Page 1

Preface, Contents

SIMATIC

Programming Device PG 720

Manual

Product Overview

Unpacking and Setting Up

the PG 720

Getting to Know the PG 720

Installing and Operating the

PG 720

PG 720 Expansions

Configuring the PG 720

Error Diagnostics

Hardware Information

Glossary, Index

1

2

3

4

5

6

7

8

C79000-G7076-C720-02

Page 2

Safety Guidelines

!

!

!

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

Danger

indicates that death, severe personal injury or substantial property damage will result if proper precautions are

not taken.

Warning

indicates that death, severe personal injury or substantial property damage can result if proper precautions are

not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or to a particular

part of the documentation.

Qualified Personnel

Correct Usage

The device/system may only be set up and operated in conjunction with this manual.

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons in the

sense of the safety guidelines of this Manual are defined as persons who are authorized to commission, to

ground and to tag equipment, systems and circuits in accordance with established safety practices and standards. Other names in this document may be trade marks whose use by third persons for own purposes

may violate the rights of the owner.

Note the following:

Warning

!

Trademarks

The reproduction, transmission or use of this document or its contents is

not permitted without express written authority. Of fenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

Siemens AG

Automation Group

Industrial Automation Systems

Postfach 4848, D-90327 Nürnberg

This device and its components may only be used for the applications described in the catalog or the technical

description, and only in connection with devices or components from other manufacturers which have been

approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and

operated and maintained as recommended.

SIMATICR and SINECR are registered trademarks of SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to

trademarks might infringe upon the rights of the trademark owners.

Disclaimer of LiabilityCopyright E Siemens AG 1995 All rights reserved

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the data in this

manual are reviewed regularly and any necessary corrections included in

subsequent editions. Suggestions for improvement are welcomed.

E Siemens AG 1995

T echnical data subject to change.

Siemens Aktiengesellschaft

Order No. 6ES7 720-0AA00-8BA0

PG 720 Programming Device

Page 3

Preface

What this Manual

is About

Who is the Manual

Intended For?

Validity of the

Manual

This manual contains all the information you need for working with the

PG 720 programming device. You can use this information to

S unpack the programming device and power it up.

S familiarize yourself with the functions and settings of the various

components (display, keyboard, programming facilities etc.).

S connect the programming device to other units of equipment

(programmable controllers, other programming devices).

S expand your system, provided you comply with the necessary conditions.

S analyze and eliminate simple problems.

The following persons require the manual:

S Users commissioning the programming device themselves or working

with it (editing, debugging).

S System administrators operating the programming device in a network.

S Service and maintenance personnel using the PG 720 for system

expansion purposes or error/fault analysis.

This manual describes the version of the PG 720 as available in March 1996.

The Product Bulletin supplied with the PG 720 contains the latest technical

specifications for the programming device.

Licences

Where to Find

Information

PG 720 Programming Device

C79000-G7076-C720-02

The approvals, certificates and licenses for your device are supplied along

with the Product Bulletin.

Along with your PG 720, you also receive the following documents which

you require for commissioning the device:

S The Product Bulletin with the valid technical data of the PG 720.

S A Product Information leaflet about the software supplied with the

PG 720.

For more detailed information about handling the software, please refer to

the appropriate manuals (for example, the STEP 5 manual).

iii

Page 4

Preface

Plan of the Text

Chapters 1 to 4 of the manual contain the most important instructions for

commissioning and using the PG 720. Chapters 5 to 8 are reference sections

required in special situations.

Setting up and getting to know your device.

Before you start to use your programming device, you should read about

setting up the device in Chapter 2 and about the components and functions of

the PG 720 in Chapter 3.

Installation

Chapter 4 describes the basic steps necessary for starting up the PG 720. This

chapter also contains instructions for working with submodules and memory

cards for programmable controllers and for connecting the programming

device to other devices.

Expansion

Chapter 5 describes how to expand your PG 720 (for example installation of

memory expansions). Please observe the safety instructions in this section.

Configuration

Modifications made to the system hardware may make it necessary for you to

adapt the original hardware configuration. This is described in Chapter 6.

Error/fault diagnostics

Chapter 7 explains how to deal with simple faults and problems that you can

diagnose and, in some cases, eliminate yourself.

Reference data

Chapter 8 contains information about hardware addresses, interrupt

assignments and connecting cables.

Queries

Glossary

The glossary defines and explains important terms.

Alphabetical index

The alphabetical index will help you to find passages in the text relating to

important terms and key words quickly and reliably.

If you have any questions concerning subjects not covered in the manual,

simply get in touch with the Siemens representative in your area or call the

SIMATIC Hotline. The addresses are listed in your product bulletin.

If you have any questions about the manual itself or would like to make or

suggestions, please complete the reply card at the end of the manual. We

would also appreciate it if you would include your own opinion and appraisal

of the manual on the reply card.

PG 720 Programming Device

iv

C79000-G7076-C720-02

Page 5

Contents

1 Product Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Unpacking and Setting Up the PG 720 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Setting Up the PG 720 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Moving the Programming Device 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Getting to Know the PG 720 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Hardware Components of the PG 720 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Display 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Keyboard 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Trackball 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Drives 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 External Power Unit and Battery 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Installing and Operating the PG 720 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Connecting the PG 720 to the Power Supply 4-2. . . . . . . . . . . . . . . . . . . . . . . .

4.2 Battery Operation 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Connecting I/O Devices 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Working with SIMATIC S5 Memory Submodules 4-11. . . . . . . . . . . . . . . . . . . . .

4.5 Working with SIMATIC Memory Cards 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Working with PCMCIA Cards 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Connecting the PG 720 to other SIMATIC S5 Units 4-15. . . . . . . . . . . . . . . . . . .

4.8 Connecting the PG 720 to a SIMATIC S7 Network (MPI/DP) 4-19. . . . . . . . . . .

4.9 Networking the PG 720 with Other Stations on SINEC L2 4-21. . . . . . . . . . . . .

4.10 Networking the PG 720 and Other Computers on SINEC H1. 4-22. . . . . . . . . .

5 PG 720 Expansions 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Opening the Unit 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Components Visible After Opening the Unit 5-4. . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Installing Memory Expansion Modules 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Replacing the Back-Up Battery 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Closing the Unit 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PG 720 Programming Device

C79000-G7076-C720-02

v

Page 6

Contents

6 Configuring the PG 720 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Changing the System Configuration with SETUP 6-2. . . . . . . . . . . . . . . . . . . . .

7 Error Diagnostics 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Hardware Information 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Hardware Address Table 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Interrupt Assignments 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Connector Pinouts 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Connecting Cables 8-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary Glossary-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PG 720 Programming Device

vi

C79000-G7076-C720-02

Page 7

Product Overview

1

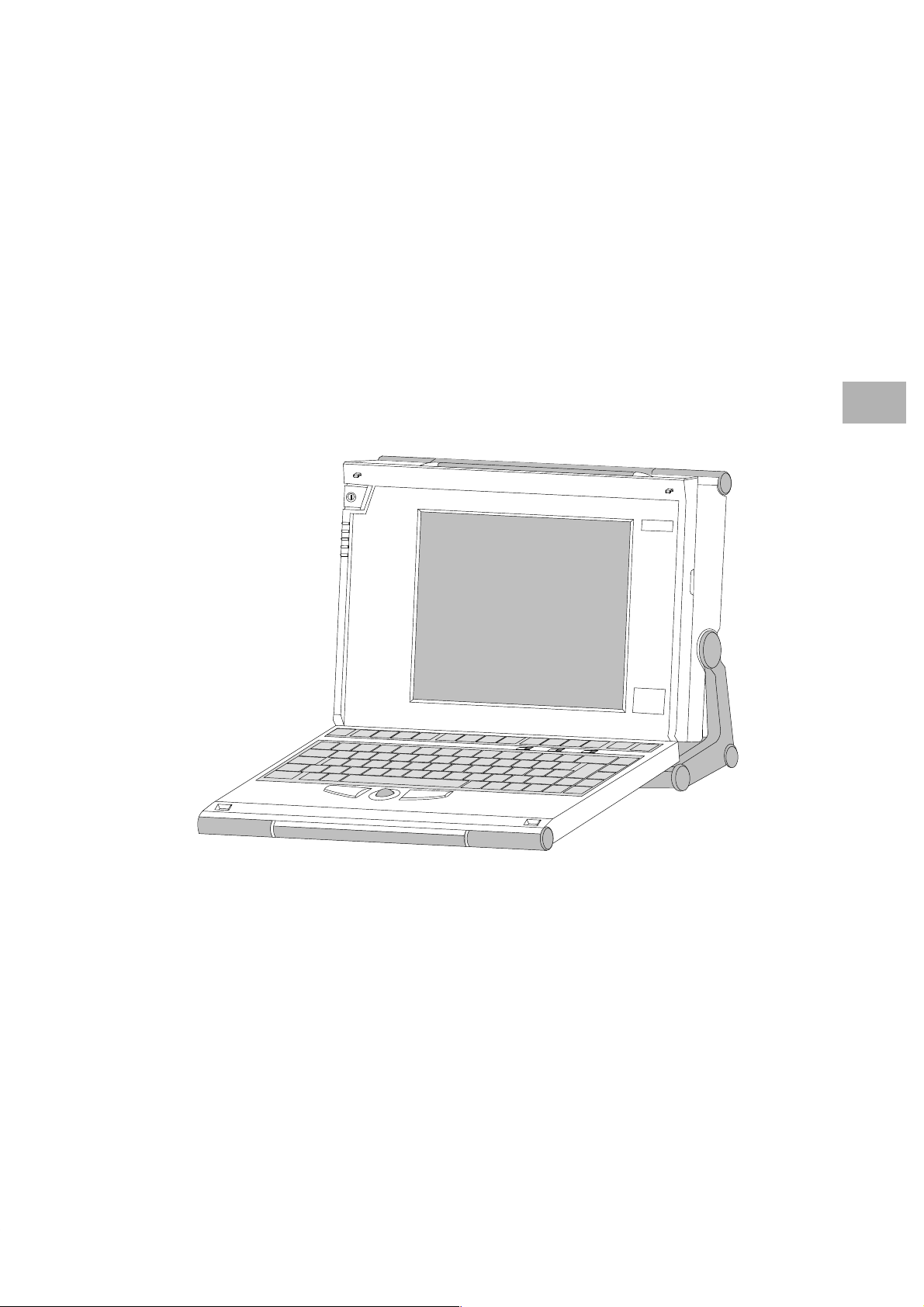

Application

The PG 720 programming device is a self-contained unit designed specifically

for an automation environment. Its performance, ergonomic design and

equipment make it a unit particularly suitable for maintenance and service as

well as for programming/configuring and testing and installing SIMATIC

programmable controllers.

SIEMENS

PG 720

1

The PG’s Hardware

and Software

PG 720 Programming Device

C79000-G7076-C720-02

You can use the PG 720 programming device to program SIMATIC S5 and

SIMATIC S7 programmable controllers. It has

S interface ports for connection to programmable controllers.

S programming facilities for S5 memory submodules and S5/S7 memory

cards.

The PG 720 is supplied with system and automation software. The software

components are listed in the Product Information leaflet.

1-1

Page 8

Product Overview

1

Advantages of the

PG 720

Compared with a PC with standard hardware and software, the PG 720

programming device of the SIMATIC family has numerous advantages:

S You can develop, debug and document user programs for SIMATIC S5

and SIMATIC S7 programmable logic controllers with the PG 720

without the need for additional hardware or software.

S The rugged design and practical functions of the PG 720 make it

particularly suitable for use on-site under tough industrial conditions. It is

extremely light and easy to transport. The PG 720 meets the specific

requirements of industrial environments such as noise immunity,

compliance with the relevant standards, ruggedness, simple transportation

and startup.

S The PG 720 is equipped with a battery allowing it to be operated without

a mains connection.

S The PG 720 can be set up and operated in a large number of different

ways and positions, and can therefore be used practically anywhere it is

needed.

S The PG 720 has all the integral ports necessary for connecting it to

SIMATIC automation devices:

– Programming interface for SIMATIC S5 memory submodules.

– Programming interface for SIMATIC S5 and SIMATIC S7 memory

cards in credit card format.

– Communication interfaces for connection to S5 and S7 programmable

controllers.

S The PG 720 is supplied with all the necessary system and automation

software already installed on the hard disk in compressed format.

S Since MS-DOS and Windows are also already installed, you can, of

course, also use the PG 720 as a stand-alone workstation, and run all the

standard software available on the market that requires MS-DOS or

Windows.

S In terms of performance and expansion capability, your programming

device meets all the normal requirements of a PC. This means that the

PG 720 can also be used as a fully-fledged personal computer.

1-2

PG 720 Programming Device

C79000-G7076-C720-02

Page 9

Unpacking and Setting Up the PG 720

2

What Does this

Chapter Contain?

Summary of

Sections

This chapter contains important information about unpacking, setting up and

transporting the PG 720, such as:

S opening and closing the keyboard,

S changing the angle of inclination of the device,

S using the extra pull-out support and

S how to move the unit.

