Page 1

Symbols, Contents

SIMATIC NET PROFIBUS Networks

Manual

PROFIBUS Networks

Topologies of SIMATIC NET PROFIBUS

Networks

Configuring Networks

Passive Components of RS–485 Networks

Active Components of RS–485 Networks

Passive Components for PROFIBUS–PA

Passive Components for Electrical Networks

Active Components for Optical Networks

Active Components for Wireless Networks

1

2

3

4

5

6

7

8

9

Testing PROFIBUS

Lightning and Surge Voltage Protection for

LAN Cables Between Buildings

Installing LAN Cables

Installing Instructions for SIAMTIC NET

PROFIBUS Plastic Fiber Optic with Simplex

Connenctors or BFOC Connectors and Pulling Loop for the FO Standard Cable

Installing Network Components in Cubicles

Dimension Drawings

Operating Instructions ILM / OLM / OBT

General Information

References

A

B

C

D

E

F

G

H

I

05/2000

6GK1970–5CA20–0AA1

Release 2

SIMATIC NET – Support and Training

Glossary, Index

J

Page 2

Safety Guidelines

Danger

!

indicates that death, severe personal injury or substantial property damage will result if proper precau-

tions are not taken.

Warning

!

indicates that death, severe personal injury or substantial property damage can result if proper precautions are not taken.

Caution

!

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment Qualified persons are

defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

Warning

!

Trademarks

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of

a utility model or design, are reserved.

This device and its components may only be used for the applications described in the catalog or the

technical description, and only in connection with devices or components from other manufacturers which

have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and operated and maintained as recommended.

SIMATICR, SIMATIC HMIR and SIMATIC NETR are registered trademarks of SIEMENS AG.

HCS is a registered trademark of Ensign–Bickford Optics Company.

Third parties using for their own purposes any other names in this document which refer to trademarks

might infringe upon the rights of the trademark owners.

Disclaimer of LiabilityCopyright Siemens AG 1999 All rights reserved

We have checked the contents of this manual for agreement with the hardware and software described. Since deviations cannot be precluded entirely,

we cannot guarantee full agreement. However, the data in this manual are

reviewed regularly and any necessary corrections included in subsequent

editions. Suggestions for improvement are welcomed.

Siemens AG

Bereich Automatisierungs– und Antriebstechnik

Geschäftsgebiet Industrielle Kommunikation

Postfach 4848, D-90327 Nürnberg

Siemens Aktiengesellschaft Order no. 6GK 1970–5AC20–0AA1

E Siemens AG 1999

Subject to technical change.

Page 3

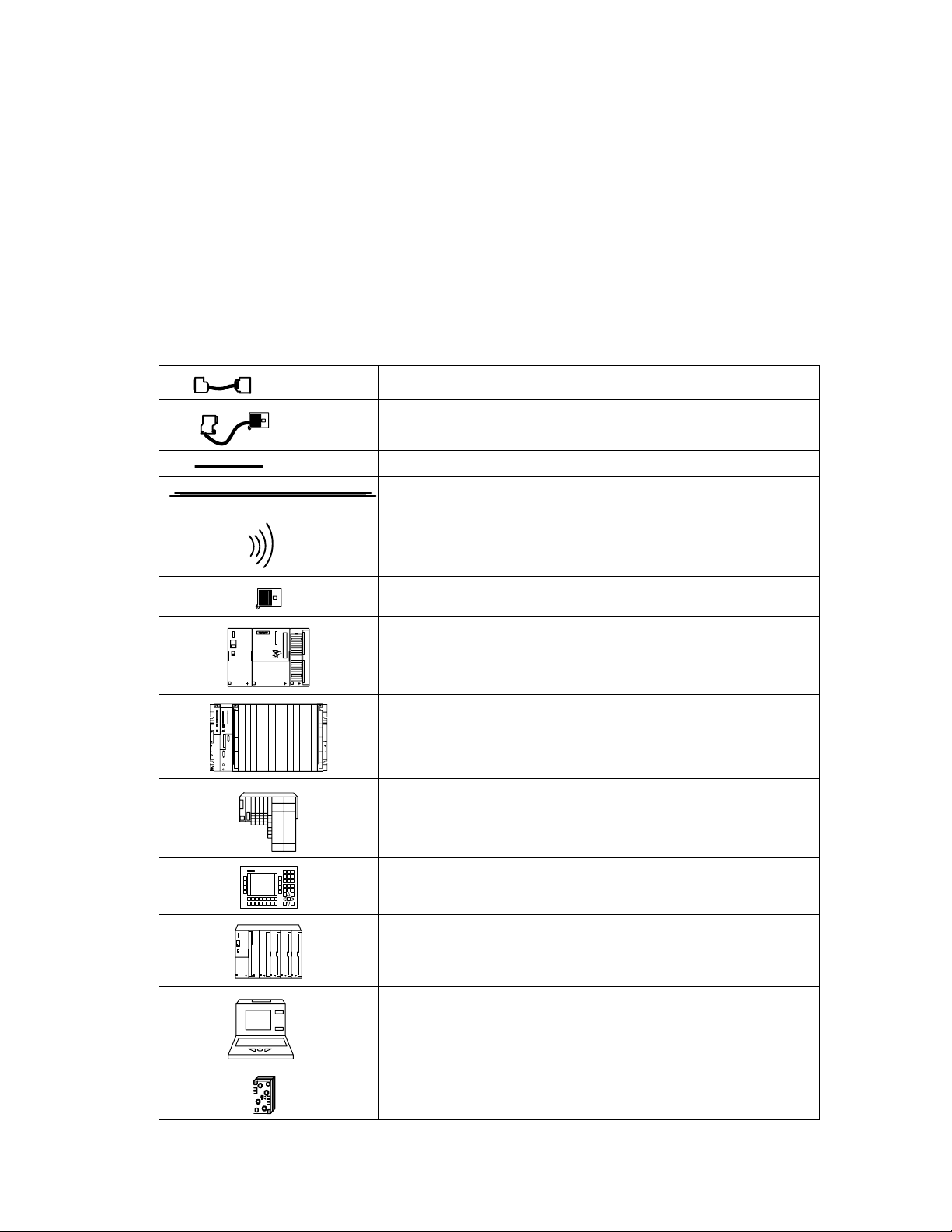

Symbols

PROFIBUS 830–1 T connecting cable

PROFIBUS 830-2 connecting cable

LAN cable (twisted-pair)

Duplex FO cable

Wireless transmission (infrared)

Bus connector

S7–300

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

S7–400

ET200S

OP25

ET 200M (with IM 153–2 FO)

PG/PC/OP

AS-i branch

i

Page 4

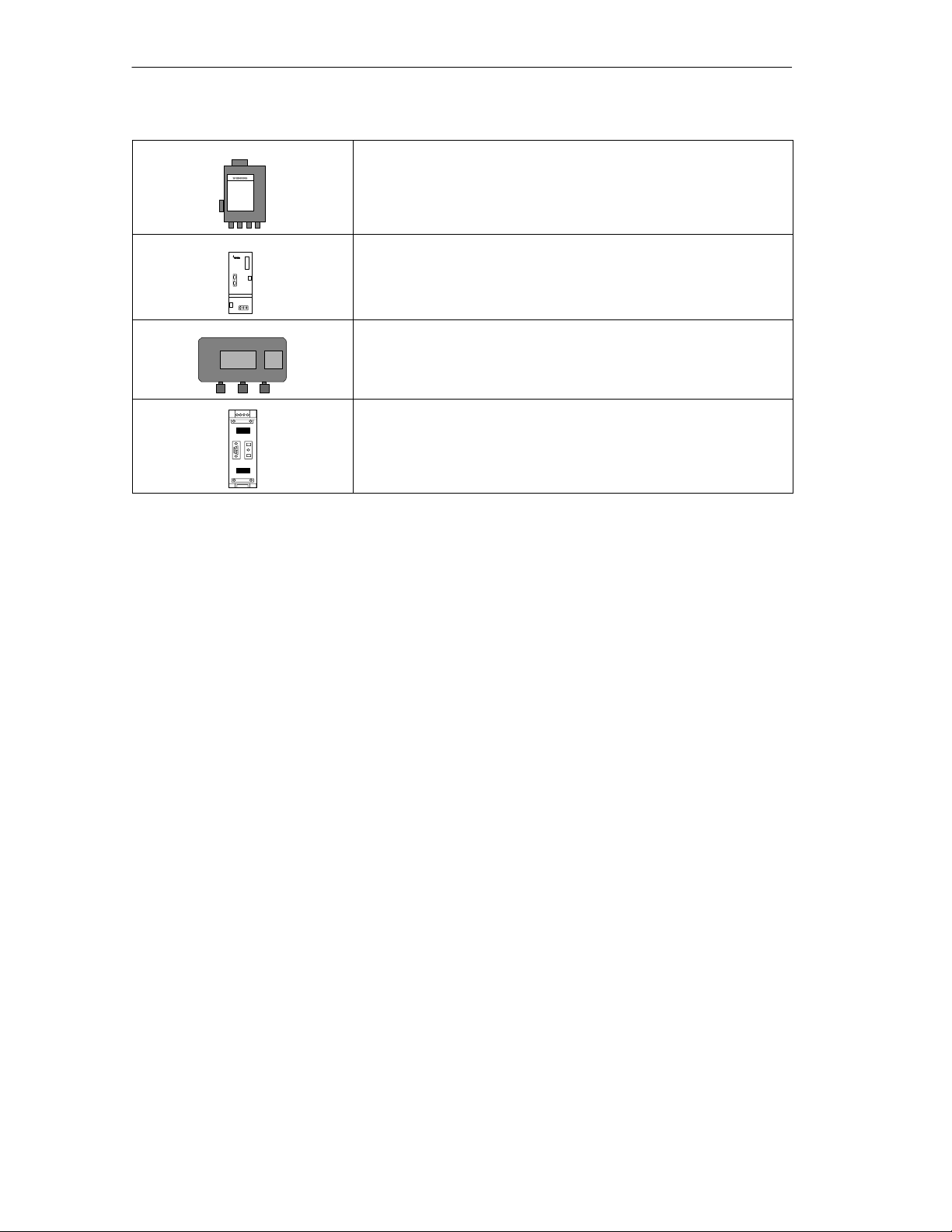

Symbols

Optical link module (OLM)

Optical bus terminal (OBT)

Infrared link module (ILM)

Repeater

PROFIBUS Networks SIMATIC NET

ii

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 5

Contents

Contents

1 PROFIBUS NETWORKS 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Local Area Networks in Manufacturing and Process Automation 1-2. . . . . . .

