Siemens SIMATIC PCS 7 FOUNDATION Fieldbus Commissioning Manual

SIMATIC

Process Control System PCS 7

FOUNDATION Fieldbus

Valid for the SIMATIC PCS 7 Process Control System

software package as of V8.1 SP1 including SIMATIC

PDM V8.2 SP1

Security information

1

Commissioning Manual

Introduction

Basics of the FOUNDATION

Fieldbus

System planning

Engineering

Commissioning

Redundancy and system

changes during operation

2

3

4

5

6

7

02/2015

A5E32711026-AC

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E32711026-AC

Ⓟ 04/2015 Subject to change

Copyright © Siemens AG 2014 - 2015.

All rights reserved

Table of contents

1 Security information......................................................................................................................................5

2 Introduction...................................................................................................................................................7

3 Basics of the FOUNDATION Fieldbus........................................................................................................11

3.1 Device integration with EDD..................................................................................................12

3.2 Device addresses...................................................................................................................14

3.3 Block model of device parameters.........................................................................................15

3.4 Capability levels (device variants)..........................................................................................18

3.5 Contact partner......................................................................................................................19

4 System planning.........................................................................................................................................21

4.1 Nodes in the FOUNDATION Fieldbus....................................................................................21

4.2 Configuration..........................................................................................................................22

5 Engineering................................................................................................................................................25

5.1 Prepare..................................................................................................................................26

5.1.1 How to integrate a device description....................................................................................26

5.2 Configuring.............................................................................................................................27

5.2.1 How to prepare a FOUNDATION Fieldbus for FF devices....................................................27

5.2.2 How to place FF devices on the FOUNDATION Fieldbus.....................................................29

5.2.3 Checking the bus parameters................................................................................................33

5.2.4 Additional notes on configuration...........................................................................................34

5.2.5 How to configure FF-internal interconnections (Control in the field)......................................35

5.2.6 “Interconnection Editor" dialog box........................................................................................37

5.2.7 Adding deleted default blocks................................................................................................39

5.2.8 How to replace an FF device.................................................................................................39

5.3 Parameter assignment...........................................................................................................40

5.3.1 How to assign parameters of the FF devices.........................................................................40

5.3.2 Bus parameters......................................................................................................................42

5.3.3 How to assign bus parameters...............................................................................................47

5.3.4 How to plan the macrocycle...................................................................................................49

5.4 Using the applications............................................................................................................52

5.4.1 Overview................................................................................................................................52

5.4.2 Identifying FF devices with SIMATIC PDM............................................................................53

5.4.3 Specifying the device identification of the FF devices (TAG name and address)..................55

5.4.4 Editing symbols (symbolic names).........................................................................................56

5.4.5 Configuring interconnections to the FF devices.....................................................................57

5.4.6 Configuring the operator station.............................................................................................58

6 Commissioning...........................................................................................................................................59

6.1 Compile and download...........................................................................................................59

6.1.1 Introduction............................................................................................................................59

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 3

Table of contents

6.1.2 Downloading objects in the FF segment................................................................................60

6.2 Diagnostics.............................................................................................................................63

6.2.1 "Modes" and "Status" menu commands.................................................................................63

6.2.2 Performing diagnostics...........................................................................................................65

7 Redundancy and system changes during operation..................................................................................67

7.1 Redundancy...........................................................................................................................67

7.2 System changes during operation..........................................................................................68

Index...........................................................................................................................................................71

FOUNDATION Fieldbus

4 Commissioning Manual, 02/2015, A5E32711026-AC

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly that

you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should also

be considered. For more information about industrial security, visit http://www.siemens.com/

industrialsecurity.

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. For more information, visit http://support.automation.siemens.com.

