Siemens SIMATIC PP7, SIMATIC PP17-I, SIMATIC PP17-II Equipment Manual

Preface, Contents

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

SIMATIC HMI

PP7, PP17-I, PP17-II

Push Button Panels

Equipment Manual

Product Description

Starting Up the Push Button

Panel

Control Bit Assignment

Installation

Unit Description PP7

Unit Description PP17-I

Unit Description PP17-II

Attach Labeling Strips

Spare Parts

1

2

3

4

5

6

7

8

9

6AV3991–1CA00–0AB0

Technical Data

System Messages

Hardware Test

Siemens Worldwide

Index

A

B

C

D

Release 06/98

Safety

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

Guidelines

!

!

This manual contains notices which you should observe to ensure your own personal safety, as

well as to protect the product and connected equipment. These notices are highlighted in the

manual by a warning triangle and are marked as follows according to the level of danger:

Warning

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not

taken.

Note

draws your attention to particularly important information on the product, handling the product,

or to a particular part of the documentation.

Qualified Personnel

Correct Usage

!

Trademarks

Equipment may be commissioned and operated only by qualified personnel. Qualified personnel within the meaning of the safety notices in this manual are persons who are authorized to

commission, ground and identify equipment, systems and circuits in accordance with safety

engineering standards.

Note the following:

Warning

The equipment may be used only for the applications stipulated in the catalog and in the technical description and only in conjunction with other equipment and components recommended

or approved by Siemens.

Startup must not take place until it is established that the machine, which is to accommodate

this component, is in conformity with the guideline 89/392/EEC.

Faultless and safe operation of the product presupposes proper transportation, proper storage,

erection and installation as well as careful operation and maintenance.

SIMATIC is a registered trademark of Siemens AG.

Some of the other designations used in these documents are also registered trademarks; the

owner’s rights may be violated if they are used be third parties for their own purposes.

Impressum

Copyright

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created

are reserved.

Siemens AG,

Bereich Automatisierungstechnik,

Bedienen und Beobachten

Postfach 4848,

Siemens Aktiengesellschaft

Editor and Publisher: A&D PT1

Siemens

by patent grant or registration of

AG 1996 All rights reserved

D-90327 Nuernberg

a utility model or design,

Disclaimer of Liability

W

e have checked the contents of this manual for agreement with

the

hardware and software described. Since deviations cannot be

precluded

the

corrections included in subsequent editions. Suggestions for improvement

T

echnical data subject to change.

Order No. 6A

entirely

data in this manual are reviewed regularly and any necessary

Siemens

Equipment

, we cannot guarantee full agreement. However

are welcomed.

AG 1997

V3991–1CA00–0AB0

Manual TP37

,

Preface

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

Purpose

This

equipment manual is designed to provide operators, installation personnel,

planners and system maintenance technicians with information concerning the

functionality

, operation and technical configuration of Push Button Panels.

Organization of the

manual

Further support

The

equipment manual for the Push Button Panels PP7, PP17-I and PP17-II

divided into the following sections:

Chapters Content

1

2

3

4

5 - 7

8

9

Appendices T

Please address technical questions to your local Siemens partners in the subsid

iaries and branch of

equipment manual for a list of addresses.

General description of the Push Button Panels

Step-by-step instructions on how to configure a Push

Button Panel

Detailed information on the interrelationship between the

Push Button Panel and PLC

Mechanical and electrical installation of the Push Button

Panels

Unit description of the various Push Button Panel

versions

Information on labelling

Information on spare parts

echnical data, system messages, hardware test

fices responsible for your area. Refer to Appendix D of this

is

-

PP7,

Release 06/98

PP17-I, PP17-II Equipment Manual

i

SIMATIC Customer Support Hotline

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

Available worldwide around the clock:

Johnson City

Nuremberg

Singapore

Nuremberg

SIMATIC BASIC Hotline

Local

time:

Mon-Fri 8:00 to

18:00

Tel.:

Fax:

E-mail: simatic.support@

SIMATIC

(chargeable,

SIMA

Times:

Tel.:

Fax:

+49 (911) 895-7000

+49 (911) 895-7002

nbgm.siemens.de

Premium Hotline

TIC Card required)

Mon-Fri 0:00 to

24:00

+49 (911) 895-7777

+49 (911) 895-7001

Simatic

Basic Hotline

Johnson City

SIMATIC BASIC Hotline

Local time:

Tel.:

Fax:

E-mail: simatic.hotline@

Mon-Fri 8:00 to

17:00

+1 423 461-2522

+1 423 461-2231

sea.siemens.com

Singapore

SIMATIC BASIC Hotline

Local time:

Tel.:

Fax:

E-mail: simatic@

Mon-Fri 8:30 to

17:30

+65 740-7000

+65 740-7001

singnet.com.sg

ii

PP7,

PP17-I, PP17-II Equipment Manual

Release 06/98

SIMATIC Customer Support Online Services

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

SIMATIC

MA

Customer Support offers you comprehensive additional information about SI

TIC products through its Online Services as follows:

Up-to-date general information is provided

–

on the

internet

–

from the

Up-to-date product information and downloads for practical use can be found

–

on the

internet

html–00/

–

from the

tomer Support Mailbox)

For calling up the mailbox, you should use a modem with up to

V

.34 (28.8 kBaud) capability and set the parameters as follows: 8, N, 1,

ANSI, or connect via ISDN (x.75, 64 kBit).

at

http://www.ad.siemens.de/simatic

fax polling service on

at

http://www.ad.siemens.de/support/

Bulletin Board System

on +49 (91

08765-93 02 77 95 00

(BBS) in Nurember

1) 895-7100.

g (

SIMA

-

TIC Cus

-

PP7, PP17-I, PP17-II Equipment Manual

Release 06/98

iii

iv

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

PP7,

PP17-I, PP17-II Equipment Manual

Release 06/98

Contents

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

1 Product

1.1 Push

1.2 Operating

2 Starting Up the Push Button Panel 2-1.

2.1 Configure

2.2 Define

2.2.1 MPI

2.2.2 PROFIBUS-DP

2.3 Configuring

2.3.1 Configuring

2.3.2 Configuring

2.4 Coordinating

3 Control

4 Installation 4-1

5 Unit

6 Unit

7 Unit

8 Attach

Description

Button Panel Overview

Configuration in PLC

connection

Bit Assignment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description PP7

Description PP17-I

Description PP17-II

Labeling Strips

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and Display Elements

Interface to PLC on the Push Button Panel

Keys/LEDs

Keys/LEDs When Using MPI Connection

Keys/LEDs When Using PROFIBUS-DP Connection

the Push Button Panel and PLC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

2-11.

