Page 1

SIMATIC Industrial PC SIMATIC Panel PC 577

DOCUMENTATION

Operating Instructions Edition 04/2006

Industrial PC

Panel PC 577

simatic

DOCUMENTATION

Page 2

Page 3

SIMATIC

Industrial PC

SIMATIC Panel PC 577

Operating Instructions

Preface

Safety instructions and

general notes

Description

Planning use

Installation

Connecting

Commissioning

1

2

3

4

5

6

Operation and configuration

Operating

Integration in TIA

Servicing and maintenance

Alarm, error and system

messages

Troubleshooting and FAQs

Technical specifications

7

8

9

10

11

12

13

Release 04/2006

A5E00798484-01

Detailed descriptions

Appendix

14

A

Page 4

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended by

Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly

as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: A5E00798484-01

Edition 04/2006

Copyright © Siemens AG

200420052006.

Technical data subject to change

Page 5

Preface

This manual

Purpose of the manual

This manual provides information based on the requirements defined by DIN 8418 regarding

mechanical engineering documentation. This information relates to the device, its place of

use, transport, storage, installation, use and maintenance.

This manual is intended for the following target groups:

• Users

• Commissioning engineers

• Service technicians

• Maintenance technicians

Please read the section "Safety instructions and general notes" carefully.

Knowledge required

A solid background in personal computers and Microsoft operating systems is required to

understand this manual. General knowledge in the field of automation control engineering is

recommended.

Scope of this manual

This manual applies to devices with the order numbers 6AV782.…

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

iii

Page 6

Preface

Related documentation

The documentation for the Panel PC includes the following sections:

• SIMATIC Panel PC 577, Operating Instructions (compact) with the following information:

– Commissioning

– Legal information

• SIMATIC Panel PC 577, Operating Instructions

The documentation is supplied with the Panel PC in electronic form as a PDF file on the

"Documentation & Drivers" CD. QuickStart for the Panel PC 577 is also supplied in printed

form. The documentation is available in German, English, French, Italian and Spanish.

Additional information about the Windows operating system is available in the Internet at the

Microsoft homepage, "www.Microsoft.com

Online Availability

The following links will bring you directly to the technical documentation collection for

SIMATIC products and systems in the languages German, English, French, Italian and

Spanish.

• SIMATIC Guide Technische Dokumentation in Deutsch:

http://www.ad.siemens.de/simatic/portal/html_00/techdoku.htm

".

Conventions

• SIMATIC guide to technical documentation in English:

http://www.ad.siemens.de/simatic/portal/html_76/techdoku.htm

The following text notation will facilitate reading this manual:

Representation Scope

"File"

"File > Edit" Operational sequences, e.g., menu items/shortcut menu items.

<F1>, <Shift>+<F1> Keys and key combinations

• Terminology that occurs in the user interface, e.g., dialog

names, tabs, buttons, menu commands.

• Inputs required, e.g., limit values, tag values

• Path information

The term "Panel PC 577", "control unit" and "computer unit" is uniformly refered to as the

"device" in these operating instructions. The full term is only used when a concrete reference

is necessary.

Note

A note is important information about the product, handling the product or a reference to

specific sections of the documentation that require special consideration.

SIMATIC Panel PC 577

iv Operating Instructions, Release 04/2006, A5E00798484-01

Page 7

Preface

Trademarks

All names labeled with ® symbol are registered trademarks of Siemens AG. Other names

used in this documentation may be trademarks, the use of which by third parties for their

own purposes could violate the rights of the owner.

HMI®

SIMATIC®

SIMATIC HMI®

SIMATIC ProTool®

SIMATIC WinCC®

SIMATIC WinCC flexible®

Panel PC 577®

Panel PC 677®

Panel PC 877®

Additional support

Representatives and offices

If you have questions concerning the use of the described product which are not answered in

this manual, please contact the Siemens representative in your area.

Find your contact partner at:

http://www.siemens.com/automation/partner

A guide to the technical documentation for the various SIMATIC products and systems is

available at:

http://www.siemens.com/simatic-tech-doku-portal

The online catalog and the online ordering system is available at:

http://mall.automation.siemens.com

Training center

To familiarize you with automation systems, we offer a variety of courses. Please contact

your regional training center or the central training center in D-90327 Nuremberg, Germany.

Phone: +49 (911) 895-3200

Internet: http://www.sitrain.com

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

v

Page 8

Preface

Technical support

You can reach the technical support for all A&D products

via the support request form on the web:

• http://www.siemens.com/automation/support-request

• Phone: + 49 180 5050 222

• Fax: + 49 180 5050 223

Additional information about our technical support is available in the Internet at:

http://www.siemens.com/automation/service

Service & support on the Internet

In addition to our documentation, we offer our complete knowledge base on the Internet at.

http://www.siemens.com/automation/service&support

There you will find:

• The newsletter which provides the latest information on your products.

• Relevant documentation for your application, which you can access via the search

function in our service & support database.

• A forum where users and experts from all over ther world exchange ideas.

• You local Automation & Drives representative.

• Information about on-site service, repairs, spare parts. And lots more under "Services".

SIMATIC Panel PC 577

vi Operating Instructions, Release 04/2006, A5E00798484-01

Page 9

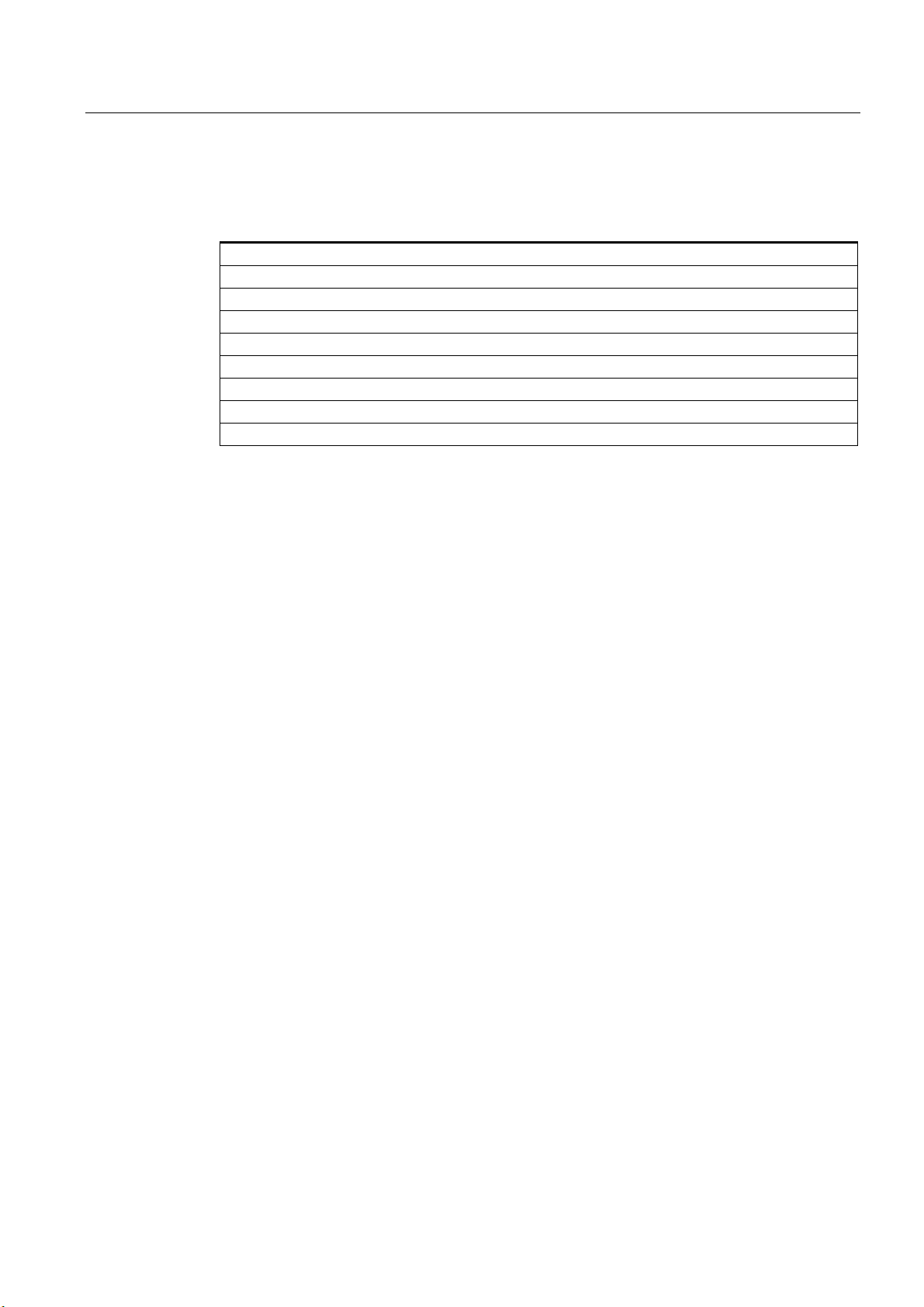

Table of contents

Preface ...................................................................................................................................................... iii

