Siemens SIMATIC MV540 H, SIMATIC MV540 S, SIMATIC MV560 X Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC Ident

Optical Identification

SIMATIC MV500

Operating Instructions

06/2018

C79000

Preface

Description

1

Safety notes

2

Image processing

3

Network and system

integration

4

Mounting

5

Connection

6

Commissioning

7

Operator control and

monitoring

8

Process interfacing via an

automation system (PLC,

PC)

9

Service and maintenance

10

Technical data

11

Dimension drawings

12

Scope of delivery and

ordering data

13

Appendix

A

List of abbreviations

B

Service & Support

C

-G8976-C494-01

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

06/2018 Subject to change

Preface

Validity of these operating instructions

Device/license

Article number

SIMATIC MV540 S

6GF3540-0CD10

SIMATIC MV540 H

6GF3540-0GE10

Product designation

Purpose of the operating instructions

Note

The operating instructions contain all the important information about the device

Read the operating instructions before starting to work with this device. The operating

instructions contain all the important information about the device.

Noting and acting on this information

•

•

This document contains information on the products listed below.

Table 1 Valid for devices/licenses with the following article numbers

SIMATIC MV560 X 6GF3560-0HE10

The optical readers of the SIMATIC MV500 series can be used for optical identification

applications in manufacturing and logistics. Typical applications are product tracking and

production control.

These operating instructions apply to firmware version V1.0.

In the remainder of this document, the term "optical reader" is also used instead of the full

product name, "SIMATIC MV540".

These operating instructions contain all the information you need for commissioning and

using the device.

They are intended for persons installing the device mechanically, connecting it electrically,

assigning the parameters and commissioning it, as well as for service and maintenance

engineers.

Ensures that the device functions correctly

Saves you service costs.

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

3

Preface

Current operating instructions on the Internet

Information

Contacts worldwide

Screenshots in the operating instructions

Recycling and disposal

You can also find the latest version of these operating instructions on the Web pages of

Siemens Industry Online Support

(https://support.industry.siemens.com/cs/ww/de/ps/15147/man

You can find additional information on the blocks described in this manual in the manual

"Ident profile and Ident blocks, standard function for Ident systems

(https://support.industry.siemens.com/cs/ww/en/view/109746389

"FB 45 (https://support.industry.siemens.com/cs/ww/en/view/21738808)".

).

)" as well as in the manual

We point out that the contents of this product documentation shall not become a part of or

modify any prior or existing agreement, commitment or legal relationship. The Purchase

Agreement contains all obligations of Siemens AG and the complete and exclusive warranty

conditions. Any statements on the device versions described in the manual do not create

new warranties or modify the existing warranty.

The contents reflect the technical status at the time of printing. We reserve the right to make

technical changes in the course of further development.

If you require further information or if unexpected problems occur, you can request the

necessary information from your contact. You will find details of your local contact on the

Internet.

The screenshots shown in these operating instructions are based on the view of Web Based

Management (WBM) from SIMATIC MV540.

The products are low in harmful substances, can be recycled and meet the requirements of

the Directive 2012/19/EU for disposal of waste electrical and electronic equipment (WEEE).

Do not dispose of the products at public disposal sites.

For environmentally compliant recycling and disposal of your electronic waste, please

contact a company certified for the disposal of electronic waste or your Siemens

representative.

Note the different country-specific regulations.

SIMATIC MV500

4 Operating Instructions, 06/2018, C79000-G8976-C494-01

Preface

License conditions

Note

Open source software

Read the license conditions for open source software carefully before using the product.

Security information

Security recommendations

You can find the license conditions in the following document:

● OSS License Summary.pdf

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For additional information on industrial security measures that may be

implemented, please visit

Link: (https://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers’ exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Link: (https://www.siemens.com/industrialsecurity

To prevent unauthorized access, observe the following security recommendations when

working with the optical readers and WBM (Web Based Management).

)

)

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

5

Preface

General

Physical access

Software (security functions)

Passwords

● Check regularly that the device complies with these recommendations and/or other

internal security policies.

● Evaluate your plant as a whole in terms of security. Use a cell protection concept with

suitable products.

● Do not connect the device directly to the Internet. Operate the device within a protected

network area.

● Restrict physical access to the device to qualified personnel.

● Lock unused hardware ports on the device. Unused ports can be used to access the

system without authorization.

● Keep the software up to date. Keep yourself informed regularly about safety updates for

the product.

You can find information about this at Link: (http://www.siemens.com/industrialsecurity

)

● Activate only protocols that you actually need to use the device.

● Limit access to the device using a firewall or rules in an access control list (ACL).

● The configuration files are available in XML format for simple use. Make sure that the

configuration files outside the device are suitably protected. You can, for example,

encrypt the files, store them at a safe location and transfer them only via secure

communications channels.

● We recommend that you disable the "CONNECT" function after initial commissioning.

● The functions for archiving as well as the remote functions (MMI) may only be activated in

networks protected by a firewall.

● Activate user management and create new user profiles.

● Change all default passwords for users before operating the device.

● Only use passwords with high password strength. Avoid weak passwords, e.g.

password1, 123456789, abcdefgh.

● Define rules for using devices and assigning passwords.

● Make sure that all passwords are protected and inaccessible to unauthorized personnel.

● Do not use the same password for different users and systems.

● Update passwords and keys regularly to improve security.

