Siemens SIMATIC HMI TP 170A Equipment Manual

Preface, Contents

SIMATIC HMI

Touch Panel

TP 170A

Equipment Manual

Introduction

Functionality

Commissioning

Operating the TP 170A

Operation of Screen Objects

System Settings

Installation

1

2

3

4

5

6

7

6AV6591–1DC11–0AB0

Release 12/99

Unit Description

Maintenance/Upkeep

Operating System Update

Appendices

Glossary, Index

8

9

10

A

E

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

Warning

!

indicates that death, severe personal injury or substantial property damage can result if proper precautions are not taken.

Caution

!

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Equipment may be commissioned and operated only by qualified personnel. Qualified personnel within

the meaning of the safety notices in this manual are persons who are authorized to commission, ground

and identify equipment, systems and circuits in accordance with safety engineering standards.

Correct Usage

!

Trademarks

Impressum

Note the following:

Warning

The equipment may be used only for the applications stipulated in the catalog and in the technical description and only in conjunction with other equipment and components recommended or approved by Siemens.

Startup must not take place until it is established that the machine, which is to accommodate this component, is in conformity with the guideline 89/392/EEC.

Faultless and safe operation of the product presupposes proper transportation, proper storage, erection

and installation as well as careful operation and maintenance.

The registered trademarks of Siemens AG are listed in the Preface.

Some of the other designations used in these documents are also registered trademarks; the owner’s

rights may be violated if they are used be third parties for their own purposes.

Editor and Publisher: A&D PT1 D1.

Disclaimer of LiabilityCopyright Siemens AG 1999 All rights reserved

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of

an utility model or design, are reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Bedienen und Beobachten

Postfach 4848, D-90327 Nuernberg

Index-2

Siemens Aktiengesellschaft Order no: 6AV6591–1DC11–0AB0

CuuDuongThanCong.com https://fb.com/tailieudientucntt

We have checked the contents of this manual for agreement with the hardware and software described. Since deviations cannot be precluded entirely,

we cannot guarantee full agreement. However, the data in this manual are

reviewed regularly and any necessary corrections included in subsequent

editions. Suggestions for improvement are welcomed.

Siemens AG 1999

T echnical data subject to change.

TP 170A Equipment Manual

Release 12/99

Preface

This manual

The TP 170A equipment manual is part of the SIMATIC HMI documentation. It

provides operation, installation, configuration and system personnel with

information concerning installation, functionality, operation and technical design of

the TP 170A.

An overview of the entire SIMATIC HMI documentation is provided in Appendix E.

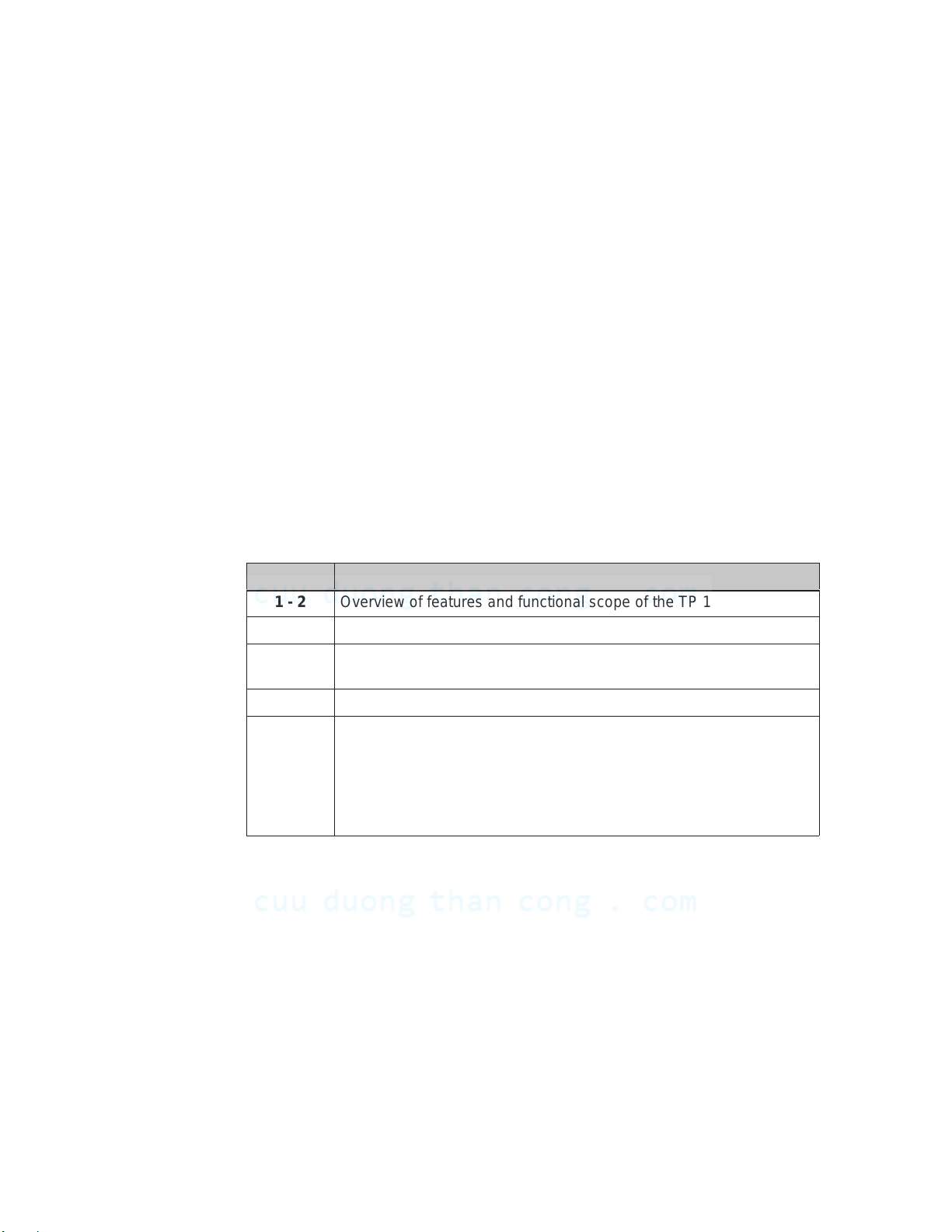

Organization of the manual

The TP 170A equipment manual is organized into the following chapters:

Chapter Contents

1 - 2 Overview of features and functional scope of the TP 170A.

3 - 6 Commissioning, operation and system settings.

7 - 9 Mechanical and electrical installation, unit description, as well as

maintenance and upkeep of the TP 170A.

10 Information on the operating system update.

Appendix Technical Data

Interface Assignments

System Messages

ESD Guidelines

SIMATIC HMI Documentation

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

i

Preface

Conventions

The following conventions are used throughout this manual:

Motor off Text in the operating unit display is presented in this

Tag

Screens

ESC The names of keys and buttons are displayed in a different

History

The various releases of this manual correspond to the following versions of the

ProTool configuration software:

typewriter font.

Symbolic names representing tag values on the screen are

presented in this italic typewriter font.

Functions available for selection are presented in this italic

font.

font.

Trademarks

Release Comment ProTool version

12/99 First release of the TP 170A equipment

From Vers. 5.2

manual.

