Page 1

_

_

_

_

_

_

_

_

_

_

_

_

_

SIMATIC HMI HMI device OP 73micro, TP 177micro (WinCC flexible)

Introduction

Overview

_____________

1

SIMATIC HMI

HMI device

OP 73micro, TP 177micro

(WinCC flexible)

Operating Instructions

Safety instructions and

general notes

_____________

Planning use

_____________

Mounting and connection

_____________

Operator control components

and LEDs

_____________

Configuring the operating

system

_____________

Preparing and backing up a

project

_____________

Operating a project

_____________

2

3

4

5

6

7

8

Order No. 6AV6691-1DF01-0AB0

Operating alarms

_____________

Maintenance and servicing

_____________

Specifications

_____________

Appendix

_____________

Abbreviations

_____________

9

10

11

A

B

09/2007

A5E01006740-02

Page 2

Safety Guidelines

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

WARNING

This device may only be used for the applications described in the catalog or the technical description and only

in connection with devices or components from other manufacturers which have been approved or

recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage,

positioning and assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order Nr.: 6AV6691-1DF01-0AB0

Ⓟ 09/2007

Copyright © Siemens AG 2007.

Technical data subject to change

Page 3

Introduction

Purpose of the operating instructions

This operating instruction manual provides information based on the requirements defined by

DIN 8418 for mechanical engineering documentation. This information relates to the device,

its place of use, transport, storage, installation, use and maintenance.

These operating instructions are intended for:

● Users

● Commissioning engineers

● Service technicians

● Maintenance technicians

Please read the section "Safety instructions and general notes" carefully.

The help integrated in WinCC flexible, the WinCC flexible Information System, contains

detailed information. The Information System contains instructions, examples and reference

information in electronic form.

Basic knowledge required

General knowledge of automation technology and process communication is needed to

understand the operating instructions.

It is also assumed that those using the manual have experience in using personal computers

and knowledge of Microsoft operating systems.

Operating instructions' range of validity

The operating instruction manual applies to the OP 73micro and TP 177micro HMI devices in

connection with the WinCC flexible software package.

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

3

Page 4

Introduction

Position in the information landscape

These operating instructions form part of the SIMATIC HMI documentation. The following

information provides you with an overview of the SIMATIC HMI information landscape.

User manuals

● WinCC flexible Micro:

Describes basic principles of configuration using the WinCC flexible Micro Engineering

System.

● WinCC flexible Compact/Standard/Advanced:

Describes basic principles of configuration using the WinCC flexible Compact

Engineering System/WinCC flexible Standard/WinCC flexible Advanced

● WinCC flexible Runtime:

Describes how to commission and operate your runtime project on a PC.

● WinCC flexible Migration:

– Describes how to convert an existing ProTool project to WinCC flexible.

– Describes how to convert an existing WinCC project to WinCC flexible.

– Describes how to convert an existing ProTool project including a change of the HMI

device, e.g. from OP7 to OP 77B or OP7 to OP 77B.

– Describes how to convert an existing ProTool project including a change from a

graphics device to a Windows CE device.

● Communication:

– Communication Part 1 describes the connection of the HMI device to SIMATIC PLCs.

– Communication Part 2 describes the connection of the HMI device to third-party PLCs.

Operating instructions

● Operating instructions for SIMATIC HMI devices.

– OP 73micro, TP 177micro

– OP 73, OP 77A, OP 77B

– TP 177A

– TP 170micro, TP 170A, TP 170B, OP 170B

– Mobile Panel 170

– TP 270, OP 270

– MP 270B

– MP 370

● Operating instructions (compact) for the HMI devices SIMATIC OP

Panel 170

77B and Mobile

OP 73micro, TP 177micro (WinCC flexible)

4 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 5

Introduction

Getting Started

● WinCC flexible for first time users:

Based on an example project, this is a step-by-step introduction to the basics of

configuring screens, alarms, recipes and screen navigation.

● WinCC flexible for advanced users:

Based on an example project, this is a step-by-step introduction to the basics of

configuring logs, project reports, scripts, user management and multilingual projects and

integration in STEP 7.

● WinCC flexible options:

Based on an example project, this is a step-by-step introduction to the basics of

configuring the WinCC flexible Sm@rtServices, Sm@rtAccess and OPC Server options.

Online availability

Technical documentation on SIMATIC products and SIMATIC systems is available in PDF

format in various languages at the following addresses:

● SIMATIC Guide Technische Dokumentation in Deutsch:

"

http://www.ad.siemens.de/simatic/portal/html_00/techdoku.htm"

Conventions

● SIMATIC Guide for Technical Documentation in English:

"

http://www.ad.siemens.de/simatic/portal/html_76/techdoku.htm"

Configuration and runtime software differ with regard to their names as follows:

● "WinCC flexible 2004," for example, refers to the configuration software.

The term "WinCC flexible" is used in a general context. The full name, for example

"WinCC flexible 2004", is always used when it is necessary to differentiate between

different versions of the configuration software.

● "WinCC flexible Runtime" refers to the runtime software that can run on HMI devices.

Text is highlighted as follows to simplify reading the operating instructions:

Notation Scope

"Add screen"

"File > Edit" Operational sequences, e.g., menu commands, context menu

<F1>, <Alt+P> Keyboard operation

• Terminology that appears in the user interface, e.g., dialog

names, tabs, buttons, menu entries

• Inputs required, e.g., limit values, tag values

• Path information

commands

Note

Notes contain important information concerning the product, its use or a specific section of

the documentation to which you should pay particular attention.

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Please observe notes labeled as follows:

5

Page 6

Introduction

Registered trademarks

Names labeled with a ® symbol are registered trademarks of the Siemens AG. Other names

used in this documentation may be trademarks, the use of which by third parties for their

own purposes could violate the rights of the owner.

®

● HMI

● SIMATIC

● SIMATIC HMI

● SIMATIC ProTool

● SIMATIC WinCC

● SIMATIC WinCC flexible

● SIMATIC OP 73micro

● SIMATIC TP 177micro

®

®

®

®

®

®

®

Representatives and offices

If you have any further questions relating to the products described in this manual, please

contact your local representative at the SIEMENS branch nearest you.

Find your contact partner at:

"

http://www.siemens.com/automation/partner"

Training center

Siemens AG offers a variety of training courses in order to familiarize you with automation

systems. Please contact your regional training center or the central training center in D90327 Nuremberg, Germany.

Phone: +49 (911) 895-3200

Internet: "

http://www.sitrain.com"

Service & support on the Internet

Service & Support offers online services for additional, comprehensive information on

SIMATIC products at

http://www.siemens.com/automation/support":

"

● The newsletter offers you the latest information about your products.

● A large document base is available using our Service & Support search engine.

● A forum for global exchange of information by users and experts

● Current product information, FAQs and downloads

● Your local Automation & Drives representative

● Information about field service, repairs, spare parts and much more under the heading

"Services"

OP 73micro, TP 177micro (WinCC flexible)

6 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 7

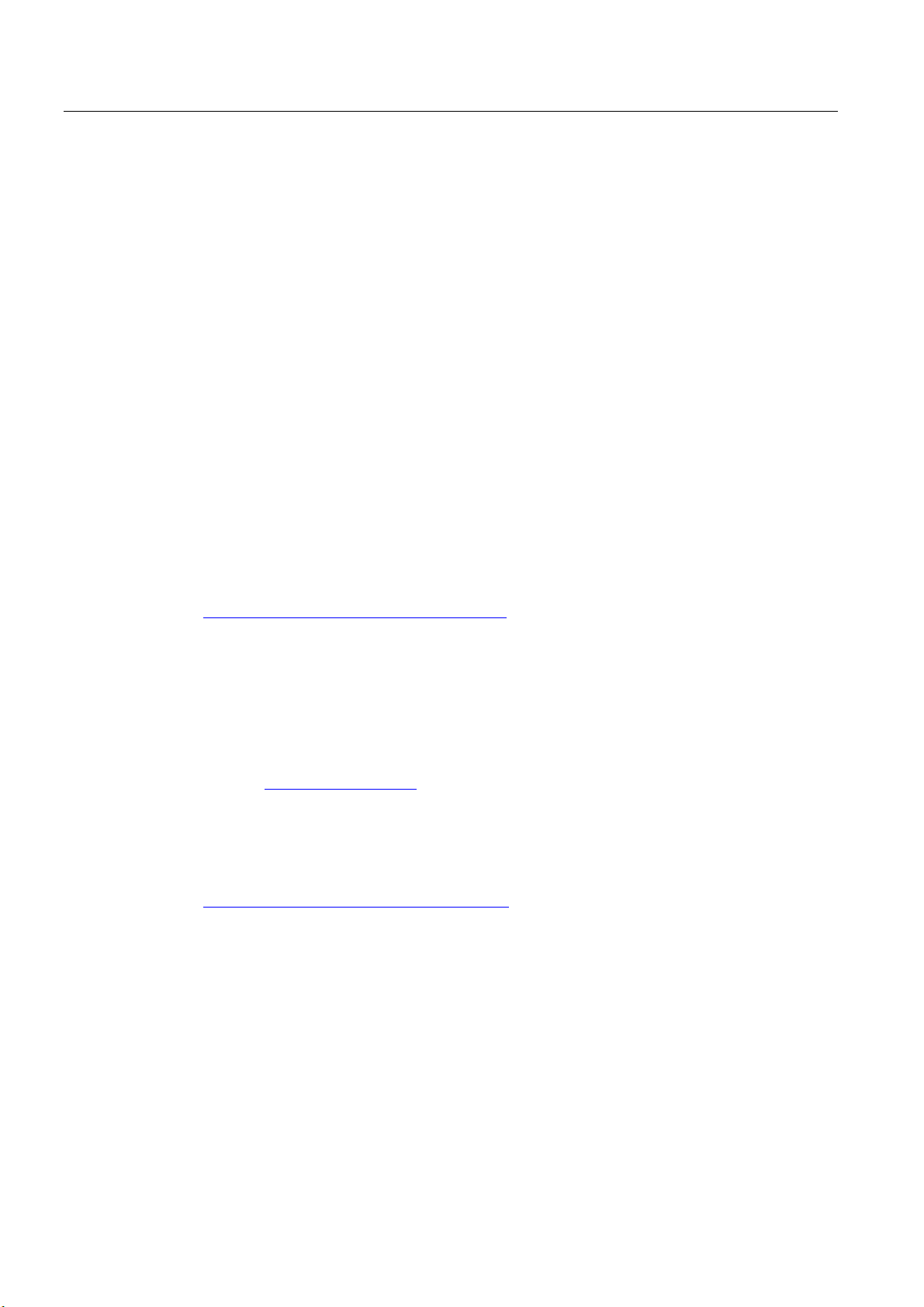

Table of contents

Introduction................................................................................................................................................ 3

1 Overview..................................................................................................................................................

1.1 Product overview .........................................................................................................................

1.2 Design of the OP 73micro HMI device.........................................................................................

1.3 Design of the TP 177micro HMI device .......................................................................................

1.4 Accessories..................................................................................................................................

1.5 Miscellaneous ..............................................................................................................................

1.6 Range of HMI software functions.................................................................................................

1.7 Communication with PLCs...........................................................................................................

2 Safety instructions and general notes......................................................................................................

2.1 Safety instructions........................................................................................................................

2.2 Standards, Certificates and Approvals ........................................................................................

2.3 Notes about usage.......................................................................................................................

2.4 Electromagnetic compatibility ......................................................................................................

2.5 Transport and storage conditions ................................................................................................

3 Planning use............................................................................................................................................

3.1 Mounting information ...................................................................................................................

3.2 Mounting the OP 73micro ............................................................................................................

3.2.1 Mounting positions and fixation....................................................................................................

3.2.2 Preparing for mounting ................................................................................................................

11

11

12

13

13

14

14

16

17

17

18

20

23

25

27

27

30

30

31

3.3 Mounting the TP 177micro...........................................................................................................

3.3.1 Mounting positions and fixation....................................................................................................

3.3.2 Preparing for mounting ................................................................................................................

3.4 Information on insulation tests, protection class and degree of protection..................................

3.5 Nominal voltages .........................................................................................................................

4 Mounting and connection.........................................................................................................................

4.1 Checking the package contents...................................................................................................

4.2 Mounting and connecting the OP 73micro...................................................................................

4.2.1 Mounting the HMI device .............................................................................................................

4.2.2 Connecting the HMI device..........................................................................................................

4.2.2.1 Interfaces .....................................................................................................................................

4.2.2.2 Connecting the equipotential bonding circuit...............................................................................

