Siemens SIMATIC NET RUGGEDCOM RST2228P Installation Manual

Installation Manual

SIMATIC NET

Rugged Ethernet Switches

RUGGEDCOM RST2228P

For RST2228

Edition 12/2019

https://www.siemens.com

Preface

SIMATIC NET

Rugged Ethernet Switches

RUGGEDCOM RST2228P

Installation Manual

Introduction

Installing the Device

Device Management

Communication Ports

Technical Specifications

Certification

1

2

3

4

5

6

For RST2228

12/2019

C79000-G8976-1403-05

Legal Information

Warning Notice System

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety

alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger

will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the

specific task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper Use of Siemens Products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Digital Industry

Process Automation

Postfach 48 48

90026 NÜRNBERG

GERMANY

© 12/2019 Subject to Change Copyright © Siemens 2019

All rights reserved

Table of Contents

Preface ............................................................................................................................................ v

Related Documents ................................................................................................................. v

Accessing Documentation ....................................................................................................... v

Disclaimer of Liability .............................................................................................................. v

Registered Trademarks ............................................................................................................ v

Training .................................................................................................................................. vi

Customer Support .................................................................................................................. vi

Contacting Siemens ............................................................................................................... vii

1 Introduction ........................................................................................................................... 1

1.1 Feature Highlights ................................................................................................. 1

1.2 Description ............................................................................................................ 2

1.3 Required Tools and Materials ................................................................................. 6

1.4 Decommissioning and Disposal ............................................................................. 6

1.5 Cabling Recommendations .................................................................................... 7

1.5.1 Protection On Twisted-Pair Data Ports .................................................................... 7

1.5.2 Gigabit Ethernet 1000Base-TX Cabling Recommendations ...................................... 7

1.5.3 Supported Fiber Optic Cables ................................................................................ 8

2 Installing the Device ............................................................................................................. 9

2.1 General Procedure ................................................................................................. 9

2.2 Unpacking the Device ......................................................................................... 10

2.3 Mounting the Device ........................................................................................... 10

2.3.1 Mounting the Device to a Rack ............................................................................ 11

2.3.2 Mounting the Device to a Panel .......................................................................... 12

2.4 Connecting the Failsafe Alarm Relay .................................................................... 13

2.5 Connecting Power ............................................................................................... 15

2.5.1 Connecting High AC/DC Power ............................................................................ 15

2.5.2 Connecting Low DC Power .................................................................................. 18

2.5.3 Connecting External PoE Power ........................................................................... 20

2.5.4 Wiring Examples .................................................................................................. 22

3 Device Management ........................................................................................................... 25

3.1 Connecting to the Device .................................................................................... 25

3.2 Configuring the Device ........................................................................................ 26

3.3 Inserting/Removing the CLP ................................................................................. 26

4 Communication Ports .......................................................................................................... 29

4.1 SFP Transceivers .................................................................................................. 29

4.2 PoE Ports ............................................................................................................. 31

RUGGEDCOM RST2228P

Installation Manual, 12/2019, C79000-G8976-1403-05

iii

Table of Contents

4.3 Available Modules ............................................................................................... 31

4.4 Installing/Removing Modules ............................................................................... 33

5 Technical Specifications ...................................................................................................... 35

5.1 Power Supply Specifications ................................................................................ 35

5.2 PoE Power Supply Specifications .......................................................................... 35

5.3 Failsafe Alarm Relay Specifications ...................................................................... 36

5.4 Supported Networking Standards ........................................................................ 36

5.5 Operating Environment ....................................................................................... 36

5.6 Mechanical Specifications .................................................................................... 37

5.7 Dimension Drawings ........................................................................................... 37

6 Certification ......................................................................................................................... 41

6.1 Approvals ............................................................................................................ 41

6.1.1 CSA ..................................................................................................................... 41

6.1.2 European Union (EU) .......................................................................................... 41

6.1.3 FCC ..................................................................................................................... 42

6.1.4 FDA/CDRH ........................................................................................................... 43

6.1.5 ISED .................................................................................................................... 43

6.1.6 TÜV SÜD ............................................................................................................. 43

6.1.7 RoHS ................................................................................................................... 43

6.1.8 Other Approvals .................................................................................................. 44

6.2 EMC and Environmental Type Tests ..................................................................... 44

iv

Installation Manual, 12/2019, C79000-G8976-1403-05

RUGGEDCOM RST2228P

Preface

This guide describes the RUGGEDCOM RST2228P. It describes the major features of

the device, installation, commissioning and important technical specifications.

It is intended for use by network technical support personnel who are responsible

for the installation, commissioning and maintenance of the device. It is also recommended for use by network and system planners, system programmers, and line

technicians.

Related Documents

Other documents that may be of interest include:

• RUGGEDCOM RST2228 Configuration Manual [https://support.industry.siemen-

s.com/cs/ww/en/view/109755340]

• RUGGEDCOM Modules Catalog for RST2228, RST2228P [https://support.indus-

try.siemens.com/cs/ww/en/view/109752858]

Accessing Documentation

The latest user documentation for RUGGEDCOM RST2228P is available online at

https://support.industry.siemens.com. To request or inquire about a user document,

contact Siemens Customer Support.

Disclaimer of Liability

Siemens has verified the contents of this document against the hardware and/or software described. However, deviations between the product and the documentation

may exist.

Siemens shall not be liable for any errors or omissions contained herein or for consequential damages in connection with the furnishing, performance, or use of this material.