The following names are registered trademarks of the Siemens AG:

S SIMATICR

S SIMATIC HMIR

S HMIR

S ProToolR

S ProTool/LiteR

S ProTool/ProR

S SIMATIC Multi PanelR

S SIMATIC Multifunctional PlatformR

S MP 270R

S ProAgentR

Other support

In the case of technical queries, please contact the Siemens representatives in the

subsidiaries and branches responsible for your area.

ii

CuuDuongThanCong.com https://fb.com/tailieudientucntt

TP 170A Equipment Manual

Release 12/99

SIMATIC Customer Support Hotline

Available worldwide, at all times:

Johnson City

Preface

Nuernberg

Singapur

SIMA TIC Basic Hotline

Nuernberg Johnson City

Singapur

SIMA TIC BASIC Hotline SIMA TIC BASIC Hotline SIMATIC BASIC Hotline

Local time Mo - Fr 7:00 to 17:00 Local time Mo - Fr 8:00 to 19:00 Local time Mo - Fr 8:30 to 17:30

T elephone: +49 (911) 895-7000 T elephone: +1 423 461-2522 T elephone: +65 740-7000

Fax: +49 (911) 895-7002 Fax: +1 423 461-2231 Fax: +65 740-7001

E-Mail: simatic.support@

nbgm.siemens.de

E-Mail: simatic.hotline@

sea.siemens.com

E-Mail: simatic.hotline@

sae.siemens.com

SIMA TIC Premium Hotline

(charged, only with SIMATIC Card)

Time: Mo - Fr 0:00 to 24:00

T elephone: +49 (911) 895-7777

Fax: +49 (911) 895-7001

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

iii

Preface

SIMATIC Customer Online Services

SIMATIC Customer Support offers comprehensive additional information

concerning SIMATIC products through its Online services as follows:

Up-to-date general information is provided

– in Internet under http://www.ad.siemens.de/simatic

– via the Fax-Polling under 08765–93 02 77 95 00

Up-to-date product information and downloads for practical use can be found:

– in Internet under http://www.ad.siemens.de/support/html–00/

iv

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Abbreviations

The abbreviations used in this equipment manual have the following meaning:

AG (PLC) Programmable Logic Controller

ANSI American National Standards Institute

AS 511 Protocol of the PU interface to SIMATIC S5

ASCII American Standard Code for Information Interchange

CCFL Cold Cathode Fluorescence Lamp

CF Compact Flash

CPU Central Processing Unit

DIL Dual-In-Line

DP Decentralized Periphery

EM Event Message

EMC Electromagnetic Compatibility

EPROM Electric Programmable Read Only Memory

ESD Electrostatic Sensitive Device

HMI Human Machine Interface

IF Interface

LCD Liquid Crystal Display

LED Light Emitting Diode

MPI Multipoint Interface (SIMATIC S7)

OP Operator Panel

PC Personal Computer

PLC Programmable Logic Control

PPI Point to Point Interface (SIMATIC S7)

PU Programming Unit

RISC Reduced Instruction Set Computing

SRAM Static Random Access Memory

STN Super Twisted Nematic

TP Touch Panel

TTL Transistor–Transistor Logic

Preface

A list of all the specialist terms together with their explanations is provided in the

Glossary at the end of this manual.

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

v

Preface

vi

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Contents

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Functionality 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Commissioning 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Initial Startup 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Recommissioning 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Download Mode Options 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Test Configuration 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating the TP 170A 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Operating Touch Elements 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Entering Values 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Operating Screens 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Operation of Screen Objects 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Overview of Screen Objects 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Status Button 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Messages 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Logging On and Off from the Operating Unit 5-7. . . . . . . . . . . . . . . . . . . . . . . .

6 System Settings 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Setting an Operating Mode 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Screen Settings 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Installation 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Mechanical Installation 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Electrical Installation 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Connect Configuration Computer 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Connect PLC 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Unit Description 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Dimensions 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Connection Elements 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Communication Options 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TP 170A Equipment Manual

Release 12/99

vii

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Contents

9 Maintenance/Upkeep 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Operating System Update 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Technical Data A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Interface Assignment B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C System Messages C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D ESD-Guidelines D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E SIMATIC HMI Documentation E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Introduction

Use of the TP 170A

The TP 170A is the basic touch panel for all SIMATIC S7 CPUs. It is the first touch

panel unit in the SIMATIC HMI product range and is bas ed on the operating system

Microsoft Windows CE.

The TP 170A is suitable for all basic functions. It has an interface which can be used

for both the MPI and the Profibus-DP. The unit memory is designed for smaller

configurations. The objects used for a configuration can be buttons, bar graphs,

graphics and messages.

Area of use of the TP 170A

The TP 170A has been conceived for machine operation and monitoring. It

provides a realistic graphical representation of the machine or system to be

monitored. Its area of use includes implementation in machine and apparatus

construction as well as in the packing and electronics industry.

The high degree of protection (IP65 on the front side) and non-implementation of

moving storage media, such as hard disks and floppy disks, ensure the TP 170A is

also suitable for use in rough industrial environments and directly on site on the

respective machine.

1

The TP 170A can be installed in switching cabinets and operating consoles.

Due to the fact that the TP 170A is equipped with high performance basic

hardware and has a minimum installation depth means that it fulfills all the

requirements for operation in the vicinity of the machine.

TP 170A Equipment Manual

Release 12/99

1-1

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Introduction

Easy to operate and observe

The TP 170A enables operating statuses and current process values concerning a

connected PLC to be graphically displayed and the relevant machine or system to

be easily monitored and operated. Display and operation of the TP 170A can be

adapted optimally for the respective process requirements by using the

configuration software ProTool/Lite, ProTool and ProTool/Pro CS (from

Version 5.2).

The TP 170A can be used to:

control and monitor the process intuitively. Setpoint values or control element

settings, for instance, can be modified by entering values or touching configured

buttons;

display processes, machines and systems graphically;

visualize operating and alarm messages and process tags, e.g. in output fields,

bar graphs or trend curves;

intervene directly in the operation by means of the touch-sensitive screen.