4.2.2.3 Connecting the PLC.....................................................................................................................

4.2.2.4 Connecting the configuration computer .......................................................................................

4.2.3 Switching on power and testing the HMI device..........................................................................

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

33

33

35

37

38

39

39

39

39

40

41

42

44

44

46

7

Page 8

Table of contents

4.3 Mounting and connecting the TP 177micro ................................................................................ 48

4.3.1 Mounting the HMI device ............................................................................................................

4.3.2 Connecting the HMI device.........................................................................................................

4.3.2.1 Interfaces ....................................................................................................................................

4.3.2.2 Connecting the equipotential bonding circuit..............................................................................

4.3.2.3 Connecting the PLC....................................................................................................................

4.3.2.4 Connecting the configuration computer ......................................................................................

4.3.3 Switching on power and testing the HMI device .........................................................................

48

49

50

50

53

53

55

4.4 Communication with S7-200 .......................................................................................................

4.4.1 Topologies...................................................................................................................................

4.4.1.1 Communication via a point-to-point connection..........................................................................

4.4.1.2 Communication in the network....................................................................................................

4.4.1.3 Configuration instructions............................................................................................................

4.4.2 Configuring communication ........................................................................................................

4.4.2.1 Configuring protocol parameters.................................................................................................

4.4.3 User data areas...........................................................................................................................

4.4.3.1 Communication between HMI device and controller ..................................................................

4.4.3.2 Permitted data types ...................................................................................................................

4.4.3.3 Time synchronization via area pointer ........................................................................................

4.4.3.4 Mechanism of error alarm acknowledgment...............................................................................

5 Operator control components and LEDs..................................................................................................

5.1 Front side operator control components and indicators on the OP 73micro ..............................

5.2 Front side operator control components and LEDs on the TP 177micro....................................

6 Configuring the operating system ............................................................................................................

6.1 Configuring the operating system for the OP 73micro................................................................

6.1.1 Overview .....................................................................................................................................

6.1.2 "Info/Settings" menu....................................................................................................................

6.1.2.1 Overview .....................................................................................................................................

6.1.2.2 Setting screen contrast ...............................................................................................................

6.1.2.3 Displaying information about the HMI device..............................................................................

6.1.2.4 Viewing information about the version of the HMI device image................................................

6.1.3 "Settings" menu...........................................................................................................................

6.1.3.1 Overview .....................................................................................................................................

6.1.3.2 Setting the delay .........................................................................................................................

6.1.3.3 Setting the screen saver .............................................................................................................

6.1.3.4 Assigning, editing and deleting passwords.................................................................................

6.1.3.5 Configure the data channel.........................................................................................................

57

57

57

58

60

60

61

63

63

63

64

66

69

69

70

71

71

71

72

72

74

74

75

75

75

76

76

77

79

6.2 Configuring the operating system for the TP 177micro ..............................................................

6.2.1 Overview .....................................................................................................................................

6.2.2 Control Panel ..............................................................................................................................

6.2.2.1 Overview .....................................................................................................................................

6.2.2.2 Changing screen settings............................................................................................................

6.2.2.3 Displaying information about the HMI device..............................................................................

6.2.2.4 Calibrating the touch screen .......................................................................................................

6.2.2.5 Changing the password setting for the Control Panel ................................................................

6.2.2.6 Setting the Screen Saver ............................................................................................................

6.2.2.7 Configure the data channel.........................................................................................................

7 Preparing and backing up a project .........................................................................................................

7.1 Overview .....................................................................................................................................

7.1.1 Setting the operating mode.........................................................................................................

7.1.2 Reusing existing projects ............................................................................................................

OP 73micro, TP 177micro (WinCC flexible)

80

80

81

81

82

84

85

86

87

88

89

89

90

91

8 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 9

Table of contents

7.1.3 Data Transfer Options..................................................................................................................92

7.2 Transfer........................................................................................................................................

7.2.1 Overview ......................................................................................................................................

7.2.2 Starting transfer............................................................................................................................

7.2.3 Testing a project ..........................................................................................................................

7.3 Backup and restore......................................................................................................................

7.3.1 Overview of backup and restoring ...............................................................................................

7.3.2 Resetting to Factory Settings for Backup and Restore................................................................

7.3.3 Backup and Restore via WinCC flexible ......................................................................................

7.3.4 Backup and Restore via ProSave................................................................................................

7.4 Updating the operating system ..................................................................................................

7.4.1 Overview ....................................................................................................................................

7.4.2 Updating the operating system using WinCC flexible................................................................

7.4.3 Updating the operating system in ProSave ...............................................................................

8 Operating a project ................................................................................................................................

8.1 Operating a project on OP 73micro ...........................................................................................

8.1.1 Overview ....................................................................................................................................

8.1.2 Setting the project language ......................................................................................................

8.1.3 Entries and help within a project................................................................................................

8.1.3.1 Overview ....................................................................................................................................

8.1.3.2 Entering and Editing Numerical and Alphanumerical Values ....................................................

8.1.3.3 Entering and editing symbolic values ........................................................................................

8.1.3.4 Entering and modifying date and time .......................................................................................

8.1.3.5 Viewing infotext..........................................................................................................................

8.1.4 Project security ..........................................................................................................................

8.1.5 Close the project. .......................................................................................................................

92

92

93

94

95

95

96

96

98

100

100

101

102

103

103

103

105

105

105

107

110

111

112

113

114

8.2 Operating a project on TP 177micro..........................................................................................

8.2.1 Overview ....................................................................................................................................

8.2.2 Setting the project language ......................................................................................................

8.2.3 Entries and help within a project................................................................................................

8.2.3.1 Overview ....................................................................................................................................

8.2.3.2 Entering and editing numerical values.......................................................................................

8.2.3.3 Entering and editing alphanumerical values..............................................................................

8.2.3.4 Entering and editing symbolic values ........................................................................................

8.2.3.5 Entering and modifying date and time .......................................................................................

8.2.3.6 Viewing infotext..........................................................................................................................

8.2.4 Project security ..........................................................................................................................

8.2.5 Close the project. .......................................................................................................................

8.2.6 Operating the Trend View..........................................................................................................

8.2.6.1 Overview ....................................................................................................................................

8.2.6.2 Operating the Trend View..........................................................................................................

9 Operating alarms ...................................................................................................................................

9.1 Overview ....................................................................................................................................

9.2 Operating alarms on the OP 73micro ........................................................................................

9.2.1 Displaying alarms.......................................................................................................................

9.2.2 Acknowledging an Alarm ...........................................................................................................

9.2.3 Editing an Alarm.........................................................................................................................

9.3 Operating alarms on the TP 177micro.......................................................................................

9.3.1 Displaying alarms.......................................................................................................................

9.3.2 Acknowledging an Alarm ...........................................................................................................

9.3.3 Editing an Alarm.........................................................................................................................

115

115

116

117

117

118

120

121

122

123

124

125

125

125

126

127

127

128

128

131

131

132

132

134

135

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

9

Page 10

Table of contents

10 Maintenance and servicing .................................................................................................................... 137

10.1 Maintenance and service ..........................................................................................................

10.1.1 Cleaning screen ........................................................................................................................

10.1.2 Protective membrane................................................................................................................

10.2 Servicing and spare parts .........................................................................................................

11 Specifications ........................................................................................................................................

11.1 Dimensional drawings ...............................................................................................................

11.1.1 Dimensional drawings, OP 73micro..........................................................................................

11.1.2 Dimensional drawings, TP 177micro ........................................................................................

11.2 Specifications ............................................................................................................................

11.2.1 Specifications of the OP 73micro..............................................................................................

11.2.2 Specifications of the TP 177micro ............................................................................................

11.3 Description of interfaces............................................................................................................

11.3.1 Power supply.............................................................................................................................

11.3.2 RS485 (IF 1B) on OP 73micro ..................................................................................................

11.3.3 RS 485 (IF 1B) on TP 177micro................................................................................................

A Appendix................................................................................................................................................

A.1 ESD Directives ..........................................................................................................................

A.2 System alarms ..........................................................................................................................

B Abbreviations.........................................................................................................................................

Glossary ................................................................................................................................................

137

138

138

139

141

141

141

142

143

143

144

146

146

146

147

149

149

151

175

177

Index......................................................................................................................................................

183

OP 73micro, TP 177micro (WinCC flexible)

10 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 11

Overview

1.1 Product overview

Micro Panels OP 73micro and TP 177micro – particularly suitable for SIMATIC S7-200

Our new Micro Panels are tailored to applications with SIMATIC S7-200 Micro PLC and

provide operating and monitoring functions for small-scale machines and plants. Short

configuration and commissioning times, and their configuration in WinCC flexible form

highlights of these panels. In addition, the panels support up to 32 configuration languages

and five online languages, including the Asian and Cyrillic character sets.

The mounting dimensions of the Operator Panel OP 73micro with its graphical 3" display unit

are compatible with OP3 and TD200.

Touch Panel TP 177micro replaces the Touch Panel TP 070/TP 170micro. It can be

mounted vertically to provide additional application. This feature enables its use even when

space is restricted.

1

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

11

Page 12

Overview

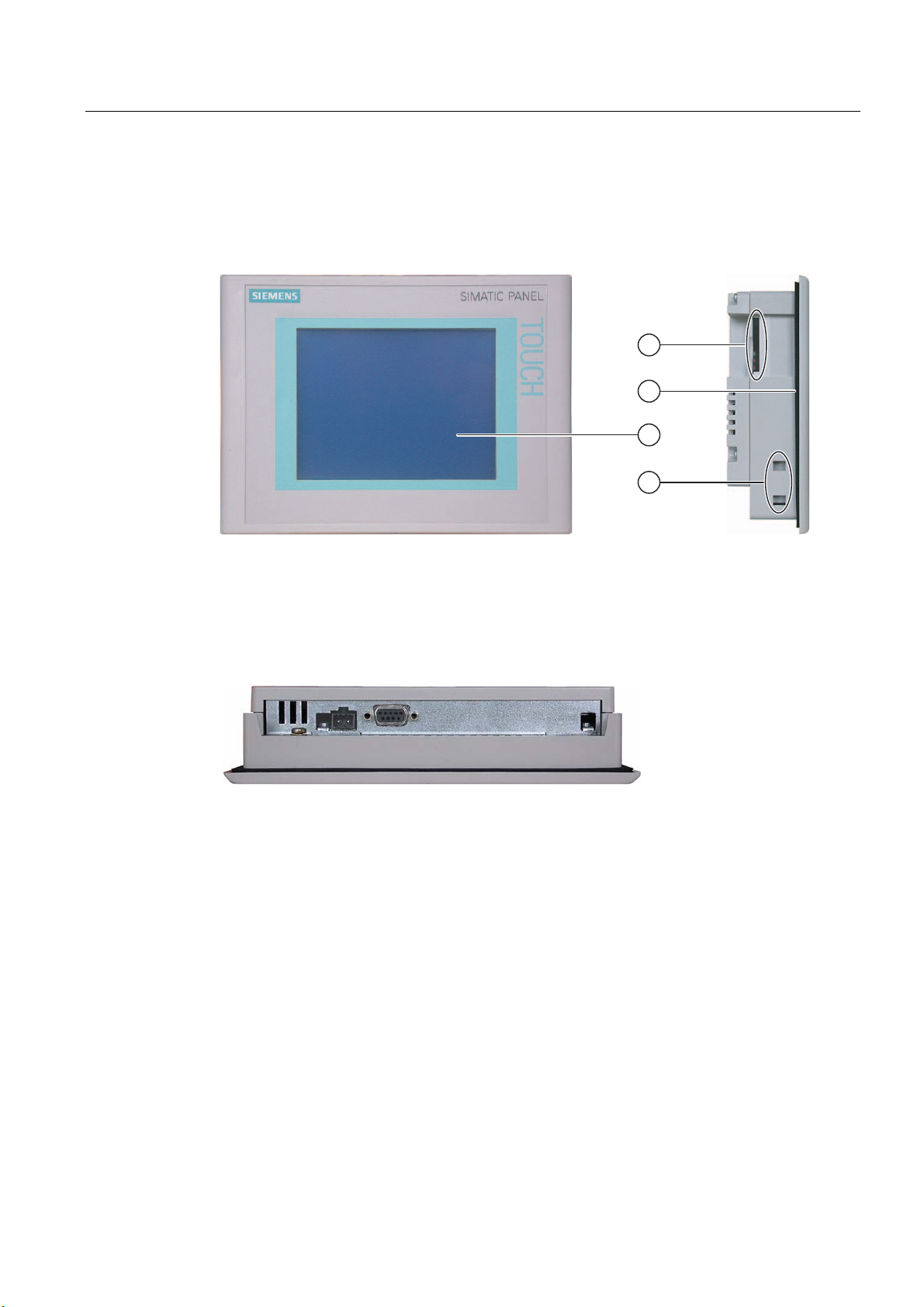

1.2 Design of the OP 73micro HMI device

1.2 Design of the OP 73micro HMI device

Views of the HMI device

1

2

3

4

Figure 1-1 Front and side view

① Display

② Membrane keyboard

③ Clamping recess

④ Mounting seal

Figure 1-2 Bottom view

OP 73micro, TP 177micro (WinCC flexible)

