Page 40

Connection

5.6

Connecting cables for the CMs

Effect of cable length on the supply voltage

CAUTION

Observe the maximum supply currents

5.6 Connecting cables for the CMs

When wiring your assembly, you need to take into account the effect of the cable length on

the supply voltage of the communications module.

The maximum supply current of the communications module is 16 A at 1L+ and 2L+ for a

maximum ambient temperature of 40 °C. At ambient temperatures of 40 °C to 55 °C, the

maximum supply current is 12 A. These values must not be exceeded.

If you do not comply with the maximum supply currents and the required line crosssections, an increased supply current can lead to overheating of the cable insulation and

the contacts. This can result in damage to the communications module.

The following figure shows the voltage drop as a function of the cable length for 16 A, using

2

the example of a copper cable with ∅ 1.5 mm

.

Figure 5-12 Voltage drop with a cable cross-section of 1.5 mm

To estimate the voltage drop in your communications module, you must add the voltage

SIMATIC RF185C, RF186C, RF188C

drops of the cables.

40 Operating Instructions, 10/2018, C79000-G8976-C512-01

2

Page 41

Connection

Example

5.6 Connecting cables for the CMs

With 16 A, the voltage drop via the two L-coded M12 plug-in connectors and in the

communications module is approximately 0.2 V. The value can vary significantly depending

on the plug connection or condition.

2

When using a 7 m power cable with ∅ 1.5 mm

, the voltage drop is approx. 2.6 V with a 16 A

load.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

41

Page 42

Connection

5.6 Connecting cables for the CMs

SIMATIC RF185C, RF186C, RF188C

42 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 43

6

6.1

Assign the IP address / device name

6.1.1

Assigning the IP address / device name with STEP 7

Requirements

Procedure

To ensure functioning communication between the controller and the communications

module, you must assign unique IP addresses or device names to the individual

communications modules. Depending on the infrastructure in which you want to operate the

communications module, the following different procedures are available:

● Operate the communications module as an S7 user in an automation environment.

The unique assignment is made via the device name using the TIA Portal (from STEP 7

Basic / Professional V15).

● Operate the communications module as OPC UA user in an IT environment.

The unique assignment is based on DHCP or the IP address using the Primary Setup

Tool V4.2 or higher (PST).

Each communications module receives a unique device identification (MAC address) at the

factory.

STEP 7 Basic / Professional is installed, the communications module is connected and has

started up.

Proceed as follows to assign a unique device name to the communications module:

1. Open the TIA Portal with "Start > All Programs > Siemens Automation > TIA Portal Vxx".

2. Create a new project.

3. Change to the Project view.

4. Using the project tree, insert a SIMATIC controller in the project with the "Add new

device" menu command.

Reaction: The device view opens and the controller is displayed.

5. Go to the network view and drag the communications module from the hardware catalog

into the project.

6. Assign the communications module to the controller.

7. Right-click on the communications module.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

43

Page 44

Configuring

6.1 Assign the IP address / device name

8. In the shortcut menu, select the menu command "Assign device name".

Reaction: The "Assign PROFINET device name" window opens.

Figure 6-1 Assign device name

9. Select the connection type in the "Online access" area in the "Type of the PG/PC

interface" drop-down list.

10.In the "PG/PC interface" drop-down list in the "Online access" area, select the network

adapter via which the communications module is connected to the PG/PC.

11.Click the "Update list" button to display all reachable devices in the network.

12.Select the required node from the list.

13.Now click the "Assign Name" button to assign the PROFINET device name to the

communications module.

Result: The configured PROFINET device name from the project is assigned to the

communications module.

SIMATIC RF185C, RF186C, RF188C

44 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 45

Configuring

Note

Assigning a device name when replacing a module

When you replace a module, you can assign the device names automatically. You will find

more information on this in the section "

Device flash test using the TIA Portal

6.1.2

Assigning the IP address / device name with the PST

Requirements

Procedure

6.1 Assign the IP address / device name

Module replacement (Page 141)".

