Siemens Simatic MP 377 Operating Instructions Manual

SIMATIC HMI HMI device MP 377 15" Touch daylight readable (WinCC flexible)

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

Preface

Overview

1

Safety instructions and

approvals

2

Planning application

3

Mounting and connecting the

HMI device

4

Operator controls

5

Configuring the operating

system

6

Service and maintenance

7

Technical specifications

8

Appendix

A

Abbreviations

B

SIMATIC HMI

HMI device

MP 377 15" Touch daylight

readable (WinCC flexible)

Operating Instructions (Compact)

04/2009

A5E02532357-01

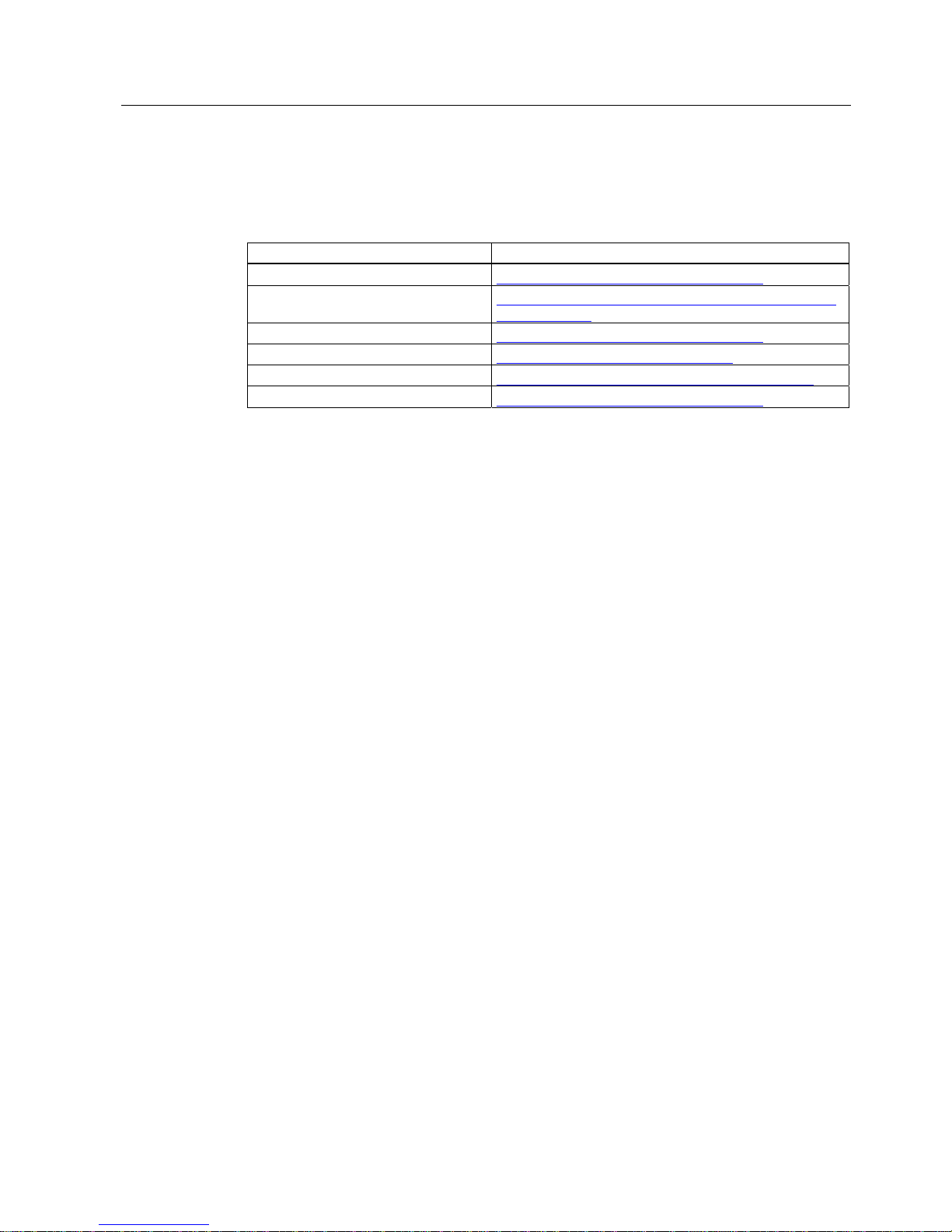

The following supplement is part of this documentation:

No. Designation Drawing number Edition

1 Product Information A5E02341631-03 06/2009

This Operating Instruction applies to

the HMI device with the

Order no. 6AV6644-8AB20-0AA0

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E02532357-01

Ⓟ 04/2009

Copyright © Siemens AG 2009.

Technical data subject to change

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

3

Preface

Purpose of this manual

This manual provides information based on the requirements defined by DIN 62079

regarding mechanical engineering documentation. This information relates to the place of

use, transport, storage, mounting, use and maintenance.

This manual is intended for:

● Installation personnel

● Operators

● Maintenance personnel

Read especially the information in the section "Safety instructions".

Required knowledge

General knowledge in the field of automation engineering is required to understand this

manual.

Scope of the manual

This manual applies to the "MP 377 15" Touch daylight readable" HMI device, order number

6AV6644-8AB20-0AA0.

Note

This manual is an amendment to the operating instructions "MP 377 (WinCC flexible)" and is

valid only in connection with the operating instructions "MP 377 (WinCC flexible)". This

manual includes the differences to the operating instructions "MP 377 (WinCC flexible)".

Preface

MP 377 15" Touch daylight readable (WinCC flexible)

4 Operating Instructions (Compact), 04/2009, A5E02532357-01

Style conventions

The following text notation will facilitate reading this manual:

Notation Scope

"Add screen"

• Terminology that appears in the user interface, for example

dialog names, tabs, buttons, menu commands

• Required input, for example, limits, tag values.

• Path information

"File > Edit" Operational sequences, for example, menu commands, shortcut

menu commands.

<F1>, <Alt+P> Keyboard operation

Please observe notes labeled as follows:

Note

A note contains important information about the product and its use or a specific section of

the manual to which you should pay particular attention.

Naming conventions

The following naming conventions apply:

Term This also applies to

Control cabinet

• Mounting cabinet

• Enclosure

• Console

• Switchboard

Plant

• Machining centers

• Machines

• Systems

Illustrations in this manual

This manual contains illustrations of the described devices. The illustrations may differ from

devices actually delivered.