12 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 13

Overview

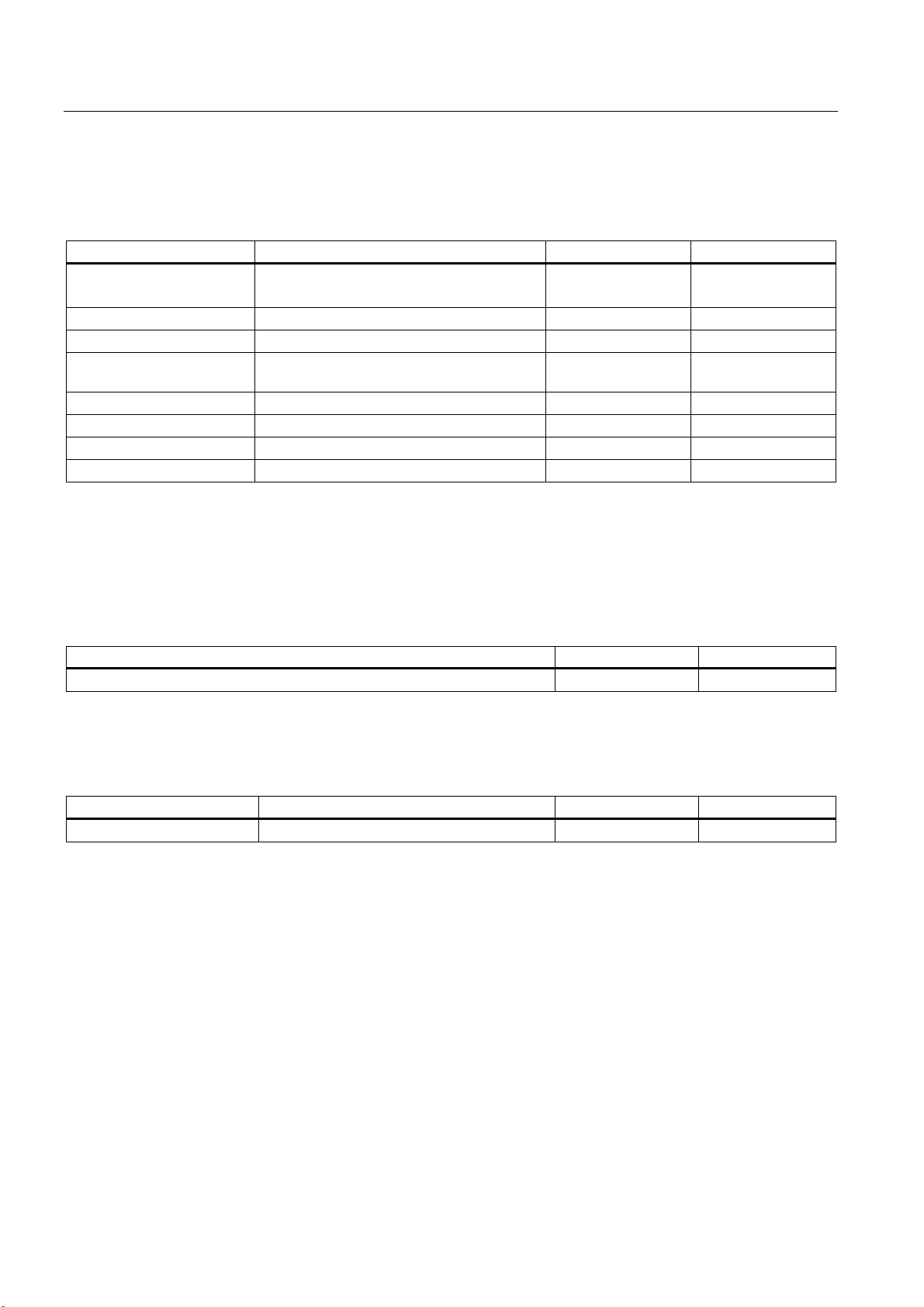

1.3 Design of the TP 177micro HMI device

1.3 Design of the TP 177micro HMI device

Views of the HMI device

Figure 1-3 Front view and side view

① Construction-related opening – not a slot for a memory card

② Mounting seal

③ Display / Touch screen

④ Clamping recess

Figure 1-4 Bottom view

1.4 Accessories

Accessory kit

The accessory kit contains the following:

● A terminal block for the power supply

● Four mounting clamps for installing a TP 177micro

● Two mounting clamps for installing an OP 73

Additional documents may be enclosed with the accessory kit.

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

13

Page 14

Overview

1.5 Miscellaneous

1.5 Miscellaneous

PC-PPI adapter

For the conversion from RS 232 to RS 485, order the PC-PPI adapter, Order No.

6ES7 901- 3CB30-0XA0, from Siemens AG. You need the PC-PPI adapter, for example, to

update the operating system or to transfer project data.

Protective membrane

A protective membrane is available for TP 177micro, order no. 6AV6 671-2XC00-0AX0.

1.6 Range of HMI software functions

General

The following tables show the objects the user can integrate in a project for an OP 73micro

and TP 177micro.

Note

The specified values are maximum values of the individual objects. Simultaneous use of

multiple objects with their maximum value can lead to problems in the active project.

Alarms

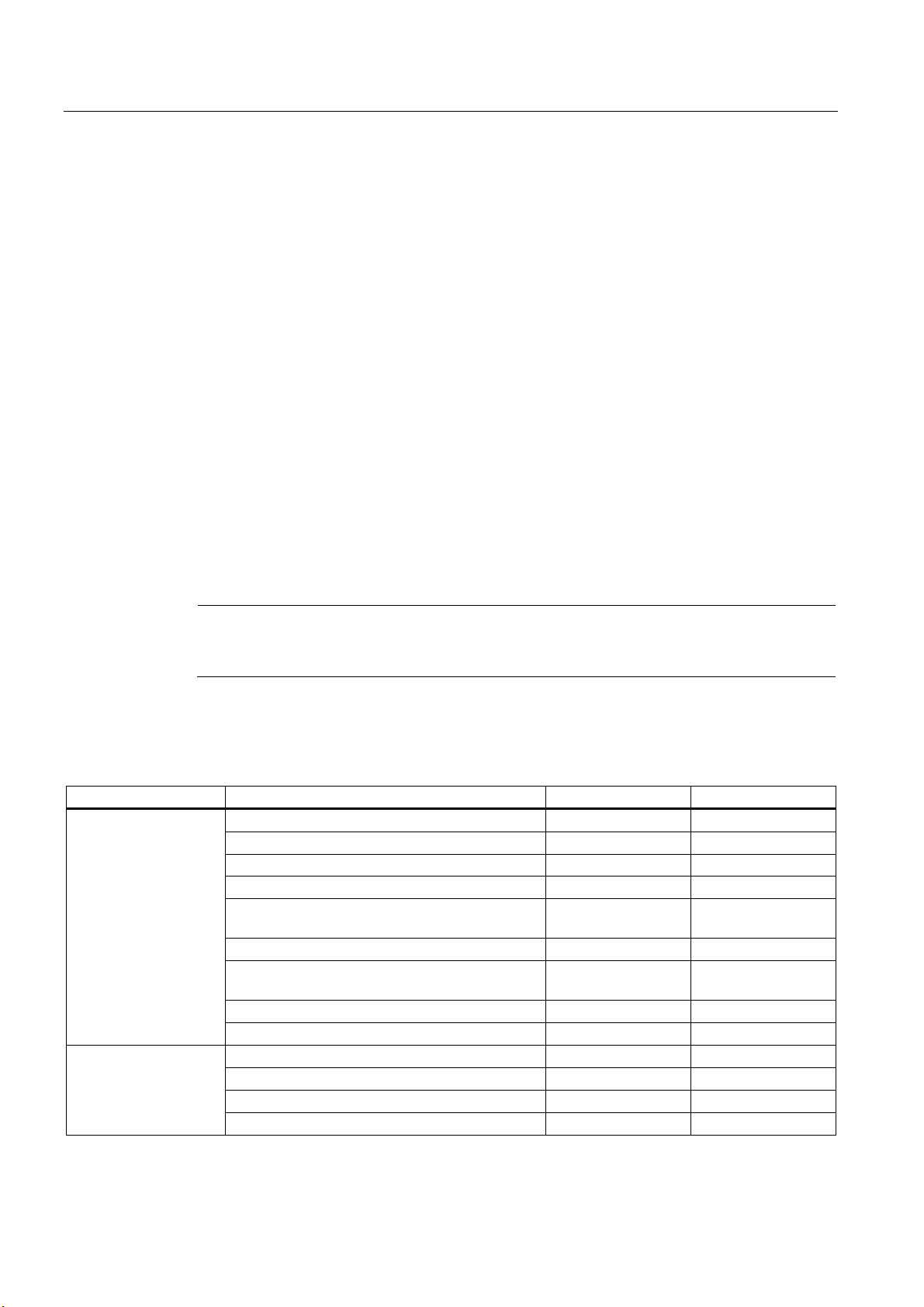

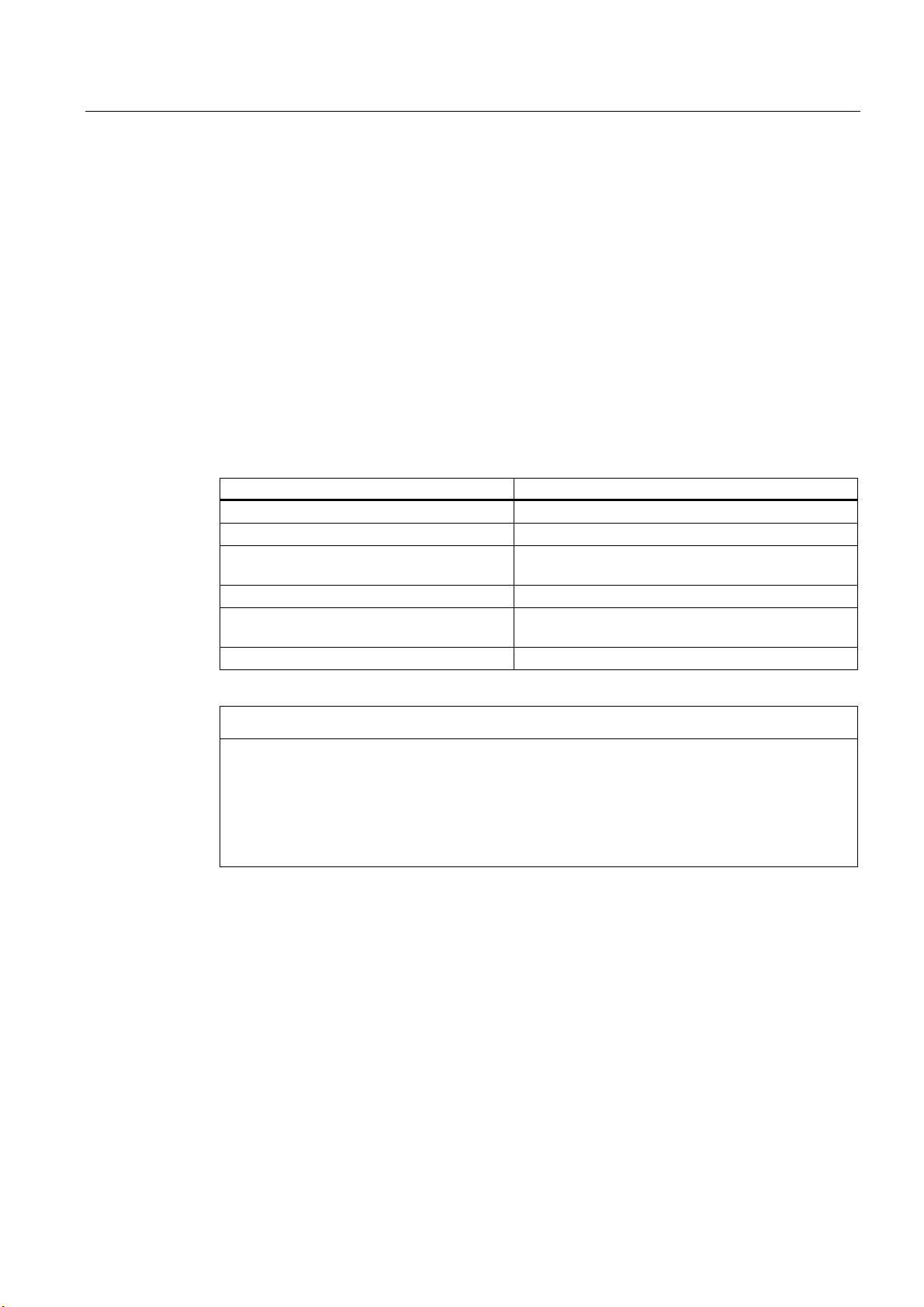

Table 1-1 Range of functions for alarms

Object Specification OP 73micro TP 177micro

Alarm

Volatile alarm buffer

Number of discrete alarms 250 500

Number of analog alarms 5 20

Length of the alarm text 80 characters 80 characters

Number of tags in an alarm Max. 8 Max. 8

Display Alarm view,

Alarm window

Acknowledge single error alarms Yes Yes

Acknowledge several error alarms simultaneously

(group acknowledgement)

