Siemens SIMATIC RF1000 Series, SIMATIC RF1060R, SIMATIC RF1070R Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC Ident

RFID systems

SIMATIC RF1000

Operating Instructions

02/2019

C79000

Introduction

1

Description

2

Installation

3

Connecting

4

Installing and commissioning

5

Programming

6

The demo application

7

Technical specifications

8

Dimension drawing

9

Appendix

A

-G8976-C432-04

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ⓟ

Copyright © Siemens AG 2017 - 2019.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

02/2019 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 5

2 Description .............................................................................................................................................. 7

2.1 Description of the readers ......................................................................................................... 7

2.2 Connection options and supported transponders ..................................................................... 8

3 Installation ............................................................................................................................................ 11

4 Connecting ........................................................................................................................................... 13

5 Installing and commissioning ................................................................................................................. 15

6 Programming ........................................................................................................................................ 17

6.1 Typical applications ................................................................................................................. 17

6.2 Programming via USB interface ............................................................................................. 18

6.2.1 Functions of the DLL ............................................................................................................... 18

6.2.1.1 brp_open_usb_session ........................................................................................................... 18

6.2.1.2 brp_set_bufsize ....................................................................................................................... 19

6.2.1.3 brp_close_session ................................................................................................................... 20

6.2.1.4 syscmd_reset .......................................................................................................................... 20

6.2.1.5 syscmd_get_info ..................................................................................................................... 21

6.2.1.6 syscmd_get_boot_status ......................................................................................................... 22

6.2.1.7 syscmd_set_port ..................................................................................................................... 22

6.2.1.8 vhl_select ................................................................................................................................ 23

6.2.1.9 vhl_get_snr .............................................................................................................................. 25

6.2.1.10 vhl_is_selected ........................................................................................................................ 26

6.2.1.11 vhl_read .................................................................................................................................. 26

6.2.1.12 vhl_write .................................................................................................................................. 27

6.2.1.13 Autoread_SetMode ................................................................................................................. 28

6.2.1.14 Autoread_GetMessage ........................................................................................................... 30

6.2.1.15 Return values .......................................................................................................................... 31

6.3 Programming via the RS232 interface .................................................................................... 32

6.3.1 Implementation of the system jobs ......................................................................................... 32

6.3.2 System jobs ............................................................................................................................ 32

6.3.2.1 syscmd_reset .......................................................................................................................... 32

6.3.2.2 syscmd_get_info ..................................................................................................................... 33

6.3.2.3 syscmd_get_boot_status .........................................................................................................

6.3.2.4 syscmd_set_port ..................................................................................................................... 34

6.3.2.5 vhl_select ................................................................................................................................ 35

6.3.2.6 vhl_get_snr .............................................................................................................................. 36

6.3.2.7 vhl_is_selected ........................................................................................................................ 37

6.3.2.8 vhl_read .................................................................................................................................. 38

6.3.2.9 vhl_write .................................................................................................................................. 39

6.3.2.10 Autoread_SetMode ................................................................................................................. 41

6.3.2.11 Autoread_GetMessage ........................................................................................................... 41

6.4 Status codes ........................................................................................................................... 43

SIMATIC RF1000

Operating Instructions, 02/2019, C79000-G8976-C432-04

34

3

Table of contents

7 The demo application ............................................................................................................................ 45

7.1 User interface of the demo application .................................................................................. 45

7.2 Create your own PC application via the USB interface ......................................................... 48

8 Technical specifications ........................................................................................................................ 51

9 Dimension drawing ............................................................................................................................... 53

A Appendix .............................................................................................................................................. 55

A.1 Certificates & approvals ......................................................................................................... 55

A.2 Ordering data ......................................................................................................................... 57

A.3 Service & Support .................................................................................................................. 58

SIMATIC RF1000

4 Operating Instructions, 02/2019, C79000-G8976-C432-04

1

Purpose of this document

This documentation provides you with an overview of the installation and programming of the

SIMATIC RF1060R and RF1070R readers. The operating instructions are intended for users

and programmers involved in configuration, commissioning and servicing of the SIMATIC

RF1060R/RF1070R.

