Siemens SIMATIC Mobile Client900RFN Operating Instructions Manual

Mobile Client900RXA

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC HMI

Customized automation

Mobile Client900RXA

Operating Instructions

07/2015

A5E36360099

Preface

Overview

1

Safety guidelines

2

Installing and connecting the

device

3

Parameter assignment of a

Mobile Client

4

Configuring the Mobile Client

and Connection box

5

Commissioning a project

6

Operating the project

7

Operating the mobile client

8

Device maintenance and

repair

9

Technical specifications

10

Technical support

A

Abbreviations

B

-AA

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E36360099-AA

Ⓟ

Copyright © Siemens AG 2015.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

07/2015 Subject to change

Preface

Purpose of the operating instructions

Knowledge required

Scope of application of the document

Note

Observe the following points:

•

•

•

These operating instructions provide information based on the requirements defined by

DIN EN 62079 for mechanical engineering documentation. This information relates to the

place of use, transport, storage, mounting, use and maintenance.

These operating instructions are intended for the following user groups:

● Operators

Operators operate and monitor the system during the process control phase.

● Commissioning engineers

The commissioning engineer integrates the HMI device into the system and ensures the

operating capability of the HMI device for the process control phase.

● Service technicians

Service technicians rectify faults that occur during the process control phase.

● Maintenance technicians

Maintenance technicians carry out regular maintenance work during the process control

phase.

General knowledge of automation technology and process communication is needed to

understand the operating instructions.

This source document was written in German, the basis for the translations, and applies to

the following HMI devices:

● SIMATIC Mobile Client900RXA, article number 6AV6645-7CG00-2AA0

This document belongs to the device and will also be required for repeat commissioning.

Keep all supplied and supplementary documentation for the entire service life of the

device.

Make sure that the persons who require these documents have access to them.

Pass on all of these documents to the subsequent owner of the device.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

3

Preface

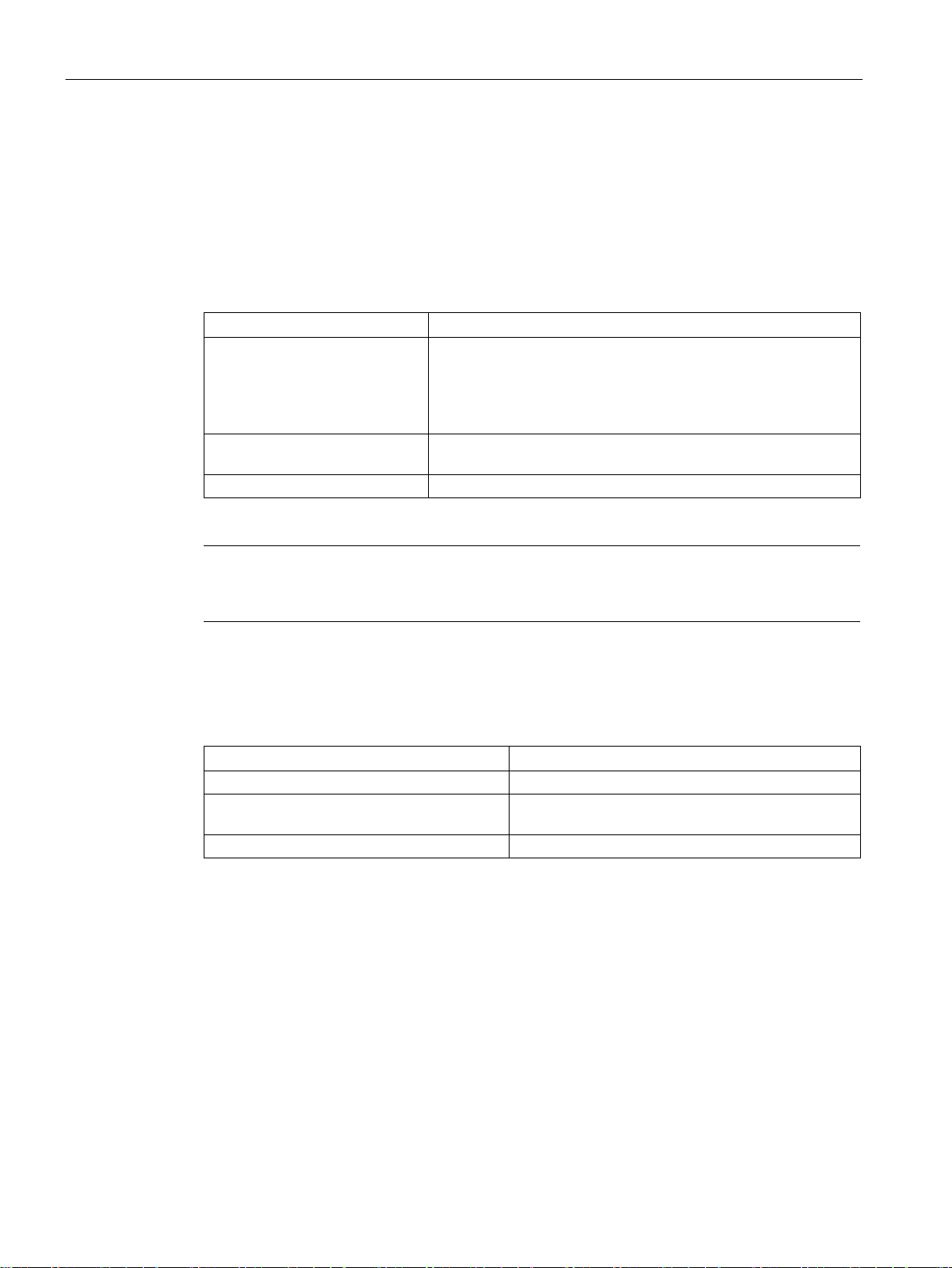

Figures

Style conventions

Representation type

Scope

<F1>, <Alt + P>

Keyboard actions

Note

Notes containing important information about the product and its use or a specific section of

the documentation to which you should pay particular attention.

Naming conventions

Item name

Term used in the document

Mobile Client all versions

Device, HMI device, Mobile Client, Mobile Panel

temperature range)

Mobile Client without Arctic extension

Non-arctic HMI device

This document contains figures of the described devices and the described software. The

figures can deviate from the particularities of the delivered device and the supplied software.

The following text notation will facilitate reading this manual:

"Add figure"

"File > Edit" Operating sequences, for example, menu commands, shortcut

Please observe notes labeled as follows:

The following terms are used in this document:

Mobile Client with Arctic extension (extended

• Terminology that appears in the user interface, for example

dialog names and buttons.

• Required inputs, for example, an IP address.

• Path information

menu commands.

Arctic HMI device

Mobile Client900RXA

4 Operating Instructions, 07/2015, A5E36360099-AA

Table of contents

Preface ................................................................................................................................................... 3

1 Overview................................................................................................................................................. 9

2 Safety guidelines ................................................................................................................................... 25

3 Installing and connecting the device ...................................................................................................... 31

1.1 Product description ................................................................................................................... 9

1.2 Design of the device ............................................................................................................... 10

1.3 Scope of delivery .................................................................................................................... 12

1.4 Accessories ............................................................................................................................. 12

1.4.1 Connecting cable .................................................................................................................... 12

1.4.2 Connection box ....................................................................................................................... 13

1.4.3 Wall-mounting bracket ............................................................................................................ 14

1.4.4 Wall-mounting bracket with cable holder ................................................................................ 15

1.4.5 Magnetic wall bracket ............................................................................................................. 16

1.4.6 Protective cover ...................................................................................................................... 18

1.4.7 Protective foil .......................................................................................................................... 18

1.4.8 Rubber strips ........................................................................................................................... 19

1.4.9 Touch pen ............................................................................................................................... 19

1.4.10 Storage media ......................................................................................................................... 20

1.5 The HMI device in the operating process ............................................................................... 20

1.6 Scope of functions with WinCC .............................................................................................. 21

1.7 Software add-ons .................................................................................................................... 23

1.8 Communication with controllers .............................................................................................. 24

2.1 General safety instructions ..................................................................................................... 25

2.2 Notes about usage .................................................................................................................. 28

2.3 Power supply .......................................................................................................................... 30

3.1 Preparing for installation ......................................................................................................... 31

3.1.1 Checking delivery .................................................................................................................... 31

3.1.2 Device identification data ........................................................................................................ 31

3.1.3 Mounting positions and type of fixation ................................................................................... 31

3.1.4 Preparing mounting of the connection box ............................................................................. 32

3.1.5 Preparing to mount the wall-mounting bracket ....................................................................... 32

3.2 Connection box and wall bracket ............................................................................................ 33

3.2.1 Mounting the connection box .................................................................................................. 33

3.2.2 Mounting the wall-mounting bracket ....................................................................................... 33

3.2.3 Mounting and using the magnetic wall-mounting bracket....................................................... 35

3.2.3.1 Mounting the magnetic wall bracket ....................................................................................... 35

3.2.3.2 Using the magnetic wall bracket ............................................................................................. 36

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

5

Table of contents

4 Parameter assignment of a Mobile Client .............................................................................................. 45

3.3 Connecting the device ........................................................................................................... 37

3.3.1 Connecting the connection box .............................................................................................. 37

3.3.1.1 Connection sequence ............................................................................................................ 37

3.3.1.2 Connecting cables and replacing fuses ................................................................................. 38

3.3.1.3 Connecting the power supply ................................................................................................. 39

3.3.2 Connecting the mobile client .................................................................................................. 41

3.3.3 Connecting the USB mouse or USB keyboard for service purposes .................................... 42

3.4 Switching on and testing the HMI device ............................................................................... 43

4.1 Desktop and Start Center ...................................................................................................... 45

4.2 Operating the desktop, Start Center and Control Panel ........................................................ 46

4.3 Installed programs ................................................................................................................. 46

4.4 Security mode ........................................................................................................................ 47

4.4.1 Overview ................................................................................................................................ 47

4.4.2 Activating and deactivating temporary security mode ........................................................... 48

4.4.3 Using the HMI device in password-protected security mode ................................................. 49

4.5 Control Panel ......................................................................................................................... 50

4.5.1 Overview ................................................................................................................................ 50

4.5.2 Functions in the Control Panel ............................................................................................... 50

4.5.3 Operating the Control Panel .................................................................................................. 51

4.5.4 Display types for the screen keyboard ................................................................................... 52

4.5.5 Configuring operation ............................................................................................................. 54

4.5.5.1 Changing the screen settings ................................................................................................ 54

4.5.5.2 Configuring the screen keyboard ........................................................................................... 56

4.5.5.3 Setting the character repeat rate of the screen keyboard ..................................................... 57

4.5.5.4 Setting the double-click .......................................................................................................... 58

4.5.5.5 Calibrating the touch screen .................................................................................................. 59

4.5.5.6 Restarting the Mobile Panel ................................................................................................... 60

4.6 General settings ..................................................................................................................... 62

4.6.1 Regional and language settings............................................................................................. 62

4.6.2 Setting the date and time ....................................................................................................... 63

4.6.3 Changing password protection .............................................................................................. 64

4.6.4 Setting the screen saver ........................................................................................................ 66

4.6.5 Configuring transfer ............................................................................................................... 67

4.6.6 Setting the memory ................................................................................................................ 69

4.6.6.1 Displaying memory distribution .............................................................................................. 69

