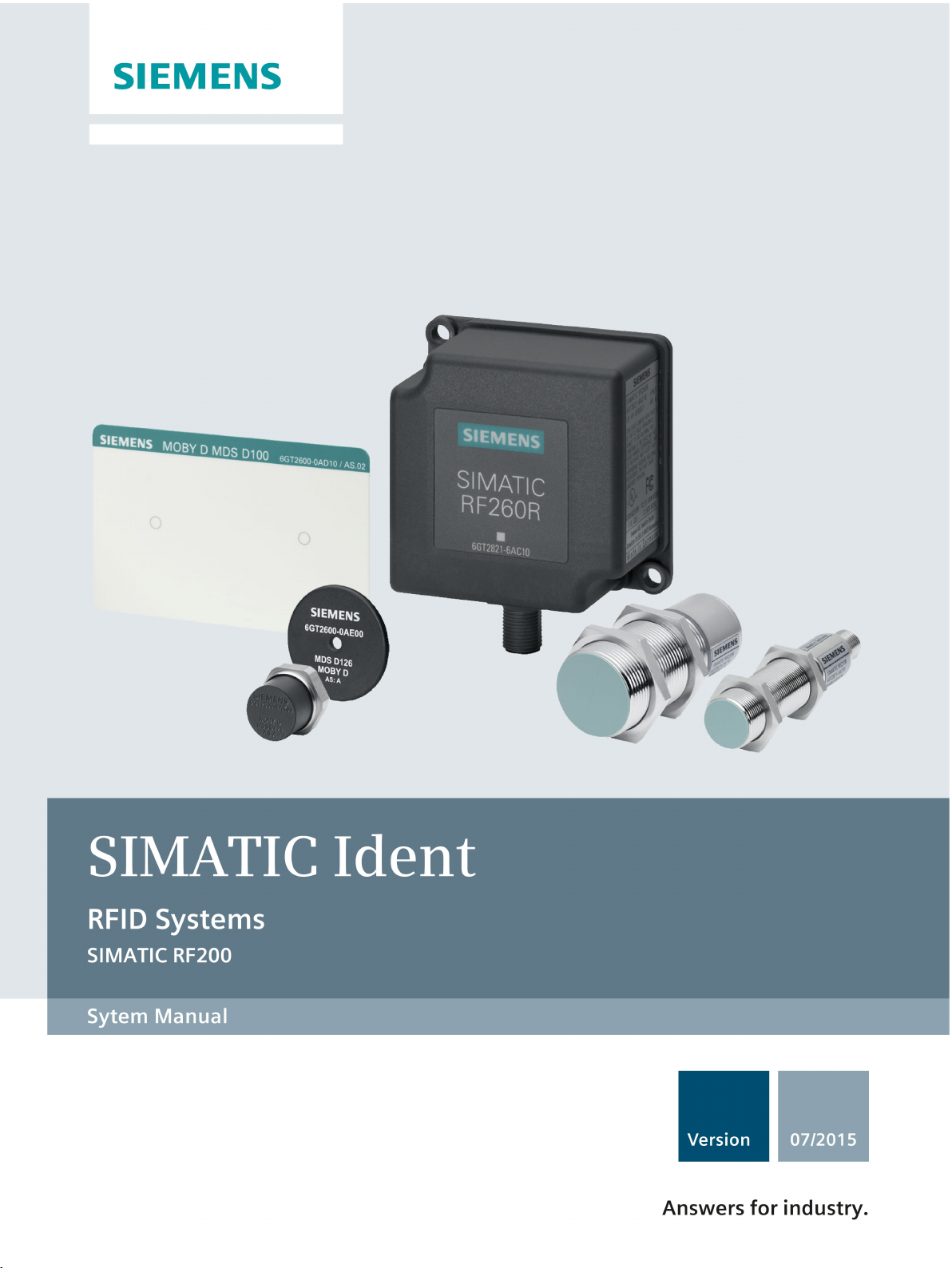

Siemens SIMATIC Ident,SIMATIC RF200 System Manual

SIMATIC RF200

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC Ident

RFID systems

SIMATIC RF200

System Manual

07/2015

J31069

Introduction

1

Safety notes

2

System overview

3

RF200 system planning

4

Readers

5

Antennas

6

Transponder

7

System integration

8

System diagnostics

9

Appendix

A

-D0227-U001-A9-7618

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

J31069-D0227-U001-A8-7618

Ⓟ

Copyright © Siemens AG 2010 - 2015.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

07/2015 Subject to change

Table of contents

1 Introduction ........................................................................................................................................... 15

2 Safety notes .......................................................................................................................................... 17

3 System overview ................................................................................................................................... 19

4 RF200 system planning......................................................................................................................... 25

1.1 Abbreviations and naming conventions .................................................................................. 16

3.1 RFID components and their function ...................................................................................... 20

3.2 Overview of transponders ....................................................................................................... 23

4.1 Fundamentals of application planning .................................................................................... 25

4.1.1 Selection criteria for SIMATIC RF200 components ................................................................ 25

4.1.2 Transmission window and read/write distance ....................................................................... 25

4.1.3 Width of the transmission window .......................................................................................... 28

4.1.4 Impact of secondary fields ...................................................................................................... 29

4.1.5 Permissible directions of motion of the transponder ............................................................... 32

4.1.6 Operation in static and dynamic mode ................................................................................... 33

4.1.7 Dwell time of the transponder ................................................................................................. 34

4.1.8 Communication between communication module, reader and transponder .......................... 35

4.2 Field data of transponders and readers .................................................................................. 36

4.2.1 Field data ................................................................................................................................ 37

4.2.2 Minimum clearances ............................................................................................................... 44

4.3 Installation guidelines.............................................................................................................. 47

4.3.1 Overview ................................................................................................................................. 47

4.3.2 Reduction of interference due to metal ................................................................................... 47

4.3.3 Effects of metal on different transponders and readers .......................................................... 49

4.3.4 Impact of metal on the transmission window .......................................................................... 50

4.3.4.1 RF210R ................................................................................................................................... 51

4.3.4.2 RF220R ................................................................................................................................... 54

4.3.4.3 RF240R ................................................................................................................................... 56

4.3.4.4 RF250R ................................................................................................................................... 59

4.3.4.5 RF260R ................................................................................................................................... 65

4.3.4.6 RF290R ................................................................................................................................... 67

4.3.5 Installation and connection of 2 to 6 antennas with one RF290R reader ............................... 71

4.3.5.1 Installation options with the antenna splitter (2-4 antennas) ..................................................

4.3.5.2 Antenna installation ................................................................................................................. 75

4.3.5.3 Installation options with the antenna multiplexer (2-6 antennas) ........................................... 79

4.3.6 Chemical resistance of the transponders ............................................................................... 80

4.3.6.1 Overview of the transponders and their housing materials .................................................... 80

4.3.6.2 Polyphenylene sulfide (PPS) .................................................................................................. 81

4.3.6.3 Polycarbonate (PC) ................................................................................................................. 82

4.3.6.4 Polyvinyl chloride (PVC) ......................................................................................................... 83

4.3.6.5 Epoxy resin ............................................................................................................................. 83

4.3.6.6 PA6.6 GF30 ............................................................................................................................ 86

72

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

5

Table of contents

5 Readers ................................................................................................................................................ 89

4.4 Further information ................................................................................................................. 87

5.1 SIMATIC RF210R .................................................................................................................. 90

5.1.1 Features ................................................................................................................................. 90

5.1.2 RF210R ordering data ........................................................................................................... 90

5.1.3 Pin assignment RF210R with RS422 interface ...................................................................... 91

5.1.4 Display elements of the RF210R reader ................................................................................ 91

5.1.5 Minimum distance between RF210R readers ........................................................................ 92

5.1.6 Technical specifications of the RF210R reader ..................................................................... 93

5.1.7 Approvals ............................................................................................................................... 94

5.1.8 Dimension drawing ................................................................................................................ 95

5.2 SIMATIC RF210M .................................................................................................................. 96

5.2.1 Features ................................................................................................................................. 96

5.2.2 Ordering data RF210M .......................................................................................................... 96

5.2.3 Installing the RF210M reader ................................................................................................. 97

5.2.4 Pin assignment RF210M with RS-422 interface .................................................................... 97

5.2.5 Display elements of the RF210M reader ............................................................................... 98

5.2.6 Technical specifications of the RF210M reader ..................................................................... 98

5.2.7 Approvals ............................................................................................................................. 100

5.2.8 Dimension drawing .............................................................................................................. 101

5.3 SIMATIC RF220R ................................................................................................................ 102

5.3.1 Features ............................................................................................................................... 102

5.3.2 RF220R ordering data ......................................................................................................... 102

5.3.3 RF220R pin assignment with RS422 interface .................................................................... 103

5.3.4 Display elements of the RF220R reader .............................................................................. 103

5.3.5 Minimum distance between RF220R readers ......................................................................

104

5.3.6 Technical specifications of the RF220R reader ................................................................... 105

5.3.7 Approvals ............................................................................................................................. 106

5.3.8 Dimension drawing .............................................................................................................. 107

5.4 SIMATIC RF240R ................................................................................................................ 108

5.4.1 Features ............................................................................................................................... 108

5.4.2 RF240R ordering data ......................................................................................................... 108

5.4.3 Pin assignment RF240R ...................................................................................................... 109

5.4.4 Display elements of the RF240R reader .............................................................................. 109

5.4.5 Minimum distance between several RF240R readers ......................................................... 110

5.4.6 Technical specifications of the RF240R reader ................................................................... 111

5.4.7 Approvals ............................................................................................................................. 113

5.4.8 Dimension drawing .............................................................................................................. 114

5.5 SIMATIC RF250R ................................................................................................................ 115

5.5.1 Features ............................................................................................................................... 115

5.5.2 Ordering data RF250R ......................................................................................................... 115

5.5.3 Pin assignment RF250R ...................................................................................................... 116

5.5.4 Display elements of the RF250R reader .............................................................................. 116