Registered trademarks

The following and possibly other names not identified by the registered trademark sign ® are

registered trademarks of Siemens AG:

SIMATIC ®, SIMATIC RF ®, MOBY ®, RF-MANAGER ® and SIMATIC Sensors ®

Recycling and disposal

The products are low in harmful substances, can be recycled and meet the requirements of

the Directive 2012/19/EU for disposal of waste electrical and electronic equipment (WEEE).

Do not dispose of the products at public disposal sites.

For environmentally compliant recycling and disposal of your electronic waste, please

contact a company certified for the disposal of electronic waste or your Siemens

representative.

Note the different country-specific regulations.

SIMATIC RF1000

Operating Instructions, 02/2019, C79000-G8976-C432-04

5

Introduction

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit

Link: (http://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers’ exposure

to cyber threats.

)

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Link: (http://www.siemens.com/industrialsecurity

)

SIMATIC RF1000

6 Operating Instructions, 02/2019, C79000-G8976-C432-04

2

2.1 Description of the readers

Companies have been using RFID-based identification card systems for years to control

access to buildings. With the increasing need for security and growing requirements for

documentation, solutions are demanded with which access to machines and plants can be

controlled on a user basis. The SIMATIC RF1060R/RF1070R readers provide the option of

using employee identification cards also when operating machines. This allows finely graded

access concepts to be implemented or user-specific instructions zo be stored - all with one

card.

