Siemens SIMATIC IPC377E Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

Industrial PC

SIMATIC IPC377E

Operating Instructions

2017/05

A5E40965249

Preface

Overview

1

Safety instructions

2

Installing and connecting the

device

3

Commissioning the device

and device functions

4

Operating the device

5

Expanding and assigning

parameters to the device

6

Maintaining and repairing the

device

7

Technical specifications

8

Appendix Motherboard

A

Technical Support

B

Markings and symbols

C

List of abbreviations

D

-AA

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E40965249-AA

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

04/2017 Subject to change

Preface

Basic knowledge required

Scope of validity of this documentation

Scope of this documentation

Conventions

History

Edition

Comment

05/2017

First edition

These operating instructions contain all the information you need for commissioning and

operating the SIMATIC IPC377E.

It is intended both for programming and testing personnel who commission the device and

connect it with other units (automation systems, programming devices), as well as for service

and maintenance personnel who install add-ons or carry out fault/error analyses.

A solid background in personal computers and Microsoft operating systems is required to

understand this manual. General knowledge in the field automation control engineering is

recommended.

These operating instructions are valid for all versions of the SIMATIC IPC377E.

The documentation for SIMATIC IPC377E consists of:

● Product information, e.g. "Important notes on your device"

● Quick Install Guide SIMATIC IPC377E

● SIMATIC IPC377E operating instructions in English

The PDF version of the documentation is supplied with the device on the

"Documentation and Drivers" CD/DVD.

The terms "PC" or "device" are used in place of the product name SIMATIC IPC377E in

these operating instructions.

In these operating instructions, "Windows Embedded Standard" is also used as a standard

term for "Windows Embedded Standard 7". "Windows 7" is used as an abbreviation for

"Windows 7 Ultimate".

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

The following earlier release versions of these operating instructions have been published:

3

Preface

SIMATIC IPC377E

4 Operating Instructions, 2017/05, A5E40965249-AA

Table of contents

Preface ................................................................................................................................................... 3

1 Overview................................................................................................................................................. 9

2 Safety instructions ................................................................................................................................. 15

3 Installing and connecting the device ...................................................................................................... 21

4 Commissioning the device and device functions .................................................................................... 37

5 Operating the device ............................................................................................................................. 41

1.1 Product description ................................................................................................................... 9

1.2 Structure of the devices .......................................................................................................... 10

1.2.1 Views of the basic device ....................................................................................................... 10

1.2.2 Interfaces and operator controls of the basic device .............................................................. 12

1.2.3 Status displays ........................................................................................................................ 13

2.1 Security Information ................................................................................................................ 15

2.2 General safety instructions ..................................................................................................... 15

2.3 Notes on usage ....................................................................................................................... 18

3.1 Preparing for installation ......................................................................................................... 21

3.1.1 Checking the delivery package ............................................................................................... 21

3.1.2 Identification data of the device .............................................................................................. 22

3.1.3 Permitted mounting positions ................................................................................................. 24

3.1.4 Preparing the mounting cutout ................................................................................................ 25

3.2 Installing the device ................................................................................................................ 27

3.2.1 Installation guidelines.............................................................................................................. 27

3.2.2 Secure with mounting clips ..................................................................................................... 28

3.2.3 VESA mounting ....................................................................................................................... 30

3.3 Connecting the device ............................................................................................................ 31

3.3.1 Notes on connecting ............................................................................................................... 31

3.3.2 Connecting the function earth ................................................................................................. 32

3.3.3 Connecting the power supply ................................................................................................. 33

3.3.4 Connect device to networks .................................................................................................... 34

4.1 General information on commissioning .................................................................................. 37

4.2 Initial commissioning ............................................................................................................... 38

4.3 Switching off the device .......................................................................................................... 39

4.4 Windows Security Center ....................................................................................................... 40

5.1 Operator input options ............................................................................................................ 42

5.2 IPC calibration function ........................................................................................................... 42

5.3 Operating the touch screen .................................................................................................... 43

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

5

Table of contents

6 Expanding and assigning parameters to the device ............................................................................... 45

7 Maintaining and repairing the device ..................................................................................................... 51

8 Technical specifications ........................................................................................................................ 67

6.1 Open the device ..................................................................................................................... 45

6.2 Installing the Mini card ........................................................................................................... 47

7.1 Maintenance ........................................................................................................................... 51

7.2 Repair information .................................................................................................................. 51

7.3 Cleaning the Device Front ..................................................................................................... 52

7.4 Recycling and disposal .......................................................................................................... 53

7.5 Installing and removing hardware .......................................................................................... 54

7.5.1 Replacing the backup battery ................................................................................................ 54

7.5.2 Replacing the drive of a basic device .................................................................................... 55

7.6 Installing the software ............................................................................................................ 56

7.6.1 Reinstalling the operating system .......................................................................................... 56

7.6.1.1 Source for installation of the operating system ...................................................................... 56

7.6.1.2 Restoring the delivery state ................................................................................................... 57

7.6.1.3 Installation of Windows 7 ....................................................................................................... 59

7.6.1.4 Installing drivers and software ............................................................................................... 62

7.6.1.5 Setting up the language selection by means of the Multilanguage User Interface (MUI)...... 62

7.6.2 Installing the drivers on Windows 7 ....................................................................................... 64

8.1 Certificates and approvals ..................................................................................................... 67

8.2 Directives and declarations .................................................................................................... 69

8.2.1 Electromagnetic compatibility for industrial environments ..................................................... 69

8.2.2 ESD guideline ........................................................................................................................ 69

8.3 Dimension drawings ............................................................................................................... 72

8.3.1 Dimension drawing 12" device ............................................................................................... 72

8.4 Technical data ........................................................................................................................ 73

8.4.1 General technical specifications ............................................................................................ 73

8.4.2 Environmental conditions ....................................................................................................... 75

8.4.3 Shipbuilding ............................................................................................................................ 76

8.4.4 Power supply 12" device ........................................................................................................ 77

8.5 Hardware description ............................................................................................................. 78

8.5.1 Technical features of the motherboard .................................................................................. 78

8.5.2 External interfaces ................................................................................................................. 78

8.5.2.1 Overview of interfaces ........................................................................................................... 78

8.5.2.2 DC in connector ..................................................................................................................... 78

8.5.2.3 Serial interface ....................................................................................................................... 79

8.5.2.4 USB 2.0 port ........................................................................................................................... 80

8.5.2.5 USB 3.0 port ........................................................................................................................... 80

8.5.2.6 DisplayPort ............................................................................................................................. 81

8.5.2.7 Ethernet port .......................................................................................................................... 81

8.5.3 Internal interface .................................................................................................................... 82

8.5.3.1 Overview of internal interfaces ............................................................................................... 82

8.5.3.2 Mini PCIe and mSATA interface ............................................................................................ 82

8.5.4 Currently allocated system resources .................................................................................... 83

SIMATIC IPC377E

6 Operating Instructions, 2017/05, A5E40965249-AA

Table of contents

A Appendix Motherboard .......................................................................................................................... 99

B Technical Support ............................................................................................................................... 103

C Markings and symbols ........................................................................................................................ 105

D List of abbreviations ............................................................................................................................ 109

Glossary ............................................................................................................................................. 113

Index................................................................................................................................................... 121

8.6 BIOS description ..................................................................................................................... 84

8.6.1 BIOS getting started ................................................................................................................ 84

8.6.2 Main setup .............................................................................................................................. 85

8.6.3 Advanced setup ...................................................................................................................... 87

8.6.4 Chipset setup .......................................................................................................................... 91

8.6.5 Security setup ......................................................................................................................... 92

8.6.6 Boot Setup .............................................................................................................................. 94

8.6.7 Save and Exit .......................................................................................................................... 96

A.1 Jumpers .................................................................................................................................. 99

B.1 Service and support .............................................................................................................. 103

B.2 Problem solving .................................................................................................................... 104

C.1 Overview ............................................................................................................................... 105

C.2 Safety .................................................................................................................................... 105

C.3 Operator controls .................................................................................................................. 105

C.4 Certificates, approvals and markings .................................................................................... 106

C.5 Interfaces .............................................................................................................................. 107

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

7

Table of contents

SIMATIC IPC377E

8 Operating Instructions, 2017/05, A5E40965249-AA

1

1.1

Product description

SIMATIC IPC377E provides high-level industrial functionality.