1 Safety instructions and general notes..................................................................................................... 1-1

1.1 Safety instructions...................................................................................................................... 1-1

1.2 General information, download "Panel PC" ............................................................................... 1-5

2 Description.............................................................................................................................................. 2-1

2.1 Application features ................................................................................................................... 2-1

2.2 Design ........................................................................................................................................ 2-2

2.3 Technical features...................................................................................................................... 2-3

3 Planning use........................................................................................................................................... 3-1

3.1 Overview .................................................................................................................................... 3-1

3.2 Unpacking and checking the delivery ........................................................................................3-2

3.3 Make note of identification data ................................................................................................. 3-4

3.4 EMC directive............................................................................................................................. 3-5

3.5 Mounting positions and fastening .............................................................................................. 3-6

3.5.1 Installation instructions............................................................................................................... 3-6

3.5.2 Permitted mounting positions..................................................................................................... 3-8

3.5.3 Mounting type............................................................................................................................. 3-8

3.5.4 Degree of protection .................................................................................................................. 3-9

3.6 Mounting cut-out ...................................................................................................................... 3-10

3.6.1 Selecting and creating the mounting cut-out ........................................................................... 3-10

3.6.2 Dimensions .............................................................................................................................. 3-11

4 Installation .............................................................................................................................................. 4-1

4.1 Securing with clamps ................................................................................................................. 4-1

4.2 Securing with screws ................................................................................................................. 4-2

4.3 Dimensions ................................................................................................................................ 4-4

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

vii

Page 10

Table of contents

5 Connecting ............................................................................................................................................. 5-1

5.1 Overview .................................................................................................................................... 5-1

5.2 Interfaces.................................................................................................................................... 5-3

5.2.1 Front interfaces .......................................................................................................................... 5-3

5.2.2 Rear interfaces........................................................................................................................... 5-4

5.3 Connecting peripherals .............................................................................................................. 5-6

5.3.1 Overview .................................................................................................................................... 5-6

5.3.2 Connecting a monitor................................................................................................................. 5-6

5.3.3 USB............................................................................................................................................ 5-7

5.4 Connecting the power supply..................................................................................................... 5-9

5.5 Uninterruptible AC power supplies........................................................................................... 5-11

5.6 Connecting the equipotential bonding...................................................................................... 5-12

6 Commissioning ....................................................................................................................................... 6-1

6.1 Removing the transport lock for the hard disk ........................................................................... 6-1

6.2 Overview .................................................................................................................................... 6-3

6.3 Switching on the device. ............................................................................................................ 6-5

6.4 Setting up the Microsoft Windows operating system ................................................................. 6-7

6.5 Installing applications and drivers, Touch-Base......................................................................... 6-8

6.6 Notes about new installation of Windows 2000 ....................................................................... 6-13

7 Operation and configuration.................................................................................................................... 7-1

7.1 Normal operation........................................................................................................................ 7-1

7.1.1 Switching the device on and off ................................................................................................. 7-1

7.2 Additional drivers and applications ............................................................................................ 7-4

7.2.1 Overview .................................................................................................................................... 7-4

7.2.2 Setting the touch screen ............................................................................................................ 7-5

7.2.3 KeyTools .................................................................................................................................... 7-7

7.2.4 SystemGuard ............................................................................................................................. 7-8

7.2.5 TouchInput ................................................................................................................................. 7-9

7.2.6 CheckLanguageID ................................................................................................................... 7-10

7.2.7 Multilingual settings for the operating system.......................................................................... 7-11

8 Operating................................................................................................................................................ 8-1

8.1 Operator controls ....................................................................................................................... 8-1

8.2 Operator controls on key panels ................................................................................................ 8-3

8.2.1 Overview .................................................................................................................................... 8-3

8.2.2 Keyboard.................................................................................................................................... 8-4

8.2.3 Labeling function keys and softkeys .......................................................................................... 8-7

8.3 Operator controls of the touch screen panels............................................................................ 8-9

8.3.1 Overview .................................................................................................................................... 8-9

8.3.2 Touch screen ........................................................................................................................... 8-10

8.4 DVD-ROM drive ....................................................................................................................... 8-11

8.5 Transferring authorizations ...................................................................................................... 8-12

SIMATIC Panel PC 577

viii Operating Instructions, Release 04/2006, A5E00798484-01

Page 11

Table of contents

9 Integration in TIA .................................................................................................................................... 9-1

9.1 Industrial communications ......................................................................................................... 9-1

9.2 PROFIBUS/MPI interface and WinAC card ............................................................................... 9-2

10 Servicing and maintenance................................................................................................................... 10-1

10.1 Servicing .................................................................................................................................. 10-1

10.2 Removing and installing hardware components ...................................................................... 10-3

10.2.1 Repairs..................................................................................................................................... 10-3

10.2.2 Opening the device.................................................................................................................. 10-5

10.2.3 View of internal components with open device........................................................................ 10-9

10.2.4 Removing/installing memory modules ................................................................................... 10-10

10.2.5 PCI/WinAC cards ................................................................................................................... 10-12

10.2.5.1 Notes on the modules ............................................................................................................ 10-12

10.2.5.2 Installing expansion modules................................................................................................. 10-13

10.2.6 Drives ..................................................................................................................................... 10-17

10.2.6.1 Removing and installing a DVD-ROM drive........................................................................... 10-17

10.2.6.2 Replacing the hard disk ......................................................................................................... 10-20

10.2.7 Changing processors and heat sinks..................................................................................... 10-24

10.2.8 Replacing the back-up battery ............................................................................................... 10-26

10.2.9 Removing/installing the power supply ................................................................................... 10-28

10.2.10 Separating the control unit from the computer unit................................................................ 10-30

10.2.11 Connecting an external monitor............................................................................................. 10-37

10.3 Installing software .................................................................................................................. 10-38

10.3.1 Overview ................................................................................................................................ 10-38

10.3.2 Supplied software CDs / DVDs.............................................................................................. 10-40

10.3.3 Restoring the factory state of the software using the Restore DVD ...................................... 10-41

10.3.4 Factory state without operating system ................................................................................. 10-43

10.3.5 Installing individual drivers..................................................................................................... 10-44

10.4 Maintenance and spare parts ................................................................................................ 10-45

11 Alarm, error and system messages ............................

.......................................................................... 11-1

11.1 BIOS error messages .............................................................................................................. 11-1

11.2 Motherboard error messages................................................................................................... 11-2

12 Troubleshooting and FAQs................................................................................................................... 12-1

12.1 General problems .................................................................................................................... 12-1

12.2 Problems when using modules of third-party manufacturers .................................................. 12-3

12.3 SystemGuard errors................................................................................................................. 12-4

13 Technical specifications........................................................................................................................ 13-1

13.1 Technical data.......................................................................................................................... 13-1

13.1.1 EMC requirements ................................................................................................................... 13-1

13.1.2 General technical data ............................................................................................................. 13-2

13.1.3 Ambient and environmental conditions.................................................................................... 13-5

13.2 Dimensional drawing of the device .......................................................................................... 13-6

13.3 Keyboard table ......................................................................................................................... 13-7

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

ix

Page 12

Table of contents

14 Detailed descriptions ............................................................................................................................ 14-1

14.1 Overview of the Panel PC 577 motherboard ........................................................................... 14-1

14.2 Riser card ................................................................................................................................. 14-2

14.3 Touch sensor ........................................................................................................................... 14-3

14.4 System resources .................................................................................................................... 14-5

14.4.1 Currently allocated system resources...................................................................................... 14-5

14.4.2 Interrupt assignment ................................................................................................................ 14-6

14.5 BIOS setup ............................................................................................................................... 14-7

14.5.1 Starting BIOS setup ................................................................................................................. 14-7

14.5.2 BIOS setup default settings...................................................................................................... 14-8

A Appendix.................................................................................................................................................A-1

A.1 Certificates and guidelines.........................................................................................................A-1

A.1.1 Guidelines and declarations.......................................................................................................A-1

A.1.2 Certificates and approvals..........................................................................................................A-3

A.1.3 ESD guideline ............................................................................................................................A-5

A.1.4 Electrostatic charging of individuals...........................................................................................A-7

A.2 Abbreviations .............................................................................................................................A-8

A.3 Glossary Definitions CU.............................................................................................................A-9

Index................................................................................................................................................ Index-1

Tables

Table 3-1 Dimensions for the mounting cut-out in mm ............................................................................ 3-12

Table 10-1 Switch settings for the various control units........................................................................... 10-36

SIMATIC Panel PC 577

x Operating Instructions, Release 04/2006, A5E00798484-01

Page 13

Safety instructions and general notes

1.1 1.1 Safety instructions

Warning

Emergencies

In the event of a device fault, remove the mains connector immediately. Inform the customer

service personnel responsible. Malfunctions can occur when the operator controls or power

cable are damaged or when liquids or foreign objects penetrate the device.

