Siemens SIMATIC TP 270, SIMATIC OP 270, SIMATIC MP 270B Operating Instructions Manual

Preface

Overview

1

SIMATIC HMI

HMI device

TP 270, OP 270, MP 270B

(WinCC flexible)

Operating Instructions

Safety notes and general

information

Plan deployment

Installation and connection

Operating elements and

indicators

Operating system and

configuration

Prepare and backup project

Runtime functionalities of a

project

2

3

4

5

6

7

8

Order number 6AV6691-1DD01-0AB0

Operate project

Operating recipes

Maintenance/Service

Technical data

Appendix

Abbreviations

Glossary

9

10

11

12

A

B

C

Edition 03/2004

A5E00280664-01

이 기기는 업무용(A급) 전자파 적합기기로서 판매자 또는 사용자는 이 점을 주의하시기 바라며 가정 외의 지역에서 사용하는 것을 목적으로 합니다.

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety as well as to avoid

property damage. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring to property damage only have no safety alert symbol.

Danger

indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Warning

indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Caution

used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Caution

used without safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

Notice

used without the safety alert symbol indicates a potential situation which, if not avoided, may result in

an undesirable result or state.

When several danger levels apply, the notices of the highest level (lower number) are always displayed. If a

notice refers to personal damages with the safety alert symbol, then another notice may be added warning of

property damage.

Qualified Personnel

The device/system may only be set up and operated in conjunction with this documentation. Only qualified

personnel should be allowed to install and work on the equipment. Qualified persons are defined as persons who

are authorized to commission, to earth, and to tag circuits, equipment and systems in accordance with

established safety practices and standards.

Intended Use

Please note the following:

Warning

This device and its components may only be used for the applications described in the catalog or

technical description, and only in connection with devices or components from other manufacturers

approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up and installed

correctly, and operated and maintained as recommended.

Trademarks

All designations marked with ® are registered trademarks of Siemens AG. Other designations in this

documentation might be trademarks which, if used by third parties for their purposes, might infringe upon the

rights of the proprietors.

Copyright Siemens AG, 2004. All rights reserved

Reproduction, transmission or use of this document or its contents is not permitted without

express written authority. Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design, are reserved.

Siemens AG

Automation and Drives Group

P.O. Box 4848, D-90327 Nuremberg (Germany)

Siemens Aktiengesellschaft 6AV6691-1DD01-0AB0

Disclaimer of Liability

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in the manual are reviewed regularly, and any

necessary corrections will be included in subsequent editions. Suggestions for

improvement are welcomed.

© Siemens AG 2004

Technical data subject to change

Preface

Purpose of the manual

This manual provides the required information and documentation for machine construction

in compliance with DIN 8418. The information contained relates to the device, its installation

site, transport, storage, use and maintenance.

The manual is aimed at the following target groups:

• Users

• Commissioners

• Service technicians

• Maintenance engineers

Read carefully the Chapter "Safety and General Information".

The help integrated in WinCC flexible, namely the WinCC flexible Information System,

contains further information. The Information System provides instructions, examples and

references in electronic form.

Basic knowledge required

A general knowledge of automation technology and process communication is necessary in

order to understand the manual.

It is assumed users have good basic knowledge in the use of personal computers and MS

Windows operating systems.

Manual application

The manual applies to the SIMATIC MP 270B, OP 270 and TP 270 in connection with the

WinCC flexible 2004 software packet.

Modifications compared to previous release 12/2001

The manual describes the use of the HMI devices together with WinCC flexible 2004. For

implementation with WinCC flexible 2004, the MP 270B 6" device model is also available.

The previous version, 12/2001, can still be used on the HMI device with ProTool.

Position in the information scheme

This manual is part of the SIMATIC HMI documentation. The information below presents an

overview of the information scheme of SIMATIC HMI.

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

i

Preface

User manual

• WinCC flexible Micro:

– Describes basic configuration principles using the WinCC flexible Micro Engineering

System

• WinCC flexible Compact/Standard/Advanced:

– Describes basic configuration principles using the WinCC flexible Compact

Engineering System/WinCC flexible Standard/WinCC flexible Advanced

• WinCC flexible Runtime:

– Describes commissioning and operating the runtime project on a PC.

• WinCC flexible Migration:

– Describes how to convert an existing ProTool project to WinCC flexible.

– Describes how to convert an existing WinCC project to WinCC flexible.

– Describes the conversion of ProTool projects together with changing the HMI device

from OP7 to OP 77B.

– Describes the conversion of ProTool projects together with changing the graphic HMI

devices to Windows CE devices.

• Communication

– Communication Part 1 describes the connection of the HMI device to SIMATIC PLCs.

– Communication Part 2 describes the connection of the HMI device to third-party PLCs.

Operating instructions

• Operating instructions for HMI devices SIMATIC OP 77B,

TP 170micro/TP 170A/TP 170B/OP 170B, SIMATIC Mobile Panel 170, SIMATIC

TP 270/OP 270/MP 270B, SIMATIC MP 370.

• Quick reference manuals for the SIMATIC OP 77B and SIMATIC Mobile Panel 170 HMI

devices.

Getting started

• WinCC flexible for beginners:

– Provides step-by-step instructions on the principles of configuring screens, alarms,

recipes and screen navigation using an project example.

• WinCC flexible for advanced users:

– Provides step-by-step instructions on the principles of configuring logs, project reports,

scripts, user administration, multilingual projects and integration in STEP 7 using an

project example.

• WinCC flexible Options:

– Provides step-by-step instructions on the principles of configuring the options

WinCC flexible Sm@rtServices, Sm@rtAccess and OPC-Server using an project

example.

TP 270, OP 270, MP 270B (WinCC flexible)

ii Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Preface

Online availability

The following links provide direct access to technical documentation on SIMATIC products

and systems in English, German, French, Italian and Spanish:

• SIMATIC Guide Technical Documentation in German:

http://www.ad.siemens.de/simatic/portal/html_00/techdoku.htm

• SIMATIC Guide for Technical Documentation in English:

http://www.ad.siemens.de/simatic/portal/html_76/techdoku.htm

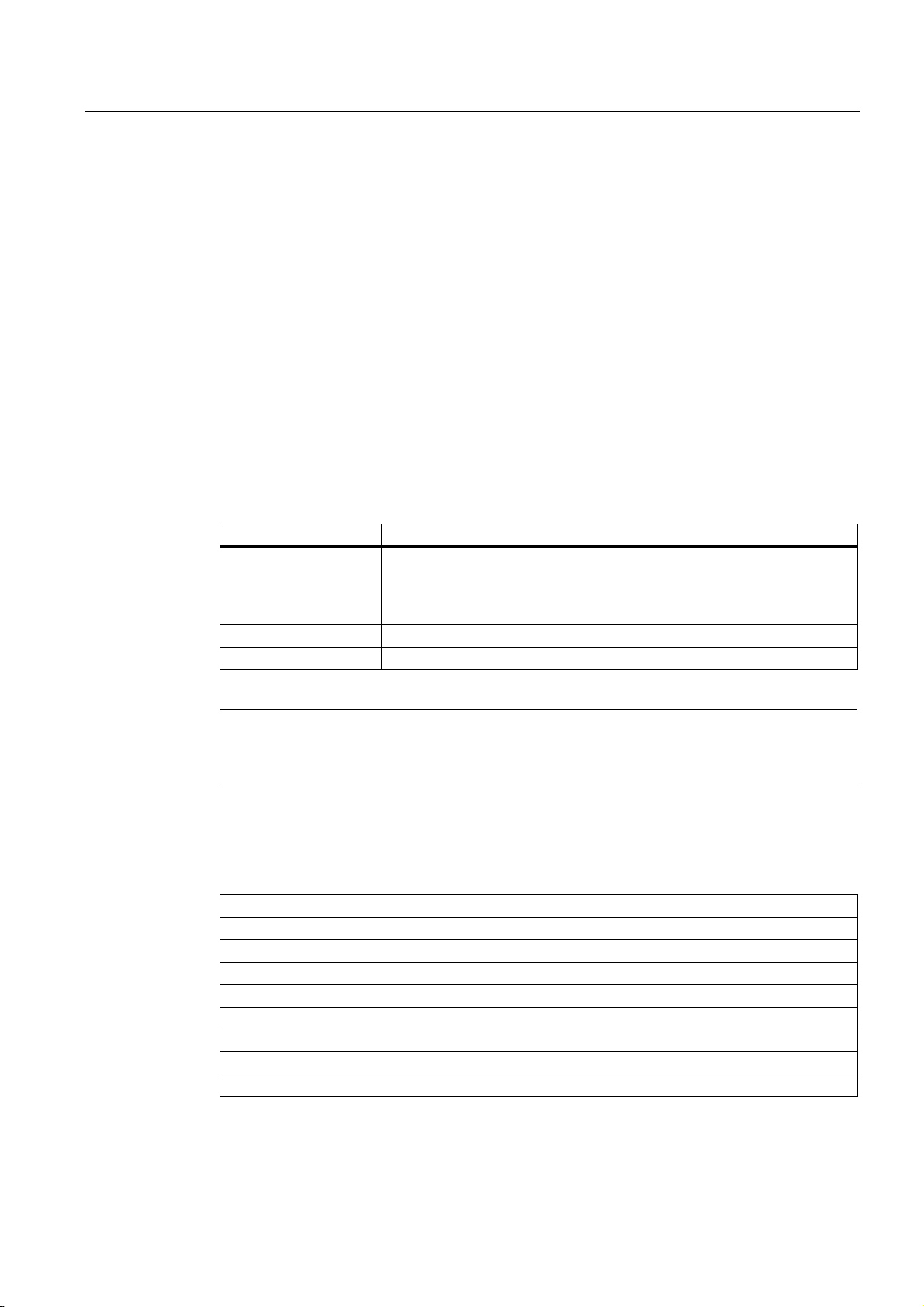

Conventions

A distinction has been made in the naming of the configuration and runtime software:

• "WinCC flexible" refers to the configuration software.

• "Runtime" refers to the runtime software capable of running on the HMI devices.

Generally, the term "WinCC flexible" is used. The version identification, e.g.

"WinCC flexible 2004", is always used when it is necessary to make a version distinction.

The following text highlights are intended to simplify reading the manual:

Display method Application

"Add screens"

"File > Edit" Operation sequences, e.g. menu commands, pop-up menu commands.

<F1>, <Alt+P> Keyboard input

• Terms which appear on the user interface, e.g. dialog names, tabs,

buttons, menu commands.

• Required input, e.g. limit vales, tag values.

• Path information

Trademarks

Also observe the information identified as follows:

Note

Notes contain important information about the product or operation of the product. Notes

also refer to areas within the documentation which require special attention.

All names identified by ® are registered trademarks of the Siemens AG.

HMI®

SIMATIC®

SIMATIC HMI®

SIMATIC ProTool®

SIMATIC WinCC®

SIMATIC WinCC flexible®

SIMATIC MP 270B®

SIMATIC OP 270®

SIMATIC TP 270®

The remaining trademarks in this publication may be trademarks whose use by third parties

for their own purposes could violate the rights of the owner.

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

iii

Preface

Representatives and agents

If you have any further queries regarding products described in the manual, please contact

the Siemens representatives or agents responsible for your area.

Contact partners can be located under:

http://www.siemens.com/automation/partner

Training center

We offer relevant courses to simplify your introduction to the world of automation systems.

Please contact your regional training center or our central training center in D 90327

Nuernberg, Germany for details.

Phone: +49 (911) 895-3200.

Internet: http://www.sitrain.com

Service & Support on the Internet

Service & Support provides comprehensive, additional information on SIMATIC products

through online services at "http://www.siemens.com/automation/service&support":

• The Newsletter, containing the latest information on your products.

• Numerous documents are available by searching through Service & Support.

• A forum, in which users and specialists can exchange experiences.

• The latest product information, FAQs and downloads.

• Contact partners for Automation & Drives are listed in the contact partner database.