2-12.

2-13.

1-1.

1-3.

1-4.

2-3.

2-6.

2-6.

2-6.

2-9.

3-1.

5-1.

6-1.

7-1.

8-1.

9 Spare

A Technical

B System

C Hardware Test C-1.

D Siemens Worldwide D-1.

PP7, PP17-I, PP17-II Equipment Manual

Release 06/98

Parts

A.1 General

A.2 Digital

A.3 Interface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

inputs and outputs

Messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

technical data

assignment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-1.

A-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-1.

A-2.

A-4.

B-1.

v

vi

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

PP7, PP17-I, PP17-II Equipment Manual

Release 06/98

Product Description

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

The

Use of Push

Button Panels

Push Button Panels can be used to display the operating statuses of a

machine or system and to control processes.

1

Until now

for this purpose. This was also a time-consuming process. In contrast to this,

installation of Push Button Panels requires only a rectangular cut-out and a bus

connection (DP or MPI). The standard configuration ensures that the panel is

ready to operate immediately after all the connections have been made. This

results in considerable advantages in respect of time compared to conventional

connections.

The Push Button Panels provide a lar

without the necessity of PLC programs:

Color

, keys and lamps had to be individually mounted, wired and tested

ge variety of features which can be used

Short-stroke keys with surface illumination according to the LED colors

Additional 24 V digital inputs and outputs

All short-stroke keys and digital 24 V inputs can also be individually

configured as switches

Integrated lamp and key test

Central release input to lock all operating actions

Integrated flash timing

-coding for LEDs, such as red, green, orange

Pulse extension for short-stroke keys and digital 24 V inputs can be

specified via parameters

Perforated cut-outs for 22.5 mm standard optional elements, such as

key-operated switch and emer

gency shutdown switch

Installation

possibilities

PP7, PP17-I, PP17-II Equipment Manual

Release 06/98

OP design, can be set in rows, without gaps

The Push Button Panels have been conceived for installation in cabinets and

can be implemented in all situations where keys, switches and lamps are re

quired.

The high degree of protection (IP65 on the front side) and the fact they are

maintenance-free make the Push Button Panels suitable for use even in rough

industrial environments.

-

1-1

Connection types

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

The

Push Button Panels can be operated using the following connections:

via MPI to a SIMA

via MPI to a SIMA

via MPI to a SIMA

via PROFIBUS-DP to a SIMA

via PROFIBUS-DP to a SIMA

via PROFIBUS-DP as standard slave to a DP master from a dif

manufacturer; possible restrictions regarding configuration of the Push

Button Panel.

TIC S7-200

TIC S7-300

TIC S7-400

TIC S5

TIC S7

ferent

Unit configuration

Parameters in the Push Button Panels are predefined and the unit is thus imme

diately ready to operate. V

certain parameters. Each key

adapted according to specific requirements.

No special configuration software is necessary for the Push Button Panel. All

adjustment of the settings is carried out either directly on the Push Button

Panel or by means of the PLC configuration software.

All adjustments to settings carried out on the Push Button Panel are stored in

its memory module. In cases where the unit electronics or the entire unit are

replaced, the interface need not be reconfigured. Only the old memory module

needs to be transferred to the new unit.

