Page 1

SIMATIC

Process Control System PCS 7

SMART

PCS 7 SMART Getting Started Part 1 (V9.0 with APL)

Security information

1

Getting Started

Preface

Requirements for Getting

Started

PCS 7 SMART overview

Initial work for the project

Creating CFCs

Creating SFCs

Compiling, downloading and

testing the charts

Configuring the operator

station

2

3

4

5

6

7

8

9

Working in runtime

Performing the additional task

Starting and adapting the

color_gs project

10

11

12

12/2017

A5E42181435-AA

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E42181435-AA

Ⓟ 11/2017 Subject to change

Copyright © Siemens AG 2017.

All rights reserved

Page 3

Table of contents

1 Security information......................................................................................................................................9

2 Preface.......................................................................................................................................................11

3 Requirements for Getting Started...............................................................................................................17

3.1 Hardware requirements for Getting Started - Part 1..............................................................17

3.2 Software requirements for Getting Started - Part 1................................................................18

3.3 Required configuration for Getting Started - Part 1................................................................19

4 PCS 7 SMART overview............................................................................................................................21

4.1 PCS 7 SMART overview........................................................................................................21

4.2 PCS 7 SMART inclusions......................................................................................................22

4.3 Introduction to SIMATIC Manager..........................................................................................23

4.4 Basic Structure of SIMATIC Manager....................................................................................24

4.5 Different views of SIMATIC Manager.....................................................................................25

4.6 Procedure...............................................................................................................................26

4.6.1 Opening SIMATIC Manager...................................................................................................26

5 Initial work for the project............................................................................................................................27

5.1 Planning the project...............................................................................................................27

5.1.1 The "color_gs" project............................................................................................................27

5.1.2 Task list for Getting Started....................................................................................................28

5.1.3 System configuration for the 'color_gs' project.......................................................................30

5.1.4 Configuration tasks overview.................................................................................................31

5.2 Preparational settings for the network....................................................................................32

5.2.1 Network and Interface settings...............................................................................................32

5.2.2 Procedure...............................................................................................................................32

5.2.2.1 Configuration console settings...............................................................................................32

5.3 Creating the project................................................................................................................34

5.3.1 "New Project" Wizard usage..................................................................................................34

5.3.2 Background knowledge for the PCS 7 Wizard.......................................................................34

5.3.3 Procedure...............................................................................................................................36

5.3.3.1 Creating the color_gs Project.................................................................................................36

5.3.3.2 Opening and Closing the "color_gs" Project..........................................................................39

5.3.3.3 How to Work in the Various Views.........................................................................................39

5.4 Configuring the stations.........................................................................................................41

5.4.1 Configuration overview...........................................................................................................41

5.4.2 Procedure...............................................................................................................................42

5.4.2.1 AS configuration.....................................................................................................................42

5.4.2.2 Renaming the PC Station.......................................................................................................44

5.4.2.3 Configuring the PC station of the OS.....................................................................................45

5.4.2.4 NetPro settings.......................................................................................................................47

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 3

Page 4

Table of contents

5.4.2.5 Configuring and downloading the PC station of the OS.........................................................49

5.4.2.6 Downloading the hardware configuration of the AS...............................................................50

5.5 Working in the plant hierarchy................................................................................................52

5.5.1 Introduction to plant hierarchy................................................................................................52

5.5.2 Plant hierarchy settings..........................................................................................................52

5.5.3 Plant view structure................................................................................................................54

5.5.4 Adapting default names.........................................................................................................54

5.5.5 Inserting additional hierarchy folders.....................................................................................57

5.5.6 Checking the assignment of AS/OS to the plant hierarchy....................................................58

5.6 Current status.........................................................................................................................59

5.6.1 Current state of your project...................................................................................................59

6 Creating CFCs............................................................................................................................................61

6.1 CFC Charts and the CFC Editor............................................................................................61

6.2 Working with libraries.............................................................................................................62

6.2.1 CFC Charts and the master data library................................................................................62

6.2.2 Storing objects in the master data library...............................................................................62

6.2.3 Working with the master data library......................................................................................63

6.2.4 Opening the libraries..............................................................................................................64

6.2.5 Storing blocks.........................................................................................................................65

6.2.6 Storing process tag types.......................................................................................................67

6.2.7 Showing and hiding libraries..................................................................................................68

6.2.8 Process to hide and show libraries........................................................................................69

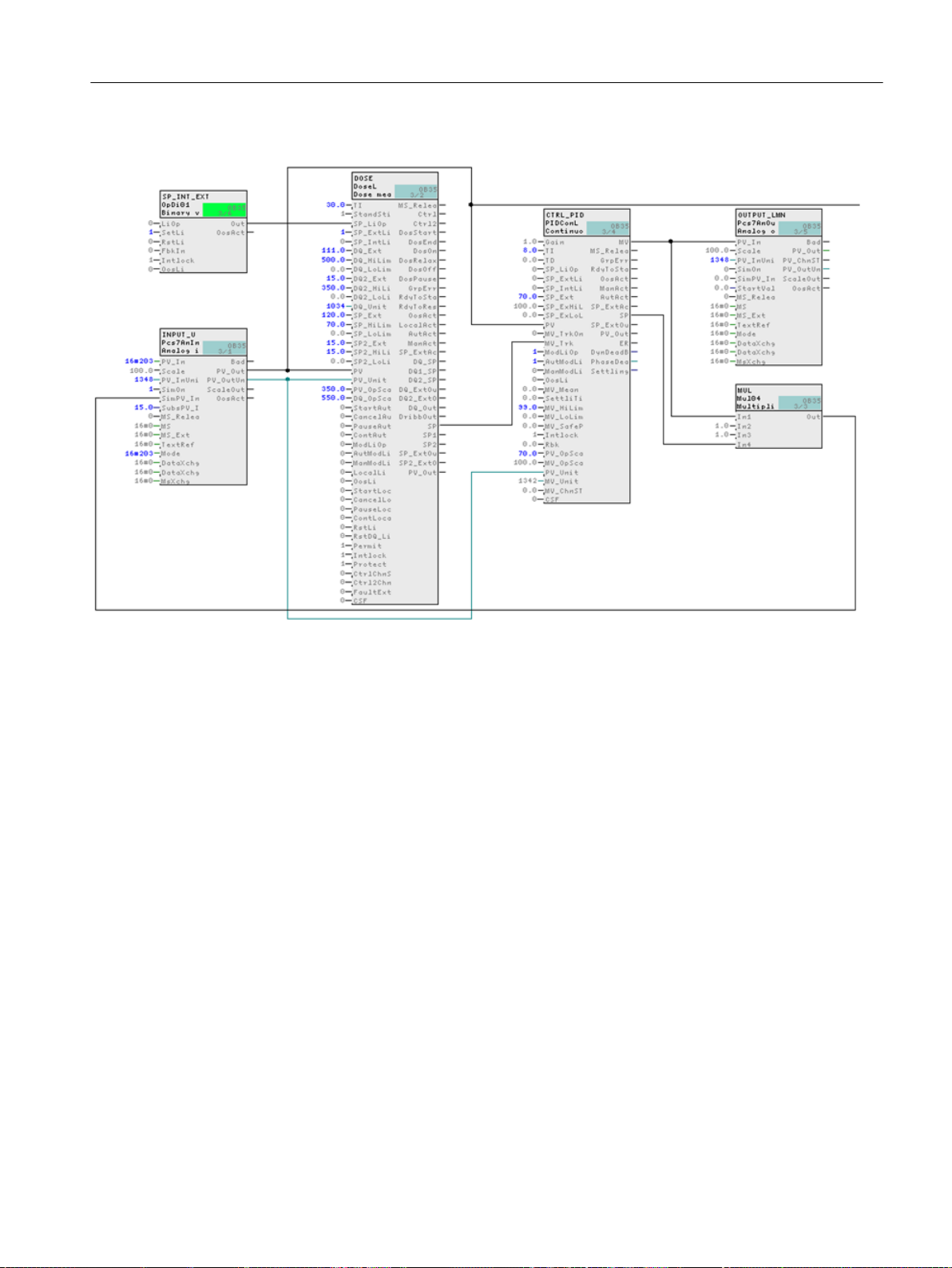

6.3 Technological significance of the charts in the project...........................................................71

6.3.1 Charts in "color_gs" project....................................................................................................71

6.3.2 Process-Related meaning of the "CFC_SETP" CFC chart....................................................71

6.3.3 Process-Related meaning of the "CFC_FC111" CFC chart...................................................72

6.3.4 Process-Related meaning of the "CFC_LI111" CFC chart.....................................................72

6.3.5 Process-Related meaning of the "CFC_NP111" CFC chart...................................................72

6.3.6 Process-Related meaning of the "CFC_NK11x" CFC chart...................................................73

6.4 CFCs in the Plant Hierarchy...................................................................................................74

6.4.1 Working with CFC charts.......................................................................................................74

6.4.2 Procedure...............................................................................................................................74

6.4.2.1 Renaming CFC charts in the Plant Hierarchy........................................................................74

6.4.2.2 Inserting new CFC charts in the Plant Hierarchy...................................................................75

6.4.2.3 Inserting the "Motor_Lean" process tag type.........................................................................76

6.5 The current status..................................................................................................................77

6.5.1 Current status of your project.................................................................................................77

6.6 Working with the CFC Editor..................................................................................................78

6.6.1 Introduction to the CFC Editor................................................................................................78

6.6.2 CFC Chart in the CFC Editor.................................................................................................78

6.6.3 Catalog in the CFC Editor......................................................................................................79

6.6.4 Configuration steps for CFC charts overview.........................................................................80

6.6.5 Opening the "CFC_SETP" CFC chart....................................................................................80

6.6.6 Assignment of block parameters in CFC charts.....................................................................81

6.6.7 Inserting the blocks into the "CFC_SETP".............................................................................81

6.6.8 Assigning parameters for the blocks in "CFC_SETP"............................................................82

6.6.9 Inserting the blocks into the "CFC_FC111"............................................................................84

6.6.10 Assigning parameters for the blocks in the "CFC_FC111".....................................................85

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

4 Getting Started, 12/2017, A5E42181435-AA

Page 5

Table of contents

6.6.11 Inserting the blocks in the "CFC_LI111".................................................................................88

6.6.12 Assigning parameters for the blocks in the "CFC_LI111"......................................................89

6.6.13 Assigning Parameters for blocks in the "CFC_NP111"..........................................................91

6.6.14 Interconnection of blocks in the CFC charts..........................................................................92

6.6.15 Interconnecting blocks in the "CFC_NP111"..........................................................................93

6.6.16 Interconnecting blocks in the "CFC_FC111"..........................................................................94

6.6.17 Interconnecting blocks in the "CFC_LI111"............................................................................95

6.6.18 Assigning parameters for the blocks in "Valve_Lean"............................................................96

6.6.19 Interconnecting the blocks in "Valve_Lean"...........................................................................97

6.7 CFCs in the process object view............................................................................................98

6.7.1 Use of the Process Object View for valve control..................................................................98

6.7.2 Procedure...............................................................................................................................98

6.7.2.1 Defining Inputs/Outputs for the Process Object View............................................................98

6.7.2.2 Inserting the "Valve_Lean" process tag type........................................................................100

6.7.2.3 Adapting the parameters for "CFC_NK11x".........................................................................101

6.7.2.4 Deleting Interconnections to addresses...............................................................................103

6.7.2.5 Selecting block icons............................................................................................................104

6.8 The current status................................................................................................................105

6.8.1 Current status of your project...............................................................................................105

7 Creating SFCs..........................................................................................................................................107

7.1 Overview of Sequential Function Charts (SFCs).................................................................107

7.2 Working with the SFC Editor................................................................................................108

7.2.1 Introduction to the SFC Editor..............................................................................................108

7.2.2 Important functions in the SFC Editor..................................................................................108

7.2.3 Properties of steps and transitions.......................................................................................109

7.2.4 Overview of the configuration steps for SFC charts.............................................................110

7.2.5 Moving an SFC chart...........................................................................................................110

7.2.6 Renaming the SFC chart......................................................................................................111

7.2.7 Opening the "SFC_RMT1" SFC Chart.................................................................................112

7.2.8 Technological structure of the sequential control system....................................................112

7.2.9 Creating the sequential control system in the SFC chart.....................................................113

7.2.10 Renaming steps...................................................................................................................115

7.2.11 Renaming transitions...........................................................................................................117

7.3 Setting parameters...............................................................................................................119

7.3.1 Assigning parameters to the steps of the SFC chart............................................................119

7.3.2 Parameters for the steps......................................................................................................122

7.3.3 Assigning parameters to the transitions of the SFC chart....................................................124

7.3.4 Parameters for the transitions..............................................................................................125