Figure 2-1 Product photo of the SIMATIC RF1060R and SIMATIC RF1070R readers

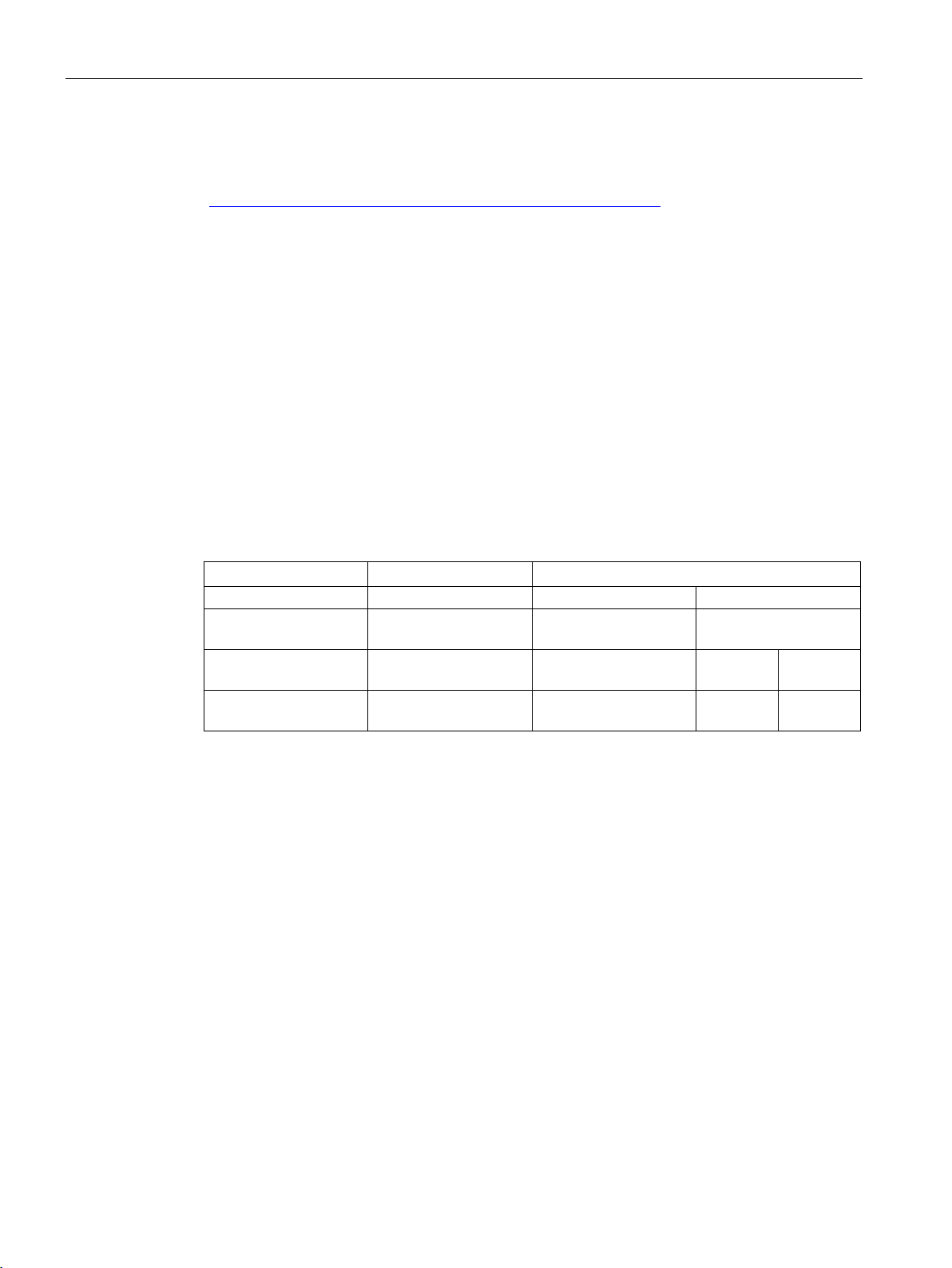

Reader-specific differences (interfaces)

The SIMATIC RF1060R/RF1070R readers are designed for connection to a Windows

computer. The connection is via a USB interface of the computer. The SIMATIC RF1070R

reader can also be connected to a Linux-based system or to a controller over the RS232

interface.

SIMATIC RF1000

Operating Instructions, 02/2019, C79000-G8976-C432-04

7

Description

SIMATIC RF1060R

SIMATIC RF1070R

Interface/Protocol

USB

USB

RS232 Freeport

demo application

demo application

200SP

2.2 Connection options and supported transponders

Interface-specific programming

On the Siemens support page "Industry Online Support

(https://support.industry.siemens.com/cs/ww/en/view/109741590

)" you will find functions for

accessing the readers in form of DLL files as well as a demo application. With operation via

the USB interface, you can implement user identification for access to your own applications

quickly and simply with the help of the DLL files. To do this, the reader reads out the serial

numbers of MIFARE, ISO 15693 and LEGIC transponders. Depending on the card type, the

serial number can be 4, 7 or 10 bytes (MIFARE / ISO 14443), 8 bytes (ISO 15693) or 4, 7 or

8 bytes (LEGIC) long.

If the SIMATIC RF1070R reader is operated via the RS232 interface, programming takes

place over the freeport protocol.

2.2 Connection options and supported transponders

Depending on the interface protocol used, the readers can be used for various applications.

The following table provides an overview of the possible uses of the readers.

Table 2- 1 Possible uses

application PM LOGON,

Connector SIMATIC Panel, PC SIMATIC Panel, PC RF170C e.g. ET

Cable Included in the scope of

delivery

PM LOGON,

Included in the scope of

delivery

STEP 7 (TIA Portal)

6GT28914UH20

6GT28912UH30

SIMATIC RF1000

8 Operating Instructions, 02/2019, C79000-G8976-C432-04

Description

SIMATIC RF1060R

SIMATIC RF1070R

Transponder families

MDS D2xx

✓ 1)

✓

MDS D4xx, D5xx ✓ --

Protocols

FeliCa

Serial number

Serial number

ISO 14443 A/B general

Serial number

Serial number

ISO 15693 general ✓ ✓

LEGIC prime

--

✓

LEGIC advant (ISO 14443 A)

Serial number

✓

LEGIC advant (ISO 15693)

Serial number

✓

Mini)

(2k, 4k, 8k)

L2, L3)

MIFARE Ultralight (C)