• Information on on-site services, repairs, spare parts and much more under the term

"Services".

TP 270, OP 270, MP 270B (WinCC flexible)

iv Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

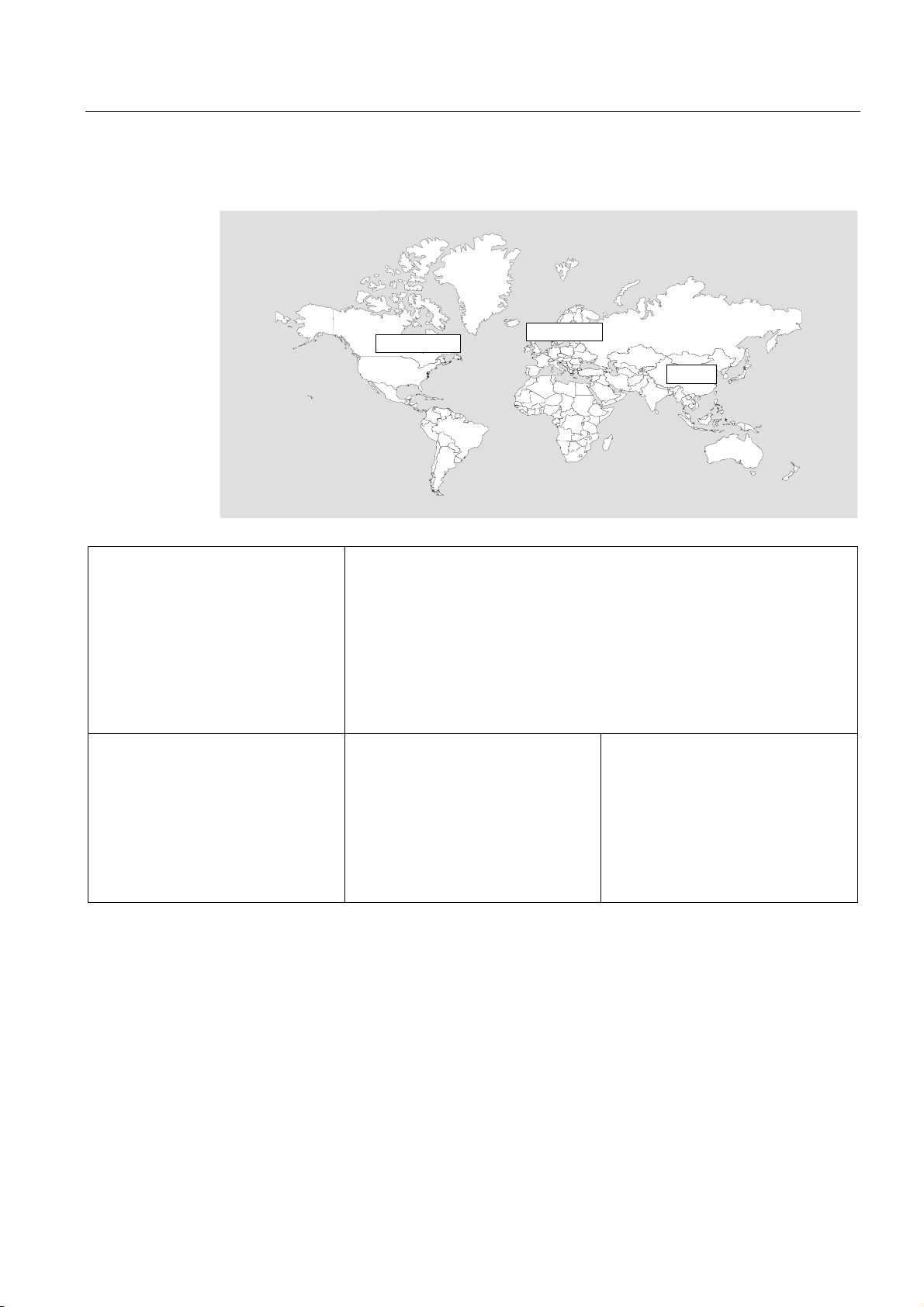

Preface

A&D Technical Support

Available round the clock, worldwide:

Worldwide (Nuremberg)

Technical Support

(Free Contact)

Local time: Mon.-Fri. 7:00 to 17:00.

Phone: +49 (0) 180 5050-222

Fax: +49 (0) 180 5050-223

E-mail: adsupport@siemens.com

GMT: +1:00

Europe/Africa (Nuremberg)

Authorization

Local time: Mon.-Fri. 7:00 to 17:00.

Phone: +49 (911) 895-7200

Fax: +49 (911) 895-7201

E-mail:

adauthorisierung@siemens.com

GMT: +1:00

Johnson City

Worldwide (Nuremberg)

Technical Support

(fee-based, only with SIMATIC Card)

Local time: 0:00 to 24:00, 365 days a year

Phone: +49 (911) 895-7777

Fax: +49 (911) 895-7001

GMT: +1:00

United States (Johnson City)

Technical Support and Authorization

Local time: Mon.-Fri. 8:00 to 19:00.

Phone: +1 423 461-2522

Fax: +1 423 461-2289

E-mail:

simatic.hotline@sea.siemens.com

GMT: -5:00

Nuremberg

SIMATIC Hotline

Beijing

Asia/Australia (Beijing)

Technical Support and Authorization

Local time: Mon.-Fri. 08:30 to 5:30 pm.

Phone: +86 10 64 75 75 75

Fax: +86 10 64 74 74 74

E-mail:

adsupport.asia@siemens.com

GMT: +8:00

Information is available in English and German.

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

v

Preface

TP 270, OP 270, MP 270B (WinCC flexible)

vi Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Table of contents

Preface ........................................................................................................................................................i

1 Overview................................................................................................................................................. 1-1

1.1 Introduction ................................................................................................................................ 1-1

1.2 Field of Application..................................................................................................................... 1-2

1.3 Configuring with WinCC flexible................................................................................................. 1-3

1.4 Features..................................................................................................................................... 1-4

1.5 Functional scope........................................................................................................................ 1-7

1.6 Communication with PLCs....................................................................................................... 1-11

1.7 Options..................................................................................................................................... 1-12

1.7.1 Hardware options..................................................................................................................... 1-12

1.7.1.1 Backup battery ......................................................................................................................... 1-12

1.7.1.2 PC card / CF card .................................................................................................................... 1-14

1.7.2 Software options ...................................................................................................................... 1-16

1.7.2.1 Internet Explorer ...................................................................................................................... 1-16

2 Safety notes and general information ..................................................................................................... 2-1

2.1 Safety notes ............................................................................................................................... 2-1

2.2 General information ................................................................................................................... 2-1

3 Plan deployment..................................................................................................................................... 3-1

3.1 Transport.................................................................................................................................... 3-1

3.2 Installation notes ........................................................................................................................ 3-2

3.3 Installation locations and type of protection...............................................................................3-3

3.4 Producing the installation cut-out............................................................................................... 3-4

4 Installation and connection ..................................................................................................................... 4-1

4.1 Check shipment ......................................................................................................................... 4-1

4.2 Installation of the HMI device..................................................................................................... 4-1

4.2.1 Installing the MP 270B Keys or OP 270 .................................................................................... 4-1

4.2.2 Installing the MP 270B Touch or TP 270 10"............................................................................. 4-3

4.3 Connecting the HMI device........................................................................................................ 4-5

4.3.1 Conditions .................................................................................................................................. 4-5

4.3.2 Interfaces ................................................................................................................................... 4-6

4.3.3 Connecting the potential equalization........................................................................................ 4-8

4.3.4 Connecting peripheral equipment..........................................................................................

4.3.4.1 Connect print

4.3.4.2 Connect external keyboard and mouse ................................................................................... 4-12

4.3.5 Connecting the PLC................................................................................................................. 4-13

4.3.6 Connecting the configuration computer ................................................................................... 4-15

4.3.7 Connecting an uninterruptible power supply (UPS)................................................................. 4-16

er.........................................................................................................................

.. 4-10

4-10

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

vii

Table of contents

4.3.8 Connecting the power supply................................................................................................... 4-17

4.4 Switch on and test the HMI device........................................................................................... 4-18

5 Operating elements and indicators ......................................................................................................... 5-1

5.1 MP 270B Touch and TP 270...................................................................................................... 5-1

5.2 MP 270B Keys and OP 270 ....................................................................................................... 5-2

5.2.1 Key pads .................................................................................................................................... 5-2

5.2.2 Function keys ............................................................................................................................. 5-5

5.2.3 System keys............................................................................................................................... 5-6

5.2.4 Labeling the softkeys ................................................................................................................. 5-8

5.3 Operation with external keyboard/mouse ................................................................................ 5-12

6 Operating system and configuration ....................................................................................................... 6-1

6.1 HMI device loader ...................................................................................................................... 6-1

6.2 Windows CE Control Panel........................................................................................................ 6-2

6.2.1 Open Control Panel.................................................................................................................... 6-2

6.2.2 Communication .......................................................................................................................... 6-5

6.2.3 Date/time.................................................................................................................................... 6-5

6.2.4 InputPanel .................................................................................................................................. 6-6

6.2.5 Network ...................................................................................................................................... 6-6

6.2.6 OP .............................................................................................................................................. 6-7

6.2.7 Printer....................................................................................................................................... 6-11

6.2.8 Regional Settings..................................................................................................................... 6-13

6.2.9 Screensaver ............................................................................................................................. 6-14

6.2.10 System ..................................................................................................................................... 6-15

6.2.11 UPS.......................................................................................................................................... 6-16

6.2.12 Volume & Sounds .................................................................................................................... 6-17

6.3 Network operation .................................................................................................................... 6-18

6.3.1 Basic principles ........................................................................................................................ 6-18

6.3.2 Configuring the HMI device for network operation................................................................... 6-19

6.3.3 Test network............................................................................................................................. 6-21

6.3.4 Configuring network access..................................................................................................... 6-22

7 Prepare and backup project.................................................................................................................... 7-1

7.1 Transfer project to the HMI device............................................................................................. 7-1

7.1.1 Commissioning for the first time.........................................................................................

7.1.2 Rec

ommiss

ioning....................................................................................................................... 7-3

........ 7-1

7.2 Transfer...................................................................................................................................... 7-3

7.2.1 Start transfer manually............................................................................................................... 7-3

7.2.2 Start transfer automatically ........................................................................................................ 7-4

7.2.3 Transfer mode options ............................................................................................................... 7-5

7.2.4 Test project ................................................................................................................................ 7-8

7.2.5 Uploading project ..................................................................................................................... 7-10

7.3 System settings........................................................................................................................ 7-12

7.3.1 Set language ............................................................................................................................ 7-12

7.3.2 Set operating mode.................................................................................................................. 7-13

7.4 Other transfer functions............................................................................................................ 7-14

7.4.1 Functions.................................................................................................................................. 7-14

7.4.2 Backup and Restore................................................................................................................. 7-15

7.4.3 Update operating system ......................................................................................................... 7-18

7.4.4 Transferring authorizations ...................................................................................................... 7-21

7.4.5 Transferring options ................................................................................................................. 7-22

TP 270, OP 270, MP 270B (WinCC flexible)

viii Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Table of contents

8 Runtime functionalities of a project ......................................................................................................... 8-1

8.1 Screen objects ........................................................................................................................... 8-1

8.2 Alarms ........................................................................................................................................ 8-2

8.3 Tags ........................................................................................................................................... 8-3

8.4 Logs ........................................................................................................................................... 8-3

8.5 Reports....................................................................................................................................... 8-5

8.6 System functions and scripts ..................................................................................................... 8-6

8.7 Safety ......................................................................................................................................... 8-7

8.8 Other operating functions........................................................................................................... 8-9

9 Operate project....................................................................................................................................... 9-1

9.1 Basic principles of operation ...................................................................................................... 9-1

9.1.1 Basics for operation in runtime .................................................................................................. 9-1

9.1.2 Operating the touch panel.......................................................................................................... 9-3

9.1.2.1 Operating touch objects ............................................................................................................. 9-3

9.1.2.2 Input of values............................................................................................................................ 9-5

9.1.2.3 Input of numeric values.............................................................................................................. 9-5

9.1.2.4 Input of alphanumeric values..................................................................................................... 9-8

9.1.2.5 Calling the operator note.......................................................................................................... 9-10

9.1.3 Operating a keyboard device ................................................................................................... 9-11

9.1.3.1 Functions of the system keys................................................................................................... 9-11

9.1.3.2 Functions of the key combinations........................................................................................... 9-12

9.1.3.3 Input of values.......................................................................................................................... 9-15

9.1.3.4 Calling the operator note.......................................................................................................... 9-15

9.2 Controlling graphic objects....................................................................................................... 9-16

9.2.1 Button....................................................................................................................................... 9-16

9.2.1.1 Description ............................................................................................................................... 9-16

9.2.1.2 Touch control ........................................................................................................................... 9-17

9.2.1.3 Keyboard control...................................................................................................................... 9-17

9.2.1.4 Mouse and keyboard control.................................................................................................... 9-18

9.2.2 Switch....................................................................................................................................... 9-18

9.2.2.1 Description ............................................................................................................................... 9-18

9.2.2.2 Touch control ........................................................................................................................... 9-19

9.2.2.3 Keyboard control...................................................................................................................... 9-19

9.2.2.4 Mouse and keyboard control.............................................................................................

