Page 1

SIMATIC

Industrial PC

SIMATIC IPC477E PRO

Operating Instructions

08/2017

A5E39912462

Preface

1

Overview

2

Safety guidelines

3

Mounting and connecting the

HMI device

4

Commissioning the device

5

Operating the device and

device functions

6

Expanding the device and

assigning the device

parameters

7

Maintaining and repairing the

device

8

Technical specifications

9

Technical support

A

Markings and symbols

B

List of abbreviations

C

-AA

Page 2

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E39912462-AA

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

may

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

07/2017 Subject to change

Page 3

Table of contents

1 Preface ................................................................................................................................................... 7

2 Overview................................................................................................................................................. 9

3 Safety guidelines ................................................................................................................................... 21

4 Mounting and connecting the HMI device .............................................................................................. 27

5 Commissioning the device .................................................................................................................... 53

2.1 Product description ................................................................................................................... 9

2.2 Installation ............................................................................................................................... 11

2.2.1 Interfaces and operator controls for PRO device ................................................................... 13

2.3 Accessory kit ........................................................................................................................... 14

2.4 Accessories ............................................................................................................................. 14

2.5 System components ............................................................................................................... 15

2.5.1 Base adapter ........................................................................................................................... 15

2.5.2 Round tube adapter ................................................................................................................ 16

2.5.3 Adapter set for support arm and stand mounting of PRO device ........................................... 18

2.5.4 Extension Unit and operator controls ...................................................................................... 19

3.1 General safety instructions ..................................................................................................... 21

3.2 Notes on usage ....................................................................................................................... 24

4.1 Preparing for mounting ........................................................................................................... 27

4.1.1 Checking the delivery package ............................................................................................... 27

4.1.2 Device identification data ........................................................................................................ 29

4.2 Permitted mounting positions ................................................................................................. 31

4.3 Mounting the device ................................................................................................................ 33

4.3.1 Notes on mounting .................................................................................................................. 33

4.3.2 Prepared for support arm or stand without extension elements (flange on top) .................... 35

4.3.3 Prepared for support arm and extension elements (flange mount) ........................................ 38

4.4 Connecting the device ............................................................................................................ 42

4.4.1 Notes on connecting ............................................................................................................... 42

4.4.2 Power supply .......................................................................................................................... 44

4.4.2.1 Opening and closing the terminal compartment cover ........................................................... 44

4.4.2.2 connecting the PE conductor .................................................................................................. 47

4.4.2.3 Connecting the 24 VDC power supply .................................................................................... 48

4.4.3 Connecting peripheral equipment ........................................................................................... 50

4.4.4 Connecting the device to networks ......................................................................................... 51

4.4.5 Securing the cables ................................................................................................................ 52

5.1 Notes on commissioning and operation .................................................................................. 53

5.2 Initial commissioning ............................................................................................................... 55

5.3 Windows Action Center........................................................................................................... 57

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

3

Page 4

Table of contents

6 Operating the device and device functions ............................................................................................ 59

7 Expanding the device and assigning the device parameters .................................................................. 75

8 Maintaining and repairing the device ..................................................................................................... 83

6.1 Operator input options ........................................................................................................... 59

6.2 Operating the device .............................................................................................................. 60

6.3 IPC Wizard functions ............................................................................................................. 62

6.4 Extended device functions ..................................................................................................... 63

6.4.1 Monitoring functions ............................................................................................................... 63

6.4.1.1 Overview of the monitoring functions ..................................................................................... 63

6.4.1.2 Temperature monitoring/display ............................................................................................ 64

6.4.1.3 Watchdog (WD)...................................................................................................................... 64

6.4.1.4 Battery monitoring .................................................................................................................. 65

6.4.1.5 Mass storage monitoring ........................................................................................................ 65

6.4.2 Enhanced Write Filter (EWF) ................................................................................................. 66

6.4.3 File Based Write Filter (FBWF) .............................................................................................. 69

6.4.4 Buffer memory NVRAM ......................................................................................................... 70

6.4.5 Active Management Technology (AMT) ................................................................................ 71

6.4.6 Trusted Platform Modul (TPM) ............................................................................................... 73

7.1 Opening and closing the backplane cover ............................................................................. 75

7.2 Installing and removing a memory module ............................................................................ 79

7.3 Installing and removing a CFast card .................................................................................... 81

7.4 Assigning CPU power consumption parameters ................................................................... 82

8.1 Maintenance ........................................................................................................................... 83

8.2 Repair information .................................................................................................................. 84

8.3 Cleaning the Device Front ..................................................................................................... 87

8.4 Installing and removing hardware .......................................................................................... 88

8.4.1 Replacing the backup battery ................................................................................................ 88

8.4.2 Replace SSD .......................................................................................................................... 89

8.5 Installing the software ............................................................................................................ 91

8.5.1 Reinstalling the operating system .......................................................................................... 91

8.5.1.1 General installation procedure ............................................................................................... 91

8.5.1.2 Restoring the factory state of the software ............................................................................ 92

8.5.1.3 Windows ................................................................................................................................. 93

8.5.1.4 Windows Embedded Standard .............................................................................................. 97

8.5.2 Partitioning the data storage medium .................................................................................... 98

8.5.2.1 Partitioning in Windows Embedded Standard 7 .................................................................... 98

8.5.2.2 Partitioning in Windows 7 Ultimate ........................................................................................ 99

8.5.2.3 Changing the partitions under Windows 7 and Windows 10 ................................................. 99

8.5.3 Installing drivers and software ............................................................................................. 100

8.5.4 Update installation ............................................................................................................... 101

8.5.4.1 Updating the operating system ............................................................................................ 101

8.5.4.2 Installing or updating application programs and drivers ...................................................... 101

8.5.5 Backing up data ................................................................................................................... 101

8.6 Recycling and disposal ........................................................................................................ 101

SIMATIC IPC477E PRO

4 Operating Instructions, 08/2017, A5E39912462-AA

Page 5

Table of contents

9 Technical specifications ...................................................................................................................... 103

9.1 Certificates and approvals .................................................................................................... 103

9.2 Directives and declarations ................................................................................................... 108

9.2.1 Electromagnetic compatibility ............................................................................................... 108

9.2.2 ESD guideline ....................................................................................................................... 108

9.3 Dimension drawings .............................................................................................................. 111

9.3.1 Dimension drawing of 15" device with capacitive multi-touch screen .................................. 111

9.3.2 Dimension drawing of 19" device with capacitive multi-touch screen .................................. 114

9.3.3 Dimension drawing of 22" device with capacitive multi-touch screen .................................. 117

9.4 Technical specifications ........................................................................................................ 120

9.4.1 General technical specifications ........................................................................................... 120

9.4.2 Environmental conditions ...................................................................................................... 125

9.4.3 Information on insulation tests, protection class and degree of protection........................... 126

9.4.4 Rated voltages ...................................................................................................................... 126

9.4.5 Power requirements of the components ............................................................................... 126

9.4.6 Integrated DC power supply ................................................................................................. 127

9.5 Hardware descriptions .......................................................................................................... 128

9.5.1 External interfaces ................................................................................................................ 128

9.5.1.1 COM1/COM2 ........................................................................................................................ 128

9.5.1.2 CFast..................................................................................................................................... 128

9.5.1.3 DisplayPort ............................................................................................................................ 129

9.5.1.4 Ethernet ................................................................................................................................ 130

9.5.1.5 USB 3.0 port ......................................................................................................................... 130

9.5.1.6 USB 2.0 ................................................................................................................................. 131

9.5.2 System resources ................................................................................................................. 131

9.5.3 Input/output areas ................................................................................................................. 133

9.5.3.1 Overview of the internal module registers ............................................................................ 133

9.5.3.2 Watchdog trigger register (read only, address 062h) ........................................................... 133

9.5.3.3 Watchdog enable register (read/write address 062h) ........................................................... 134

9.5.3.4 Battery status register (read only, if the RTC_BAT_SURVEY_EN address is set to "1";

404Dh) .................................................................................................................................. 135

9.5.3.5 NVRAM address register ...................................................................................................... 135

9.6 BIOS description ................................................................................................................... 136

9.6.1 Overview ............................................................................................................................... 136

9.6.2 Opening the BIOS selection menu ....................................................................................... 137

9.6.3 Structure of the BIOS Setup menu ....................................................................................... 139

9.6.4 Exit menu .............................................................................................................................. 141

9.6.5 BIOS update ......................................................................................................................... 142

9.6.6 Alarm, error and system messages ...................................................................................... 144

9.7 Active Management Technology (AMT)

...............................................................................

9.7.1 Introduction ........................................................................................................................... 145

9.7.2 Overview of AMT .................................................................................................................. 146

9.7.3 Enabling Intel® AMT / basic configuration ............................................................................ 146

9.7.4 Resetting the Intel® AMT to the default settings and disabling AMT ................................... 148

9.7.5 Determining the network address ......................................................................................... 148

9.7.6 Forcing user consent ............................................................................................................ 149

9.8 Functional scope in Windows ............................................................................................... 150

9.8.1 Windows Embedded Standard 7 .......................................................................................... 150

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

145

5

Page 6

Table of contents

A Technical support................................................................................................................................. 153

B Markings and symbols ......................................................................................................................... 157

C List of abbreviations ............................................................................................................................. 161

Glossary .............................................................................................................................................. 167

Index ................................................................................................................................................... 175

A.1 Service and support ............................................................................................................. 153

A.2 Problem solving.................................................................................................................... 154

A.3 Notes on the use of third-party modules .............................................................................. 155

B.1 Overview .............................................................................................................................. 157

B.2 Safety ................................................................................................................................... 157

B.3 Operator controls ................................................................................................................. 157

B.4 Certificates, approvals and markings ................................................................................... 158

B.5 Interfaces ............................................................................................................................. 159

SIMATIC IPC477E PRO

6 Operating Instructions, 08/2017, A5E39912462-AA

Page 7

1

Purpose of the Operating Instructions

Basic knowledge required

Scope of the operating instructions

Scope of this documentation

These operating instructions contain all the information you need for commissioning and

operating the SIMATIC IPC477E PRO.

It is intended both for programming and testing personnel who commission the device and

connect it with other units (automation systems, programming devices), as well as for service

and maintenance personnel who install add-ons or carry out fault/error analyses.

A solid background in personal computers and Microsoft operating systems is required to

understand this manual. General knowledge in the field automation control engineering is

recommended.

These operating instructions apply to "SIMATIC IPC477E PRO" industrial PCs with article

numbers6AV7251-...-... .

The documentation for the IPC includes the following:

● Product information, e.g. "Important notes on your device"

● Quick Install Guide SIMATIC IPC477E PRO

● SIMATIC IPC477E PRO Operating Instructions

The documentation is supplied with the IPC in multiple languages as PDF on the USB stick

supplied in the documentation package.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

7

Page 8

Preface

Conventions

Note

A note is important information about the product, handling the product or a reference to

specific sections of the documentation that require special consideration.

History

Edition

Comments

08/2017

First edition

In these operating instructions, "device" is used as the standard term for "SIMATIC IPC477E

PRO".

In these operating instructions, the terms "Windows Embedded Standard 7 P" and "Windows

Embedded Standard 7 E" are also abbreviated with the term "Windows Embedded

Standard". "Windows 7" is used as an abbreviation for "Windows 7 Ultimate".

A touch device generally refers to a device with a capacitive multi-touch screen or a resistive

single touch screen. Touch screen is the general term for a resistive single touch screen or a

capacitive multi-touch screen.