● Compact design

● Rugged

● Maintenance-free operation possible

SIMATIC IPC377E is available with various operating units that differ with regard to the

display size. This display is a color display with a backlit "wide-screen" format TFT color

display.

Display is available for the SIMATIC IPC377E:

● 12" touch

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

9

Overview

1.2

Structure of the devices

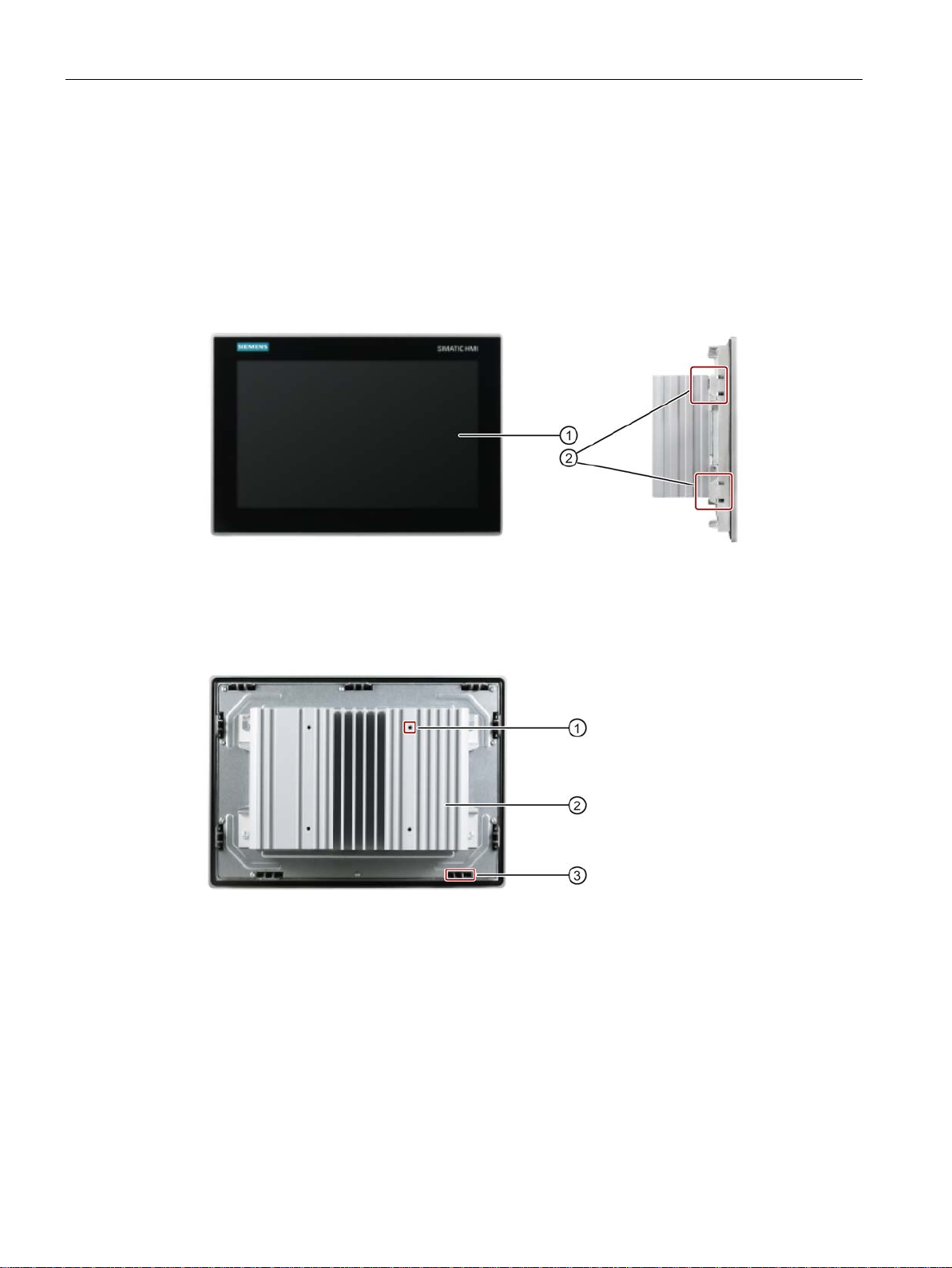

1.2.1

Views of the basic device

Front and side view

①

Display/touch screen

②

Recesses for mounting clips

Rear view

①

Recesses hole for VESA mounting

②

Cooling fin

③

Recesses for mounting clips

1.2 Structure of the devices

SIMATIC IPC377E

10 Operating Instructions, 2017/05, A5E40965249-AA

Overview

Bottom view

①

Interfaces and operating elements

②

Recesses for mounting clips

Top view

①

Product label

1.2 Structure of the devices

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

11

Overview

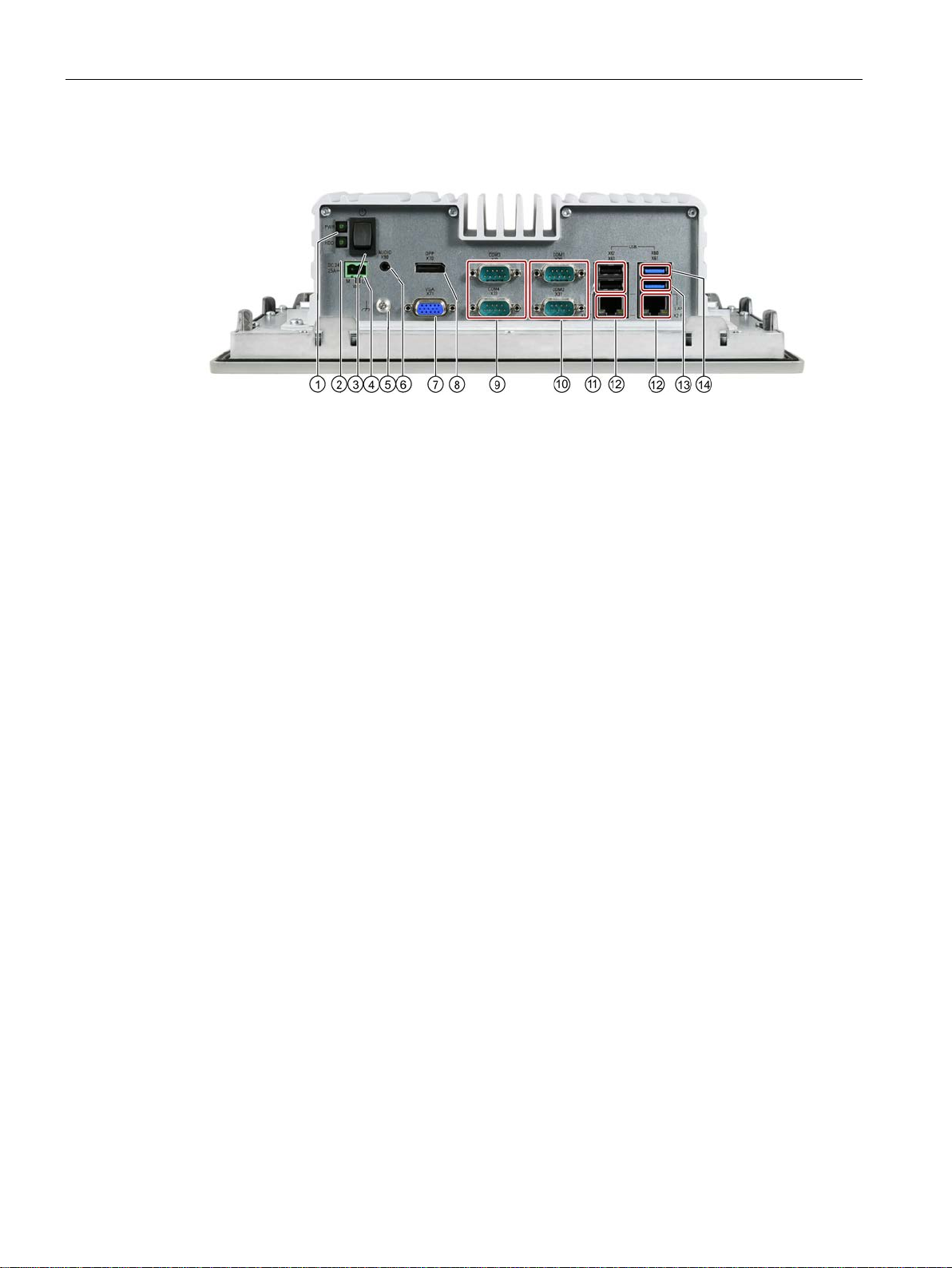

1.2.2

Interfaces and operator controls of the basic device

①

Power status display

②

HDD status display

③

On/off switch.

