Page 1

SIMATIC IPC677E

SIMATIC

Industrial PC

SIMATIC IPC677E

Operating Instructions

04/2019

A5E45

Preface

Product description

1

Safety instructions

2

Mounting and connecting the

device

3

Commissioning the device

4

Operating the device

5

Expanding the device and

assigning device parameters

6

Maintaining and servicing

your device

7

Technical specifications

8

Dimension drawings

9

Standards and approvals

10

Hardware descriptions

A

Technical support

B

Markings and symbols

C

List of abbreviations

D

117996-AA

Page 2

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E45117996-AA

Ⓟ

Copyright © Siemens AG 2019.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

04/2019 Subject to change

Page 3

Preface

Edition

Comment

04/2019

First edition

Purpose of the operating instructions

These operating instructions contain all the information you need for the installation,

electrical connection, commissioning and expansion of the SIMATIC IPC677E and to

maintain and repair the device. They are intended for the following qualified specialist

personnel:

● Installation personnel

● Commissioning engineers

● IT administrators

● Service and maintenance personnel

Basic knowledge required

A solid background in electrical installation, personal computers, Microsoft operating

systems and network technology is required to understand this manual. General knowledge

in the field automation control engineering is recommended.

Scope of the operating instructions

These operating instructions are valid for all order versions of the SIMATIC IPC677E.

History

The following editions of these operating instructions have already been published:

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

3

Page 4

Preface

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens' products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit (http://www.siemens.de/industrialsecurity).

Siemens' products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers' exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.de/industrialsecurity).

Disclaimer for third-party software updates

This product includes third-party software. Siemens AG only provides a warranty for

updates/patches of the third-party software, if these have been distributed as part of a

Siemens software update service contract or officially released by Siemens AG. Otherwise,

updates/patches are undertaken at your own risk. You can find more information about our

Software Update Service offer on the Internet at Software Update Service

(http://www.automation.siemens.com/mcms/automation-software/en/software-update-

service).

SIMATIC IPC677E

4 Operating Instructions, 04/2019, A5E45117996-AA

Page 5

Table of contents

Preface ...................................................................................................................................................... 3

1 Product description .................................................................................................................................. 11

1.1 Important instructions and manuals for operating the device ................................................. 11

1.2 Product highlights ................................................................................................................... 13

1.3 Applications ............................................................................................................................. 15

1.4 External design of the device .................................................................................................. 16

1.4.1 Side view, right ........................................................................................................................ 16

1.4.2 Side view, left .......................................................................................................................... 17

1.4.3 Status displays ........................................................................................................................ 19

1.5 Internal design of the device ................................................................................................... 21

1.6 Accessories and spare parts .................................................................................................. 22

1.6.1 Accessories: Hardware ........................................................................................................... 22

1.6.2 Accessories: Software ............................................................................................................ 23

2 Safety instructions ................................................................................................................................... 25

2.1 General safety instructions ..................................................................................................... 25

2.2 Note on transport and storage ................................................................................................ 27

2.3 Notes on mounting .................................................................................................................. 28

2.4 Notes on ambient and environmental conditions .................................................................... 28

2.5 Information on I/O devices ...................................................................................................... 30

2.6 Notes on device and system extensions ................................................................................ 31

3 Mounting and connecting the device........................................................................................................ 33

3.1 Preparing for mounting ........................................................................................................... 33

3.1.1 Scope of delivery .................................................................................................................... 33

3.1.2 Checking the delivery package ............................................................................................... 35

3.1.3 Identification data of the device .............................................................................................. 36

3.1.4 Mounting positions .................................................................................................................. 37

3.1.5 Preparing the mounting cutout ................................................................................................ 39

3.2 Mounting the device ................................................................................................................ 41

3.2.1 Installation guidelines ............................................................................................................. 41

3.2.2 Mounting the device with mounting clips ................................................................................ 42

3.3 Connecting the device ............................................................................................................ 46

3.3.1 Country-specific information on supply voltage ...................................................................... 46

3.3.2 Connection of equipotential-bonding cable ............................................................................ 47

3.3.3 Connecting the power supply ................................................................................................. 48

3.3.3.1 Connecting 100-240 VAC power supply ................................................................................. 48

3.3.3.2 Connecting the 24 VDC power supply .................................................................................... 50

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

5

Page 6

Table of contents

3.3.4 Connecting I/O devices .......................................................................................................... 52

3.3.5 Connecting the device to networks ........................................................................................ 53

3.3.6 Connecting Ethernet/USB strain relief ................................................................................... 54

4 Commissioning the device ....................................................................................................................... 55

4.1 Switching on the device ......................................................................................................... 55

4.2 Configuring automatic switch-on of device ............................................................................ 55

4.3 Switching off the device ......................................................................................................... 56

5 Operating the device ................................................................................................................................ 59

5.1 Multi-monitoring ...................................................................................................................... 59

5.2 Drive configurations ............................................................................................................... 59

5.2.1 RAID1 system ........................................................................................................................ 59

5.3 Operating RAID systems ....................................................................................................... 60

5.3.1 Display of a defective drive of a RAID system ....................................................................... 60

5.3.2 RAID1 system: Installation options for drives ........................................................................ 60

5.3.3 Configure the onboard RAID system ..................................................................................... 60

5.3.4 Monitoring the onboard RAID system with "Intel® Rapid Storage Technology" ................... 62

5.3.5 Integrating a new drive into the onboard RAID system ......................................................... 63

5.3.6 Data synchronization in the RAID system ............................................................................. 64

5.4 Monitoring of the device ......................................................................................................... 65

5.4.1 Monitoring functions ............................................................................................................... 65

5.4.2 SIMATIC IPC DiagBase ......................................................................................................... 66

5.4.3 SIMATIC IPC DiagMonitor ..................................................................................................... 66

5.5 Remote maintenance of the device ....................................................................................... 67

5.5.1 Remote maintenance functions ............................................................................................. 67

5.5.2 SIMATIC IPC Remote Manager ............................................................................................. 68

5.6 Trusted Platform Module (TPM) ............................................................................................. 69

5.7 Buffer memory NVRAM (optional) ......................................................................................... 69

6 Expanding the device and assigning device parameters ......................................................................... 71

6.1 Opening the Device ............................................................................................................... 71

6.2 Expansion cards .................................................................................................................... 73

6.2.1 Usable expansion cards ......................................................................................................... 73

6.2.2 Installing/removing expansion cards ...................................................................................... 73

6.3 Memory modules.................................................................................................................... 76

6.3.1 Usable memory modules ....................................................................................................... 76

6.3.2 Installing and removing memory module ............................................................................... 77

6.4 Drives ..................................................................................................................................... 79

6.4.1 Changing the drive in the removable tray .............................................................................. 79

6.4.2 Changing internal SSD .......................................................................................................... 81

6.4.3 Changing internal hard disk drive .......................................................................................... 84

6.4.4 Replacing a drive in the RAID system ................................................................................... 86

6.4.5 Replacing M.2 NVMe SSD ..................................................................................................... 87

SIMATIC IPC677E

6 Operating Instructions, 04/2019, A5E45117996-AA

Page 7

Table of contents

7 Maintaining and servicing your device ..................................................................................................... 89

7.1 Repair information ................................................................................................................... 89

7.2 Maintenance intervals ............................................................................................................. 90

7.3 Cleaning the Device Front ...................................................................................................... 91

7.4 Removing and installing hardware .......................................................................................... 92

7.4.1 Replacing device fans ............................................................................................................. 92

7.4.2 Replace power supply fan ...................................................................................................... 95

7.4.3 Changing the backup battery .................................................................................................. 98

7.4.4 Replace power supply .......................................................................................................... 100

7.4.5 Replacing the bus board ....................................................................................................... 102

7.4.6 Replacing the processor ....................................................................................................... 106

7.5 Installing operating system, software and drivers ................................................................. 109

7.5.1 Installing the operating system ............................................................................................. 109

7.5.2 Installing software and drivers .............................................................................................. 109

7.6 Configuring firmware/BIOS ................................................................................................... 110

7.7 Backing up data and changing partitions .............................................................................. 110

7.8 Recycling and disposal ......................................................................................................... 110

8 Technical specifications ......................................................................................................................... 111

8.1 Applicability of technical specifications ................................................................................. 111

8.2 General technical specifications ........................................................................................... 111

8.3 Current/power consumption and power supply .................................................................... 113

8.3.1 Current/power consumption of the system components ...................................................... 113

8.3.2 Technical specifications AC power supply (AC) ................................................................... 114

8.3.3 Technical specifications of direct voltage power supply (DC) .............................................. 114

8.4 Electromagnetic compatibility ............................................................................................... 115

8.5 Ambient conditions ................................................................................................................ 115

8.6 Technical specifications of the drives ................................................................................... 116

8.7 Technical specifications of the motherboard ........................................................................ 116

8.8 Technical specifications of graphics/display ......................................................................... 117

8.9 Technical specifications of the interfaces ............................................................................. 117

8.10 Technical specifications of the operating systems ............................................................... 119

9 Dimension drawings .............................................................................................................................. 121

9.1 Dimension drawing of 19" device with capacitive multi-touch screen .................................. 121

9.2 Dimension drawing of 22" device with capacitive multi-touch screen .................................. 122

9.3 Dimension drawing of 24" device with capacitive multi-touch screen .................................. 123

9.4 Dimension drawing of the expansion cards .......................................................................... 124

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

7

Page 8

Table of contents

10 Standards and approvals ....................................................................................................................... 125

10.1 CE marking .......................................................................................................................... 125

10.2 DIN ISO 9001 certificate and software license agreements ................................................ 126

10.3 UL approval .......................................................................................................................... 126