4.6.6.2 Setting the project storage location and start delay ............................................................... 70

4.6.7 Backing up registry information and temporary data ............................................................. 71

4.6.8 Changing the printer properties ............................................................................................. 72

4.6.9 Displaying general system properties .................................................................................... 73

4.6.10 Displaying information about the Mobile Panel ...................................................................... 74

4.7 Changing Internet settings ..................................................................................................... 75

4.7.1 Changing general Internet settings ........................................................................................ 75

4.7.2 Setting the proxy server ......................................................................................................... 76

4.7.3 Changing the privacy settings ................................................................................................ 77

4.7.4 Importing, displaying and deleting certificates ....................................................................... 78

4.8 Enabling NTP ......................................................................................................................... 80

Mobile Client900RXA

6 Operating Instructions, 07/2015, A5E36360099-AA

Table of contents

5 Configuring the Mobile Client and Connection box .............................................................................. 101

6 Commissioning a project ..................................................................................................................... 103

7 Operating the project ........................................................................................................................... 115

4.9 Configuring network operation ................................................................................................ 81

4.9.1 Overview ................................................................................................................................. 81

4.9.2 Entering the Mobile Panel computer name............................................................................. 83

4.9.3 Specifying the IP address and name server ........................................................................... 84

4.9.4 Specifying the logon data ....................................................................................................... 85

4.9.5 Configuring e-mail ................................................................................................................... 86

4.9.6 Configuring Telnet for remote control ..................................................................................... 88

4.10 Functions for service and commissioning ............................................................................... 88

4.10.1 Saving to external storage medium – backup ......................................................................... 88

4.10.2 Restoring from external storage medium – Restore ............................................................... 91

4.10.3 Restoring from external storage medium – Restore ............................................................... 93

4.10.4 Update operating system ........................................................................................................ 95

4.10.5 Setting a communication connection to the PLC .................................................................... 97

4.10.5.1 Overview ................................................................................................................................. 97

4.10.5.2 Changing the network configuration ....................................................................................... 97

5.1 Required configuration software ........................................................................................... 101

5.2 Configuring the device .......................................................................................................... 101

5.3 Configuring the Connection Box ........................................................................................... 101

6.1 Overview ............................................................................................................................... 103

6.2 Operating modes .................................................................................................................. 103

6.3 Using existing projects .......................................................................................................... 104

6.4 Data transmission options .................................................................................................... 105

6.5 Transfer ................................................................................................................................. 105

6.5.1 Setting the transfer mode ..................................................................................................... 105

6.5.2 Starting the transfer .............................................................................................................. 107

6.5.3 Testing a project ................................................................................................................... 108

6.6 Backup and restore ............................................................................................................... 109

6.6.1 Overview ............................................................................................................................... 109

6.6.2 Backing up and restoring data of the HMI device ................................................................. 110

6.7 Updating the operating system ............................................................................................. 111

6.7.1 Updating the operating system ............................................................................................. 111

6.7.2 Updating the operating system of the HMI device ................................................................ 111

6.8 Managing add-ons and license keys .................................................................................... 113

6.8.1 Transferring license keys ...................................................................................................... 113

7.1 Overview ............................................................................................................................... 115

7.2 Setting the project language ................................................................................................. 116

7.3 Entering and modifying the value, date and time ................................................................. 117

7.4 Operating the Sm@rtClient view .......................................................................................... 119

7.5 Displaying infotext ................................................................................................................. 121

7.6 Closing the project ................................................................................................................ 122

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

7

Table of contents

8 Operating the mobile client ................................................................................................................... 123

9 Device maintenance and repair ............................................................................................................ 131

10 Technical specifications ....................................................................................................................... 135

A Technical support................................................................................................................................. 151

B Abbreviations ....................................................................................................................................... 153

Glossary .............................................................................................................................................. 155

Index ................................................................................................................................................... 157

8.1 Holding and setting down the mobile client ......................................................................... 123

8.2 Special operating modes ..................................................................................................... 124

8.3 Using the override function .................................................................................................. 125

8.4 LED display .......................................................................................................................... 126

8.5 Switching the device on and off ........................................................................................... 129

8.6 Possible errors when powering on ....................................................................................... 130

9.1 Cleaning the device ............................................................................................................. 131

9.2 Spare parts and repairs ....................................................................................................... 132

9.3 Recycling and disposal ........................................................................................................ 132

9.4 Maintenance application ...................................................................................................... 132

10.1 Certificates and approvals ................................................................................................... 135

10.2 Directives and declarations .................................................................................................. 136

10.2.1 Electromagnetic compatibility .............................................................................................. 136

10.2.2 ESD guideline ...................................................................................................................... 138

10.3 Dimension drawings ............................................................................................................. 140

10.3.1 Mobile client ......................................................................................................................... 140

10.3.2 Connection box .................................................................................................................... 141

10.3.3 Wall-mounting bracket ......................................................................................................... 142

10.3.4 Magnetic wall bracket .......................................................................................................... 143

10.4 Specifications ....................................................................................................................... 144

10.4.1 Technical specifications Mobile Client ................................................................................. 144

10.4.2 Technical specifications Connection Box ............................................................................ 145

10.4.3 Technical specifications of the wall-mounting brackets ....................................................... 146

10.4.4 Ambient conditions for transport and storage ...................................................................... 146

10.4.5 Ambient conditions during operation ................................................................................... 147

10.5 Contact assignment of the USB port.................................................................................... 149

A.1 Service and support ............................................................................................................. 151

A.2 Problem solving.................................................................................................................... 152

Mobile Client900RXA

8 Operating Instructions, 07/2015, A5E36360099-AA

1

1.1

Product description

The SIMATIC Mobile Client900RFN is a portable HMI device with a rugged and ergonomic

design. A high-performance processor and Ethernet capability mean the device is excellently

suited to a wide range of uses. The device is lightweight and robust, has an easy-to-read

display and can be operated by both left-handed and right-handed users.

The device also has the following additional features:

● Ethernet, integrated with connecting cable

● 9" TFT screen with color depth of 24 bits

● USB port for service purposes

● Heating system

The device heats up, if necessary, and keeps the internal temperature within the optimum

temperature range for as long as the heat output permits.

The SIMATIC Mobile Client connection box, connection box for short, is designed to be

mounted to the wall of the control cabinet. It provides the power supply and control system

connections in the control cabinet. The device is connected to the connection box with a

connecting cable.

The device is used as a mobile handheld terminal. The connecting cable can be easily

connected and disconnected at both the connection box and the handheld terminal. The

device enables you to use text- or graphic-based projects even more efficiently for simple

and medium-complexity operator control and monitoring tasks on machines and systems.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

9

Overview

Area of application

Note

Please observe the relevant requirements and safety meas

of use.