1

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 5

Security information

FOUNDATION Fieldbus

6 Commissioning Manual, 02/2015, A5E32711026-AC

Introduction

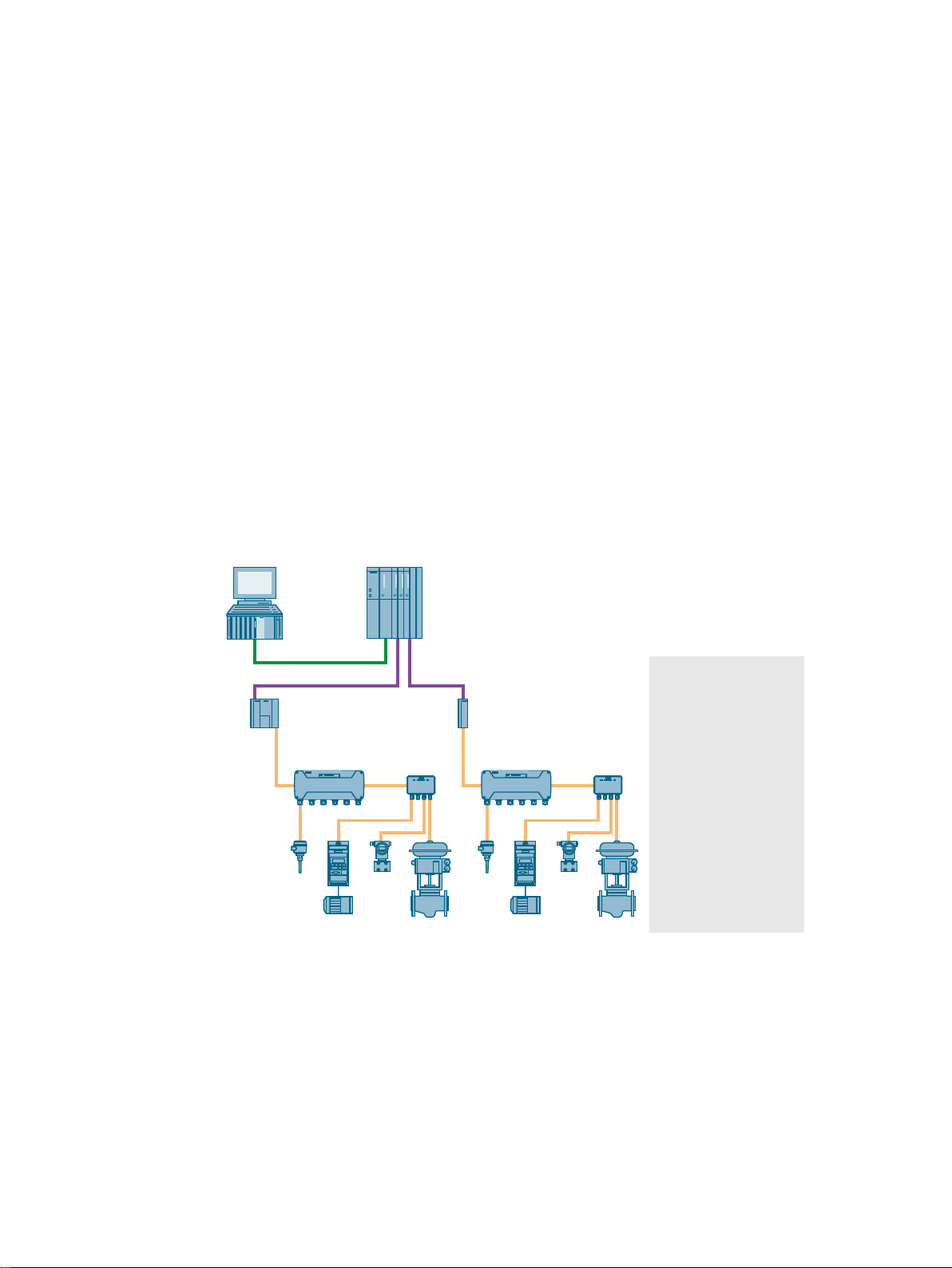

))VHJPHQW

%XVOLQN

&RPSDFW))OLQN

%XVOLQNV%XVOLQN

))OLQN

$FWLYHILHOGGLVWULEXWRUV

))VHJPHQW

)LHOGGHYLFHV

))VHJPHQW

352),%86'3

(WKHUQHW

SIMATIC PCS 7 provides the option of integrating field devices on FOUNDATION Fieldbus

H1 (hereafter referred to simply as FF). FF devices are generally connected to a SIMATIC

station via a bus link on PROFIBUS DP (e.g. FF Link). Bus links are gateways between bus

systems and enable the communication connection of the bus systems.

The following bus links are typically used for the communication between PROFIBUS DP and

FOUNDATION Fieldbus in PCS 7 systems.

● FF Link

● Compact FF Link

Examples for configuration of FF segments in PCS 7

The display shows an example of the connection of FF devices to the automation system. The

additional use of the active field distributor enables mutual decoupling in case of FF device

faults.

2

SIMATIC PCS 7 supports the connection of FF devices

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 7

SIMATIC PCS 7 supports the connection of FF devices by way of the following functions:

● Central engineering without additional tools

● Import of the electronic device descriptions (EDD) of FF devices

(you can find additional information about this in the section "Device integration with EDD

(Page 12)")

Introduction

● Channel blocks of the PCS 7 library: Advanced Process Library (APL)

● PCS 7 Asset Management

Basic knowledge required

This documentation is intended for personnel working in the fields of configuration,

commissioning, and service.

Basic knowledge of the general use of the PC/programming device and of the use of the

Windows operating system is required.

Knowledge of the functions and configurations of the following products is required:

● SIMATIC PCS 7

● SIMATIC S7 (S7-400, STEP 7)

● SIMATIC NET

● SIMATIC PDM

Basic knowledge of the FOUNDATION Fieldbus is required.

An understanding of the operating instructions of the bus link is required.

Information for FF users

Users who have configured only FF up to now can acquire the necessary knowledge of PCS

7 with the help of the PCS 7 documentation. You can find an introduction to working with PCS 7

in the

Conventions

Some of the information in this documentation applies to several components. To ensure that

the products to which such information applies are clearly identifiable, we have used the

following designations:

Designation Validity

Bus link The associated information pertains to the components you can order as a

FF Link The associated information pertains to the FF Link. The following modules

Compact FF Link The associated information pertains to the Compact FF Link. The following

SIMATIC PCS 7 Process Control System; PCS 7 - Getting Started

gateway from PROFIBUS DP to the FOUNDATION Fieldbus for an automa‐

tion system.

are used in this bus link:

● IM 153-2 FF

● FDC 157

The FF Link can be configured redundantly.

module is used in this bus link: Compact FF Link (IM 655-5 FF)

The Compact FF Link can be configured redundantly.

documentation.

FOUNDATION Fieldbus

8 Commissioning Manual, 02/2015, A5E32711026-AC

Changes compared to older versions

Below, you can find an overview of the most important changes in the documentation compared

to the previous version:

As of PCS 7 V8.1 SP1

● Use of the "Compact FF Link (IM 655-5 FF)" bus link

As of PCS 7 V8.1

SIMATIC PCS 7, together with SIMATIC PDM as of V8.2, is certified for Class 61 hosts (Host

Interoperability Support Test, Host: Profile Classes 61a / 61b).

The following FF functions can be implemented with it for example:

● Cross block references (device level access)

● Multiple capability levels

● Instantiable blocks

Introduction

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 9

Introduction

FOUNDATION Fieldbus

10 Commissioning Manual, 02/2015, A5E32711026-AC

Basics of the FOUNDATION Fieldbus

FOUNDATION Fieldbus (FF) and PROFIBUS PA operate according to IEC 61158-2. The

communication on the fieldbus and the voltage supply of the bus nodes are combined in one

shielded two-wire cable. Up to 32 bus nodes are possible on one FF segment (bus link +

maximum of 31 field devices). Data packets are modulated and transmitted on the supply

voltage for the fieldbus nodes. The transfer rate is 31.25 Kbps.

The most important distinctions between PROFIBUS PA and FOUNDATION Fieldbus

Licensing

● You need the "PDM Foundation Fieldbus" license key to work with SIMATIC PDM.

Operating mode

● PROFIBUS PA devices are operated in master/slave mode.

● FF devices are operated in publisher/subscriber mode.

Connection to PROFIBUS DP

● PROFIBUS PA devices are connected to up to five FDC 157 DP/PA couplers via DP/PALink (redundancy with 2 fieldbus couplers possible).

3

● FF devices are connected to the automation system via a bus link. The following bus links

are approved for PCS 7:

– FF Link

Configuration with an IM 153-2 FFinterface module and FDC 157 fieldbus coupler

(redundancy with 2 fieldbus couplers possible)

– Compact FF Link

Configuration with Compact FF Link (redundancy with 2 Compact FF Link possible)

Communication with the automation system

● PROFIBUS PA devices only communicate via the automation system. An exception to this

rule is the direct access to a PA device.

● FF devices can communicate on the FF segment without involvement of the automation

system. The name of this function is "Control in the field" (CiF). CiF enables technological

function between FF devices.

Terms used for FOUNDATION Fieldbus (FF)

Publisher and Subscriber

In the time period during which an FF device sends data to the FF, it is referred to as the

Publisher.

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 11

Basics of the FOUNDATION Fieldbus

3.1 Device integration with EDD

In the time period during which an FF device reads data from the FF, it is referred to as the

Subscriber. The schedule defines when a Publisher sends data and when a Subscriber

receives data.

Client and Server

The client-server principle is used for acyclic services.

Communication types

Two types of communication are used with FF:

● Cyclic communication

Cyclic communication is defined in the schedule. It includes tasks such as closed-loop

control of process values (control functions) and operator control and monitoring functions.

● Acyclic communication

Acyclic communication is used for transmitting unscheduled information. Examples of this

information are:

– Maintenance/diagnostic data

– Configuration data

– Parameter assignment data

Schedule and LAS (Link Active Scheduler)

The time at which an FF device transmits or reads cyclic data is defined in the schedule for

the FF. The schedule prevents conflicts on the FF segment during communication. A bus link

performs the LAS function in PCS 7 during normal operation. If no bus link is online on the FF

segment, suitable FF devices (Link Master) can assume the LAS function.