Trademarks

The following designations marked with the symbol ® are registered trademarks of

Siemens AG:

● HMI

®

● SIMATIC

®

● WinCC

®

Preface

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

5

Additional information

You can find additional information about products described in the manual under "Contact"

in the following table:

Request Contact

Contact persons and office locations "http://www.siemens.com/automation/partner"

Additional technical documentation "http://www.automation.siemens.com/simatic/portal/html_7

6/techdoku.htm"

Training Center "http://sitrain.automation.siemens.com/sitrain"

Technical Support "http://support.automation.siemens.com"

Online support request form "http://www.siemens.com/automation/support-request"

Service "http://www.siemens.com/automation/service"

Recycling and disposal

The HMI devices described in these operating instructions can be recycled due to the low

levels of pollutants. Contact a certified disposal service company for environmentally sound

recycling and disposal of your old devices.

Used batteries and rechargeable batteries

Used batteries and lithium ion batteries are hazardous waste. Always dispose of used

batteries and lithium ion batteries in accordance with the regulations in effect. Identify the

transport packaging with a "Used batteries and accumulators" label.

Preface

MP 377 15" Touch daylight readable (WinCC flexible)

6 Operating Instructions (Compact), 04/2009, A5E02532357-01

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

7

Table of contents

Preface ...................................................................................................................................................... 3

1

Overview.................................................................................................................................................... 9

1.1

Product overview ...........................................................................................................................9

1.2

Design..........................................................................................................................................11

1.3

Scope of delivery .........................................................................................................................13

1.4

Service pack.................................................................................................................................13

2

Safety instructions and approvals............................................................................................................ 15

2.1

Validity..........................................................................................................................................15

2.2

Safety notes .................................................................................................................................15

2.3

Standards, certificates and approvals..........................................................................................16

2.4

Notes about Usage ......................................................................................................................19

2.5

Electro-Magnetic Compatibility ....................................................................................................22

3

Planning application................................................................................................................................. 25

3.1

General information .....................................................................................................................25

3.2

Mounting positions and type of fixation........................................................................................25

3.3

Preparation for mounting .............................................................................................................26

4

Mounting and connecting the HMI device................................................................................................ 29

4.1

Mounting the HMI device .............................................................................................................29

4.2

Connecting the HMI device..........................................................................................................31

4.2.1

Overview ......................................................................................................................................31

4.2.2

Connecting the Fan......................................................................................................................33

4.2.3

Connecting the power supply.......................................................................................................33

4.2.4

Switching on and testing the HMI device.....................................................................................35

5

Operator controls..................................................................................................................................... 37

5.1

Front operator controls.................................................................................................................37

5.2

Removing the memory card cover...............................................................................................38

6

Configuring the operating system ............................................................................................................ 39

6.1

Introduction ..................................................................................................................................39

6.2

Calibrating the touch screen ........................................................................................................39

6.3

Setting the display brightness......................................................................................................42

6.4

Setting the screen saver ..............................................................................................................46

6.5

Restarting the HMI device............................................................................................................48

Table of contents

MP 377 15" Touch daylight readable (WinCC flexible)

8 Operating Instructions (Compact), 04/2009, A5E02532357-01

7 Service and maintenance ........................................................................................................................ 51

7.1 Maintenance and Care................................................................................................................ 51

7.2

Repair.......................................................................................................................................... 52

8

Technical specifications........................................................................................................................... 53

8.1

Dimension drawing...................................................................................................................... 53

8.2

Technical Specifications.............................................................................................................. 54

8.3

Ambient conditions...................................................................................................................... 56

8.4

Transport and Storage Conditions .............................................................................................. 57

A

Appendix.................................................................................................................................................. 59

A.1

ESD guideline ............................................................................................................................. 59

A.2

Configure "SetBrightness" function............................................................................................. 61

A.2.1

Overview ..................................................................................................................................... 61

A.2.2

Add-on "SetBrightness"............................................................................................................... 62

B

Abbreviations........................................................................................................................................... 65

Glossary .................................................................................................................................................. 67

Index........................................................................................................................................................ 69

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

9

Overview

1

1.1 Product overview

The SIMATIC HMI device "MP 377 15" Touch daylight readable" offers a special display and

touch technology. This technology offers a brighter display that lets operators monitor and

operate even under very bright light conditions. Good readability is ensured even in direct

sunlight due to the transflective properties of the display. You can dim the backlighting of the

display on the display itself as well as externally and centrally via process value (tag), for

example by means of a potentiometer via the PLC. This means you can use the panel in

control cabins for drilling rigs and in control stations onboard ships.

You can operate the HMI device outdoors if it is installed in a suitable control cabinet. The

necessary, extended ambient temperature range during operation can be created with the

help of active heating and cooling in the control cabinet. We recommend that you consult an

experienced control cabinet designer for appropriate sizing. Intelligent control of heating and

cooling is available with the retrofit panel option "TEK - Temperature Extension Kit".

Certifications are in preparation for operation in the Oil&Gas industry as well as applications

in shipbuilding. These include ATEX Zone 2/22, Class I, Div. 2 as well as country-specific

shipbuilding certificates.

The display offers a large viewing angle that makes for fatigue-free operating and

monitoring. Mounted fans make it possible that you can install the HMI device vertically as

well as inclined in a control cabinet.

Overview

1.1 Product overview

MP 377 15" Touch daylight readable (WinCC flexible)

10 Operating Instructions (Compact), 04/2009, A5E02532357-01

Advantages of the MP 377 15" Touch daylight readable

● Device front is suitable for rough environmental conditions

– Front frame made of aluminum coated with impact-resistant paint

– Decorative foil with UV protection

– Hardened glass – Mohs 7

– High resistance against commercial cleaning agents and chemicals

– Certifications for potentially explosive atmospheres (in preparation)

– Certifications for control stations onboard ships (in preparation)

● Daylight readable display with LED backlighting

– High brightness, up to 560 cd/m²

– Energy-saving LED backlighting, dimming range from 0 to 100 %

– High contrast, up to 700 : 1

– Suitable for daylight applications

The transflective technology combines the advantages of reflective and transmissive

displays. The reflective properties of the display offer good readibility even in direct

sunlight. The transmissive component ensures good readibility even in dark

environments.