1-2

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

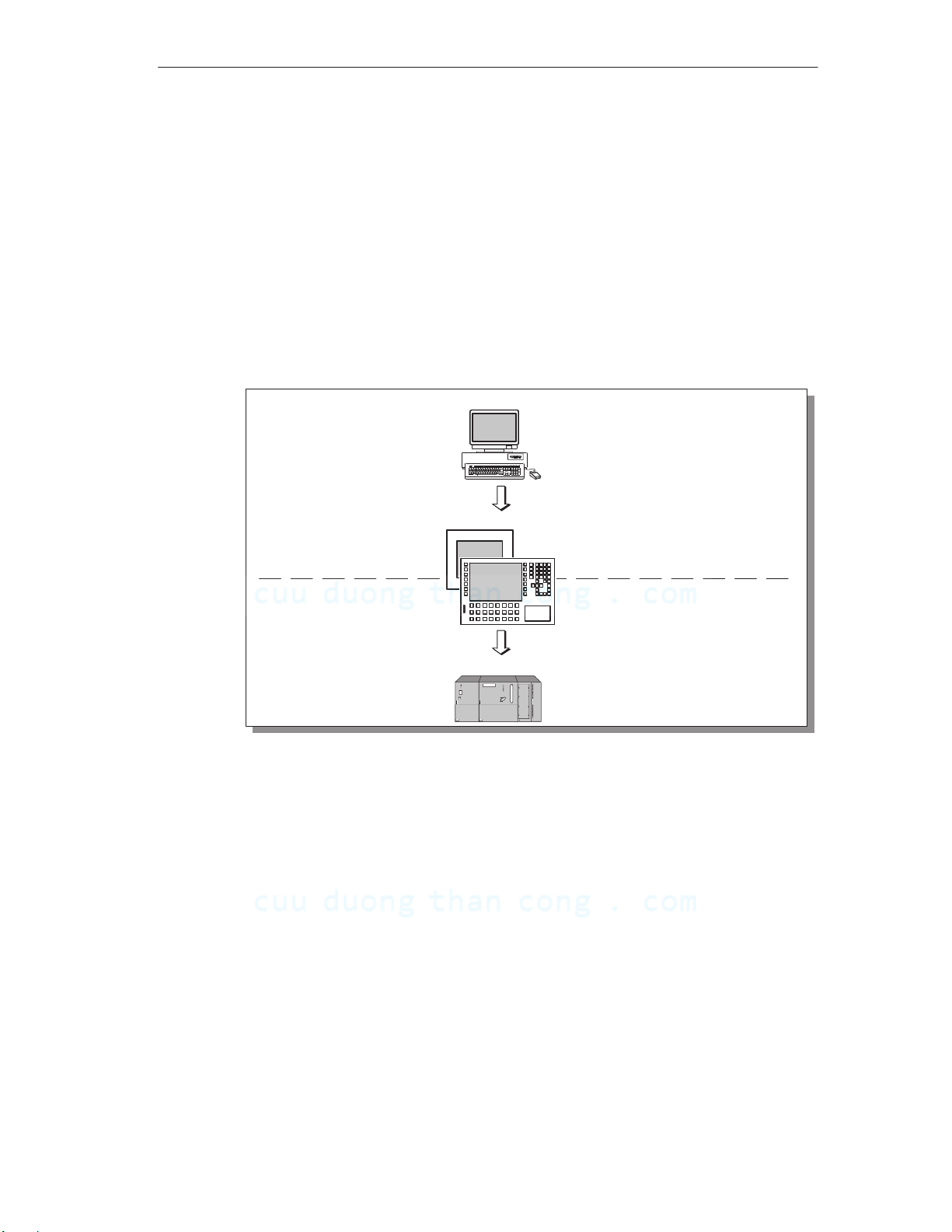

Operating unit configuration (principles)

Graphics, texts and operating and display elements which need to be represented

on the operating unit must first be created on a configuration computer (PC or PU)

using the configuration software. The configuration computer must be connected to

the operating unit in order to download the project to the operating unit (refer to

“Configuration phase” in Figure 1-1).

Once the project has been successfully downloaded, connect the operating unit to

the PLC. The operating unit can then communicate with the PLC and respond

according to the information configured for running the program in the PLC (refer to

“Process control phase” in Figure 1-1).

Configuration phase

Operating unit

Introduction

PC/ PU

Create project data

Store project data

T est project

Simulate project

Download project data

TP

OP

Connected to PLC

PLC

Figure 1-1 Configuration and process control phase

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

1-3

Introduction

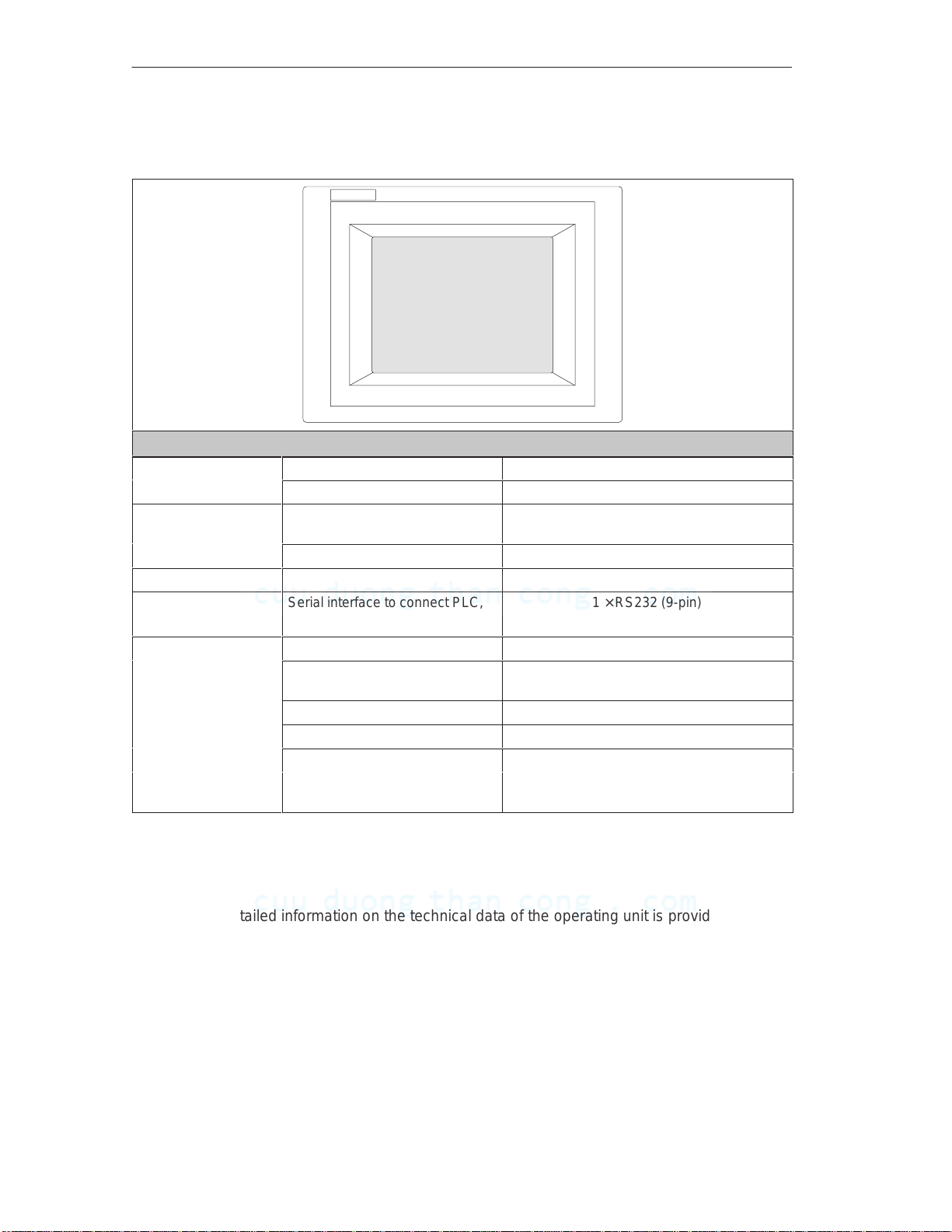

Overview of the TP 170A

Overview: Model TP 170A

Processor

Memory

Software Operating system MicrosoftR WindowsR CE

Interfaces Serial interface to connect PLC,

Display

1) Refer to the Glossary for a definition.