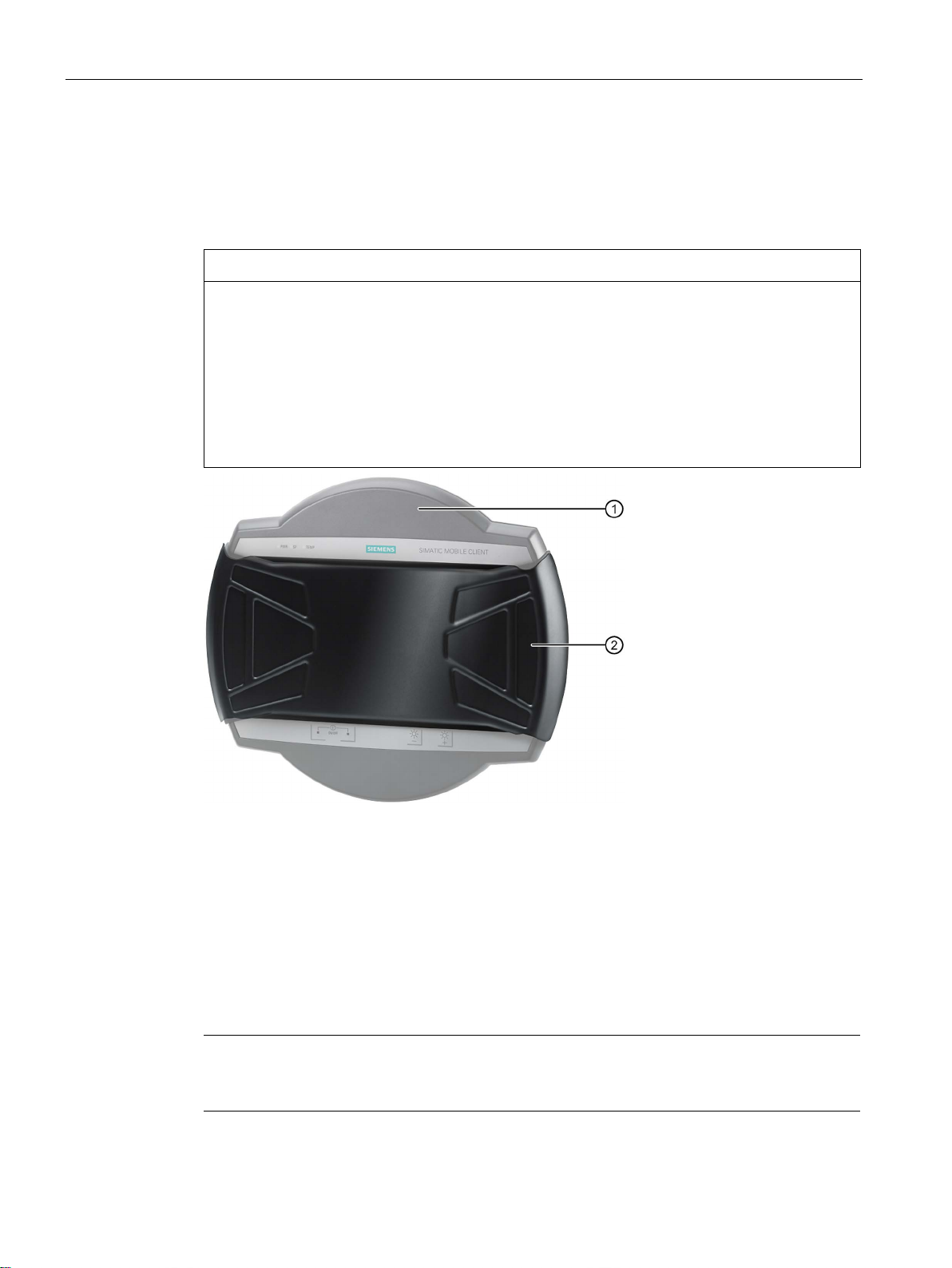

1.2

Design of the device

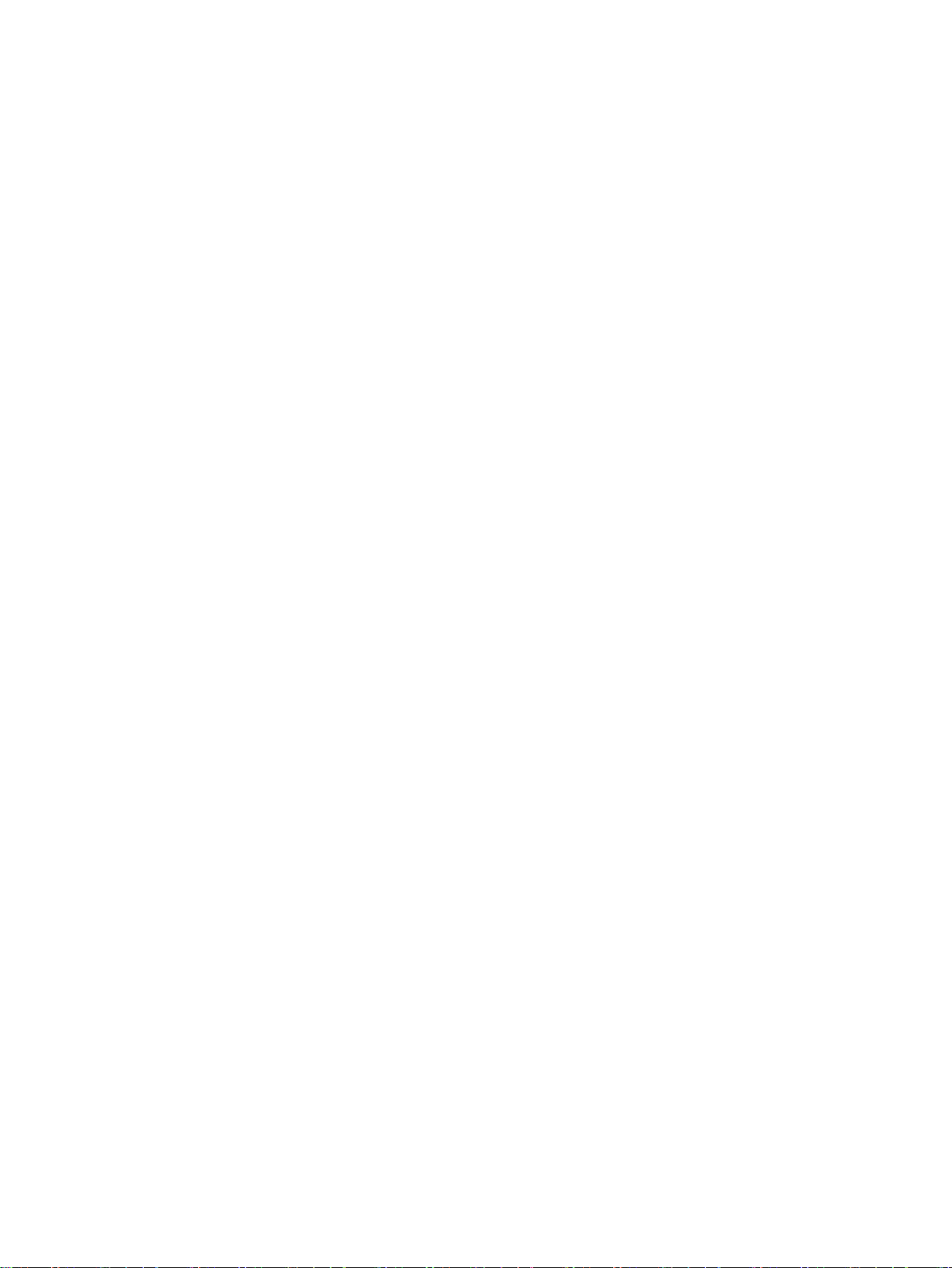

Front view

①

LED display

②

Display with touch screen

③

Handle

④

Button for brightness control

⑤

On/off button, two present

1.2 Design of the device

The device is intended for uses ranging from operation and monitoring, parameter

assignment, and commissioning to troubleshooting for industrial systems, in particular wind

turbines.

ures for the application and place

Mobile Client900RXA

10 Operating Instructions, 07/2015, A5E36360099-AA

Overview

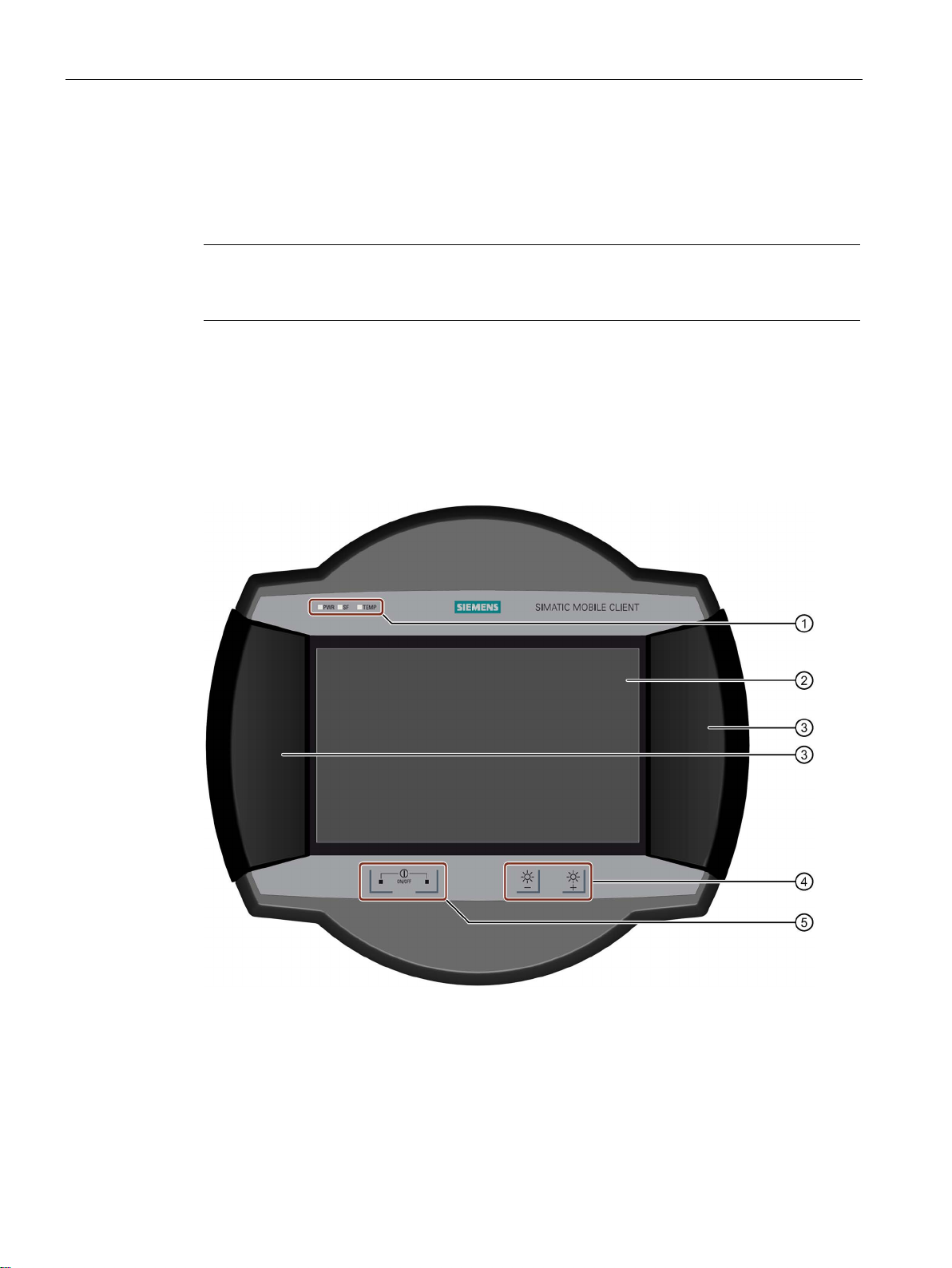

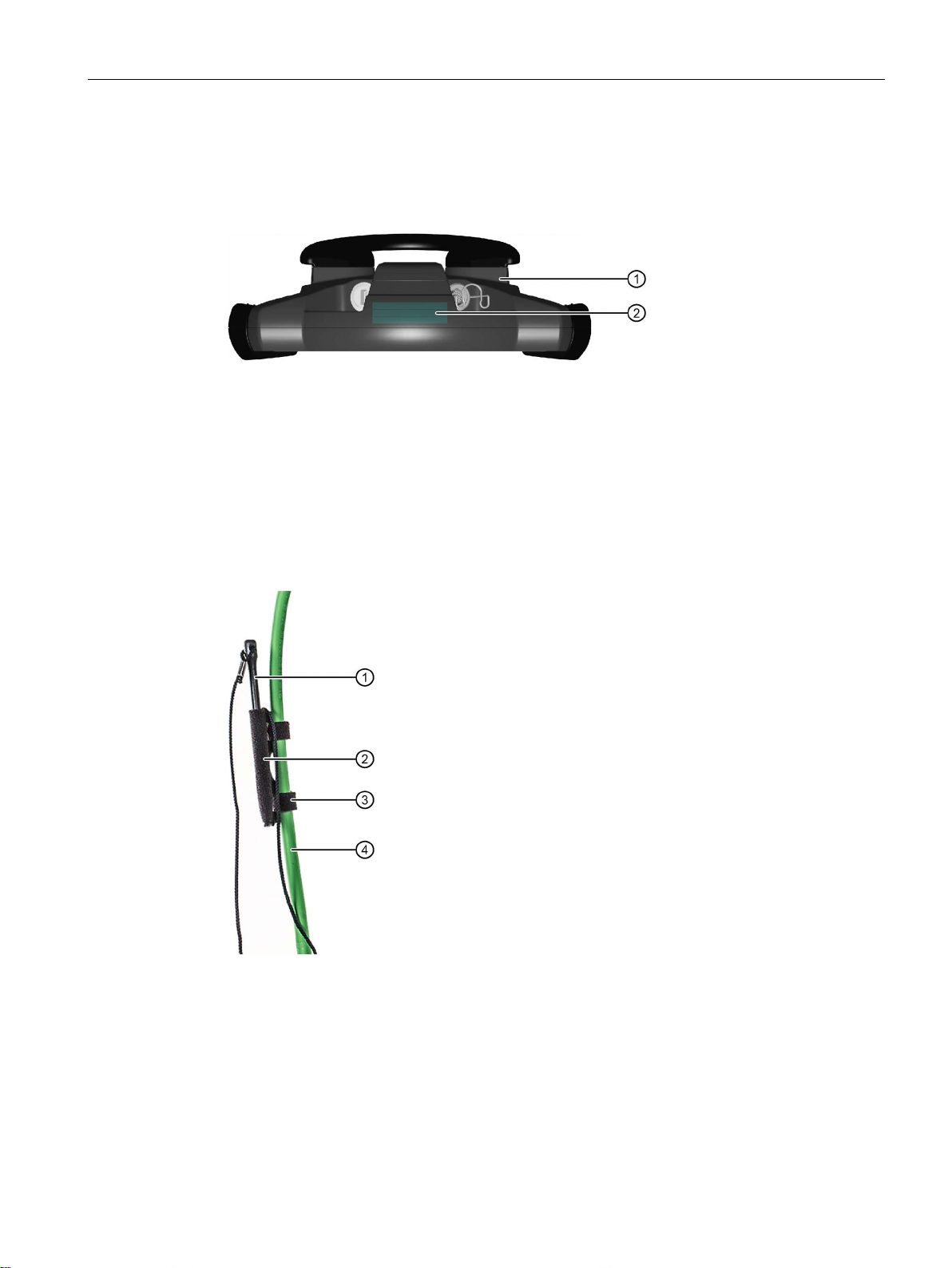

Bottom view

①

Handle

②

Stand

Rear view

①

Rating plate

②

Space for customized rating plate

③

USB port for service purposes

④

Pressure compensation valve

⑤

Port for connecting cable, with locking clip

1.2 Design of the device

The supporting surfaces of the handle and stand are made of anti-slip material.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

11

Overview

Note

The device ensures a degree of protection of IP65 even without the connecting cable

plugged in.