– High saturation and brightness as well as a large viewing angle of up to 160 degrees

● Sturdy touch surface for rough environmental conditions

– Surface of hardened glass – Mohs 7

– Excellent optical properties

– No drift, no recalibration required

– Can be operated even with gloves

– Touch operation even with dust, humidity, rain, snow, ice

Overview

1.2 Design

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

11

1.2 Design

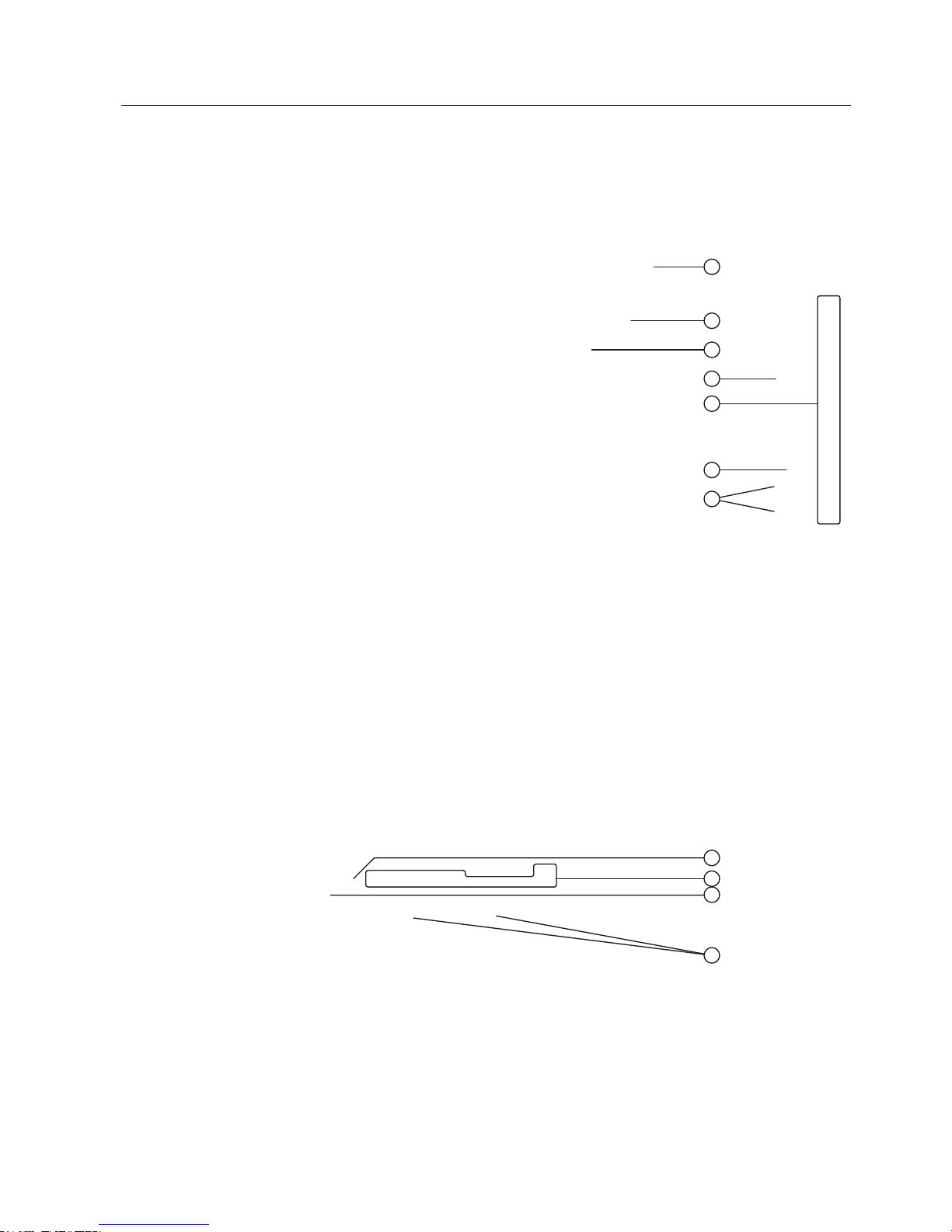

Front view and side view

① Housing frame

② Front membrane

③ Display/touch screen

④ Protection for memory cards

⑤ Oblong holes for mounting clamps/air vents

⑥ Fans

⑦ Fixing element for strain relief

The term "front operating panel" as used in this manual corresponds to the front view with

operating elements.

Bottom view

① Mains terminal for power supply of HMI device

② Interfaces

③ Mains terminal for power supply of fans

④ Fans

Overview

1.2 Design

MP 377 15" Touch daylight readable (WinCC flexible)

