Siemens SIMATIC NET IE/AS-INTERFACE LINK PN IO User Manual

Preface, Contents

Technical Description,

Installation Guidelines, Operation

1

SIMATIC NET

IE/AS−INTERFACE LINK PN IO

as of hardware version 1, as of firmware version V2.0

Manual

Procedure − Configuration

Getting Started − Commissioning

with STEP 7

Keypad and Display

Display / WBM Configuration

Configuring with STEP 7 or a

GSDML File

Data Exchange between

PROFINET IO Controller and

AS−i Slave

Using the Data Record Interface

Diagnostics

Dealing with Problems /

Error Displays

Anhang

2

3

4

5

6

7

8

9

10

Release

C79000−G8976−C216−03

08/2018

AS−Interface Protocol Implemen−

tation Conformance Statement

References

Notes on the CE Label

Glossary

Index

A

B

C

D

Classification of the Safety−Related Notices

This manual contains notices which you should observe to ensure your own personal safety, as well as to protect the product and connected equipment. These notices are highlighted in the manual by a warning triangle and are marked as follows

according to the level of danger:

Danger

!

!

!

indicates that death, severe personal injury will result if proper precautions are not

taken.

Warning

indicates that death, severe personal injury can result if proper precautions are not

taken.

Caution

with warning triangle indicates that minor personal injury can result if proper

precautions are not taken.

Caution

without warning triangle indicates that damage to property can result if proper

precautions are not taken.

Notice

indicates that an undesirable result or status can occur if the relevant notice is

ignored.

Note

highlights important information on the product, using the product, or part of the

documentation that is of particular importance and that will be of benefit to the

user.

2

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

Trademarks

SIMATICR, SIMATIC HMIR and SIMATIC NETR are registered trademarks of

SIEMENS AG.

Third parties using for their own purposes any other names in this document which

refer to trademarks might infringe upon the rights of the trademark owners.

Safety Instructions Regarding your Product

Before you use the product described here, read the safety instructions below thoroughly.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment.

Qualified persons are defined as persons who are authorized to commission, to

ground, and to tag circuits, equipment, and systems in accordance with established safety practices and standards.

Correct Usage of Hardware Products

Note the following:

Warning

!

This device and its components may only be used for the applications described in

the catalog or the technical description, and only in connection with devices or

components from other manufacturers which have been approved or

recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set

up, and installed correctly, and operated and maintained as recommended.

Before you use the supplied sample programs or programs you have written

yourself, make certain that no injury to persons nor damage to equipment can

result in your plant or process.

EC Notice: Commissioning must not be carried out until it has been established

that the machine in which this component is to be installed complies with the

conditions of directive 98/37/EC.

Correct Usage of Software Products

Note the following:

Warning

!

This software may only be used for the applications described in the catalog or the

technical description, and only in connection with devices or software products

from other manufacturers which have been approved or recommended by

Siemens.

Before you use the supplied sample programs or programs you have written

yourself, make certain that no injury to persons nor damage to equipment can

result in your plant or process.

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

3

Prior to Startup

Before putting the product into operation, note the following:

Caution

Prior to startup you must observe the instructions in the relevant documentation.

For ordering data of the documentation please refer to the catalogs or contact your

local SIEMENS representative.

DisclaimerCopyright E Siemens AG 2006 − 2008 All rights reserved

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of

a utility model or design, are reserved.

4

Siemens AG

Industry Automation

Industrial Communication

Postfach 4848, D-90327 Nürnberg

Siemens Aktiengesellschaft G79000−G8900−C216−03

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

We have checked the contents of this manual for agreement with the hardware and software described. Since deviations cannot be precluded entirely,

we cannot guarantee full agreement. However, the data in this manual are

reviewed regularly and any necessary corrections included in subsequent

editions. Suggestions for improvement are welcomed.

Technical data subject to change.

Release 03/2008

C79000−G8976−C216−03

Preface

Purpose of the Manual

This manual supports you when using the IE/AS-INTERFACE LINK PN IO

module. The product name is also shortened to IE/AS-i LINK in the manual. It

contains information about how PROFINET IO controllers can address AS-i

actuators and AS-i sensors via this module.

Validity of the Manual

This manual is valid for the IE/AS-INTERFACE LINK PN IO module as of hardware

version 1 and as of firmware version V2.0 and the STEP 7 configuration software

as of V5.4 SP3 / NCM PC as of V5.4 SP3.

What’s new?

This issue of the manual includes several corrections.

We recommend the following procedure

... If you want an overall picture of the AS-Interface:

... If you want to set up an AS-i system and include the IE/AS-i LINK in it:

... If you want to know how to operate the IE/AS-i LINK from the point of view of

Requirements

To understand this manual, you require the following:

S A working knowledge of PROFINET IO

S Knowledge of the manual ’AS-Interface Introduction and Basic Information’

− First read the ‘AS-Interface Introduction and Basic Information’ manual (not

part of this documentation package). This contains general information

about the AS-Interface, abbreviated to AS-i in the following chapters.

− You will find the information you require about connecting and operating the

IE/AS-i LINK in Chapter 1 and 3.

the PROFINET IO

controller:

− Read Chapters 5 − 6 in this manual.

− Chapter 8 explains the data record interface.

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

5

Preface

GSDML file

The GSDML file that you optionally require for configuring the IE/AS−i LINK

(see Chapter 6) can be downloaded from the Internet at the following link:

http://support.automation.siemens.com/WW/view/en/23742537

Symbols used in the manual

You will find this symbol in Chapter 5 where it is used to identify the description of

menu sequences on the display and keyboard.

FAQs

You will find FAQs on Siemens AS−i products on the Internet on the Service and

Support pages of Industry Automation at the following address:

http://support.automation.siemens.com/WW/view/en/10805888

-

6

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

Contents

Preface 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Technical Description, Installation Guidelines, Operation 11. . . . . . . . . . . . . . . . .

1.1 General Notes on Operation − Safety Warnings 11. . . . . . . . . . . . . . . . . .

1.2 Uses of the Module 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Technical Specifications of the Module 15. . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Approvals 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Installation Guidelines and Installing the Module 17. . . . . . . . . . . . . . . . . .

1.6 Front Panel − Access to all Functions 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 Connection Elements 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 Connectors for the AS-i Cable(s) and Power Supply 21. . . . . . . . . . . . . . .

1.8 C-PLUG (Configuration Plug) 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 Display and Control Elements 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 Settings when Using a Firewall 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Procedure − Configuration 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 What to do − an Overview 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Configuration Options 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Getting Started − Commissioning with STEP 7 32. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Commissioning the IE/AS-INTERFACE LINK PN IO 32. . . . . . . . . . . . . .

3.1.1 Requirements 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Procedure 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Keypad and Display 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Configuration and Modes 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Buttons and Working in the Menus 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Working Examples 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Example: Changing the status

“Protected mode” <−> “Configuration mode” 40. . . . . . . . . . . . . . . . . . . .

4.3.2 Example: Changing the PROFINET device name 41. . . . . . . . . . . . . . . . .

4.4 Menu Structure 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Display / WBM Configuration 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Web Based Management (WBM) with the IE/AS-i LINK 47. . . . . . . . . . . .

