Siemens SIMATIC HMI Series, SIMATIC IFP V2, SIMATIC IFP V2 PRO Operating Instructions Manual

SIMATIC HMI

Industrial Flat Panels V2

IFP V2, IFP V2 PRO

Operating Instructions

08/2019

A5E46641410

Preface

Overview

1

Safety information

2

Installing and connecting the

device

3

Commissioning the IFP

4

Operating the IFP

5

Maintaining and servicing

your device

6

Technical information

7

Technical Support

A

Markings and symbols

B

List of abbreviations

C

IFP V2, IFP V2 PRO

-AA

Siemens AG

Digital Industries

Postfach 48 48

90026 NÜ

GERMANY

Ⓟ

Copyright © Siemens AG 2019.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

RNBERG

08/2019 Subject to change

Preface

These operating instructions contain all the information you need for commissioning and

using the Industrial Flat Panel SIMATIC IFP V2 and the Transceiver Unit.

These operating instructions are intended both for programming and testing personnel who

commission the devices and connect them to other units (automation systems, programming

devices), and for service and maintenance technicians who carry out maintenance work or

fault analyses.

Basic knowledge required

A solid background in personal computers and Microsoft operating systems is required to

understand this manual. General knowledge in the field automation control engineering is

recommended.

Scope of the operating instructions

These operating instructions apply to the following SIMATIC IFP V2 devices with article

numbers 6AV7863-.....-2...:

● SIMATIC IFP1500 V2, IFP1900 V2, IFP2200 V2, IFP2400 V2

● SIMATIC IFP1500 V2 extended, IFP1900 V2 extended, IFP2200 V2 extended,

IFP2400 V2 extended

● SIMATIC IFP1500 V2 PRO, IFP1900 V2 PRO, IFP2200 V2 PRO

These operating instructions for the Transceiver Unit with the article number

6AV7860-3EH00-0AA0 also apply.

Scope of this documentation

With the SIMATIC IFP V2 you receive the following documents:

● In printed form: Quick Install Guide for installation and commissioning

● Electronically as PDF file on the "Documentation and Drivers" CD/DVD:

– "IFP V2, IFP V2 PRO" operating instructions

– "Panel Drivers and Tools PDT" operating manual

You can find the Operating Manual in the PDT installation directory after PDT has

been installed.

With the Transceiver Unit you receive a Quick Install Guide in printed form.

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

3

Preface

Edition

Comment

08/2019

First Edition

Conventions

The following conventions apply in these operating instructions:

● The term "device" is used for all SIMATIC IFP V2 devices, SIMATIC IFP V2 PRO devices

and the Transceiver Unit.

● The term "IFP" is also used for all SIMATIC IFP V2 devices and SIMATIC IFP V2 PRO

devices.

● The devices IFP1500 V2, IFP1900 V2, IFP2200 V2 and IFP2400 V2 are referred to as

"standard versions" of the SIMATIC IFP V2 devices.

● The devices IFP1500 V2 extended, IFP1900 V2 extended, IFP2200 V2 extended and

IFP2400 V2 extended are called "extended versions" of the SIMATIC IFP V2 devices.

● The standard versions and extended versions are referred to as "built-in devices".

● The devices IFP1500 V2 PRO, IFP1900 V2 PRO and IFP2200 V2 PRO are referred to as

"PRO devices".

● The projective-capacitive multi-touch screen of the devices is also referred to as

"capacitive multi-touch screen" or "touch screen".

The following applies to the possible operating modes of an IFP:

Figures

History

● In "standard mode", an IFP is directly connected to the PC via a USB cable and a

DVI/DisplayPort cable ≤ 5 m long.

● In "Extended mode", an extended version or a PRO device can be connected via a

Cat. 6A Ethernet cable > 5 m and the Transceiver Unit connected to the PC.

This manual contains figures of the described devices. The supplied device may differ in

some details from the figures. Within some of the figures, one device is used to represent

several devices.

Picture components are marked with black position numbers on a white background

①, ②, ③, etc.

Steps in the figures are identified with white process numbers on a black background

according to the sequence in which they have to be executed: , , , ...

The following earlier release versions of these operating instructions have been published:

IFP V2, IFP V2 PRO

4 Operating Instructions, 08/2019, A5E46641410-AA

Table of contents

Preface ........................................................................................................................................ 3

1 Overview ...................................................................................................................................... 9

1.1 Product description .............................................................................................................. 9

1.2 Scope of delivery of the IFPs ............................................................................................. 11

1.3 Structure of the built-in devices .......................................................................................... 12

1.4 Design of the PRO devices ................................................................................................ 14

1.4.1 PRO devices for support arm (not extendable, flange top) ................................................. 14

1.4.2 PRO devices for pedestal (extendable, flange bottom) ....................................................... 15

1.4.3 PRO devices for support arm (extendable, round tube) ...................................................... 17

1.5 Interfaces .......................................................................................................................... 18

1.6 System components and accessories ................................................................................ 18

1.6.1 System components for IFPs ............................................................................................. 19

1.6.2 System components for PRO devices ................................................................................ 21

1.6.3 Accessories ....................................................................................................................... 25

2 Safety information ....................................................................................................................... 27

2.1 General safety instructions ................................................................................................ 27

2.2 Notes about usage ............................................................................................................ 30

2.3 Use in hazardous areas ..................................................................................................... 33

3 Installing and connecting the device .............................................................................................. 35

3.1 Preparing for installation .................................................................................................... 35

3.1.1 Checking the delivery package .......................................................................................... 35

3.1.2 Built-in devices .................................................................................................................. 37

3.1.2.1 Permitted mounting positions ............................................................................................. 37

3.1.2.2 Required clearance ........................................................................................................... 39

3.1.2.3 Preparing the mounting cutout ........................................................................................... 40

3.1.2.4 Installing a strain relief ....................................................................................................... 41

3.1.3 PRO devices ..................................................................................................................... 42

3.1.3.1 Permitted mounting positions ............................................................................................. 42

3.1.4 Transceiver Unit ................................................................................................................ 43

3.1.4.1 Permissible mounting positions.......................................................................................... 43

3.1.4.2 Required clearance ........................................................................................................... 43

3.1.4.3 Fastening the mounting rail ............................................................................................... 44

3.2 Installing the built-in unit .................................................................................................... 45

3.2.1 Notes on installation .......................................................................................................... 45

3.2.2 Positions of the mounting clips .......................................................................................... 45

3.2.3 Fasten built-in device using mounting clips ........................................................................ 47

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

5

Table of contents

3.3 Mounting the PRO device ...................................................................................................49

3.3.1 Notes on mounting .............................................................................................................49

3.3.2 PRO devices for support arm (not extendable, flange top) and for pedestal

(extendable, flange bottom) ................................................................................................51

3.3.3 PRO devices for support arm (extendable, round tube) .......................................................53

3.4 Installing Transceiver Unit ..................................................................................................56

3.5 Connecting the device ........................................................................................................58

3.5.1 Notes on connection ...........................................................................................................58

3.5.2 Connecting the equipotential bonding circuit .......................................................................60

3.5.3 Connecting the power supply..............................................................................................62