1.3

Scope of delivery

1.4

Accessories

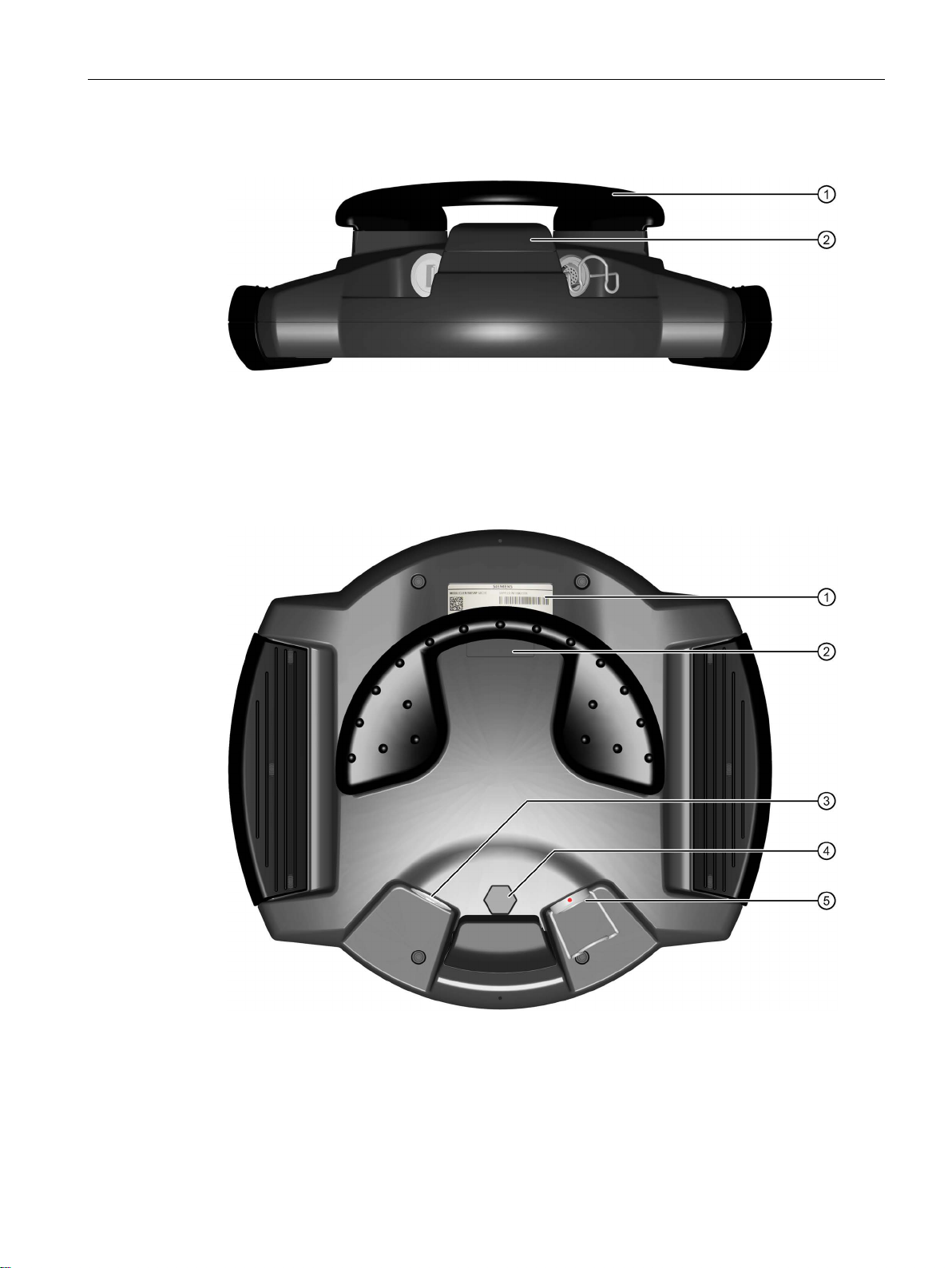

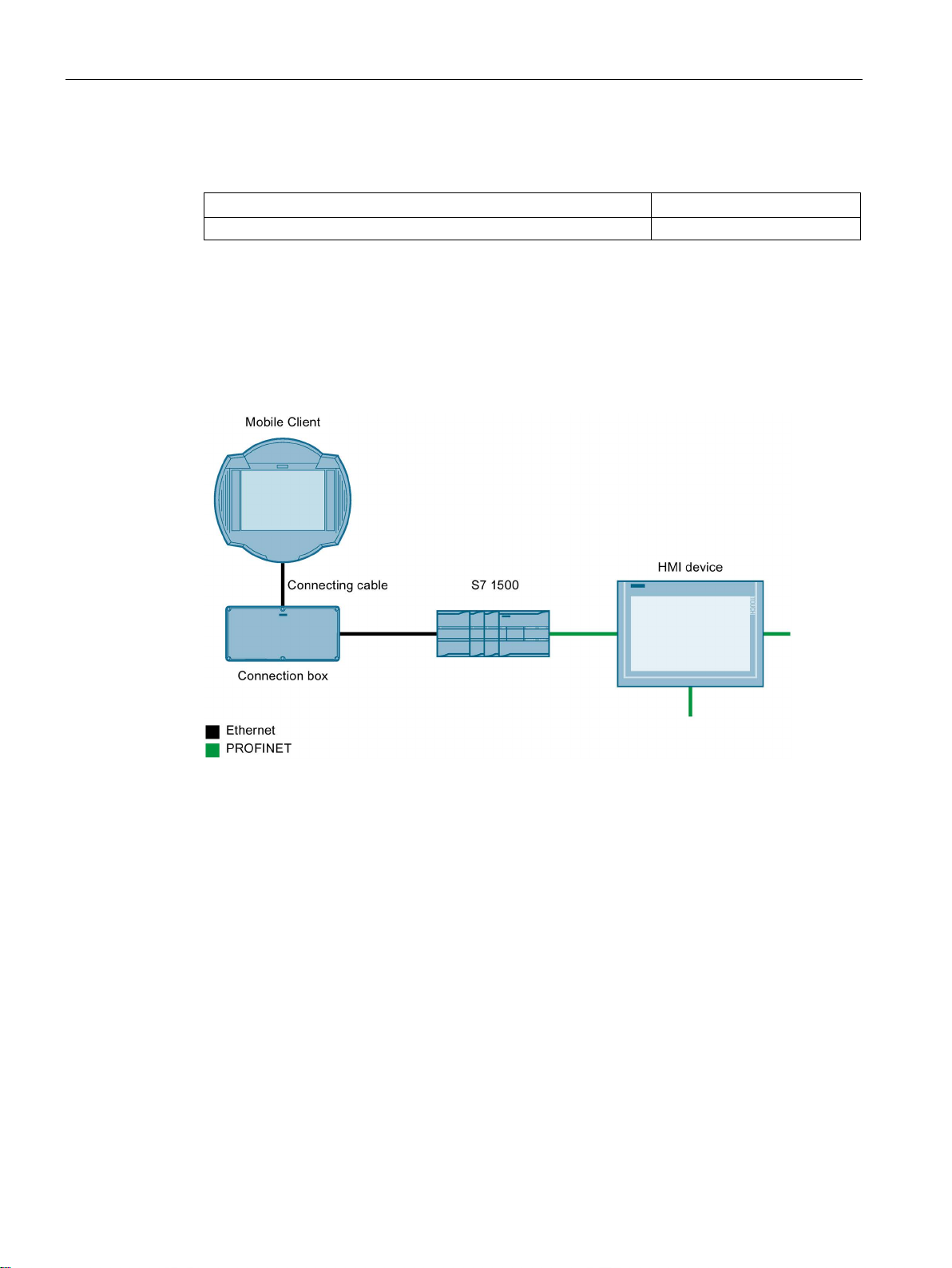

1.4.1

Connecting cable

①

Circular connector, female connector for connection to the device

②

Circular connector, male connector for connection to the connection box

1.3 Scope of delivery

● 1 × HMI device

● 1 × packaging

Packaging is used for shipping and protection of the device. You can reuse the packaging

if you are returning the device.

Accessories are not included with the device. You can order accessories by entering the

corresponding article number at the following link:

Industry Mall (https://mall.industry.siemens.com

The connecting cable connects the device with the connection box:

)

Mobile Client900RXA

12 Operating Instructions, 07/2015, A5E36360099-AA

Overview

Length

Article number

Functional status

5 m

6AV6645-7CY03-1WP0

FS 02

15 m

6AV6645-7CY05-1WP0

FS 02

1.4.2

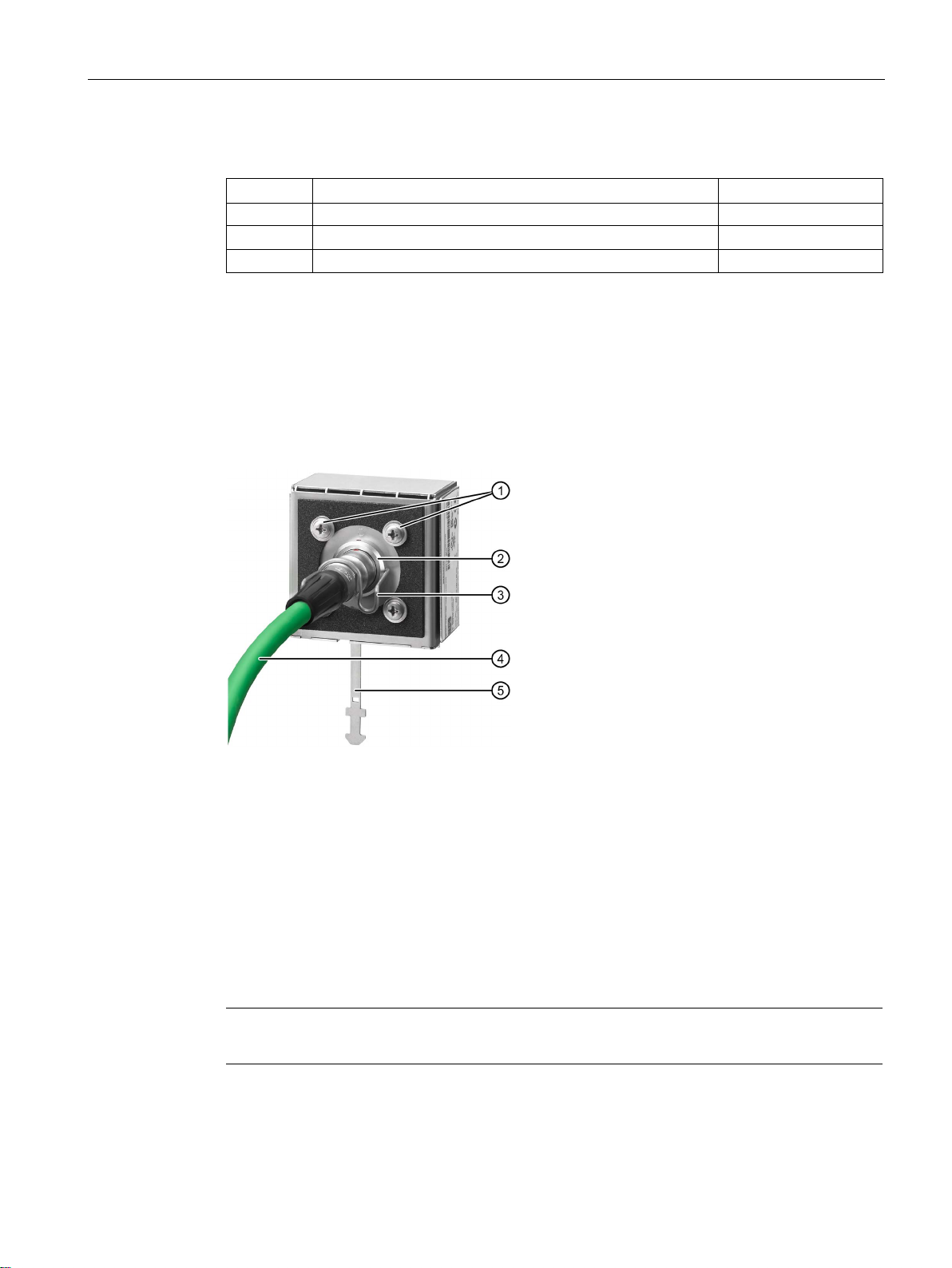

Connection box

①

Screws for fixing the connection box

②

Socket for the connecting cable

③

Locking bracket for the circular connector

④

Connecting cable

⑤

Attach

Article number:

Note

IP65 can only be guaranteed for the

1.4 Accessories

The connecting cable is available in the following lengths:

10 m 6AV6645-7CY04-1WP0 FS 02

The connecting cable is an industrial cable and is therefore resistant to many solvents and

lubricants. The flexural strength of the connecting cable is geared to the actual usage

conditions.

The connection box supplies power to the device and connects it to the Ethernet network.

A mechanical foolproofing device means that only the correct connecting cable circular

connector can be plugged into the connection box.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

ment for cable ties for strain relief

6AV6645-7CX06-1WP0

connection box when the connecting cable is attached.

13

Overview

1.4.3

Wall-mounting bracket

①

②

1.4 Accessories

The scope of delivery of the connection box includes:

● 1 × connection box

● 1 x accessory pack with the following contents:

– 4 M5 × 8 screws

– 1 mains terminal for the power supply

● 1 × Product Information

The wall bracket ensures secure fastening of the Mobile Panel during stationary operation.

Hook for the grip on the HMI device

Screw flange

The wall bracket is not included with the HMI device. The wall bracket is available with order

number 6AV6574-1AF04-4AA0.

Mobile Client900RXA

14 Operating Instructions, 07/2015, A5E36360099-AA

Overview

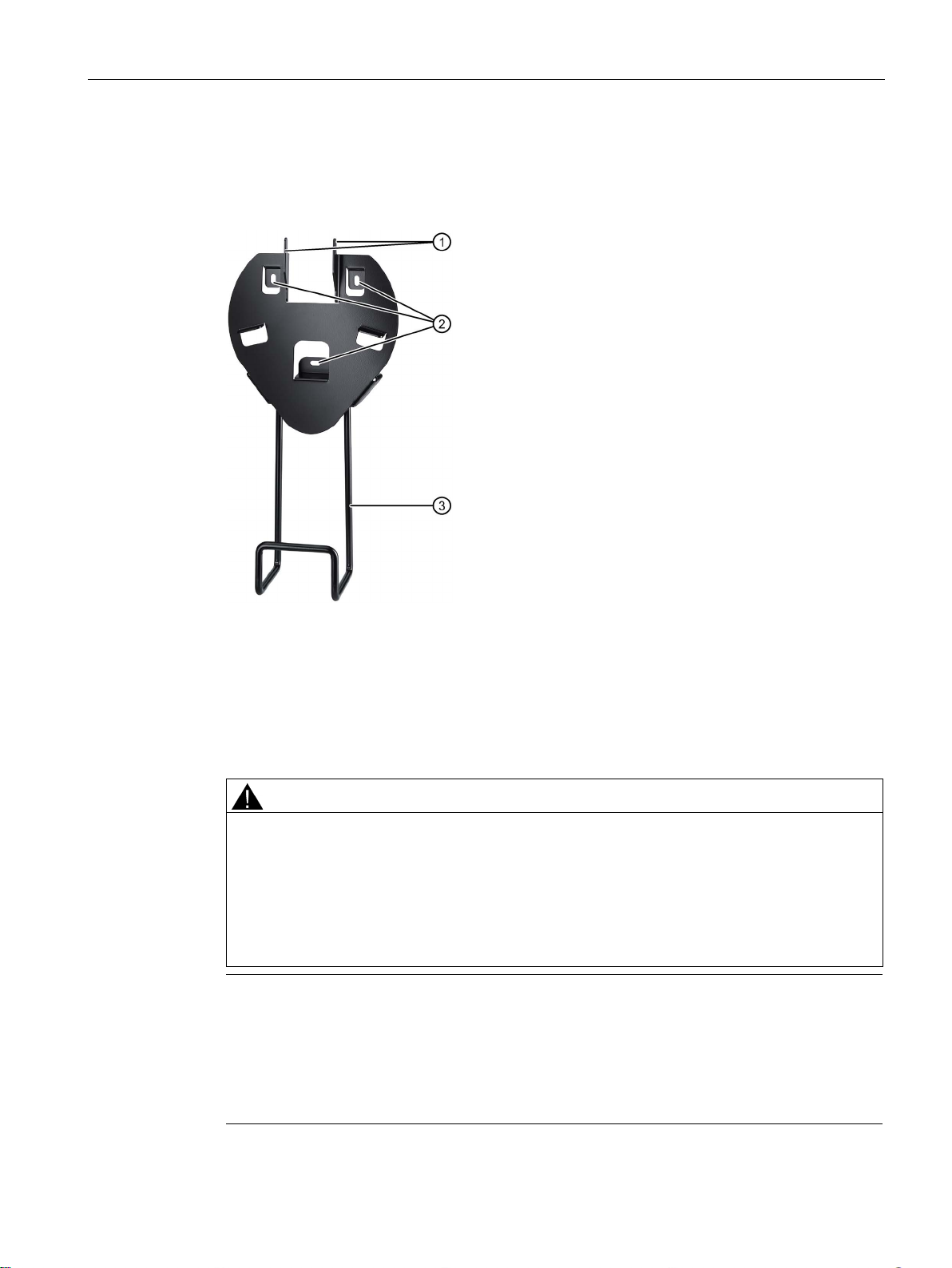

1.4.4

Wall-mounting bracket with cable holder

①

Hooks

You attach the handle of the Mobile Client to the hooks.

②

Mounting holes

③

Holder for the connecting cable

Article number:

CAUTION

Risk of injury when device drops

Note

The wall bracket is designed for fixed used and is always to be screwed to the wall.

•

•

•

1.4 Accessories

The wall bracket is used as a secure holder for the device during stationary operation and to

store the device when it is not in use.

6AV6645-7CX04-1WP0

The device can fall out of the wall bracket even when handled carefully.

• Never stand below the fitted wall bracket.

• The wall bracket is permitted for indoor use only.

• Do not mount the wall bracket on doors or covers.

• Do not fit the wall bracket anywhere where the device may fall out of the bracket.

The wall bracket should not be used to store tools or for other purposes.

Ensure that the wall bracket is used correctly. If the wall bracket is not in use, it should be

stored in a suitable location.

Make sure that no one can trip over the cable and cause the device to fall.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

15

Overview

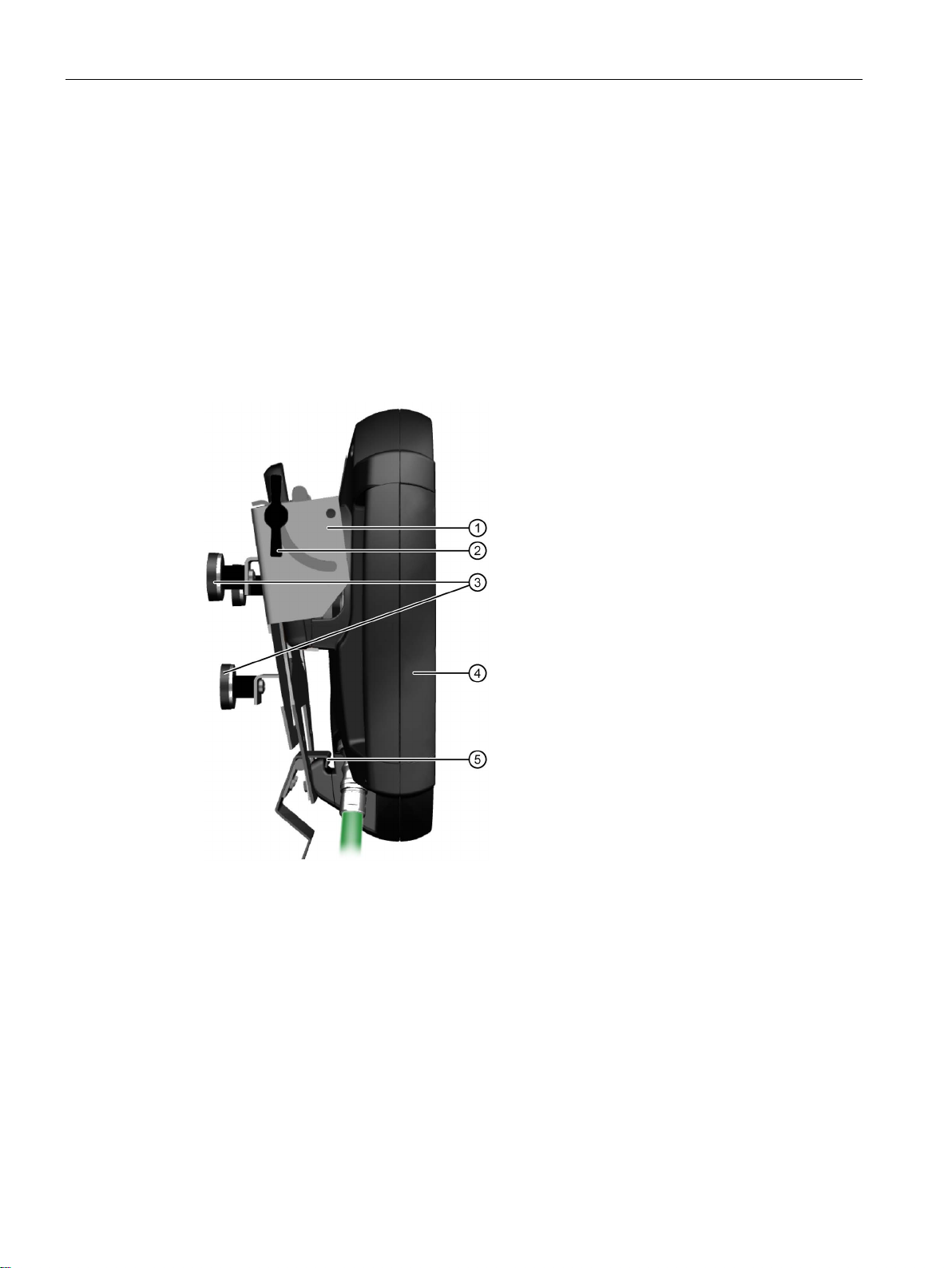

1.4.5

Magnetic wall bracket

①

Joint to set the inclination of the device

②

Wing screw to secure the inclination of the device

③

Magnets

④

Mobile Client

⑤

Locking hook

Article number:

1.4 Accessories

The magnetic wall bracket provides a safe hold for the SIMATIC Mobile Client when used in

stationary mode.