5.1.1 WBM − Requirements and Starting Up 47. . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Working with WBM 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Configuration and Diagnostics 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

7

Contents

5.2.1 Navigation “System −> System Configuration” 51. . . . . . . . . . . . . . . . . . . .

5.2.1.1 General 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1.2 Identification & Maintenance 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1.3 Settings 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Navigation “System −> Reset” 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Navigation “System −> Save & Download” 56. . . . . . . . . . . . . . . . . . . . . . .

5.2.3.1 HTTP (Hypertext Transfer Protocol) 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3.2 TFTP (Trivial File Transfer Protocol) 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Navigation “System −> Password” 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Navigation “System −> Device Display” 59. . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 Navigation “System −> Diagnostic >Buffer” 60. . . . . . . . . . . . . . . . . . . . . .

5.2.6.1 Diagnostic Buffer 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6.2 Events 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.7 Navigation “System −> C-PLUG” 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.8 Navigation “System −> Internet” 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.9 Navigation “Industrial Ethernet −> Configuration” 65. . . . . . . . . . . . . . . . .

5.2.9.1 IP Configuration 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.9.2 Events 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.9.3 E-mail 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.9.4 SNMP 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.9.5 Time Synchronization 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.10 Navigation “Industrial Ethernet −> Ports” 73. . . . . . . . . . . . . . . . . . . . . . . .

5.2.10.1 Ports 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.10.2 FDB (forwarding database) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.10.3 ARP (Address Resolution Protocol) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.11 Navigation “Industrial Ethernet −> Statistics” 75. . . . . . . . . . . . . . . . . . . . .

5.2.11.1 Throughput 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.11.2 Packet Type 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.11.3 Packet Size 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.11.4 Error 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.12 Navigation “PROFINET IO −> Status” 78. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.12.1 Status 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.13 Navigation “AS-i Line 1 −> Overview” 79. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.13.1 Lifelist 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.13.2 Error Statistics 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.14 Navigation “AS-i Line 1 −> Configuration” 83. . . . . . . . . . . . . . . . . . . . . . . .

5.2.14.1 Status 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.14.2 Total Configuration 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.15 Navigation “AS-i Line 1 −> Slaves” 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.15.1 Diagnostics 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.15.2 Configuration 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.15.3 Cyclic Data 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.15.4 Current Parameters 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.15.5 String Transfer 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.16 Navigation “AS-i line 1 −> Change Address” 94. . . . . . . . . . . . . . . . . . . . .

5.2.16.1 Change Address 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.16.2 Change ID1 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

5.2.16.3 Automatic Addressing 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Configuring with STEP 7 or a GSDML File 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 General Information on Configuration 97. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Basics 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Choosing the Configuration Method 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Configuring with STEP 7 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Configuring the IE/AS-i LINK 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Configuring and Assigning Parameters to the AS-i Slaves 103. . . . . . . . . .

6.3 Configuration with the GSDML File 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Installing the GSDML File 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Configuring the IE/AS-i LINK 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Configuring and Assigning Parameters to the AS-i Slaves 109. . . . . . . . . .

7 Data Exchange between PROFINET IO Controller and AS-i Slave 111. . . . . . . . . .

7.1 How the interfaces work 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Transferring AS-i Digital Values 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Addressing AS-i Slaves 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Special Feature of AS-i Analog Slaves 114. . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Special Features of AS-i Safety Slaves 114. . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

7.3 Transferring AS-i Analog Values 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Accessing AS-i Analog Data using Acyclic Services 116. . . . . . . . . . . . . . .

7.3.2 Special Situations in Analog Value Transfer 117. . . . . . . . . . . . . . . . . . . . . .

8 Using the Data Record Interface 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Data Record Interface of the IE/AS-i LINK 118. . . . . . . . . . . . . . . . . . . . . . .

8.2 Description of the AS-i Line and AS-i Slave Calls 122. . . . . . . . . . . . . . . . .

8.2.1 AS-i Line Calls 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.1 Store_Actual_Parameters 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.2 Store_Actual_Configuration 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.3 Set_LPS 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.4 Get_LPS_LAS_LDS_LPF_Flags 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.5 Get_LAS_CDI_PI_Flags 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.6 Set_LPS_PCD_PP_Flags 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.7 Set_Operation_Mode 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.8 Set_Offline_Mode 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.9 Change_Slave_Address 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.10 Set_Auto_Addr_Enable 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.11 Write_Extended_ID−Code_1 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.12 Read_AIDI 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.13 Write_AODI 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.14 Read_AS-i_Line_Errorcounters 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1.15 Read_and_Delete_AS-i_Line_Errorcounters 148. . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 AS-i Slave Calls 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.1 Set_Permanent_Parameter 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

9

Contents

8.2.2.2 Get_Permanent_Parameter 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.3 Write_Parameter 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.4 Read_Parameter 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.5 Set_Permanent_Configuration 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.6 Get_Permanent_Configuration 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.7 Read_Actual_Configuration 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.8 Read_Parameter_String 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.9 Write_Parameter_String 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.10 Read_Diagnostic_String 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.11 Read_Identification_String 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.12 Write_CTT2_String 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.13 Read_CTT2_String 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.14 Read_I/O_Configuration 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.15 Read_ID−Code 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.16 Read_Extended_ID−Code_1 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.17 Read_Extended_ID−Code_2 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.18 Read_Status 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.19 Get_Write_Parameter_Echo 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.20 Write_Analog_Output_Data 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.21 Read_Analog_Input_Data 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.22 Read_AS-i_Slave_Errorcounters 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2.23 Read_and_Delete_AS-i_Slave_Errorcounters 172. . . . . . . . . . . . . . . . . . . . . . .

9 Diagnostics 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Overview 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Interrupts 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Remove/Insert Module Interrupts 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Diagnostic Interrupts 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Diagnose Data Records 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Dealing with Problems / Error Displays 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Replacing a Defective AS-i Slave/Automatic Address Programming 176.

10.2 Error Displays/Remedying Errors 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A AS-Interface Protocol Implementation Conformance Statement (PICS) 180. . . . .

B References 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Notes on the CE Mark 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Glossary 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.1 Terms Relating to AS-Interface 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 Terms Relating to PROFINET 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines,

Operation

This chapter...

This chapter will familiarize you with the performance characteristics, basic

functions and installation of the IE/AS-INTERFACE LINK PN IO master module.

You will learn the following:

S How to install the IE/AS-i LINK

S Which display and control elements the IE/AS-i LINK provides.

1.1 General Notes on Operation − Safety Warnings

Warning

!

WARNING − EXPLOSION HAZARD: DO NOT DISCONNECT EQUIPMENT

WHEN A FLAMMABLE OR COMBUSTIBLE ATMOSPHERE IS PRESENT.

Warning

!

!

When used under hazardous conditions (zone 2), devices of the

IE/AS-INTERFACE LINK PN IO product line must be installed in an enclosure.

To comply with ATEX95 (previously ATEX100a) EN 60079-15, this enclosure must

meet the requirements of at least IP54 in compliance with EN 60529.

Warning

When used under hazardous conditions:

S If the temperature of the cable or wiring entry point exceeds 70°C or the

temperature of the connecting terminal on the IE/AS-i LINK exceeds 80 °C,

special precautions must be taken:

If the IE/AS-i LINK is operated at ambient temperatures 50°C to 60°C, only

cables with a maximum permitted temperature of at least 80°C may be used.

