Siemens SIMATIC NET TeleControl S7-1200 CP 1243-1 Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC NET

S7-1200 - TeleControl

CP 1243-1

Operating Instructions

12/2016

C79000

Preface

Application and properties

1

LEDs and connectors

2

Installation, connecting up,

commissioning

3

Configuration

4

Diagnostics and upkeep

5

Technical data

6

Approvals

A

Dimension drawings

B

Documentation references

C

-G8976-C365-02

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

C79000-G8976-C365-02

Ⓟ

Copyright © Siemens AG 2014 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

12/2016 Subject to change

Preface

Validity of this manual

CP 1243-1

This document contains information on the following telecontrol product:

●

Article number 6GK7 243-1BX30-0XE0

Hardware product version 2

Firmware version V2.1.77

The CP 1243-1 is the communications processor for connecting the SIMATIC S7-1200 to

a control center with TeleControl Server Basic (V3) via the public infrastructure (e.g.

DSL).

With the help of VPN technology and the firewall, the CP allows protected access to the

S7-1200.

The CP can also be used as an additional interface of the CPU for S7 communication.

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

Figure 1 CP 1243-1

3

Preface

Product names and abbreviations

TCSB

STEP 7

ES

Purpose of the manual

New in this issue

Replaced manual issue

Behind the top hinged cover of the module housing, you will see the hardware product

version to the right of the article number printed as a placeholder "X". If the printed text is, for

example, "X 2 3 4", "X" would be the placeholder for hardware product version 1.

You will find the firmware version of the CP as supplied behind the top hinged cover of the

housing to the left below the LED field.

You will find the MAC address under the lower hinged cover of the housing.

● CP

The term "CP" is used below instead of the full product name CP 1243-1.

●

This abbreviation ill be used below for the "TeleControl Server Basic", version V3.

●

This short form will be used below for the STEP 7 Basic / Professional configuration tool.

●

PC with the STEP 7 project

This manual describes the properties of this module and supports you when installing and

commissioning it.

The required configuration steps are described as an overview and there are explanations of

the relationship between firmware functions and configuration.

You will also find information about the diagnostics options of the device.

● New functions in the firmware version named above:

– Changed behavior during time-of-day synchronization, see section Time-of-day

– Changed selection of supported data types, see section Datapoint types (Page 71).

– Changing the IP address during runtime, see section Address and authentication data

– Support of S7 routing

● Functional improvement of data point configuration as of STEP 7 V13 + SP1. see section

Configuring data points and messages (Page 65).

synchronization (Page 50).

(Page 37).

● Editorial revision

Release 07/2014

CP 1243-1

4 Operating Instructions, 12/2016, C79000-G8976-C365-02

Preface

Current manual release on the Internet

Required experience

Cross references

Sources of information and other documentation

License conditions

Note

Open source software

The product contains open source software. Read the license conditions for open sourc

software carefully before using the product.

Firmware

Security information

You will find the current version of this manual on the Internet pages of Siemens Industry

Online Support:

Link: (https://support.industry.siemens.com/cs/ww/en/ps/15922/man)

To install, commission and operate the CP, you require experience in the following areas:

● Automation engineering

● Setting up the SIMATIC S7-1200

● SIMATIC STEP 7 Basic / Professional

In this manual there are often cross references to other sections.

To be able to return to the initial page after jumping to a cross reference, some PDF readers

support the command <Alt>+<Left arrow>.

You will find an overview of further reading and references in the Appendix of this manual.

You will find license conditions in the following document on the supplied data medium:

● OSS-CP1243-1_86.pdf

The firmware is signed and encrypted. This ensures that only firmware created by Siemens

can be downloaded to the device.

e

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

5

Preface

SIMATIC NET glossary

Training, Service & Support

Recycling and disposal

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

Link: (http://www.siemens.com/industrialsecurity)

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Link: (http://www.siemens.com/industrialsecurity).

Explanations of many of the specialist terms used in this documentation can be found in the

SIMATIC NET glossary.

You will find the SIMATIC NET glossary on the Internet at the following address:

Link: (https://support.industry.siemens.com/cs/ww/en/view/50305045)

You will find information on Training, Service & Support in the multi--language document

"DC_support_99.pdf" on the data medium supplied with the documentation.

The product is low in pollutants, can be recycled and meets the requirements of the WEEE

directive 2012/19/EU "Waste Electrical and Electronic Equipment".

Do not dispose of the product at public disposal sites. For environmentally friendly recycling

and the disposal of your old device contact a certified disposal company for electronic scrap

or your Siemens contact.

Keep to the local regulations.

You will find information on returning the product on the Internet pages of Siemens Industry

Online Support:

Link: (https://support.industry.siemens.com/cs/ww/en/view/109479891)

CP 1243-1

6 Operating Instructions, 12/2016, C79000-G8976-C365-02

Table of contents

Preface ................................................................................................................................................... 3

1 Application and properties ..................................................................................................................... 11

2 LEDs and connectors ............................................................................................................................ 21

3 Installation, connecting up, commissioning ............................................................................................ 27

4 Configuration ........................................................................................................................................ 33

1.1 Properties of the CP ................................................................................................................ 11

1.2 Communications services ....................................................................................................... 11

1.3 Other services and properties ................................................................................................. 12

1.4 Industrial Ethernet Security ..................................................................................................... 13

1.5 Configuration limits and performance data ............................................................................. 15

1.6 Configuration examples .......................................................................................................... 17

1.7 Requirements for use.............................................................................................................. 18

1.7.1 Hardware requirements .......................................................................................................... 18

1.7.2 Software requirements ............................................................................................................ 19

2.1 Opening the covers of the housing ......................................................................................... 21

2.2 LEDs ....................................................................................................................................... 22

2.3 Electrical connectors ............................................................................................................... 25

2.3.1 Power supply .......................................................................................................................... 25

2.3.2 Ethernet interface X1P1 .......................................................................................................... 25

3.1 Important notes on using the device ....................................................................................... 27

3.1.1 Notices on use in hazardous areas ........................................................................................ 27

3.1.2 Notices on use in hazardous areas according to IECEx / ATEX ............................................ 28

3.1.3 Notices regarding use in hazardous areas according to UL HazLoc ..................................... 29

3.1.4 Notices on use in hazardous areas according to FM ............................................................. 29

3.2 Installing, connecting up and commissioning ......................................................................... 30

3.3 Note on operation ................................................................................................................... 32

4.1 Security recommendations ..................................................................................................... 33

4.2 Configuration in STEP 7 ......................................................................................................... 36

4.3 Address and authentication data ............................................................................................ 37

4.4 Communication types ............................................................................................................. 39

4.5 Ethernet interface (X1) > Advanced options ........................................................................... 39

4.6 SNMP ...................................................................................................................................... 42

4.7 Partner stations ....................................................................................................................... 42

4.7.1 Partner stations > Telecontrol server ...................................................................................... 42

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

7

Table of contents

5 Diagnostics and upkeep ........................................................................................................................ 91

4.7.2 Addressing in the redundant TCSB system ........................................................................... 45

4.7.3 Partner for inter-station communication ................................................................................. 45

4.8 Security .................................................................................................................................. 47

4.8.1 Parameter overview ............................................................................................................... 47

4.8.2 CP identification ..................................................................................................................... 48

4.8.3 Firewall ................................................................................................................................... 49

4.8.3.1 Pre-check of messages by the MAC firewall. ........................................................................ 49

4.8.3.2 Notation for the source IP address (advanced firewall mode) ............................................... 49

4.8.3.3 Firewall settings for configured connection connections via a VPN tunnel ........................... 49

4.8.3.4 Settings for online security diagnostics and downloading to station with the firewall

activated ................................................................................................................................. 49

4.8.4 Time-of-day synchronization .................................................................................................. 50