If several IO devices are connected to the controller, it is possible to make the LEDs of the

device flash. In this case, compare the MAC address of the device with the MAC address

displayed and then select the desired IO device. With the help of the device flash test you

can quickly and easily identify the desired IO device.

Proceed as follows to identify the relevant IO device using the flashing test:

1. In the üroject tree, select the menu command "Online access > Your online access >

Update accessible devices".

The available devices are displayed.

2. Select the required RF18xC and click the entry "Online & Diagnostics" in the folder of the

selected device.

3. Select the option "Functions > Assign name".

4. Click the "Flash LED" button.

Reaction: The LEDs on the selected communications module flash.

5. Click the "Flash LED" button again to stop the flashing.

The Primary Setup Tool (V4.2 or higher) is installed and the communications module is

connected and running. You can find the Primary Setup Tool on the DVD accompanying the

communications module or on the Internet at "Ident Systems, Software & Documentation

(https://support.industry.siemens.com/cs/ww/en/view/109482436

)".

Proceed as follows to assign a new, unique IP address and a unique device name to the

communications module:

1. Open the Primary Setup Tool with "Start > All Programs > Siemens Automation >

SIMATIC > Primary Setup Tool".

2. In the menu bar under "Settings > Set PG/PC interface..." select the network adapter

through which the communications module is connected to the PC and confirm with "OK".

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

45

Page 46

Configuring

Note

Waiting time

Wait until the IP address / the device name has been updated. To display the change,

you need to activate the search function using the "Search" ico

6.1 Assign the IP address / device name

3. Click on the "Search" icon in the toolbar.

A dialog box opens with the information that a device was found in the network.

4. Click on the "+" character beside the folder symbol in the structure tree and click the entry

"Ind. Ethernet interface".

Figure 6-2 Assign IP address and device name

5. To assign a new IP address to the communications module, select the "Assign IP

parameters" option.

6. Enter a new, unique IP address for the communications module in the "IP address" input

box.

7. Enter the subnet mask of your network in the "Subnet mask" input box.

8. Click on "Assign Name" to assign a unique device name to the communications module.

9. Click the "Load" icon

to transfer the settings to the communications module.

10.Confirm the next dialog box with "Yes".

n .

Result: The communications module is assigned the new IP address and a new device

name.

SIMATIC RF185C, RF186C, RF188C

46 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 47

Configuring

Device flash test using the PST

6.2

Configuration via PROFINET IO

Requirements

Procedure

6.2 Configuration via PROFINET IO

If several communications modules are connected to the network/PC, it is possible to make

the LEDs of the device flash. Using the device flash test, you can identify the required

communications module quickly and simply.

Proceed as follows to identify the relevant communications module using the flash test:

1. In the menu bar, select the menu command "Network > Browse".

2. Select the required module from the device list.

3. In the menu bar, select the menu command "Module > Flash".

4. Click the "Start" button.

Reaction: The LEDs on the selected communications module flash.

5. Click the "Stop" button to stop the flashing.

As of STEP 7 Basic / Professional V15.1, the RF18xC communications modules are

integrated in the TIA Portal and can be integrated into SIMATIC automation systems. The

connection is made via PROFINET, the basic configuration as well as operation of the

communications module is made via the Ident library of the TIA Portal. You can further

configure the communications module using WBM.

The GSDML file corresponding to the communications module is stored on the

communications module and can be downloaded from it.

STEP 7 Basic / Professional is installed and started, and a project is open. The

communications module is connected to the controller or PC via Industrial Ethernet or

PROFINET and has been powered up.

The communications module has a valid IO device name.

Follow these steps to configure the communications module via PROFINET IO using the TIA

Portal:

1. Change to the Project view.

2. Using the project tree, insert a SIMATIC controller in the project with the "Add new

device" menu command.

The device view opens and the controller is displayed.

3. Go to the network view and drag the communications module from the hardware catalog

into the project.