Serial number

Serial number

HID iClass, Inside PicoPass

Serial number

Serial number

NXP NTAG21x

Serial number

Serial number

✓

2.2 Connection options and supported transponders

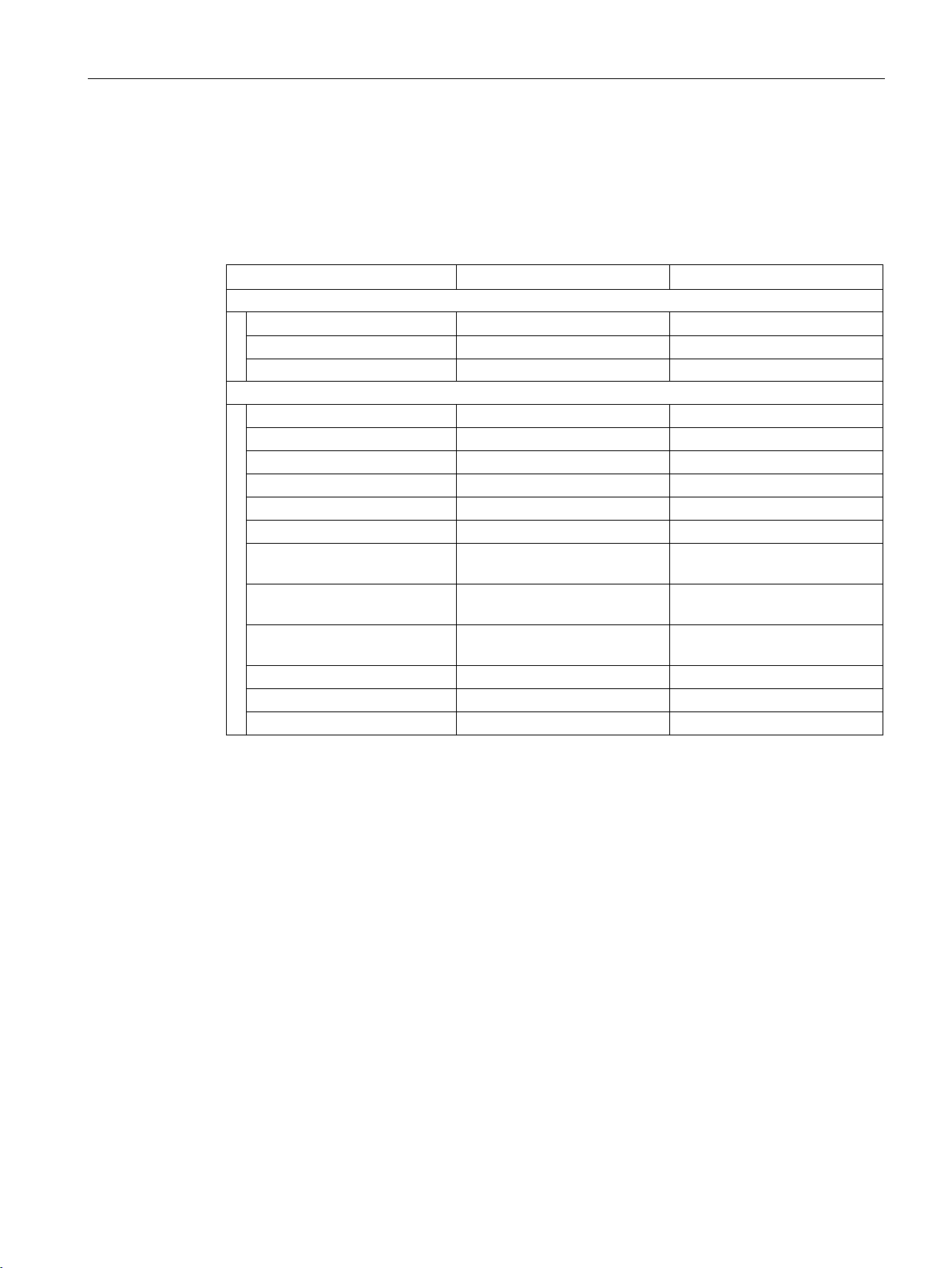

Supported transponders and protocols

The following table provides an overview of the transponders and protocols supported by the

readers.

Table 2- 2 Supported transponders and protocols

MDS D1xx, D3xx, E6xx ✓ ✓

MIFARE Classic, EV1 (1k, 4k,

MIFARE DESFire, EV1/EV2

MIFARE Plus, EV1 (S, X, L1,

: Reading the serial number as well as reading and writing the user memory area

1)

Only for read-only access

✓ ✓

✓ ✓

✓ Serial number

Please note that serial numbers (UIDs) of transponders that begin with the byte "0x08" are

always newly generated by the transponder. This makes an assignment of serial numbers

and transponders impossible. Note that when the serial number is read for transponders with

combo chip (e.g. LEGIC CTC4096), only the LEGIC Prime serial number is displayed and

not the serial number of the ISO chip 14443/15693.

The reader can be addressed and controlled by functions, for example to change the status

of the reader or to communicate with a transponder. With the aid of the functions, you can for

example control the three-color reader LED. Which functions exist and how you use them is

described in this manual.