The following editions of these operating instructions have already been published:

SIMATIC IPC477E PRO

8 Operating Instructions, 08/2017, A5E39912462-AA

Page 9

2

2.1

Product description

Features

SIMATIC IPC477E PRO provides high-level industrial functionality.

● Compact design

● Maintenance-free operation

● IP65 degree of protection

● Rugged

● Ex approval

● Used for shipping and offshore applications

● Expansion with system components

The range has been expanded by the PRO device with all-round IP65 degree of protection;

the device not only impresses with its ease of servicing, but also with its sophisticated design

and low mounting depth.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

9

Page 10

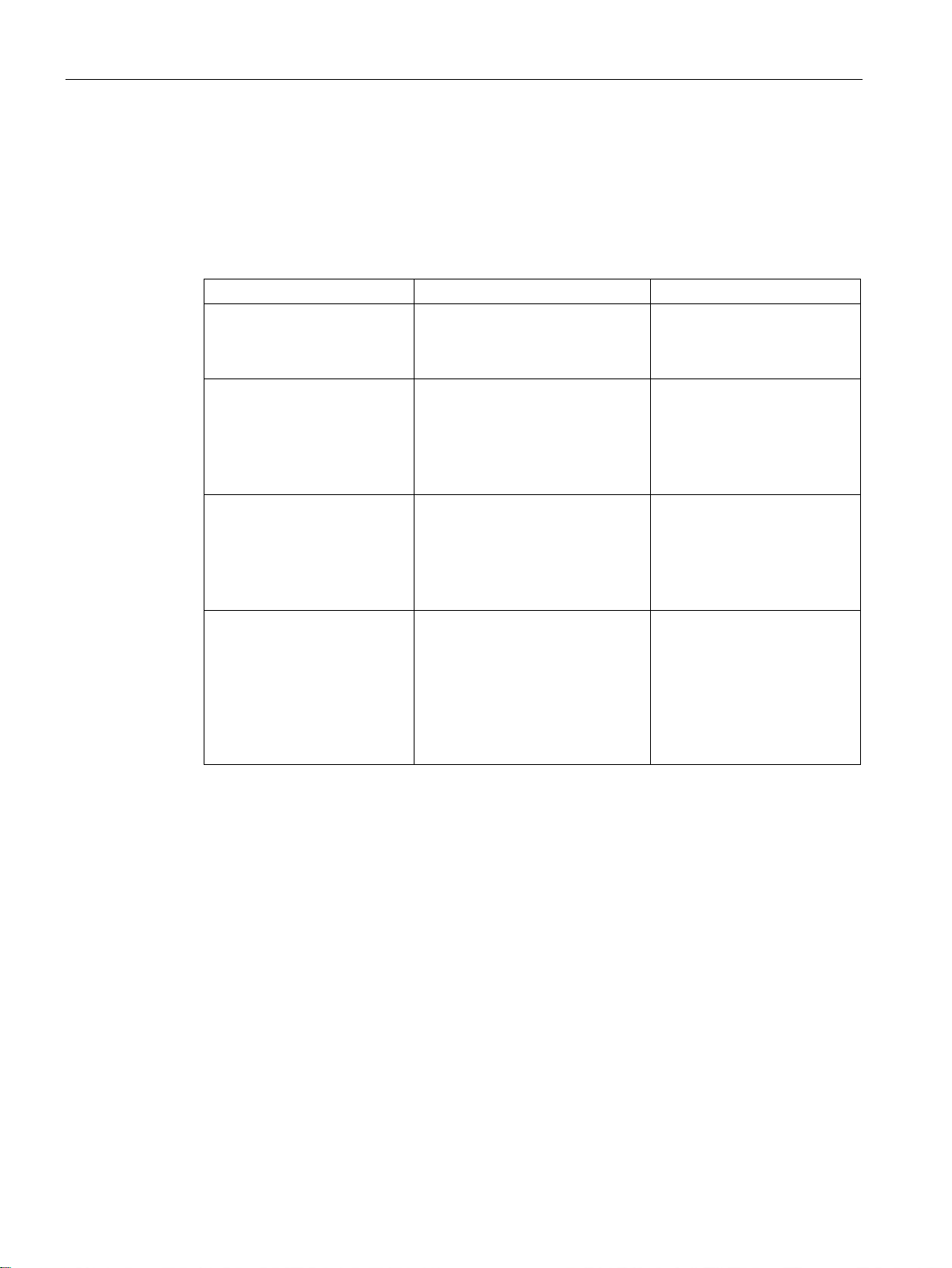

Overview

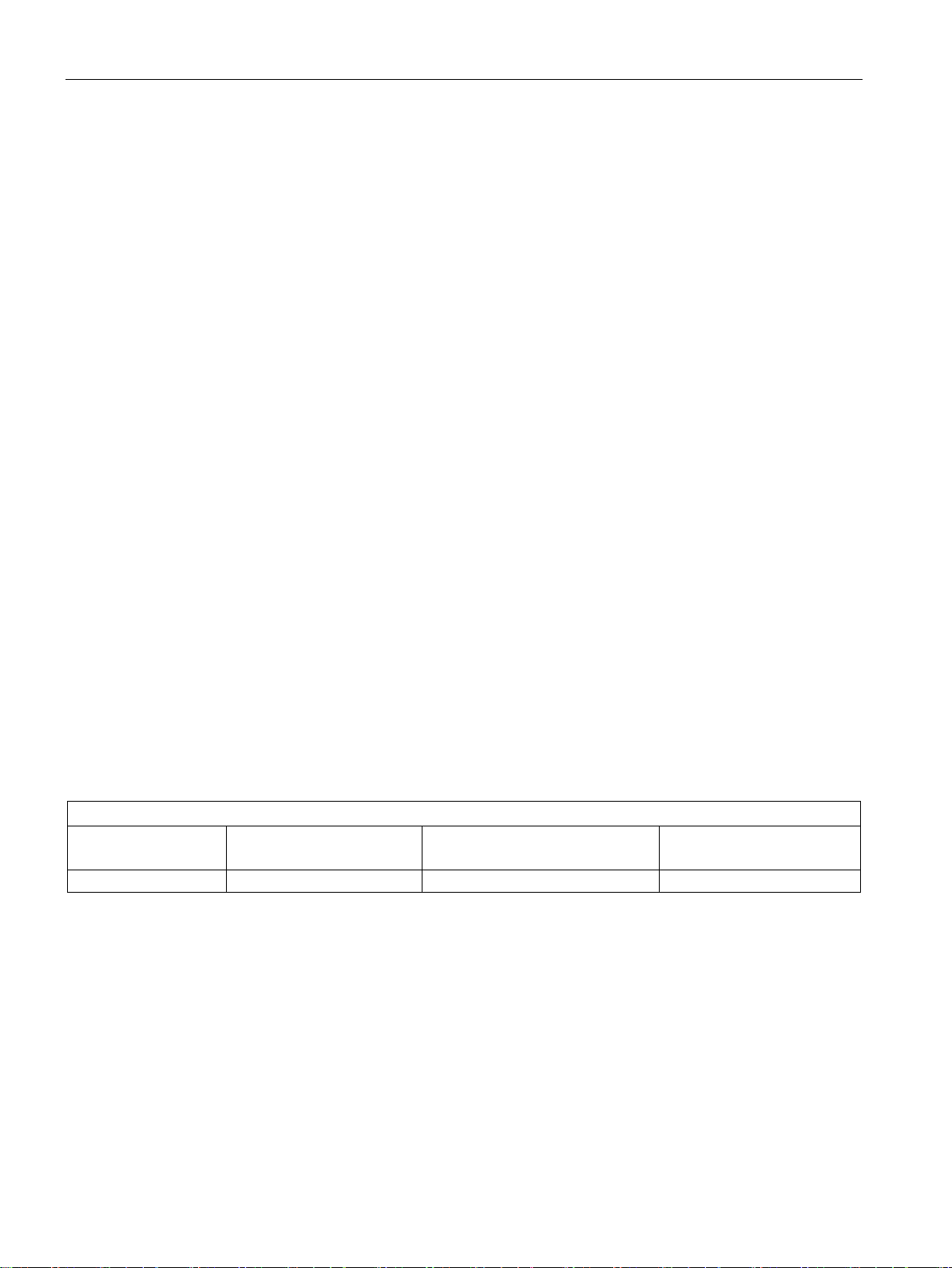

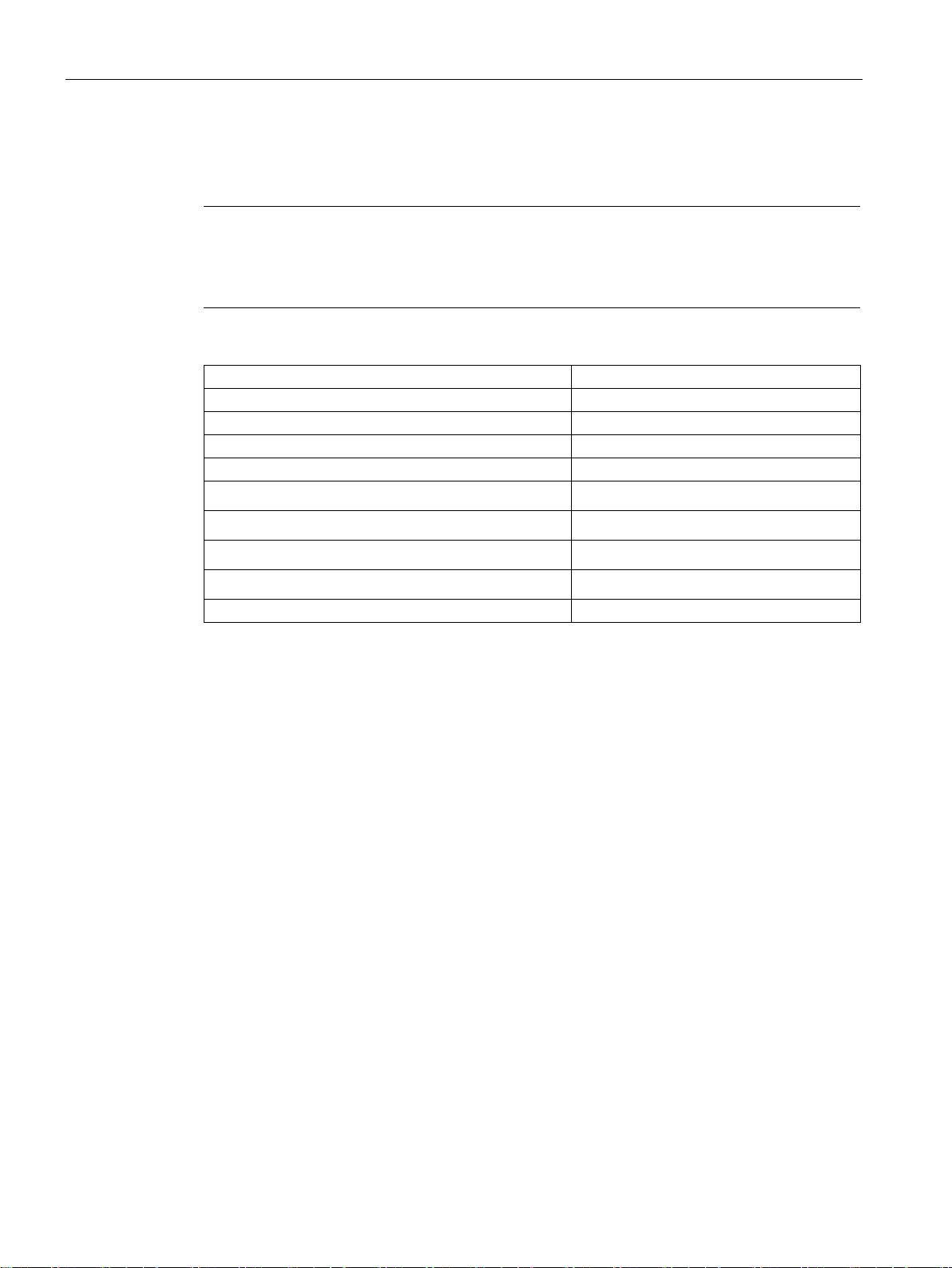

Device variants

PRO device with capacitive multi-touch screen

Operating systems

Operating system

Windows 10 IoT Enterprise (64-bit)

Windows 7 Ultimate

(32/64-bit)

Windows Embedded

Standard 7 P (32-bit)

Windows Embedded

Standard 7 E (32/64-bit)

x x x

x*

* WES7E is also supplied with IPC477E PRO devices. Multitouch is operated in single touch mode with WES7E.