4. Connect the communications module with the controller.

5. Configure the communications module (e.g. device name, address range).

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

47

Page 48

Configuring

Parameter assignment with the device configuration

"Web Based Management" parameter group

Parameter

Description

assigned and the TIA configuration must be loaded into the SIMATIC controller.

"Configuration management" parameter group

Parameter

Description

Note that the user must have the required rights.

Password

Enter the password for the user

device

project

6.2 Configuration via PROFINET IO

6. Assign parameters to the communications module (e.g. module parameters).

7. Save the configuration, or download it to the PROFINET IO controller.

You can find additional information in the section "Assign the IP address / device name

(Page 43)".

You can set the basic parameters of the communications module, as well as the parameters

of the readers connected to the communications module, using the properties window of the

communications module. You can set all module-specific parameters using the following

parameter groups.

You can start Web Based Management in this parameter group.

Table 6- 1 Parameters of the "Web Based Management" parameter group

Web Based Management

Start Web Based Management of the communications module.

Web Based Management (WBM) offers extensive functions for configuring the communications

module.

Note: WBM can only be started when either the PROFINET connection between CPU and com-

munications module has been established or the IP address stored in the project has been assigned to the communications module. This means that the device name must have been

You can load or save configuration data in this parameter group.

Table 6- 2 Parameters of the "Configuration management" parameter group

User name User name of a user created on the communications module

Load configuration to

Save configuration in

Load configuration data from the STEP 7 project into the communications module.

Save configuration data of the communications module in the current STEP 7 project.

SIMATIC RF185C, RF186C, RF188C

48 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 49

Configuring

Requirement

Note

User name and password only necessary if user management is enabled

The "User name" and "Password" text boxes only need to be completed if the user

management of the WBM is enabled.

"Module parameters" parameter group

Parameter

Parameter value

Default value

Description

On

6.2 Configuration via PROFINET IO

The following requirements must be met so that configuration data can be loaded or saved:

● The "PROFINET interface [X1]" entry contains the correct IP address of the

communications module.

● The user name and the corresponding password are created in WBM.

● The specified user has the required rights to perform the download/upload.

In this parameter group, you can configure all module-specific parameters of the

communications module.

Table 6- 3 Parameters in the "Module parameters" parameter group

Diagnostic interrupt on

the device

Off

On Switch diagnostic interrupt messages for the

communications module on/off

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

49

Page 50

Configuring

Parameter group "Module parameters" of the connected readers

Parameter

Parameter value

Default value

Description

troller

dressed with physical addresses.

the transmission speed selected for the reader.

by the S7 diagnostics.

6.2 Configuration via PROFINET IO

In this parameter group, you can configure all module-specific parameters of the connected

readers.

Table 6- 4 Parameters of the parameter group "Module parameters" of the connected readers

User mode RFID standard profile

FB 45

MOBY mode RF200/RF300/RF600;

MV400/MV500; MOBY

U/D normal addr.

Transmission

speed

Diagnostics

messages

19.2 kBd

57.6 kBd

115.2 kBd

None

Hard errors

Hard/soft errors

RFID standard profile

RF200/RF300/RF60

0; MV400/MV500;

MOBY U/D normal

addr.

115.2 kBd With this parameter, you set the data transmis-

None With this parameter, you determine the extent

With this parameter, you select the block:

• RFID standard profile:

The program block for the Ident profile is

used in the controller.

• FB 45:

Single tag mode. FB 45 is used in the con-

With this parameter, you set the mode of the

communications module.

• RF200/RF300/RF600; MOBY U/D normal

addr.

Normal addressing: The transponder is ad-

sion speed between the communications module and reader.

When an optical reader is connected: The

transmission speed selected here must match

to which the reader-related diagnostic interrupt

messages are to be reported.

• None:

SIMATIC RF185C, RF186C, RF188C

50 Operating Instructions, 10/2018, C79000-G8976-C512-01

No alarms are generated.

• Hard errors:

Critical hardware errors/faults are reported

by the S7 diagnostics.