Edit alarm Yes Yes

Alarm indicator Yes Yes

Alarm buffer capacity 100 alarms 128 alarms

Simultaneously queued alarm events Max. 30 Max. 32

View alarm Yes Yes

Delete alarm buffer Yes Yes

Yes Yes

Alarm view,

Alarm window

OP 73micro, TP 177micro (WinCC flexible)

14 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 15

Overview

1.6 Range of HMI software functions

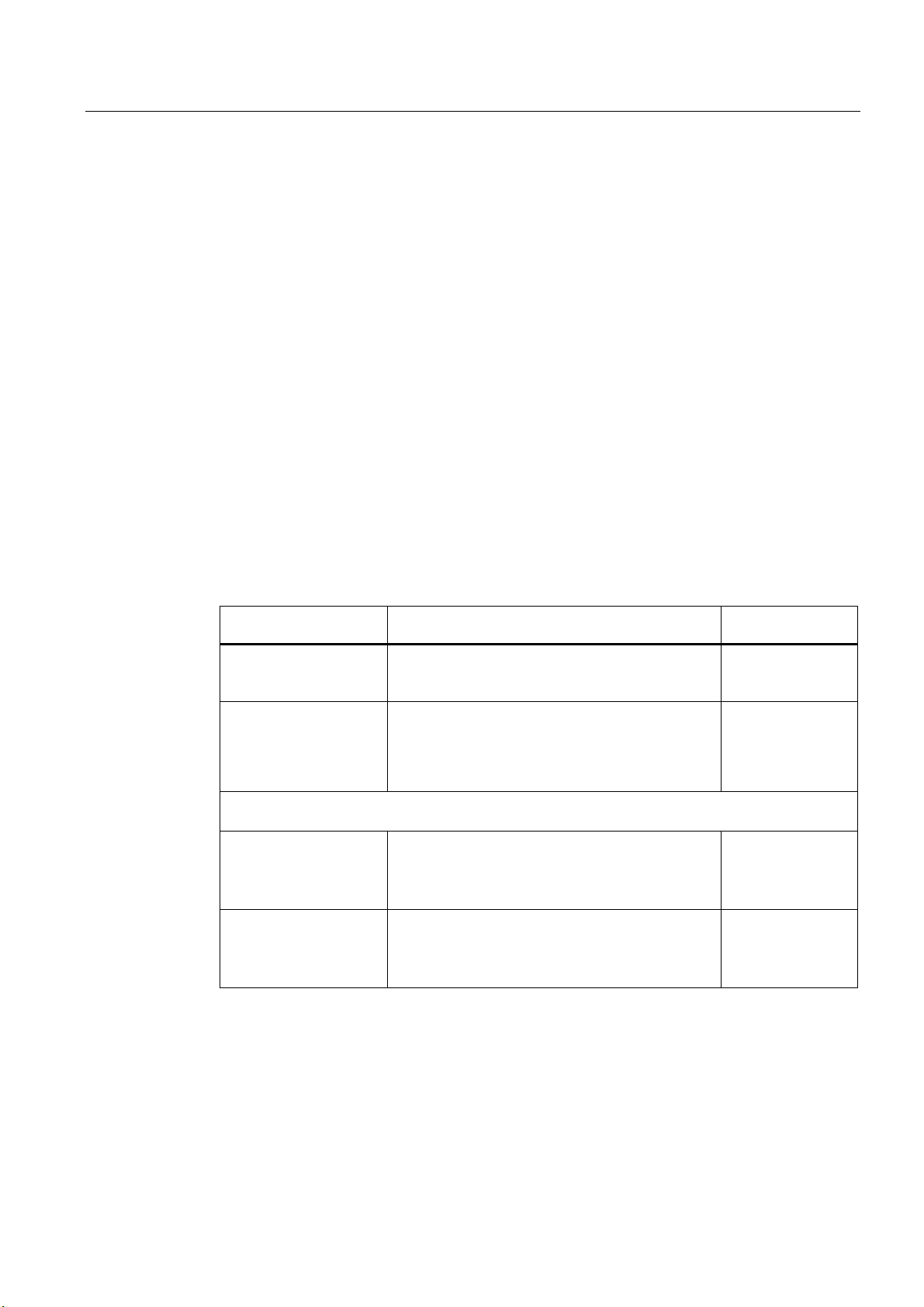

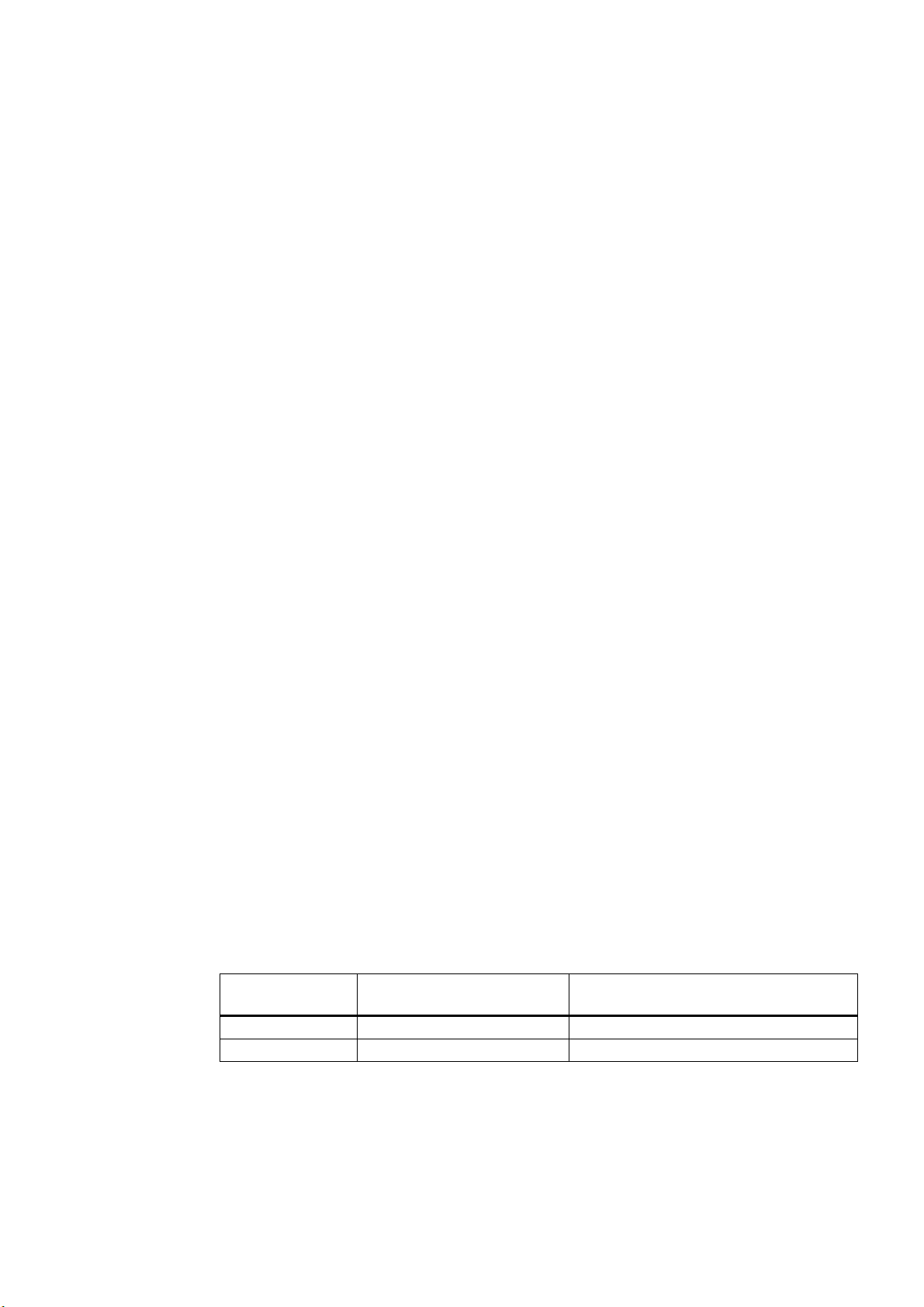

Tags, values and lists

Table 1-2 Range of functions for tags, values and lists

Object Specification OP 73micro TP 177micro

Tags Number 500 250

Limit-value monitoring Input Input/Output

Linear Scaling Input/Output Yes Yes

Text lists Number 150 150

Screens

Table 1-3 Range of functions for screens

Object Specification OP 73micro TP 177micro

Screen

Number 250 250

Fields per screen 20 20

Tags per screen 20 20

Complex objects per screen (e.g. bars) 5 5

Template Yes Yes

Infotext

Table 1-4 Range of functions for infotext

Object Specification OP 73micro TP 177micro

Infotext

Length (no. of characters) 320 320

For alarms Yes Yes

For screens Yes Yes

For screen objects (e.g. IO fields) Yes Yes

Help indicator Yes No

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

15

Page 16

Overview

1.7 Communication with PLCs

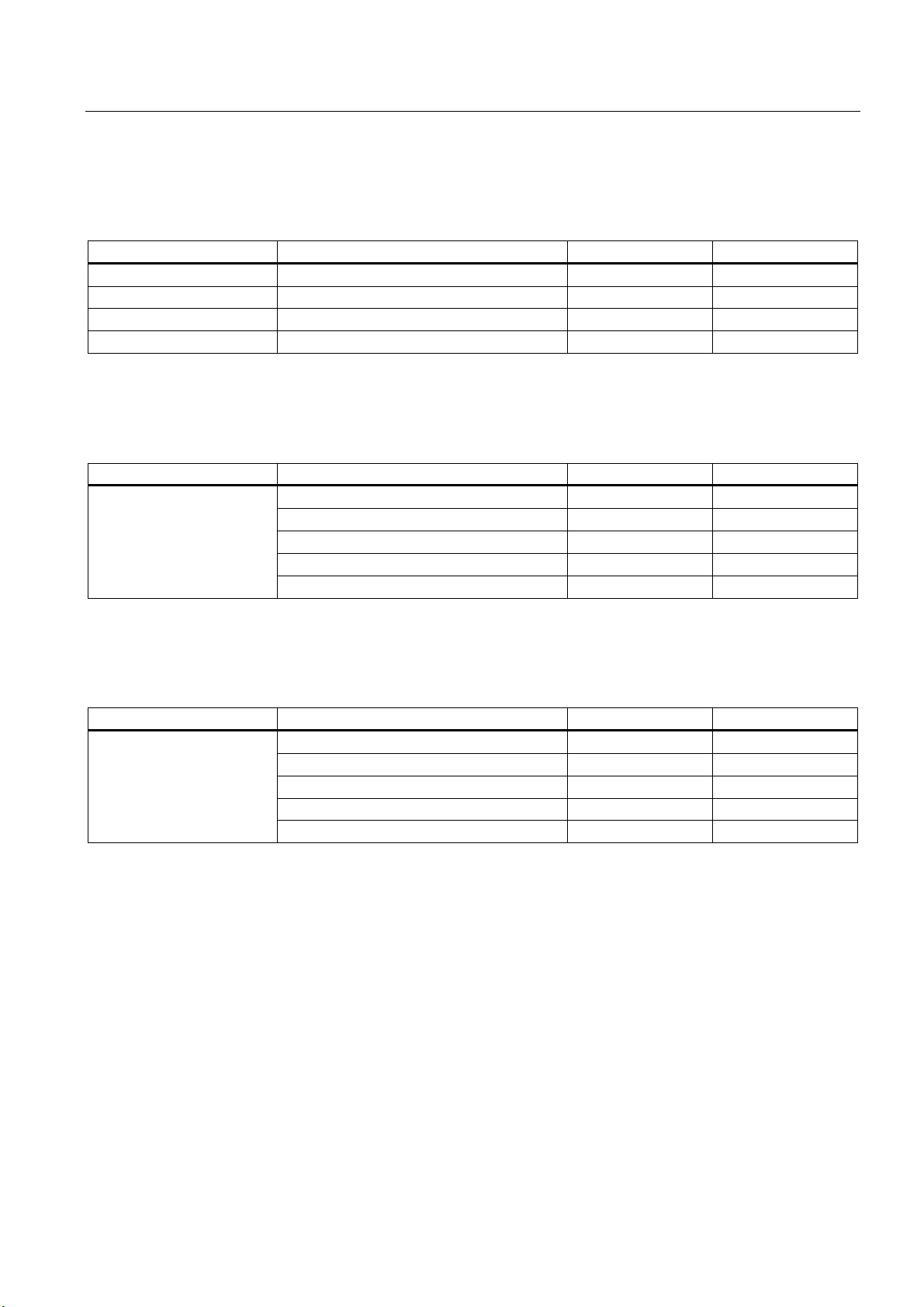

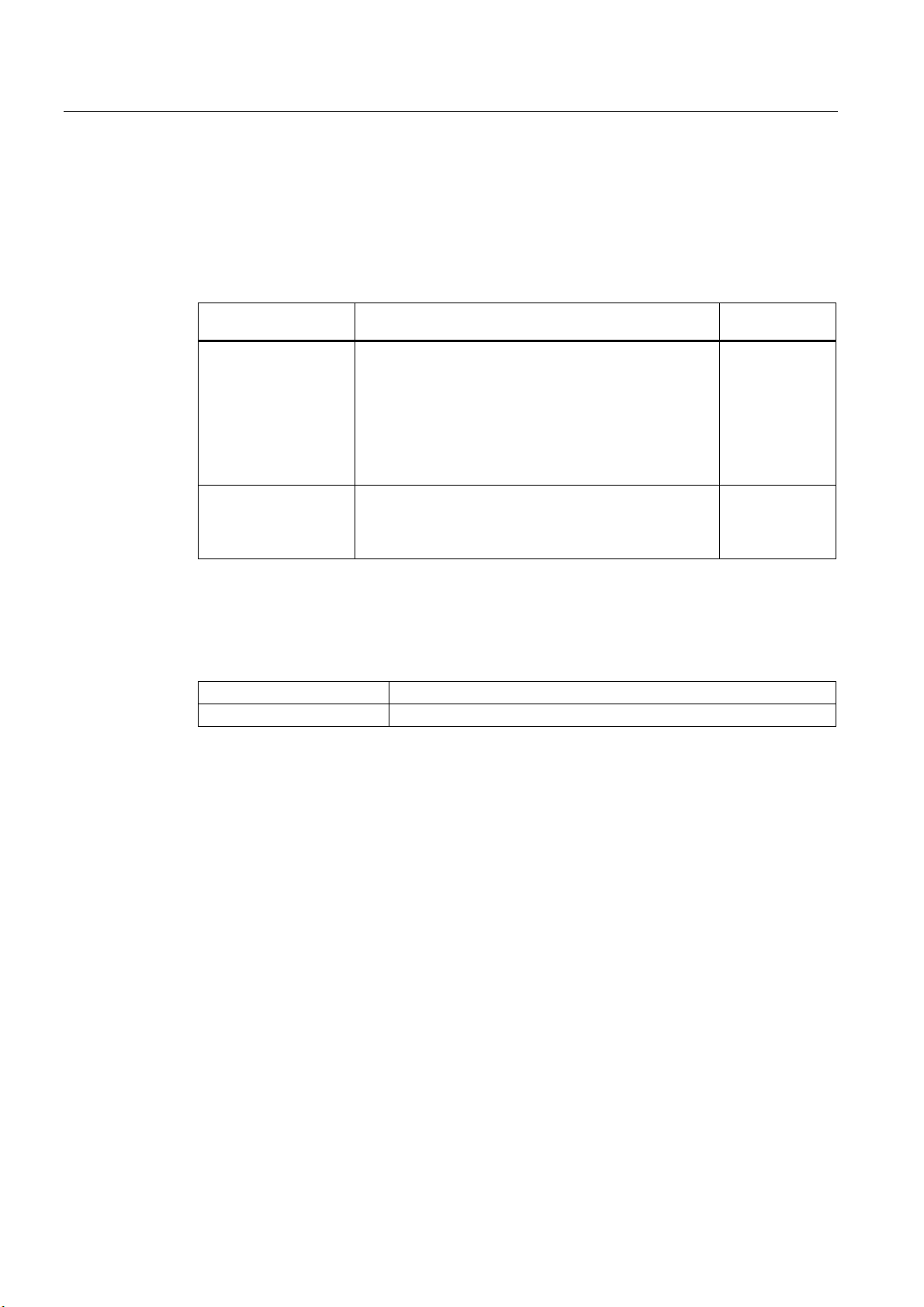

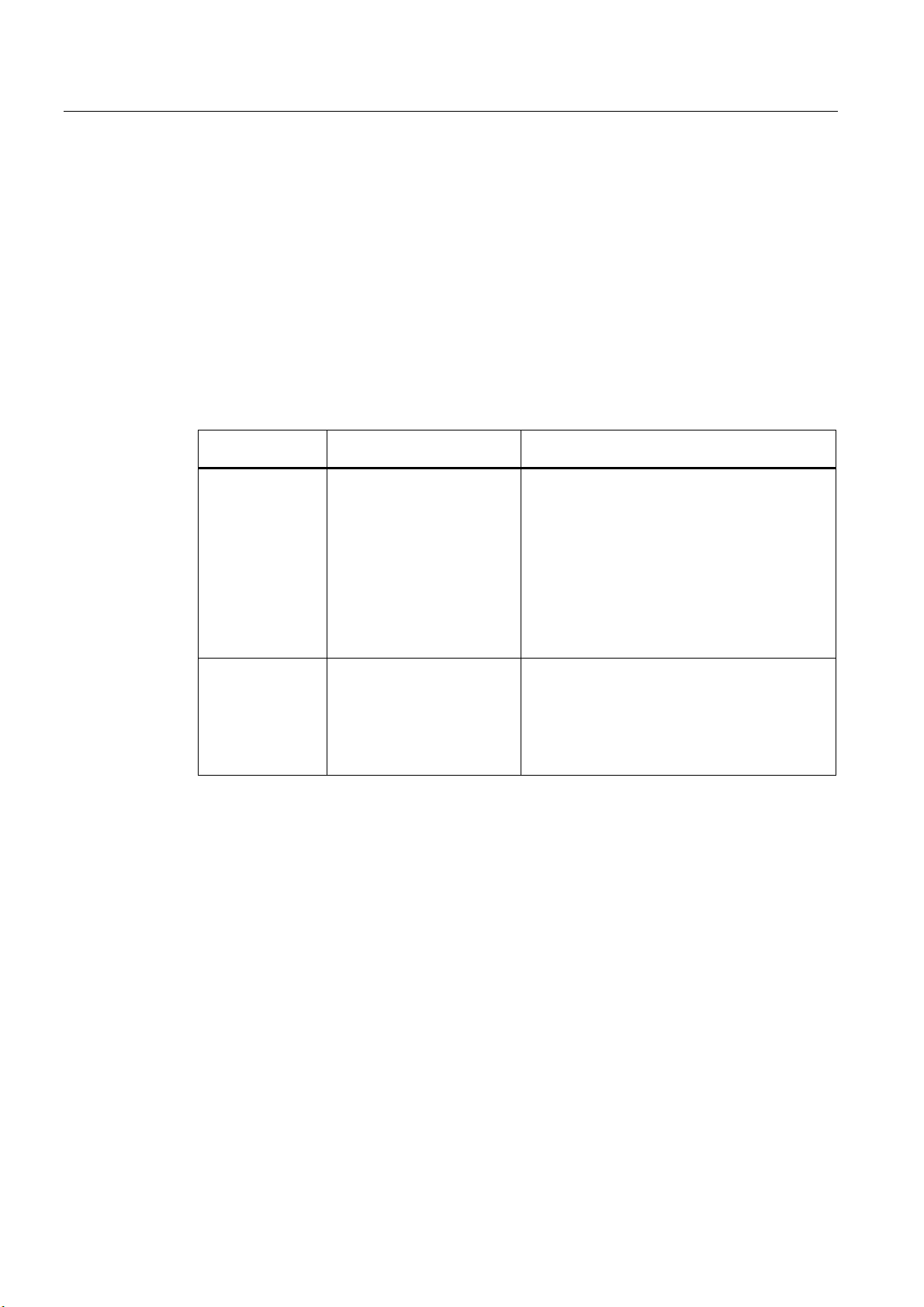

Additional functions

Table 1-5 Range of additional functions

Object Specification OP 73micro TP 177micro

Monitor settings Contrast

Touch screen calibration

Screen saver - Yes Yes

Language switching Number of languages 5 5

Graphic object Graphics Graphics / vector

Trend views Number - 25

Trends per view Number 4

Text object Number 2500 500

Password protection Number of passwords 1 1

Yes

No

Yes

Yes

graphic

1.7 Communication with PLCs

Number of connections

Interconnection OP 73micro TP 177micro

Number for MPI/PROFIBUS DP 1 1

Siemens PLCs

The following table shows the Siemens PLCs and protocols or profiles that can be used.

PLC Protocol / profile OP 73micro TP 177micro

S7-200 MPI1 yes yes

1

See also

If you require a baud rate of 9.6 Kbps, use the "DP" profile in WinCC flexible.