2.1 Product description

The delivery note contains information on the precise scope of functions and product

package for your device.

The SIMATIC IPC477E PRO is available in the following device variants, which differ in

regard to the display size, operating method and optional expansions:

● Display:

– 15" display, resolution 1366 × 768 pixels

– 19" display, resolution: 1366 x 768 pixels

– 22" display, resolution: 1920 x 1080 pixels

● optionally prepared for:

– Support arm without extension components (flange at top)

– Support arm and extension components (round tube)

– Pedestal/extension components (flange at bottom)

● A base adapter and adapter sets that can be ordered separately support mounting

● Fully dust-proof and splash-proof with IP65 degree of protection and Enclosure Type

The following table shows the operating systems that are available:

systems from various manufacturers.

– Base adapter for support arm and pedestal included in the product package.

– Cover plate for device version for support arm and extension components included in

the product package.

4X / 12 (indoor use only)

SIMATIC IPC477E PRO

10 Operating Instructions, 08/2017, A5E39912462-AA

Page 11

Overview

2.2

Installation

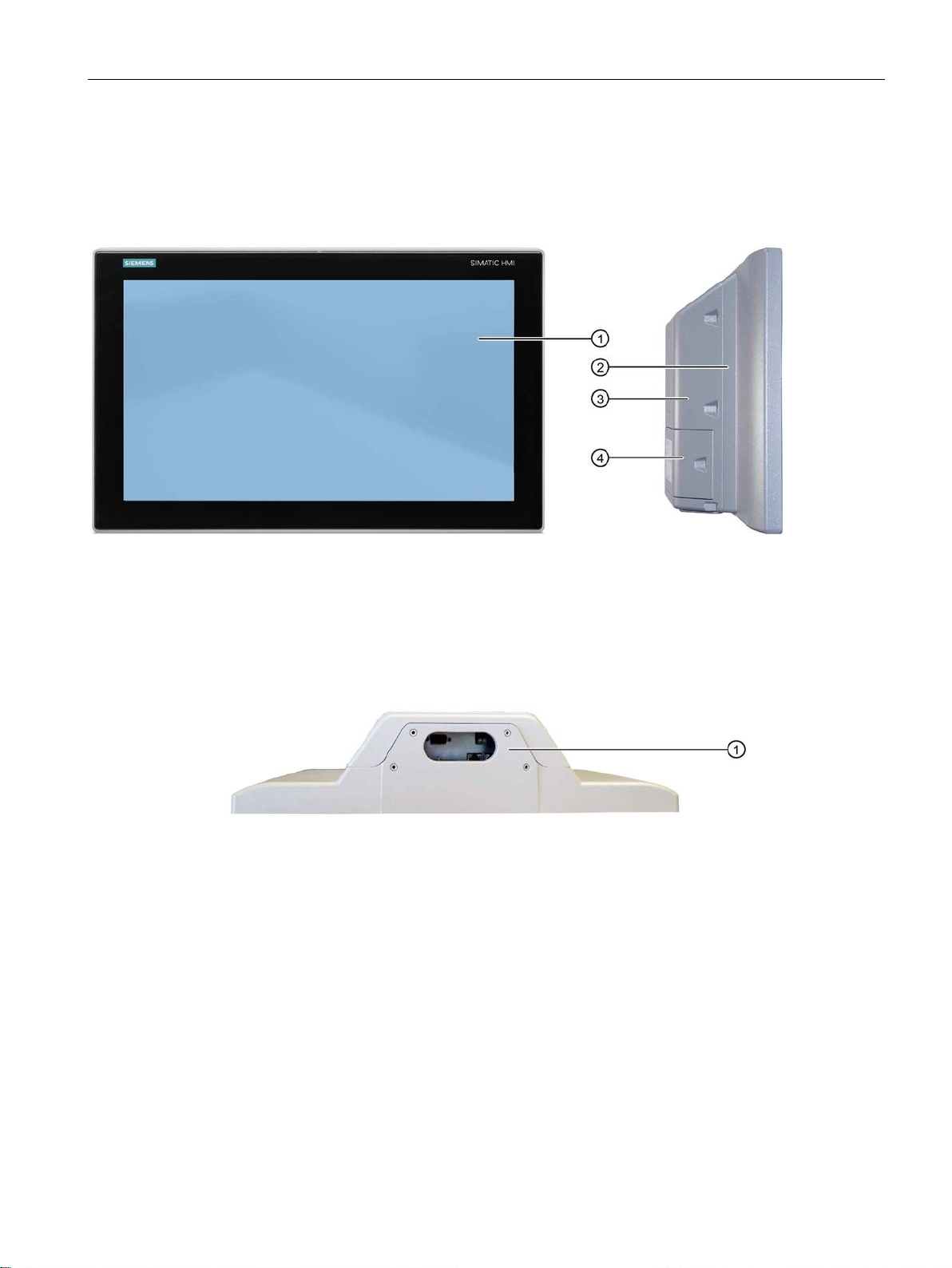

Front view and side view

①

Display with multi-touch screen

②

Enclosure

③

Backplane cover

④

Terminal compartment cover

Bottom view

①

Mechanical interface for mounting/base adapter

2.2 Installation

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

11

Page 12

Overview

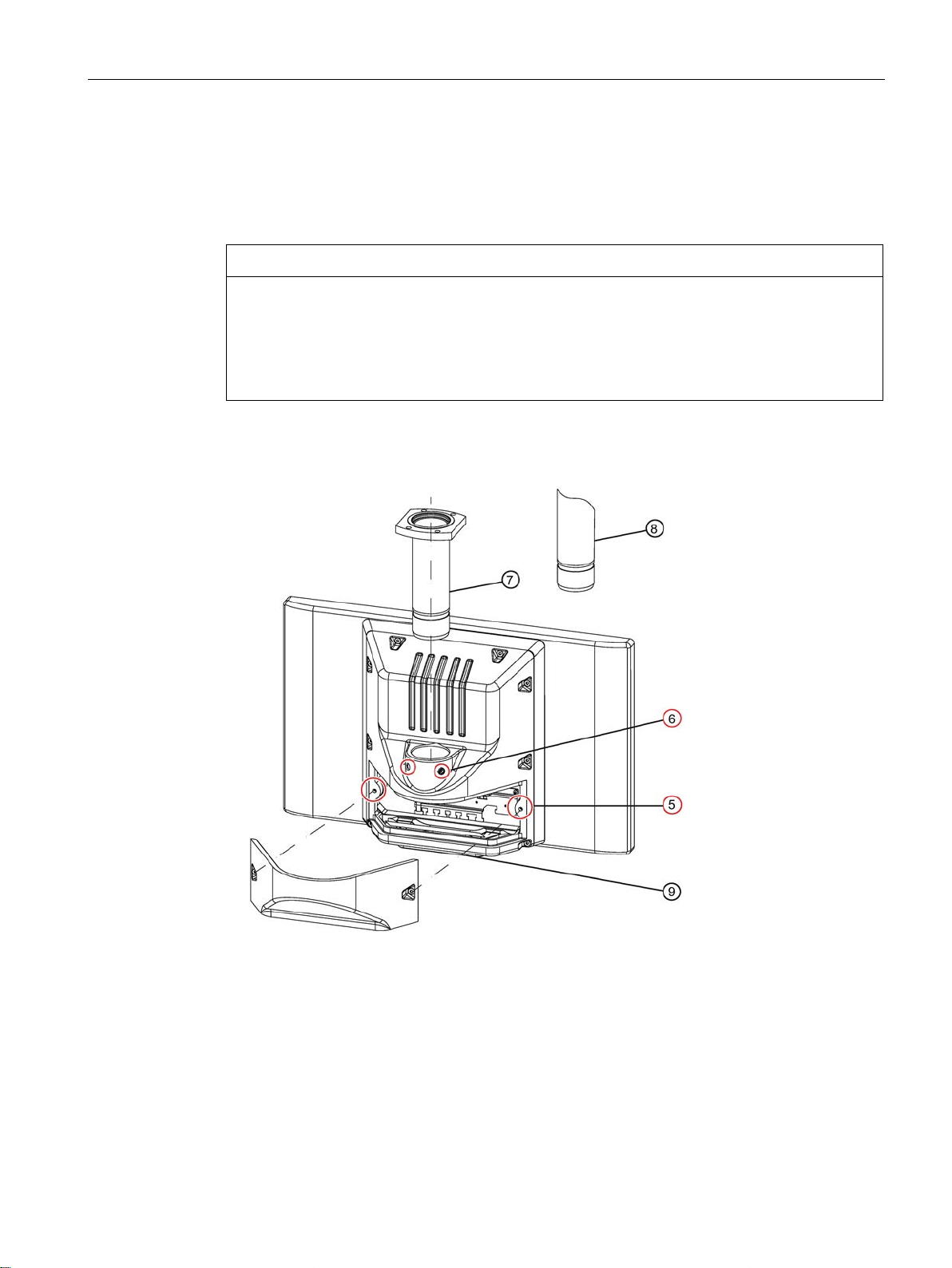

Rear view - device version "prepared for pedestal/extension components" and "prepared for support

arm without extension components".

①

Backplane cover

②

Terminal compartment cover

③

Mechanical interface for mounting/base adapter

Rear view - device version "prepared for support arm and extension components"

①

Terminal compartment cover

2.2 Installation

SIMATIC IPC477E PRO

12 Operating Instructions, 08/2017, A5E39912462-AA

Page 13

Overview

Note

The device version "prepared for support arm and extension components" is intended for

devices with an extension (see

Bottom - device version "prepared for support arm and extension elements"

①

Cover plate

2.2.1

Interfaces and operator controls for PRO device

①

4 x USB port

USB 3.0 high speed/high current

②

Slot for CFast card

Behind the strain relief

③

COM1/2 port (optional)

Serial port, 9-pin D-sub connector

④

Display port

⑤ 3 × Ethernet port

RJ45 Ethernet port, 10/100/1000 Mbps

⑥

24 V DC power supply

⑦

On/off switch

⑧

Protective conductor connection

2.2 Installation

System components (Page 15)).

Connection terminal

The assignment of the interfaces is shown inside the terminal compartment cover.

Connection terminal inserted in delivered condition

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

13

Page 14

Overview

2.3

Accessory kit

PRO device

2.4

Accessories

SIMATIC IPC CFast cards

2.3 Accessory kit

● The base adapter including four M4x12 screws is included in the scope of delivery for

devices "prepared for support arm without extension elements (flange on top)" and

devices "prepared for stand/extension elements (flange on bottom)".