SIMATIC MV500

6 Operating Instructions, 06/2018, C79000-G8976-C494-01

Preface

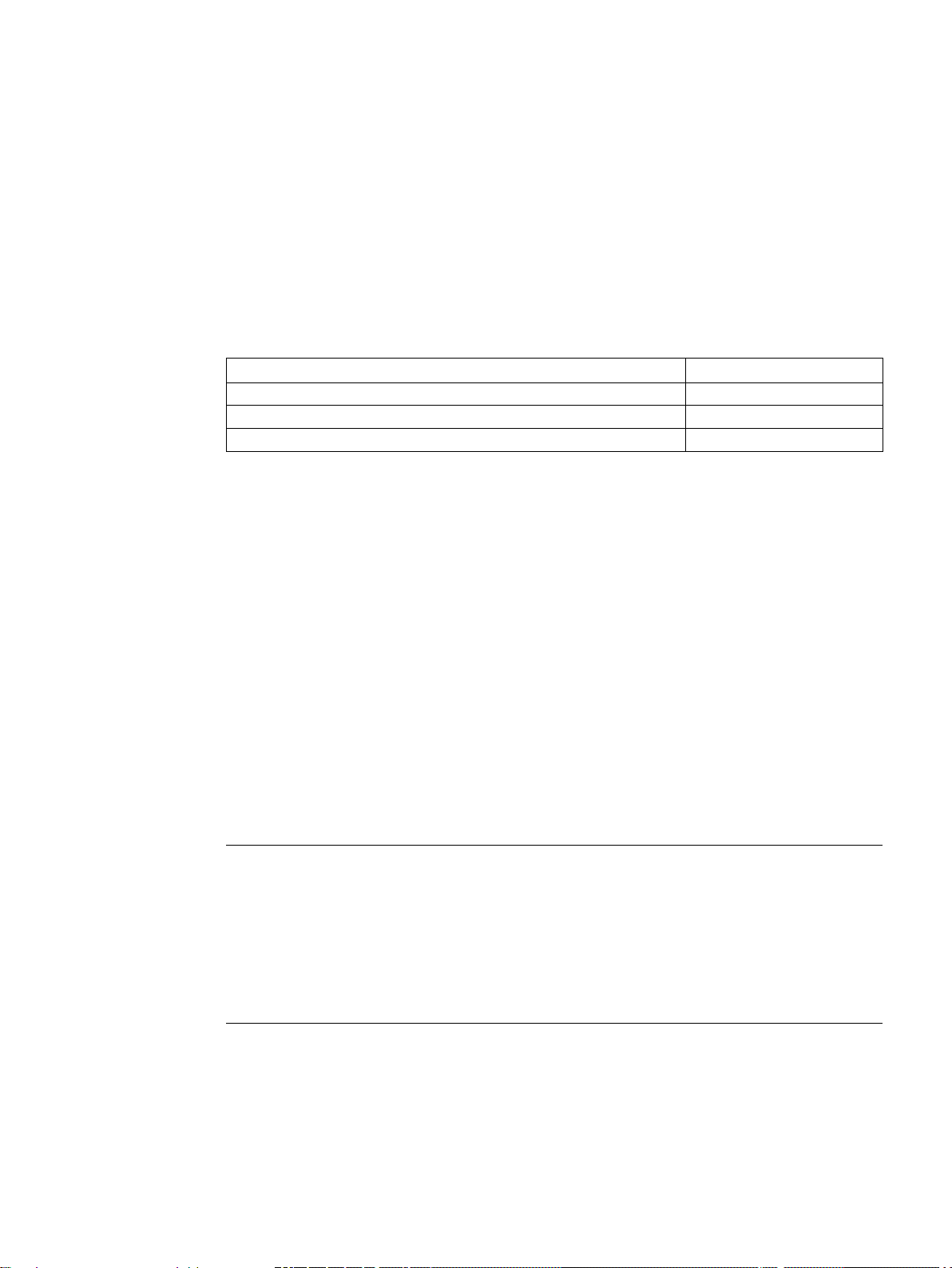

Firmware encryption

Secure/non-secure protocols

List of available protocols

Protocol

Port number

Default port

status

Port activation

Authentication

Encryption

HTTP

TCP/80

Open

--

No

No

NTP

UDP/123

Closed

✓

No

No

TCP

TCP Config

Closed

✓

No

No

SSH

TCP/22

Closed

✓

Yes

Yes

DNS

TCP/53

Closed 1)

--

No

No

DHCP

UDP/68

Closed 1)

--

No

No

SNMP

UDP/161

Open

--

Yes

No

UDP/57345-57346

Scanner portal

TCP/666

Closed

✓

No

No

MMI

TCP dynamic

Closed

✓

No

No

ALM LIC

TCP/65278

Open 2)

--

No

No

1)

2)

Only when the reader is in "Stop".

The firmware itself is signed and encrypted. This ensures that only authentic firmware can be

downloaded to the device.

● Check whether it is necessary to use SNMPv1. SNMPv1 is classified as non-secure.

Make use of the possibility to prevent write access. The product offers corresponding

settings for this.

● If SNMP is activated, change the community names. If unrestricted access is not

necessary, limit access via SNMP.

● Use secure protocols if access to the device is not protected by means of physical

safeguards.

The following protocols provide secure alternatives:

HTTP → HTTPS

● To prevent unauthorized access to the device or network, set up appropriate safeguards

against non-secure protocols.

● Enable only the services (protocols) that will actually be used on the device. The same

applies to the installed interfaces/ports. Unused ports could be used to access the

network downstream from the device.

All available protocols and their ports that are used with SIMATIC MV500 are listed below.

Table 2 List of available protocols

HTTPS TCP/443 Open -- Yes Yes

PROFINET UDP/34964

Open -- No No

This protocol is only used when the "CONNECT" button is used.

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

7

Preface

NOTICE

Opening ports by changing the parameter settings

Trademarks

Explanation of the table:

● Authentication

Specifies whether authentication of the communication partner takes place.

● Encryption

Specifies whether the transfer is encrypted.

Make sure that port "TCP/8765" is open when enabling the "Archiving/MMI" parameter.

Make sure that port "TCP/8000" is open when enabling the "TCP" parameter.

You can find additional information about these parameters in the section "Communication

> Interfaces" of the WBM online help.