7.3.5 Optimizing the run sequence...............................................................................................127

7.4 The current status................................................................................................................128

7.4.1 Current status of your project...............................................................................................128

8 Compiling, downloading and testing the charts........................................................................................129

8.1 Overview of compiling, downloading, and testing................................................................129

8.2 Procedure.............................................................................................................................130

8.2.1 Compiling and Downloading CFC and SFC charts..............................................................130

8.2.2 Testing the program.............................................................................................................133

8.2.3 Testing the program in the SFC Editor.................................................................................134

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 5

Page 6

Table of contents

8.2.4 Testing the program in the CFC Editor................................................................................135

8.3 The current status................................................................................................................137

8.3.1 Current status of your project...............................................................................................137

9 Configuring the operator station...............................................................................................................139

9.1 Introduction to the OS project editor....................................................................................139

9.2 Operator station in process mode........................................................................................140

9.3 Configuration of the operator station....................................................................................141

9.4 Working in the SIMATIC Manager.......................................................................................142

9.4.1 Preparations in SIMATIC Manager......................................................................................142

9.4.2 Procedure.............................................................................................................................143

9.4.2.1 Editing picture properties.....................................................................................................143

9.4.2.2 Deleting unnecessary pictures.............................................................................................144

9.4.2.3 Creating block icons.............................................................................................................145

9.4.2.4 Compiling the OS.................................................................................................................147

9.4.2.5 Starting the PCS7 SMART OS.............................................................................................150

9.5 Working on the OS...............................................................................................................151

9.5.1 Structure of the OS - WinCC Explorer.................................................................................151

9.5.2 Function of process pictures................................................................................................151

9.5.3 Setting the OS activation for the ES.....................................................................................151

9.6 Working in general with the Graphics Designer...................................................................153

9.6.1 Introduction to the Graphics Designer..................................................................................153

9.6.2 Opening a Process Picture..................................................................................................153

9.6.3 Opening various toolbars.....................................................................................................154

9.6.4 Objects in the Graphics Designer........................................................................................155

9.6.5 Static objects........................................................................................................................156

9.6.6 Text fields.............................................................................................................................156

9.6.7 Working with tag interconnection.........................................................................................156

9.7 Creating the process picture................................................................................................157

9.7.1 Inserting pipes and a tank into the process picture..............................................................157

9.7.2 Labeling the parts of the plant..............................................................................................160

9.7.3 Step 1 - Inserting a text field................................................................................................160

9.7.4 Step 2 - Setting the text field................................................................................................160

9.7.5 Step3 - Duplicating the text field..........................................................................................161

9.7.6 Current status of the process picture...................................................................................163

9.7.7 Adapting process pictures....................................................................................................163

9.7.8 Connecting the raw material tank with the process value....................................................164

9.7.9 Step 3 - Adding explanatory text..........................................................................................167

9.7.10 Step 4 - Configuring the setpoint default..............................................................................168

9.7.11 Completing the work............................................................................................................169

9.8 The current status................................................................................................................170

9.8.1 Current status of your project...............................................................................................170

10 Working in runtime....................................................................................................................................171

10.1 Planning the user interface..................................................................................................171

10.1.1 Operator station in process mode........................................................................................171

10.1.2 User interface in process mode...........................................................................................171

10.2 Operator control and monitoring in process mode...............................................................173

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

6 Getting Started, 12/2017, A5E42181435-AA

Page 7

Table of contents

10.2.1 WinCC language settings.....................................................................................................173

10.2.2 Activating process mode......................................................................................................173

10.2.3 Starting the process.............................................................................................................174

10.2.4 Stopping the process...........................................................................................................177

10.2.5 Controlling the process by means of the process picture....................................................177

10.2.6 Specifying the reactor..........................................................................................................177

10.2.7 Opening the faceplates........................................................................................................178

10.2.8 Changing the setpoint..........................................................................................................178

10.2.9 Working with messages.......................................................................................................182

10.2.10 Process mode exit................................................................................................................184

11 Performing the additional task..................................................................................................................185

11.1 Introduction to the additional task........................................................................................185

11.2 Copying the existing 'RMT1' part of the plant.......................................................................186

11.3 Process mode preparation...................................................................................................188

11.4 Compile and download the changes....................................................................................189

11.5 Adapting the OS configuration.............................................................................................194

11.6 Starting process mode.........................................................................................................195

12 Starting and adapting the color_gs project...............................................................................................197

12.1 color_gs project....................................................................................................................197

12.2 Procedure.............................................................................................................................198

12.2.1 Opening the color_gs project...............................................................................................198

12.2.2 Adapting the hardware for the color_gs project....................................................................198

12.2.3 Adapting the blocks for the color_gs project........................................................................199

12.2.4 Adapting the project data for the color_gs project................................................................200

12.2.5 Compiling and downloading the color_gs project.................................................................201

Index.........................................................................................................................................................205

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 7

Page 8

Table of contents

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

8 Getting Started, 12/2017, A5E42181435-AA

Page 9

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines, and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be connected

to an enterprise network or the internet if and to the extent such a connection is necessary

and only when appropriate security measures (e.g. firewalls and/or network segmentation) are

in place.

For additional information on industrial security measures that may be implemented, please

visit:

https://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends that product updates are applied as soon as they are available

and that the latest product versions are used. Use of product versions that are no longer

supported, and failure to apply the latest updates may increase customer’s exposure to cyber

threats.

1

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

https://www.siemens.com/industrialsecurity.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 9

Page 10

Security information

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

10 Getting Started, 12/2017, A5E42181435-AA

Page 11

Preface

About this document

2

Prerequisites

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

SMART process control system, enabling you to create a simple project. You can configure

the project on an existing SIMATIC PC station.

PCS 7 SMART is suitable for companies that need cost efficient automation for small plant

configurations.

This Getting Started document is aimed at beginners who work on the following areas:

● Configuration

● Commissioning and service

In the rest of the document, we address the document as

You must have knowledge in the following areas:

● The following Microsoft operating systems:

– Windows 7 Ultimate / Enterprise SP1 (64-Bit)

– Windows 7 Professional SP1 (64-Bit, English version only)

– Windows 10 Enterprise 2015 LTSB (64-Bit)

● Basic knowledge in the field of process automation

● Functions and configuration of SIMATIC S7 (S7-410, STEP 7)

gives you an overview of the PCS 7

Getting Started - Part 1.

● Functions and configuration of SIMATIC NET (network components, transmission media)

Note

● SIMATIC PCS 7 SMART is based on PCS 7 Asia. PCS 7 SMART is specifically designed

for smaller projects with up to 2400 Process Objects (PO) within the Chinese and Indian

markets. With PCS 7 SMART portfolio, we offer a custom-fit product for projects with up to

eight PCS 7 SMART OS Single Stations. Specifically, the combination of SMART software

and SMART hardware increases functionality and, therefore, makes PCS 7 SMART a

suitable software for such projects in China and India.

● PCS 7 SMART does not come with a trial version. A USB hardlock must be plugged in

permanently for configuration and runtime.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 11

Page 12

Preface

Accessing PCS 7 SMART documentation

You can find the PCS 7 SMART documentation at the following locations:

● On the

● On the computer, in the installation folder

● On the Internet:

– Region India (https://support.industry.siemens.com/cs/in/en/ps/21144)

– Region China (https://support.industry.siemens.com/cs/cn/zh/ps/21144)

In this entry, you can also find the manual on PCS 7 SMART, which shows the differences

between PCS 7 SMART and PCS 7.

Process Control System; SIMATIC PCS 7 SMART

Information about PCS 7 basic system on the Internet

All product and order information regarding PCS 7:

● Internet link (https://www.siemens.com/PCS7)

Overview of the most important technical information and solutions for PCS 7 in the Industry

Online Support:

● Internet link (https://support.industry.siemens.com/cs/document/63481413)

All information on Support and Service in the Industry Online Support:

● Internet link (https://support.industry.siemens.com)

Note

DVD

We recommend you to subscribe to the newsletter, which keeps you constantly updated with

current information about our products.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

12 Getting Started, 12/2017, A5E42181435-AA

Page 13

Contents of the PCS 7 Readme files

The PCS 7 V9.0 SMART Readme file is available in various versions:

1. PCS 7 SMART Readme (offline)

It is installed during the PCS 7 setup and it contains general notes and links to documents

on the internet.

2. PCS 7 SMART Readme (online)

This document contains specific information on the installation and use of PCS 7 SMART.

It is only available on the internet so that we can keep it up to date.

You can download the current version of the document under the entry ID 109744321 in

the Industry Online Support:

Preface

– Region India (

https://support.industry.siemens.com/cs/in/en/view/109744321)

– Region China (https://support.industry.siemens.com/cs/cn/zh/view/109744321)

3. PCS 7 Readme (online)

This document contains general information on the installation and use of PCS 7.

You can download the current version of the document under the entry ID 109744312 in

the Industry Online Support:

– Internet link (https://support.industry.siemens.com/cs/ww/en/view/109744312)

Note

It is vital that you use the information from the most recent version of the SMART and PCS 7

Readme (online) before you begin the installation or use of PCS 7 V9.0 SMART version.

The information in the PCS 7 SMART Readme (online) supersedes the information in the

PCS 7 Readme (online).

Each of the products comes with product-specific information in the form of readme files.

The information contained in these readme files also applies to using products in PCS 7

SMART.

Electronic manuals and help system for the basic system PCS 7

Pre-installed manuals

Once you have installed PCS 7 on your computer, the following PCS 7 documentation is

immediately available.

● You can find this documentation in the section SIEMENS Automation > SIMATIC >

Documentation or the product information in the "Start" menu of Windows:

– PCS 7 - Catalog Overview (PDF)

– PCS 7 - Operating Instructions - OS Process Control (PDF)

– PCS 7 - Installation Manual - PC Configuration (PDF)

– PCS 7 - Configuration Manual - Engineering System (PDF)

– PCS 7 - Configuration Manual - Operator Station (PDF)

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 13

Page 14

Preface

Complete documentation for PCS 7 on the internet and document updates

The complete PCS 7 documentation is available in multiple languages at the following Internet

site:

● Internet link (https://www.siemens.com/pcs7-documentation)

You also have the option of updating the installed PCS 7 help system and post-installing the

PCS 7 system documentation. The "PCS 7 Documentation Portal Setup" required for this is

available for download under the entry ID 109744320 in the Industry Online Support:

● Download link (https://support.industry.siemens.com/cs/ww/en/view/109744320)

Note

Timeliness of online documents

Documents available online may be up-to-date than the version of documents installed with

PCS 7 Setup. The statements in documents available online should therefore be given priority

over installed documents.

Information on modified documents

In order to keep yourself informed about changes to the PCS 7 readme and the other PCS 7

documentation, we recommend that you activate the relevant notification in the Industry Online

Support:

● Internet link (https://support.industry.siemens.com)

Guide

Getting Started - Part 1

You will find important information required to understand the steps in this Getting Started as

well as detailed instructions on how to work through them.

Getting Started - Part 2

you will configure a unit for the color project and become familiar with the functions of rational

engineering.

You can download the completed PCS 7 SMART project color_gs and the documentation

Getting Started - Part 1 and Getting Started - Part 2

● Getting Started - Part 1 (https://support.industry.siemens.com/cs/in/en/view/109751150)

● Getting Started - Part 2 (https://support.industry.siemens.com/cs/in/en/view/109751151)

● To download the project, click the icon:

Open the projects on the Engineering Station (ES) to view the configuration data and compare

the data with your own configuration data. Activate the project on an Operator Station (OS) in

order to operate and monitor the process.

explains the individual steps required to create the color_gs project.

is a continuation of

Getting Started - Part 1

from the internet:

. In this Getting Started,

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

14 Getting Started, 12/2017, A5E42181435-AA

Page 15

Conventions

Preface

Note

● To test the color_gs project in process mode, the hardware configuration of the project must

correspond to your actual hardware configuration. If necessary, replace the hardware

components of the color_gs project with the actual hardware components present.

● You will find additional information about opening and adapting the color_gs project in the

"Starting and adapting the color gs project" chapter.

In this document, all the instructions are given using their full menu commands. You can also

access virtually all of the functions through the shortcut menu or by double-clicking.

Note

In this documentation, the versions of profiles, libraries and modules are always displayed as

Vxx.

Ensure that you use an appropriate version for your hardware or software.

Example:

● Profile: PCS7_Vxx

● PCS 7 AP Library Vxx

● IE General: SW Vxx

Note

The names of elements in the software interface are specified in the language of this

documentation. If you have installed a multi-language package for the operating system, some

of the designations will be displayed in the base language of the operating system after a

language switch and will, therefore, differ from the designations used in the documentation.