5.5.5 Technical specifications of the RF250R reader ................................................................... 117

5.5.6 Approvals ............................................................................................................................. 118

5.5.7 Dimension drawing .............................................................................................................. 120

5.6 SIMATIC RF260R ................................................................................................................ 121

5.6.1 Features ............................................................................................................................... 121

5.6.2 Ordering data for RF260R ................................................................................................... 121

SIMATIC RF200

6 System Manual, 07/2015, J31069-D0227-U001-A9-7618

Table of contents

6 Antennas ............................................................................................................................................ 141

5.6.3 Pin assignment RF260R ....................................................................................................... 122

5.6.4 Display elements of the RF260R reader ............................................................................... 122

5.6.5 Minimum distance between several RF260R ....................................................................... 123

5.6.6 Technical data of the RF260R reader................................................................................... 124

5.6.7 Approvals .............................................................................................................................. 126

5.6.8 Dimension drawing ............................................................................................................... 127

5.7 SIMATIC RF290R ................................................................................................................. 128

5.7.1 Features ................................................................................................................................ 128

5.7.2 Ordering data RF290R.......................................................................................................... 129

5.7.3 Pin assignment RF290R ....................................................................................................... 130

5.7.4 Display elements of the RF290R reader ............................................................................... 132

5.7.5 Installing the RF290R reader ................................................................................................ 133

5.7.5.1 Wall mounting ....................................................................................................................... 133

5.7.5.2 Installing on the S7-300 standard rail ................................................................................... 134

5.7.5.3 Installation on a DIN rail ........................................................................................................ 134

5.7.6 Technical specifications of the RF290R reader .................................................................... 136

5.7.7 Approvals .............................................................................................................................. 137

5.7.8 Note on the use of the RF290R as a replacement for SLG D10 / SLG D10S ...................... 139

5.7.9 Dimension drawing ............................................................................................................... 140

6.1 ANT 3 .................................................................................................................................... 142

6.1.1 Features ................................................................................................................................ 142

6.1.2 Ordering data ........................................................................................................................ 142

6.1.3 Mounting on/in metal............................................................................................................. 143

6.1.4 Operating / limit distances .................................................................................................... 144

6.1.5 Minimum spacing .................................................................................................................. 144

6.1.6 Technical data ....................................................................................................................... 146

6.1.7 Dimension drawing ............................................................................................................... 147

6.2 ANT 8 .................................................................................................................................... 148

6.2.1 Features ................................................................................................................................ 148

6.2.2 Ordering data ........................................................................................................................ 148

6.2.3 Transmission window............................................................................................................ 149

6.2.4 Flush-mounted in metal ........................................................................................................ 149

6.2.5 Minimum spacing .................................................................................................................. 150

6.2.6 Technical data ....................................................................................................................... 151

6.2.7 Dimension drawing ............................................................................................................... 152

6.3 ANT 12 .................................................................................................................................. 153

6.3.1 Features ................................................................................................................................ 153

6.3.2 Ordering data ........................................................................................................................ 153

6.3.3 Transmission window............................................................................................................ 154

6.3.4 Flush-mounted in metal ........................................................................................................ 154

6.3.5 Minimum spacing .................................................................................................................. 155

6.3.6 Technical data ....................................................................................................................... 156

6.3.7 Dimension drawing ...............................................................................................................

157

6.4 ANT 18 .................................................................................................................................. 158

6.4.1 Features ................................................................................................................................ 158

6.4.2 Ordering data ........................................................................................................................ 158

6.4.3 Transmission window............................................................................................................ 159

6.4.4 Flush-mounted in metal ........................................................................................................ 159

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

7

Table of contents

7 Transponder ........................................................................................................................................ 187

6.4.5 Minimum spacing ................................................................................................................. 160

6.4.6 Technical data ...................................................................................................................... 161

6.4.7 Dimension drawing .............................................................................................................. 162

6.5 ANT 30 ................................................................................................................................. 163

6.5.1 Features ............................................................................................................................... 163

6.5.2 Ordering data ....................................................................................................................... 163

6.5.3 Transmission window ........................................................................................................... 164

6.5.4 Flush-mounted in metal ....................................................................................................... 165

6.5.5 Minimum spacing ................................................................................................................. 165

6.5.6 Technical data ...................................................................................................................... 167

6.5.7 Dimension drawing .............................................................................................................. 168

6.6 ANT D5 ................................................................................................................................ 169

6.6.1 Features ............................................................................................................................... 169

6.6.2 Ordering data ....................................................................................................................... 169

6.6.3 Transmission window ........................................................................................................... 170

6.6.4 Flush-mounted in metal ....................................................................................................... 171

6.6.5 Minimum spacing ................................................................................................................. 171

6.6.6 Technical data ...................................................................................................................... 173

6.6.7 Dimension drawing .............................................................................................................. 174

6.7 ANT D6 ................................................................................................................................ 175

6.7.1 Features ............................................................................................................................... 175

6.7.2 Ordering data ....................................................................................................................... 175

6.7.3 Transmission window ........................................................................................................... 176

6.7.4 Metal-free area ..................................................................................................................... 177

6.7.5 Minimum spacing ................................................................................................................. 177

6.7.6 Technical data ...................................................................................................................... 178

6.7.7 Dimensional diagram ........................................................................................................... 179

6.8 ANT D10 .............................................................................................................................. 180

6.8.1 Features ............................................................................................................................... 180

6.8.2 Ordering data ....................................................................................................................... 180

6.8.3 Transmission window ........................................................................................................... 181

6.8.4 Metal-free area ..................................................................................................................... 182

6.8.5 Minimum spacing ................................................................................................................. 183

6.8.6 Technical data ...................................................................................................................... 184

6.8.7 Dimensional diagram ........................................................................................................... 185

7.1 Memory configuration of ISO the transponders ................................................................... 187

7.2 MDS D100 ............................................................................................................................ 188

7.2.1 Characteristics ..................................................................................................................... 188

7.2.2 Ordering data ....................................................................................................................... 189

7.2.3 Metal-free area ..................................................................................................................... 189

7.2.4 Technical data ...................................................................................................................... 191

7.2.5 Dimension drawing .............................................................................................................. 192

7.3 MDS D117 ............................................................................................................................ 193

7.3.1 Features ............................................................................................................................... 193

7.3.2 Ordering data ....................................................................................................................... 193

7.3.3 Mounting in metal ................................................................................................................. 193

7.3.4 Technical specifications ....................................................................................................... 194

SIMATIC RF200

8 System Manual, 07/2015, J31069-D0227-U001-A9-7618

Table of contents

7.3.5 Dimension drawing ............................................................................................................... 195

7.4 MDS D124 ............................................................................................................................ 196

7.4.1 Characteristics ...................................................................................................................... 196

7.4.2 Ordering data ........................................................................................................................ 196

7.4.3 Mounting on metal ................................................................................................................ 197

7.4.4 Technical specifications ........................................................................................................ 198

7.4.5 Use of the MDS D124 in hazardous area ............................................................................. 199

7.4.6 Dimension drawing ............................................................................................................... 201

7.5 MDS D126 ............................................................................................................................ 201

7.5.1 Characteristics ...................................................................................................................... 201

7.5.2 Ordering data ........................................................................................................................ 202

7.5.3 Technical specifications ........................................................................................................ 202

7.5.4 Dimension drawing ............................................................................................................... 203

7.6 MDS D127 ............................................................................................................................ 204

7.6.1 Features ................................................................................................................................ 204

7.6.2 Ordering data ........................................................................................................................ 204

7.6.3 Mounting in metal .................................................................................................................. 205

7.6.4 Technical specifications ........................................................................................................ 206

7.6.5 Dimension drawing ............................................................................................................... 207

7.7 MDS D139 ............................................................................................................................ 208

7.7.1 Characteristics ...................................................................................................................... 208

7.7.2 Ordering data ........................................................................................................................ 208

7.7.3 Metal-free area ......................................................................................................................

209

7.7.4 Mounting in metal .................................................................................................................. 210

7.7.5 Cleaning the transponder ..................................................................................................... 210

7.7.6 Technical specifications ........................................................................................................ 211

7.7.7 Use of the MDS D139 in hazardous areas ........................................................................... 212

7.7.8 Dimension drawings .............................................................................................................. 214

7.8 MDS D160 ............................................................................................................................ 215

7.8.1 Characteristics ...................................................................................................................... 215

7.8.2 Ordering data ........................................................................................................................ 215

7.8.3 Mounting on metal ................................................................................................................ 216

7.8.4 Technical specifications ........................................................................................................ 217

7.8.5 Dimension drawings .............................................................................................................. 219

7.9 MDS D165 ............................................................................................................................ 220

7.9.1 Features ................................................................................................................................ 220

7.9.2 Ordering data ........................................................................................................................ 220

7.9.3 Technical data ....................................................................................................................... 221

7.9.4 Dimension drawing ............................................................................................................... 222

7.10 MDS D200 ............................................................................................................................ 223

7.10.1 Features ................................................................................................................................ 223

7.10.2 Ordering data ........................................................................................................................ 223

7.10.3 Mounting on metal ................................................................................................................ 224

7.10.4 Technical data ....................................................................................................................... 225

7.10.5 Dimension drawing ............................................................................................................... 227

7.11 MDS D261 ............................................................................................................................ 227

7.11.1 Features ................................................................................................................................