SIMATIC RF1000

Operating Instructions, 02/2019, C79000-G8976-C432-04

9

Description

2.2 Connection options and supported transponders

SIMATIC RF1000

10 Operating Instructions, 02/2019, C79000-G8976-C432-04

3

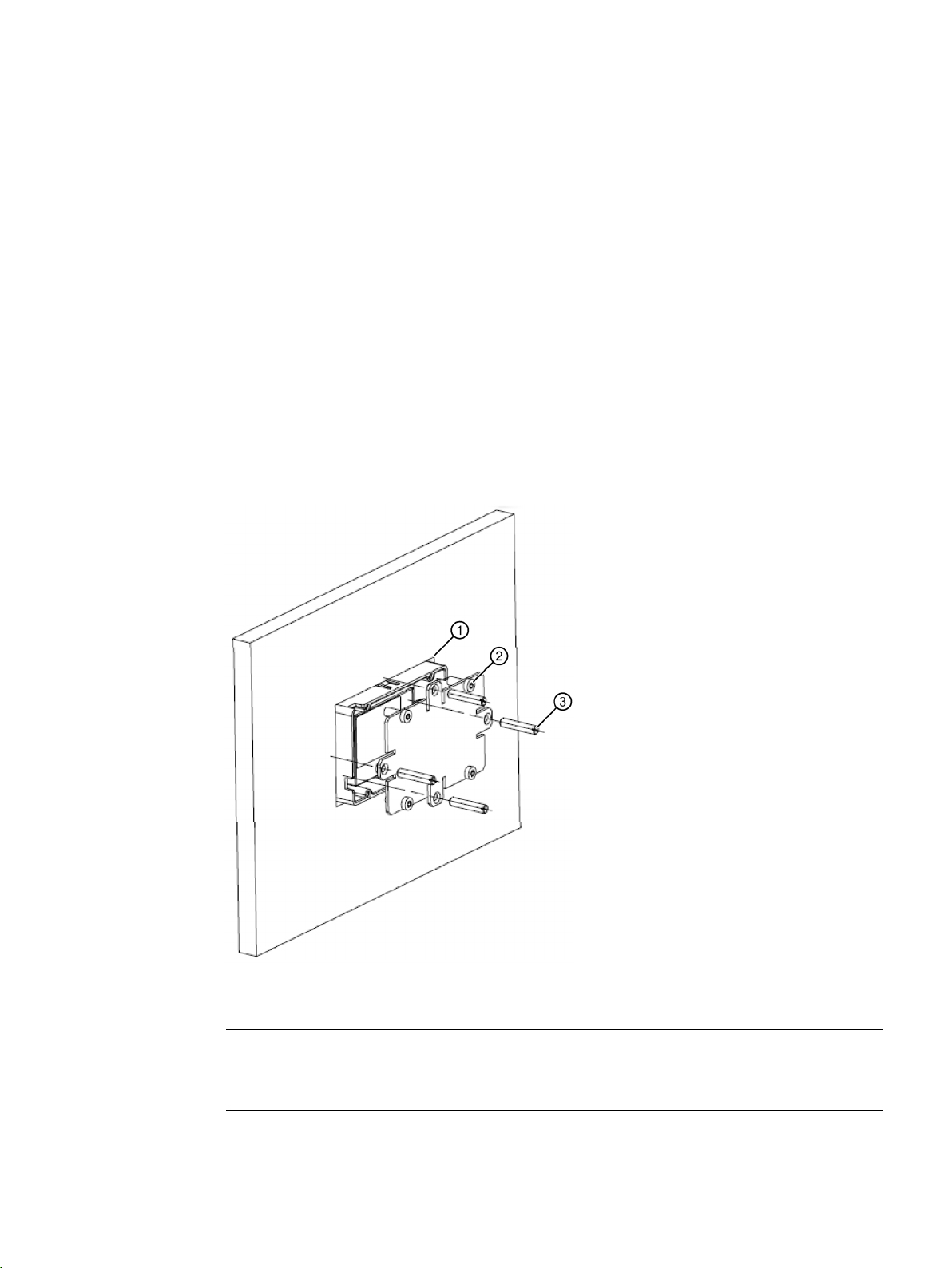

Note

Minimum/maximum thickness of the mounting wall

The thickness of the wall on which the reader is mounted must be 2

Proceed as follows to install the RF1060R/RF1070R readers:

1. Push the reader through the mounting opening intended for this purpose (76 × 48 ± 0.3

mm)

①.