10.4 FCC (USA) ........................................................................................................................... 127

10.5 Canada ................................................................................................................................. 127

10.6 Australia / New Zealand ....................................................................................................... 128

10.7 Eurasion Customs Union EAC ............................................................................................. 128

10.8 Korea .................................................................................................................................... 128

A Hardware descriptions ........................................................................................................................... 129

A.1 Motherboard ......................................................................................................................... 129

A.1.1 Layout of the motherboard ................................................................................................... 129

A.1.2 Position of the interfaces on the motherboard ..................................................................... 130

A.2 Internal Interfaces ................................................................................................................ 131

A.2.1 Assignment of the internal interfaces ................................................................................... 131

A.2.2 Device fan supply (X512) ..................................................................................................... 131

A.2.3 Supply for the power supply fan (X515) ............................................................................... 132

A.2.4 Supply for the serial ATA drives (X516 - X521) ................................................................... 132

A.3 Bus board ............................................................................................................................. 133

A.3.1 Design and principle of operation of the bus board ............................................................. 133

A.3.2 Pin assignment 12 V power supply connection for expansion cards ................................... 134

A.4 External interfaces ............................................................................................................... 135

A.5 System resources ................................................................................................................ 136

A.5.1 Currently allocated system resources .................................................................................. 136

A.5.2 I/O address allocation .......................................................................................................... 136

A.5.3 Interrupt Assignments .......................................................................................................... 138

A.5.4 Exclusive PCI hardware interrupt ......................................................................................... 141

A.5.5 Memory address assignments ............................................................................................. 142

B Technical support .................................................................................................................................. 143

B.1 Service and support ............................................................................................................. 143

B.2 Troubleshooting ................................................................................................................... 144

B.2.1 Problems with device functions ............................................................................................ 144

B.2.2 Problems when booting the device ...................................................................................... 145

B.2.3 Problems with RAID systems ............................................................................................... 146

B.2.4 Problems when using expansion cards ............................................................................... 146

SIMATIC IPC677E

8 Operating Instructions, 04/2019, A5E45117996-AA

Page 9

Table of contents

C Markings and symbols ........................................................................................................................... 147

C.1 Overview ............................................................................................................................... 147

C.2 Safety .................................................................................................................................... 147

C.3 Operator controls .................................................................................................................. 147

C.4 Certificates, approvals and markings .................................................................................... 148

C.5 Interfaces .............................................................................................................................. 149

D List of abbreviations ............................................................................................................................... 151

D.1 Abbreviations ........................................................................................................................ 151

Index ...................................................................................................................................................... 155

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

9

Page 10

Table of contents

SIMATIC IPC677E

10 Operating Instructions, 04/2019, A5E45117996-AA

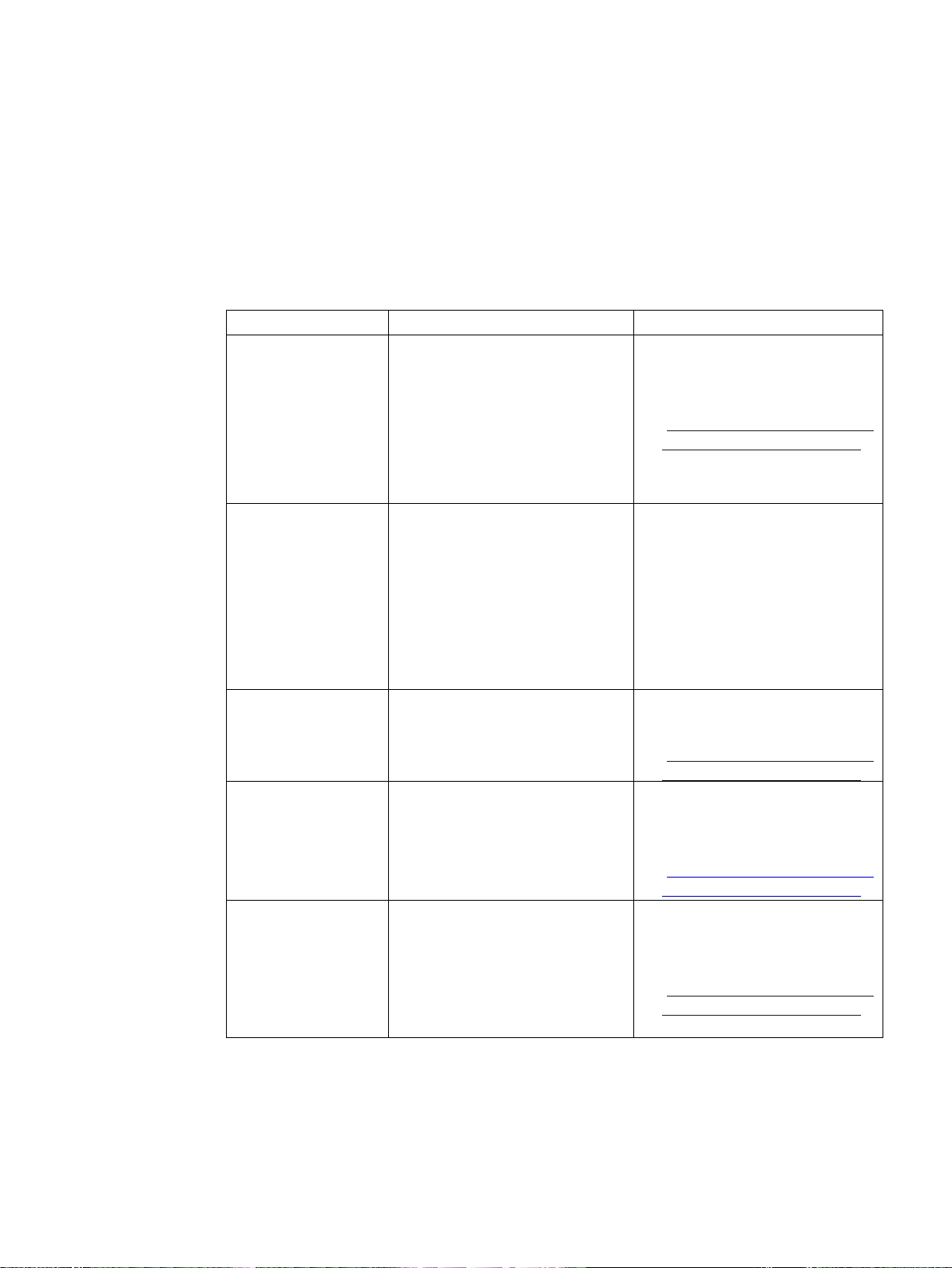

Page 11

1

Documentation

Contents

Source

com/cs/ww/en/view/109760621)

1.1 Important instructions and manuals for operating the device

Operating Instructions

Quick Install Guide Information on:

Current product information

Firmware/BIOS description

Windows® operating

system

• Product description

• Technical specifications

• Installation of the device

• Operation of the device

• Installing and removing hard-

ware

• Dimension drawings

• Operating Instructions of the

device

• Installation of the device

• Connecting the device to the

power supply

• Connecting I/O devices

• Switching the device on

• Current notes on the device

• Changes compared with these

Operating Instructions

Information on:

• Important firmware settings

• Firmware settings in the delivery

state

• Boot modes

Information on:

• Commissioning the operating

system

• Restoring the operating system

• Configuration of the operating

system

• Supplied data storage medium

• Online at:

SIMATIC IPC Documentation

(https://support.industry.siemens.

com/cs/ww/en/view/109760621)

• Supplied in printed form with the

device

• Supplied data storage medium

• Online at:

SIMATIC IPC Documentation

(https://support.industry.siemens.

• Supplied data storage medium

• Online at:

Firmware/BIOS description

(https://support.industry.siemens.

com/cs/ww/en/view/109760621)

• Supplied data storage medium

• Online at:

Microsoft® Windows® 10

(https://support.industry.siemens.

com/cs/ww/en/view/109749498)