The magnetic wall bracket is equipped with magnets for permanent or temporary mounting

on ferromagnetic surfaces. The following applies to the magnetic holding power:

● Under normal circumstances, the wall bracket can be removed from the surface without

tools.

● When the wall bracket is used as intended, there is no danger of it falling unintentionally

with the HMI device.

The magnetic wall bracket features a retaining mechanism for the HMI device.

Mobile Client900RXA

16 Operating Instructions, 07/2015, A5E36360099-AA

6AV6645-7CX05-1WP0

Overview

Safety information on the magnetic wall bracket

CAUTION

Risk of injury when device drops

Risk of injury or damage from magnetic fields

Note

•

•

•

Adjustable inclination

CAUTION

Tighten the wing screws sufficiently

1.4 Accessories

The magnetic wall bracket should be regarded as a suspended load and can fall. However,

under normal circumstances and if handled properly, the magnetic wall bracket is designed

in such a way that there is no risk of the wall bracket and device unintentionally falling and

the wall bracket can be taken down without tools.

In the case of improper locking, the device could fall out of the wall bracket.

• Never stand below the fitted wall bracket.

• Do not mount the wall bracket overhead or in places where the wall bracket or the

device held in it could fall.

• The wall bracket is permitted for indoor use only.

• Do not mount the wall bracket on doors or covers.

• The magnetic holding power is affected by the material, thickness and structure of the

mounting surface. Ensure that the holding power at the mounting location is sufficient. If

necessary, choose a different mounting location.

Strong magnetic fields attract magnetic parts and damage or destroy electromagnetic

elements and devices. This also applies to pacemakers.

• Do not bring any iron parts (tools, nails, knives) into the vicinity of the magnets.

• Keep electronic devices and magnetic data carriers away from the magnets.

• Do not process the magnets mechanically, for example, by sawing or drilling.

• Keep the magnets away from open heat and flames.

The wall bracket should not be used to store tools etc.

Ensure that the wall bracket is used correctly. If the wall bracket is not in use, it should be

stored in a suitable location.

Make sure that no one can trip over the cable and cause the device to fall.

The inclination can be adjusted in the range from almost parallel to almost perpendicular to

the mounting surface. To adjust the inclination, loosen the wing screws located on both sides

of the wall bracket. With very large inclinations, the device cannot be removed from the wall

bracket. In this case, reduce the inclination in order to remove the device safely from the wall

bracket.

Loosen the wing screws only when you wish to adjust the inclination. Afterwards, tighten

the two wing screws. Check that the wing screws and the device are tightly in place.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

17

Overview

1.4.6

Protective cover

NOTICE

Overheating

Damage to the touch screen

①

Device

②

Protective cover

Article number:

1.4.7

Protective foil

Article number:

Note

Particles of dirt can scratch the touch screen when you attach the protective sheet. Clean the

touch screen before attaching the protective sheet.

1.4 Accessories

The protective cover provides mechanical protection of the display and is attached to both

handles. It protects the device from being damaged when transported, for example, in a tool

bag together with other tools.

If you use the protective cover when the HMI device is on, the device may overheat.

Make sure the HMI device is off before you fit the protective cover.

Particles of dirt can scratch the touch screen when you attach the protective cover.

Clean the touch screen before attaching the protective cover or use a protective sheet

according to chapter "Protective foil (Page 18)".

Mobile Client900RXA

18 Operating Instructions, 07/2015, A5E36360099-AA

The protective sheet prevents the touch screen getting scratched or dirty.

The set contains 10 protective sheets.

6AV6645-7CX02-1WP0

6AV6645-7CX07-1WP0

Overview

1.4.8

Rubber strips

①

Device

②

3 rubber strips

Article number:

1.4.9

Touch pen

①

Touch pen

②

Holder

③

Velcro strap

④

Connecting cable

Article number:

1.4 Accessories

The rubber strips prevent the device from slipping. You can also use rubber strips to angle

the device, for example.

The touch pen makes it easier to operate the touch screen. The touch pen is to be attached

to the connecting cable.

6AV6645-7CX01-1WP0

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

6FC5348-0AA08-4AA0

19

Overview

1.4.10

Storage media

Name

Article number

USB flash drive 8 GB

6ES7648-0DC50-0AA0

1.5

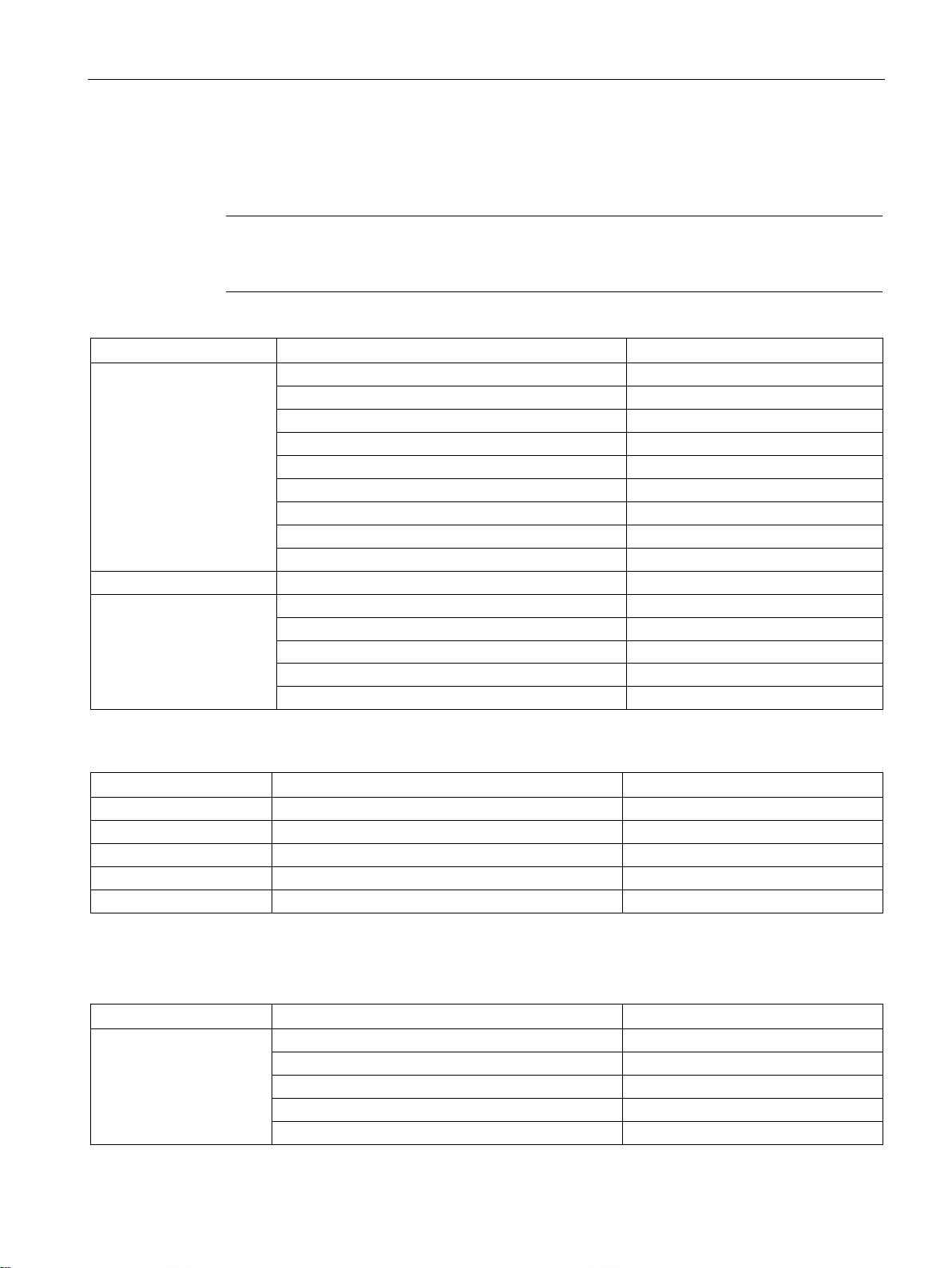

The HMI device in the operating process

1.5 The HMI device in the operating process

The HMI device is part of the operating process. Operation is based on two-way

communication between the HMI device and the PLC. The following figure shows an

exemplary system design.

The HMI device is used for monitoring or controlling the operating process. The controller in

turn supplies the results of the operating process, which are displayed on the Mobile Client.

Mobile Client900RXA

20 Operating Instructions, 07/2015, A5E36360099-AA

Overview

1.6

Scope of functions with WinCC

Note

The specified values are maximum values of the individual objects. Simultaneous use of

multiple objects with their maximum value can lead to problems in the active project.