arious options can also be activated by adjusting

, LED, digital input and output can be individually

-

1-2

PP7,

PP17-I, PP17-II Equipment Manual

Release 06/98

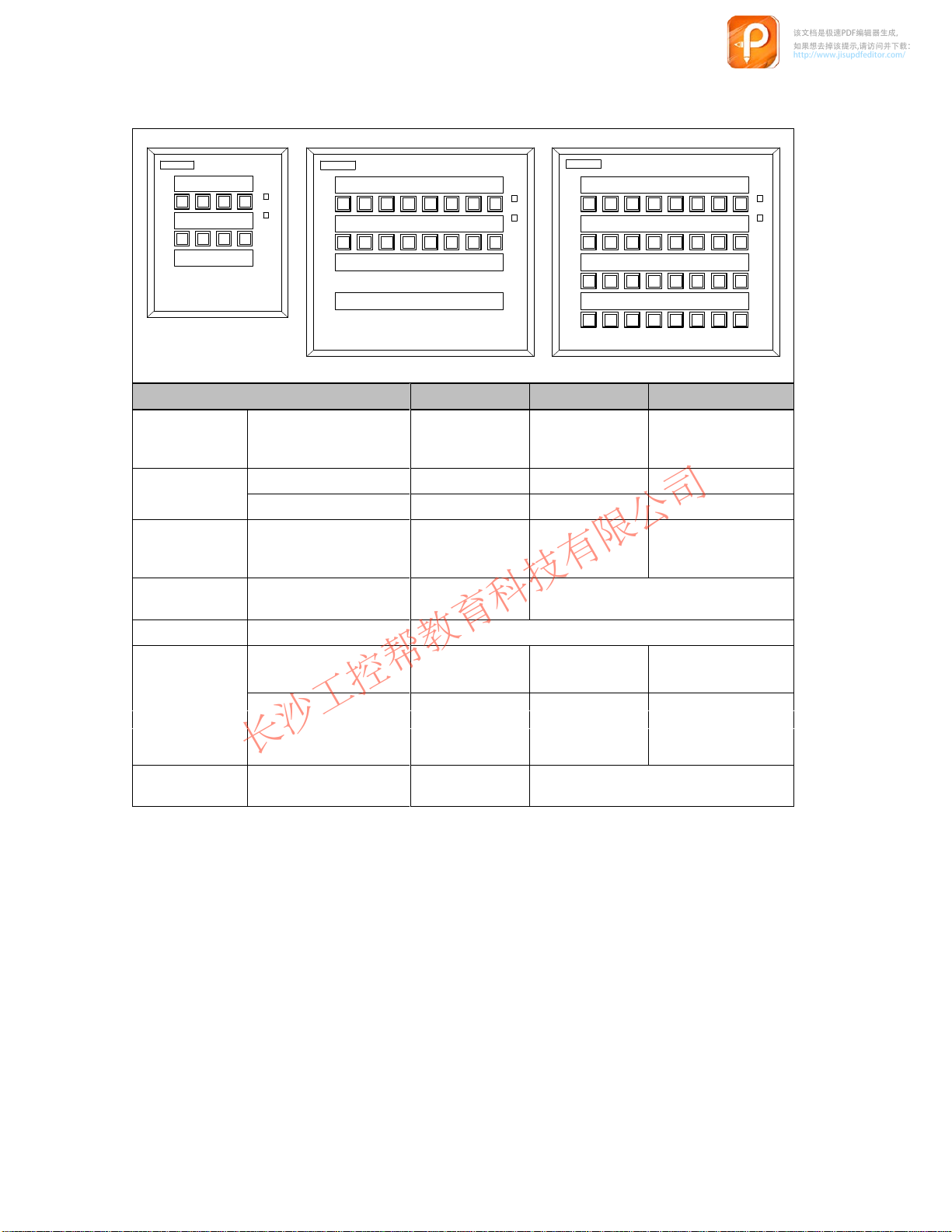

1.1 Push

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

Short-stroke

keys, surface illumination

Inputs/Outputs

p p

Installable operating elements

Release input Lock operation of the

Interfaces PLC connection MPI or Profibus DP

Communication SIMATIC S5

Data transmission

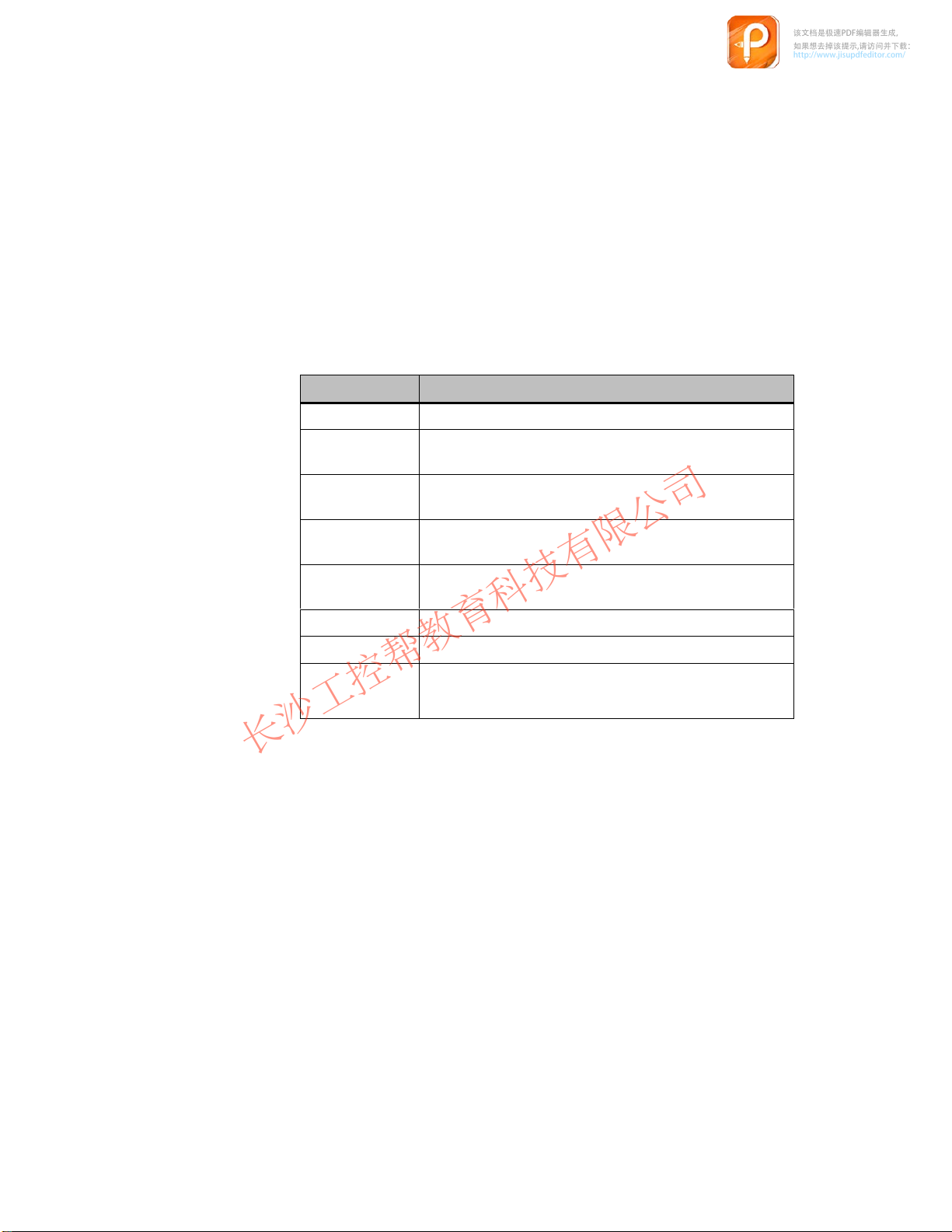

Button Panel Overview

PP7 PP17-I PP17-II

Hardware PP7 PP17-I PP17-II

Number of short-stroke

-

keys

Number of digital inputs 4 16 16

Number of digital outputs - 16 16

Number of 22.5 mm ele-

ments which can be integrated

Push Button Panel

–

– PROFIBUS-DP

SIMATIC S7/M7

SIMATICS7/M7

–

– MPI

– PROFIBUS-DP

PROFIBUS DP

Baud rate Max. 1.5 MBaud Max. 12 MBaud

-

8 16 32

3 12 –

-

PP7,

Release 06/98

PP17-I, PP17-II Equipment Manual

1-3

1.2 Operating and Display Elements

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

The

Standard operating

and display elements

Push Button Panels are all equipped with a keyboard containing shortstroke keys. The individual keys can be configured in respect of their function

as either switches or keys.