Type 32 bit RISC

Clock frequency 66 MHz

Flash EPROM for operating

system and configuration

Working memory 8 MB

PC/PU

Type STN LCD/Blue mode

Active screen area

(B × H) in mm

Resolution (pixels) 320 × 240

Monochrome 4-level

Back-lighting CCFL tube

Half Brightness Life1)

approx. (hr)

2 MB

1 × RS232 (9-pin)

1 × RS422/RS485

1 16 × 87 (5.7’ ’)

50,000

Further information

Detailed information on the technical data of the operating unit is provided in

Appendix A of this manual.

Information on the configuration of the operating unit is provided in the

ProTool Configuring Windows-based Systems

Connection of the operating unit to the PLC is described in the

Communication for Windows-based Systems

New information, for which there was insufficient time to include in the manuals, is

contained in the file README.WRI on the SIMATIC ProTool/Pro CD.

1-4

CuuDuongThanCong.com https://fb.com/tailieudientucntt

user’s guide.

user’s guide.

TP 170A Equipment Manual

Release 12/99

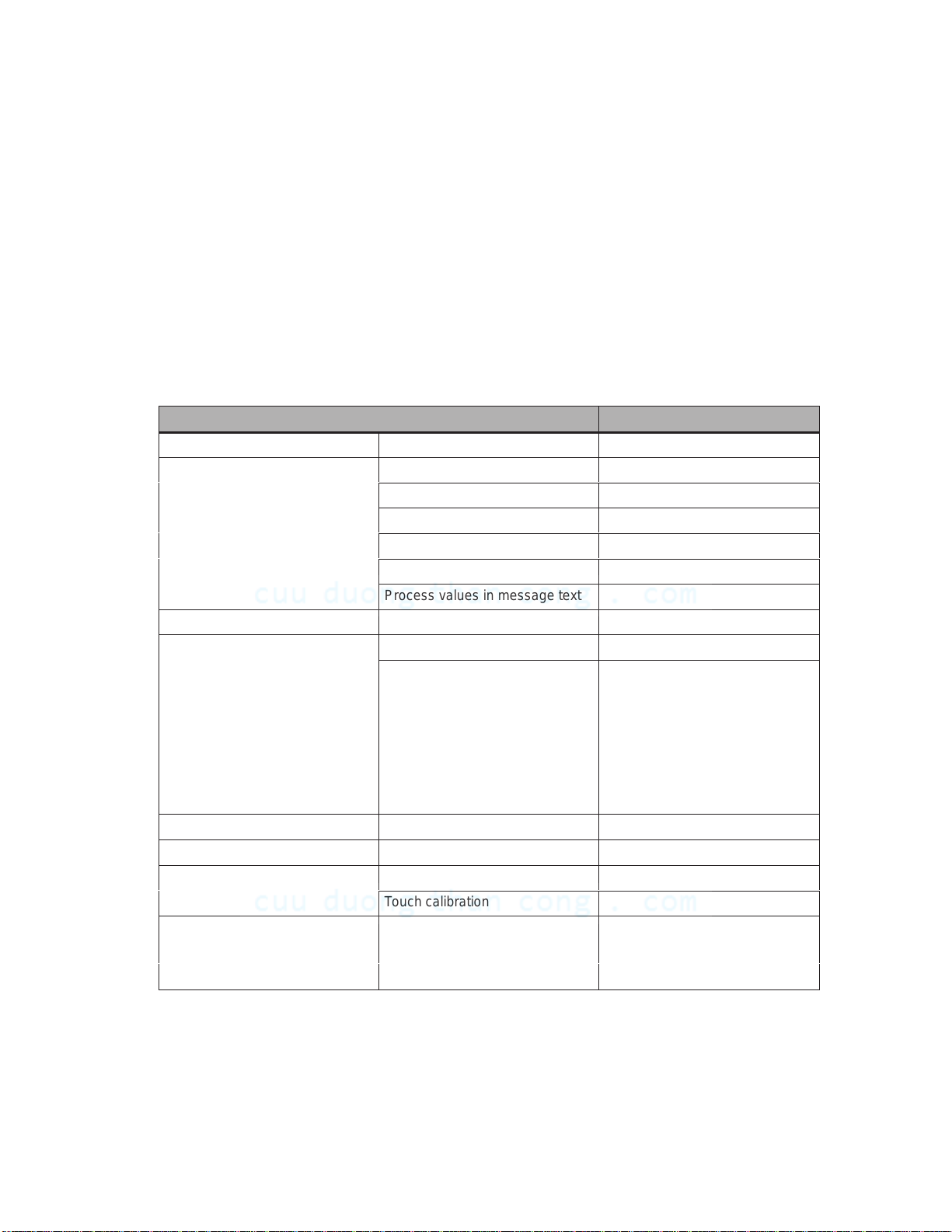

Functionality

The table below summarizes the functional scope of the operating unit. The values quoted are

the maximum values which can be managed by the operating unit. The values are limited by the

size of the memory used.

Function Comment

Configuration memory Capacity , in kByte 256

Messages Number 100

Display In message display

Type of display First/Last

Message text length 70 characters

Pending message events 16

Process values in message text 8

Message acquisition Time of occurrence Date and time

Screens View 4

Screen objects Output field

2

Input field

Text

Graphics

Status button

Bar

Message view

Limit value monitoring Inputs/outputs 4

Password protection Passwords 1

Screen settings Contrast 4

Touch calibration 4

Communication SIMATIC S7

MPI (to 1.5 Mbits/s) 4

PROFIBUS-DP 4

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

2-1

Functionality

2-2

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Commissioning

In this chapter

This chapter provides information on:

starting up the operating unit for the first time (Page 3-2)

restarting the operating unit (from Page 3-3)

the options for Download mode (from Page 3-5)

testing a configuration (Page 3-7)