The following and possibly other names not identified by the registered trademark sign ® are

registered trademarks of Siemens AG:

SIMATIC ®, SIMATIC NET ®, SIMATIC MV ®, SIMATIC RF ®, SIMATIC Sensors ®

SIMATIC MV500

8 Operating Instructions, 06/2018, C79000-G8976-C494-01

Table of contents

Preface ................................................................................................................................................... 3

1 Description ............................................................................................................................................ 13

2 Safety notes .......................................................................................................................................... 25

3 Image processing .................................................................................................................................. 29

4 Network and system integration ............................................................................................................ 53

1.1 Area of application .................................................................................................................. 13

1.2 Product characteristics............................................................................................................ 14

1.3 Design of the SIMATIC MV540 ............................................................................................... 17

1.4 Structure of the nameplate ..................................................................................................... 18

1.5 System configuration .............................................................................................................. 19

1.6 System components ............................................................................................................... 20

1.7 Functional description ............................................................................................................. 21

3.1 Code reading (1D/2D codes) .................................................................................................. 29

3.1.1 Area of application and examples ........................................................................................... 29

3.1.1.1 Applications for two-dimensional codes.................................................................................. 30

3.1.1.2 Applications for one-dimensional codes ................................................................................. 32

3.1.2 Performance characteristics when reading codes .................................................................. 34

3.1.2.1 Complex data matrix codes with "ID-Genius" detection ......................................................... 34

3.1.2.2 Quality of data matrix codes ................................................................................................... 35

3.1.2.3 QR codes ................................................................................................................................ 36

3.1.2.4 PDF417 codes ........................................................................................................................ 36

3.1.2.5 DotCodes ................................................................................................................................ 37

3.1.2.6 One-dimensional codes .......................................................................................................... 38

3.1.3 Reading multiple codes in the image ...................................................................................... 39

3.2 Code verification ..................................................................................................................... 40

3.2.1 Overview ................................................................................................................................. 40

3.2.2 Grading ................................................................................................................................... 42

3.2.3 Verification of printed labels .................................................................................................... 42

3.3 Options for image acquisition and image processing ............................................................. 43

3.3.1 Image acquisition option "Individual trigger" ........................................................................... 44

3.3.2 Image acquisition option "Auto-trigger" ................................................................................... 45

3.3.3 "Scan" image acquisition option ............................................................................................. 48

3.3.4 Image acquisition in program sequence mode ....................................................................... 49

3.3.5 Simple comparison for Track&Trace (MATCH mode/command) ........................................... 50

4.1 Overview ................................................................................................................................. 53

4.2 System configuration via PROFINET/PROFIBUS with CM .................................................... 54

4.3 System configuration of the optical reader as PROFINET IO device with CM and FB

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

79 or Ident profile .................................................................................................................... 55

9

Table of contents

5 Mounting ............................................................................................................................................... 63

6 Connection ........................................................................................................................................... 75

7 Commissioning ..................................................................................................................................... 87

8 Operator control and monitoring ............................................................................................................ 99

9 Process interfacing via an automation system (PLC, PC) ..................................................................... 103

4.4 System configuration via the Ethernet interface with switch .................................................. 56

4.5 System setup via the RS-232 interface ................................................................................. 57

4.6 System configuration with CM and RFID reader ................................................................... 58

4.7 System configuration with CM and auto-trigger ..................................................................... 59

4.8 System configuration with WinCC flexible/HTML browser and switch .................................. 60

4.9 System configuration with external ring light ......................................................................... 61

4.10 Other system extensions ....................................................................................................... 61

5.1 Notes on installation ............................................................................................................... 63

5.2 Mounting with built-in ring light and mini-lens ........................................................................ 64

5.3 Mounting with built-in ring light and EF lens .......................................................................... 67

5.4 Mounting attachments for built-in ring lights .......................................................................... 70

5.5 Mounting with external ring light ............................................................................................ 72

6.1 Guidelines for installation free of electrical interference ........................................................ 75

6.2 Power supply using Power over Ethernet (PoE) .................................................................... 76

6.3 Connecting the power supply ................................................................................................. 77

6.4 Wiring examples..................................................................................................................... 83

6.5 Operating optical reader with external ring light .................................................................... 84

7.1 Prerequisites .......................................................................................................................... 87

7.2 Connecting using the "CONNECT" button ............................................................................. 87

7.3 Connecting and setting up the reader using the PST ............................................................ 90

7.4 Selecting connection alternatives .......................................................................................... 95

9.1 Integration via onboard PROFINET IO ................................................................................ 104

9.2 Integration via communication modules .............................................................................. 108

9.3 Control with Ident profile ...................................................................................................... 108

9.3.1 Assigning parameters to the Ident profile (standard profile V1.19) ..................................... 109

9.3.2 Control with MV commands via Ident profile ....................................................................... 110

9.3.2.1 Status display of the optical reader ...................................................................................... 111

9.3.2.2 Initialization .......................................................................................................................... 112

9.3.2.3 "PHYSICAL WRITE" commands / MV command interface ................................................. 112

9.3.2.4 "PHYSICAL READ" commands ........................................................................................... 119

9.3.2.5 Result evaluation of a command .......................................................................................... 123

9.3.2.6 Preconditions for the commands ......................................................................................... 124

9.3.2.7 Group error ........................................................................................................................... 125

SIMATIC MV500

10 Operating Instructions, 06/2018, C79000-G8976-C494-01

Table of contents

10 Service and maintenance .................................................................................................................... 175

11 Technical data .................................................................................................................................... 195

9.4 Control with FB 79 ................................................................................................................ 126

9.4.1 Assignment of the interfaces relevant to PROFINET IO ...................................................... 126

9.4.2 Select operating modes using the control/status byte .......................................................... 131

9.4.3 Example program for data exchange if code length ≤ 27 bytes ........................................... 136

9.4.4 Programming data fragmentation ......................................................................................... 138

9.4.5 FB 79 "VS130-2_CONTROL" ............................................................................................... 139

9.4.5.1 How it works .......................................................................................................................... 141

9.4.5.2 Parameter overview .............................................................................................................. 142

9.4.5.3 Job execution ........................................................................................................................ 146