12 Operating Instructions (Compact), 04/2009, A5E02532357-01

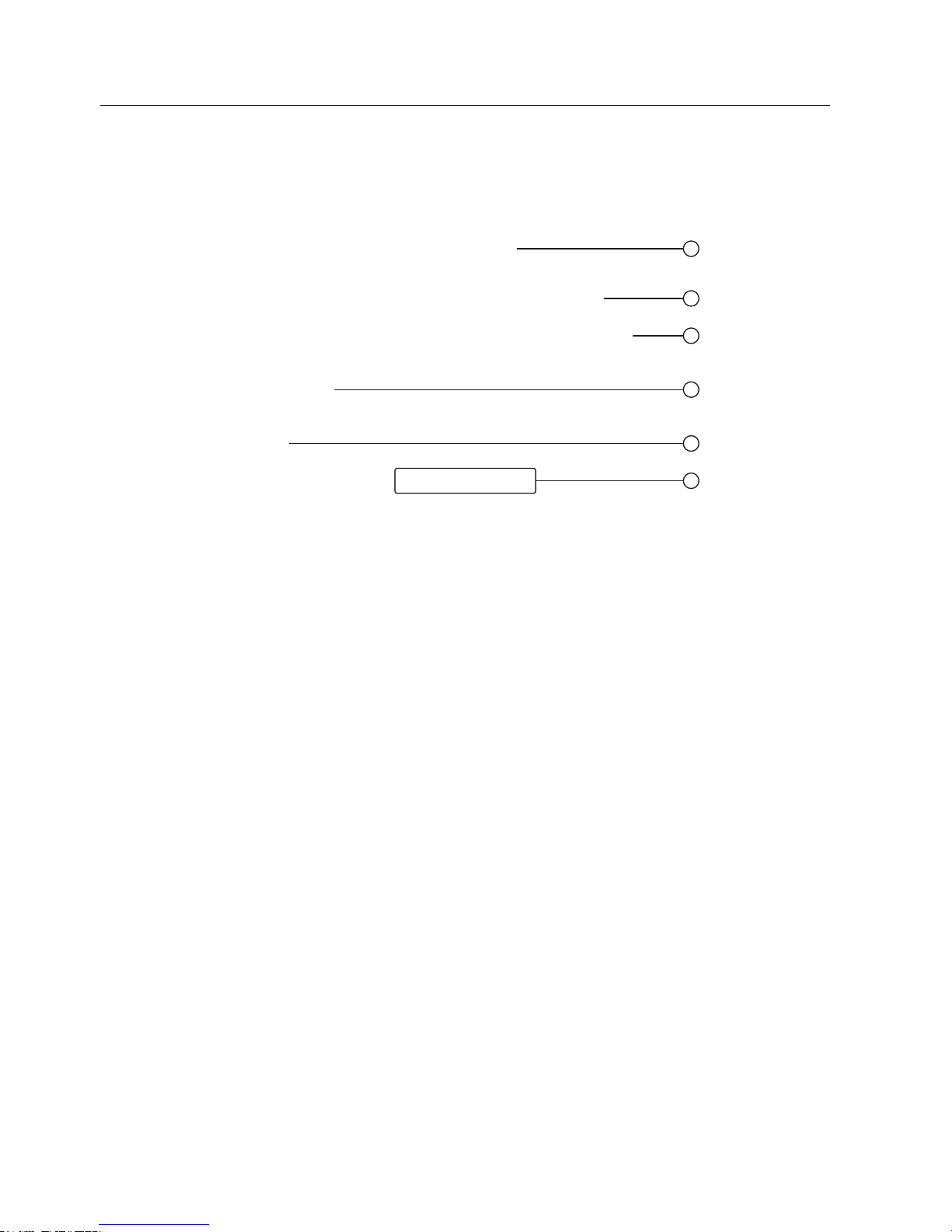

Rear view

① Rating plate

② Protection for memory cards

③ Mounting seal

④ DIP switch

⑤ Mains terminal for power supply of fans

⑥ Fixing elements for strain relief

Overview

1.3 Scope of delivery

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

13

1.3 Scope of delivery

The following components are included in the scope of delivery:

● An HMI device

● A CD with the following content:

– HMI device image for "MP 377 15" Daylight readable"

– Installation file "MP377 SetBrightness" for the add-on "SetBrightness" (.msi-Format)

– Readme file

● A pouch with the following content:

– Mounting clamps for mounting the HMI device

– One mains terminal for power supply of HMI device

– One mains terminal for power supply of fans

– One product information "Installing HMI device"

1.4 Service pack

A service pack is available for the MP 377 15" daylight readable.

The service pack includes the following components:

● A mounting seal

● A pouch with the following content:

– Mounting clamps for mounting the HMI device

– One mains terminal for power supply of HMI device

– One mains terminal for power supply of fans

– One product information "Installing HMI device"

The service pack can be ordered with the order number 6AV6675-4CA00-0AX0.

Overview

1.4 Service pack

MP 377 15" Touch daylight readable (WinCC flexible)

14 Operating Instructions (Compact), 04/2009, A5E02532357-01

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

15

Safety instructions and approvals

2

2.1 Validity

This manual includes important information on the operation of the MP 377 15" Touch

daylight readable in potentially explosive atmospheres of zones 2 and 22.

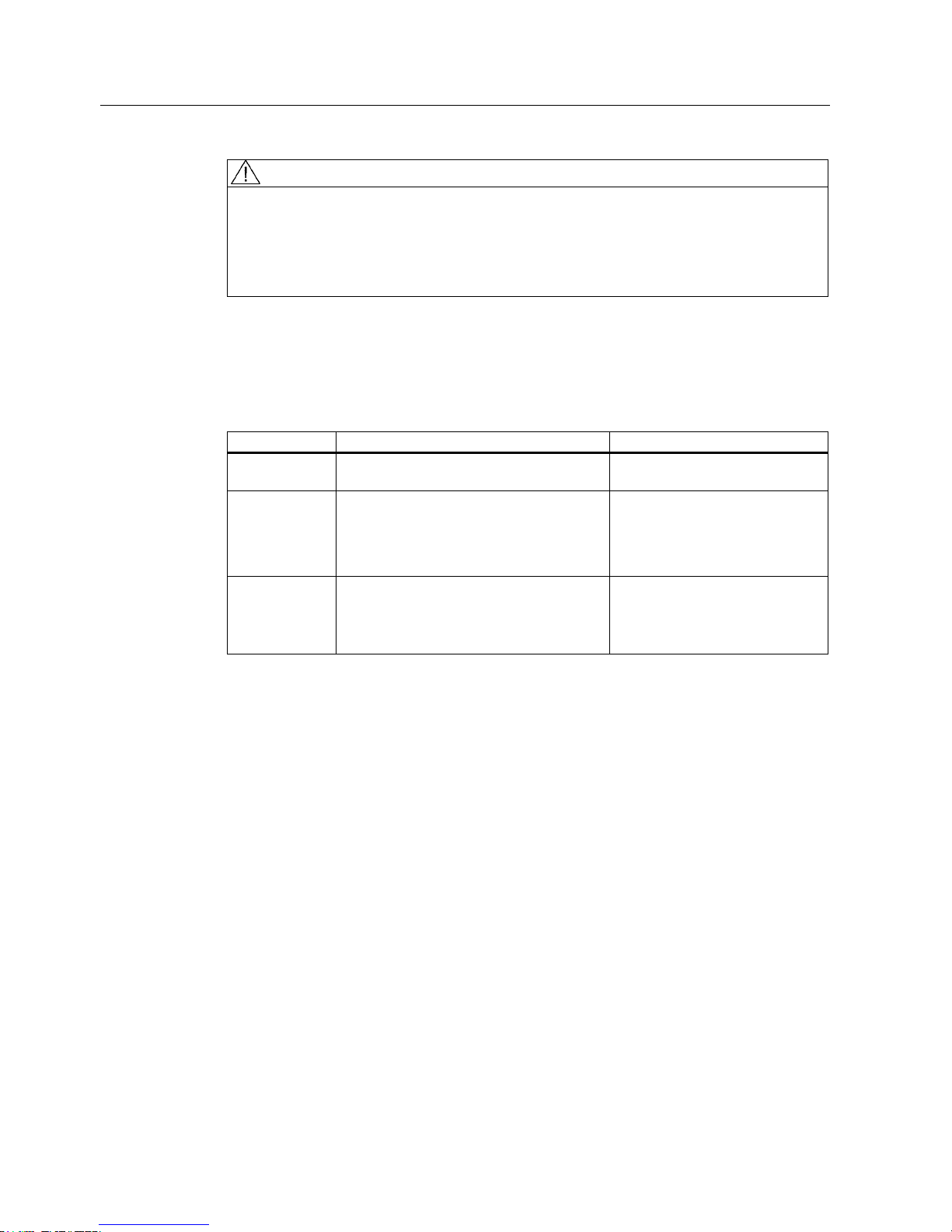

WARNING

Read all sections of this manual. Please observe all safety guidelines contained within the

sections. These safety instructions apply to all HMI devices that have an "Ex protection"

identifier on their type plates.