9.2.3 I/O field

9.2.3.1 Des

..................................................................................................................................... 9-20

cription ............................................................................................................................... 9-20

....... 9-19

9.2.3.2 Touch control ........................................................................................................................... 9-20

9.2.3.3 Keyboard control...................................................................................................................... 9-21

9.2.3.4 Mouse and keyboard control.................................................................................................... 9-21

9.2.4 Graphic I/O field ....................................................................................................................... 9-22

9.2.4.1 Description ............................................................................................................................... 9-22

9.2.4.2 Touch control ........................................................................................................................... 9-22

9.2.4.3 Keyboard control...................................................................................................................... 9-23

9.2.4.4 Mouse and keyboard control.................................................................................................... 9-23

9.2.5 Symbolic I/O field ..................................................................................................................... 9-24

9.2.5.1 Description ............................................................................................................................... 9-24

9.2.5.2 Touch control ........................................................................................................................... 9-24

9.2.5.3 Keyboard control...................................................................................................................... 9-25

9.2.5.4 Mouse and keyboard control.................................................................................................... 9-25

9.2.6 Alarm indicator ......................................................................................................................... 9-26

9.2.6.1 Description ............................................................................................................................... 9-26

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

ix

Table of contents

9.2.6.2 Touch control ........................................................................................................................... 9-26

9.2.6.3 Mouse control........................................................................................................................... 9-27

9.2.7 Alarm view................................................................................................................................ 9-27

9.2.7.1 Description ............................................................................................................................... 9-27

9.2.7.2 Touch control ........................................................................................................................... 9-28

9.2.7.3 Keyboard control ...................................................................................................................... 9-29

9.2.7.4 Mouse and keyboard control.................................................................................................... 9-29

9.2.8 Simple alarm view .................................................................................................................... 9-30

9.2.8.1 Description ............................................................................................................................... 9-30

9.2.8.2 Touch control ........................................................................................................................... 9-31

9.2.8.3 Keyboard control ...................................................................................................................... 9-31

9.2.8.4 Mouse and keyboard control.................................................................................................... 9-31

9.2.9 Recipe view.............................................................................................................................. 9-32

9.2.9.1 Description ............................................................................................................................... 9-32

9.2.9.2 Touch control ........................................................................................................................... 9-33

9.2.9.3 Keyboard control ...................................................................................................................... 9-33

9.2.9.4 Mouse and keyboard control.................................................................................................... 9-34

9.2.10 Simple recipe view ................................................................................................................... 9-35

9.2.10.1 Description ............................................................................................................................... 9-35

9.2.10.2 Touch control ........................................................................................................................... 9-36

9.2.10.3 Keyboard control ...................................................................................................................... 9-36

9.2.10.4 Mouse and keyboard control.................................................................................................... 9-37

9.2.11 Bar............................................................................................................................................ 9-38

9.2.12 Trend view................................................................................................................................ 9-39

9.2.12.1 Description ............................................................................................................................... 9-39

9.2.12.2 Touch control ........................................................................................................................... 9-40

9.2.12.3 Keyboard control ...................................................................................................................... 9-41

9.2.12.4 Mouse and keyboard control.................................................................................................... 9-41

9.2.13 Slider control ............................................................................................................................ 9-42

9.2.13.1 Description ............................................................................................................................... 9-42

9.2.13.2 Touch control ........................................................................................................................... 9-43

9.2.13.3 Keyboard control ...................................................................................................................... 9-43

9.2.13.4 Mouse and keyboard control............................................................................................

9.2.14 Gauge.......................................................................................................................................

9.2.15 Date/time field ..........................................................................................................................

........ 9-44

9-44

9-45

9.2.15.1 Description ............................................................................................................................... 9-45

9.2.15.2 Touch control ........................................................................................................................... 9-45

9.2.15.3 Keyboard control ...................................................................................................................... 9-46

9.2.15.4 Mouse and keyboard control.................................................................................................... 9-46

9.2.16 Clock ........................................................................................................................................ 9-47

9.2.17 User view ................................................................................................................................. 9-48

9.2.17.1 Description ............................................................................................................................... 9-48

9.2.17.2 Touch control ........................................................................................................................... 9-49

9.2.17.3 Keyboard control ...................................................................................................................... 9-49

9.2.17.4 Mouse and keyboard control.................................................................................................... 9-49

9.2.18 Simple user view ...................................................................................................................... 9-50

9.2.18.1 Description ............................................................................................................................... 9-50

9.2.18.2 Touch control ........................................................................................................................... 9-50

9.2.18.3 Keyboard control ...................................................................................................................... 9-50

9.2.18.4 Mouse and keyboard control.................................................................................................... 9-51

9.2.19 Status/Force............................................................................................................................. 9-52

9.2.19.1 Description ............................................................................................................................... 9-52

9.2.19.2 Touch control ........................................................................................................................... 9-53

9.2.19.3 Keyboard control ...................................................................................................................... 9-53

9.2.19.4 Mouse and keyboard control.................................................................................................... 9-54

9.2.20 Sm@rtClient view..................................................................................................................... 9-55

9.2.20.1 Description ............................................................................................................................... 9-55

TP 270, OP 270, MP 270B (WinCC flexible)

x Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Table of contents

9.2.20.2 Touch control ........................................................................................................................... 9-57

9.2.20.3 Keyboard control...................................................................................................................... 9-57

9.2.20.4 Mouse and keyboard control.................................................................................................... 9-58

9.2.21 Symbol library .......................................................................................................................... 9-58

9.2.21.1 Description ............................................................................................................................... 9-58

9.2.21.2 Touch control ........................................................................................................................... 9-59

9.2.21.3 Mouse control........................................................................................................................... 9-59

10 Operating recipes ................................................................................................................................. 10-1

10.1 Recipes .................................................................................................................................... 10-1

10.2 Structure of recipes.................................................................................................................. 10-3

10.3 Structure of recipe data records............................................................................................... 10-4

10.4 Recipe application.................................................................................................................... 10-5

10.4.1 Transfer of recipe data records................................................................................................ 10-5

10.4.2 Configuration of recipes ........................................................................................................... 10-6

10.4.3 Scenario: Entering recipe data records in Runtime ................................................................. 10-8

10.4.4 Scenario: Manual production sequence ................................................................................ 10-10

10.4.5 Scenario: Automatic production sequence ............................................................................ 10-12

10.5 Displaying recipes.................................................................................................................. 10-13

10.5.1 Viewing and editing recipes in Runtime................................................................................. 10-13

10.5.2 Behavior of the recipe view in Runtime ................................................................................. 10-15

10.6 Recipe data record administration ......................................................................................... 10-15

10.6.1 Recipe data record administration ......................................................................................... 10-15

10.6.2 Synchronizing a recipe data record ....................................................................................... 10-17

10.6.3 Read recipe data record from PLC ........................................................................................ 10-18

10.6.4 Transfer recipe record to PLC................................................................................................ 10-18

10.6.5 Exporting and importing recipe data records ......................................................................... 10-19

10.6.6 Reactions to modifications of the recipe structure ................................................................. 10-20

10.7 Example ................................................................................................................................. 10-21

10.7.1 Example: Creating a recipe.................................................................................................... 10-21

10.7.2 Example: Configuring a recipe screen................................................................................... 10-23

11 Maintenance/Service ............................................................................................................................ 11-1

11.1 Clean screen/keyboard foil ................................................................................................

11.1.1 General information

11.1.2

Notes on the touch panel ......................................................................................................... 11-2

................................................................................................................. 11-1

...... 11-1

11.2 Replacing the optional backup battery..................................................................................... 11-3

12 Technical data ...................................................................................................................................... 12-1

12.1 Dimension drawings................................................................................................................. 12-1

12.1.1 MP 270B 10" Touch, TP 270 10" dimensions.......................................................................... 12-1

12.1.2 MP 270B 6" Touch, TP 270 6" dimensions.............................................................................. 12-2

12.1.3 Dimensions, MP 270B 10" Keys, OP 270 10" ......................................................................... 12-3

12.1.4 Dimensions, OP 270 6"............................................................................................................ 12-4

12.2 Technical data.......................................................................................................................... 12-5

12.3 EMC requirements ................................................................................................................... 12-8

12.4 Interfaces ................................................................................................................................. 12-9

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

xi

Table of contents

A Appendix.................................................................................................................................................A-1

A.1 Certificates and Directives .........................................................................................................A-1

A.1.1 Approvals ...................................................................................................................................A-1

A.1.2 ESD guidelines...........................................................................................................................A-2

A.2 System alarms ...........................................................................................................................A-3

B Abbreviations..........................................................................................................................................B-1

B.1 Abbreviations .............................................................................................................................B-1

C Glossary .................................................................................................................................................C-1

Index

Tables

Table 1-1

Table 1-2 Communication with PLCs from other manufacturers ............................................................. 1-11

Table 12-1 9-pin Sub-D plug (pin).............................................................................................................. 12-9

Table 12-2 9-pin Sub-D socket (configuration via switch).......................................................................... 12-9

Table 12-3 9-pin Sub-D plug (pin)............................................................................................................ 12-10

Table 12-4 RJ45 plug connection............................................................................................................. 12-10

Table 12-5 USB standard plug................................................................................................................. 12-11

Communication with SIMATIC PLCs ....................................................................................... 1-11

TP 270, OP 270, MP 270B (WinCC flexible)

xii Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Overview

1.1 Introduction

HMI devices in the middle performance range

The Multi Panel MP 270B, Touch Panel TP 270 and Operator Panel OP 270 extend the

product spectrum in the middle performance range.

The HMI devices are based on the innovative standard operating system, Microsoft Windows

CE. The robustness and speed of the dedicated hardware solutions are combined with the

flexibility of the PC world.

The MP 270B represents the "Multifunctional Platform" product category and is distinguished

by its variable deployment. This product category is positioned in the product hierarchy

between the process-related, optimized application components, such as operator panels

and controllers, and industrial PCs.