● The device version "prepared for support arm and extension components" includes a

cover plate with four M4x12 screws in the product package.

● Additional documents may be supplied with the accessory kit.

Accessories are available for your device. These are not included in the product package.

You can find Information on available accessories on the Internet at:

Industry Mall (https://mall.industry.siemens.com)

Expansion components and accessories (http://www.automation.siemens.com/mcms/pc-

based-automation/en/industrial-pc/expansion_components_accessories)

System components for devices with all-round IP65 protection

https://mall.industry.siemens.com/mall/de/de/Catalog/Products/10268745?tree=CatalogTree)

(

● 2 GB optional or

● 4 GB optional or

● 8 GB optional or

● 16 GB optional or

● 30 GB optional

SIMATIC IPC477E PRO

14 Operating Instructions, 08/2017, A5E39912462-AA

Page 15

Overview

2.5

System components

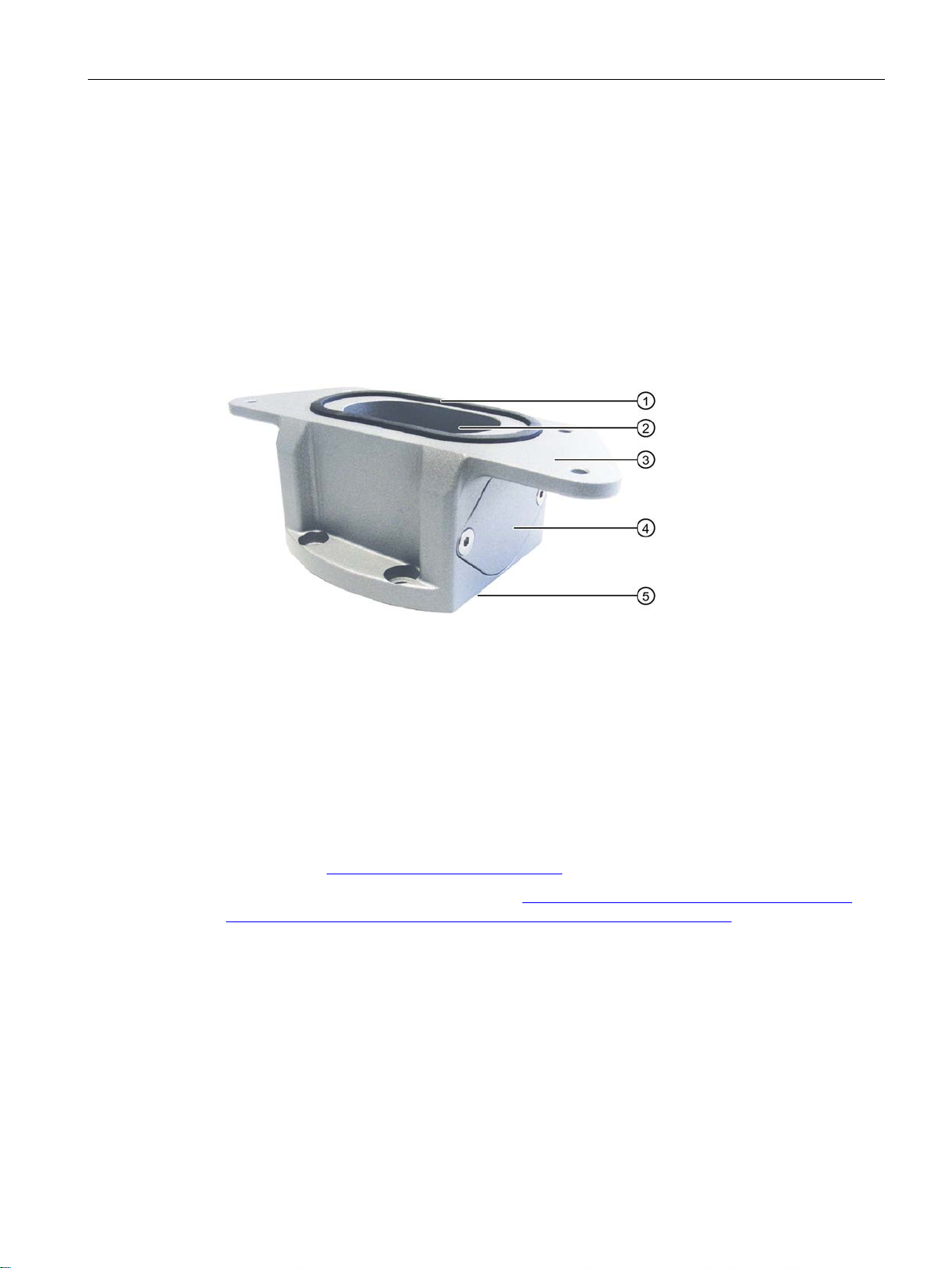

2.5.1

Base adapter

①

Seal

②

Cable channel

③

Mechanical interface to the PRO device

④

Cover

⑤

Mechanical interface to support arm or stand

See also

2.5 System components

PRO devices of the type "suitable for support arm" or "suitable for stand" can be mounted on

a support arm or stand using the base adapter. Depending on the support arm system used,

an adapter plate may have to be installed in addition (see Accessories (Page 14)).

A base adapter is included with the corresponding PRO devices. The base adapter can also

be ordered separately.

Article number for the base adapter as accessory: 6AV7674-1KA00-0AA0.

Prepared for support arm or stand without extension elements (flange on top) (Page 35)

Industry Mall (https://mall.industry.siemens.com)

Expansion components and accessories (http://www.automation.siemens.com/mcms/pc-

based-automation/en/industrial-pc/expansion_components_accessories)

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

15

Page 16

Overview

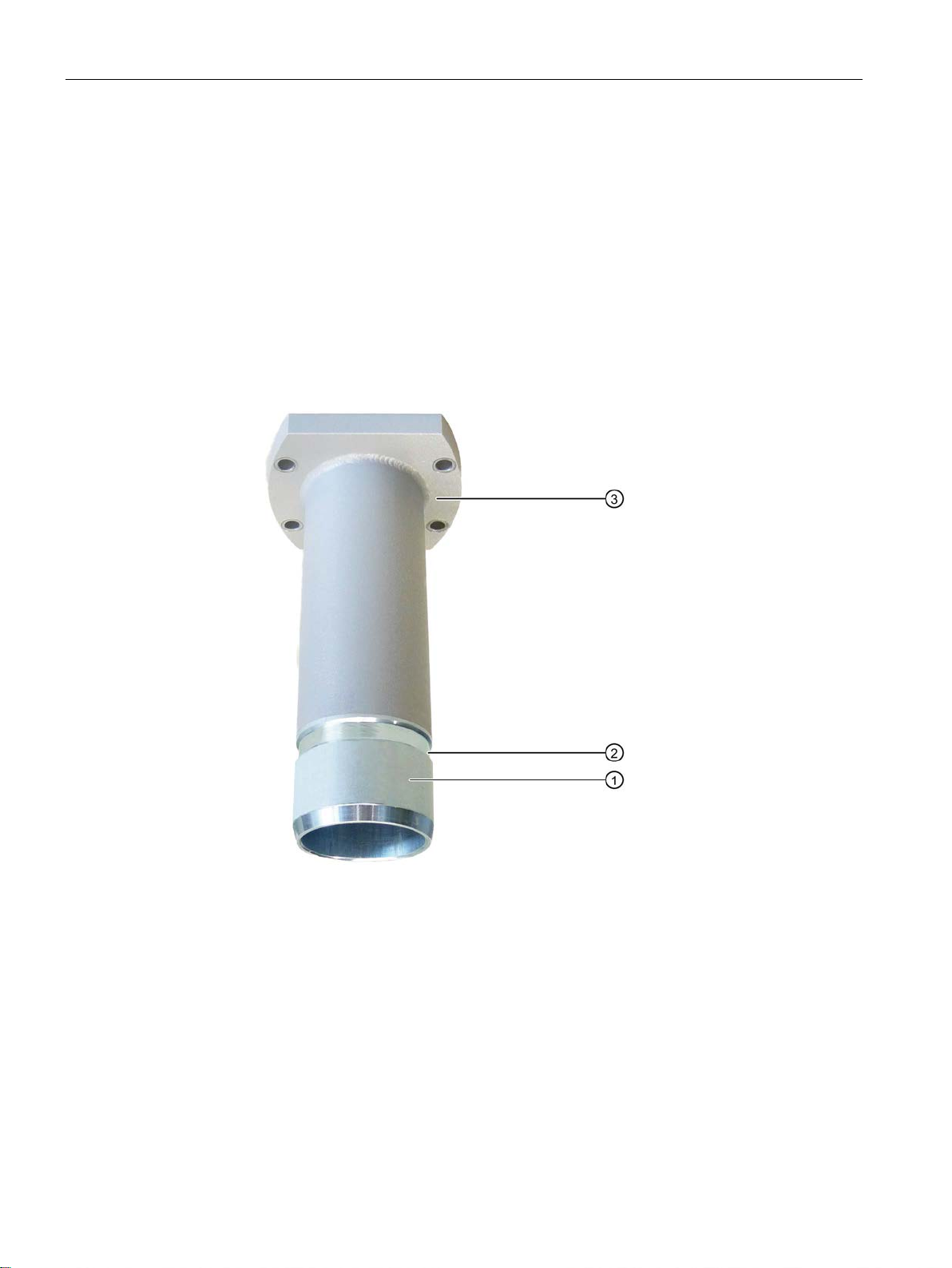

2.5.2

Round tube adapter

Flange mount for device version "prepared for support arm and extension components"

①

Flange mount

②

Ring groove for fastening on PRO device with setscrews

③

Mechanical interface to support arm

2.5 System components

An optional flange mount that is not included in the product package is available for the

device version "prepared for support arm and extension components".

The flange mount converts the flange mount connection into a mechanically compatible

interface to the base adapter. The flange of the flange mount has the same drilling pattern as

the base adapter. This means you can use all couplings of the support arm or pedestal

systems with mechanical interface for the base adapter.

Article number of the flange mount: 6AV7674-1KF00-0AA0

SIMATIC IPC477E PRO

16 Operating Instructions, 08/2017, A5E39912462-AA

Page 17

Overview

Additional information

See also

2.5 System components

You can find information on mounting the PRO device at Prepared for support arm and

extension elements (flange mount) (Page 38).