The information given in this document is reviewed regularly and any necessary corrections will be included in subsequent editions. We appreciate any suggested improvements. We reserve the right to make technical improvements without notice.

Registered Trademarks

RUGGEDCOM™ and ROS™ are trademarks of Siemens AG.

RUGGEDCOM RST2228P

Installation Manual, 12/2019, C79000-G8976-1403-05

v

Preface

Training

Training

Other designations in this manual might be trademarks whose use by third parties

for their own purposes would infringe the rights of the owner.

Siemens offers a wide range of educational services ranging from in-house training

of standard courses on networking, Ethernet switches and routers, to on-site customized courses tailored to the customer's needs, experience and application.

Siemens' Educational Services team thrives on providing our customers with the essential practical skills to make sure users have the right knowledge and expertise to

understand the various technologies associated with critical communications network infrastructure technologies.

Siemens' unique mix of IT/Telecommunications expertise combined with domain

knowledge in the utility, transportation and industrial markets, allows Siemens to

provide training specific to the customer's application.

For more information about training services and course availability, visit https://-

www.siemens.com or contact a Siemens Sales representative.

Customer Support

Customer support is available 24 hours, 7 days a week for all Siemens customers.

For technical support or general information, contact Siemens Customer Support

through any of the following methods:

Online

Visit http://www.siemens.com/automation/support-request to submit a

Support Request (SR) or check on the status of an existing SR.

Telephone

Call a local hotline center to submit a Support Request (SR). To locate a local hotline center, visit https://w3.siemens.com/aspa_app/?lang=en.

Mobile App

Install the Industry Online Support app by Siemens AG on any Android,

Apple iOS or Windows mobile device and be able to:

• Access Siemens' extensive library of support documentation, including FAQs and manuals

• Submit SRs or check on the status of an existing SR

• Contact a local Siemens representative from Sales, Technical Support,

Training, etc.

• Ask questions or share knowledge with fellow Siemens customers

and the support community

vi

Installation Manual, 12/2019, C79000-G8976-1403-05

RUGGEDCOM RST2228P

Contacting Siemens

Address Siemens AG

Telephone Toll-free: 1 888 264 0006

E-Mail ruggedcom.info.i-ia@siemens.com

Web https://www.siemens.com

Preface

Contacting Siemens

Industry Sector

300 Applewood Crescent

Concord, Ontario

Canada, L4K 5C7

Tel: +1 905 856 5288

Fax: +1 905 856 1995

RUGGEDCOM RST2228P

Installation Manual, 12/2019, C79000-G8976-1403-05

vii

Preface

Contacting Siemens

viii

Installation Manual, 12/2019, C79000-G8976-1403-05

RUGGEDCOM RST2228P

Introduction

The RUGGEDCOM RST2228P is a utility grade, fully managed, industrial Ethernet

switch designed to operate reliably in harsh environments. With a rugged metal enclosure and an optional conformal coating, the RUGGEDCOM RST2228P provides a

high level of immunity to electromagnetic interference and heavy electrical surges,

and can withstand temperatures between -40 and 85 °C (-40 and 185 °F).

Highly modular, the RUGGEDCOM RST2228P switch supports up to 24 PoE ports and

28 optical interfaces with data transfer rates of 10/100/1000 Mbit/s. Four ports include data transfer rates of 10000Mbit/s. This makes it the ideal industry-standard

switch for constructing electrical and/or optical line, ring and star topologies.

The RUGGEDCOM RST2228P switch is supported by RUGGEDCOM RST2228P, which

provides advanced Layer 2 networking functions, and advanced cyber security features.

1.1 Feature Highlights

1

Power over Ethernet (PoE)

• Supports up to 24 PoE ports with data transfer rates of 10/100/1000 Mbit/s

• Supports 4-pair or 60 W/port

• Supports up to 120 W of PoE power/module (e.g. two 60 W ports or four 30 W

ports)

• Supports up to maximum 500 W/system

• Data and power over a single Ethernet cable

• No mid-span patch panel required

• Fully compatible with IEEE 802.3af and IEEE 802.3at powered devices

• Auto-sensing ports that provide power only to PoE end devices

• Power to port is turned off if cables are removed

Extreme Flexibility

• Support for up to a total of 28 non-blocking ports (six 4-port modules and four

fixed ports)

• Mixture of fiber optic or copper Gigabit ports with up to 28 Gig Ethernet ports,

including 4 ports capable of 10 Gigabits.

• Galvanized steel and aluminum construction

RUGGEDCOM RST2228P

Installation Manual, 12/2019, C79000-G8976-1403-05

1

Introduction

1.2Description

Compact 1U Form Factor

• Space-saving design

Front Loading Modular Design

• Allows for simple, cost effective in-field servicing and upgrading

Dual Redundant Smart Power Supplies

• HI voltage AC/DC: 88-300 VDC or 85-264 VAC

• LO voltage DC: 10.5-15 VDC, 13-36 VDC or 36-72 VDC

• Smart power supplies able to detect loss of input voltage

Reliability in Harsh Environments

• Immunity to EMI and heavy electrical surges

• Zero-Packet-Loss Technology

• Supports Siemens FastConnect RJ45 Cabling System

• -40 to 85 °C (-40 to 185 °F) operating temperature (fan-less)

• Conformal coated printed circuit boards (optional)

1.2 Description

The RUGGEDCOM RST2228P features various ports, controls and indicator LEDs for

connecting, configuring and troubleshooting the device.

