Siemens SIMATIC PN/M-Bus LINK Operating Instructions Manual

Operating Instructions

SIMATIC

Network transitions

PN/M-Bus LINK

03/2018Edition

siemens.com

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

03/2018

A5E44260928

Introduction

1

Safety information

2

System overview

3

Functions

4

Application planning

5

Mounting/Extending

6

Connecting

7

Commissioning

8

Configuring / Programming

9

Diagnostics

10

Maintenance and service

11

Technical specifications

12

Appendix

A

Network transitions

P

N/M-Bus LINK

Operating Instructions

-AA

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E44260928-AA

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

04/2018 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 5

2 Safety information ................................................................................................................................... 7

3 System overview ................................................................................................................................... 10

4 Functions .............................................................................................................................................. 15

5 Application planning .............................................................................................................................. 19

6 Mounting/Extending .............................................................................................................................. 24

7 Connecting ........................................................................................................................................... 26

1.1 Preface ...................................................................................................................................... 5

1.2 Documentation guide ................................................................................................................ 6

2.1 Safety information ..................................................................................................................... 7

2.2 Security information .................................................................................................................. 9

2.3 IT security ................................................................................................................................. 9

3.1 Field of application .................................................................................................................. 10

3.2 Features .................................................................................................................................. 11

3.3 System configuration .............................................................................................................. 12

3.4 System requirements .............................................................................................................. 13

3.5 Design ..................................................................................................................................... 14

4.1 Cyclic and acyclic data exchange ........................................................................................... 15

4.2 Response to errors ................................................................................................................. 18

5.1 Installation guidelines.............................................................................................................. 19

5.2 Installation location ................................................................................................................. 20

5.3 Transportation ......................................................................................................................... 23

5.4 Storage ................................................................................................................................... 23

5.5 Scope of delivery .................................................................................................................... 23

6.1 Installing the device ................................................................................................................ 24

7.1 Safety instructions and guidelines .......................................................................................... 26

7.2 Power supply and potential ratios ........................................................................................... 28

7.3 Connecting 24 V DC ............................................................................................................... 31

7.4 Connecting the functional ground ........................................................................................... 32

7.5 Connecting PROFINET........................................................................................................... 33

7.6 Connecting the M-Bus ............................................................................................................ 34

PN/M-Bus LINK

Operating Instructions, 03/2018, A5E44260928-AA

3

Table of contents

8 Commissioning ..................................................................................................................................... 35

9 Configuring / Programming ................................................................................................................... 36

10 Diagnostics ........................................................................................................................................... 41

11 Maintenance and service ...................................................................................................................... 47

12 Technical specifications ........................................................................................................................ 50

A Appendix .............................................................................................................................................. 54

Glossary ............................................................................................................................................... 57

Index .................................................................................................................................................... 59

8.1 Commissioning PN/M-Bus LINK ............................................................................................ 35

9.1 Overview ................................................................................................................................ 36

9.2 TIA Portal Devices & Networks .............................................................................................. 36

9.3 Inserting and configuring M-Bus devices ............................................................................... 38

9.4 Checking and compiling the configuration ............................................................................. 40

10.1 Status LEDs ........................................................................................................................... 41

10.1.1 Operating state of the PN/M-Bus LINK / PROFINET diagnostics ......................................... 41

10.1.2 Connection status of the M-Bus ............................................................................................. 43

10.1.3 Connection status of Ethernet interfaces ............................................................................... 44

10.2 Diagnostic messages to the S7 controller ............................................................................. 45

10.2.1 Events that trigger a diagnostic message .............................................................................. 45

10.2.2 Status byte in cyclic IO image ................................................................................................ 46

11.1 Firmware update .................................................................................................................... 47

11.2 Reset to factory settings ........................................................................................................ 47

11.3 Replacing PN/M-Bus LINK ..................................................................................................... 48

11.4 Recycling and disposal .......................................................................................................... 49

12.1 Technical specifications ......................................................................................................... 50

12.2 Dimension drawing ................................................................................................................ 53

A.1 Certificates and approvals ..................................................................................................... 54

A.2 Contact address ..................................................................................................................... 55