9.4.5.4 Error information ................................................................................................................... 150

9.5 Controlling the I/O interface "DI/DQ" .................................................................................... 152

9.6 Control via TCP/IP and RS232 ............................................................................................. 153

9.6.1 Trigger ................................................................................................................................... 154

9.6.2 Write match string ................................................................................................................. 154

9.6.3 Setting/resetting DISA bit ...................................................................................................... 155

9.6.4 Query status .......................................................................................................................... 155

9.6.5 Select program number ........................................................................................................ 156

9.6.6 Save program with internal trigger ........................................................................................ 157

9.6.7 Save program with external trigger ....................................................................................... 157

9.6.8 Reset command .................................................................................................................... 159

9.6.9 Set digital out ........................................................................................................................ 160

9.7 Remote client ........................................................................................................................ 161

9.7.1 XML backup and XML restore .............................................................................................. 161

9.7.2 XML backup .......................................................................................................................... 162

9.7.3 XML restore .......................................................................................................................... 164

9.8 SNMP .................................................................................................................................... 167

9.9 Example programs ................................................................................................................ 169

9.9.1 Connection of the optical reader to a SIMATIC controller using FB 79 ................................ 169

9.9.2 Archiving of images and diagnostic information on a PC ..................................................... 170

10.1 Error and diagnostics messages .......................................................................................... 175

10.1.1 Message types ...................................................................................................................... 175

10.1.2 Error messages ..................................................................................................................... 176

10.1.3 Error output of the read results ............................................................................................. 180

10.1.4 Read and verification error messages .................................................................................. 181

10.1.5 Filter error messages ............................................................................................................ 184

10.1.6 Diagnostics via the LED display ........................................................................................... 185

10.1.7 IO device diagnostics ............................................................................................................ 188

10.1.7.1 Reading out the diagnostics information with STEP 7 .......................................................... 188

10.1.7.2 Diagnostics with PROFINET IO ............................................................................................ 189

10.2 Maintenance and repair ........................................................................................................ 191

10.3 Replacing a module .............................................................................................................. 192

11.1 Technical specifications of SIMATIC MV540 ........................................................................ 195

11.2 Technical specifications of the EF lens ................................................................................. 198

11.3 Technical specifications built-in ring light .............................................................................. 199

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

11

Table of contents

12 Dimension drawings ............................................................................................................................. 201

13 Scope of delivery and ordering data ..................................................................................................... 207

A Appendix ............................................................................................................................................. 219

B List of abbreviations ............................................................................................................................. 233

C Service & Support ................................................................................................................................ 237

11.4 Technical specifications of ring light (external) .................................................................... 200

12.1 SIMATIC MV540 .................................................................................................................. 201

12.2 Built-in ring lights for SIMATIC MV500 ................................................................................ 201

12.3 D65 protective tube for SIMATIC MV500 ............................................................................ 202

12.4 D65 protective tube extension ............................................................................................. 202

12.5 Mounting plate for SIMATIC MV500 .................................................................................... 203

12.6 SIMATIC MV500 with external ring light .............................................................................. 204

12.7 Ring light (external) .............................................................................................................. 205

12.8 Ring light holder for external ring light ................................................................................. 205

13.1 Ordering data ....................................................................................................................... 207

13.2 Optical readers ..................................................................................................................... 208

13.3 Accessories .......................................................................................................................... 209

13.3.1 Lens ..................................................................................................................................... 209

13.3.2 Built-in ring lights .................................................................................................................. 210

13.3.3 External ring lights ............................................................................................................... 211

13.3.4 Protective lens barrel ........................................................................................................... 212

13.3.5 PoE switches for power supply ............................................................................................ 213

13.3.6 Cables and other accessories .............................................................................................. 213

13.3.7 Mounting/calibration boards ................................................................................................. 217

A.1 Finding the suitable lens ...................................................................................................... 219

A.2 Certificates, approvals & guidelines ..................................................................................... 220

A.2.1 Certificates & approvals ....................................................................................................... 220

A.2.2 ESD Guidelines .................................................................................................................... 222

A.3 Alternative user interfaces ................................................................................................... 224

A.3.1 User-defined user interface .................................................................................................. 224

A.3.2 Integrated HTML pages ....................................................................................................... 225

A.3.3 Use of saved images ........................................................................................................... 231

SIMATIC MV500

12 Operating Instructions, 06/2018, C79000-G8976-C494-01

1

1.1

Area of application

Key functions of the optical reader

Industrial applications

The products of the SIMATIC MV500 series are optical readers designed specifically for the

recognition and processing of numerous machine-readable codes and plain text in industrial

production.

The optical readers provide a wide range of options for identification:

● Reading numerous machine-readable 1D and 2D codes

● A combination of the options listed above

Over and above this, the optical readers provide important functions for:

● Verification of the marking quality of machine-readable codes (according to standards).

● "OK"/"N_OK" evaluation based on numerous criteria.

● Position and orientation recognition, for example for "pick & place" tasks.

In the SIMATIC MV500 device series, particular emphasis was placed on:

● Ruggedness

● Reliability

● Easy installation

● Browser-based, no-installation, user interface / Web Based Management (WBM)

● Ease of operation

This applies not only to the mechanical properties but also to the high-quality image

processing functions of all devices in the SIMATIC MV500 product series.

● Reading machine-readable markings

The list of readable codes includes all common matrix and barcodes that can usually be

detected reliably regardless of the print technique or the carrier medium used.

● "OK"/"N_OK" evaluation

Whether for checking quality criteria, match criteria, position or angle of rotation deviation

using SIMATIC MV500, actuators can be controlled directly to take workpieces that do

not meet the requirements out of the production process.

Due to their ruggedness and high degree of protection, the optical readers are suitable for

industrial applications in which optical identification tasks are necessary. This applies equally

to production processes and logistics processes.