4.8.5 E-mail configuration ............................................................................................................... 53

4.8.6 Log settings - Filtering of the system events ......................................................................... 54

4.8.7 SNMP ..................................................................................................................................... 54

4.8.8 Certificate manager ................................................................................................................ 55

4.8.9 Handling certificates ............................................................................................................... 56

4.8.10 VPN ........................................................................................................................................ 58

4.8.10.1 VPN (Virtual Private Network) ................................................................................................ 58

4.8.10.2 Creating a VPN tunnel for S7 communication between stations ........................................... 59

4.8.10.3 VPN communication with SOFTNET Security Client (engineering station) ........................... 61

4.8.10.4 Creating the VPN connection telecontrol server .................................................................... 62

4.8.10.5 Establishment of VPN tunnel communication between the CP and SCALANCE M ............. 62

4.8.10.6 CP as passive subscriber of VPN connections ...................................................................... 63

4.8.10.7 SYSLOG ................................................................................................................................ 63

4.8.11 Configuration of the TeleService access ............................................................................... 63

4.9 Data points ............................................................................................................................. 65

4.9.1 Configuring data points and messages ................................................................................. 65

4.9.2 Syntax of the data point names ............................................................................................. 71

4.9.3 Datapoint types ...................................................................................................................... 71

4.9.4 Status IDs of data points ........................................................................................................ 72

4.9.5 Data point index ..................................................................................................................... 73

4.9.6 Read cycle ............................................................................................................................. 74

4.9.7 Process image, type of transmission, event classes, triggers ............................................... 75

4.9.8 "Trigger“ tab ........................................................................................................................... 78

4.9.9 Threshold value trigger ................................................................

.......................................... 79

4.9.10 Analog value preprocessing ................................................................................................... 81

4.9.11 Partner stations: Configuring the inter-station communication .............................................. 87

4.10 Messages ............................................................................................................................... 88

4.11 Access to the Web server ...................................................................................................... 90

5.1 Diagnostics options ................................................................................................................ 91

5.2 Online security diagnostics via port 8448 .............................................................................. 92

5.3 Online functions and TeleService .......................................................................................... 93

5.4 SNMP ..................................................................................................................................... 94

5.5 Processing status of e-mails .................................................................................................. 96

5.6 Downloading firmware ........................................................................................................... 98

CP 1243-1

8 Operating Instructions, 12/2016, C79000-G8976-C365-02

Table of contents

6 Technical data .................................................................................................................................... 101

A Approvals ............................................................................................................................................ 103

B Dimension drawings ............................................................................................................................ 107

C Documentation references .................................................................................................................. 109

Index................................................................................................................................................... 111

5.7 Module replacement ............................................................................................................. 100

6.1 Technical specifications of the CP 1243-1............................................................................ 101

6.2 Pinout of the Ethernet interface ............................................................................................ 102

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

9

Table of contents

CP 1243-1

10 Operating Instructions, 12/2016, C79000-G8976-C365-02

1

1.1

Properties of the CP

Application

1.2

Communications services

Communications services

Telecontrol communication

S7 communication and PG/OP communication with the following functions:

The CP is intended for operation in an S7-1200 automation system. The CP allows

connection of the S7-1200 to Industrial Ethernet or via the Internet to a control center with

TELECONTROL SERVER BASIC (TCSB version V3).

With the combination of different security functions such as firewall and protocols for data

encryption, the CP protects the station and even entire automation cells from unauthorized

access and protects the communication between the remote S7 station and the master

station (TCSB) from espionage and manipulation.

The following communications services are supported:

●

The CP is a communications processor of the SIMATIC S7-1200 for system connection to

control centers with the OPC server application TCSB.

The communications protocol used allows IP-based data transmission for telecontrol

applications. As an integrated (unconfigurable) Security function, the telecontrol protocol

encrypts the data for transfer between the CP and telecontrol server.

For a description of the configurable Security functions, refer to the section Industrial

Ethernet Security (Page 13).

●

– PUT/GET as client and server for data exchange with remote stations (S7-

300/400/1200/1500)

– PG functions

– Operator control and monitoring functions (HMI)

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

11

Application and properties

1.3

Other services and properties

Other services and properties

Data point configuration

IP configuration - IPv4 and IPv6

Time-of-day synchronization

Redundancy

Storage of events

Data transfer is on request or triggered

1.3 Other services and properties

●

Due to the data point configuration in STEP 7, programming program blocks in order to

transfer the process data is unnecessary. The individual data points are processed oneto-one in the control system.

●

– IPv4 / IPv6

The CP supports IP addresses according to IPv4 and IPv6.

For telecontrol applications in IPv6 networks, an IPv6 address can be used in addition

to an IPv4 address.

– Address assignment

The IP address, the subnet mask and the address of a gateway can be set manually

in the configuration.

As an alternative, the IP address can be obtained from a DHCP server or by other

means outside the configuration.

●

– When telecontrol communication is enabled, the CP obtains its local time of day as

UTC time from the partner (TCSB). The time of day can be read from the CPU. The

mechanisms are described in the STEP 7 information system.

For information on the format of the time stamp, refer to the section Datapoint types

(Page 71).

– If telecontrol communication is disabled, the time of day can be obtained from an NTP

server or from the CPU.

– If the security functions are enabled, the secure method NTP (secure) can be used.

For more information, refer to the section Time-of-day synchronization (Page 50).

●

The CP can communicate with a redundant installation of TCSB.

●

The CP can store events of different classes chronologically and transfer them

spontaneously or together to the telecontrol server.

●

The telecontrol communication with TCSB is triggered in two ways:

– After a request by TCSB or an OPC client connected to TCSB

– Triggered by various selectable criteria

CP 1243-1

12 Operating Instructions, 12/2016, C79000-G8976-C365-02

Application and properties

Messages / e-mail

Analog value processing

Online functions / TeleService

SNMP

1.4

Industrial Ethernet Security

Industrial Ethernet Security

1.4 Industrial Ethernet Security

●

With configured events in the process image of the CPU, the CP can send messages as

e-mails. The data sent by e-mail is configured using PLC tags.

●

Analog values can be preprocessed on the CP according to various methods.

●

From the engineering station you can access the station via the CP with the online

functions of STEP 7.

The following online functions are available:

– Downloading project or program data from the STEP 7 project to the station

– Querying diagnostics data on the station

– Downloading firmware files to the CP

For information on the online functions, refer to the section Online functions and

TeleService (Page 93).

●

As an SNMP agent, the CP supports data queries using SNMP (Simple Network

Management Protocol).

For more detailed information, refer to section SNMP (Page 94).

With Industrial Ethernet Security, individual devices, automation cells or network segments

of an Ethernet network can be protected. The data transfer via the CP can be protected from

the following attacks by a combination of different security measures:

● Data espionage

● Data manipulation

● Unauthorized access

Secure underlying networks can be operated via additional Ethernet/PROFINET interfaces of

the CPU.

The security functions can be used independently of telecontrol communication.

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

13

Application and properties

Security functions of the CP

Firewall

Communication made secure by IPsec tunnels (VPN)

Logging

NTP (secure)

SNMPv3

Protection for devices and network segments

Note

Plants with security requirements - recommendation

Use the following options:

•

•

See also section

1.4 Industrial Ethernet Security

As a result of using the CP, as a security module, the following security functions are

accessible to the S7-1200 station on the interface to the external network:

●

– IP firewall with stateful packet inspection (layer 3 and 4)

– Firewall also for "non-IP" Ethernet frames according to IEEE 802.3 (layer 2)

– Limitation of the transmission speed ("Bandwidth limitation")

– Global firewall rules

●

VPN tunnel communication allows the establishment of secure IPsec tunnels for

communication with one or more security modules.

The CP can be put together with other modules to form VPN groups during configuration.