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

11

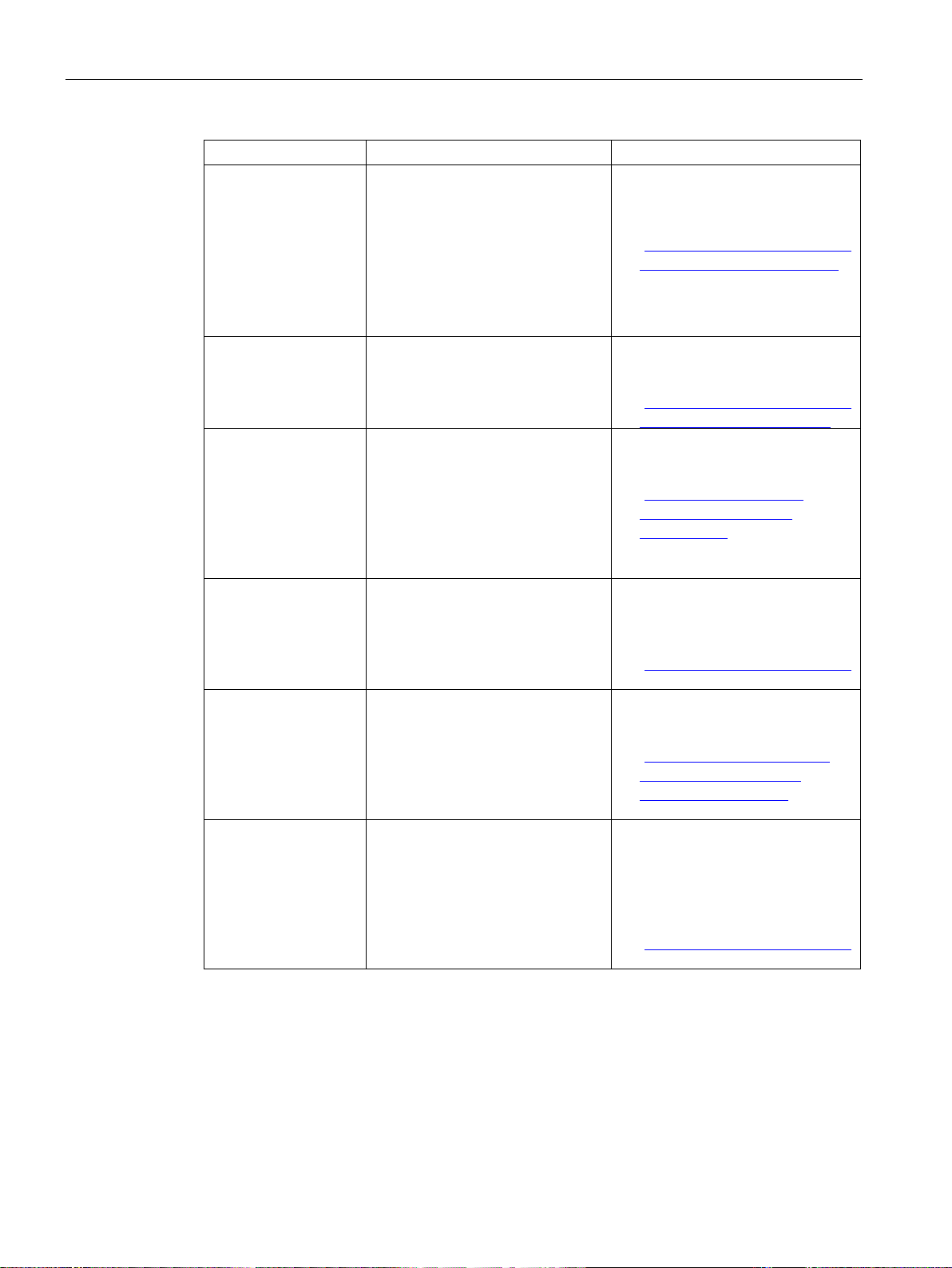

Page 12

Product description

Documentation

Contents

Source

com/cs/ww/en/view/39129913)

com/cs/de/en/view/21766418)

/Default.aspx)

com/cs/ww/en/view/109751260)

1.1 Important instructions and manuals for operating the device

SIMATIC IPC DiagBase

SIMATIC IPC DiagMonitor

SIMATIC IPC Remote

Manager

SIMATIC IPC Image &

Partition Creator

Information on:

• Temperature monitoring

• Fan monitoring

• Monitoring drives

• Watchdog

• Operating hours counter

• Battery monitoring

Monitoring functions such as with

SIMATIC IPC DiagBase with additional extended functions.

Information on:

• Remote maintenance of

SIMATIC Industrial PCs (IPCs)

via a management PC.

• Using Intel ®Active Management

Technology (Intel® AMT).

Information on:

• Backup and recovery of files,

directories, drive partitions.

• Supplied data storage medium

• Online at:

SIMATIC IPC DiagBase

(https://support.industry.siemens.

com/cs/ww/en/view/109749690)

• Online at:

SIMATIC IPC DiagMonitor

(https://support.industry.siemens.

• Online at:

SIMATIC IPC Remote Manager

(http://support.automation

.siemens.com/WW/view

/en/48707158)

• Online at:

SIMATIC IPC Image Partition

Creator

(https://support.industry.siemens.

SIMATIC NET Industrial communication

SIMATIC Industrial PC

Panel Drivers and

Tools

Information on:

• Setting the brightness

• Configuration of the screen sav-

er

• Touch settings for resistive touch

and multi-touch

• Online at:

SIMATIC NET

(http://w3.siemens.com/mcms

/automation/en/industrialcommunications/Pages

• Online at:

SIMATIC Industrial PC Panel

Drivers and Tools V1.3 PDT

IPC/IFP with capacitive multitouch screen

(https://support.industry.siemens.

SIMATIC IPC677E

12 Operating Instructions, 04/2019, A5E45117996-AA

Page 13

Product description

Note

Depending on the

manual may differ from the features of your device.

1.2 Product highlights

1.2 Product highlights

The SIMATIC IPC677E is a powerful industrial PC. It is perfectly suited for PC applications

with high-level industry functionality.

Device view

configuration ordered the features and illustrations described in this

Maximum industrial compatibility for 24-hour continuous use in industrial environments

● Maximum processor power (in full configuration) without loss of power (throttling) at up to

+45 °C ambient temperature

● Full metal enclosure with high electromagnetic compatibility (EMC) for use in industry

● Independent industrial product design for high shock and vibration resistance

● CE marking for the industrial field

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

13

Page 14

Product description

1.2 Product highlights

High productivity through fast data processing

● 8th generation Intel® processors: Celeron, Core i3 and i7

● Graphics controller (630/P630) integrated in processor up to 4K Ultra HD resolution, three

independent graphic interfaces

● Maximum performance, e.g. through Intel C246 chip set, DDR4 memory (up to 64 GB)

with support of dual channel technology

● High data transfer rates, e.g. with PCI Express Gen 3 technology, USB 3.1 Gen 2

SuperSpeed (SuperSpeed+) (10 Gbps), M.2 NVMe

● Low noise level due to variable-speed fans

High system availability thanks to minimization of standstill times

● Hot swap (swapping of drive during operation) in removable drive bays in RAID systems

● Efficient event diagnostics through the SIMATIC IPC DiagBase or DiagMonitor monitoring

software (optional) and signaling software OPC/SNMP/LAN

● Remote control and remote maintenance of the device through iAMT (Intel® Active

Management Technology)

● SSD as 2.5" SATA or M.2 NVMe

● Preventative data backup with the SIMATIC IPC Image & Partition Creator

High investment protection

● Platform with embedded Intel components for long-term stability

● Availability: 3 to 6 years

● Assured spare parts availability: 5 years after end of production

● Certified for worldwide marketing (cULus)

● Support of legacy interfaces (COM)

● Compatible installation across device generations

● Worldwide service and support

Device variants

Devices with capacitive multi-touch screen display:

● 19" display, resolution: 1920 x 1080 pixels

● 22" display, resolution: 1920 x 1080 pixels

● 24" display, resolution: 1920 x 1080 pixels

SIMATIC IPC677E

14 Operating Instructions, 04/2019, A5E45117996-AA

Page 15

Product description

1.3 Applications

User-friendly application scenarios for commissioning, use and service

● High flexibility and expandability thanks to integrated interfaces and up to 2 slots (PCI and

PCI Express)

● Pre-installed and activated operating system

● Fast restoration of delivery state of the operating system (with supplied data storage

medium)

● Gbit LAN with teaming capability (3 x LAN 10/100/1000 Mbps connections)

● Service-friendly equipment design (modifications, service)

● Can be used flexibly in a wide variety of positions

1.3 Applications

The device offers industrial PC systems for high-performance and space-saving applications

in particular for manufacturers in the field of machine, plant and control cabinet engineering:

● Operating, process and visualization applications

● Industrial image processing

● Quality assurance and monitoring tasks

● Measurement, control and rule-based tasks

● Data acquisition and management

The SIMATIC IPC has the CE mark for use in industrial environments.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