Macro cycle

The macro cycle is a time period that must be defined for each system. The following tasks

must be performed during this time period:

● All FF devices must be processed.

● Information must be transmitted by means of acyclic communication.

The FF specification recommends that at least 50% of the bus time be kept free for acyclic

communication.

3.1 Device integration with EDD

FF devices are integrated in the control system in PCS 7 using the application SIMATIC PDM.

Note

Integrating FF device descriptions

Device descriptions of FF devices that you do not find on the "Device Library..." DVD provided

with SIMATIC PDM must be modified before the integration. Please speak with your contact

(Page 19) about this.

FOUNDATION Fieldbus

12 Commissioning Manual, 02/2015, A5E32711026-AC

Liability

Siemens explicitly declines any liability for damages resulting from the use of the following

device description files and use in conjunction with the associated devices:

● For device-specific device description files for non-Siemens devices, the Siemens warranty

only applies up to the interface.

● For device description files integrated through catalogs

NOTICE

Important note on the device description files included with the SIMATIC PDM

The device description files of non-Siemens field devices have not been developed by

Siemens and are included with the shipped products free of charge. The licensee is entitled

to use the device description files of these devices in the same manner as a trial license

in accordance with the general terms and conditions for the supply of software for

automation and drive technology. This right of use may be exercised by the licensee as

long as the right of use for the PDM software is in effect.

Standardized device descriptions

Basics of the FOUNDATION Fieldbus

3.1 Device integration with EDD

Standardized device descriptions enable intelligent field devices from different manufacturers

to be integrated in different control systems. The IEC 61804-3 standard governs the structure

of device descriptions (DD). This standard was developed in cooperation with the following

organizations:

● PROFIBUS User Organization (PNO)

● Hart Communication Foundation (HCF)

● Fieldbus FOUNDATION

● OPC Foundation

The device descriptions are based on the EDDL (Electronic Device Description Language).

Information in device descriptions

Device descriptions contain all information required for correct interpretation of device data.

● Pre-defined device descriptions (standard DDs) describe the key parameters. These

standard DDs are available from the user organizations, for example, through the Fieldbus

FOUNDATION.

FF devices can interpret and display the data and functions of this standard DD. The basic

functions of the user interface are stored in the standard DD.

● Device-specific functions and parameters can be stored in an extended device description.

● The device description specifies the rules for the instantiation of blocks:

– Number and type of the initially automatically created, deletable blocks (default blocks)

– Maximum of all instantiable blocks

– Maximum of the instantiable blocks of a certain type

– Hardware-dependent, type-specific limitations of the maximum number of blocks

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 13

Basics of the FOUNDATION Fieldbus

3.2 Device addresses

Additional information

● IEC 61804-2

● IEC 61804-3

● Section "Block model of device parameters (Page 15)"