Caution

Please observe the safety instructions on the back of the cover sheet of this documentation.

You should not expand your device unless you have read the relevant safety instructions.

1

This device is compliant with the relevant safety measures to IEC, EN, VDE, UL, and CSA. If

you have questions about the validity of the installation in the planned environment, please

contact your service representative.

Repairs

Only authorized personnel are permitted to repair the device.

Warning

Unauthorized opening and improper repairs can cause considerable damage to property or

danger for the user.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

1-1

Page 14

Safety instructions and general notes

1.1 Safety instructions

System expansions

Only install system expansion devices designed for this device. The installation of other

expansions can damage the system and violate the radio-interference suppression

regulations. Contact your technical support team or where you purchased your PC to find out

which system expansion devices may safely be installed.

Battery

Caution

If you install or exchange system expansions and damage your device, the warranty

becomes void.

This device is equipped with a Lithium battery. Batteries may only be replaced by qualified

personnel.

Caution

There is the risk of an explosion if the battery is not replaced as directed. Replace only with

the same type or with an equivalent type recommended by the manufacturer. Dispose of

used batteries in accordance with local regulations.

Warning

Risk of explosion and release of harmful substances!

Therefore, do not throw Lithium batteries into an open fire, do not solder or open the cell

body, do not short-circuit or reverse polarity, do not heat up above 100° C, dispose of in

accordance with regulations and protect against direct exposure to sunlight, moisture and

condensation.

SIMATIC Panel PC 577

1-2 Operating Instructions, Release 04/2006, A5E00798484-01

Page 15

Safety instructions and general notes

1.1 Safety instructions

ESD guidelines

Modules containing electrostatic sensitive devices (ESDs) can be identified by the following

label:

Strictly follow the guidelines mentioned below when handling modules which are sensitive to

ESD:

• Always discharge your body´s static electricity before handling modules which are

sensitive to ESD (for example, by touching a grounded object).

• All devices and tools must be free of static charge.

• Always pull the mains connector and disconnect the battery before you install or remove

modules which are sensitive to ESD.

• Handle modules fitted with ESDs by their edges only.

• Do not touch any wiring posts or conductors on modules containing ESDs.

Warning

Following the results of a risk analysis, additional protection equipment on the machine or

the system is necessary to avoid endangering persons. With this, especially the

programming, configuration and wiring of the inserted I/O modules have to be executed, in

accordance with the safety performance (SIL, PL or Cat.) identified by the necessary risk

analysis. The intended use of the device has to be ensured.

The proper use of the device has to be verified with a function test on the system. This test

can detect programming, configuration and wiring errors. The test results have to be

documented and, if necessary, entered into the relevant documents that verify safety.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

1-3

Page 16

Safety instructions and general notes

1.1 Safety instructions

Electrical connection

Warning

Disconnect the device from the mains before every intervention.

Do not touch power cables or data transmission cables during electrical storms and do not

connect any cables.

High frequency radiation

Caution

Unintentional operating situations

High frequency radiation, e.g. from cell phones, can cause unintentional operating situations

under some circumstances. For more details, consult the technical data in the "EMC

requirements" chapter.

SIMATIC Panel PC 577

1-4 Operating Instructions, Release 04/2006, A5E00798484-01

Page 17

Safety instructions and general notes

1.2 General information, download "Panel PC"

1.2 1.2 General information, download "Panel PC"

Overview

Transport

Caution

The device is approved for operation in closed rooms only. The guarantee is void if this

stipulation is ignored.

Avoid extreme environmental operating conditions. Protect your device against dust,

moisture and heat. For additional information, refer to the Technical data.

Do not place the device in direct sunlight.

Unpack the device at its installation location.

Notice

Fitting the hard disk transport lock again

Transport the device only in the original packaging. Fit the hard disk transport lock again for

this purpose: Switch off the device and place it in the operating position. Screw in the knurled

screws as far as the stop.

Notice

Adhere to these stipulations each time the device is transported, otherwise the guarantee is

void.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

1-5

Page 18

Safety instructions and general notes

1.2 General information, download "Panel PC"

Caution

Condensation

When transporting the device in low temperatures, ensure that no moisture gets on or into

the device. This also applies if the device is subjected to extreme changes in temperature.

Commissioning

Allow the device to slowly adjust to room temperature before commissioning the device. Do

no place the device near direct heat radiation. If moisture condensation occurs, wait at least

about 12 hours before you switch on the device.

Vibration

DVD drives are sensitive to vibration. Prohibited vibration during operation may result in loss

of data or damage to the drive or data medium.

Before transporting the device, wait at least 20 seconds to allow the drive to stop completely.

Tools & downloads

Please check regularly whether updates and hotfixes are available for download to your

device.

Downloads are available on the Internet at "http://www.siemens.com/asis

Click on "Tools & Demosoftware" on "Overview Panel PCs". Using the global search

function, you can then also search for any downloads you require.

" under "Support".

Processor and CD-ROM drive

Caution

Danger of overheating the processor!

Do not activate the "Silent mode" option in the BIOS setup.

Notice

A CD-ROM drive should only be operated in a mechanically undisturbed environment

without vibrations and shock.

SIMATIC Panel PC 577

1-6 Operating Instructions, Release 04/2006, A5E00798484-01

Page 19

Safety instructions and general notes

1.2 General information, download "Panel PC"

Safety-relevant applications

Warning

Maloperation

Do not perform safety-relevant functions of the user software with the touch screen.

Chemical resistance

Caution

Adhere to the information regarding chemical resistance. Please refer to the "Tools &

Demosoftware" Internet site for more information. Enter "Chemical resistance" as the search

term. The available articles are displayed.

Sources of light

Notice

Position the screen so that it is not subject to direct sunlight or other strong sources of light.

Defective pixels in the display

At present, the manufacturing process of modern displays does not guarantee that all pixels

of the display will be perfect. A small number of defective pixels in the display is therefore

unavoidable. This does not present a functional problem as long as the defective pixels are

not bunched in one location.

Refer to the "Technical data" section for more information.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

1-7

Page 20

Safety instructions and general notes

1.2 General information, download "Panel PC"

Burn-in effect on TFT displays

A permanent picture with bright images can lead to a burn-in effect on the TFT LCD.

If a screen saver is activated, please observe the following:

• The liquid crystals in screen savers which actuate active black when the backlighting is

on, e.g. flying stars "starfield simulation," renew themselves. Pay attention to the length of

time the backlighting is activated.

• The following applies to screen savers which turn off the backlighting: Each time the

backlighting is turned on, its life is reduced by 50 minutes.

Consider the following carefully:

• Screensaver

• Switch off the backlighting regularly

• Permanent display of the customer application

SIMATIC Panel PC 577

1-8 Operating Instructions, Release 04/2006, A5E00798484-01

Page 21

Description

2.1 2.1 Application features

Introduction

The Panel PC 577 provides a high standard of quality based on the protection type of the

control unit, high-level EMC and CE certification for industrial application.

The device is designed for 24 hour operation. Further information is available in the section

"Ambient and environmental conditions of the "Technical data" chapter.

The Panel PC 577 is scalable beginning with the processor type and the memory modules

all the way to the operating system.

Interfaces

• The integrated Ethernet interface ensures communication with the office world and the

management level.

• PC peripherals can be connected via the integrated USB interfaces at the rear and front

of the device.