7.11.2 Ordering data ........................................................................................................................ 227

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

227

9

Table of contents

7.11.3 Technical data ...................................................................................................................... 228

7.11.4 Dimension drawing .............................................................................................................. 229

7.12 MDS D324 ............................................................................................................................ 230

7.12.1 Characteristics ..................................................................................................................... 230

7.12.2 Ordering data ....................................................................................................................... 230

7.12.3 Metal-free area ..................................................................................................................... 231

7.12.4 Technical specifications ....................................................................................................... 232

7.12.5 Dimension drawing .............................................................................................................. 233

7.13 MDS D339 ............................................................................................................................ 234

7.13.1 Characteristics ..................................................................................................................... 234

7.13.2 Ordering data ....................................................................................................................... 234

7.13.3 Mounting on metal ............................................................................................................... 235

7.13.4 Mounting in metal ................................................................................................................. 236

7.13.5 Cleaning the transponder ..................................................................................................... 236

7.13.6 Technical specifications ....................................................................................................... 237

7.13.7 Use of the MDS D339 in hazardous areas .......................................................................... 238

7.13.8 Dimensional drawing ............................................................................................................ 240

7.14 MDS D400 ............................................................................................................................ 241

7.14.1 Features ............................................................................................................................... 241

7.14.2 Ordering data ....................................................................................................................... 241

7.14.3 Mounting on metal ............................................................................................................... 242

7.14.4 Technical specifications ....................................................................................................... 243

7.14.5 Dimension drawing .............................................................................................................. 245

7.15 MDS D421 ............................................................................................................................ 246

7.15.1 Characteristics ..................................................................................................................... 246

7.15.2 Ordering data ....................................................................................................................... 246

7.15.3 Mounting on metal ............................................................................................................... 247

7.15.4 Technical specifications ....................................................................................................... 249

7.15.5 Dimension drawing .............................................................................................................. 250

7.16 MDS D422 ............................................................................................................................ 251

7.16.1 Characteristics ..................................................................................................................... 251

7.16.2 Ordering data ....................................................................................................................... 251

7.16.3 Mounting in metal ................................................................................................................. 251

7.16.4 Technical specifications ....................................................................................................... 252

7.16.5 Dimension drawing .............................................................................................................. 253

7.17 MDS D423 ............................................................................................................................ 254

7.17.1 Characteristics ..................................................................................................................... 254

7.17.2 Ordering data ....................................................................................................................... 254

7.17.3 Mounting on metal ............................................................................................................... 255

7.17.4 Technical specifications ....................................................................................................... 256

7.17.5 Dimensional drawing ............................................................................................................ 258

7.18 MDS D424 ............................................................................................................................ 258

7.18.1 Characteristics ..................................................................................................................... 258

7.18.2 Ordering data ....................................................................................................................... 259

7.18.3 Mounting on metal ............................................................................................................... 259

7.18.4 Technical specifications .......................................................................................................

260

7.18.5 Dimension drawing .............................................................................................................. 262

SIMATIC RF200

10 System Manual, 07/2015, J31069-D0227-U001-A9-7618

Table of contents

7.19 MDS D425 ............................................................................................................................ 262

7.19.1 Characteristics ...................................................................................................................... 262

7.19.2 Ordering data ........................................................................................................................ 263

7.19.3 Application example of MDS D425 ....................................................................................... 263

7.19.4 Technical specifications ........................................................................................................ 264

7.19.5 Dimension drawing ............................................................................................................... 265

7.20 MDS D426 ............................................................................................................................ 266

7.20.1 Characteristics ...................................................................................................................... 266

7.20.2 Ordering data ........................................................................................................................ 266

7.20.3 Technical specifications ........................................................................................................ 267

7.20.4 Dimension drawing ............................................................................................................... 268

7.21 MDS D428 ............................................................................................................................ 269

7.21.1 Characteristics ...................................................................................................................... 269

7.21.2 Ordering data ........................................................................................................................ 269

7.21.3 Application example .............................................................................................................. 270

7.21.4 Technical specifications ........................................................................................................ 270

7.21.5 Dimension drawing ............................................................................................................... 272

7.22 MDS D460 ............................................................................................................................ 272

7.22.1 Characteristics ...................................................................................................................... 272

7.22.2 Ordering data ........................................................................................................................ 273

7.22.3 Mounting on metal ................................................................................................................ 273

7.22.4 Technical specifications ........................................................................................................ 274

7.22.5 Dimension drawings ..............................................................................................................

275

7.23 MDS D521 ............................................................................................................................ 276

7.23.1 Characteristics ...................................................................................................................... 276

7.23.2 Ordering data ........................................................................................................................ 276

7.23.3 Mounting on metal ................................................................................................................ 276

7.23.4 Technical specifications ........................................................................................................ 279

7.23.5 Dimension drawing ............................................................................................................... 280

7.24 MDS D522 ............................................................................................................................ 281

7.24.1 Characteristics ...................................................................................................................... 281

7.24.2 Ordering data ........................................................................................................................ 281

7.24.3 Mounting in metal .................................................................................................................. 281

7.24.4 Technical specifications ........................................................................................................ 282

7.24.5 Dimension drawing ............................................................................................................... 283

7.25 MDS D522 special variant .................................................................................................... 284

7.25.1 Characteristics ...................................................................................................................... 284

7.25.2 Ordering data ........................................................................................................................ 284

7.25.3 Mounting in metal .................................................................................................................. 285

7.25.4 Installation instructions.......................................................................................................... 286

7.25.5 Technical specifications ........................................................................................................ 287

7.25.6 Dimensional drawing............................................................................................................. 288

7.26 MDS D524 ............................................................................................................................ 289

7.26.1 Characteristics ...................................................................................................................... 289

7.26.2 Ordering data ........................................................................................................................ 289

7.26.3 Mounting on metal ................................................................................................................ 290

7.26.4 Technical specifications ........................................................................................................ 291

7.26.5 Dimension drawing ............................................................................................................... 292

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

11

Table of contents

8 System integration ............................................................................................................................... 301

9 System diagnostics .............................................................................................................................. 305

A Appendix ............................................................................................................................................. 309

7.27 MDS D526 ............................................................................................................................ 293

7.27.1 Characteristics ..................................................................................................................... 293

7.27.2 Ordering data ....................................................................................................................... 293

7.27.3 Technical specifications ....................................................................................................... 294

7.27.4 Dimension drawing .............................................................................................................. 295

7.28 MDS D528 ............................................................................................................................ 296

7.28.1 Characteristics ..................................................................................................................... 296

7.28.2 Ordering data ....................................................................................................................... 296

7.28.3 Application example ............................................................................................................. 297

7.28.4 Technical specifications ....................................................................................................... 297

7.28.5 Dimension drawing .............................................................................................................. 299

9.1 Error codes of the RF200 readers ....................................................................................... 305

9.2 Diagnostic functions ............................................................................................................. 306

9.2.1 Reader diagnostics with SLG STATUS ............................................................................... 306

9.2.2 Transponder diagnostics with MDS STATUS ...................................................................... 308

A.1 Certificates and approvals ................................................................................................... 309

A.2 Accessories .......................................................................................................................... 311

A.2.1 Antenna splitter .................................................................................................................... 311

A.2.2 Antenna multiplexer SIMATIC RF260X ............................................................................... 313

A.2.2.1 Characteristics ..................................................................................................................... 313

A.2.2.2 Ordering data ....................................................................................................................... 313

A.2.2.3 Description ........................................................................................................................... 314

A.2.2.4 Principle of operation ........................................................................................................... 314

A.2.2.5 Connectors ........................................................................................................................... 315

A.2.2.6 Configuration ........................................................................................................................ 316

A.2.2.7 Parameterization .................................................................................................................. 317

A.2.2.8 RF260X commands ............................................................................................................. 318

A.2.2.9 Technical specifications ....................................................................................................... 319

A.2.2.10 Dimensional drawing ............................................................................................................ 320

A.2.3 Wide-range power supply unit for SIMATIC RF systems .................................................... 321

A.2.3.1 Features ............................................................................................................................... 321

A.2.3.2 Scope of supply.................................................................................................................... 322

A.2.3.3 Ordering data ....................................................................................................................... 322

A.2.3.4 Safety Information ................................................................................................................ 322

A.2.3.5 Connecting ........................................................................................................................... 323

A.2.3.6 Technical specifications ....................................................................................................... 324

A.2.3.7 Pin assignment of DC outputs and mains connection ......................................................... 326

A.2.3.8 Dimension drawing .............................................................................................................. 327

A.2.3.9 Certificates and approvals ...................................................................................................

328

A.2.4 Transponder holders ............................................................................................................ 329

A.3 Connecting cable ................................................................................................................. 335

A.3.1 Reader RF2xxR (RS-422) with ASM 456 / RF160C / RF170C / RF180C / RF182C .......... 335

A.3.2 Reader RF2xxR (RS-422) with ASM 475 ............................................................................ 337

A.3.3 Reader RF2xxR (RS-422) with RF120C .............................................................................. 338

A.3.4 Reader RF240R/RF260R/RF290R (RS232) with PC .......................................................... 338

SIMATIC RF200

12 System Manual, 07/2015, J31069-D0227-U001-A9-7618

Table of contents

Glossary ............................................................................................................................................. 353

Index................................................................................................................................................... 359

A.4 Ordering data ........................................................................................................................ 340

A.5 Service & Support ................................................................................................................. 350

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

13

Table of contents

SIMATIC RF200

14 System Manual, 07/2015, J31069-D0227-U001-A9-7618

1

Introduction

Scope of validity of this document

Registered trademarks

Further information

SIMATIC RF200 is a compact RFID system in the SIMATIC RFID product family. The

product range comprises cost-efficient RF readers that are ideal for use in small assembly

lines or in intralogistics. SIMATIC RF200 RFID readers only support the RFID standard ISO

15693 and are therefore ideal for operation with the extensive range of ISO 15693

transponders.

The readers of the RF200 product family are available with the following interfaces:

● RS-422 for connecting to the communications modules

● RS-232 with a simple ASCII protocol for connection to PCs and third-party controllers

● IO-Link for connection to IO Link masters from Siemens and third-party controllers

Readers with an internal antenna have a particularly compact design

(RF210R/RF220R/RF240R/RF260R). RF250R and RF290R are designed for operation with

external antennas either to achieve longer distances or larger field sizes (RF290R with ANT

D5/D6/D10) or to allow installation where there is very little space (RF250R with ANT

3/8/12/18/30).

This documentation is valid for all variants of the SIMATIC RF200 system and describes the

devices shipped as of July 2015.