3.2 Device addresses

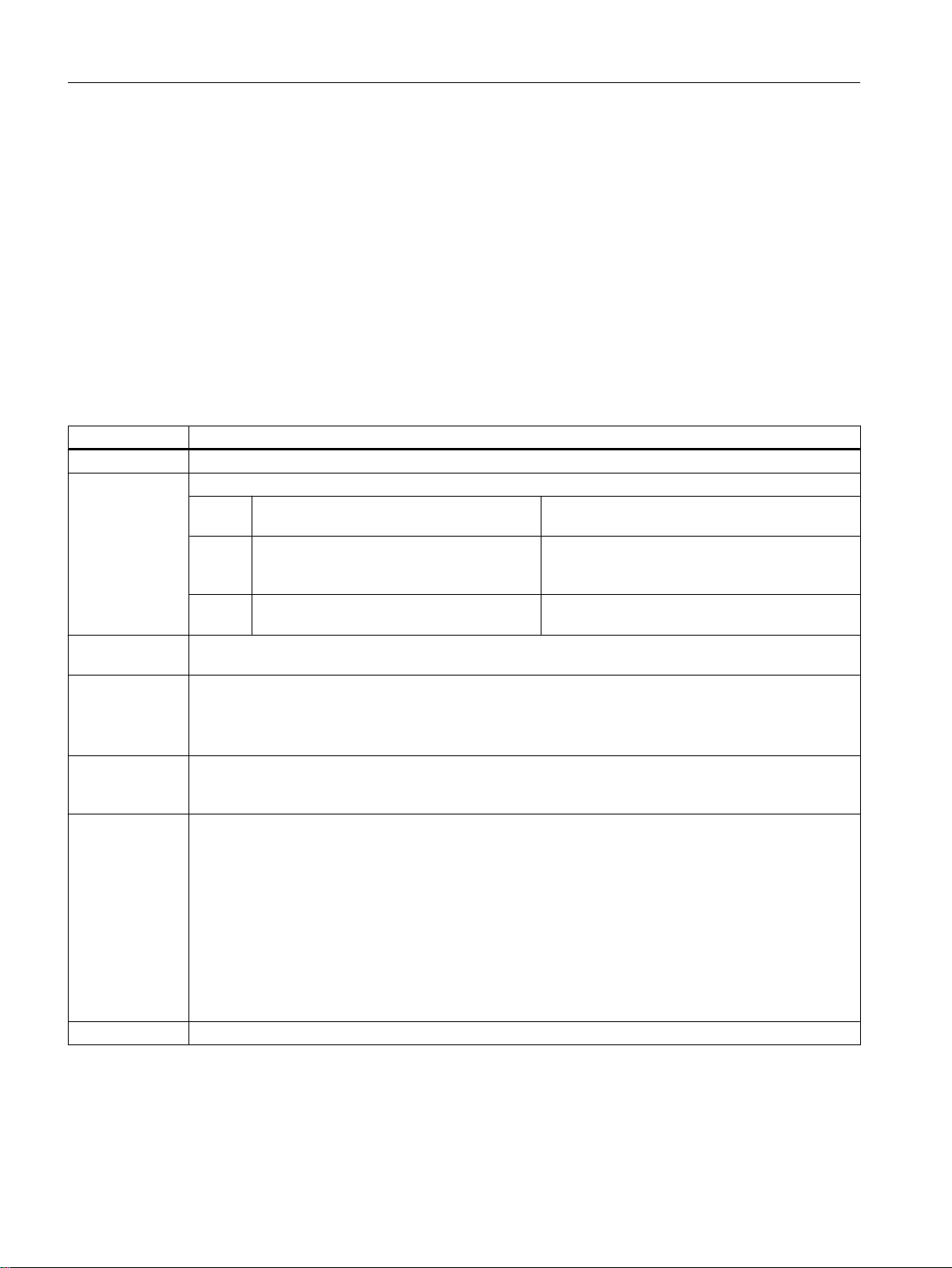

Address ranges in PCS 7

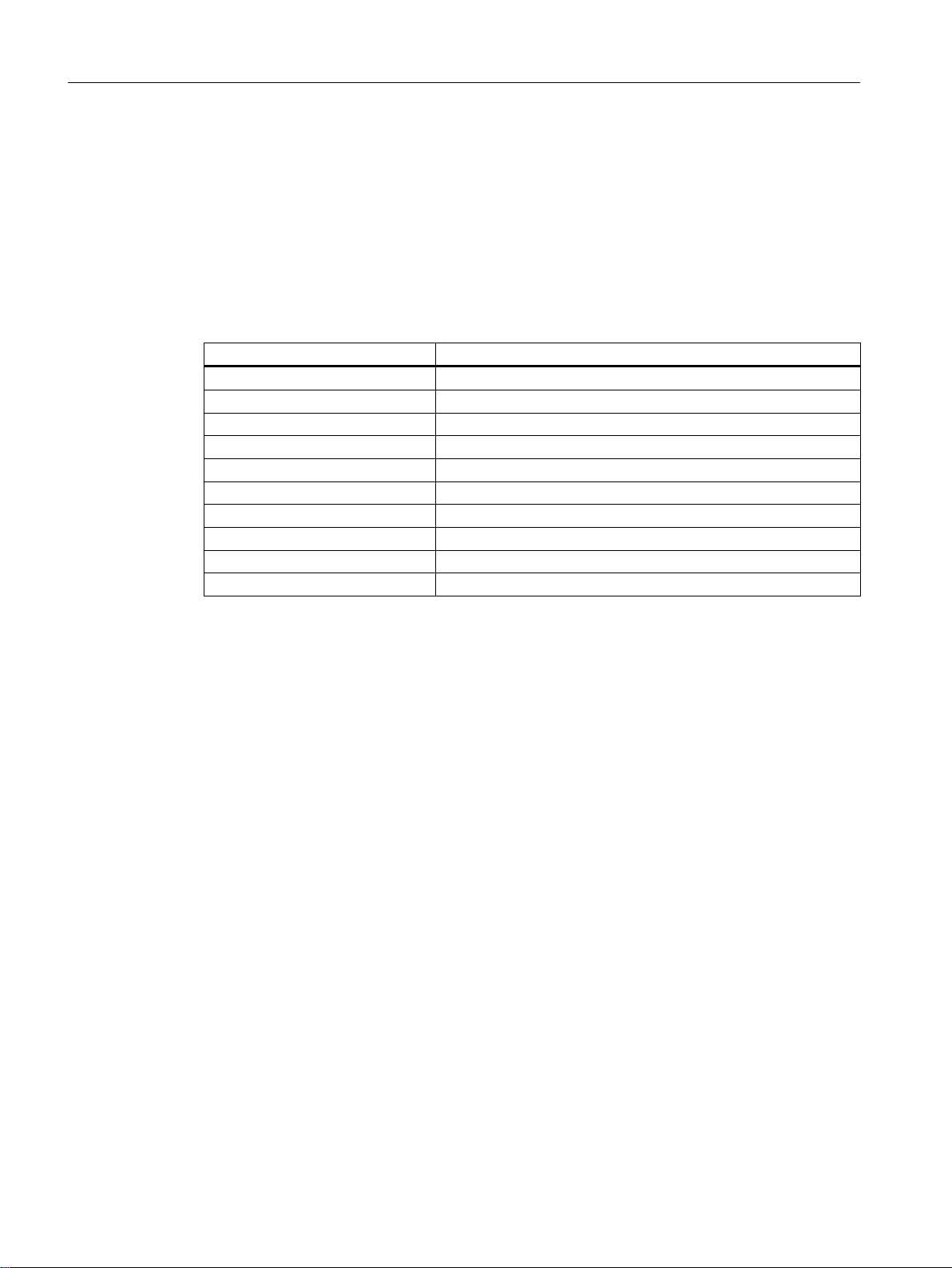

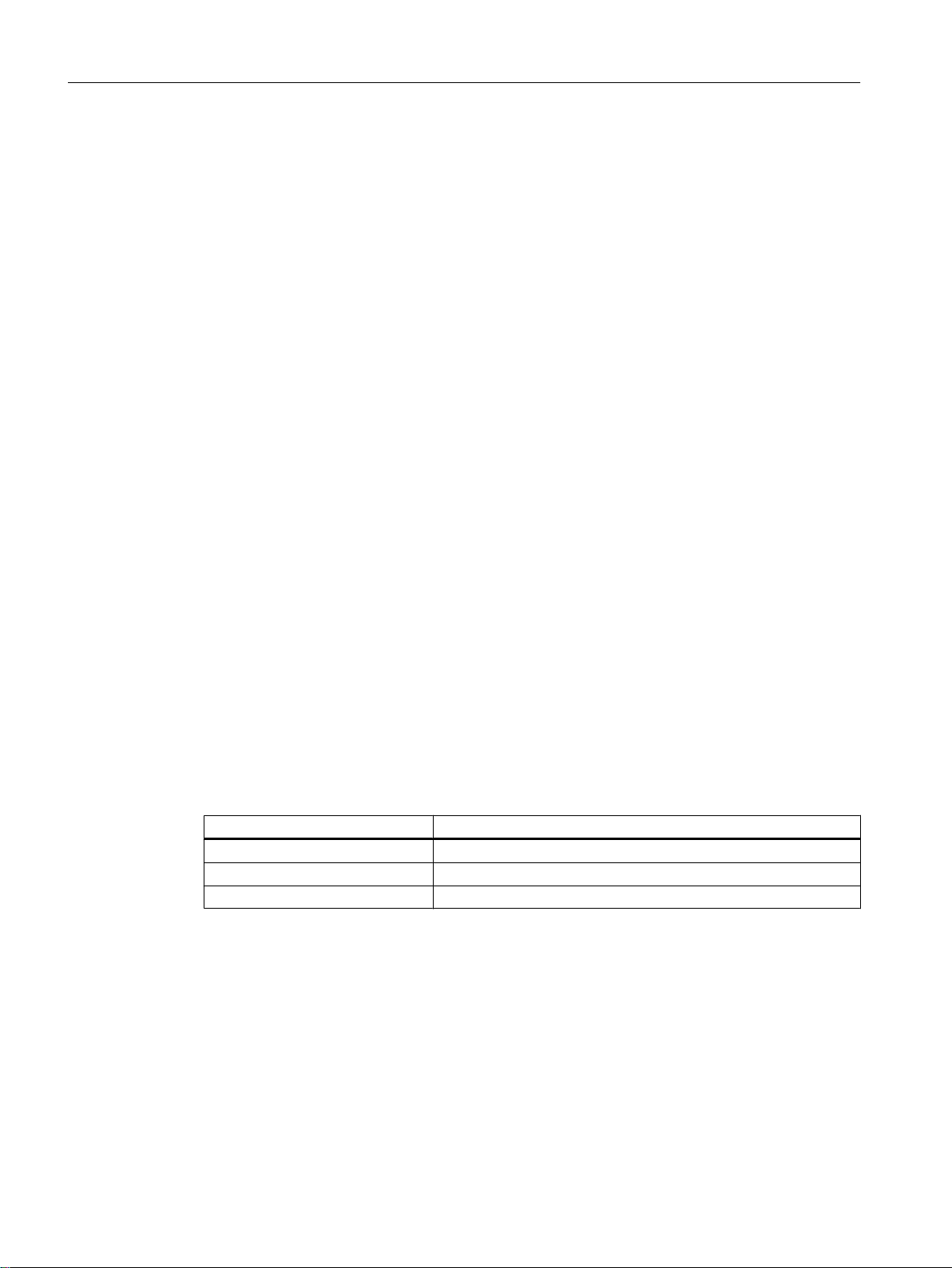

The following table shows the distribution of address ranges for the FF segment:

Address range Information on the address range

0 to 15 Reserved by the system (use not permitted)

16 to 19 Reserved range for bus link:

Ad‐

dress

16: IM for PROFIBUS DP

17 with redundant configuration: right IM with redundant configuration: right Compact FF

20 to 35 SIEMENS Polled Range:

reserved for cyclical data exchange with FF devices (optional expansion up to 50)

36 to 231 SIEMENS Unpolled Range:

FF devices in this address range are only recognized if the "standard range" has been extended. You

can find information on this in the section "Specifying the device identification of the FF devices (TAG

name and address) (Page 55)".

232 to 247 SIEMENS reserve range:

Reserved address range for new FF devices or FF devices that are not in operation, and for FF devices

that are only temporarily connected

248 to 251 Range for temporary FF devices

● Devices that are made available and that require a device address.

● Devices that are moved to this range by the automatic address conflict resolution (up to four FF

● Devices that were removed from processing (using the "Reset address" function)

Note for users:

Make sure that there are always free addresses in this range. This enables automatic assignment of a

temporary address to new FF devices. Some actions of SIMATIC PDM are based on the availability of

this address range (e.g., "Assign address and TAG").

252 to 255 Range for LAS-compliant temporary FF devices

FF Link (IM 153‑2 und FDC 157) Compact FF Link (IM 655‑5 FF with integrated

(with redundant configuration: left IM)

devices)

You will find information on this in the online help of SIMATIC PDM

Field Device Coupler)

Compact FF Link

(with redundant configuration: left Compact FF

Link)

Link

Automatic address conflict resolution for device addresses

Connected FF devices will be detected automatically at the FF segment.

FOUNDATION Fieldbus

14 Commissioning Manual, 02/2015, A5E32711026-AC

Basics of the FOUNDATION Fieldbus

3.3 Block model of device parameters

In the case of an address conflict, one of the FF devices affected by the address conflict will

automatically be assigned a temporary address during runtime. The procedure is repeated

automatically until the existing address conflicts are resolved.

The device addresses 248 to 251 have been reserved for automatic address conflict resolution

at the FF segment.

Note

The device address that was assigned to an FF device by automatic address conflict resolution

will not be saved in the FF device.

Note the following when you use automatic address conflict resolution:

● You may not connect or switch on for the first time more than 4 new FF devices with the

same address at the FF segment.

● You have to change the device addresses of FF devices that have been assigned to one

of the temporary addresses.

3.3 Block model of device parameters

The parameters (functions and data of an FF device) are assigned to block types in the device

descriptions of the FF devices:

Block type Note

Resource block One resource block per FF device.

Function block Multiple function blocks are possible for an FF device

Transducer block Multiple transducer blocks are possible for an FF device.

Note

Parameter assignment with SIMATIC PDM

The SIMATIC PDM application is used in PCS 7 for parameter assignment of the FF devices.

Block types

Resource block

The resource block contains device-specific information of the manufacturer.

Examples of this are:

● Manufacturer

● Device type

● Device number

● Serial number

● Hardware version

● Firmware version

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 15

Basics of the FOUNDATION Fieldbus

3.3 Block model of device parameters

Function block

Function blocks provide information about the functions available in an FF device as well as

their tasks. The schedules of the clocked data transmission defined in the schedule are based

on these function blocks. Access to the functions and their inputs and outputs is defined via

the function blocks. Each FF device has at least one function block.

Standard profiles for function blocks are defined in the FF specification. A description of the

basic functions is possible with the help of these standard profiles.

Table 3-1 Examples of the most important standard profiles for function blocks:

Block designation Function

AI Analog input

AO Analog output

B Offset (bias)

CS Control selector

DI Digital input

DO Digital output

ML Manual loader

PD PD controller (proportional/derivative)

PID PID controller (proportional/integral/derivative)

RA Ratio controller

Transducer block

Transducer blocks make it possible to influence the input and output variables of a function

block.

Examples of this are:

● Calibration and conversion of measured and control data

● Linearization of characteristic curves

● Conversion of physical quantities using other process data

Multiple capability levels

Some manufacturers offer FF devices in variants with a scalable scope of function and

transducer blocks. These variants are designated as capability levels in FOUNDATION

Fieldbus.

You can find information on this in the section "Capability levels (device variants) (Page 18)".