Make sure that the reader locks in place so that it cannot fall out,

2. Mount the cover plate on the rear of the reader with the 4 Torx screws (max. 1.5 Nm)

3. Tighten the 4 x stud screws (max. 0.5 Nm)

4. If required, mount the optional card holder on the front of the reader.

To do this, place the card holder on the side of the reader housing and press it over the

reader front so that the card holder locks in place.

③.

②.

Figure 3-1 Mounting the RF1060R/RF1070R

SIMATIC RF1000

Operating Instructions, 02/2019, C79000-G8976-C432-04

-7 mm.

11

Installation

Note

Installation in a cabinet or metal housing

When operating the reader in an industrial environment installation in a cabinet or closed

metal housing is recommended.

NOTICE

Repair and maintenance

Do not try to repair the reader in case of a problem. Repair and maintenance work must

only be carried out by qualified personnel. Contact Siemens Support in case of repair or

maintenance problems. For more information, refer to the section "Service & Support".

SIMATIC RF1000

12 Operating Instructions, 02/2019, C79000-G8976-C432-04

4

Required tools

When using preassembled cables 6GT2891-4UH20 und 6GT2891-2UH30, you need the

following tool:

● Torx screwdriver (T8)

● Additional tools depending on the connector used

Accessories required

You need the following accessories:

● For communication via the USB interface

the connecting cable included in the scope of delivery

Connect the plug

● For communication with the RF170C communication module via the RS232 interface

the connecting cable (6GT2891-4UH20)

● For communication via the RS232 interface

The connecting cable with open ends (6GT2891-2UH30)

The procedure for connecting the reader depends on the interface over which the reader is

being operated.

Connection via USB interface

Proceed as follows to connect the SIMATIC RF1060R/RF1070R reader via the USB

interface:

1. Connect the reader to the PC or Panel using the USB cable.

Connection via RS232 interface

Proceed as follows to connect the SIMATIC RF1070R reader via the RS232 interface:

1. When using the cable 6GT2891-2UH30, you may have to install the cable connector.

You can find the connector assignment in the following table.

2. Loosen the cleat on the USB cable and remove the USB cable.

3. Connect the RS232 cable to the RS232 interface (5-pin socket).

4. Fasten the RS232 cable using the cleat.

5. Connect the reader to the communication module or the controller with the RS232 cable.

SIMATIC RF1000

Operating Instructions, 02/2019, C79000-G8976-C432-04

13

Connecting

Wire color

Assignment

red

+5 V

brown

Data line, RxD

black

GND

The table below contains the connector assignment for the connecting cable with open ends

(6GT2891-2UH30).