④

Connection for a

⑤

Function earth

⑥

Connection for analog audio source and speaker

⑦

VGA interface

⑧

Display Port connection

⑨

Serial interface, 9

•

⑩

Serial interface, 9

•

•

•

⑪

USB 2.0, high current

⑫

RJ45 Etherne

⑬

USB 3.0 port 2, high current

⑭

USB 3.0 port 1, high current

1.2 Structure of the devices

RS-232

RS-232

RS-422

RS-485

Observe the printing on the rear of the device.

24 VDC power supply

-pin

-pin

t connection for 10/100/1000 Mbps

SIMATIC IPC377E

12 Operating Instructions, 2017/05, A5E40965249-AA

Overview

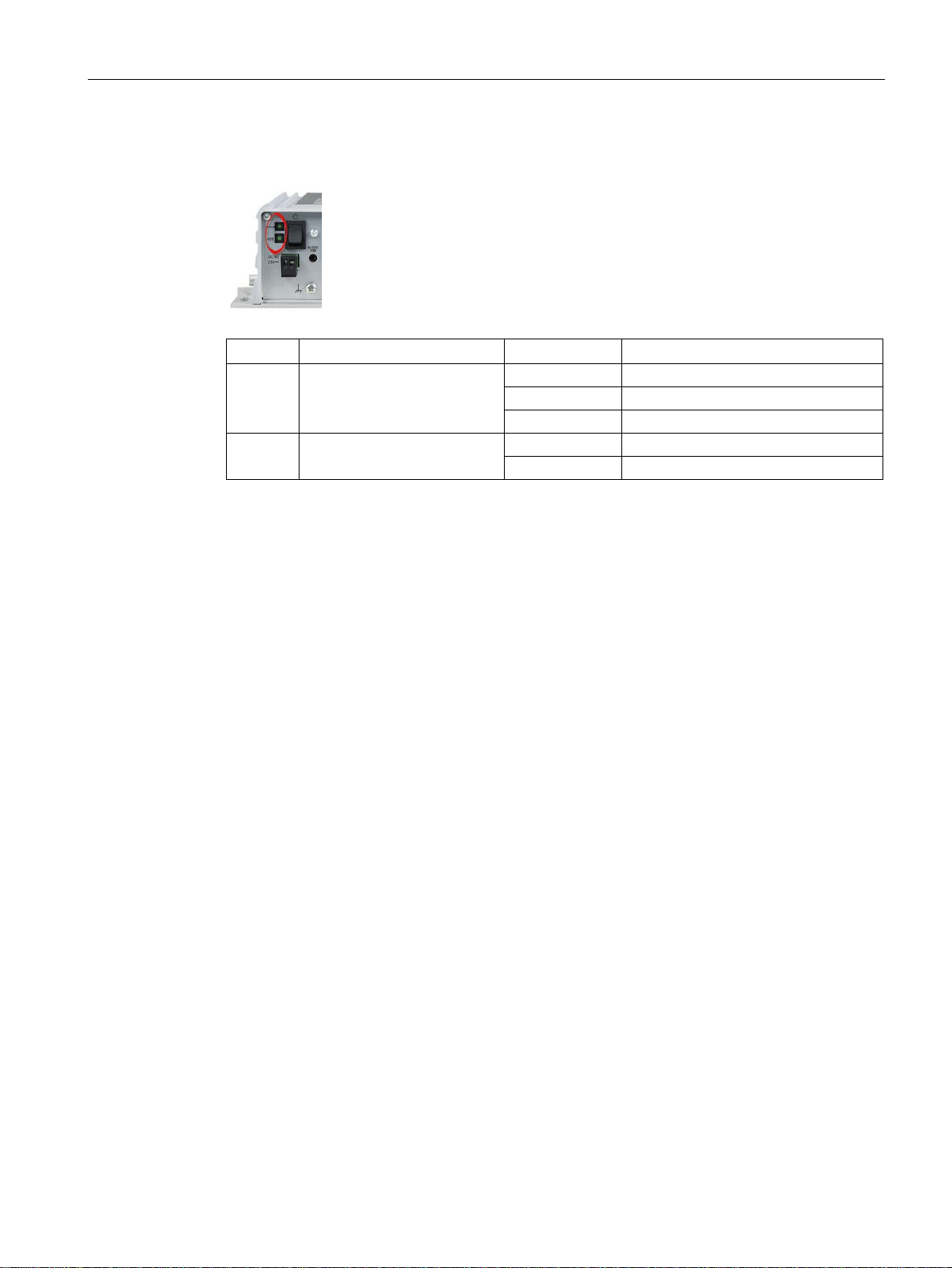

1.2.3

Status displays

Display

Meaning

LED

Description

Off

Hibernate, switched off or unplugged

Green

PC is in operation.

Green flashing

standby

Off

No accessing

Green flashing

Accessing data

1.2 Structure of the devices

PWR PC operating status display

HDD Display for hard disk access

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

13

Overview

1.2 Structure of the devices

SIMATIC IPC377E

14 Operating Instructions, 2017/05, A5E40965249-AA

2

2.1

Security Information

Industrial Security

2.2

General safety instructions

WARNING

Life-threatening voltages are present with an open control cabinet

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

When you install the device in a control cabinet, some areas or components in the open

control cabinet may be carrying life-threatening voltages.

If you touch these areas or components, you may be killed by electric shock.

Switch off the power supply to the cabinet before opening it.

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

15

Safety instructions

System expansions

NOTICE

Damage through system expansions

WARNING

Risk of fire

NOTICE

"Open Type" UL61010-2-201

2.2 General safety instructions

Device and system expansions may be faulty and can affect the entire machine or plant.

The installation of expansions can damage the device, machine or plant. Device and

system expansions may violate safety rules and regulations regarding radio interference

suppression. If you install or exchange system expansions and damage your device, the

warranty becomes void.

Note the following for system expansions:

● Only install system expansion devices designed for this device. Contact your technical

support team or where you purchased your PC to find out which system expansion

devices may safely be installed.

● Observe the information on electromagnetic compatibility (Page 69).

For vertical installation in upright format, observe the following:

Install the device in an enclosure that meets the requirements of paragraphs 4.6 and 4.7.3

of the standards EN 60950-1:2006 and IEC/UL/EN/DIN-EN 60950-1.

Note that the device is classified as "Open Type" for use in the area of Industrial Control

Equipment (UL61010-2-201). A UL61010-2-201 conform enclosure is therefore a

mandatory requirement for approval or operation according to UL61010-2-201.

SIMATIC IPC377E

16 Operating Instructions, 2017/05, A5E40965249-AA

Safety instructions

Battery

WARNING

Risk of explosion and release of harmful substances

Strong high-frequency radiation

NOTICE

Observe immunity to RF radiation

ESD Guideline

NOTICE

Electrostatic sensitive devices (ESD)

2.2 General safety instructions

Improper handling of lithium batteries can result in an explosion of the batteries.

Explosion of the batteries and the released pollutants can cause severe physical injury.

Worn batteries jeopardize the function of the device.

Note the following when handling lithium batteries:

• Replace used batteries in good time; see the section "Replacing the backup battery

(Page 54)" in the operating instructions.

• Replace the lithium battery only with an identical battery or types recommended by the

manufacturer (type: CR2032).

• Do not throw lithium batteries into fire, do not solder on the cell body, do not recharge,

do not open, do not short-circuit, do not reverse polarity, do not heat above 100°C, and

protect from direct sunlight, moisture and condensation.