1.1.1 General Introduction 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Overview of the SIMATIC NET System 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Basics of the PROFIBUS Network 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Standards 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Access Techniques 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Transmission Techniques 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Transmission Techniques According to EIA Standard RS-485 1-10. . . . . . . . .

1.2.5 Transmission Techniques for Optical Components 1-12. . . . . . . . . . . . . . . . . . .

1.2.6 Transmission Technique for Wireless Infrared Technology 1-14. . . . . . . . . . . . .

1.2.7 Transmission Technique for PROFIBUS-PA 1-15. . . . . . . . . . . . . . . . . . . . . . . . .

2 Topologies of SIMATIC NET PROFIBUS Networks 2-1. . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Topologies of RS-485 Networks 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Components for Transmission Rates up to 1.5 Mbps 2-3. . . . . . . . . . . . . . . .

2.1.2 Components for Transmission Rates up to

12 Mbps 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Topologies of Optical Networks 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Topology with Integrated Optical Interfaces 2-6. . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Topologies with OLMs 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Combination of Integrated Optical Interfaces and OLMs 2-13. . . . . . . . . . . . . .

2.3 Topologies of Wireless Networks 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Topologies with PROFIBUS-PA 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Connectivity Devices 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 DP/DP Coupler 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Connecting to PROFIBUS-PA 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 DP/PA Coupler 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 DP/PA Link 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.5 Connecting PROFIBUS-DP to RS-232C 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.6 Connecting with the DP/AS-Interface Link 65 2-30. . . . . . . . . . . . . . . . . . . . . . .

2.5.7 Connecting with the DP/AS-Interface Link 20 2-33. . . . . . . . . . . . . . . . . . . . . . . .

2.5.8 Connecting PROFIBUS-DP to instabus EIB 2-36. . . . . . . . . . . . . . . . . . . . . . . . .

3 Configuring Networks 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Configuring Electrical Networks 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Segments for Transmission Rates up to a Maximum of 500 Kbps 3-3. . . . . .

3.1.2 Segments for a Transmission Rate of 1.5 Mbps 3-4. . . . . . . . . . . . . . . . . . . . .

3.1.3 Segments for Transmission Rates up to a Maximum of

12 Mbps 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Configuring Electrical Networks with RS-485 Repeaters 3-9. . . . . . . . . . . . . .

3.2 Configuring Optical Networks 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 How a Fiber-Optic Cable Transmission System Works 3-12. . . . . . . . . . . . . . .

3.2.2 Optical Power Budget of a Fiber-Optic Transmission System 3-14. . . . . . . . . .

3.2.3 Cable Lengths for Plastic and PCF FO Paths 3-17. . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Calculating the Power Budget of Glass Fiber Optical Links with OLMs 3-18. .

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

iii

Page 6

Contents

3.3 Transmission Delay Time 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Configuring Optical Buses and

Star Topologies with OLMs 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Configuring Redundant Optical Rings with OLMs 3-27. . . . . . . . . . . . . . . . . . . .

3.3.3 Example of Configuring the Bus Parameters in STEP 7 3-31. . . . . . . . . . . . . . .

4 Passive Components for RS-485 Networks 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 SIMATIC NET PROFIBUS Cables 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 FC Standard Cable 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 FC-FRNC Cable (LAN cable with halogen-free outer sheath) 4-8. . . . . . . . . .

4.1.3 FC Food Cable 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.4 FC Robust Cable 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.5 PROFIBUS Flexible Cable 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.6 FC Underground Cable 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.7 FC Trailing Cable 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.8 PROFIBUS Festoon Cable 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.9 SIENOPYR-FR Marine Cable 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 FastConnect Bus Connector 4-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 The FastConnect System 4-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Area of Application and Technical Specifications of the FastConnect Bus

Connector 4-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Using the FastConnect Stripping Tool for Preparing FC Cables 4-30. . . . . . . .

4.3 Bus Connectors 4-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Area of Application and Technical Specifications of the Bus Connector 4-33. .

4.4 Attaching the LAN Cable to the Bus Connector 4-37. . . . . . . . . . . . . . . . . . . . . .

4.4.1 Attaching the LAN Cable to Bus Connector (6ES7 972-0B.11..) 4-37. . . . . . . .

4.4.2 Connecting the LAN Cable to Bus Connector (6ES7 972-0BA30-0XA0) 4-40.

4.4.3 Connecting the LAN Cable to Bus Connector (6ES7 972-0B.40) 4-42. . . . . . .

4.5 Installing the Bus Connector with Axial Cable Outlet 4-44. . . . . . . . . . . . . . . . . .

4.6 Plugging the Bus Connector into the Module 4-46. . . . . . . . . . . . . . . . . . . . . . . .

4.7 Bus Terminals for RS-485 Networks 4-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.1 Versions 4-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.2 Design and Functions of the RS-485 Bus Terminal 4-49. . . . . . . . . . . . . . . . . . .

4.7.3 Design and Functions of the 12M Bus Terminal 4-52. . . . . . . . . . . . . . . . . . . . . .

4.7.4 Mounting/Attaching the LAN Cables 4-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.5 Grounding 4-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.6 Technical Data of the RS-485 Bus Terminal 4-60. . . . . . . . . . . . . . . . . . . . . . . . .

4.7.7 Technical Data of the 12M Bus Terminal 4-61. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Cable Connections 4-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.1 Cable Connections to Network Components 4-63. . . . . . . . . . . . . . . . . . . . . . . .

4.8.2 Cable Connection without Bus Connection Elements 4-63. . . . . . . . . . . . . . . . .

4.9 Preassembled Connecting Cables 4-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9.1 830-1T Connecting Cable 4-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9.2 830-2 Connecting Cable 4-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Active Components for RS-485 Networks 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 RS-485 Repeater 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Possible Configurations with the RS-485 Repeater 5-6. . . . . . . . . . . . . . . . . . .

PROFIBUS Networks SIMATIC NET

iv

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 7

Contents

5.3 Installing and Uninstalling the RS-485 Repeater 5-9. . . . . . . . . . . . . . . . . . . . .

5.4 Ungrounded Operation of the RS-485 Repeater 5-12. . . . . . . . . . . . . . . . . . . . .

5.5 Connecting the Power Supply 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Connecting the LAN Cable 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 PROFIBUS Terminator 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Passive Components for PROFIBUS-PA 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 FC Process Cable 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 SpliTConnect Tap 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Passive Components for Electrical Networks 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Fiber-Optic Cables 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Plastic Fiber-Optic Cables 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Plastic Fiber Optic, Duplex Cord 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Plastic Fiber-Optic, Standard Cables 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 PCF Fiber-Optic Cables 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Glass Fiber-Optic Cables 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Fiber-Optic Standard Cable 7-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 INDOOR Fiber-Optic Cable 7-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.3 Flexible Fiber-Optic Trailing Cable 7-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.4 SIENOPYR Duplex Fiber-Optic Marine Cable 7-22. . . . . . . . . . . . . . . . . . . . . . .

7.3.5 Special Cables 7-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Fiber-Optic Connectors 7-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1 Connectors for Plastic Fiber-Optic Cables 7-26. . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.2 Simplex Connector and Adapter for Devices with Integrated Optical Interfaces .

7-26

7.4.3 BFOC Connectors for OLMs 7-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.4 Connectors for Glass Fiber Cables 7-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Active Components for Optical Networks 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Optical Bus Terminal OBT 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Optical Link Module OLM 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Active Components for Wireless Networks 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Infrared Link Module ILM 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Testing PROFIBUS A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Hardware Test Device BT200 for PROFIBUS-DP A-2. . . . . . . . . . . . . . . . . . . .

A.1.1 Possible Uses A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.2 Area of Application A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.3 Logging Functions A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.4 Design A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.5 Functions A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.6 How the Unit Functions A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Testing FO Transmission Paths A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.1 Necessity of a Final Test A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2 Optical Power Source and Meter A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.3 Optical Time Domain Reflectometer (OTDR) A-9. . . . . . . . . . . . . . . . . . . . . . . .

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

v

Page 8

Contents

A.2.4 Checking the Optical Signal Quality with PROFIBUS OLM V3 A-12. . . . . . . . .

B Lightning and Surge Voltage Protection for LAN Cables Between Buildings B-1

B.1 Why Protect Your Automation System From Overvoltage? B-2. . . . . . . . . . . .

B.2 Protecting LAN Cables from Lightning B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.1 Instructions for Installing Coarse Protection B-5. . . . . . . . . . . . . . . . . . . . . . . . .

B.2.2 Instructions for Installing Fine Protection B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.3 General Information on the Lightning Protection Equipment from the Firm of

Dehn & Söhne B-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Installing LAN Cables C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 LAN Cables in Automation Systems C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 Electrical Safety C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 Mechanical Protection of LAN Cables C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4 Electromagnetic Compatibility of LAN Cables C-7. . . . . . . . . . . . . . . . . . . . . . .

C.4.1 Measures to Counter Interference Voltages C-7. . . . . . . . . . . . . . . . . . . . . . . . .

C.4.2 Installation and Grounding of Inactive Metal Parts C-8. . . . . . . . . . . . . . . . . . .

C.4.3 Using the Shields of Electrical LAN Cables C-8. . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.4 Equipotential Bonding C-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.5 Routing Electrical LAN Cables C-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.5.1 Cable Categories and Clearances C-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.5.2 Cabling within Closets C-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.5.3 Cabling within Buildings C-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.5.4 Cabling outside Buildings C-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.5.5 Special Noise Suppression Measures C-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.6 Electromagnetic Compatibility of Fiber-Optic Cables C-20. . . . . . . . . . . . . . . . .

C.7 Installing LAN Cables C-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.7.1 Instructions for Installing Electrical and Optical LAN cables C-21. . . . . . . . . . . .

C.8 Additional Instructions on Installing Fiber-Optic Cables C-24. . . . . . . . . . . . . . .

D Installation Instructions for SIMATIC NET PROFIBUS Plastic Fiber-Optic with

Simplex Connectors or BFOC Connectors and Pulling Loop for the FO Standard

Cable D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Installing Network Components in Cubicles E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.1 IP Degrees of Protection E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.2 SIMATIC NET Components E-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Dimension Drawings F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.1 Dimension Drawings of the Bus Connectors F-2. . . . . . . . . . . . . . . . . . . . . . . . .

F.2 Dimension Drawings of the RS-485 Repeater F-5. . . . . . . . . . . . . . . . . . . . . . .

F.3 Dimension Drawing of the PROFIBUS Terminator F-6. . . . . . . . . . . . . . . . . . .

F.4 Dimension Drawings of the RS-485 Bus Terminal F-7. . . . . . . . . . . . . . . . . . . .

F.5 Dimension Drawings of the BT12M Bus Terminal F-8. . . . . . . . . . . . . . . . . . . .

