Page 1

Preface, Contents

SIMATIC

IM 178-4

Manual

This manual is part of the product

with order number:

6ES7 178-4BH00-0AE0

Part 1: User Information

Product Overview

Installing and Removing the

Module

Wiring

Parameter Assignment

Preparing for Startup

Part 2: Reference Section

Functions of the IM 178-4

Diagnostics

1

2

3

4

5

6

7

Appendix

Technical Specifications

Configuration and

Parameter Assignment

Frame for the IM 178-4

Glossary, Index

A

B

Page 2

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

Danger

!

indicates that death, severe personal injury or substantial property damage will result if proper

precautions are not taken.

Warning

!

indicates that death, severe personal injury or substantial property damage can result if proper precautions are not taken.

Caution

!

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and

systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

Warning

!

Trademarks

This device may only be used for the applications described in the catalog or the technical description,

and only in connection with devices or components from other manufacturers which have been approved

or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed

correctly , and operated and maintained as recommended.

SIMA TICR, SIMA TIC HMIR and SIMA TIC NETR are registered trademarks of SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to trademarks

might infringe upon the rights of the trademark owners.

Disclaimer of LiabilityCopyright E Siemens AG 1998 All rights reserved

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of

a utility model or design, are reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschaeftsgebiet Industrie Automatisierungssystem

Postfach 4848, D- 90327 Nuernberg

Index-2

Siemens Aktiengesellschaft C79000-G7076-C178

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the data in this

manual are reviewed regularly and any necessary corrections included in

subsequent editions. Suggestions for improvement are welcomed.

E Siemens AG 1998

Subject to change without prior notice.

C79000-G7076-C178-01

IM 178-4

Page 3

Preface

Purpose of the Documentation

This manual describes all the steps necessary to use the function module

IM 178-4. It will help you to become familiar with the functions of the IM 178-4

quickly and effectively.

Content of the Manual

This manual describes the hardware and software of the IM 178-4. It deals with the

following topics:

S Product overview

S Installation and removal of the module

S Wiring

S Parameter assignment

S Starting up

S Functions

S Diagnostics

S Appendix

Audience

The manual is intended for the following audience:

S Fitters

S Programmers

S Commissioning engineers

S Service and maintenance personnel

Applicability of the Manual

This manual contains the description of the function module IM 178-4 valid at the

time of publication. We reserve the right to describe modifications in the

functionality of the IM 178-4 in a Product Information leaflet.

IM 178-4

C79000-G7076-C178-01

iii

Page 4

Preface

Finding Your Way in the Manual

To help you find specific information quickly, the manual includes the following :

S At the start of the manual, you will find a complete table of contents.

S In the Appendix, you will find a glossary in which the most important

terminology used in the manual is explained.

S At the end of the manual, you will find a comprehensive index with which you

can locate topics and specific information quickly.

Other Literature Required

To understand this manual, you should also be familiar with the manual

Distributed I/O System

Standards

The S7-300 programmable controller complies with the standard IEC 1131.

Recycling and Disposal

The SIMATIC S7-300 is an environmentally friendly product!

The SIMATIC S7-300 has the following environmental features:

S Plastic casing highly fireproof despite halogen–free flame protection

S Labeled by laser (in other words no unnecessary labels)

S Plastic materials indicated in compliance with DIN 54840

S Less material used due to small dimensions, less components due to

integration in ASICs

The SIMATIC S7-300 is suitable for recycling due to its low pollutant content .

For environmentally friendly recycling and disposal of your old SIMATIC PLC using

the most modern methods, contact:

ET 200

.

Siemens Aktiengesellschaft

Anlagenbau und Technische Dienstleistungen

ATD TD 3 Kreislaufwirtschaft

Postfach 32 40

D-91050 Erlangen

Germany

Phone: ++49 / 91 31 / 73 36 98

Telefax: ++ 49 / 91 31 / 72 66 43

This Siemens department offers individual counseling and a comprehensive and

flexible disposal system at a fixed price. Following disposal, you receive a

breakdown of the materials and a certification of the materials.

iv

C79000-G7076-C178-01

IM 178-4

Page 5

CD-ROM

You can also order the entire SIMATIC S7 documentation on a CD-ROM.

Further Support

If you have questions about using the product described in the manual and cannot

find the answer here, please contact your local Siemens representative. You will

find the addresses in the appendix ”SIEMENS Worldwide” in the

Programmable Controller, Hardware and Installation, CPU Data”

If you have questions or comments about the manual itself, please complete the

reply card at the end of the manual and send it to address shown. Please take a

few minutes to give your own personal assessment of the manual on the reply

card.

To familiarize users with the SIMATIC automation systems, we offer a variety of

training courses. If you are interested in these courses, please contact your

Regional Training Center or the Central Training Center in D-90327 Nürnberg,

Germany, Tel. ++49/911/895 3154.

Preface

”S7-300, M7-300

manual

.

The Latest Information

You can always obtain the very latest information about SIMATIC products from

the following sources:

S On the Internet: http://www.aut.siemens.de/

S By calling fax polling no. 08765-93 00 5000

Our SIMATIC Customer Support also supports you with up-to-date information and

downloads, that you may find helpful when using SIMATIC products:

S On the Internet: http://www.aut.siemens.de/simatic–cs

S In the SIMATIC Customer Support Mailbox: number

+49 (911) 895-7100

If you connect to the mailbox, use a modem with up to V.34

(28.8 Kbauds), with the following parameter settings:

8, N, 1, ANSI, or dial on ISDN (x.75, 64 Kbps).

SIMATIC Customer Support is available at the following phone and fax numbers or

e–mail addresses. You can also send enquiries by mail on the Internet or by mail to

the mailbox number above.

IM 178-4

C79000-G7076-C178-01

v

Page 6

Preface

Nuremberg

Johnson City

Singapore

Simatic Basic Hotline

Nuremberg

SIMA TIC BASIC Hotline

Local time: Mo.-Fr . 8:00

to 18:00

Phone: +49 (911) 895-7000

Fax: +49 (911) 895-7002

E-mail: simatic.support@

nbgm.siemens.de

SIMA TIC Premium Hotline

(charged, only with

SIMA TIC Card)

Time: Mo.-Fr . 0:00 to 24:00

Phone: +49 (911) 895-7777

Fax: +49 (911) 895-7001

Johnson City

SIMA TIC BASIC Hotline

Local time: Mo.-Fr . 8:00

to 17:00

Phone: +1 423 461-2522

Fax: +1 423 461-2231

E-mail: simatic.hotline@

sea.siemens.com

Singapore

SIMA TIC BASIC Hotline

Local time: Mo.-Fr . 8:30

to 17:30

Phone: +65 740-7000

Fax: +65 740-7001

E-mail: simatic@

singnet.com.sg

vi

C79000-G7076-C178-01

IM 178-4

Page 7

Contents

1 Product Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 What Can the IM 178-4 Do? 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Fields of Application of the IM 178-4 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 The Hardware of the IM 178-4 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Installing and Removing the Module 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Wiring 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Pinout of the Front Connector 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Description of the Individual Pins (Notes, Explanations) 3-4. . . . . . . . . . . . . . .

3.3 Wiring the Front Connector 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Wiring and Connecting the Bus Connector 3-8. . . . . . . . . . . . . . . . . . . . . . . . . .

4 Parameter Assignment 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Methods of Assigning Parameters to the IM 178-4 4-1. . . . . . . . . . . . . . . . . . .

4.2 GSx File 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Preparing for Startup 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Setting the PROFIBUS Address of the IM 178-4 5-1. . . . . . . . . . . . . . . . . . . . .

5.2 Checklist of the Mechanical Construction 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Checklist for Configuration/Parameter Assignment 5-3. . . . . . . . . . . . . . . . . . .

6 Functions of the IM 178-4 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Description of the Functions 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Cyclic Processing 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Error Monitoring 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 User Data Interface 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Diagnostics 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Status and Diagnostic LEDs 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Diagnostic Data of the IM 178-4 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Structure of Slave Diagnostics 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Structure of the First 6 Bytes of the Slave Diagnostic Data 7-4. . . . . . . . . . . .

7.2.3 Structure of the ID-Related and Device-Related Slave Diagnostic Data 7-6.

IM 178-4

C79000-G7076-C178-01

vii

Page 8

Contents

A Technical Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Technical Data of the IM 178-4 A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Configuration and Parameter Assignment Frame for the IM 178-4 B-1. . . . . . . . . .

B.1 Structure of the Configuration Frame B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Structure of the Parameter Assignment Frame B-2. . . . . . . . . . . . . . . . . . . . . .

B.2.1 Standard Section of the Parameter Assignment Frame B-2. . . . . . . . . . . . . . .

B.2.2 Parameters for the DP Attachment B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.3 Technological Parameters B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary Glossary-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

C79000-G7076-C178-01

IM 178-4

Page 9

Product Overview

Order Number

The product has the order number: 6ES7 178-4BH00-0AE0

Components of the product

1 Module

1 CD ROM with the following content:

S the readme.wri, liesmich.wri, lisezmoi.wri, leggimi.wri and leame.wri files

S the Englisch, German, French and Italian manual for the IM 178-4

(IM178_E.PDF, IM178_D.PDF, IM178-4_F.PDF, IM178-4_I.PDF)

S Device database:

– German: SIEM8064.GSG

– English: SIEM8064.GSE

– French: SIEM8064.GSF

1

– Italian: SIEM8064.GSI

S the bitmap files IM178__N.BMP and IM178__S.BMP

S Acrobat Reader

IM 178-4

C79000-G7076-C178-01

1-1

Page 10

Product Overview

1.1 What Can the IM 178-4 Do?

What Can the IM 178-4 Do?

The IM 178-4 is a DP slave with a fixed number of I/Os and has the same design

as S7-300 modules. It has two technologically identical but independent channels

for position detection of incremental position encoders and/or SSI position

encoders and for controlling analog drives ("10 V). The module is attached to the

DP network via a 9 pin sub-D male connector.

Per channel, the module has the following:

S One input for position detection with SSI position encoders or incremental

encoders with 5 V differential signals

S One analog output "10 V

S 3 digital inputs (2 with fixed functions)

S 3 digital outputs that you can use as required.

1.2 Fields of Application of the IM 178-4

Where can you use the IM 178-4?

The IM 178-4 is required mainly by users who want to create distributed position

detection and positioning systems in conjunction with conventional drives with an

analog interface ("10 V) and conventional displacement measuring systems (SSI,

incremental position encoders with 5V differential signals). The technological

functionality is no longer in the individual positioning modules as previously but in a

powerful centralized controller.