2.2 Safety notes

Working on the control cabinet

WARNING

Open Equipment

The HMI device is an open equipment. This means that the HMI device may only be

installed in a control cabinet, whereby the device can be operated from the front panel.

Access to the control cabinet in which the HMI device is installed should only be possible

by means of a key or tool and only for trained and authorized personnel.

Dangerous Voltage

Opening the control cabinet will expose high voltage parts. Contact with these parts could

be fatal.

Switch off the power supply to the cabinet before opening it.

High frequency radiation

NOTICE

Unintentional operating situations

High frequency radiation, e g. from a cellular phone, can cause unintentional operating

situations.

Safety instructions and approvals

2.3 Standards, certificates and approvals

MP 377 15" Touch daylight readable (WinCC flexible)

16 Operating Instructions (Compact), 04/2009, A5E02532357-01

Intended purpose

WARNING

Commissioning of the HMI device is forbidden until it has been absolutely ensured that the

machine in which the HMI device is to be installed complies with Directive 98/37/EC or

Directive 2006/42/EG as of 29 December 2009.

2.3 Standards, certificates and approvals

Note

The following overview shows possible approvals. The HMI device itself is certified as shown

on the label on its rear panel.

Ex approval

For the HMI device

● EN 60079-0

● EN 60079-15

● EN 61241-0

● EN 61241-1

the following approvals are in place:

II 3 G Ex nA II Tx

II 3 D Ex tD A22 IP6X T xx °C

x ... Temperature values, see design examination certificate

The design examination certificate is available at the following Internet address:

"

http://support.automation.siemens.com"

CE approval

The HMI device meets the general and safety-related requirements of the following EC

directives and conforms to the harmonized European standards (EN) for programmable logic

controllers published in the official gazettes of the European Union:

● 2004/108/EC "Electromagnetic Compatibility Directive" (EMC Directive)

● 2006/95/EC "Electrical Equipment Designed for Use within Certain Voltage Limits" (LowVoltage Directive)

● 94/9/EU "Devices and protection systems for use in potentially explosive areas"

(Guidelines for Explosion Protection)

Safety instructions and approvals

2.3 Standards, certificates and approvals

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

17

EC Declaration of Conformity

The EC Declarations of Conformity are available to the relevant authorities at the following

address:

Siemens AG

Industry Sector

I IA AS R&D ST

PO Box 1963

92209 Amberg

Germany

UL approval

Underwriters Laboratories Inc., to

● UL 508 (Industrial Control Equipment)

● CSA C22.2 No. 142 (Process Control Equipment)

or

Underwriters Laboratories Inc., to

● UL 508 (Industrial Control Equipment)

● CSA C22.2 No. 142 (Process Control Equipment)

● UL 1604 (Hazardous Location)

● CSA-213 (Hazardous Location)

Approved for use in

● Class I, Division 2, Group A, B, C, D Tx

● Class I, Zone 2, Group IIC Tx or

● non-hazardous locations

FM approval

Factory Mutual Research (FM) conforming to

● Approval Standard Class Number 3611, 3600, 3810

Approved for use in

● Class I, Division 2, Group A, B, C, D Tx

● Class I, Zone 2, Group IIC Tx

Safety instructions and approvals

2.3 Standards, certificates and approvals

MP 377 15" Touch daylight readable (WinCC flexible)

18 Operating Instructions (Compact), 04/2009, A5E02532357-01

Tick mark for Australia

The HMI device fulfills the requirements of standard AS/NZS 2064 (Class A).

IEC 61131

The HMI device meets the requirements and criteria conforming to IEC 61131-2,

Programmable Logic Controllers, Part 2, equipment requirements and testing.

Requesting certificates

Copies of the certificates and reports can be requested from the following address:

Siemens AG

Industry Sector

I IA AS R&D ST

PO Box 1963

92209 Amberg

Germany

Certificates are also available at the following Internet address:

"

http://support.automation.siemens.com"

Select "Product Support".

Safety instructions and approvals

2.4 Notes about Usage

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

19

2.4 Notes about Usage

Operation in industrial environments

The HMI device is designed for industrial use, limit class A. The following standards are met:

● Requirements for emissions EN 61000-6-4: 2007

● Requirements for interference immunity DIN EN 61000-6-2: 2005

Note

Operation in residential areas

The HMI device is not suitable for operation in residential areas: Operation of an HMI

device in residential areas can have a negative impact on radio and TV reception.

If the HMI device is used in a residential area, you must take measures to achieve Limit

Class B conforming to EN 55011 for RF interference.

Suitable measures for achieving the required RF interference level for Limit Class B include

for example:

● Installation of the HMI device in a grounded control cabinet

● Use of filters in electrical supply lines

Individual acceptance is required.

Operation in potentially explosive atmosphere, zone 2 and 22

DANGER

Degree of hazard

There is an explosion hazard when operating an HMI device that does not have explosion

protection.

Operate the HMI device in potentially explosive zones 2 and 22 only if it has been approved

and certified for such environments.

If an HMI device is operated in potentially explosive atmospheres of zone 22, pay attention

to the product information "Use in potentially explosive atmospheres of zones 2 and 22." The

product information is available at the following Internet address:

"

http://support.automation.siemens.com/WW/view/en/291285"

Safety instructions and approvals

2.4 Notes about Usage

MP 377 15" Touch daylight readable (WinCC flexible)

20 Operating Instructions (Compact), 04/2009, A5E02532357-01

WARNING

Personal injury and damage to property

Personal injury and property damage can occur in potentially explosive atmospheres if an

electric plug is disconnected from the HMI device while the system is in operation.

In potentially explosive atmospheres, always turn off power to the HMI device before

disconnecting any connectors.

Potentially explosive atmosphere zones 2 and 22

Areas subject to explosion hazard are divided into zones. The zones are differentiated

according to the probability of the existence of an explosive atmosphere.