F.6 Dimension Drawings of the Optical Bus Terminal OBT F-9. . . . . . . . . . . . . . . .

PROFIBUS Networks SIMATIC NET

vi

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 9

Contents

F.7 Dimension Drawings Infrared Link Module ILM F-11. . . . . . . . . . . . . . . . . . . . . .

F.8 Dimension Drawings Optical Link Module OLM F-12. . . . . . . . . . . . . . . . . . . . . .

G Operating Instructions ILM / OLM / OBT G-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H General Information H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.1 Abbreviations/Acronyms H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I References I-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J SIMATIC NET – Support and Training J-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary Glossary-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

vii

Page 10

Contents

viii

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 11

PROFIBUS NETWORKS

1

Page 12

PROFIBUS NETWORKS

1.1 Local Area Networks in Manufacturing and Process Automation

1.1.1 General Introduction

Communication Systems

The performance of control systems is no longer simply determined by the

programmable logic controllers, but also to a great extent by the environment in

which they are located. Apart from plant visualization, operating and monitoring,

this also means a high-performance communication system.

Distributed Systems

Distributed automation systems are being used increasingly in manufacturing and

process automation. This means that a complex control task is divided into smaller

“handier” subtasks with distributed control systems. As a result, efficient

communication between the distributed systems is an absolute necessity. Such

structures have, for example, the following advantages:

S Independent and simultaneous startup of individual sections of plant/system

S Smaller, clearer programs

S Parallel processing by distributed automation systems

This results in the following:

– Shorter reaction times

– Reduced load on the individual processing units

S System-wide structures for handling additional diagnostic and logging functions

S Increased plant/system availability since the rest of the system can continue to

operate if a substation fails.

A comprehensive, high-performance communication system is a must for a

distributed system structure.

1-2

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 13

SIMATIC NET

With SIMATIC NET, Siemens provides an open, heterogeneous communication

system for various levels of process automation in an industrial environment. The

SIMATIC NET communication systems are based on national and international

standards according to the ISO/OSI reference model.

The basis of such communication systems are local area networks (LANs) which

can be implemented in one of the following ways:

S Electrically

S Optically

S Wireless

S Combined electrical/optical/wireless

S Electrically, intrinsically safe

PROFIBUS NETWORKS

1.1.2 Overview of the SIMATIC NET System

SIMATIC NET is the name of the communication networks connecting SIEMENS

programmable controllers, host computers, work stations and personal computers.

SIMATIC NET includes the following:

S The communication network consisting of transmission media, network

attachment and transmission components and the corresponding transmission

techniques

S Protocols and services used to transfer data between the devices listed above

S The modules of the programmable controller or computer that provide the

connection to the LAN (communications processors “CPs” or “interface

modules”).

To handle a variety of tasks in automation engineering, SIMATIC NET provides

different communication networks to suit the particular situation.

The topology of rooms, buildings, factories, and complete company complexes and

the prevalent environmental conditions mean different requirements. The

networked automation components also make different demands on the

communication system.

To meet these various requirements, SIMATIC NET provides the following

communication networks complying with national and international standards:

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

1-3

Page 14

PROFIBUS NETWORKS

Industrial Ethernet/Fast Ethernet

A communication network for the LAN and cell area using baseband technology

complying with IEEE 802.3 and using the CSMA/CD medium access technique

(Carrier Sense Multiple Access/Collision Detection). The network is operated on

S 50 Ω triaxial cable

S 100 Ω Twisted pair cables

S Glass fiber-optic cable

AS-Interface

The actuator sensor interface (AS-i) is a communication network for automation at

the lowest level for connecting binary actuators and sensors to programmable logic

controllers via the AS-i bus cable.

PROFIBUS

A communication network for the cell and field area complying with EN 50170-1-2

with the hybrid medium access technique token bus and master slave. Networking

is on twisted pair, fiber-optic cable or wireless.

PROFIBUS-PA

PROFIBUS-PA is the PROFIBUS for process automation (PA). It connects the

PROFIBUS-DP communication protocol with the IEC 61158-2 transmission

technique.

1-4

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 15

1.2 Basics of the PROFIBUS Network

EN 50170

SIMATIC NET PROFIBUS products and the networks they make up comply with

the PROFIBUS standard EN 50170 (1996). The SIMATIC NET PROFIBUS

components can also be used with SIMATIC S7 to create a SIMATIC MPI subnet

(MPI = Multipoint Interface).

Attachable Systems

The following systems can be connected:

S SIMATIC S5/S7/M7/C7 programmable controllers

S ET 200 distributed I/O system

S SIMATIC programming devices/PCs

PROFIBUS NETWORKS

S SIMATIC operator control and monitoring devices or systems

S SICOMP IPCs

S SINUMERIK CNC numerical controls

S SIMODRIVE sensors

S SIMOVERT master drives

S SIMADYN D digital control system

S SIMOREG

S Micro-/Midimasters

S SIPOS reversing power controllers/actuators

S SIPART industry/process controllers

S MOBY identification systems

S SIMOCODE low-voltage switchgear

S Circuit breakers

S SICLIMAT COMPAS compact automation stations

S TELEPERM M process control system

S Devices from other manufacturers with a PROFIBUS-compliant interface

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

1-5

Page 16

PROFIBUS NETWORKS

Transmission Media

PROFIBUS networks can be implemented with the following:

S Shielded, twisted pair cables (characteristic impedance 150 Ω)

S Shielded, twisted pair cables, intrinsically safe (with PROFIBUS-PA)

S Fiber-optic cables

S Wireless (infrared technology)

The various communication networks can be used independently or if required can

also be combined with each other.

1-6

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 17

1.2.1 Standards

SIMATIC NET PROFIBUS is based on the following standards and directives:

IEC 61158–2 to 6: 1993/2000

EN 50170-1-2: 1996

PROFIBUS User Organization Guidelines:

PROFIBUS NETWORKS

Digital data communications for measurement and control –

Fieldbus for use in industrial control systems

General purpose field communication system

Volume 2 : Physical Layer Specification and Service Definition

PROFIBUS Implementation Guide to DIN 19245

Part 3 (Draft)

Version 1.0 dated 14.12.1995

Fiber Optic Data Transfer for PROFIBUS

Version 2.1 dated 12.98

EIA RS-485: 1983

Standard for Electrical Characteristics of Generators and

Receivers for Use in Balanced Digital Multipoint Systems

SIMATIC NET PROFIBUS-PA is based on the following standards and directives:

EN 50170-1-2: 1996

General Purpose Field Communication System

Volume 2 : Physical Layer Specification and Service Definition

IEC 61158-2: 1993

Fieldbus standard for use in industrial control systems

Part 2 : Physical layer specification and service definition

EN 61158-2: 1994

Fieldbus standard for use in industrial control systems

Part 2 : Physical layer specification and service definition

PTB-Bericht W-53: 1993

Untersuchungen zur Eigensicherheit bei Feldbussystemen

Braunschweig, March 1993

PNO-Richtlinie: 1996

PROFIBUS-PA Inbetriebnahmeleitfaden (Hinweise zur Nutzung

der IEC 61158-2-Technik für PROFIBUS, Art.-Nr. 2.091)

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

1-7

Page 18

PROFIBUS NETWORKS

1.2.2 Access Techniques

TOKEN BUS/Master-Slave Method

Network access on PROFIBUS corresponds to the method specified in EN 50170,

Volume 2 “Token Bus” for active and “Master-Slave” for passive stations.

Master

Master

Master

Token rotation

(logical ring)

Master

Master

Slave

Master = active node

Slave = passive node

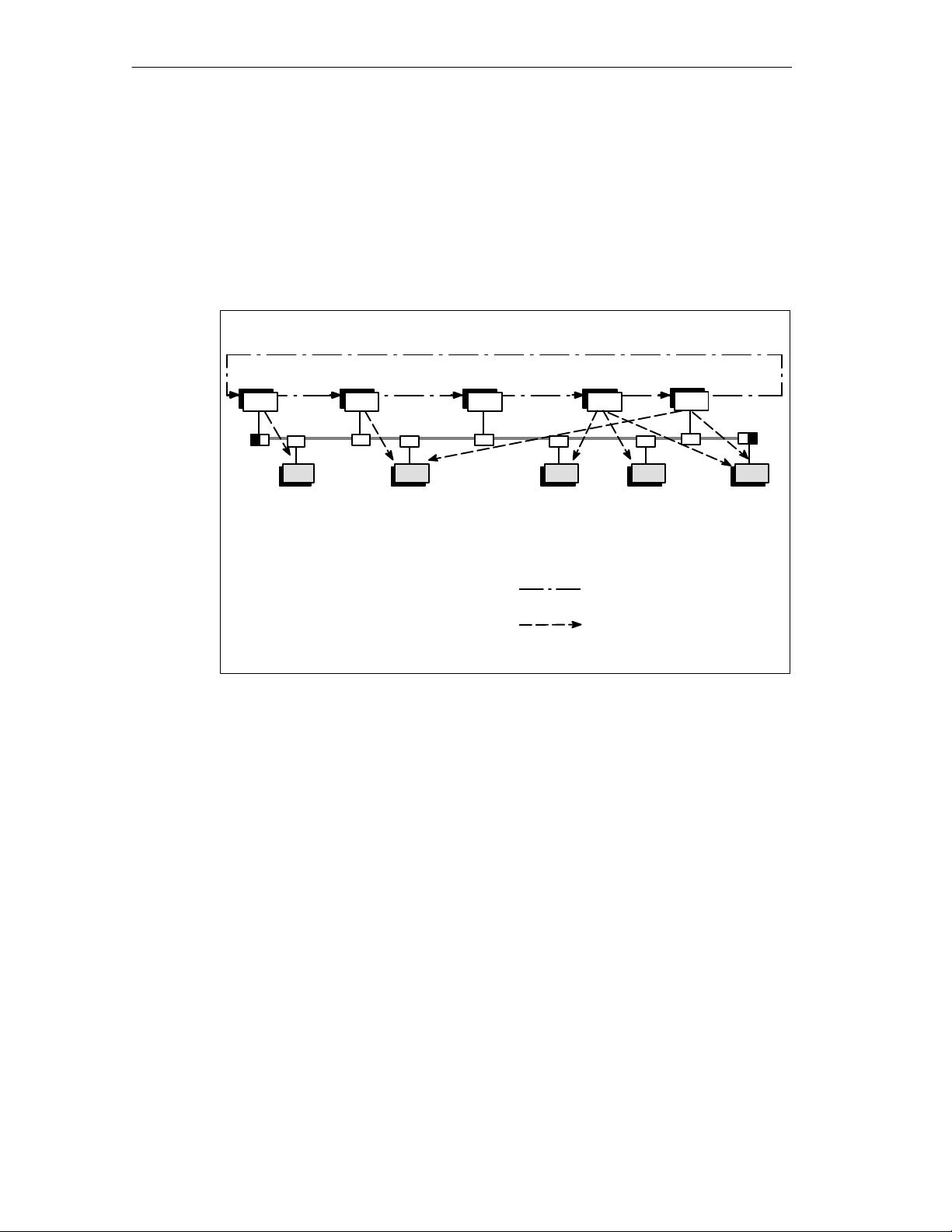

Figure 1-1 Principle of the PROFIBUS Medium Access Technique

Slave

Slave

Slave

Logical token ring

Master-slave relationship

Slave

1-8

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 19

Active and Passive Nodes

The access technique is not dependent on the transmission medium. Figure 1-1

“Principle of the PROFIBUS Medium Access Technique” shows the hybrid

technique with active and passive nodes. This is explained briefly below:

S All active nodes (masters) form the logical token ring in a fixed order and each

active node knows the other active nodes and their order in the logical ring (the

order does not depend on the topological arrangement of the active nodes on

the bus).