2

Installation Manual, 12/2019, C79000-G8976-1403-05

RUGGEDCOM RST2228P

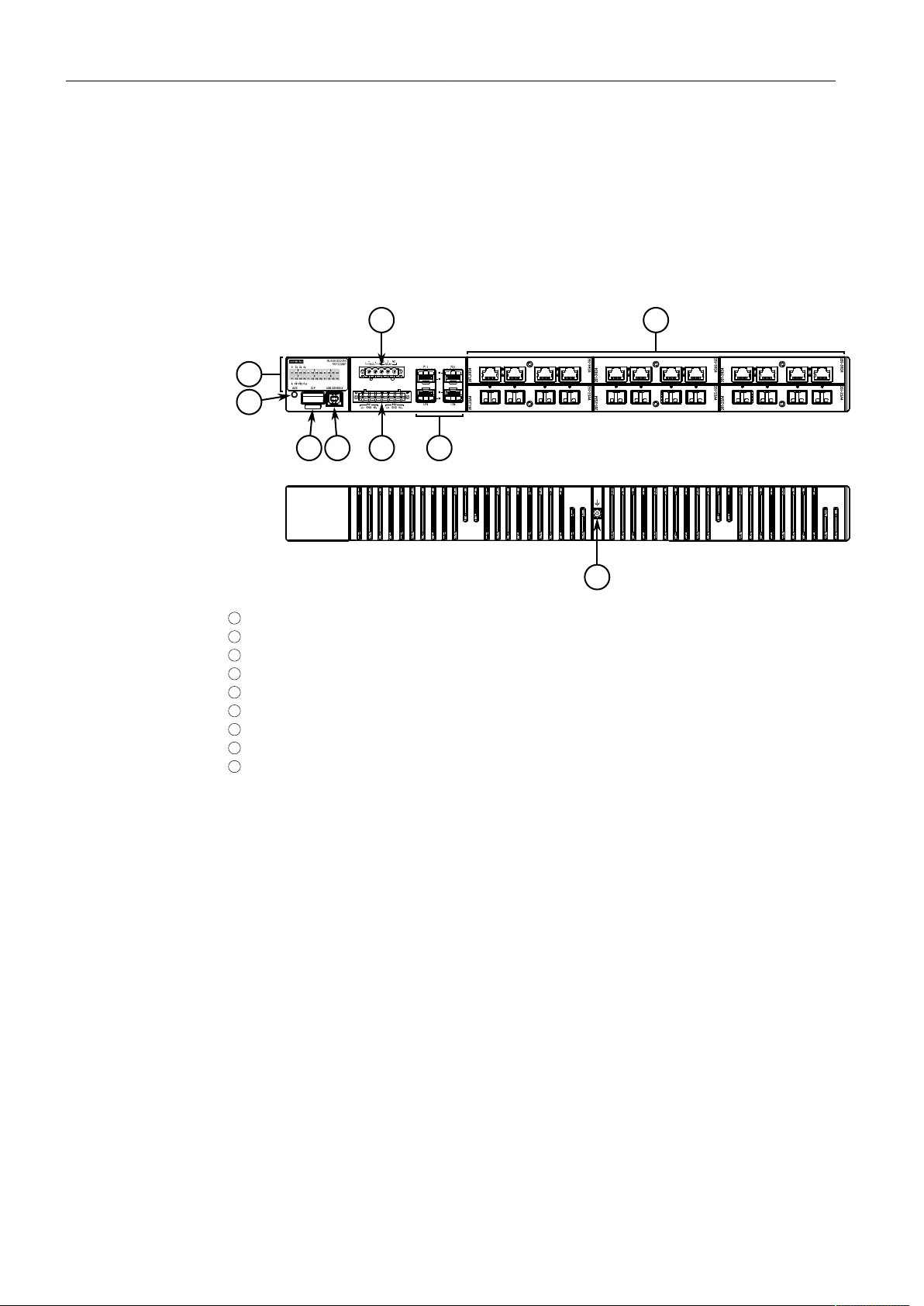

Orientation Options

9

2

1

3

4

5

6

7

8

The RUGGEDCOM RST2228P is available in one of two options:

• Option 1

Introduction

1.2Description

Status panel, alarm LED, ACO Button, CLP port and USB console port are located

on the front panel.

1

Status Panel

2

ACO Button

3

CLP Port

4

USB Console Port

5

PoE Power and Failsafe Alarm Relay Terminal Block

6

Power Terminal Block

7

SFP/SFP+ Transceiver Sockets

8

Media Modules

9

Chassis Ground Terminal

Figure1.1 RUGGEDCOM RST2228P (Front Panel Orientation)