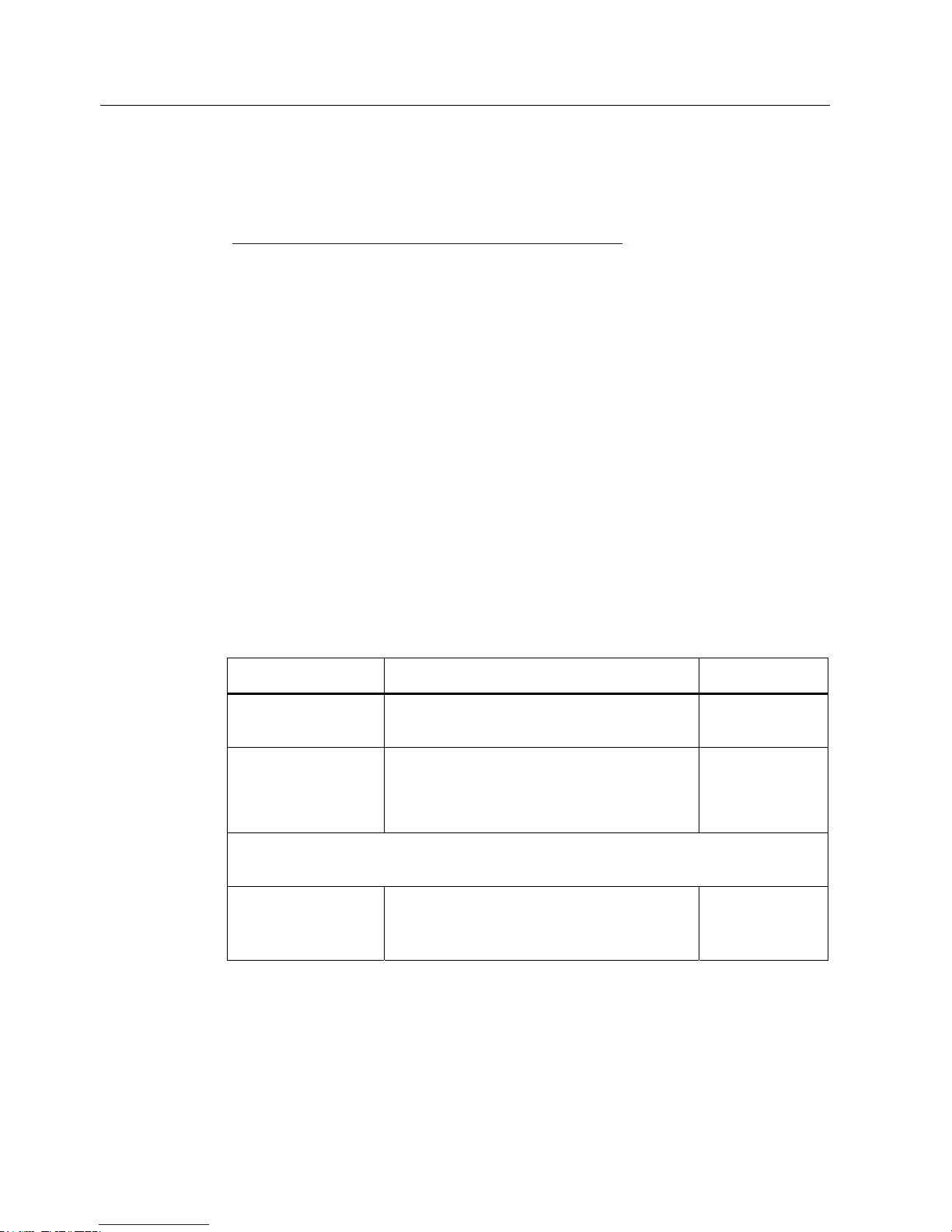

Zone Degree of hazard Example

2 Explosive gaseous atmosphere occurs only

seldom and for a short period

Areas around flanged pipe joints

with flat gaskets in closed rooms

22 Area in which a potentially explosive

atmosphere in the form of a cloud in the air

containing flammable dust does not usually

occur or occurs only briefly during normal

operation .

–

Safe zone No

• Outside zone 2

• Outside zone 22

• Standard applications of

distributed I/Os

Safety instructions and approvals

2.4 Notes about Usage

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

21

Operating conditions for Zones 2 and 22

The following operating conditions apply for Zones 2 and 22:

● The HMI device must be installed in a control cabinet. The control cabinet must meet the

following in accordance with EN 60529:

– Protection type IP54 or higher for Zone 2

– Protection type IP5x or higher for Zone 22 in case of non conductive dust

– Protection type IP6x or higher for Zone 22 in case of conductive dust

You must install the HMI device so that you provide at least protection type IP54 or IP5x

to EN 60529 on the front of the device. Consult the operating instructions of control

cabinet and HMI device for this purpose.

Make allowances for the operating and ambient conditions under which you operate the

HMI device. A manufacturer's declaration must be provided for the control cabinet in

accordance with EC Directive 94/9, stating it is fit for purpose.

● The ambient temperature range is 0 °C ≤ T ≤ 50 °C. Under these conditions, the HMI

device will satisfy temperature class Tx for category 3G and support a maximum surface

temperature of xx °C for category 3D. (x ... Temperature value, see design examination

certificate).

Refer to the operating instructions for details of limitations resulting from the ambient

temperature range.

● In situations where the temperature on the cable at the cable inlet of the control cabinet

exceeds a temperature of 70 °C, or where the temperature on the wire branching point

exceeds 80 °C under operating conditions, the temperature specifications of the cables

must match the actually measured temperatures.

● Put measures in place to ensure the rated voltage is not exceeded.

Any transient interference voltages above the rated value must not exceed 40 %.

● Protect the HMI device from mechanical loads > 7 J and the display from mechanical

loads > 4 J.

● Ensure that the atmosphere is not explosive during servicing.

Measures that impair or remove the protection type of the HMI device are not permitted

while the system is in operation.

● If the HMI device was dismantled, check the mounting seal for damage before

reassembling the HMI device. A damaged, porous or used mounting seal no longer

meets the requirements of the protection type. In this case, the mounting seal must be

replaced.

● Turn off the HMI dev

ice and the entire electrical installation in the control cabinet, if the

film on the front of the HMI device or the glass of the display on the HMI device are

damaged by a tear or hole or if the front film starts to peel off.

Exchange the HMI device. Restart the system again after the device has been

exchanged.

Safety instructions and approvals

2.5 Electro-Magnetic Compatibility

MP 377 15" Touch daylight readable (WinCC flexible)

22 Operating Instructions (Compact), 04/2009, A5E02532357-01

Approved HMI device

The HMI devices with approval for operation in potentially explosive atmospheres are listed

at the following Internet address:

"

http://support.automation.siemens.

com/WW/view/en/291285"

2.5 Electro-Magnetic Compatibility

Introduction

The HMI device fulfils, among other things, the requirements of the EMC laws pertaining to

the European domestic market.

EMC-compliant Mounting of the HMI Device

EMC-compliant mounting of the HMI device and the use of interference-proof cables will

ensure trouble-free operation. The "Directives for interference-free installation of PLCs" and

the "PROFIBUS Networks" manual also apply for the installation of the HMI device.