1-2

C79000-G7076-C178-01

IM 178-4

Page 11

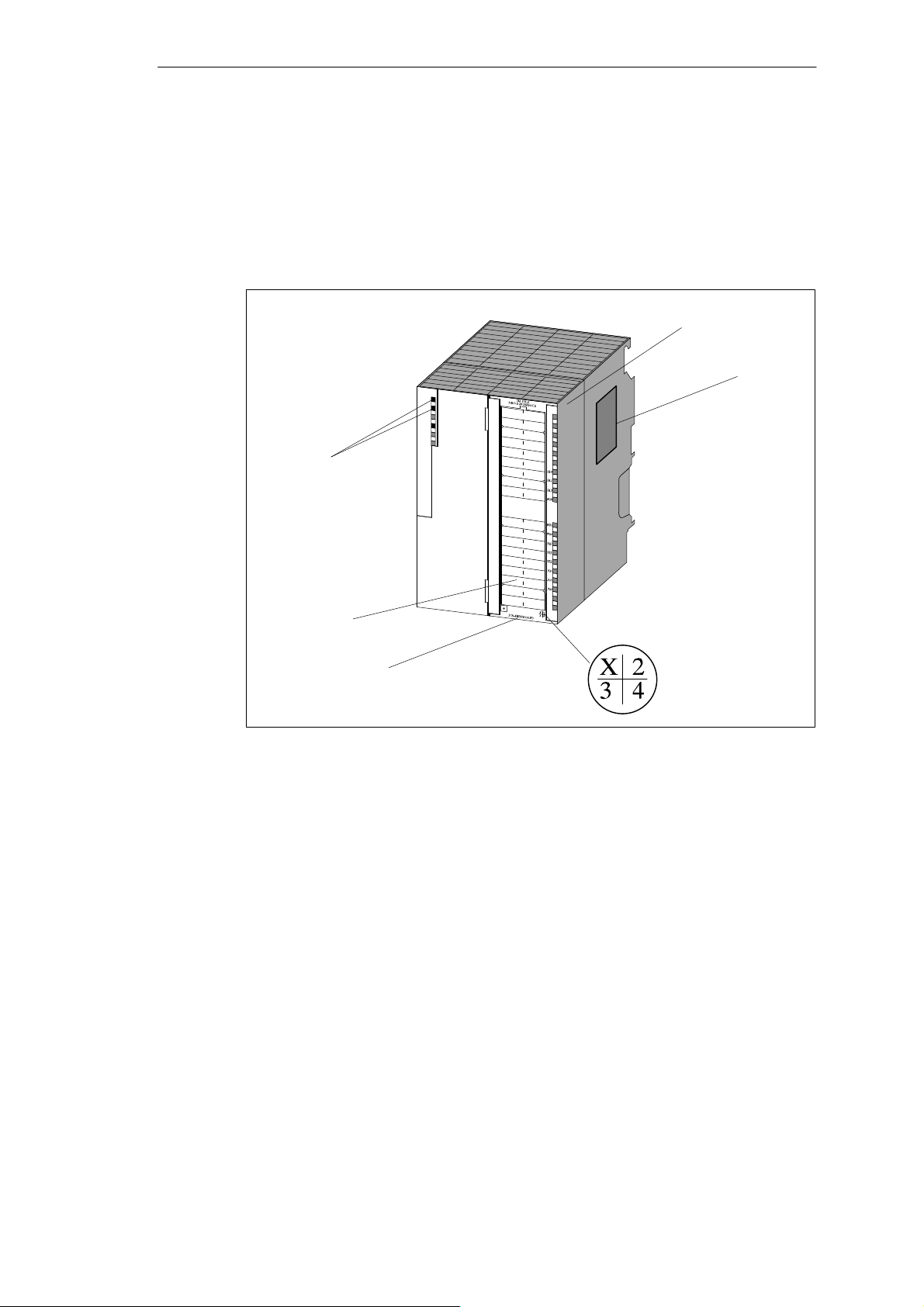

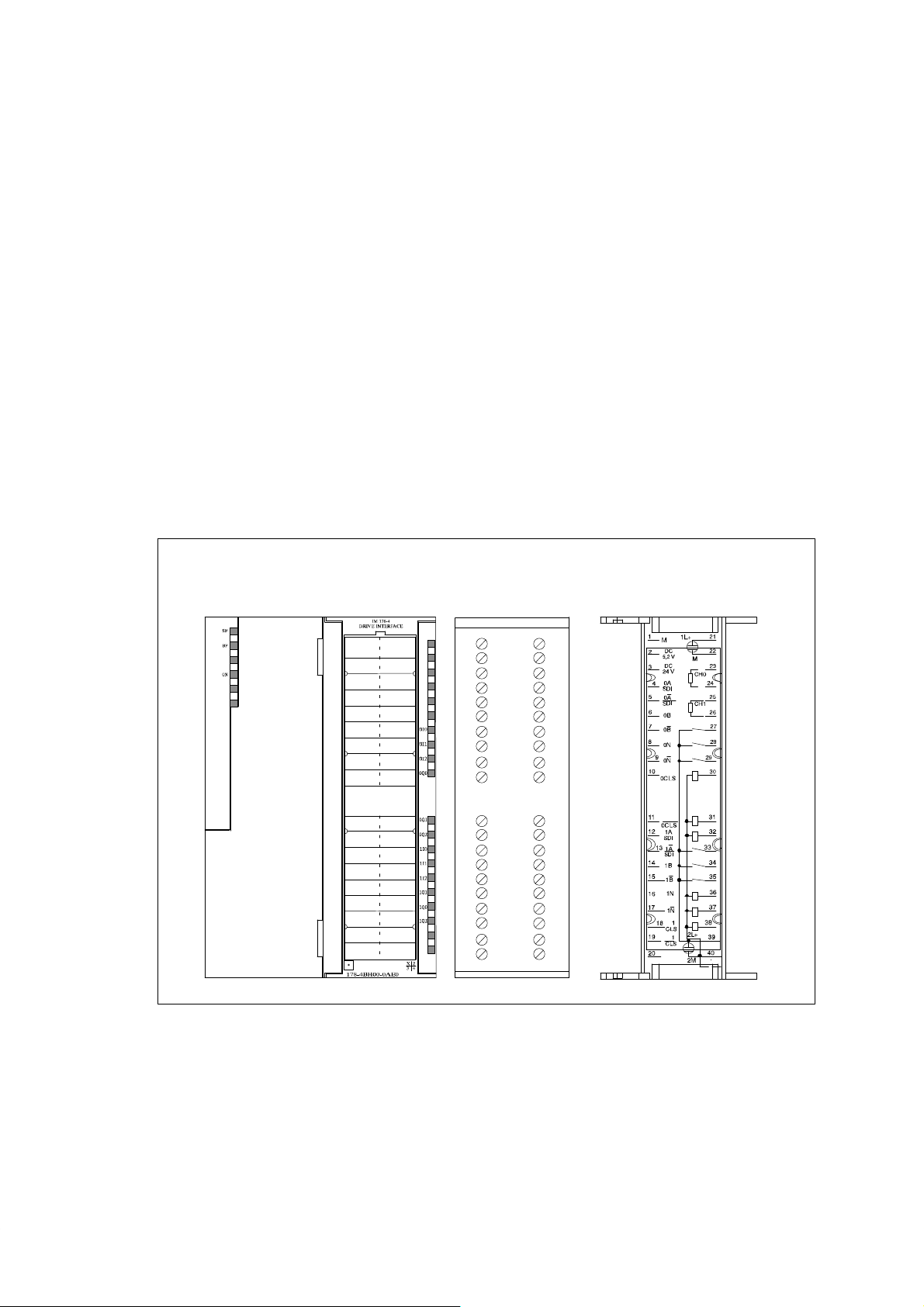

1.3 The Hardware of the IM 178-4

Module Overview

The following diagram shows the IM 178-4 module with its front connector.

Diagnostic LEDs

Product Overview

Front Connector

Type Label

Labeling Strip

Figure 1-1 The IM 178-4 Module

Front Connector

With the IM 178-4, the following attachments are possible via the front connector:

S 2 inputs for position detection with SSI position encoders or incremental

position encoders with 5 V differential signals

S 6 digital inputs

S 6 digital outputs

S 2 analog outputs "10 V

S Power supply 1L+

S Load voltage 2L+

The front connector must be ordered separately (order number

6ES7 392-1AM00-0AA0

Order Number

Version

IM 178-4

C79000-G7076-C178-01

1-3

Page 12

Product Overview

Labeling Strip

The module has a labeling strip on the right front panel that you can label with your

signal names.

The inner side of the right front panel has the pinout of the IM 178-4.

Order Number and Version

The order number and version are shown at the bottom of the front panel.

Status and Diagnostics LEDs

Labeling Color Function

SF red Group error (technology)

BF red Bus error

ON green Operating display

0I0 green Digital input 0 of channel 0

0I1 green Digital input 1 of channel 0

0I2 green Digital input 2 of channel 0

0Q0 green Digital output 0 of channel 0

0Q1 green Digital output 1 of channel 0

0Q2 green Digital output 2 of channel 0

1I0 green Digital input 0 of channel 1

1I1 green Digital input 1 of channel 1

1I2 green Digital input 2 of channel 1

1Q0 green Digital output 0 of channel 1

1Q1 green Digital output 1 of channel 1

1Q2 green Digital output 2 of channel 1

1-4

C79000-G7076-C178-01

IM 178-4

Page 13

Installing and Removing the Module

Selecting the Location

A horizontal installation is preferable. If you install the module vertically, remember

that the ambient temperature is restricted (max. 40 _C).

Important Safety Rules

For modules in the S7-300 design, there are important rules that must be kept to.

These rules and regulations are explained in the manual

Controller, Hardware and Installation, CPU Data

Rules

When installing the IM 178-4, no particular measures are necessary regarding

electrostatic discharge (ESD).

Required Tools

.

2

S7-300 Programmable

Installation

To install or remove the IM 178-4, you require a 4.5 mm screwdriver.

To install the IM 178-4 on a rail, follow the steps outlined below. For further

information about installing modules, refer to the manual

Controller, Hardware and Installation, CPU Data

1. Hook the IM 178-4 on to the rail and push in the bottom section of the module.

2. Screw the IM 178-4 tight (torque approximately 0.8 to 1.1 Nm).

3. Plug in the front connector and screw it tight.

4. Fit the shield contact element.

The order number of the shield contact element is 6ES7 390-5AA00-0AA0.

5. Plug in the bus connector.

The order number of the bus connector is 6ES7 972-0BA10-0XA0 or

6ES7 972-0BB10-0XA0.

.

S7-300 Programmable

IM 178-4

C79000-G7076-C178-01

2-1

Page 14

Installing and Removing the Module

Removing/Replacing the Module

To remove the IM 178-4, follow the steps outlined below. For further information

about removing modules, refer to the manual

Hardware and Installation, CPU Data

1. Turn off the auxiliary voltage and the load voltage at the front connector.

2. Open the front panel. If you require it, remove the label from inside the panel.

3. Release the mounting screw on the front connector and remove the connector.

4. Unplug the bus connector.

Note

If the LAN cable is connected through, you can remove the bus connector from the

DP interface without interrupting the data exchange on the bus.

5. Release the mounting screw on the module.

S7-300 Programmable Controller,

6. Pull out the bottom of the module from the rail and remove it upwards.

7. If required, install the new module.

2-2

C79000-G7076-C178-01

IM 178-4

Page 15

Wiring

3.1 Pinout of the Front Connector

Front connector

You connect the position encoders, the analog outputs, the digital inputs and

outputs, the sensor power supply and the module voltage via the 40-pin front

connector.

Figure 3-1 shows the front of the module, the front connector and the inner side of

the front panel with the pinout plan.