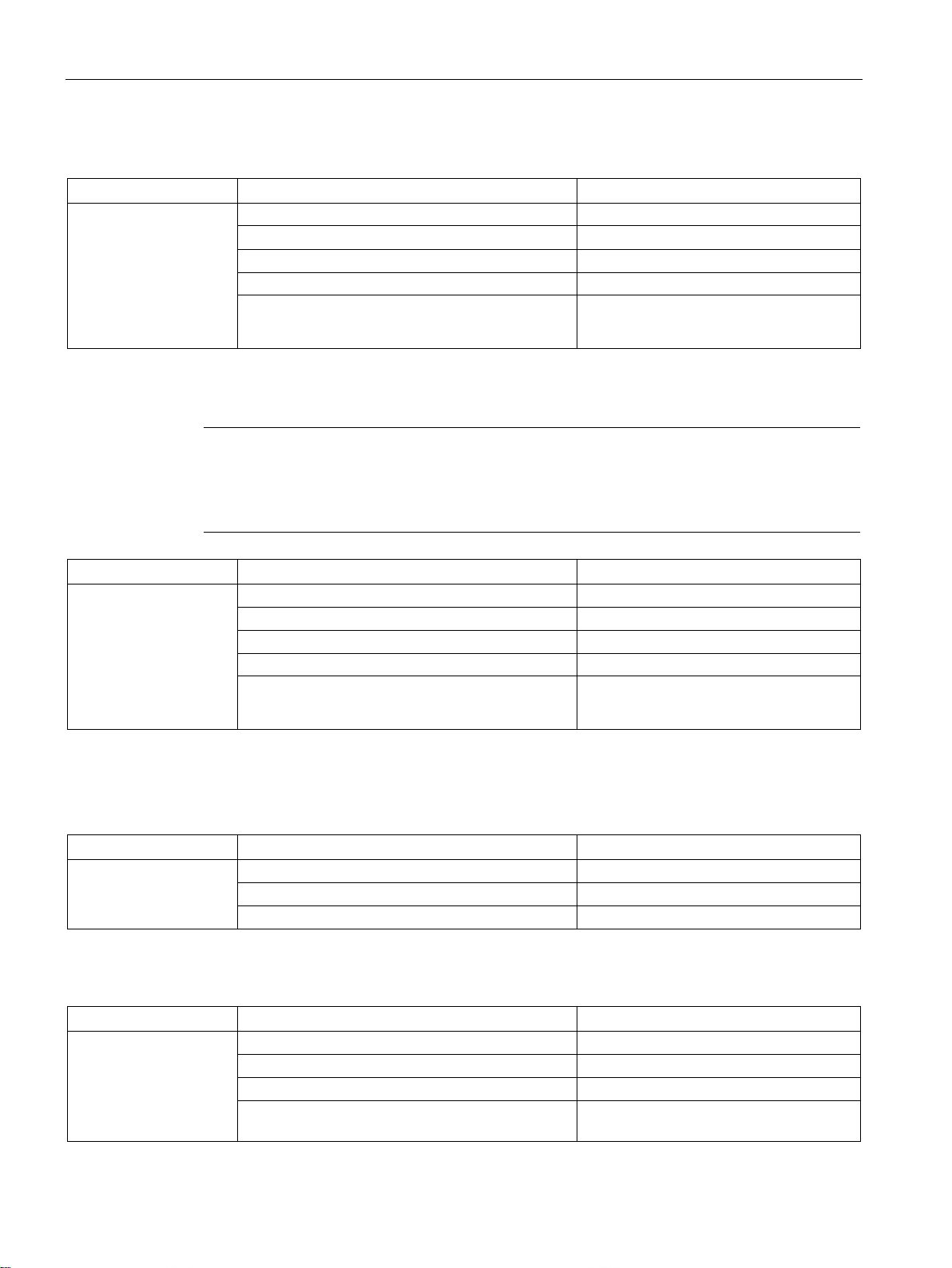

Alarms

Object

Specification

Configuration

Number of discrete alarms

4000

Number of analog alarms

200

Alarm length

80 characters

Number of tags / process values in an alarm

Max. 8

Number of alarm classes

32

Display

Alarm window, alarm view

Acknowledge error alarm individually

Yes

Edit alarm

Yes

Alarm indicator

Yes

ALARM_S

Display S7 alarms

Yes

Alarm buffer capacity

1024

View alarm

Yes

Print alarms line by line

Yes

Tags, values and lists

Object

Specification

Configuration

Limit value monitoring

Input/output

Yes

Linear scaling

Input/output

Yes

Text lists

Number

500 1

Graphics lists

Number

500 1

1

The maximum total of text and graphics lists is 500.

Screens

Object

Specification

Configuration

Number

500

Objects per screen

400

Tags per screen

400

Complex objects per screen (for example, bars)

20

Template

Yes

1.6 Scope of functions with WinCC

The tables below show the objects that can be integrated in a project.

Alarms

Alarm buffer, retentive

Simultaneously queued alarm events 500

Delete alarm buffer Yes

Tags Number 2048

Screens

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

21

Overview

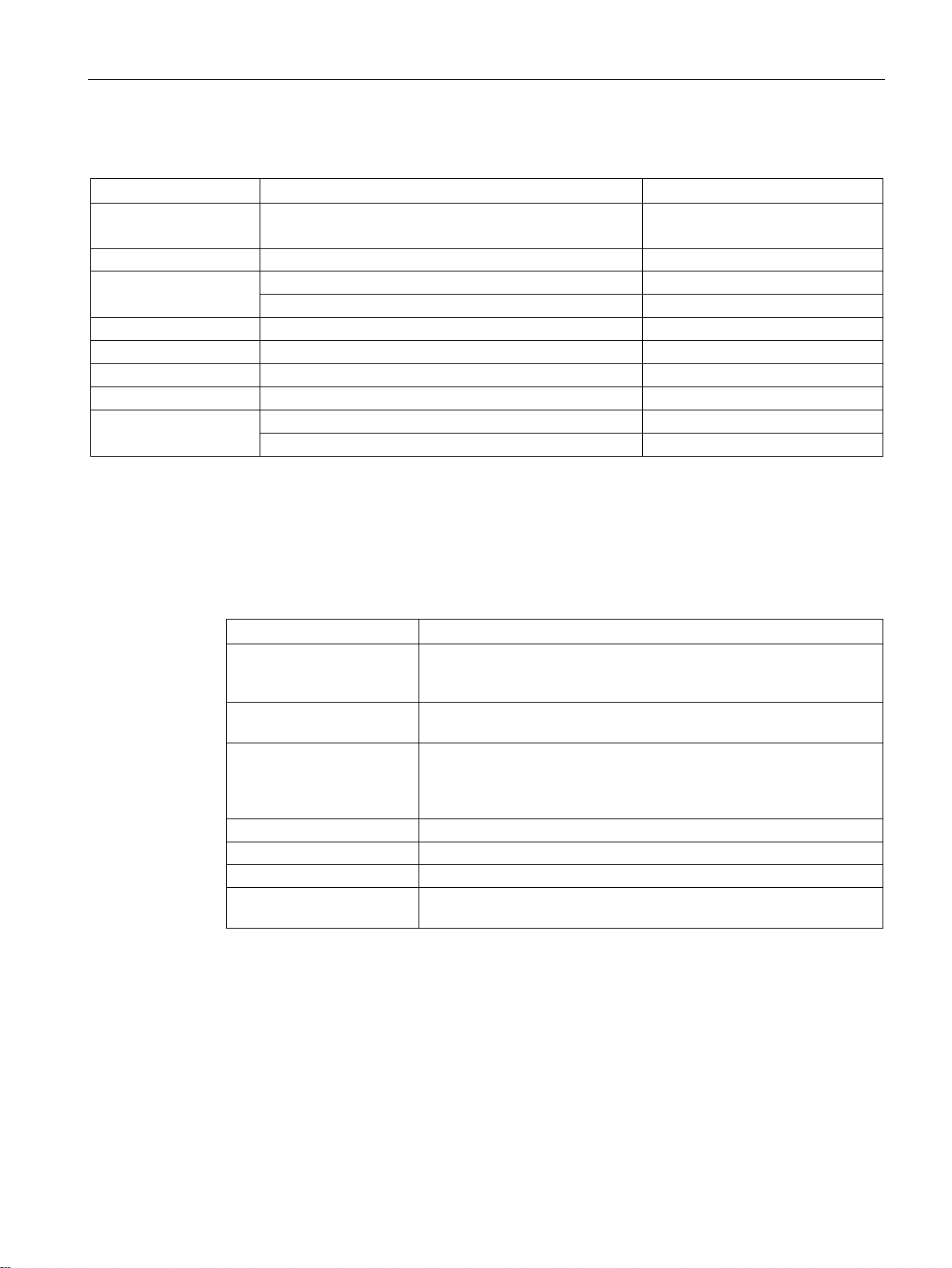

Recipes

Object

Specification

Configuration

Number

300

Entries per data record

1000

Recipe memory

256 KB

1

The number of recipe data records may be restricted by the capacity of the storage medium.

Logs

Note

The HMI devices are suitable for the logging of relatively small volumes of data.

Manage the data in several adjacent logs in a segmented circular log. The use of a large

circular log has a negative effect on performance.

Object

Specification

Configuration

Number of logs

50

Number of partial logs in a segmented circular log

400

Entries per log 1

20000

Filing format

CSV with ANSI character set, RDB, TXT

1

The number of entries in the log may be restricted by the capacity of the storage medium.

Safety

Object

Specification

Configuration

Number of users

50

Number of authorizations/user permissions

32

Infotexts

Object

Specification

Configuration

Length (no. of characters)

320 (depending on font)

For alarms

Yes

For screens

Yes

invisible button)

1.6 Scope of functions with WinCC

Recipes

Data records per recipe 500

Logs

Storage location 1

• USB storage medium

• Network drive

Storage location

• USB storage medium

• Network drive

User view Number of user groups 50

Infotexts

For screen objects (e.g. I/O field, switch, button,

Mobile Client900RXA

22 Operating Instructions, 07/2015, A5E36360099-AA

Yes

Overview

Additional functions

Object

Specification

Configuration

Brightness setting

Yes

User-specific extension of the functionality

Yes

Graphic objects

Vector and pixel graphics

Yes

Trends

Number

300

Task planner

Number of tasks

48

Text objects

Number

40000

PROFIBUS DP direct keys

No

PROFINET IO direct keys

No

1

For HMI devices with touch screen only

1.7

Software add-ons

Add-on

Description

you to set up communication between different HMI systems.

for recording operations in an audit trail and electronic signature.

connected via the USB port.

Microsoft PDF Viewer 3

Microsoft PDF Viewer enables you to display PDF documents.

all HMI device print options.

1

2

3

Pre-installed; no license key is required for use

1.7 Software add-ons

Screen settings Touch screen calibration 1

Language change Number of languages per project 32

VBScript

Number of scripts 100

Direct keys

Yes

The following software add-ons are available for the HMI devices:

WinCC /Sm@rtServer 1 The WinCC /Sm@rtServer add-on enables you to access a remote

HMI device from the HMI device or PC via Ethernet. It also enables

WinCC /Audit 1 The WinCC /Audit add-on extends the HMI device to include functions

Uninterruptable

Powersupply (UPS)

with USB support 2

Microsoft Excel Viewer 3 Microsoft Excel Viewer enables you to display Excel documents.

Microsoft Word Viewer 3 Microsoft Word Viewer enables you to display Word documents.

Printer driver The printer driver option enables PostScript, HTML and PDF output for