15

Page 16

Product description

①

Removable drives

Slots for removable drives

②

RAID status indicators

HDD alarm

③

Battery compartment

CMOS backup battery

④

Front fan

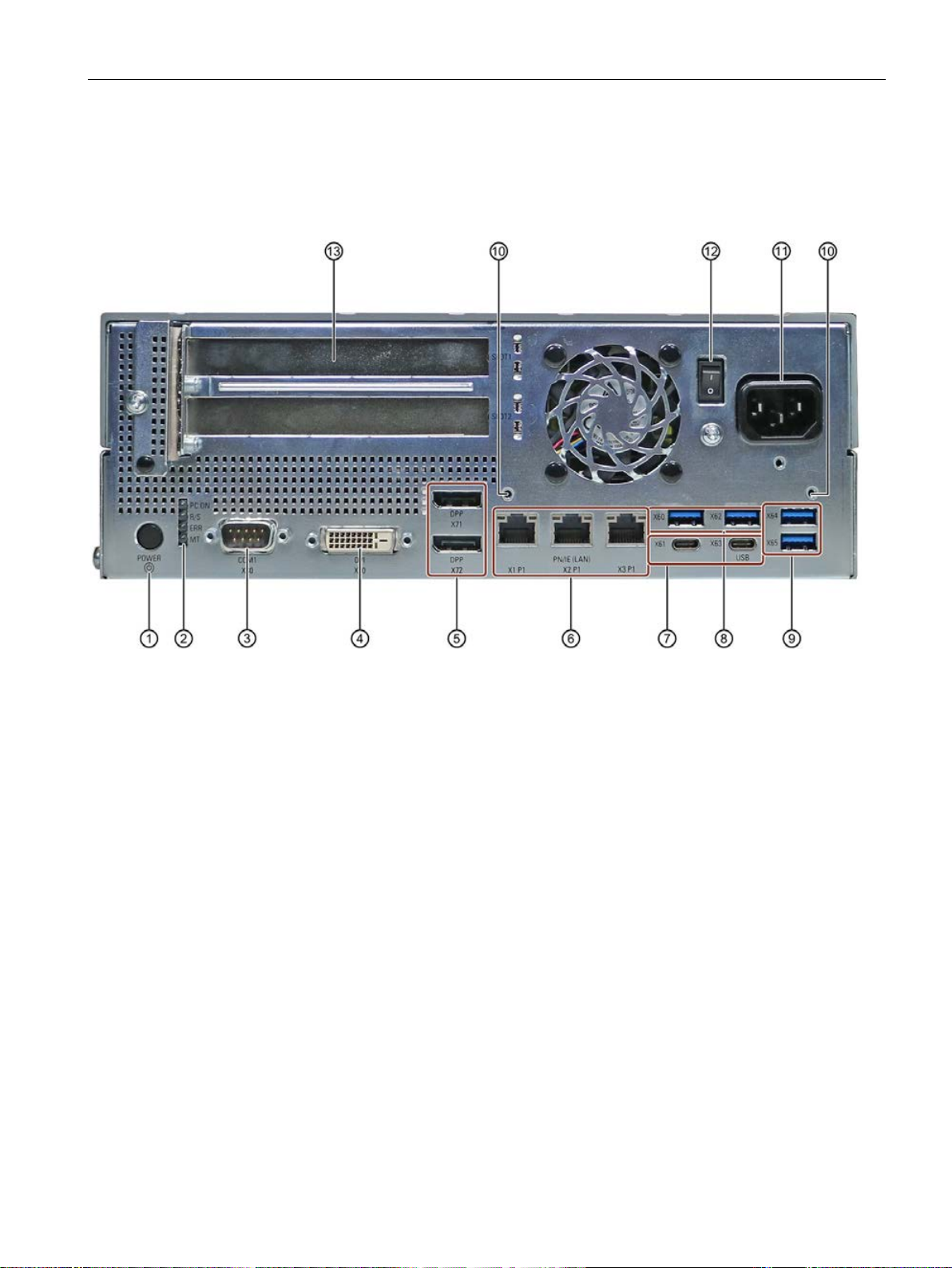

1.4 External design of the device

1.4 External design of the device

1.4.1 Side view, right

SIMATIC IPC677E

16 Operating Instructions, 04/2019, A5E45117996-AA

Page 17

Product description

①

device is switched on with the on/off switch. You then do not need to press the on/off button.

②

4 status LEDs

Status display of the status indicators (Page 19)

③

COM1 X30

Serial interface

④

DVI/VGA X70

DVI-D connection for CRT or LCD monitor with DVI port

⑤

X71/X72

⑥

1.4 External design of the device

1.4.2 Side view, left

Connection side

On/off button The on/off button has three functions:

• Switch on the PC: Briefly press once

• Shut down operating system and switch off PC: Briefly press once

• Switch off PC without shutting down the operating system (hardware reset): Press for more

than 4 seconds.

Note: The BIOS setup entry "After Power Failure" has been set to "Power On". This means the

DisplayPort

3 × Ethernet

X1P1/X2P1/X3P1

DisplayPort connection for digital monitor

• X1P1, left: RJ45 Ethernet port 1 (exclusive PCI interrupt) with 10/100/1000 Mbps, iAMT ca-

pable

• X2P1, center: RJ45 Ethernet port 2 (shared PCI interrupt) with 10/100/1000 Mbps

• X3P1, right: RJ45 Ethernet port 3 (shared PCI interrupt) with 10/100/1000 Mbps

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

17

Page 18

Product description

⑦

2 × USB X61/X63

USB 3.1 GEN 2 Type C high current, backward compatible with USB 3.0/2.0/1.1

⑧

2 × USB X60/X62

USB 3.1 GEN 2 Type A high current, backward compatible with USB 3.0/2.0/1.1

⑨

2 × USB X64/X65

USB 3.1 GEN 2 Type A high current, backward compatible with USB 3.0/2.0/1.1

⑩

strain relief

⑪

V AC

⑫

symbol is pressed inward on the device. Position "OFF" is the delivery state.

⑬

al)

1.4 External design of the device

Fixing screws for

100 V AC to 240

On/off switch You switch on the device with the on/off switch. This requires that the BIOS setup entry "After

PCI/PCIe expan-

sion cards,

USB on expan-

sion card (option-

Power supply connection

Power Failure" is set to "Power On".

The on/off switch does not isolate the device from the power supply. Position "ON", when the "-)"

2 slots for expansion cards (Slot1/X101, Slot2/X102)