IPsec tunnels (VPN) are created between all security modules of a VPN group. All

internal nodes of these security modules can communicate securely with each other

through these tunnels.

●

To allow monitoring, events can be stored in log files that can be read out using the

configuration tool or can be sent automatically to a Syslog server.

●

For secure transfer during time-of-day synchronization

●

For secure transmission of network analysis information safe from eavesdropping

●

The protection provided by the firewall can cover individual devices, several devices or

even entire network segments.

If you have systems with high security requirements, use the secure protocols

NTP (secure), HTTPS and SNMPv3.

If you connect to public networks, you should use the firewall. Think about the services

you want to allow access to the station via public networks. By using the "bandwidth

limitation" of the firewall, you can restrict the possibility of flooding and DoS attacks.

Security recommendations (Page 33).

For configuring the security functions refer to the section Security (Page 47).

You will find further information on the functionality and configuration of the security functions

in the information system of STEP 7 and in the manual /4/ (Page 110).

CP 1243-1

14 Operating Instructions, 12/2016, C79000-G8976-C365-02

Application and properties

1.5

Configuration limits and performance data

Number of CMs/CPs per station

Connection resources

Telecontrol connections

TCP connections

Online functions

S7 connections

PG/OP connections

Number of data points for the data point configuration

User data

1.5 Configuration limits and performance data

In each S7-1200 station, up to three CMs/CPs can be plugged in and configured; this allows

three CP 1243-1 modules.

To use telecontrol communication, three CP 1243-1 modules can be plugged in per station

that communicate with three telecontrol servers.

●

The CP can establish corrections to non-redundant or redundant telecontrol servers

(TCSB).

In addition to this, inter-station communication with up to 4 S7 stations with a CP 1243-1

can be operated via the telecontrol server.

●

The CP can establish connections to up to 4 communications partners (S7 stations).

●

1 connection resource is reserved for online functions.

●

8 connection resources for S7 connections (PUT/GET)

●

– 1 connection resource for PG connections

– 3 connection resources for OP connections

The maximum number of configurable data points is 200.

The data to be transferred by the CP is assigned to various data points in the STEP 7

configuration.

The size of the user data per data point depends on the data type of the relevant data point.

You will find details in the section Datapoint types (Page 71).

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

15

Application and properties

Frame memory (send buffer)

Messages / e-mail

IPsec tunnel (VPN)

Firewall rules

1.5 Configuration limits and performance data

The CP has a frame memory (send buffer) for the values of data points configured as an

event.

The send buffer has a maximum size of 64000 events divided into equal parts for all

configured communications partners. The size of the frame memory can be set in STEP 7,

refer to the section SNMP (Page 42).

Up to 10 messages can be configured in STEP 7 and sent as e-mails.

Up to 8 IPsec terminals can be established for secure communication with other security

modules.

The maximum number of firewall rules in advanced firewall mode is limited to 256.

The firewall rules are divided up as follows:

● Maximum 226 rules with individual addresses

● Maximum 30 rules with address ranges or network addresses

(e.g. 140.90.120.1 - 140.90.120.20 or 140.90.120.0/16)

● Maximum 128 rules with limitation of the transmission speed ("Bandwidth limitation")

CP 1243-1

16 Operating Instructions, 12/2016, C79000-G8976-C365-02

Application and properties

1.6

Configuration examples

Telecontrol with a non-redundant master station (TCSB)

Communication between S7 stations and a master station (TCSB)

1.6 Configuration examples

Figure 1-1

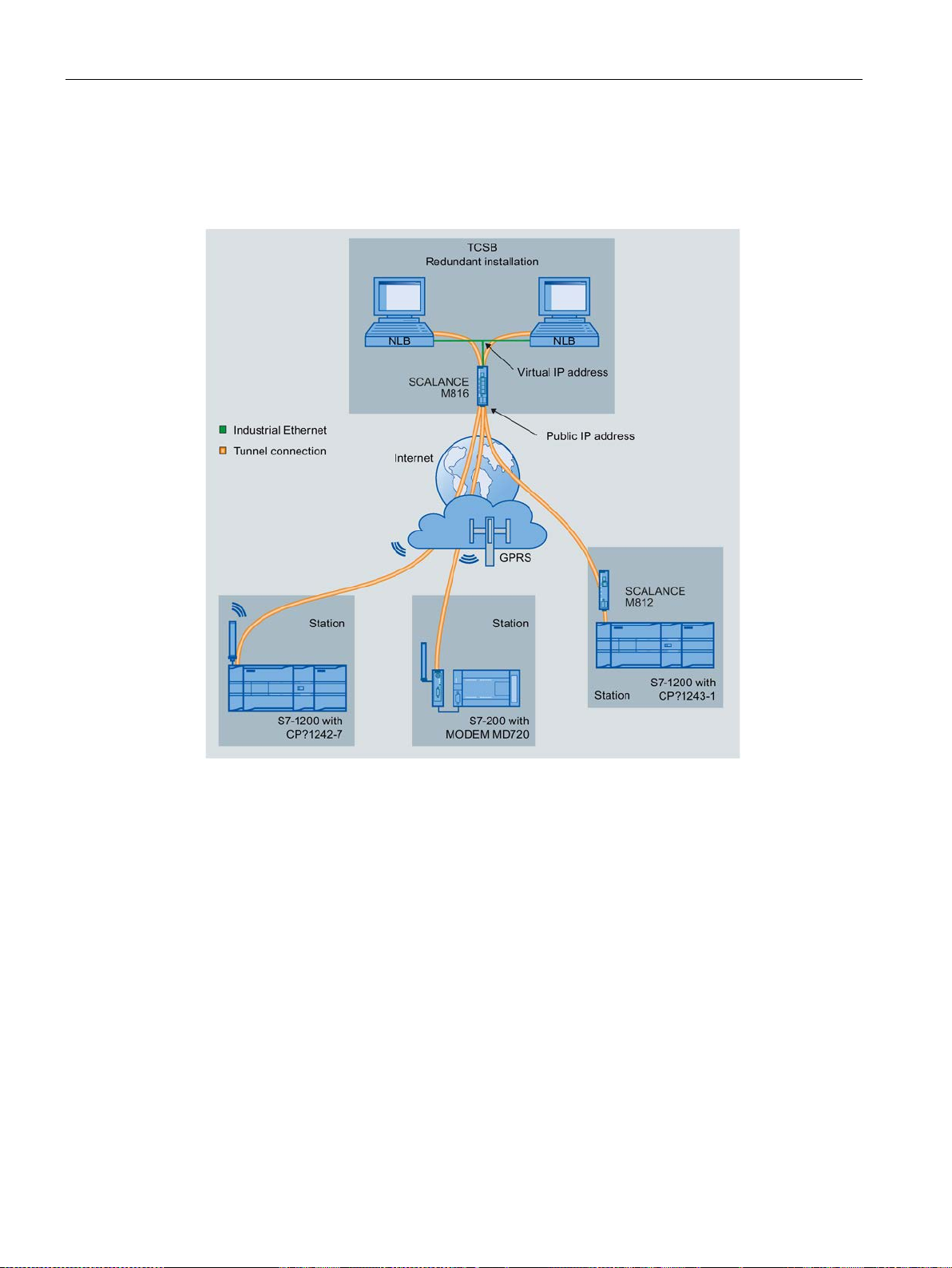

In the telecontrol applications of the example shown, SIMATIC S7 stations communicate with

a non-redundant telecontrol server (TCSB) in the master station.

● Telecontrol communication between stations and master station

The communication is via the following paths and communications modules:

– Communication via the Internet: S7-1200 with CP 1243-1

– Communication via the GSM network and the Internet: S7-1200 with CP 1242-7 or

The establishment of terminal connections with encryption is initiated automatically by the

telecontrol protocol used by the various communications modules.