In PCS 7 SMART, you can use standard Windows functions in many situations:

● Multiple selection using the "Ctrl" and "Shift" keys

● Column sorting in tables by clicking on the column header

● Use of "drag and drop" instead of "copy and paste"

The individual tutorials in this document build on each other to create a complete PCS 7

SMART project step-by-step by working through all the modules in the specified sequence.

For this reason, please work through all the tutorials in the given sequence.

PCS 7 SMART glossary

The PCS 7 SMART glossary containing the definitions of important technical terms used in

the documentation are available within the PCS 7 SMART software through the Help menu in

the SIMATIC Manager ( Help>Contents).

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 15

Page 16

Preface

Additional information

You can find detailed background information and general context in the following

documentation, which you can use for reference purposes:

● Configuration manual

● Configuration manual;

This documentation is available as an online help and in the PDF format.

● Online help

– In the PCS 7 software in SIMATIC Manager, select Help > Topics.

● PDF file

– In the "Start" menu, under the SIEMENS Automation > SIMATIC > Documentation

folder, in the preferred language.

– In the _Manuals folder of the

If you wish to familiarize yourself with specific topics, refer to the appropriate manuals. For

example: SFC and CFC.

; Process Control System PCS 7; Engineering System

Process Control System PCS 7; Operator Station

SIMATIC PCS 7

SMART DVD.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

16 Getting Started, 12/2017, A5E42181435-AA

Page 17

Requirements for Getting Started

3.1 Hardware requirements for Getting Started - Part 1

Hardware components

The list below shows the hardware components you need for Getting Started. For some

hardware components, you must use a specific version because it is not possible to work on

Getting Started with an older version.

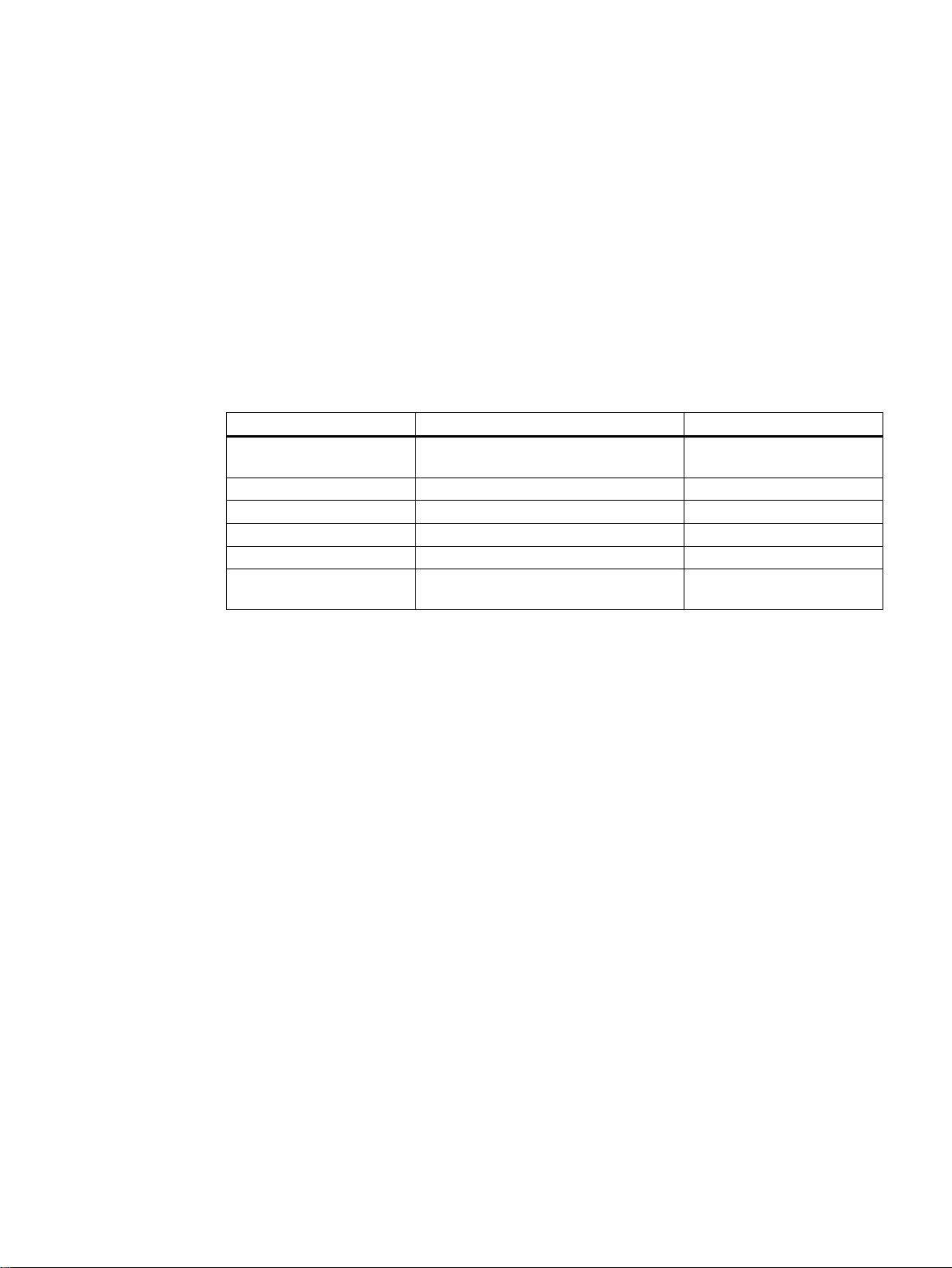

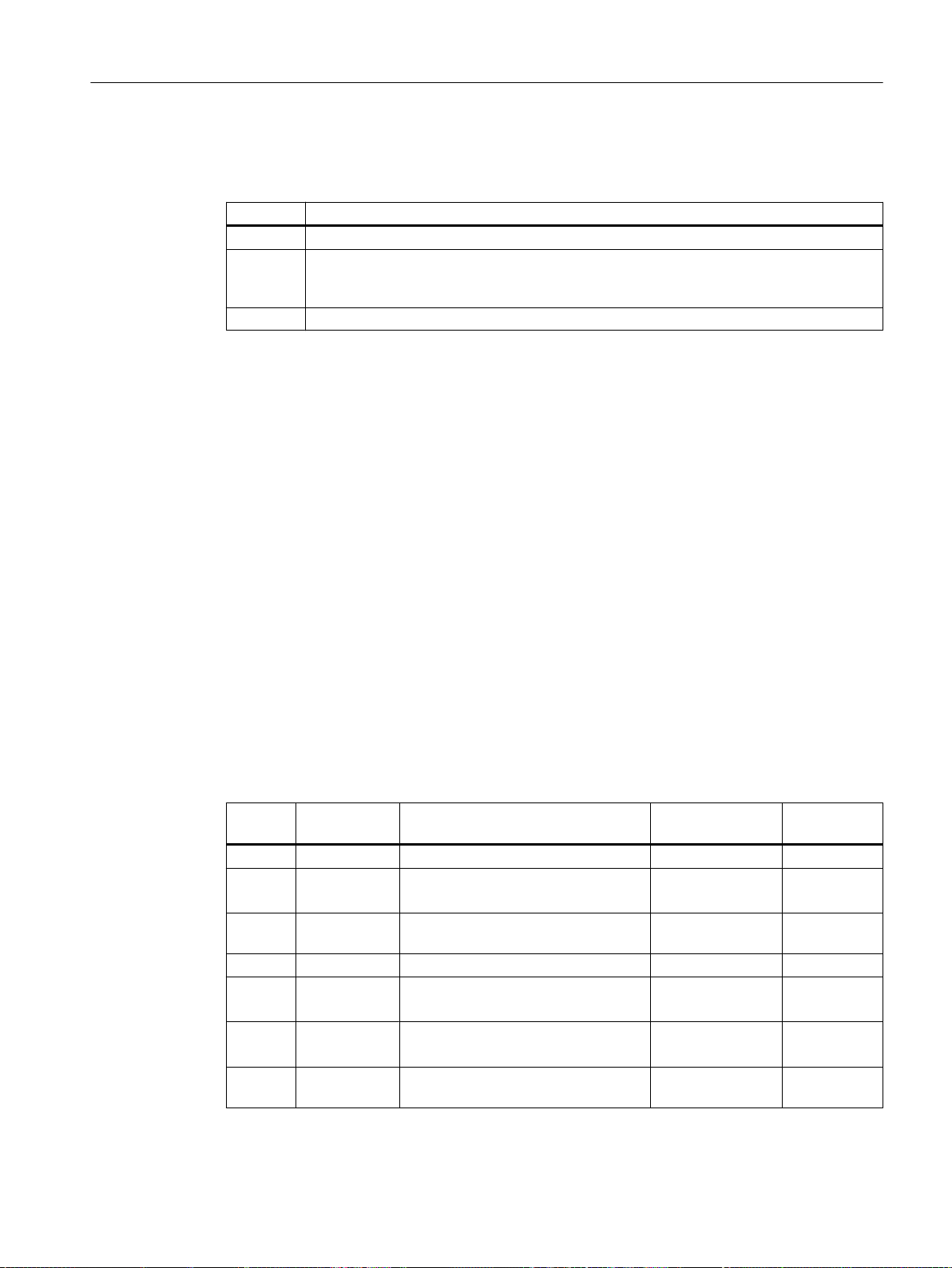

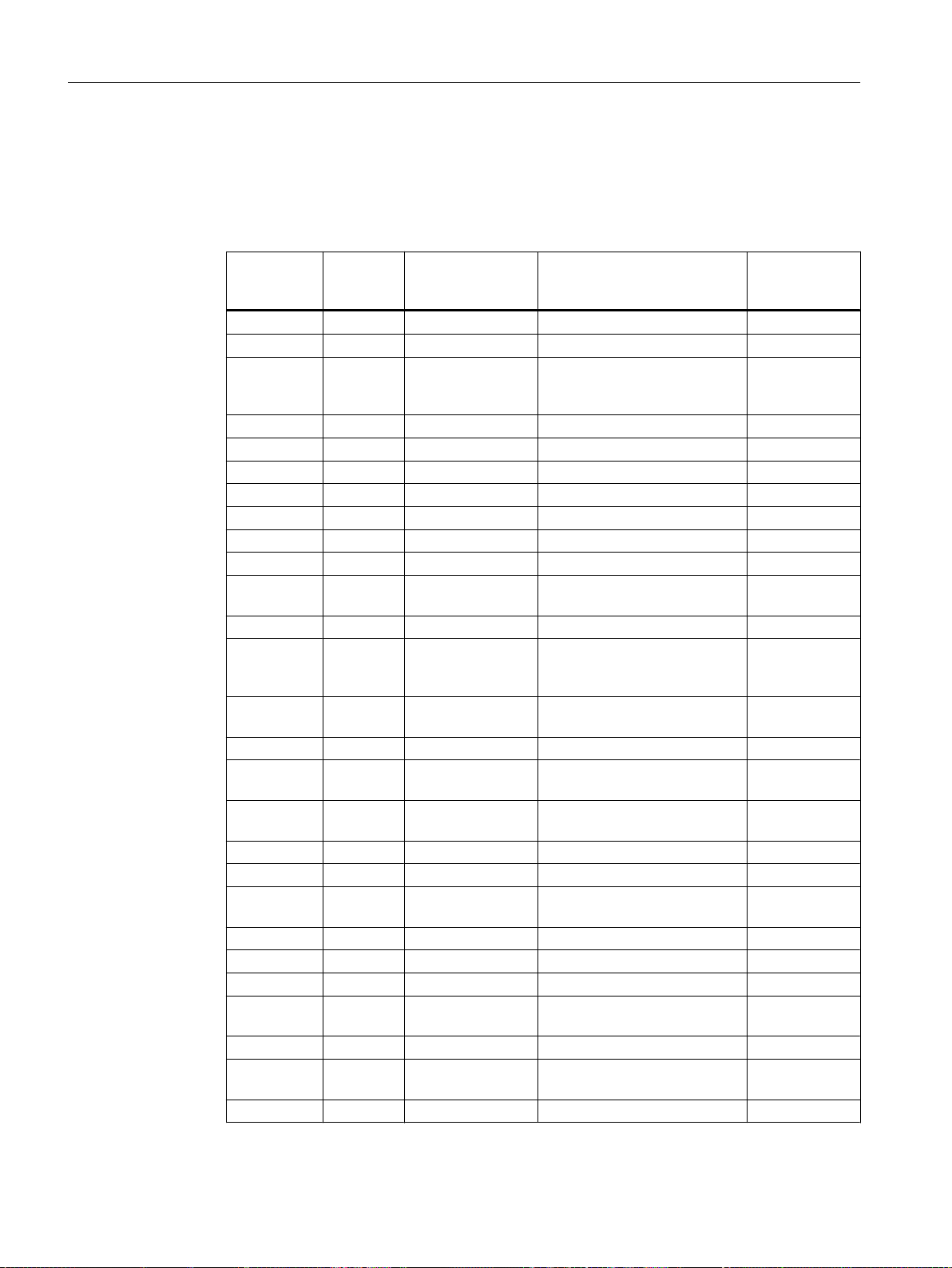

Hardware Component Version Used in Getting Started Other Version Possible

PG or PC with a standard

network card

Rack UR2 Yes

Power supply PS 407 4A Yes

CPU CPU 410 SMART Firmware V8.2 Yes

Crossover cable No

USB hardlock PCS 7 SMART V9.0 No (Hardlocks are version

Intel® PRO/1000 Yes

specific)

3

Use of other hardware components

If you are using other hardware components, you must place them in the relevant places. For

example, in HW Config, we recommend the usage of same components that are used in

Getting Started.