The device has an increased immunity to RF radiation according to the specifications on

electromagnetic compatibility in the technical specifications.

Radiation exposure in excess of the specified immunity limits can impair device functions,

result in malfunctions and therefore injuries or damages.

Read the information on immunity to RF radiation in the technical specifications.

Electrostatic sensitive devices can be labeled with an appropriate symbol.

When you touch electrostatic sensitive components, you can destroy them through voltages

that are far below the human perception threshold.

If you work with components that can be destroyed by electrostatic discharge, observe the

ESD Guideline (Page 69).

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

17

Safety instructions

2.3

Notes on usage

WARNING

Risks associated with the unprotected machine or plant

Environment

NOTICE

Ambient conditions and chemical resistance

2.3 Notes on usage

According to the results of a risk analysis, certain hazard potentials associated with the

unprotected machine exist. These hazards could lead to personal injury.

Avoid such hazards by taking the following precautions in accordance with the risk analysis:

• Installation of additional safety equipment on the machine or plant. In particular, the

programming, parameter assignment and wiring of the inserted I/O must be executed in

accordance with the safety performance identified by the necessary risk analysis (SIL,

PL or Cat.).

• Use as intended must be validated for the device by means of a function test on the

plant. These tests help you to identify programming, parameter assignment and wiring

errors.

• Documentation of the test results that you can enter in the relevant safety verification

documents, if necessary.

Unsuitable environmental conditions have a negative impact on device operation. Chemical

substances such as cleaners or fuels may alter the color, shape and structure of the device

surface, for example, the front panel.

The device may be damaged. possibly resulting in malfunctions.

For this reason, please observe the following precautions:

• Always operate the device in closed rooms. All warranties shall be void in the case of

noncompliance.

• Operate the device only in accordance with the ambient conditions specified in the

technical specifications.

• Protect the device against dust, moisture and heat.

• Do not expose the device to direct sunlight or to other strong sources of light.

• Without additional safety measures, such as a supply of clean air, the device may not be

used in locations with harsh operating conditions caused by acidic vapors or gases.

• Always use suitable cleaning agents. Read the information about chemical resistance in

the Internet, see "SIMATIC IPC after-sales information system

(http://www.siemens.com/asis)".

SIMATIC IPC377E

18 Operating Instructions, 2017/05, A5E40965249-AA

Safety instructions

Note

Use in an industrial environment without additional protective measures

The device has been designed for use in a norma

IEC

TFT displays

NOTICE

Burn-in effect and backlighting

Defective pixels in the display

2.3 Notes on usage

l industrial environment in accordance with

60721-3-3 (pollutant class 3C2 for chemical influences, 3S2 for sand and dust).

A permanent picture with bright screen objects leads to a burn-in effect. The longer the

same screen contents are displayed, the longer it will take for the burn-in effect to

disappear. Screensavers (for example, "starfield simulation") for the backlit active black

mode reduce the burn-in effect. The brightness of the backlighting deteriorates over the

course of the screen's life cycle.

The service life of the screen and backlighting is extended by the following measures:

• Switch on the screensaver. The backlight brightness is reduced while the screensaver is

active.

• You should also reduce the backlighting.

• Observe the backlighting operating time.

At present, the manufacturing process of modern displays does not guarantee that all pixels

of the display will be perfect. A small number of defective pixels in the display is therefore

unavoidable. This does not present a functional problem as long as the defective pixels are

not bunched in one location.

Additional information is available in the section "Technical specifications (Page 67)".

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

19

Safety instructions

2.3 Notes on usage

SIMATIC IPC377E

20 Operating Instructions, 2017/05, A5E40965249-AA

3

3.1

Preparing for installation

3.1.1

Checking the delivery package

Procedure

Note

Damage to the device during transport and storage

If a device is transported or stored without packaging, shocks, vibrations, pressure and

moisture may impact the unprotected unit. A damaged packaging indicates that ambient

conditions have already had a massive impact on the device

The device may be damaged.

Do not dispose of the original packaging. Pack the device during transportation and

storage.

1. When accepting a delivery, please check the packaging for visible transport damage.

2. If any transport damage is present at the time of delivery, lodge a complaint at the

shipping company in charge. Have the shipper confirm the transport damage

immediately.

3. Unpack the device at its installation location.

4. Keep the original packaging in case you have to transport the unit again.

.

5. Check the contents of the packaging and any accessories you may have ordered for

completeness and damage. You will find the accessories, such as mounting hardware

and Ethernet connector strain relief, under the foam insert in the box.

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

21

Installing and connecting the device

WARNING

Electric shock and fire hazard due to damaged device

NOTICE

Damage from condensation

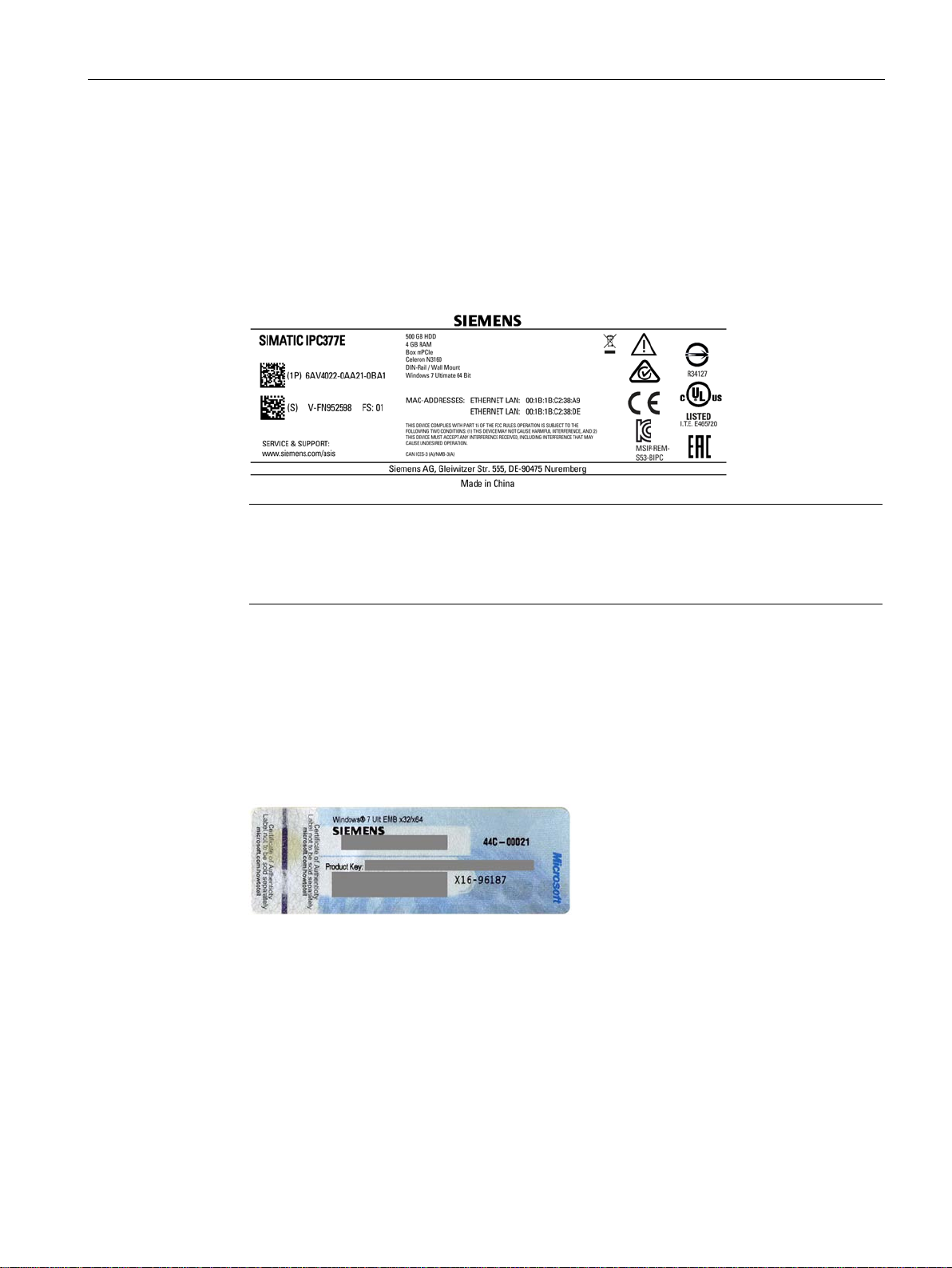

3.1.2

Identification data of the device

Order number

6AV...