3.5.4 Connecting the IFP to a PC ................................................................................................64

3.5.4.1 Important notes for connecting ...........................................................................................64

3.5.4.2 Connecting the standard version to a PC ............................................................................65

3.5.4.3 Connect extended version or PRO device to PC .................................................................66

3.5.5 Connecting the USB device to the IFP ................................................................................69

3.5.6 Securing the cables ............................................................................................................70

3.5.6.1 Securing cables at the IFP..................................................................................................70

3.5.6.2 Secure cables at the Transceiver Unit ................................................................................71

3.5.6.3 Securing cables for use in hazardous areas........................................................................72

3.6 Removing the device ..........................................................................................................73

3.6.1 Removing the built-in unit ...................................................................................................73

3.6.2 Removing a PRO device ....................................................................................................73

3.6.3 Removing Transceiver Unit ................................................................................................74

4 Commissioning the IFP ................................................................................................................ 75

5 Operating the IFP........................................................................................................................ 77

5.1 Operator input options ........................................................................................................77

5.2 Operating the capacitive multi-touch screen........................................................................78

5.3 Extended functions .............................................................................................................80

6 Maintaining and servicing your device ........................................................................................... 81

6.1 General information on maintenance and servicing .............................................................81

6.2 Cleaning the device ............................................................................................................81

6.3 Spare parts and repairs ......................................................................................................82

6.4 Recycling and disposal .......................................................................................................82

7 Technical information .................................................................................................................. 83

7.1 Certificates and approvals ..................................................................................................83

7.2 Electromagnetic compatibility .............................................................................................88

7.3 Mechanical environmental conditions .................................................................................90

7.3.1 Storage conditions..............................................................................................................90

7.3.2 Operating Conditions ..........................................................................................................90

7.4 Climatic ambient conditions ................................................................................................91

7.4.1 Long-term storage ..............................................................................................................91

7.4.2 Transport and short-term storage .......................................................................................91

7.4.3 Operating Conditions ..........................................................................................................92

IFP V2, IFP V2 PRO

6 Operating Instructions, 08/2019, A5E46641410-AA

Table of contents

7.5 Information on insulation tests, protection class and degree of protection ........................... 93

7.6 Dimension drawings .......................................................................................................... 95

7.6.1 Dimension drawing of the IFP1500 V2 and IFP1500 V2 extended ...................................... 95

7.6.2 Dimension drawing of the IFP1900 V2 and IFP1900 V2 extended ...................................... 96

7.6.3 Dimension drawing of the IFP2200 V2 and IFP2200 V2 extended ...................................... 97

7.6.4 Dimension drawing of the IFP2400 V2 and IFP2400 V2 extended ...................................... 98

7.6.5 Dimension drawing of the IFP1500 V2 PRO ...................................................................... 99

7.6.6 Dimension drawing of the IFP1900 V2 PRO .................................................................... 102

7.6.7 Dimension drawing of the IFP2200 V2 PRO .................................................................... 105

7.6.8 Dimension drawing of the Transceiver Unit ...................................................................... 108

7.7 Rating plate ..................................................................................................................... 108

7.8 Technical specifications of the IFPs ................................................................................. 109

7.9 Technical specifications of the Transceiver Unit ............................................................... 111

7.10 Interface description ........................................................................................................ 111

7.10.1 24 V DC .......................................................................................................................... 111

7.10.2 DVI-D .............................................................................................................................. 112

7.10.3 DisplayPort ...................................................................................................................... 113

7.10.4 USB hub Type A.............................................................................................................. 113

7.10.5 USB Type B .................................................................................................................... 114

7.10.6 RJ45 ............................................................................................................................... 114

A Technical Support ..................................................................................................................... 115

A.1 Service and support ........................................................................................................ 115

B Markings and symbols ............................................................................................................... 117

B.1 Safety-relevant symbols .................................................................................................. 117

C List of abbreviations ................................................................................................................... 119

Glossary ................................................................................................................................... 121

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

7

Table of contents

IFP V2, IFP V2 PRO

8 Operating Instructions, 08/2019, A5E46641410-AA

1

1.1 Product description

SIMATIC IFPs are industrial LCD monitors with a brilliant TFT display that can be connected

to SIMATIC IPCs and to almost all commercially available PCs.

Features of the built-in units

● Rugged front in different design versions

● Brilliant TFT display with high viewing angle, Full HD resolution and up to 16 million

colors

● Capacitive multi-touch screen in all sizes, switchable via software from multi-touch mode

to single-touch mode

● Can be placed up to 5 m from the IPC

● DVI-D and DisplayPort V1.2 interface

● Multi-monitoring support

● Backlighting can be dimmed via software

● Two USB 2.0 ports

● Power supply 24 V DC, AC power supply unit available as system component

● In installed condition, front degree of protection IP65 or Enclosure Type 4X/12 (indoor use

only, front face only)

Features of the extended versions

The extended versions have a DisplayPort V1.2 interface and the following features in

addition to the built-in devices:

● Possible via Transceiver Unit up to 100 m distance to the PC

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

9

Overview

1.1 Product description

Features of the PRO devices

The PRO devices are connected to a 24 V DC power supply and have the following features

in addition to the extended versions:

● All-round dust-proof and splash-proof with degree of protection IP65 and

Enclosure Type 4X/12 (indoor use only)

● Can be mounted directly on the machine

● Device versions for mounting:

– PRO device for pedestal (extendable, flange bottom)

– PRO device for support arm (not extendable, flange top)

– PRO device for support arm (extendable, round tube)

Adapters and adapter sets that can be ordered separately support mounting systems

from various manufacturers.

– Base adapter, included in the product package of PRO devices for pedestal

(extendable, flange bottom) and for support arm (not extendable, flange top).

– With PRO devices for support arm (extendable, round tube):