RUGGEDCOM RST2228P

Installation Manual, 12/2019, C79000-G8976-1403-05

3

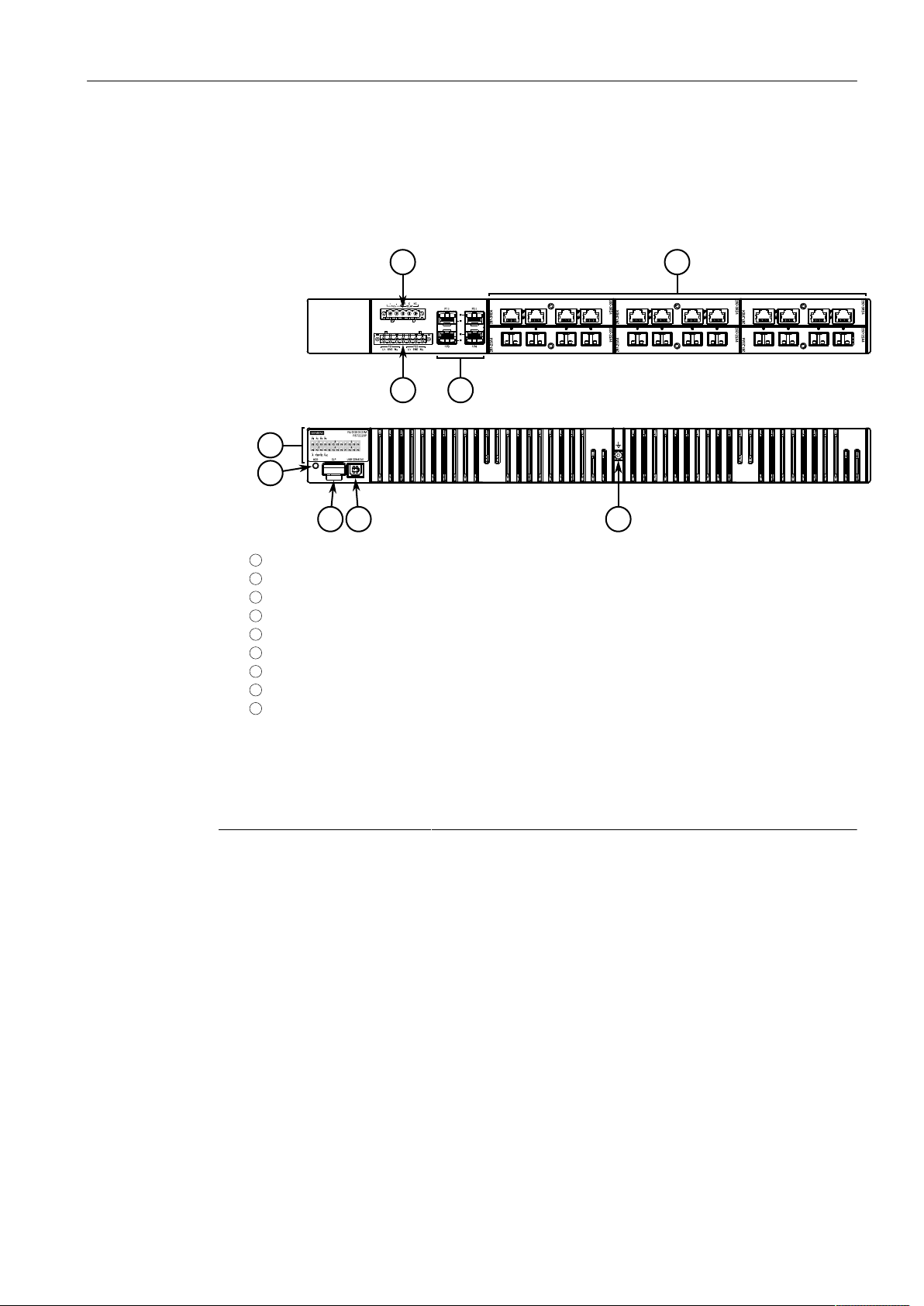

Introduction

9

2

1

3

4

5

6

7

8

1.2Description

• Option 2

Status panel, alarm LED, ACO Button, CLP port and USB console port are located

on the rear panel.

Key Features

1

Status Panel

2

ACO Button

3

CLP Port

4

USB Console Port

5

PoE Power and Failsafe Alarm Relay Terminal Block

6

Power Terminal Block

7

SFP/SFP+ Transceiver Sockets

8

Media Modules

9

Chassis Ground Terminal

Figure1.2 RUGGEDCOM RST2228P (Rear Panel Orientation)