SIMATIC ®, SIMATIC RF ®, MOBY ®, RF MANAGER ® and SIMATIC Sensors ® are registered

trademarks of Siemens AG.

For additional information, refer to the manuals:

● Function manual "Ident profile and Ident blocks"

(https://support.industry.siemens.com/cs/us/en/view/106368029

● Function manual "FB 45"

(https://support.industry.siemens.com/cs/ww/en/view/21738808

)

)

● Operating instructions "RF200 IO-Link"

(https://support.industry.siemens.com/cs/ww/en/view/60641859

● System manual "MOBY D"

(https://support.industry.siemens.com/cs/ww/en/view/13628689

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

)

)

15

Introduction

History

Output

Note

03/2011

First edition

RS-232 interface

09/2011

Expansion of the documentation with the device variant RF240R

1.1

Abbreviations and naming conventions

Write/read device (SLG)

Readers

Mobile data storage unit (MDS)

Transponder, tag

Interface module (ASM)

Communications module (CM)

1.1 Abbreviations and naming conventions

● Operating instructions "RF310M"

(https://support.industry.siemens.com/cs/us/en/view/51812642

)

● Product information "RF200 command set"

(https://support.industry.siemens.com/cs/us/en/view/44864850

)

The following issues of the SIMATIC RF200 system manual have been published:

05/2011 Expansion of the documentation with the addition of the device variant RF260R with

03/2013 Expansion of the documentation with the device variant RF290R

09/2013 Expansion of the documentation by the following:

• the device variant RF250R

• the device variants RF240R and RF260R with ASCII interface

• Antennas ANT 8, ANT 12, ANT 18 and ANT 30

• Transponders

07/2015 Expansion of the documentation by the following:

• ANT 3 antennas

• MDS D5xx transponder

• Mobile reader RF210R

The following terms/abbreviations are used synonymously in this document:

SIMATIC RF200

16 System Manual, 07/2015, J31069-D0227-U001-A9-7618

2

NOTICE

Repairs

WARNING

System expansion

NOTICE

SIMATIC RFID products comply with the salient safety specifications to IEC, VDE, EN, UL

and CSA. If you have questions about the validity of the installation in the planned

environment, please contact your service representative.

Alterations to the devices are not permitted.

Failure to observe this requirement shall constitute a revocation of the radio equipment

approval, CE approval and manufacturer's warranty.

Repairs may only be carried out by authorized qualified personnel.

Unauthorized opening of and improper repairs to the device may result in substantial

damage to equipment or risk of personal injury to the user.

Only install system expansion devices designed for this device. If you install other upgrades,

you may damage the system or violate the safety requirements and regulations for radio

frequency interference suppression. Contact your technical support team or your sales outlet

to find out which system upgrades are suitable for installation.

If you cause system defects by installing or exchanging system expansion devices, the

warranty becomes void.

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

17

Safety notes

SIMATIC RF200

18 System Manual, 07/2015, J31069-D0227-U001-A9-7618

3

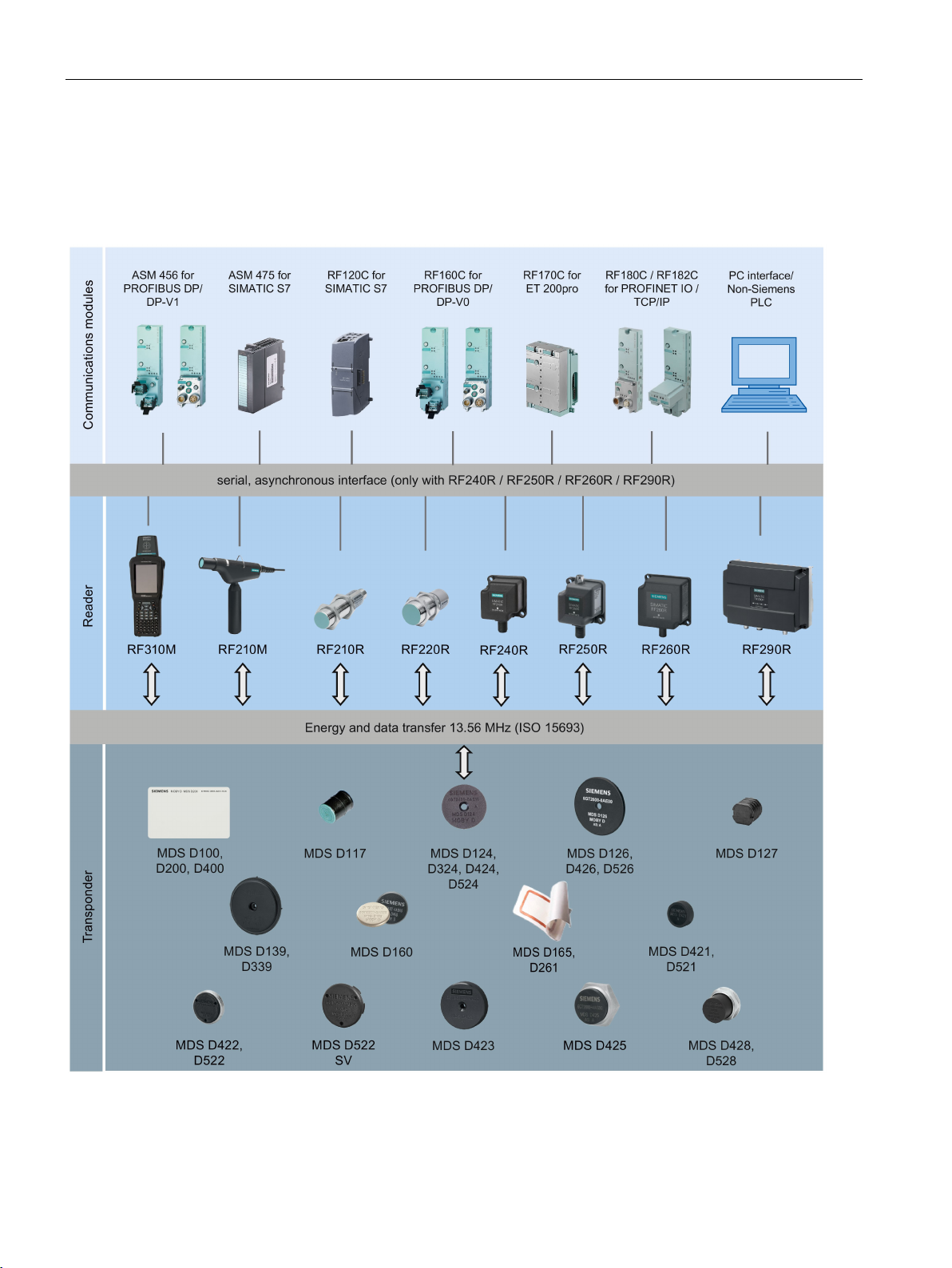

SIMATIC RF200 is an inductive identification system that is compatible with the ISO 15693

standard and was specially designed for use in industrial production for the control and

optimization of material flows.

In contrast to SIMATIC RF300, SIMATIC RF200 is intended for RFID applications where

performance requirements are not very high, for example with regard to data volume,

transfer rate or diagnostics options. SIMATIC RF200 is characterized by particularly

favorable prices.

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

19

System overview

3.1

RFID components and their function

RF200 system components

3.1 RFID components and their function

Figure 3-1 RF200 system overview

SIMATIC RF200

20 System Manual, 07/2015, J31069-D0227-U001-A9-7618

System overview

Transponder

RF210R/

RF210M

RF220R

RF240R

RF250R

with

RF260R

RF290R 4)

RF310M

ANT 3

ANT 8

ANT 12

ANT 18

ANT 30

MDS

D100

MDS

D117

MDS

D124

MDS

D126

MDS

D127

MDS

D139 1)

MDS

D160 2)