SIMATIC IPC677E

18 Operating Instructions, 04/2019, A5E45117996-AA

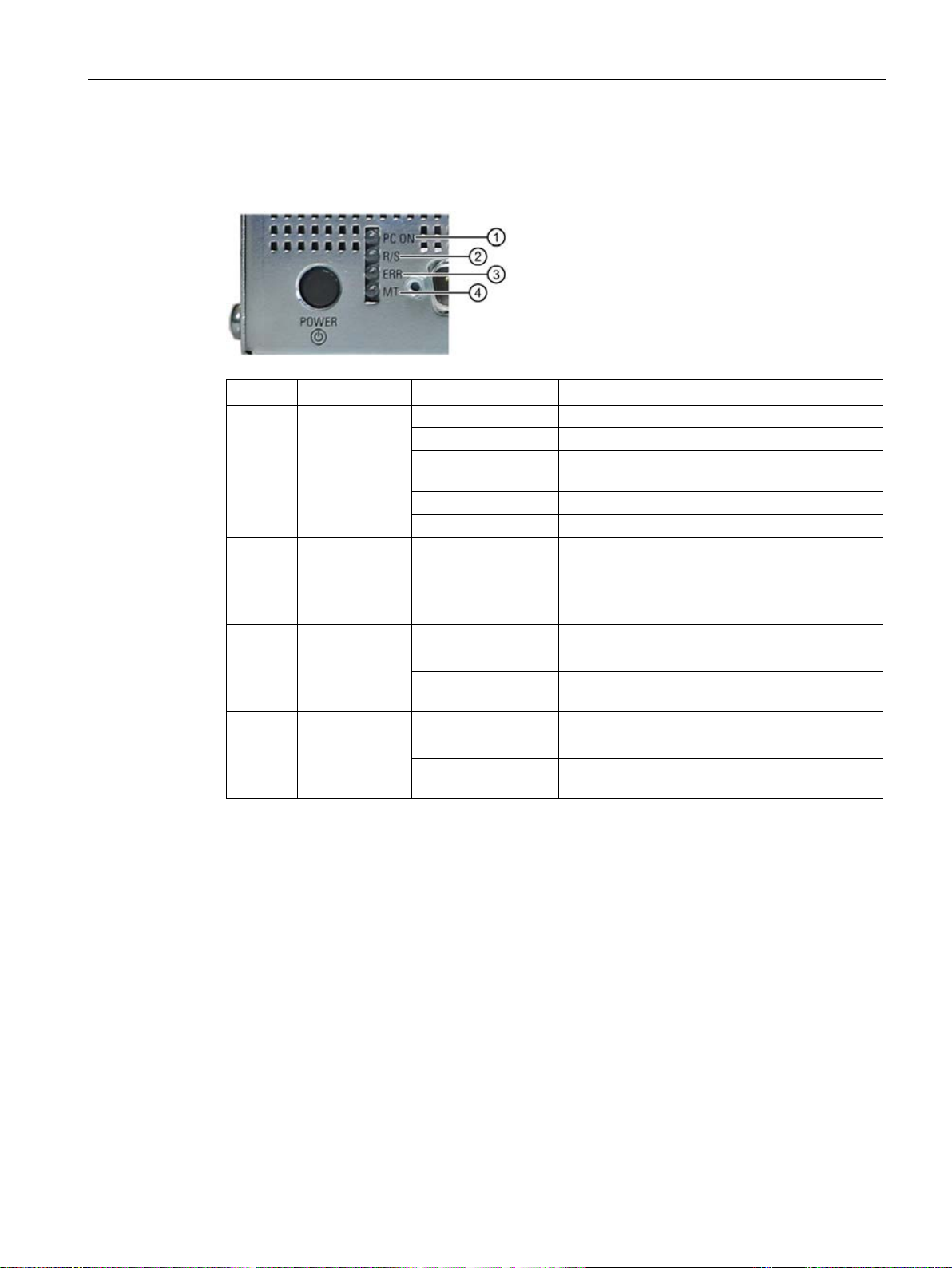

Page 19

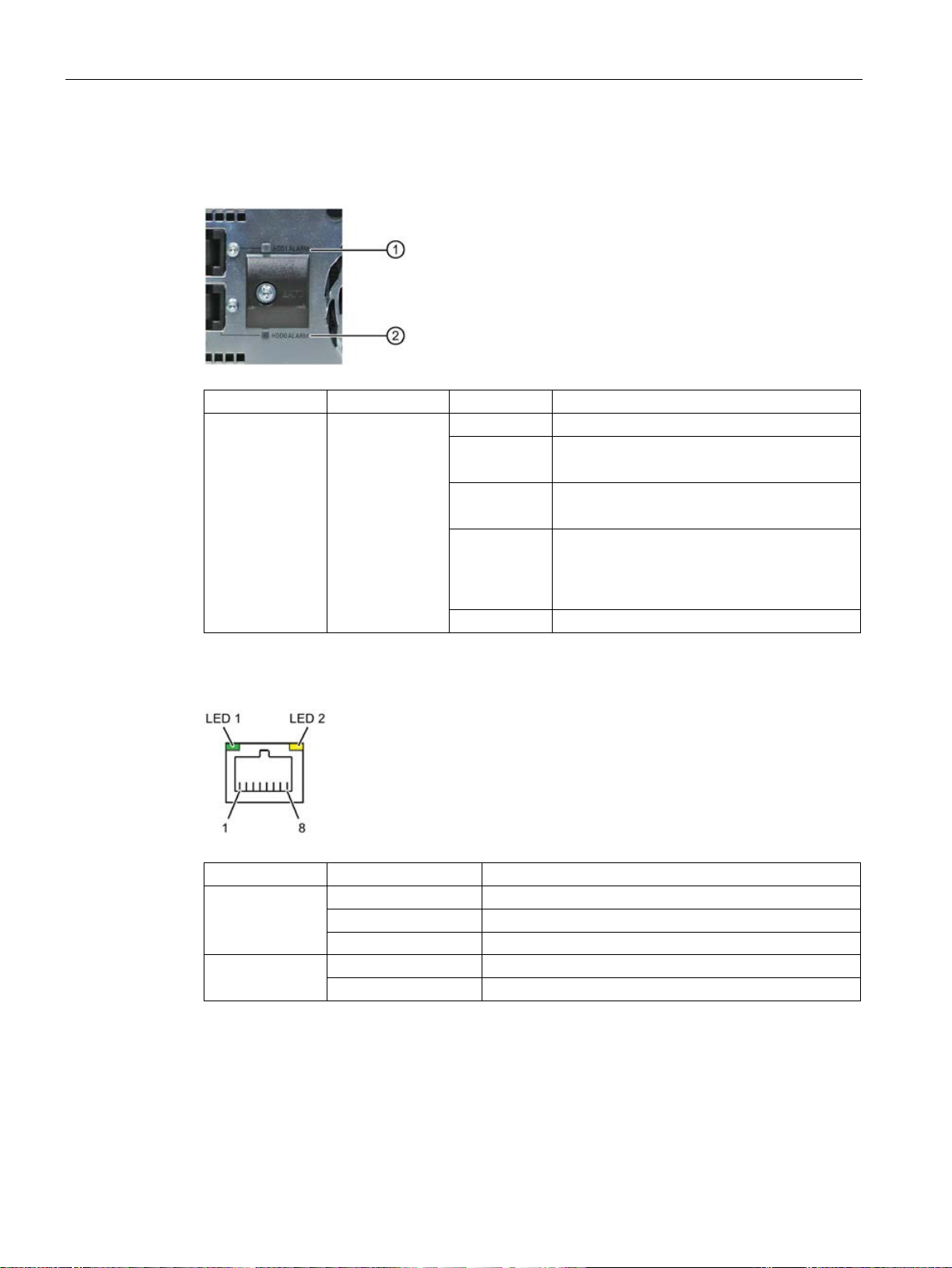

Product description

Position

Status indicator

Color

Description

①

Off - Green

BIOS ready to boot

green/yellow (1 Hz)

Yellow

Idle state

Flashing red (1 Hz)

Watchdog status display: active

Off - Green

Can be controlled by user program

(e.g. SoftPLC)

Off - Red

-

program (e.g. SoftPLC)

④

Off - Yellow

-

(e.g. SoftPLC)

1.4 External design of the device

1.4.3 Status displays

The status display consists of four multi-colored LEDs.

②

③

PC ON/WD

RUN/STOP

or L1

ERROR

or L2

MAINT

or L3

Flashing

Yellow Can be controlled by controller program

Flashing red Can be controlled by user program or controller

Red Can be controlled by controller program

BIOS in POST, power switch on

For additional information on controlling the LEDs or the NVRAM with a Windows operating

system, please refer to "Buffer memory NVRAM (optional) (Page 69)". Example programs for

controlling the LEDs under Windows operating systems are available on the Internet at the

following address: Technical support (https://support.industry.siemens.com/cs/ww/en/)

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

19

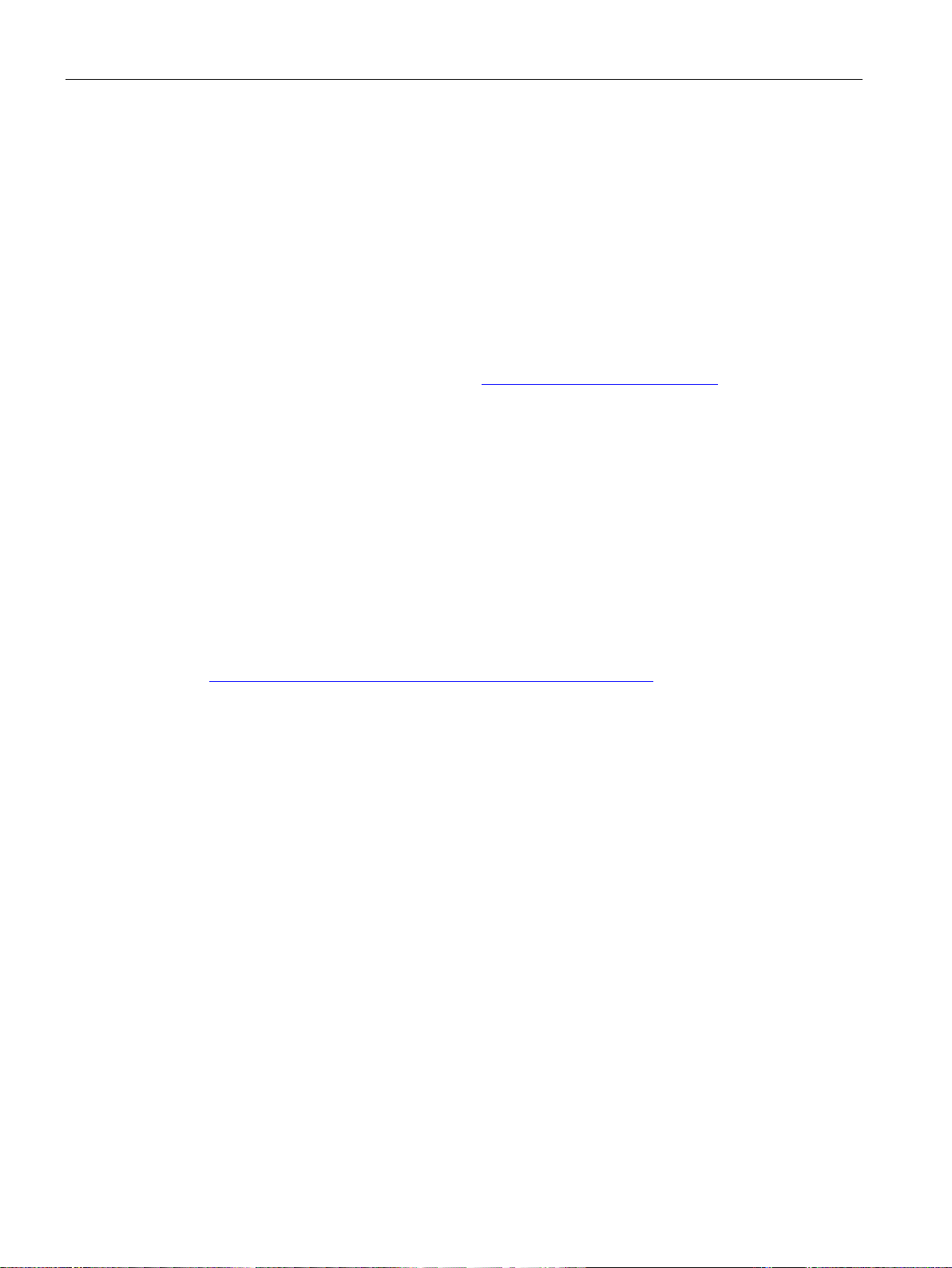

Page 20

Product description

Display

Meaning

Color

Description

Both off

RAID is OK

up red

up red

RAID system in the RAID software".

Both flash

RAID is synchronized

Status indicator

Status

Meaning of the status

Off

10 Mbps

Lit green

100 Mbps

Lit orange

1000 Mbps

Lit

Connection exists

1.4 External design of the device

RAID status indicators in removable drive bay

Status indicator position, see also Side view, right (Page 16).

LED "HDDx

ALARM"

Ethernet status indicators

HDD alarm in

connection with

RAID and monitoring software

LED ① lights

LED ② lights

Both light up

red

HDD1 is not OK

HDD2 is not OK

RAID is not OK

For information on locating the hard disk, see

section "Displaying a defective hard disk of a

LED 1

LED 2

SIMATIC IPC677E

20 Operating Instructions, 04/2019, A5E45117996-AA

Flashes Activity

Page 21

Product description

①

100 V AC to 240 V AC power supply

②

Slots for removable drives

③

Expansion card slots

④

Heat sink of the processor

⑤

Expansion card slots

⑥

Motherboard

⑦

Slots for memory modules

⑧

Retainer for expansion cards

1.5 Internal design of the device

1.5 Internal design of the device

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

21

Page 22

Product description

1.6 Accessories and spare parts

1.6 Accessories and spare parts

1.6.1 Accessories: Hardware

Accessories from Siemens are available for your device that are not included in the scope of

delivery.

Obtaining accessories and original spare parts via the SIEMENS Industry Mall

1. On the Internet, go to Industry Mall (https://mall.industry.siemens.com).

2. Log in with your customer data.

3. Select your user language.

4. Go to your device in the product catalog (tree structure on left):

"Automation technology > PC-based Automation > Industrial PC > Box PC> ..."

5. In the tree structure on the left, click on: SIMATIC IPC677E.

6. Select the "Accessories" tab in the display area.

SIEMENS spare parts services

Information on ordering, the provision and delivery of spare parts can be found under

"Industry Online Support: Spare parts services

(http://support.automation.siemens.com/WW/view/en/16611927)".