FOUNDATION Fieldbus

16 Commissioning Manual, 02/2015, A5E32711026-AC

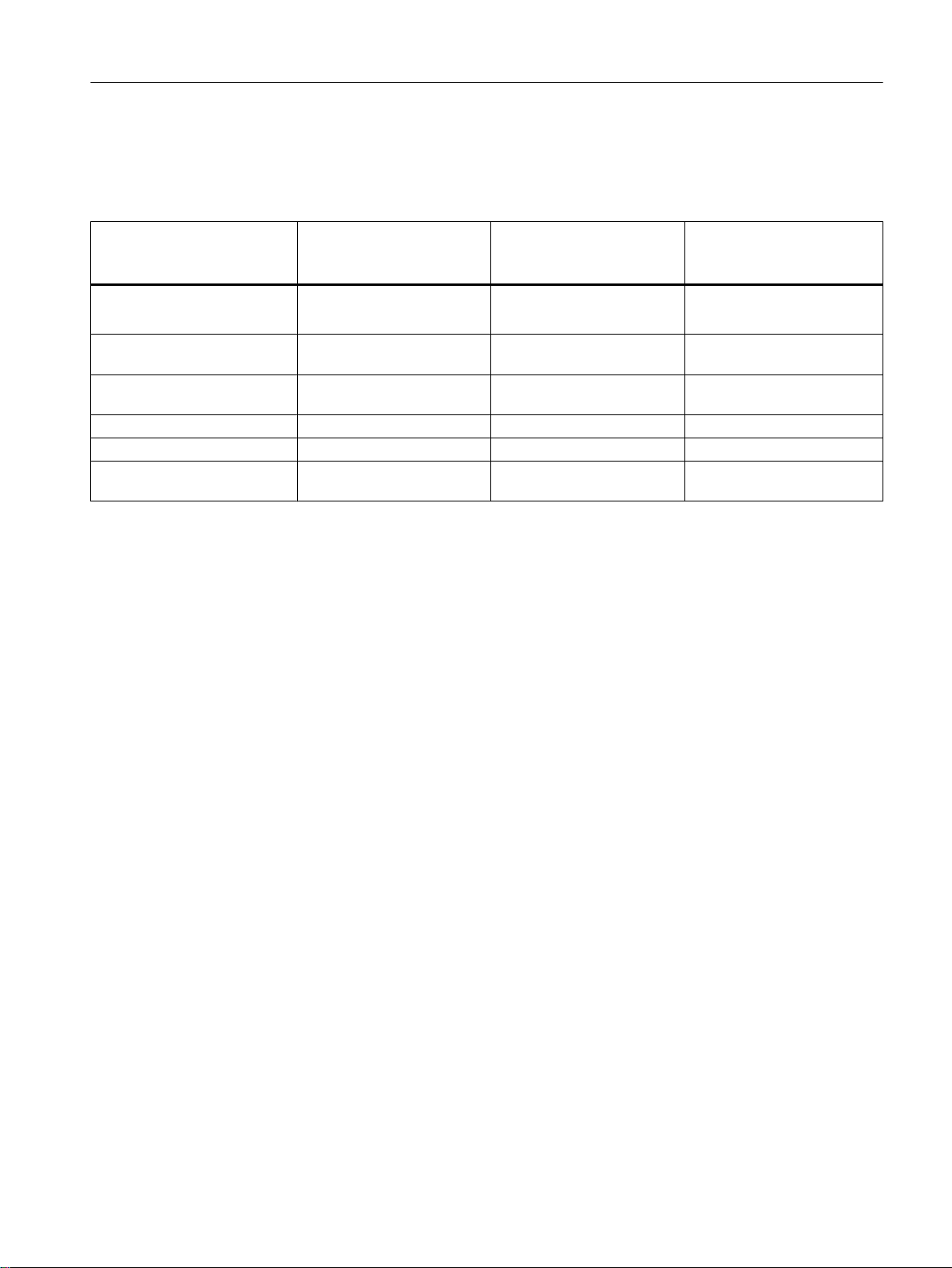

Block types in HW Config and in SIMATIC PDM

In the device catalogs of HW Config and SIMATIC PDM, you will find the following groups of

device-specific blocks:

Basics of the FOUNDATION Fieldbus

3.3 Block model of device parameters

Property

Identifier in the configuration in

HW Config

Font in the configuration in

HW Config

Section with attributes in the

device description

Visibility in the catalog Not visible Visible Visible

Configuration Automatically created Automatically created Must be inserted manually

Deletion capability Cannot be deleted Can be deleted and re-inser‐

Permanent blocks

FB

Italic

Per instance Per instance Per block type

Default blocks

FB

Not italic Not italic

ted

Instantiable blocks

(only for devices with capabil‐

ity level)

● FB TYPE

● TB TYPE

Can be deleted

Objects of the block model

In PCS 7, applications in the PC stations assume the functions of FF-specific objects:

Engineering station

● Configuration of the FOUNDATION Fieldbus

● Interconnection of the FF devices

– Interconnections for the process image

You can find information on this in the section "How to replace an FF device (Page 39)".

– Interconnections within the FF devices

You can find information about this in the following sections:

- Section "“Interconnection Editor" dialog box (Page 37)"

- Section "How to configure FF-internal interconnections (Control in the field) (Page 35)"

Operator stations and Maintenance Station

● Output of signals

– Alarms

– Events

● Monitoring

– Process control

– Maintenance

● Long-term archiving

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 17

Basics of the FOUNDATION Fieldbus

3.4 Capability levels (device variants)

3.4 Capability levels (device variants)

Some manufacturers offer FF devices in device variants with a scaled scope of functions.

These device variants are designated as "capability levels" in FOUNDATION Fieldbus.

Common features and differences based on capability level

Common features

● The devices use the same device description.

● The general device properties defined in the device description are identical.

Differences

● Within the capability level, the following types of function and transducer blocks are defined:

– Permanent blocks

– Initially created, deletable default blocks

– Instantiable blocks (for devices with capability level)

● The type and number of blocks can be different.

● Instantiable blocks can only be selected if at least one capability level is defined for a device.

Selecting the capability level in the device catalogs

In the device catalogs of HW Config and SIMATIC PDM, you will find capability levels at the

following place:

In the tree view as a hierarchy level below the device revision of the FF devices.