MDS

D165

MDS

D200

MDS

D261

MDS

D324

MDS

D339

MDS

D400

MDS

D421

MDS

D422

MDS

D423

MDS

D424

MDS

D425

MDS

D426

MDS

D428

MDS

D460

MDS

D521

3.1 RFID components and their function

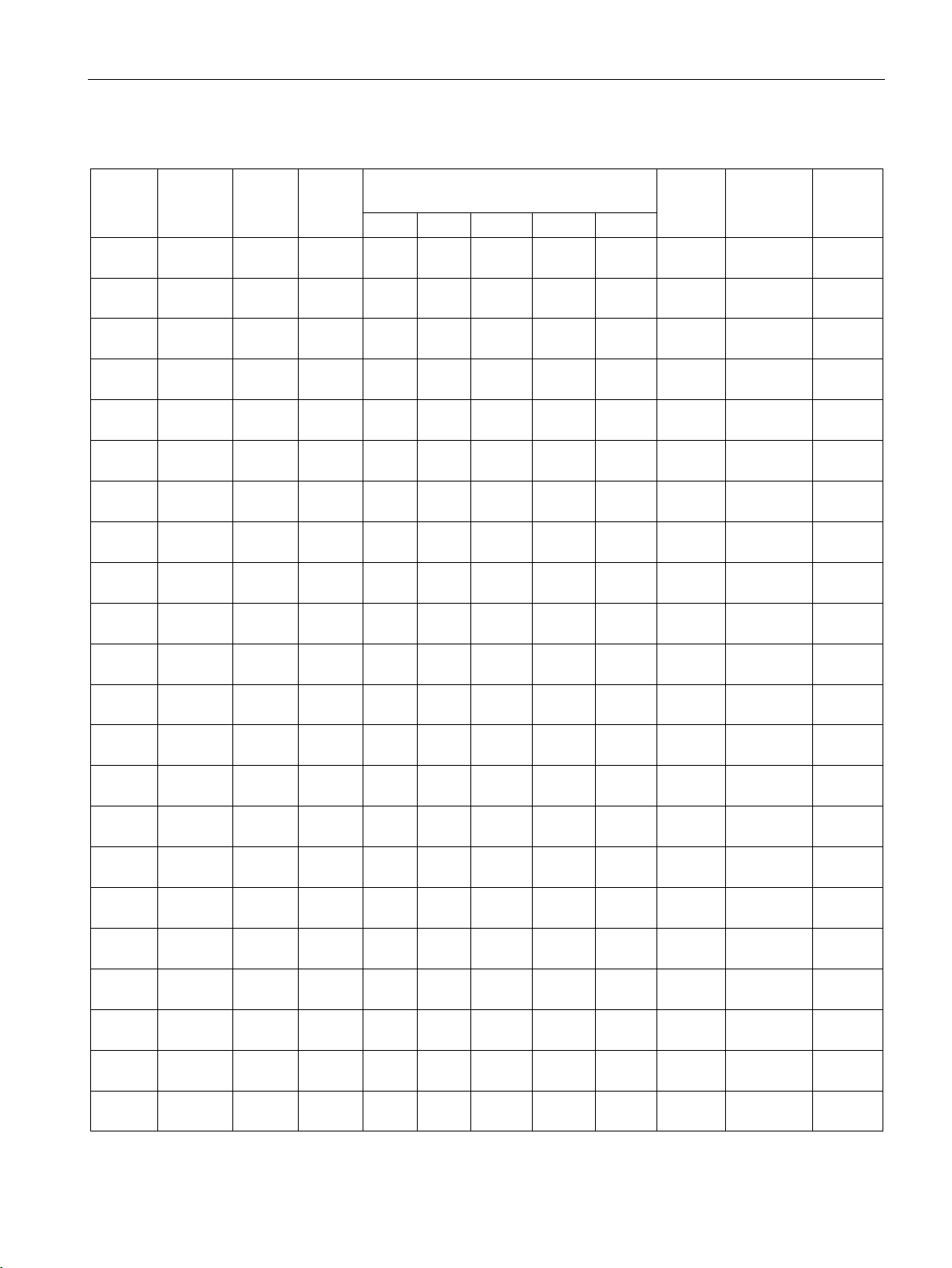

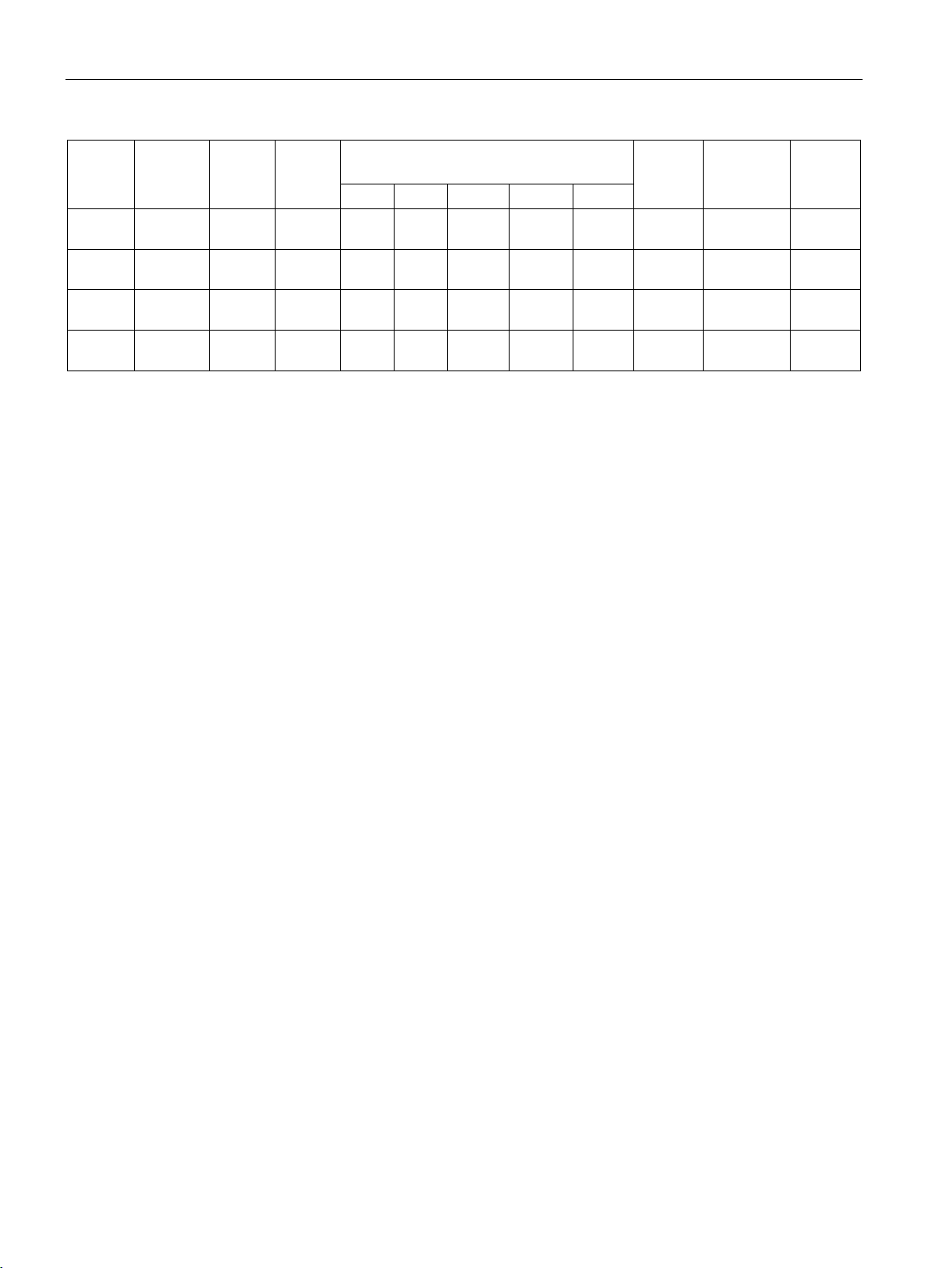

Table 3- 1 Possible reader-transponder combinations

-- ○ ✓ ○ -- -- -- ○ ✓ ✓ ✓

○ -- -- -- ✓ ✓ -- -- -- -- ✓

✓ ✓ ✓ ✓ -- -- ✓ ✓ ✓ ✓ ✓

-- ✓ ✓ ✓ -- -- -- ✓ ✓ ✓ ✓

6)

✓ -- -- -- ✓ ✓ -- -- -- -- ✓

-- ○ ○ ○ -- -- -- ○ ✓ ✓ ✓

✓ ✓ ✓ ✓ -- ✓ ✓ ✓ ✓ ✓ ✓

-- ○ ✓ ○ -- -- -- ○ ✓ ✓ ✓

-- ○ ✓ ○ -- -- -- ○ ✓ ✓ ✓

-- ○ ✓ ○ -- -- -- ○ ✓ ✓ ✓

✓ ✓ ✓ ✓ -- ○ ✓ ✓ ✓ ✓ ✓

-- ○ ○ ○ -- -- -- ○ ✓ ✓ ✓

-- -- ✓ ○ -- -- -- ○ ✓ ✓ ✓

✓ ○ -- -- ✓ ✓ ✓ -- -- -- ✓

✓ ✓ ✓ ✓ -- ✓ ✓ ✓ -- -- ✓

✓ ✓ ✓ ✓ -- -- ✓ ✓ ✓ -- ✓

6)

6)

6)

✓ ✓ ✓ ✓ -- -- ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ -- ✓ ✓ ✓ -- -- ✓

-- ✓ ✓ ✓ -- -- -- ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ -- ✓ ✓ ✓ ✓ -- ✓

✓ ✓ ✓ ✓ -- ✓ ✓ ✓ ✓ ○ / ✓ 5) ✓

✓ ○ -- -- ✓ ✓ ✓ -- -- -- ✓

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

6)

21

System overview

Transponder

RF210R/

RF210M

RF220R

RF240R

RF250R

with

RF260R

RF290R 4)

RF310M

ANT 3

ANT 8

ANT 12

ANT 18

ANT 30

MDS

D522

MDS

D524

MDS

D526

MDS

D528

1)

2)

3)

4)

5)

6)

only in conjunction with RF310M for external antennas (6GT2803-1AC10)

✓

Combination possible

--

Combination not possible

Combination possible, but not recommended

3.1 RFID components and their function

3)

✓ ✓ ✓ ✓ -- -- ✓ ✓ ✓ ✓ ✓

-- ✓ ✓ ✓ -- -- -- ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ -- ✓ ✓ ✓ ✓ -- ✓

only with the article number 6GT2600-0AA10

only with the article number 6GT2600-0AB10

The transponder MDS D522 special variant has the same compatibility as the transponder MDS D522.

in conjunction with ANT D5, D6 or D10

combination recommended only in conjunction with ANT D5.