Serial number

S V

Product version

FS

Windows "Product Key"

Ethernet address 1 (MAC)

Ethernet address 2 (MAC)

3.1 Preparing for installation

6. If the contents of the packaging are incomplete, damaged or do not match your order,

inform the responsible delivery service immediately. Fax the enclosed form "SIMATIC

IPC/PG Quality Control Report".

A damaged device can be under hazardous voltage and trigger a fire in the machine or

plant. A damaged device has unpredictable properties and states.

Death or serious injury could occur.

Make sure that the damaged device is not inadvertently installed and put into operation.

Label the damaged device and keep it locked away. Send off the device for immediate

repair.

If the device is subjected to low temperatures or extreme fluctuations in temperature

during transportation, for example in cold weather, moisture could build up on or inside

the HMI device.

Moisture causes a short circuit in electrical circuits and damages the device.

In order to prevent damage to the device, proceed as follows:

• Store the device in a dry place.

• Bring the device to room temperature before starting it up.

• Do not expose the device to direct heat radiation from a heating device.

• If condensation develops, wait approximately 12 hours or until the device is

completely dry before switching it on.

7. Please keep the enclosed documentation in a safe place. It belongs to the device. You

need the documentation when you commission the device for the first time.

8. Write down the identification data of the device.

The device can be clearly identified with the help of this identification data in case of repairs

or theft.

Enter the identification data in the following table:

SIMATIC IPC377E

22 Operating Instructions, 2017/05, A5E40965249-AA

Installing and connecting the device

Procedure

Note

Replacement device without storage media

When you order a replacement device, remove all the storage

for example HDD. Insert the storage media in the replacement device.

Example of a COA label

3.1 Preparing for installation

You can find this information on the rating plate and COA label. The rating plate is located on

the back of the unit. The COA label is only available with pre-installed Windows operating

systems and is affixed to the rear of the device.

1. Transfer order number, serial number, production version (FS), and Ethernet addresses

from the rating plate. Below is an example of a product label.

2. Take down the Windows "Product Key" from the COA label.

Microsoft Windows "Product Key" on the "Certificate of Authenticity" (COA):

The COA label is only attached to the rear of the device containing a Windows Embedded

Standard 7 or Windows 7 operating system.

● COA label of a device with Windows 7 operating system

media from your device,

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

23

Installing and connecting the device

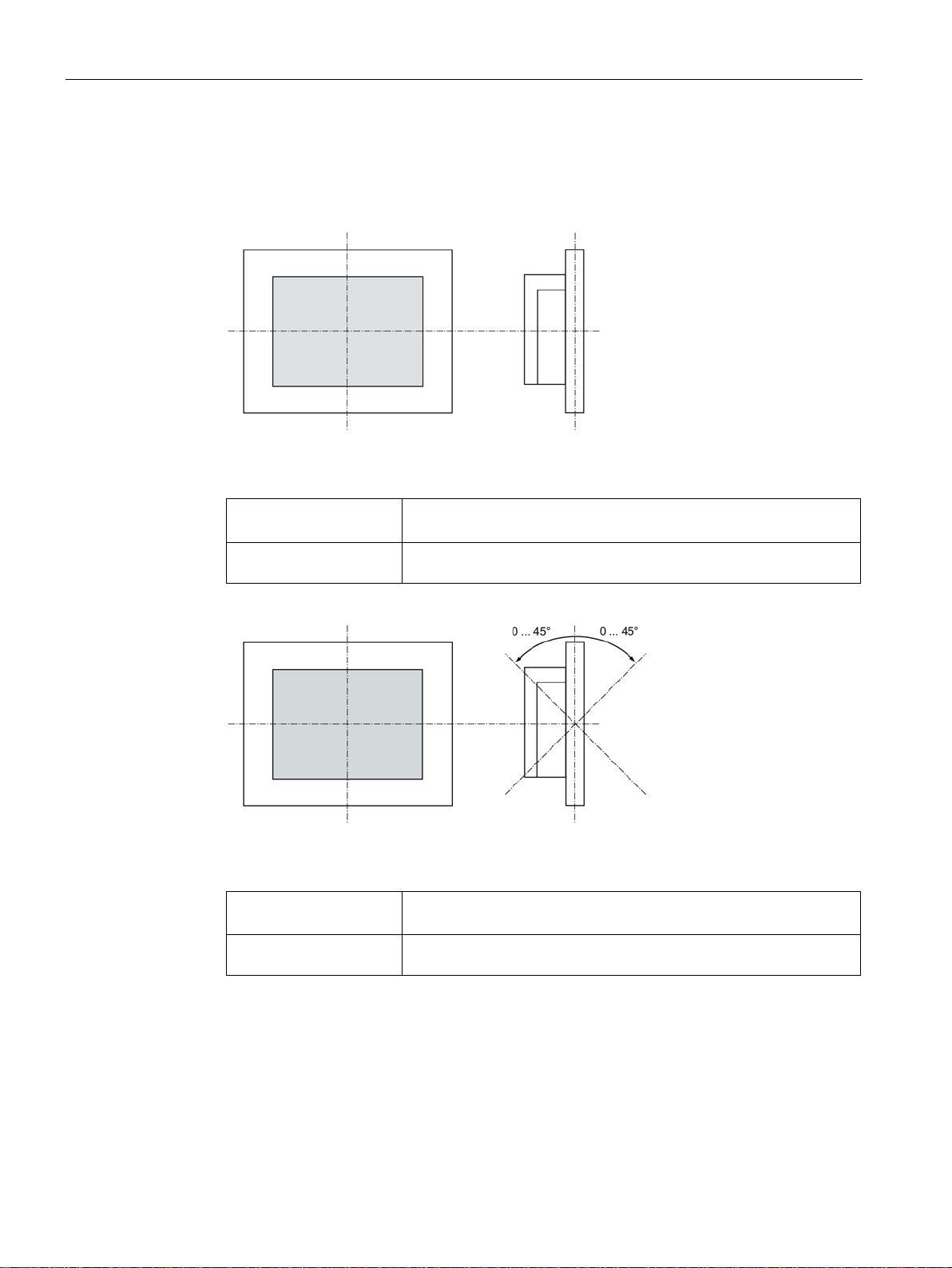

3.1.3

Permitted mounting positions

Maximum ambient tem-

perature at the device

Comment

sure.

Maximum ambient tem-

perature at the device

Comment

3.1 Preparing for installation

The device may be mounted in the following positions:

● Standard position: Vertical installation in horizontal format

For vertical installation in horizontal format, the following ambient temperatures are

permitted:

40 °C The device enclosure fulfills the requirement of a fire protection enclo-

● Inclined installation in horizontal format with a vertical inclination of maximum ±45 °

For inclined installation in horizontal format, the following ambient temperatures are

permitted:

40 °C The device enclosure fulfills the requirement of a fire protection enclo-

sure.