A.3 Licenses ................................................................................................................................. 55

A.4 Service & Support .................................................................................................................. 56

A.4.1 Technical Support .................................................................................................................. 56

A.4.2 Siemens Industry Online Support .......................................................................................... 56

A.4.3 Online catalog and ordering system ...................................................................................... 56

PN/M-Bus LINK

4 Operating Instructions, 03/2018, A5E44260928-AA

1

1.1

Preface

Purpose of this documentation

Knowledge required

Trademarks

History

Edition

Remarks

These operating instructions contain all the information required for configuring, installing,

commissioning and operating the PN/M-Bus LINK.

These operating instructions are intended for qualified personnel in the following target

groups:

● Commissioning engineers

● Operating and service personnel

● System integrator

The following knowledge is required in order to understand the operating instructions:

● Knowledge of programming a SIMATIC S7 controller

● Knowledge in the application of the TIA configuration environment

● Knowledge of working with the PROFINET fieldbus

● Well-founded knowledge in the M-Bus communication protocol

● General knowledge in the field of automation technology

● General knowledge of communication networks

SIMATIC® is a registered trademark of Siemens AG.

03/2018 First edition

PN/M-Bus LINK

Operating Instructions, 03/2018, A5E44260928-AA

5

Introduction

Naming conventions

1.2

Documentation guide

Additional documentation

Subject

Documentation

Most important contents

1.2 Documentation guide

In this documentation, the following terms are used instead of the complete product

designation "SIMATIC PN/M-Bus LINK":

● "PN/M-Bus LINK"

● "Device"

Additional documentation is listed below, which supplements these operating instructions for

the PN/M-Bus LINK and is available on the Internet.

Designing interference-free

controllers

PROFINET SIMATIC PROFINET System Description

Function Manual Designing interference-free

controllers

(https://support.industry.siemens.com/cs/ww/en/view

/59193566)

(https://support.industry.siemens.com/cs/ww/en/view

/19292127)

• Basics

• Electromagnetic

compatibility

• Lightning protection

• Basics

• Installation

• Functions

• Configuration examples

The latest manuals for SIMATIC products are available for download free of charge from the

Internet (https://support.industry.siemens.com/cs/ww/en/ps/man).

The TIA Portal information system also supports you in configuring and programming your

automation system and PN/M-Bus LINK.

PN/M-Bus LINK

6 Operating Instructions, 03/2018, A5E44260928-AA

2

2.1

Safety information

CAUTION

NOTICE

Intended use

NOTICE

Repairs

WARNING

The device contains no user-serviceable parts.

May cause death or serious injury

Observe the safety instructions on the inside front cover of this documentation.

SIMATIC M-Bus LINK devices adhere to the approvals printed on the nameplate. If you have

questions about whether it is permissible to install the device in the planned environment,

please contact your service representative.

Alterations to the devices are not permitted.

Failure to observe this requirement shall constitute a revocation of the CE approval and

manufacturer's warranty.

PN/M-Bus LINK may only be used for the applications specified in the catalog and the

corresponding technical documentation. If the device is used in a manner other than the

one specified by Siemens, the protection offered by the device might be impaired.

See also the section "Legal notices" at the beginning of this manual.

Unauthorized opening or improperly performed repairs can cause considerable damage to

property and/or danger to users. Contact Siemens Support

(http://support.automation.siemens.com) in case of error.

PN/M-Bus LINK

Operating Instructions, 03/2018, A5E44260928-AA

7

Safety information

Safety information

WARNING

Connection only over safety extra-low voltage / protective extra-low voltage

May cause death or serious injury

Working on the device or on connected components

WARNING

Risk of electric shock

May cause death or serious injury

2.1 Safety information

The device is designed for operation using directly connectable safety extra-low voltage

(SELV) with safe electrical separation according to IEC 60950-1 / EN 60950-1 /

VDE 0805-1 or IEC 61131-2 / EN 61131-2 / DIN EN 61131-2.

In order to maintain the safe characteristics of the low voltage circuits of the PN/M-Bus

LINK, the 24 V rated voltage supply and external connections to communication ports must

be supplied from approved sources which meet the requirements of various standards for

SELV / PELV voltage-limited sources.