S Provisions shall be made to prevent the rated voltage from being exceeded by

transient disturbances of more than 40%.

This criterion is fulfilled, if supplies are derived from SELV (Safety Extra Low

Voltage), only.

S The IE/AS-i LINK is intended only for vertical installation.

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

11

1 Technical Description, Installation Guidelines, Operation

Warning

!

S ”WARNING” − Explosion Hazard − Do not disconnect while circuit is live unless

area is known to be non-hazardous.

S ”WARNING” − Explosion Hazard − Substitution of components may impair

suitability for Class I, Division 2 or Zone 2.

S This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D;

Class I, Zone 2, Group IIC or non-hazardous locations.

Caution

!

When handling and installing the IE/AS-INTERFACE LINK PN IO, make sure that

you adhere to the ESD guidelines.

Note

The IE/AS-i LINK can be configured, installed and started up independent of the

PROFINET installation.

12

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines, Operation

1.2 Uses of the Module

PROFINET IO Device and AS-Interface Master

The IE/AS-i LINK is both a PROFINET IO device and AS-Interface master:

S IE/AS-i LINK connects the actuator-sensor interface with PROFINET IO.

S Using the IE/AS-i LINK module, you can access the inputs and outputs of the

AS-i slaves from PROFINET IO Depending on the slave type, you can access

binary values and / or analog values.

The following AS-i slaves can be used:

− Standard slaves / analog slaves / combi slaves

− Slaves with the extended addressing mode

− Slaves with data transfer mechanisms complying with the AS-i specification

V3.0 − Combined Transaction Type (CTT) 1−5.

PROFINET

Industrial Ethernet

AS-Interface

Power

supply

Safe

slave with

EMERGENCYSTOP

ET 200SP

Slave

Laser

scanner

SCALANCE

XC208

ET 200pro

MSS

ASIsafe

SIMATIC

Software Controller

3RA2 load

feeders

SIMATIC/

SIMOTION

IE/AS-i Link PN IO

When IE/AS-i Link PN IO is used

as double master

Power

supply

Safe

slave with

EMERGENCYSTOP

Slave

SIMATIC HMI

AS-Interface

MSS

ASIsafe

IK10_40017c

Figure 1-1 Example of a System Configuration with the IE/AS-INTERFACE LINK PN IO (double

master)

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

13

1 Technical Description, Installation Guidelines, Operation

Features

The IE/AS-INTERFACE LINK PN IO is a PROFINET device (complying with IEC

61158) and AS-Interface master (complying with the AS-Interface specification

V3.0 according to EN 50 295) and allows transparent data access to the

AS-Interface from PROFINET IO.

PROFINET IO controllers can exchange IO data cyclically with the lower-level

AS-Interface slaves. Acyclic services can also be used for AS-i calls (parameters,

diagnostics).

Apart from the digital I/O data, analog data is also stored quickly in the cyclic I/O

area of an SIMATIC S7 CPU (no separate communication block call necessary).

The IE/AS-i LINK is available as a single or double master

(applications with large numbers of slaves −> doubles the configuration limits).

The complete underlying AS-i line can be configured on an integrated operator

display in the IE/AS-i LINK (for example addressing the AS-i slaves, I/O test of all

digital and analog slaves).

During operation, you have detailed diagnostic information available on the display

allowing a fault to be localized immediately, when necessary.

The essential features are as follows:

S Single and double AS-Interface master (complying with AS-Interface

specification V3.0) for the connection of 62 AS-Interface slaves per master and

integrated analog value transfer

S Support of the real-time function (RT) of PROFINET IO

S Integrated ground fault monitoring for the AS-Interface cable

S Convenient diagnostics and commissioning on site using full graphics display or

over Web interface with standard browser

S Configuration with STEP 7 or integration using the PROFINET type file

(GSDML file)

S Vertical integration (standard Web interface) over Industrial Ethernet

S Power supply from the AS-Interface cable (line 1), therefore no extra power

supply necessary. As an alternative, a 24 V DC power supply can be used.

S Module replacement without PG by using C-PLUG

Components of the Product

14

The IE/AS-i LINK product includes the following components:

S IE/AS-INTERFACE LINK PN IO

S Product information for the IE/AS-INTERFACE LINK PN IO

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines, Operation

1.3 Technical Specifications of the Module

The IE/AS-INTERFACE LINK module has the following technical data:

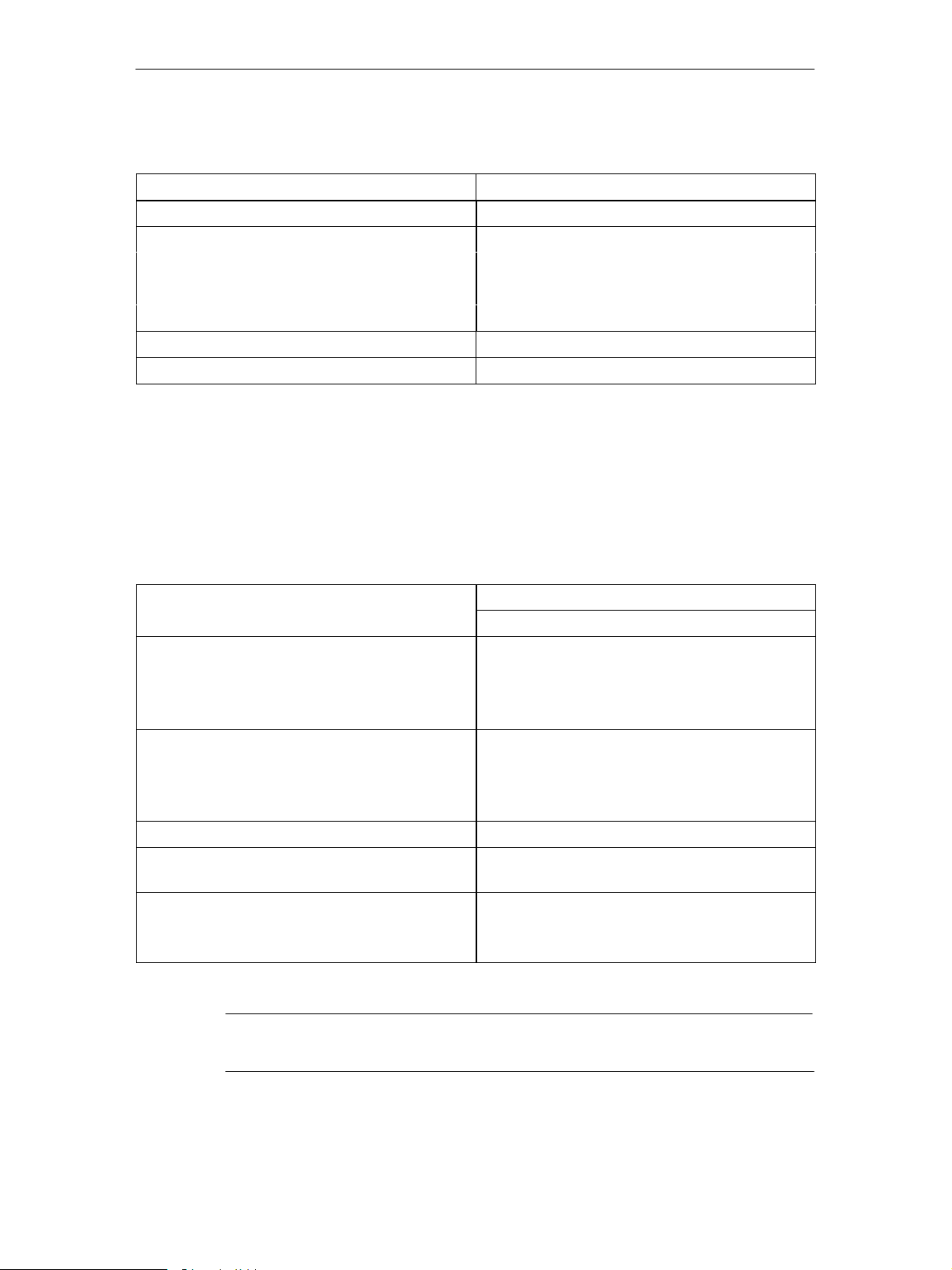

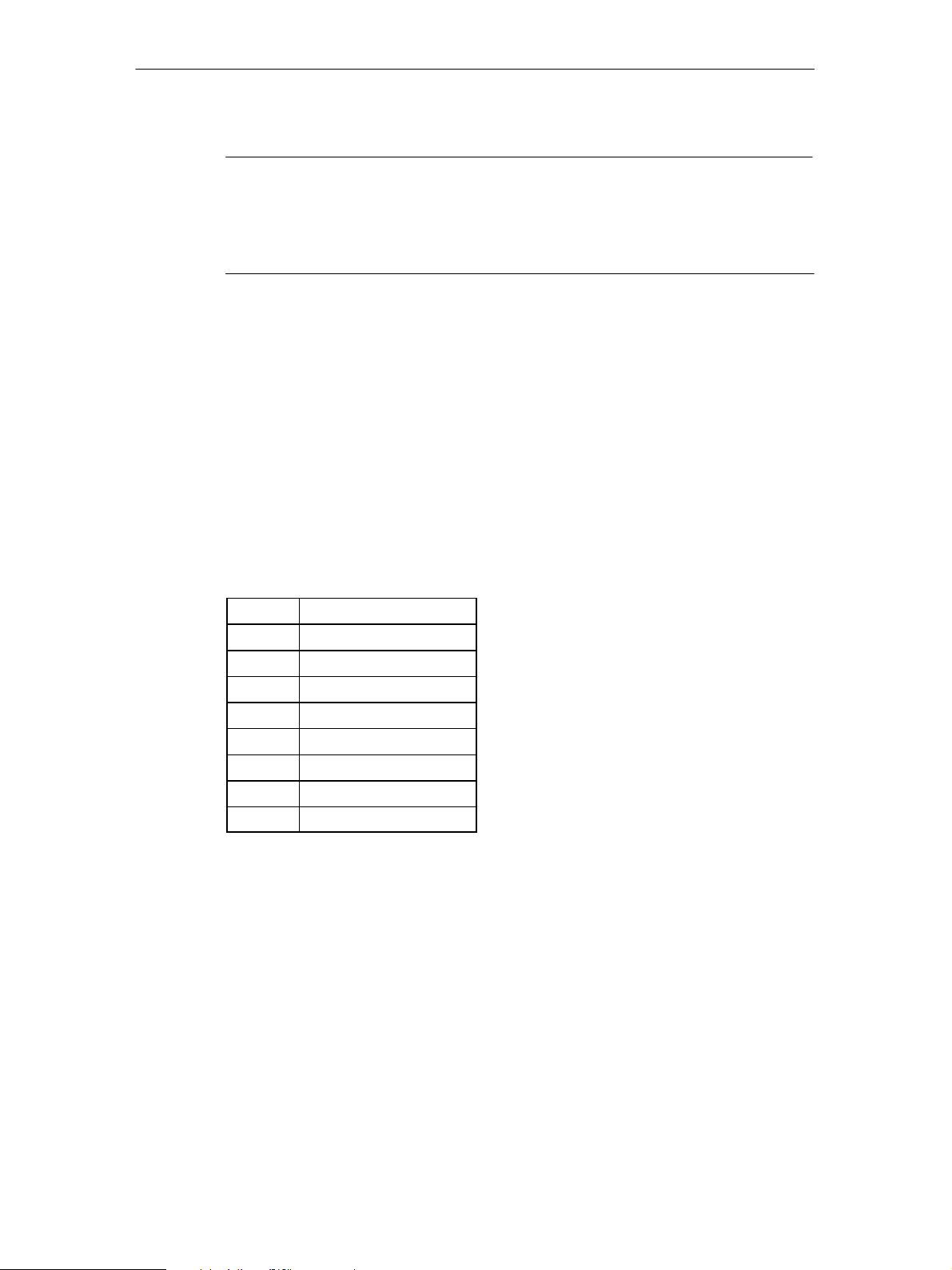

Table 1-1 Technical Specifications

Feature Explanation/Values

AS-i cycle time

(The values apply for the possible full configuration

of an AS-i network on the IE/AS-INTERFACE LINK

in each case)

Configuration of the AS-Interface S via keyboard and display

Supported AS-i master profiles M1-M4

Connector for AS-i cable

(single and double master)

S 5 ms for 31 slaves with standard addressing

S 10 ms for 62 slaves with A/B addressing

S 10 ms for inputs according to profile S-7.A.7

S 20 ms for outputs according to profile S-7.A.7

S 40 ms for inputs/outputs according to profile

7.A.A

S-

S 20 ms for

S-7.A.8 and S-7.A.9

fast analog according

S 5 ms for super fast analog according to profile

S-6.0.X

S using STEP 7 or with GSDML file

S using Web Based Management (WBM)

S using the user program (data record interface)

over plug-in screw contacts (4-pin);

Permitted current loading from pin 1 to pin 3 or pin

2 to pin 4, maximum 3 A

to profile

LAN connectors (2) RJ-45 (10/100 Mbps)

as equal switch ports with full duplex capability

Setting of PROFINET device name and IP

parameters

Setting:

S via keyboard and display

S using STEP 7

S using Web Based Management (WBM)

Power supply from the AS-i cable (line 1)

Current consumption from the AS-i cable

Power consumption max. 9.6 W

Cable length max. 100 m

Cable cross-section (AS-i cable) 2 x 1.5 mm2 (2 x 0.8 mm2)

Optional external power supply

(plug-in screw contacts 3-pin)

Cable cross-section (power supply) 0.5 to 2.5 mm

Ambient conditions

29.5 to 31.6 V DC in compliance with EN 50 295

max. 320 mA at 30 V

24 V DC, functional earthing

(18 − 32 V DC)

SELV / LPS or NEC Class 2 is mandatory.