SIMATIC IPC677E

22 Operating Instructions, 04/2019, A5E45117996-AA

Page 23

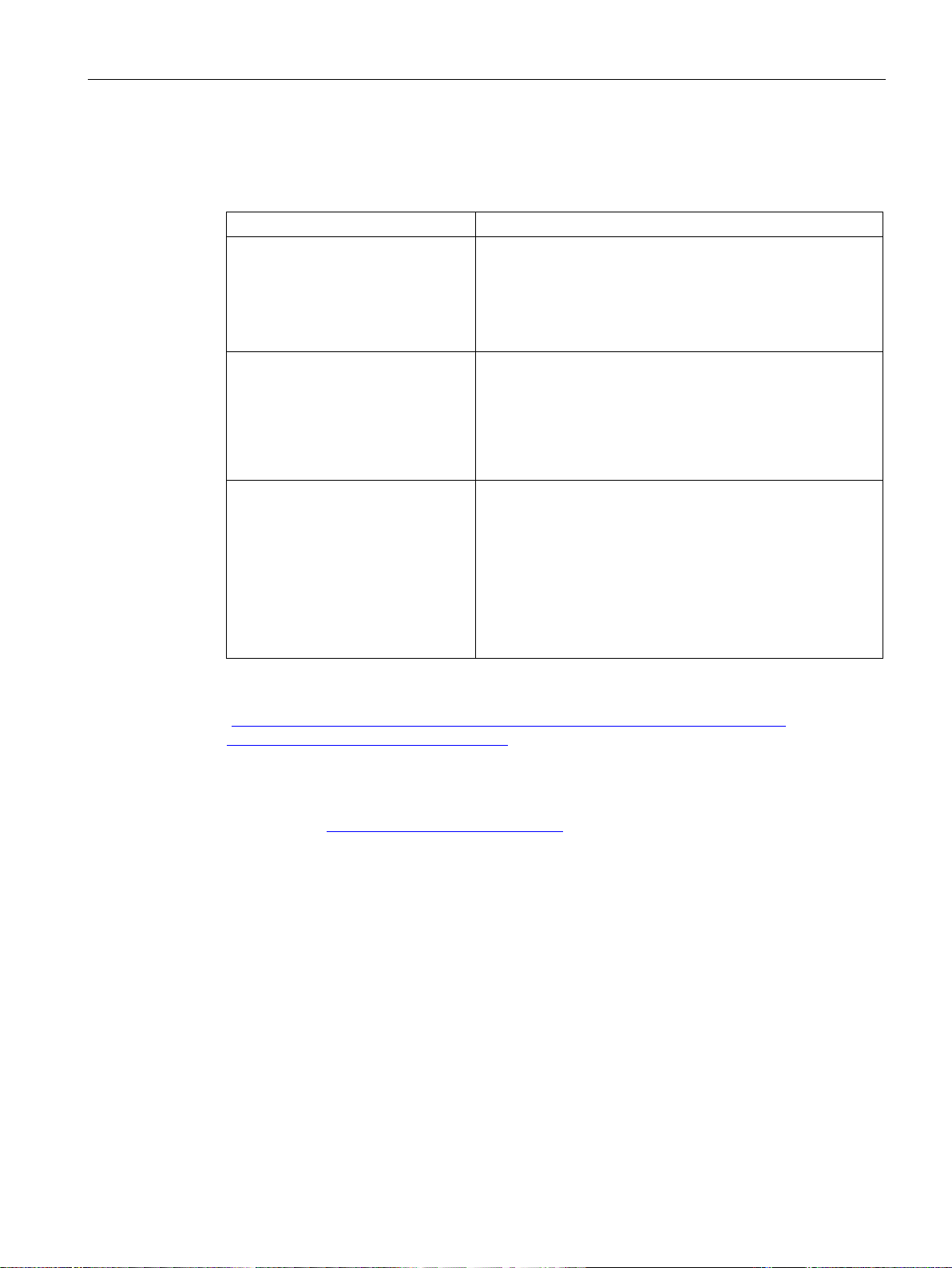

Product description

Software

Description

(https://mall.industry.siemens.com).

Processors of the type i7 offer iAMT functionality.

1.6 Accessories and spare parts

1.6.2 Accessories: Software

The following software products, among others, can be additionally ordered for your device:

SIMATIC IPC Image & Partition Creator

SIMATIC IPC DiagMonitor The SIMATIC IPC DiagMonitor software offers additional

SIMATIC IPC Remote Manager The SIMATIC IPC Remote Manager enables the use of Intel®

This tool provides convenient and efficient functions for backing up and restoring the full content of memory cards, hard

disks and individual partitions (images).

The SIMATIC IPC Image & Partition Creator can be ordered

using the Siemens online ordering system

alarm and linking options in addition to the local monitoring

functions of the SIMATIC IPC DiagBase software and includes:

• The software for the stations to be monitored.

• A library for creating user-specific applications.

Active Management Technology (Intel® AMT).

Remote access to SIMATIC IPCs enables, for example, sys-

tem or program errors to be corrected as well as firmware/BIOS and program updates to be performed from a

control room (without deployment in the field).

Access is possible even if the operating system no longer

starts.

Further information on the software products and references to the online catalog and

ordering system (Industry Mall) can be found on the SIMATIC IPC software

(http://www.automation.siemens.com/mcms/pc-based-automation/en/industrial-

pc/expansion_components_accessories) homepage.

See also

Industry Mall (https://mall.industry.siemens.com)

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

23

Page 24

Product description

1.6 Accessories and spare parts

SIMATIC IPC677E

24 Operating Instructions, 04/2019, A5E45117996-AA

Page 25

2

WARNING

The installer of the system is responsible for the safety of a system in which the device is

integrated.

WARNING

Risk of electric shock

DANGER

Risk of lightning strikes

2.1 General safety instructions

There is a risk of malfunction which could result in death or serious injury.

• Ensure that only suitably qualified personnel perform the work.

Risk due to electric shock

Risk of lightning strikes

The on/off button and on/off switch do not fully disconnect the device from the supply

voltage.

There is also a risk of fire if the device or connecting lines are damaged.

• Always fully disconnect the device from the supply voltage before performing work on

the device or when the device will not be used over an extended period of time.

• For control cabinet mounting: Use a central, easily accessible AC circuit breaker close

to the device, if possible.

• When you install the device, make sure that the power supply connector is easily

accessible.

A lightning flash may enter the mains cables and data transmission cables and jump to a

person.

Death, serious injury and burns may result.

• Disconnect the device from the power supply in good time when a thunderstorm is

approaching.

• Do not touch power cables and data transmission cables during a thunderstorm.

• Keep sufficient distance from electric cables, distributors, systems, etc.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

25

Page 26

Safety instructions

NOTICE

Possible functional restrictions in case of non-validated plant operation

Note

Burn-in effect and backlighting

The brightness of the backlighting deteriorates over the course of the screen's life cycle. A

permanent picture with bright screen objects leads to a burn

•

Note

Defective pixels in the display

The manufacturing process of modern displays does not currently guarantee that all pixels of

the display are perfect. It is therefore inevitable that the display will contain a

of defective pixels. This does not limit the function in any way provided the defective pixels

are not all in one location.

Note

Use in an industrial environment without additional protective measures

This device was designed for use in a normal industrial environment according to

IEC

NOTICE

Electrostatic sensitive devices (ESD)

2.1 General safety instructions

Avoiding functional restrictions

The device is tested and certified on the basis of the technical standards. In rare cases,

functional restrictions can occur during plant operation.

Validate the correct functioning of the plant to avoid functional restrictions.

TFT displays

-in effect.

Use a screen saver to extend the life of the screen and the backlighting and to prevent

the burn-in effect.

Use in industrial environments

60721-3-3.

ESD directive

Electrostatic sensitive devices can be labeled with an appropriate symbol.

small number

The device contains electronic components which may be destroyed by electrostatic

charge. This can result in malfunctions and damage to the machine or plant.

Take corresponding precautionary measures before you open the device.

SIMATIC IPC677E

26 Operating Instructions, 04/2019, A5E45117996-AA

Page 27

Safety instructions

NOTICE

Damage to the device during transport and storage

WARNING

Electric shock and fire hazard due to damaged device

NOTICE

Damage from condensation

2.2 Note on transport and storage

2.2 Note on transport and storage

Damage caused by transportation and storage

If a device is transported or stored without packaging, shocks, vibrations, pressure and

moisture may impact the unprotected unit. Damaged packaging indicates that ambient

conditions have already had a massive impact on the device and it may be damaged.

This may cause the device, machine or plant to malfunction.

• Keep the original packaging.

• Pack the device in the original packaging for transportation and storage.

Damage from condensation

A damaged device can be under hazardous voltage and trigger a fire in the machine or

plant. A damaged device has unpredictable properties and states.

Death or serious injury could occur.

• Avoid installing and commissioning a damaged device.

• Label the damaged device and keep it locked away. Send off the device for immediate

repair.

If the device is subjected to low temperatures or extreme fluctuations in temperature during

transportation, moisture could occur on or inside the HMI device (condensation).

Moisture can cause a short-circuit in electrical circuits and damage the device.

• Store the device in a dry place.

• Bring the device to room temperature before starting it up.

• Do not expose the device to direct heat radiation from a heating device.

• If condensation develops, wait approximately 12 hours or until the device is completely

dry before switching it on.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

27

Page 28

Safety instructions

DANGER

Electrocution risk when control cabinet is open

NOTICE

Voided approvals

NOTICE

Ambient conditions and chemical resistance

2.3 Notes on mounting

2.3 Notes on mounting

Device in the control cabinet

When you open the control cabinet, there may be a dangerous voltage at certain areas or

components.

Touching these areas or components can cause death or serious bodily injury.

• Always disconnect the cabinet from the mains before opening it.

• Ensure that the power to the control cabinet cannot be turned on accidentally.