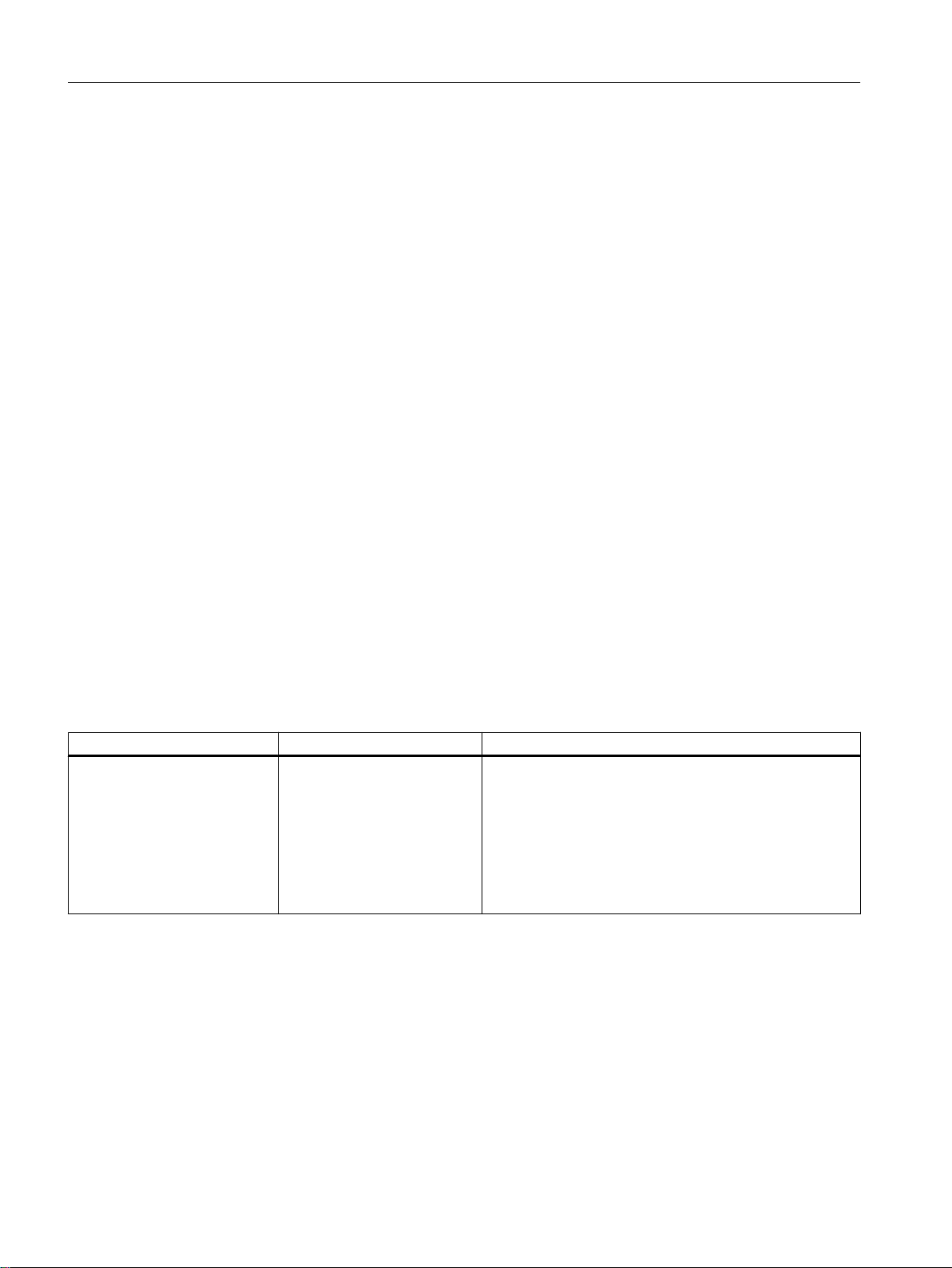

Examples

Device without capability level Device with capability level Device with instantiable blocks

Device

● Device revision

● Device revision

Device

● Device revision

● Device revision

– Capability level 1

– Capability level 2

Device

● Device revision

● Device revision

– Capability level 1

– Capability level 2

- Instantiable block FB TYPE <...>

- Instantiable block FB TYPE <...>

Configuring the capability level

1. In the hardware configuration, select the capability level supported by your device.

2. Configure the blocks for the device (add/delete).

Observe the following sections:

– You can find information about the properties of the blocks in the section "Block model

of device parameters (Page 15)".

– You can find information about the device description in the section "Device integration

with EDD (Page 12)".

FOUNDATION Fieldbus

18 Commissioning Manual, 02/2015, A5E32711026-AC

Communication and downloading of FF devices with capability level

When the FF segment is downloaded, the instantiated blocks are created in the devices. You

can find additional information about downloading in the section "Downloading objects in the

FF segment (Page 60)".

The automation system (host) can only communicate with the device if the capability level of

the device matches the configured capability level.

3.5 Contact partner

Your contact partner (not for demo version)

Questions on SIMATIC STEP 7 / SIMATIC PCS 7 / hardware / SIMATIC PDM / problems with

S7 communication

Mailing address: SIEMENS AG

Customer Support

D-90475 Nuremberg, Germany

E-mail: online-support.industry@siemens.com

Internet: http://www.siemens.com/automation/service&support (http://

www.siemens.com/automation/service&support)

Basics of the FOUNDATION Fieldbus

3.5 Contact partner

Questions on devices and GSD files

Please get in touch with your contact partner at the device manufacturer.

For more information, refer to the "List of integrated devices". You will find this on the "SIMATIC

PDM Device Library 2#2015" DVD in the "\_manuals" directory.

Follow-up installations and additional information on SIMATIC PDM are available on the

Internet at "http://www.siemens.com/simatic-pdm (www.siemens.de/simatic-pdm)".

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 19

Basics of the FOUNDATION Fieldbus

3.5 Contact partner

FOUNDATION Fieldbus

20 Commissioning Manual, 02/2015, A5E32711026-AC

System planning

4.1 Nodes in the FOUNDATION Fieldbus

An FF segment contains all nodes communicating via the FOUNDATION Fieldbus. The

following information is used for the system-specific optimization of FF segments.

Size of the process image

An FF segment is restricted to the size of the process image of the bus link (max. 244 bytes I/

O in each case).

The 244 bytes for inputs can be divided among the FF devices:

● Digital inputs (2 bytes per value, however maximum 40 DI)

● Analog inputs (5 bytes per value, however maximum 40 AI)

The 244 bytes for outputs can be divided among the FF devices:

● Digital outputs (2 bytes per value, however maximum 40 DO)

● Analog outputs (5 bytes per value, however maximum 40 AO)

A maximum of 64 bytes can be used for outputs and 64 bytes for inputs for each FF device.

4

Nodes in an FF segment

The maximum number of nodes in an FF segment depends on the requirements of a plant

regarding update times.

Typical number of FF devices that are integrated in a plant in an FF segment: 8 to 10 (maximum

number 31)

The time for a macro cycle is influenced primarily by the share of cyclic communication. This

share depends on the following factors:

● Properties of the FF devices used in the FF segment

● Number of input values and output values of all components connected to the FF segment

You can specify a target value for the macro cycle as well as for the ratio between the cyclic

and acyclic share. The schedule is calculated for these conditions.

If a mean time of approximately 30 ms is assumed for the output of a value from FF devices,

and the block run time is considered as acyclic bus time, then the minimum macro cycle for

15 transmitted values will be approximately one second. The time for output of a value depends

on the device in question.

FOUNDATION Fieldbus

Commissioning Manual, 02/2015, A5E32711026-AC 21

System planning

4.2 Configuration

Sample calculation

● 15 x 30 ms = 450 ms, corresponds to the cyclic bus time

● Reserved bus time for acyclic communication

● Recommended macro cycle = between 1500 ms and 9000 ms

Current consumption

The permissible current consumption of all components on an FF segment depends on the

type of bus link:

● FF Link: Maximum 1 A

● Compact FF Link: Maximum 500 mA

I/O data

The parameters, inputs and outputs of FF devices are distributed over function blocks. An FF

device can have several function blocks. Only configure the required I/O data of an FF device.

The number of processed function blocks has an effect on the macro cycle.

1050 ms (recommended 70%), 450 ms (recommended, at least 50%)