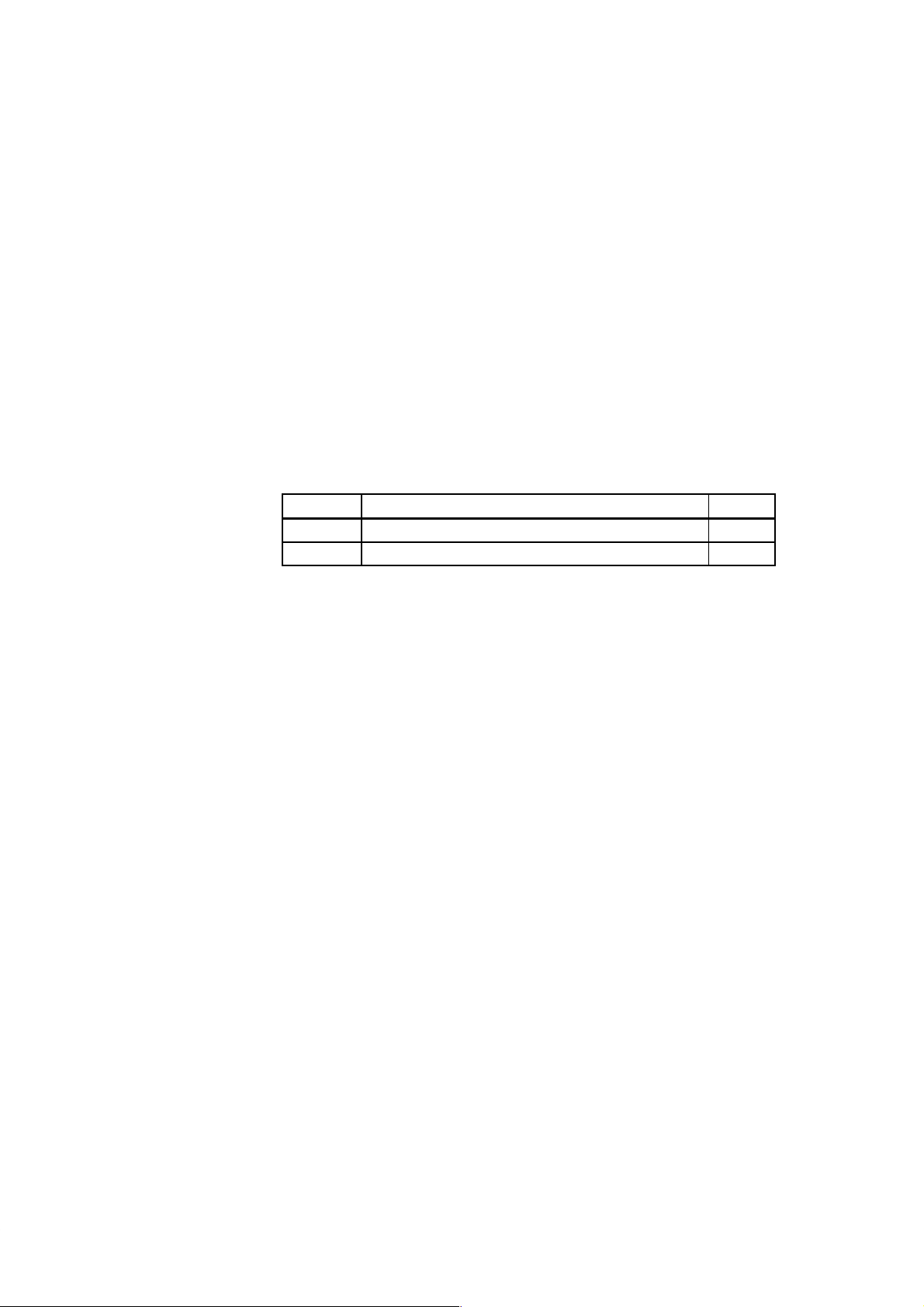

In Section You Will Find On Page

2.1 Setting Up the PG 720 2-2

2.2 Moving the Programming Device 2-6

PG 720 Programming Device

C79000-G7076-C720-02

2-1

Page 10

Setting Up the PG 720

2.1 Setting Up the PG 720

2

Unpacking Your

PG 720

!

Setting up on a

Desk Top

Unpack your PG 720 as follows:

1. Remove the packing.

2. Do not throw the original packing away. Keep it in case you have to ship

or transport the unit again at some time in the future.

3. Check the packing list to make sure that no components are missing.

Caution

Risk of damage!

Moisture inside the unit can cause serious damage.

When transporting the unit in cold weather, when it may be submitted to

extreme variations in temperature, make sure that the unit is allowed to

reach room temperature slowly before you switch it on.

If condensation has formed, this must be allowed to evaporate before you

switch on. If, for example, the unit is subjected to a temperature change from

–20° C to +20° (–4° F to +68° F) you should wait approximately 12 hours

before switching on the unit.

The PG 720 is used primarily on a desk or table top. T o ensure a comfortable

working position, the PG 720 can be adapted as follows to suit the work

place:

1. Place the PG 720 on the desk or table top.

2. Open the keyboard lock by pulling up the gray handle.

3. Lower the keyboard into position.

Handle

Figure 2-1 The Programming Device before Opening

2-2

PG 720 Programming Device

C79000-G7076-C720-02

Page 11

Setting Up the PG 720

Changing the

Angle of

Inclination

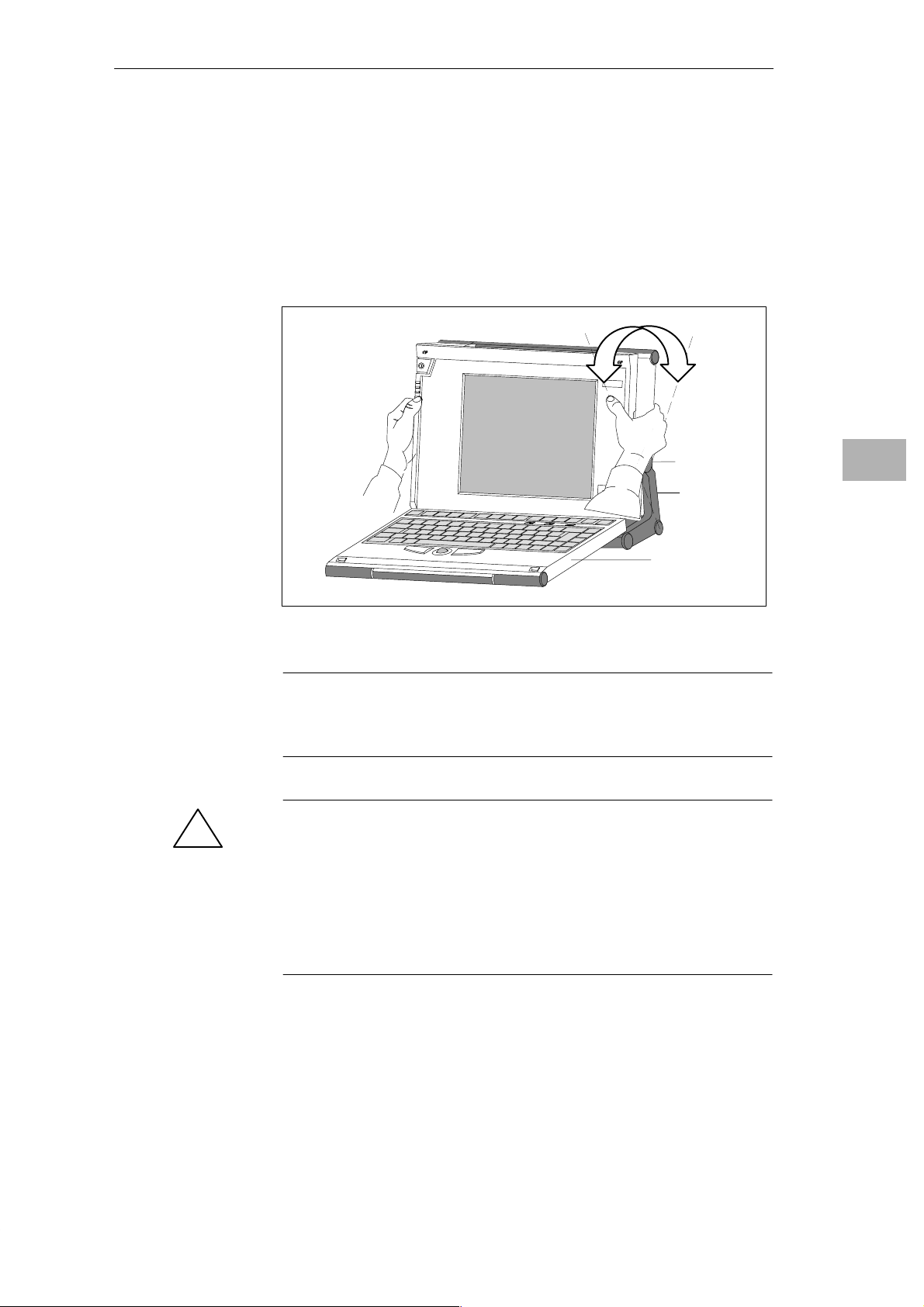

With the keyboard open, you can incline the unit to any angle between 0° and

90°. To adjust the angle, proceed as follows:

1. Lower the keyboard into position.

2. Pull the support (Figure 2-4) out of the rear of the stand and if necessary

pull out the extra support hoop.

3. Incline the unit to an angle that will allow you to work comfortably.

SIEMENS

Pivot

PG 720

Stand

Keyboard opened

2

Figure 2-2 Changing the Angle of Inclination

Note

When you change the angle of inclination, make sure that the keyboard

cable is not trapped between the device and the stand.

Caution

!

Risk of injury!

There is a danger of the unit tipping over if it is set up at an angle of

inclination of more than 15°

lead to personal injury and also damage to the unit.

If the angle of inclination is greater than 15°, you must use the pull-out

support and if necessary the extra support hoop in the stand.

without using the pull-out support. This could

PG 720 Programming Device

C79000-G7076-C720-02

2-3

Page 12

Setting Up the PG 720

2

Detaching the

Keyboard

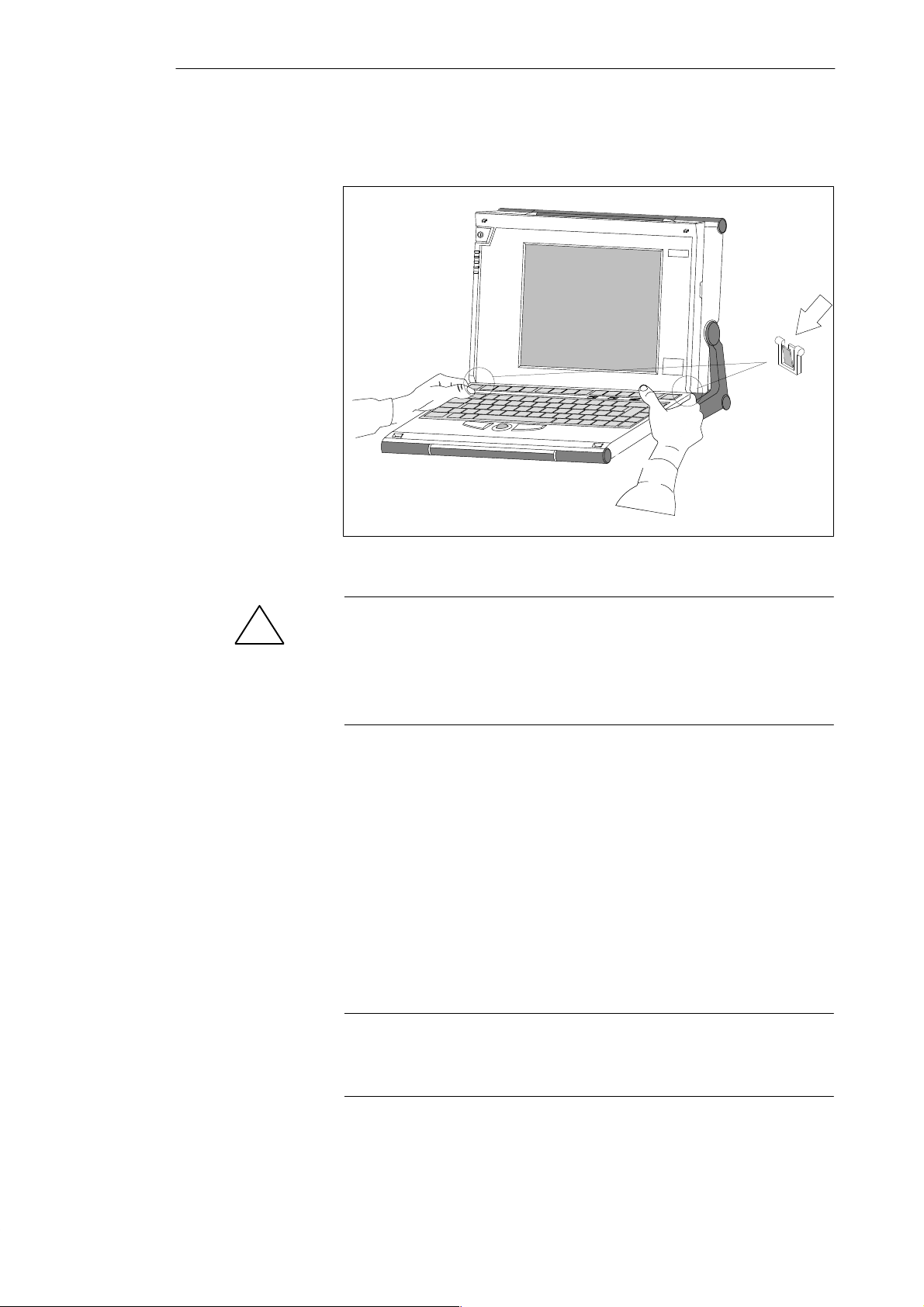

In certain situations, it is helpful to remove the keyboard.

Press in the catches in the

middle of the hinges

Figure 2-3 Detaching the Keyboard

Detaching

Refitting

Caution

!

Risk of tipping!

If the keyboard is detached, there is a risk of the unit tipping over. Before

removing the keyboard, make sure that you pull out the support from the

device stand (Figure 2-4) and pull out the additional hoop.

You detach the keyboard as follows:

1. Grip the keyboard hinges in the stand behind the keyboard.

2. Pull the locks in the middle of the hinge assembly towards the keyboard.

3. Pull the keyboard up and out.

4. Place the keyboard on a suitable surface, using the hinge assembly as a

stand.

You attach the keyboard again as follows:

1. Place the keyboard cable in the cable conduit in the stand.

2. Snap the keyboard hinges into the receptacles in the stand.

Note

When attaching the keyboard, make sure that the cable is lying correctly in the

cable conduit and is fixed in position.

2-4

PG 720 Programming Device

C79000-G7076-C720-02

Page 13

Setting Up the PG 720

Keyboard Angle

Horizontal

Position

Adjustment

When the keyboard is attached to the unit, its angle of inclination is 6°, the

height of the middle row of keys is 30 mm (about 1 inch). When it is

detached, the angle of inclination is 4.5°, and the height of the middle row of

keys is 27 mm. This is an ideal ergonomic design to allow a comfortable

working position.