You can find Information on available accessories on the Internet at:

● Industry Mall (https://mall.industry.siemens.com)

● System components for devices with all-round IP65 protection

https://mall.industry.siemens.com/mall/de/de/Catalog/Products/10268745?tree=CatalogTree)

(

Prepared for support arm or stand without extension elements (flange on top) (Page 35)

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

17

Page 18

Overview

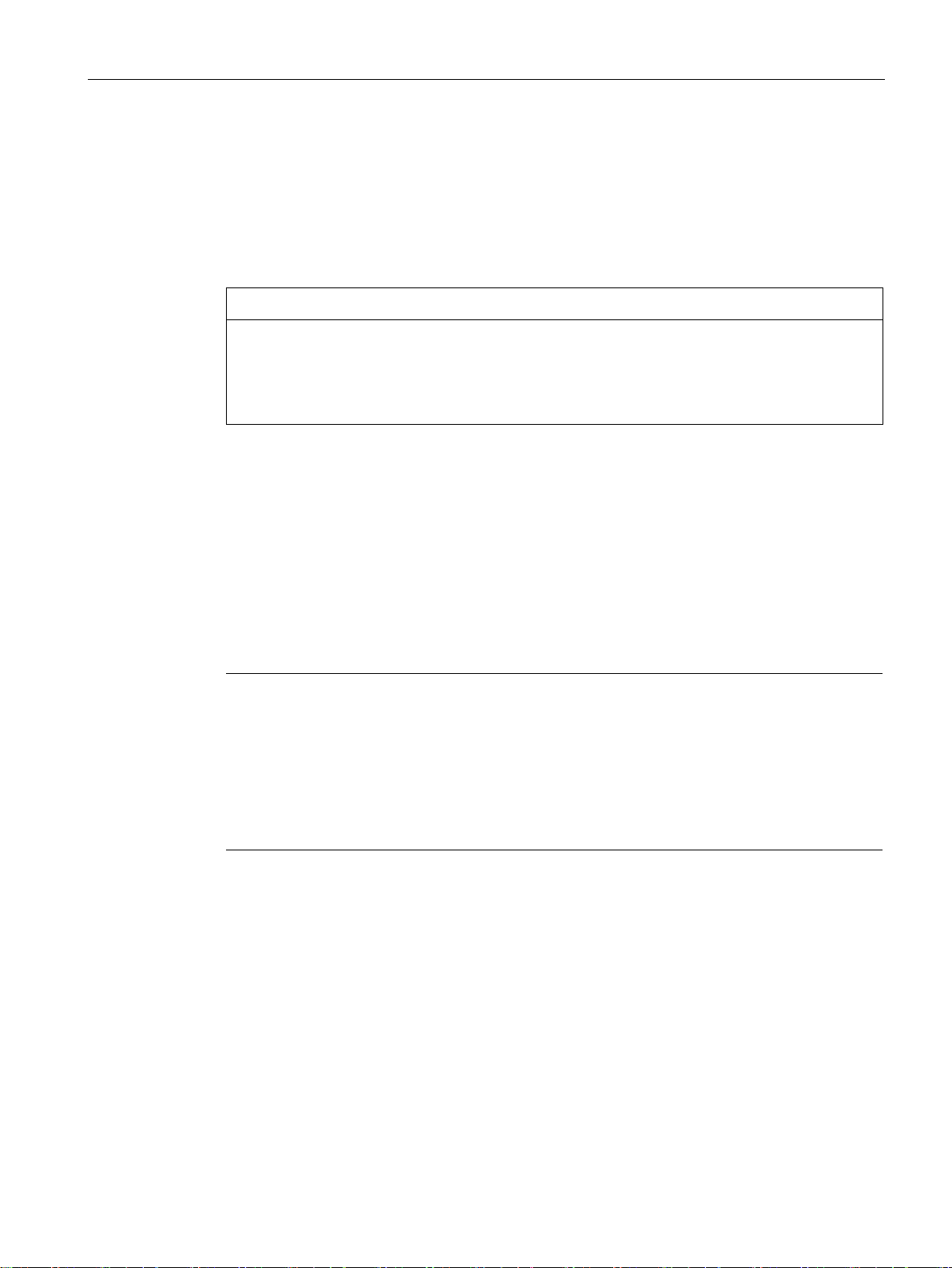

2.5.3

Adapter set for support arm and stand mounting of PRO device

Adapter set

Suitable for support arm systems

Article number

Information provided without guarantee.

2.5 System components

The PRO device can be mounted on systems from third-party vendors (see section

"Mounting the device (Page 33)"). For this you will need the Siemens base adapter (see

Base adapter (Page 15)) and a proprietary adapter set.

Siemens also offers its own adapter for VESA-compatible third-party systems:

SIEMENS:

• Adapter set VESA75

• Adapter set VESA100

RITTAL:

Adapter for

Siemens PRO-Panel

• Intermediate plate

• Screws

ROLEC:

Adapter for

Siemens PRO-Panel

• Intermediate plate

• Screws

BERNSTEIN:

Coupling for Siemens

SIMATIC PRO

• No intermediate plate re-

quired

• Coupling with integrated

adaptation for PRO device

• VESA75-compatible systems

• VESA100-compatible systems

• CP40 steel

• CP60/120 for

Support arm connection

120 × 65 mm

• profiPlus-50

• taraPLUS for ∅ 65 mm hole

circle

• CS-3000 • 1015300187 RAL 9006

• 6AV7674-0KE00-0AA0

• 6AV7674-0KD00-0AA0

• 6206.500

• 142.024.000

white aluminum

• 1015300043 RAL 7016

anthracite gray

SIMATIC IPC477E PRO

18 Operating Instructions, 08/2017, A5E39912462-AA

Page 19

Overview

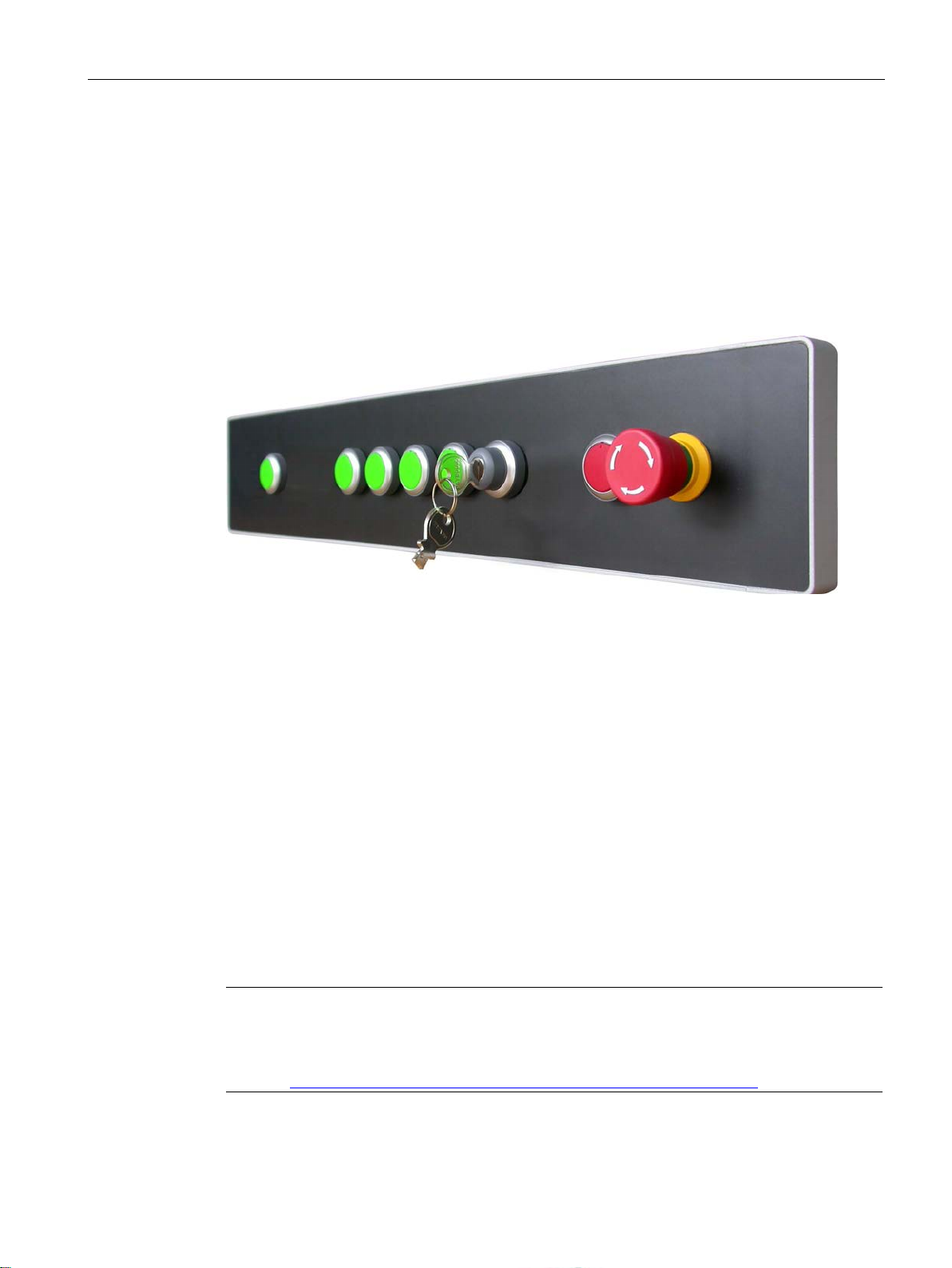

2.5.4

Extension Unit and operator controls

Extension components - Extension Unit

Note

Only operator controls with Siemens approval may be installed in the Extension Unit.

You can find information on "System components for PRO device Extension Units" on the

Internet (

2.5 System components

The Extension Unit is used to install additional operator controls under a SIMATIC PRO

device of the type "Suitable for extension components" with 16:9 display.

The example in the figure below shows the Extension Unit 22" with eight operator controls

including emergency stop button.

The Extension Units have individual configuration possibilities and are supplied without

operator controls. The available slots are suitable for installation of operator controls.

The extension units are available in 4 different sizes:

● 12"

● 15"

● 19"

● 22"

For greater flexibility, three different connection options can be selected per size for the PLC

connection of the operator controls:

● Hardwired

● PROFINET

● PROFIsafe

In addition, different operator controls such as emergency stop, selector switch, illuminated

pushbutton, keyswitch, indicator light or RFID reader are available.

https://support.industry.siemens.com/cs/de/de/view/109742323/en).

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

19

Page 20

Overview

Additional information

2.5 System components

Information on system components for devices with all-round IP65 protection is available on

the Internet

(https://mall.industry.siemens.com/mall/de/de/Catalog/Products/10268745?tree=CatalogTree).

SIMATIC IPC477E PRO

20 Operating Instructions, 08/2017, A5E39912462-AA

Page 21

3

3.1

General safety instructions

WARNING

Life-threatening voltages are present with an open control cabinet

System expansions

NOTICE

Damage through system expansions

When you install the device in a control cabinet, some areas or components in the open

control cabinet may be carrying life-threatening voltages.

If you touch these areas or components, you may be killed by electric shock.

Switch off the power supply to the cabinet before opening it.

Device and system expansions may be faulty and can affect the entire machine or plant.

The installation of expansions can damage the device, machine or plant. Device and

system expansions may violate safety rules and regulations regarding radio interference

suppression. If you install or exchange system expansions and damage your device, the

warranty becomes void.

Note the following for system expansions:

• Only install system expansion devices designed for this device. Contact your technical

• Read the information on electromagnetic compatibility (Page 108).

support team or where you purchased your PC to find out which system expansion

devices may safely be installed.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

21

Page 22

Safety guidelines

Battery and rechargeable battery

WARNING

Risk of explosion and release of harmful substances

Strong high-frequency radiation

NOTICE

Observe immunity to RF radiation

ESD Guideline

NOTICE

Electrostatic sensitive devices (ESD)

3.1 General safety instructions

Improper handling of lithium batteries can result in an explosion of the batteries.

Explosion of the batteries and the released pollutants can cause severe physical injury.

Worn batteries jeopardize the function of the device.

Note the following when handling lithium batteries:

• Replace spent batteries promptly. You can find information on installing and removing

the backup battery in the Operating Instructions.

• Replace the lithium battery only with an identical battery or types recommended by the

manufacturer.

• Do not throw lithium batteries into fire, do not solder on the cell body, do not recharge,

do not open, do not short-circuit, do not reverse polarity, do not heat above 100°C and

protect from direct sunlight, moisture and condensation.

The device has an increased immunity to RF radiation according to the specifications on

electromagnetic compatibility in the technical specifications.

Radiation exposure in excess of the specified immunity limits can impair device functions,

result in malfunctions and therefore injuries or damages.