- Cover for the mechanical interface below, included in the product package

- Flange mount adapter available as accessory

IFP V2, IFP V2 PRO

10 Operating Instructions, 08/2019, A5E46641410-AA

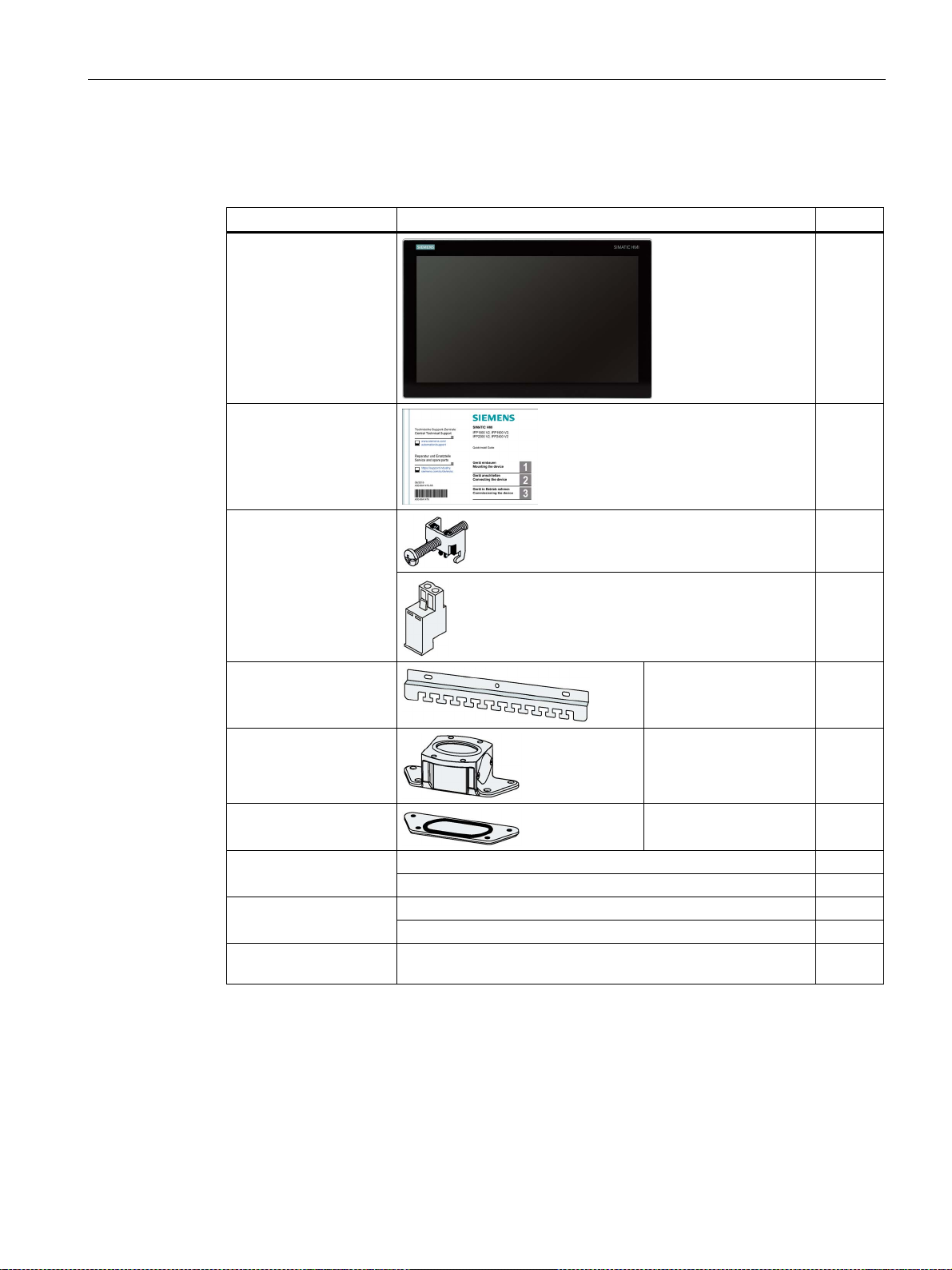

Overview

Name

Figure

Number

DisplayPort cable, length 2 m

1

USB cable Type B connector - Type A connector, length 2 m

1

Ferrite for power supply cables, white

1

Ferrite for the Ethernet cable to the Transceiver Unit, black

1

Drivers" DVD

1

2

3

4

5

Only for extended versions and PRO devices

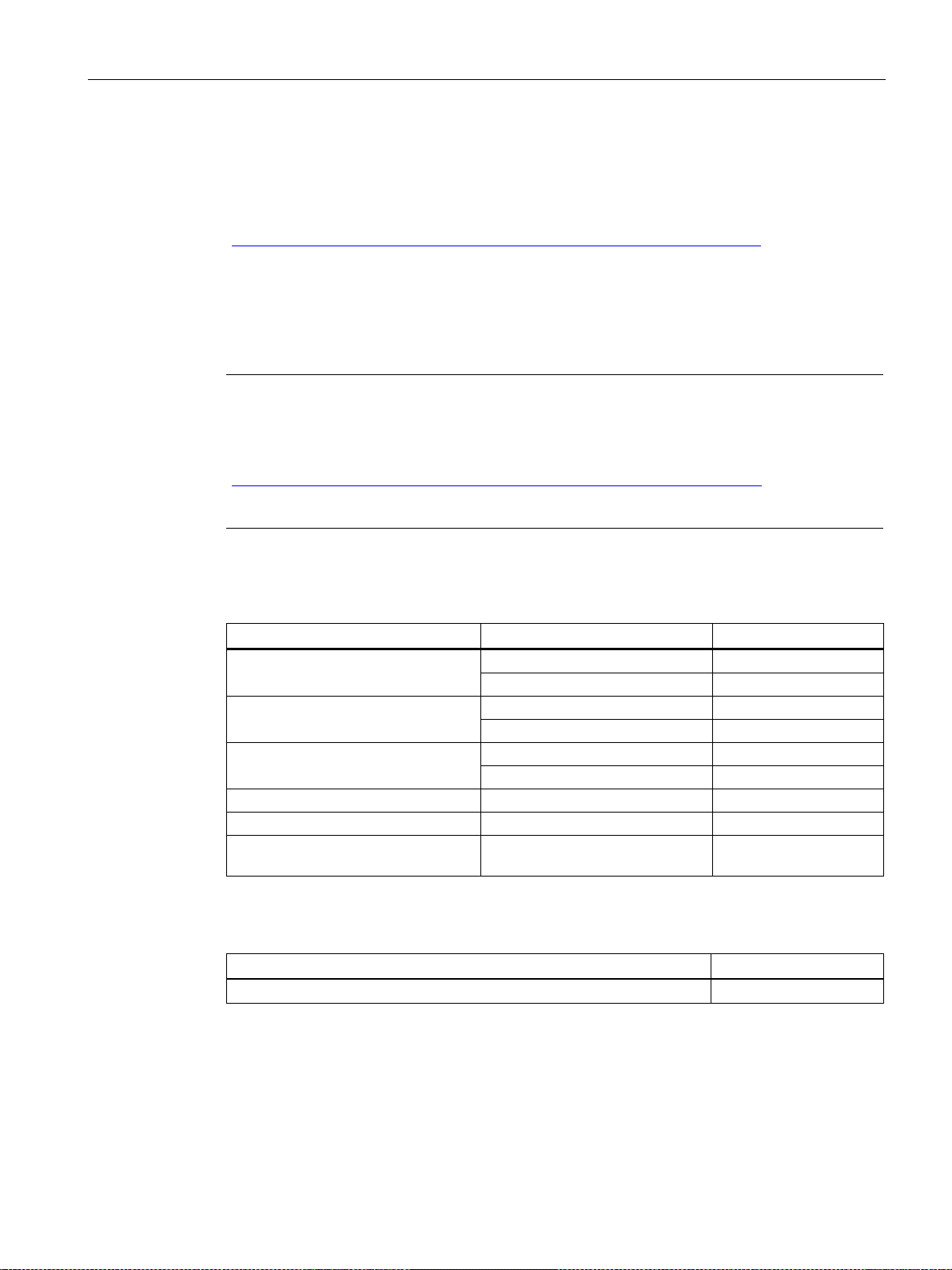

1.2 Scope of delivery of the IFPs

1.2 Scope of delivery of the IFPs

The product package includes the following components:

IFP

Installation instructions

(Quick Install Guide)