S The right to access the medium, the “Token”, is passed from active node to

active node in the order of the logical ring.

S If a node has received the token (addressed to it), it can send frames. The time

in which it is allowed to send frames is specified by the token holding time.

Once this has expired, the node is only allowed to send one high priority

message. If the node does not have a message to send, it passes the token

directly to the next node in the logical ring. The token timers from which the

maximum token holding time is calculated are configured for all active nodes.

PROFIBUS NETWORKS

S If an active node has the token and if it has connections configured to passive

nodes (master-slave connections), the passive nodes are polled (for example

values read out) or data is sent to the slaves (for example setpoints).

S Passive nodes never receive the token.

This access technique allows nodes to enter or leave the ring during operation.

1.2.3 Transmission Techniques

The physical transmission techniques used depend on the SIMATIC NET

PROFIBUS transmission medium:

S RS-485 for electrical networks on shielded, twisted pair cables

S Optical techniques according to the PROFIBUS User Organization guideline /3/

on fiber-optic cables

S Wireless techniques based on infrared radiation

S IEC 61158-2 technique for intrinsically safe and non-intrinsically safe electrical

networks in process control (PROFIBUS-PA) based on shielded, twisted pair

cables.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

1-9

Page 20

PROFIBUS NETWORKS

1.2.4 Transmission Techniques According to EIA Standard RS-485

EIA Standard RS-485

The RS-485 transmission technique corresponds to balanced data transmission as

specified in the EIA Standard RS-485 /4/. This transmission technique is

mandatory in the PROFIBUS standard EN 50170 for data transmission on twisted

pair cables.

The medium is a shielded, twisted pair cable.

The bus cable is terminated at both ends with the characteristic impedance. Such

a terminated bus cable is known as a segment.

The attachment of the node to the bus is via a bus terminal with a tap line or a bus

connector (maximum 32 nodes per segment). The individual segments are

interconnected by repeaters.

The maximum length of a segment depends on the following:

S The transmission rate

S The type of cable being used

Advantages:

S Flexible bus or tree structure with repeaters, bus terminals, and bus connectors

S Purely passive passing on of signals allows nodes to be deactivated without

S Simple installation of the bus cable without specialized experience.

for attaching PROFIBUS nodes

affecting the network (except for the nodes that supply power to the terminating

resistors)

1-10

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 21

Restrictions:

S Distance covered reduces as the transmission rate increases

S Requires additional lightning protection measures when installed outdoors

Properties of the RS-485 Transmission Technique

The RS-485 transmission technique in PROFIBUS has the following physical

characteristics:

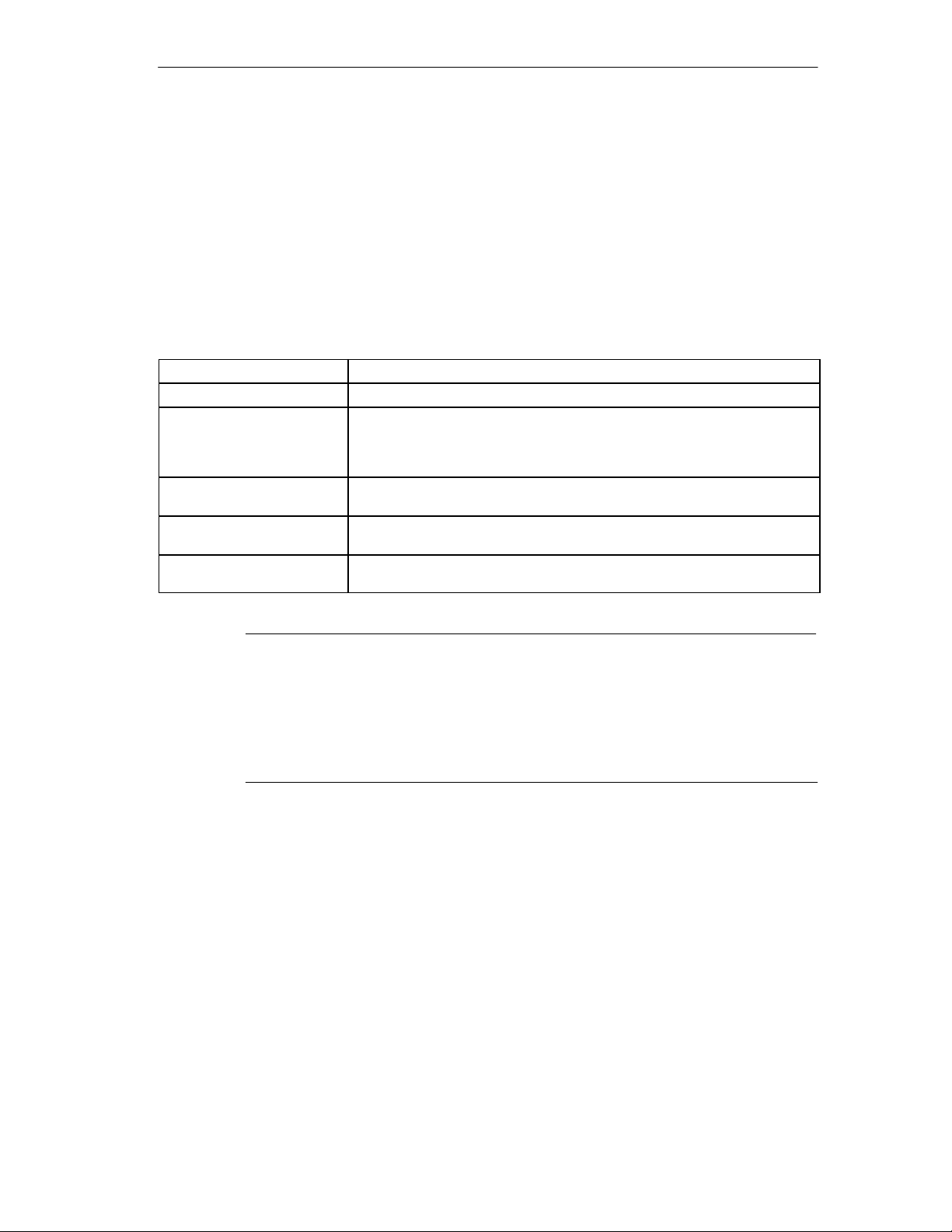

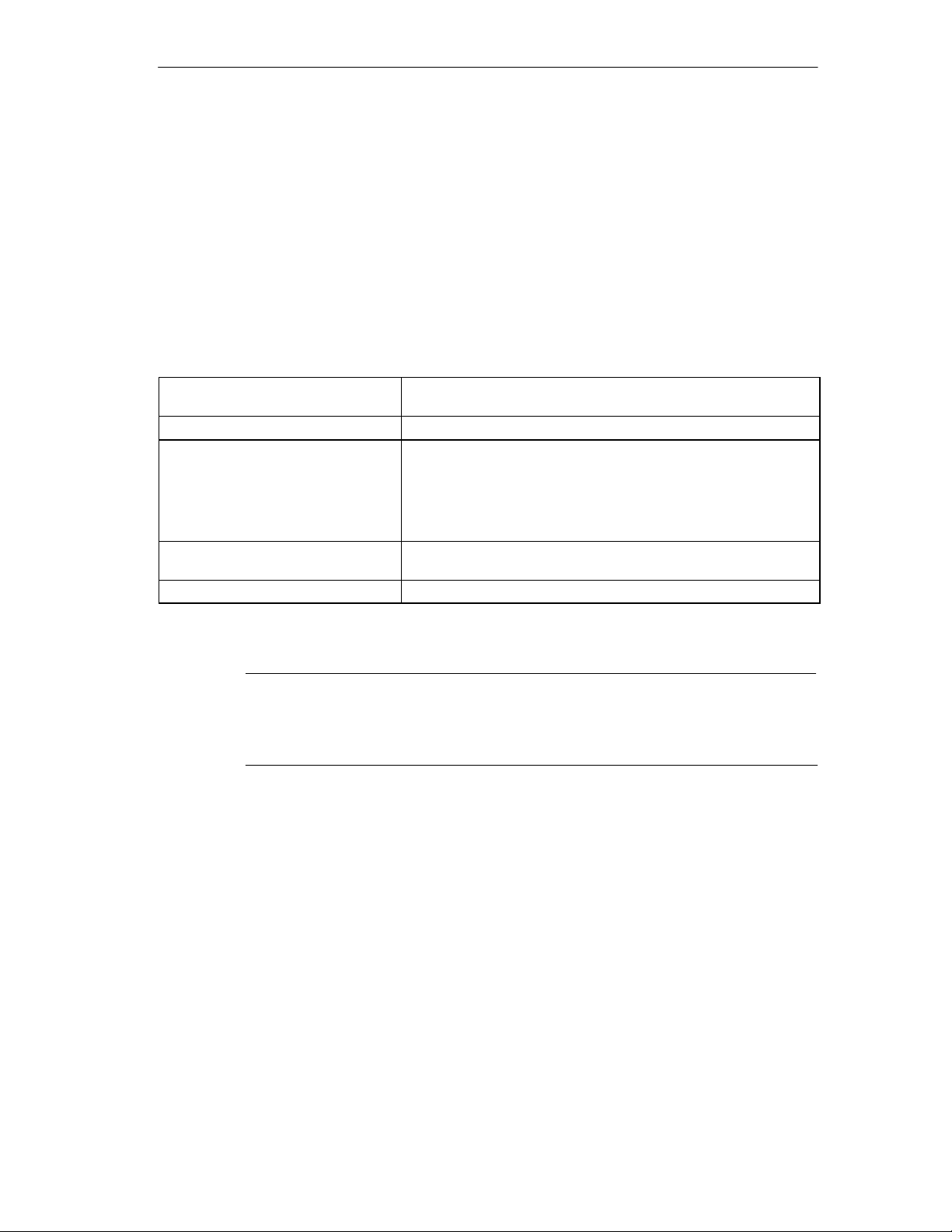

Table 1-1 Physical Characteristics of the RS-485 Transmission Technique

PROFIBUS NETWORKS

Network topology:

Medium: Shielded, twisted pair cable

Possible segment lengths:

(depending on the cable

type, see Table 3.1)

Number of repeaters connected in series:

Number of nodes: Maximum 32 on one bus segment

Transmission rates: 9.6 Kbps, 19.2 Kbps, 45.45 Kbps, 93.75 Kbps, 187.5 Kbps, 500 Kbps, 1.5

Bus, tree structure with the use of repeaters

1,000 mFor transmission rates up to 187.5 Kbps

400 m For a transmission rate of 500 Kbps

200 m For a transmission rate of 1.5 Mbps Mbps

100 m For transmission rates of 3.6 and 12 Mbps

Maximum 9

Maximum 127 per network when using repeaters

Mbps, 3 Mbps, 6 Mbps, 12 Mbps

Note

The properties listed in 1-1 assume a bus cable of type A and a bus terminator

according to the PROFIBUS standard EN 50170–1–2. The SIMATIC NET

PROFIBUS cables and bus connectors meet this specification. If reductions in the

segment length are necessary when using special versions of the bus cable with

increased d.c. loop resistance, this is pointed out in the sections on

“Configuration” and “SIMATIC NET PROFIBUS Cables”.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

1-11

Page 22

PROFIBUS NETWORKS

1.2.5 Transmission Techniques for Optical Components

PROFIBUS User Organization Guideline

The optical transmission technique complies with the PROFIBUS User

Organization guideline:

“Fiber Optic Data Transfer for PROFIBUS” /3/.

Integrated Optical Interfaces, OBT, OLM

The optical version of SIMATIC NET PROFIBUS is implemented with integrated,

optical ports, optical bus terminals (OBT) and optical link modules (OLM).

Duplex fiber-optic cables are used as the medium made of glass, PCF or plastic

fibers. Duplex fiber-optic cables consist of two conducting fibers surrounded by a

common jacket to form a cable.

Modules with integrated optical ports and optical bus terminals (OBTs) can be

interconnected to form optical networks only with a bus structure.

Using OLMs, optical networks can be installed using a bus, star and ring structure.

The ring structure provides a redundant signal transmission path and represents

the basis for networks with high availability.

Advantages:

S Regardless of the transmission rate, large distances can be covered between

S Electrical isolation between nodes and transmission medium

S When plant components at different ground potential are connected, there are

S No electromagnetic interference

S No additional lightning protection elements are required

S Simple laying of fiber-optic cables

S High availability of the LAN due to the use of a ring topology

S Extremely simple attachment technique using plastic fiber-optic cables over

two DTEs

(connections between OLM and OLM up to 15,000 m)

no shield currents

shorter distances.

1-12

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 23

PROFIBUS NETWORKS

Restrictions:

S Frame throughput times are increased compared with an electrical network

S The assembly of glass fiber-optic cables with connectors requires specialist

experience and tools

S The absence of a power supply at the signal coupling points (node attachments,

OLMs, OBTs) stops the signal flow

Characteristics of the Optical Transmission Technique

The optical transmission technique has the following characteristics:

Network topology: Bus structure with integrated optical ports and OBT;

bus, star or ring structure with OLMs

Medium: Fiber-optic cables with glass, PCF or plastic fibers

Link lengths

(point-to-point)

Transmission rate: 9.6 Kbps, 19.2 Kbps, 45.45 Kbps, 93.75 Kbps, 187.5 Kbps, 500

Number of nodes: Maximum of 127 per network (126 with ring structure with OLMs)

With glass fibers up to 15,000 m dependent on the fiber and OLM

type

with plastic fibers:

OLM: 0 m to 80 m

OBT: 1 m to 50 m

Kbps, 1.5 Mbps, 3 Mbps*, 6 Mbps*, 12 Mbps

* not with integrated optical ports and OBT

Note

The optical ports of the OLMs are optimized for greater distances. The direct

coupling of the optical ports of an OLM with an OBT or integrated optical ports is

not possible due to differences in the technical specifications.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

1-13

Page 24

PROFIBUS NETWORKS

1.2.6 Transmission Technique for Wireless Infrared Technology

The wireless PROFIBUS network uses infrared light for signal transmission. The

only transmission medium is a free line-of-sight connection between two nodes.

The maximum distance covered is approximately 15 m. Wireless networks are

implemented using infrared link modules (ILM). The nodes to be networked are

attached to the electrical port of the ILM.

Advantages:

S High mobility of attached plant components (for example trolleys)

S Coupling and decoupling from the fixed network with no wear and tear (for

example substitute for a slip ring)

S Coupling without cable installation (temporary setup, inaccessible areas)

S Not protocol dependent

S Electrical isolation between nodes and hardwired network

Restrictions

S Transmission rate <= 1.5 Mbps

S Free line-of-sight path required between nodes

S Maximum distance covered <= 15 m

S Only for single master networks

Characteristics of the Wireless Infrared Transmission Technique

The wireless infrared transmission technique has the following characteristics:

Network topology: Point-to-point

Point-to-multipoint

Medium: Free space with line-of-sight path

Maximum link length: 15 m

Transmission rate ILM: 9.6 Kbps, 19.2 Kbps, 45.45 Kbps, 93.75 Kbps, 187.5 Kbps,

500 Kbps, 1.5 Mbps

Number of nodes: Maximum 127 per network

1-14

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 25

1.2.7 Transmission Technique for PROFIBUS-PA

IEC 61158-2 Standard

The transmission technique corresponds to the IEC 61158-2 standard (identical

with EN 61158-2).

The transmission medium is a shielded, twisted pair cable. The signal is

transmitted as a synchronous data stream Manchester-coded at 31.25 Kbps. In

general, the data line is normally also used to supply power to the field devices.

Advantages:

S Simple cabling with twisted pair

S Remote power supply via the signal cores

S Intrinsically safe operation possible (for hazardous areas)

PROFIBUS NETWORKS

S Bus and tree topology

S Up to 32 nodes per cable segment

Restrictions:

S Transmission rate restricted to 31.25 Kbps

Characteristics of the IEC 61158-2 Transmission Technique

The main characteristics of the IEC 61158-2 transmission technique are as follows:

Network topology: Bus, star and tree topology

Medium:

Achievable segment lengths: 1900 m

Transmission rate:

Number of nodes: Maximum 127 per network

Shielded, twisted pair cable

31.25 Kbps

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

1-15

Page 26

PROFIBUS NETWORKS

1-16

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 27

Topologies of SIMATIC NET PROFIBUS Networks

2

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-1

Page 28

Topologies of SIMATIC NET PROFIBUS Networks

2.1 Topologies of RS-485 Networks

Transmission Rate

When operating SIMATIC NET PROFIBUS in the RS-485 transmission technique,

the user can select one of the transmission rates below:

9.6 Kbps, 19.2 Kbps, 45.45 Kbps, 93.75 Kbps, 187.5 Kbps, 500 Kbps,

1.5 Mbps, 3 Mbps, 6 Mbps or 12 Mbps

Depending on the transmission rate, transmission medium, and network

components different segment lengths and therefore different network spans can

be implemented.

The bus attachment components can be divided into two groups:

S Components for transmission rates from 9.6 Kbps to a maximum of 1.5 Mbps

S Components for transmission rates from 9.6 Kbps to a maximum of 12 Mbps

LAN Cable

The transmission media used are the SIMATIC NET PROFIBUS cables described

in Chapter 4. The technical information below applies only to networks

implemented with these cables and SIMATIC NET PROFIBUS components.

Node Attachment

The nodes are attached to the LAN cables via bus connectors, bus terminals or

RS-485 repeaters.

Cable Termination

Each bus segment must be terminated at both ends with its characteristic

impedance. This cable terminator is integrated in the RS-485 repeaters, the bus

terminals, the ILM and the bus connectors and can be activated if required.

Before the cable terminator can be activated, the component must be supplied with

power. With the bus terminals and the bus connectors, this power is supplied by

the connected DTE, whereas the RS-485 repeater, the ILM, and the terminator

have their own power supply.

2-2

The RS-485 transmission technique allows the attachment of a maximum of 32

devices (DTEs and repeaters) per bus segment. The maximum permitted cable

length of a segment depends on the transmission rate and the LAN cable used.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 29

Topologies of SIMATIC NET PROFIBUS Networks

Connecting Segments Using RS-485 Repeaters

By using RS-485 repeaters, segments can be interconnected. The RS-485

repeater amplifies the data signals on the LAN cables. You require an RS-485

repeater when you want to attach more than 32 nodes to a network or when the

permitted segment length is exceeded. A maximum of 9 repeaters can be used

between any two nodes. Both bus and tree structures can be implemented.

Figure 2-1 shows a typical topology using the RS-485 technique with 3 segments

and 2 repeaters.

S7-400

OP 25

OP 25

Terminating resistor activated

PG attached via tap line (6ES7 901-4BD00-0XA0)

for maintenance purposes

S7-300 S7-300

PG

S7-400

Tap line

OP 25

RS-485

repeater

PG

RS-485

repeater

S7-400

Figure 2-1 Topology Using the RS-485 Technique

Increasing the overall span of a network by using repeaters can lead to longer

transmission times that may need to be taken into account when configuring the

network (see Chapter 3).

2.1.1 Components for Transmission Rates up to 1.5 Mbps

All SIMATIC NET bus attachment components can be used for transmission rates

≤ 1.5 Mbps.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-3

Page 30

Topologies of SIMATIC NET PROFIBUS Networks

2.1.2 Components for Transmission Rates up to

12 Mbps

The following bus attachment components can be used for transmission rates up

to 12 Mbps:

Table 2-1 Bus Attachment Components for Transmission Rates up to 12 Mbps

Order number

PROFIBUS bus connector with

6GK1 500-0EA02

axial cable outlet

PROFIBUS FastConnect bus connector RS-485

Plug 180

with 180° cable outlet 6GK1500-0FC00

RS-485 bus connector with vertical cable outlet

Without PG interface

With PG interface

6ES7 972-0BA11-0XA0

6ES7 972-0BB11-0XA0

PROFIBUS FastConnect RS-485 bus connector

with 90° cable outlet with insulation displacement terminal

system

max. transmission rate 12 Mbps

Without PG interface

6ES7 972-0BA50-0XA0

6ES7 972-0BB50-0XA0

With PG interface

RS-485 bus connector with 35o cable outlet

Without PG interface

With PG interface

6ES7 972-0BA40-0XA0

6ES7 972-0BB40-0XA0

SIMATIC NET 830-1T connecting cable, preassembled, fitted

with terminating resistors, as link between electrical interface

of an OLM or OBT and the PROFIBUS interface of a

PROFIBUS node.