Read the information on immunity to RF radiation in the technical specifications.

Electrostatic sensitive devices can be labeled with an appropriate symbol.

When you touch electrostatic sensitive components, you can destroy them through voltages

that are far below the human perception threshold.

If you work with components that can be destroyed by electrostatic discharge, observe the

ESD Guideline (Page 108).

SIMATIC IPC477E PRO

22 Operating Instructions, 08/2017, A5E39912462-AA

Page 23

Safety guidelines

Industrial Security

Disclaimer for third-party software updates

Notes on protecting administrator accounts

3.1 General safety instructions

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit.

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under.

This product includes third-party software. Siemens AG only provides a warranty for

updates/patches of the third-party software, if these have been distributed as part of a

Siemens software update service contract or officially released by Siemens AG. Otherwise,

updates/patches are undertaken at your own risk. You can find more information about our

Software Update Service offer on the Internet at Software Update Service.

A user with administrator privileges has extensive access and manipulation options in the

system.

Therefore, ensure there are adequate safeguards for protecting the administrator accounts

to prevent unauthorized changes. To do this, use secure passwords and a standard user

account for normal operation. Other measures, such as the use of security policies, should

be applied as needed.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

23

Page 24

Safety guidelines

3.2

Notes on usage

WARNING

Risks associated with the unprotected machine or plant

Environment

NOTICE

Ambient conditions and chemical resistance

3.2 Notes on usage

According to the results of a risk analysis, certain hazard potentials associated with the

unprotected machine exist. These hazards could lead to personal injury.

Avoid such hazards by taking the following precautions in accordance with the risk analysis:

• Installation of additional safety equipment on the machine or plant. In particular, the

programming, parameter assignment and wiring of the inserted I/O modules must be

executed in accordance with the safety performance identified by the necessary risk

analysis (SIL, PL or Cat.).

• Use as intended must be validated for the device by means of a function test on the

plant. These tests help you to identify programming, parameter assignment and wiring

errors.

• Documentation of the test results that you can enter in the relevant safety verification

documents, if necessary.

Unsuitable environmental conditions have a negative impact on device operation. Chemical

substances such as cleaners or fuels may alter the color, shape and structure of the device

surface, for example, the front panel.

The device may be damaged. possibly resulting in malfunctions.

For this reason, please observe the following precautions:

• Always operate the device in closed rooms. All warranties shall be void in the case of

noncompliance.

• Operate the device only in accordance with the ambient conditions specified in the

technical specifications.

• Protect the device against heat.

• Do not expose the device to direct sunlight or to other strong sources of light.

• Without additional safety measures, such as a supply of clean air, the device may not be

used in locations with harsh operating conditions caused by acidic vapors or gases.

• Always use suitable cleaning agents. Read the information about Chemical resistance of

the HMI devices and industrial PCs

(http://support.automation.siemens.com/WW/view/en/39718396) on the Internet.

SIMATIC IPC477E PRO

24 Operating Instructions, 08/2017, A5E39912462-AA

Page 25

Safety guidelines

Note

Use in an industrial environment without additional protective measures

The device has been designed for use in a normal industrial

IEC

TFT displays

NOTICE

Burn-in effect and backlighting

Defective pixels in the display

3.2 Notes on usage

environment in accordance with

60721-3-3 (pollutant class 3C2 for chemical influences, 3S2 for dust without sand).

A permanent picture with bright screen objects leads to a burn-in effect. The longer the

same screen contents are displayed, the longer it will take for the burn-in effect to

disappear. Screensavers (for example, "starfield simulation") for the backlit active black

mode reduce the burn-in effect. The brightness of the backlighting deteriorates over the

course of the screen's life cycle.

The service life of the screen and backlighting is extended by the following measures:

• Switch on the screensaver. The backlight brightness is reduced while the screensaver is

active.

• You should also reduce the backlighting.

• Observe the backlighting operating time.

At present, the manufacturing process of modern displays does not guarantee that all pixels

of the display will be perfect. A small number of defective pixels in the display is therefore

unavoidable. This does not present a functional problem as long as the defective pixels are

not bunched in one location.

Additional information is available in the section "General technical specifications

(Page 120)".

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

25

Page 26

Safety guidelines

3.2 Notes on usage

SIMATIC IPC477E PRO

26 Operating Instructions, 08/2017, A5E39912462-AA

Page 27

4

4.1

Preparing for mounting

4.1.1

Checking the delivery package

Procedure

Note

Damage to the device during transport and storage

If a device is transported or stored without packaging, shocks, vibrations, pressure and

moisture may impact the unprotected unit. Damaged packaging indicates that ambient

conditions

This may cause the device, machine or plant to malfunction.

•

•

1. When accepting a delivery, please check the packaging for visible transport damage.

2. If any transport damage is present at the time of delivery, lodge a complaint at the

shipping company in charge. Have the shipper confirm the transport damage

immediately.

3. Unpack the device at its installation location.

4. Keep the original packaging in case you have to transport the unit again.

have already had a massive impact on the device and it may be damaged.

Keep the original packaging.

Pack the device in the original packaging for transportation and storage.

5. Check the contents of the packaging and any accessories you may have ordered for

completeness and damage.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

27

Page 28

Mounting and connecting the HMI device

WARNING

Electric shock and fire hazard due to damaged device

NOTICE

Damage from condensation

4.1 Preparing for mounting

6. Please inform the delivery service immediately if the package contents are incomplete or

damaged or do not correspond with your order. Fax the enclosed form "SIMATIC IPC/PG

Quality Control Report".

A damaged device can be under hazardous voltage and trigger a fire in the machine or

plant. A damaged device has unpredictable properties and states.

Death or serious injury could occur.

Make sure that the damaged device is not inadvertently installed and put into operation.

Label the damaged device and keep it locked away. Send off the device for immediate

repair.

If the device is subjected to low temperatures or extreme fluctuations in temperature

during transportation, as is the case in cold weather, for example, moisture can build up

on or inside the device (condensation).

Moisture causes a short circuit in electrical circuits and damages the device.

In order to prevent damage to the device, proceed as follows:

• Store the device in a dry place.

• Bring the device to room temperature before starting it up.

• Do not expose the device to direct heat radiation from a heating device.

• If condensation develops, wait approximately 12 hours or until the device is

completely dry before switching it on.

7. Please keep the enclosed documentation in a safe place. It belongs to the device. You

need the documentation when you commission the device for the first time.