2

S Operating temperature (vertical installation only) 0 to +60°C

S Transportation and storage temperature

S Operating altitude

−30°C to +70°C

max. 3000 m above sea level

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

15

1 Technical Description, Installation Guidelines, Operation

Table 1-1 Technical Specifications

Feature Explanation/Values

S Relative humidity Max. 95% at +25°C

Construction

S Type of protection IP 20

S Dimensions (W x H x D) in mm 90 x 132 x 85.5

S Weight approx. 380 g

Receptacle for optional C-PLUG

Full graphics display and 6 control buttons 128 x 64 pixels

1.4 Approvals

Table 1-2 Description of the Approvals

c−UL−us

c−UL−us for hazardous locations UL 1604, UL 2279PT.15

FM FM 3611

C−TICK AS/NZS 2064 (Class A)

CE EN 61000−6−2, EN 61000−6−4 (replaces

ATEX Zone 2 EN 60079−15:2005, EN 60079−0:2006

UL 508

CSA C22.2 No. 142

CL. 1, Div. 2 GP.A.B.C.D T4

CL. 1, Zone 2, GP.IIC, T4

CL. 1, Zone 2, AEx nC IIC T4

CL. 1, Div. 2 GP.A.B.C.D T4

CL. 1, Zone 2, GP.IIC. T4

Ta: 0...+60°C

EN 50081−2)

II 3 G EEx nA II T4

KEMA 08 ATEX 0003X

16

Note

The current approvals are printed on the module.

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines, Operation

1.5 Installation Guidelines and Installing the Module

Caution

!

Noise immunity / grounding

To ensure the immunity of the IE/AS-INTERFACE LINK PN IO, the IE/AS-i LINK,

the AS-i power supply unit and the power supply of the IE/AS-i LINK must be

grounded according to the regulations.

Notice

If you do not adhere to the EMC directive 2004/108/EC (CE) when setting up

systems and devices, this can lead to connection aborts in communication between

the PROFINET IO controller and the IE/AS-INTERFACE LINK PN IO.

Possibilities

The IE/AS-i LINK has type of protection IP 20.

You can install the IE/AS-i LINK on a standard rail (DIN rail complying with EN

50022).

Ground the DIN rail over as short a distance as possible and with low inductance.

If the rail is installed in a cabinet, make sure that it makes good contact over a

large area with the grounded mounting plate.

Installation on a DIN Rail

If you decide to install a module on a DIN rail, please note the following points:

1. The module is placed on the rail from above and then pushed down until the

catch at the bottom of the module snaps into position.

2. Other modules can be arranged to the left and right of the module.

Removing the Module from the DIN Rail

To remove the module from the DIN rail, follow the procedure below:

1. When removing the module from the DIN rail, the power supply and signal

cables must first be removed.

2. After the cables have been disconnected, press down the catch on the base of

the device using a screwdriver and pull the module out of the rail towards the

top.

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

17

1 Technical Description, Installation Guidelines, Operation

Convection

Make sure that you leave at least 5 cm clearance above and below the module to

allow heat dissipation.

Caution

The DIN rail may only be installed horizontally.

The IE/AS-i LINK must be mounted vertically to ensure the required heat dissipation through the ventilation openings and at the top of the device.

18

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines, Operation

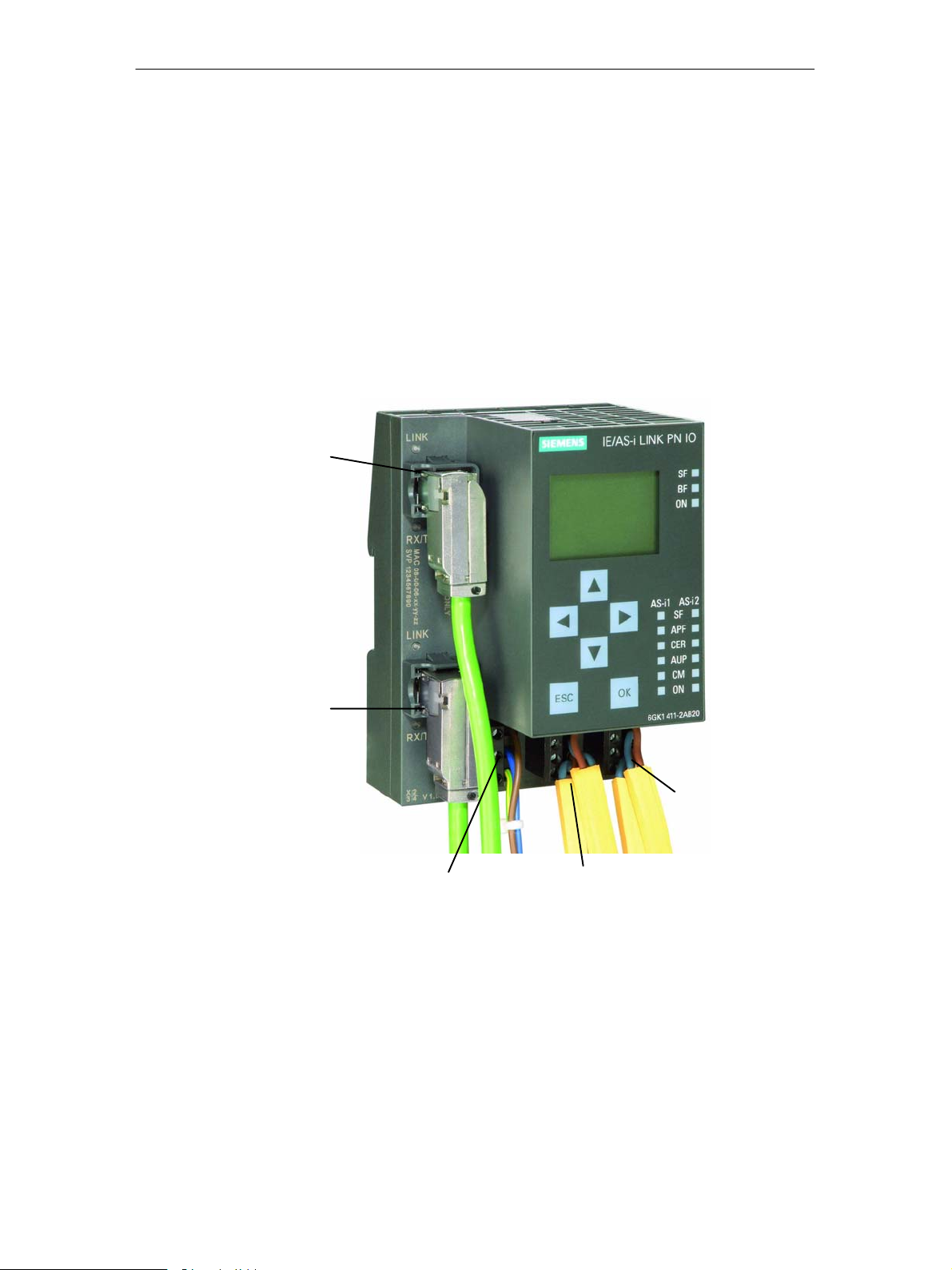

1.6 Front Panel − Access to all Functions

Connection, Display and Control Elements

On the front panel, you have access to all the connection, display and control

elements of the IE/AS-i LINK module.