1.5 m

3 m

6XV1830-1CH15

6XV1830-1CH30

SIMATIC NET 830-2 connecting cable for PROFIBUS,

preassembled cable with two sub-D, 9-pin male connectors,

terminating resistors can be activated.

3 m

5 m

10 m

6XV1830-2AH30

6XV1830-2AH50

6XV1830-2AN10

SIMATIC S5/S7 PROFIBUS connecting cable

for connecting programming devices up to 12 Mbps

preassembled with 2 sub-D connectors, length 3 m 6ES7 901-4BD00-0XA0

PROFIBUS RS-485 repeater 24 V DC, casing with IP 20

6ES7 972-0AA01-0XA0

degree of protection

Bus terminal BT12M 6GK1 500-0AA10

Optical Link Module OLM V3 6GK1 502-_C_00

PROFIBUS Networks SIMATIC NET

2-4

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 31

Topologies of SIMATIC NET PROFIBUS Networks

Table 2-1 Bus Attachment Components for Transmission Rates up to 12 Mbps, continued

Optical Bus Terminal OBT 6GK1 500-3AA0

PROFIBUS Terminator 6ES7 972-0DA00-0AA0

2.2 Topologies of Optical Networks

Interfacing Electrical and Optical Networks/Components

If you want to cover larger distances with the fieldbus regardless of the

transmission rate or if the data traffic on the bus is threatened by extreme levels of

external noise, you should use fiber-optic cables instead of copper cable.

To interface electrical cables with fiber-optic cables, you have the following

possibilities:

S The PROFIBUS nodes with a PROFIBUS DP interface (RS-485) are attached

to the optical network using an optical bus terminal (OBT) or using an optical

link module (OLM).

S PROFIBUS nodes with an integrated FO port (for example ET 200M (IM 153-2

FO), S7-400 (IM 467 FO)) can be connected directly to an optical network with

a bus topology.

S Optical networks with a larger network span or structured as redundant rings

should be implemented using OLMs.

The structure of optical networks using optical link modules (OLMs) is described in

detail in later chapters in this manual.

For information about the structure of an optical PROFIBUS network with

PROFIBUS nodes having an integrated FO interface, refer also to the ET200

system manual.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-5

Page 32

Topologies of SIMATIC NET PROFIBUS Networks

2.2.1 Topology with Integrated Optical Interfaces

The optical PROFIBUS network with nodes having an integrated FO interface is

structured as a bus topology. The PROFIBUS nodes are interconnected in pairs

by duplex fiber-optic cables.

Up to 32 PROFIBUS nodes with integrated FO interfaces can be connected in

series in an optical PROFIBUS network. If a PROFIBUS node fails, the bus

topology means that all DP slaves on the side away from the DP master are no

longer obtainable for the DP master.

S7-400 with IM 467 FO

PG/PC/OP

2

Distances between 2

OBT

Terminating resistor activated

1 FO cable

2 LAN cable for PROFIBUS

Figure 2-2 PROFIBUS DP Network with Nodes Having Integrated FO Interfaces

1

Plastic FO cable up to 50 m

PCF FO cable up to 300 m

1

nodes:

ET 200M with

IM 153-2 FO

1

OBT

S7-300

For short distances, the preassembled 830-1T or 830-2 connecting cables can be

used as an alternative to the PROFIBUS cable.

2

OP 25

2

other

nodes

Transmission Rate

An optical PROFIBUS network with a bus topology can be operated at the

following transmission rates:

9.6 Kbps, 19.2 Kbps, 45.45 Kbps, 93.75 Kbps, 187.5 Kbps, 500 Kbps, 1.5 Mbps

and 12 Mbps

2-6

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 33

PROFIBUS Optical Bus Terminal (OBT)

Using a PROFIBUS optical bus terminal (OBT), an individual PROFIBUS node

without an integrated FO port or a PROFIBUS RS-485 segment can be attached to

the optical PROFIBUS network (see Figure 2-2 ).

The attachment is made to the RS-485 interface of the OBT using a PROFIBUS

cable or a preassembled connecting cable. The OBT is included in the optical

PROFIBUS bus via the FO interface.

2.2.2 Topologies with OLMs

OLMs

The OLMs have a floating electrical channel (similar to the channels on a repeater)

and depending on the version, they have one or two optical channels.

Topologies of SIMATIC NET PROFIBUS Networks

The OLMs are suitable for transmission rates of 9.6 Kbps to 12 Mbps. The

transmission rate is detected automatically.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-7

Page 34

Topologies of SIMATIC NET PROFIBUS Networks

Bus Topologies

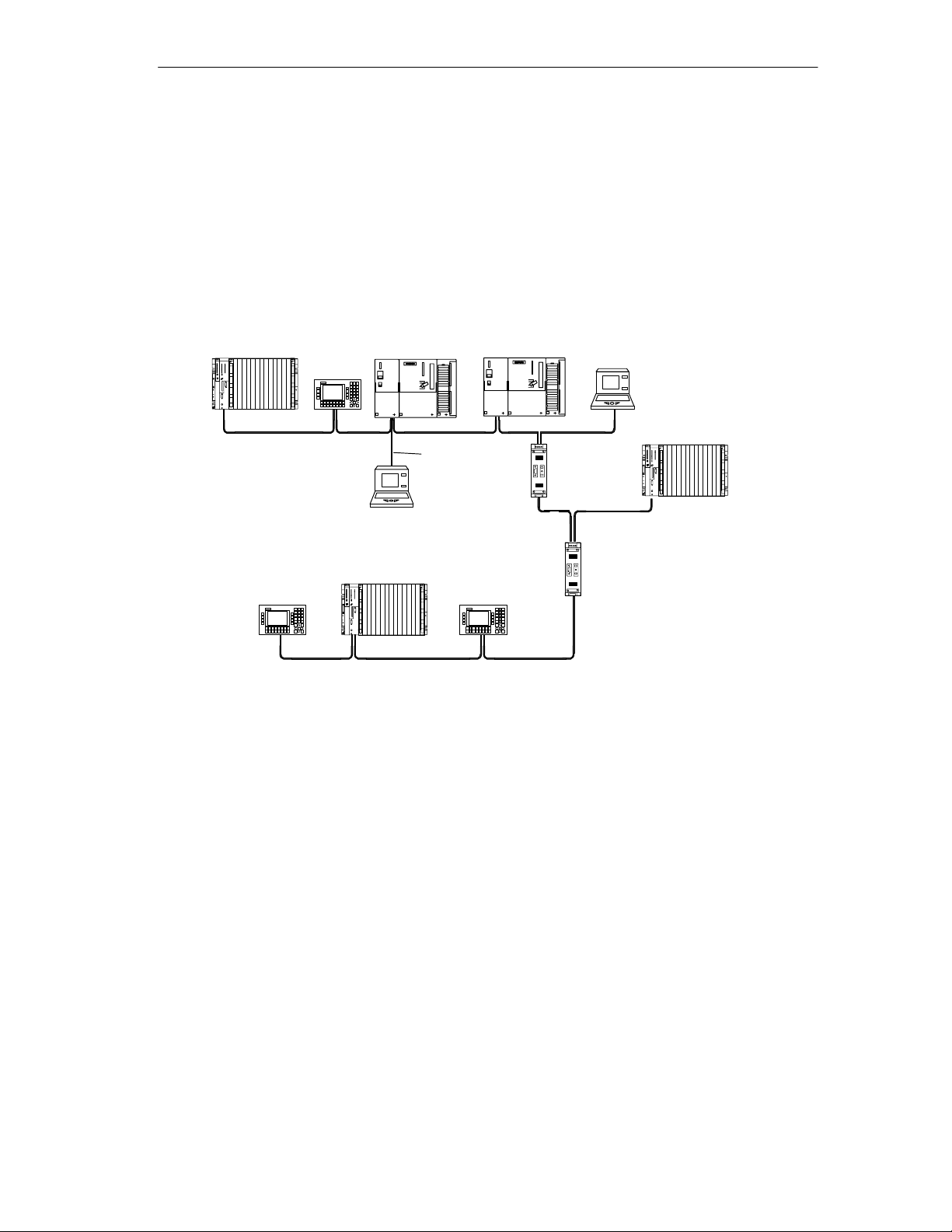

Figure 2-3 shows a typical example of a bus topology

In a bus structure, the individual SIMATIC NET PROFIBUS OLMs are connected

together in pairs by duplex fiber-optic cables.

At the start and end of a bus, OLMs with one optical channel are adequate, in

between, OLMs with two optical channels are required.

The DTEs are attached to the electrical interfaces of the OLMs. Either individual

DTEs or complete PROFIBUS segments with a maximum of 31 nodes can be

connected to the RS-485 interface.

PG

3

OP 25

2

ET 200M

2

ET 200S

4

OP 25

4

1

Bus connector

Terminating resistor activated

1 FO cable

2 LAN cable for PROFIBUS

3 PROFIBUS 830-1T connecting cable

4 PROFIBUS 830-2 connecting cable

Figure 2-3 Example of a Bus Topology with OLMs

1

1

2-8

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 35

Star Topologies with OLMs

Several optical link modules are grouped together to form a star coupler via a bus

connection of the RS-485 interfaces. This RS-485 connection allows the

attachment of further DTEs until the maximum permitted number of 32 bus

attachments per segment is reached.

S7-400

OP 25

4

Topologies of SIMATIC NET PROFIBUS Networks

Star hub

2

2

1

2

PG

S7-400

Terminating resistor activated

1 FO cable

2 LAN cable for PROFIBUS

4 PROFIBUS 830-2 connecting cable

Figure 2-4 Example of a Star Topology with OLMs

Optical Channels

The OLMs are connected to the star coupler by duplex fiber-optic cables.

Both DTEs and electrical bus segments can be connected to the OLMs attached

by the duplex fiber-optic cables. Depending on the requirements and the distance,

the duplex cables can be implemented with plastic, PCF or glass (OLM only)

fibers.

2

1

4

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-9

Page 36

Topologies of SIMATIC NET PROFIBUS Networks

Monitoring FO Links

Using the echo function, the connected OLMs can monitor the fiber-optic sections.

A break on a link is indicated by a display LED and by the signaling contact

responding.