The HMI device can communicate only with one S7-200 at a time. The HMI device can be

connected to the S7-200 using a PtP connection or a network.

Communication via a point-to-point connection (Page 57)

Communication in the network (Page 58)

OP 73micro, TP 177micro (WinCC flexible)

16 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 17

Safety instructions and general notes

2.1 Safety instructions

Working on the cabinet

WARNING

Open equipment

The HMI device is an open equipment. This means that the HMI device may only be

installed in cubicles or cabinets, whereby the device can be operated from the front panel.

Access to the cubicle or cabinet in which the HMI device is installed should only be possible

by means of a key or tool and for personnel who have received instruction or are

authorized.

Danger, high voltage

Opening the cabinet will expose high voltage parts. Contact with these parts could be fatal.

Switch off the power supply to the cabinet before opening it.

2

Hazardous areas

High frequency radiation

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

When operating the HMI device in hazardous areas the following warning applies.

WARNING

Explosion Hazard

Do not disconnect while circuit is live unless area is known to be non-hazardous.

Substitution of components may impair suitability for Class I, Division 2 or Zone 2.

NOTICE

Unintentional operating situations

High frequency radiation, from mobile phones for example, can cause unintentional

operating situations.

17

Page 18

Safety instructions and general notes

2.2 Standards, Certificates and Approvals

2.2 Standards, Certificates and Approvals

Valid approvals

CE approval

CAUTION

Valid approvals

The overview below provides information on available approvals

The HMI device itself is certified as shown on the label on its rear panel.

The automation system meets the general and safety-related requirements of the following

EC directives and conforms to the harmonized European standards (EN) for programmable

logic controllers published in the official gazettes of the European Union:

● 89/336/EEC "Electromagnetic Compatibility" (EMC guideline)

● 94/9/EG "Equipment and protective systems intended for use in potentially explosive

atmospheres" (ATEX).