Therefore only connect safety extra-low voltages (SELV) with safe electrical separation

according to IEC 60950-1 / EN 60950-1 / VDE 0805-1 to the supply voltage connections

and the communications interfaces.

• Voltages > 60 V DC or 30 V AC may be present in the control cabinet. Therefore

appropriate safety precautions must be taken to prevent contact during commissioning

and maintenance work.

• Before carrying out any work on the device or on connected components, make sure

that the installation is in a zero-voltage state.

• Use cable types with UL approval for UL-approved systems.

PN/M-Bus LINK

8 Operating Instructions, 03/2018, A5E44260928-AA

Safety information

2.2

Security information

2.3

IT security

Protective measures for SIMATIC PN/M-Bus LINK

NOTICE

2.2 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

Only authorized personnel are permitted to access the system and carry out modifications.

PN/M-Bus LINK

Operating Instructions, 03/2018, A5E44260928-AA

9

3

3.1

Field of application

PN/M-Bus LINK is a communication gateway and enables the connection of SIMATIC

controllers to the M-Bus fieldbus via PROFINET. It enables data and information exchange

between PROFINET and M-Bus.

Figure 3-1 SIMATIC PN/M-Bus LINK

PN/M-Bus LINK

10 Operating Instructions, 03/2018, A5E44260928-AA

System overview

3.2

Features

General features

M-Bus features

3.2 Features

● 1 M-Bus connector (3-pin screw-type terminal).

● The device supports baud rates between 300 and 9600 baud.

● Communication with the individual slaves in the M-Bus network can be performed with

different baud rates.

● The PN/M-Bus LINK can be used in the line, star and tree network topologies.

● PN/M-Bus LINK is always the M-Bus master. The M-Bus master reads the measurement

data from the M-Bus slaves and supplies the M-Bus with power.

● You can connect up to 40 M-Bus slaves to the M-Bus network (standard loads with

current consumption < 1.5 mA). If the current consumption of individual M-Bus slaves is

more than a standard load, fewer M-Bus slaves can be connected.

● When an M-Bus slave is in a short-circuit state, the PN/M-Bus LINK can still communicate

with other M-Bus slaves.

● PN/M-Bus LINK supports the "Primary address" and "Secondary address" addressing

modes.

● 2 PROFINET interfaces (integrated switch) enable PROFINET line operation according to

Conformance Class B (CC-B).

● PN/M-Bus LINK is configured in the TIA Portal via a GSDML file.

Implemented M-Bus functions:

● SND_NKE: Establish communication with M-Bus slave

● REQ_UD2: Request data from slave

● SND_UD: Enables addressing over secondary address

PN/M-Bus LINK

Operating Instructions, 03/2018, A5E44260928-AA

11

System overview

3.3

System configuration

System configuration

Purpose and function of the system components

3.3 System configuration

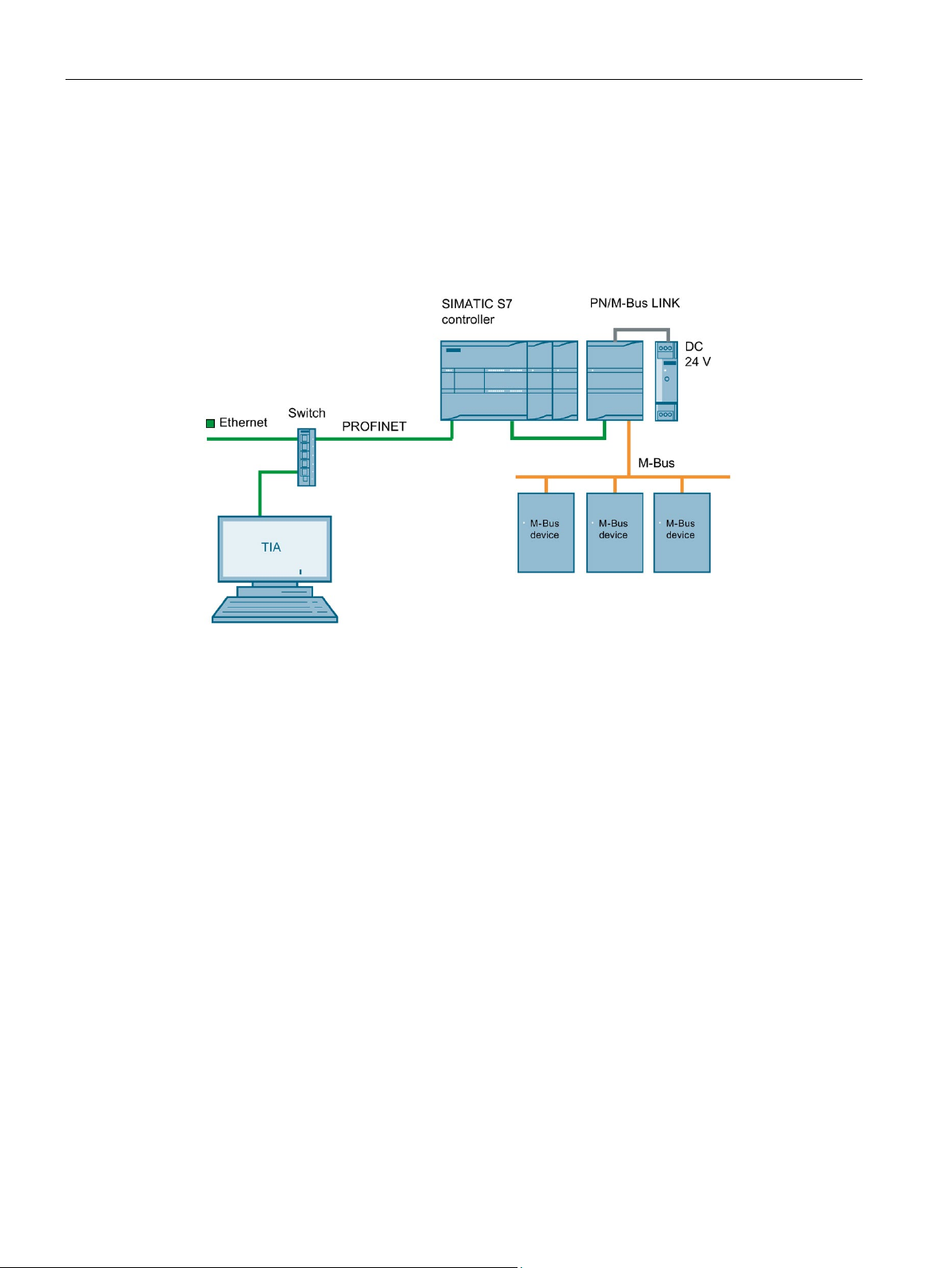

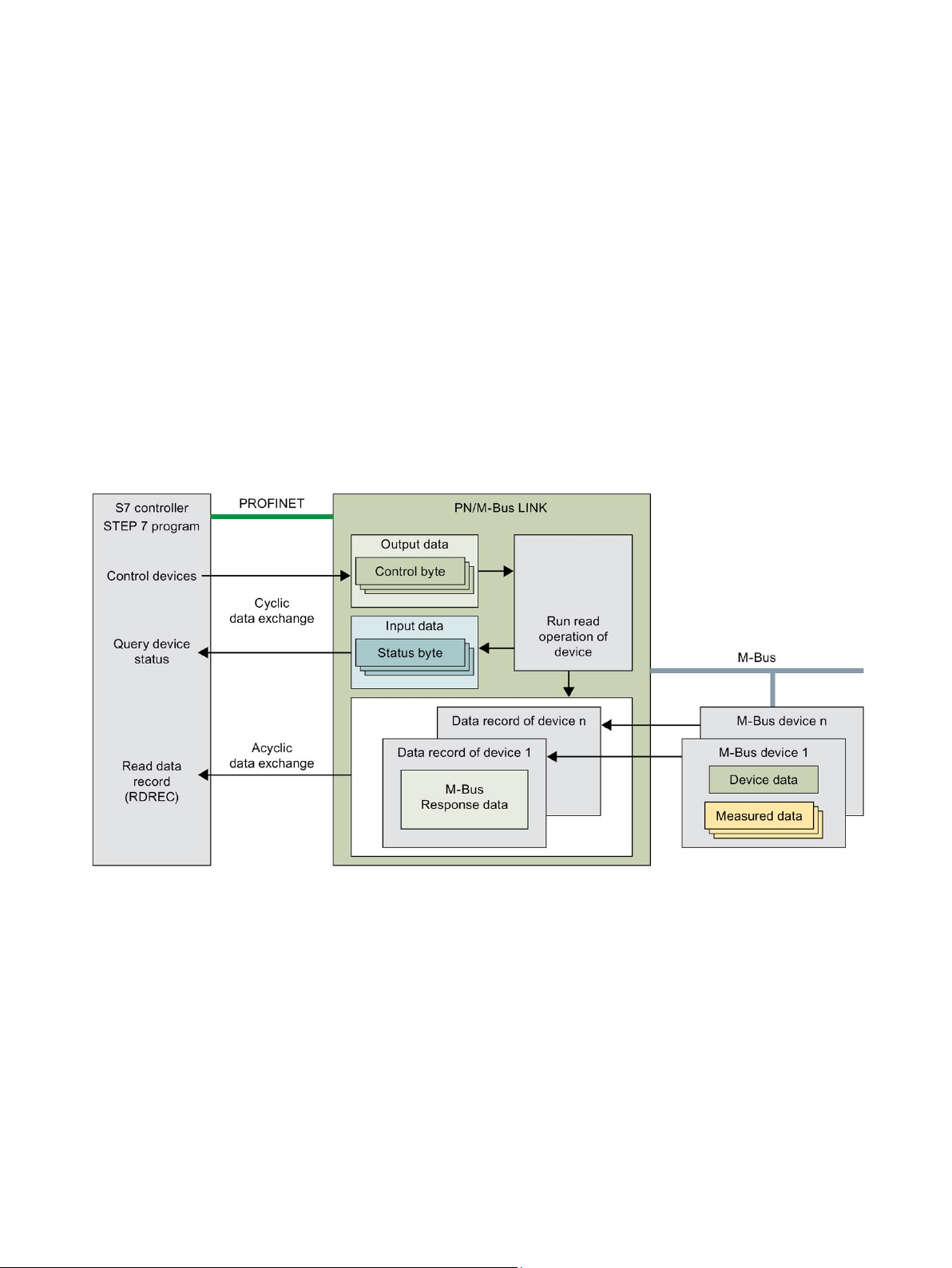

The following figure shows a basic system configuration with PN/M-Bus LINK as a

communication gateway between a PROFINET network and an M-Bus network.

Figure 3-2 System configuration with PN/M-Bus LINK

PN/M-Bus LINK enables the connection of the M-Bus to PROFINET.

PN/M-Bus LINK communicates with the CPU of the S7 controller exclusively via the

PROFINET interface.

From a PROFINET point of view, PN/M-Bus LINK is an IO device according to Conformance

Class B (CC-B).

Cyclic data exchange between the PN/M-Bus LINK and the connected SIMATIC-CPU is

performed by updating the IO image. Acyclic communication is handled via the "Read Data

Record" service.

The power is supplied to the PN/M-Bus LINK either via an external power supply unit with

24 V DC or via the 24 V power supply of the SIMATIC S7 system.

The TIA Portal is used for configuring. A GSDML file is available for this purpose.

PN/M-Bus LINK

12 Operating Instructions, 03/2018, A5E44260928-AA

System overview

3.4

System requirements

System requirements

3.4 System requirements

● PN/M-Bus LINK

● Controller: Supported are SIMATIC S7-1200, SIMATIC S7-1500, SIMATIC ET 200SP,

SIMATIC OpenController

● 24 V power supply

● M-Bus network

● PROFINET bus

● Windows PC (for configuring, commissioning and diagnostics)

● TIA Portal V15

● We recommend a switch for configuring, commissioning and diagnostics.