The panels TP 270 and OP 270 are downgraded models and less expensive, but still provide

convincing functionality

The comprehensive product range allows users to choose the HMI device most suited to

their needs. All HMI devices include the following advantages:

1

• High degree of configuration efficiency

• Configuration simulation on the configuration computer - no PLC required

• Clear display and easy process operation using a Window-Based user interface

• Large selection of predefined screen objects for use during configuration

• Dynamic screen objects, e.g. moving objects

• Uncomplicated and quick handling of recipes and data records in recipe screens and

recipe views

• Logging of alarms, process values and login/logout procedures

• Creation of vector graphics using the WinCC flexible configuration software without an

external graphics editor,

• Transfer:

– Automatic switchover to transfer mode

– Transfer via MPI, PROFIBUS DP, USB and Ethernet

– Serial transfer

– Transfer via TeleService

• Standard connections to SIMATIC S5/DP, SIMATIC S7 and SIMATIC 505, as well as to

PLCs from other manufacturers

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

1-1

Overview

1.2 Field of Application

Position in the SIMATIC HMI environment

The HMI devices were designed for the middle performance range. They meet the demands

placed on performance, display possibilities and price/performance ratio. In addition, they

extend the communication potential of the office world. Customer needs and requests were

taken into account in respect to extending data transfer functions, simplifying operation, and

increasing acceptance when compared with Windows CE units.

The HMI devices not only support the classic HMI applications (visualization with WinCC

flexible) but also additional applications, such as process diagnostics (ProAgent).

1.2 Field of Application

Overview

The HMI device allows graphic display of operating statuses, current process data and errors

of connected PLCs. The user can operate and observe the machine or system being

monitored easily using the HMI device.

Applicable areas of use include machine and apparatus construction sectors, printing and

packing industries, automobile and electrical industries and chemical and pharmaceutical

industries.

The high degree of protection (IP65 on the front side) and avoidance of moving storage

media, such as hard disks and floppy disks, ensure that the HMI device is suitable for use in

rough industrial environments and on site where a machine is located.

Possible installation locations for the HMI device:

• Switching cabinets/consoles

• 19" cabinets/racks (keyboard units)

Connection options for external peripherals (keyboard, mouse and printer) via a USB port,

for example, and the possible use of CF and PC cards support multifunctionality. Due to the

fact that the HMI device is equipped with high performance basic hardware and has a

minimum installation depth means that it fulfills all the requirements for operation in the

vicinity of the machine.

The HMI device can be used to:

• Operate and monitor the process using the menu system. Setpoint values or control

element settings can be modified by entering values or activating configured softkeys

• Display processes, machines and systems on full-graphic, dynamic screens

• Display and process alarms and tags through output fields, bar graphs or trend curves

• Use input to intervene directly in the running process

TP 270, OP 270, MP 270B (WinCC flexible)

1-2 Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Overview

1.3 Configuring with WinCC flexible

1.3 Configuring with WinCC flexible

Introduction

In order to operate a machine or system using an HMI device, the user interface must be

configured for the HMI device. This procedure is referred to as the "configuration phase".

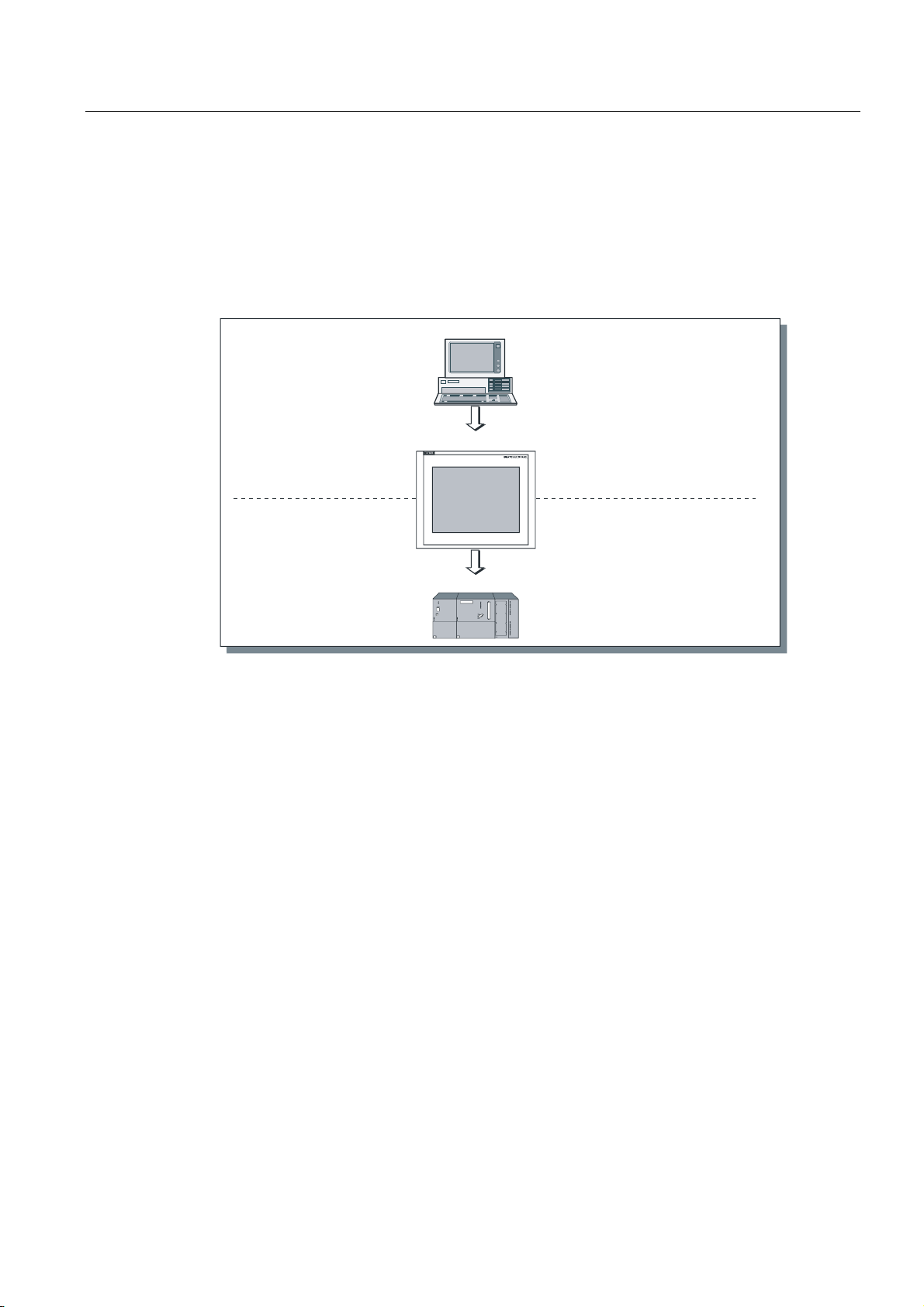

PC/PU

Create project data

Configuration phase

Save project data

Test the configuration

Simulate configuration

Principle

Operating unit

PLC

Process running phase

Figure 1-1 Configuration and process running phases

Download project data

Connected to PLC

1. Configuring the functionality of the user interface. This includes the following:

– Graphics

– Text

– Customized functions

– Operating and indicator objects

Use a configuration computer (PC or PU) with the WinCC flexible configuration software.

2. Connect the configuration computer to the HMI device.

The following connection options are available:

– Serial

– MPI/PROFIBUS DP

– USB or Ethernet interface

– Standard modem path

3. Transfer the configuration to the HMI device.

4. Connect the HMI device to the PLC.

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

1-3

Overview

1.4 Features

Result

The HMI device communicates with the PLC and responds to the program progress in the

PLC ("process running phase") according to the information configured.