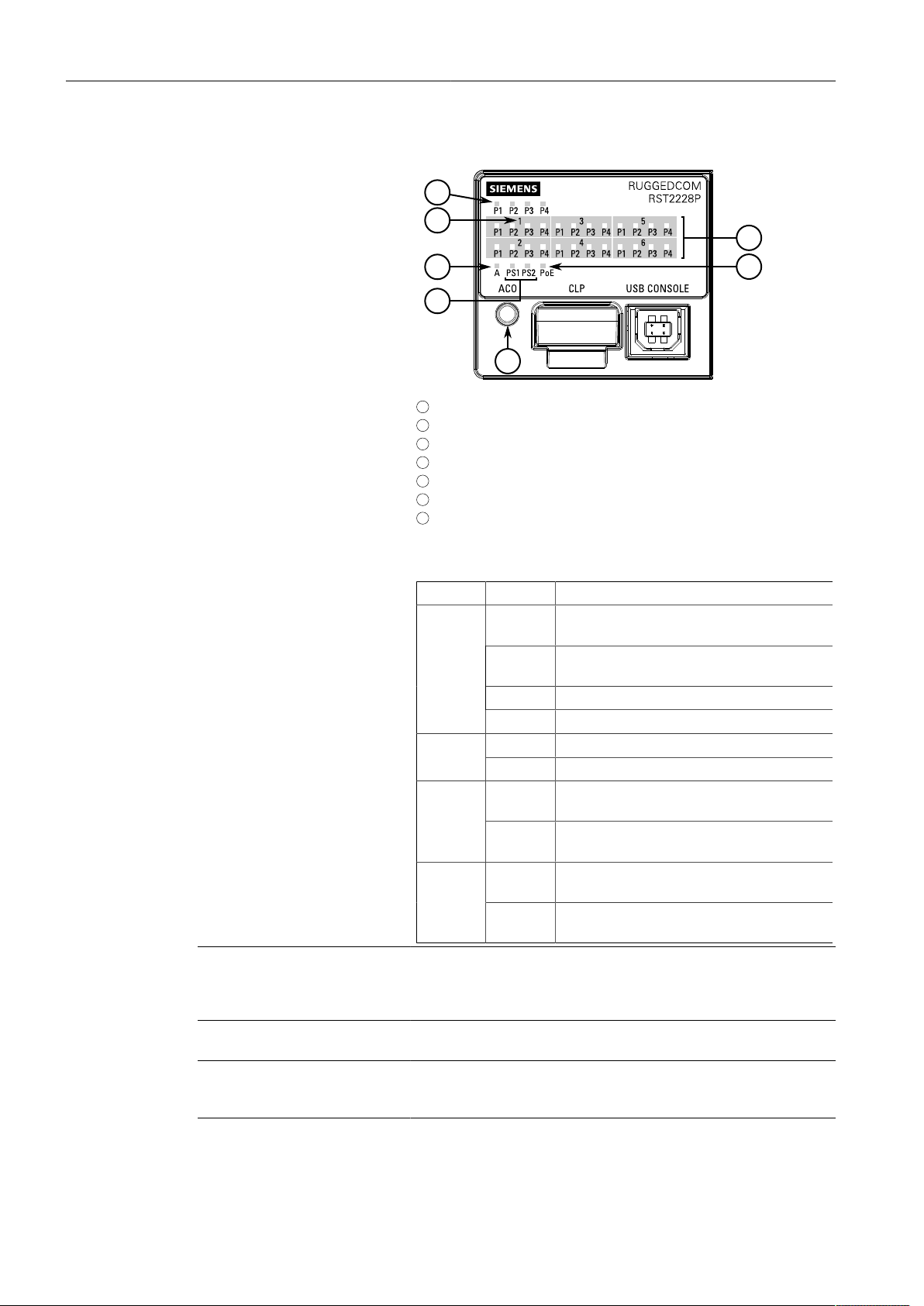

Status Panel The status panel displays the real-time status of the device.

Six module slot locators indicate the physical location of each media

module in relation to the available chassis slots. Module ports are

numbered from left to right when installed in the chassis. A dedicated LED is assigned to each module port.

4

Installation Manual, 12/2019, C79000-G8976-1403-05

RUGGEDCOM RST2228P

1

4

3

5

6

7

2

1

LEDs for 10GBase SFP+ Transceivers (Slot 0)