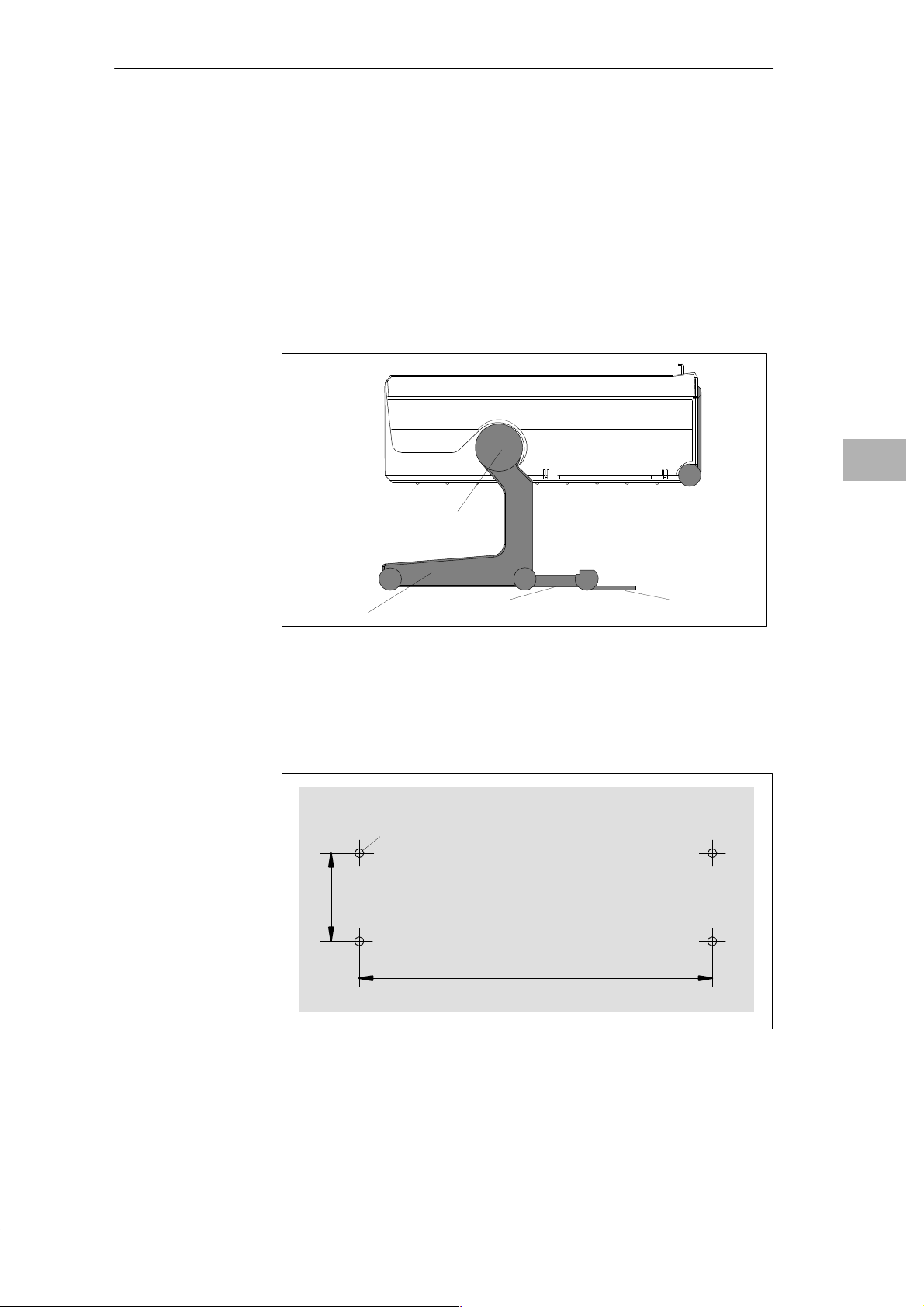

If no table or desk is available, the unit can be operated on the floor. You can

adjust the casing and display through approximately 90

plane.

Pivot

o

into the horizontal

2

Wall Mounting

Stand

Figure 2-4 Horizontal Operating Position Without Keyboard

The basic unit can be attached to a wall. Four drilled holes (6 mm diameter)

are provided in the unit stand for this purpose.

Support

Extra support hoop

6

46

267

Figure 2-5 Drilling Template for Wall Mounting (dimensions in millimeters)

PG 720 Programming Device

C79000-G7076-C720-02

2-5

Page 14

Setting Up the PG 720

2.2 Moving the Programming Device

2

Preparations

The PG 720 is easy to carry. Before carrying it, however, you should take the

following measures:

1. Switch the PG 720 off and wait about 20 seconds until the drives have

come to a complete stop.

2. Unplug all the connecting cables.

3. Close the covers protecting the ports and connections on the right-hand

and left-hand side panels.

4. Bring the unit into an upright position.

5. Raise the keyboard and lock it by pressing it against the front panel of the

unit. The latches on the right and left snap in. Make sure that both catches

are properly locked.

6. If you only want to carry the unit for a short distance use the handle.

7. If you want to move the PG 720 over larger distances, pack the unit and

all its accessories in the carrying bag supplied.

Carrying the

PG 720

2-6

Figure 2-6 PG 720 Ready for Carrying

Despite the rugged design of the PG 720, its internal components are

sensitive to severe vibration or jolts. When moving the PG 720 you must

therefore make sure that it is protected from severe mechanical forces.

Use the original packing material if you have to ship the PG 720 from one

location to another.

PG 720 Programming Device

C79000-G7076-C720-02

Page 15

Getting to Know the PG 720

3

What Does this

Chapter Contain?

Summary of

Sections

This chapter contains all the information you require about the most

important components of the device such as:

S LED displays

S drives

S keyboard

S programming facilities of the PG 720

S external power unit and battery.

In Section You Will Find On Page

3.1 Hardware Components of the PG 720 3-2

3.2 Display 3-6

3.3 Keyboard 3-8

3.4 Trackball 3-14

3.5 Drives 3-15

3.6 External Power Unit and Battery 3-17

PG 720 Programming Device

C79000-G7076-C720-02

3-1

Page 16

Getting to Know the PG 720

3.1 Hardware Components of the PG 720

3

Front

You can access all the important operator controls and displays from the front

or sides of the unit. Figure 3-1 shows the front of the PG 720.

12Detail

1

7

6

8

1 On/Off switch

2 Carrying handle

3 Liquid crystal display

4 Cover for submodule, memory card,

PCMCIA interfaces and floppy disk drive

5 Stand

1) The covers protect the interface ports from dust

and can be taken off and snapped back on again.

11

2

9

4

3

10

5

6 Keyboard

7 Cover for COM1, COM2,

LPT1/printer, mouse, MPI interface

8 Trackball

1)

9 Catches for locking keyboard

10 Pivot

11 Locking handle

Power LED

green: In operation, battery is charged

orange: In operation, battery being

charged

red: Battery run down to minimum,

the unit will soon switch off

Figure 3-1 The Front of the PG 720

3-2

Detail

12

Other LEDs

Hard disk access

Floppy disk access

Submodule programming

active

MPI port

PG 720 Programming Device

C79000-G7076-C720-02

Page 17

p

pp

Getting to Know the PG 720

Left-Hand Side

Panel

(Communications

Side)

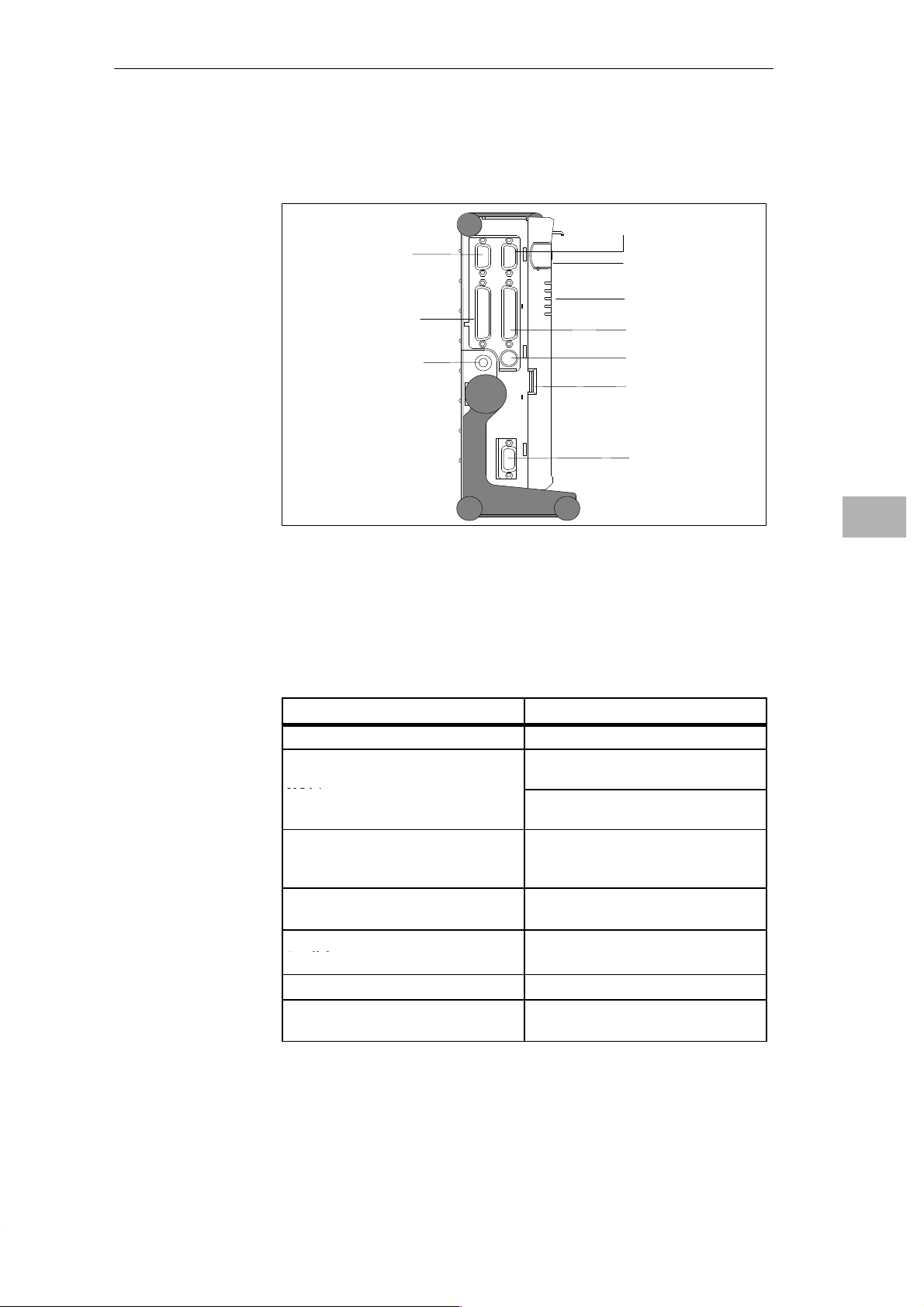

All the connectors and interface ports for connecting to external devices are

located on the left side panel of the PG 720 (communications side).

VGA port

COM 2 port

Power

switch

LED displays

COM 1 port

Connector for

external power

supply unit

Figure 3-2 Left-Hand Side Panel with Cover Plates Removed

LPT port

PS/2 mouse

Contrast control

MPI/DP interface

3

Connectors and

Ports

The following table contains an overview of the various interface ports and

connectors.

Table 3-1 Connectors on the Left Panel of the Unit

Ports and Connectors

VGA port Connection for external monitor

COM 2

Serial port

V.24 / mouse

Serial port

COM 1

V.24 /MODEM /PLC

Serial port

MPI (multipoint interface) Connection for S7 programmable

LPT 1 printer

Parallel port

PS/2 mouse Connection for PS/2 mouse

External power supply unit Connection for 17 V DC from external

Connection for serial mouse

Connection for serial printer

Connection for S5 programmable

controller

controller

Connection for parallel printer

power supply unit

Function

PG 720 Programming Device

C79000-G7076-C720-02

3-3

Page 18

Getting to Know the PG 720

3

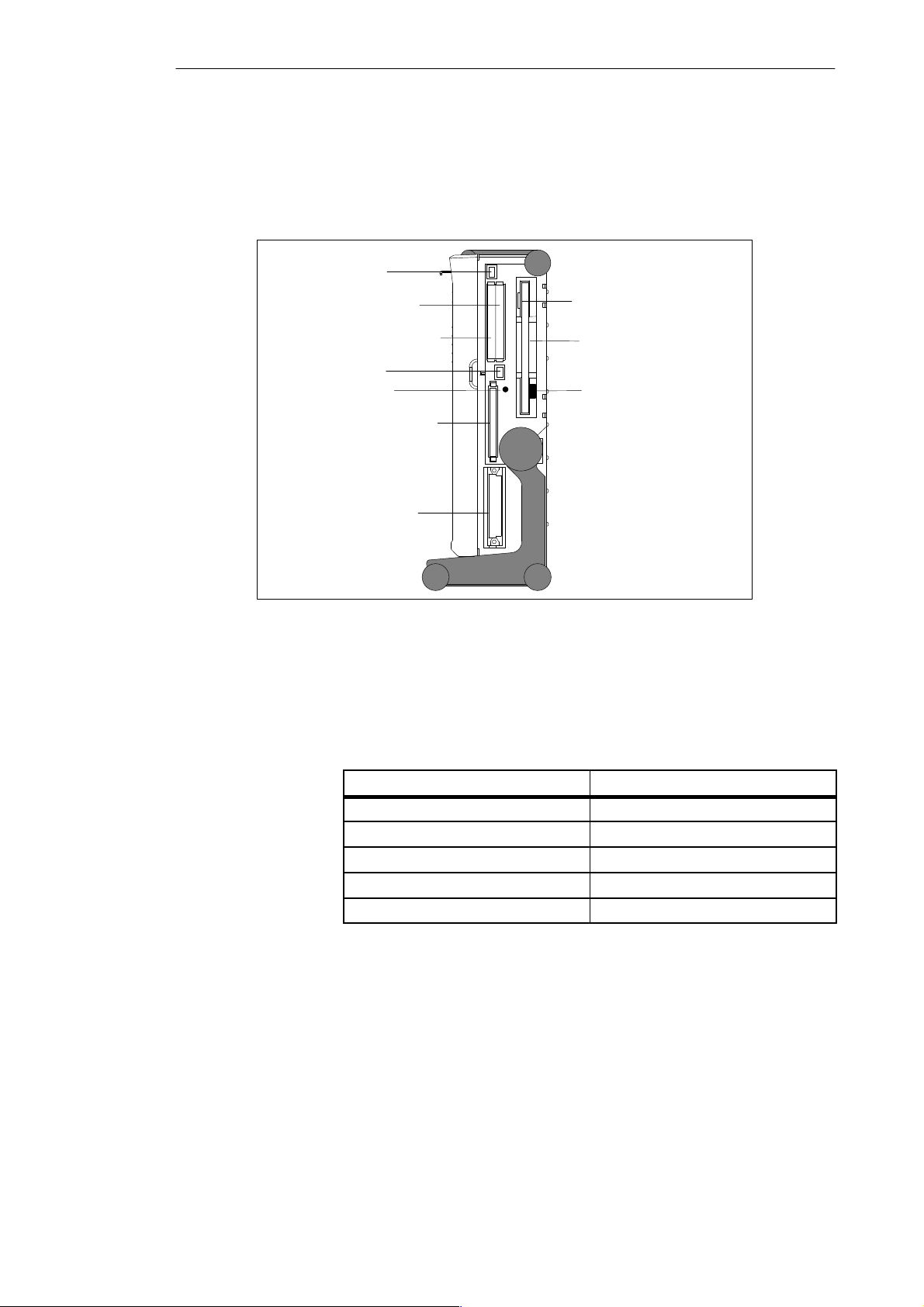

Right-Hand Side

Panel (Processing

Side)