The creation of VPN connections between the CP 1243-1 and telecontrol server is

optional.

The telecontrol server monitors the connections established by the remote stations.

● Inter-station communication

Stations of the same type, for example S7-1200 with CP 1243-1, can communicate with

each other by sending the frames via the telecontrol server.

S7-200 with MODEM MD720

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

17

Application and properties

Telecontrol with a redundant master station (TCSB)

S7 station communication with a redundant a master station

1.7

Requirements for use

1.7.1

Hardware requirements

1.7 Requirements for use

The following figure shows a possible configuration with S7 stations communicating with a

redundant master station (TCSB).

Figure 1-2

CP 1243-1

18 Operating Instructions, 12/2016, C79000-G8976-C365-02

The following description relates to a configuration with telecontrol communication with

TCSB.

Rails, housing, cabling and other accessories are not taken into account.

Depending on the configuration of your plant, you require the following devices and firmware

versions.

Application and properties

Application example: Telecontrol communication with TCSB

In the S7-1200 station:

In the master station:

For the configuration of the S7 station with CP:

1.7.2

Software requirements

Software for configuration and online functions

1.7 Requirements for use

● CPU with firmware version: 4.x

● Mobile wireless router SCALANCE M812

● PC with TCSB (version V3)

● Mobile wireless router SCALANCE M816

For more detailed information on the structure of TCSB , refer to the section /3/ (Page 110).

● When using online functions: Engineering station with STEP 7 (refer to the section

Software requirements (Page 19)).

Engineering station with STEP 7

To configure the CP, the following configuration tool is required:

● STEP 7 Basic / Professional V13.0 with support package 0093

or

● STEP 7 Basic / Professional V13.0 + SP1

To use all the functions of the CP with the firmware version mentioned in the preface, the

following configuration tool is required:

● STEP 7 Basic / Professional V14

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

19

Application and properties

1.7 Requirements for use

CP 1243-1

20 Operating Instructions, 12/2016, C79000-G8976-C365-02

2

2.1

Opening the covers of the housing

Location of the display elements and the electrical connectors

Opening the covers of the housing

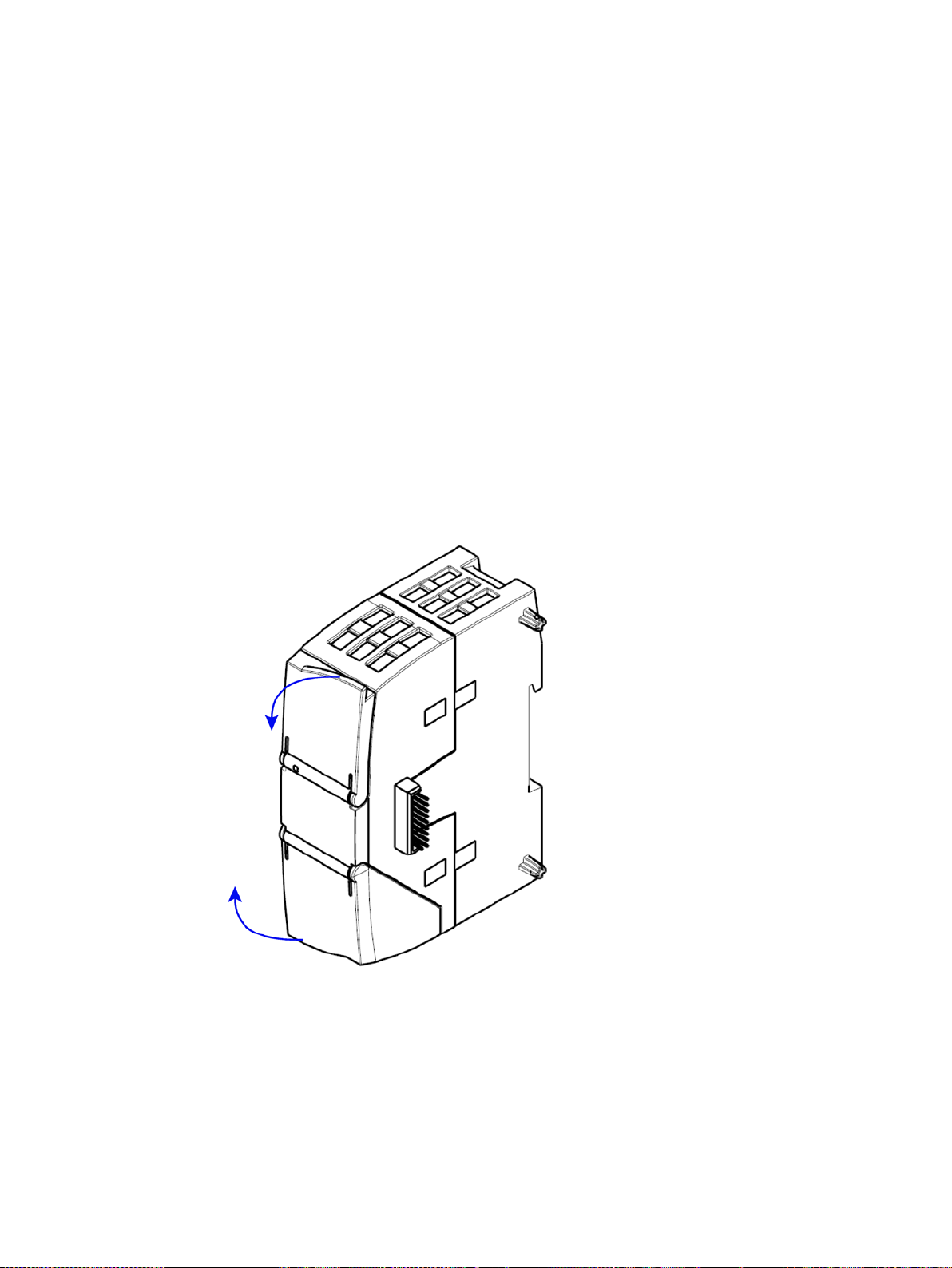

The LEDs for the detailed display of the module statuses are located behind the upper cover

of the module housing.

The Ethernet connector is located behind the lower hinged cover of the module.

Open the upper or lower cover of the housing by pulling it down or up as shown by the

arrows in the illustration. The covers extend beyond the housing to give you a grip.

Figure 2-1 Opening the covers of the housing

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

21

LEDs and connectors

2.2

LEDs

LEDs of the module

LED on the front panel

LEDs below the upper cover of the housing

LED on the front panel

LED / colors

Name

Meaning

DIAG

LEDs below the upper cover of the housing

LED (color)

Name

Meaning

(green)

LINK

(green)

CONNECT

(green)

VPN

(green)