2

• Connection to the process is made with communication cards and PC expansion

modules in the available PC slots.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

2-1

Page 22

Description

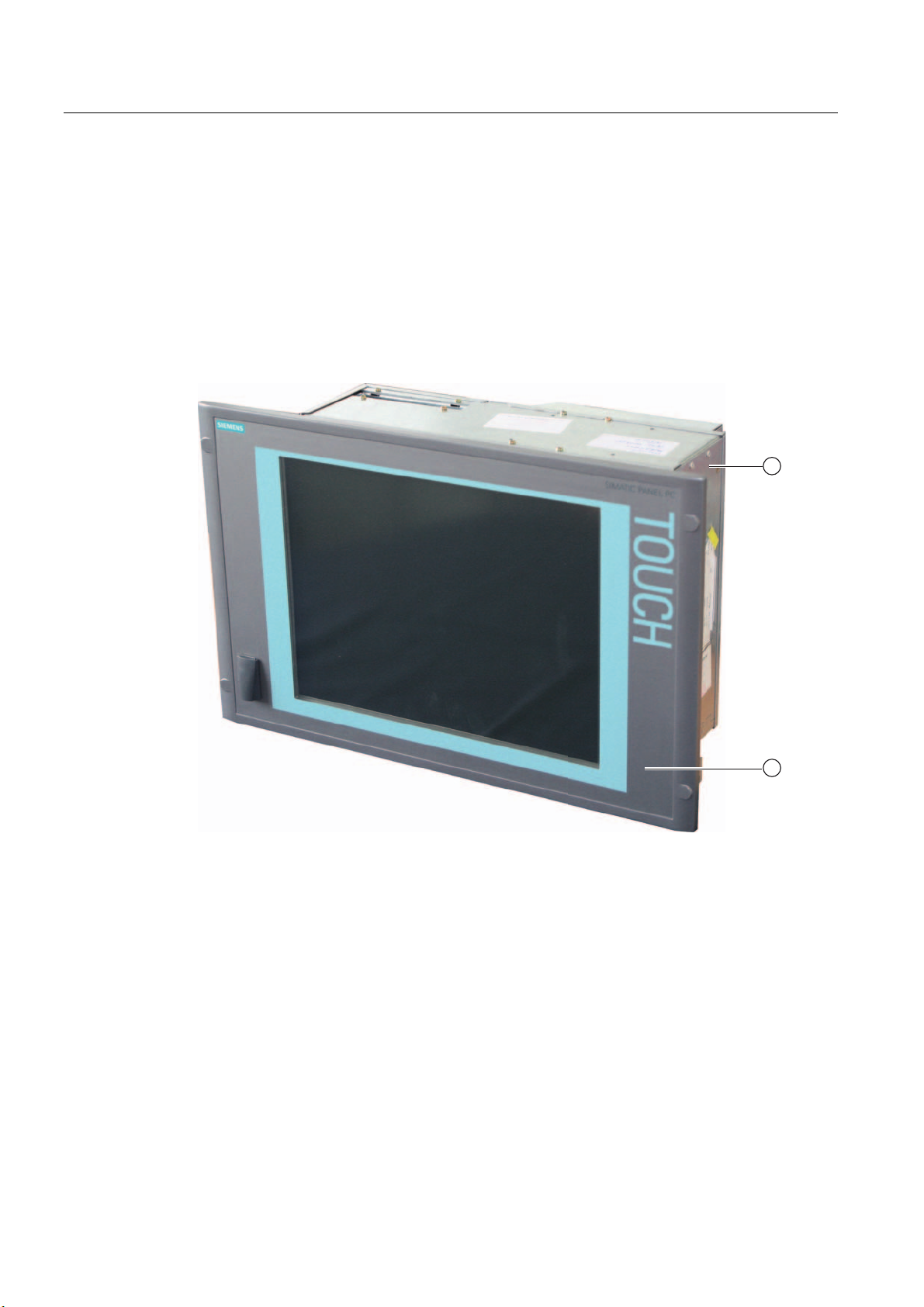

2.2 Design

2.2 2.2 Design

The device serves as a base for PC-based HMI devices, the Panel PCs. The Panel PC 577

fulfills the basic requirements for industrial compatibility and provides high performance at a

low price.

The device consists of the control unit with a key or touch panel and the computer unit. The

control unit is screwed to the back of the computer unit.

Figure 2-1 Panel PC 577

1 Control unit

2 Computer unit

SIMATIC Panel PC 577

2-2 Operating Instructions, Release 04/2006, A5E00798484-01

Page 23

Description

2.3 Technical features

2.3 2.3 Technical features

General features

Processor - Intel® Pentium 4 2.4 GHz

- Intel® Celeron 2.0 GHz

Chipset Intel 865G

Main memory 256 MB = 2 x 128 MB SDRAM or

1 x 256 MB SDRAM

512 MB = 2 x 256 MB SDRAM

4 slots, expandable to 4 GB maximum

Slots for add-ons

Device variants

The device is available with different control

units which are distinguished by the size of the

display and by a membrane keyboard or touch

screen.

Graphics On-board graphics (865G chipset)

Power supply 110/230 V AC, 350 W; variable voltage with short-

Drives optional CD-ROM drive

Hard disks ≥ 40 GB HDD small, 1x 2.5"

Operating system, optional Preinstalled, also installed on the Restore CD

• Uppermost slot is suitable for WinAC Slot

module

• 2 x PCI 175 mm long (below)

Keyboard variants

• 12"/15" TFT technology

• Color display with backlighting

• Membrane keyboard with alphanumeric keys,

numeric keys, cursor keys and control keys

• Function keys and softkeys

• Integrated mouse

• Softkeys, <Shift> und <ACK>

• Front-mounted USB 2.0 interface for

connecting external I/O modules

Touch screen variants

• 12''/15''/19'' TFT technology

• Color display with backlighting

• Front-mounted USB 2.0 interface for

connecting external I/O modules

12'': 800 x 600, 60 Hz

15'': 1024 x 768, 60 Hz

19'': 1280 x 1024, 60 Hz

term buffering against power failure at maximum

16 ms

- Windows 2000 Professional MUI*

- Windows XP Professional MUI*

*MUI: Multi-language user interface; German,

English, French, Italian, Spanish, Japanese,

Korean, Chinese simplified and Chinese

traditional

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

2-3

Page 24

Description

2.3 Technical features

Interfaces

Installed via expansion cards: PROFIBUS / MPI CP 5611-compatible

(not included in the scope of supply)

Ethernet LAN 10/100/1000 Mbps

USB 4x USB 2.0 high current, external

2x USB 2.0 high current available, internal

via male connector

1x USB 2.0 high current, front mounted

Serial interfaces COM1 V.24

Parallel interfaces LPT1

Keyboard PS/2

Mouse PS/2

Accessories not supplied with the device package

SIMATIC PC

Image Creator SW

Film for protecting the touch screen panel

against dirt and scratches

for the 12" touch screen variant

for the 15" touch screen variant

for the 19" touch screen variant

Labeling strips

for 12" keyboard variant

for 15" keyboard variant

Screw fixing elements

for 19'' touch screen variant

Software for local data backup

6AV7671-2BA00-0AA0

6AV7671-4BA00-0AA0

6AV7672-1CE00-0AA0

6AV7672-0DA00-0AA0

The labeling strips and printing templates can be

obtained from the Internet address mentioned in

the preface.

6AV7672-8KE00-0AA0

SIMATIC Panel PC 577

2-4 Operating Instructions, Release 04/2006, A5E00798484-01

Page 25

Description

2.3 Technical features

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

2-5

Page 26

Description

2.3 Technical features

SIMATIC Panel PC 577

2-6 Operating Instructions, Release 04/2006, A5E00798484-01

Page 27

Planning use

3.1 3.1 Overview

Introduction

This section describes the first steps after unpacking, the permitted mounting positions and

the fixation. This section describes the necessary considerations for EMC.

Field of application

The Panel PC is an industry-standard PC platform for demanding tasks in the field of PCbased automation. The Panel PC is designed for on-site use on the machine, installed for

example in:

• Control cabinets

• Swivel arms

• In consoles

3

Note

In the following, the term "control cabinet" also refers to rack, mounting rack, switchboard,

operator panel and console. The term "device" represents the Panel PC and its variants.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

3-1

Page 28

Planning use

3.2 Unpacking and checking the delivery

3.2 3.2 Unpacking and checking the delivery

Procedure

1. Please check the packaging material for transport damage upon delivery.

2. If any transport damage is present at the time of delivery, lodge a complaint at the

shipping company in charge. Have the shipper confirm the transport damage

immediately.

3. Unpack the device.

Caution

Do not lie the device on its back. This will avoid any damage to an optical drive which

may be present. Lie the front side on a soft surface to avoid damaging the front panel

USB interface.

4. Keep the packaging material in case you have to transport the unit again.

Notice

The packaging protects the device during transport and storage. Therefore, never

dispose of the original packaging material!

5. Please keep the enclosed documentation in a safe place. You will need the

documentation when you start up the device for the first time.

6. Check the package contents for completeness and any visible transport damage. Check

for completeness using the "Contents of Delivery" list in the Operating Instructions

(compact).

7. Notify the delivery service in charge immediately if the packages contents are incomplete

or damaged.

Warning

Make sure that a damaged device is not installed or put into operation.

8. Note the identification information as described in the "Operating Instructions (compact)"

document.

SIMATIC Panel PC 577

3-2 Operating Instructions, Release 04/2006, A5E00798484-01

Page 29

Planning use

3.2 Unpacking and checking the delivery

Warning

Risk of damage

Do not transport the device when it is mounted. During transport, use the hard disk

transport lock (if present).

The device is approved for use with the following operating systems:

Approvals

• Windows 2000 Professional Multi-Language SP4 and higher, German, English, French,

Italian, Spanish, Japanese, Korean, Chinese Simplified and Chinese Traditional

• Windows XP Professional Multi-Language, German, English, French, Italian, Spanish,

Japanese, Korean, Chinese Simplified and Chinese Traditional

Windows XP Professional is only approved as of Service Pack 2.