✓ ✓ ✓ ✓ -- ✓ ✓ ✓ -- -- ✓

○

6)

SIMATIC RF200

22 System Manual, 07/2015, J31069-D0227-U001-A9-7618

System overview

3.2

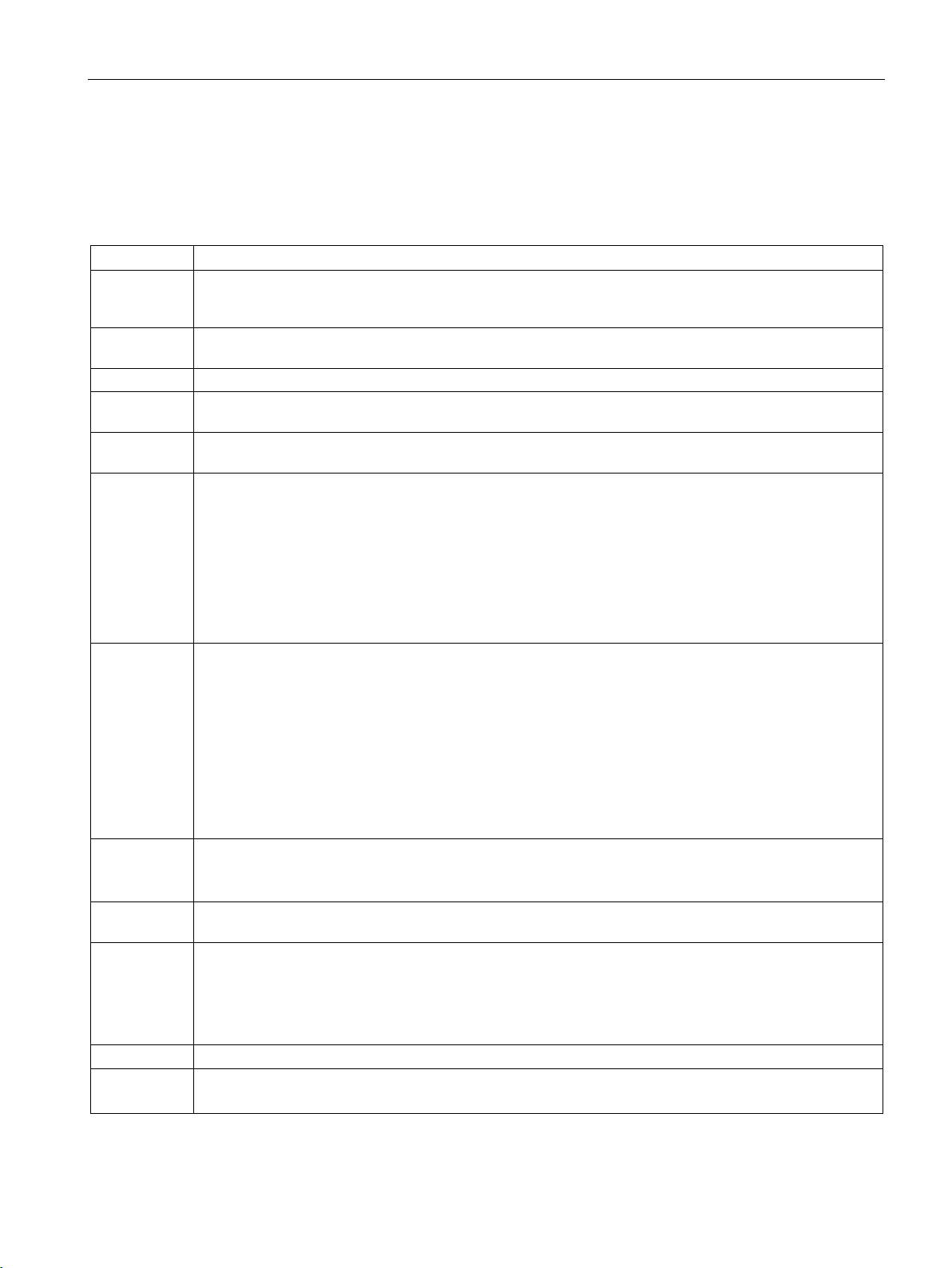

Overview of transponders

Overview of typical areas of application of ISO transponders for RF200

Transponder

Area of application

ranges are achieved in combination with the SIMATIC RF260R reader.

tool identification.

MDS D124

Application areas in factory automation (e.g. small paintshops to 180°C).

logistics; can also be deployed in harsh conditions.

identification.

and distribution logistics, right up to product identification

and distribution logistics, right up to product identification.

and distribution logistics, right up to product identification.

For typical areas of application, see "MDS D139".

3.2 Overview of transponders

MDS D100 From simple identification such as electronic barcode replacement or supplementation, through ware-

house and distribution logistics, right up to product identification. With this transponder, the maximum

MDS D117 Very compact data carrier that can be cemented into objects where precise positioning is necessary. e.g.

MDS D126 Compact and rugged ISO transponder; suitable for identification of transport units in production-related

MDS D127 Very compact data carrier that can be screwed into areas where precise positioning is necessary. e.g. tool

MDS D139 1) Applications in production automation with high temperature demands (up to +220 °C).

Typical application areas:

• Paintshops and their preparatory treatments

• Primer coat, electrolytic dip area, cataphoresis with the associated drying furnaces

• Top coat area with drying furnaces

• Washing areas at temperatures > 85 °C

• Other applications with higher temperatures

MDS D160 2) Typical applications are, for example:

• Rented work clothing

• Hotel laundry

• Surgical textiles

• Hospital clothing

• Dirt collection mats

• Clothing for nursing homes/hostels

• Assembly lines with very small workpiece holders

MDS D165 Smart label (self-adhesive label)

From simple identification such as electronic barcode replacement/supplementation, through warehouse

MDS D200 From simple identification such as electronic barcode replacement/supplementation, through warehouse

MDS D261 Smart label (self-adhesive label)

The design of the transponder (self-adhesive label) permits a variety of designs in order to ensure optimum dimensioning for the widest variety of applications.

From simple identification such as electronic barcode replacement/supplementation, through warehouse

MDS D324 Production and distribution logistics as well as in assembly and production lines

MDS D339 Applications in production automation with high temperature demands (up to +220 °C).

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

23

System overview

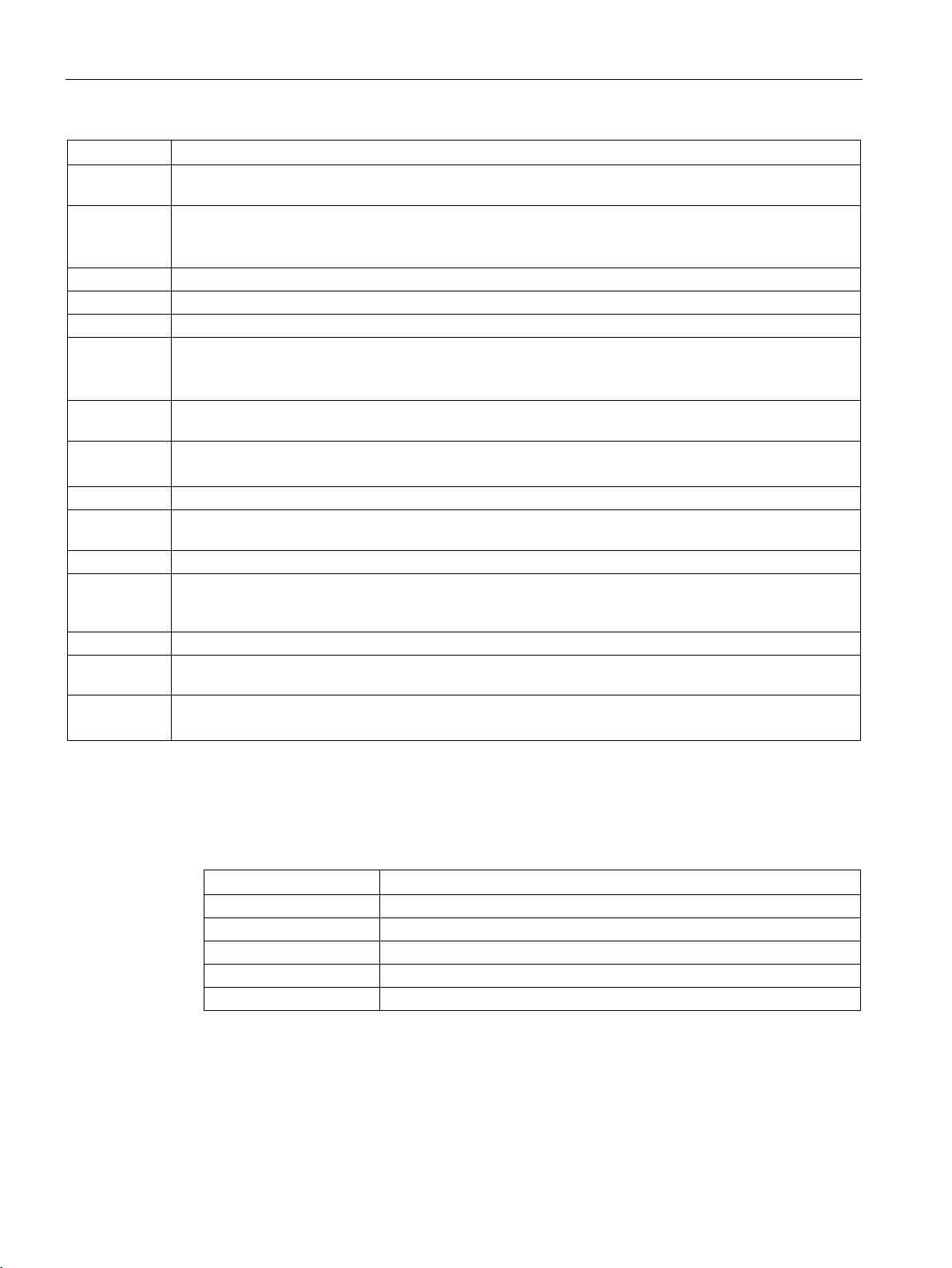

Transponder

Area of application

tion logistics right through to product identification.

workpiece holders

MDS D422

Identification of metallic workpiece holders, workpieces or containers

MDS D424

Production and distribution logistics as well as in assembly and production lines

and workpiece holders

logistics; can also be deployed in harsh conditions

Use in assembly and production lines in the powertrain sector

MDS D460

Assembly lines with very small workpiece holders

carriers and exact positioning are required, e.g. tool identification, workpiece holders.

MDS D522

Identification of metallic workpiece holders, workpieces or containers

ants

logistics; can also be deployed in harsh environmental conditions

Use in assembly and production lines in the powertrain sector

1)

2)

Only with the MLFB 6GT2600-0AB10

Overview of the memory sizes of the ISO transponders for RF200

Transponder

Memory size

MDS D1xx

112 bytes of EEPROM

MDS D2xx

256 bytes of EEPROM

MDS D3xx

992 bytes of EEPROM

MDS D4xx

2000 bytes FRAM

MDS D5xx

8192 bytes FRAM

3.2 Overview of transponders

MDS D400 Simple identification such as electronic barcode replacement/supplements, from warehouse and distribu-

MDS D421 The MDS D421 is designed for tool coding according to DIN 69873.