SIMATIC IPC377E

24 Operating Instructions, 2017/05, A5E40965249-AA

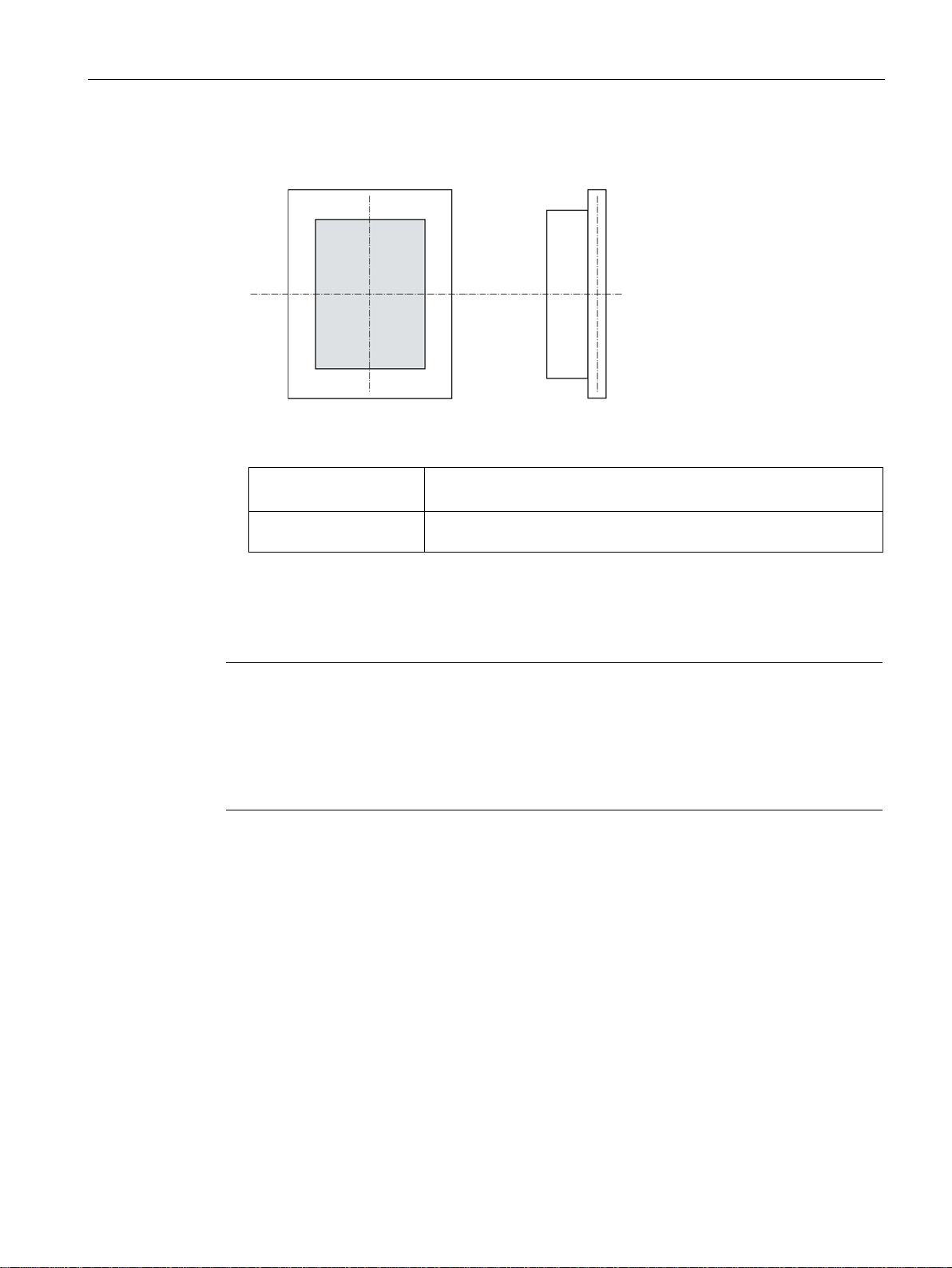

Installing and connecting the device

Maximum ambient tem-

perature at the device

Comment

"General safety instructions (Page 15)").

3.1.4

Preparing the mounting cutout

Note

Stability of the mounting cutout

The material in the area of the mounting cutout must provide sufficient strength to guarantee

the enduring and safe mounting of the HMI device.

To achieve the degrees of prote

of the material cannot occur due to the force of the mounting clips or operation of the device.

Degrees of protection

3.1 Preparing for installation

● Vertical installation in upright format, display turned through ±90 ° compared with the

standard position

For vertical installation in upright format, the following ambient temperatures are

permitted:

40 °C The device must be installed in a fire protection enclosure (see

The degrees of protection of the HMI device can only be guaranteed if the following

requirements are met:

● Material thickness at the mounting cutout for IP65 degree of protection, or for

enclosure type 4X/type 12 (indoor use only): 2 mm to 6 mm

● Permissible deviation from plane at the mounting cutout: ≤ 0.5 mm

This condition must be fulfilled for the mounted HMI device.

● Permissible surface roughness in the area of the seal: ≤ 120 µm (R

ction described below, it must be ensured that deformation

120)

z

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

25

Installing and connecting the device

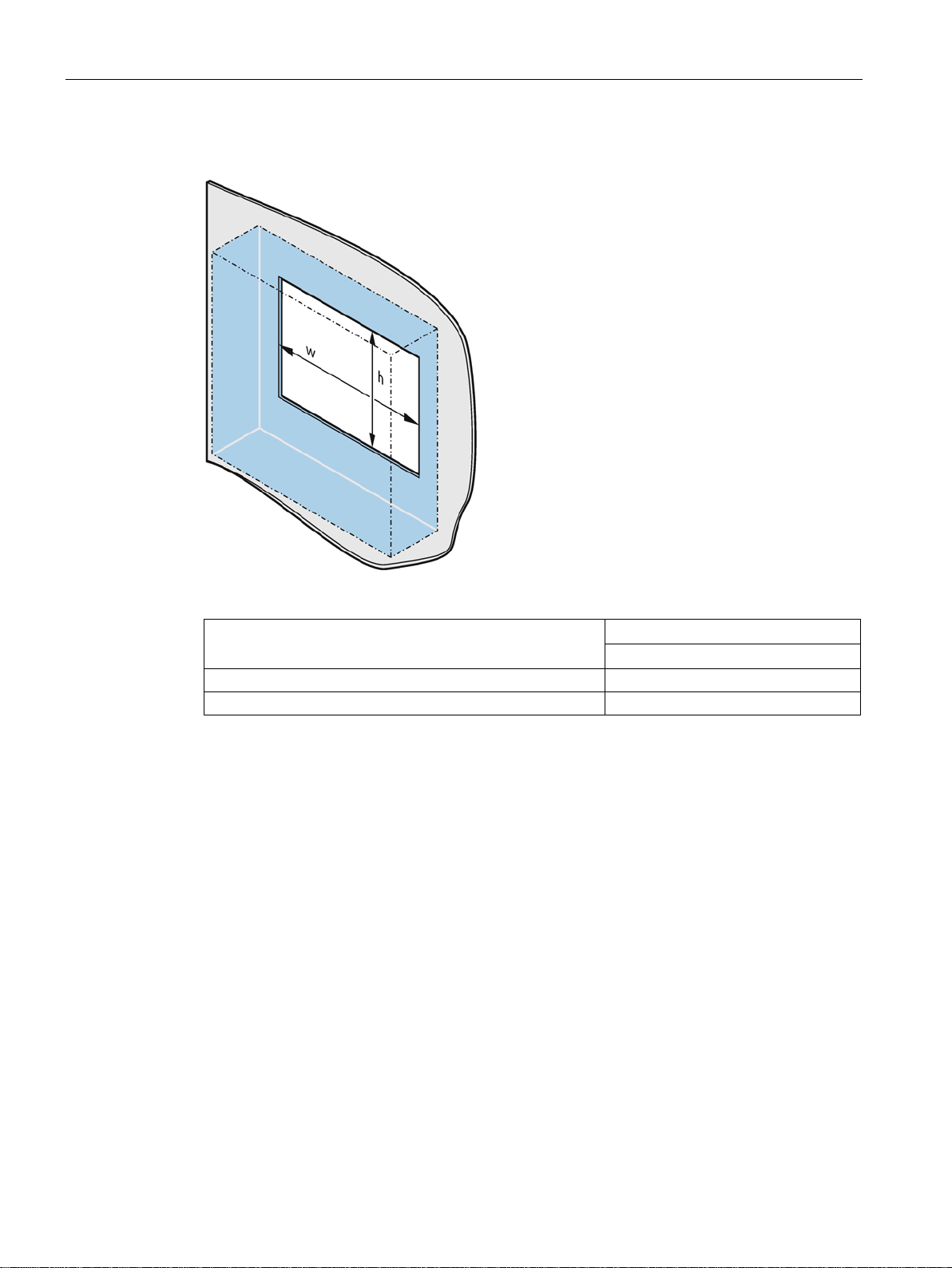

Dimensions of the mounting cutout

Mounting cutout

Device

12 inch

Width w *

302+1 mm

Height h *

208+1 mm

*

Width and height should be reversed accordingly when mounting in vertical format.