If you have different hardware, you can find additional information in the "

Manual

".

ES Configuration

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 17

Page 18

Requirements for Getting Started

3.2 Software requirements for Getting Started - Part 1

3.2 Software requirements for Getting Started - Part 1

Software requirements

● Information about installation and operation of the PCS 7 SMART software is available in

the

Process Control System PCS 7; PCS 7 Readme

● You will find information on the installation of the PCS 7 SMART software in these

documents:

Note

Engineering system

PC stations with a pre-installed Engineering System contain all the necessary software

components. However, you must transfer the license keys to PC stations.

Process Control System PCS 7; PCS 7 PC Configuration

file (see "Preface (Page 11)").

.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

18 Getting Started, 12/2017, A5E42181435-AA

Page 19

Requirements for Getting Started

3.3 Required configuration for Getting Started - Part 1

3.3 Required configuration for Getting Started - Part 1

If you have not purchased a bundle PC with the Getting Started, note the PC settings to be

performed for PCS 7 SMART.

For more information, refer to

Process Control System; PCS 7 PC Configuration

manual.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 19

Page 20

Requirements for Getting Started

3.3 Required configuration for Getting Started - Part 1

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

20 Getting Started, 12/2017, A5E42181435-AA

Page 21

PCS 7 SMART overview

4.1 PCS 7 SMART overview

Description

PCS 7 SMART is a powerful process control system with many automatic functions to assist

you during configuration of a plant. It enables you to create a project quickly and conveniently.

You will get to know about the automatic functions in this Getting Started document. PCS 7

SMART also provides many options for creating individual, project-specific solutions

customized to your requirements. These individual solutions are not part of this Getting Started

document. For more information, refer to the configuration manuals.

A PCS 7 SMART project includes the following objects:

● Hardware configuration

● Blocks

● CFC charts and SFC charts

These objects are always included regardless of the number of operator stations, modules,

and networks.

4

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 21

Page 22

PCS 7 SMART overview

4.2 PCS 7 SMART inclusions

4.2 PCS 7 SMART inclusions

PCS 7 SMART applications

You create a smart project on an Engineering Station (ES), which provides various

applications. All applications have simplified user interface to ease your operations and display

your configuration data. When you work through Getting Started project, you will use the

following applications:

● SIMATIC Manager - the central application and gateway to all other applications that you

use to create a PCS 7 SMART project. SIMATIC Manager is the starting point for creating

your entire project.

● HW Config - used to configure entire hardware of a system, for example, CPUs, power

supply, and communications processors.

● Continuous Function Chart (CFC) and Sequential Function Chart (SFC) Editors - used to

create CFCs and SFCs.

● Operator Station (OS) - used to configure the OS.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

22 Getting Started, 12/2017, A5E42181435-AA

Page 23

4.3 Introduction to SIMATIC Manager

SIMATIC Manager

SIMATIC Manager is the central application within the PCS 7 SMART system and is used to

access all the other applications to configure your PCS 7 SMART project.

SIMATIC Manager and all other applications are linked. For example, all the blocks you have

inserted into a CFC chart using the CFC editor.

This linking provides convenient access to all the data created in SIMATIC Manager and its

applications. For example, you can visualize a process tag from a CFC chart quickly and easily

when configuring the OS.

Due to the central function of SIMATIC Manager within PCS 7 SMART, it is worth taking time

to become familiar with its structure and functions.

PCS 7 SMART overview

4.3 Introduction to SIMATIC Manager

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 23

Page 24

PCS 7 SMART overview

4.4 Basic Structure of SIMATIC Manager

4.4 Basic Structure of SIMATIC Manager

Structure of SIMATIC Manager

SIMATIC Manager has a split window similar to Windows Explorer:

● In the left pane, a tree view is displayed with different content depending on the View

(Page 25) selected.

● In the right pane, the detail window, you can view details of the object you have selected

in the tree view.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

24 Getting Started, 12/2017, A5E42181435-AA

Page 25

4.5 Different views of SIMATIC Manager

Different views of SIMATIC manager

SIMATIC Manager provides you with three views. An important feature of these views is that

the objects they contain exist only once in reality but can be displayed and edited in the various

views.

The structural principle of the views is the same. The left pane displays the tree view and the

right pane displays the detail view. Each view has advantages for performing certain tasks:

● Component view : Displays the physical memory location of the individual objects. For

example, charts and blocks. In this view, you can view the mapping of blocks and charts

to the relevant AS.

● Plant view: Displays the exact hierarchical structure of your plant. You can divide the plant

into units and see which charts and which process pictures belong to which unit.

● Process object view : Displays the details of individual objects from the plant view. This is

applicable when you want to assign the same parameter value to a large number of objects

or if you want to add the same comments or make the same interconnections for these

objects.

PCS 7 SMART overview

4.5 Different views of SIMATIC Manager

The Getting Started step by step instructions guide you in selecting the SIMATIC Manager

views. PCS 7 SMART automatically saves all the work that you perform.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 25

Page 26

PCS 7 SMART overview

4.6 Procedure

4.6 Procedure

4.6.1 Opening SIMATIC Manager

Procedure

You can start SIMATIC Manager in two ways:

● Double-click the STEP 7 icon

Or

● On the "Start" menu, select Siemens Automation > SIMATIC > SIMATIC Manager.

When you start SIMATIC Manager, the previously opened project automatically appears.

on your desktop.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

26 Getting Started, 12/2017, A5E42181435-AA

Page 27

Initial work for the project

5.1 Planning the project

5.1.1 The "color_gs" project

Introduction

After a brief overview of PCS 7 SMART (Page 21), you can start creating the color_gs project.

Additional theoretical knowledge is required to understand these instructions. Hence, each

topic is provided with some background information.

Plant description

Only a small part of the entire plant will be configured for automatic dye production since

configuring the entire plant will be out of scope for this Getting Started project. This minimal

plant configuration will be integrated with the entire plant to understand the overall context in

a better way.

5

The individual phases of the production process are:

Phase I - Raw Materials

The liquid raw materials for the product are stored in two raw material tanks and are pumped

from these tanks to the reactors.

The solid raw materials are stored in three silos. Screw conveyors are used to measure out

the solid raw materials from the silos to a weigh hopper for weighing. Another screw conveyor

and a blower are used to blow the raw materials into one of the two mixing tanks in the correct

mixing ratio.

Phase II – Production

The required quantities of liquid material are fed from the two raw material tanks to Reactor 1

or Reactor 2 by means of valves. The solid materials from the mixing containers are transported

via screw conveyors to the reactors where they are blended using an agitator. The product is

produced in the reactors by agitating, heating and cooling the raw materials together with the

additives. Valves and actuators control the temperature in the reactors. If required, water from

a filtration plant can be introduced into the reactors using a flow controller.

Phase III - Holding Phase

The product is pumped to a holding tank for post processing. Here, it is stirred slowly and kept

at a constant temperature.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 27

Page 28

Initial work for the project

5.1 Planning the project

Phase IV – Filling

After the holding phase, the product is temporarily stored in a filling tank. From there, it is filled

into bulk tank trucks or small packing drums.

Phase V – Cleaning

The reactors, piping, valves, actuators, holding tank, and filling tank can be cleaned by a

cleaning-in-place (CIP) system. The resulting wastewater is collected in a separate effluent

tank and disposed.

5.1.2 Task list for Getting Started

Specific Configuration Task

You will now configure part of Phase I – Raw Materials:

Specifically, you will configure the storage of the liquid raw materials in two raw material tanks

and the pump control used to pump these raw materials to the two reactors.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

28 Getting Started, 12/2017, A5E42181435-AA

Page 29

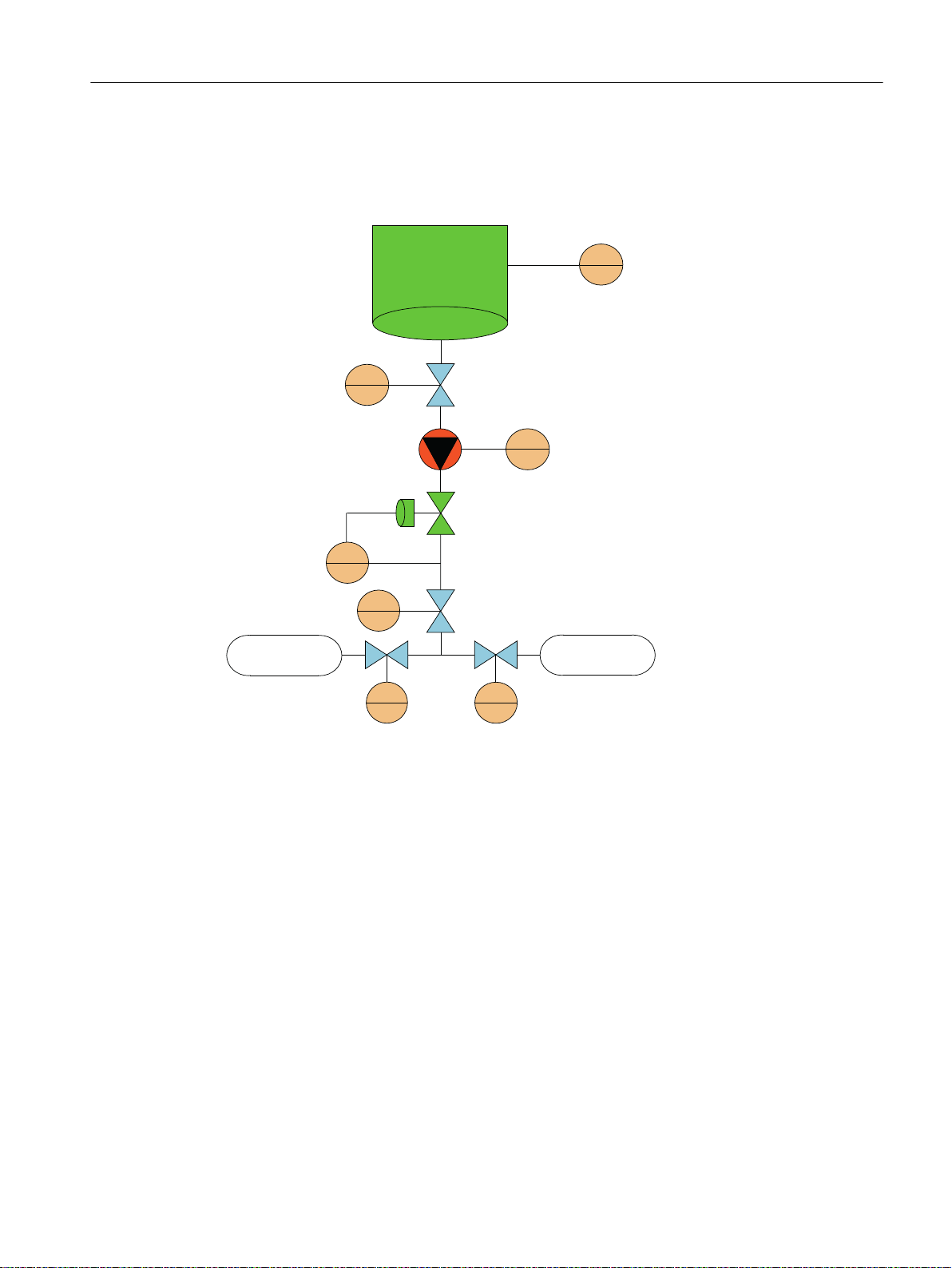

Piping and Instrumentation Diagram (P&ID)

5DZPDWHULDO

WDQN

5HDFWRU5HDFWRU

/,

1.