Function momentary–contact switch:

The corresponding bit in the PLC is set as long as the

key is pressed.

Operating concept

Digital inputs and

outputs

Release input

Function switches:

T

wo LEDs are integrated in the keys and are used to display the bit status of

the connected PLC. The LEDs can indicate four dif

which can be defined via parameters.

All the operating elements of the Push Button Panels are linked to bits in the

PLC. The keys on the Push Button Panel can be used to influence the bits in

the PLC and thus control the af

indicate the bit status of the PLC and, thus, the operating status of the process

being monitored.

When several keys are pressed simultaneously

ton Panel and the bits are set in the PLC. After restarting the system following

a power failure, all the bits are set to 0.

Additional 22.5 mm elements can be connected using the digital inputs and

outputs. Non-connected digital inputs are automatically set to 0.

The release input serves to lock the Push Button Panel. A key-operated switch

can be connected here, for example. The release input permits switching be

tween normal operation (open contact) and monitoring mode (closed contact).

In normal operation, all the functions on the Push Button Panel are available

for use, whereas in monitoring mode, the following restrictions are valid

Pressing the key sets the corresponding bit, pressing

again resets it.

ferent statuses, one of

fect of processes. At the same time, the LEDs

, it is detected by the Push But

-

-

1-4

the inputs are locked, no signal exchanges are reported to the PLC,

the last status of all the keys is maintained by the PLC until normal

operation returns.

PP7,

PP17-I, PP17-II Equipment Manual

Release 06/98

Pulse

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

diagrams

The

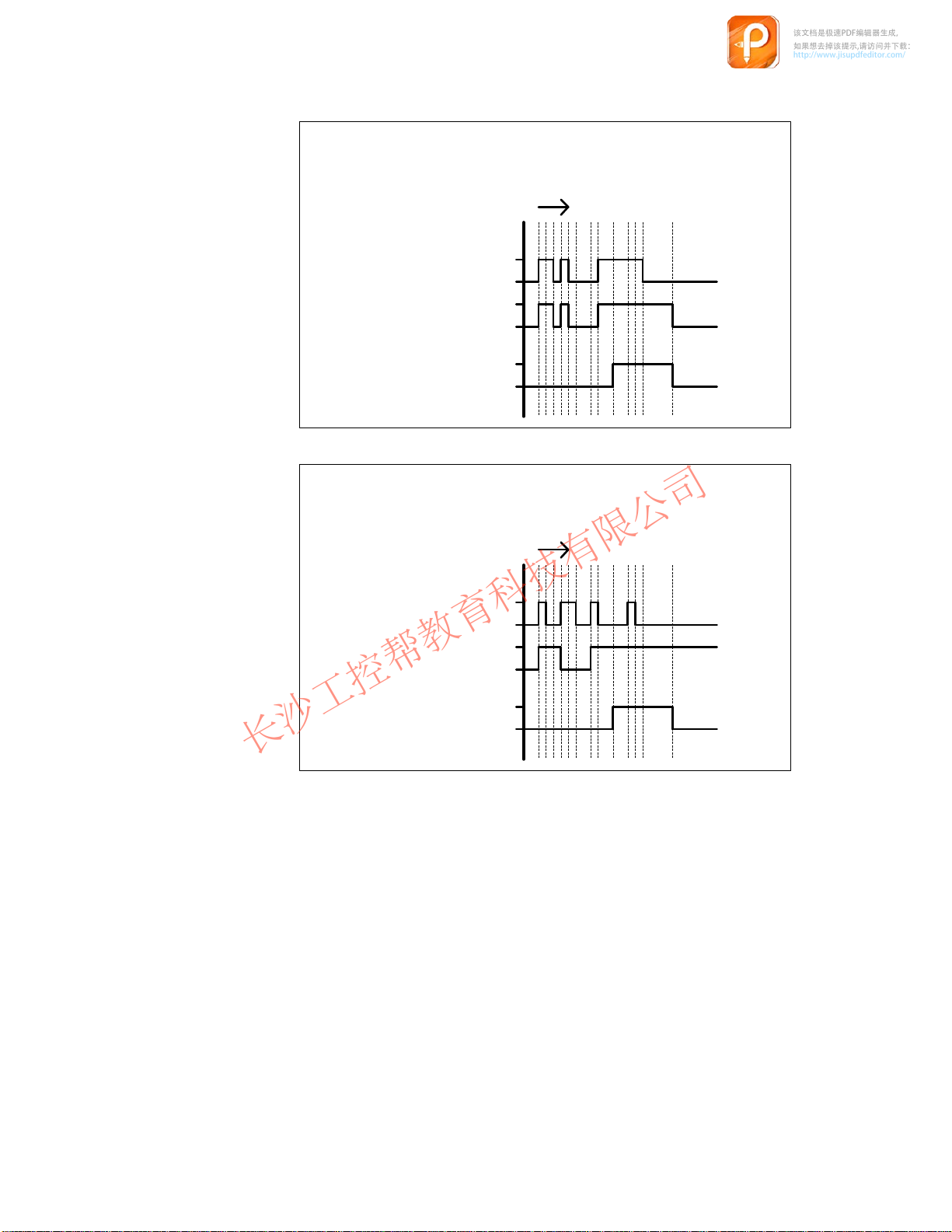

following pulse diagrams elucidate the relationship between the actions

initiated on the Push Button Panel and changing bit status in the PLC:

Function

Key

Bit

in

PLC

Contact

Release

input

Key

Bit

in

PLC

as momentary–contact switch

Time

pressed

not pressed

1

0

closed

open

Function as switch

Time

pressed

not pressed

1

0

Lamp/Key test

PP7,

PP17-I, PP17-II Equipment Manual

Release 06/98

Contact

Release

input

The

Lamp/Key test serves to test the functional capabilitity of all the keys and

closed

open

lamps on the Push Button Panel. The Lamp/Key test can be activated by the

following measures in normal operation:

By pressing the key assigned to the Lamp/Key test function by the

corresponding parameter

By setting the two LED bits of the key assigned to the Lamp/Key test

.

function according to the configuration. The bits must be set in the PLC

using a relevant program.