Transferred with the project; a license key is required for use

Must be transferred as an option; no license key is required for use

When interfacing an uninterruptible power supply, the HMI device is

shut down in a controlled manner after a buffer time in the event of a

power failure. The HMI devices support SITOP DC UPS modules

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

23

Overview

See also

1.8

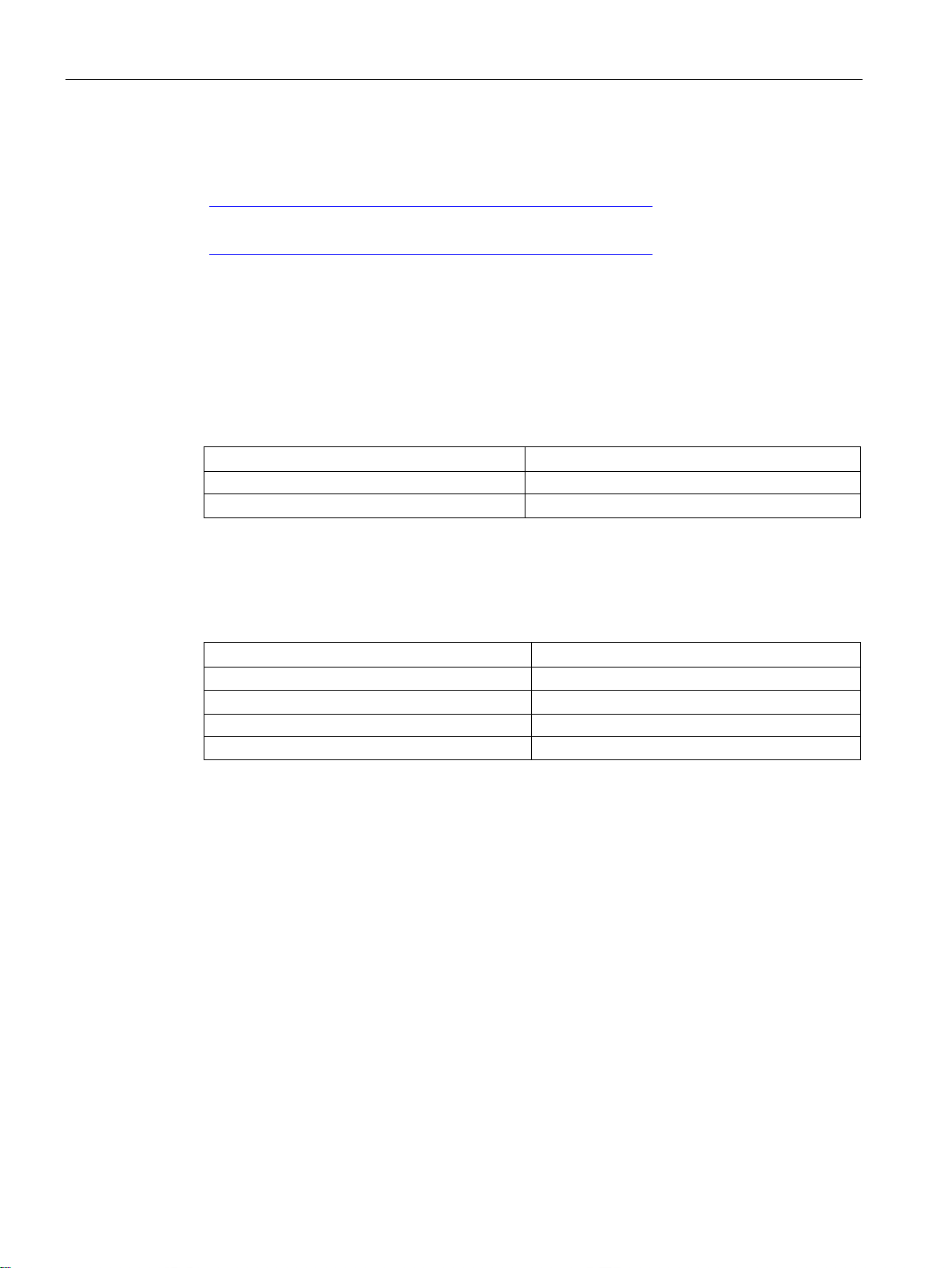

Communication with controllers

Number of connections

Number of connections

Number of connection boxes

With bus connection

8

PLC that can be connected

PLC

HMI devices

SIMATIC S7-1500

Yes

SIMATIC S7-300

Yes

1.8 Communication with controllers

Printers approved for SIMATIC Panels and Multi Panels

)

)

(http://support.automation.siemens.com/WW/view/en/11376409

Printing with SIMATIC Comfort HMI devices

(http://support.automation.siemens.com/WW/view/en/58205602

The table below shows the number of connection boxes that can be connected.

With "SIMATIC HMI HTTP protocol" 8

The table below shows the number of PLCs that can be connected to the connection boxes.

Controllers that are not compatible with PROFINET services are marked with a footnote.

SIMATIC S7-400 Yes

SIMATIC HTTP protocol Yes

Mobile Client900RXA

24 Operating Instructions, 07/2015, A5E36360099-AA

2

2.1

General safety instructions

Safety regulations

WARNING

Hazards

WARNING

Voltage dips and memory changes

WARNING

Safety-related features after impact

Strictly observe all instructions in these operating instructions at all times. Otherwise,

hazardous situations can arise or the safety mechanisms in the HMI device can be

rendered ineffective.

Observe the safety and accident prevention instructions applicable to your application in

addition to the safety instructions given in this manual.

The configuration engineer for a machine or system PLC must take precautions so that an

interrupted program can be restarted normally after voltage dips or power failures.

Dangerous operating conditions must not occur, even temporarily.

If faults in the system can cause bodily injury or significant property damage, additional

measures must be taken outside of the system. These measures must also ensure safe

operating conditions in the system in the event of a fault.

The system's configuration engineer must take precautions to ensure that memory changes

that could lead to a dangerous situation can only be undertaken by authorized persons.

After a hard impact to the HMI device, check the safety-relevant features for functional

capability, for example in the event that the HMI device is dropped.

If the system is operated with the HMI device:

Ensure that current operation is only possible by means of the HMI device and not from any

other point on the system.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

25

Safety guidelines

Safety when working in and on electrical systems

Note

The safety regulations must be

carried out on electrical systems. The safety regulations must be applied in reverse order on

completion of all tasks on the electrical system.

Proper use

WARNING

Commissioning

High frequency radiation

Note

High

operating situations.

2.1 General safety instructions

Only authorized persons are allowed to work in or on electrical equipment. The following

safety regulations for prevention of electrical shock are valid:

1. Isolation of the system from power

2. Securing the system against restart

3. Verification of isolation from power at all poles

4. Grounding and shorting the system

5. Covering or fencing off adjacent live parts

applied in the aforementioned order before any work is

Identify the electrical system in accordance with valid safety regulations when working on

this system.

Observe the valid safety regulations of the respective country.

Commissioning of the HMI device is forbidden until it has been absolutely ensured that the

machine in which the HMI device is to be installed complies with Directive 98/37/EC or

Directive 2006/42/EC as ofDecember 29, 2009.

-frequency radiation from cellular phones, for example, can lead to undesirable

Mobile Client900RXA

26 Operating Instructions, 07/2015, A5E36360099-AA

Safety guidelines

Industrial Security

Disclaimer for third-party software updates

Notes on protecting administrator accounts

2.1 General safety instructions

Siemens offers products and solutions with Industrial Security functions that support the safe

operation of equipment, solutions, machines, devices and/or networks. They are important

components in a comprehensive Industrial Security concept. As a result the products and

solutions from Siemens are constantly evolving. Siemens recommends obtaining regular

information regarding product updates.

For safe operation of Siemens products and solutions appropriate protective measures (e.g.,

cell protection concept) must be taken and each component must be integrated in a

comprehensive Industrial Security concept, which corresponds with the current state of

technology. The products of other manufacturers need to be taken into consideration if they

are also used. You can find addition information on Industrial Security under

(http://www.siemens.com/industrialsecurity

Sign up for our product-specific newsletter to receive the latest information on product

updates. For more information, see under (http://www.siemens.de/automation/csi_en_WW

).

).

This product includes third-party software. Siemens AG only provides a warranty for

updates/patches of the third-party software, if these have been distributed as part of a

Siemens software update service contract or officially released by Siemens AG. Otherwise,

updates/patches are undertaken at your own risk. You can find more information about our

Software Update Service offer on the Internet at Software Update Service

http://www.automation.siemens.com/mcms/automation-software/en/software-update-

(

service).

A user with administrator privileges has extensive access and manipulation options in the

system.

Therefore, ensure there are adequate safeguards for protecting the administrator accounts

to prevent unauthorized changes. To do this, use secure passwords and a standard user

account for normal operation. Other measures, such as the use of security policies, should

be applied as needed.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

27

Safety guidelines

2.2

Notes about usage

Intended use of the Mobile Client

NOTICE

Wall bracket

Note

The device is not compatible with other system components, in particular not with those of

the SIMATIC Mobile Panel product family. You may only use the original

components defined here.

Industrial applications

2.2 Notes about usage

The SIMATIC Mobile Client is intended for uses ranging from operator control and

monitoring, parameter assignment, and commissioning to troubleshooting for industrial

systems, in particular wind turbines.

The system consists of the following components:

● Device

● Connecting cable

● Connection box

Ambient conditions for intended use:

● Industrial environment according to EN 61131-2:2007

● Indoor use protected from weather

● Ambient temperature range 0 ... 45 °C

The connection box is designed as bushing for installation in a control cabinet wall. The

device connecting cable can be easily unplugged and plugged back for moving the device

from one operating location to another.

Objects placed on the wall-mounting bracket may fall off and cause injury.

Do not use the wall-mounting bracket to hold other objects, for example tools.

The HMI device is designed for industrial applications. It conforms to the following standards:

● Emission requirements, EN 61000-6-4:2007

● Immunity requirements, DIN EN 61000-6-2:2005

system

Mobile Client900RXA

28 Operating Instructions, 07/2015, A5E36360099-AA

Safety guidelines

Use in residential areas

Note

The HMI device is not suitable for operation in residential areas. Operation of an HMI device

in resident

Mechanical and climatic conditions of use

NOTICE

Climatic factors at the place of use

WARNING

The product must not be used for the following applications

2.2 Notes about usage

ial areas can have a negative impact on radio and TV reception.

If you are to use the HMI device in a residential area, you must ensure Limit Class B

conforming to EN 55011 for radio frequency interference.

One suitable measure for achieving the required RF interference level for limit class B is:

● To use filters in electrical supply lines

Individual acceptance is also required.

Check the mechanical and climatic environmental conditions according to the following

chapters:

● Ambient conditions for transport and storage (Page 146)

● Ambient conditions during operation (Page 147)

Fluctuations in temperature cause condensation inside the device. The device is exposed

to heat and to the cold even when not in operation.

• Do not expose the device to extreme temperature fluctuations.

The device has a pressure compensation valve to provide additional protection in the event

of temperature fluctuations. The pressure compensation valve contains a membrane which

helps to reduce the level of moisture in the device.

Please note the following:

• The valve must always be freely ventilated and must be protected from dirt.

• The device is always supplied with power so that the waste heat from the electronics

• The following is valid for the arctic HMI device with reference to the heating system: The

system keeps the interior temperature slightly higher than the exterior temperature. This

reduces the likelihood of malfunctions caused by condensation and creates a sufficient

vapor pressure for ventilation.

heating system will not function without the power supply. The heating system stabilizes

the temperature inside the device and can significantly reduce the likelihood of

malfunctions caused by condensation.

• Applications in potentially explosive atmospheres / fire risk areas

• Use in mining

Explosion-proof products must be used for such applications.

Mobile Client900RXA

Operating Instructions, 07/2015, A5E36360099-AA

29

Safety guidelines

Instructions

Use with additional measures

2.3

Power supply

Safety specifications

WARNING

Electric shock hazard

2.3 Power supply

● Make sure that no-one can trip on the cable and injure themselves or cause the device to

fall out.

● Make sure that there are no objects crushing and potentially damaging the cable.

● Avoid laying the cable over sharp edges as this can chafe the cable sheath.

● Never place the device on unsteady surfaces. It could fall down and be damaged.

● Never expose the device to direct sunlight or heat sources.

● Make sure that the device is sufficiently ventilated. Do not cover it. Never operate the

device with the protective cover on.

● Avoid subjecting the device to mechanical shocks, excessive amounts of dust, moisture,

and strong magnetic fields.

Examples of applications where the use of the HMI device requires additional measures:

● In locations with a high degree of ionizing radiation

● In locations with difficult operating conditions - for example due to:

● In systems that require special monitoring, for example:

The HMI device corresponds to protection class III according to EN 61131-2 or EN 50178.

The 24 VDC supply must be isolated from touch-hazardous voltages, for example by

means of a safety isolation transformer or similar equipment.

• Observe the power supply limit values specified in the Technical Specifications.

• Fuse all equipment in the control cabinet in accordance with local safety regulations.

– Corrosive vapors, gases, oils or chemicals

– Electrical or magnetic fields of high intensity

– Elevators

– Systems in especially hazardous rooms

Mobile Client900RXA

30 Operating Instructions, 07/2015, A5E36360099-AA

Loading...

Loading...