Ejector for

PCMCIA cards

PCMCIA type II; slot 1

PCMCIA type II/III; slot 0

Ejector for

PCMCIA cards

Orientation mark

Memory card port

S5 submodule port

You access the slots for programming S5 submodules, S5/S7 memory cards,

the PCMCIA port, and the disk drive from the right-hand side of the unit

(processing side).

Disk ejector

3.5’’ disk drive

Access LED

Figure 3-3 Right-Hand Side Panel (with Port Covers Removed)

The following table contains an overview of the ports and connectors on the

right-hand panel:

Table 3-2 Connectors on the Right Panel of the Unit

Interface Port Function

PCMCIA type II port ; slot 1 Connection for PCMCIA type II cards

PCMCIA type III port; slot 0 Connection for PCMCIA type II/III cards

S5 submodule port Programming SIMATIC S5 submodules

Memory card port Programming SIMATIC memory card

Disk drive Working with 3.5” disks

3-4

PG 720 Programming Device

C79000-G7076-C720-02

Page 19

Getting to Know the PG 720

Ventilation Slits

!

There are ventilation slits on the top and bottom panels of the unit. These

slits must not be covered or blocked in any way (for example by carpeting).

Caution

Risk of overheating!

If you cover the inlet or outlet ventilation slits, you may cause damage to the

PG 720.

Do not place any objects so that they obstruct the ventilating slits in any

way .

3

PG 720 Programming Device

C79000-G7076-C720-02

3-5

Page 20

Getting to Know the PG 720

3.2 Display

3

Available Displays

Monochrome

PG 720 Display

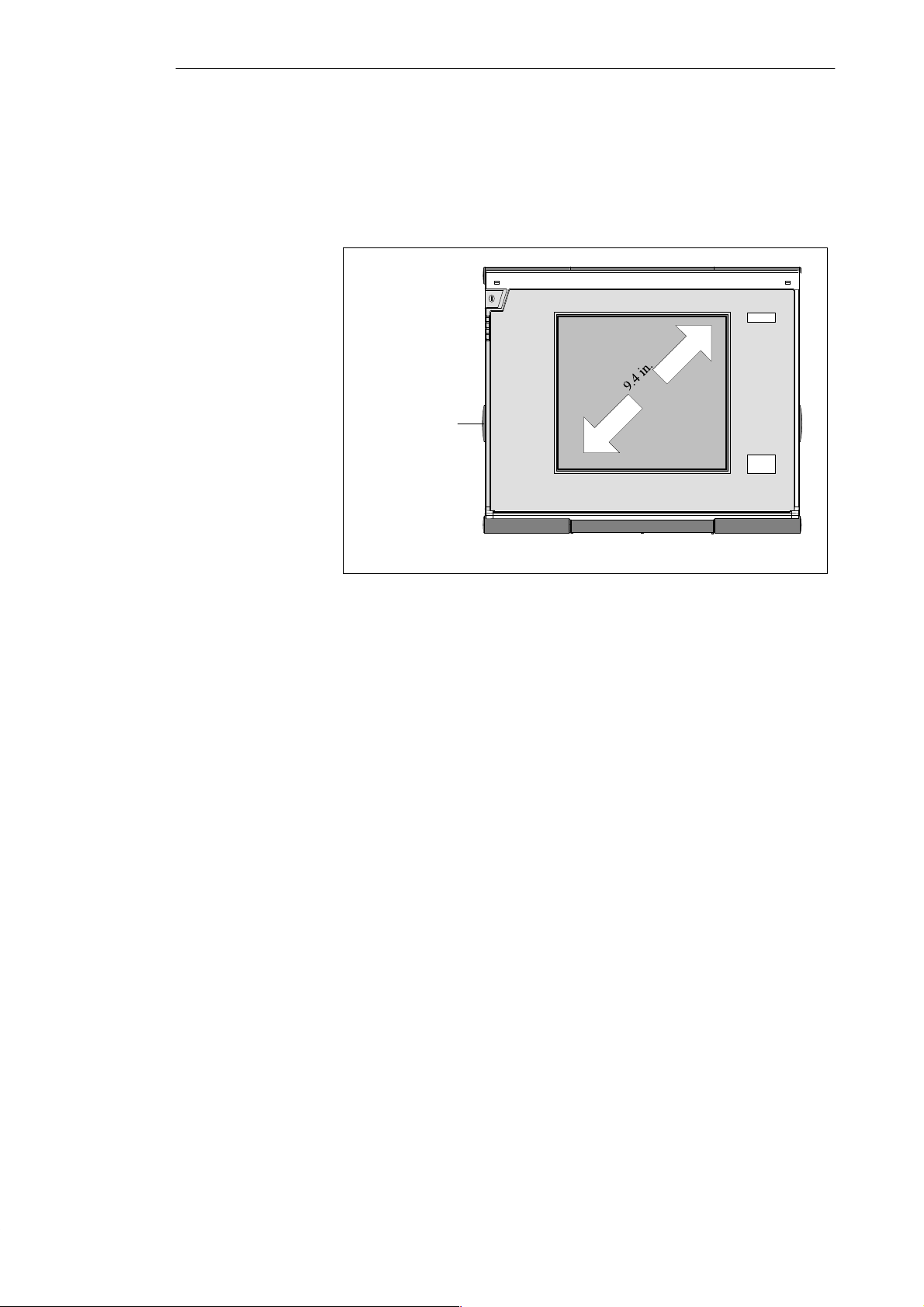

The PG 720 has a monochrome or color display.

Contrast control

Figure 3-4 Display PG 720 / PG 720 C

The display is an STN (STN = Super T wist Nematic) monochrome display

with a 9.4 in. diagonal and a resolution of 640 x 480 pixels. With the

monochrome device, up to 64 gray half-tones can be displayed. The contrast

can be adjusted with a control to the left of the display.

Color PG 720 C

Display

3-6

The display of the color PG 720 is an STN color display with a diagonal of

9.4 in. and a resolution of 640 x 480 pixels.

The three primary colors, red, green and blue, can each be displayed in eight

different shades. This means that, including all the secondary colors, a

maximum of 256 different colors can be displayed. The contrast can be

adjusted with a control to the left of the display.

PG 720 Programming Device

C79000-G7076-C720-02

Page 21

Getting to Know the PG 720

Note

Depending on the gray tone or color shade in the display, passive STN

displays are subject to varying degrees of interference known as the Moiré

effect. This is a physical characteristic and is not a fault.

Caution

!

Risk of injury!

If a display is damaged, liquid crystals may escape. Do not touch this liquid

or allow it to come into contact with your skin in any way, and do not breath

in the vapors. If you do come into contact with the liquid, wash those parts

of the skin affected immediately with alcohol, and rinse with plenty of water.

Then consult a physician immediately.

Use only a cotton cloth and a neutral cleansing agent to clean the display. Do

not use water or aggressive solvents (such as alcohol or acetone). Never

touch the display with hard, sharp objects. Avoid asserting any pressure on

the display surface.

3

PG 720 Programming Device

C79000-G7076-C720-02

3-7

Page 22

Getting to Know the PG 720

3.3 Keyboard

3

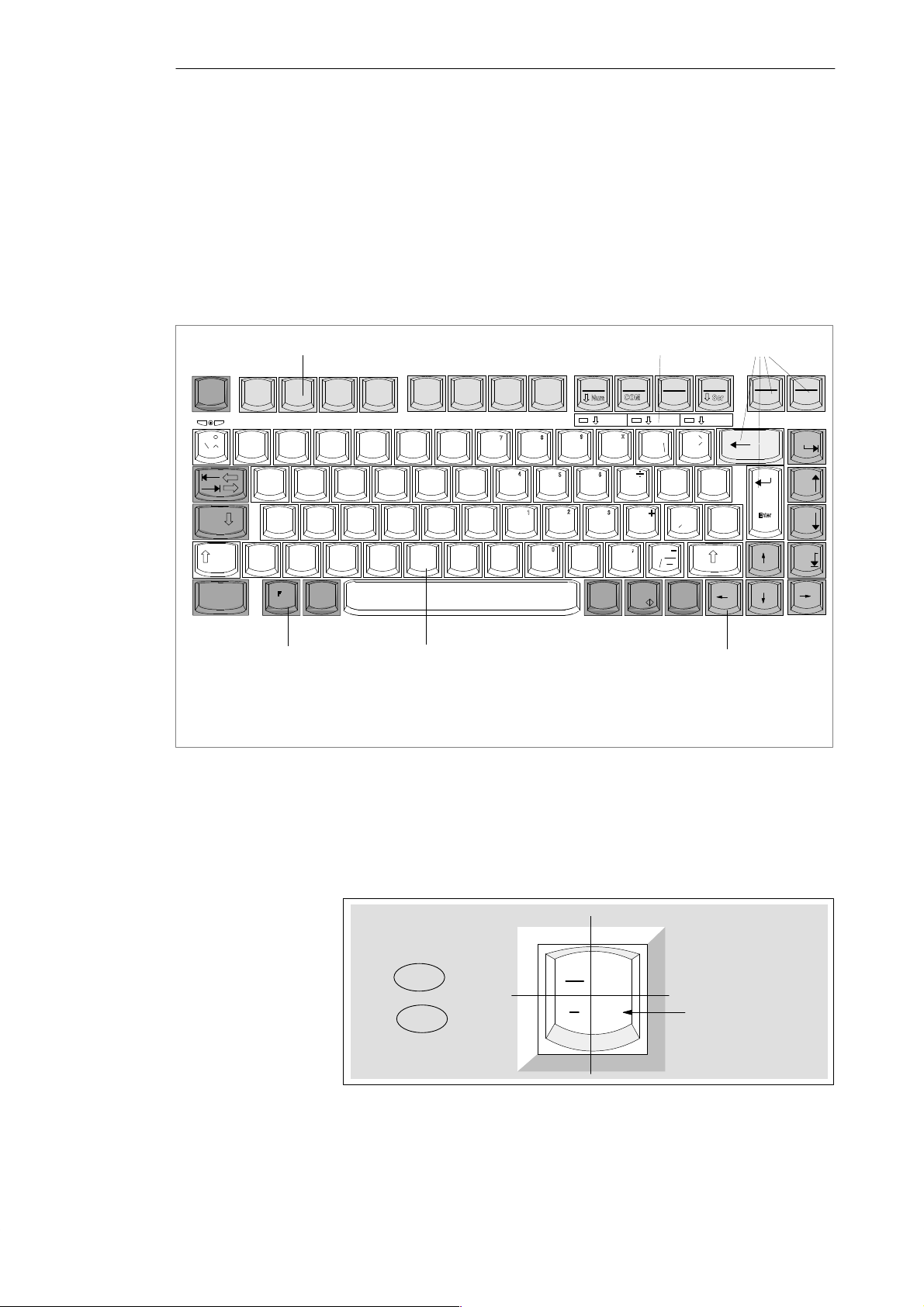

Keyboard Layout

Esc

~

Cap

F1 F2 F3 F4 F5 F6 F7 F8

!

@ ”

1234 567{890– ß

QWER TY U IOP Ü

@

ASDFGH JK L

s

Loc

k

Ctrl Alt

>

<

n

The keyboard is divided into the following areas:

S Alphanumeric or typewriter keyboard with special keys

S LED displays

S Function keys

S Cursor control keys.

3

$ % ^ & & / * ( ( ) ) = __?

# w

Y

XC BN

Z

V

[

< ;,> :.?

M

5

F9

F10

F11 F12

kkk

Num Scroll

}

{

[

Ö

Ä

”

Delete

:

;

Insert

Alt

Gr

+

=

}

*

+

]

\

~

|

’

#

2

Print Pause

BreakSysRq

Home

Page

Page

End

2

1 Alphanumeric keyboard

2 Special keys

Figure 3-5 Keyboard Layout

Repeat Function

All the keys on the keyboard are of the autorepeat type. The character is

repeated as long as the key is pressed.

Keyboard Labeling

The keyboard has international labeling.

Figure 3-6 The Keyboard Labeling System

1

Shift

Unshift

3 Function keys

4 Cursor control keys

International

5 LED display

National

?

\

ß

4

Example: German

Font size and

thickness reduced

T ogether

with the ALT

GR

key

3-8

PG 720 Programming Device

C79000-G7076-C720-02

Page 23

Getting to Know the PG 720

Alphanumeric

Keyboard

Special Keys

The largest block of keys on the keyboard is the alphanumeric keyboard with all

the keys for the letters of the alphabet, numerals and special characters. The

characters are arranged in basically the same way as on a normal typewriter.