Accessory kit

"Mounting clips

1

and

power supply connector"

Strain relief plate 1

Including 3 screws T10,

M3x8

1

1

12

1

1

Base adapter 2

Cover for mechanical

3

interface

"Connecting cables"

4

accessory kit

Ferrites 5

"Documentation and

Only for built-in devices, not for PRO devices

Only with PRO devices for pedestal (extendable, flange bottom) and for support arm (not

extendable, flange top)

Only with PRO devices for support arm (extendable, round tube)

Only for standard versions

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

Including 4 screws T20,

M4x12

Including 4 screws T20,

M4x12

Includes software, drivers, and documentation 1

1

1

11

Overview

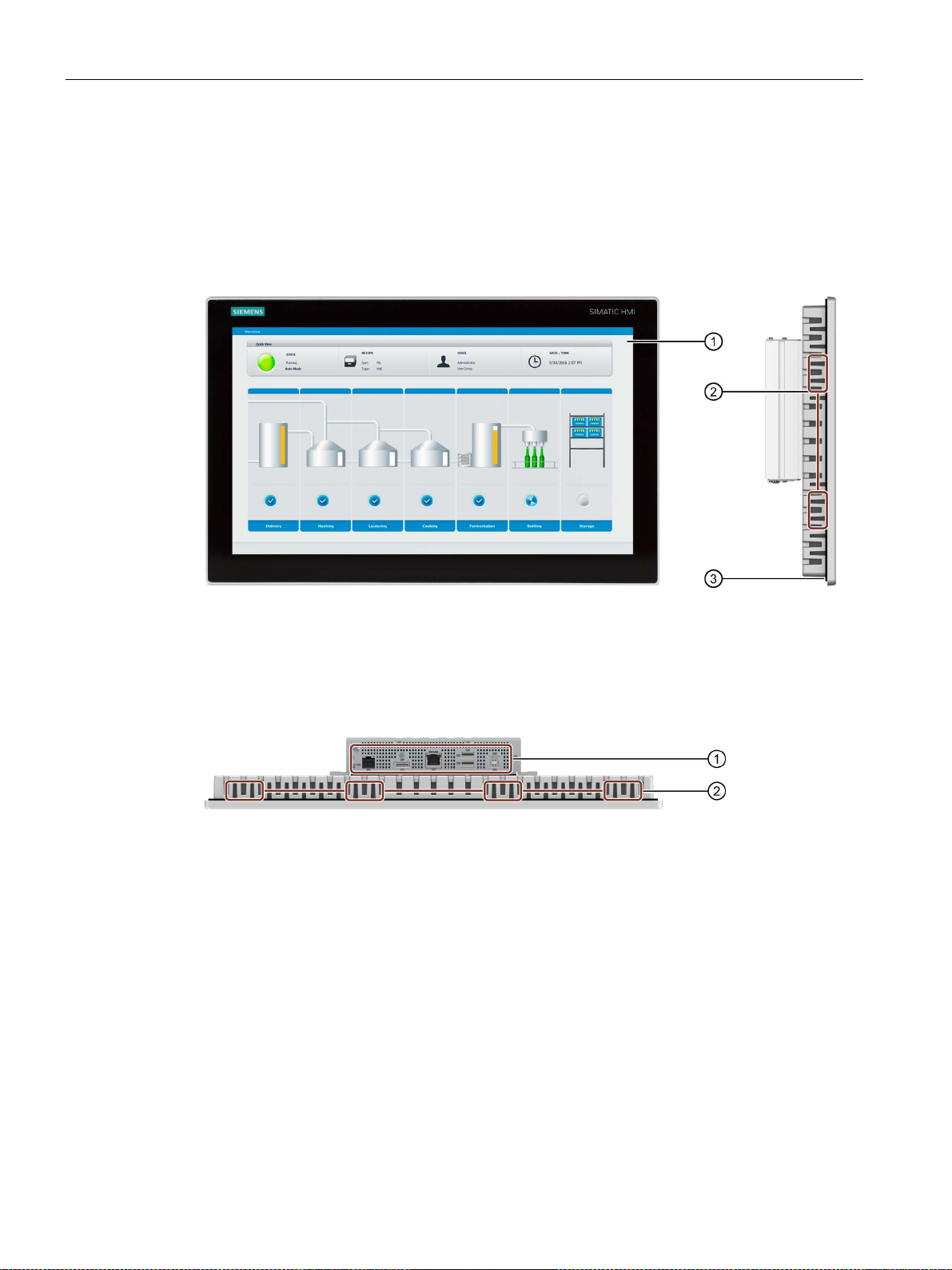

①

Display and capacitive multi-touch screen

②

Recesses for mounting clips

③

Mounting seal

①

Interfaces

②

Recesses for mounting clips

1.3 Structure of the built-in devices

1.3 Structure of the built-in devices

This section describes the structure of the built-in devices using the example of the

IFP1900 V2 extended.