The operating system is provided with the Windows function modes "Hibernate" and

"Standby" deactivated when shutting down the operating system and with "Fast User

Switch" (Windows XP Professional) deactivated.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

3-3

Page 30

Planning use

3.3 Make note of identification data

3.3 3.3 Make note of identification data

Procedure

1. Write down the Microsoft Windows product key of the Certificate of Authenticity COA in

the table at the end of this section. The product key can be found on the back of the

device. You will need the product key during the reinstallation of the operating system.

2. Write down the manufacturer's number SVP and the order number , e.g. "6AV782...", in

the table. If repairs are necessary, the device can be identified by the service center on

the basis of the SVP number and order number.

Both numbers can be found on the rating plate attached to the side of the device where

the power unit is located.

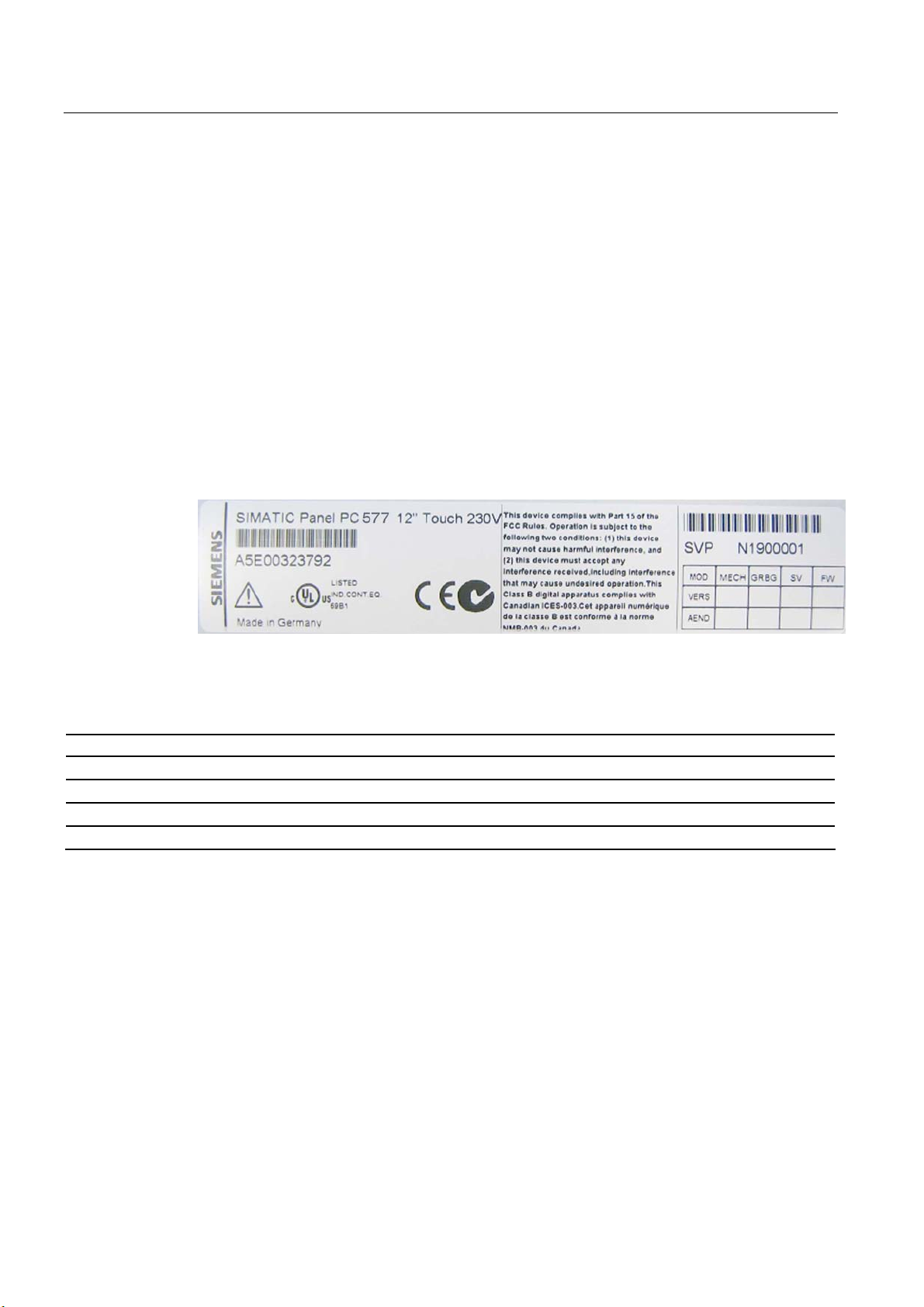

Figure 3-1 Rating plate

3. Enter the Ethernet address of the device: The Ethernet address is located in the "Main"

menu of the BIOS setup, "Hardware Options > Ethernet Address."

Identification Number

1 Microsoft Windows Product Key

2 SVP number

3 Order number

10 Ethernet address (MAC address)

SIMATIC Panel PC 577

3-4 Operating Instructions, Release 04/2006, A5E00798484-01

Page 31

Planning use

3.4 EMC directive

3.4 3.4 EMC directive

Electromagnetic compatibility

The device fulfills the requirements of the EMC law of the Federal Republic of Germany as

well as the EMC directive of the Single European Market.

The device is designed as a built-in model with front-sided IP65 degree of protection. Ensure

compliance with the EN 61000-4-2 standard by installing the device in grounded metal

cabinets, e.g. 8 MC cabinets, Siemens catalog NV21.

Note

For additional information about EMC requirements, refer to the Technical data section.

Installing the device according to EMC directive

Basics for interference-free operation:

• Install the controller according to EMC directive

• Use interference-immune cable

Note

The instructions "Guidelines for the assembly of interference-immune programmable logic

controllers" with the article ID 1064706 and the manual "PROFIBUS networks" with the

article ID 1971286, which also applies to the installation of the device, is located on the

"Documentation and Drivers" CD.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

3-5

Page 32

Planning use

3.5 Mounting positions and fastening

3.5 3.5 Mounting positions and fastening

3.5.1 Installation instructions

Before mounting the device, read the following general notes relating to installation.

Warning

Dangerous Voltage

Isolate the power supply to the control cabinet before opening it. Ensure that the power to

the control cabinet cannot be turned on accidentally.

Caution

The device is approved for operation in closed rooms only.

• Ensure that the grounding outlet of the building installation is easily accessible and that

there is a mains disconnect switch in control cabinet installations.

• Position the screen in an ergonomic position favorable to the user. Choose a suitable

mounting height.

• Position the screen so that it is not subject to direct sunlight or other strong sources of

light.

• DVD drives are susceptible to shock. Shocks during operation can lead to the loss of data

or damage to the drive or data carrier. Burners and DVDs are not suitable for continous

operation.

• Applies to devices which are installed in swivel arm housings: Avoid rapid or jerky

movements of the swivel arm during operation. The ensuing forces could lead to possible

irreversible damage of the hard disk.

• Provide adequate volume in the control cabinet for air circulation and heat transport.

Keep at least 10 cm distance between the device and control cabinet.

• Do not allow the maximum air intake temperature to exceed 45° C. Decisive is the

temperature measured at a distance of 10 cm from an air intake. The maximum air intake

temperature must be accounted for especially when sizing closed control cabinets.

• Position the device so that the air vents of the housing are not covered up following

mounting.

• Ensure there is enough free space in the control cabinet to allow the sheet metal cover to

be removed. You will otherwise have to remove the device from the control cabinet or

swivel arm when replacing the memory or the battery.

SIMATIC Panel PC 577

3-6 Operating Instructions, Release 04/2006, A5E00798484-01

Page 33

Planning use

3.5 Mounting positions and fastening

• Also provide enough free space to add on to the device.

• Equip the control cabinet with struts for stabilizing the mounting cut-out. Install struts

where necessary.

• Avoid extreme environmental operating conditions. Protect your device against dust,

moisture and heat.

• Install the device in such a way that it poses no danger, e.g. by falling over.

• During assembly, please comply with the approved mounting positions.

Notice

The device must be mounted in a fireproof cabinet to fulfill the requirements for UL508

certification.

To fulfill the requirements for EN 60950, the device must be mounted in a permitted

position.

For additional information, refer to the dimensional drawings in the appendix.

Warning

Function test while installing the device in machines or execute systems

Following the results of a risk analysis, additional protection equipment on the machine or

the system is necessary to avoid endangering persons. With this, especially the

programming, configuration and wiring of the inserted I/O modules have to be executed, in

accordance with the safety performance (SIL, PL or Cat.) identified by the necessary risk

analysis. The intended use of the device has to be ensured.