PN/M-Bus LINK

Operating Instructions, 03/2018, A5E44260928-AA

13

System overview

3.5

Design

PN/M-BUS LINK setup

Design

grounding

②

uses on PROFINET

for PROFINET

PROFINET (X1P2)

⑥

PROFINET (X1P1)

state

⑨

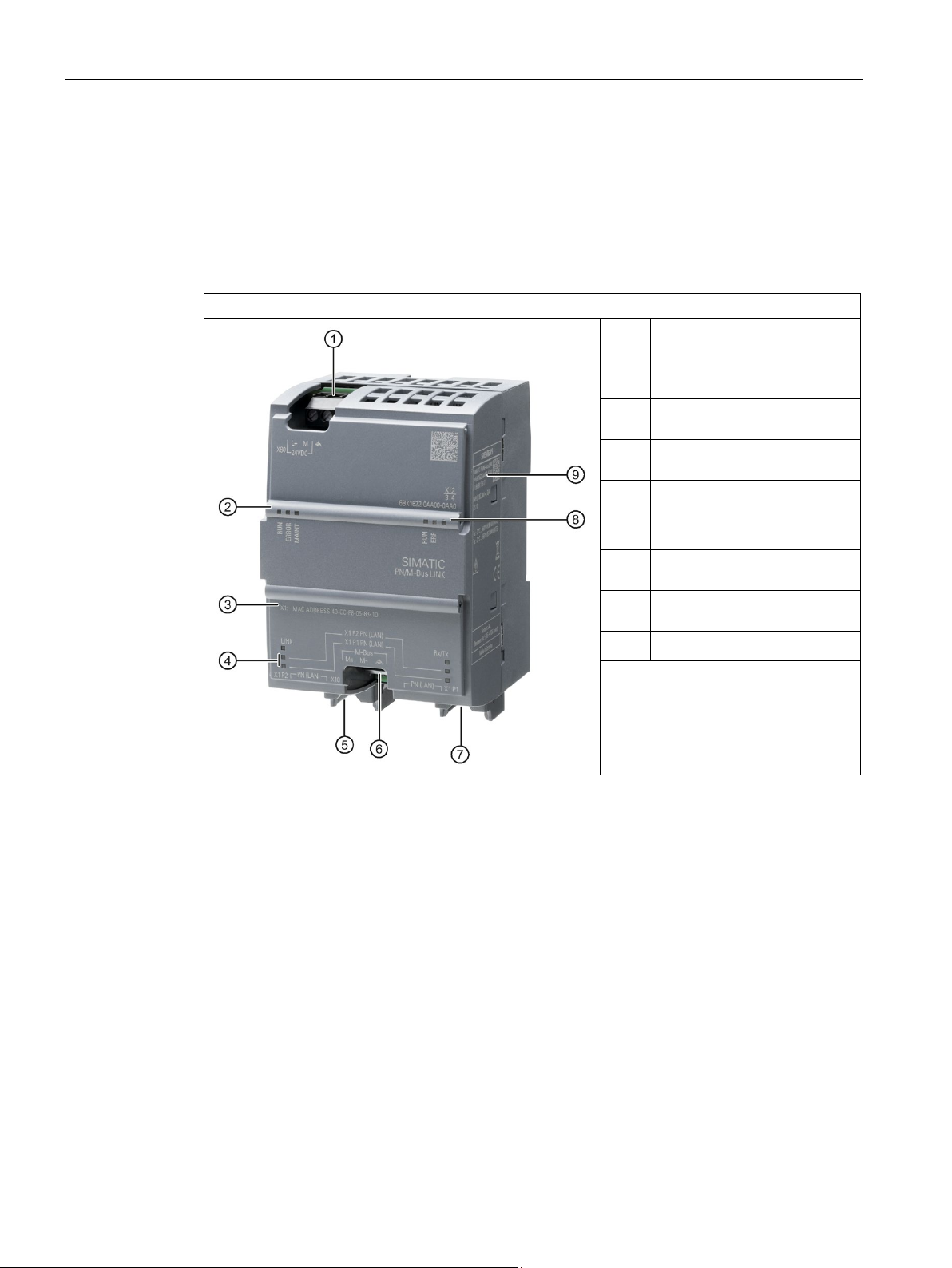

3.5 Design

The following figure shows the arrangement of the connection and display elements on

PN/M-Bus LINK. The figure shows the device without a top and bottom enclosure cover.