2.4 Notes on ambient and environmental conditions

Certifications and approvals

If the following conditions for system installation are not observed, approvals in accordance

with UL 61010-2-201 and EN 61010-2-201 are rendered void and there is a risk of

overheating and personal injury.

• You should observe the following information on ambient and environmental conditions.

Ambient and environmental conditions

Unsuitable environmental conditions can cause faults or damage the device.

Failure to comply nullifies the warranty in accordance with IEC/EN/UL 61010-2-201.

• Operate the device only in closed rooms.

• Only operate the device in the ambient conditions specified in the technical

specifications.

• Observe the permitted mounting positions of the device.

• Do not obstruct the venting slots of the device.

• Please note that when the device is operated in severe environments which are subject

to caustic vapors or gases, the provision of clean air is ensured.

• Clean the enclosure surface with a damp cloth and make sure that no water enters the

device.

SIMATIC IPC677E

28 Operating Instructions, 04/2019, A5E45117996-AA

Page 29

Safety instructions

CAUTION

Immunity to RF interference

2.4 Notes on ambient and environmental conditions

When you plan your project, you should make allowances for:

● Take note of the climatic and mechanical ambient conditions (Page 115).

● You must observe the Mounting positions (Page 37) when mounting the device.

● For installation in a cabinet, observe the SIMATIC setup guidelines as well as the relevant

DIN/VDE requirements or the applicable country-specific regulations.

● When the device is used in the programmable controller area in accordance with

IEC/EN/UL61010-2-201, note that the device is classified as "Open Equipment". An

IEC/EN/UL61010-2-201 compliant enclosure is therefore a mandatory requirement for

approval or operation according to IEC/EN/UL61010-2-201.

● The device must be installed in such a way that it is part of a restricted access location

(e.g. a locked control cabinet, control panel or server room).

● Always maintain a minimum clearance of 100 mm to the area of the ventilation slots and

do not cover the ventilation slots of the enclosure.

High frequency radiation

The device has an increased immunity to RF radiation according to the specifications on

electromagnetic compatibility in the technical specifications.

High frequency radiation, e g. from a cellular phone, can result in malfunctioning of the

device.

Persons are injured and the plant is damaged.

• Avoid high-frequency radiation.

• Remove radiation sources from the environment of the device.

• Switch off radiating devices.

• Reduce the radio output of radiating devices.

• Read the information on electromagnetic compatibility.

• Read the information in the technical specifications.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

29

Page 30

Safety instructions

CAUTION

Fault caused by I/O devices

NOTICE

Damage through regenerative feedback

Note

Checking the regenerative feedback

When

•

•

•

2.5 Information on I/O devices

2.5 Information on I/O devices

The connection of I/O devices can cause faults in the device.

The result may be personal injury and damage to the machine or plant.

• Only connect I/O devices which are approved for industrial applications in accordance

with EN 61000-6-2 and IEC 61000-6-2.

• I/O devices that are not hotplug-capable may only be connected after the device has

been disconnected from the power supply.

Regenerative feedback of voltage to ground by a connected or installed component can

damage the device.

Connected or built-in I/Os, for example, a USB drive, are not permitted to supply any

voltage to the device.

Regenerative feedback is generally not permitted.

measuring the counter emf, remember the following:

The computer in question must be turned off and the power supply connector must be

plugged in.

During the measurement, all cables from the plant to the computer should be connected.

All other components in the plant must be active.

SIMATIC IPC677E

30 Operating Instructions, 04/2019, A5E45117996-AA

Page 31

Safety instructions

CAUTION

Fire hazard due to overheating of the device

NOTICE

Damage caused by device and system extensions

NOTICE

"Open Equipment" IEC/EN/UL61010

2.6 Notes on device and system extensions

2.6 Notes on device and system extensions

Device and system extensions

Expansion cards generate additional heat. The device can overheat or cause a fire.

• Observe the safety and installation instructions for the expansion cards.

• Observe the max. permissible power consumption values.

Device and system expansions may contain faults and affect the entire device, machine or

plant. They may also violate safety rules and regulations regarding radio interference

suppression.

If you install or replace device or system expansions and damage your device, the warranty

is voided.

• Always disconnect the power plug before you open the device.

• Only install device or system expansions designed for this device.

• Observe the information on "Electromagnetic compatibility" provided in the technical

Contact your technical support team or the point of sale to find out which device and system

expansions are suitable for installation.

The device is designed for use as a programmable controller, OpenType according to

IEC/EN/UL 61010-2-201. The installation of the device in a fire protection housing in

accordance with IEC/EN/UL 61010-2-201 is therefore a mandatory requirement for

approval or operation.

Limitation of liability

● Observe the installation instructions for expansion components in the associated

specifications.

documentation.

● UL approval of the device only applies when the UL-approved components are used

according to their "Conditions of Acceptability".

● We are not liable for functional limitations caused by the use of third-party devices or

components.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

31

Page 32

Safety instructions

2.6 Notes on device and system extensions

SIMATIC IPC677E

32 Operating Instructions, 04/2019, A5E45117996-AA

Page 33

3

3.1 Preparing for mounting

3.1.1 Scope of delivery

Device and hardware for the device

● Panel PC SIMATIC IPC677E

● Mounting clips

● Strain relief

● Power plug latch

● USB stick

Optional:

● DiagMonitor

● Image & Partition Creator

● Power supply cable

Supplied data medium

On the supplied data medium (read-only), you can find:

● Software and tools to restore your ordered Microsoft® Windows® operating system.

● Device drivers for installation in operating systems

● SIMATIC IPC677E Quick Install Guide

● SIMATIC IPC677E Operating Instructions

● Product information

● Firmware/BIOS description

● Operating instructions for your ordered Microsoft® Windows® operating system on this

device

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

33

Page 34

Mounting and connecting the device

3.1 Preparing for mounting

Operating system

Depending on the ordered device configuration, the device comes with an installed operating

system.

● Microsoft® Windows® 10

(https://support.industry.siemens.com/cs/ww/de/view/109749498/en?dl=en)

● Without operating system

Installed software

● Monitoring software SIMATIC IPC DiagBase (only with installed Microsoft® Windows®

operating system)

● SIMATIC Panel Driver and Tools (only with installed Microsoft® Windows® operating

system)

You will find the latest information on additional software for your device under: Accessories

and spare parts (Page 22)

Printed documents

● SIMATIC IPC677E Quick Install Guide

● Product Information "Important notes on your device"

● SIMATIC IPC/PG Quality Control Report

SIMATIC IPC677E

34 Operating Instructions, 04/2019, A5E45117996-AA

Page 35

Mounting and connecting the device

WARNING

Electric shock and fire hazard due to damaged device

3.1 Preparing for mounting

3.1.2 Checking the delivery package

Damaged devices due to improper storage or transport may lead to personal injury and/or

substantial damage to equipment.

• You must observe the warnings in "Note on transport and storage (Page 27)".

Procedure

1. Check the packaging and package contents for visible transport damage.

If any transport damage is present at the time of delivery, lodge a complaint at the

shipping company in charge. Have the shipper confirm the transport damage

immediately.

2. Unpack the device at its installation location.

3. Keep the original packaging in case you have to transport the unit again.

4. Check the Scope of delivery (Page 33) and any accessories you may have ordered for

completeness and damage. Please inform the delivery service immediately if the package

contents are incomplete or damaged or do not correspond with your order. Fax the

enclosed form "SIMATIC IPC/PG Quality Control Report".

5. Please keep the enclosed documentation in a safe place. It belongs to the device. You

need the documentation when you commission the device for the first time.

6. Write down the Identification data of the device (Page 36) identification data of the device.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

35

Page 36

Mounting and connecting the device

3.1 Preparing for mounting

3.1.3 Identification data of the device

The device can be clearly identified with the help of this identification data in case of repairs

or loss.

The following illustrations are examples. The data of your device may differ from the data in

these examples.

Nameplate

The following image shows the nameplate on the SIMATIC IPC677E as an example.

COA label

Microsoft Windows "Product Key" is the "Certificate of Authenticity" (COA):

The COA label is only available for devices delivered with Microsoft® Windows® operating

system installed and is located on the rear of the device.

Example of COA label for the Microsoft® Windows® 10 operating system:

The Microsoft® Windows® 10 COA label has an additional security feature which conceals

part of the product key.

● The scratch-off panel consists of a small transparent label with a silver-colored scratch

coating, which was applied to conceal part of the 25-character product key. This scratchoff panel is designed to protect the product key from being obtained and used by

unauthorized third parties.

● You usually do not need this product key for commissioning because a valid product key

has already been integrated into the pre-installed operating system.

See also

Important instructions and manuals for operating the device (Page 11)

SIMATIC IPC677E

36 Operating Instructions, 04/2019, A5E45117996-AA

Page 37

Mounting and connecting the device

NOTICE

"Open Equipment" IEC/EN/UL61010

Note

Operation in closed rooms

The device is approved for

(Page

Note

Mounting precautions

•

3.1 Preparing for mounting

3.1.4 Mounting positions

The device is designed for use as a programmable controller, OpenType according to

IEC/EN/UL 61010-2-201. The installation of the device in a fire protection housing in

accordance with IEC/EN/UL 61010-2-201 is therefore a mandatory requirement for

approval or operation.

The following mounting positions are permitted for the device.

For information on the maximum permissible ambient temperatures during operation, refer to

section "Ambient conditions (Page 115)".

Mounting positions according to UL61010

operation in closed rooms only. Note the Ambient conditions

115).

Mounting in horizontal format

The total power for USB and PCI/PCIe expansions cannot exceed 30 W.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

37

Page 38

Mounting and connecting the device

Note

Operation in closed rooms

The device is approved for operation in closed rooms only. Note the

(Page

Note

Mounting precautions

•

3.1 Preparing for mounting

Additional mounting positions according to UL61010/CSA 22.2 No. 142

Ambient conditions

115).