The Lamp/Key test function is assigned to Key 1 (top right) in the pre-adjusted

system settings.

1-5

On

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

activating the Lamp/Key test, the unit switches to the corresponding oper

ating mode. In this case

the ERROR LED blinks,

the LEDs integrated in the Push Button Panel keyboard are activated,

all the Push Button Panel digital outputs are set to 1.

After pressing any key when in operating mode Lamp/Key test,

the LED/lamps go out for the period in which the key is pressed,

all the Push Button Panel digital outputs are set to 1.

This is valid for the period in which the key is pressed. All the keys and digital

inputs can be tested in this way

In order that no unwanted signals are transmitted to the PLC during the Lamp/

Key test, the following restrictions are valid in respect of Push Button Panel

operation:

the inputs are locked and no signal exchanges are reported to the PLC,

the last status of all the keys is maintained by the PLC until normal

operation returns.

The last key operation reported to the PLC is the pressing of the Lamp/Key test

button.

T

o terminate the Lamp/Key test,

.

-

release the corresponding key

reset the corresponding bits in the PLC

The unit returns to normal operation and the restrictions regarding the Push

Button Panel operation are released.

, or

1-6

PP7,

PP17-I, PP17-II Equipment Manual

Release 06/98

Starting Up the Push Button Panel

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

The

following section provides help regarding the configuration possibilities of

the Push Button Panel. Connection type MPI is pre-selected in the system set

tings.

2

-

MPI connection

The system settings for the MPI connection are:

MPI address:

Baud rate:

Data area type:

Memory word:

Configuring data block:

PLC address:

PLC type:

Highest station address:

Number of MPI masters:

The following table provides an overview of the possibilities for modifying the

defined system settings:

Intention Procedure Chap-

Modify MPI address

Change baud rate Change baud rate on Push

Change data area type

Configure Push Button Panel

properties which deviate from

p p

dj d i

pre-adjusted system settings

3

187.5 KBaud

Marker byte

100

0

2

300 (S7-300)

126

1

Set MPI address on Push

Button Panel

Button Panel

Change data area type on

Push Button Panel

Set up configuring data block

in the PLC

Set parameter

ters

2.1

2.1

2.1

2.3.1

2.3

PP7,

Release 06/98

PP17-I, PP17-II Equipment Manual

Set the number of the config

uring data block on the Push

Button Panel

-

2.1

2-1

h devi

DP connection

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

The

system settings for the DP connection are:

DP slave address:

Baud rate:

The following table provides an overview of the possibilities for modifying the

defined system settings:

Intention Procedure Chap-

Set connection type DP Set connection type DP on the

Change DP slave address

Change baud rate Change baud rate on Push

Configure Push Button Panel

properties whic

pre-adjusted system settings

ate from

3

1500 KBaud

Push Button Panel

Change the DP slave address

on the Push Button Panel

Button Panel

Set parameter in the configu-2.3

ration software

ters

2.1

2.1

2.1

2-2

PP7,

PP17-I, PP17-II Equipment Manual

Release 06/98

2.1 Configure Interface to PLC on the Push Button Panel

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

The

Calling in and

operating

configuration

mode

settings of the interface to the PLC are menu-controlled and can be de

fined via the rear side display of the Push Button Panel. The so-called configu

ration mode is provided for this.

All the parameters concerning the interface to the PLC are stored in the Push

Button Panel memory module. In cases where the unit electronics or the entire

unit are replaced, the interface need not be reconfigured. Only the old memory

module needs to be transferred to the new unit.