①

③

④

⑤

⑦

⑧

24 V DC + functional

Status LEDs device operating

state + PROFINET

MAC address that the device

Status LEDs Ethernet interface

Ethernet connection for

Connection for M-Bus

Ethernet connection for

Status LEDs, M-Bus operating

Rating plate

PN/M-Bus LINK

14 Operating Instructions, 03/2018, A5E44260928-AA

4

4.1

Cyclic and acyclic data exchange

Communication paths

PN/M-Bus LINK is always the M-Bus master. The functions of the PN/M-Bus LINK enable

you to read measured data from connected M-Bus devices. To do this, the M-Bus functions

"SND_NKE", "SND_UD" and "REQ_UD2" are implemented in PN/M-Bus LINK. It is not

possible to configure or write to M-Bus devices.

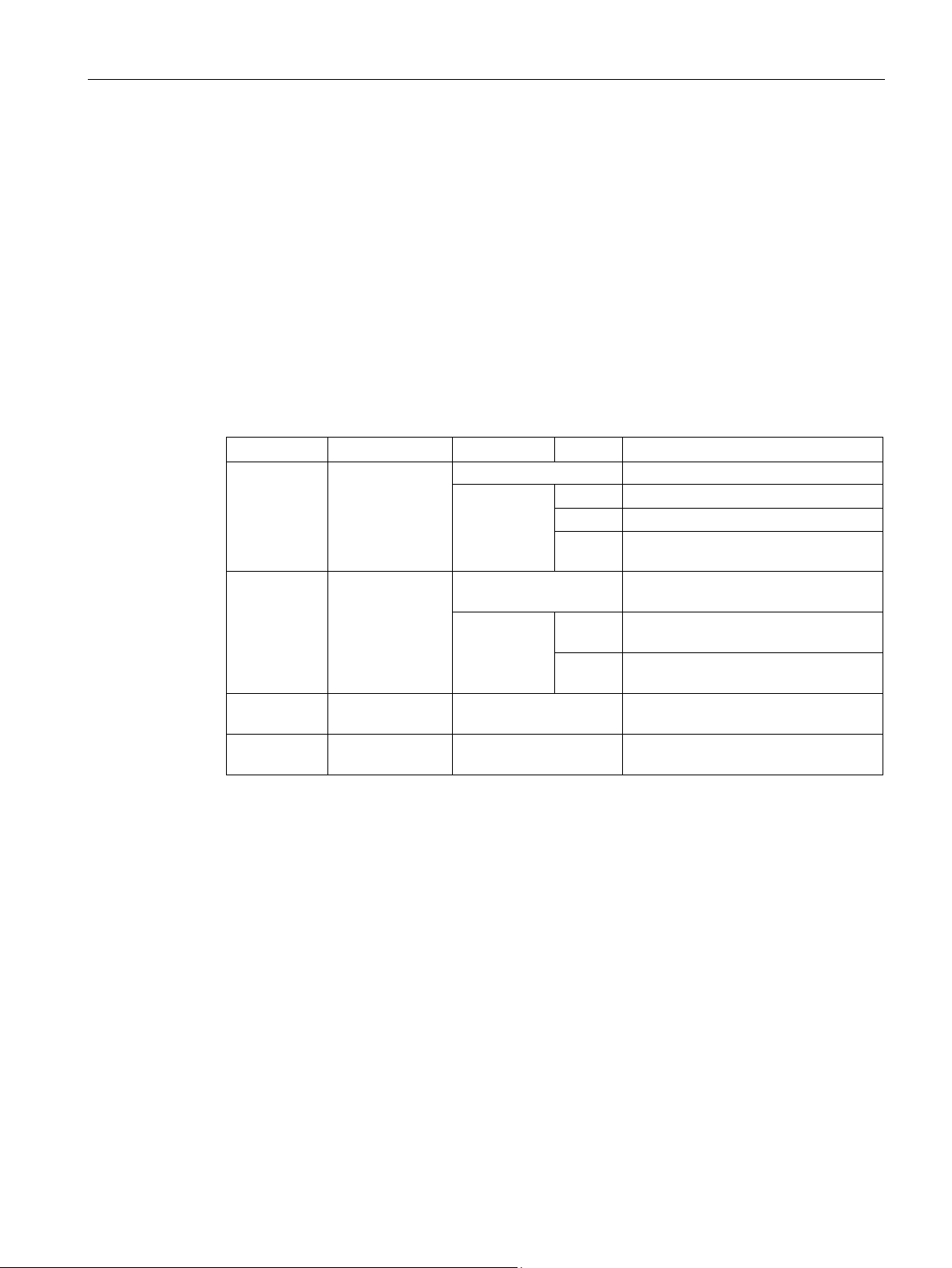

The following figure shows the interrelationships in the communication between the

S7 controller, PN/M-Bus LINK and connected M-Bus devices.

Figure 4-1 Communication paths between S7 controller, PN/M-Bus LINK and M-Bus devices

PN/M-Bus LINK

Operating Instructions, 03/2018, A5E44260928-AA

15

Functions

Cyclic data exchange: Control and status information

Bit

Meaning

Value

0

No action

M-Bus device

1 ... 7

Not used

--

--

Bit

Meaning

Value

1

Read operation in progress

0

No error occurred during last read operation

1

Error occurred during last read operation

2 ... 7

Not used

--

--

4.1 Cyclic and acyclic data exchange

The transmission of control and status information between the S7 controller and

PN/M-Bus LINK is performed via the cyclic IO process image.

In order to read measurement data from a specific M-Bus device, the S7 user program sets

the control bit for the respective M-Bus slave in the cyclic output data from the value "0" to

the value "1".

Table 4- 1 Cyclic output data (Byte 0)

0 Control bit for read request

1 Read request to read measured data from

If the PN/M-Bus LINK accepts the call, it sets the corresponding status bit in the cyclic input

data from "0" to "1". After the PN/M-Bus LINK has read the measurement data from the