3.1 Preparing for installation

The following table shows the dimensions of the required mounting cutout:

SIMATIC IPC377E

26 Operating Instructions, 2017/05, A5E40965249-AA

Installing and connecting the device

3.2

Installing the device

3.2.1

Installation guidelines

WARNING

Dangerous voltage in control cabinet

NOTICE

Risk of fire

Note

In the standard installation position, the device meets the requirements for fire protection

enclosures in accordance with EN 60950-1. It can therefore be installed without an additional

fire protection covering.

3.2 Installing the device

The installer of the plant is responsible for proper installation of the device.

A high voltage may be present in the switchgear cabinet and could cause a dangerous

electric shock.

It may result in death or serious physical injury.

Isolate the power supply to the control cabinet before opening it. Ensure that the power to

the control cabinet cannot be turned on accidentally.

If you install the device in an unapproved mounting position or if you do not observe the

ambient conditions, the device can overheat.

Overheating can cause a fire. Proper functioning of the device is no longer guaranteed.

Before you install the device, note the following general installation information.

● Install the device only in one of the permitted mounting positions.

● For installation in a control cabinet, observe the applicable country-specific regulations.

● Ensure that the device is classified as "Open Type" when using it in the area of Industrial

Control Equipment (UL61010-2-201). A UL61010-2-201 conform enclosure is therefore a

mandatory requirement for approval or operation according to UL61010-2-201.

● Provide adequate volume in the control cabinet for air circulation and heat transport.

Keep at least 5 cm distance between the device and control cabinet.

● The ventilation slots of the device may not be covered or obstructed.

● The minimum distance between the device and the cabinet is 5 cm at the air output end.

● Ensure there is enough free space in the control cabinet to allow the cover to be

removed.

● Equip the control cabinet with struts for stabilizing the mounting cut-out. Install struts

where necessary.

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

27

Installing and connecting the device

IP65 degree of protection

WARNING

Risk of electric shock

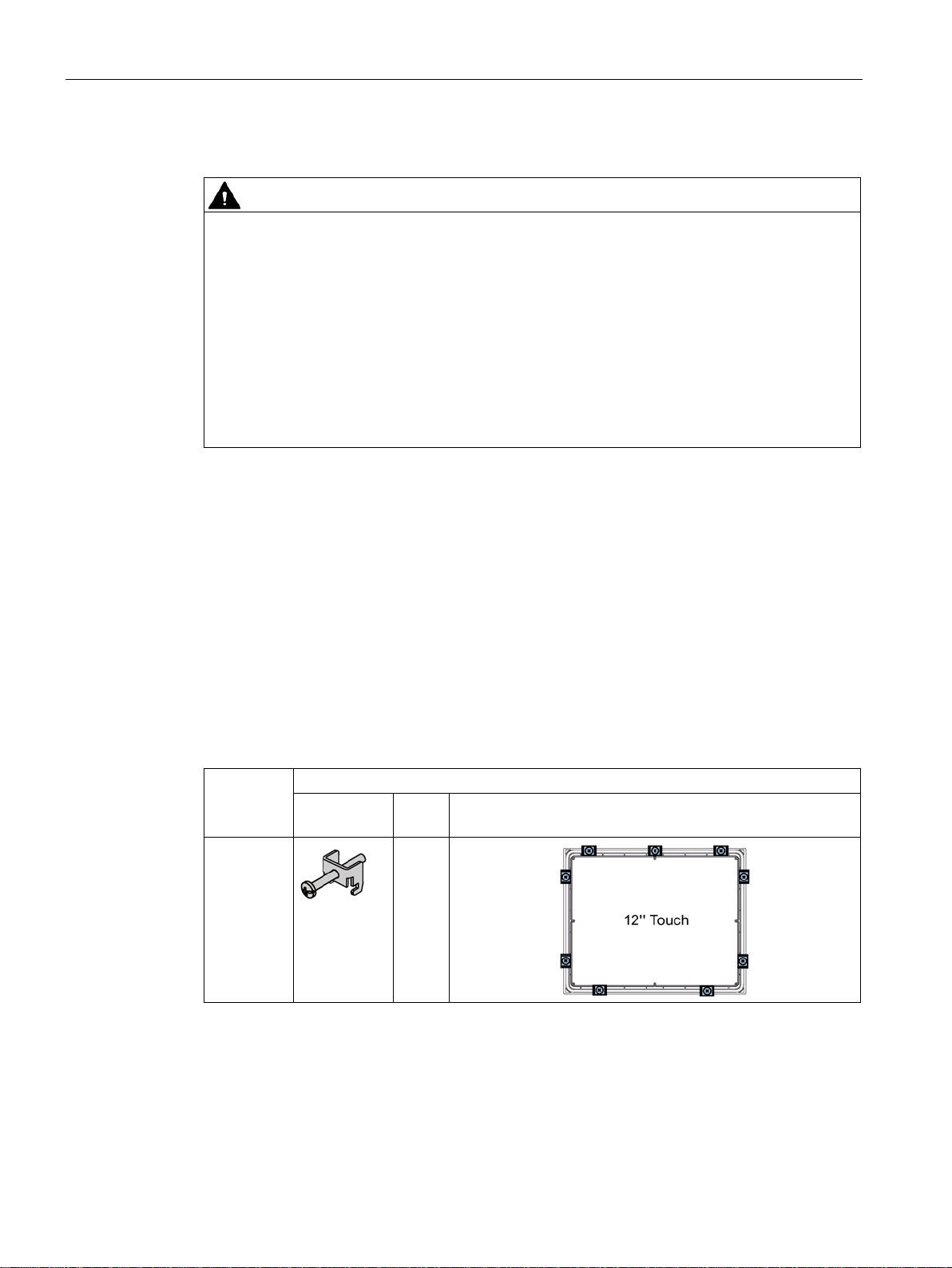

3.2.2

Secure with mounting clips

Positions of the mounting clips

HMI device

Mounting clips

Type

Quan-

tity

Position on the HMI device

Requirement

3.2 Installing the device

The specified degree of protection cannot be guaranteed if the device is not correctly

installed. Moisture or water could leak in and cause electric shock or destroy the plant.

The degree of protection IP65 is ensured for the front of the device under the following

conditions:

• The mounting cutout was prepared based on the correct dimensions; see chapter

"Preparing the mounting cutout (Page 25)".

• The device was secured with the supplied mounting clamps or with clamps which can

be optionally ordered.

• The mounting seal is undamaged.

To achieve the degree of protection for the HMI device, the positions for the mounting clips

shown below must be adhered to.

The positions of the mounting clips are marked by stamps on the cutouts. Fit the mounting

clips in all the stamped cutouts.

The following table shows the type, number, and position of the mounting clips needed for

the respective HMI devices.