C-PLUG

Display

LED “LINK” 1

connection to

Ethernet partner

LAN connector

X1

(independent

switch port)

LED “RX/TX” 1

data traffic with

Ethernet partner

LED “LINK” 2

connection to

Ethernet partner

LAN connector

X2

(independent

switch port)

LED “RX/TX” 2

data traffic with

Ethernet partner

(optional)

LEDs

IE/AS-i LINK

SF = system fault

BF = bus fault

ON = power

LEDs

AS-i line

SF = system fault AS-i

APF = AS-i power fail

CER = configuration error

AUP = autoprog available

CM = configuration mode

ON = AS-i online

Keypad

for

− AS-i configuration

− Link configuration

− Diagnostics

X = placeholder

for hardware

version

Firmware version

Figure 1-2 Front View of the IE/AS-INTERFACE LINK PN IO

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

Power supply

connector 24 V DC

(as alternative to

supply over line 1)

Release catch

for

DIN rail mounting

(bottom of device)

AS-i line 1

connector

AS-i line 2

connector

(only with

double master)

19

1 Technical Description, Installation Guidelines, Operation

1.7 Connection Elements

Connectors

The IE/AS-i LINK has the following connectors:

S Two separate connectors for the AS-i cable (on double master)

S One connector for alternative power supply 24 V DC (optional) and functional

earthing

S Two RJ-45 LAN connectors as independent switch ports

LAN

connector 1

LAN

connector 2

Power supply

connector 24 V DC

(alternative)

Figure 1-3 Connectors for the AS-i Cable(s) and Power Supply

AS-i line 1

connector

(power supply from

AS-i line 1)

AS-i line 2

connector

(only with

double master)

20

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines, Operation

1.7.1 Connectors for the AS-i Cable(s) and Power Supply

Caution

!

!

Connectors for the AS-i Cable(s)

When connecting up the module, keep to the installation guidelines in Section 1.5.

Caution

The IE/AS-INTERFACE LINK PN IO may only be connected when the AS-i power

supply unit is turned off.

The IE/AS-i LINK has two connectors for the AS-i cables (line 1 and line 2). Each

is connected over a 4-pin plug with two + and two − contacts that are jumpered

internally.

This allows the IE/AS-i LINK to be looped into the AS-i cable.

Caution

!

The permitted current loading of the AS-i connection contacts is 3 A. If this value

is exceeded on the AS-i cable, the IE/AS-INTERFACE LINK PN IO must not be

looped into the AS-i cable but must be connected with a tap line (only one pair of

connectors of the IE/AS-i LINK is used).

Pin assignment of the AS-i line

PIN no. line 1 Signal

1 AS-i 1 +

2 AS-i 1 −

3 AS-i 1 +

4 AS-i 1 −

Pins 1 and 3 and pins 2 and 4 are jumpered internally.

PIN no. line 2 Signal

1 AS-i 2 +

2 AS-i 2 −

3 AS-i 2 +

4 AS-i 2 −

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

21

1 Technical Description, Installation Guidelines, Operation

Power Supply from the AS−Interface

Caution

!

The AS-i power supply unit used and the optional external power supply must

provide an extra low voltage safely isolated from the mains supply. This safe

isolation can be implemented according to the following requirements:

S VDE 0100 Part 410 = HD 384-4-4 = IEC 364-4-41

(as functional extra-low voltage with safe isolation) or

S VDE 0805 = EN60950 = IEC 950

(as safety extra-low voltage SELV) or

S VDE 0106 Part 101

The IE/AS-i LINK can be supplied fully from the AS-Interface (only AS-i line 1). The

current consumption from the AS-Interface is 320 mA at 30 V.

As an alternative, the IE/AS-i LINK can be supplied by a separate power supply

unit (24 V DC).

Power Supply from external Power Supply

Warning

!

The device is designed for operation with safety extra−low voltage (SELV). This

means that only safety extra−low voltages (SELV) complying with

IEC950/EN60950/ VDE0805 may be connected to the power supply terminals.

The power unit for supplying the device must comply with NEC Class 2 as described by the National Electrical Code(r) (ANSI/NFPA 70).

The power of all connected power units in total must correspond to a limited power

source (LPS).

Never operate the IE/AS-INTERFACE LINK PN IO with AC current or DC current

higher than 32 V.

With a double master, you require a separate power unit each for AS−i line 1 + 2.

If the cable to the external power unit is very long and liable to energy spikes,

connect a surge protection element.

Pin assignment of the power supply

PIN no. line 1 Signal

1 Power +

2 Power −

3 PE

22

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines, Operation

Note

Functional earthing

IE/AS-INTERFACE LINK PN IO has a connector for functional earthing. This

connector is required if the integrated ground fault monitoring is used. It should be

connected to the PE conductor with as little resistance as possible.

LAN Connectors (PROFINET IO, PC with WBM)

As connectors for PROFINET and a PC (or network) there are two RJ-45 jacks

(recommendation: 90° FC connector).

One LAN connector is intended for the PROFINET system, the second LAN

connector of the IE/AS-i LINK is used, for example, for configuration with Web

Based Management and for diagnostics. The two LAN connectors have equal

status.

The IE/AS-i LINK supports autocrossing, in other words, both crossover and

straight-through cables can be used.