EC declaration of conformity

The EC declarations of conformity are kept available for the responsible authorities at the

following address:

Siemens Aktiengesellschaft

Automation & Drives

A&D AS RD ST PLC

PO Box 1963

D-92209 Amberg

UL certification

Underwriters Laboratories Inc. conforming to

● UL 508 (Industrial Control Equipment)

● CSA C22.2 No. 142, (Process Control Equipment)

or

OP 73micro, TP 177micro (WinCC flexible)

18 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 19

Safety instructions and general notes

2.2 Standards, Certificates and Approvals

Underwriters Laboratories Inc. conforming to

● UL 508 (Industrial Control Equipment)

● CSA C22.2 No. 142, (Process Control Equipment)

● UL 1604 (Hazardous Location)

● CSA-213 (Hazardous Location)

Approved for use in

● Class I, Division 2, Group A, B, C, D or

● Class I, Zone 2, Group IIC or

● non-hazardous locations

FM Approval

Ex approval

FM

APPROVED

Factory Mutual Research (FM) conforming to

● Approval Standard Class Number 3611, 3600, 3810

Approved for use in

● Class I, Division 2, Group A, B, C, D T4

● Class I, Zone 2, Group IIC T4

In compliance with EN 50021 (Electrical apparatus for potentially explosive atmospheres;

Type of protection "n")

● II 3 G/D EEx nA II T4

● IP65

● 04 ATEX 1297X

Tick-mark for Australia

N117

The HMI device fulfills the requirements of standard AS/NZS 2064 (Class A).

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

19

Page 20

Safety instructions and general notes

2.3 Notes about usage

IEC 61131

The HMI device fulfills the requirements and criteria conforming to IEC 61131-2,

Programmable Logic PLCs, Part 2: Operating resource requirements and tests.

2.3 Notes about usage

Use in industry

The HMI device is designed for industrial use. The following standards are met:

● Requirements of the emission of interference EN 61000-6-4: 2001

● Requirements for noise immunity EN 61000-6-2: 2001

Residential use

If the HMI device is used in a residential area, you must take measures to achieve Limit

Class B conforming to EN 55011 for RF interference.

Suitable measures to achieve Limit Class B for suppression of radio interference include:

● Installation of the HMI device in a grounded control cabinet

● Use of filters in electrical supply lines

Use in potentially explosive atmosphere, Zone 2

DANGER

Risk of explosion

Operate the HMI device only in a Zone 2 potentially explosive atmosphere if it has been

identified as approved for such environments.

Figure 2-1 Explosion protection label

● II 3 G/D EEx nA II

● IP65

● 04 ATEX 1297X

WARNING

Personal injury and property damage can occur.

Personal injury and property damage can occur in potentially explosive atmospheres if

an electric plug is disconnected from the HMI device while the system is in operation.

In potentially explosive atmospheres, always turn off power to the HMI device before

disconnecting any connectors.

OP 73micro, TP 177micro (WinCC flexible)

20 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 21

Safety instructions and general notes

2.3 Notes about usage

Potentially explosive atmosphere, Zone 2

Potentially explosive atmospheres are organized by zones. The zones are classified

according to the probability of the presence of an explosive atmosphere.

Zone Risk of explosion Example

2 Infrequent and brief development

of an explosive gas atmosphere

Safe zone no

Areas around flanged pipe joints with flat

gaskets in closed rooms

• Outside Zone 2

• Standard applications of distributed IO

WARNING

Observe the degree of protection

The HMI device must be installed in a metal enclosure or in a cabinet The minimum degree

of protection of these is IP54 (conforming to EN 60529). Make allowances for the ambient

conditions under which you install the HMI device. The enclosure must have a

manufacturer's declaration for Zone 2 (conforming to EN 50021).

Special conditions for operation in potentially explosive atmospheres of Zone 2

● In situations where the temperature on the cable or at the cable inlet of this enclosure

exceeds 70° C is or the temperature on the wire branching point exceeds 80° C under

operating conditions, the properties of the cables used must ensure that these can

withstand the actually measured temperatures.

● The cable inlets must be compliant with the required degree of protection (conforming

to 50021.)

● All peripheral devices connected to the HMI device must be certified conforming to

explosion protection types EEx nA or EEx nC.

● Measures must be taken to prevent transient voltages from causing the voltage to exceed

its nominal value by more than 40%.

● Ambient temperature range: 0° C ... 50° C vertical

● The temperature of the HMI device's cabinet surface should not exceed 60° C.

● The HMI device should be switched off immediately and replaced if damaged.

Such damage might be:

– Tears or detachment of individual membranes

– A tear in proximity to the viewing window

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

21

Page 22

Safety instructions and general notes

2.3 Notes about usage

● A label with the following warning must be attached to the inside of the switch

cabinet/cubing at a place that is clearly visible upon opening:

:DUQLQJ

7KHFRQWUROFDELQHWHQFORVXUHLVRQO\DOORZHG

WREHRSHQIRUDVKRUWWLPHHJJUDSKLFGLDJQRVWLFV

,QWKHPHDQWLPH\RXDUHQRWDOORZHGWRSUHVVDVZLWFKSXOORULQVHUW

PRGXOHVDQGGLVFRQQHFWDQ\HOHFWULFOLQHVFRQQHFWRUV

7KLVZDUQLQJGRHVQRWKDYHWREHWDNHQLQWRFRQVLGHUDWLRQ

LI\RXDUHDZDUHWKDWWKHUHLVQRH[SORVLRQKD]DUG

List of approved HMI devices

The list of approved HMI devices is available on the Internet under:

"

http://www4.ad.siemens.de/view/cs"

under article ID 13702947.

Further information

The "HMI device in potentially explosive atmospheres of Zone 2 and Zone 22" flyer is part of

the package and must be complied with.

Maintenance

Defective HMI devices must be returned to the manufacturer for repair. Repair may only be

carried out by the manufacturer at his site.

Location of the manufacturer:

Siemens AG

Automation & Drives

Werner-von-Siemens-Straße 50

92224 Amberg

Germany

Approval

Note

HMI devices with approval to II 3 G EEx nA II T4 may only be used on SIMATIC systems of

device category 3.

OP 73micro, TP 177micro (WinCC flexible)

22 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 23

Safety instructions and general notes

2.4 Electromagnetic compatibility

2.4 Electromagnetic compatibility

Introduction

The HMI device fulfills requirements of the EMC Directive of the domestic European market

and other requirements.

EMC-compliant installation of HMI devices

An EMC-compliant installation of the HMI device and the use of interference-proof cables

form the basis of trouble-free operation. The "Directives for interference-free installation of

PLCs" and the "PROFIBUS Networks" manual also apply for the installation of the HMI

device.

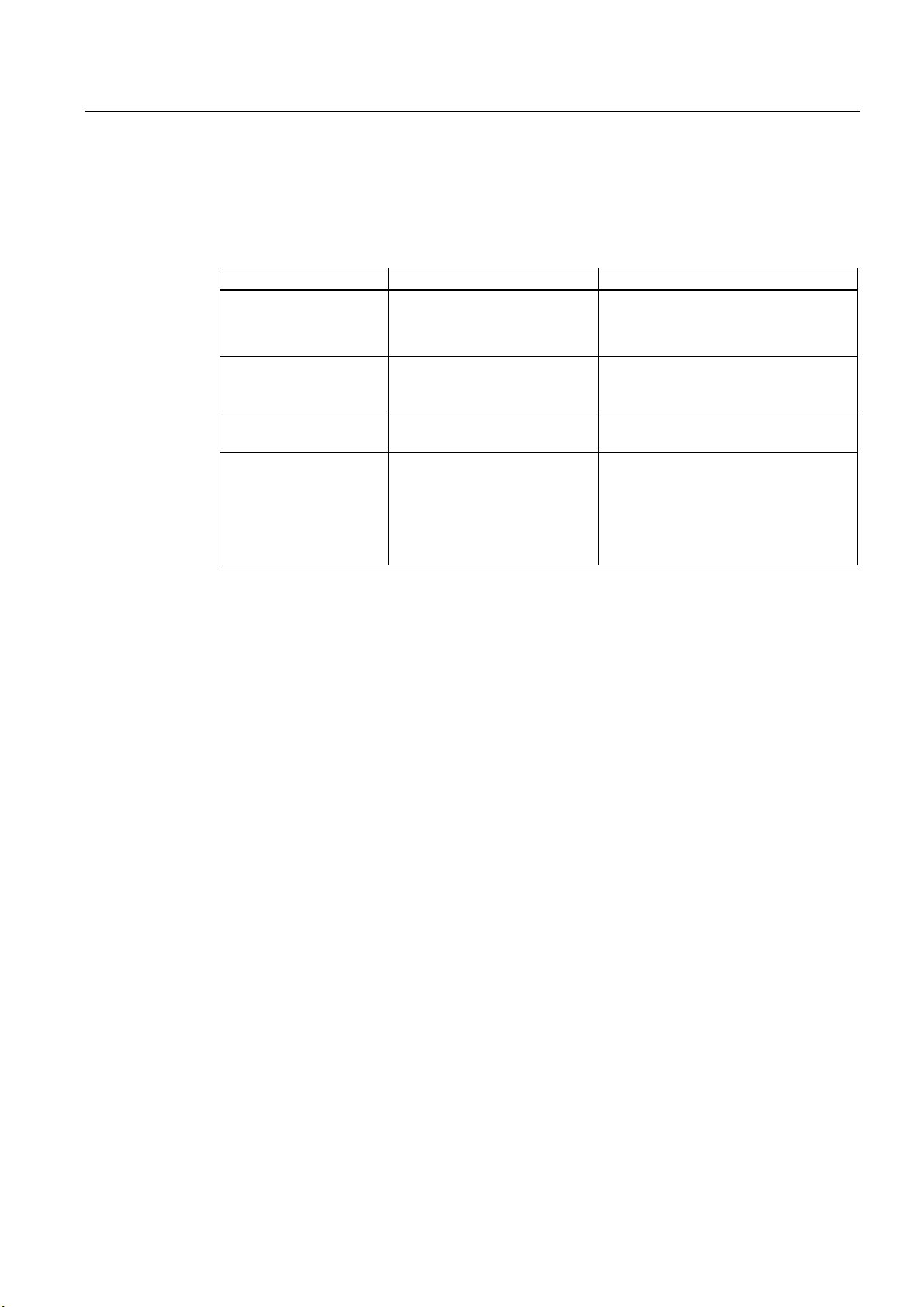

Pulse-shaped interference

The following table shows the EMC properties of the modules with respect to pulse-shaped

interference. A requirement for this is that the HMI device meets the specifications and

directives regarding electrical installation.

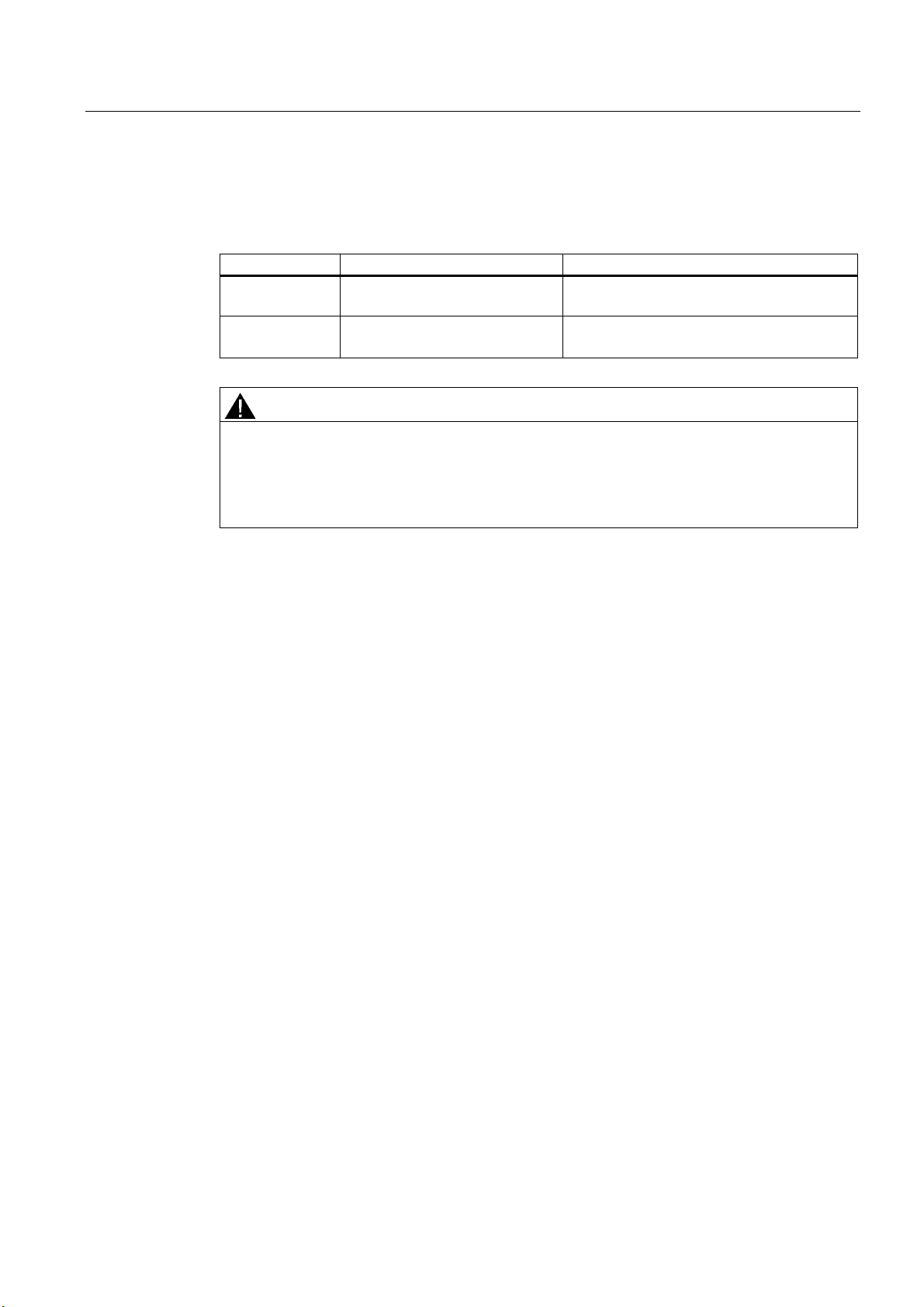

Table 2-1 Pulse-shaped interference

Pulse-shaped

interference

Electrostatic discharge

conforming to

IEC 61000-4-2

Burst pulses

(high-speed transient

interference)

conforming to

IEC 61000-4-4

High-power surge pulses conforming to IEC 61000-4-5, external protective circuit required (refer to

S7 300 PLC, Installation, chapter “Lightning and overvoltage protection”).