Front view and side view

Bottom view

IFP V2, IFP V2 PRO

12 Operating Instructions, 08/2019, A5E46641410-AA

Overview

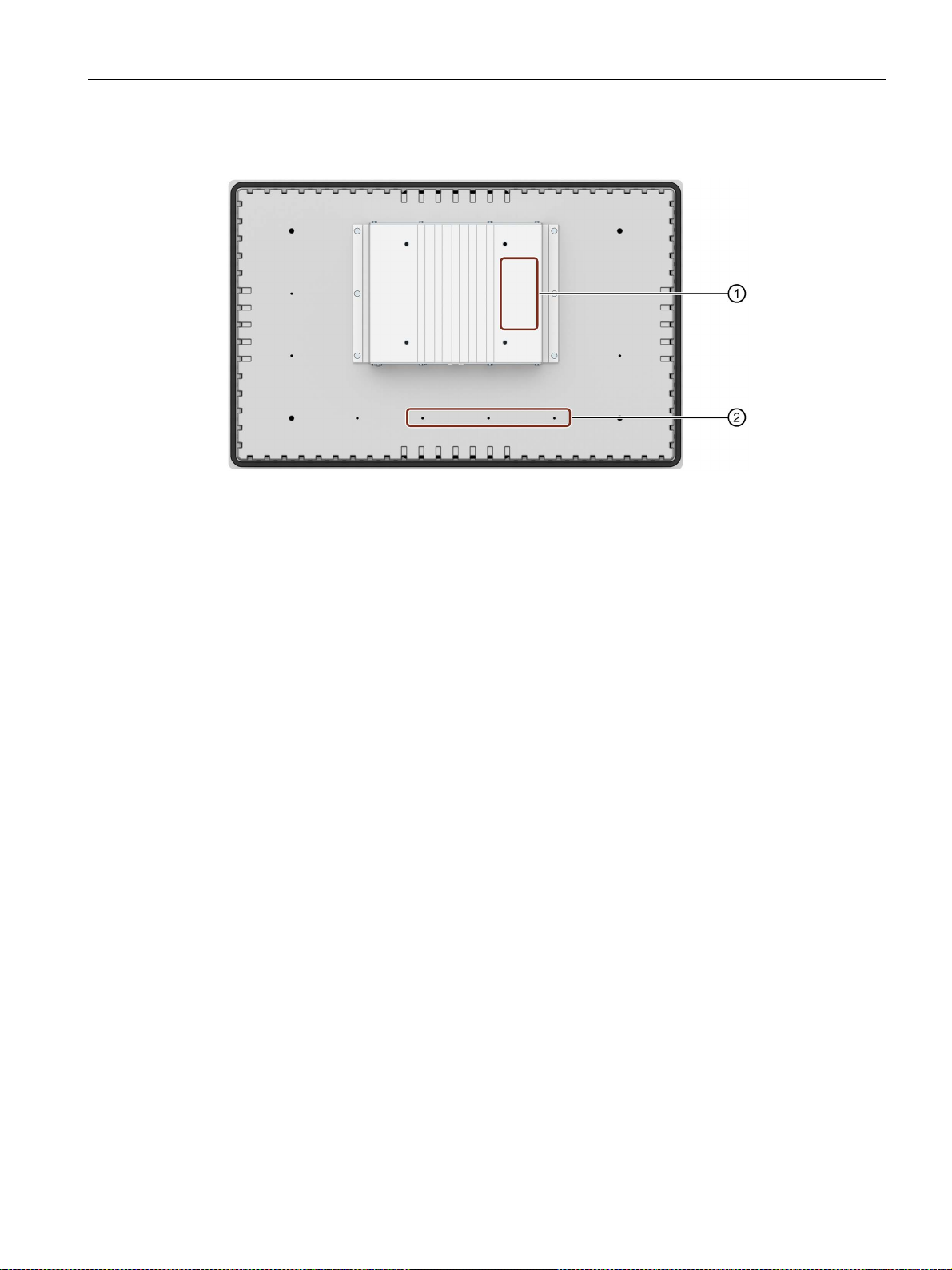

①

Position of rating plate

②

Threaded holes for fastening the strain relief plate

1.3 Structure of the built-in devices

Rear view

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

13

Overview

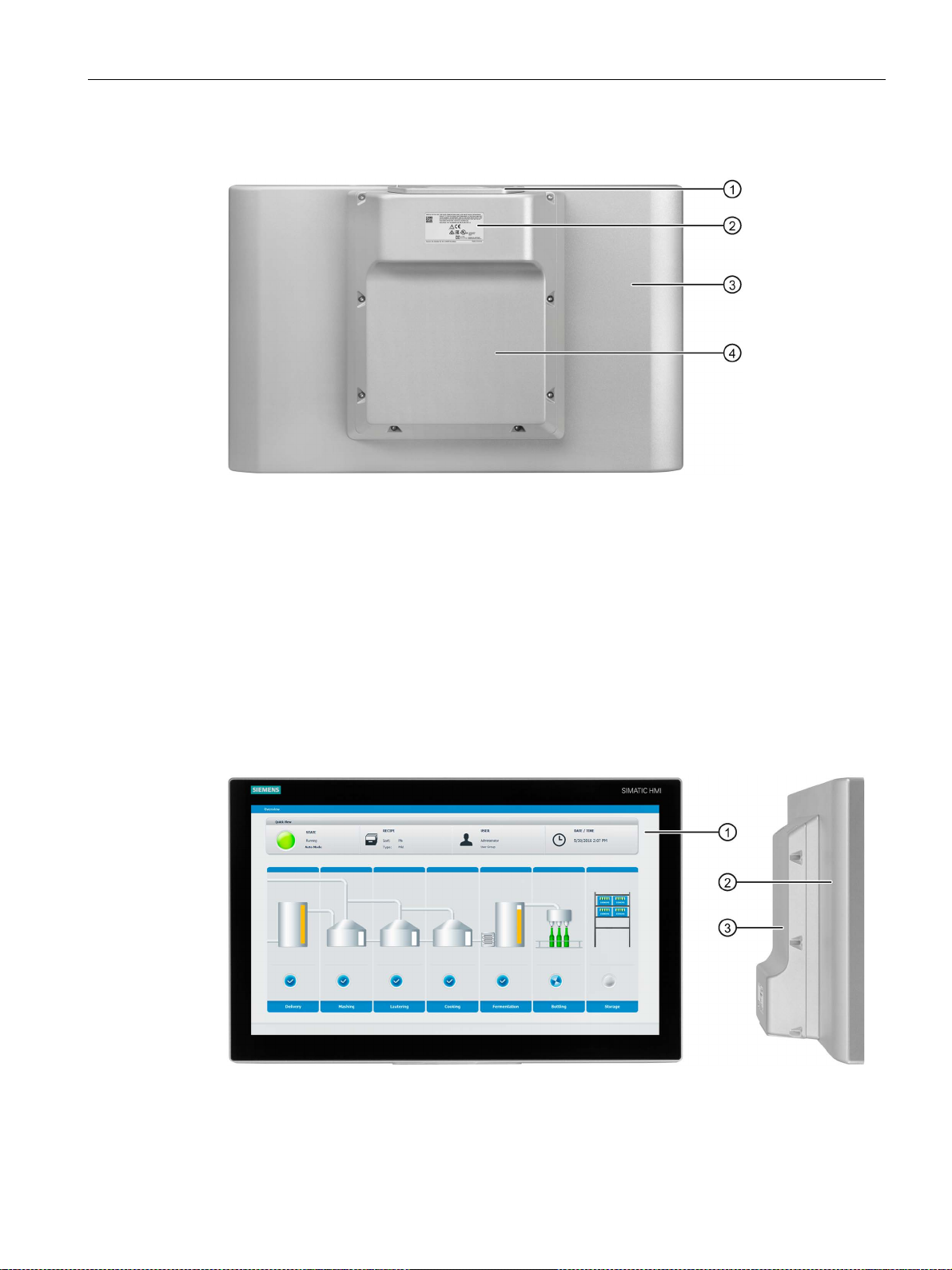

①

Display and capacitive multi-touch screen

②

Enclosure

③

Backplane cover

①

Mechanical interface for fastening

1.4 Design of the PRO devices

1.4 Design of the PRO devices

1.4.1 PRO devices for support arm (not extendable, flange top)

This section describes the structure of the PRO devices for support arm (not extendable,

flange top) using the example of the IFP1900 PRO for support arm (not extendable, flange

top).

Front view and side view

Top view

IFP V2, IFP V2 PRO

14 Operating Instructions, 08/2019, A5E46641410-AA

Overview

①

Mechanical interface for fastening

②

Rating plate

③

Enclosure

④

Backplane cover

①

Display and capacitive multi-touch screen

②

Enclosure

③

Backplane cover

1.4 Design of the PRO devices

Rear view

1.4.2 PRO devices for pedestal (extendable, flange bottom)

This section describes the structure of the PRO devices for pedestal (extendable, flange

bottom) using the example of the IFP1900 PRO for pedestal (extendable, flange bottom).