However, there are a number of special keys which have special functions for

the PG 720.

The special keys in the alphanumeric keyboard have the following functions:

Table 3-3 Functions of the Special Keys

Key Function

Backspace Key

This key moves the cursor one space to the left and deletes the

character at this position.

Enter Key

(Return, Enter, Line Feed)

Enter

Caps

Lock

F9

The return or enter key is used mainly to terminate a command

line in the operating system; that is, the command you have

typed in is executed when you press this key. For other uses of

this key, please refer to the User Manual of the relevant

application program.

CAPS LOCK Key

If you press this key, the middle LED at the top right-hand

corner of your keyboard lights up. All upper case characters

and other characters are output normally . If you want to type

lower case letters in this position, you must first press the shift

key.

If you are using an international keyboard, you cancel this

function by pressing the CAPS LOCK key again. The LED then

goes out.

If you have a German keyboard, you must press the shift ⇑ key

to cancel this function.

NUM Key

With these keys F

switched from the alphanumeric keyboard to numeric keys. The

LED display lights up. Press this key again to return to cursor

control.

T abulator Key

This moves the cursor depending on the selected tabulator

positions.

+ ⇓ NUM , the emulated numeric block is

n

3

PG 720 Programming Device

C79000-G7076-C720-02

“Fn” Special Key (combination key)

n

In conjunction with a second key (key combination), you

activate other key codes for special applications with this key

(see Figure 3-9 Function Keys). This key is also used to

emulate the numeric block (Figure 3-8 Numeric Block).

3-9

Page 24

3

Getting to Know the PG 720

Table 3-3 Functions of the Special Keys

Key Function

CTRL Key (combination key)

Ctrl

Alt

Alt

Gr

Print

SysRq

Pause

Break

This key is only used in combination with other keys. For

example, you press CTRL + ALT + Delete to reset and restart

the operating system. For other uses of this key , please refer to

the User Manual of the relevant application program.

ALT Key (combination key)

This key is only used in combination with other keys. For

example, you can enter the hexadecimal value of an ASCII

character using this key and the numeric keypad for example,

+ ALT + 123 corresponds to “{”.

F

n

ALT

Key (combination key)

Gr

You can use this key together with the other combination keys

to generate other key codes. For example, you can generate

the “\” character on the German keyboard by typing AL T

PRINT (combination key)

Using the Print key, you can output the current screen display

to a printer.

P AUSE (combination key)

The Pause key interrupts program execution in the majority of

applications.

Gr

+ ß.

LED Displays

The LED displays for the keys NUM LOCK and SCROLL LOCK are located

below the function keys F9 to F12 and display the current status of the keys.

S NUM LOCK

S CAPS LOCK

S SCROLL LOCK

When the programming device is powered up, the NUM LOCK, CAPS LOCK

and SCROLL LOCK light up briefly twice. The keyboard is then ready for

operation.

3-10

PG 720 Programming Device

C79000-G7076-C720-02

Page 25

Getting to Know the PG 720

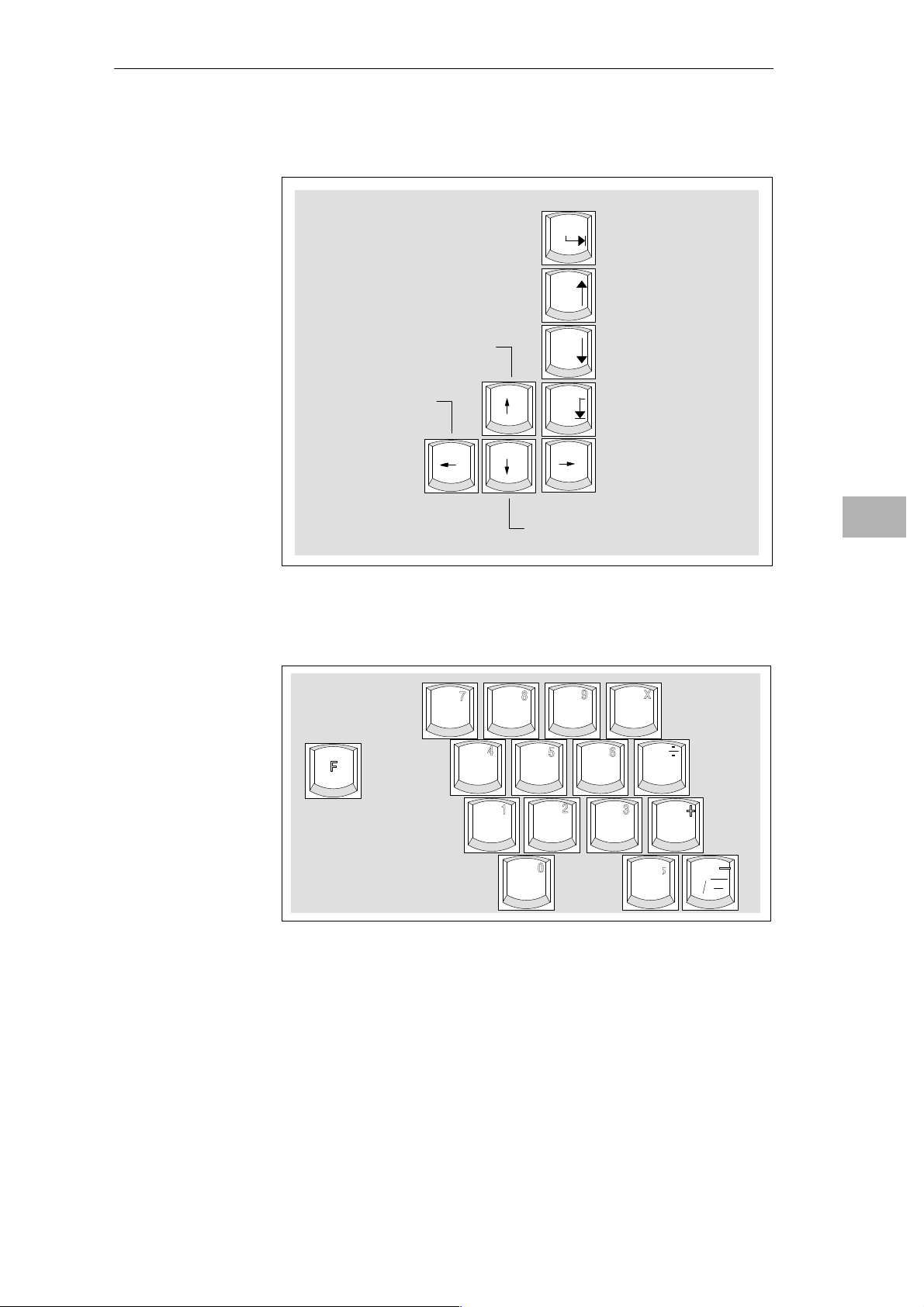

Cursor Keys

The key block shown in the picture below is used for cursor control.

Move cursor up

Move cursor left

Figure 3-7 Cursor Control Keys

Home

Page

Page

End

Move cursor down

Move cursor to

beginning of file

Page back

Page forward

Move cursor to end

of file

Move cursor right

3

Numeric Keypad

with Fn Key

Function Keys

By pressing Fn and one of these keys, the numbers and characters can be used

provided Num Lock is switched on.

& / * ( ( ) ) =

7{ 8 9 0

n

+

Figure 3-8 Numeric Keypad

UIOP

[

JK L

M

}

> :

.

:

Ö

;

?

There is a row with twelve function keys located above the alphanumeric

keyboard. The assignment of the individual functions keys depends on the

software you are working with.

F

+ F9 can also be used to switch the numeric keypad from alphanumeric

n

keys to numeric keys.

Keys with Specific

Functions for S5

PG 720 Programming Device

C79000-G7076-C720-02

The following function keys have specific functions in conjunction with the

STEP 5 programming software.

3-11

Page 26

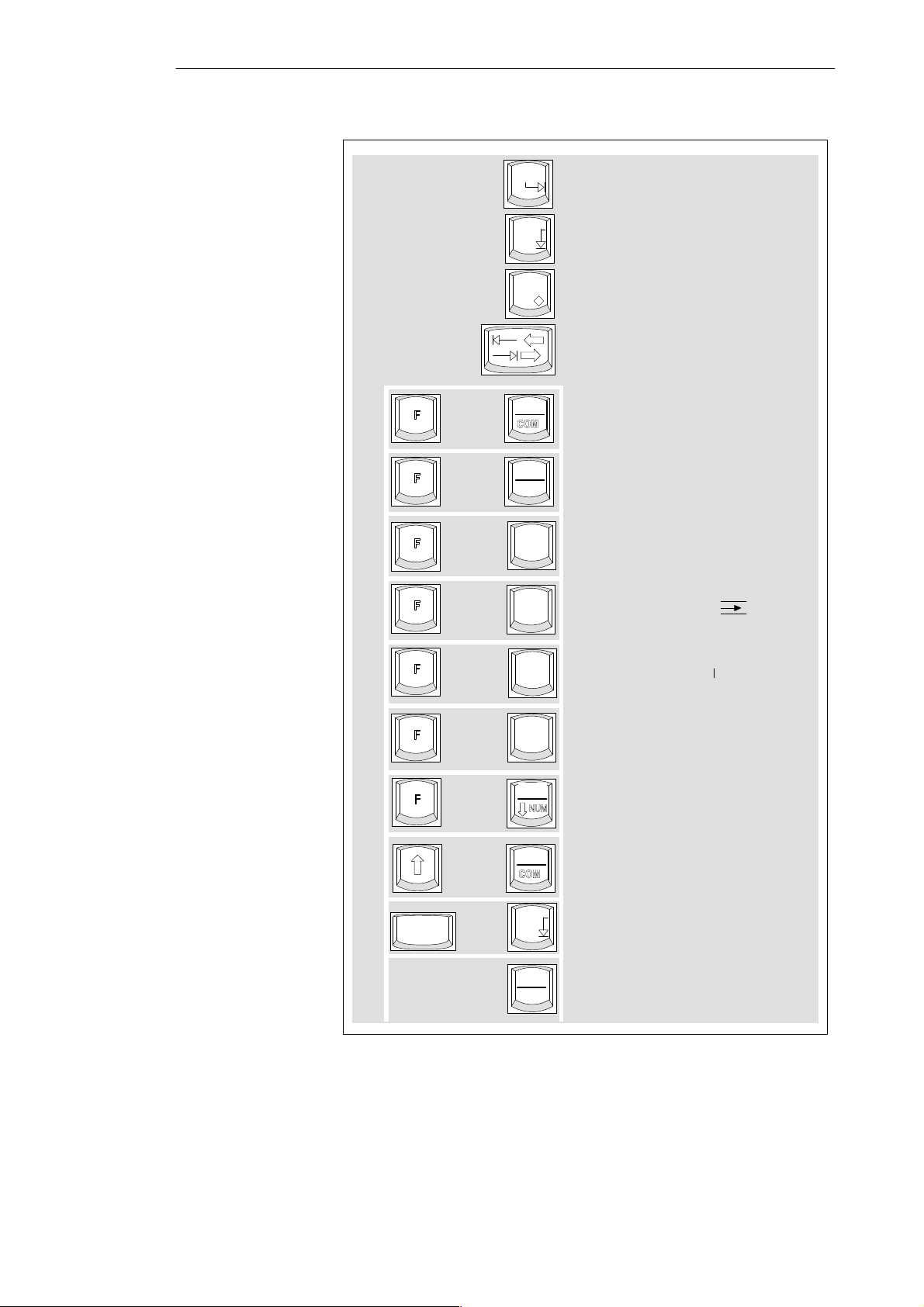

Getting to Know the PG 720

Home

Horizontal expand

3

End

Insert

n

n

n

n

n

+

+

+

+

+

F10

F11

kkk

F1

F2

F3

Vertical expand

Enter key

Cursor right/

cursor left

Title/comment input

in segments

End of segment

Help

Insert segment

Delete segment (X

)

3-12

n

n

+

+

F4

F9

F10

+

CTRL

Figure 3-9 Function Keys (STEP 5)

+

End

Pause

Break

Correction (CORR)

Switch the emulated numeric

keypad from alphanumeric to

numeric keys

Zoom (in Graph 5)

Zoom (in Graph 5)

Half screen (in Graph 5)