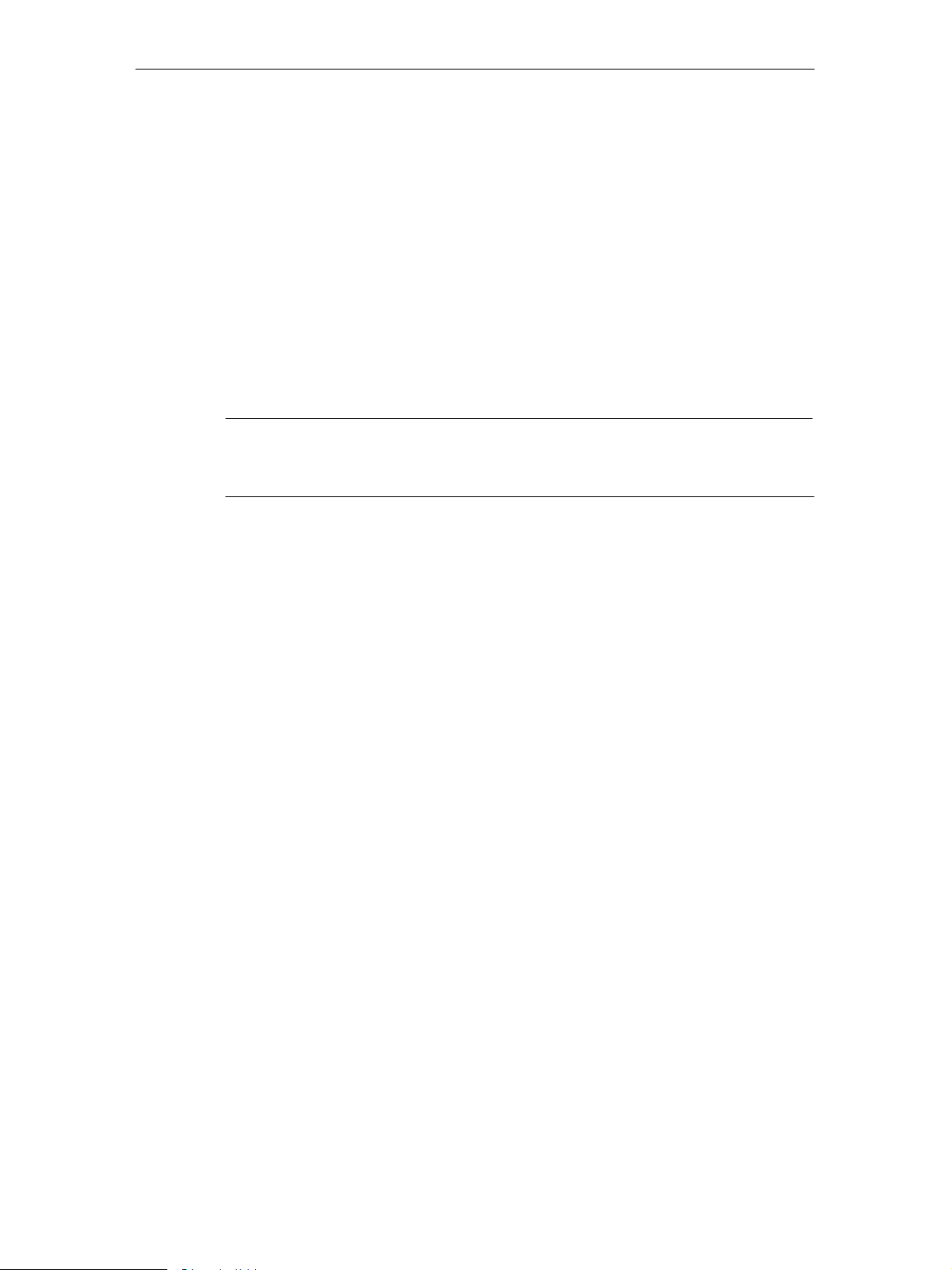

Pin Assignment of the LAN Connector

Pin no. Signal

1 RXP

2 RXN

3 TXP

4 n.c.

5 n.c.

6 TXN

7 n.c.

8 n.c.

n.c. = not connected

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

23

1 Technical Description, Installation Guidelines, Operation

1.8 C-PLUG (Configuration Plug)

Area of Application

The C-PLUG (order number: 6GK1 900-0AB00) is an optional exchangeable

medium for saving the configuration and project engineering data of the basic

device (IE/AS-i LINK) and the AS-i slaves.

When powered down, the C-PLUG retains all data permanently. This means that

configuration data remains available when a basic device is replaced (module

replacement without PG is therefore possible).

The C-PLUG is accessible from the top of the housing.

The IE/AS-i LINK has internal memory for permanent storage of the configuration

data of the basic device and the AS-i slaves. Replacing a module without a PG is,

however, possible only with the C-PLUG.

Inserting in the C-PLUG Slot

The slot for the C-PLUG is on the top panel of the device.

To insert the C-PLUG, the cover of the receptacle must be removed. The C-PLUG

is inserted in the receptacle. The cover must then be replaced over the receptacle

and closed correctly.

Notice

The C-PLUG may only be inserted or removed when the power is off!

Cover of the receptacle

for the C-PLUG

Figure 1-4 Position of the C-PLUG (removing the C-PLUG from the device with a screwdriver)

24

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

Function

1 Technical Description, Installation Guidelines, Operation

If an empty C-PLUG (as supplied) is inserted, all the configuration data of the

IE/AS-i LINK is written to it when the device starts up. Changes to the

configuration during operation are also written automatically to the C-PLUG.

If the C-PLUG is inserted, the basic device automatically uses the configuration

data of the C-PLUG. This assumes that the data was written by a compatible

device type.

If a fault occurs, the basic device can then be replaced much faster and more

simply. If a device needs to be replaced, the C-PLUG is simply taken from the

failed component and inserted in the replacement. As soon as it starts up, the

replacement automatically has the same device configuration as the failed device.

Notice

If a C-PLUG is inserted when you reset to the factory settings, the factory settings

are stored on the C-PLUG !

Using the C-PLUG

When using a C-PLUG, the following situations must be distinguished:

S Inserting an empty C-PLUG:

The IE/AS-i LINK detects when a C-PLUG is inserted and automatically writes

the data of the internal memory to the C-PLUG.

S Inserting a C-PLUG of a different device type:

If you insert a C-PLUG that is not intended for the IE/AS-i LINK, this can also

be used. The IE/AS-i LINK signals an error and changes to the error state

(WBM and display, see also Section 5.2.7).

To clear the problem, the message must be acknowledged. At the same time,

this triggers the transfer of the data from the internal memory to the C-PLUG.

S Inserting the C-PLUG of another IE/AS-i LINK:

If a C-PLUG with valid data of another IE/AS-i LINK is inserted, the device

changes to operational (starts up with the data of the C-PLUG). The data from

the internal memory is, however, not transferred automatically to the C-PLUG.

The transfer must be triggered manually using the keypad and display (or

WBM) (System > Configuration > C-PLUG > Internal memory > C-PLUG; see

Section 4.4). The next time the module starts up, the internal memory is

deleted.

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

25

1 Technical Description, Installation Guidelines, Operation

1.9 Display and Control Elements

LED Displays

The following LED displays are located on the front panel of the IE/AS-i LINK:

S Displays for the LAN connectors (separate for X1 and X2)

− LINK: Connection to Ethernet partner

− RX/TX: Data traffic

S Displays of the IE/AS-i LINK

− SF: system fault

− BF: bus fault

− ON: Power supply IE/AS-i LINK

S Displays for the AS-i line

− SF: AS-i system fault

− APF: AS-i power fail

− CER: configuration error

− AUP: automatic address programming

− CM: configuration mode

− ON: AS-i status online / offline

Meaning of the IE/AS-i LINK LEDs

LED (color) Status Meaning

SF (red) System fault

(link)

The LED is lit in the following situations:

S In protected mode, a diagnostic interrupt (entering state) was

triggered on the PROFINET IO controller.

S The IE/AS-i LINK has detected an internal error (for example

EEPROM defective).

BF (red) Bus fault The LED flashes in the following situations:

S The connection between the PROFINET IO controller and the

IE/AS-i LINK has broken down or the PROFINET IO controller is

not active.

S IE/AS-i LINK was not or was incorrectly assigned parameters by

the PROFINET IO controller.

ON (green) The LED is lit when the IE/AS-i LINK is supplied with power.

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

26

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines, Operation

Meaning of the AS-i Line LEDs

LED (color) Status Meaning

SF (red) System fault

(line)

APF (red) AS-i Power Fail This indicates that the voltage supplied to the AS-i cable by the AS-i

The LED is lit when a diagnostic interrupt (entering state) was

triggered by the PROFINET IO controller in protected mode.

power supply unit is too low or is faulty.

CER (yellow) Configuration

Error

This LED indicates whether the slave configuration detected on the

AS-i cable matches the expected configuration on the

DP/AS-INTERFACE LINK Advanced. If they do not match, the “CER”

LED is lit.

The “CER” LED is lit in the following situations:

S A configured AS-i slave does not exist on the AS-i cable (for

example failure of the slave).

S An AS-i slave exists on the AS-i cable but it was not previously

configured.

S An attached AS-i slave has different configuration data (I/O

configuration, ID code) from the slave configured on the IE/AS-i

LINK.

S The IE/AS-i LINK is in the offline mode.

AUP (green) Autoprog

available

CM (yellow) Configuration

Mode

In the protected mode of the IE/AS-i LINK module, the LED indicates

that automatic address programming of an AS-i slave is possible. The

automatic address programming makes it much easier to exchange a

defective AS-i slave on the AS-i cable (for more detailed information

refer to Section 10.1).

This LED displays the mode of the IE/AS-i LINK.

S Indicator on: configuration mode

S Indicator off: protected mode

The configuration mode is only required for installing and starting up

the IE/AS-i LINK module. In the configuration mode, the IE/AS-i LINK

activates all connected AS-i slaves and exchanges data with them.