Front view and side view

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

15

Overview

①

Mechanical interface for fastening

①

Backplane cover

②

Enclosure

③

Rating plate

④

Mechanical interface for fastening

1.4 Design of the PRO devices

Bottom view

Rear view

IFP V2, IFP V2 PRO

16 Operating Instructions, 08/2019, A5E46641410-AA

Overview

①

Display and capacitive multi-touch screen

②

Enclosure

③

Mechanical interface for fastening (round tube)

④

Terminal compartment cover

⑤

Mechanical interface to the optional Extension Unit or to the supplied cover

①

Mechanical interface for fastening (round tube)

②

Terminal compartment cover

③

Rating plate

④

Mechanical interface to the optional Extension Unit or to the supplied cover

⑤

Lower cover, included in the product package

1.4 Design of the PRO devices

1.4.3 PRO devices for support arm (extendable, round tube)

This section describes the structure of the PRO devices for support arm (extendable, round

tube) using the example of the IFP1500 PRO for support arm (extendable, round tube).

Front view and side view

Rear view

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

17

Overview

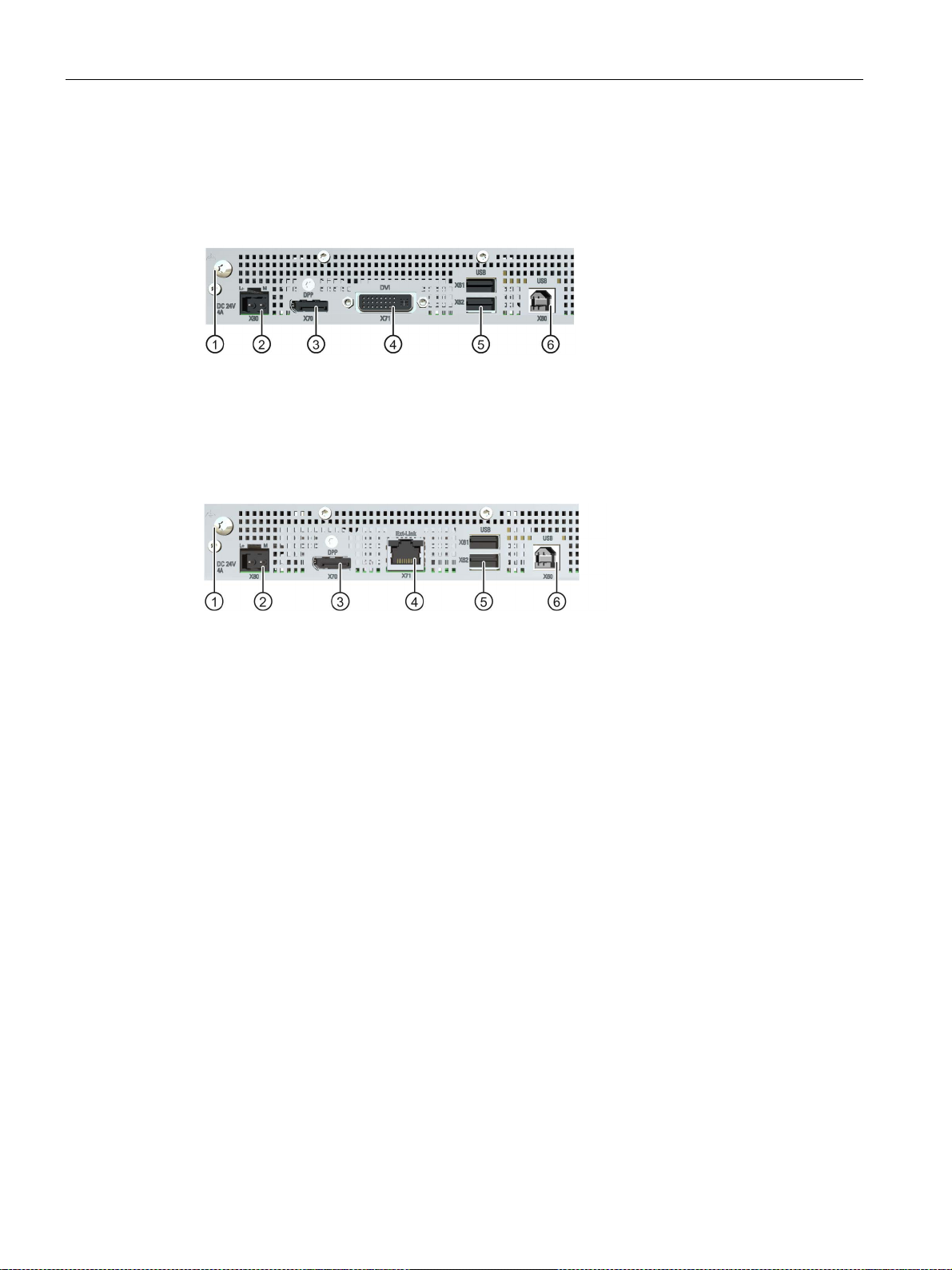

①

Connection for functional ground

④

X71 DVI-D interface

②

X80 connector for 24 V DC power supply

⑤

X61/X62 USB Type A

③

X70 DisplayPort interface

⑥

X60 USB Type B

①

Connection for functional ground

④

X63 RJ45 interface to the Transceiver Unit

②

X80 connector for 24 V DC power supply

⑤

X61/X62 USB Type A

③

X70 DisplayPort interface

⑥

X60 USB Type B

1.5 Interfaces

1.5 Interfaces

Standard versions

Extended versions and PRO devices

1.6 System components and accessories

System components are products that have been developed for a specific system and can

not be used in general, for example, like the base adapter. System components are always

directly related to a core product.

Accessories can typically be used for multiple devices from the same or different device

families, for example, batteries, touch pens or protective membranes.

IFP V2, IFP V2 PRO

18 Operating Instructions, 08/2019, A5E46641410-AA

Overview

①

Hole for the screw to fasten the mounting rail

⑧

"LNK" LED

②

Guide for the "left" mounting rail

⑨

Mounting rail

③

Connection for functional ground

⑩

Lower elongated hole of the mounting rail

④

X80 connector for 24 V DC power supply

⑪

X70 DisplayPort interface

⑤

Opening for fastener for "left" strain relief

⑫

Opening for fastener for "right" strain relief

⑥

X71 RJ45 interface to the IFP

⑬

X60 USB Type B

⑦

Guide for the "rear" mounting rail

⑭

Guide for the "right" mounting rail

1.6 System components and accessories

1.6.1 System components for IFPs

Transceiver Unit for extended versions and PRO devices

With the Transceiver Unit you can bridge a distance of up to 100 m between a PC and an

extended version or a PRO device. The Transceiver Unit is mounted close to the PC.

The Transceiver Unit can be attached on a DIN rail or in various positions on a wall using the

fixing accessories supplied.

Article number of the Transceiver Unit: 6AV7860-3EH00-0AA0

Scope of delivery

● A Transceiver Unit

● One mounting rail for attachment to DIN rail or wall mounting

● Two retaining elements for strain relief

● One DisplayPort cable, length 0.5 m

● One USB cable Type B connector - Type A connector, length 0.5 m

● A power supply connector 24 V DC, 2-pin

● A ferrite for the power supply cables, white

● One ferrite for the Ethernet line to the IFP, black

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

19

Overview

WARNING

Do not use the power supply unit in hazardous areas.