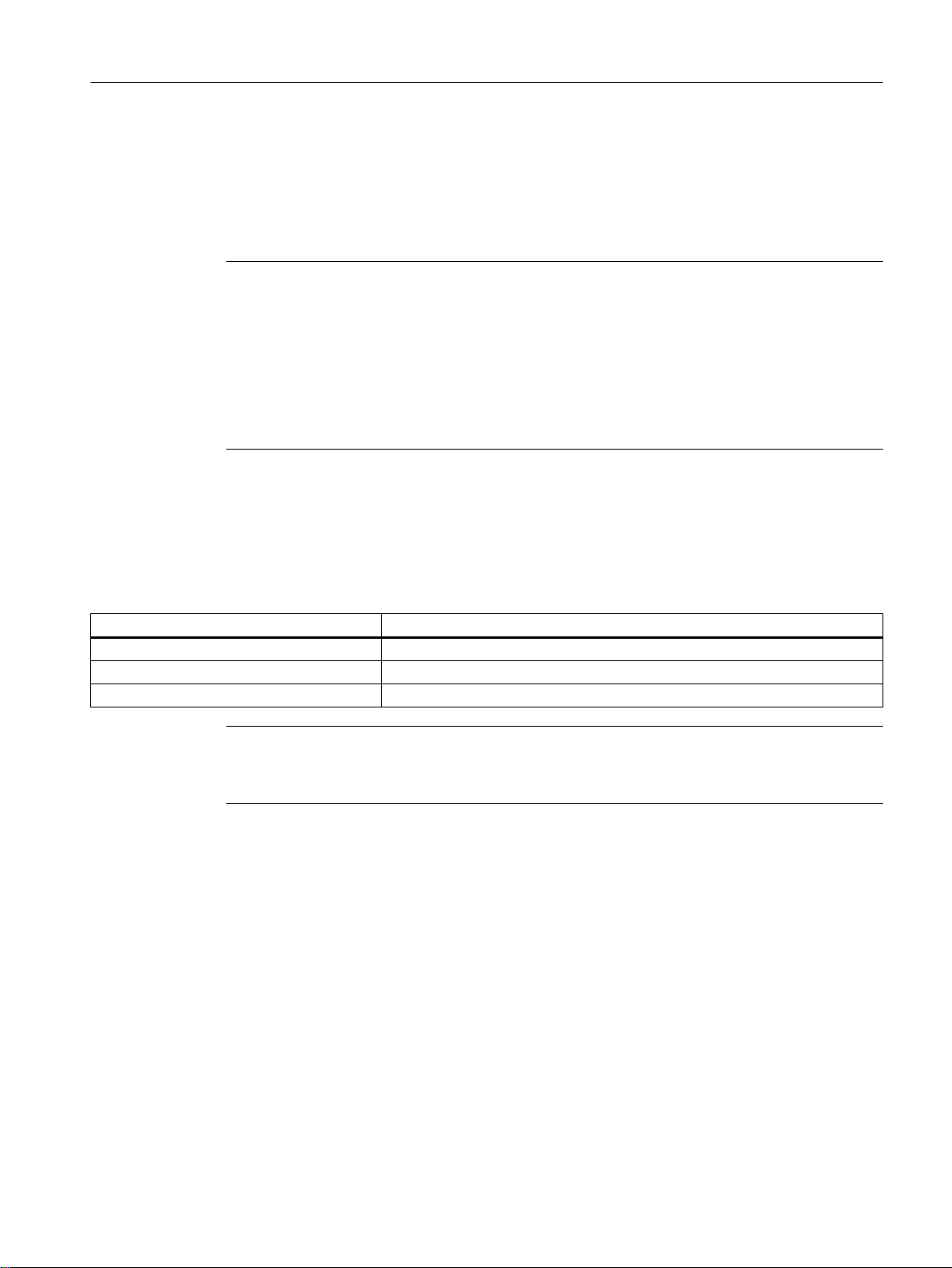

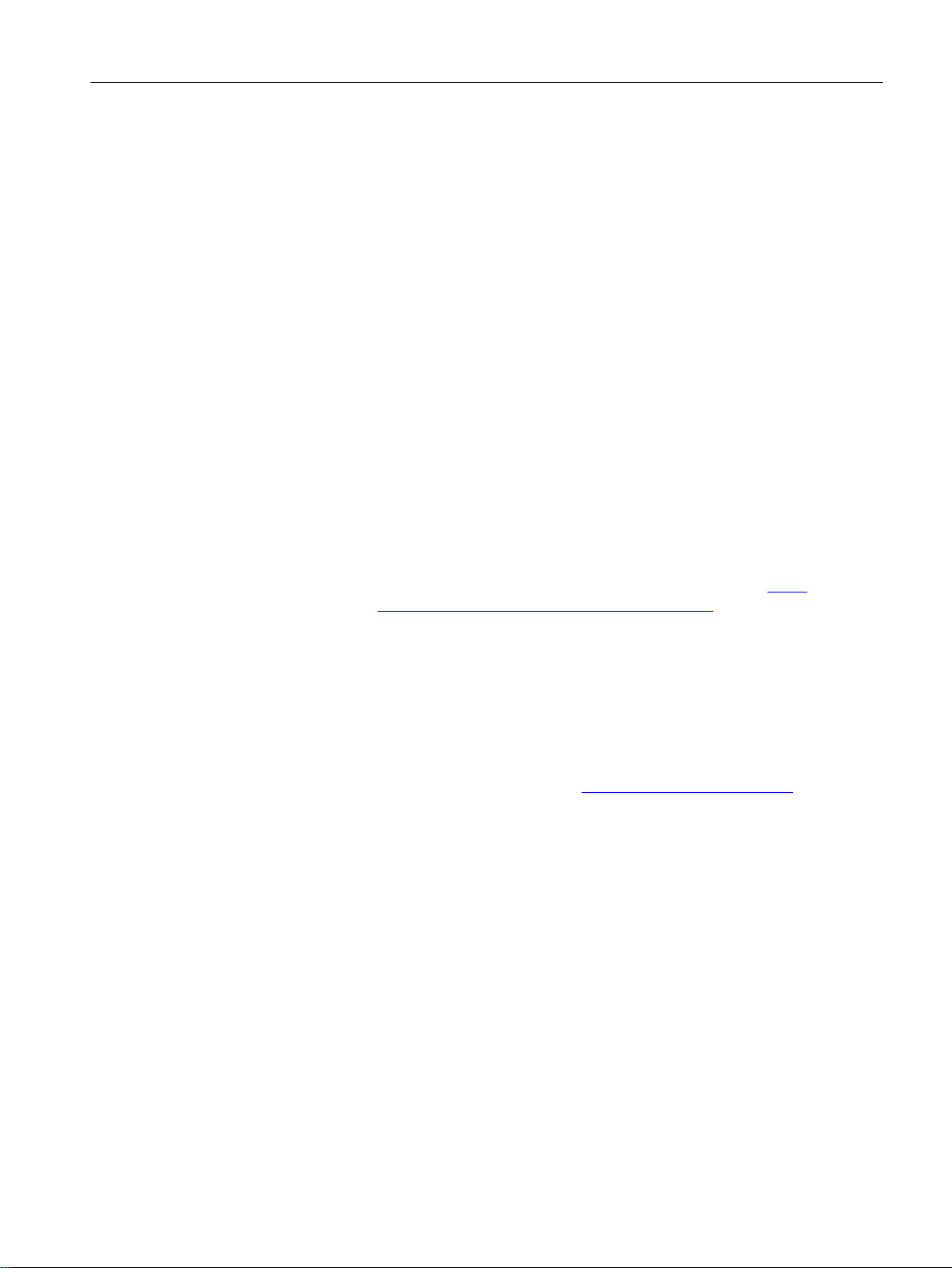

4.2 Configuration

Hardware

Always connect an FF segment to the automation system via PROFIBUS DP. You need a

suitable bus link for the transition between PROFIBUS DP and the FF segment.

The bus link can be operated on the integrated line of the CPU if the CPU supports the data

record gateway.

The table shows possible CPU versions:

CPU type As of version

SIMATIC S7 41x V5.1

SIMATIC S7 41xH V6.0

WinAC RTX V4.6

Network configuration

The following structures are typical for the configuration of FF segments in PCS 7:

● Line

● Redundant configuration (see also section "Redundancy (Page 67)")

FOUNDATION Fieldbus

22 Commissioning Manual, 02/2015, A5E32711026-AC

Loading...

Loading...