For more information about the configuration mode, refer to Section

4.1.

ON (green) The LED lights up when the AS-i line is operated “Online” (the

AS-i master sends AS-i frames).

In the following situations, the LED goes off:

S when the AS-i line is operated “Offline” (the AS-i master does not

send AS-i frames).

S when no I/O modules were configured for the line in HW Config

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

27

1 Technical Description, Installation Guidelines, Operation

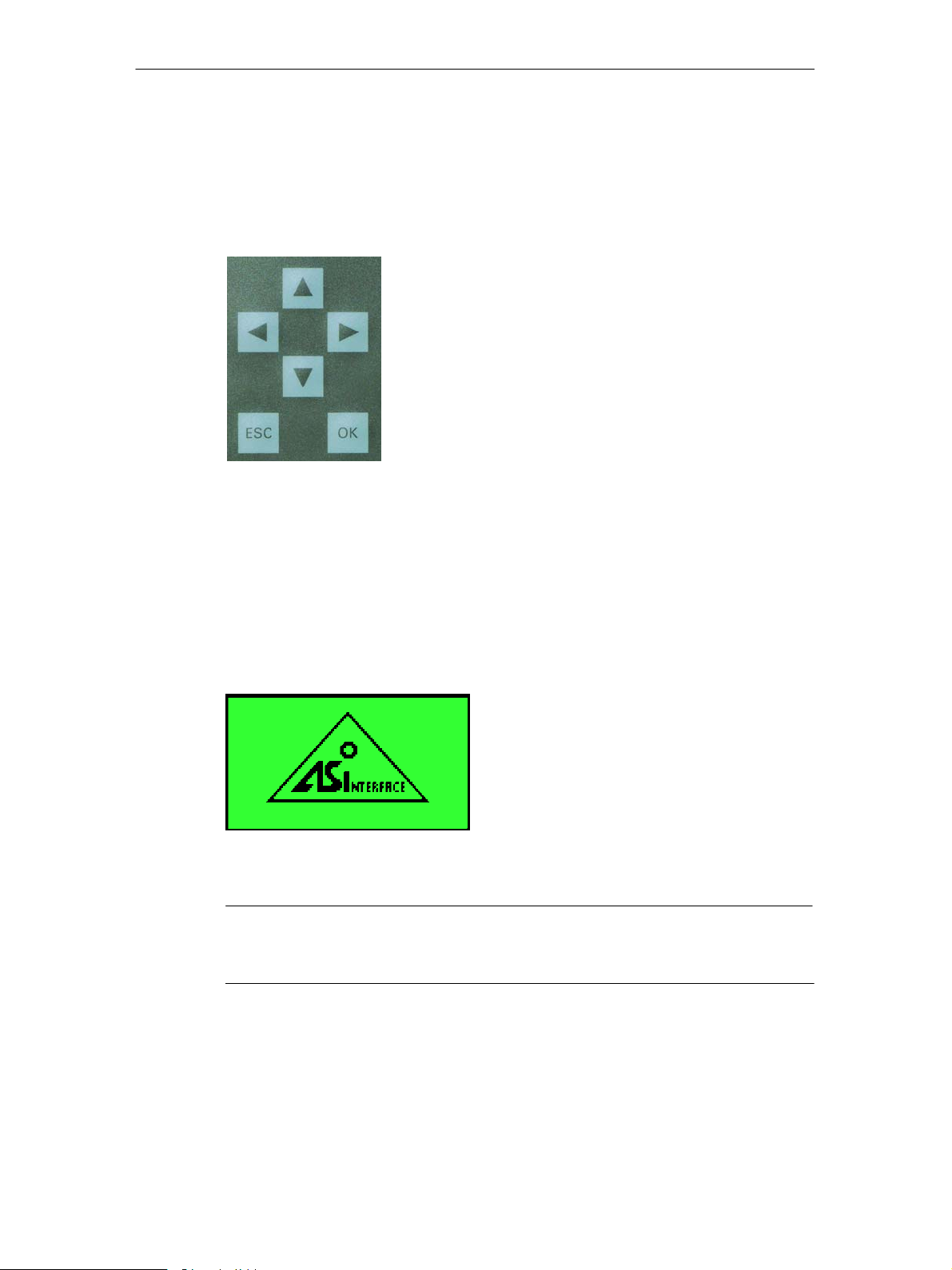

Keypad

The mode can be changed using the control buttons. You configure the underlying

AS-i line interactively with the display using the control buttons.

The following buttons are located on the front panel of the IE/AS-i LINK:

Display

The graphic display has a resolution of 128 x 64 pixels.

You configure the underlying AS-i line using the keypad and the display. This

allows on-site commissioning and diagnostics.

The following display appears after turning on the device and if there has been no

input over the keypad for a longer period of time (see Section 4.4).

Figure 1-5 Display − Logo

Note

If a fault occurs during operation, the resulting error message will be displayed

even if the Logo was previously displayed.

28

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

1 Technical Description, Installation Guidelines, Operation

As soon as any entry is made using the keypad, the main menu appears allowing

you to navigate through the menu structure.

Figure 1-6 Display − Main Menu

If you have selected an entry in the list (displayed inversely), a tooltip will appear

after a brief time with further information on the entry (does not occur in the main

menu).

1.10 Settings when Using a Firewall

Please note the following when using firewalls:

Note

When using a firewall access to the following ports must be permitted depending

on the service being used:

S http Port 80/TCP (for WBM)

S TFTP Port 69

S SNMP Port 161/UDP

S SNTP Port 123 (can be changed)

S SMTP Port 25

S Trap Port 162/UDP

-

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

Release 08/2018

C79000−G8976−C216−03

29

1 Technical Description, Installation Guidelines, Operation

1.11 Restrictions due to broadcast or multicast communication

The IE/AS-i LINK PN IO is designed for operating on PROFINET networks where

the configured participants are connected and communicate error-free. It is

imperative to prevent high levels of broadcast or multicast communication on the

PROFINET network.

Notice

If the level of broadcast or multicast communication is too high, the Ethernet

interface of the IE/AS-i LINK can become overloaded, resulting in data

transmission delays, or even device failure.

Broadcast or multicast communication arises when the PROFINET controller is

looking for PROFINET nodes, for example. The search is periodically repeated,

especially when configured PROFINET nodes are not available on the PROFINET

network. Depending on the PROFINET controller and its settings, it is possible that

the communication cycle time is subject to significant fluctuations.

This scenario can occur during step-by-step commissioning of a PROFINET

network. Broadcast or multicast communication can be reduced by adapting the

network configuration to the actual design, e.g. via STEP 7 hardware configuration

or by calling the SFC "D_ACT_DP" SIMATIC system function (Deactivate/activate

distributed I/O devices; SFC 12) in the user program.

Distributing the PROFINET or Ethernet nodes into separate networks can also

reduce broadcast or multicast communication.

Broadcast or multicast communication usually also arises when other network

devices such as computers or PCs are connected to the Ethernet network.

Using SCALANCE managed Industrial Ethernet switches also makes it possible to

limit broadcast or multicast communication at the IE/AS-i Link by filtering Ethernet

communication.

30

IE/AS−INTERFACE LINK PN IO as of hardware version 1, as of firmware version V2.0

C79000−G8976−C216−03

Release 08/2018

Loading...

Loading...