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

13

Description

Communication interfaces

Simple operation and commissioning

1.2

Product characteristics

Reading code

Integrated communications interfaces

1.2 Product characteristics

The optical readers have all the conventional communications interfaces of industrial

sensors and can therefore be connected to a wide variety of systems. Through the

communications module interface, they can also be seamlessly combined with the

communications modules (ASM/CM), for example, via PROFIBUS.

The optical readers are particularly easy to use and commission, despite the wide variety of

possible applications. For most applications, the parameters are set automatically. If,

however, readjustment becomes necessary, the parameters can be assigned using the

integrated Web server and an Internet browser without prior software installation.

The optical reader is a compact camera system with an integrated processing unit for

industrial applications with the following product characteristics:

● For codes with maximum quality, the read reliability for data matrix code is 99.999 %

(compare quality grading).

● Maximum reading speed of 80 reads per second (Rps) in SIMATIC MV500 S

● Software-guided read distance variable due to exchangeable lens (typically: 100 mm to

3000 mm)

● Object speed up to 10 m/s

● Code sizes (example: DMC) from 1 mm

● Auto-trigger and scan mode

● Up to 15 parameter sets and code reading settings can be saved and selected.

● Up to 150 codes can be read per image acquisition (SIMATIC MV500 U/X)

● Code verification according to ISO/IEC 16022

● Ethernet 10/100 Mbps for TCP/IP and PROFINET IO

● 1 trigger input and 1 flash output

– Response time of the trigger input: 50-70 us

2

to 200 mm2

– Jitter (fluctuation of response time): max. 40 ns

Incoming triggers during a running image acquisition do not interrupt it. Triggers that are

incoming during an image acquisition are handled as NOK processing procedures and

included in the processing statistics.

● Communication module interface

SIMATIC MV500

14 Operating Instructions, 06/2018, C79000-G8976-C494-01

Description

Extended communication via communication modules

Power over Ethernet

Robust construction, suitable for industry

Class of protection IP67

Protective lens barrel

Optical system

Lighting

1.2 Product characteristics

● RS232 with TxD and RxD

● 2 configurable DI/DQs

● ASM 456 for PROFIBUS DP/V1

● RF120C, RF170C and RF180C for PROFINET

Integrate power supply via Ethernet cable (PoE)

With screw-on protective lens barrel

Barrel with filter thread

● Mechanical mini-lenses

● Electronic focus lenses (via software-controlled focal plane)

● High-intensity built-in ring lights with up to 12 red LEDs

– Fast change of focal plane

– Wear-free (without moving mechanics)

– temperature stabilized

– In the versions: Multi, (Basic, Remote)

– With switchable lighting segments

– With switchable polarization filter

– With integrated reflection protection

● External ring lights

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

15

Description

Operation on the device

Web Based Management (WBM)

Configuration backup

1.2 Product characteristics

Fast, uncomplicated connection between PC and reader without installed software using the

"CONNECT" button.

Quick adaption to the reading situation using the "READ" button.

● Completely installation-free

● Modern HTML5 design

● Fast response times

● Auto-adaption function

● Secure communication over https

● Login and user management

● Versatile HTML pages for monitoring the reader

● Extensive operator control and monitoring functions even in processing mode

● Wide-ranging diagnostics and logging functions:

● Firmware update

● System backup and restoration

● Option of user-defined, integrated user interfaces

Allows automatic saving of complete device configuration on micro SD card (not included in

scope of delivery).

– Error image memory

– Event logging

SIMATIC MV500

16 Operating Instructions, 06/2018, C79000-G8976-C494-01

Description

1.3

Design of the SIMATIC MV540

①

④

(M12, 12-pin)

②

⑤

Power over Ethernet (M12, 4-pin)

③

Built-in ring light

⑥

Nameplate

1.3 Design of the SIMATIC MV540

The following figure shows the design of the SIMATIC MV540 optical reader.