8. Write down the identification data of the device.

SIMATIC IPC477E PRO

28 Operating Instructions, 08/2017, A5E39912462-AA

Page 29

Mounting and connecting the HMI device

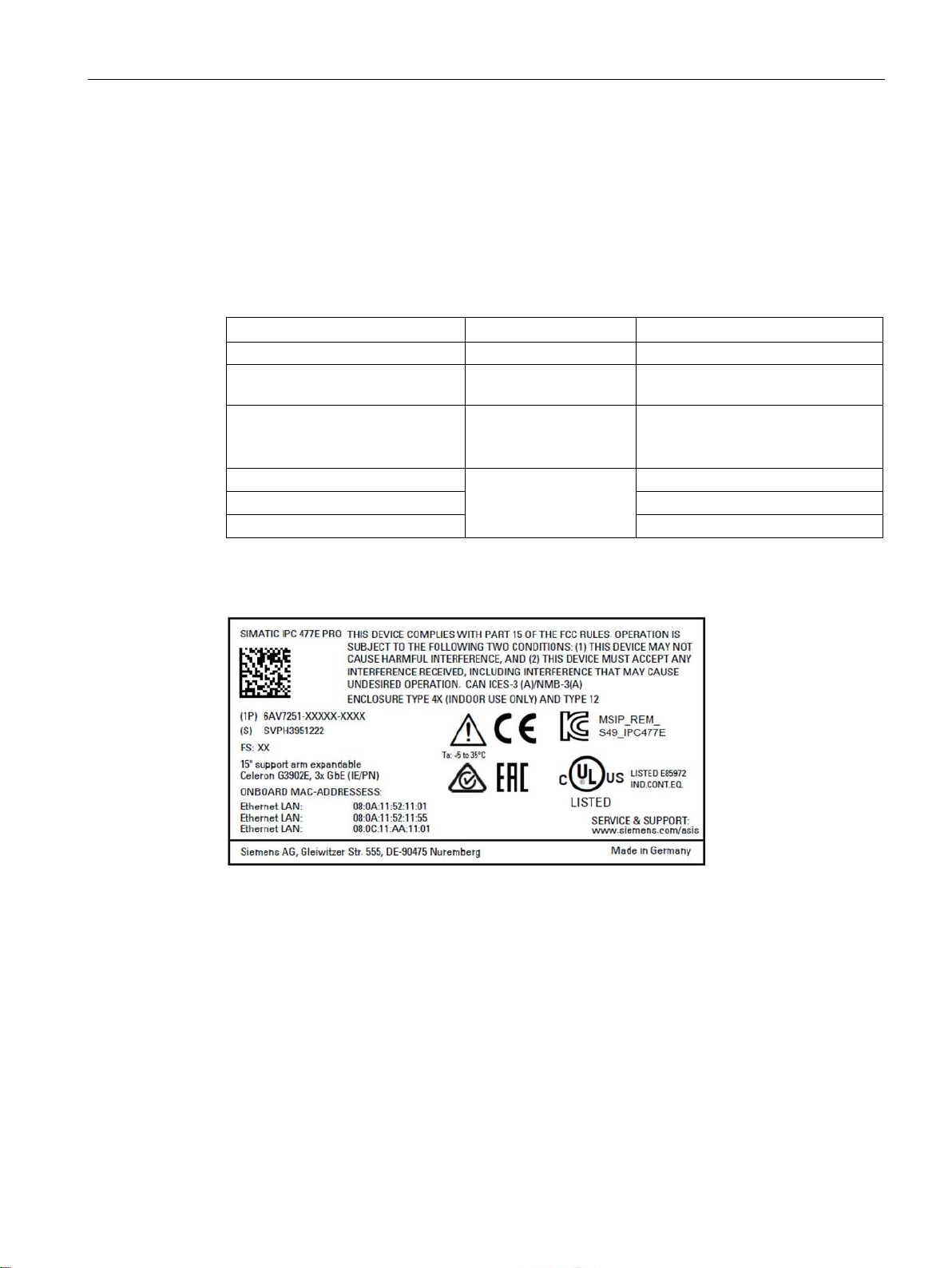

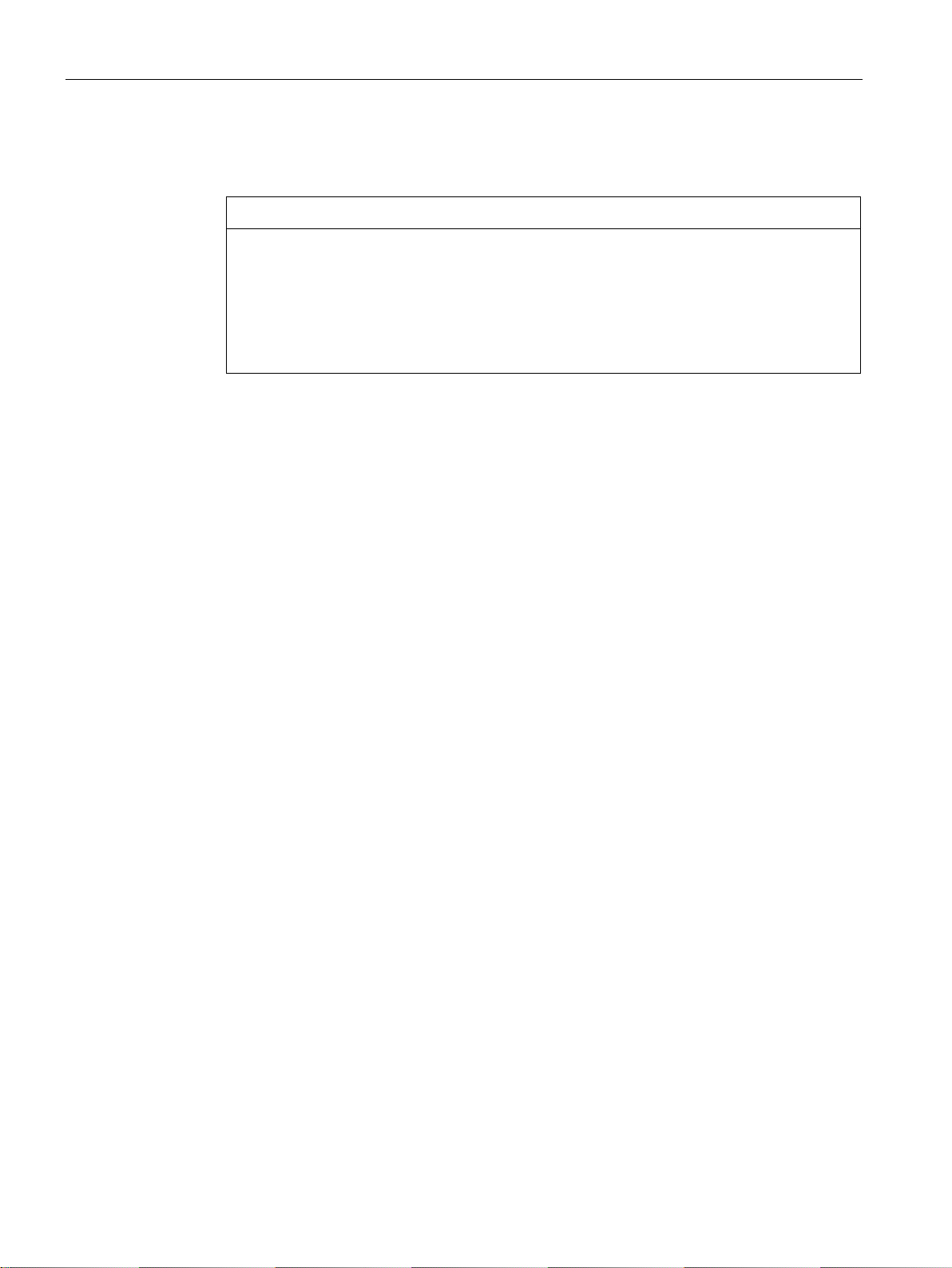

4.1.2

Device identification data

Unpacking the device

Identification date

Source

Value

Serial number

Rating plate

S VP ...

(SIMATIC IPC477E PRO)

Windows operating system.

Ethernet address 1

Ethernet address 2

Ethernet address 3

Example of a SIMATIC IPC477E PRO rating plate

4.1 Preparing for mounting

The device can be clearly identified with the help of this identification data in case of repairs

or theft.

Enter the identification data in the table below:

Article number of the device Rating plate 6AV7251...

Microsoft Windows Product Key

Certificate of Authenticity

In the device (remove

cover of terminal compartment)

BIOS setup, "Advanced"

menu

The COA label is for available with

pre-installed

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

29

Page 30

Mounting and connecting the HMI device

COA label

4.1 Preparing for mounting

Microsoft Windows "Product Key" from the "Certificate of Authenticity" (COA):

The COA label is present only when Windows Embedded Standard 7 or Windows 7 is

installed.

● COA label of a device with the Windows Embedded Standard 7 operating system

● COA label of a device with Windows 7 operating system

● COA label of a device with Windows 10 operating system

SIMATIC IPC477E PRO

30 Operating Instructions, 08/2017, A5E39912462-AA

Page 31

Mounting and connecting the HMI device

4.2

Permitted mounting positions

Mounting position

Device version "prepared for pedestal/extension components (flange at bottom)"

position

①

Inclined

≤ 45°

②

Vertical

0°

Device version "prepared for support arm without extension components (flange at top)"

Mounting position

①

Inclined

≤ 45°

②

Vertical

0°

4.2 Permitted mounting positions

The mounting positions described below are permitted for the PRO devices.

● Standard mounting position: Vertical installation in horizontal format

● Inclined installation in horizontal format with a vertical inclination of maximum ±45°

Upright mounting in vertical format is prohibited for the PRO device

Mounting

Deviation from the vertical

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

31

Page 32

Mounting and connecting the HMI device

Device version "prepared for support arm and extension components (round tube)"

Mounting position

①

Inclined

≤ 45°

②

Vertical

0°

4.2 Permitted mounting positions

SIMATIC IPC477E PRO

32 Operating Instructions, 08/2017, A5E39912462-AA

Page 33

Mounting and connecting the HMI device

4.3

Mounting the device

4.3.1

Notes on mounting

WARNING

The device must be mounted securely.

NOTICE

Degree of protection for overall device

4.3 Mounting the device

Inadequately dimensioned fasteners may cause the device to fall down. Serious physical

injury may result.

Make sure that fasteners are adequately dimensioned during installation. Make sure to

consider the weight of the device and the forces acting on the device when dimensioning.

This applies in particular to dynamic load of the device. All fasteners including mounting

surfaces, support arm systems, and fastening elements such as screws must be able to

carry at least four times the weight of the device.

Observe any further statutory specifications applying at the location of use of the device

and further applicable regulations with regard to fastening the device.

Pay attention to the torque specifications in the following sections.

If you are using a support arm system or a pedestal system that does not have IP65 degree

of protection or Enclosure Type 4X / 12 (indoor use only), IP65 degree of protection and

Enclosure Type 4X / 12 (indoor use only) are voided for the entire device. Spray and water

jets as well as penetrating substances can then damage the device.

Only use a support arm system or pedestal system that has IP65 degree of protection and

Enclosure Type 4X / 12 (indoor use only).

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

33

Page 34

Mounting and connecting the HMI device

Note

Liability disclaimer

The device is mounted to a pedestal or a support arm via the mechanical interface with

screws. Siemens AG assumes no liability for the consequences of incorrect installation.

Warranty at risk

If you do not install the HMI device in accordance with the specifications in these operating

instructions, the warranty for the device is voided.

•

•

IP65 degree of protection and Enclosure Type 4X / 12 (indoor use only) at risk

If there are no seals on the mechanical interfaces or if they are damaged, IP65 degree of

protection and Enclo

proper seating of the seals.

NOTICE

Damaging the seal when opening

4.3 Mounting the device

Always install the device according to these operating instructions.

If the seal on the backplane cover is damaged, it can be repaired. For a repair scenario,

following the instructions in the section "Repair information (Page 84)".

sure Type 4X / 12 (indoor use only) is at risk. Check the condition and

If the device has not been opened for a long time, the backplane cover or terminal

compartment cover may stick to the seal of the enclosure. Opening the device with

excessive force or with tools will destroy the seal. Spray and water jets as well as

penetrating substances can then damage the device.

Open the terminal compartment cover gently, without too much pressure.

SIMATIC IPC477E PRO

34 Operating Instructions, 08/2017, A5E39912462-AA

Page 35

Mounting and connecting the HMI device

4.3.2

Prepared for support arm or stand without extension elements (flange on top)

Note

Mounting without base adapter

If you install the device without a base adapter, you must adjust the mechanical interface

between the support arm or pedestal and

appropriate seal on the mechanical interface of the device.

Requirements

4.3 Mounting the device

the unit accordingly, including placement of an

● All packaging components and protective films have been removed.

● Siemens base adapter with screws (supplied with the device version "prepared for

support arm without extension components (flange at top)" and "prepared for

pedestal/extension components (flange at bottom)").

● One of the following support arms or pedestal systems:

– Support arm or pedestal with mechanical VESA interface and the corresponding

Siemens adapter set

– Support arm or pedestal with mechanical interface for the Siemens base adapter

The type of mechanical interface differs depending on the type of support arm or

pedestal.

See section "System components (Page 15)"

● The following cables are fed through the pedestal or the support arm to which the device

is mounted:

– Protective conductor

– Power supply cable

– Data cables, e.g. USB

For even large connectors to fit, run their cables through the pedestal or support arm

first.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

35

Page 36

Mounting and connecting the HMI device

Procedure

NOTICE

Observe the torques

too much

too low

4.3 Mounting the device

This section describes the mounting of the device to a support arm system. Installation on a

pedestal is carried out in the same way.

For devices of the type "suitable for support arm", the base adapter is screwed to the device

from the top; for devices of the type "suitable for pedestal", it is screwed from below.

A device for a support arm system cannot be used on a pedestal, and vice versa.

If you apply

torque to tighten the screws of the backplane cover and the terminal

compartment cover or the screws for fastening the device to a support arm or pedestal, the

threads of the enclosure, intermediate plate or support arm may be damaged.

If you tighten the screws with a torque that is

, the device is not sealed.

1. If an adapter plate for the Siemens base adapter is included in your support arm system,

attach the adapter plate to the support arm with 4 M6x12 screws. Pay attention to the

torque that is specified for the support arm.

2. Attach the base adapter with 4 M6x12 screws to the mechanical interface of the support

arm from below. Pay attention to the torque that is specified for the support arm.

SIMATIC IPC477E PRO

36 Operating Instructions, 08/2017, A5E39912462-AA

Page 37

Mounting and connecting the HMI device

①

Support arm head

②

Intermediate plate

③

Base adapter

④

Countersunk head screws for device

⑤

Screws for terminal compartment cover

Recommendation

4.3 Mounting the device

3. Remove the screws ⑤ of the terminal compartment cover.

4. Open the terminal compartment cover ⑤ and set it aside safely.

5. Insert all connection cables through the opening of the PRO device.

Make sure that the connecting cables are not damaged.

through the pedestal or support arm first.

6. Attach the device with 4 M4x12 countersunk head screws to the base adapter

the top, torque 2.5 Nm.

Make sure that the connecting cables are not pinched.

7. Connect all cables according to the description in the section Connecting the device

(Page 42).

8. Fasten the cover plate

Check that the seal is sitting correctly.

: Route large connectors (e.g. RS232 connectors) and their cables

③ from

⑤ to the device with the 2 screws, torque 1.5 Nm.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

37

Page 38

Mounting and connecting the HMI device

4.3.3

Prepared for support arm and extension elements (flange mount)

Requirements

4.3 Mounting the device

● One of the following support arm systems:

– Support arm with round tube end with an exterior diameter of 48.3 mm +/-0.5 mm,

appropriate for the opening of the PRO device

When selecting the flange mount, ensure its inner diameter is large enough to allow all

required cables and their connectors to pass through.

– Support arm with mechanical interface, appropriate for the flange of the flange mount,

and Siemens flange mount (not included in product package)

– Support arm with mechanical VESA interface, the corresponding Siemens adapter set

and the Siemens flange mount (not included in product package)

See System components (Page 15))

● All packaging components and protective films have been removed.

● The lower cover of the PRO device is included in the accessory kit.

● The following cables are fed through the support arm to which the device is mounted:

– Protective conductor

– Power supply cable

– Data cables, e.g. USB

For even large connectors to fit, run their cables through the pedestal or support arm

first, for example, RS232.