3

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

3-1

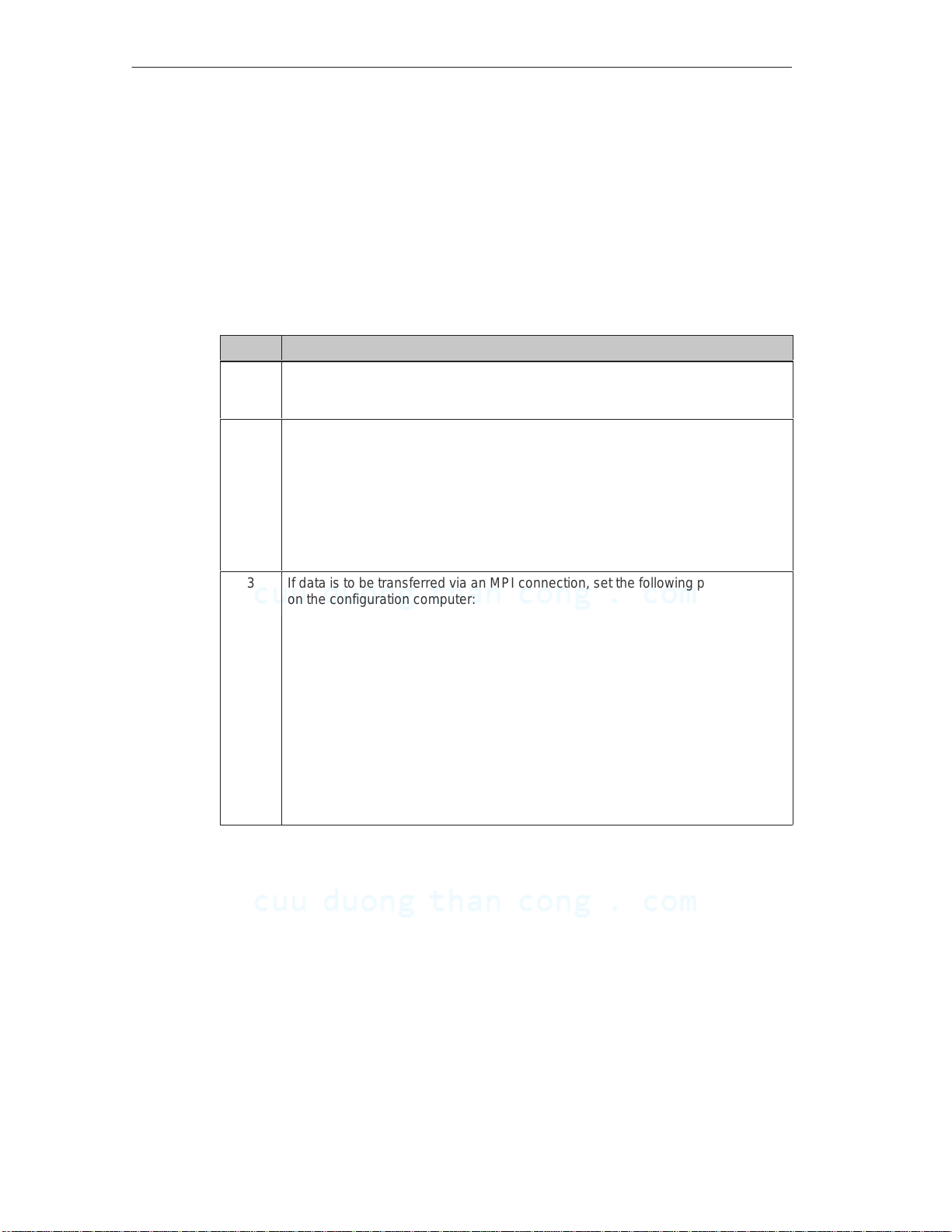

Commissioning

3.1 Initial Startup

Procedure

When the operating unit is started up for the first time, there is no configuration

loaded. Proceed as follows, observing the sequence, in order to download a

configuration from the configuration computer to the operating unit which is

necessary to put the unit into service:

Step Procedure

1 Connect the interface IF1A (RS232) or IF1B (RS485) on the operating unit to the

configuration computer, according to the setting in the Configuration menu

(Figure 3-2, Page 3-5), using an appropriate standard cable.

2 Switch on the power supply for the operating unit.

Since no configuration has been loaded at this point, the operating unit

automatically switches to Download mode. The operating unit displays the

message Connecting to host until it receives data from the configuration

computer or the button

If the message Connecting to host does not appear, it is possible that the

option for Download mode has been set incorrectly (refer to the note on

Page 3-6).

3 If data is to be transferred via an MPI connection, set the following parameters

on the configuration computer:

OP Address: 1

Transmission rate: 187.5 kBaud

Start the data transfer to the operating unit from the configuration computer.

The configuration computer checks the connection to the operating unit. If the

connection is not available or defective, it issues the corresponding error

message.

If downloading from the configuration computer is interrupted due a compatibility

conflict, please proceed according to the description in the Chapter 10.

If the connection is correct, the configuration is downloaded to the operating unit.

Following successful downloading, the operating unit restarts and displays the

start screen of the configuration that has just been loaded.

Cancel

is pressed.

3-2

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Commissioning

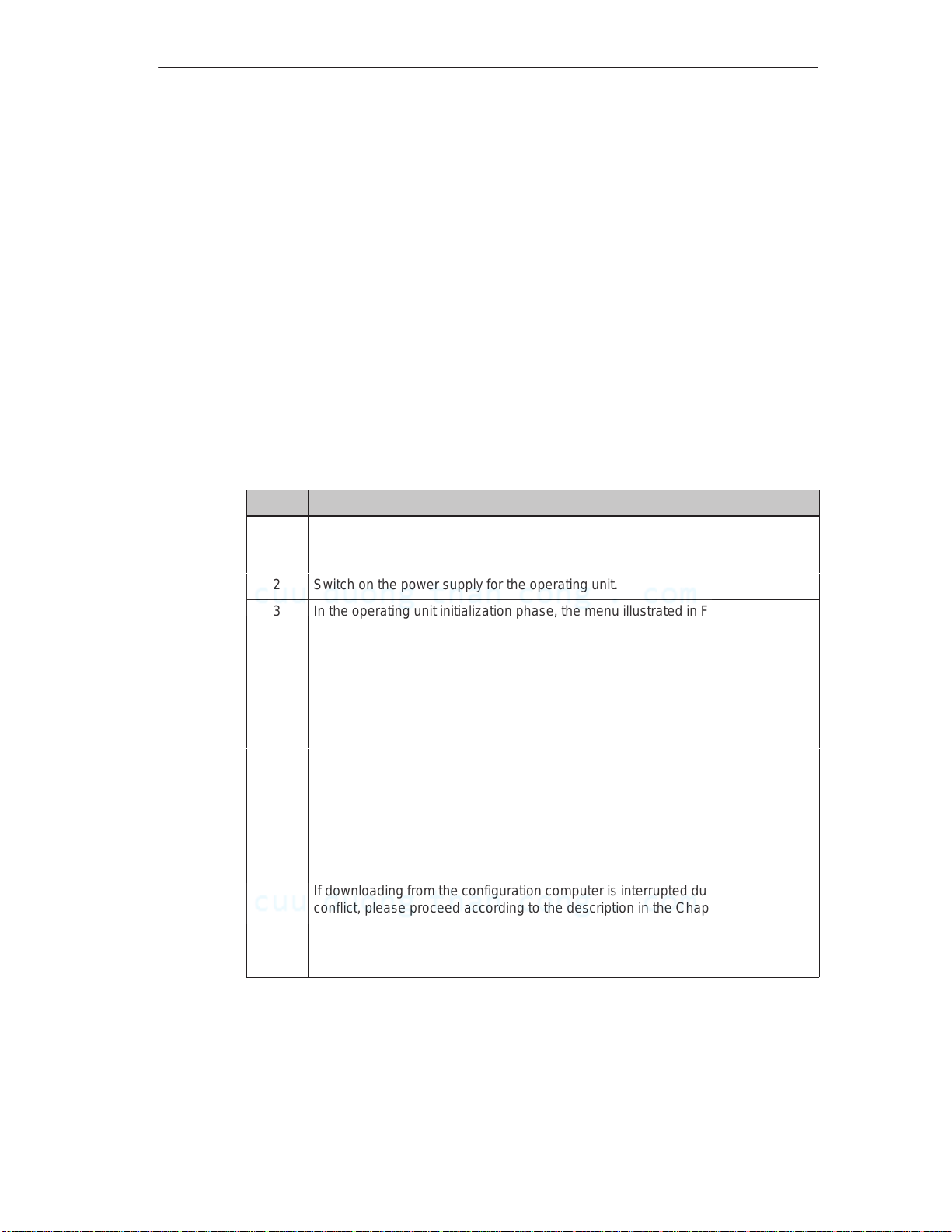

3.2 Recommissioning

Purpose

Following a restart, the configuration in the operating unit is replaced by a different

one. The new configuration is downloaded from the configuration computer to the

operating unit.