13

)&

1.

1.

1.

The piping and instrumentation diagram illustrates the precise sequence of the configuration

task and displays all the associated relevant process tags:

Initial work for the project

5.1 Planning the project

Explanation of the piping and instrumentation flow diagram

The terms used have the following meanings:

● LI111 (level indicator): measurement of the current fill level of the raw material tank.

● NK111 and NK112 (customer-specific identifier for valves): shut-off valves which must

always be opened for dosing raw materials.

● NP111 (customer-specific identifier for motors): pump that transports the raw material to

the reactors.

● NK113 or NK114 (customer-specific identifier for valves): valves, of which only one may

be open at a given time, in order to transport the raw material to either reactor 1 or reactor

2.

● FC111 (flow control) : actuator which regulates quantities for the raw material.

The states of the valves NK111 to NK114 can be displayed and monitored in the operator

station. You also have the possibility to influence the dosing via FC111.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 29

Page 30

'LUHFWFRQQHFWLRQXVLQJFURVVRYHUFDEOH

6LQJOHVWDWLRQV\VWHP

6,0$7,&6DXWRPDWLRQV\VWHP

(QJLQHHULQJVWDWLRQ(6RSHUDWRU

VWDWLRQ26

Initial work for the project

5.1 Planning the project

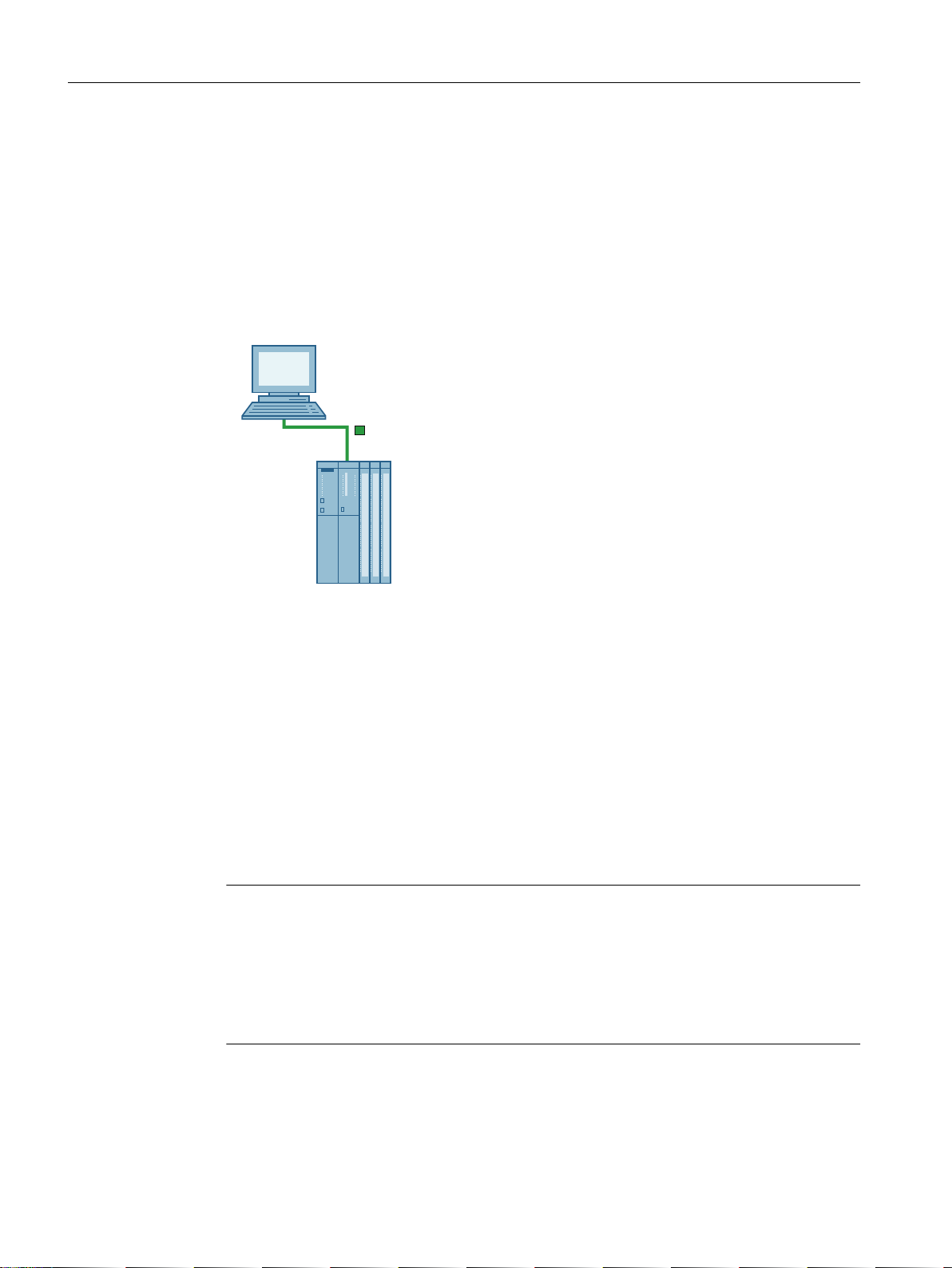

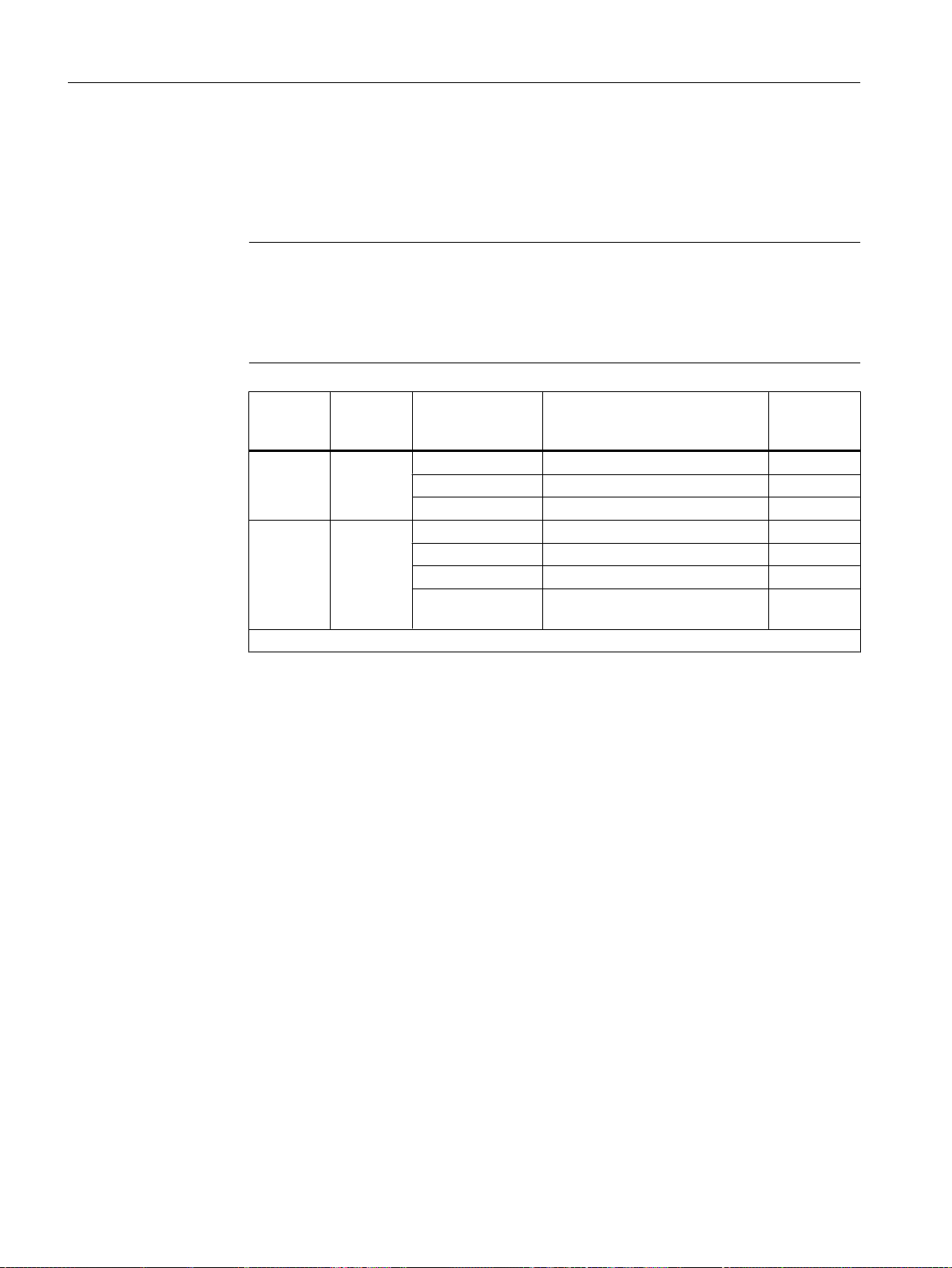

5.1.3 System configuration for the 'color_gs' project

Structure

The color_gs project will be implemented on a minimum system consisting of a single

automation system with a combined engineering station and operator station. The operator

station is designed as a single station system. The following figure illustrates the system

configuration.

Description

In Getting Started, you will build a control system which contains the following components:

● Automation system (AS):

The individual components are described in the section "Requirements for performing the

Getting Started".

● Program, which controls the "color_gs" plant:

You create this program in the ES and download it to the CPU. The CPU executes the

loaded program and displays the process values.

● Operator station (OS):

The plant operator controls and monitors the plant during runtime. You can create the

process picture seen by the plant operator on the OS.

Note

Plant configuration and hardware settings that result from it need to be especially adapted

to the requirements of this Getting Started.

When you configure a real project, you will use more automation systems and also operate

the engineering station and operator station(s) on several computers. In this case, the

hardware settings will be more complex. This will no longer correspond to the Getting

Started descriptions.

30 Getting Started, 12/2017, A5E42181435-AA

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Page 31

5.1.4 Configuration tasks overview

Configuration Sequence

You will configure the system components in the following configuration steps:

● Setting the Parameters for the Network (Page 32)

● Creating the Project (Page 34)

● Configuring the Stations (Page 41)

● Working in the Plant Hierarchy (Page 52)

● Creating CFC Charts (Page 61)

● Creating SFC Charts (Page 107)

● Compiling, Downloading, and Testing Charts (Page 129)

● Configuring operator stations (Page 141)

● Creating the Process Pictures (Page 153)

● Working in Process Mode (Page 171)

Initial work for the project

5.1 Planning the project

● Performing the Additional Task (Page 185)

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 31

Page 32

Initial work for the project

5.2 Preparational settings for the network

5.2 Preparational settings for the network

5.2.1 Network and Interface settings

Settings

Before you configure the color_gs project, perform the following settings:

● Network adapter settings on the configuration console (Page 32)

PCS 7 SMART automatically identifies the network adapters installed on your computer

during startup. You can use this information to program the interfaces on the configuration

console.

Note

These settings are usually made immediately after PCS 7 SMART is installed. Verify the

settings and make necessary modifications if required.

● Selecting the network adapter

Select the network adapter used to communicate.

5.2.2 Procedure

5.2.2.1 Configuration console settings

Prerequisites

● All the necessary hardware components must be inserted on the rack and switched on.

● The crossover cable must be connected between the 3Com network adapter of your ES

computer and the Ethernet connection of the CPU.

Procedure

1. On the "Start" menu, Select Siemens Automation > SIMATIC > SIMATIC NET >

Communication Settings. The "Siemens Communication Settings" dialog box is displayed.

2. Open the "Modules" folder in the tree view.

3. Select the network adapter by which communication between the automation system and

the OS takes place.

4. Double-click the "General" entry in the detail view. The detail view for "General" is displayed.

5. In the detail view, select the "Configured mode" entry from the "Mode of the module" dropdown list.

6. Click "Apply". This button is only active if you have made changes. Your settings are now

saved. The network adapter is activated now.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

32 Getting Started, 12/2017, A5E42181435-AA

Page 33

Initial work for the project

5.2 Preparational settings for the network

7. Select the "Access points" folder in the tree view.

8. Double-click the "S7ONLINE" access point in the detail view. The detail view for "Access

point" is displayed.

9. In the "Associated interface parameter assignment" drop-down list, select "PC internal.local.

1". Click "Apply" to save your settings.

10.Specify "PG mode" as the "Mode of the module" for all other network adapters.

11.Close the configuration console.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 33

Page 34

Initial work for the project

5.3 Creating the project

5.3 Creating the project

5.3.1 "New Project" Wizard usage

PCS 7 "New Project" Wizard

The PCS 7 New Project wizard starts automatically when you open SIMATIC Manager using

default settings. You can enable or disable this option in the PCS 7 New Project wizard.