3

Front connectorFront view of the module Inside the front panel

Figure 3-1 Front Connector of the IM 178-4

1

2

3

4

5

6

7

8

9

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

1

0

2

1

2

2

2

2

3

4

2

5

2

6

2

7

2

2

8

2

9

0

3

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

3

IM 178-4

C79000-G7076-C178-01

3-1

Page 16

Wiring

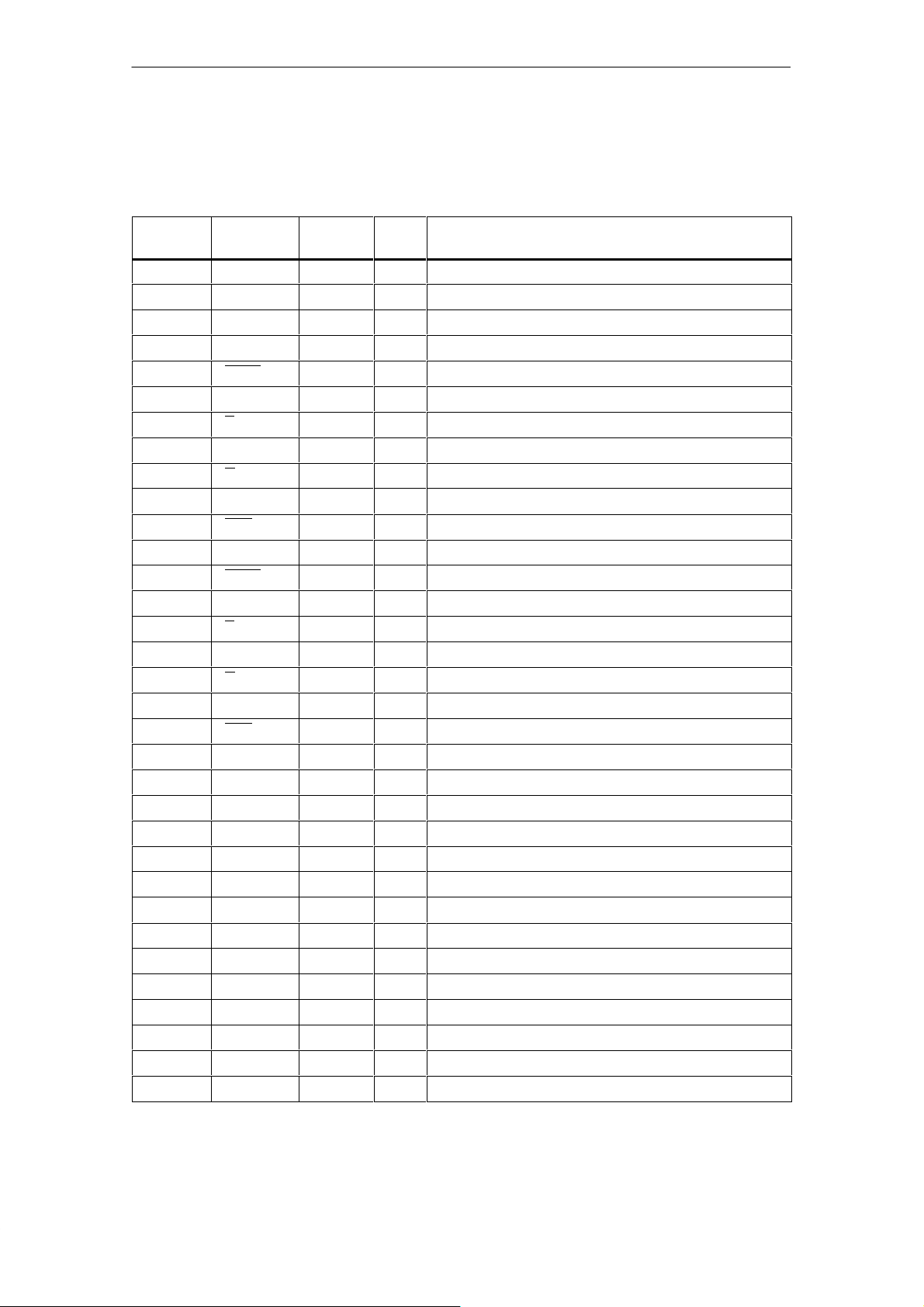

Pinout of the Front Connector

Table 3-1 Pinout of the Front Connector

Pin

1 M OUT – Sensor power supply ground

2 5.2 V DC OUT – 5 V sensor power supply

3 24 V DC OUT – 24 V sensor power supply

4 0A/SDI IN – Channel 0 count signal A / serial data input

5 0A/SDI IN – Channel 0 count signal A / serial data input, inverted

6 0B IN – Channel 0 count signal B

7 0B IN – Channel 0 count signal B, inverted

8 0N IN – Channel 0 zero mark

9 0N IN – Channel 0 zero mark, inverted

10 0CLS OUT – Channel 0 shift clock CLS

11 0CLS OUT – Channel 0 shift clock CLS, inverted

12 1A/SDI IN – Channel 1 count signal A / serial data input

13 1A/SDI IN – Channel 1 count signal A / serial data input, inverted

14 1B IN – Channel 1 count signal B

15 1B IN – Channel 1 count signal B inverted

16 1N IN – Channel 1 zero mark

17 1N IN – Channel 1 zero mark, inverted

18 1CLS OUT – Channel 1 shift clock CLS

19 1CLS OUT – Channel 1 shift clock CLS, inverted

20 –

21 1L+ IN – Auxiliary voltage 1L+

22 M IN – Auxiliary voltage ground

23 0AO OUT – Analog output 0AO

24 0BS OUT – Reference signal 0BS

25 1AO OUT – Analog output 1AO

26 1BS OUT – Reference signal 1BS

27 0I0 IN green Digital input 0I0

28 0I1 IN green Digital input 0I1

29 0I2 IN green Digital input 0I2

30 0Q0 OUT green Digital output 0Q0

31 0Q1 OUT green Digital output 0Q1

32 0Q2 OUT green Digital output 0Q2

33 1I0 IN green Digital input 1I0

Name Input/

Output

LED Function

3-2

C79000-G7076-C178-01

IM 178-4

Page 17

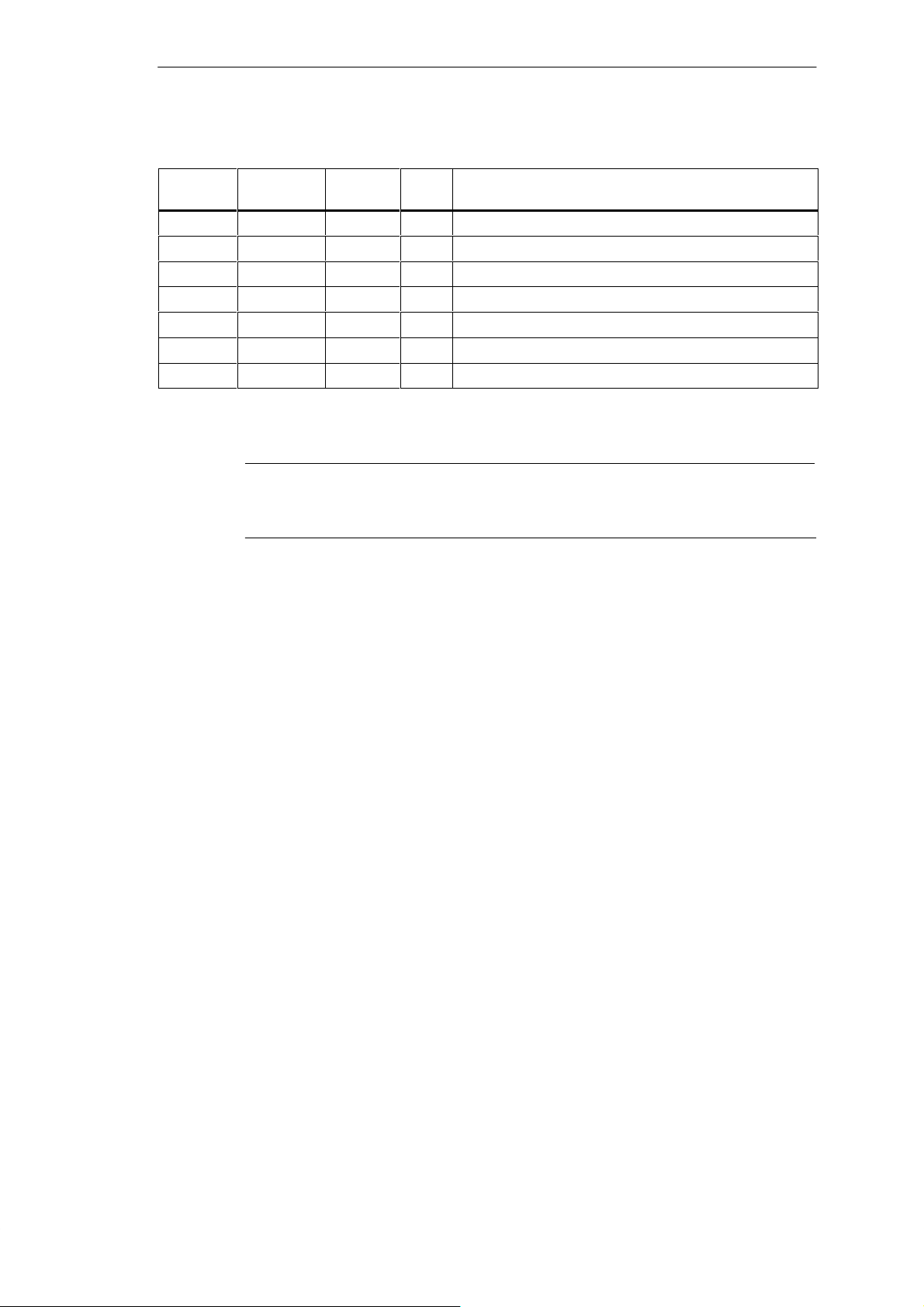

Table 3-1 Pinout of the Front Connector

Wiring

Pin FunctionLEDInput/

34 1I1 IN green Digital input 1I1

35 1I2 IN green Digital input 1I2

36 1Q0 OUT green Digital output 1Q0

37 1Q1 OUT green Digital output 1Q1

38 1Q2 OUT green Digital output 1Q2

39 2L+ IN – Load voltage 2L+

40 2M IN – Load voltage ground

Name

Output

Note

If you supply the sensor with an external voltage, connect the ground of the

external voltage to the ground of the module (terminal 1 or 22).

IM 178-4

C79000-G7076-C178-01

3-3

Page 18

Wiring

3.2 Description of the Individual Pins (Notes, Explanations)

24 V Power Supply

For the power supplies of the IM 178-4, connect a DC voltage of 24 V to pins 1L+

and M and 2L+ and 2M.

Caution

!

Make sure that the polarity of the 24 V power supply is correct otherwise the

module will be damaged.

The 24 V power supply must meet the following requirements:

Only an extra-low DC voltage of ≤ 60 V that is safely isolated from the main power

supply must be used as the 24 V power supply. Safe isolation of the power supply

can be achieved by adhering to the requirements of VDE 0100 Part 410 / HD

384-4-41 / IEC 364-4-41 (as functional extra-low voltage with safe isolation) or

VDE 0805 / EN 60950 / IEC 950 (as safety extra-low voltage SELV) or VDE 0106

Part 101.

5.2 V and 24 V Sensor Power Supplies

From the 24 V power supply 1L+/M, the module generates a voltage of 5.2 V. This

voltage is applied to DC5.2V (pin 2) as a short-circuit proof power supply for the

sensors and can accept a maximum load of 600 mA. The ground of the sensor

power supply is connected to M (Pin 1).

For sensors that require a power supply of 24 V, the short-circuit protected

auxiliary voltage is available at DC24V (Pin 3).

Note

A short-circuit of the 5.2 V sensor power supplies leads to a failure of the module.

Sensor Pins

Per channel, you can connect two different sensor types using shielded cables, as

follows:

S Incremental sensors complying with RS 422:

The signals A, A, B, B and N, N are connected via the correspondingly labeled

pins.

3-4

S SSI position encoders:

The signals SDI, SDI and CLS, CLS are connected to the correspondingly

labeled pins.

C79000-G7076-C178-01

IM 178-4

Page 19

Digital Inputs I0 to I2

Per channel, the IM 178-4 has three digital inputs. These are operated with a rated

voltage of 24 V.

The digital inputs are electrically isolated from the DP interface and the sensor

signals.

The digital inputs I0 and I1 have fixed functions depending on the parameter

assignment (see Chapter 6). Pin I0 must be connected using a shielded cable.

Digital Outputs Q0 to Q2

Per channel, the IM 178-4 has three digital outputs. These are supplied from the

24 V power supply 2L+.

The digital outputs are electrically isolated from the DP interface and the sensor

signals.

The digital outputs are current–sourcing switches and can accept a load current of

0.5 A. They are protected against overload and short–circuits.

Wiring

Note

The direct connection of relays and contactors is possible without external

protective circuits.

Analog Outputs

Per channel, the IM 178-4 has one analog output of ±10 V with a resolution of ±13

bits.

The analog outputs must be connected using shielded cables.

Note

Turning on the auxiliary voltage 1L+ can lead to the analog outputs supplying a

spurious pulse for several ms. This spurious pulse must not cause the power

circuits to be activated. This must be avoided by appropriate external wiring of the

module (digital output to enable the power circuits).

IM 178-4

C79000-G7076-C178-01

3-5

Page 20

Wiring

3.3 Wiring the Front Connector

Cables

When selecting suitable cables, follow the rules outlined below:

S The cables for digital inputs 0I0 and 1I0 must be shielded.

S The cables for the position encoder signals must be shielded; the pairs of cores

must be twisted.

S The shields of the cables for the count signals must be connected to ground

both at the position encoder and in the immediate vicinity of the module, for

example using the shield contact element.

S Use flexible cables with cross–sections of 0.25 to 1.5 mm2.

S The cables for the analog outputs must be shielded.

Note

If the sensor is supplied with power from the module, the conductor cross-section

must be large enough so that the required voltage is applied to the sensor despite

the voltage drop along the cable.

S A wire-end ferrule is not required. If you use wire-end ferrules, use only those

without an insulation collar according to DIN 46228 form A, short version!

Tools Required

A 3.5 mm screwdriver.

3-6

C79000-G7076-C178-01

IM 178-4

Page 21

Wiring Procedure

When wiring the front connector, follow the steps outlined below:

Warning

!

Risk of personal injury.

If you wire the front connector of the IM 178-4 with the power supply on, you may

be injured by the electrical current.

Make sure that you wire the IM 178-4 only when the power supply is turned off.