1.6 System components and accessories

Functions of the "LNK" LED

● LED lit green: Active link available

● LED not illuminated: No active link available

AC power supply unit for built-in devices

Connect a built-in device to the power supply via the AC power supply unit, input voltage

range 100 V to 240 V. Use the supplied fixing accessories to mount the AC power supply

unit on the rear of the built-in device.

Article number of the AC power supply unit: 6AV7860-3PA00-0AA0

You can find the documentation for the AC power supply unit with the article number on the

Internet (https://support.industry.siemens.com).

The power supply unit is not approved for use in hazardous areas. If the power supply unit

is mounted on a built-in device with Ex approval, the Ex approval of the built-in device

expires.

Operation of the power supply unit in a hazardous area may result in an explosion, death or

serious injury.

Never operate the power supply unit in a hazardous area.

IFP V2, IFP V2 PRO

20 Operating Instructions, 08/2019, A5E46641410-AA

Overview

①

Seal

②

Channel cable

③

Mechanical interface to the PRO device

④

Cover

⑤

Mechanical interface to the support arm or pedestal including seal

1.6 System components and accessories

1.6.2 System components for PRO devices

Base adapter

You use the base adapter to mount PRO devices for support arm (not extendable,

flange top) or for pedestal (extendable, flange bottom) on the support arm or on the pedestal.

A base adapter is included with the product package of the corresponding PRO device. The

base adapter can also be ordered separately.

Article number: 6AV7674-1KA00-0AA0

Adapter sets and couplings

The following mechanical adapter versions are also available for mounting a PRO device

for support arm (not extendable, flange top) or for pedestal (extendable, flange bottom) via

the base adapter:

● Adapter set VESA75 for VESA75-compatible systems, Article number

6AV7674-0KE00-0AA0

● Adapter set VESA100 for VESA100-compatible systems, Article number

6AV7674-0KD00-0AA0

In addition, other manufacturers offer support arm or pedestal systems with mechanical

interfaces or adapters for Siemens PRO devices, e.g. RITTAL, ROLEC, BERNSTEIN,

HASEKE, ROSE. Observe the specifications provided by the respective manufacturer.

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

21

Overview

①

Flange mount adapter

②

Ring groove for fastening on PRO device with setscrews

③

Mechanical interface to support arm

1.6 System components and accessories

Flange mount adapter

A flange mount adapter is available for mounting a PRO device for support arm (extendable,

round tube).

Round tube plug

Article number: 6AV7674-1KF00-0AA0

If you do not need the mechanical interface of a PRO device for support arm (extendable,

round tube) you can install the round tube plug into the mechanical interface. With the round

tube plug, the degree of protection IP65 is maintained all around for the PRO device.

Article number: 6AV7674-1LB40-0AA0

IFP V2, IFP V2 PRO

22 Operating Instructions, 08/2019, A5E46641410-AA

Overview

①

Extension Unit

stop button.

②

Extension Unit box

controls.

③

Handles, set to match the 22" PRO device

④

Keyboard tray for mounting the keyboard tray plate or installing a suitable keyboard

⑤

Keyboard tray plate

Note

Maximum two Extension Units permissible

A maximum of two Extension Units are permitted under a PRO device for

(extendable, flan

1.6 System components and accessories

Extensions for PRO devices:

The following example shows a PRO device for a support arm (extendable, round tube) with

Extension Unit, Extension Unit box as well as the PRO Options handles and keyboard tray

with keyboard tray plate.

, Example: Extension Unit 22" with eight operator controls including emergency

, deep empty enclosure, example: Extension unit box 22" without operator

pedestal

ge bottom) or for support arm (extendable, round tube).

Extension Unit

The Extension Unit is used to install additional operator controls below a SIMATIC PRO

device for pedestal (extendable, flange bottom) or for support arm (extendable, round tube).

The Extension Unit can be custom-equipped and is supplied without operator controls. The

front of the Extension Unit is fitted with pre-perforated installation points for operator controls.

The Extension Unit are available in four different sizes:

● Extension Unit 12", article number 6AV7674-1LA3x-0AA0

● Extension Unit 15", Article number 6AV7674-1LA4x-0AA0

● Extension Unit 19", Article number 6AV7674-1LA5x-0AA0

● Extension Unit 22", Article number 6AV7674-1LA6x-0AA0

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

23

Overview

Note

Only operator controls with Siemens approval may be installed in the Extension Unit.

1.6 System components and accessories

In each Extension Unit size, you have the flexibility to choose between the following interface

variants (x) for connection to the system:

● Hardwired (x=1)

● PROFINET (x=2)

● PROFIsafe (x=3)

In addition, different operator controls, such as emergency stop button, selector switch,

illuminated button, keyswitch and indicator light are available.

Extension Unit box

The Extension Unit box offers a deep empty housing to install larger customer-specific

components underneath a 16:9 SIMATIC PRO device for pedestal (extendable,

flange bottom) or for support arm (extendable, round tube).

The extension unit is supplied without operator controls; the front is not prepared for

installation of operator controls. The Extension Unit box are available in four different sizes:

● Extension Unit box 12", Article number 6AV7674-1LA30-0AA0

● Extension Unit box 15", Article number 6AV7674-1LA40-0AA0

● Extension Unit box 19", Article number 6AV7674-1LA50-0AA0

● Extension Unit box 22", Article number 6AV7674-1LA60-0AA0

Handles

The adjustable width handles make it easier to align or position the device as a whole

without touch the display of the PRO device.

Article number: 6AV7674-1LB10-0AA0

Keyboard tray

On the keyboard tray, you can install the keyboard tray plate or a suitable keyboard. In

addition, the keyboard tray has two face-side openings for USB interfaces and two rear-side

openings for cable glands.

Article number: 6AV7674-1NF01-0AA0

Keyboard tray plate

The keyboard tray plate offers enough space for keyboard and mouse.

Article number: 6AV7674-1NG00-0AA0

Replacement adapter

The replacement adapter makes it easier to dismantle and mount a SIMATIC PRO device

mounted above an Extension Unit.

Article number: 6AV7674-1LB50-0AA0

IFP V2, IFP V2 PRO

24 Operating Instructions, 08/2019, A5E46641410-AA

Overview

Note

This section contains a selection of accessories suitable for your device. You can find

additional versions of this selection and the complete accessories po

Mall on the Internet

(

such

Industry Mall under the respective article numbers.

Name

Specification

Article number

3 m long

6AV7860-0BH30-0AA0

5 m long

6AV7860-0BH50-0AA0

3 m long

6AV7860-0DH30-0AA0

5 m long

6AV7860-0DH50-0AA0

3 m long

6AV7860-0CH30-0AA0

5 m long

6AV7860-0CH50-0AA0

Power supply connector 2-pin

Screw-type connection

6AV6671-8XA00-0AX0

Power supply connector 2x2-pin

Spring-loaded terminals

6ES7193-4JB00-0AA0

screen

Name

Article number

Set with steel mounting clips

6AV6671-8XK00-0AX3

1.6 System components and accessories

Additional information

Additional Extension Units and information on system components for all-round protected

devices with degree of protection IP65 and Enclosure Type 4X/12 (indoor use only) are

available on the Internet

(https://mall.industry.siemens.com/mall/en/WW/Catalog/Products/10268745).