The New Project wizard guides you in creating a new project and offers default settings. The

PCS 7 wizard automatically creates various objects according to the default settings or user

defined settings.

color_gs objects

The following objects are essential for the color_gs project:

● Hardware objects: SIMATIC stations, for example a SIMATIC 400 station for the AS, a

SIMATIC PC station for the OS.

● Hierarchy folders representing the hierarchy levels of the plant structure. The number of

hierarchy folders created corresponds to the setting you enter in the PCS 7 wizard.

● A CFC chart

● An SFC chart

● One picture per plant hierarchy folder

● A master data library

5.3.2 Background knowledge for the PCS 7 Wizard

What happens in the background when a new project is created?

The next two sections provide you with some theoretical background knowledge for the

PCS 7 New Project wizard. Two objects that are of great importance for working with PCS 7

SMART are:

● Multiproject

● Master data library

How does a multiproject function?

When you create a new project with the PCS 7 wizard, a multiproject is created automatically.

A multiproject consists of a number of single projects.

In the context of the color_gs project, the multiproject is structured as follows: The multiproject

represents the entire plant and all of the single projects within this multiproject based on the

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

34 Getting Started, 12/2017, A5E42181435-AA

Page 35

Initial work for the project

5.3 Creating the project

individual phases of the process for producing paint. Since you are configuring only one phase

of the overall plant in this Getting Started, your multiproject contains only a single project.

Multiprojects give you an advantage to distribute single projects to different configuration

engineers who can then edit them. Once the configuration of the single projects is complete,

they can be merged to form a complete project.

In Getting Started, although you will be working within a multiproject, you will not be using the

wide range of functions provided by this multiproject engineering.

Detailed information is available in the

Manual.

What is a master data library?

When you create a new project with the PCS 7 wizard, a master data library is created

automatically. You store all the blocks required for the entire project in this library. Before you

create a CFC, for example, you first store all the standard blocks you will insert in this CFC in

your master data library.

A master data library provides the following advantages:

● When you archive a project, the master data library is automatically archived along with it.

● You can also adapt the blocks and use copies (instances) of these adapted blocks

repeatedly in the project.

In the context of a multiproject, the master data library is important because it allows you to

provide all the project engineers who are involved with blocks of a defined version so that you

can ensure that only this version is used in the project.

Process Control System PCS 7; Engineering System

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 35

Page 36

Initial work for the project

5.3 Creating the project

5.3.3 Procedure

5.3.3.1 Creating the color_gs Project

Procedure

The PCS 7 Wizard assists you in creating the "color_gs" project. To create the "color_gs"

project:

1. Open SIMATIC Manager.

2. Select File > 'New Project' Wizard.

The "PCS 7 Wizard: 'New Project'" is displayed.

3. In step 2(4) "Which CPU are you using in your project?", in the "CPU" drop-down list, select

the required CPU.

All available automation systems of the selected CPU type is listed with MLFB numbers

and brief descriptions.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

36 Getting Started, 12/2017, A5E42181435-AA

Page 37

Initial work for the project

5.3 Creating the project

4. In the "Bundle" section, select the required "MLFB" entry, and then click "Next".

5. In Step 3(4) "Which objects are you still using?", perform the following settings:

– Select "4" from the "Number of levels" drop-down list.

– Under "AS objects", verify that the "CFC" and "SFC" check boxes are selected.

– Select the "PCS 7 OS" check box under "OS objects". The "Single station system" option

is automatically selected.

6. Click "Next".

7. In Step 4(4), enter the name "color_gs_prj" in the "Directory name" box and accept the

default storage location.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 37

Page 38

Initial work for the project

5.3 Creating the project

8. Click "Preview >>>" to see a preview of your current configuration status.

This preview corresponds to the appearance of the project in SIMATIC Manager.

9. Click "Finish".

Note

● When you start SIMATIC Manager, the previously opened project is displayed, to close the

previous project and to open the "color_gs_prj" project, follow the instructions provided in

the section "How to close and open the "color_gs" project (Page 39)".

● To activate different views, follow the instructions provided in the section "How to work with

the various views (Page 39)".

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

38 Getting Started, 12/2017, A5E42181435-AA

Page 39

Result

The project is displayed in the plant view of the SIMATIC Manager as follows:

5.3.3.2 Opening and Closing the "color_gs" Project

Procedure for Closing a Project

1. If you have other projects open in SIMATIC Manager, close these projects.

Initial work for the project

5.3 Creating the project

2. Select Window > [Name of project] and select the project you want to close.

SIMATIC Manager displays the project in the foreground.

3. Select File > Close. The project is closed.

Procedure for Opening a Project

1. Open SIMATIC Manager.

2. If your project "color_gs" does not open automatically, select File > Open. The "Open

Project" dialog box is displayed.

3. Select the "Multiprojects" tab and select "color_gs_prj_MP".

4. Click "OK". The project with the associated master data library is displayed.

5.3.3.3 How to Work in the Various Views

Introduction

Once you have opened your project in SIMATIC Manager, you can display the project in various

views and switch between these views.

Procedure

Select View > [Name of the desired view] in SIMATIC Manager:

● Component view

● Plant view

● Process object view

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 39

Page 40

Initial work for the project

5.3 Creating the project

or

Select Window > [Name of the project (name of the view)] if you have already opened several

projects.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

40 Getting Started, 12/2017, A5E42181435-AA

Page 41

5.4 Configuring the stations

5.4.1 Configuration overview

Overview

Configure the control system components which the PCS 7 wizard: 'New Project' has

automatically inserted. This includes components such as the AS, the OS, and the associated

connections.

For this purpose you must perform the following configuration steps:

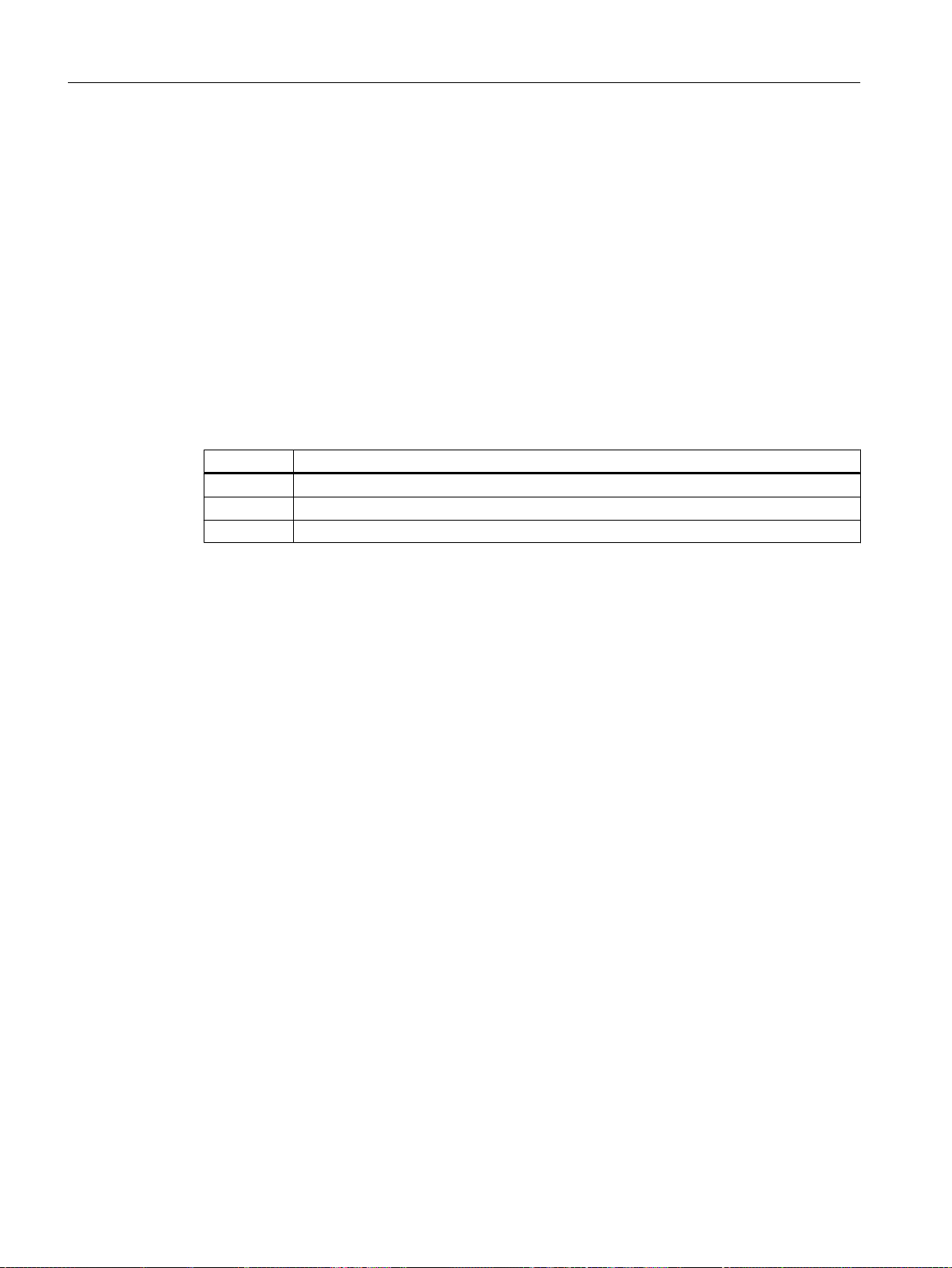

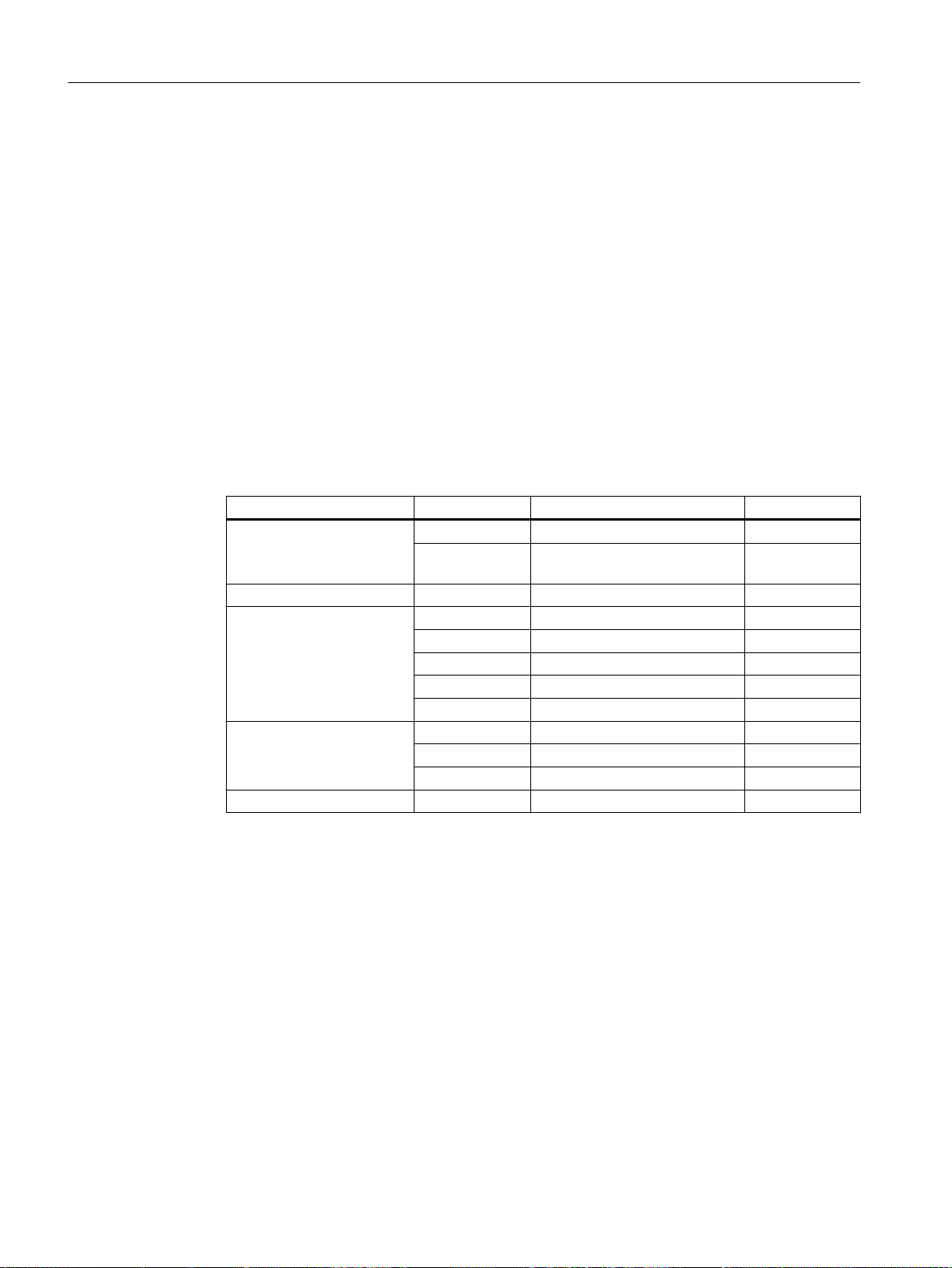

Step Action

1 Configure AS (Page 42)

2 Rename PC station (Page 44)

3 Configure OS (Page 45)

4 Set connection in NetPro (Page 47)

5 Download hardware configuration (Page 50)

Initial work for the project

5.4 Configuring the stations

Local PC station

The plant configuration for this Getting Started is a single station system; the ES and OS are

on one computer. In this way, the local PC station you configure represents the ES and the