1.4 Features

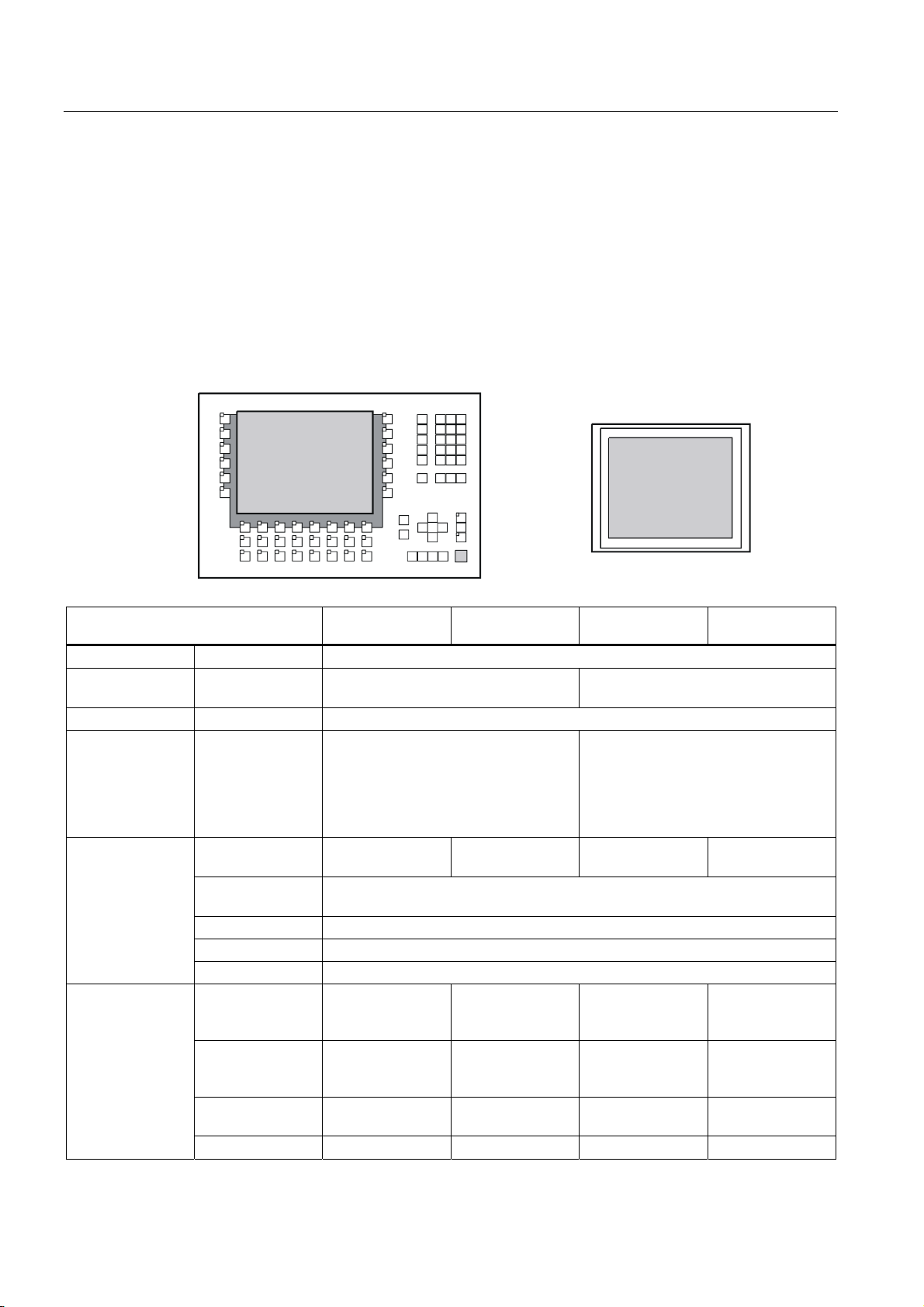

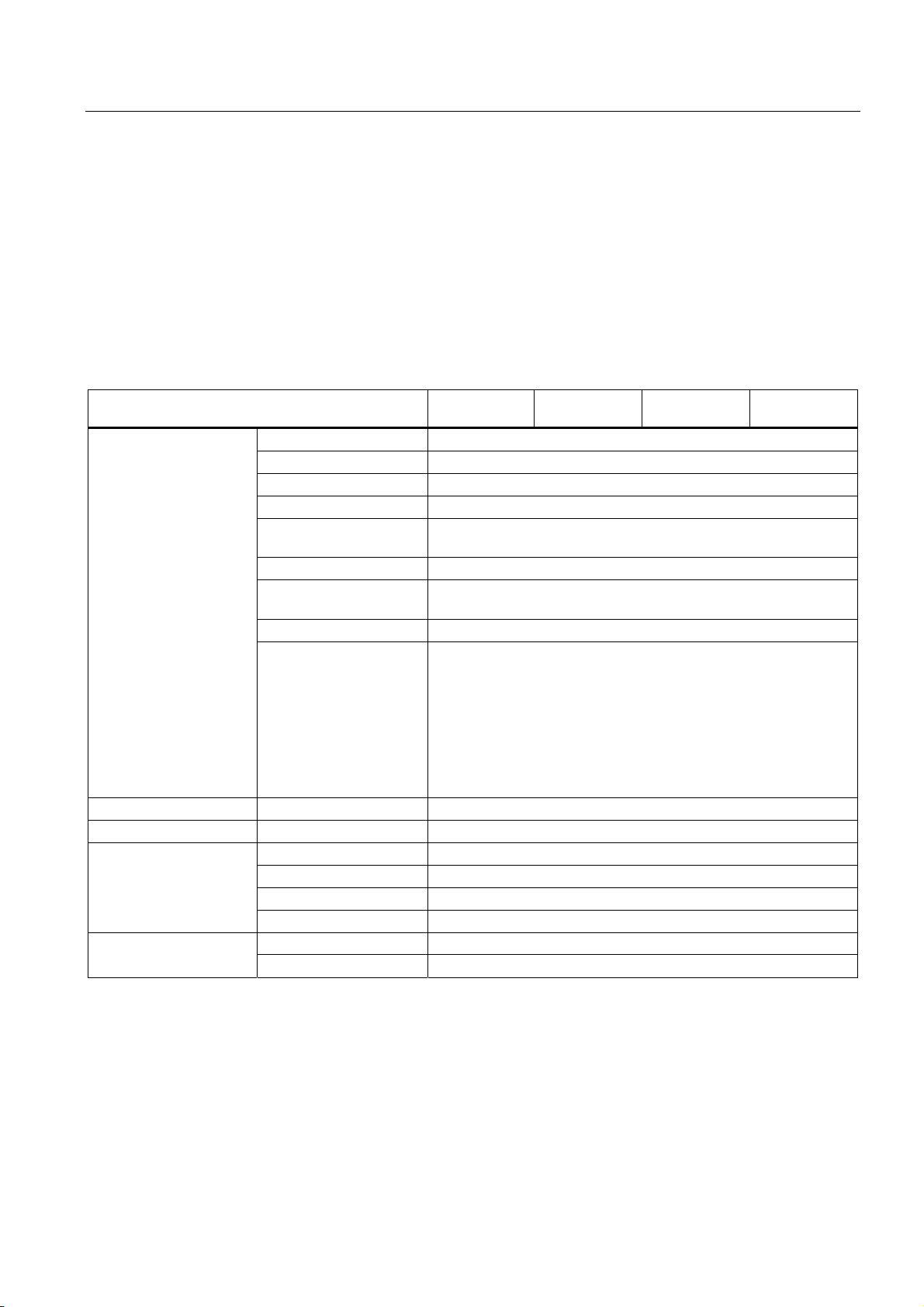

Overview of MP 270B 10", OP 270 10" and TP 270 10"

Features MP 270B 10" Keys MP 270B 10"

Touch

Processor Type RISC CPU

Memory for

configuration

Software Operating system Microsoft Windows CE

Interfaces Interfaces for

Color display

Membrane

keyboard

Capacity (max.) 4 MB 2 MB

• 2 x RS 232, 1 x RS 422, 1 x RS 485

connecting PLC,

PC/PU, printer,

network, external

mouse and

keyboard

Type TFT LCD TFT LCD with

Active screen

diagonals

Resolution (pixels) 640 x 480

Possible colors 256

Back-lighting CCFL tubes

System keys with

dedicated

functions

Softkeys with

configurable

functions

Those for local

assignment

Softkey labeling With labeling strips - With labeling strips -

• 1 x PC card slot

• 1 x CF card slot

• 1 x USB

• 1 x Ethernet (RJ45)

touch panel

38 (3 with LEDs) - 38 (3 with LEDs) -

36 (28 with LEDs) - 36 (28 with LEDs) -

20 (12 with LEDs) - 20 (12 with LEDs) -

OP 270 10" TP 270 10"

• 2 x RS 232, 1 x RS 422, 1 x RS 485

• 1 x CF card slot

• 1 x USB

STN LCD STN LCD with

10,4 "

touch panel

TP 270, OP 270, MP 270B (WinCC flexible)

1-4 Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Overview

1.4 Features

Features MP 270B 10" Keys MP 270B 10"

Touch

Acoustic

acknowledgement

Special features

In the case of

touch control

DP direct keys

(touch buttons as

I/O periphery)

DP direct keys

(keys as I/O

periphery)

External memory

extension for

recipes, logs and

alarms etc.

Slot for PC card x x - -

Slot for CF card x x x x

- x - x

- x - x

x - x -

x x x x

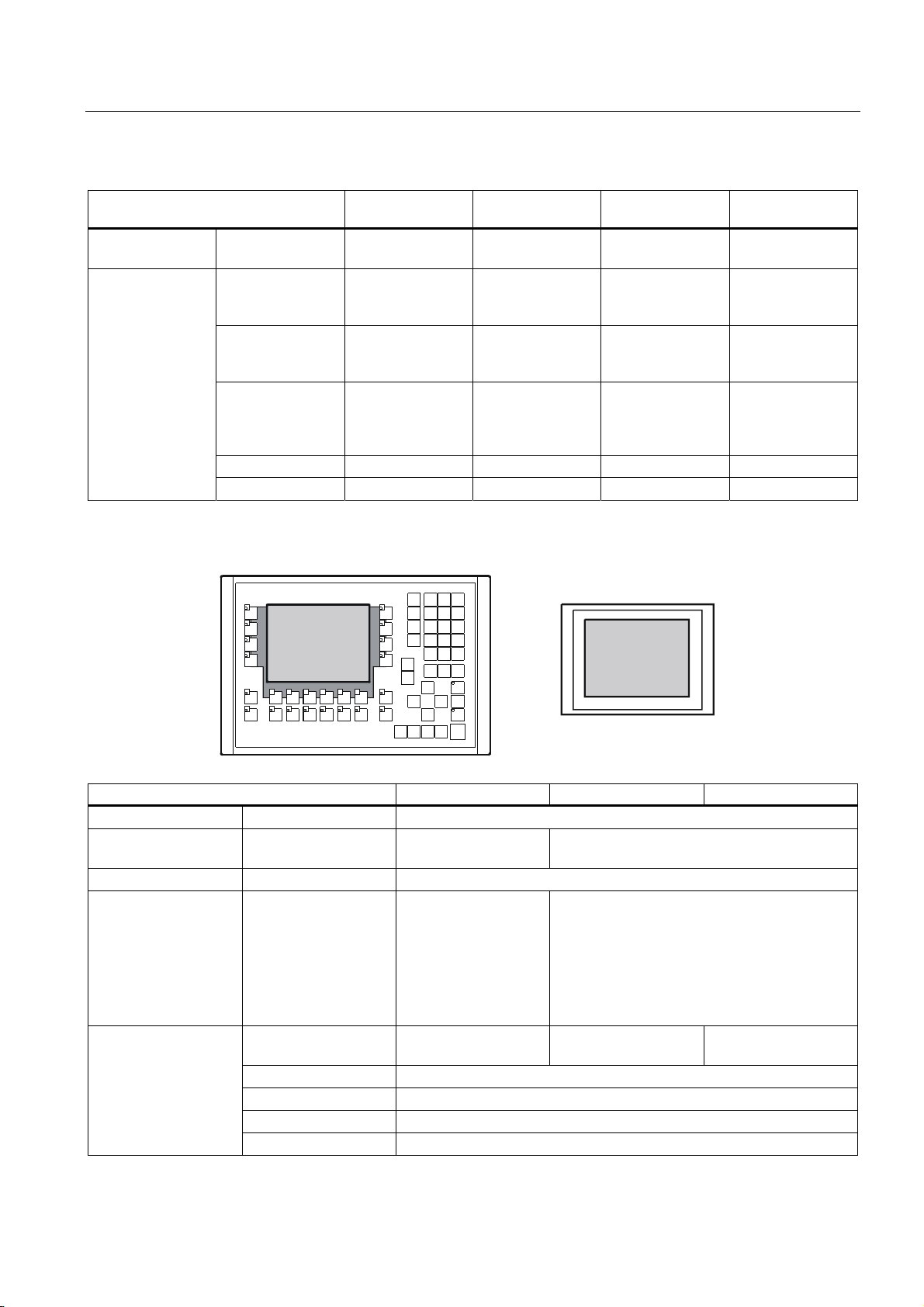

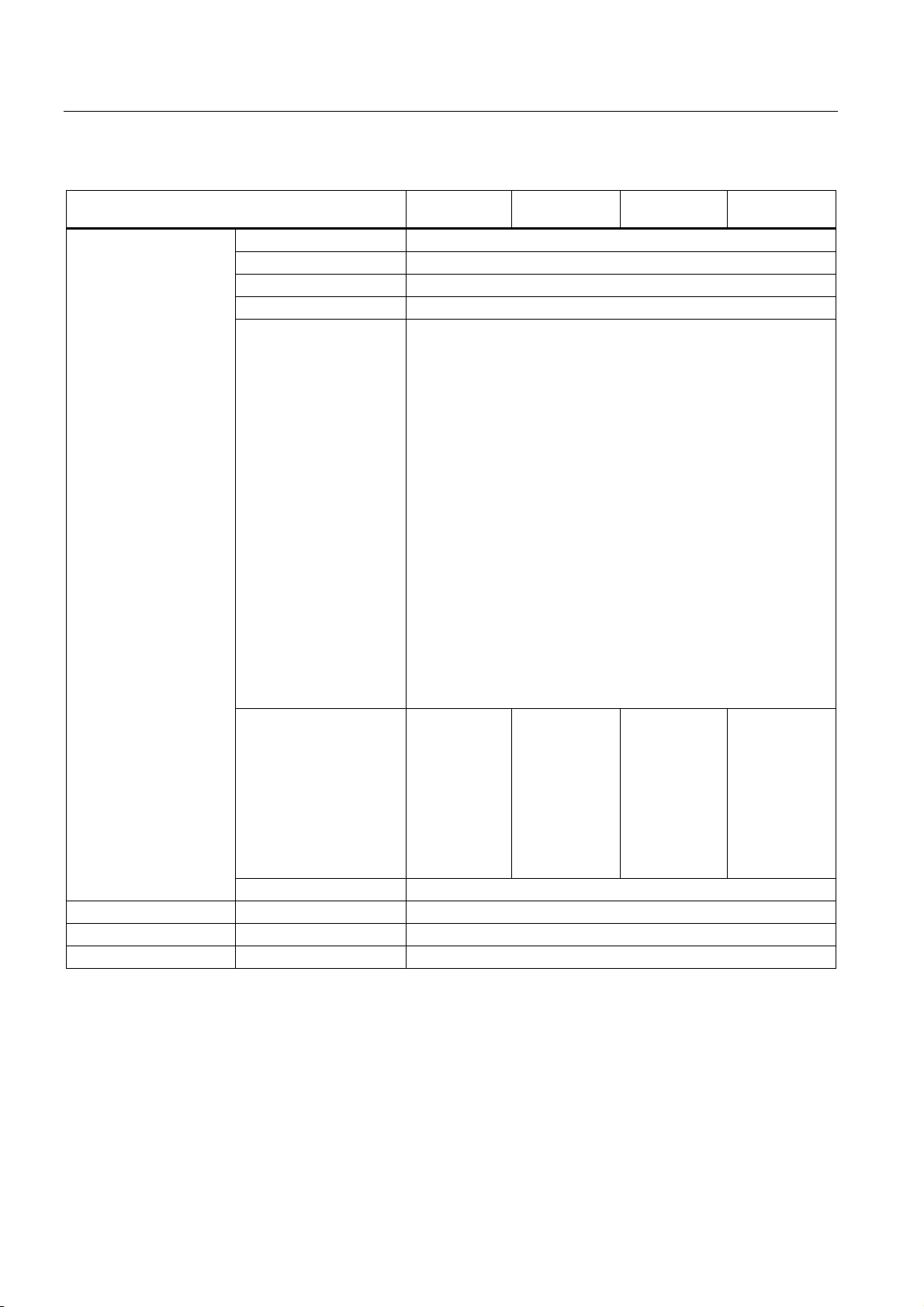

Overview of MP 270B 6" Touch, OP 270 6" and TP 270 6"

OP 270 10" TP 270 10"

Features MP 270B 6" Touch OP 270 6" TP 270 6"

Processor Type RISC CPU

Memory for

configuration

Software Operating system Microsoft Windows CE

Interfaces Interfaces for

Color display

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Capacity (max.) 4 MB 2 MB

• 2 x RS 232, 1 x RS

connecting PLC,

PC/PU, printer,

network, external

mouse and keyboard

Type TFT LCD with touch

Active screen diagonal 5,7 "

Resolution (pixels) 320 x 240

Possible colors 256

Back-lighting CCFL tubes

422, 1 x RS 485

• 1 x PC card slot

• 1 x CF card slot

• 1 x USB

• 1 x Ethernet

(RJ45)

panel

• 2 x RS 232, 1 x RS 422, 1 x RS 485

• 1 x CF card slot

• 1 x USB

CSTN LCD CSTN LCD with touch

panel

1-5

Overview

1.4 Features

Features MP 270B 6" Touch OP 270 6" TP 270 6"

Membrane keyboard

Acoustic

acknowledgement

Special features

System keys with

dedicated functions

Softkeys with

configurable functions

Those for local

assignment

Softkey labeling - System-specific with

In the case of touch

control

DP direct keys (touch

buttons as I/O

periphery)

DP direct keys (keys

as I/O periphery)

External memory

extension for recipes,

logs and alarms etc.