1. Open the front panel and bring the front connector into a position so that you

can wire it.

2. Strip the insulation from the wires (remove 6 mm of the insulation).

3. Are you using wire–end ferrules?

If yes: Crimp the wire-end ferrules onto the wires.

Wiring

4. Thread the accompanying strain relief into the front connector.

5. If the wires are led out towards the bottom, start wiring from the bottom,

otherwise from the top. You should also screw down terminals that are not in

use (tightening torque 0.6 to 0.8 Nm).

6. Pull the strain relief for the cables tight.

7. Screw the front connector into the operating position.

8. Establish contact between the shields of the cables on the shield contact

element or on the shield contact rail.

9. Enter the terminal assignments on the pinout plan.

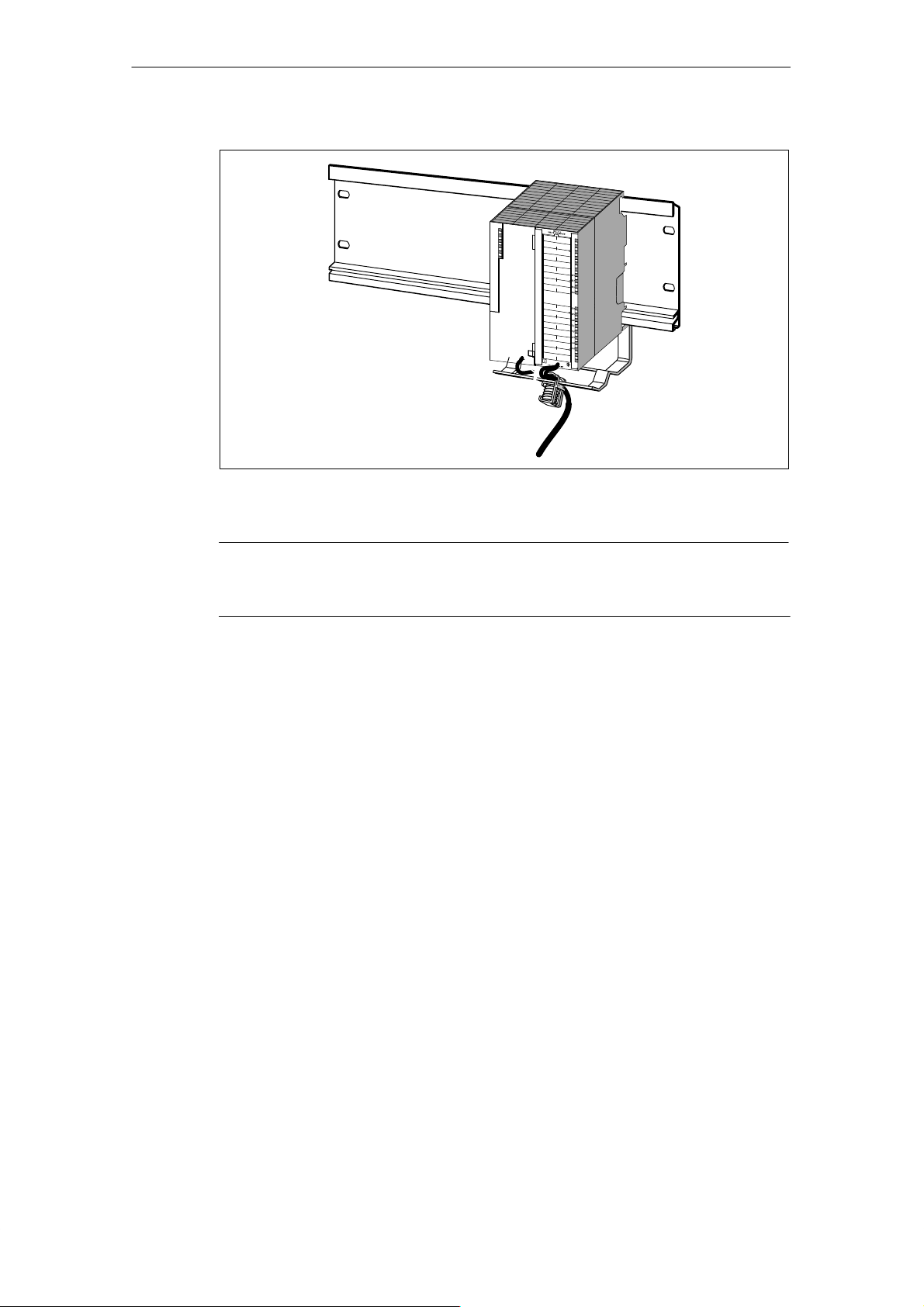

Figure 3-2 shows the IM 178-4 with shielded cables and a shield contact element.

IM 178-4

C79000-G7076-C178-01

3-7

Page 22

Wiring

Figure 3-2 Connecting Shielded Cables to the IM 178-4

Note

For a detailed description of wiring the front connector, refer to the manual

Programmable Controller, Hardware and Installation, CPU Data

3.4 Wiring and Connecting the Bus Connector

LAN Cable

As the LAN cable, use the PROFIBUS shielded twisted pair cable or fiber-optic

cable. For ordering information, refer to the Catalog

Cable Lengths

For information about the length of the LAN cable in a segment and about

interconnecting segments, refer to the manuals describing the DP master.

The cable lengths specified in these manuals are only guaranteed for the

PROFIBUS cable (see Catalog

ST 70

).

ST 70

S7-300

.

.

3-8

C79000-G7076-C178-01

IM 178-4

Page 23

Attaching the LAN Cable

Connect the LAN cable to the bus connector with order numbers

6ES7 972-0BA10-0XA0 or 6ES7 972-0BB10-0XA0 ... as follows:

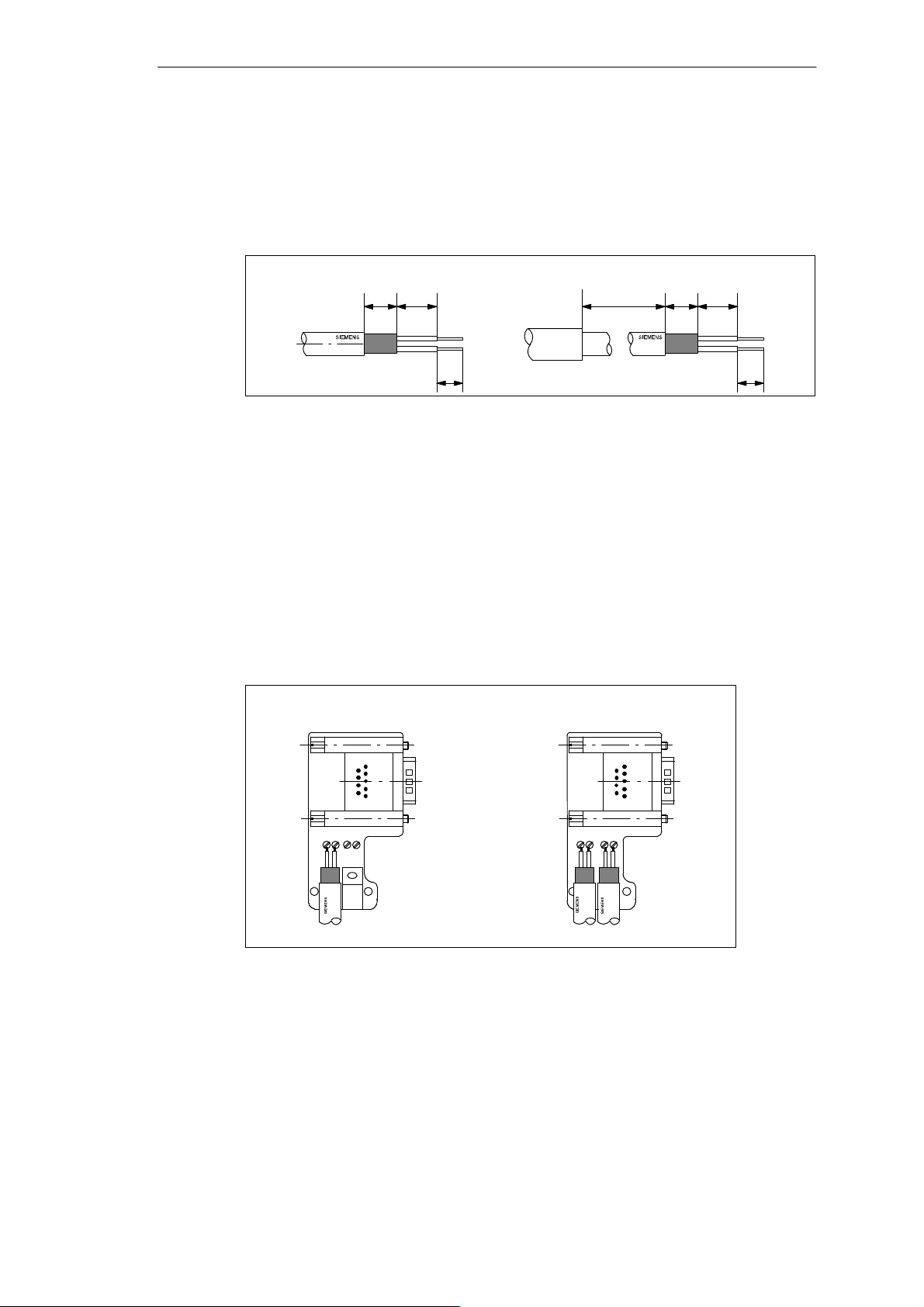

1. Strip the insulation from the LAN cable as shown in Figure 3-3.

6XV1 830–0AH10/-3BH10 6XV1 830–3AH10

Wiring

7,5 9

6

Figure 3-3 Lengths for Stripping Insulation for the Bus Connector (6ES7 972-0B?0-0XA0)

120

7,5 9

6

2. Open the casing of the bus connector by undoing the casing screws and

removing the cover.

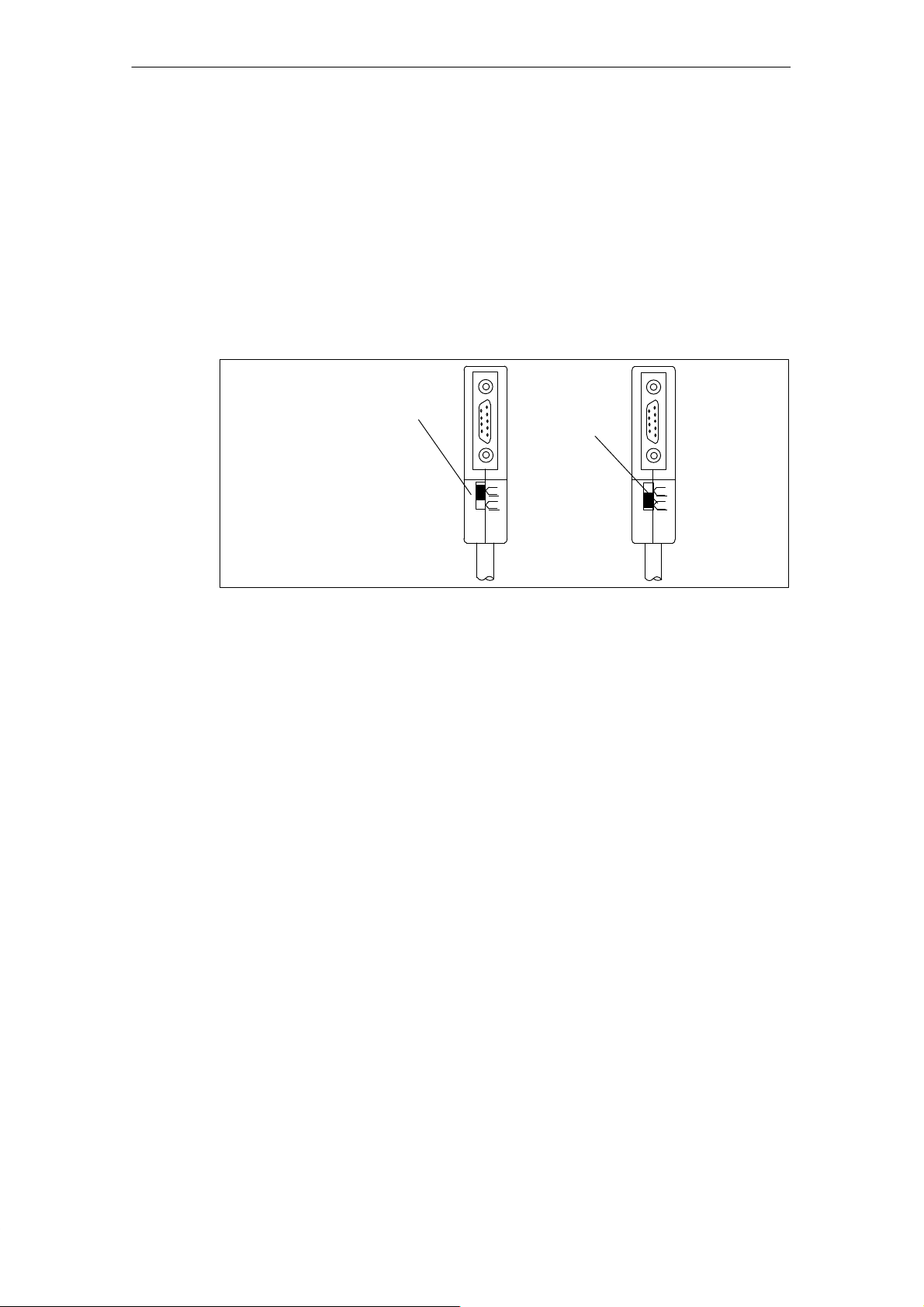

3. Fit the green and red wire in to the screw terminal block as shown in Figure 3-4.

Make sure that you always connect the same wire to the same terminal A or B

(for example terminal A is always wired with the green wire and terminal B

always with the red wire).