OS at the same time.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 41

Page 42

Initial work for the project

5.4 Configuring the stations

5.4.2 Procedure

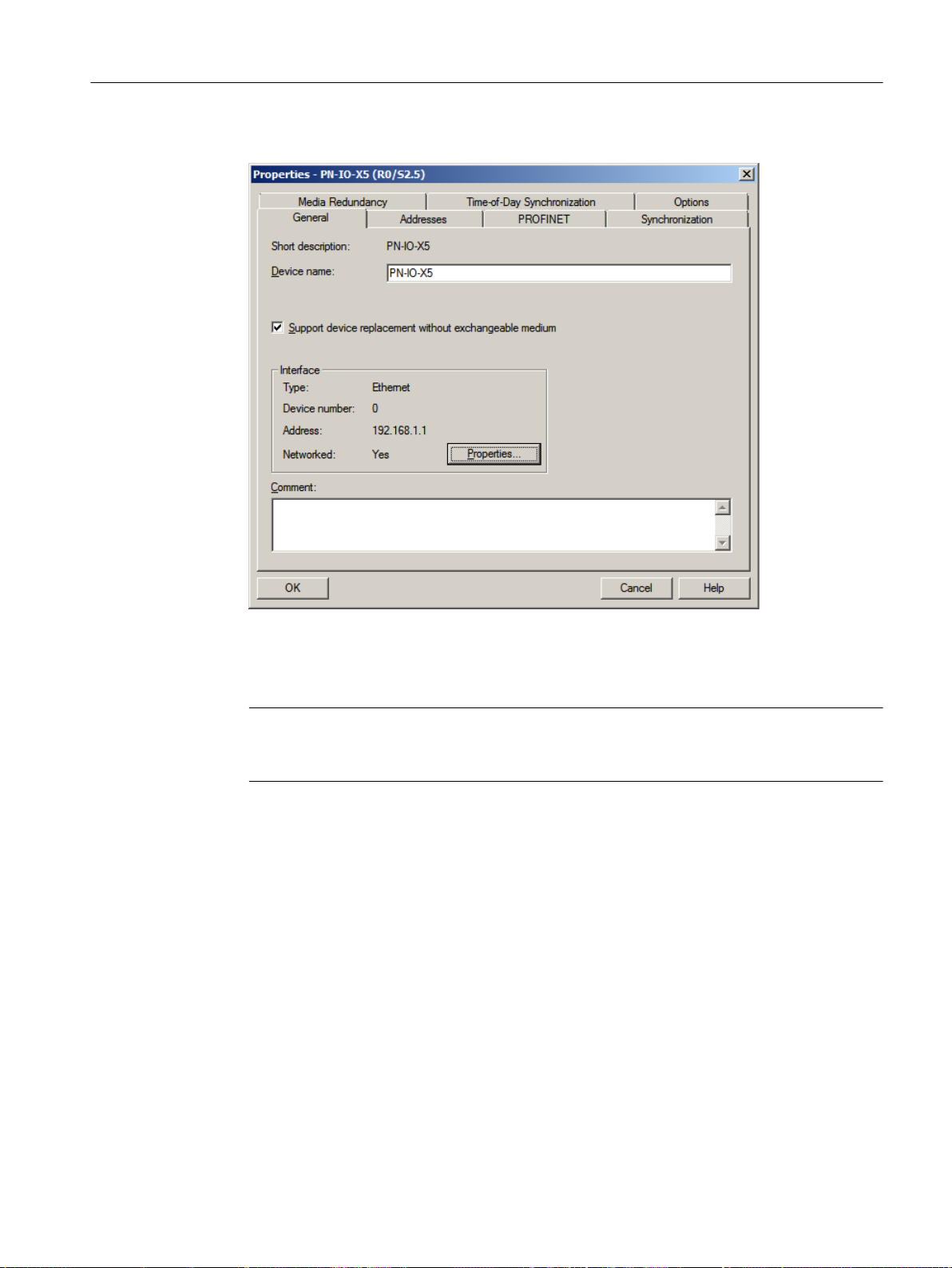

5.4.2.1 AS configuration

Procedure

1. In SIMATIC Manger, in "Component View", select "color_gs_prj_MP\color_gs_prj_Prj

\SIMATIC 400(1)" folder in the tree view.

2. Select "Hardware" object in the detail view. Click Edit > Open Object.

HW Config opens and the hardware structure of your plant is displayed.

Note

Select View > Catalog if the hardware catalog is not displayed.

The hardware catalog opens and the "PCS7_Vxx_SMART" profile is enabled.

3. Select the X5 slot (PN-IO-X5 module) and then select the menu command Edit > Object

Properties.

The "Properties - PN-IO-X5(R0/S2.5)" dialog box is displayed.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

42 Getting Started, 12/2017, A5E42181435-AA

Page 43

4. In the "General" tab, in the "Interface" group, click "Properties".

Initial work for the project

5.4 Configuring the stations

The "Properties - Ethernet interface PN-IO-X5(R0/S2.5)" dialog box is displayed.

5. In the "IP address" box, enter an available IP address within the address range of your

computer.

Note

To find an appropriate IP address, in SIMATIC Manager, use the PLC > Edit Ethernet

Node option.

6. In the "Subnet mask" box, enter the correct subnet mask for your computer.

7. Click "New" to create a new network connection. The CPU uses this network connection

to communicate with the ES.

The "Properties - New subnet Industrial Ethernet" dialog box is displayed.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 43

Page 44

Initial work for the project

5.4 Configuring the stations

8. Click "OK" to apply all the default settings.

The "Ethernet(1)" entry is entered in the "Subnet" list and is already selected.

9. Click "OK".

Your settings are applied and the dialog box closes.

10.Click "OK".

Your settings are applied and the dialog box closes.

11.Select Station > Save and Compile.

12.Close HW Config.

5.4.2.2 Renaming the PC Station

Prerequisites

● The color_gs project is open in SIMATIC Manager.

● The component view is activated.

Procedure

1. Select the "color_gs_prj_MP\color_gs_prj_Prj\SIMATIC PC Station(1)" object in the tree

view.

2. Click Edit > Object Properties. The "Properties - SIMATIC PC Station" dialog box is

displayed.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

44 Getting Started, 12/2017, A5E42181435-AA

Page 45

Initial work for the project

5.4 Configuring the stations

3. In the "Name" input box, enter the name of the local computer as it is displayed in the

network.

Note

To find the computer name, select Control Panel > System and view the "Computer name,

domain, and workgroup settings" section.

4. In the "Computer name" area, select the "Computer name identical to PC station name"

check box.

The computer name is automatically entered in the "Computer name" field at the bottom of

the dialog box.

5. Click "OK".

Your settings are applied and the dialog box closes.

The component view identifies the PC station icon with a yellow arrow.

Note

If the PC station is not labeled with a yellow arrow, press F5 to refresh the screen.