1.6.3 Accessories

Each device comes with an accessory pack containing the necessary accessories.

rtfolio in the Industry

https://mall.industry.siemens.com/mall/en/WW/Catalog/Products/10144445). Details

as the delivery quantity and technical specifications of accessories can be found in the

Accessories for all IFPs

DVI line

DisplayPort line

USB cable

Type A connector - Type B connector

Touch pen For capacitive and resistive touch

Accessories for built-in devices

6AV2181-8AV20-0AX0

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

25

Overview

Name

Specification

Article number

10 m long

6AV7860-0EH01-0AA0

15 m long

6AV7860-0EH01-5AA0

20 m long

6AV7860-0EH02-0AA0

30 m long

6AV7860-0EH03-0AA0

10 m long

6AV7860-1EX21-0AB1

15 m long

6AV7860-1EX21-5AB1

20 m long

6AV7860-1EX22-0AB1

Name

Article number

6AV7860-1EY00-0AA0

Cat. 6A plug RJ45, suitable for Cat.6A Ethernet cable 6XV1878-2A

6AV7860-1EY00-0AA0

1.6 System components and accessories

Accessories for extended versions and PRO devices

Cat. 6A Ethernet cable

Cable set, consisting of

• Transceiver Unit with:

– Two ferrites

– USB cable, length 0.5 m Type A connector -

Type B connector

– DisplayPort cable, length 0.5 m

• Cat. 6A Ethernet cable, length see "Specification"

Use the following components to pre-assemble longer or individual cable lengths:

30 m long 6AV7860-1EX23-0AB1

Cat. 6A Ethernet cable, sold by the meter, for connection to Cat. 6A plug

6XV1878-2A

IFP V2, IFP V2 PRO

26 Operating Instructions, 08/2019, A5E46641410-AA

2

WARNING

The device may only be used in machines which comply with the Machinery Directive

NOTICE

Observe immunity to high-frequency radiation

2.1 General safety instructions

The device is designed for use in the industrial sector for operating and monitoring plant

processes.

Machinery Directive

The Machinery Directive specifies precautions to be taken when commissioning and

operating machinery within the European Economic Area.

Failure to follow these precautions is a breach of the Machinery Directive. Such failure may

also cause personal injury and damage depending on the machine operated.

The machine in which the HMI device is to be operated must conform to Directive

2006/42/EC.

Observe the safety and accident prevention instructions applicable to your application in

addition to the safety information given in the device documentation.

Strong high-frequency radiation

The device has an increased immunity to high frequency radiation according to the

specifications on electromagnetic compatibility in the technical specifications.

Radiation exposure in excess of the specified immunity limits can impair device functions

and result in malfunctions and therefore injuries or damage.

Read the information on immunity to high frequency radiation in the technical specifications.

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

27

Safety information

WARNING

The built-in device is an open equipment at the rear

The enclosure, the cabinet or the electrical operating rooms must provide protection against

Electrocution risk when control cabinet is open

not

WARNING

The device constitutes open equipment

rotection against

Electrocution risk when control cabinet is open

not

2.1 General safety instructions

Additional notes for built-in units

The built-in device is an open equipment at the rear. This means that you have to integrate

the built-in device into an enclosure or a cabinet, where the built-in device is operated via

the front panel.

electric shock and the spread of fire. The requirements regarding the mechanical strength

must also be taken into account.

Access to the enclosure or cabinet in which the built-in device is installed should only be

possible by means of a key or tool and for trained and qualified personnel.

When you open the control cabinet, there may be a dangerous voltage at certain areas or

components.

If you touch these areas or components, you may be killed by electric shock.

Disconnect the cabinet from the mains before opening it. Do

system component during operation.

Additional information for the Transceiver Unit

The device is open equipment. This means that the device may only be integrated in an

enclosure or cabinet.

The enclosure, the cabinet or the electrical operating rooms must provide p

electric shock and the spread of fire. The requirements regarding the mechanical strength

must also be considered.

Access to the enclosure or cabinet in which the device is installed should only be possible

by means of a key or tool and for trained and qualified personnel.

When you open the control cabinet, there may be a dangerous voltage at certain areas or

components.

If you touch these areas or components, you may be killed by electric shock.

plug in or pull out the

Disconnect the cabinet from the mains before opening it. Do

components during operation.

IFP V2, IFP V2 PRO

28 Operating Instructions, 08/2019, A5E46641410-AA

plug in or pull out system

Safety information

2.1 General safety instructions

ESD

An electrostatically sensitive device is equipped with electronic components. Due to their

design, electronic components are sensitive to overvoltage and thus to the discharge of

static electricity. Note the corresponding regulations when handling ESD.

Industrial Security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit (http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply latest updates may increase customer’s exposure to

cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

Disclaimer for third-party software updates

This product includes third-party software. Siemens AG only provides a warranty for

updates/patches of the third-party software, if these have been distributed as part of a

Siemens software update service contract or officially released by Siemens AG. Otherwise,

updates/patches are undertaken at your own risk. You can find more information about our

Software Update Service offer on the Internet at Software Update Service

(http://www.automation.siemens.com/mcms/automation-software/en/software-update-

service).

Notes on protecting administrator accounts

A user with administrator privileges has extensive access and manipulation options in the

system.

Therefore, ensure there are adequate safeguards for protecting the administrator accounts

to prevent unauthorized changes. To do this, use secure passwords and a standard user

account for normal operation. Other measures, such as the use of security policies, should

be applied as needed.

IFP V2, IFP V2 PRO

Operating Instructions, 08/2019, A5E46641410-AA

29

Safety information

NOTICE

Device approved for indoor use only

Note

Operate the device only in a normal atmospheric environment

The technical characteristics of the device described in the operating instructions are

gu

composition.

Note

The device is intended for

IEC/EN

•

•

•

Additional information is available in the section "

2.2 Notes about usage

2.2 Notes about usage

The device may be damaged if operated outdoors.

Operate the device indoors only ("Indoor use only").

aranteed if you operate the device in normal ambient air conditions with usual air

operation in an SELV/PELV circuit according to

61010-2-201 in a dry environment, which means for the various device types:

Built-in devices: dry environment on the rear of the device

PRO devices: dry environment inside the housing

Transceiver Unit: dry environment all around

Industrial applications

The device is designed for industrial use. It conforms to the following standards:

● Requirements for interference emissions EN 61000-6-4

● Requirements for interference immunity EN 61000-6-2

Use in mixed-use zone

Under certain circumstances you can use the device in a mixed-use zone. A mixed-use zone

is used for housing and commercial operations that do not have a significant impact on

residents.

When you use the device in a mixed-use zone, you must ensure that the limits of the generic

standard EN 61000-6-3 regarding emission of radio frequency interference are observed.

Suitable measures for achieving these limits for use in a mixed-use zone include:

● Installation of the device in grounded control cabinets

● Use of filters in electrical supply lines

Individual acceptance is required.

Operating Conditions (Page 92)".

IFP V2, IFP V2 PRO

30 Operating Instructions, 08/2019, A5E46641410-AA

Loading...

Loading...