The proper use of the device has to be verified with a function test on the system. This test

can detect programming, configuration and wiring errors. The test results have to be

documented and, if necessary, entered into the relevant documents that verify safety.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

3-7

Page 34

Planning use

3.5 Mounting positions and fastening

3.5.2 Permitted mounting positions

Approval

Only certain mounting positions are approved for the device.

Figure 3-2 Permitted mounting position

The device can be mounted in a vertical position with deviations between +5° and -5° in the

given directions.

3.5.3 Mounting type

The control unit is secured in the mounting cut-out either with clamps or screws.

Notice

Securing with screws is not possible with the 12" touch screen variant.

For securing the 19'' touch screen variant with screws, you will need the accessory with

MLFB No. 6AV7672-8KE00-0AA0

Select the type of mounting suitable to your requirements for the degree of protection.

SIMATIC Panel PC 577

3-8 Operating Instructions, Release 04/2006, A5E00798484-01

Page 35

Planning use

3.5 Mounting positions and fastening

3.5.4 Degree of protection

Principle

The degree of protection provided at the front is assured when the mounting seal lies

completely against the mounting cut-out.

Caution

Please ensure that the material strength at the mounting cut-out is a maximum of 6 mm.

Please follow the specifications for the dimensions in the "Mounting cut-out" section.

The degrees of protection are only guaranteed when the following is observed:

• The material strength at the mounting cut-out is at least 2 mm.

• The surface plane deviation of the mounting cut-out in relation to the external dimensions

of the control unit amounts to ≤ 0.5 mm when the control unit is mounted.

IP65 degree of protection and NEMA4

The IP65 degree of protection and NEMA4 is only provided for clamp mounting together with

a ring seal.

IP54 degree of protection

This degree of protection is assured when fixed using screws and the mounting components

for 19" rack accessories.

Note

For screw fixing of the 19" touch panel front, a backing plate is available as an accessory.

For further information, see "http://mall.ad.siemens.com/

".

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

3-9

Page 36

Planning use

3.6 Mounting cut-out

3.6 3.6 Mounting cut-out

3.6.1 Selecting and creating the mounting cut-out

Requirement

The degree of protection suitable to the field of application and thereby the mounting method

have been selected.

Procedure

1. Follow the installation instructions.

2. Select a location suitable for installation, taking into account the installation instructions

and the chosen mounting position.

3. On the basis of the dimensional drawings, check whether the required screw and

pressure points on the rear and the hatched seal area are easily accessible after the

completion of the mounting cut-out. Otherwise the mounting cut-out is useless.

4. Complete the mounting cut-out in accordance with the dimensions. You can also obtain

these dimensions from the mounting template supplied with the device.

SIMATIC Panel PC 577

3-10 Operating Instructions, Release 04/2006, A5E00798484-01

Page 37

Planning use

3.6 Mounting cut-out

3.6.2 Dimensions

The following illustration shows the dimensions for the mounting cut-out. You can also obtain

these dimensions from the mounting template supplied with the device.