• Asymmetric coupling

• Asymmetric coupling

Tested with Corresponds to test

intensity

Air discharge: 8 kV

Contact discharge: 4 kV

2 KV power supply cable

2 KV signal cable, > 30 m

1 KV signal cable, < 30 m

2 kV power cable

DC voltage with protective elements

2 KV signal/data cable, > 30 m,

with protective elements as required

1 kV power cable

DC voltage with protective elements

1 KV signal cable, > 30 m,

with protective elements as required

3

3

3

3

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

23

Page 24

Safety instructions and general notes

2.4 Electromagnetic compatibility

Sinusoidal interference

The table below shows the EMC properties of the modules with respect to sinusoidal

interference. A requirement for this is that the HMI device meets the specifications and

directives regarding electrical installation.

Table 2-2 Sinusoidal interference

Sinusoidal interference Test values Corresponds to

test intensity

RF interference

(electromagnetic fields)

• conforming to

IEC 61000-4-3

• conforming to

IEC 61000-4-3

RF interference current

on cables and cable

shielding conforming to

IEC 61000-4-6

10 V/m with 80 % amplitude modulation of 1 kHz in the

range from 80 MHz to 1 GHz and 1.4 GHz to 2 GHz

10 V/m with 50% pulse modulation at 900 MHz

10 V/m with 50% pulse modulation at 1.89 GHz

Test voltage 10 V with 80% amplitude modulation of

1 kHz in the range from 9 kHz to 80 MHz

3

3

Emission of radio interference

Emission of electromagnetic interference conforming to 55011,

Limit value class A, Group 1, measured at a distance of 10 m:

From 30 to 230 MHz < 40 dB (V/m) quasi-peak

From 230 to 1000 MHz < 47 dB (V/m) quasi-peak

Additional measures

Before you connect an HMI device to the public network, ensure that it is compliant with Limit

Class B conforming to 55022.

OP 73micro, TP 177micro (WinCC flexible)

24 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 25

Safety instructions and general notes

2.5 Transport and storage conditions

2.5 Transport and storage conditions

Mechanical and climatic transport and storage conditions

The transport and storage conditions of this HMI device exceed requirements conforming to

IEC 61131-2. The following specifications apply to the transport and storage of an HMI

device in its original packing.

The climatic conditions comply to the following standards:

● IEC 60721-3-3, Class 3K7 for storage

● IEC 60721-3-2, Class 2K4 for transport

The mechanical requirements are compliant with EC 60721-3-2, Class 2M2.

Table 2-3 Transport and storage conditions

Type of condition Permissible range

Drop test (in transport package) ≤ 1 m

Temperature from –20° C to +60° C

Atmospheric pressure from 1080 hPa to 660 hPa,

corresponds to an elevation of - 1000 m to 3500 m

Relative humidity from 10% to 90% without condensation

Sinusoidal vibration conforming to

IEC 60068-2-6

Shock conforming to IEC 60068-2-29 250 m/s2, 6 ms, 1000 shocks

5 Hz to 9 Hz: 3.5 mm

9 Hz to 150 Hz: 9.8 m/s2

NOTICE

Ensure that no condensation (dewing) develops on or inside the HMI device after

transporting it at low temperatures or after it has been exposed to extreme temperature

fluctuations.

The HMI device must have acquired room temperature before it is put into operation. Do

not expose the HMI device to direct radiation from a heater in order to warm it up. If dewing

has developed, wait approximately four hours before you switch on the HMI device.

Prerequisite for the trouble-free and safe operation of the HMI device is proper transport and

storage, installation and assembly and careful operation and maintenance.

Warranty for the HMI device is deemed void if these specifications are ignored.

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

25

Page 26

Safety instructions and general notes

2.5 Transport and storage conditions

OP 73micro, TP 177micro (WinCC flexible)

26 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 27

Planning use

3.1 Mounting information

Mechanical and climatic conditions of use

The HMI device is intended for installation in weatherproof permanent locations. The

conditions of use are compliant with requirements to DIN IEC 60721-3-3:

● Class 3M3 (mechanical requirements)

● Class 3K3 (climatic requirements)

Use with additional measures

Examples of applications where the use of the HMI device requires additional measures:

● In locations with a high degree of ionizing radiation

● In locations with extreme operating conditions resulting from situations as follows:

– Corrosive vapors, gases, oils or chemicals

– Electrical or magnetic fields of high intensity

3

● In plants requiring special monitoring features, for example:

– Elevator systems

– Systems in especially hazardous rooms

Mechanical ambient conditions

The mechanical ambient conditions for the HMI device are specified in the following table in

terms of sinusoidal vibration.

Table 3-1 Mechanical ambient conditions

Frequency range

in Hz

10 ≤ f ≤ 58 Amplitude 0.0375 mm Amplitude 0.075 mm

58 ≤ f ≤ 150 0.5 g constant acceleration Constant acceleration 1 g

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Continuous Occasional

27

Page 28

Planning use

3.1 Mounting information

Reduction of vibration

If the HMI device is subjected to greater shocks or vibrations, you must take appropriate

measures to reduce acceleration or amplitudes.

We recommend fitting the HMI device to vibration-absorbent material (on metal shock

absorbers, for example).

Check of mechanical ambient conditions

The following table provides information on the type and scope of the check of mechanical

ambient conditions.

Table 3-2 Check of mechanical ambient conditions

The check

includes

Vibrations Vibration test conforming to

Shock Shock test conforming to

Test standard Remarks

IEC 60068, part 2–6

(sinusoidal)

IEC 60068, part 2–29

Type of vibration:

Transitional rate of the frequency:

1 octave/minute.

10 ≤ f ≤ 58,

Constant amplitude 0.075 mm

58 ≤ f ≤ 150,

Constant acceleration 1 g

Vibration duration:

10 frequency cycles per axis in each of the three

axes vertical to each other

Type of shock: Half-sine

Shock intensity:

Peak value 15 g, duration 11 ms

Direction of impact:

3 shocks in ± direction of axis in each of the

three axes vertical to each other

OP 73micro, TP 177micro (WinCC flexible)

28 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 29

Planning use

3.1 Mounting information

Climatic ambient conditions

The HMI device may be used under the following climatic ambient conditions:

Table 3-3 Climatic ambient conditions

Ambient conditions Permissible range Remarks

Temperature

• Vertical mounting

• Inclined mounting

Relative humidity 10% to 90% Without condensation, corresponds to a

Atmospheric pressure 1080 hPa to 795 hPa Corresponds to an elevation of -1000 to

Pollutant concentration SO2: < 0.5 ppm;

from 0° C to 50° C

from 0 °C to 40 °C

relative humidity < 60%, no

condensation

H

S: < 0.1 ppm;

2

relative humidity < 60 %, no

condensation

See the "Mounting positions and type of

fixation" section

relative humidity, stress class 2

conforming to IEC 61131, part 2

2000 m

Test: 10 ppm; 4 days

Test: 1 ppm; 4 days

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

29

Page 30

Planning use

3.2 Mounting the OP 73micro

3.2 Mounting the OP 73micro

3.2.1 Mounting positions and fixation

Mounting position

The HMI device is designed for mounting in racks, switch cabinets, switchboards and

consoles. In the following, all of these mounting options are referred to by the general term

"cabinet."

The HMI device is self-ventilated and approved for vertical and inclined mounting in

stationary cabinets.

–+

Figure 3-1 Approved deviations from the vertical mounting position of the OP 73micro without

auxiliary ventilation

Mounting position Deviation from the vertical

① Inclined ≤ –80°

② Vertical 0°

③ Inclined ≤ 80°

CAUTION

Impermissible ambient temperatures

Do not operate the HMI device without auxiliary ventilation if the maximum permissible

ambient temperature is exceeded. The HMI device may otherwise get damaged and its

approvals and warranty will be void!

OP 73micro, TP 177micro (WinCC flexible)

30 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 31

Planning use

3.2 Mounting the OP 73micro

Type of fixation

Spring clamps are provided for mounting the device. Hook the clamps into the recesses of

the HMI device. The overall HMI device dimensions are not exceeded by this.

1

2

Figure 3-2 View of a mounting clamp

① Hook

② Recessed head screw

3.2.2 Preparing for mounting

HMI mounting location

What to observe when selecting the mounting location:

● Position the HMI device so that it is not subjected to direct sunlight.

● Position the HMI device to provide an ergonomic position for the operator and select a

suitable mounting height.

● Ensure that the air vents are not covered as a result of the mounting.

● Observe the permissible mounting positions for the HMI device.

Preparing the mounting cut-out

The degrees of protection are only guaranteed when the following is observed:

● Material thickness at the mounting cut-out: 2 mm to 4 mm

● The deviation from plane for the panel cut-out is ≤ 0.5 mm.

This condition must be fulfilled for the mounted HMI device.

● Permissible surface roughness in the area of the seal: ≤ 120 µm (R

The figure below shows the required mounting cut-out:

138

120)

z

+1

+1

68

Figure 3-3 Mounting cut-out for OP 73micro

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

31

Page 32

Planning use

3.2 Mounting the OP 73micro

Maintaining clearances

The HMI device must be installed with sufficient clearance:

5050

1515

Figure 3-4 Clearance around the OP 73micro

At least 10 mm clearance is required at the rear.

NOTICE

Ensure that the maximum ambient temperature is not exceeded when mounting the device

in a cabinet and especially in a closed enclosure.

OP 73micro, TP 177micro (WinCC flexible)

32 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 33

Planning use

3.3 Mounting the TP 177micro

3.3 Mounting the TP 177micro

3.3.1 Mounting positions and fixation

Mounting position

The HMI device is designed for mounting in racks, cabinets, control boards and consoles. In

the following, all of these mounting options are referred to by the general term "cabinet."

The HMI device is self-ventilated and approved for vertical and inclined mounting in

stationary cabinets.