PG 720 Programming Device

C79000-G7076-C720-02

Page 27

Getting to Know the PG 720

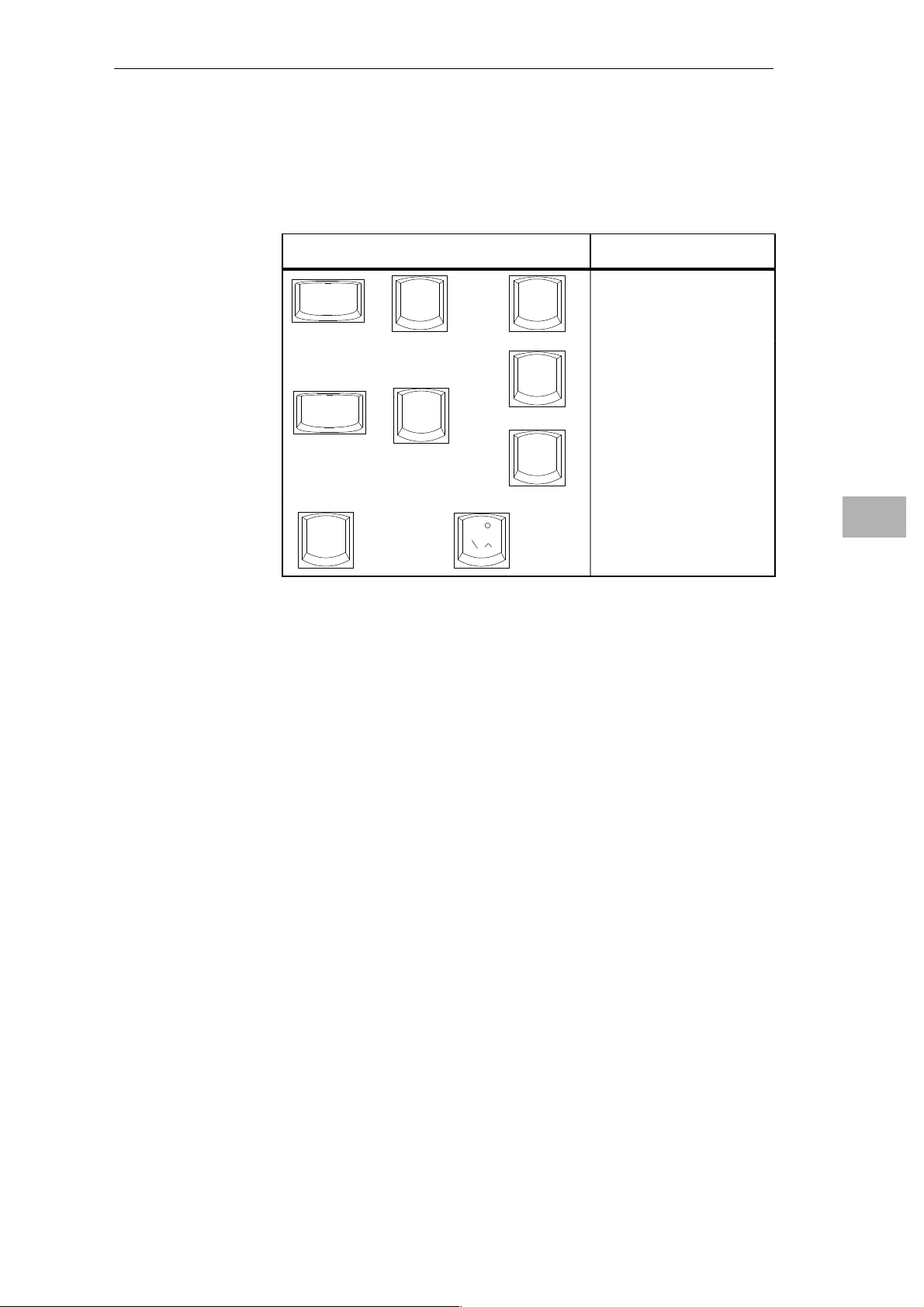

Key Combinations

A selection of some of the most important key combinations are shown in the

following table.

Table 3-4 Key Combinations

Key Combination Effect

Ctrl

Ctrl

F

+

Alt

+

Alt

n

+

+

Delete

F1

+

F2

~

Soft restart

Switch over to international

character set

Switch over to German

character set: the German

keyboard driver must be

loaded.

Trackball active / passive

3

PG 720 Programming Device

C79000-G7076-C720-02

3-13

Page 28

Getting to Know the PG 720

3.4 Trackball

3

Trackball

Cleaning the

Trackball

The trackball is a pointing device for cursor control and menu selection in

many programs that support mouse operation. By moving the trackball, the

cursor can be positioned anywhere on the screen.

By pressing the left-hand button, you set a marker. The function of the

right-hand button depends on the particular application you are using. You

can select objects or items in a menu and start functions with the trackball.

The trackball is in a roller housing which normally prevents dust collecting

on the ball or transmission mechanism. Nevertheless, you should clean the

trackball at regular intervals.

Cleaning the trackball:

1. Switch off your programming device.

2. Remove the cover of the trackball housing by turning it

counter-clockwise, for example by inserting tweezers or a similar tool

into the holes in the ring.

3. You can now take the trackball out of its housing.

4. Wash the trackball in a solution of tap water and mild cleansing agent.

5. Blow any residual dust out of the trackball housing.

6. Dry the trackball and return it to its housing.

7. Replace the cover and tighten it by turning it in a clockwise direction.

3-14

PG 720 Programming Device

C79000-G7076-C720-02

Page 29

3.5 Drives

Getting to Know the PG 720

Drive Types

Floppy Disk Drive

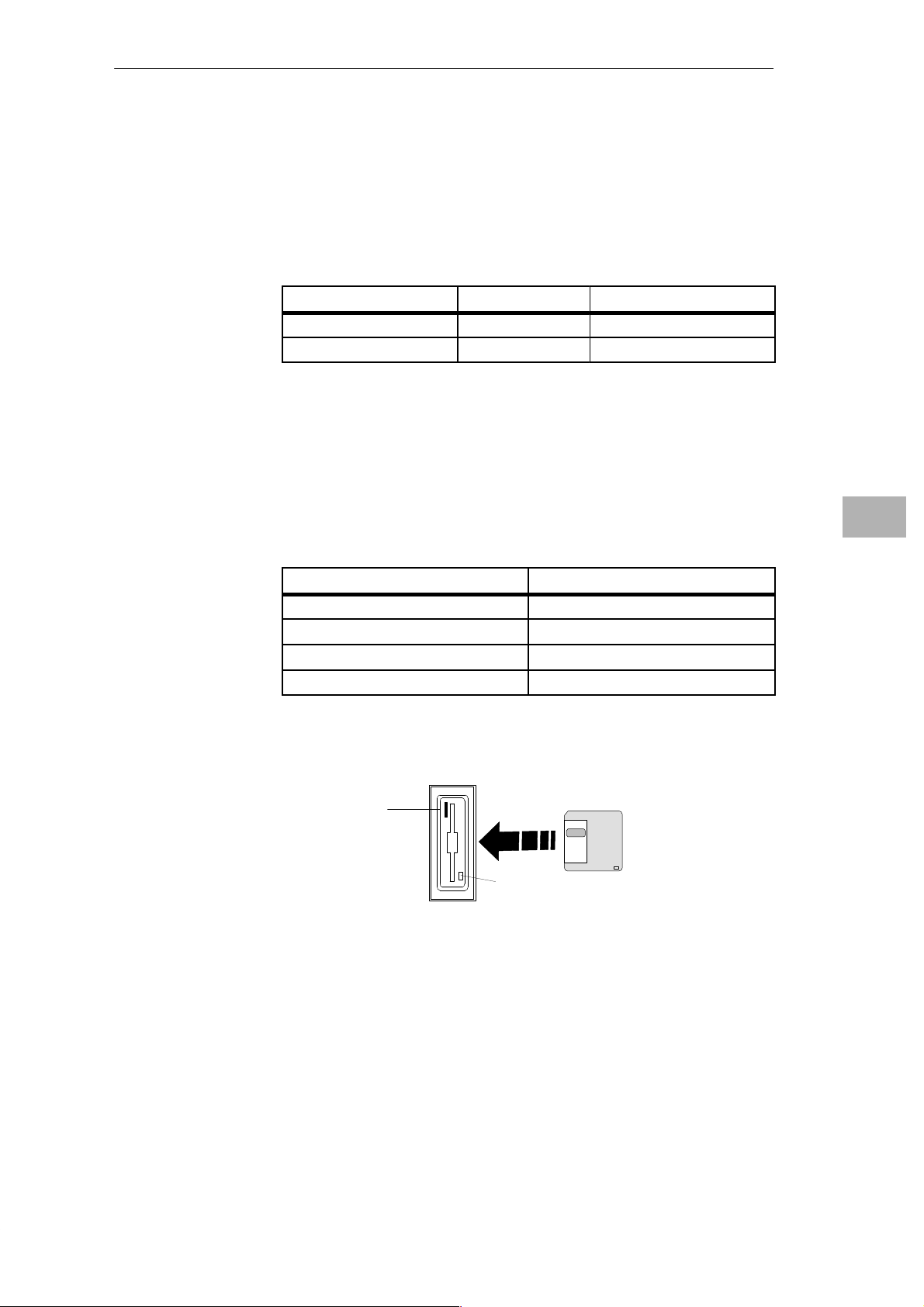

Types of Diskette

The PG 720 is equipped with the following drives as standard:

Table 3-5 Standard Drives

Type of Drive Format Capacity

Floppy (diskette) drive 3.5 inch 1.44 Mbytes

Hard disk drive 2.5 inch See Product Bulletin

Using the floppy disk drive you can save programs and data on diskettes or

load them on the PG 720.

You can use the following diskettes:

Table 3-6 Types of Diskette

Double-Sided High-Density Diskette

3.5 inch 3.5 inch

1.44 Mbytes (135 TPI) 720 Kbytes

80 tracks per side 80 tracks per side

PG 720 recognizes disks by their coding PG 720 recognizes disks by their coding

Double-Sided Double-Density Diskette

3

Handling Diskettes

PG 720 Programming Device

C79000-G7076-C720-02

You insert diskettes into the drive as shown below:

Ejector

Access LED

The access LED for the diskette drive lights up on the front of the device

when the diskette is being accessed.

3-15

Page 30

Getting to Know the PG 720

Caution

!

Risk of data loss!

You must not remove the diskette as long as the access LED is lit.

Otherwise, you may lose the data on the diskette.

Do not remove the diskette until the access LED on the drive or on the front

panel of the PG 720 has gone out.

3

Hard Disk Drive

Self-Test

!

You can use a number of different hard disk drives in your PG 720. The memory

capacity of the particular type of hard disk can be found in the Product

Information Bulletin and SETUP program.

Whenever the PG 720 is switched on or reset, the hard disk drive runs

through a self-test which is repeated during operation.

Whenever the hard disk drive is accessed, the access LED on the front of the unit

lights up.

Caution

Risk of data loss and damage to drive!

Drives are sensitive to vibration and shock. Any vibration occurring during

operation can lead to loss of data or damage to the drive.

If you intend to move the unit, switch it off and wait until the drive has come

to a stop (after about 20 seconds) before you move it.

3-16

PG 720 Programming Device

C79000-G7076-C720-02

Page 31

3.6 External Power Unit and Battery

Getting to Know the PG 720

External Power

Unit

!

The external power unit is used to supply the PG 720 with power when it is

being operated with 115 V or 230 V mains supplies. The voltage is set

automatically. In mains power supply operation, the integrated battery is

charged at the same time. The connecting cable to the PG 720 has an external

power supply unit. For connection to the power system, the external power

supply unit has a connector for non-heating appliances.

Figure 3-10 External Power Supply Unit

3

Caution

Danger of overheating!

The external power supply unit can be damaged if the ventilation slits are

covered.

Do not place any objects on the ventilation slits.

Battery

PG 720 Programming Device

C79000-G7076-C720-02

The PG 720 has an integrated nickel-cadmium battery. This makes the unit a

portable device that can be used when no mains power supply is available.

The battery also prevents loss of data if there is a power outage.

Once the external power supply unit is connected, the battery is charged. The

following conditions are important:

S When charging, the battery temperature must be between + 5° C and

+ 40° C (40° F and 100°F).

S Charging stops as soon as the battery is fully charged.

S In storage, a fully charged battery runs down in approximately 2 months.

It must then be re-charged.

Note

Whenever possible, avoid running down the battery too far. Switch off the

unit when it is not in use.

Before the battery is completely discharged, the red power LED lights up.

3-17

Page 32

Getting to Know the PG 720

3

3-18

PG 720 Programming Device

C79000-G7076-C720-02

Page 33

Installing and Operating the PG 720

4

What Does This

Chapter Contain?

Summary of

Sections

This chapter describes what you have to do to set up your PG 720 correctly

for operation. This includes

S the basic steps for starting up your PG 720

S working in the battery mode and changing the battery

S working with memory submodules and cards for the programmable

controllers and

S connecting your PG 720 to other devices.

In Section You Will Find On Page

4.1 Connecting the PG 720 to the Power Supply 4-2

4.2 Battery Operation 4-3

4.3 Connecting I/O Devices 4-5

4.4 Working with SIMATIC S5 Memory Submodules 4-11

4.5 Working with SIMATIC Memory Cards 4-13

4.6 Working with PCMCIA Cards 4-15

4.7 Connecting the PG 720 to other SIMATIC S5 Units 4-16

4.8 Connecting the PG 720 to a SIMATIC S7 Network

(MPI/DP)

4.9 Networking the PG 720 with Other Stations on SINEC L2 4-22

4.10 Networking the PG 720 and Other Computers on

SINEC H1

4-20

4-23

PG 720 Programming Device

C79000-G7076-C720-02

4-1

Page 34

Installing the PG 720

4.1 Connecting the PG 720 to the Power Supply

4

Connecting to the

Power Supply

You can operate the PG 720 on 115 V and 230 V power systems using the

external power supply unit. The voltage is selected automatically.

1. Plug the power supply cable supplied with the unit into the connector on

the external power supply unit.

2. Connect the power cable to a socket outlet with a grounded protective

conductor.

3. Connect the low voltage connector to the connection for the external

power supply unit on the unit. The power supply cable to the PG 720 is

integrated in the external power supply unit.

4. The device is now ready for power supply operation and if the battery is

not fully charged it will be charged.

Connection for

external power unit

U

= 17 V DC

N

4-2

Figure 4-1 Power Supply Connection

Note

The power plug must be disconnected to isolate the unit completely from the

supply .

For operation in Canada and the US, a CSA or UL listed power supply cable

must be used.

The external power supply unit is intended for operation with grounded power

supply networks.

The unit is not intended for operation with non-grounded or

impedance-grounded systems.

PG 720 Programming Device

C79000-G7076-C720-02

Page 35

4.2 Battery Operation

Installing the PG 720

Battery Operation

If no external power supply unit is connected, you can operate the PG 720

using the integrated battery.

1. Switch on the device. Make sure that the battery is sufficiently charged

before you start work. The power LED is lit green as long as the battery is

sufficiently charged.

2. Work as normal with your PG 720.

3. As soon as the power LED lights up red in battery operation, this

indicates that the battery is almost run down. Stop working and save your

data.

Note

You should only begin working in the battery mode when the battery is

completely charged. Only then can you be sure that the full operating time is

available and that the battery running down will be indicated in good time. The

battery is fully charged when the power LED changes from charging (orange)

to charged (green) after switching on with the unit connected to the mains power

system.

4

When you first start up, the battery may be partly or completely discharged.

Connect the programming device to the power supply using the power supply

unit to charge the battery.