2

Module Slot Locators

3

LEDs for Module Ports

4

Alarm Status LED

5

Power Supply Status LEDs

6

PoE Status LED

7

ACO Button

Introduction

1.2Description

Figure1.3 Status Panel

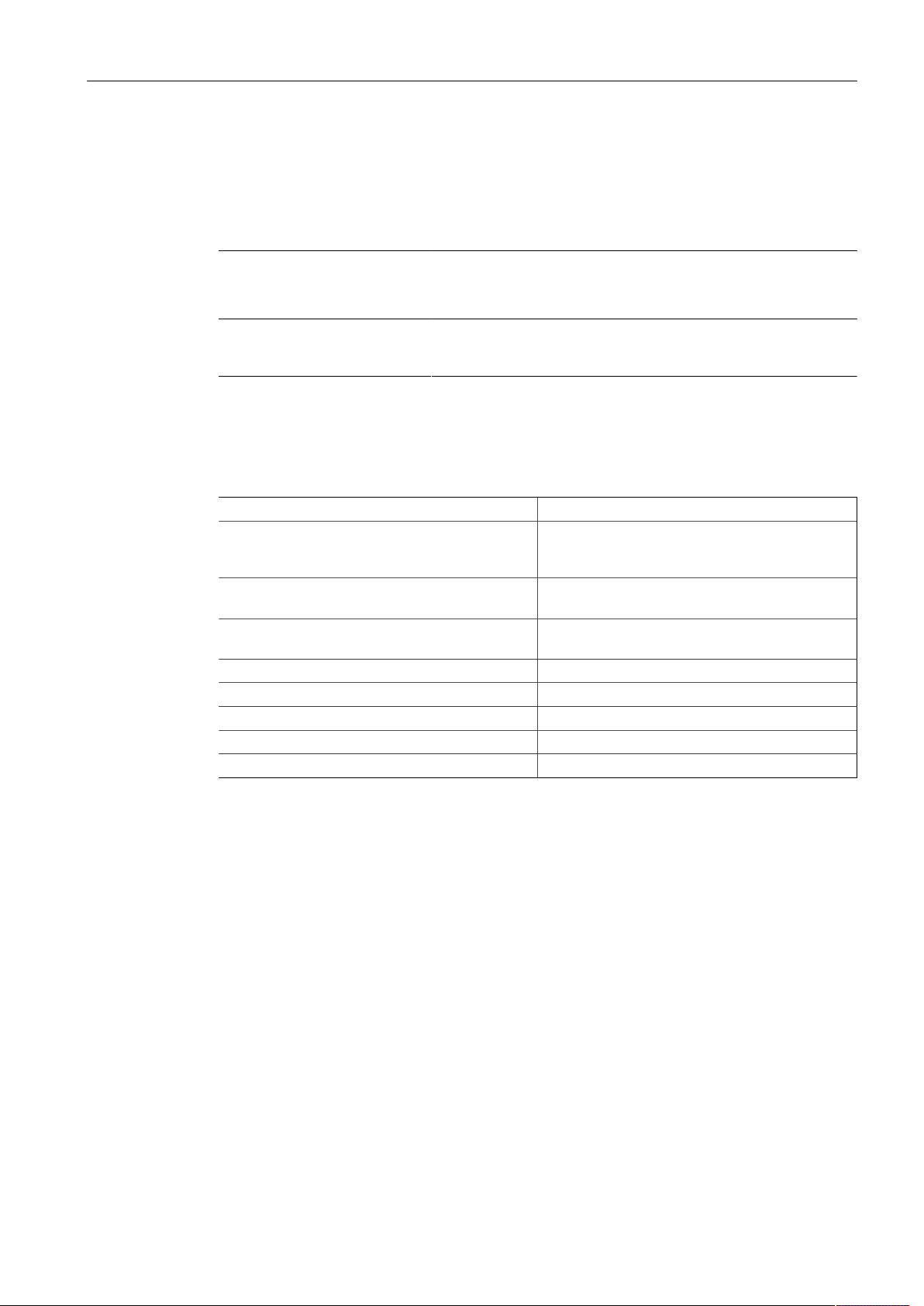

LED State Description

P{number}

Solid

(Green)

Solid

Link detected

Link detected and PoE established

(Yellow)

Blinking Link activity

Off No link detected

Solid An alarm condition existsA

Off No active alarm conditions exist

PS1/PS2

Solid The power source is supplying power to the

device

Off The power source is not supplying power to

the device

PoE

Solid The PoE power source is supplying power

to the device

Off The PoE power source is not supplying

power to the device

USB Console Port The serial console port is for interfacing directly with the device and

accessing initial management functions. For information about connecting to the device via the serial console port, refer to "Connect-

ing to the Device (Page 25)".

Alarm Indicator LED The alarm indicator LED illuminates when an alarm condition exists.

Pressing the Alarm Cut-Off (ACO) button clears the alarm(s).

Removable Media The device features sockets for up to four SFP/SFP+ transceivers and

slots for up to six removable media modules. For more information,

refer to "Communication Ports (Page 29)".

RUGGEDCOM RST2228P

Installation Manual, 12/2019, C79000-G8976-1403-05

5

Introduction

1.3Required Tools and Materials

PoE Power and Failsafe Alarm

Relay

Power Supply Terminal Block A pluggable terminal block. For more information, refer to:

Chassis Ground Terminal Protects the device from power surges and accumulated static elec-

Latches to default state when a power disruption or other alarm

condition occurs. For more information, refer to:

• "Connecting the Failsafe Alarm Relay (Page 13)"

• "Failsafe Alarm Relay Specifications (Page 36)"

• "Connecting External PoE Power (Page 20)"

• "Connecting Power (Page 15)"

• "Power Supply Specifications (Page 35)"

tricity. For information about grounding the device, refer to "Con-

necting Power (Page 15)".