addressed M-Bus device, it sets the corresponding status bit in the cyclic input data

from "1" to "0".

If an error occurs during a read attempt, the PN/M-Bus LINK also sets the corresponding

status bit to "0" but sets the error bit at the same time. In this case, the data record does not

contain measured values.

Table 4- 2 Cyclic input data (Byte 0)

0 Status bit for read request 0 Device inactive

1 Error bit for feedback of the read

operation

PN/M-Bus LINK

16 Operating Instructions, 03/2018, A5E44260928-AA

Functions

Acyclic data exchange: Reading measurement data from M-Bus devices

Byte

Name

Data type

Value

Description

UINT16

Device error information

1

No data available

structure

CI1 = 72h/76h

CI1 = 73h/77h

bytes

starting with the first DIF (EN1434-3)

1) CI field (control information field) from received RSP_UD response telegram

4.1 Cyclic and acyclic data exchange

The measured values are transferred from the PN/M-Bus LINK to the S7 control system

through data records. The PN/M-Bus LINK always reads all available measured values from

an M-Bus device and saves the measured values as a data record.

A data record is read via "Read Data Record" (RDREC). The default index number is 600.

A data record contains the user data from the RSP_UD response telegram with the

transmitted measured values, starting with the first DIF. The telegram header is not included

in the data record.

The data block with the measured data contained in the data record is transferred to the

S7 controller without any changes. The corresponding evaluation and further processing of

the measurement data must be performed by the user program.

A data record has the following structure:

0 … 1 ResponseCode

0 No error

2 M-Bus communication error - no data

available

2 … 3 Mode UINT16 Specification of the M-Bus data

0 Variable data structure

1 Fixed data structure

4 … 5 Length UINT16 Total length of the M-Bus STRUCT in

6 … <END> Measured data M-Bus STRUCT Measured data from M-Bus device,

PN/M-Bus LINK

Operating Instructions, 03/2018, A5E44260928-AA

17

Loading...

Loading...