The following options are available for downloading a configuration:

Start downloading manually during the operating unit initialization phase

Start downloading automatically while the operating unit is in operation

Start downloading via a correspondingly configured operating element while the

operating unit is in operation (refer to the Chapter 6.1)

Start downloading manually during the operating unit initialization phase

Step Procedure

1 Connect the interface IF1A (RS232) or IF1B (RS485) on the operating unit to the

configuration computer, according to the setting in the Configuration menu

(Figure 3-2, Page 3-5), using an appropriate standard cable.

2 Switch on the power supply for the operating unit.

3 In the operating unit initialization phase, the menu illustrated in Figure 3-1

appears briefly . Touch the

mode before it is initialized.

The operating unit displays the message Connecting to host until it receives

data from the configuration computer or the button

If the message Connecting to host does not appear, it is possible that the

option for Download mode has been set incorrectly (refer to the note on Page

3-6).

4 If downloading should be performed via an MPI connection, set the OP address

and transmission rate valid for the operating unit on the configuration computer

(refer to the note on Page 3-4).

Start data transfer to the operating unit from the configuration computer.

The configuration computer checks the connection to the operating unit. If the

connection is not available or defective, the configuration computer issues the

corresponding error message.

If downloading from the configuration computer is interrupted due a compatibility

conflict, please proceed according to the description in the Chapter 10.

If the connection is correct, the new configuration is downloaded to the operating

unit. Following successful downloading, the operating unit restarts and displays

the start screen of the configuration that has just been loaded.

Download

button to set the operating unit to Download

Cancel

is pressed.

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

3-3

Commissioning

Start downloading automatically when the operating unit is in operation

The operating unit can be switched automatically to Download mode from normal

operation as soon as downloading is started on the connected configuration

computer. This option is especially recommended for the test phase of a new

configuration because the transfer is performed without intervention in the

operating unit. A condition for this is that the following settings are defined in the

Configuration menu (Figure 3-2):

MPI connection:

Option

Option

MPI Transfer Enable

MPI Transfer Remote

activated

activated

Serial connection:

Option

Option

Serial Transfer Enable

Serial Transfer Remote

activated

activated

A detailed description of the possible settings in the Configuration menu is

provided on Page 3-5.

Note:

The bus parameters (e.g. MPI address, baud rate, etc.) are read out of the

configuration which has been loaded on the operating unit. Important: A new

project with new parameters must initially be loaded on the operating unit with the

old settings (on the configuration computer) because the old parameters apply

here.

3-4

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

3.3 Download Mode Options

Purpose

The following options can be set for Download mode:

The operating unit can be switched from normal operation to Download mode

automatically as soon as downloading is started on the connected configuration

computer.

Download mode can be restricted to a specific connection type so that

downloading is only performed via a serial or an MPI connection.

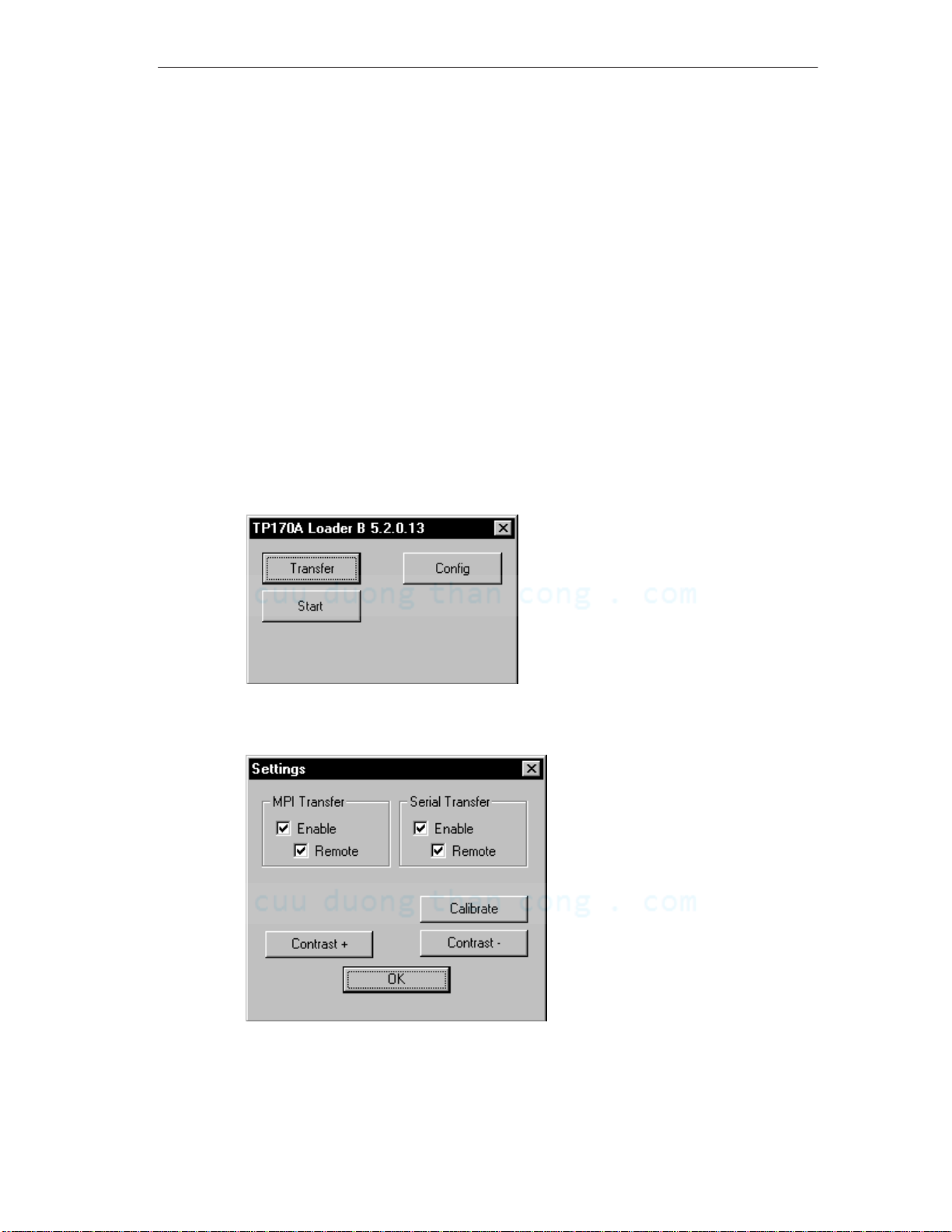

Call in the Configuration menu

The options for Download mode can only be set when the operating unit is in its

initialization phase. During the operating unit initialization phase, the Start menu,

illustrated in Figure 3-1 appears briefly. Touch the

Configuration menu displayed in Figure 3-2.

Config

button to call in the

Commissioning

Figure 3-1 TP 170A Start menu

Figure 3-2 Configuration menu

TP 170A Equipment Manual

Release 12/99

3-5

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Commissioning

Define settings

The downloading options defined in the Configuration menu have the following

effects:

Option

MPI Transfer Enable

If this option is deactivated, the operating unit does not permit downloading via

an MPI connection (refer to the Note below).