SERVICE

LED colors and illustration of the LED statuses

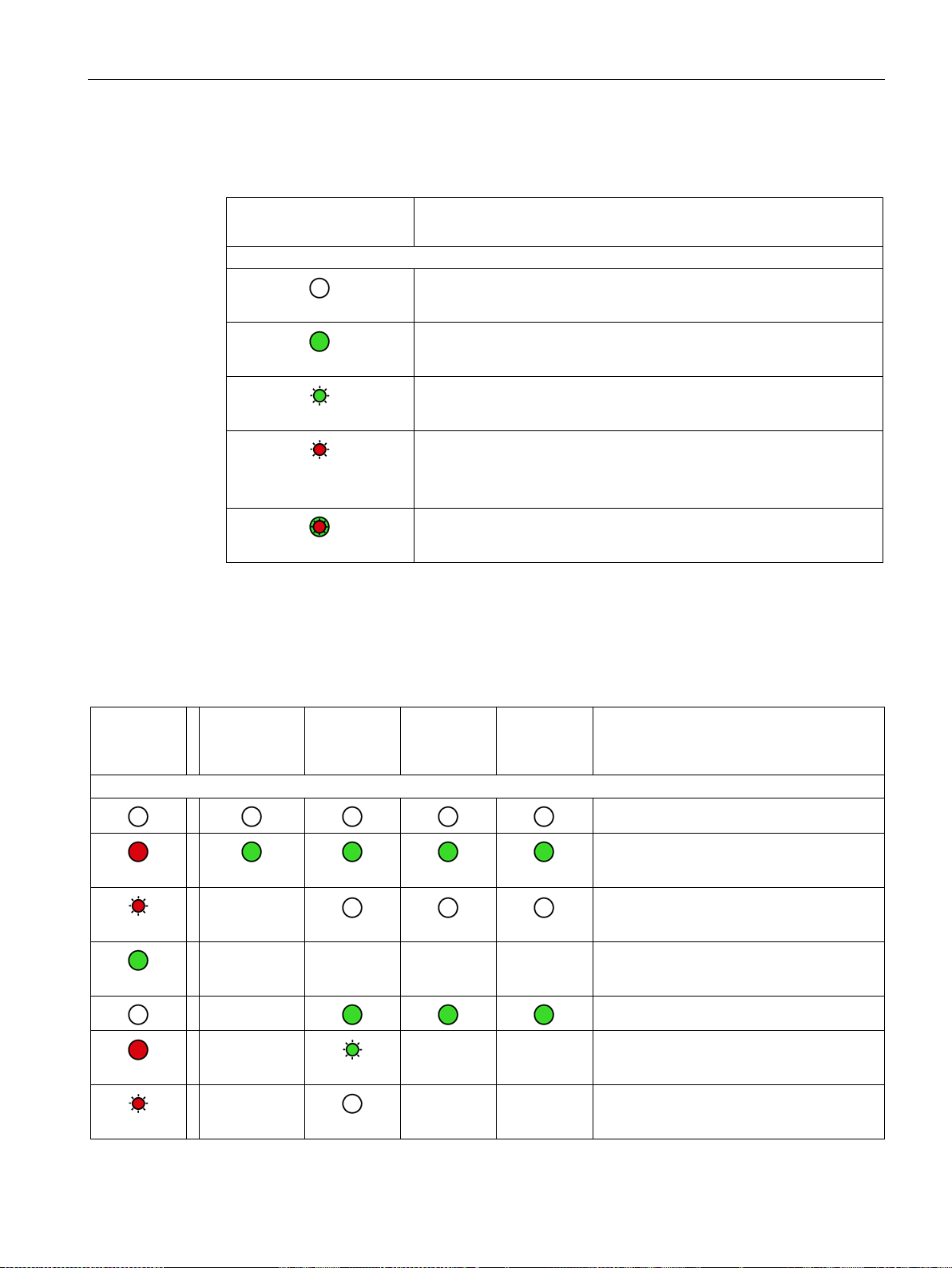

Meaning of the LED symbols

Symbol

LED status

OFF

ON (steady light)

Flashing

Not relevant

Note

LED colors when the module starts up

When the module start

color mixture. At this point in time, the color of the LEDs is not clear.

2.2 LEDs

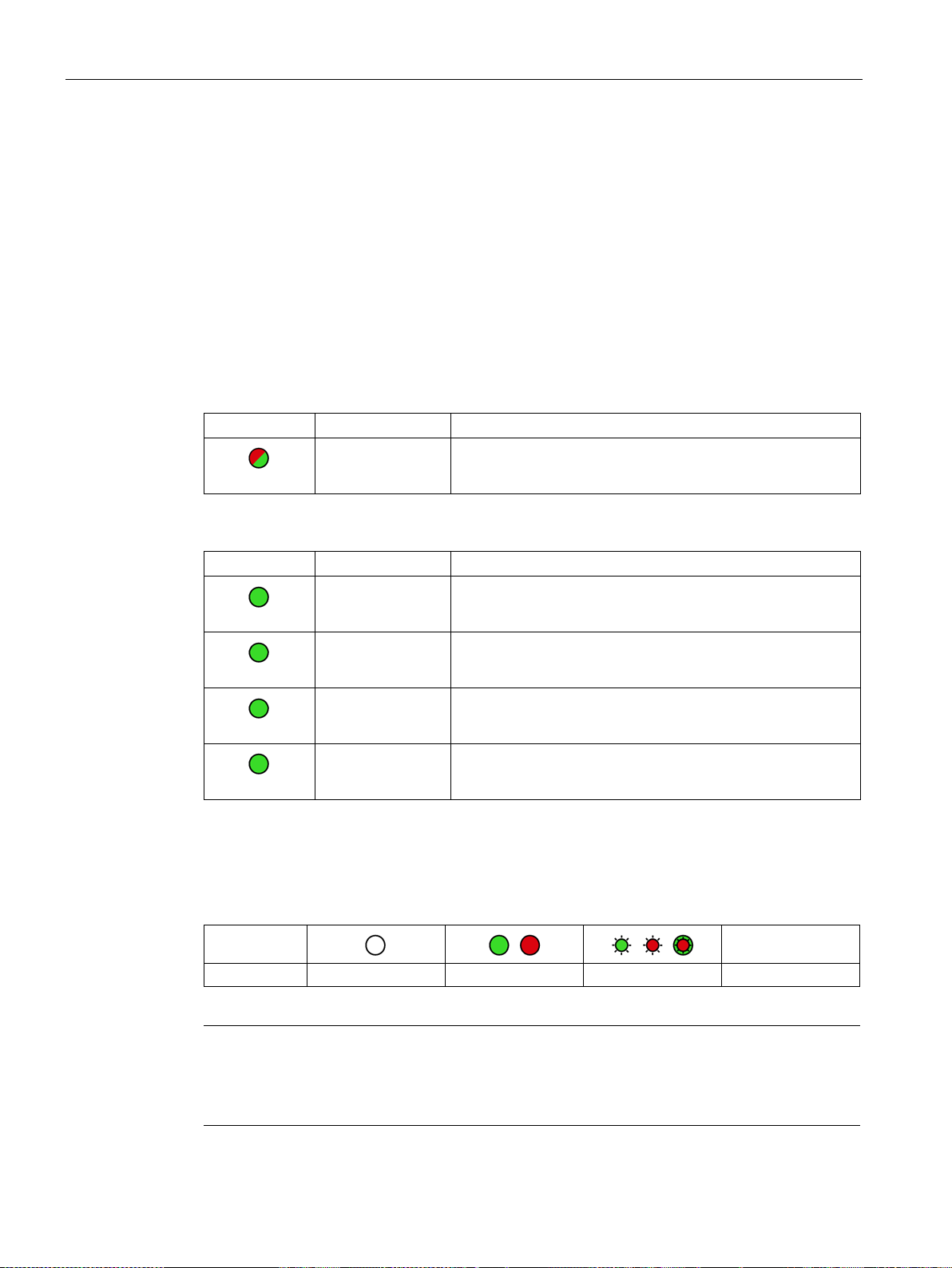

The module has various LEDs for displaying the status:

●

The "DIAG" LED that is always visible shows the basic statuses of the module.

●

The LEDs below the upper cover provide more detailed information on the module status.