Even if only one transmission direction is lost, the segmentation triggered by the

monitoring function leads to safe disconnection of the OLM from the star coupler.

The remaining network can continue to work without problems.

Mixed Structure

The star coupler can be made up with combinations of OLM/P, OLM/G and

OLM/G-1300 modules and at the RS-485 end with all types.

Redundant Optical Rings using OLMs

Redundant optical rings are a special form of bus topology. By closing the optical

bus to form a ring, a high degree of operational reliability is achieved

S7-400

S7-400

OP 25

ET 200M

4

2

4

1

1

Path 1

1

Path 2

Terminating resistor activated

1 FO cable

2 LAN cable for PROFIBUS

3 PROFIBUS 830-1T connecting cable

4 PROFIBUS 830-2 connecting cable

Figure 2-5 Network Structure in a Redundant, Optical, Two-Fiber Ring Topology

PG

3

1

2-10

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 37

Topologies of SIMATIC NET PROFIBUS Networks

A break on a fiber-optic cable between two modules is detected by the modules

and the network is reconfigured to form an optical bus. The entire network remains

operational.

If a module fails, only the DTEs or electrical segments attached to the module are

separated from the ring; the remaining network remains operational as a bus.

The problem is indicated by LEDs on the modules involved and by their signaling

contacts.

After the problem is eliminated, the modules involved cancel the segmentation

automatically and the bus is once again closed to form a ring.

Note

To increase the availability, the duplex cables for the outgoing and incoming paths

in the ring should be routed separately.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-11

Page 38

Topologies of SIMATIC NET PROFIBUS Networks

Alternative Cabling Strategy

If the distance between two OLMs turns out to be too long, a structure as shown in

Figure 2-6 can be implemented.

4

4

ET 200M

ET 200M

OP 25

4

1

1

OP 25

4

2

1

2

PG/PC/OP

PG/PC/OP

PG

3

4

1

PG

3

1

4

S7-400

S7-400

1

1

1

1

1

1

1

Terminating resistor activated

1 FO cable

2 LAN cable for PROFIBUS

3 PROFIBUS 830-1T connecting cable

4 PROFIBUS 830-2 connecting cable

Figure 2-6 Alternative Cabling of a Network Structure in an Optical Two-Fiber Ring Topology

PROFIBUS Networks SIMATIC NET

2-12

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 39

Topologies of SIMATIC NET PROFIBUS Networks

2.2.3 Combination of Integrated Optical Interfaces and OLMs

Note

The optical ports of the OLMs are optimized for greater distances. The direct

coupling of the optical ports of an OLM with an OBT or integrated optical ports is

not possible due to differences in the technical specifications.

Attaching Glass FO Cables to Buses Made up of Integrated Optical Interfaces

The operating wavelength of the integrated optical interfaces and the OBT is

optimized for the use of plastic or PCF fibers. The direct attachment of glass FO

cables is not possible.

If a link with glass FO cable is required, for example to span distances of more

than 300 m, this link must be implemented with OLMs. The attachment of glass

links to the optical bus made up of integrated optical interfaces is via the RS-485

interface of an OBT. The following schematic shows an example of an application:

ET 200M with

PG

OBT

4

1

Terminating resistor activated

1 FO cable

2 LAN cable for PROFIBUS

Figure 2-7 Attachment of an Optical Glass Link to an Optical Bus Made up of Integrated Optical

Interfaces

OBT

3

1

3

up to 15 km

IM 153-2 FO

OBT

11

1

3 PROFIBUS 830-1T connecting cable

4 PROFIBUS 830-2 connecting cable

Field device without

FO interface

OBT

2

Further

nodes

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-13

Page 40

Topologies of SIMATIC NET PROFIBUS Networks

2.3 Topologies of Wireless Networks

Infrared Link Module (ILM)

In SIMATIC NET, wireless PROFIBUS networks are implemented with the “Infrared

Link Module (ILM)”.

Figure 2-8 PROFIBUS ILM

Maximum Length of a Link

Regardless of the transmission rate, the maximum length of a link is 15 m. The

infrared light used for data transmission is radiated at an angle of +/- 10o around

the mid axis. This means that at a distance of 11 m, an ILM illuminates a circular

area with a diameter of 4 m. The communication partner must be within this

illuminated area. There must be an uninterrupted line-of-sight path between both

ILMs. The ILMs are suitable for transmission rates of 9.6 Kbps to 1.5 Mbps.

Point-to-Point Link

To implement a point-to-point link, two ILMs are positioned opposite each other so

that each is located within the infrared light cone of the other. The maximum

distance between two modules is 15 m.

2-14

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 41

Master OP 25

Master

PG/PC/OP

2

Topologies of SIMATIC NET PROFIBUS Networks

Infrared

link

0.5 to 15 m

ILM ILM

Slave

ET 200M

2

2

Master

S7-400

Terminating resistor activated

2 LAN cable for PROFIBUS

Figure 2-9 Point-to-Point Link with Two PROFIBUS ILMs

PROFIBUS

master network segment

Figure 2-9 illustrates the typical structure of a PROFIBUS network with master and

slave nodes and an infrared link with two PROFIBUS ILMs. The infrared link is

implemented as a point-to-point link between the two PROFIBUS ILMs. The two

PROFIBUS ILMs replace a cable connection between the two network segments.

Remember that only slave nodes are permitted in the slave network segment.

PROFIBUS

slave network segment

2

Slave

ET 200S

2

Point-to-Multipoint Link

Several ILMs are positioned opposite to a single ILM so that several ILMs are in

the infrared light cone of another ILM. Only the ILMs positioned opposite each

other can exchange data. A data exchange between adjacent ILMs is only possible

by using a surface that reflects infrared light. If you consider this option, remember

that the length of the link is the path from the ILM to the reflector and from the

reflector to the partner ILM. Signal attenuation will also occur since the reflector

can only reflect part of the infrared light to the partner ILM. Such losses mean a

reduction in the maximum length of a link.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-15

Page 42

Topologies of SIMATIC NET PROFIBUS Networks

Slave

ET 200M

Master

S7-400

Master

PG/PC/OP

2

Master OP 25

Slave

ET 200M

Slave

S7-300

ILM

2

Infrared

link 1

0.5 to 15 m

2

2

PROFIBUS

slave network segment 1

Infrared

Slave

ET 200M

ILM

link 2

0.5 to 15 m

ILM

2

2

PROFIBUS

slave network segment 2

Slave

S7- 300

2

Infrared

2

link 3

0.5 to 15 m

Slave

ET 200S

ILM

2

Terminating resistor activated

2 LAN cable for PROFIBUS

PROFIBUS

slave network segment 3

Figure 2-10 Point-to-Multipoint Link Using PROFIBUS ILMs (One Master Subnet, Three Subnets with

Slaves)

PROFIBUS Networks SIMATIC NET

2-16

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 43

Topologies of SIMATIC NET PROFIBUS Networks

2.4 Topologies with PROFIBUS-PA

Bus and Star Topology

With PROFIBUS-PA, the topology can be either a bus or star.

SpliTConnect System

The SpliTConnect tap (T tap) allows the structuring of a bus segment with DTE

attachment points. The SpliTConnect tap can also be cascaded with the

SpliTConnect coupler to form attachment distributors. Using the SpliTConnect

terminator, the tap can be extended to become the segment terminator.

Star

Main cable

PROFIBUS-PA

DP/PA coupler

(bus terminator

integrated)

24 V DC

Figure 2-11 Bus and Star Topology

PROFIBUS-DP

T tap

Tap line

Field Device Power Supply via PROFIBUS-PA

When using the DP/PA bus coupler, the power for the field devices is supplied via

the data line of PROFIBUS-PA.

Design

Tap line

Distributor made

up of T taps

Bus

T tap with

integrated

bus terminator

Field devices attached

via M12 connector

The total current of all field devices must not exceed the maximum output current

of the DP/PA coupler. The maximum output current therefore limits the number of

field devices that can be attached to PROFIBUS-PA.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-17

Page 44

Topologies of SIMATIC NET PROFIBUS Networks

DP/PA coupler Ex [i]

6ES7 157-0AD00-0XA0

Protection EEx [ia] II C

I

x 90 mA

max

DP/PA coupler Ex [i]

6ES7 157-0AD80-0XA0

Protection EEx [ib] II C

x 110 mA

I

max

DP/PA coupler

6ES7 157-0ACx0-0XA0

I

x 400 mA

max

PROFIBUS-PA

I

max

24 V DC

PROFIBUS-DP

PROFIBUS-PA

I

max

24 V DC

PROFIBUS-DP

I

1

Field device

1

I

1

Field device

1

I

2

Field device2Field device

Explosion-protected area

I

2

Field device2Field device

I

3...

3...

I

3...

3...

...I

n

Field device

...I

m

Field device

...n

...m

Figure 2-12 Field Device Power Supply in the Hazardous and Non-Hazardous Area

Expansion

If the maximum output current of the DP/PA coupler is exceeded, you must include

a further DP/PA coupler.

Total Cable

The total cable is the total of the main cable and all the tap lines.

When using a standard PROFIBUS-PA cable with a cross-sectional area of

0.8 mm2, the maximum length of the total cable (with a maximum number of field

devices and worst-case positioning at the end of the cable) is as follows:

S 560 m for DP/PA coupler (6ES7 157-0AC00-0XA0)

S 680 m for DP/PA coupler (6ES7 157-0AD80-0XA0)

S 790 m for DP/PA coupler Ex [i] (6ES7 157-0AD00-0XA0)

Tap Line

The maximum permitted tap line lengths are listed in Table 2-2. You should also

remember the maximum length of the total cable (see above).