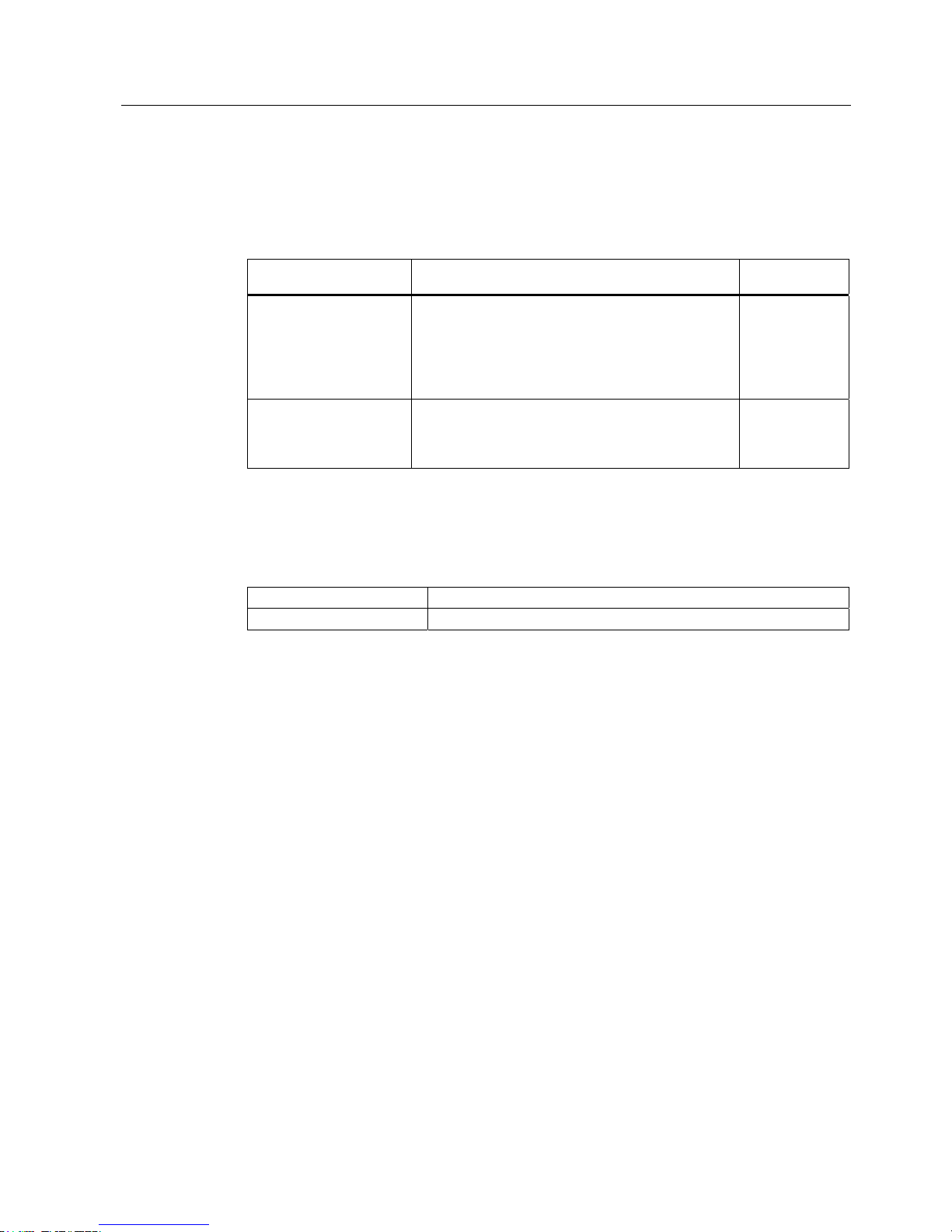

Pulse-shaped Interference

The table below shows the electromagnetic compatibility of modules in relation to pulseshaped interference. This requires the HMI device to meet the specifications and directives

for electrical installation.

Pulse-shaped

interference

Tested with Corresponds to

severity

Electrostatic discharge

in accordance with

IEC 61000-4-2

Air discharge: 8 kV

Contact discharge: 6 kV

3

Burst pulses

(high-speed transient

interference)

conforming to

IEC 61000-4-4

2 kV power supply cable

2 kV signal cable, > 30 m

1 kV signal cable, < 30 m

3

High-power surge pulses conforming to IEC 61000-4-5, external protective circuit required (refer to

the manual, Programmable Controller S7-300, Installation, chapter “Lightning and Overvoltage

Protection”).

Asymmetric coupling 2 kV power cable

DC voltage with protective elements

2 kV signal/data cable, > 30 m,

with protective elements as required

3

Safety instructions and approvals

2.5 Electro-Magnetic Compatibility

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

23

Sinusoidal disturbance

The table below shows the EMC properties of the modules with respect to sinusoidal

interference. This requires the HMI device to meet the specifications and directives for

electrical installation.

Sinusoidal interference Test values Corresponds to

severity

HF radiation

(electromagnetic fields)

according to IEC 610004-3

• 80% amplitude modulation at 1 kHz

with 10 V/m in the range of 80 MHz to 1 GHz

with 3 V/m in the range 1.4 GHz to 2 GHz

with 1 V/m the range 2 GHz to 2.7 GHz

• 10 V/m with 50 % pulse modulation at 900 MHz

10 V/m with 50 % pulse modulation at 1.89 GHz

3

HF interference current

on cables and cable

shielding conforming to

IEC 61000-4-6

Test voltage 10 V at 80% amplitude modulation of

1 kHz in the range from 9 kHz to 80 MHz

3

Emission of radio interference

Emission from electromagnetic fields according to EN 55011, limit value Class A, Group 1,

measured at a distance of 10 m:

30 to 230 MHz < 40 dB (μV/m) quasi-peak

230 to 1 000 MHz < 47 dB (μV/m) quasi-peak

Safety instructions and approvals

2.5 Electro-Magnetic Compatibility

MP 377 15" Touch daylight readable (WinCC flexible)

24 Operating Instructions (Compact), 04/2009, A5E02532357-01

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

25

Planning application

3

3.1 General information

Proper transport and storage, installation and assembly as well as careful operation and

maintenance are required to ensure trouble-free and safe operation of the HMI device.

The warranty for the HMI device will be deemed void if these stipulations are not heeded.

3.2 Mounting positions and type of fixation

Permitted mounting positions

The HMI device is designed for mounting in stationary cabinets, for example for mobile

drilling rigs and ships.