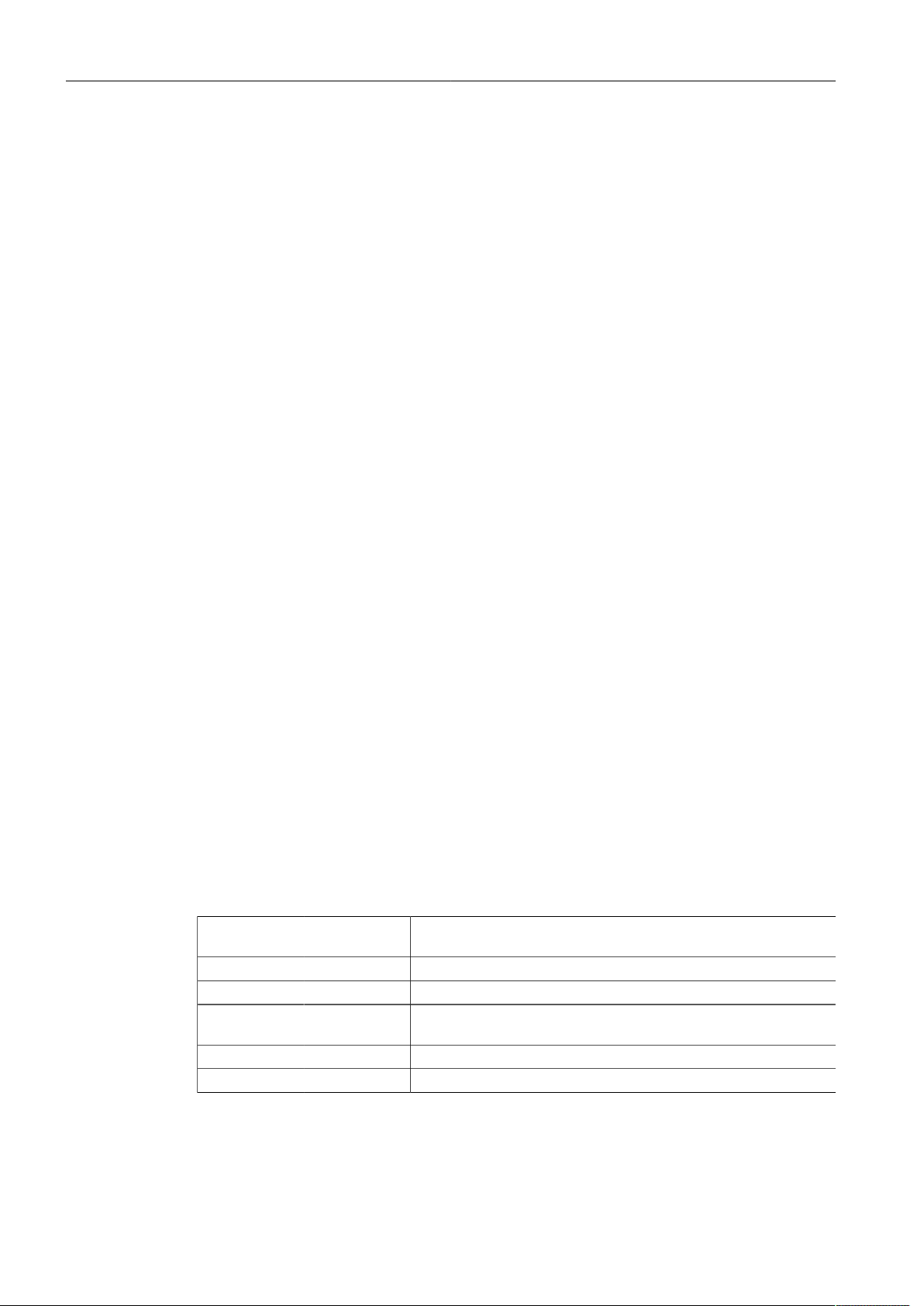

1.3 Required Tools and Materials

The following tools and materials are required to install the RUGGEDCOM RST2228P:

Tools/Materials Purpose

AC/DC power cord For connecting power to the device. For the re-

Lightning protector For protecting the device from harmful electrical

Flathead screwdriver For removing or installing modules and terminal

Torx T10 screwdriver For removing or installing modules.

Phillips screwdriver For removing or installing terminal blocks.

8 x M6 or #10-32 screws For mounting the device to a panel.

8 x M6 or #10-32 screws For mounting the device to a rack.

Braided or equivalent ground wire For grounding the device to safety Earth.

quired. To determine the proper wire gage, refer

to "Power Supply Specifications (Page 35)".

strikes.

blocks.

1.4 Decommissioning and Disposal

Proper decommissioning and disposal of this device is important to prevent malicious

users from obtaining proprietary information and to protect the environment.

Decommissioning

This device may include sensitive, proprietary data. Before taking the device out of

service, either permanently or for maintenance by a third-party, make sure it has

been fully decommissioned.

For more information, refer to the associated Configuration Manual.

6

Installation Manual, 12/2019, C79000-G8976-1403-05

RUGGEDCOM RST2228P

Recycling and Disposal

For environmentally friendly recycling and disposal of this device and related accessories, contact a facility certified to dispose of waste electrical and electronic equipment. Recycling and disposal must be done in accordance with local regulations.

1.5 Cabling Recommendations

Siemens recommends using SIMATIC NET industrial Ethernet shielded cables for all

Ethernet ports.

1.5.1 Protection On Twisted-Pair Data Ports

All copper Ethernet ports on RUGGEDCOM products include transient suppression

circuitry to protect against damage from electrical transients and conform with IEC

61850-3 and IEEE 1613 Class 1 standards. This means that during a transient electrical event, communications errors or interruptions may occur, but recovery is automatic.

Introduction

1.5Cabling Recommendations

Siemens also does not recommend using copper Ethernet ports to interface with devices in the field across distances that could produce high levels of ground potential

rise (i.e. greater than 2500 V), during line-to-ground fault conditions.

1.5.2 Gigabit Ethernet 1000Base-TX Cabling Recommendations

The IEEE 802.3ab Gigabit Ethernet standard defines 1000 Mbit/s Ethernet communications over distances of up to 100 m (328 ft) using all 4 pairs in category 5 (or

higher) balanced, unshielded twisted-pair cabling. For wiring guidelines, system designers and integrators should refer to the Telecommunications Industry Association

(TIA) TIA/EIA-568-A wiring standard that characterizes minimum cabling performance

specifications required for proper Gigabit Ethernet operation. For reliable, error-free

data communication, new and pre-existing communication paths should be verified

for TIA/EIA-568-A compliance.

The following table summarizes the relevant cabling standards:

Cabling

Category

< 5 No New wiring infrastructure required.

5 Yes Verify TIA/EIA-568-A compliance.

5e Yes No action required. New installations should

6 Yes No action required.

> 6 Yes Connector and wiring standards to be determined.

1000Base-

TX Compliant

Required Action

be designed with Category 5e or higher.

RUGGEDCOM RST2228P

Installation Manual, 12/2019, C79000-G8976-1403-05

7

Introduction

1.5.3Supported Fiber Optic Cables

Follow these recommendations for copper data cabling in high electrical noise environments:

• Data cable lengths should be as short as possible, preferably 3 m (10 ft) in

length. Copper data cables should not be used for inter-building communications.

• Power and data cables should not be run in parallel for long distances, and

should be installed in separate conduits. Power and data cables should intersect

at 90° angles when necessary to reduce inductive coupling.

• Shielded/screened cabling can be used when required. Care should be taken to

avoid the creation of ground loops with shielded cabling.