It can be used wherever small data carriers and exact positioning are required, e.g. tool identification,

MDS D423 Identification of metallic workpiece holders, workpieces or containers, production automation

MDS D425 Compact and rugged ISO transponder; suitable for screw mounting.

Use in assembly and production lines in the powertrain sector; ideal for mounting on motors, gearboxes,

MDS D426 Compact and rugged ISO transponder; suitable for identification of transport units in production-related

MDS D428 Compact and rugged ISO transponder; suitable for screw mounting

MDS D521 The MDS D521 is constructed for tool coding according to DIN 69873. It can be used wherever small data

MDS D522

If Identification of metallic workpiece holders or workpieces

Special vari-

MDS D524 Production and distribution logistics as well as in assembly and production lines

MDS D526 Compact and rugged ISO transponder; suitable for identification of transport units in production-related

MDS D528 Compact and rugged ISO transponder; suitable for screw mounting

Only with the MLFB 6GT2600-0AA10

SIMATIC RF200

24 System Manual, 07/2015, J31069-D0227-U001-A9-7618

4

4.1

Fundamentals of application planning

4.1.1

Selection criteria for SIMATIC RF200 components

4.1.2

Transmission window and read/write distance

Assess your application according to the following criteria, in order to choose the right

SIMATIC RF200 components:

● Static or dynamic data transfer

● Data volume to be transferred

● Speed in case of dynamic transfer

● Ambient conditions such as relative humidity, temperature, chemical impacts, etc.

The reader generates an inductive alternating field. The field is strongest close to the reader;

however, a read/write distance of "zero" between reader and transponder is not

recommended.

The strength of the field decreases in proportion to the distance from the reader. The

distribution of the field depends on the structure and geometry of the antennas in the reader

and transponder

A prerequisite for the function of the transponder is a minimum field strength at the

transponder, which is still barely achieved at distance S

from the reader.

g

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

25

RF200 system planning

Sa

Operating distance between transponder and reader

sponder, at which the transmission can still function under normal conditions)

L

Diameter of a transmission window

SP

Intersection of the axes of symmetry of the transponder

4.1 Fundamentals of application planning

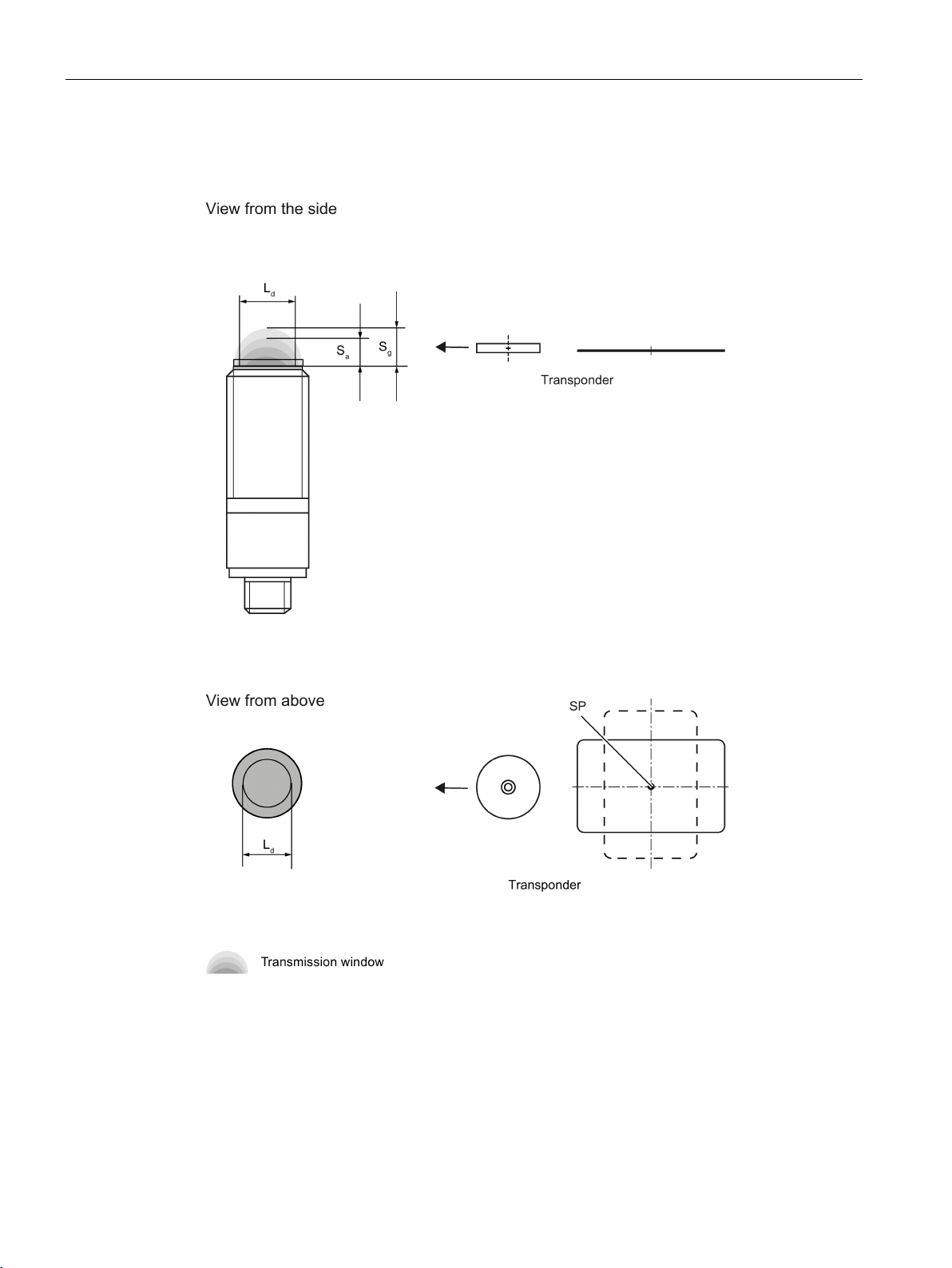

The picture below shows the transmission window of the SIMATIC RF210R and

SIMATIC RF220R readers between transponder and reader:

Sg Limit distance (maximum clear distance between upper surface of the reader and the tran-

Figure 4-1 RF210R/RF220R transmission window

SIMATIC RF200

26 System Manual, 07/2015, J31069-D0227-U001-A9-7618

RF200 system planning

Sa

Operating distance between transponder and reader

sponder, at which the transmission can still function under normal conditions)

L

Length of a transmission window

M

Field centerpoint

4.1 Fundamentals of application planning

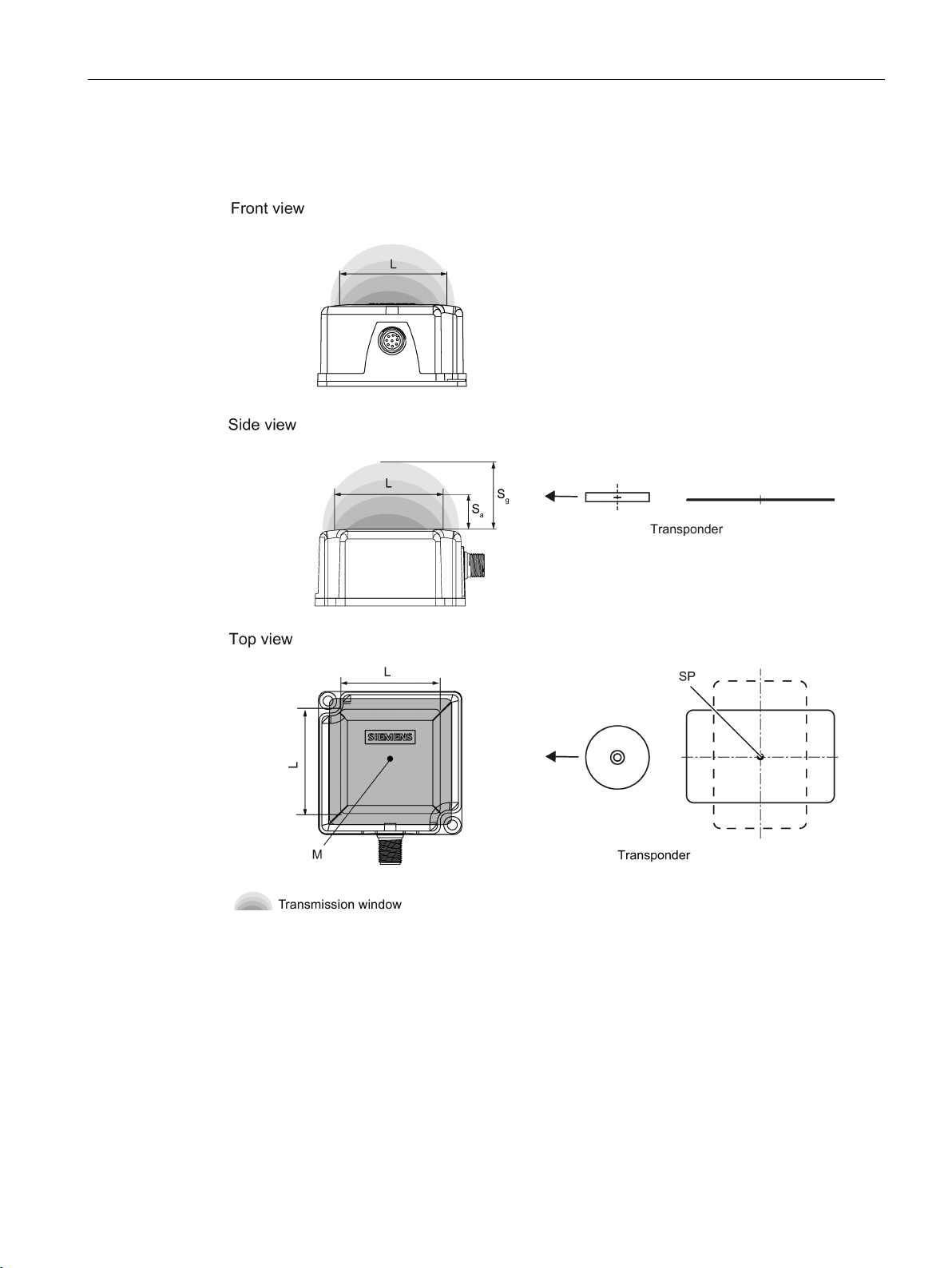

The figure below shows the transmission window of the SIMATIC RF240R and SIMATIC

RF260R readers between transponder and reader:

Sg Limit distance (maximum clear distance between upper surface of the reader and the tran-

Figure 4-2 RF240R/RF260R transmission window

The transponder can be used as soon as the intersection (SP) of the transponder enters the

area of the transmission window.