• Hard/soft errors:

Critical hardware faults and errors occurring

when processing commands are reported

Page 51

Configuring

Description of block commands

6.3

Configuration via OPC UA

6.3 Configuration via OPC UA

You can find a description of the block-specific commands in the respective block manuals:

● FB 45 for MOBY U, MOBY D, RF200, RF300

● RFID standard profile; standard function for RFID systems

● Ident profile and Ident blocks, standard function for Ident systems

Configuration of the communications module is not necessary for pure OPC UA work. You

can continue directly with configuration via WBM and with programming via OPC UA

interface.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

51

Page 52

Configuring

6.3 Configuration via OPC UA

SIMATIC RF185C, RF186C, RF188C

52 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 53

7

7.1

Starting WBM

Requirement

Procedure

The communications modules are equipped with a Web server that provides Web Based

Management (WBM) for configuring the communications modules. This can be opened via a

Web browser.

The communications module is connected, turned on and ready for operation ("RUN" LED is

lit or flashing green) and the relevant communications module has been assigned an IP

address.

To achieve a good workflow with the WBM, we recommend that you use a PC that meets the

following minimum requirements:

● CPU: DualCore

● RAM: 2 GB

You can call WBM using the versions of the following Web browsers current at the time of

publication of this manual: Microsoft Internet Explorer, Microsoft Edge, Mozilla Firefox and

Google Chrome. The user interface of the WBM is designed for a screen resolution of 1366 x

768 pixels.

Proceed as follows to start the WBM:

1. Start your Web browser.

2. Enter the IP address of the communications module in the address field of your browser.

3. Confirm your entry by pressing the <Enter> key.

Result: WBM of the communications module opens.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

53

Page 54

Configuring with the WBM

Note

Connection to the communications module cannot be established

If a connection to the communications module cannot be established,

points:

•

•

• Check the IP addresses of the PC and the communications module as well as the subnet

•

•

7.1 Starting WBM

Figure 7-1 The start page of the WBM

Make sure that all cables are correctly connected.

Ensure that the communications module has started up ("RUN" LED lit/flashing green).

mask. Both IP addresses must be located in the same subnet.

Make sure that the connection is not blocked by a firewall.

Use a ping request to check the connection between the PC and the communications

module.

SIMATIC RF185C, RF186C, RF188C

54 Operating Instructions, 10/2018, C79000-G8976-C512-01

check the following

Page 55

Configuring with the WBM

7.2

The WBM

NOTICE

Security recommendation: Enable user management

NOTICE

Access to the reader

7.2 The WBM

You can use the WBM to configure the SIMATIC RF18xC communications modules.

After starting the WBM the first time, no user management is enabled. To make sure that

no unauthorized persons can access the communications module settings, we recommend

that you enable the user management and create new user profiles after the first login.

For further information on logging in to WBM and creating/deleting user profiles, refer to the

section "The "User management" menu item (Page 80)".

Note that you can simultaneously access a communications module via two browsers but

this is not recommended.

If changes are made when two browsers are accessing a reader at the same time, this can

lead to errors in the configuration or to an undesired result.

When you have created new user profiles you need to log in with one of these user profiles

when you restart the WBM.

SIMATIC RF185C, RF186C, RF188C

Operating Instructions, 10/2018, C79000-G8976-C512-01

55

Page 56

Configuring with the WBM

Layout of the WBM

The WBM start window is divided into the following areas:

①

Toolbar/status bar and log-on

②

Menu tree

③

Main window

④

Message area

⑤

Information bar

7.2 The WBM

Once the connection to the communications module has been successfully established, the

WBM start window appears:

Figure 7-2 Start window of the WBM

SIMATIC RF185C, RF186C, RF188C

56 Operating Instructions, 10/2018, C79000-G8976-C512-01

Page 57

Configuring with the WBM

Toolbar and status bar

Icon

Description

Key combination: Ctrl + L

Key combination: Ctrl + G

Key combination: Ctrl + S

Key combination: Ctrl + O

Note

Transferring a configuration

Please note that transferring a configuration can disrupt running user applications. In WBM,

an orange ba