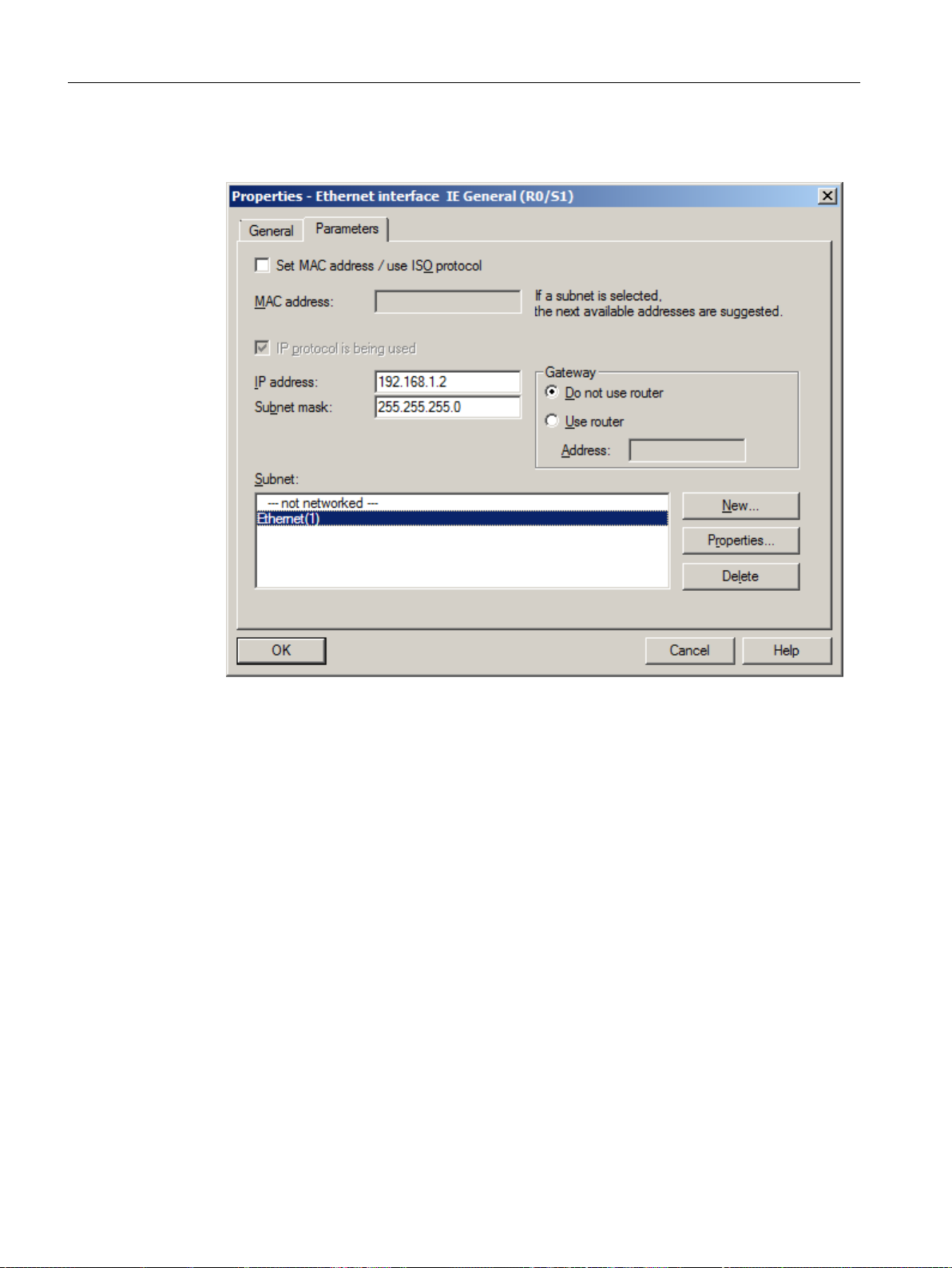

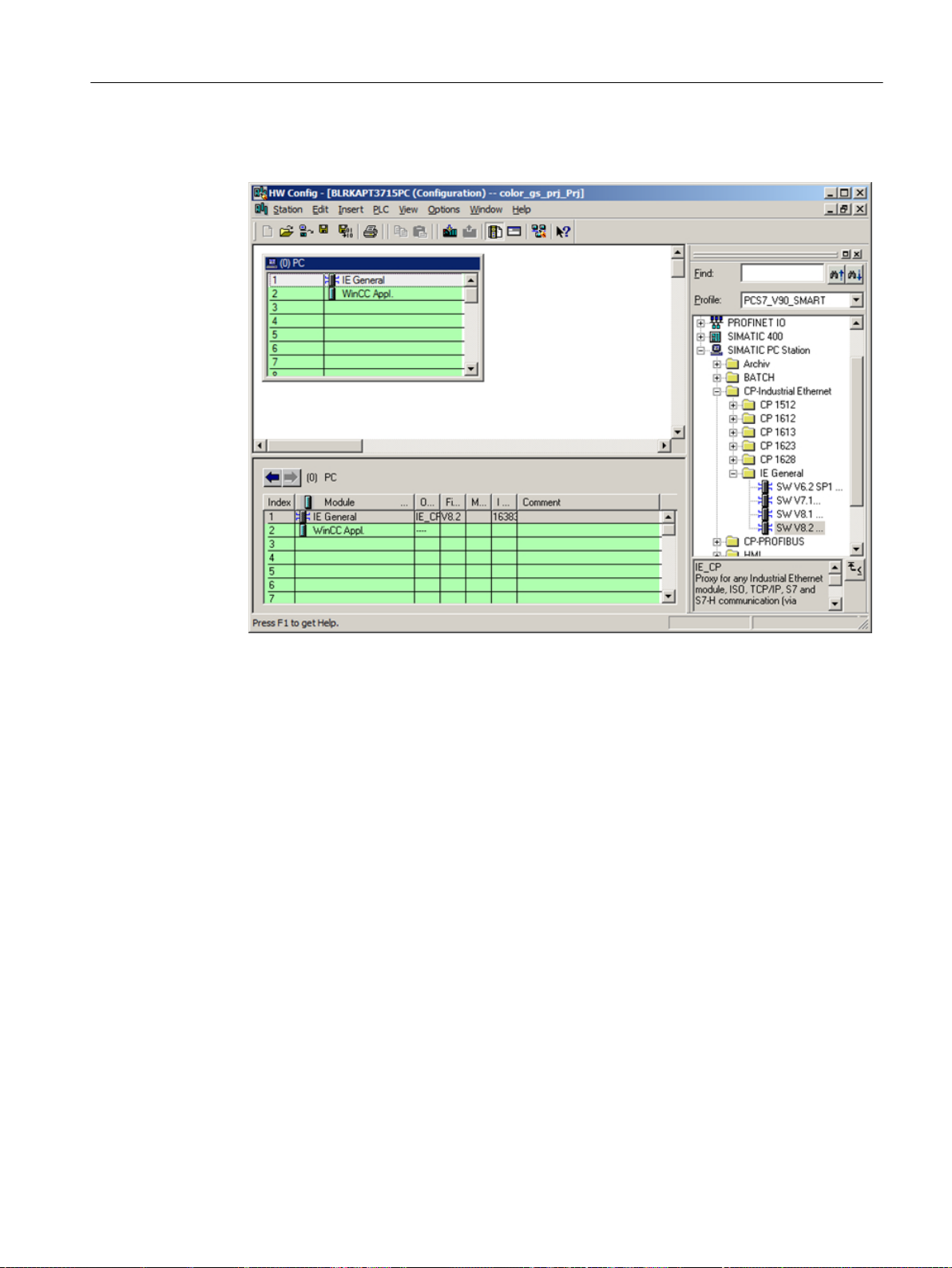

5.4.2.3 Configuring the PC station of the OS

Prerequisites

● The color_gs project is open in SIMATIC Manager.

● The component view is activated.

Procedure

1. Select the "color_gs_prj_MP\color_gs_prj_Prj\[name of the PC station]" folder in the tree

view.

2. Select the "Configuration" object in the detail view, and select Edit > Open Object.

HW Config opens and the OS components are displayed.

HW Config opens with the settings you made when configuring the AS:

– The hardware catalog is open.

– The "PCS7_Vxx" profile is active.

3. Select the following CP from the hardware catalog: "SIMATIC PC Station\CP Industrial

Ethernet\IE General/SW Vxx..." and move it to slot 1 using drag-and-drop.

The "Properties - Ethernet Interface IE General (R0/S1)" dialog box is displayed.

4. Verify that the "Set MAC address/use ISO protocol" check box is not selected.

5. Verify that the "IP protocol is being used" check box is selected.

6. In the "IP address" box, enter the IP address of your computer.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

Getting Started, 12/2017, A5E42181435-AA 45

Page 46

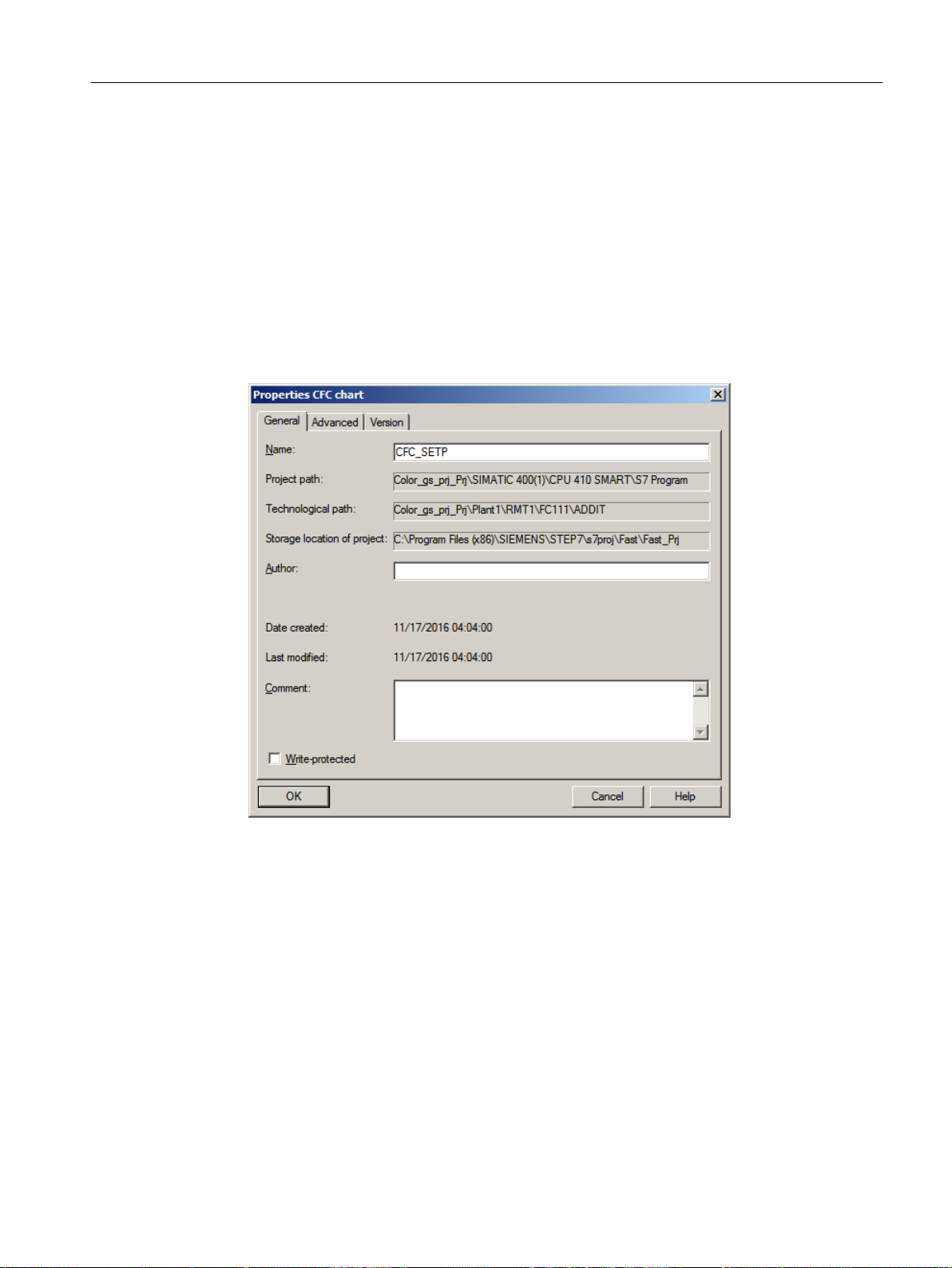

Initial work for the project

5.4 Configuring the stations

7. Select "Ethernet(1)" from the "Subnet" list.

This is the connection that you have already configured for the CPU.

PCS 7 SMART Getting Started - Part 1 (V9.0 with APL)

46 Getting Started, 12/2017, A5E42181435-AA

Page 47

8. Click "OK" to apply your settings.

The dialog box closes and the HW Config window is displayed.

Initial work for the project

5.4 Configuring the stations

9. Select Station > Save and Compile.

10.Close HW Config.

5.4.2.4 NetPro settings

Prerequisites

● The color_gs project is open in SIMATIC Manager.

● The component view is activated.

Procedure

1. Select the "color_gs_prj_MP\color_gs_prj_Prj\[name of the local computer]\WinCC Appl."

object in the tree view.

2. Select "Connections" in the detail view. Now, select Edit > Open Object.

NetPro opens.

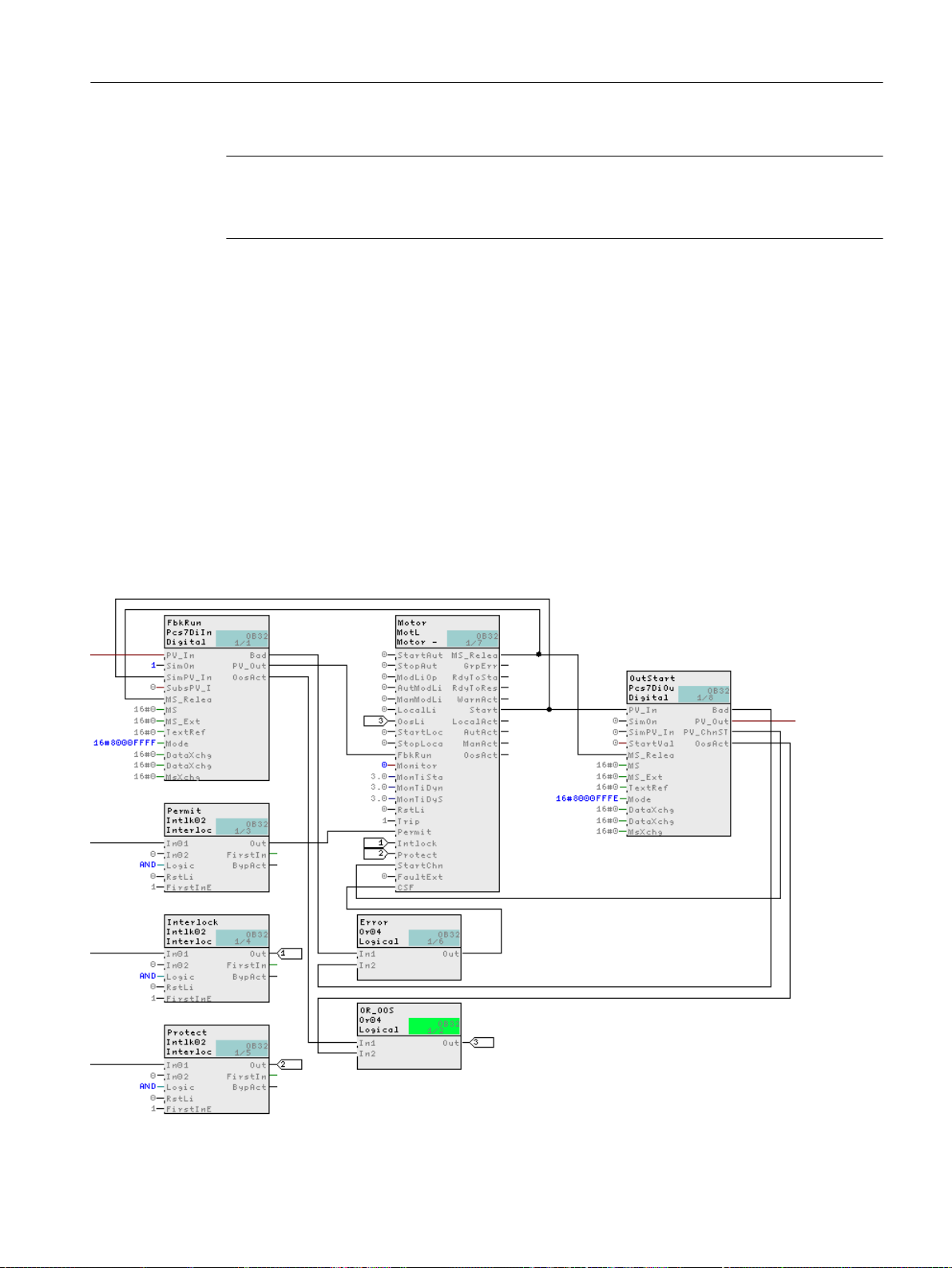

3. Select the "WinCC Appl." object for the SIMATIC PC station.