The HMI device is approved for horizontal mounting. The HMI device can be installed as

follows:

● Vertical

● Inclined at an angle between 0° and 90°

● Horizontal

Temperature Extension Kit

The "Temperature Extension Kit" lets you use the HMI device relatively independent of the

actual ambient conditions. You accomplish this feat because the "Temperature Extension

Kit" creates an environment in the cabinet that is within the limits permitted for operation of

the MP 377 15" Touch daylight readable.

If you are going to equip the HMI device with the "Temperature Extension Kit" option, you

need to select a cabinet of the appropriate size. Make allowances for the fact that the

thermal conductivity of control cabinets made of stainless steel is not as good as that of an

aluminum cabinet, for example.

You will find additional information in the "Temperature Extension Kit" operating instructions.

Planning application

3.3 Preparation for mounting

MP 377 15" Touch daylight readable (WinCC flexible)

26 Operating Instructions (Compact), 04/2009, A5E02532357-01

3.3 Preparation for mounting

Selecting the mounting location for the HMI device

Points to observe when selecting the mounting location:

● Position the HMI device so that it is not subjected to direct sunlight.

The display was designed for operation in direct sunlight.

● Position the HMI device such that it is ergonomically accessible for the user.

Choose a suitable mounting height and mounting angle.

● Make sure that you do not cover the fan and the air vents of the HMI device during

installation.

Ensuring degree of protection

The degree of protection according to the information in the chapter "Technical

Specifications (Page 54)" can only be ensured if the HMI dev

ice is installed with the supplied

mounting clamps. Additional fastening bore holes or threaded bolts are not required for the

mounting cutout.

The front material has to consist of sheet steel or material of a strength that corresponds to

at least the stability of sheet steel.

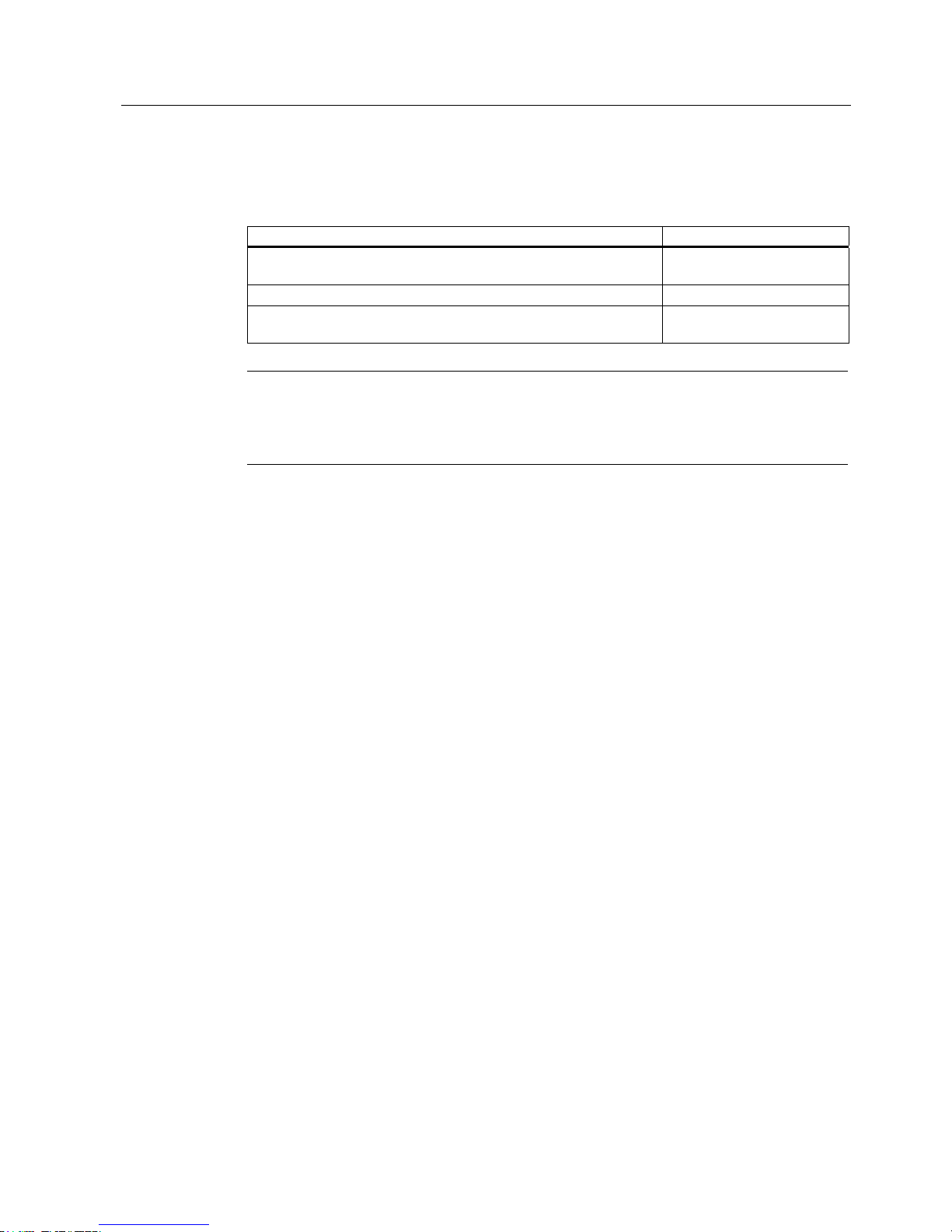

Mounting cutout

The following conditions apply to the mounting cutout:

Mounting cutout Dimensions

Material thickness with IP66 degree of protection 1.5 to 5 mm

Material thickness with enclosure type 4X/type 12 (indoor use only) 3 to 5 mm

Permitted deviation from plane

This condition must be fulfilled for the mounted HMI device.

≤ 0.5 mm

Permitted surface roughness in the area of the mounting seal ≤ 120 µm (Rz 120)

The following table shows the dimensions of the mounting cutout:

Dimensions HMI device

Width 367+1 mm

Height 289+1 mm

Depth 105.5 mm

Planning application

3.3 Preparation for mounting

MP 377 15" Touch daylight readable (WinCC flexible)

Operating Instructions (Compact), 04/2009, A5E02532357-01

27

Maintaining clearances

The HMI device must be installed with the following clearances:

Where Clearance

Observe a clearance above and below the mounting cutout for

ventilation of

50 mm

Right and left of the mounting cut-out for the mounting clamps 18 mm

At the rear in addition to the mounting depth of the HMI device at

least

≥ 10 mm

Note

Ensure that the maximum ambient temperature is not exceeded when mounting the device

in a control cabinet.

You can install the option "TEK – Temperature Extension Kit", if necessary.

Loading...

Loading...