$

$

6

/

/

/

/ /

/ 6 6 /

66

/ 6 6 /

/

/

/

/

Figure 3-3 Drill holes for the screws and pressure points for the clamp screws

/

PP

(1) Drill hole for screw attachment (4) Clamp

(2) Pressure points for clamp (5) R

(3) Setscrews (6) Seal area

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

120 in the seal area

Z

3-11

Page 38

Planning use

3.6 Mounting cut-out

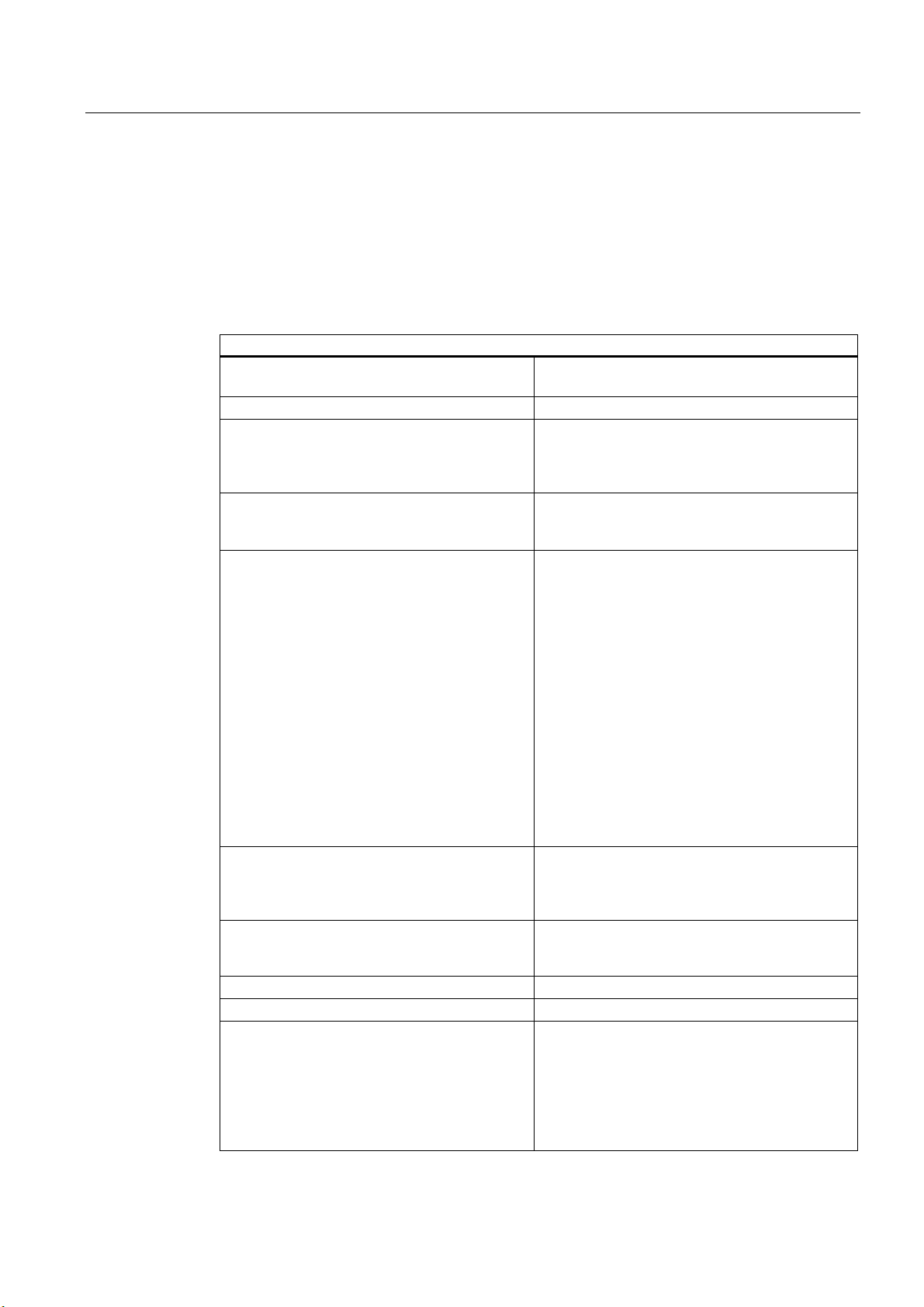

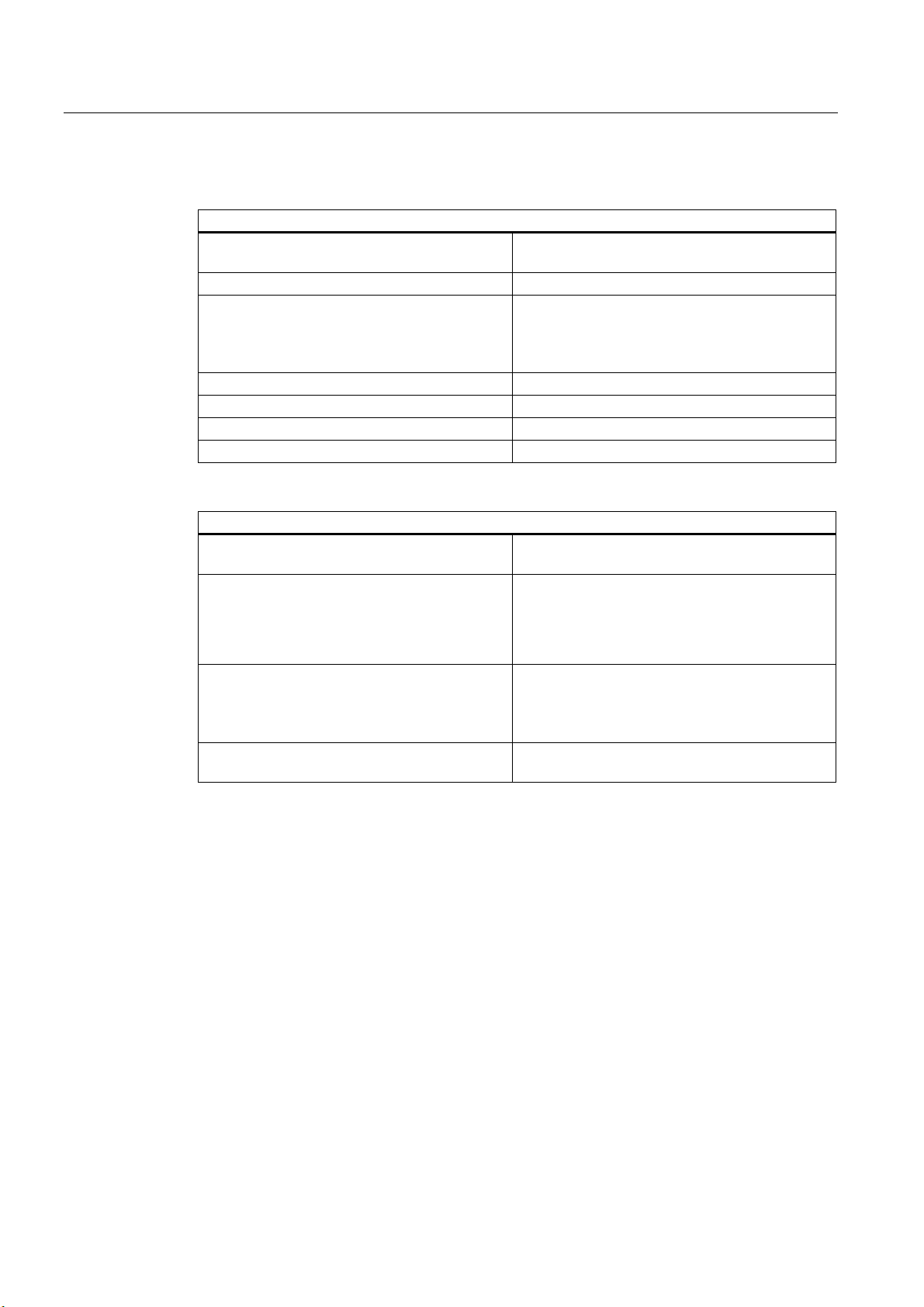

Table 3-1 Dimensions for the mounting cut-out in mm

1)

Control

L1 L2 L3

L4

L5 L6

1)

units

Tolerance +1 +1 ±0.2 ±0.2 ±0.5 ±0.5 ±0.5 ±0.5 +1 ±1 ±1 ±1 ±1 ±1 ±1 ±1 ±1 ±1

Key

panels

12" TFT

15" TFT

Touch

screen

panels

12" TFT

15" TFT

450

450

368

450

450

290

321

290

290

380

465

465

—

465

465

235

279

—

235

235

112

112

112

112

112

19" TFT

1)

M6 thread or drill holes with a diameter of 7 mm

2)

Cut-outs for the shafts of the insert strips are only necessary for 15" key panels.

3)

Only for 19" touch panels are two clamps necessary for vertically securing clamps.

—

186

—

—

—

2)

L7

2)

—

135

—

—

—

2)

2)

L8

—

25

—

—

—

L9

A1 A2 S1 S2 S3 S4 S53) S63)S73)

56

78

78

78

78

10

16

—

56

51

51

51

51

17

16

165

56

35

35

35

19

10

16

—

56

81

81

81

81

10

16

—

—

46

46

46

46

10

16

—

—

—

—

—

33

—

—

—

—

33

More information about device dimensions, e.g. mounting depth, can be found in the

"Dimensional drawings" section.

SIMATIC Panel PC 577

3-12 Operating Instructions, Release 04/2006, A5E00798484-01

Page 39

Installation

4.1 4.1 Securing with clamps

Scope

Skip this step if you have selected "screw mounting."

Requirement

Note

The 12" touch screen variant can only be fixed in place using clamps.

• The mounting cut-out has been completed.

• Clamps are readily available in the accessories. Clamps and setscrews are included in

the contents of delivery.

4

Figure 4-1 Clamp assembly

Procedure

1. Follow the installation instructions.

2. Working from the front, insert the device into the mounting cut-out.

3. Secure the control unit in the mounting cut-out from behind with the clamps, as shown in

the mounting cut-out in the dimensions. Tighten the setscrews to a torque of 0.4-0.5 Nm.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

4-1

Page 40

Installation

4.2 Securing with screws

4.2 4.2 Securing with screws

Scope

Skip this step if you have selected "clamp mounting."

Requirement

Notice

Securing with screws is not possible with the 12" touch screen variant.

For securing the 19'' touch screen variant with screws, you will need the accessory with

MLFB No. 6AV7672-8KE00-0AA0

The mounting cut-out has been completed.

SIMATIC Panel PC 577

4-2 Operating Instructions, Release 04/2006, A5E00798484-01

Page 41

Installation

4.2 Securing with screws

Procedure

1. Follow the installation instructions.

2. Drill suitable holes at the prepared mounting cut-out in accordance with the specifications

for L4 and L5, as shown in the mounting cut-out in the dimensions.

3. Carefully drill the respective holes in the control unit at the designated location (1) from

the rear.

Figure 4-2 Designated location for holes on the control unit

4. Working from the front, insert the device into the mounting cut-out.

5. Secure the control unit by inserting suitable screws through the holes and attaching nuts.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

4-3

Page 42

Installation

4.3 Dimensions

4.3 4.3 Dimensions

The mounting depth increases by 28 mm when a DVD-ROM drive is installed in the device.

Refer to the dimensional drawings in the "Technical specifications" section for the exact

measurements.

SIMATIC Panel PC 577

4-4 Operating Instructions, Release 04/2006, A5E00798484-01

Page 43

Connecting

5.1 5.1 Overview

Introduction

Once you have mounted the device, connect it.

Warning

Do not touch power cables or data transmission cables during electrical storms and do not

connect any cables.

Unplug the mains connector from the socket to be sure the electricity is disconnected.

Caution

Connection sequence

Follow the described sequence when connecting the device to avoid damaging it.

5

Commissioning

Allow the device to adjust to the room temperature before connecting the device. Do no

place the device near direct heat radiation. If moisture condensation occurs, wait at least

about 12 hours before you switch on the device.

Risk of data loss!

Do not disconnect the power supply when the device is in operation. Disconnect the power

only after the device has been correctly shut down.

Requirement

• The device has been installed in conformity with the EMC directive

• The device has been installed according to the information provided in these operating

instructions.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

5-1

Page 44

Connecting

5.1 Overview

Procedure

1. Connect the equipotential bonding.

2. Connect peripherals:

– Connect an external monitor if desired.

– Connect the PS/2 mouse.

– Connect the PS/2 keyboard.

– Connect a USB device such as a USB mouse if desired.

– Connect a printer.

3. Connect the power supply.

SIMATIC Panel PC 577

5-2 Operating Instructions, Release 04/2006, A5E00798484-01

Page 45

Connecting

5.2 Interfaces

5.2 5.2 Interfaces

5.2.1 Front interfaces

Introduction

A USB interface is located on the front side. For more information, please refer to the

chapter "Operation." Attach an external keyboard or an external mouse, for example, to the

USB interface. The front-side USB interface supports the standard USB 2.0.

Caution

Wait at least 10 seconds between the unplugging and replugging of USB devices. This also

applies in particular to touch control in control units with touch screen panels.

Notice

When the cover over the USB interface is opened in order to connect a USB component, the

degree of protection for the device is no longer guaranteed.

When using standard USB peripherals, please bear in mind that their EMC immunity level is

frequently designed for office applications only. These devices are adequate for

commissioning and servicing purposes. However, only industry-standard devices are

allowed for industrial operation.

The peripherals are developed and marketed by individual vendors. The respective

manufacturers offer support for the peripherals. Moreover, the terms of liability of the

individual vendors or suppliers apply here.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

5-3

Page 46

Connecting

5.2 Interfaces

5.2.2 Rear interfaces

Interfaces

Arrangement of the interfaces

Item Name Description

(1) KEYBOARD Connection for a PS/2 keyboard

(2) Mouse Connection for a PS/2 mouse

(3) USB 2.0 Connection for USB devices

(4) COM 1 Serial interface, 9-pin Sub-D

connector

(5) LPT 1 Parallel interface, 25-pin sub D

socket

(6) VGA VGA connection

(7) USB 2.0 Connection for USB devices

(8) Ethernet RJ 45 Ethernet connection

10/100/1000 Mbps

SIMATIC Panel PC 577

5-4 Operating Instructions, Release 04/2006, A5E00798484-01

Page 47

Connecting

5.2 Interfaces

Power supply

Position of the IEC power connector Description

IEC power connector (2) for the AC power

supply to the device. The maximum

permitted power supply range is 120 V AC

to 230 V AC.