SIMATIC IPC477E PRO

38 Operating Instructions, 08/2017, A5E39912462-AA

Page 39

Mounting and connecting the HMI device

Procedure

NOTICE

Observe the torques

too much

too low

⑤

Screws for terminal compartment cover

⑥

Setscrews

⑦

Flange mount (not included in the product package; see System components (Page 15))

⑧

Third-party round tube (∅ 48 mm)

⑨

Cover plate (Included in the product package; see Accessory kit (Page 14))

4.3 Mounting the device

The following description shows an example of how to attach the PRO device to a support

arm system using the optionally available Siemens flange mount

round tube

⑧ that fits the opening of the PRO device is performed in a similar fashion.

⑦. Mounting to a 48.3 mm

If you apply

torque to tighten the screws of the backplane cover and the terminal

compartment cover or the screws for fastening the device to a support arm or pedestal, the

threads of the enclosure, intermediate plate or support arm may be damaged.

If you tighten the screws with a torque that is

, the device is not sealed.

1. Remove the screws ⑤ of the terminal compartment cover.

2. Open the terminal compartment cover and set it aside safely.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

39

Page 40

Mounting and connecting the HMI device

NOTICE

48.3 mm round tube ⑧

4.3 Mounting the device

3. Grease the flange mount ⑦ or 48.3 mm round tube ⑧ with grease suitable for NBR

seals, and insert the flange mount

opening of the PRO device.

Make sure that the sealing ring (O-ring) is not damaged. Fasten the flange mount with the

2 setscrews

Observe the appropriate torque:

⑥ M8x10 from the accessory kit.

⑦ or 48.3 mm round tube ⑧ into the corresponding

– Siemens flange mount

– 48.3 mm round tube of steel

– 48.3 mm round tube of aluminum

For the device to not loosen and drop in case of vibrations, the round tube must offer a

groove into which the setscrews can be fitted.

Otherwise the device can become loose due to vibrations and drop.

4. If an adapter plate ⑨ for the Siemens flange mount is included with your support arm,

attach the adapter plate to the support arm with 4 M6x12 screws. Pay attention to the

torque that is specified for the support arm.

⑦: 8 Nm

⑧: 8 Nm

⑧: 5 Nm

SIMATIC IPC477E PRO

40 Operating Instructions, 08/2017, A5E39912462-AA

5. Insert all connection cables through the opening of the flange mount or 48.3 mm round

tube into the connection compartment of the PRO device. Make sure that the connection

cables are not damaged.

6. Attach the device with 4 M4x12 screws to the support arm from the below.

The screws are not included in the product package of the PRO device.

Pay attention to the torque that is specified for the support arm.

Make sure that all connecting cables are fed through the flange mount into the interior of

the device without damage.

7. Connect all cables according to the description in the section Connecting the device

(Page 42).

Page 41

Mounting and connecting the HMI device

4.3 Mounting the device

8. Fasten the cover plate ⑤ to the device with the 2 screws, torque 1.5 Nm. Check that the

seal is sitting correctly.

9. Fasten the cover plate

⑨ from the PRO device product package with 4 M4x12 screws,

torque 1.5 Nm.

Alternatively, you can extend the PRO device by adding an Extension Unit at the bottom.

Read the associated documentation.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

41

Page 42

Mounting and connecting the HMI device

4.4

Connecting the device

4.4.1

Notes on connecting

WARNING

Risk of fire and electric shock

WARNING

Risk of lightning strikes

NOTICE

Fault caused by I/O devices

4.4 Connecting the device

The on/off switch does not isolate the device from the power supply. Risk of electric shock if

the device is opened incorrectly or defective. There is also a risk of fire if the device or

connecting lines are damaged.

You should therefore protect the device as follows:

• Always pull out the power plug when you are not using the device or if the device is

defective. The power plug must be freely accessible.

• Connect the device to a protective conductor as instructed, see section "Connecting the

protective conductor".

• Use a central isolating switch in the case of cabinet installation.

A lightning flash may enter the mains cables and data transmission cables and jump to a

person.

Death, serious injury and burns can be caused by lightning.

Take the following precautions:

• Disconnect the device from the power supply in good time when a thunderstorm is

approaching.

• Do not touch mains cables and data transmission cables during a thunderstorm.

• Keep a sufficient distance from electric cables, distributors, systems, etc.

The connection of I/O devices can cause faults in the device.

The result may be personal injury and damage to the machine or plant.

Note the following when connecting I/O devices:

• Read the documentation of the I/O devices. Follow all instructions in the documentation.

• Only connect I/O devices which are approved for industrial applications in accordance

with EN 61000-6-2 and IEC 61000-6-2.

• I/O devices that are not hotplug-capable may only be connected after the device has

been disconnected from the power supply.

SIMATIC IPC477E PRO

42 Operating Instructions, 08/2017, A5E39912462-AA

Page 43

Mounting and connecting the HMI device

NOTICE

Damage through regenerative feedback

4.4 Connecting the device

Regenerative feedback of voltage to ground by a connected or installed component can

damage the device.

Connected or built-in I/Os, for example, a USB drive, are not permitted to supply any

voltage to the device. Regenerative feedback is generally not permitted.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

43

Page 44

Mounting and connecting the HMI device

4.4.2

Power supply

4.4.2.1

Opening and closing the terminal compartment cover

Requirements

Opening the terminal compartment cover

4.4 Connecting the device

● The device is disconnected from the power supply.

● Torx TX20 screwdriver

Opening the terminal compartment cover for pedestal and support arm device versions

without extension components.

SIMATIC IPC477E PRO

44 Operating Instructions, 08/2017, A5E39912462-AA

Page 45

Mounting and connecting the HMI device

NOTICE

Damaging the seal when opening

4.4 Connecting the device

Opening the terminal compartment for device version prepared for support arm and

extension components (round tube).

1. Loosen the indicated M4x16 screws.

If the device has not been opened for a long time, the backplane cover and terminal

compartment cover may stick to the enclosure due to the seal. Opening the device with

excessive force or with tools will destroy the seal. Spray and water jets as well as

penetrating substances can then damage the device.

Open the terminal compartment cover gently, without too much pressure.

2. Carefully lift up the terminal compartment cover and set it aside.

The assignment of the interfaces is shown on the inside of the terminal compartment

cover.

3. Run the connecting cables through the support arm or pedestal

① into the PRO device

and connect them to the interfaces on the inside.

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

45

Page 46

Mounting and connecting the HMI device

Closing the terminal compartment cover

Note

IP65 degree of protection at risk

If the seal on the terminal compartment cover is damaged, IP65 degree of protection is at

risk. The

(Page

Note

Do not exceed the permissible torque

If you tighten up the M4x16 screws with a torque of >

threading in the enclosure.

4.4 Connecting the device

1. Check that the seal is properly seated on the terminal compartment cover.

device must be repaired. Proceed as described in the section Repair information

84).

2. Place the terminal compartment cover on the backplane cover. Make sure that no cables

are crimped.

Secure the terminal compartment cover from falling down.

1.5 Nm, you may damage the

3. Tighten the M4x16 screws of the terminal compartment cover using a maximum torque of

1.5 Nm.

SIMATIC IPC477E PRO

46 Operating Instructions, 08/2017, A5E39912462-AA

Page 47

Mounting and connecting the HMI device

4.4.2.2

connecting the PE conductor

Requirements

Procedure

1.

Clamp the cable lug onto the protective conductor.

2. Connect the cable lug to the screw at the

designated protective conductor conne

tion.

Tighten the M4 screw with a torque of

max. 1.5 Nm.

3. Connect the protective conducto

cabinet from which the PRO device is supplied.

4.4 Connecting the device

The connection for the protective conductor is labeled with the following symbol:

● The device is installed.

● 1 protective conductor with minimum core cross-section of 2.5 mm

● 1 T20 screwdriver

● 1 cable lug for M4

c-

2

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

r to the protective conductor connection of the control

47

Page 48

Mounting and connecting the HMI device

4.4.2.3

Connecting the 24 VDC power supply

WARNING

Electric shock and risk of fire

Note

The 24 V

specifications).

Requirements

4.4 Connecting the device

Voltages that exceed an extra-low voltage can cause electric shock or fire. Death or serious

bodily injury can result.

• The device may only be connected to a 24 V DC power supply that meets the

requirements of a safe extra-low voltage (SELV) according to IEC/EN/DIN

EN/UL 60950-1.

• The supplying source must be fused for a power rating < 240 VA; recommended fuse

rating ≤ 8 A.

DC power supply must be adapted to the input data of the device (see technical

● The device is installed.

● The protective conductor is connected.

● The connection terminal is wired.

● The corresponding 24 V DC power supply is switched off.

● A two-core cable with a cable cross-section of ≥ 0.5 mm

2

● A slotted screwdriver with approx. 3 mm blade.

for the 24 V DC connection.

SIMATIC IPC477E PRO

48 Operating Instructions, 08/2017, A5E39912462-AA

Page 49

Mounting and connecting the HMI device

Procedure

supply.

snap into the connection socket.

4.4 Connecting the device

Switch off the 24 V DC power

supply.

Connect the wires of the power

Plug the connecting terminal into

the connection socket at the indicated position.

The connecting terminal must

Secure the power supply cable to

the strain relief with a cable tie.

Similar to figure

SIMATIC IPC477E PRO

Operating Instructions, 08/2017, A5E39912462-AA

49

Page 50

Mounting and connecting the HMI device

4.4.3

Connecting peripheral equipment

Note

Ensure suitability for industrial applications

Connect only I/O devices approved for industrial applications according to EN

2.

Note

I/O devices capable of hot-plugging (USB)

I/O devices capable of hot

operation.

NOTICE

I/O devices incapable of hot-plugging

Note

Wait at least ten seconds between removing and reinserting USB devices.

When using standard USB devices, bear

designed only for office environments. These USB devices are adequate for commissioning

and servicing purposes. Only industrial grade USB devices are permitted for use in industrial

environments. The USB

The product supplier in each case provides support for the USB devices. Moreover, the

terms of liability of the individual vendors or suppliers apply here.

Note

Strain relief

Use the metal

4.4 Connecting the device

IEC 61000-6-

-plugging (USB) may also be connected while the IPC is in

I/O devices incapable of hot-plugging may only be connected after the device has been

disconnected from the power supply. Strictly adhere to the specifications for peripheral

equipment.

in mind that their EMC immunity level is frequently

devices are developed and marketed by the respective provider.

eyelets on the rear side to mount the cable strain reliefs for cable ties.

SIMATIC IPC477E PRO

50 Operating Instructions, 08/2017, A5E39912462-AA

Page 51

Mounting and connecting the HMI device

4.4.4

Connecting the device to networks

Ethernet

Industrial Ethernet

Note

You need a category 6 Ethernet cable for operation at 1000 Mbps.

PROFINET

SIMATIC NET

Additional information

4.4 Connecting the device

The following options are available for integrating the device in existing or planned system

environments and networks.

You can use the integrated Ethernet interfaces (10/100/1000 Mbps) for communication and

data exchange with automation devices, e.g. SIMATIC S7.

You need a suitable software to use this functionality: STEP 7, WinCC, WinAC,

SIMATIC NET.

You can establish a network between the device and other computers via Industrial Ethernet.

The on-board LAN interfaces are twisted-pair TP interfaces that support data transmission

rates of 10/100/1000 Mbps.

PROFINET can be operated via:

● Standard Ethernet interfaces (RT)

Use this software package to create, operate and configure an innovative network for Field &

Control level. Information on this can be found on the SIMATIC NET Manual Collection CD.

The software package and the documentation are not included in the product package.

You can find additional information on the Internet at: Technical Support

(https://support.industry.siemens.com)

SIMATIC IPC477E PRO