4. Press the cable jacket between the two clamping posts. This fixes the cable in

place.

5. Screw the green and red wire into the terminal block.

LAN cable connection for first and

last node in the segment

1

LAN cable connection for all

other nodes in the segment

1

: The LAN cable can be connected to the right or left terminals!

Figure 3-4 Connecting the LAN Cable to the Bus Connector (6ES7 972-0B?10 0XA0)

6. Screw the casing back together.

Make sure that the cable shield makes contact with the shield clamp.

IM 178-4

C79000-G7076-C178-01

A B A B A B A B

3-9

Page 24

Wiring

Connecting the Bus Connector

To connect the bus connector, follow the steps outlined below:

1. Plug the bus connector on to the IM 178-4.

2. Secure the bus connector on the IM 178-4 with the screws.

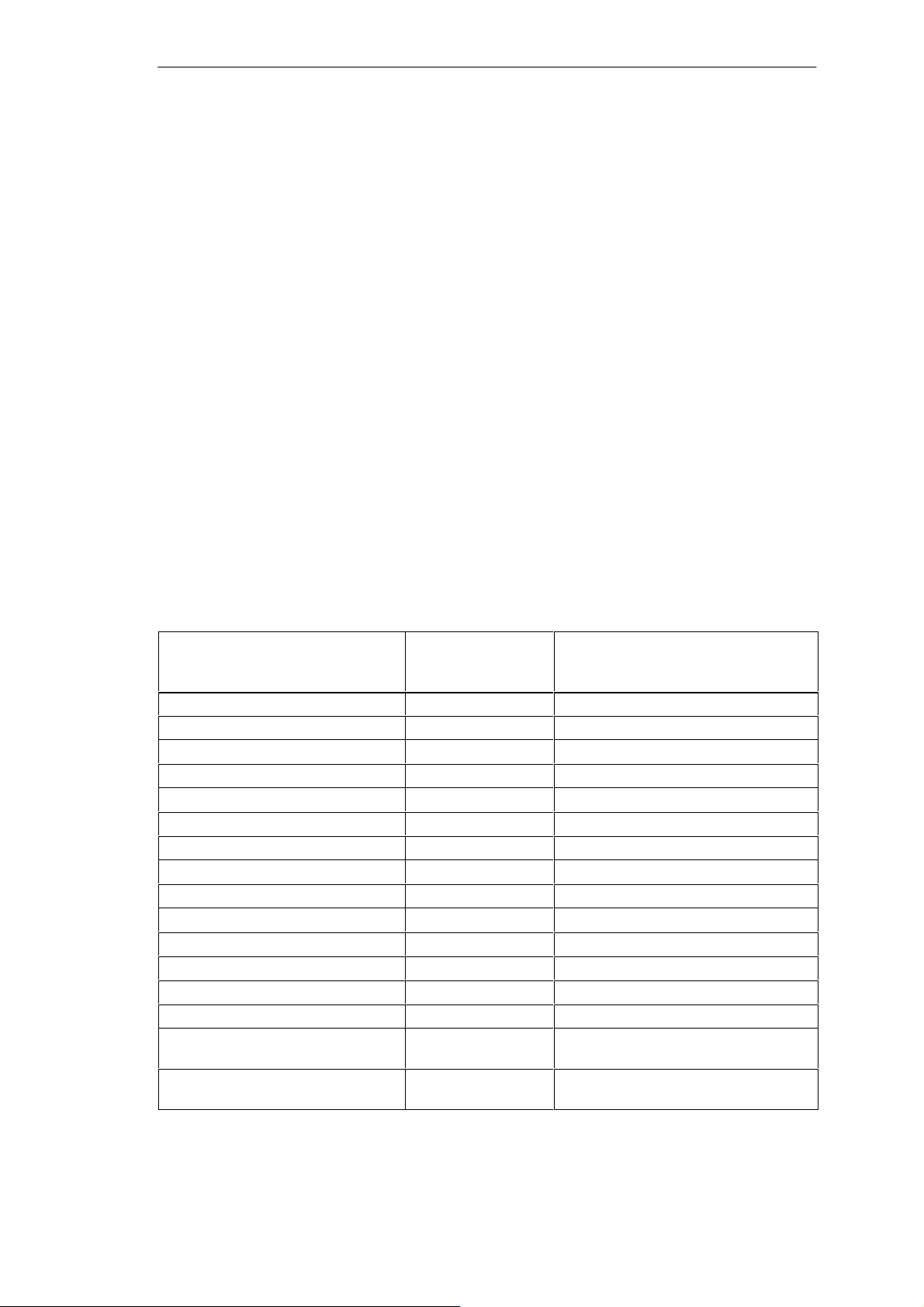

3. If the bus connector is at the start or end of a segment, the terminating resistor

must be activated (switch setting ”ON”) (see Figure 3-5).

Make sure that the nodes on which the terminating resistor is activated are always

supplied with voltage during startup and operation.

Terminating

resistor

activated

on

off

Terminating

resistor not

activated

on

off

Figure 3-5 Bus connector (6ES7 972-0B?10-0XA0): Terminating resistor activated and

deactivated

3-10

C79000-G7076-C178-01

IM 178-4

Page 25

Parameter Assignment

4.1 Methods of Assigning Parameters to the IM 178-4

Requirements for Assigning Parameters with Hardware Configuration

To use Hardware Configuration when assigning parameters to the IM 178-4, make

the following preparations:

1. Copy the file SIEM8064.gse to the STEP 7 directory S7DATA\GSD, for

example using the menu command Options"Install New DDB ...

2. Copy the files im178__n.bmp and im178__s.bmp to the STEP 7 directory

S7DATA\NSBMP.

3. Update the local module catalog (in STEP 7 V4.02 with the menu command

Options"Update Catalog).

You will then find the IM 178-4 in the hardware catalog under Other FIELD

DEVICES\OTHER.

4

Requirements for Parameter Assignment With COM PROFIBUS

Before you can use COM PROFIBUS to assign parameters to the IM 178-4, you

must make the following preparations:

1. Copy the files SIEM8064.gsd, SIEM8064.gse, SIEM8064.gsf and

SIEM8064.gsi to the PROFIBUS GSD folder.

2. Copy the files im178__n.bmp and im178__s.bmp to the COM PROFIBUS

Bitmaps folder.

3. Update the local module catalog (menu command File"Scan GSD Files).

The station type IM 178-4 is then available in the slave family “Other”.

IM 178-4

C79000-G7076-C178-01

4-1

Page 26

Parameter Assignment

Note

In slot 4, configure one of the proposed technology slots:

S Q4 words / I12 words:

Word consistency in the Q and I areas

S Q4 words / I12 words consistent (standard situation):

Word consistency in the Q area, consistency over the entire I area

If you only require the less significant 16 bits of the actual position value, you can

also select “Q4 words / I12 words” .

Requirements for Parameter Assignment with a Parameter Assignment Frame

To assign parameters to the IM 178-4 using a parameter assignment frame, you

must know how the configuration and parameter assignment frames are

structured. This is explained in Appendix C.

Parameter Assignment

Each DP standard slave receives its parameters from the DP master when it starts

up itself or when the master is started.

Successful parameter assignment is indicated by the value TRUE in the PARA

status bit for each channel. A parameter assignment error is indicated by FALSE in

the PARA status bit and an entry in the slave diagnostic data if this is enabled.

The diagnostic LED remains lit until both channels have been assigned error-free

parameters.

Until parameter assignment is successful, the inputs for the actual position value

and actual reference value have the value 0.

The parameters cannot be read back from the module.

4-2

C79000-G7076-C178-01

IM 178-4

Page 27

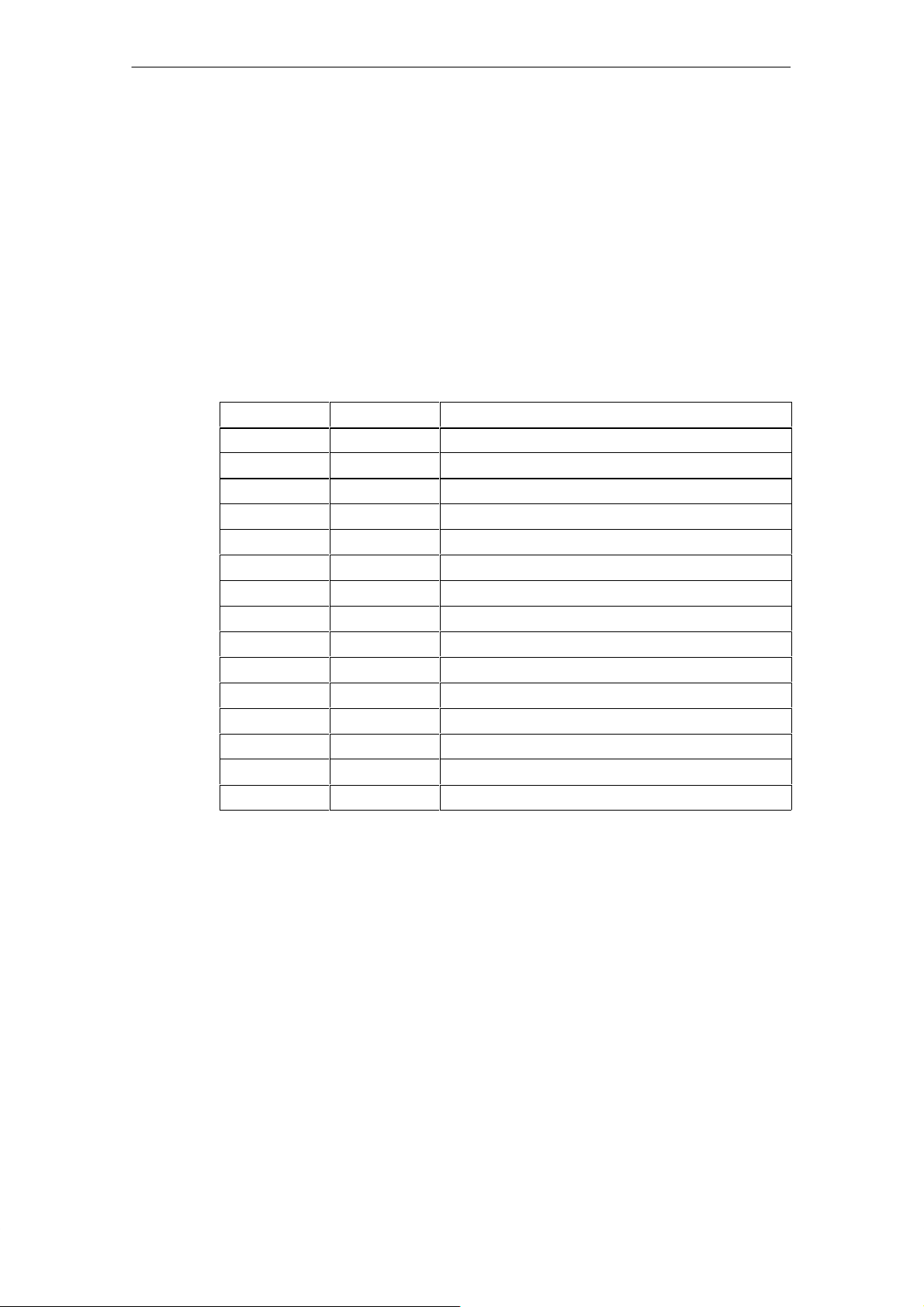

4.2 GSx File

Definition: GSx File

A device database file (*.GSx where x = language identifier) contains all the

parameters or properties specific to a particular slave. The format of the GSx file is

stipulated in the standard EN 50170, Volume 2, PROFIBUS.