LED display

Protective lens barrel

Figure 1-1 Design of the SIMATIC MV540

Combination interface for

power supply, DI/DQ, RS232 and CM

Ethernet interface

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

17

Description

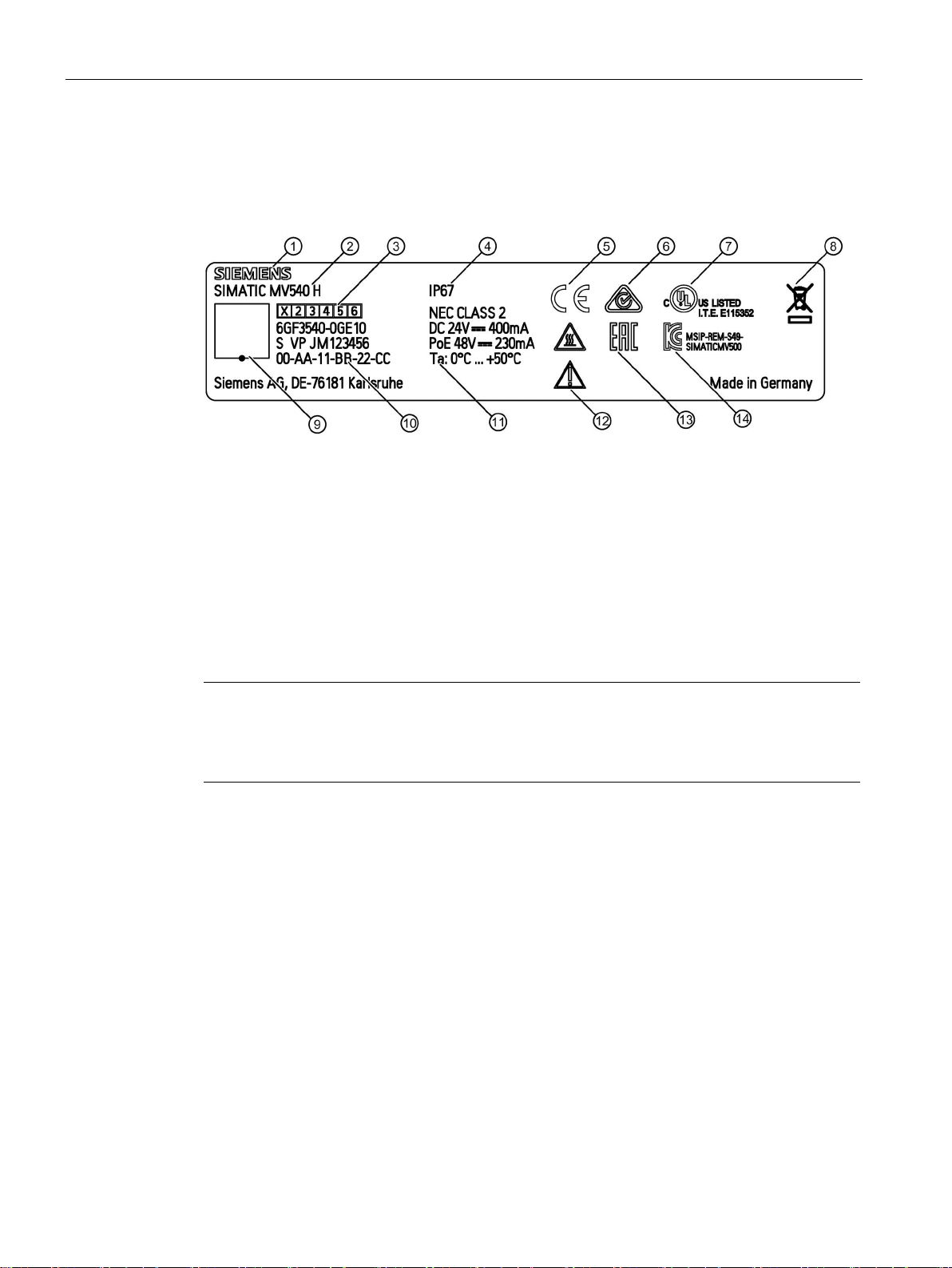

1.4

Structure of the nameplate

①

Manufacturer

⑧

Disposal label

②

Product designation

⑨

Data matrix code

③

⑩

number and MAC address (12 digits)

④

IP rating

⑪

Technical specifications

⑤

CE mark

⑫

Warning symbols

⑥

C-Tick mark

⑬

EAC marking

⑦

UL Listing mark

⑭

KCC test mark

Note

Reserved MAC address

A second MAC address is also reserved when the device supplied. This MAC address of the

specified MAC address on the nameplate +1.

1.4 Structure of the nameplate

The nameplate is located on the housing of the optical reader and shows the article number

and other important product information.

Product version of the device

Figure 1-2 Example of the SIMATIC MV540 nameplate

Article number, production code/serial

SIMATIC MV500

18 Operating Instructions, 06/2018, C79000-G8976-C494-01

Description

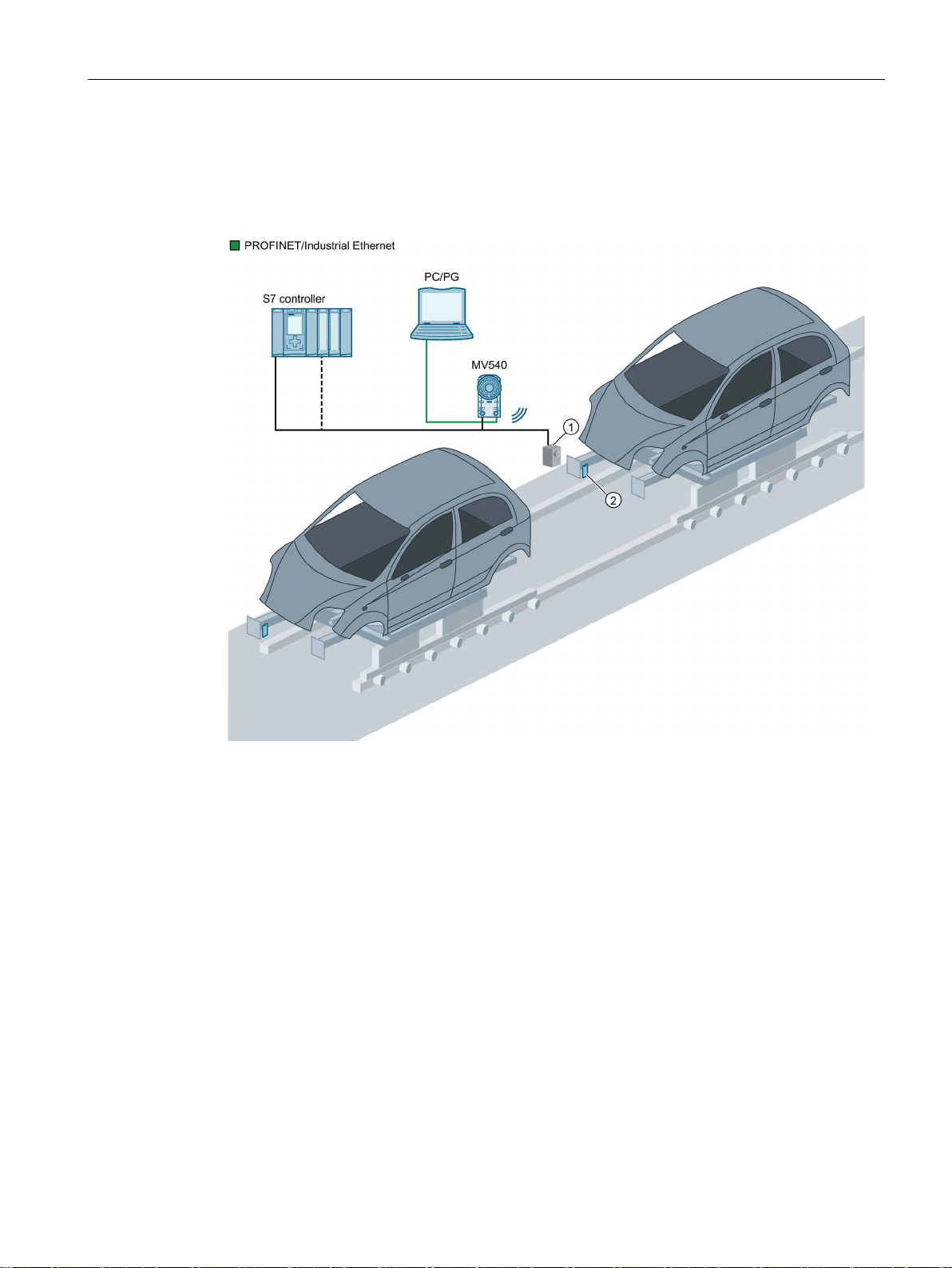

1.5

System configuration

①

Optical sensor or light barrier (for trigger signal)