Slot for PC card x -

Slot for CF card x x

- 36 (3 with LEDs) -

- 24 (18 with LEDs) -

- 14 (8 with LEDs) -

-

labeling strips

x - x

x - x

- x -

x x

Further information

The creation of projects for HMI devices and functions for the configuration software is

described in detail in the "WinCC flexible" user manual and in the WinCC online help.

Information on connecting the HMI device to the PLC is provided in the "WinCC flexible

Communication" user manual.

The "Readme.chm" file on the WinCC flexible CD contains the most current information

which could not be included in the manuals and online help due to time constraints.

TP 270, OP 270, MP 270B (WinCC flexible)

1-6 Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Overview

1.5 Functional scope

1.5 Functional scope

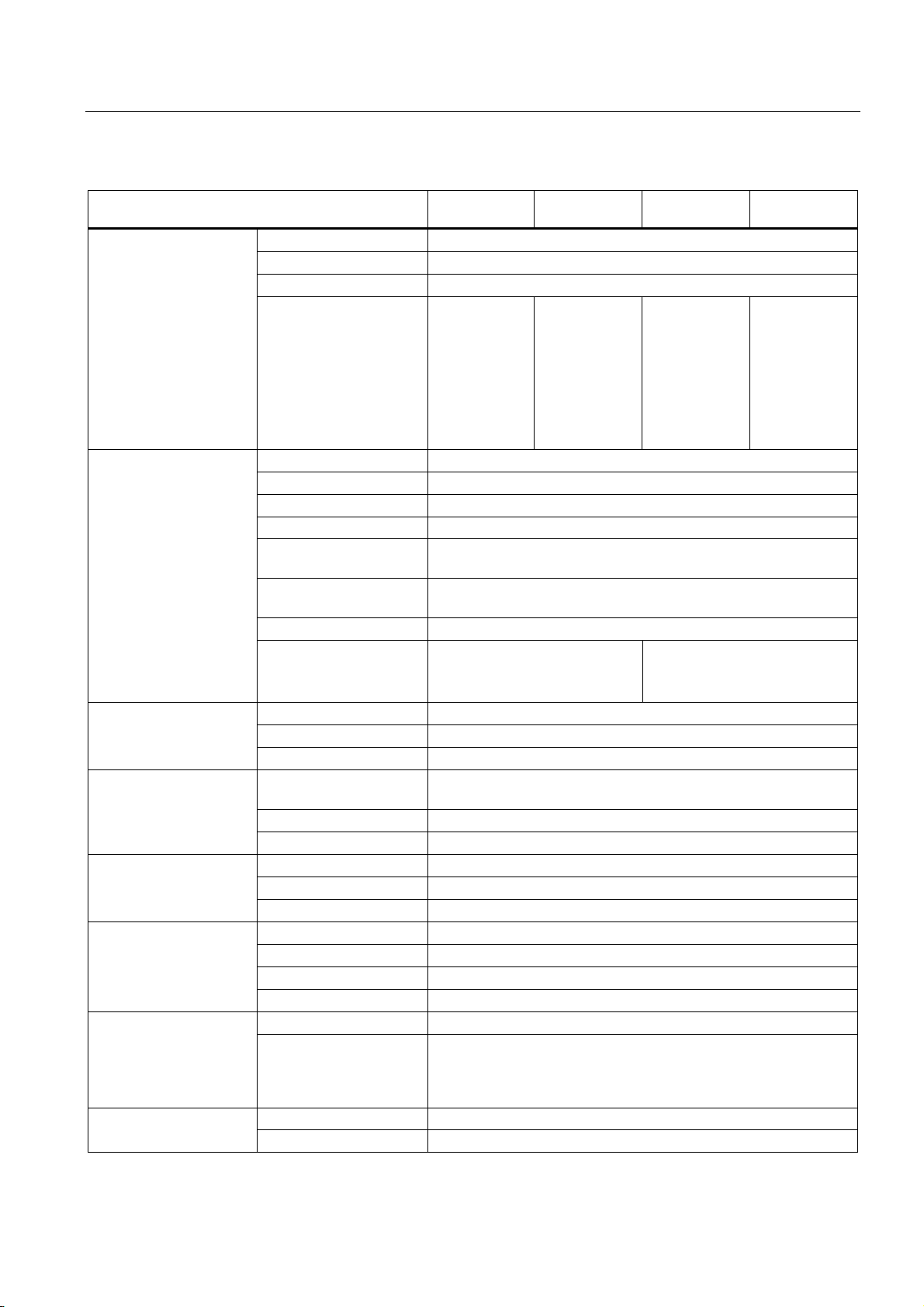

General information

The following table summarizes the range of functions provided by the HMI device. The

numeric values are maximum values which the HMI device is capable of managing. These

values are not cumulative. It is not possible to simultaneously configure 4000 alarms and

300 screens each with 400 tags per screen.

The defined values are also limited by the size of the configuration memory.

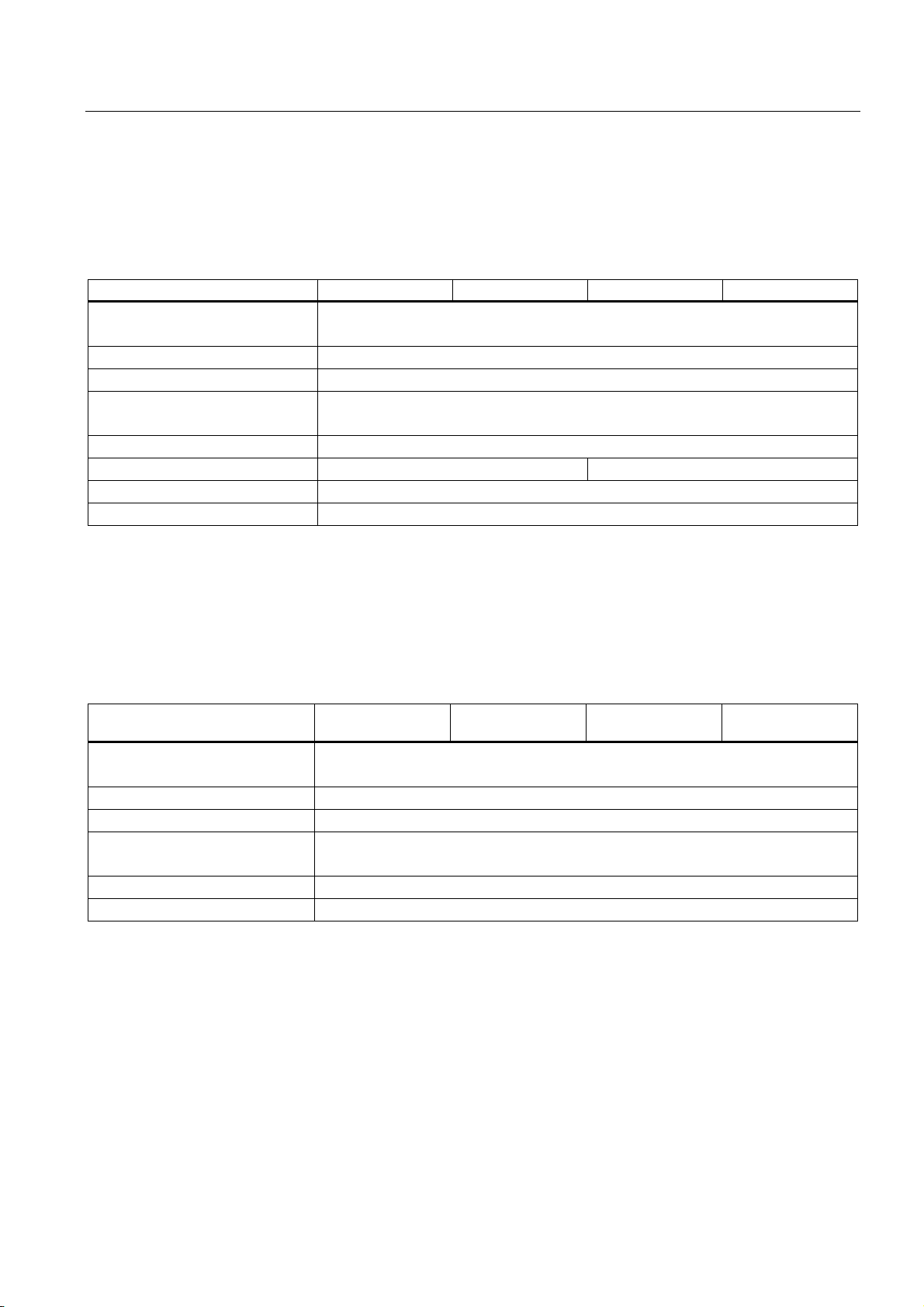

Function MP 270B Keys MP 270B

Touch

Alarms

ALARM_S Display S7 alarms x

Alarm logging Output to printer x

Volatile alarm buffer

Number 4000

Discrete alarms Yes

Analog alarms Yes

Indicators Alarm line/Alarm window/alarm view

Process values in alarm

text

Length of the alarm text 80 characters (dependent on font)

Color-coding of different

alarm states

Warning alarms x

Error alarms

Type of display

Acknowledge individual

alarms

Acknowledge several

error alarms

simultaneously (group

acknowledgement)

Alarm buffer capacity 512 alarm events, circular buffer

View alarms x

Delete x

Print x

Time of occurrence Date/time Alarm acquisition

Alarm events Arrived, departed, acknowledged

First/last, selectable

16 acknowledgment groups

OP 270 TP 270

8

x

x

x

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

1-7

Overview

1.5 Functional scope

Function MP 270B Keys MP 270B

Touch

Screens

Tags Number 2048

Limit value monitoring Input/output x

Conversion functions Input/output x

Number 500

Text objects 10000 text elements

Fields per screen 200

Tags per screen 200

Operating elements

Operator prompting

Help text

Animation

Unhide/hide objects

Softkey icons

Tab order

LEDs in softkeys

Fixed window x

• Button

• Switch

• I/O field

• Graphic I/O field

• Symbolic I/O field

• Alarm indicator

• Alarm view

• Alarm window

• Recipe view

• Bar

• Trend view

• Slider control

• Gauge

• Date / time field

• Clock

• User view

• Status force

• Sm@rtClient view

• Symbol library

x

x

x

x

x

x

x

x

x

-

-

-

OP 270 TP 270

x

x

x

x

x

x

1)

x

x

x

-

-

-

TP 270, OP 270, MP 270B (WinCC flexible)