Option

This option is only available for selection when the

MPI Transfer Remote

MPI Transfer Enable

option

is active.

When this option is active, the operating unit automatically switches from

normal operation to Download mode in the case of an MPI transfer from the

configuration computer.

Option

Serial Transfer Enable

If this option is deactivated, the operating unit does not permit downloading via

a serial connection (refer to the Note below).

Option

This option is only available for selection when the

Serial Transfer Remote

Serial Transfer Enable

option

is active.

When this option is active, the operating unit automatically switches from

normal operation to Download mode in the case of serial transfer from the

configuration computer.

Use the OK button to confirm the current settings for downloading options. The

Configuration menu is closed and the Start menu illustrated in Figure 3-1 is

displayed.

Note:

If both the options

MPI Transfer Enable

and

Serial Transfer Enable

are

deactivated, it is not possible to download a configuration from the configuration

computer to the operating unit.

Exit the Start menu

If no configuration is loaded on the operating unit, it switches to Download mode

automatically after 10 seconds. Touch the

unit to Download mode manually.

If a configuration has already been loaded on the operating unit, it starts it up

automatically after 10 seconds. The configuration can be started manually by

touching the

3-6

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Start

button.

Download

button to switch the operating

TP 170A Equipment Manual

Release 12/99

3.4 T est Configuration

Simulation on a configuration computer

A simulator is supplied with the configuration software which can be used to test

your configuration without the necessity of a connection to a PLC. A condition for

this is that the runtime software is installed on the same configuration computer on

which the configuration software is loaded. The runtime software is contained on

the configuration software installation CD.

The simulator is an individual application. It simulates the configuration offline, i.e.

without the necessity of a physical connection to a PLC. The PLC is simulated by

the software.

Start the simulator by clicking on the symbol depicted on the left or by using

the menu command

File → Test → Start simulator

Commissioning

.

Detailed information on operating the simulator is provided in the

Configuring Windows-based Systems

software online help.

Note:

For the test phase of a configuration, it is recommended to initiate Download mode

from normal operation automatically. Further information is available on Page 3-4.

Test with connected PLC

When a PLC is connected, it is possible to test the communication between the

operating unit and PLC. This test also determines whether the correct data areas

have been configured.

Check the following configuration elements, for example:

messages,

screen selection,

input field.

ProTool

user’s guide and in the configuration

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

3-7

Commissioning

3-8

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Operating the TP 170A

In this chapter

This chapter contains information on how to:

operate touch elements (from Page 4-2)

enter values (from Page 4-4)

operate screens (Page 4-6)

Information regarding operation for special screen objects is provided in Chapter 5.

4

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

4-1

Operating the TP 170A

4.1 Operating Touch Elements

Operating concept

The screen is used to observe the operating status of the machine or system being

monitored and, at the same time, to intervene directly in the process running

simply by touching the buttons and input fields displayed.

Definition

Touch elements are contact–sensitive operating elements provided on the touch

panel screen, such as buttons and input fields. Their operation is basically no

different from pressing conventional keys. Touch elements are operated by

touching them lightly with your finger or a suitable object.

Note

Never use pointed or sharp instruments to operate the Touch Panel to prevent

damage to the plastic surface of the touch screen.

Caution

!

Never touch more than one touch panel screen element at a time. If you do, an

unintended action may be initiated.

4-2

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Operation acknowledgement

As soon as the touch panel detects valid contact with a touch element, it responds

by displaying a visual acknowledgement. An acknowledgment is independent of

communication with the PLC. It is not an indication of the required action actually

having been executed.

The type of visual acknowledgement is dependent on the operating element

touched:

Buttons

In the case of 3D–effect configurations, visual representation is distinguished

according to the statuses

are illustrated below by means of the Status button:

Operating the TP 170A

touched

and

untouched

. Examples of representation

UntouchedTouched

Input fields

After an input field has been touched, the system keyboard illustrated in

Figure 4-1 appears as the operation acknowledgement.

Password protected operating elements

If an operating element is touched which has been assigned with a password

protection, without the user having logged in on the operating unit beforehand, a

system message is triggered. The password protected function is not executed.

Further information on this subject is available in the Chapter 5.4.

TP 170A Equipment Manual

Release 12/99

CuuDuongThanCong.com https://fb.com/tailieudientucntt

4-3

Operating the TP 170A

4.2 Entering Values

Principles of operation

Input fields are used to enter digits and texts (characters 0 to 9 and A to F). To do

so, touch the corresponding field. The system keyboard appears.

After an entry has been made correctly, the system keyboard automatically

disappears and the entered value is accepted in the input field.