Uses of the GSx File

Configuration tools such as COM PROFIBUS can interpret the GSx file and

provide you with a convenient method for configuring and assigning parameters to

the IM 178-4.

You can download GSx files from the interface center in Fürth using a modem

(telephone number ++94–911–737972).

Parameter Assignment

The Most Important Properties

If you do not have the GSE file available, the most important properties of the IM

178-4 are listed in the table below. This information is adequate to install and start

up the IM 178-4 in conjunction with the CP 5431.

Property

Vendor ID Ident_Number 8064

FMS supported FMS_supp no

9.6 Kbps supported 9.6_supp yes

19.2 Kbps supported 19.2_supp yes

45.45 Kbps supported 45.45_supp yes

93.75 Kbps supported 93.75_supp yes

187.5 Kbps supported 187.5_supp yes

500 Kbps supported 500_supp yes

1.5 Mbps supported 1.5M_supp yes

3 Mbps supported 3M_supp yes

6 Mbps supported 6M_supp yes

12 Mbps supported 12M_supp yes

FREEZE control command supported Freeze_Mode_supp yes

SYNC control command supported Sync_Mode_supp yes

Automatic transmission rate search

supported

Software modification of PROFIBUS

address

DP Keyword as in

EN 50170, V olume 2,

PROFIBUS

Auto_Baud_supp yes

Set_Slave_Add_supp no

IM 178-4

H

IM 178-4

C79000-G7076-C178-01

4-3

Page 28

Parameter Assignment

Property IM 178-4

DP Keyword as in

EN 50170, V olume 2,

PROFIBUS

Length of user-specific parameter

User_Prm_Data_Len 24 bytes

assignment data

User–specific parameter assignment

data for the DP attachment (default)

Minimum interval between two slave

User_Prm_Data 40H, 20H, 00H, ...

1

Min_Slave_Intervall 5 (0.5 ms)

polling cycles

Modular station Modular_Station 1

Maximum number of modules Max_Module 4

Maximum number of inputs Max_Input_Len 24 bytes

Maximum number of outputs Max_Output_Len 8 bytes

Maximum number of inputs and

Max_Data_Len 32 bytes

outputs together

Central display of vendor-specific

Unit_Diag_Bit not used

status and error messages

Assignment of values in

Unit_Diag_Area not used

device-related diagnostic field to texts

IDs of all modules of a modular DP

Module, End_Module yes

slave

Assignment of vendor–specific error

Channel_Diag no

types in the channel related

diagnostic field to texts

1

For an explanation of the user–specific parameter assignment data (technological parameters) refer to

Appendix C.

4-4

C79000-G7076-C178-01

IM 178-4

Page 29

Preparing for Startup

5.1 Setting the PROFIBUS Address of the IM 178-4

Definition

Each node must be assigned a PROFIBUS address to identify it uniquely in the

PROFIBUS DP network.

Rules

The following rules apply to the PROFIBUS address of the IM 178-4:

S The PROFIBUS addresses 0 to 125 are permitted.

S The PROFIBUS address must only be assigned once on the bus.

5

IM 178-4

C79000-G7076-C178-01

5-1

Page 30

Preparing for Startup

Setting the PROFIBUS Address

You set the PROFIBUS address using a screwdriver with the front panel open.

The PROFIBUS address is the sum of the switches set to the right (position ”ON”).

IM 178-4

BUS

ADDRESS

OFF ON

64

32

16

8

4

2

1

PROFIBUS address =

Figure 5-1 Setting the PROFIBUS Address

Changing the PROFIBUS Address

You can change the set PROFIBUS address at any time. The IM 178-4 only

adopts the new PROFIBUS address after the 25 V power supply (1L+) has been

switched off and on again.

64

+ 32

+ 2

+ 1

= 99

5-2

C79000-G7076-C178-01

IM 178-4

Page 31

5.2 Checklist of the Mechanical Construction

Table 5-1 Checklist of the Mechanical Construction

Preparing for Startup

Step

1 Installation of the IM 178-4 (see Chapter 2) 2 Wiring the IM 178-4 (see Chapter 3)

What needs to be done?

S Digital inputs

S Digital outputs

S Analog outputs

S Sensor connections

S Power supplies

3 Peripheral connector

The peripheral connector must be locked and secured by screws.

4 Setting the DP address (see Section 5.1) 5 Bus connector

The bus connector must be secured by screws

6 Check the shields of the individual cables 7 Turn on the power supplies -

5.3 Checklist for Configuration/Parameter Assignment

-

-

-

-

-

-

T able 5-2 Checklist for Configuration/Parameter Assignment

Step

1 Have you copied the GSE file and the bitmap file to the local module

catalog? (see Section 4.1)

2 Does the PROFIBUS address set on the module match the configured

address?

3 Have you set the user-specific parameter assignment data for the DP

attachment to 40H, 20H, 00H? (see Section B.2.2)

4 Have you configured the technological slot depending on your requirements

to ”Q4 words/I12 words” or ”Q4 words/I12 words consistent”? (see Section

B.1)

5 Have you set the user-specific parameters to values suitable for the position

encoder being used?

IM 178-4

C79000-G7076-C178-01

What needs to be done?

-

-

-

-

-

5-3

Page 32

Preparing for Startup

5-4

C79000-G7076-C178-01

IM 178-4

Page 33

Functions of the IM 178-4

6.1 Description of the Functions

6.1.1 Cyclic Processing

The user data area of the outputs is evaluated and the user data area of the inputs

is updated cyclically (for the update rate, refer to Section A.1).

Detecting the Actual Position Value with Absolute Position Encoders

When using absolute position encoders (13, 21 or 25 bit frame), then depending on

the parameter assignment, the sensor signals are sent and normalized via a

selectable serial Gray/binary converter. By using the normalization function, you

can shift out a selectable number of bits following the sensor values. Some

sensors provide additional information in these subsequent bits, such as power

error or to indicate that a limit value has been reached. If the absolute position

encoder you are using supplies less bits than the selected frame contains, the

following bits must either be masked out in your program or shifted out by

normalization.

6

Gray code sensors whose frame does not begin with the MSB can only be used

when all the preceding bits (special bits such as power error) always have the

value 0.

The IM 178-4 enters the actual position value as a 32-bit value in the user data

area of the inputs. If an SSI frame error occurs, the last correct actual position

value is retained.

The Synchronization parameter is not evaluated.

IM 178-4

C79000-G7076-C178-01

6-1

Page 34

Functions of the IM 178-4

Detecting the Actual Position Value With Incremental Sensors

The count pulses are always evaluated four times. If signal sequence A comes

before signal sequence B, this means movement in a positive direction. You can

invert the direction of movement by changing the parameter setting for the sensor

type to ”Incremental Sensor Inverted”.

If there is a line fault, sensor fault or zero mark error, the actual position value

continues to be updated but is incorrect.

Apart from the cyclic updating of the actual position value, the IM 178-4 detects the

current direction of movement and enters this in the status bit +/– of the user data

area of the inputs.

The parameters Gray/binary converter, baud rate, monoflop time, normalization

are not evaluated.

Analog Output

You specify the setpoint for the rotational speed as a 16–bit value: Bit 15 contains

the sign, bits 14 to 2 contain the value, bits 0 and 1 are irrelevant.

Table 6-1 Range of Values of the Rotational Speed Setpoint

INT Value

0 to +32767 0 V to + FS

–1 to –32768 –1,2 mV to – FS

+30440 +10 V

For full scale (FS), approximately 10.763 V is set.

Detecting the Actual Reference Value

The actual reference value is detected as follows:

S Depending on the digital input I0 (corresponding control bit: REF0) or

S With digital input I1 and the zero mark (corresponding control bit: REF1),

however only when using incremental sensors.

On the IM 178-4, both methods for detecting the actual reference value cannot be

active at the same time. If you set the control bits REF0 and REF1 simultaneously

in the user data area of the outputs; with an incremental encoder, the actual

reference value detection is started with I1 and zero mark; with an absolute

position encoder, the actual reference value detection is started with I0.

Once you have started detection of the actual reference value, you must complete

this in a defined manner before the function can be started again. This is described

below.

Corresponds to

6-2

C79000-G7076-C178-01

IM 178-4

Page 35

Detecting the Actual Reference Value Dependent on I0

By setting parameters (edge selection I0), you decide when the actual reference

value will be detected, as follows:

S On the falling edge of I0

S On the rising edge of I0

S On both edges of I0

The following mechanism is used to detect the actual reference value for each

channel:

S You trigger the function by assigning the value TRUE to the REF0 control bit.

This is only possible when at this time the REF0_Q status bit has the value

FALSE.

S The next time that the selected edge condition is satisfied by I0, the IM 178-4

generates the actual reference value and enters it in the user data area of the

inputs. The module then sets the REF0_Q status bit of the corresponding

channel.

Functions of the IM 178-4

S You can now evaluate the actual reference value and terminate detection of the

actual reference value by resetting the REF0 control bit.

S Following this, the module resets the REF0_Q status bit. Detection of the actual

reference value can now be started again.

Control bit

REF0

t

Digital

input I0

Status bit

REF0_Q

Figure 6-1 Handshaking between the user program and IM 178-4 during actual reference

value detection with a rising edge at I0.

User requests

actual reference

value detection

IM 178-4 signals

existence of the new

actual reference value

User terminates

actual reference

value detection

t

t

IM 178-4

C79000-G7076-C178-01

6-3

Page 36

Functions of the IM 178-4

Detecting the Actual Reference Value With I1 and Zero Mark

The actual reference value is detected on the rising edge of the first zero mark

after a falling edge is detected at digital input I1. This type of actual reference

value detection is only possible with incremental sensors.

The actual reference value is acquired using a mechanism analogous to that

described above for I0. You start the function by setting the REF1 control bit. A

new actual reference value exists when the IM 178-4 has set the REF1_Q status

bit. If you reset the REF1 status bit, the module clears the REF1_Q status bit.

Following this, detection of the actual reference value can be started again.

Synchronization

Synchronization means the resetting of the actual position value. This is only

possible with incremental encoders. You specify the conditions for synchronization

during parameter assignment.

The following synchronization conditions are possible:

S Trigger by software (setting the SYN control bit)

S Rising edge of the zero mark

S Rising edge of digital input I1

S Digital input I1 and zero mark (first rising edge of the zero mark after falling

edge at I1)

The mechanism for synchronization by the software is as follows:

S You start the function by assigning the value TRUE to the SYN control bit.

S The IM 178-4 sets the SYN_Q status bit and performs the synchronization

(SYNC = 1).

S You complete synchronization by resetting the SYN control bit.

S Following this, the module resets the SYN_Q status bit.

6-4

C79000-G7076-C178-01

IM 178-4

Page 37

Control bit

SYN

Functions of the IM 178-4

User terminates

synchronization after

detecting SYN_Q=1.

User requests

Status bit

SYN_Q

status bit

SYNC

Figure 6-2 Handshaking Between the User Program and IM 178-4 with Software

Synchronization

synchronization

t

t

t

If synchronization is started using the zero mark, I1, or zero mark and I1, the

IM 178-4 does not monitor the SYN control bit for a rising edge, but for the value

TRUE. If SYN has the value TRUE, then each time the synchronization condition

occurs, the actual position value is reset and marked as synchronized (SYN status

bit has the value TRUE). SYN_Q is not set.

This allows you, for example, to implement a rotary axis with incremental sensors.

6.1.2 Error Monitoring

Startup Tests

During its startup, the IM 178-4 tests the hardware. If a fault is detected, only the

SF LED is lit (see Section 7.1) and the module does not change to normal

operation.