–+

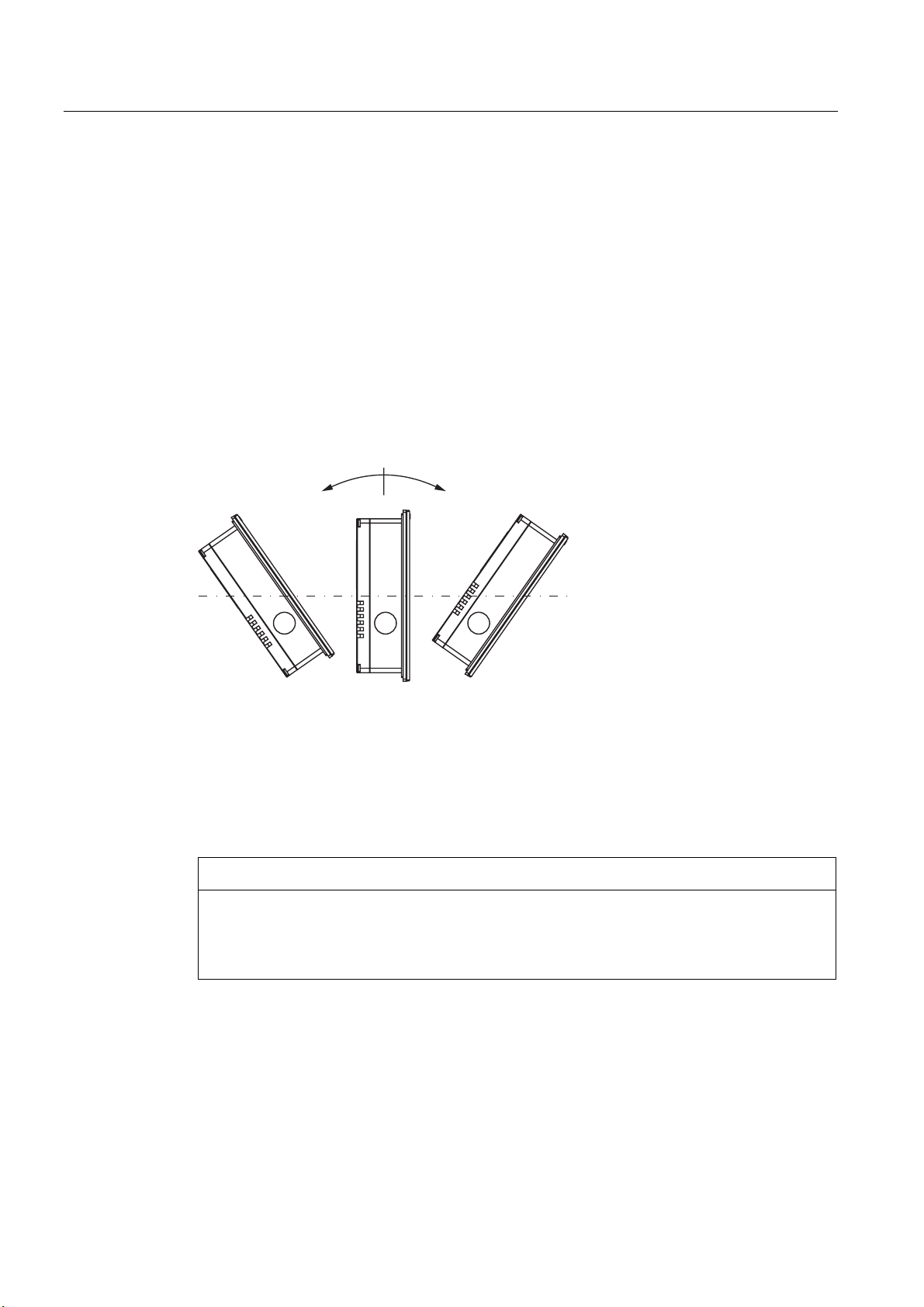

Figure 3-5 Permitted mounting positions

Mounting position Deviation from the vertical

① Inclined ≤ –35°

② Vertical 0°

③ Inclined ≤ 35°

CAUTION

Impermissible ambient temperatures

Do not operate the HMI device without auxiliary ventilation if the maximum permissible

ambient temperature is exceeded. The HMI device may otherwise get damaged and its

approvals and warranty will be void!

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

33

Page 34

Planning use

3.3 Mounting the TP 177micro

Horizontal mounting

When mounted horizontally, the cable inlets are located at the bottom.

Vertical mounting

When mounted vertically, the cable inlets are on the right.

Type of fixation

Spring clamps are provided for mounting the device. Hook the clamps into the recesses of

the HMI device. The overall HMI device dimensions are not exceeded by this.

1

2

Figure 3-6 View of a mounting clamp

① Hook

② Recessed head screw

OP 73micro, TP 177micro (WinCC flexible)

34 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 35

Planning use

3.3 Mounting the TP 177micro

3.3.2 Preparing for mounting

Select the HMI device mounting location

What to observe when selecting the mounting location:

● Position the HMI device so that it is not subjected to direct sunlight.

● Position the HMI device to provide an ergonomic position for the operator and select a

suitable mounting height.

● Ensure that the air vents are not covered as a result of the mounting.

● Observe the permissible mounting positions for the HMI device.

Preparing the mounting cut-out

The degrees of protection are only guaranteed when the following is observed:

● Material thickness at the mounting cut-out: 2 mm to 6 mm

● The deviation from plane for the panel cut-out is ≤ 0.5 mm

This condition must be fulfilled for the mounted HMI device.

● Permissible surface roughness in the area of the seal: ≤ 120 µm (R

The figure below shows the required mounting cut-out:

198

–1

–1

142

Figure 3-7 Mounting cut-out for the HMI device

120)

z

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

35

Page 36

Planning use

3.3 Mounting the TP 177micro

Maintaining clearances

The following clearance is required around the HMI device in order to its ensure selfventilation:

Figure 3-8 Clearance around the HMI device

At least 10 mm clearance is required at the rear.

NOTICE

Ensure that the maximum ambient temperature is not exceeded when mounting the device

in a cabinet and especially in a closed enclosure.

OP 73micro, TP 177micro (WinCC flexible)

36 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 37

Planning use

3.4 Information on insulation tests, protection class and degree of protection

3.4 Information on insulation tests, protection class and degree of

protection

Test voltages

Insulation strength is demonstrated in the type test with the following test voltages

conforming to IEC 61131-2:

Table 3-4 Test voltages

Circuits with a nominal voltage of U

circuits or ground

< 50 V 500 V DC

Class of protection

Protection Class I conforming to IEC 60536, i.e. grounding conductor to profile rail required!

Protection from foreign objects and water

Degree of protection conforming to

IEC 60529

Front panel

Rear panel

The degree of protection provided by the front side can only be guaranteed when the

mounting seal lies completely against the mounting cut-out.

NOTICE

Degree of protection IP65

The degrees of protection are only guaranteed when the following is observed:

• The material strength at the mounting cut-out is at least 2 mm.

• The deviation from the plane of the mounting cut-out in an installed HMI device is

≤ 0.5 mm.

to other

e

Test voltage

Explanation

IP65 in mounted state

IP20

protection against contact with standard test probes

There is no protection against ingress by water.

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

37

Page 38

Planning use

3.5 Nominal voltages

3.5 Nominal voltages

The following table shows the permitted nominal voltage and the corresponding tolerance

range.

Table 3-5 Permitted nominal voltages

Nominal voltage Tolerance range

+24 V DC 20.4 V to 28.8 V (–15%, +20%)

OP 73micro, TP 177micro (WinCC flexible)

38 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 39

Mounting and connection

4.1 Checking the package contents

4.2 Mounting and connecting the OP 73micro

4.2.1 Mounting the HMI device

Check the package contents for visible signs of transport damage and for completeness.

NOTICE

Do not install parts damaged during shipment. In the case of damaged parts, contact your

Siemens representative.

Keep the supplied documentation in a safe place. The documentation belongs to the HMI

device and is required for subsequent commissioning.

4

Requirements

Two mounting clamps from the accessories are required for installation. The mounting seal

must be available on the HMI device. If the mounting seal is damaged, order a replacement

seal.

Mounting

NOTICE

Always mount the HMI device according to the instructions in this manual.

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

39

Page 40

Mounting and connection

4.2 Mounting and connecting the OP 73micro

Proceed as follows:

1. Check that the mounting seal is fitted on the HMI device.

Do not install the mounting seal turned inside out. This may cause leaks in the mounting

cut-out.

2. Insert the HMI device into the mounting cut-out from the front.

3. Insert the mounting clamps into the recesses on the side of the HMI device.

Adjust and then fasten the clamps.

Figure 4-1 Insert the mounting clamp on the OP 73micro.

4. Tighten the clamps by screwing down the recessed head screw; permitted torque: 0.15

N/m.

NOTICE

Check the fit of the mounting seal on the front. The mounting seal must not protrude

from the HMI device.

Otherwise, repeat steps 1 to 4.

4.2.2 Connecting the HMI device

Requirements

The HMI device must be mounted according to the specifications of these operating

instructions.

Connection sequence

Connect the HMI device in the following sequence:

1. Equipotential bonding

2. Power supply

Perform a power-up test to ensure that the correct polarity of the supply voltage.

3. PLC/configuration computer as necessary

OP 73micro, TP 177micro (WinCC flexible)

40 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 41

Mounting and connection

4.2 Mounting and connecting the OP 73micro

NOTICE

Connection sequence

Always follow the correct sequence for connecting the HMI device. Failure to do so may

result in damage to the HMI device.

Connecting the cables

When connecting the cables, ensure that you do not bend any of the contact pins.

Secure the connectors with screws.

Always use shielded data cable. Always use standard cables. For further information, refer to

the SIMATIC HMI Catalog ST 80.

The pin assignment of the interfaces is described in the specifications.

See also

Safety instructions (Page 17)

4.2.2.1 Interfaces

The figure below shows the interfaces of the HMI device.

Figure 4-2 Interfaces of the HMI device

① Power supply connector

② RS 485 interface (IF 1B)

③ Chassis ground terminal

See also

Power supply (Page 146)

RS485 (IF 1B) on OP 73micro (Page 146)

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

41

Page 42

Mounting and connection

4.2 Mounting and connecting the OP 73micro

4.2.2.2 Connecting the equipotential bonding circuit

Potential differences

Differences in potential between spatially separated system parts can lead to high equalizing

currents over the data cables and therefore to the destruction of their interfaces. This

situation may arise if the cable shielding is terminated at both ends and grounded at different

system parts.

Potential differences may develop when a system is connected to different mains.

General requirements of equipotential bonding

Potential differences must be reduced by means of equipotential bonding in order to ensure

trouble-free operation of the relevant components of the electronic system. The following

must therefore be observed when installing the equipotential bonding circuit:

● The effectiveness of equipotential bonding increases as the impedance of the

equipotential bonding conductor decreases or as its cross-section increases.

● If two system parts are connected to each other via shielded data lines with shielding

connected to the grounding/protective conductor on both sides, the impedance of the

additionally installed equipotential bonding cables may not exceed 10% of the shielding

impedance.

● The cross-section of a selected equipotential bonding conductor must be capable of

handling the maximum equalizing current. The best results for equipotential bonding

2

between two cabinets were achieved with a minimum conductor cross-section of 16 mm

.

● Use equipotential bonding conductors made of copper or galvanized steel. Establish a

large-surface contact between the equipotential bonding conductors and the

grounding/protective conductor and protect these from corrosion.

● Terminate the shielding of the data cable on the HMI device flush and near the

equipotential busbar using suitable cable clamps.

● Route the equipotential bonding conductor and data cables in parallel with minimum

clearance between these. See the wiring diagram.

NOTICE

Equipotential bonding conductor

Cable shielding is not suitable for equipotential bonding. Always use the prescribed

equipotential bonding conductors. The minimum cross-section of a conductor used for

equipotential bonding is 16 mm². When you install MPI and PROFIBUS DP networks,

always use cables with a sufficient crosssection since otherwise the interface modules

may be damaged or destroyed.

OP 73micro, TP 177micro (WinCC flexible)

42 Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

Page 43

Mounting and connection

4.2 Mounting and connecting the OP 73micro

Wiring diagram

1

2

3 3

See also

4

65

Figure 4-3 Installing the equipotential circuit

① Chassis ground terminal on the HMI device (example)

② Equipotential bonding conductor cross-section: 4 mm

③ Cabinet

④ Equipotential bonding conductor cross-section: min. 16 mm

⑤ Ground terminal

⑥ Cable clamp

⑦ Voltage bus

⑧ Parallel routing of the equipotential bonding conductor and data cable

87

2

2

Electromagnetic compatibility (Page 23)

OP 73micro, TP 177micro (WinCC flexible)

Operating Instructions, 09/2007, 6AV6691-1DF01-0AB0

43

Page 44

Mounting and connection

4.2 Mounting and connecting the OP 73micro

4.2.2.3 Connecting the PLC

Wiring diagram

The following diagram illustrates the connection between the HMI device and PLC.

S7-200

Figure 4-4 Connection to the PLC

The interfaces are described in the Specifications section.

Note when connecting

NOTICE

Always use the approved cables to connect a SIMATIC S7 PLC.

Standard cables are available for the connection. For further information, refer to the

SIMATIC HMI Catalog ST 80.

See also

Communication via a point-to-point connection (Page 57)

Communication in the network (Page 58)

Interfaces (Page 41)

4.2.2.4 Connecting the configuration computer

Wiring diagram