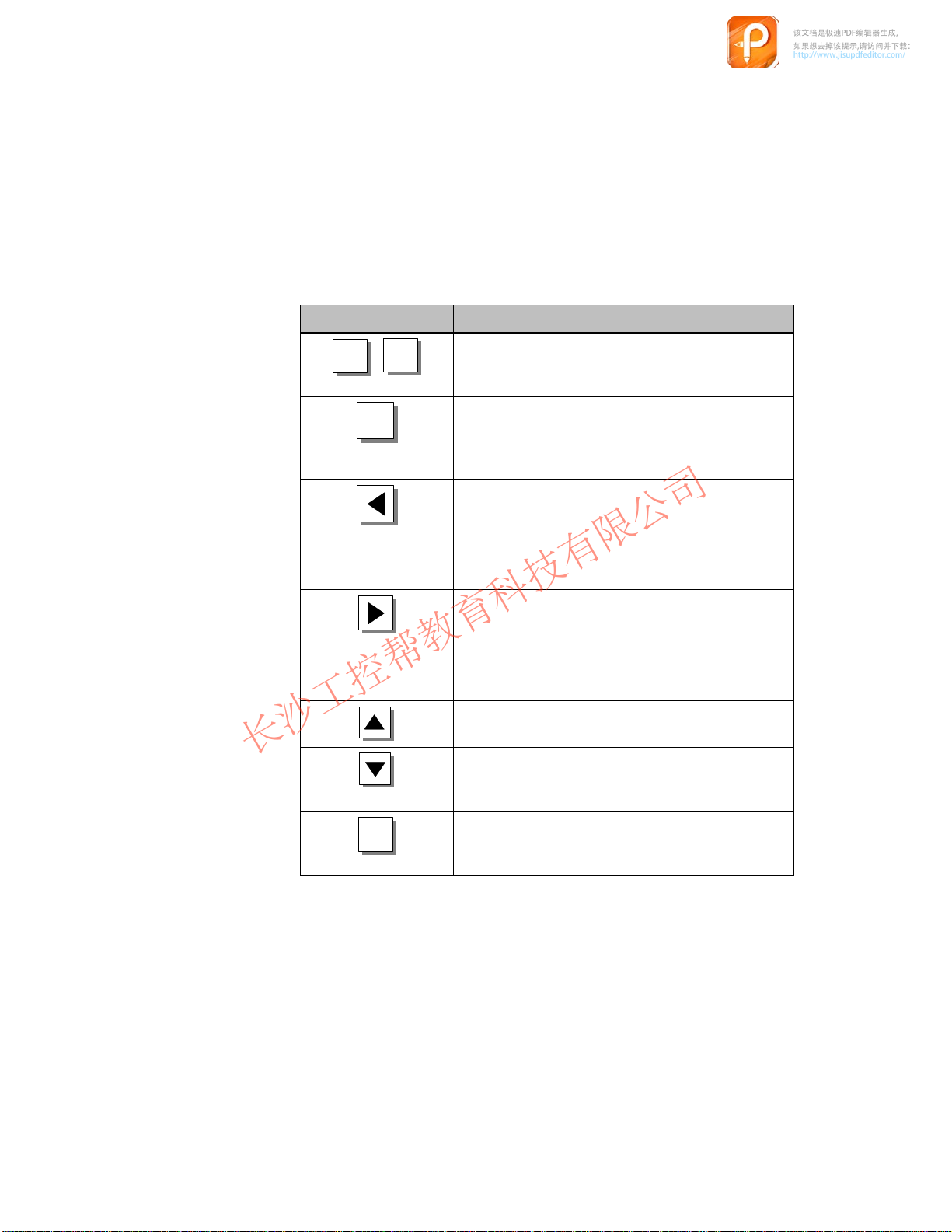

Key Description

-

-

ESC

OK

+

If this key combination is pressed while the unit is

starting up (directly after switching on), the unit

enters configuration mode.

OK

In configuration mode, this key serves to store a

modification in the current menu level and skip for

ward to the next menu level. The key has no func

-

-

tion in the bottom menu level.

In configuration mode, this key serves to skip back

to the superordinated menu level. The key has no

function in the top menu level.

Caution: Any modifications carried out to the set

-

tings in the current menu level are not stored.

In configuration mode, this key serves to skip for

ward to the next menu level. The key has no func

-

-

tion in the bottom menu level.

Caution: Any modifications carried out to the set

-

tings in the current menu level are not stored.

In configuration mode, this key serves to scroll up

-

wards through the alternatives within a menu level.

In configuration mode, this key serves to scroll

downwards through the alternatives within a menu

level.

PP7,

Release 06/98

PP17-I, PP17-II Equipment Manual

ESC

This key serves to exit from configuration mode.

The current settings are stored. The key can be

operated in any menu level.

2-3

The

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

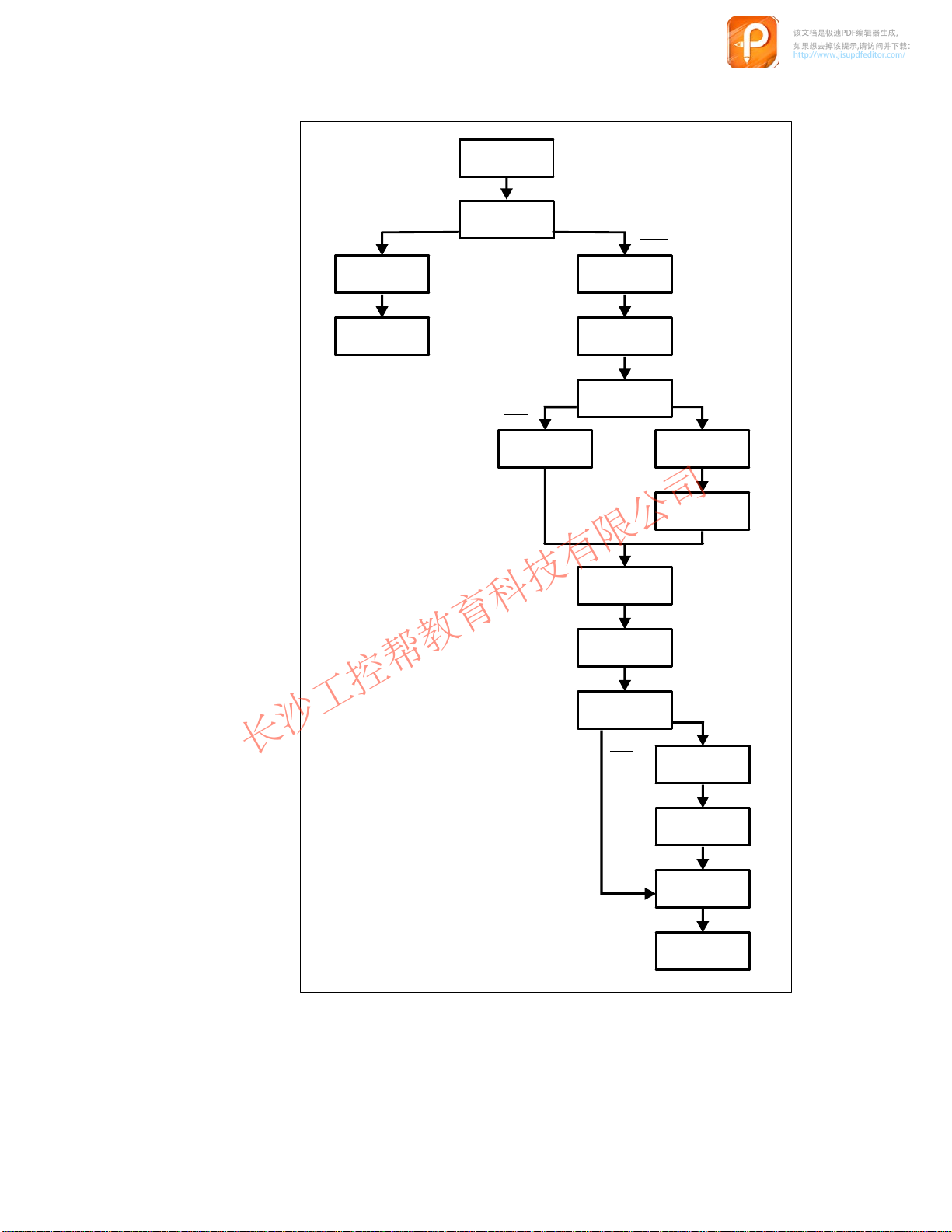

following menu structure is displayed in configuration mode (the numeric

values and underlined alternatives indicate the predefined system settings):