Replacing the

Battery

PG 720 Programming Device

C79000-G7076-C720-02

You can replace a discharged or faulty battery with a fully charged spare

battery (order number see Product Information Bulletin), as follows:

1. Switch off the device.

2. Pull out the support from the stand and open out the extra support.

3. Tilt the unit through approximately 90°.

4. Open the battery cover on the bottom of the device by pushing it down.

5. Disconnect the battery connections and remove the battery.

6. Insert the new battery and connect it.

7. Close the cover.

4-3

Page 36

Installing the PG 720

1

2

3

4

4

Disposal of Used

Batteries

1 Battery connector

2 Battery

Figure 4-2 Changing the Battery

Note

Whenever possible, avoid running down the battery to a low level. Switch

off the unit after use. Once the device is connected to the power supply using

the external power supply unit, a discharged battery is recharged, even if the

programming device itself is not switched on.

Nickel-cadmium batteries can be completely recycled. Their components can

be used as materials for new batteries or other products. Effective recycling

of batteries is only possible when the used batteries are collected according

to type.

Note

Observe the local regulations for disposal of materials.

3 Support

4 Battery compartment cover

4-4

PG 720 Programming Device

C79000-G7076-C720-02

Page 37

4.3 Connecting I/O Devices

Installing the PG 720

Recommended

Printers

Connecting the

Printer to the

Parallel Port

Siemens printers with a parallel interface and IBM character set are

recommended for use with the PG 720 programming device.

T o connect your printer, proceed as follows:

1. Switch off the PG 720 and the printer.

2. Open the cover to the interface ports on the left-hand panel.

3. Plug the printer cable into the LPT1 parallel port.

4. Plug the printer cable into the printer.

5. Screw the connector tight at the interface port.

COM2

COM1

(serial)

(serial)

LPT1

(parallel)

4

!

PG 720 Programming Device

C79000-G7076-C720-02

Figure 4-3 The Printer Ports

Caution

Risk of damage to the unit!

Switch the unit off before connecting the parallel printer to the LPT 1 port

(the printer should also be switched off).

Make sure that you use the correct port. If you use the wrong port or

wrong connecting cables, the port may be damaged.

Before plugging in the cables, the electrostatic charge of your body, the unit

and the cables must be equalized. T o do this, touch the mounting plate for the

ports on the left-hand side of the unit.

Only use original connecting cables.

4-5

Page 38

Installing the PG 720

4

Connecting the

Printer to the

Serial Port

Redirecting Printer

Output

You can also connect your printer to the PG 720 using a serial COM port. You

will find information about how to adapt and set your interface and which

connecting cable you require in the description of your printer .

The standard interface for printer output is LPT1. you can redirect printer output

to another interface port (COM2). Table 4-1 shows examples of how to change

the ports using the Mode MS-DOS command.

Table 4-1 Changing Ports in MS-DOS

Port Command Effect

Redirect LPT 1parallel port

to

COM 2 / V.24 / V.28 /

serial port

Configure COM 2 for

printer

Switch LPT 1 port back to

parallel port

MODE LPT1:=COM2 Printer is assigned

to communication

port 2

MODE COM2:96,n,8,1,p* COM 2 is initialized

for printer

MODE LPT1: LPT 1 is switched

back to the parallel

port

*Mode: 9600 bps, no parity, 8 data bits,1 stop bit

Note

It is advisable to write the required command in the AUTOEXEC.BAT file

or another BATCH file to avoid having to type in the command every time

you restart or reset the hardware.

4-6

PG 720 Programming Device

C79000-G7076-C720-02

Page 39

Installing the PG 720

Recommended

Monitors

Connecting

Monitors

You connect external multisynchronous monitors using the standard VGA

connector on the left-hand panel of the unit. We recommend that you use

Siemens monitors.

You must switch the PG 720 off before connecting the monitor cable. You

will find further information about the connector pinout in Chapter 8.

VGA socket

4

Figure 4-4 Connecting the Monitor

Connect the monitor as follows:

1. Switch off the PG 720 and the monitor.

2. Open the port cover on the left-hand panel.

3. Plug the monitor cable into the VGA socket connector.

4. Secure the connector with the screws.

5. Plug the other end of the monitor cable into the monitor.

6. Switch on the PG 720 and the monitor.

7. Make the necessary changes in the SETUP program (menu ”SIEMENS

PG 720 Hardware Control”, CRT/LCD selection: ”Simultaneous ” or with

higher resolutions ”CRT”).

Caution

!

Danger of damaging the monitor!

If you want to set higher clock frequencies and resolutions, first make sure

that the monitor you are using is suitable for a higher clock frequency and

resolution.

If the clock frequency is too high, this can cause damage to the monitor.

PG 720 Programming Device

C79000-G7076-C720-02

4-7

Page 40

Installing the PG 720

4

Using a Mouse

Connecting a PS/2

Mouse

You can connect both a PS/2 and a serial mouse to the PG 720. When the

PG 720 is supplied, the mouse driver for the trackball and PS/2 mouse is

already loaded.

You can connect an external PS/2 mouse or another external pointing device

to an additional PS/2-compatible mouse connector.

COM2

Port for

serial mouse

Port for

PS/2 mouse

Switching over

between Internal

Trackball and PS/2

Mouse

Figure 4-5 Connecting a PS/2 Mouse

Connect the mouse as follows:

1. Switch off your device.

2. Open the port cover on the left-hand panel.

3. Plug the cable of the PS/2 mouse or another external pointing device into

the mouse connector.

4. Secure the connector with the screws.

5. Switch on your PG 720 again.

Once you have plugged in the external mouse and restarted your PG 720, the

internal trackball is deactivated and remains inactive until the PG 720 is

powered up again without the external mouse.

Table 4-2 Trackball/External Mouse Mode

Situation

No mouse Active

External mouse connected Deactivated Active

Internal Trackball External PS/2 Mouse

4-8

PG 720 Programming Device

C79000-G7076-C720-02

Page 41

Installing the PG 720

Connecting a

Serial Mouse

Choosing Another

Keyboard

You can connect a serial mouse to the COM2 serial port. To operate a serial

mouse, the appropriate mouse driver must be initialized and assigned

parameters. You will find the information you need to do this in the

description of your mouse or in the description of the operating system.

1. Switch off your device.

2. Open the cover of the interface ports on the left-hand panel.

3. Plug in the serial mouse into the mouse connector labeled COM2.

4. Secure the connector with the screws.

5. Switch on your PG 720 again.

You can connect another PS/2-type keyboard to your PG 720 instead of the

one supplied with it.

4

Connecting a PS/2

Keyboard

PG 720 Programming Device

C79000-G7076-C720-02

Keyboard connection

Figure 4-6 Connecting a PS/2 Keyboard

You connect the keyboard as follows:

1. Switch off your device.

2. Unplug the keyboard connector and cable from the unit.

3. Plug in the PS/2-type keyboard connector.

4-9

Page 42

Installing the PG 720

Note

It is advisable to use a keyboard cable with an angled connector, so that the

connector does not extend beyond the back panel.

The keyboard cable must be inserted in the cable conduit on the back panel

of the unit otherwise the connector can work loose when the device is tilted.

4

4-10

PG 720 Programming Device

C79000-G7076-C720-02

Page 43

4.4 Working with SIMATIC S5 Memory Submodules

Installing the PG 720

Working with

SIMATIC S5

Submodules

You can read and program SIMATIC S5 EPROMs and EEPROMs using the

48-pin S5 EPROM and EEPROM programming port. You will find

information about using the programming software in the STEP 5 Manual.

S5 EPROM/

EEPROM port

Figure 4-7 S5 Submodule (EPROM/EEPROM) Programming Port

4

Proceed as follows when working with the S5 submodule programming ports:

1. Switch on your device.

2. Start the EPROM function in your STEP 5 software (version V 6.x and

higher).

3. Plug the S5 memory submodule into the 48-pin programming port.

4. Read, program or erase (EEPROMs only) your S5 memory submodule

with the EPROM programming package of your STEP 5 software.

5. Remove the S5 memory submodule.

6. T erminate the EPROM programming package of your STEP 5 software.

Note

Only program SIMATIC S5 submodules when you are operating using the

power supply system (the external power supply unit must be plugged in).

Only then can you be sure that the programming will not be interrupted by a

power outage if the battery is low.

PG 720 Programming Device

C79000-G7076-C720-02

4-11

Page 44

Installing the PG 720

!

Caution

Risk of damage to EPROMs or EEPROMs!

If you insert or remove the EPROM or EEPROM while it is in use, there is a

danger that it will be damaged.

You must not remove the S5 EPROM or EEPROM while the LED indicating

that the EPROM or EEPROM is being read etc. is lit. You cannot work

simultaneously with S5 memory submodules and memory cards.

Before inserting or removing S5 EPROMs or EEPROMs, you must equalize

the static charge on your body with the potential on the unit. You can do this

by briefly touching the metal mounting plate of the ports on the left-hand

panel of the unit.

4

4-12

PG 720 Programming Device

C79000-G7076-C720-02

Page 45

4.5 Working with SIMATIC Memory Cards

Installing the PG 720

Working with

SIMATIC Memory

Cards

SIMATIC memory cards can be read, programmed and erased using the

68-pin connector. SIMATIC memory cards are available for SIMATIC S5 and

SIMATIC S7 software.

Orientation point

SIMATIC memory cards

Figure 4-8 Slot for SIMATIC Memory Cards

Proceed as follows when working with SIMATIC memory cards:

1. Switch on your device.

4

2. Start your SIMATIC programming function.

3. Plug the SIMATIC memory card into the 68-pin connector.

4. Read, program or erase the memory card with the programming function

of your SIMATIC programming software.

5. T erminate the programming function of your SIMATIC software.

6. Remove the SIMATIC memory card from the programming port for

further use in a programmable logic controller.

PG 720 Programming Device

C79000-G7076-C720-02

4-13

Page 46

Installing the PG 720

!

Caution

Risk of damage to memory cards and the PG 720!

You must insert the memory card into the 68-pin connector with the type

label pointing to the rear of the unit. Make sure that the orientation point

beside the slot matches the point on the card.

If you attempt to plug in the memory card the wrong way round, you may

damage your PG 720 or memory card.

You must not remove the memory card while the LED indicating that the

card is being read etc. is lit. You cannot work simultaneously with S5

memory submodules and memory cards.

4

4-14

PG 720 Programming Device

C79000-G7076-C720-02

Page 47

4.6 Working with PCMCIA Cards

Installing the PG 720

PCMCIA Cards

The PG 720 has two PCMCIA interface ports. You can plug communication

cards for MODEM, FAX-MODEM, ISDN, token ring, ETHERNET , memory

expansion and SCSI interface cards in credit-card format into this port. Either

two cards of type II or one card of type III can be plugged in.

PCMCIA port type II

(Slot 0)

PCMCIA port type II/III

(Slot 1)

Figure 4-9 PCMCIA Port

Ejector for

PCMCIA cards

4

!

PG 720 Programming Device

C79000-G7076-C720-02

Caution

Risk of damage to the PCMCIA cards and the PG 720!

You must insert the PCMCIA card with the front side pointing the rear of

your PG 720. This side is generally labeled with a company or product

designation and the wording “this side up” or words to that effect.

If you attempt to insert the PCMCIA card the wrong way round, you may

damage your PG 720 and the PCMCIA card.

Note

PCMCIA cards must not be used along with a SIMATIC S5 memory

submodule or a SIMATIC memory card. Please read the notes in your

Product Bulletin!

4-15

Page 48

Installing the PG 720

4.7 Connecting the PG 720 to other SIMATIC S5 Units

4

Point-T o-Point

Link

Suggestions for

Configuring TTY

Interfaces (20 mA)

Rules

In this section, you will learn how to connect your PG 720 to a programming

device or programmable control using a point-to-point link.

You can establish a point-to-point link by connecting the PG 720 to another

programming device or a programmable controller using

S a V.24 connection

S a TTY connection

T o ensure reliable data transfer, several factors must be taken into account.

You can reduce interference by choosing the right transmission cable and

connecting it properly and by observing the following guidelines.

S Use a shielded cable with a low DC resistance (130 W / km) (about 40 W kft)

and low capacitance (90 pF/m) (about 27 pF/ft). T wisted-pair cables are

less susceptible to noise and interference. A low DC resistance results in

reduced voltage excursions and shorter charge reversal times. The DC

resistance decreases with increasing conductor cross-section for the same

length of cable.

S The shorter the transmission link, the higher the maximum possible data

transfer rate.

S If there is an active sender and an active receiver at the same end of the

transmission link, the sequence of access priority to the transmission circuit

must be taken into account in order to achieve the longest possible

transmission link.

S Signal lines and power lines must not run together. Signal lines must be

installed as far away as possible from sources of strong interference (for

example, 400 V 3-phase power cables).

S The active TTY interface with a 12 V no-load voltage has been tested on a

1000 m (3300 ft) long cable at a transmission rate of 9600 bps in an

environment with normal levels of noise (field strength 3 V/m or 1 V/ft). If

a shielded LiYCY 5 x 1 x 0.14 shielded cable is used, reliable transmission

is possible over a distance of up to 1000 m (3300 ft). The AS511 protocol

(only one transmitter at a time) was used for testing.

Note

The interference field of the source decreases exponentially with the

distance.

4-16

PG 720 Programming Device

C79000-G7076-C720-02

Page 49

Installing the PG 720

Connecting the

PG 720 to S5

Programmable

Controllers

You can connect the PG 720 to a SIMATIC S5 programmable logic controller

using the COM1/TTY interface port. The required cable is supplied with the

PG 720 (Order no.:6ES5734-2BD20).

COM 1

(socket)

Figure 4-10 Connecting the PG 720 to an S5 Programmable Logic Controller

You connect your PG 720 to a SIMATIC S5 programmable logic controller as

follows:

4

1. Switch off your device.

2. Open the cover of the interface ports on the left-hand panel.

3. Plug the cable into the COM1/V.24 modem/PLC interface port.

4. Secure the connector with screws.

5. Plug the cable into the corresponding port on the CPU of the

programmable logic controller.

Caution

!

Risk of damage to the PG 720.

The interface port may be damaged if you confuse the connections or use the

wrong connecting cables.

Make sure that the TTY cable of the PG 720 is plugged into the

COM1/TTY port and not into the LPT1 port.

Before plugging the cable in, the static charge on your body, on the unit and

on the connecting cables must be equalized. You can do this by briefly

touching the metal mounting plate for the interfaces on the left panel of the

device.