Mounting in vertical format

The total power for USB and PCI/PCIe expansions cannot exceed 30 W.

SIMATIC IPC677E

38 Operating Instructions, 04/2019, A5E45117996-AA

Page 39

Mounting and connecting the device

Note

Stability of the mounting cutout

The material in the area of the mounting cutout must provide sufficient strength to guarantee

the enduring and safe mounting of the HMI device.

The force of the clamps or operation of the device may not lead to deformation of the

material in order to achieve the degrees of protection described below.

Note

Read the information in the section "

3.1 Preparing for mounting

3.1.5 Preparing the mounting cutout

Installation guidelines (Page 41)".

Requirements for complying with degree of protection

The degree of protection of the HMI device can only be guaranteed if the following

requirements are met:

● Material thickness at the mounting cutout for IP65 degree of protection, or for

enclosure type 4X/type 12 (indoor use only): 2 mm to 6 mm

● Permissible deviation from plane at the mounting cutout: ≤ 0.5 mm

This condition must be fulfilled for the mounted HMI device.

● Permissible surface roughness in the area of the mounting seal: ≤ 120 µm (R

Dimensions of the mounting cutout

120)

z

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

39

Page 40

Mounting and connecting the device

Mounting cutout

Multi-touch device 2

19"

22"

24"

Width w 1

448+1 mm

513+1 mm

569+1 mm

Height h 1

278+1 mm

315+1 mm

347+1 mm

1

2

Device with capacitive multi-touch screen

3.1 Preparing for mounting

Width and height must be interchanged for mounting in vertical format.

Installation depth

Information on the overall depth is available in the section "Dimension drawings

(Page 121)".

SIMATIC IPC677E

40 Operating Instructions, 04/2019, A5E45117996-AA

Page 41

Mounting and connecting the device

WARNING

Dangerous voltage and fire hazard

NOTICE

Insufficient load carrying capacity

NOTICE

Incorrect fixing elements

Note

•

•

•

•

•

•

•

3.2 Mounting the device

3.2 Mounting the device

3.2.1 Installation guidelines

Procedure during installation and mounting

Improper actions during installation and assembly may lead to personal injury and/or

substantial damage to equipment.

You should observe the installation and assembly notes under:

• Notes on mounting (Page 28)

• Notes on ambient and environmental conditions (Page 28)

If the wall it is mounted on does not have a sufficient load-bearing capacity, the device may

fall and be damaged.

• Ensure that the mounting surface on the wall can bear four times the total weight of the

The device may not be securely fitted if you use fixing elements other than those specified

below for mounting. The device can fall and may be damaged.

• Use only the specified fixing elements.

device, including fixing elements.

See the notes under Preparing the mounting cutout (Page 39).

For installation in control cabinets, note the SIMATIC setup guidelines as well as the

relevant DIN/VDE requirements or the country-specific regulations.

Ensure that the device is classified as "Open Equipment" when using it in the area of

Industrial Control Equipment (UL 61010). A UL 61010 compliant enclosure is therefore a

mandatory requirement for approval or operation according to UL 61010.

Provide adequate volume in the control cabinet for air circulation and heat transport.

Keep at least 5 cm distance between the device and control cabinet.

The ventilation slots of the device may not be covered or obstructed.

Ensure there is enough clearance in the control cabinet to allow the backplane cover to

be removed.

Equip the control cabinet with struts for stabilizing the mounting cut-out. Install struts

where necessary.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

41

Page 42

Mounting and connecting the device

Note

If the mounting seal is damaged or protrudes from the device, the guaranteed degree of

protection is not ensured.

It is prohibited from mounting the device if the mount

3.2 Mounting the device

See also

Ambient conditions (Page 115)

Mounting positions (Page 37)

3.2.2 Mounting the device with mounting clips

Positions of the mounting clips

To achieve the degree of protection for the device, the positions for the mounting clips

shown below must be adhered to.

Requirement

● All packaging components and protective films have been removed from the device.

● To install the device, you need the mounting clips from the accessory kit.

Procedure

● The mounting seal on the front of the device is not managed.

ing seal is damaged.

SIMATIC IPC677E

42 Operating Instructions, 04/2019, A5E45117996-AA

Page 43

Mounting and connecting the device

3.2 Mounting the device

1. Working from the front, insert the device into the mounting cut-out.

2. Make sure that all four spring fasteners latch fully into place on the upper and lower side

of the device. If necessary, press the device again carefully into the mounting slot at the

place that is not fully latched into position.

3. Insert a mounting clip into the cutout provided on the device.

Note the correct position of the mounting clips.

4. To secure the mounting clip, tighten the grub screw with the slot screwdriver, torque 0.5

Nm.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

43

Page 44

Mounting and connecting the device

Device

Position

3.2 Mounting the device

5. Repeat steps 3 and 4 until all mounting clips are securely fastened.

6. Check the fit of the mounting seal.

Position of the mounting clips for multi-touch devices

Fasten the mounting clips to the positions as illustrated.

24" display

22" display

SIMATIC IPC677E

44 Operating Instructions, 04/2019, A5E45117996-AA

Page 45

Mounting and connecting the device

Device

Position

3.2 Mounting the device

19" display

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

45

Page 46

Mounting and connecting the device

3.3 Connecting the device

3.3 Connecting the device

3.3.1 Country-specific information on supply voltage

USA and Canada

Supply voltage 120 V / 230 V / 240 V AC

Ensure that the power cords used are rated for the maximum current input and ambient

temperature of the device and meet the requirements of the following standards:

● ANSI/UL 817

● CSA C22.2 No. 21

Ensure that the device connectors, connection sockets and connection materials are rated

for the maximum current input and ambient temperature of the device and meet the

requirements of the following standards:

● ANSI/UL 498 and CSA C22.2 No. 42

● CSA C22.2 No. 182.1

● CSA C22.2 No. 182.2

● CSA C22.2 No. 182.3

For countries other than the USA and Canada

Supply voltage 230 V AC

This device is supplied with a safety-tested power cord and may only be connected to a

grounded SCHUKO socket outlet.

If you do not use the power supply cord, use a flexible cable that is rated for the maximum

current consumption and highest ambient temperature of the device and complies with the

safety regulations of the country in which the device is installed.

The power supply cord and the plug connector must bear the prescribed markings.

SIMATIC IPC677E

46 Operating Instructions, 04/2019, A5E45117996-AA

Page 47

Mounting and connecting the device

3.3 Connecting the device

3.3.2 Connection of equipotential-bonding cable

A low-resistance ground connection ensures that interference signals generated by external

power supply cables, signal cables or cables to the I/O modules are safely discharged to

ground.

The connection for functional earthing on a device has a large surface, makes contact over a

large area and is marked with the following symbol:

Requirements

For the equipotential bonding connection, you require:

● A T20 screwdriver

● An equipotential bonding cable with a minimum cross-section of 2.5 mm

Procedure

2

1. Connect the marked equipotential bonding connection (M4 thread) of the device with the

equipotential bonding cable.

Make sure the equipotential bonding cable has contact with the enclosure over a large

area.

2. Connect the equipotential bonding cable with the central grounding point of the control

cabinet.

Make sure the equipotential bonding cable has contact with the central grounding point

over a large area.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

47

Page 48

Mounting and connecting the device

WARNING

Injury to persons or damage to property when operated on an incorrect power supply

system

WARNING

Safety regulations- connecting cable

WARNING

Risk of electric shock

Note

The varying voltage power supply module is designed for operation on 120/230/240 V AC

networks. The setting of the voltage range takes place automatically.

3.3 Connecting the device

3.3.3 Connecting the power supply

3.3.3.1 Connecting 100-240 VAC power supply

If you connect the device to an unsuitable power supply, the device receives voltages and

currents that are too high or too low.

Injuries to persons, malfunctions or a damage to the device can result.

• The permissible rated voltage of the device must match the local supply voltage.

• Operate the device only in grounded power supply networks (TN networks in

accordance with VDE 0100, Part 100 or IEC 60364-1).

• Operation in non-grounded or impedance-grounded networks is not permitted.

Use only AC or DC connecting cables which comply with the local safety regulations.

Otherwise, there is a risk of fire and electric shock. This can result in personal injury or

property damage.

• Ensure that the AC or DC connecting cables comply with the safety regulations of the

country in which the device is installed and bear the marks required in each case.

• Connect the protective conductor in accordance with the operating instructions.

The on/off button and on/off switch do not fully disconnect the device from the mains.

There is also a risk of fire if the device or connecting lines are damaged.

• Always fully disconnect the device from the line voltage before performing work on the

device or when the device will not be used over an extended period of time.

• For control cabinet mounting: Use a central AC circuit breaker as near as possible to the

device and connect the device to a protective conductor.

• When you install the device, make sure that the power supply connector is easily

accessible.

SIMATIC IPC677E

48 Operating Instructions, 04/2019, A5E45117996-AA

Page 49

Mounting and connecting the device

3.3 Connecting the device

Requirement

● You have observed the information under "Country-specific information on supply voltage

(Page 46)".

● Screwdriver T10

Procedure

1. Make sure that the ON/OFF switch is in position "I" (Off) to avoid unintentional startup of

the device when you plug in the power cord.

2. Connect the appliance connector to the device.

3. Connect the power cable with the safety power outlet.

4. If necessary, install the enclosed cable grip.

SIMATIC IPC677E

Operating Instructions, 04/2019, A5E45117996-AA

49

Page 50

Mounting and connecting the device