12" display

9

SIMATIC IPC377E

28 Operating Instructions, 2017/05, A5E40965249-AA

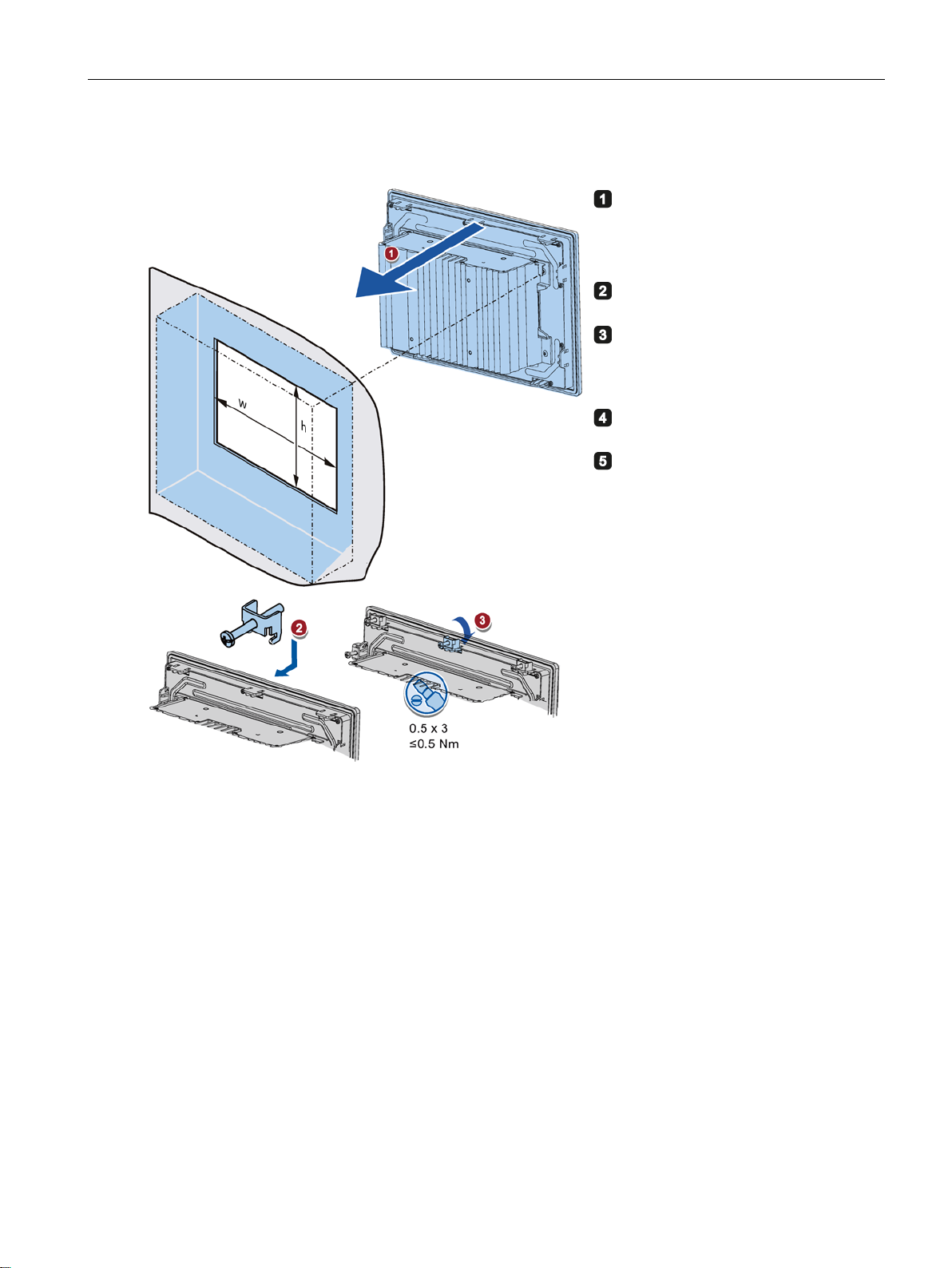

● All packaging components and protective films should be removed from the device.

● To install the panel, you need the mounting clips from the accessories kit.

Installing and connecting the device

Procedure

Insert the panel device into the mounting

cutout from the front.

Insert a mounting clip into the cutout

provided on the device.

Tighten the threaded pin to secure the

mounting clip. The threaded pins have a

maximum tightening torque of 0.5 Nm on

the 12 inch variants.

Repeat steps 2 and 3 for all mounting

clips.

Check the fit of the mounting seal.

Result

3.2 Installing the device

The device is mounted and the relevant degree of protection is ensured at the front.

SIMATIC IPC377E

Operating Instructions, 2017/05, A5E40965249-AA

29

Installing and connecting the device

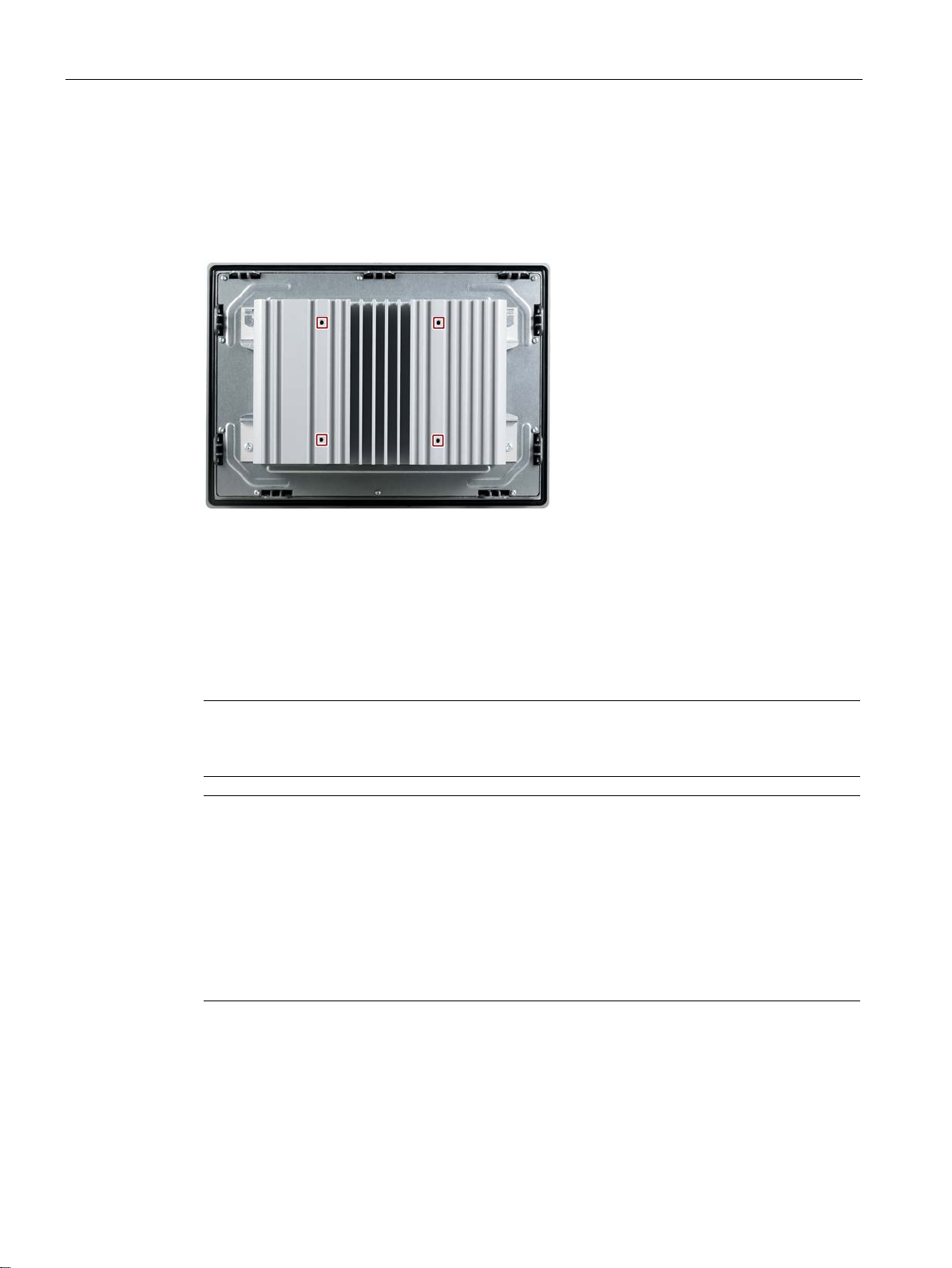

3.2.3

VESA mounting

Requirements

Procedure

Note

Make sure your support application is VESA100 compliant. Otherwise, you can not use it to

support IPC377E.

Note

Observe the torques

If you use too much

support arm or stand, the support arm may be damaged. If you tighten the screws with a

torque that is too low

Tighten the screws with the following torques, which

Adhere to the torque specifications of the third

1.5

3.2 Installing the device

IPC377E is VESA (Video Electronics Standards Association) compliant and can be mounted

on all kinds of applications utilizing the standard VESA100 mounting interfaces.

Its rear panel provides access to retention screw holes that support VESA mounting.

● All packaging components and protective films have been removed.

● VESA support application (for example, an arm or a stand) from a third party

torque to tighten the screws of the screws for fastening the device to a

, the device is not sealed.

may not be exceeded.

-party vendors:

Nm for connecting the device and the VESA mounting interface.

Secure the device to the mounting interface with four M4 x 10 screws.

SIMATIC IPC377E

30 Operating Instructions, 2017/05, A5E40965249-AA

Loading...

Loading...