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

27

RF200 system planning

4.1.3

Width of the transmission window

Determining the width of the transmission window

B:

Width of the transmission window

L:

Length of the transmission window

Tracking tolerances

4.1 Fundamentals of application planning

From the diagrams above, it can also be seen that operation is possible within the area

and Sg. The active operating area reduces as the distance increases, and

a

. Only static mode should thus be used in the area

g

and Sg.

a

between S

shrinks to a single point at distance S

between S

The following approximation formula can be used for practical applications:

The width of the transmission window (B) is particularly important for the mechanical tracking

tolerance. The formula for the dwell time is valid without restriction when B is observed.

SIMATIC RF200

28 System Manual, 07/2015, J31069-D0227-U001-A9-7618

RF200 system planning

4.1.4

Impact of secondary fields

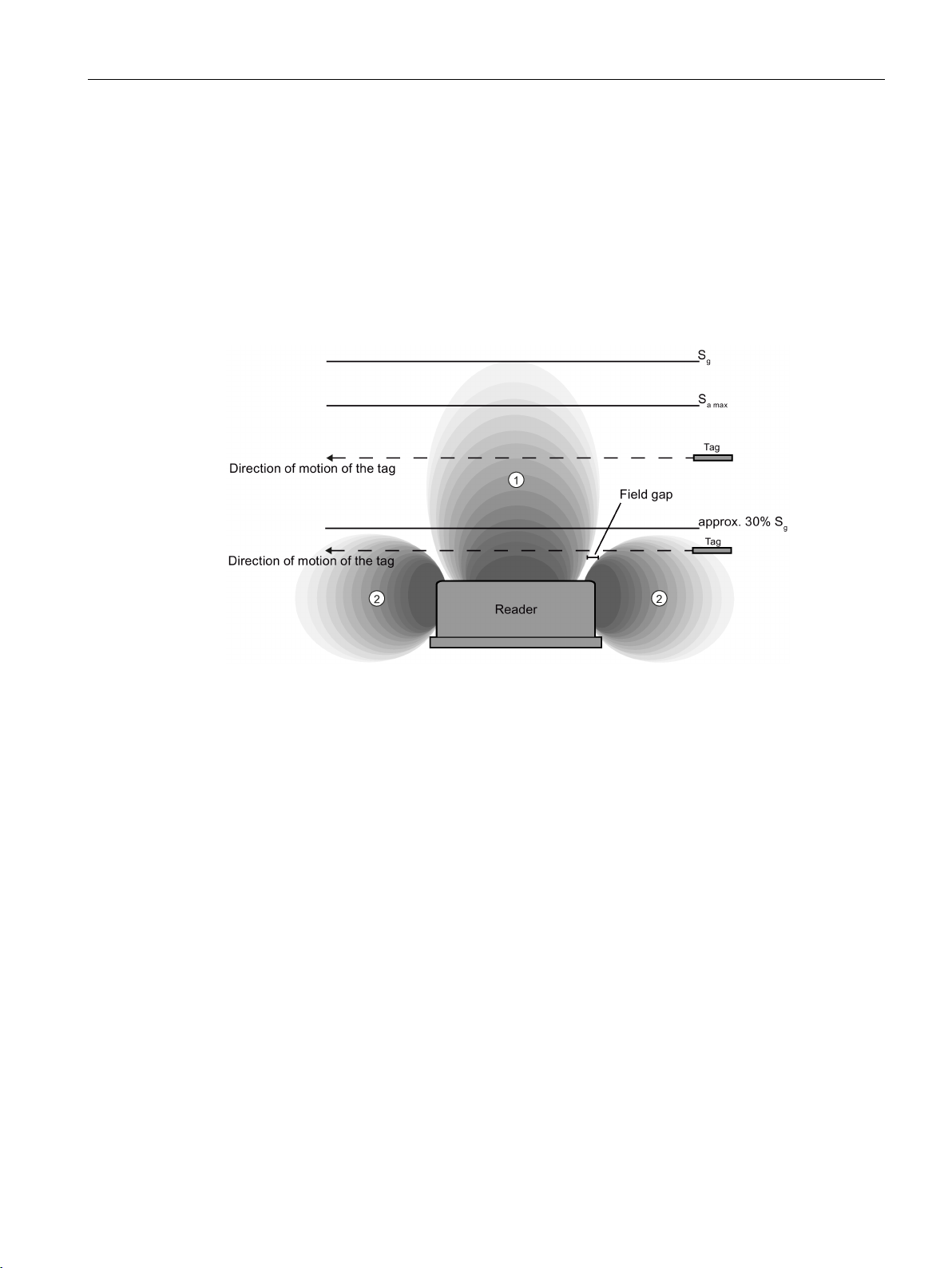

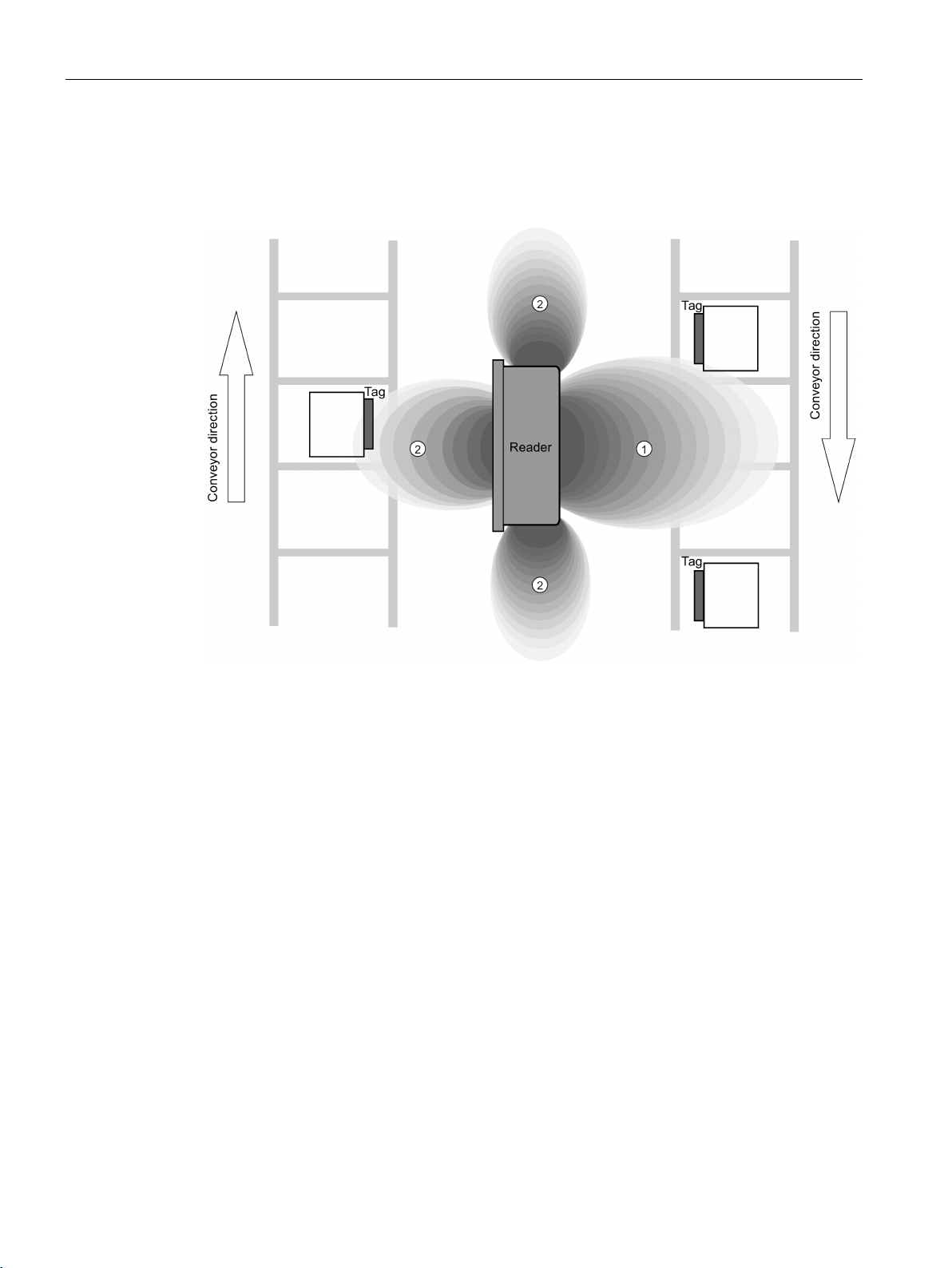

①

Main field

②

Secondary field

4.1 Fundamentals of application planning

Secondary fields in the range from 0 mm to 30% of the limit distance (Sg) generally always

exist.

They should, however, only be used during configuration in exceptional cases, since the

read/write distances are very limited. Exact details of the secondary field geometry cannot be

given, since these values depend heavily on the operating distance and the application.

When working in dynamic mode, remember that during the transition from the secondary

field to the main field the presence of the tag is lost temporarily. It is therefore advisable to

select a distance > 30 % of S

.

g

Figure 4-3 Gap in the field resulting from secondary fields

SIMATIC RF200

System Manual, 07/2015, J31069-D0227-U001-A9-7618

29

RF200 system planning

Secondary fields without shielding

①

Main field

②

Secondary field

4.1 Fundamentals of application planning