Only use original cables to connect up with the programmable logic

controller.

PG 720 Programming Device

C79000-G7076-C720-02

4-17

Page 50

TTY interface

programmable controller

Installing the PG 720

4

Connecting the

PG 720 Using an

Adapter

Connecting the

PG 720 to Other

Programming

Devices

(V.24, TTY)

The connecting cable 6ES5 734-2BD20 is supplied with the PG 720. An

adapter is available for connecting the programmable logic controller using

older standard cables.

Table 4-3 Adapter for the PG 720 Connecting Cable.

Port

COM1 as

TTY interface

Link Connecting

PG 720 with SIMATIC S5

ro

rammable controller

Cable

Order No.

6ES5 734-2BD20

6ES5 731-1xxx0

15-pin

6ES5 731-0xxx0

25-pin

Adapter

6ES5 731-6AG00

6ES5 731-6AG00

T o allow a data transfer rate of 9600 bps up to a distance of 100 m (1100 ft), the

receiving diode is connected to ground (reference) via the connecting cable.

Note

Cables of various lengths are available under Order No. 6ES5 734-2xxx0

(xxx stands for the length in meters).

If you want to connect your PG 720 to another programming device, you can

plug the appropriate connecting cable into the V.24 or TTY interface port.

You will find more detailed information about the connecting cables listed

below in Chapter 8.

Table 4-4 Connecting the PG 720 to Other Programming Devices

4-18

Port

COM1 as

V.24 interface

COM1 as

TTY interface

Link Connecting cable

PG 7xx with

PG 7xx

PG 7xx with

PG 6xx

6ES5 733-5BD20

Series connection of

6ES5733-2xxx0

and

6ES5731-6AG00

order no:

6ES5 731-6AG00

1)

Note

1)

When connecting the programming devices in series, make sure you

connect the cable the right way round (see Figure 4-11).

Adapter Connecting cable

PG 7XX

6ES5 731-6AG00 6ES5 733-2xxx0

Figure 4-11 Direction of Connection: Adapter-Connecting Cable

active passive

PG 720 Programming Device

C79000-G7076-C720-02

Adapter

PG 6XX

Page 51

Installing the PG 720

Note

If you connect two programming devices using the TTY interface, you must

deactivate the TTY interface (COM1) on one of the devices by changing the

jumper settings. When supplied, this interface is always active.

Activating/

Deactivating the

PG 720

Jumper Settings

When your PG 720 is supplied, the COM1 (TTY) serial port is active (20 mA

current loop). When you connect two programming devices using the COM1

(TTY) serial port, you must deactivate the port on one of these devices. The

PG 720 has jumpers on the motherboard for this purpose.

These jumpers are accessible if you open the battery compartment cover.

Change the jumper settings as shown in Figure 4-12.

4

deactivated

12345

Changing the

Jumper Setting

PG 720 Programming Device

C79000-G7076-C720-02

activated

12345

TTY receive

TTY send, open

TTY send

TTY receive

Figure 4-12 Activating/Deactivating the TTY Port Using Jumpers

Proceed as follows to deactivate the port on the PG 720:

1. Switch off your device.

2. Adjust the position of the PG 720 so that it is horizontal.

3. Open the battery compartment cover.

4. Remove jumpers 2-3 and 4-5 at the top left beside the battery.

5. Insert the jumper in location 1-2 (see Figure 4-12).

6. Close the battery compartment cover.

4-19

Page 52

Installing the PG 720

4.8 Connecting the PG 720 to a SIMATIC S7 Network (MPI/DP)

4

Connection of an

S7 Programmable

Controller via

MPI/DP Interface

You can connect your PG 720 to a SIMATIC S7 programmable logic

controller using the floating MPI/DP interface. The MPI cable for connection

to SIMATIC S7 CPUs is supplied with the PG 720.

(Order No.:6ES7901-0BF00-0AA0)

In a high-interference area:

Bus connector

6ES5762-1AA21

6ES7901-0BF00-0AA0

5 m long (about 16 ft.)

MPI port

Figure 4-13 Connection Using the Multipoint Interface

Connecting

Proceed as follows when connecting to a SIMATIC S7 programmable

controller:

1. Switch off your device.

2. Open the interface cover on the left side of the device.

3. Connect the cable to the MPI/DP interface.

Caution

!

Risk of damage to the PG 720!

Before plugging in the cables, the static charge on your body, the unit and

the cables must be equalized. You can do this by briefly touching the metal

mounting plate for the interfaces on the left-hand panel.

Via the MPI/DP interface, you can connect your programming devices to

S MPI networks (S7-200, S7-300 and S7-400) or

S PROFIBUS DP networks (DP components).

The supplied MPI cable can be used for connection to MPI networks with

transmission rates up to 187.5 Kbps.

4-20

PG 720 Programming Device

C79000-G7076-C720-02

Page 53

Installing the PG 720

MPI/PROFIBUS DP

Network

Up to 32 devices (PC, programming device or programmable controller) can

be connected to the MPI/DP interface to form a network segment. The

physical connection to the MPI/PROFIBUS DP network is via a floating

RS485 interface which is a component of the programming device basic

module.

Several MPI/PROFIBUS DP network segments can be connected via

repeaters. The complete MPI/PROFIBUS DP network can comprise up to

127 stations. The data transmission rate in the MPI network is 187.5 Kbps.

Data transmission rates from 9.6 Kbps to 1.5 Mbps are possible in the

PROFIBUS DP via the MPI/DP interface.

Note

You can find information on setting up an MPI/DP network in the manual

“Setting up an S7-300”, Order No.: 6ES 7030-0AA00-8BA0.

4

PG 720 Programming Device

C79000-G7076-C720-02

4-21

Page 54

Installing the PG 720

4.9 Networking the PG 720 with Other Stations on SINEC L2

4

Networking the

PG 720 on SINEC

L2 (PROFIBUS)

How the Network

Functions

Hardware

SINEC L2 is an open and robust bus system for industrial applications. It can

be used to configure networks with up to 32 stations per segment. The data

transfer rate for SINEC L2 is 1.5 Mbps.

The SINEC L2 network operates on the master-slave principle with token

passing (complying with DIN19245, PROFIBUS). It distinguishes between

active and passive stations. An active station receives the token and passes it

on to the next station within a specified time.

Using the following components, for example, you can connect or network

the PG 720 with SINEC L2:

S PCMCIA interface module (in development)

S RS485 interface (adapter for PCMCIA)

S Shielded, twisted pair (bus cable or connecting cable to network).

Note

You will find more detailed information about the SINEC modules in the

SINEC Catalog IK 10 (Order No.:E86060-K6710-A101-Ax-7600).

For information about installing the modules and making modifications to

the network configuration, please refer to the installation instructions for the

appropriate modules.

Make absolutely sure that you do not use interrupt 12 since this interrupt is

assigned to the integrated trackball.

4-22

PG 720 Programming Device

C79000-G7076-C720-02

Page 55

Installing the PG 720

4.10 Networking the PG 720 and Other Computers on SINEC H1.

Networking the

PG 720 on

SINEC H1

(ETHERNET)

How the Network

Functions

Hardware

SINEC H1 is a bus system for industrial applications based on ETHERNET

(ISO 8802/3). The main features of SINEC H1 are speed (10 Mbps), simple

expansion, open communication and widespread application.

SINEC H1 is the name of Siemens networks and network components

operating according to the CSMA and / CD (ETHERNET) principle. SINEC

H1 is a bus-type LAN that uses a triaxial cable (H1) as its transmission

medium.

T o connect or network the PG 720 with SINEC H1, a PCMCIA-ETHERNET

interface module is required:

S PCMCIA-ETHERNET interface module (Order No.: 6GK1151-1AA00).

Note

4

You will find more detailed information about the SINEC modules in the

SINEC Catalog IK 10 (Order No.: E86060-K6710-A101-Ax-7600).

For information about installing the modules and making any modifications

to the network configuration, please refer to the installation instructions for

the various modules.

PG 720 Programming Device

C79000-G7076-C720-02

4-23

Page 56

Installing the PG 720

4

4-24

PG 720 Programming Device

C79000-G7076-C720-02

Page 57

PG 720 Expansions

5

What Does this

Chapter Contain?

Summary of

Sections

You can enhance the performance of your PG 720 by adding additional

memory . This chapter describes how to expand your PG 720. Please observe

the relevant safety guidelines.

In Section You Will Find On Page

5.1 Opening the Unit 5-2

5.2 Components Visible After Opening the Unit 5-4

5.3 Installing Memory Expansion Modules 5-6

5.4 Replacing the Back-Up Battery 5-8

5.5 Closing the Unit 5-10

PG 720 Programming Device

C79000-G7076-C720-02

5-1

Page 58

PG 720 Expansions

5.1 Opening the Unit

5

Prerequisites

!

Limitation of

Liability

The device is designed for easy maintenance so that any work that is

necessary can be done quickly and at low cost.

Caution

The electronic components on the cards are extremely sensitive to

electrostatic discharge. Certain precautionary measures are therefore

necessary when handling such components. These measures are explained in

the guidelines for handling electrostatically sensitive devices at the end of

this manual.

All technical specifications and licences apply only to expansion functions

approved by SIEMENS.

No liability can be accepted for impairment of functions caused by the use of

devices and components of other manufacturers.

All the modules and components in the PG 720 are electrostatically sensitive.

Please read the ESD guidelines at the end of this book carefully. The

following symbol warns that electrostatically sensitive modules are present.

Before Opening

the Unit

5-2

It is essential that the following rules are adhered to when carrying out any

work on the open unit and you should read them carefully before opening the

unit.

S Before you disconnect the power supply cable, discharge any electrostatic

charge on your body. You can do this by touching the metal mounting

plate for the interfaces on the left panel of the unit.

S Discharge any electrostatic charge from tools that you are using.

S Wear a grounding wrist-strap if you are handling components.

S Leave components and modules in their packing until you are ready to

install them.

S Disconnect the PG 720 from its power supply and remove the battery

before plugging in or removing any modules or components.

S T ouch components and modules only on their edges. Above all, do not

touch the connecting pins and printed conductors.

S Never operate the PG 720 with the cover open.

PG 720 Programming Device

C79000-G7076-C720-02

Page 59

PG 720 Expansions

Tools

Opening the

PG 720

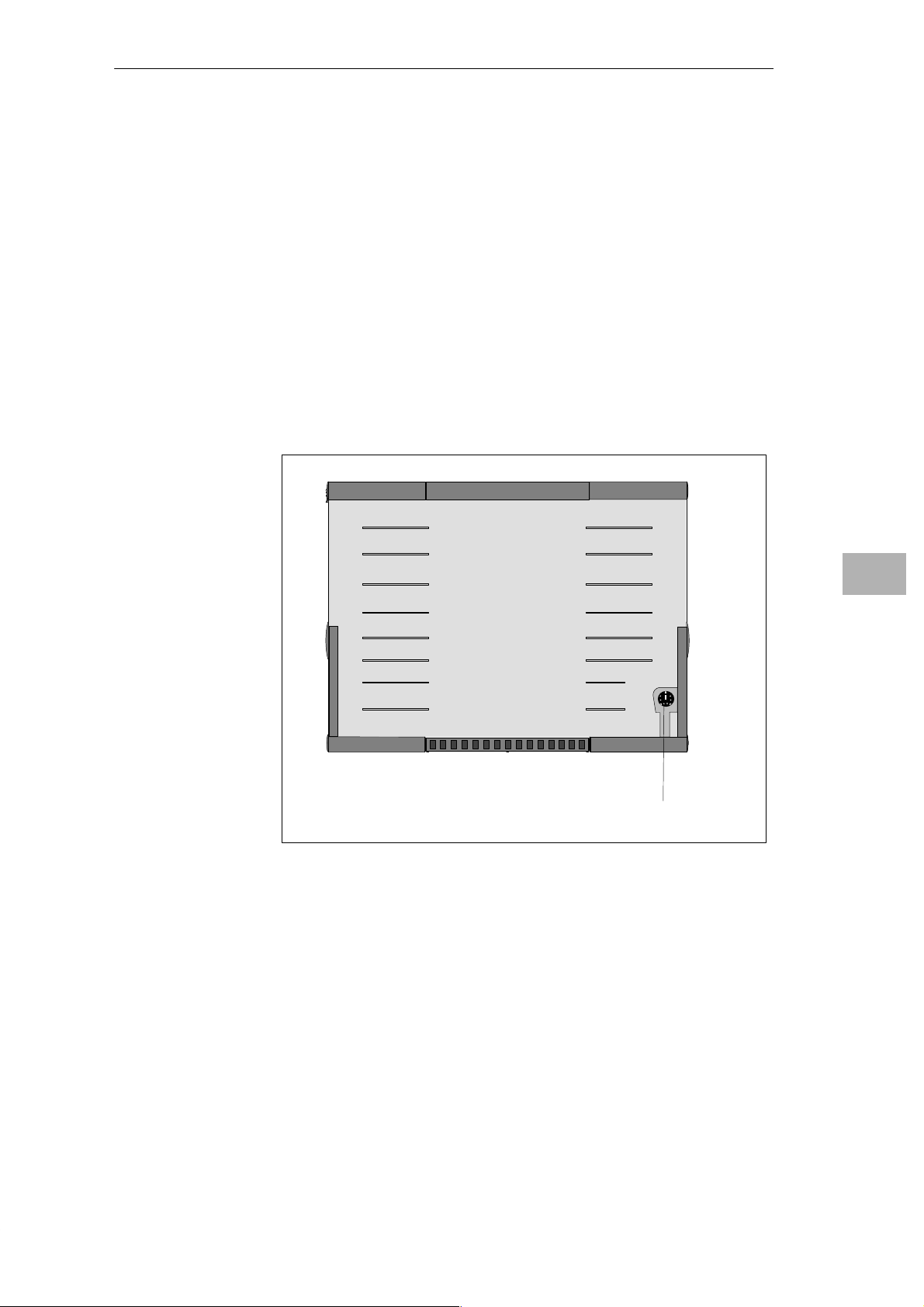

Use a screwdriver to open the unit.

Open your PG 720 as follows:

1. Switch off the PG 720, pull out the power supply connector and remove