Table 2- 1

(red / green)

Table 2- 2

Basic status of the module

Status of the connection to Industrial Ethernet

Status of the connections to the communications partner

Status of the VPN configuration

Status of a connection for online functions

The LED symbols in the following tables have the following significance:

Table 2- 3

s up, all its LEDs are lit for a short time. Multicolored LEDs display a

CP 1243-1

22 Operating Instructions, 12/2016, C79000-G8976-C365-02

-

LEDs and connectors

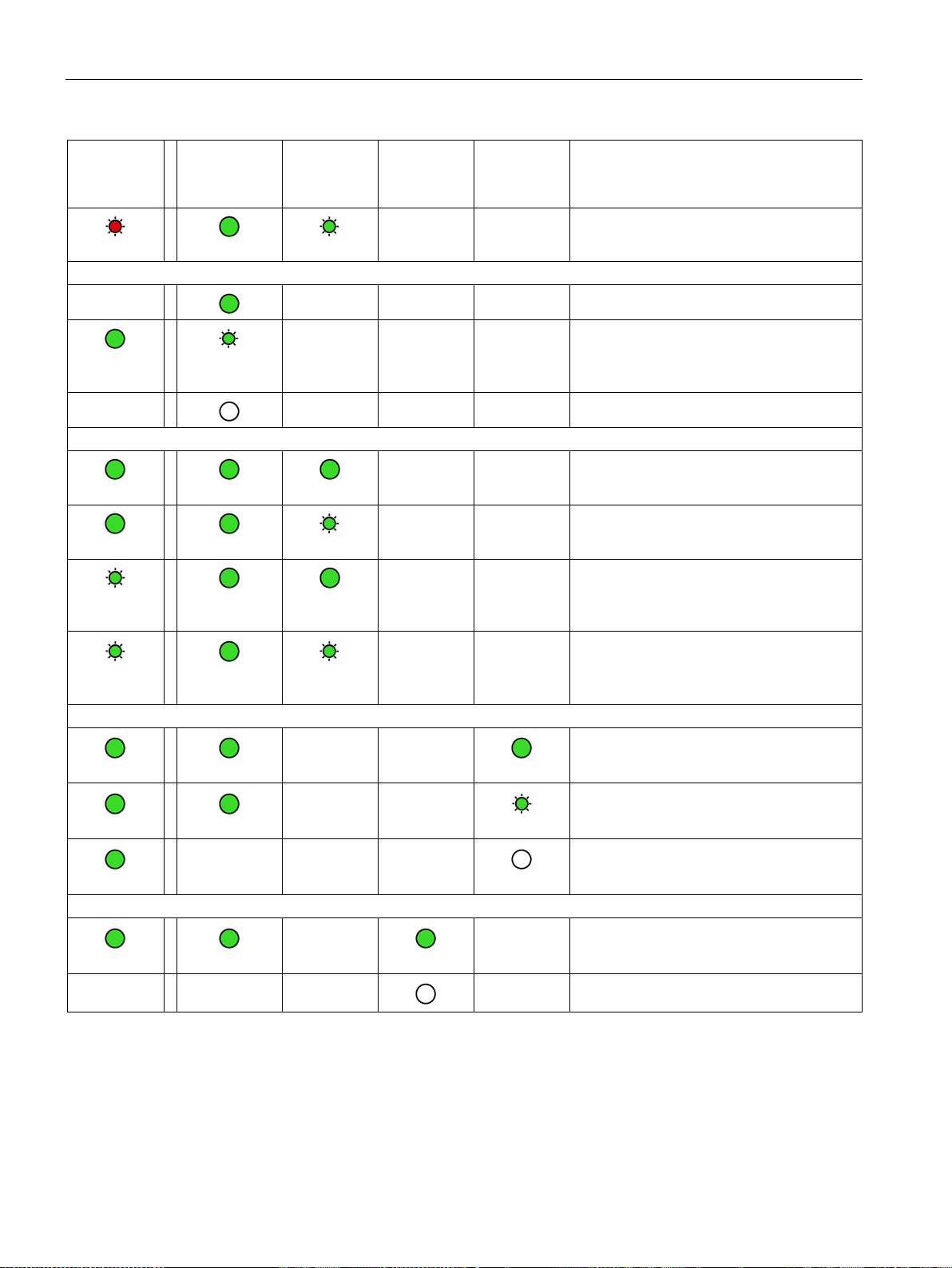

Display of the basic statuses of the CP ("DIAG" LED)

DIAG

(red / green)

Meaning

(if more than one point listed: alternative meaning)

Basic statuses of the CP

green

flashing green

flashing red-green

Display of the operating and communications statuses

DIAG

-

LINK

CONNECT

VPN

SERVICE

Meaning

(if more than one point listed: alternative

meaning)

Module startup (STOP → RUN) or error statuses

red

flashing red

green

red

flashing red

2.2 LEDs

Table 2- 4 Display of the basic statuses of the CP

flashing red

• Power OFF

• Incorrect startup

Running (RUN) without serious error

• Partner not connected

• Firmware loaded successfully

• Starting up

• Module fault

• Invalid STEP 7 project data

Error loading firmware

The LEDs indicate the operating and communications status of the module according to the

following scheme:

Table 2- 5 Display of the operating and communications statuses

(red / green)

(green)

(green)

(green)

(green)

-

- - - - Running (RUN) without serious error

-

-

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

Power OFF

Startup - phase 1

Startup - phase 2

Incorrect startup

- - Invalid STEP 7 project data

- - Missing STEP 7 project data

23

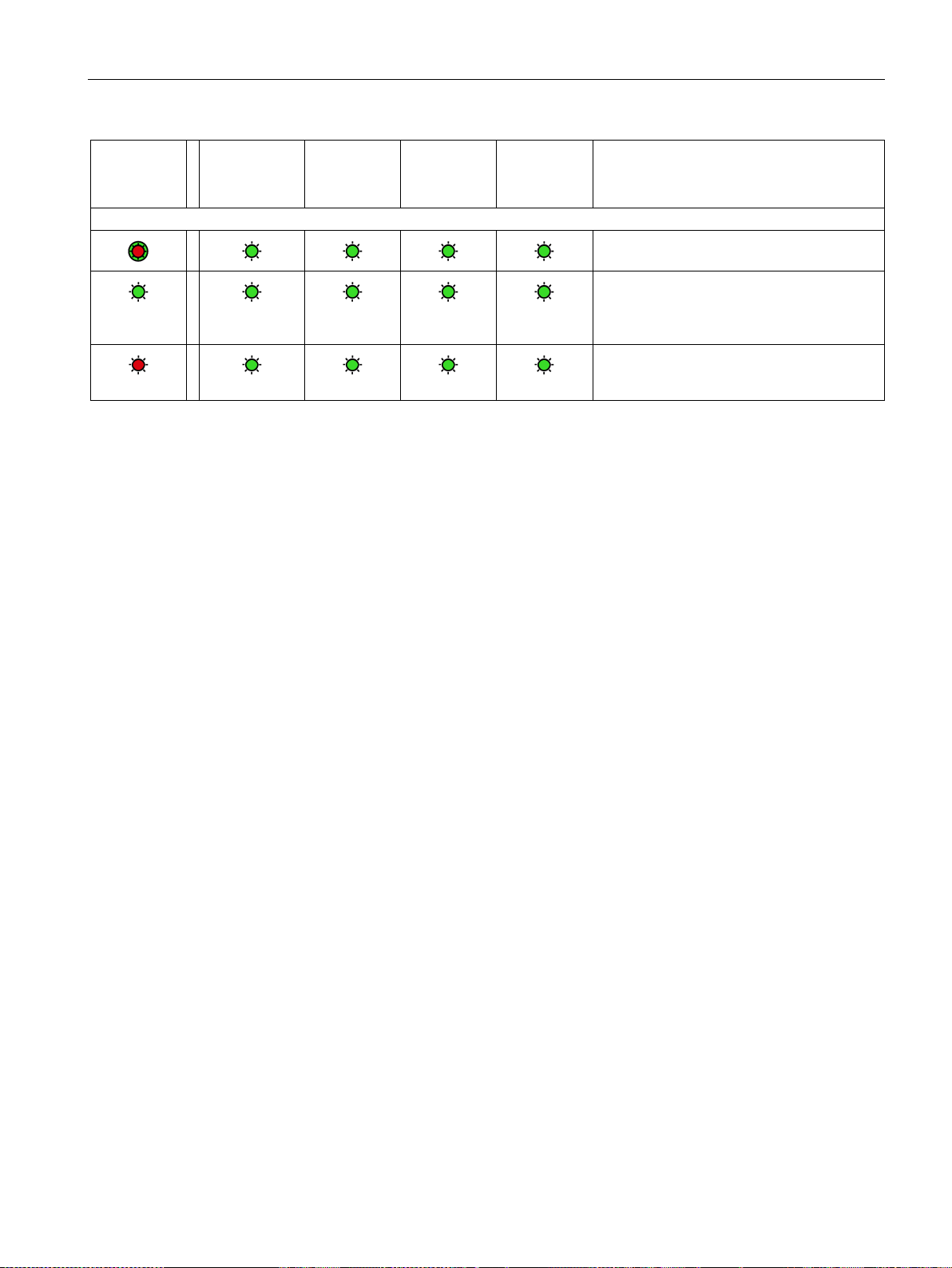

LEDs and connectors

DIAG

-

LINK

CONNECT

VPN

SERVICE

Meaning

(if more than one point listed: alternative

meaning)