Watchdog

Watchdog timers monitor the module functions. If a timeout occurs, the SF LED is

lit (see Section 7.1) and the module stops normal functions. You can only clear this

status by turning off the 24 V module power supply (1L+) and then turning it on

again.

IM 178-4

C79000-G7076-C178-01

6-5

Page 38

Functions of the IM 178-4

Monitoring Position Encoder Errors

If the parameter assignment is free of errors, the IM 178-4 monitors the connected

position encoders. Any errors detected are indicated in the EXTF0, EXTF1 and

EXTF2 status bits of each of the two channels. If you have enabled diagnostic

interrupts, an external diagnostic message is also generated.

The mechanism for detecting and acknowledging an error is as follows:

S The IM 178-4 detects a position encoder error and then sets the EXTF0,

EXTF1 or EXTF2 bit for the channel affected. This is only possible when none

of the bits EXTF0, EXTF1, EXTF2 of the affected channel is set at the time

when the error is detected and the group error acknowledgment EXTF_Q of the

channel has the value FALSE.

S You can eliminate the indicated error and acknowledge it by assigning the value

TRUE to the EXTF_Q bit of the affected channel.

S The module then clears the EXTF0, EXTF1 or EXTF2 bit belonging to the

position encoder error. When resetting the bit, the module does not check

whether the original position encoder error still exists nor whether another

position encoder error has occurred for this channel.

S You assign the value FALSE to the EXTF_Q bit of the corresponding channel.

Following this, the module resumes error monitoring.

Status bit

EXTF0

t

IM 178-4 detects

position encoder

error

Status bit

EXTF_Q

t

LED SF

lights up

Figure 6-3 Handshaking Between the IM 178-4 and User Program When a Position

Encoder Error Occurs (Example EXTF0)

6-6

If a position encoder error occurs, the SF LED is lit until the error is eliminated and

you assign the value TRUE to the EXTF_Q bit of the affected channel.

If the error is eliminated in the Stop mode of the CPU (CLEAR mode), it does not

need to be acknowledged.

C79000-G7076-C178-01

IM 178-4

Page 39

Table 6-2 Overview of Position Encoder Errors

Functions of the IM 178-4

T ype of Error

Start/stop bit error Absolute posi-

Edge error Incremental

Sensor signal

cable error

Zero mark monito-

ring error

Sensors with

Which Error is

Possible

tion encoder

(SSI)

sensor

Absolute

position

encoder (SSI)

and

incremental

encoder

Incremental

sensor

Possible Causes of the

Error

S Sensor cable not

connected

S Break on the sensor cable

S Parameters on the

IM 178-4 do not match the

connected sensor

S Sensor defective

S Interference

Interference on the sensor

cable

S Wire break

S Cable not plugged in

S Short–circuit between

wires, to ground or to

sensor power supply

S Interference on the sensor

cable

S Sensor defective

Reaction of the

IM 178-4

S EXTF1 status

bit (sensor

error) is set

S Last correct

actual value is

retained

EXTF1 status bit

(sensor error) is

set

EXTF0 status bit

(sensor signal

cable error) is set

S EXTF2 status

bit (zero mark

error) is set

S Synchroni-

zation is

cleared, SYNC

status bit is

reset

Zero Mark Monitoring

Zero mark monitoring is only possible when using an incremental sensor with at

least 4 increments (corresponds to 16 count pulses) per revolution. After assigning

parameters to the IM 178-4, zero mark monitoring is only active after successful

synchronization (synchronization condition rising edge of the zero mark or digital

input I1 and zero mark).

IM 178-4

C79000-G7076-C178-01

6-7

Page 40

Functions of the IM 178-4

pp(g

6.2 User Data Interface

Addresses

The inputs and outputs of the IM 178-4 are addressed starting at the input or

output module base address.

Assignment of the User Data Area of the Outputs

Table 6-3 User Data Area of the Outputs

Byte

Bit Name or Value Meaning Data Format

Channel 0

0 0 0Q0 Digital output 0 BOOL

1 0Q1 Digital output 1 BOOL

2 0Q2 Digital output 2 BOOL

3 0 reserved

4 0 reserved

5 0 reserved

6 0 reserved

7 E0AO Enable analog output BOOL

1 0 REF1 Trigger actual reference value detection

with OI1 and zero mark

1 REF0 Trigger actual reference value detection

with 0I0

2 SYN Trigger synchronization BOOL

3 0 reserved

4 0 reserved

5 0 reserved

6 0 reserved

7 EXTF_Q Group error acknowledgment BOOL

2 Rotational speed setpoint (bit15: sign, bit

3

2 to 14: value, bit 0 and 1: irrelevant)

BOOL

BOOL

INT

6-8

C79000-G7076-C178-01

IM 178-4

Page 41

Functions of the IM 178-4

pp(g

Table 6-3 User Data Area of the Outputs

Byte Data FormatMeaningName or ValueBit

Channel 1

4 0 1Q0 Digital output 0 BOOL

1 1Q1 Digital output 1 BOOL

2 1Q2 Digital output 2 BOOL

3 0 reserved

4 0 reserved

5 0 reserved

6 0 reserved

7 E1AO Enable analog output BOOL

5 0 REF1 Trigger actual reference value detection

with 1I1 and zero mark

1 REF0 Trigger actual reference value detection

with 1I0

2 SYN Trigger synchronization BOOL

3 0 reserved

4 0 reserved

5 0 reserved

6 0 reserved

7 EXTF_Q Group error acknowledgment BOOL

6 Rotational speed setpoint (bit15: sign, bit

7

2 to 14: value, bit 0 and 1: irrelevant)

BOOL

BOOL

INT

IM 178-4

C79000-G7076-C178-01

6-9

Page 42

Functions of the IM 178-4

p

Assignment of the User Data Area of the Inputs

Table 6-4 User Data Area of the Inputs

Byte

Bit Name or Value Meaning Data Format

Channel 0

0 0 REF1_Q Acknowledgment for actual reference

value detection with 0I1 and zero mark

1 REF0_Q Acknowledgment for actual reference

value detection with 0I0

2 SYN_Q Acknowledgment for synchronization BOOL

3 0 reserved

4 +/– Direction of movement (0=negative di-

rection, 1=positive direction)

5 SYNC Actual value synchronized (only valid

after setting SYN)

6 P ARA Channel parameter assignment error–

free

7 – irrelevant

1 0 0I0 Digital input 0 BOOL

1 0I1 Digital input 1 BOOL

2 0I2 Digital input 2 BOOL

3 0 reserved

4 EXTF0 Sensor signal cable error 0 BOOL

5 EXTF1 Sensor error BOOL

6 EXTF2 Zero mark error BOOL

7 0 reserved

2

0000

3

4

5

H

reserved

BOOL

BOOL

BOOL

BOOL

BOOL

6

7

8

9

10

11

6-10

Actual position value Channel 0

Actual reference value Channel 0

C79000-G7076-C178-01

DINT

DINT

IM 178-4

Page 43

Functions of the IM 178-4

Table 6-4 User Data Area of the Inputs

Byte Data FormatMeaningName or ValueBit

Channel 1

12 0 REF1_Q Acknowledgment for actual reference

value detection with 1I1 and zero mark

1 REF0_Q Acknowledgment for actual reference

value detection with 1I0

2 SYN_Q Acknowledgment for synchronization BOOL

3 0 reserved

4 +/– Direction of movement (0=negative di-

rection, 1=positive direction)

5 SYNC Actual value synchronized (only valid

after setting SYN)

6 P ARA Channel parameter assignment error–

free

7 – irrelevant

13 0 1I0 Digital input 0 BOOL

1 1I1 Digital input 1 BOOL

2 1I2 Digital input 2 BOOL

3 0 reserved

4 EXTF0 Sensor signal cable error 0 BOOL

5 EXTF1 Sensor error BOOL

6 EXTF2 Zero mark error BOOL

7 0 reserved

14

15

0000

H

reserved

16

17

18

Actual position value channel 1 DINT

19

20

21

22

Actual reference value channel 1 DINT

23

BOOL

BOOL

BOOL

BOOL

BOOL

IM 178-4

C79000-G7076-C178-01

6-11

Page 44

Functions of the IM 178-4

6-12

C79000-G7076-C178-01

IM 178-4

Page 45

Diagnostics

g

y

7.1 Status and Diagnostic LEDs

2 diagnostic LEDs (red) and 13 status LEDs (green) on the front panel of the

module provide information about the state of the IM 178-4.

S The SF diagnostic LED (red, group error) basically indicates the status of the

hardware.

S The BF diagnostic LED (red, bus error) provides information about the

connection to PROFIBUS DP.

S The ON status LED (green) indicates that the module is ready for operation.

S The status LEDs 0I0, 0I1, 0I2, 0Q0, 0Q1, 0Q2, 1I0, 1I1, 1I2, 1Q0, 1Q1, 1Q2

indicate the state of the digital inputs and outputs.

IM 178-4

7

Table 7-1 ON Status LED and Diagnostic LEDs on the IM 178-4

SF

BF

ON

LEDs Meaning Remedy

ON BF SF

* * The voltage is applied to the IM 178-4,

* The IM 178-4 has incorrect parameters

SF: red

BF: red

ON:green

Hardware defect on the IM 178-4. The module is defective and must be

the module has detected no hardware

error.

– there is no data exchange between

the DP master and IM 178-4.

Causes:

S Check the PROFIBUS address.

IM 178-4

C79000-G7076-C178-01

replaced.

–

S Check the IM 178-4.

S Check the configuration and

parameter assignment.

7-1

Page 46

Diagnostics

g

y

Tabelle 7-1 ON Status LED and Diagnostic LEDs on the IM 178-4, continued

SF

BF

ON

LEDs Meaning Remedy

ON BF SF

* Transmission rate search or illegal

SF: red

BF: red

ON:green

PROFIBUS address

Causes:

S The watchdog time has elapsed

S Bus communication via PROFIBUS

DP to the IM 178-4 is interrupted

Set a valid PROFIBUS address (1 to

125) on the IM 178-4 or check the bus

structure.

S Check whether the bus connector is

correctly plugged in.

S Check whether there is a break on

the LAN cable to the DP master.

S Turn the switch for 24 V DC on the

power supply module off and on

again.

* External error on a channel or a

channel was not assigned error-free

parameters.

Data exchange between the DP master

and IM 178-4 is taking place.

Both channels are free of errors.

Check the peripherals of the channels,

check the parameter assignment

–

*

Note relevant off lit flashing

Breakdown of Bus Communication

If there is a breakdown of communication on PROFIBUS DP, for example caused

by the failure of the DP master, the digital outputs are deactivated (value 0 is

output) and 0 V is applied to the analog outputs. The diagnostic LED BF is lit (see

Table 7-1).

7-2

C79000-G7076-C178-01

IM 178-4

Page 47

7.2 Diagnostic Data of the IM 178-4

Definition

Diagnostics is the detection and localization of errors. The structure of the

diagnostic functions is specified in the standard EN 50170, Volume 2, PROFIBUS.

The diagnostic functions of the IM 178-4 comply with the standard. The slave

diagnostics of the IM 178-4 are explained in the following sections.

7.2.1 Structure of Slave Diagnostics

Structure of Slave Diagnostics

The diagnostic data of the IM 178-4 is a maximum of 29 bytes long and has the

following structure:

Diagnostics

Availability

Table 7-2 Structure of Slave Diagnostics

Byte

0 Station status 1 Information about the DP slave

1 Station status 2 Additional information about the DP

2 Station status 3 reserved

3 Master PROFIBUS address Address of the parameter

4 High byte of the vendor ID

5 Low byte of the vendor ID

6 to 8 ID-related diagnostics

9 to max. 28 Device-related diagnostics

Assignment Description

slave

assignment master

The first 6 bytes of the slave diagnostic data are always available.

The ID and device-related diagnostic data is only prepared by the IM 178-4 when

you have enabled the diagnostic interrupt in the parameter assignment.

IM 178-4

C79000-G7076-C178-01

7-3

Page 48

Diagnostics

Diagnostics When Using an S7/M7 DP Master

Requesting slave diagnostics is particularly useful when you have enabled the

diagnostic interrupt in the parameter assignment. If the IM 178-4 detects an error,

it provides external diagnostic data if this has been selected in the parameter

assignment.