Table 4- 1 Connector assignment of the cable 6GT2891-2UH30

orange Data line, TxD

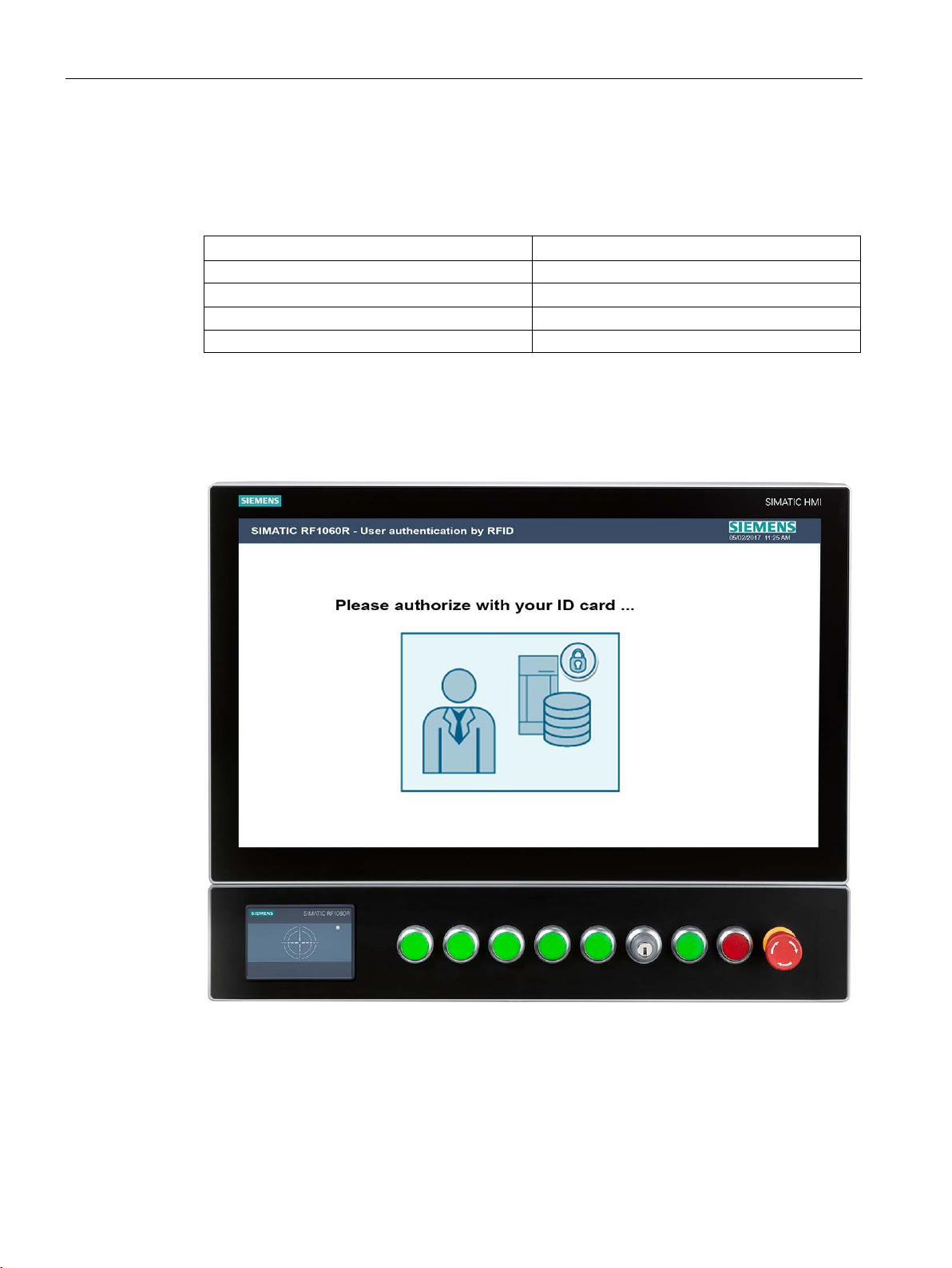

Application example

The following picture shows an example of an application of the SIMATIC RF1060R in

conjunction with a SIMATIC HMI.

SIMATIC RF1000

14 Operating Instructions, 02/2019, C79000-G8976-C432-04

Figure 4-1 Example of an application of a SIMATIC RF1060R in conjunction with a SIMATIC HMI

(e.g. 6AV7250-ODC03-0AH0) with extension unit (e.g. 6AV7674-1LA61-0AA0)

5

The procedure for installing and commissioning the reader depends on the interface over

which the reader is being operated.

Installation and commissioning via the USB interface

Proceed as follows to install and commission the SIMATIC RF1060R/RF1070R reader via

the USB interface:

1. Connect the reader to the PC or Panel using the USB cable.

Reaction: The message "A USB device was installed successfully." appears.

2. Copy the DLL drivers and the demo application on your PC using the installation file

"RF10x0R.exe".

You will find the file on the Internet on the pages of the Industry Online Support

(https://support.industry.siemens.com/cs/ww/en/view/109741590

).

3. Start the demo application by double-clicking on the file "AccessControlDemo.exe".

4. Program the reader using the demo application and the DLL functions.

You will find more information on the demo application in the section "The demo application

(Page 45)".

Installation and commissioning via the RS232 interface

Proceed as follows to install and commission the SIMATIC RF1070R reader via the RS232

interface:

1. Connect the reader to the communication module or the controller with the RS232 cable.

2. Program the PLC blocks using the freeport protocol.

You will find more information on the freeport protocol in the section "Programming via the

RS232 interface (Page 32)".