②

Object with code

1.5 System configuration

The following figure shows a typical system configuration with a SIMATIC MV540 optical

reader.

Figure 1-3 Example of a system configuration on a production line (illustrated with SIMATIC MV540)

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

19

Description

1.6

System components

Optical reader

PC/PG

1.6 System components

To equip an application with optical readers, you need the following hardware components:

● SIMATIC MV500 optical reader

● Lens suitable for code size and read distance

● Ring light

● Protective lens barrel

● 24 V DC, 2 A power supply (tolerance: 19.2 ... 28.8 V):

– Alternatively via I/O / CM cable

– Alternatively via Power over Ethernet

● Communication connection:

– RS232/RS422 integrated in the I/O / CM cable

– Ethernet cable

Apart from the components for operating the optical reader, you also require a PC/PG to

commission the device:

● PC/PG minimum configuration:

– Ethernet interface with at least 100 Mbps

– CPU: DualCore with 3 GHz

– RAM: 4 GB

● Software:

– Microsoft Windows 7 operating system or newer

– Web browser with HTML5 support

Tested Web browsers: Microsoft Internet Explorer as of V11, Mozilla Firefox as of V52

and Google Chrome as of V57

The system requirements of SIMATIC MV500 optical readers for communication partners in

the process depend on the selected communication connection. You can find more

information on communication connections in the section "Network and system integration

(Page 53)".

SIMATIC MV500

20 Operating Instructions, 06/2018, C79000-G8976-C494-01

Description

1.7

Functional description

Image acquisition

Web Based Management (WBM)

1.7 Functional description

The optical readers detect the object characteristics required for the task using digital image

acquisition.

Following image acquisition, the image is analyzed by a powerful digital signal processor.

Depending on the application, multilevel complex algorithms are used during the analysis:

● To find and decode the codes contained in the image.

● To verify codes.

The results of the evaluation are transferred to an automation system connected via the

communications interfaces.

The user is supported in the use of the optical reader by a variety of feedback messages:

● Live image display

● Auto-detection for code type recognition

● Result and quality preview

● Display of diagnostics images

● Warning and error messages

● 3-language online help in the optical reader

The WBM is based on Web server technology. This means that only a computer with an

Internet browser connected with an optical reader via Ethernet is necessary. The optical

reader is then called using its IP address. The display of the WBM appears in the display

window of the Internet browser. Display via Ethernet allows convenient setting and control of

all parameters of the optical reader. Operator control of the optical readers is supported by

context-sensitive online help.

If automatic adjustment does not lead to an optimum result due to special conditions, you

can use the WBM to readjust individual parameters of the optical reader manually. You can

save 15 different settings in the optical reader.

Depending on the task, up to 12 processing steps can be set as a sequence in one program.

The following processing steps are available:

● Decoder step for reading 1D/2D codes

You can store up to 15 different programs on the reader.

The settings for communication with other devices must be made in the WBM.

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

21

Description

Processing

User management and access protection

Configuration via remote client

Diagnostics functions

1.7 Functional description

The actual processing is triggered by different events.

● In the simplest situation, the optical reader generates the trigger event itself. Optical

readers have an auto-trigger function for this purpose.

● Depending on the application, it may be advisable to provide the trigger event via the I/O

cable. In this case, the optical reader obtains the signal, for example, from a light barrier.

The trigger signal immediately triggers image acquisition followed by evaluation. The

result of the evaluation is then transferred to the higher-level control system through the

selected communications connection. Once the evaluation result has been transferred,

reading can be started again.

The functions of the optical reader can be protected from unauthorized access and

manipulation. The access rights can be assigned to various personified users in the form of

user roles.

The configuration of the optical reader can be backed up and restored automatically, for

example, when there is a shift change, using a connected PC. This means the validation of

your production plant can be restored at the press of a button.

The optical reader has comprehensive diagnostics functions. If incorrect readings are made,

the diagnostics functions can be used to find reasons for the errors based on the recorded

images. This is necessary, for example, if problems occurred in the prior marking process.

SIMATIC MV500

22 Operating Instructions, 06/2018, C79000-G8976-C494-01

Description

Compatibility with MV400

SIMATIC MV400

SIMATIC MV500

Digital inputs

/outputs

4 configurable DI/DQs

2 DQs

RS232 interface

DISA bit (via)

RS232, CM, TCP/IP, PN, DI

RS232, CM, TCP/IP, PN

DHCP modes

WebAPI

(incompatible with MV400)

NOTICE

Compatibility restrictions

1.7 Functional description

The functions, communication protocols and configurations are largely compatible with the

devices of the SIMATIC MV400 series. The device configurations for these devices can be

imported into the readers of the SIMATIC MV500, enabling a seamless transition from

SIMATIC MV400 to MV500.

Note that after importing an MV400 device configuration, the program must be saved again.

Table 1- 1 Differences / possible incompatibilities

DI trigger, DQ strobe,

9.6 ... 115 KB

1 ◆ 1.5 ◆ 2 stop bits

Client and server Client

✓ ✓

DI trigger, DQ strobe,

9.6 ... 115 KB

1 ◆ 2 stop bits

(CONNECT button)

The MV400 "Resolution, half" function is no longer available on MV500 due to faster image

acquisition times.