DEFAULT

YES / NO

CONNECTION

DP

DP MPI

/ MPI

SLAVE-ADR

BAUDRATE

3

1500 KBaud

100

MB

MW

PP-MPI-ADR

BAUDRATE

MB / DB

PARAM.-DB

PLC-ADR

PLC-TYPE

2 / 3 / 400

200

DATA

300

3

187,5 KBaud

DB

DB

DW

0

2

400

RACK-NO

100

0

0

2-4

SLOT-NO

HSA

NUMBER OF

MPI-MASTER

PP7,

PP17-I, PP17-II Equipment Manual

3

126

1

Release 06/98

Refer

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

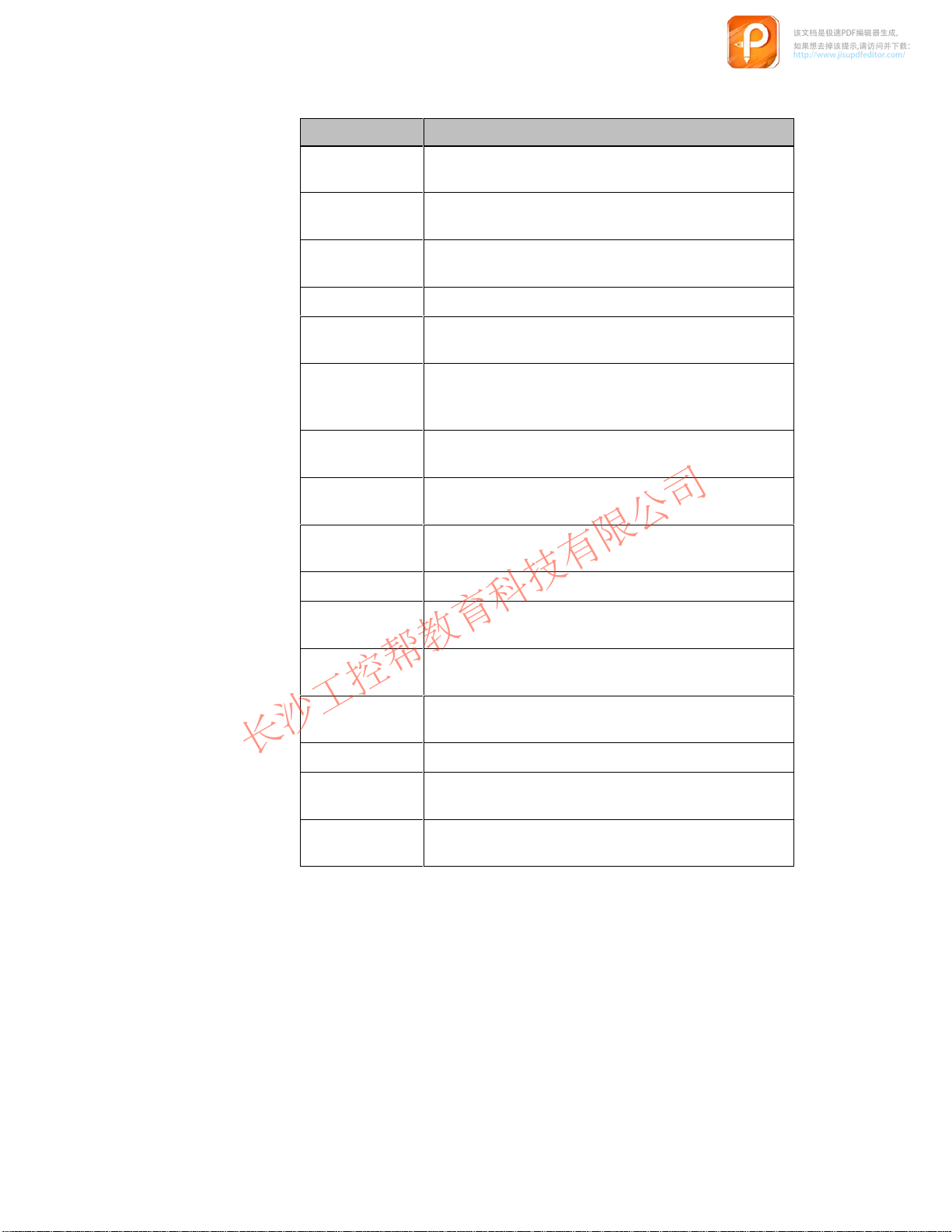

to the following table for the significance of the various menu items:

Name Explanation

DEFAULT

CONNECTION

DP/MPI

SLAVE-ADR

PP-MPI-ADR

BAUDRATE

DAT

A MB/DB

MW

DB

DW

PARAM.-DB

Used to select whether all the parameters should be reset

to the predefined system settings values.

Used to select the system connection type. Either MPI or

PROFIBUS-DP.

Defines the slave address of the Push Button Panel in

the PROFIBUS-DP system.

Defines the MPI address of the Push Button Panel.

Defines the baud rate for data transmission using con

nection type MPI or PROFIBUS-DP in KBaud.

Used to select whether the data area for the Push Button

Panel is created as a Memory Byte (MB) or Data Block

(DB).

Defines the number of the first, reserved memory word

for the Push Button Panel.

Defines the number of the data block in which the data

area for the Push Button Panel is reserved.

Defines the number of the first, reserved data word for

the Push Button Panel in the data block.

Defines the number of the configuring data block.