On / Off switch (1)

Note

You can also switch on the device using the soft power key. Refer to the "Operator controls"

chapter for more information.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

5-5

Page 48

Connecting

5.3 Connecting peripherals

5.3 5.3 Connecting peripherals

5.3.1 Overview

When connecting the device for the first time, connect a PS/2 keyboard and PS/2 mouse.

Connect any required USB components such as a USB hub.

Caution

Disconnect the device from the power supply before connecting peripherals. This does not

apply to connecting and disconnecting USB devices.

Connect only I/O modules approved for industrial applications according to EN 61000-6-

2:2001. Use shielded cables and metal connectors to connect peripherals. Otherwise, the

specified standards and specifications declared by Siemens AG are no longer valid. Secure

the plugs of the interface cables to the device housing with screws. This improves the

electrical shielding.

Mouse

Connect a PS/2 or USB mouse.

5.3.2 Connecting a monitor

The front panel is activated as the display by default when the operating system starts. An

external monitor connected to the VGA port is therefore deactivated.

Learn how to activate an external monitor by reading the section "Installing and removing

hardware components" in the "Service and maintenance" chapter.

SIMATIC Panel PC 577

5-6 Operating Instructions, Release 04/2006, A5E00798484-01

Page 49

Connecting

5.3 Connecting peripherals

5.3.3 USB

Introduction

Commercially available USB peripherals can be easily and flexibly connected via the USB

interface. For example, you can connect an external USB keyboard and a USB mouse. If the

USB keyboard has a USB interface, you can connect other USB peripherals, such as a USB

mouse, directly to the keyboard.

USB interface

There are several types of USB peripherals:

• Low power devices: maximum 100 mA power consumption, e.g. mouse and keyboard

• High power devices maximum 500 mA power consumption, e.g. hard disk and floppy

drive

Note

The general USB specifications apply to the USB interfaces on the computer unit.

The USB interface on the front panel has been approved for a maximum of one additional

USB hub.

Using USB peripherals

Notice

When installing a USB device for the first time, make sure you have the required device

driver.

Before removing an intelligent USB device, deactivate the device in the operating system

using the dialog "Unplug or Eject Hardware". For additional information, refer to the

documentation for the operating system.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

5-7

Page 50

Connecting

5.3 Connecting peripherals

Connecting USB devices

Procedure

Caution

Wait at least 10 seconds between removal and reconnection of USB devices. This also

applies to control units with touch screens, especially for touch operation.

Notice

When using standard USB peripherals, please bear in mind that their EMC immunity level is

frequently designed for office applications only. These devices are adequate for

commissioning and servicing purposes. However, only industry-standard devices are

allowed for industrial operation.

The peripherals are developed and marketed by individual vendors. The respective

manufacturers offer support for the peripherals. Moreover, the terms of liability of the

individual vendors or suppliers apply here. More information about connecting USB devices

is available in the "Commissioning" section.

1. Insert the USB cable into one of the USB interfaces. The device is automatically detected

by the Plug and Play operating system. The operating system may prompt you to install a

driver when necessary.

SIMATIC Panel PC 577

5-8 Operating Instructions, Release 04/2006, A5E00798484-01

Page 51

Connecting

5.4 Connecting the power supply

5.4 5.4 Connecting the power supply

Principle

The device can be optionally operated on 110 or 230 V AC systems. The device features an

automatic voltage switch and a power switch.

Caution

Do not touch power cables or data transmission cables during electrical storms and do not

connect any cables.

Unplug the mains connector from the socket to be sure the electricity is disconnected.

The device features a safety-certified power cable. Connect the device only to a grounding

outlet. Operate the device only on grounded power cables and not on impedance grounding

systems such as IT systems.

Make sure that the local supply voltage complies with the permissible rated voltage for the

device.

Warning

Select an adequately large cable diameter so that the device is not damaged by the cable

during a short circuit.

Localized information

Outside of the USA and Canada, 230 V AC power supply:

If you do not use the safety-certified power cable, use a flexible cable with the following

characteristics:

• At least 18 AWG conductor cross-section

• Grounding plug 15 A, 250 V

Notice

Ensure that the cable set conforms to the respective national safety regulations and is

appropriately labeled.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

5-9

Page 52

Connecting

5.4 Connecting the power supply

For USA and Canada:

A UL-listed power supply cable must be used in the United States and Canada.

110V power supply

Use a flexible cable with the following characteristics:

• UL approval

• Type SJT with three conductors

• At least 18 AWG conductor cross-section

• Maximum 4.5 m length

• Parallel grounding plug 15 A, min. 125 V

230V power supply

Use a flexible cable with the following characteristics:

• UL approval

Procedure

• Type SJT with three conductors

• At least 18 AWG conductor cross-section

• Maximum 4.5 m length

• Tandem grounding plug 15 A, min. 250 V

1. Insert the supplied power cable into the AC/DC power socket of the device.

2. Lock the power plug with the interlocking device supplied in the package. This will

prevent unintentional detachment of the IEC power connector on the device.

SIMATIC Panel PC 577

5-10 Operating Instructions, Release 04/2006, A5E00798484-01

Page 53

Connecting

5.5 Uninterruptible AC power supplies

5.5 5.5 Uninterruptible AC power supplies

Introduction

This chapter describes the considerations involved in using an uninterruptible AC power

supply (AC UPS) for the Panel PC.

Due to legal regulations related to reducing reactive-power consumption in public and private

electrical networks, all AC voltage supplies in Panel PCs feature a power factor correction

(PFC) circuit. Technically, there is passive PFC and active PFC.

Active PFC

All Panel PC 87x, Panel PC 577 and Panel PC 677 feature an active PFC. Active PFC

requires almost perfect sinusoidal input voltage.

Caution

Uninterruptible AC power supplies (AC UPS) with non-sinusoidal wave form damage the

power supply unit of Panel PCs with active PFC.

Make that the AC UPS supplies a sinusoidal output voltage in normal and battery mode for

use on a Panel PC with active PFC.

Selection criteria for an uninterruptible power supply

Uninterruptible power supplies with sinusoidal output voltage in normal and battery mode are

classified as "VFI-SS-…" or "VI-SS-…".

UPS characteristics are described and classified in EN 50091-3 and IEC 62040-3.

Note

More information is available on the Internet at "www.ad.siemens.de

Solutions." Click on "Service & Support" under "Services" and search for the article ID

"17241008" on the "Product Support" page. At the end of the article there is a link to the

document, "UPS Classification Based On Operational Performance".

" under "Products &

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

5-11

Page 54

Connecting

5.6 Connecting the equipotential bonding

5.6 5.6 Connecting the equipotential bonding

A low-resistance ground connection ensures that interference signals generated by external

power supply cables, signal cables or cables to the I/O modules are safely discharged to

ground.

The equipotential bonding connection of the device is located at the connection elements of

the computer unit and is identified by the following symbol:

Figure 5-1 Equipotential bonding

Connecting the equipotential bonding

Required tool for equipotential bonding terminal: TORX T20 screwdriver

Steps for connecting the equipotential bonding

1 Connect the equipotential bonding connection

(M4 thread) on the device (1) (large surface,

large-area contact) with the central grounding

point of the control cabinet.

The minimum conductor cross-section may not

amount to less than 5 mm2.

SIMATIC Panel PC 577

5-12 Operating Instructions, Release 04/2006, A5E00798484-01

Page 55

Connecting

5.6 Connecting the equipotential bonding

Avoiding differences in potential

Differences in potential arise between separated system parts, which in some cases lead to

high equalization currents. This situation may arise if the cable shielding is terminated at

both ends and grounded at different system parts. Potential differences can be caused, for

example, by different power inputs.

Reduce the differences in potential by laying the equipotential bonding cables in such a way

that the affected electronic components function properly. Observe the following guidelines

when setting up equipotential bonding:

• When two system parts are connected by means of a shielded signal cable, and their

shields are both connected to the ground or protective conductor, the following must be

observed: The impedance of the additional equipotential bonding cable amounts to 10%

of the shield impedance, at the most.

• Ensure that the equipotential bonding cable cross-section is selected to accommodate

the maximum equalization current. The equipotential bonding conductor cross-section

that has proven best in practice is 16 mm

• Use equipotential bonding conductors made of copper or galvanized steel. Connect the

cables to the ground or protective conductor over a wide area. Protect the ground or

protective conductor from corrosion.

2

.

• Lay the equipotential bonding cable in such a way that the area between the equipotential

bonding cable and signal cables is as small as possible.

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

5-13

Page 56

Connecting

5.6 Connecting the equipotential bonding

SIMATIC Panel PC 577

5-14 Operating Instructions, Release 04/2006, A5E00798484-01

Page 57

Connecting

5.6 Connecting the equipotential bonding

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00798484-01

5-15

Page 58

Page 59

Commissioning

6.1 6.1 Removing the transport lock for the hard disk

Note

Not every device has a hard disk transport lock.