Note that software release V1.0 does not support the following functions of MV400:

• Calibrated verification (Veri-Genius license),

• Vericode

• OCR (Text Genius) and

• Locator function (Pat genius)

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

23

Description

1.7 Functional description

SIMATIC MV500

24 Operating Instructions, 06/2018, C79000-G8976-C494-01

2

Qualified personnel

Proper use

Repairs

WARNING

Risk of injury/material damage

This device conforms to the pertinent safety regulations according to IEC, VDE and EN. If

you have questions about whether it is permissible to install the device in the planned

environment, please contact your service representative.

Startup and operation of the device/system in question must only be performed using this

documentation. Commissioning and operation of a device/system may only be performed by

qualified personnel. Qualified personnel as referred to in the safety guidelines in this

documentation are those who are authorized to start up, earth and label units, systems and

circuits in accordance with the relevant safety standards.

The unit may be used only for the applications described in the catalog or the technical

description, and only in combination with the equipment, components and devices of other

manufacturers where recommended or permitted by Siemens. This product can only function

correctly and safely if it is transported, stored, set up, and installed correctly, and operated

and maintained as recommended.

Repairs to the device may only be performed by authorized specialists.

Unauthorized opening or improperly performed repairs can cause considerable damage to

property or danger to users.

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

25

Safety notes

System expansions

NOTICE

Invalidation of the warranty

NOTICE

Voltage can destroy electrostatic-sensitive modules

Install only system expansions that are intended for this device. Installing other expansions

can damage the system or violate the safety provisions and regulations for radio interference

suppression. You can obtain information on system expansions suitable for installation from

the technical customer service or from the sales office responsible for your area.

Any damage to the device caused by installing or replacing system expansion products will

void the warranty.

The device contains modules that are sensitive to electrostatic discharge. ESD devices can

be destroyed by voltages well below the threshold of human perception. Such voltages

occur if you touch a component or electrical connectors of a module without first

discharging the static from your body. The damage caused by overvoltage on a module

cannot normally be detected immediately and only becomes apparent after a longer period

of operation.

Measures for protecting against discharge of static electricity:

• Before working with modules, make sure that you discharge static from your body, for

example by touching a grounded object.

• The devices and tools used must also be free of static charges.

• Interrupt the power supply.

• Pick up the modules only on their edges and do not touch any pins or printed

conductors.

SIMATIC MV500

26 Operating Instructions, 06/2018, C79000-G8976-C494-01

Safety notes

Connecting the 24 V DC power supply

WARNING

Requirement: Safe extra low voltage

24 V DC power supply (19.2 to 28.8 V)

Overvoltage protection

NOTICE

Protection of the external power supply

The device should only be connected to a 24 V DC power supply which satisfies the

requirements of safe extra low voltage (SELV).

When the device is operated on a wall, in an open rack or other similar locations, an NEC

Class 2 current source is needed for compliance with UL requirements (according to

UL 60950-1). In all other cases (according to IEC/EN/DlN EN 60950-1), a current source

with limited power (LPS = Limited Power Source) is required.

The generation of the 24 V DC supply voltage by the line-side power supply must be

implemented as functional extra-low voltage with safe electrical isolation (floating)

according to IEC 80364-4-41, or as SELV according to IEC/EN/DlN EN 60950-1 and

LPS/NEC class 2.

If the optical reader is supplied via extensive supply lines or networks, interference by

strong electromagnetic pulses on the supply lines is possible, e.g. from lightning or the

switching of large loads.

The connection of the external power supply is not protected against strong

electromagnetic pulses. An external overvoltage protection module is required for this

purpose. The requirements according to EN 61000-4-5, Surge test on power supply lines,

are only met when a suitable protective element is used. A suitable device would be, for

example, the Dehn Blitzductor BVT AVD 24, article number 918 422, or a comparable

protective element.

Manufacturer:

DEHN+SOEHNE GmbH+Co.KG, Hans-Dehn-Str.1, P.O. Box 1640, D-92306 Neumarkt,

Germany

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

27

Safety notes

Use in an area of plants with high-energy radiation

NOTICE

Protection of the image sensor from damaging radiation

When the SIMATIC MV500 optical reader is used in an environment of plants with highenergy radiation, for example, laser light or arcs, the image sensor of the optical reader

must be protected from damaging radiation.

The image sensor is protected by means of suitable daylight filters:

• Radiation outside the visible light spectrum (IR and UV radiation) is filtered out.

• Visible light can pass without problem.

SIMATIC MV500

28 Operating Instructions, 06/2018, C79000-G8976-C494-01

3

3.1

Code reading (1D/2D codes)

3.1.1

Area of application and examples

Two-dimensional codes

One-dimensional codes

The optical reader reads the types of code listed below.

● DMC

● PDF417

● QR

● DotCode

● Codabar

● Code 32

● Code 39 (without checksum)

● Code 39+CS (with checksum)

● Code 93

● Code 128

● EAN 8

● EAN 13

● GS1 Databar Expanded

● GS1 Databar Limited

● GS1 Databar Omnidirectional

● GS1 Databar Stacked

● Int. 2/5 (without checksum)

● Int. 2/5+CS (with checksum)

● Pharmacode

● Postnet

● UPC-A

● UPC-E

SIMATIC MV500

Operating Instructions, 06/2018, C79000-G8976-C494-01

29

Image processing

3.1.1.1

Applications for two-dimensional codes

Printed code

Laser code (plastic surface)

Laser code (pcb)

Code created with an ink jet printer.

Punched code

Data Matrix ECC080

3.1 Code reading (1D/2D codes)

Below, you can find several examples of data matrix codes, QR codes, PDF417 codes and

dot codes:

SIMATIC MV500

30 Operating Instructions, 06/2018, C79000-G8976-C494-01

Loading...

Loading...