You can request the slave diagnostic data using SFC13 “DPNRM_DG” (see

System and Standard Functions

reference manual).

7.2.2 Structure of the First 6 Bytes of the Slave Diagnostic Data

Structure of Station Status 1

Station status 1 provides information about the DP slave and has the following

structure:

Table 7-3 Structure of Station Status 1 (Byte 0)

Bit Meaning Remedy

0 1: The DP slave cannot be

accessed by theDP master.

S Is the correct PROFIBUS

address set on the DP slave?

S Is the bus connector plugged in?

S Voltage on the DP slave?

S RS 485 repeater set correctly?

S Reset the DP slave

1 1: The DP slave is not ready for

data exchange

2 1: The configuration data sent by

the DP master to the DP slave do

not match the structure of the DP

slave.

3 1: Device-related and/or ID-related

diagnostic data from the IM 178-4

exist.

4 1: The function is not supported, for

example modifying the PROFIBUS

address with the software.

Wait, the DP slave is currently

starting up.

Correct station type or correct

structure of the DP slave entered in

the configuration?

You can read out the diagnostic

data.

Check the configuration.

7-4

5 1: The DP master cannot interpret

the response of the DP slave.

Check the physical properties of the

bus.

C79000-G7076-C178-01

IM 178-4

Page 49

Table 7-3 Structure of Station Status 1 (Byte 0)

Bit RemedyMeaning

Diagnostics

6 1: The DP slave type does not

match the software configuration.

7 1: The DP slave was assigned

parameters by a different DP master

from the DP master currently

accessing the DP slave.

Structure of Station Status 2

Station status 2 provides further information about the DP slave and has the

following structure:

Table 7-4 Structure of Station Status 2 (Byte 1)

Bit

0 1: The DP slave must be reassigned parameters.

1 1: A diagnostic message exists. The DP slave cannot continue until the

error is cleared (static diagnostic message).

2 1: The bit is always set when a DP slave with this PROFIBUS address

exists.

3 1: The watchdog has responded.

4 1: The slave has received the “FREEZE” control command.

5 1: The DP slave has received the “SYNC” control command.

6 The bit is always reset.

7 1: The DP slave is deactivated, in other words it has been taken out of

the current processing.

Correct station type entered in the

configuration?

This bit is always 1 if, for example,

you are currently accessing the DP

slave with the programming device

or with a different DP master. The

PROFIBUS address of the

parameter assignment master is

located in the diagnostic byte

”Master PROFIBUS Address”.

Meaning

1)

1)

1)

The bit is only updated when a further diagnostic message also changes.

Structure of Station Status 3

Station status 3 is reserved and is not relevant for the diagnostics of a DP slave.

Master PROFIBUS Address

The master PROFIBUS address diagnostic byte contains the PROFIBUS address

of the DP master that assigned parameters to the DP slave.

IM 178-4

C79000-G7076-C178-01

7-5

Page 50

Diagnostics

Vendor ID

The vendor ID contains a code that describes the type of DP slave.

Table 7-5 Structure of the Vendor ID

Byte

4 80

5 64

Content

H

H

7.2.3 Structure of the ID-Related and Device-Related Slave Diagnostic Data

ID-Related Diagnostic Data

On the IM 178-4, the ID-related diagnostic data is structured as follows:

Table 7-6 Structure of the ID-Related Diagnostic Data

Byte

6 43

7 00H or 08

8 00

Content Meaning

H

H

H

Code and length (including byte 6) of the ID-related

diagnostic data

00H, is no error has occurred:

08H, if an error has occurred

reserved

Device-Related Diagnostic Data

The diagnostic data record DS 1 typical for SIMATIC S7 is entered in the

device-related diagnostic data. The data records and diagnostic data are described

for SIMATIC S7/M7 in the

Table 7-7 Structure of the Device-Related Diagnostic Data

Byte

9 14

10 01

11 4 Slot 4

12 00

13 to 28 Diagnostic data

The diagnostic data consists of a module-specific section (bytes 13 to 16) and a

channel-specific section (bytes 17 to 28).

7-6

Content Meaning

System and Standard Functions

H

H

H

Code and length (including byte 9) of the device-related diagnostic data

Code for S7 diagnostics

reserved

reference manual.

C79000-G7076-C178-01

IM 178-4

Page 51

Diagnostics

Table 7-8 Structure of the Module-Specific Section of the Diagnostic Data (1 means error)

Byte

13 0 Module fault

14 0..3 08H (ID for module class: FM)

15 0..7 00H (not used)

16 0 ..7 00H (not used)

17 0..6 74H (ID for channel type: FM-POS)

18 0..7 10H (number of diagnostic bits per channel)

19 0..7 02H (number of channels of same type)

20 0 Channel error channel 0

Bit Content/Meaning

1 Internal error

2 External error

3 Channel error exists

4 0 (not used)

5 0 (not used)

6 0 (not used)

7 0 (not used)

4 Channel information exists

5 0 (not used)

6 0 (not used)

7 0 (reserved)

7 0 (no further channel type exists)

Channel error vector

1 Channel error channel 1

2 0 (not used)

3 0 (not used)

4 0 (not used)

5 0 (not used)

6 0 (not used)

7 0 (not used)

IM 178-4

C79000-G7076-C178-01

7-7

Page 52

Diagnostics

Table 7-9 Structure of the Channel-Specific Section of the Diagnostic Data (1 means

error)

Byte Bit Content/Meaning

Channel-specific error channel 0

21 0 Sensor signal cable error (corresponds to status bit EXTF0)

1 Sensor error (corresponds to status bit EXTF1)

2 Zero mark monitoring error (corresponds to status bit EXTF2)

3 0 (not used)

4 0 (not used)

5 0 (not used)

6 0 (not used)

7 0 (not used)

22 0 Incorrect parameter assignment *

1 0 (not used)

2 0 (not used)

3 0 (not used)

4 0 (not used)

5 0 (not used)

6 0 (not used)

7 0 (not used)

Channel-specific error channel 1

23 0 Sensor signal cable error (corresponds to status bit EXTF0)

1 Sensor error (corresponds to status bit EXTF1)

2 Zero mark monitoring error (corresponds to status bit EXTF2)

3 0 (not used)

4 0 (not used)

5 0 (not used)

6 0 (not used)

7 0 (not used)

24 0 Incorrect parameter assignment *

1 0 (not used)

2 0 (not used)

3 0 (not used)

4 0 (not used)

5 0 (not used)

6 0 (not used)

7 0 (not used)

7-8

C79000-G7076-C178-01

IM 178-4

Page 53

Diagnostics

Table 7-9 Structure of the Channel-Specific Section of the Diagnostic Data (1 means

error)

Byte Content/MeaningBit

reserved

25 0..7 00H (reserved)

26 0..7 00H (reserved)

27 0..7 00H (reserved)

28 0..7 00H (reserved)

* For example incorrect sensor type or reserved values not 0 or normalization value too high.

IM 178-4

C79000-G7076-C178-01

7-9

Page 54

Diagnostics

7-10

C79000-G7076-C178-01

IM 178-4

Page 55

Technical Specifications

UL/CSA Approval

The following approvals exist for the IM 178-4:

UL Recognition Mark

Underwriters Laboratories (UL) complying with

Standard UL 508, File E 116536

CSA Certification Mark

Canadian Standard Association (CSA) complying with

Standard C 22.2 No. 142, File LR 48323

A

IM 178-4

C79000-G7076-C178-01

A-1

Page 56

Technical Specifications

FM Approval

The FM approval exists for the S7-300:

FM approval complying with Factory Mutual Approval Standard Class Number

3611, Class I, Division 2, Group A, B, C, D.

!

Warning

Personal injury and damage to property are possible.

Warning

!

WARNING - DO NOT DISCONNECT WHILE CIRCUIT IS LIVE UNLESS

LOCATION IS KNOWN TO BE NONHAZARDOUS

CE Approval

Our products meet the requirements and aims of the following EU directives and

are in accordance with the harmonized European standards (EN) published in the

official documentation of the European Union for programmable logic controllers,

as follows:

S 89/336/EEC “Electromagnetic Compatibility” (EMC directive)

S 73/23/EEC ”Electrical Equipment for Use within Certain Voltage Limits”

In accordance with the directives listed above, the EU conformity certificates are

kept for the relevant authorities at the following address:

Application

SIMATIC products are designed for use in an industrial environment.

(extra-low voltage directive)

Siemens Aktiengesellschaft

Bereich Automatisierungstechnik

A&D AS E 48

Postfach 1963

D-92209 Amberg

Application Requirements for

Noise emission Noise immunity

Industry EN 50081-2 : 1993 EN 50082-2 : 1995

A-2

C79000-G7076-C178-01

IM 178-4

Page 57

Adherence to Installation Instructions

SIMATIC products meet the requirements providing you adhere to the installation

and start up instructions in the manuals during installation and operation.

General Technical Specifications

General technical specifications are as follows:

S Electromagnetic compatibility

S Transport and storage conditions

S Mechanical and environmental conditions

S Information about isolation tests, class of protection and degree of protection.

The general technical specifications include standards and test values with which

the S7-300 complies and meets or indicates the test criteria with which the S7-300

was tested. The general technical specifications can be found in the manual

S7-300 Programmable Controller, Hardware and Installation, CPU Data

Technical Specifications

.

IM 178-4

C79000-G7076-C178-01

A-3

Page 58

Technical Specifications

A.1 Technical Data of the IM 178-4

Dimensions and Weight

Dimensions W x H x D

(mm)

Weight approx. 460 g

V oltages, Currents, Potentials

Auxiliary voltage 1L+/M

S Range

S Reverse polarity

protection

S Electrical isolation

Load voltage 2L+/2M

S Range

S Reverse polarity

protection

S Electrical isolation

Sensor power supply 5.2 V

S Output voltage

S Output current

Sensor power supply 24 V

S Output voltage

S Output current

Current consumption

S from 1L+ (no load)

S from 2L+ (no load)

Power dissipation of the

module

Status, Interrupts,

Diagnostics

Status display yes, 13 green LEDs

Diagnostic functions

80 x125 x120

1L+

20.4 to 28.8 V

no

yes from DP

interface and

2L+/2M

2L+

20.4 to 28.8 V

no

yes, from DP

interface and 1L+/M

5.2 V ±5%

max. 600 mA,

short-circuit proof

1L+ – 0.8 V

max. 500 mA,

short-circuit proof

approx. 135 mA

approx. 5 mA

approx. 7 W

for Status

yes

S Fault display on module

for group fault

S Fault display on module

for bus fault

S Diagnostic information

readable

yes, red LED

yes, red LED

yes

Specifications of the Inputs and Outputs

Sensor inputs

Position detection

Signal voltages

Data transfer rate and cable

length for absolute position

encoders (shielded)

incremental1),

absolute

symmetrical inputs:

5 V to RS 422

S at 125 kHz

max. 320 m

S at 250 kHz

max. 160 m

S at 500 kHz

max. 60 m

S at 1 MHz

max. 20 m

Input frequency and cable

length for incremental encoders with 5 V supply (shielded)

Input frequency and cable

length for incremental encoders with 24 V supply

(shielded)

Input signals

S incremental

S absolute

max. 1 MHz at 32 m

max. 1 MHz at

100 m

2 pulse trains, 90 °

shift, 1 zero pulse

SSI frame

A-4

C79000-G7076-C178-01

IM 178-4

Page 59

Technical Specifications

Digital inputs

S Input voltage

S Input current

S input delay of 0I0, 1I0

S Input delay of 0I1, 0I2,

1I1, 1I2

S Electrical isolation

S Cable length shielded

S Coincidence factor

with horizontal

installation

with vertical installation

S Status display

0 signal: – 3 to +

5 V; 1 signal: 11 V to

30.2 V

0 signal: v 2 mA

1 signal: 9 mA

(typical)

max. 50 ms

typical 3 ms

yes, from DP

interface and sensor

signals

100 m

2)

up to 40 ° C: 100%

up to 60 ° C: 100%

up to 40 ° C: 100%

yes, green LED

Digital outputs

S Output current

S Coincidence factor

S Status display

S Output delay

S Signal level for 1 signal

S Activation of a standard

digital input

S Activation of a fast

digital input

S Short-circuit proof

S Limitation of inductive

circuit interruption

voltage

S Switching rate

S Aggregate current of all

digital outputs with

horizontal installation

S Aggregate current of all