-

PLC-ADR

PLC-TYPE

2/3/400

RACK-NO

SLOT-NO

HSA

NUMBER OF

MPI-MASTER

Defines the address of the PLC to which the Push But

ton Panel is connected.

Used to select the type of PLC to which the Push Button

Panel is connected.

Defines the number of the rack in which the PLC is

installed.

Defines the number of the slot within the rack.

Defines the highest station address within the MPI sys

tem.

Defines the number of the MPI master in the system.

-

-

PP7,

Release 06/98

PP17-I, PP17-II Equipment Manual

2-5

2.2 Define Configuration in PLC

该文档是极速PDF编辑器生成,

如果想去掉该提示,请访问并下载:

http://www.jisupdfeditor.com/

长沙工控帮教育科技有限公司

www.gkbpx.com

2.2.1 MPI connection

If

connection type MPI is used for the Push Button Panel, no hardware config

uration is necessary

Panel.

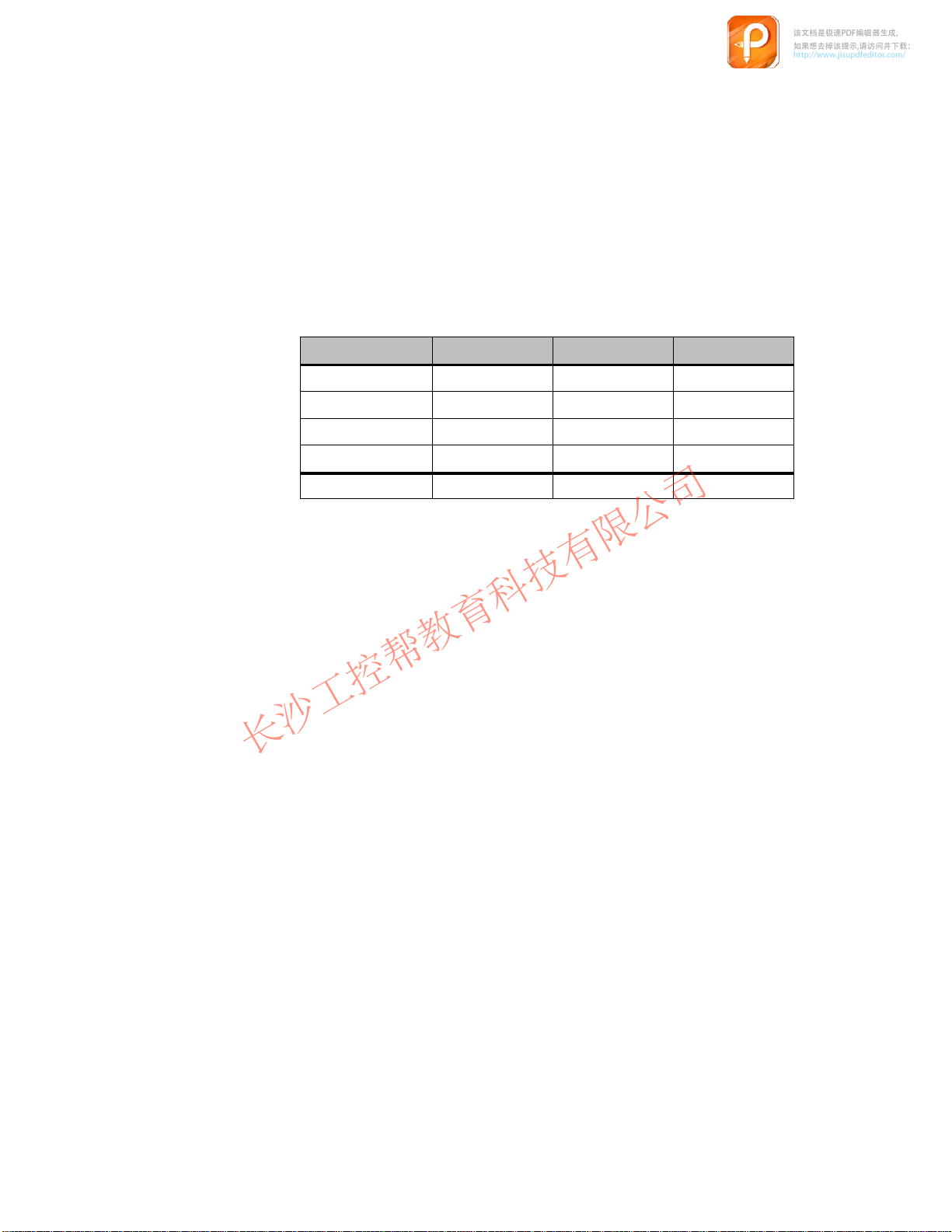

Interrelated memory areas must be set up in the PLC for the keys, LEDs and

digital inputs and outputs. The following table indicates the length of the

memory areas to be set up for the various unit versions.

. Only the MPI address needs to be set on the Push Button

-

Memory ar

Keys

Digital inputs

LEDs

Digital outputs

Total

In order to modify system settings, a data block must be created in the PLC

which contains the configuration data for the Push Button Panel. The structure

of this configuring data block is depicted in Chapter 2.4. The number of the

configuring data block must be specified when configuring the Push Button

Panel.

ea PP7 PP17-I PP17-II

2.2.2 PROFIBUS-DP connection

When

connection type PROFIBUS-DP is used, the Push Button Panel must be

installed in the PROFIBUS configuration software as a slave in the network. In

the case of SIMA

and for SIMA

CONFIG. The configuration software defines the following:

TIC S5, the configuration software used is COM-PROFIBUS,

TIC S7 connection to the network is performed via HW

1 Byte

1 Byte

2 Bytes 4 Bytes 8 Bytes

–

4 Bytes

2 Bytes 4 Bytes

2 Bytes 2 Bytes

4 Bytes 4 Bytes

12 Bytes 18 Bytes

-

2-6

station address,

the I/O area used

and the configuration of the buttons and LEDs.

Ensure that the same station address is specified that is set on the Push Button

Panel.

PP7,

PP17-I, PP17-II Equipment Manual

Release 06/98

Loading...

Loading...