SIMATIC RF1000

Operating Instructions, 02/2019, C79000-G8976-C432-04

15

Installing and commissioning

Configuration card and VHL file

You transfer the reader configurations (e.g. memory areas, addresses, passwords, write

permissions, etc.) to the reader using the configuration card (6GT2300-0CC00-0AX0) or an

identification card (LEGIC). These configurations are saved as VHL file in the reader.

Multiple configurations (VHL files) of a configuration card can be stored on a reader.

To change the configuration of a reader with the configuration card, you must set the

"AllowConfig = true" tag when calling the function "vhl_select()" and then hold the card into

the antenna field of the reader. After you have changed the configuration, the reader

automatically restarts. After the restart you must set the "AllowConfig" tag back to "false".

The configuration card is blank upon delivery. If you prefer to receive the configuration cards

with preconfigured, customer-specific configurations, please contact Service & Support

(services.ci.industry@siemens.com).

SIMATIC RF1000

16 Operating Instructions, 02/2019, C79000-G8976-C432-04

6

Depending on the interface over which the SIMATIC RF1000 readers are being operated,

programming must take place either over the USB or the RS232 interface.

6.1 Typical applications

Below you will find typical applications for using the SIMATIC RF1060R/RF1070R readers.

The applications are shown as an example using the DLL functions. They can also be

implemented with system jobs.

Cyclic reading of serial numbers

A card that is located in the antenna field is selected with the "vhl_select" function. The serial

number of the respective card is read with the "vhl_get_snr" function.

Read and write user memory

Prerequisite for reading/writing the memory areas is that the corresponding card type and

the application are stored in the reader.

A card that is located in the antenna field is selected with the "vhl_select" function. You can

read or write to a required memory area of the respective card with the functions "vhl_read" /

"vhl_write". Because there are multiple configurations (VHL files) on the reader, the desired

configuration is selected with the "VHLFile" tag.

Autonomous reading ("Autoread")

Prerequisite for autonomous reading of the memory areas is that an "Autoread" configuration

is stored in the reader. The "Autoread" configuration can be transferred to the reader using

the configuration card.

During autonomous reading you can automatically read a desired memory area of the

respective card up to 16 bytes. The "Autoread_SetMode" function switches autonomous

reading permanently or one time on or off. During autonomous reading the reader

synchronizes the card in the antenna field with the stored configurations. If a match is found,

the corresponding memory area is read and output with "Autoread_GetMessage".

SIMATIC RF1000

Operating Instructions, 02/2019, C79000-G8976-C432-04

17

Programming

Note

Parallel operation not possible

Note that with the application, a connection can only be established to one reader at any one

time. For this reason "brp_open_usb_session" may only be called once and before it can be

called again must first be closed by the function "brp_close_session".

After a "brp_open_usb_session" the parameter "Handle" m

parameter ≠ "0", there is either an error or the function "brp_open__usb_session" was called

several times in succession.

6.2 Programming via USB interface

6.2 Programming via USB interface

You can program the reader using access functions. On the Siemens support page "Industry

Online Support (https://support.industry.siemens.com/cs/ww/en/view/109741590

obtain the file "RF10x0R.zip". It includes the DLL files ("BrpDriver_x64" and

"BrpDriver_x86"), the DLL functions as well as a demo application which demonstrates the

use of the DLL functions.

With the demo application "AccessControlDemo" you can address the reader directly from

your application via the USB interface. A precompiled DLL file for Windows systems that

provides this function is included in the package.

The DLL files provide various DLL functions for communication with the reader for integration

in your application. The reader has return values and status codes to inform you of the

reader status and execution of the functions.

You can integrate the DLL files in your application under Microsoft Windows 7/8/10 and use

them to call the described functions directly.

6.2.1 Functions of the DLL

)" you will

6.2.1.1 brp_open_usb_session

The function opens a connection to the reader via the USB interface and returns a session

key that is required for all functions and continued communication via this connection. If the

connection was successfully established, the value "BRP_OK" is returned.

Note that all the following functions can only be executed after you have established a

connection to the reader with the function "brp_open_usb_session". If this is not the case, an

error is signaled back.

Function call

int

brp_open_usb_session(

int * Handle,

DWORD ProductID

);

ust always be = "0". If the

SIMATIC RF1000

18 Operating Instructions, 02/2019, C79000-G8976-C432-04

Loading...

Loading...