1-8 Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Overview

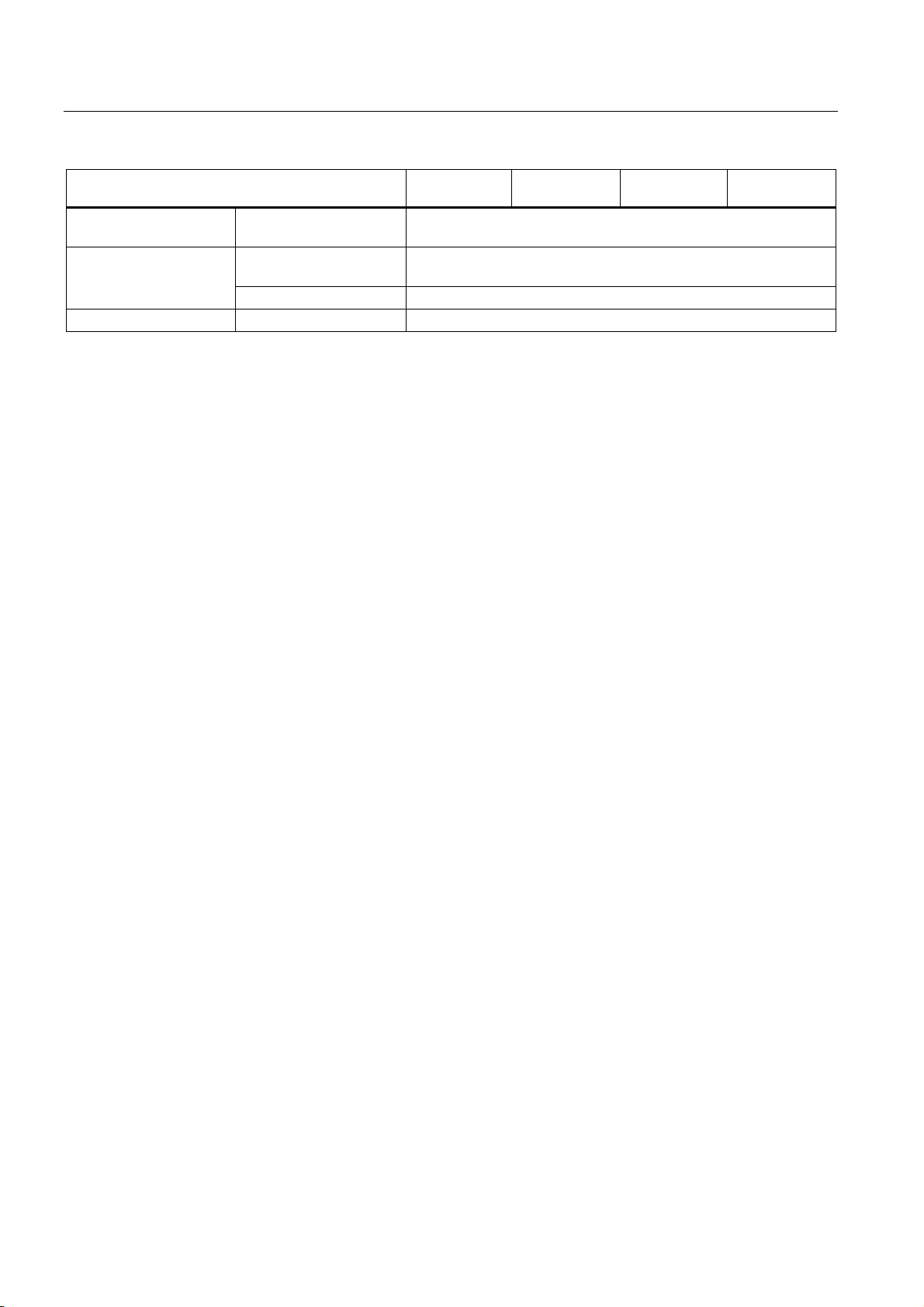

1.5 Functional scope

Help text

Logging

Lists

Print functions

Safety

Recipes

force)

Function MP 270B Keys MP 270B

Touch

Lines/characters 7/35 (dependent on font)

For alarms x

For screens x

For screen objects

I/O field

Symbolic I/O field

Graphic I/O field

Button

Switch

Hidden button

x

x

x

x

x

x

x

x

x

-

-

-

Alarms x

Tags x

Log type Circular/sequential log

Number of logs 20

Number of tags for

logging

Number of sequential

logs

Entries per log 500000, limited by storage medium

Memory location

• PC card

• CF card

• Ethernet

Number 500

Graphics lists 400

Text lists 500

Hardcopy of the screen

content, also in color

Direct alarm logging x

Freely configurable logs x

Number of user groups 50

No. of users 50

No. of authorizations 32

Number 300

Data records per recipe 500, limited by storage medium

Elements per recipe 1000

Recipe memory 64 KB (integr. Flash, expandable)

Number of languages 5 Online languages

Project languages (with

system alarms)

Chinese (simplified), Chinese (traditional), Czechoslovakian,

Danish, Dutch, English, Finnish, French, German, Greek,

Hungarian, Italian, Japanese, Korean, Norwegian, Polish,

Portuguese, Russian, Spanish, Swedish, Turkish

SIMATIC S5 x PU functions (status

SIMATIC S7 x

OP 270 TP 270

x

x

x

x

x

x

20

400

• CF card

• Ethernet (optional)

x

2)

x

x

x

-

-

-

2)

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

1-9

Overview

1.5 Functional scope

Function MP 270B Keys MP 270B

Touch

Scheduler Trigger functions

cyclically or once

User-specific expansions

of functionality

Number of scripts 50

Connections 3) Number 6

OP 270 TP 270

x

x VBScript

1) Maximum total number for PowerTags and internal tags

2) Storage media refers to PC cards, CF cards and network drives

3) With SIMATIC S7

TP 270, OP 270, MP 270B (WinCC flexible)

1-10 Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Overview

1.6 Communication with PLCs

1.6 Communication with PLCs

The following tables list the PLCs which can be connected to the HMI device.

Table 1-1 Communication with SIMATIC PLCs

PLC MP 270B Keys MP 270B Touch OP 270 TP 270

SIMATIC S5 AS511 1)

SIMATIC S5 DP

SIMATIC S7–200 x

SIMATIC S7–300/400 x

SIMATIC 500/505 serial

SIMATIC 500/505 DP

SIMATIC HMI HTTP Protocol x

OPC 2) x -

SIMATIC WinAC x

SIMOTION x

x

x

x

x

1) Only via converter cable

2) Data exchange only via XML (connection to OPC-XML server)

Table 1-2 Communication with PLCs from other manufacturers

PLC MP 270B Keys MP 270B Touch OP 270 10"/OP 270

6"

Allen Bradley DF1

Allen Bradley DH485

LG GLOFA-GM x

Modicon MODBUS x

Mitsubishi FX

Mitsubishi Protocol 4

GE Fanuc SNP x

Omron Hostlink/Multilink x

x

x

x

x

TP 270 10"/TP 270

6"

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

1-11

Overview

1.7 Options

1.7 Options

1.7.1 Hardware options

1.7.1.1 Backup battery

Function of the backup battery

The battery ensures that in the event of a power failure, the HMI device's internal hardware

clock continues to run. If no battery is available, the clock continues for approx. three days

as long as the HMI device was in operation for 6 to 8 hours, without interruption, beforehand.

The battery is not supplied with the HMI device.

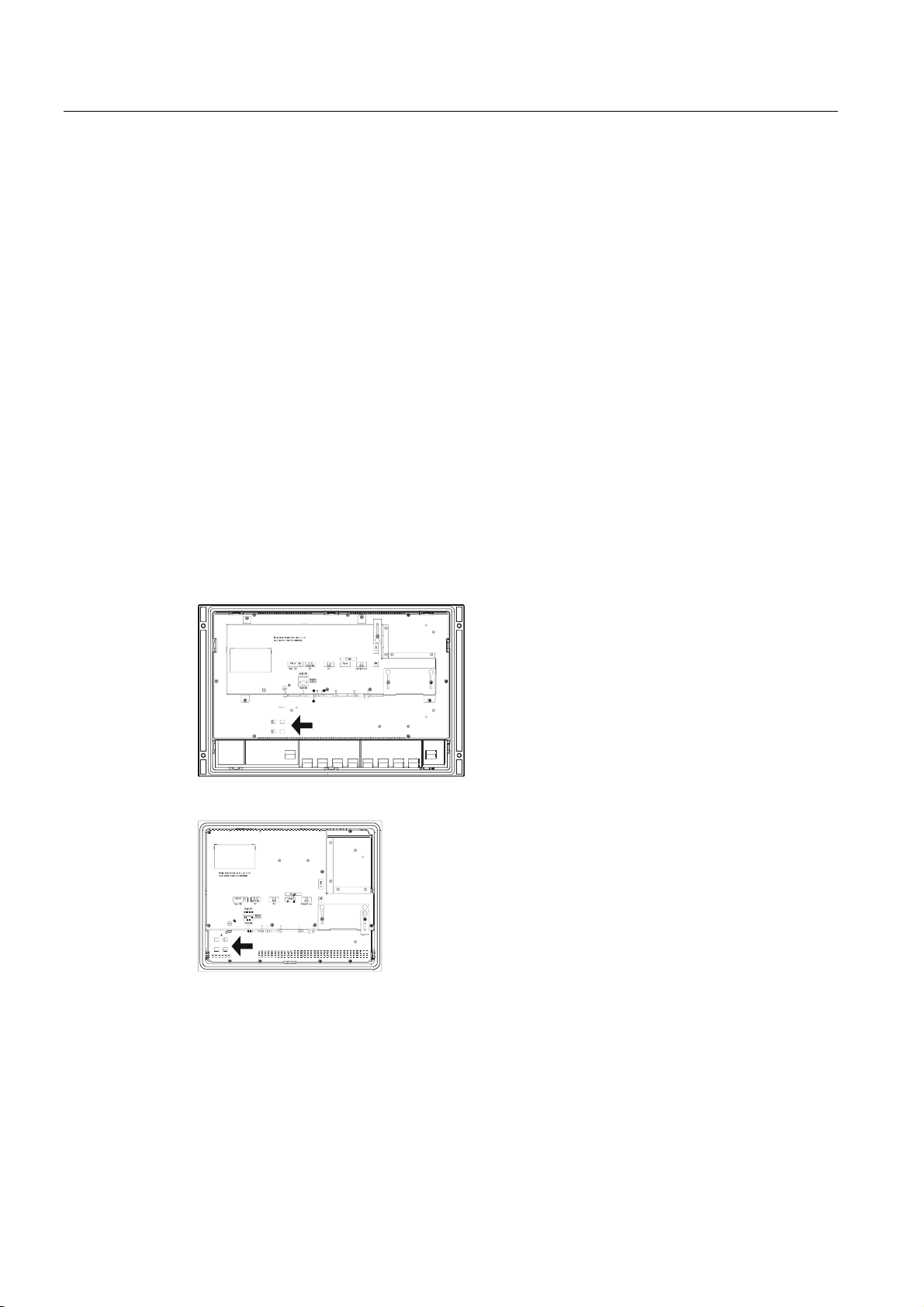

Installation in the MP 270B 10", TP 270 10" or OP 270 10"

1. Secure the battery with two cable ties to the back of the HMI device. The position is

indicated by an arrow in the following figures.

Figure 1-2 MP 270B 10" Keys / OP 270 10"

Figure 1-3 MP 270B 10" Touch / TP 270 10"

2. Insert the battery lead connector into the two-pin socket. The plug is coded to prevent

reversed poling.