flashing red

Connection to Industrial Ethernet

Connection to communications partners

green

green

green

Connection for online functions

green

green

green

VPN connection

green

2.2 LEDs

(red / green)

-

green

-

flashing

(green)

(green)

- - - Connection to Industrial Ethernet exists

- - -

- - - No connection to Industrial Ethernet

(green)

- - Backplane bus error

- - Connection established to at least one

- - Partner reachable, CPU in STOP mode

- - Partner not reachable, CPU in RUN mode

(green)

• Connection to Industrial Ethernet being

established.

• IP address being obtained.

partner

flashing

green

- - -

- - -

- -

- -

-

- - Partner not reachable, CPU in STOP mode

Connection for online functions established

Attempt to establish connection for online

functions

No connection to engineering station

- VPN connection configured on the CP

- No VPN connection configured on the CP

CP 1243-1

24 Operating Instructions, 12/2016, C79000-G8976-C365-02

LEDs and connectors

DIAG

-

LINK

CONNECT

VPN

SERVICE

Meaning

(if more than one point listed: alternative

meaning)

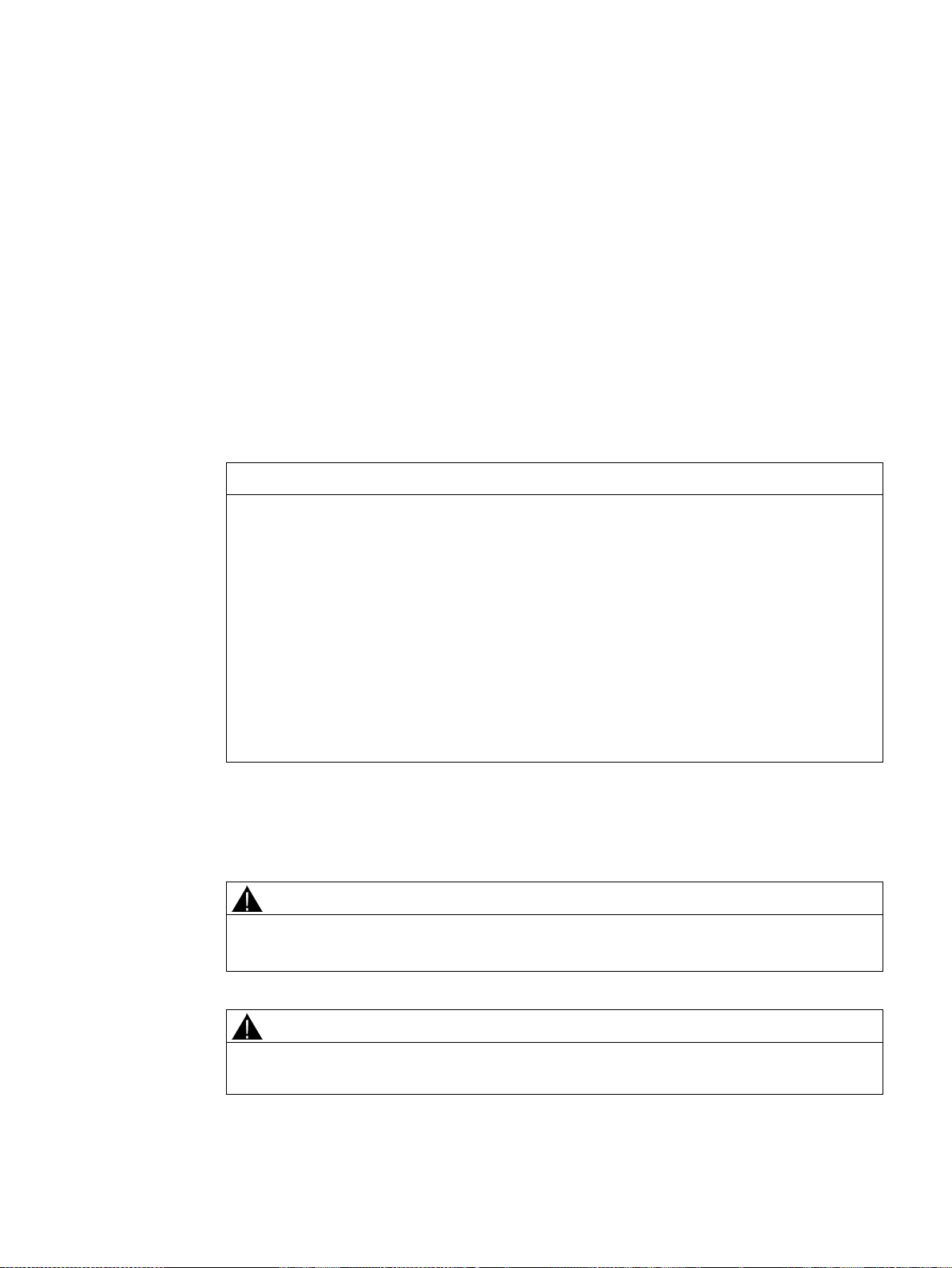

Loading firmware

green

flashing red

2.3

Electrical connectors

2.3.1

Power supply

Power supply

2.3.2

Ethernet interface X1P1

Ethernet interface

2.3 Electrical connectors

(red / green)

flashing

(green)

(green)

(green)

(green)

Loading firmware. The DIAG LED flashes

alternating red and green.

Firmware was successfully loaded.

Error loading firmware

The CM is supplied with power from the backplane bus. It does not require a separate power

supply.

The Ethernet connector is located behind the lower hinged cover of the module. The

interface is an RJ-45 jack according to IEEE 802.3.

The pin assignment and other data relating to the Ethernet interface can be found in the

section Technical data (Page 101).

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

25

LEDs and connectors

2.3 Electrical connectors

CP 1243-1

26 Operating Instructions, 12/2016, C79000-G8976-C365-02

3

3.1

Important notes on using the device

Safety notices on the use of the device

Overvoltage protection

NOTICE

Protection of the external power supply

3.1.1

Notices on use in hazardous areas

WARNING

EXPLOSION HAZARD

WARNING

Note the following safety notices when setting up and operating the device and during all

associated work such as installation, connecting up or replacing the device.

If power is supplied to the module or station over longer power cables or networks, the

coupling in of strong electromagnetic pulses onto the power supply cables is possible. This

can be caused, for example by lightning strikes or switching of higher loads.

The connector of the external power supply is not protected from strong electromagnetic

pulses. To protect it, an external overvoltage protection module is necessary. The

requirements of EN61000-4-5, surge immunity tests on power supply lines, are met only

when a suitable protective element is used. A suitable device is, for example, the Dehn

Blitzductor BVT AVD 24, article number 918 422 or a comparable protective element.