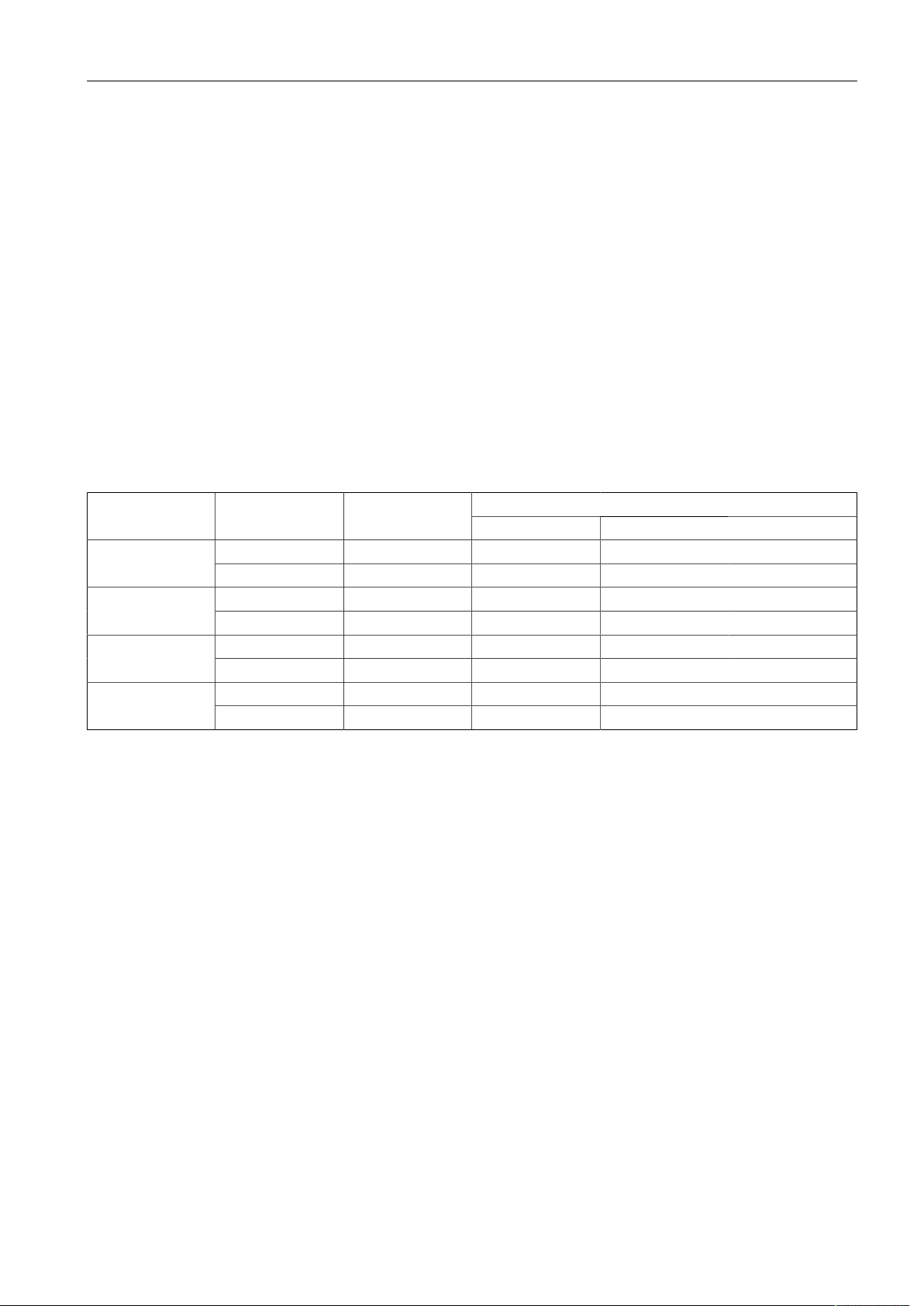

1.5.3 Supported Fiber Optic Cables

The following fiber optic cable types are supported under the stated conditions.

width (MHz·km)

850 200 — 275 33OM1 (62.5/125)

1300 500 2000 — —

850 500 — 550 82OM2 (50/125)

1300 500 2000 — —

a

Laser optimized.

a

a

850 1500 — 550 300OM3 (50/125)

1300 500 2000 — —

850 3500 — 550 400OM4 (50/125)

1300 500 2000 — —

Distance (m)Cable Type Wavelength (nm) Modal Band-

100Base-FX 1000Base-SX 10GBase-SR

8

Installation Manual, 12/2019, C79000-G8976-1403-05

RUGGEDCOM RST2228P

Installing the Device

This chapter describes how to install the device, including mounting the device, connecting power, and connecting the device to the network.

DANGER

Electrocution hazard – risk of serious personal injury and/or damage to equipment.

Before performing any maintenance tasks, make sure all power to the device has

been disconnected and wait approximately two minutes for any remaining energy

to dissipate.

WARNING

Radiation hazard – risk of serious personal injury.

This product may contain a laser system and is classified as a CLASS 1 LASER PRODUCT. Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

2

NOTICE

This product contains no user-serviceable parts. Attempted service by unauthorized

personnel shall render all warranties null and void.

Changes or modifications not expressly approved by Siemens AG could invalidate

specifications, test results, and agency approvals, and void the user's authority to

operate the equipment.

NOTICE

This product should be installed in a restricted access location where access can only

be gained by authorized personnel who have been informed of the restrictions and

any precautions that must be taken. Access must only be possible through the use of

a tool, lock and key, or other means of security, and controlled by the authority responsible for the location.

2.1 General Procedure

The general procedure for installing the device is as follows:

NOTICE

The user is responsible for the operating environment of the device, including maintaining the integrity of all protective conductor connections and checking equip-

RUGGEDCOM RST2228P

Installation Manual, 12/2019, C79000-G8976-1403-05

9

Loading...

Loading...