TP 270, OP 270, MP 270B (WinCC flexible)

1-12 Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Overview

1.7 Options

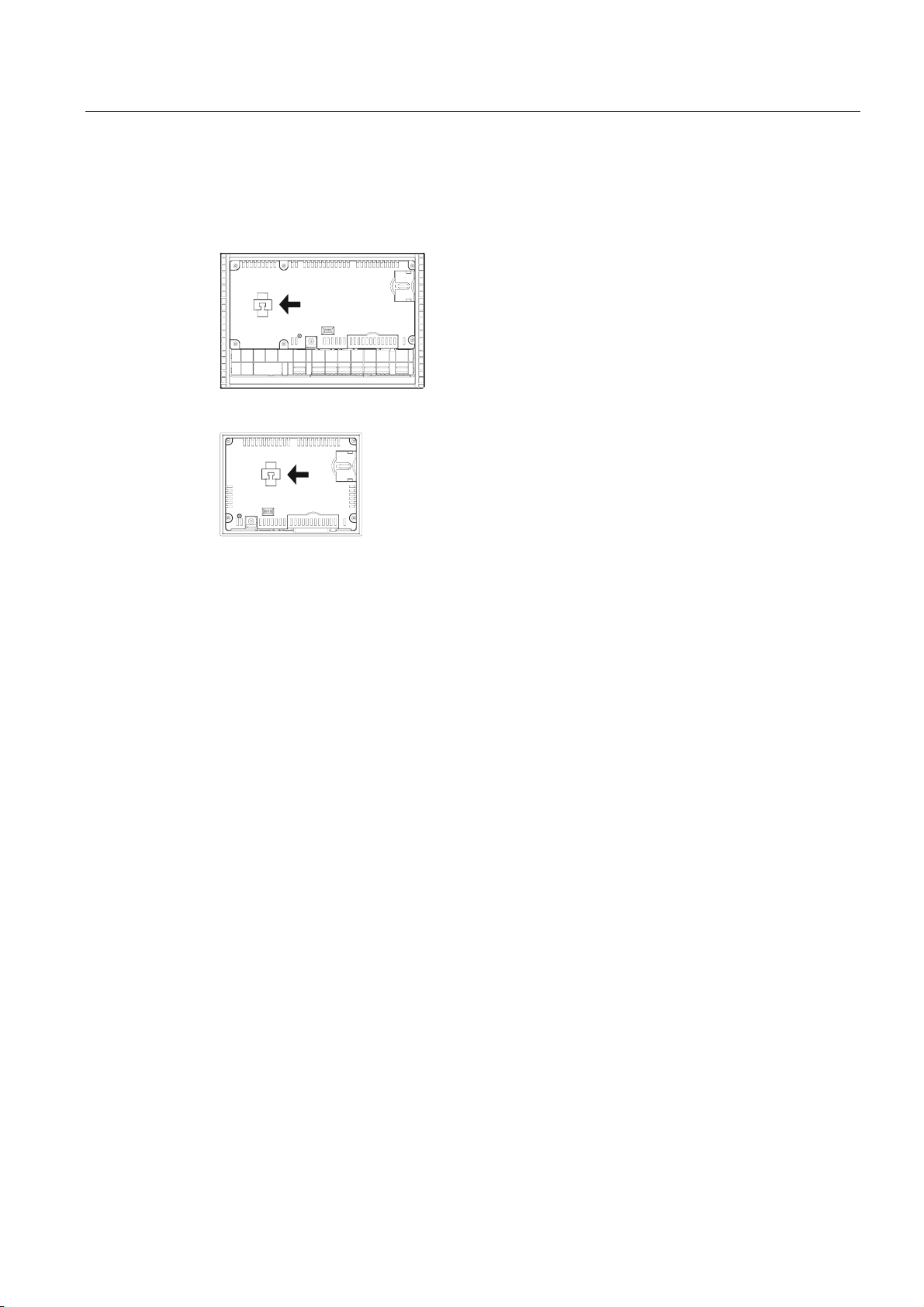

Assembly on MP 270B 6" Touch, TP 270 6" and OP 270 6"

1. Secure the battery to the back of the HMI device with one cable tie. The position is

indicated by an arrow in the following figures.

Figure 1-4 OP 270 6"

Figure 1-5 MP 270B 6" Touch / TP 270 6"

See also

2. Insert the battery lead connector into the two-pin socket. The plug is coded to prevent

reversed poling.

Replacing the optional backup battery (Page 11-3)

Interfaces (Page 4-6)

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

1-13

Overview

1.7 Options

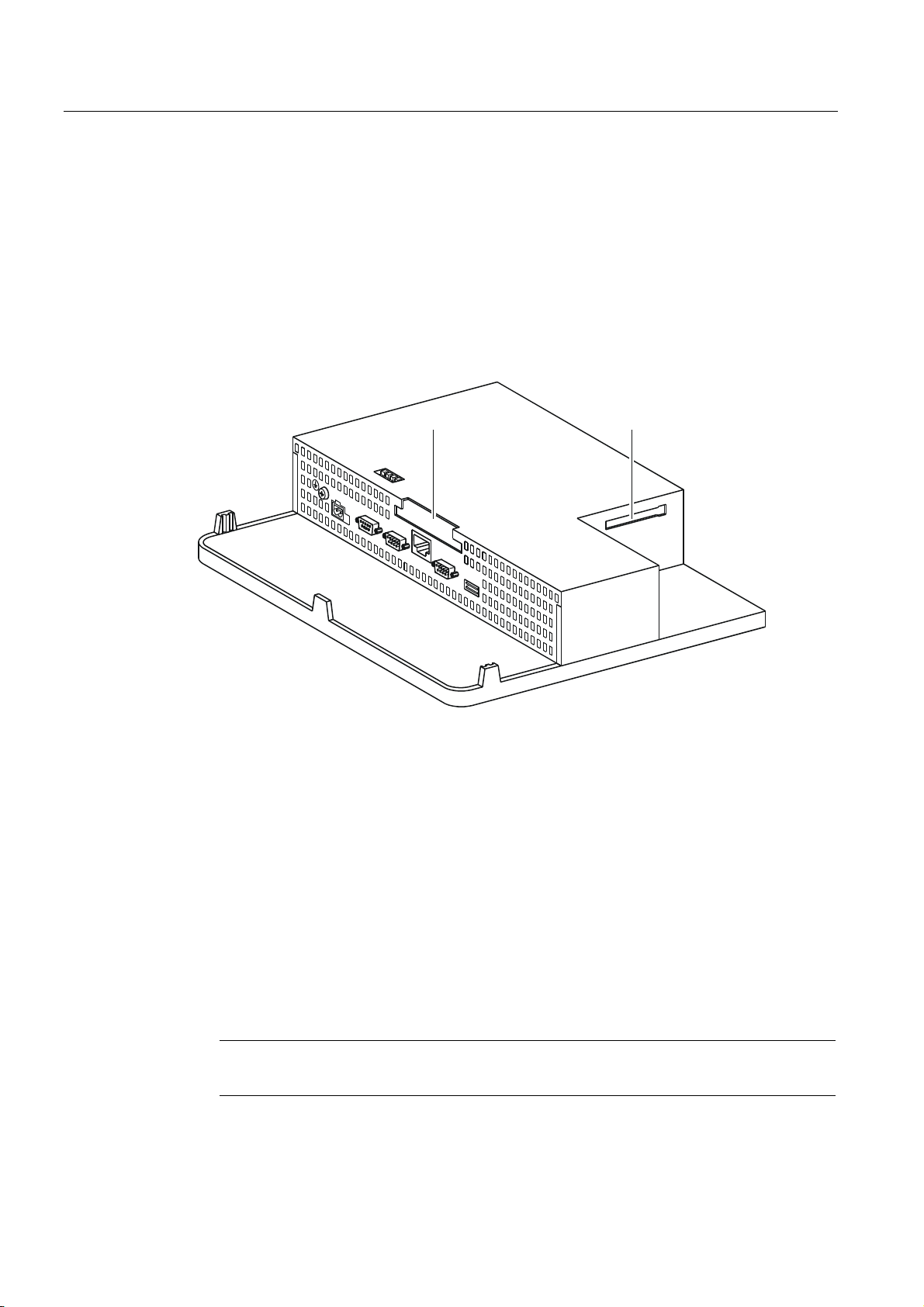

1.7.1.2 PC card / CF card

Purpose

Changeable PC cards and CF cards can be inserted in the two slots, Slot A and Slot B on

the back of the MP 270B. They are not supplied.

The TP 270 and OP 270 have only one slot for CF cards (Slot B).

Changeable memory cards can be used, for example, to store important process data or

execute a backup/restore of the internal flash memory.

Slot A Slot B

Cards supported

Figure 1-6 Position of the slots (example of MP 270B 10" Keys)

The HMI device supports standard cards which operate with a programming voltage of 5 V:

• Slot A (PC card) (type I and II) (for MP 270B only):

– ATA Flash card

– SRAM card

– NE2000-compatible Ethernet card

• Slot B (CF card) (type I):

– ATA Flash card

– NE2000-compatible Ethernet card

Caution

The current limitation is 300 mA per slot.

TP 270, OP 270, MP 270B (WinCC flexible)

1-14 Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Overview

1.7 Options

Remove memory card

Caution

Ensure that the HMI device does not access the memory card during the removal process.

Otherwise, the contents of the memory card will be fully destroyed.

1. Terminate access made by the HMI device to the memory card.

If the configuration engineer has defined an operating element linked to the

"CloseAllLogs" system function, press the element. Otherwise, press the operating

element linked to the "StopRuntime" system function in the configuration. This ends

runtime.

2. Wait unit the HMI device displays the loader.

Changeover to the loader may take several minutes depending on the size and number

of logs stored.

3. Remove the memory card.

Switch off the HMI device with memory card inserted

Caution

Always terminate the runtime software before switching off the voltage supply in order to

prevent loss of data.

1. Terminate runtime.

Press the operating element linked to the "StopRuntime" system function in the

configuration.

2. Wait unit the HMI device displays the loader.

Changeover to the loader may take several minutes depending on the size and number

of logs stored.

3. Switch off the power supply.

If the power supply is interrupted during normal operation, the HMI device checks the

memory card after power is restored and repairs any defect sectors.

See also

HMI device loader (Page 6-1)

TP 270, OP 270, MP 270B (WinCC flexible)

Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

1-15

Overview

1.7 Options

1.7.2 Software options

1.7.2.1 Internet Explorer

Overview

The Internet Explorer supplied with the HMI device has been specially adapted to the

Windows CE operating system and has a restricted functional scope (Pocket Internet

Explorer). Only simple HTML pages, about 100 kb, can be displayed.

Prior to installation, use the system settings to set 1.5 Mb memory for the DRAM file system.

Caution

If too much memory is provided for the DRAM file system, runtime has too little working

memory available. Therefore, in the case of incorrect settings, there is no guarantee that the

runtime can run properly.

Caution

The operation of runtime together with the Internet Explorer can only be guaranteed when

the run-capable configuration (*.fwx) generated is a maximum of 2 Mb.

The installation of Internet Explorer is performed using the ProSave service tool or WinCC

flexible configuration software.

Files created in Internet Explorer, e.g. Favorites, are stored in the DRAM file system. The

DRAM file system is deleted when the unit is switched off. However, using the system

settings (OP Properties > Persistent Storage > Save Files), it is possible to backup the data

currently available in the DRAM file system to the Flash memory. When the device is started

up, the backup data is automatically restored.

If you remove the Internet Explorer, the files created from Internet Explorer must also be

deleted. To do this, delete the files in the DRAM file system using the standard Explorer.

Then backup the DRAM file system ("OP Properties > Persistent Storage > Save Files").

Reset the size of the DRAM file system to the preset value of 2 Mb.

Note

The initial configuration can be restored simply by updating the operating system.

See also

System (Page 6-15)

Update operating system (Page 7-18)

Transferring options (Page 7-22)

TP 270, OP 270, MP 270B (WinCC flexible)

1-16 Operating Instructions, Edition 03/2004, 6AV6691-1DD01-0AB0

Loading...

Loading...