Manufacturer:

DEHN+SOEHNE GmbH+Co.KG Hans Dehn Str.1 Postfach 1640 D-92306 Neumarkt,

Germany

DO NOT OPEN WHEN ENERGIZED.

The device may only be operated in an environment with pollution degree 1 or 2 (see IEC

60664-1).

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

27

Installation, connecting up, commissioning

WARNING

WARNING

EXPLOSION HAZARD

WARNING

EXPLOSION HAZARD

WARNING

3.1.2

Notices on use in hazardous areas according to IECEx / ATEX

WARNING

Requirements for the cabinet/enclosure

WARNING

3.1 Important notes on using the device

The equipment is designed for operation with Safety Extra-Low Voltage (SELV) by a

Limited Power Source (LPS).

This means that only SELV / LPS complying with IEC 60950-1 / EN 60950-1 / VDE 0805-1

must be connected to the power supply terminals. The power supply unit for the equipment

power supply must comply with NEC Class 2, as described by the National Electrical Code

(r) (ANSI / NFPA 70).

If the equipment is connected to a redundant power supply (two separate power supplies),

both must meet these requirements.

DO NOT CONNECT OR DISCONNECT EQUIPMENT WHEN A FLAMMABLE OR

COMBUSTIBLE ATMOSPHERE IS PRESENT.

SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION

2 OR ZONE 2.

When used in hazardous environments corresponding to Class I, Division 2 or Class I,

Zone 2, the device must be installed in a cabinet or a suitable enclosure.

To comply with EU Directive 94/9 (ATEX95), the enclosure or cabinet must meet the

requirements of at least IP54 in compliance with EN 60529.

If the cable or conduit entry point exceeds 70 °C or the branching point of conductors

exceeds 80 °C, special precautions must be taken. If the equipment is operated in an air

ambient in excess of 50 °C, only use cables with admitted maximum operating temperature

of at least 80 °C.

CP 1243-1

28 Operating Instructions, 12/2016, C79000-G8976-C365-02

Installation, connecting up, commissioning

WARNING

3.1.3

Notices regarding use in hazardous areas according to UL HazLoc

WARNING

EXPLOSION HAZARD

3.1.4

Notices on use in hazardous areas according to FM

WARNING

EXPLOSION HAZARD

WARNING

EXPLOSION HAZARD

3.1 Important notes on using the device

Take measures to prevent transient voltage surges of more than 40% of the rated voltage.

This is the case if you only operate devices with SELV (safety extra-low voltage).

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D or nonhazardous locations only.

This equipment is suitable for use in Class I, Zone 2, Group IIC or non-hazardous locations

only.

Do not connect or disconnect while the circuit is live or unless the area is known to be free

of ignitible concentrations.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D or nonhazardous locations only.

This equipment is suitable for use in Class I, Zone 2, Group IIC or non-hazardous locations

only.

The equipment is intended to be installed within an ultimate enclosure. The inner service

temperature of the enclosure corresponds to the ambient temperature of the module. Use

installation wiring connections with admitted maximum operating temperature of at least

30 ºC higher than maximum ambient temperature.

CP 1243-1

Operating Instructions, 12/2016, C79000-G8976-C365-02

29

Installation, connecting up, commissioning

3.2

Installing, connecting up and commissioning

Prior to installation and commissioning

CAUTION

Read the system manual "S7-1200 Programmable Controller"

Pulling/plugging the module

NOTICE

Turning off the station when plugging/pulling the module

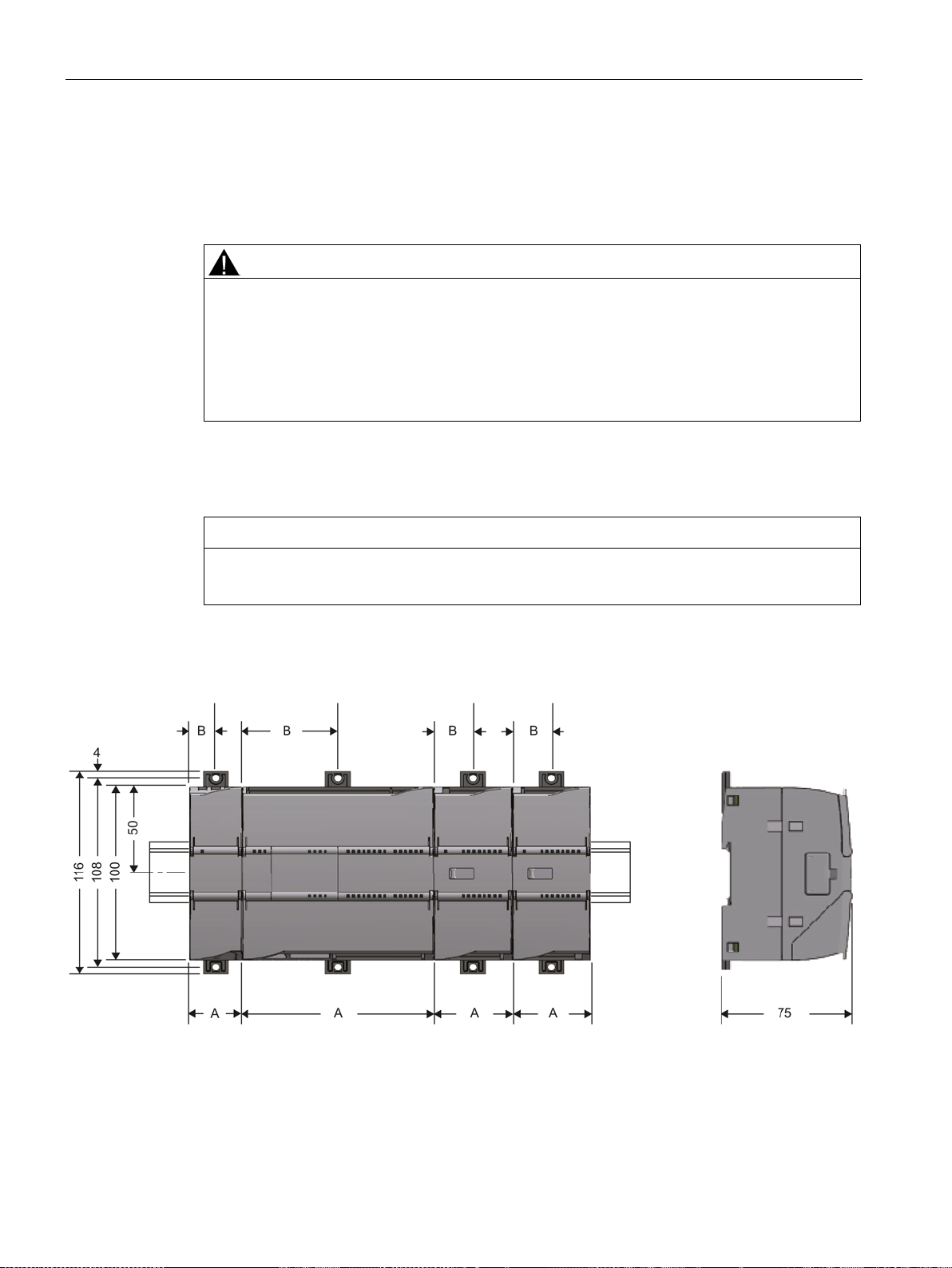

Dimensions for installation

3.2 Installing, connecting up and commissioning

Prior to installation, connecting up and commissioning, read the relevant sections in the

system manual "S7-1200 Programmable Controller", refer to the documentation in the

Appendix.

When installing and connecting up, keep to the procedures described in the system manual

"S7-1200 Programmable Controller".

Before pulling or plugging the module, always turn off the power supply to the station.

Figure 3-1 Dimensions for installation of the S7-1200

CP 1243-1

30 Operating Instructions, 12/2016, C79000-G8976-C365-02

Loading...

Loading...