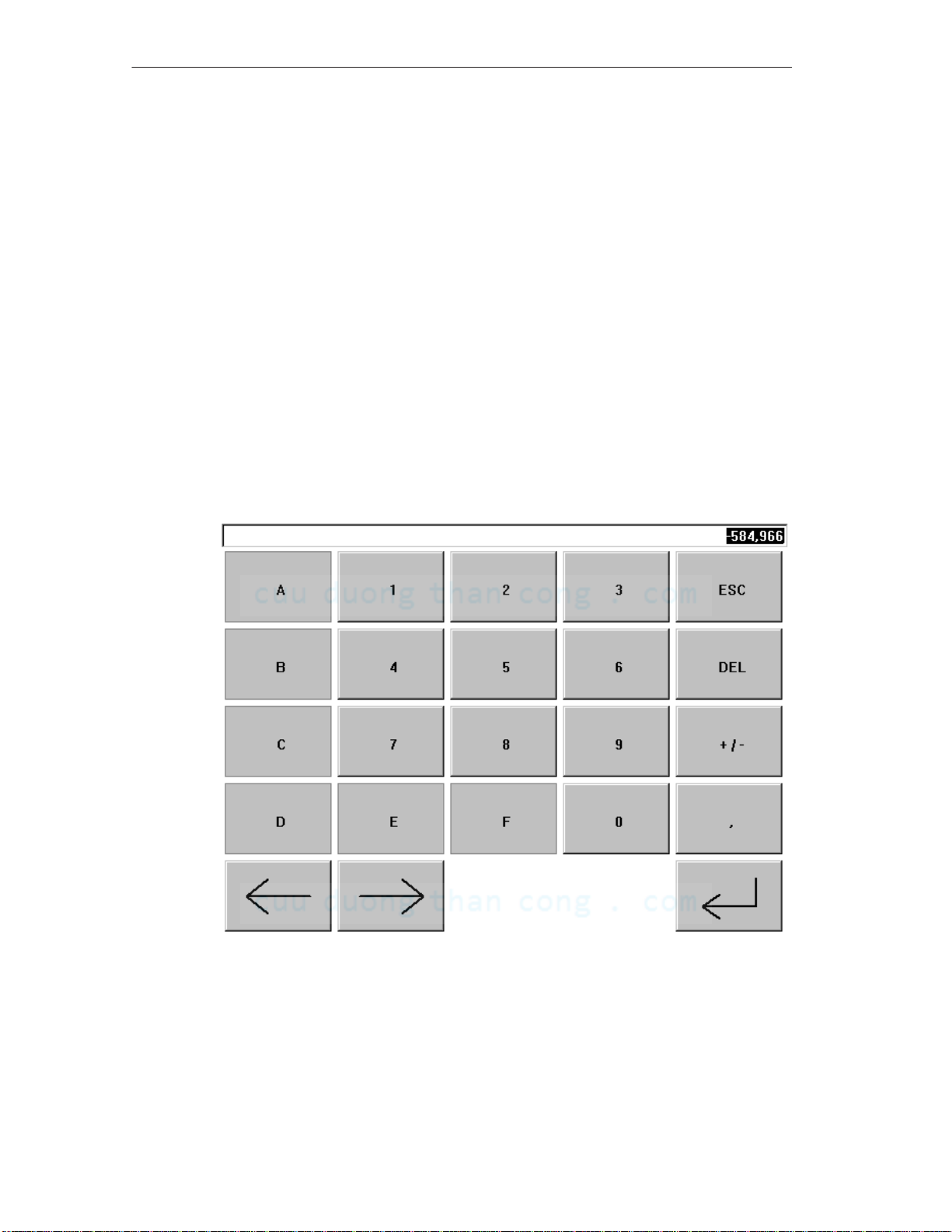

System keyboard

The buttons available for operation on the system keyboard are dependent on the

type of value to be entered. Buttons which are available for operation are

highlighted, and those not available appear simply as empty areas.

Figure 4-1 illustrates an example of the system keyboard for entering decimal

values. Table 4-1 explains the significance of each individual button.

4-4

Figure 4-1 System keyboard

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Meanings of buttons

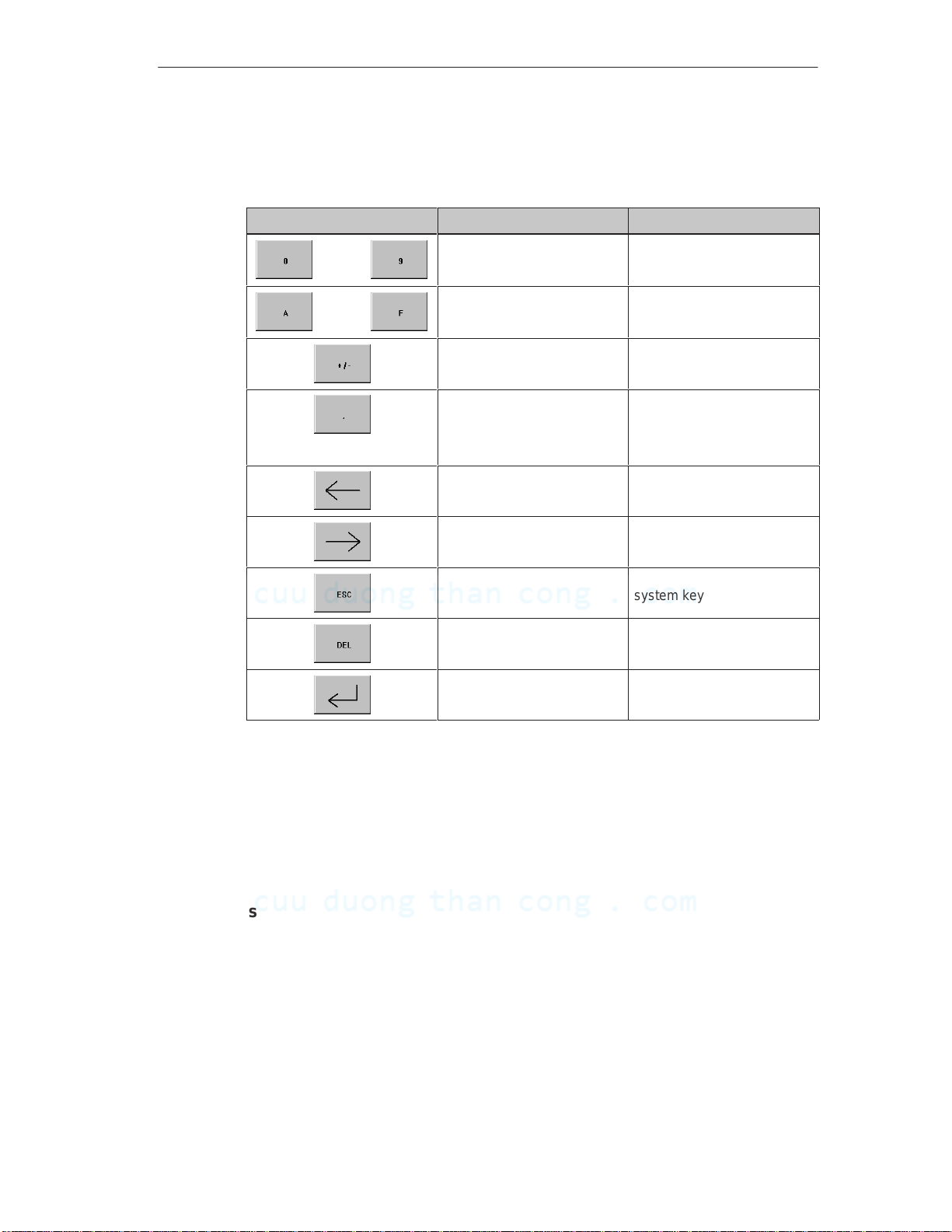

Table 4-1 Significance of buttons

Operating the TP 170A

Button Function Purpose

Enter digits Enter digits 0 to 9.

...

...

Enter characters Enter the characters A to F.

Change sign Change sign from + to – and

back.

Enter decimal point Enter decimal point or

comma. The assignment

and labeling of this button is

language–dependent.

Move input position

to the left

Move input position

to the right

Cancel (Escape) Discard input and close the

Delete character Delete the character to the

Enter Confirm input and close the

Move current input position

one character to the left.

Move current input position

one character to the right.

system keyboard.

left of the input position.

system keyboard.

Enter value

Characters entered are aligned to the right. On entering a new character, all those

already entered are shifted one position to the left (pocket calculator format).

On exceeding the maximum number of characters, the last character entered is

overwritten.

Limit values

Limit values can be configured for numeric input fields. In this case, values

entered are only accepted when they lie within the limits configured.

Note:

If an attempt is made to enter a value which is outside the configured limit values,

the system keyboard is closed and the original value reinserted. In addition, a

system message is triggered.

TP 170A Equipment Manual

Release 12/99

4-5

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Operating the TP 170A

4.3 Operating Screens

What is a screen?

Screens visualize the progress of processes and display specified process values.

A screen contains logically related process data which the operating unit can both

display and modify by operating the individual values.

Screen partitions

A screen is basically composed of static and dynamic sections. The terms “static”

and “dynamic” do not refer to the possibility of dynamically positioning screen

partitions but to the connection to the PLC.

Static partitions, e.g. text and graphics, are not updated by the PLC. Dynamic

partitions, e.g. input and output fields and bars, can be linked to the PLC and

display current values constantly read in from the PLC memory. Their connection

to the PLC is established by means of tags.

Screen objects

Various screen elements are used to display and operate a screen:

Output fields

Input fields

Texts

Graphics

Status buttons

Bar graphs

Message view

A summary of all the screen objects which a TP 170A project may contain is

provided in Chapter 5.

4-6

TP 170A Equipment Manual

CuuDuongThanCong.com https://fb.com/tailieudientucntt

Release 12/99

Loading...

Loading...