2-18

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 45

Topologies of SIMATIC NET PROFIBUS Networks

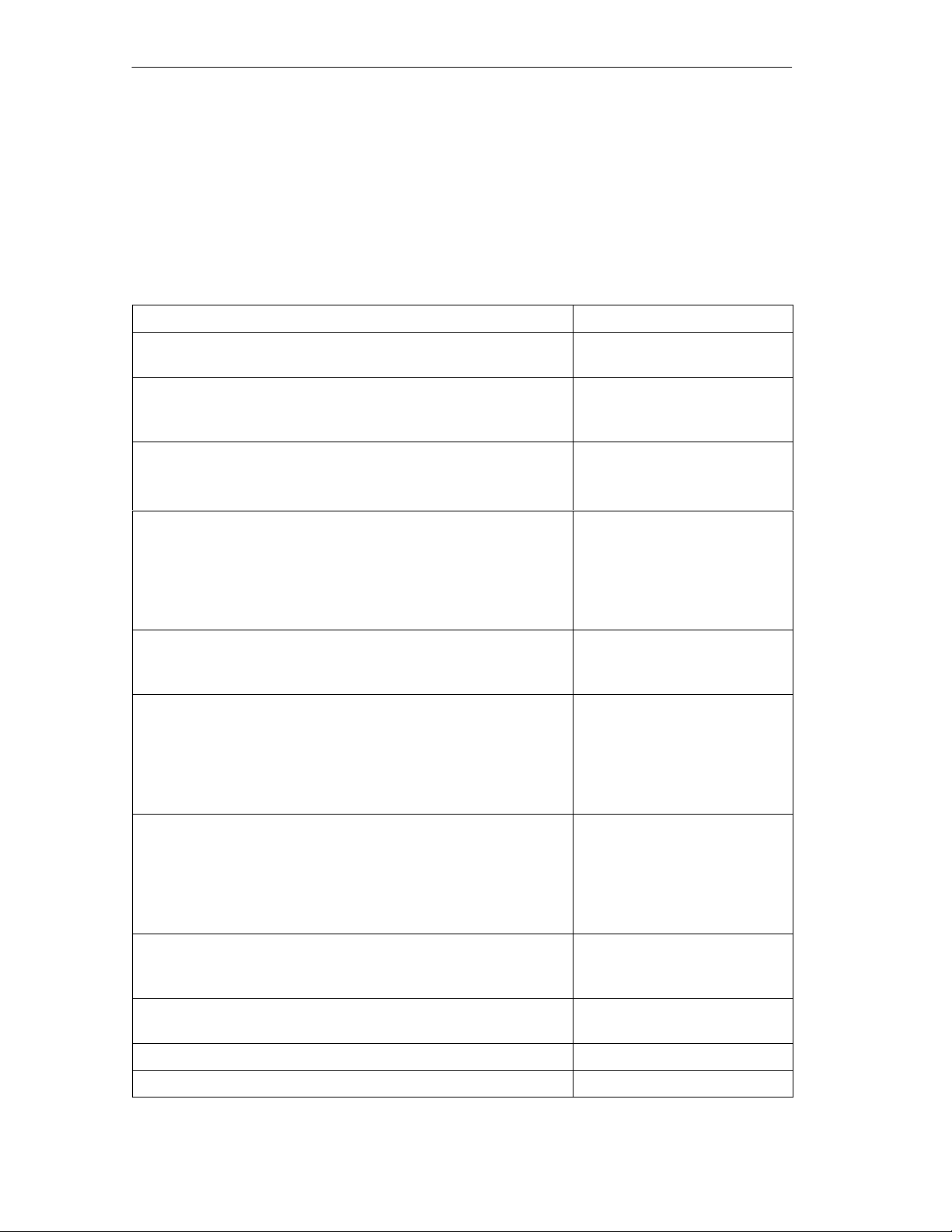

Table 2-2 Tap Line Lengths for DP/PA Couplers

Number of tap lines

1 to 12 max. 120 m max. 30 m

13 to 14 max. 90 m max. 30 m

15 to 18 max. 60 m max. 30 m

19 to 24 max. 30 m max. 30 m

Maximum length of the tap line

DP/PA coupler DP/PA coupler Ex [i]

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-19

Page 46

Topologies of SIMATIC NET PROFIBUS Networks

2.5 Connectivity Devices

2.5.1 DP/DP Coupler

Uses

The PROFIBUS-DP/DP coupler is used to link two PROFIBUS-DP networks

together. Byte data (0 to 244 bytes) is transmitted from the DP master of a first

network to the DP master of another network and vice-versa.

This principle corresponds to the hardware wiring of inputs and outputs. The

coupler has two independent DP interfaces with which it attaches to the two DP

networks.

The DP/DP coupler is a slave attached to the DP networks. The data exchange

between the two DP networks involves internal copying within the coupler.

2-20

Figure 2-13 DP/DP Coupler

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 47

Design

Topologies of SIMATIC NET PROFIBUS Networks

The DP/DP coupler is installed in a compact, 40 mm wide casing.

The module can be installed (vertically when possible) on a standard rail with no

gaps being necessary.

The coupler is attached to each PROFIBUS-DP network via an integrated 9-pin

sub-D connector.

Master OP 25

2

Master

S7-400

SIEMENS

2

2

DP/DP COUPLER

Master

PG/PC/OP

Terminating resistor activated

2 LAN cable for PROFIBUS

Figure 2-14 Configuration Example of the DP/DP Coupler

Master

S7-300

2

Slave

ET 200M

2

Slave

ET 200M

2

How the DP/DP Coupler Works

The DP/DP coupler permanently copies output data of one network to the input

data of the other network (and vice-versa).

Parameter Assignment

The PROFIBUS-DP addresses are set using two DIP switches on the top of the

device. The configuration is set using the GSD file and the configuration tool of the

attached PROFIBUS-DP master. The data length is set with the relevant

configuration tool.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-21

Page 48

Topologies of SIMATIC NET PROFIBUS Networks

2.5.2 Connecting to PROFIBUS-PA

DP/PA Bus Coupling

The DP/PA bus coupler is the link between PROFIBUS-DP and PROFIBUS-PA.

This means that it connects the process control systems with the field devices of

the process automation (PA).

The DP/PA bus coupler is made up of the following modules:

S DP/PA Coupler Ex [i] (6ES7 157-0ADx0-0XA0)

S DP/PA Coupler (6ES7 157-0ACx0-0XA0)

S DP/PA Link IM 157 (6ES7 157-0AA80-0XA0)

To implement a DP/PA link in redundant operation, you also require the following:

S Bus module BM IM 157 for 2 x IM 157 (6ES7 195-7HE80-0XA0)

S Bus module BM DP/PA Coupler for 1 DP/PA Coupler (6ES7 195-7HF80-0XA0)

2-22

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 49

2.5.3 DP/PA Coupler

Figure 2-15 below illustrates how the DP/PA coupler is included in the system.

Process control

level

Industrial Ethernet

Topologies of SIMATIC NET PROFIBUS Networks

“Programming, Operating

and Monitoring”

SIMATIC PCS 7 or other

tool for parameter assignment

PDM or other tool for parameter assignment

Cell level

Field level

Figure 2-15 Linking the DP/PA Coupler into the System

DP master

ET200X

PROFIBUS-DP

DP/PA coupler Ex [i]

Explosion-protected

area

Uses of the DP/PA Coupler

The DP/PA coupler is available in two versions:

S DP/PA coupler Ex [i]: You can attach all field devices certified for

PROFIBUS-PA and that are located within the hazardous area.

DP/PA coupler

PROFIBUS-PA

S DP/PA coupler: You can attach all field devices that are certified for

PROFIBUS-PA and that are outside the hazardous area.

The DP/PA coupler is an accompanying component according to EN 50014 or

EN 50020 and must be installed outside the hazardous area.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-23

Page 50

Topologies of SIMATIC NET PROFIBUS Networks

Properties of the DP/PA Coupler (General)

The DP/PA coupler has the following characteristics:

S Electrical isolation between PROFIBUS-DP and PROFIBUS-PA

S Conversion of the physical transmission mechanism between RS-485 and IEC

61158-2

S Diagnostics using LEDs

S Transmission rate on PROFIBUS-DP 45.45 Kbps

S Transmission rate on PROFIBUS-PA 31.25 Kbps

S Integrated power supply unit

Properties of the DP/PA Coupler Ex [i]

The DP/PA coupler Ex [i] (6ES7 157-0AD00-0XA0) has the following additional

characteristics:

S Type of Protection EEx [ia] II C

S Intrinsic safety

S Integrated, intrinsically safe power supply unit and integrated barrier

The DP/PA coupler Ex [i] (6ES7 157-0AD80-0XA0) has the following

characteristics that differ from the DP/PA coupler EX [i] (6ES7 157-0AD00-0XA0):

S Type of protection EEx [ib] II C

S Extended environmental conditions (SIMATIC outdoor)

Configuring the DP/PA Coupler

S The DP/PA coupler can be used in SIMATIC S5 and S7 and with all DP masters

that support 45.45 Kbps.

S The DP/PA coupler does not need to be configured. You must only set the

transmission rate of 45.45 Kbps for the relevant DP network during

configuration.

You then configure the PA field devices just as normal DP slaves using the DP

configuration tool and the appropriate GSD file. You can configure the PA field

devices with SIMATIC PDM or with any other vendor-specific software

configuration tool.

2-24

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

Page 51

2.5.4 DP/PA Link

Definition

The DP/PA link consists of the IM 157 and up to a maximum of five DP/PA

couplers. The DP/PA link is a DP slave at the PROFIBUS-DP side and a PA

master at the PROFIBUS-PA side.

Uses

With the DP/PA link, you have an isolated interconnection between PROFIBUS-PA

and PROFIBUS-DP with transmission rates of 9.6 Kbps to

12 Mbps.

The DP/PA link can only be used in SIMATIC S7.

Figure 2-16 below shows where the DP/PA link fits in.

Topologies of SIMATIC NET PROFIBUS Networks

Process control

level

S7-DP master

Gateway

S7-400

Cell level

Field level

Figure 2-16 Location of the DP/PA Link

Industrial Ethernet

PROFIBUS-DP

ET200X

“Programming, Operating

and Monitoring”

SIMATIC PCS 7 or other

tool for parameter assignment

PDM or other tool for parameter assignment

DP/PA Link

DP/PA coupler

12 34 5

IM 157

PROFIBUS-PA

Field devices of PROFIBUS-PA

The DP/PA link must be installed outside the hazardous area.

The DP/PA link is configured with STEP 7, Version 4.02 or higher.

PROFIBUS Networks SIMATIC NET

6GK1970-5CA20-0AA1 Release 2 05/2000

2-25

Page 52

Topologies of SIMATIC NET PROFIBUS Networks

Properties

The DP/PA link has the following characteristics:

S Diagnostics with LEDs and the user program

S DP slave and PA master

S Can be operated at all transmission rates (9.6 Kbps to 12 Mbps)

S Only DP/PA couplers can be operated with an IM 157

How the DP/PA Link Works

Figure 2-17 shows how the DP/PA link with the IM 157 and the DP/PA couplers

functions.

S The DP/PA link maps the underlying PROFIBUS-PA system on a DP slave.

S With the DP/PA link, PROFIBUS-DP is completely isolated from

PROFIBUS-PA.

S The PA master and PA slaves form a separate, underlying bus system.

S The number of DP/PA couplers simply reflects the amount of current required.

All DP/PA couplers along with the attached PA field devices form one common

PROFIBUS-PA bus system.

DP/PA Link

DP

IM 157

DP slave

DP/PA coupler

(max. 5)

S7 backplane bus

PA

PA PA

P A master

PA

2-26

Figure 2-17 The DP/PA Link with DP/PA Couplers