Siemens SIMATIC HMI OP3 Equipment Manual

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

DATASHEET

www.rgbautomatyka.pl

www.rgbelektronika.pl

OTHER SYMBOLS:

KEYPAD 6AV3503-1DB10

KEYPAD6AV35031DB10, KEYPAD6AV3503 1DB10, KEYPAD6AV3503-1DB10, KEYPAD 6AV35031DB10, KEYPAD

6AV3503 1DB10, KEYPAD 6AV3503-1DB10

SIEMENS

YOUR

PARTNER IN

MAINTENANCE

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

OUR SERVICES

ENCODERS

SERVO

DRIVERS

LINEAR

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

MOTORS

POWER

SUPPLIERS

OPERATOR

PANELS

CNC

CONTROLS

INDUSTRIAL

COMPUTERS

PLC

SYSTEMS

Repair this product with RGB ELEKTRONIKA

ORDER A DIAGNOSIS

∠

Buy this product at RGB AUTOMATYKA

BUY

∠

Preface, Contents

Part I Introduction

1

2

Part II Functions of the OP3

3

12

Part III Installation and

Commissioning

13

14

Part IV Device Description,

Test and

Monitoring Functions

15

16

Part V Appendices

A

E

Glossary, Index

Release 11/99

OP3

Operator Panel

Equipment Manual

SIMATIC HMI

6AV3591–1AD00–1AB0

This manual contains notices which you should observe to ensure your own personal safety, as

well as to protect the product and connected equipment. These notices are highlighted in the

manual by a warning triangle and are marked as follows according to the level of danger:

!

Warning

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

!

Caution

indicates that minor personal injury or property damage can result if proper precautions are not

taken.

Note

draws your attention to particularly important information on the product, handling the product,

or to a particular part of the documentation.

Equipment may be commissioned and operated only by qualified personnel. Qualified person-

nel within the meaning of the safety notices in this manual are persons who are authorized to

commission, ground and identify equipment, systems and circuits in accordance with safety

engineering standards.

Note the following:

!

Warning

The equipment may be used only for the applications stipulated in the catalog and in the tech-

nical description and only in conjunction with other equipment and components recommended

or approved by Siemens.

Startup must not take place until it is established that the machine, which is to accommodate

this component, is in conformity with the guideline 89/392/EEC.

Faultless and safe operation of the product presupposes proper transportation, proper storage,

erection and installation as well as careful operation and maintenance.

The approvals that apply to the device are detailed in the Chapter Technical Data.

The registered trademarks of Siemens AG are listed in the Preface. Some of the other

designations used in these documents are also registered trademarks; the owner’s rights may be

violated if they are used be third parties for their own purposes.

Editor and Publisher: A&D PT1

We have checked the contents of this manual for agreement with

the hardware and software described. Since deviations cannot be

precluded entirely , we cannot guarantee full agreement. However ,

the data in this manual are reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions for im-

provement are welcomed.

Technical data subject to change.

Siemens AG 1999

Disclaimer of LiabilityCopyright Siemens AG 1999 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG,

Automation & Drives

SIMATIC Human Machine Interface

A&D PT1 D1

Postfach 4848, D-90327 Nuernberg

Siemens Aktiengesellschaft Order No. 6AV3591–1AD00–1AB0

Safety Guidelines

Qualified Personnel

Correct Usage

Approvals

Trademarks

Impressum

i

Operator Panel OP3

Edition 11/99

Preface

This equipment manual provides operators, fitters, configurers and system

support engineers with information about the functionality and technical

design of the OP3.

The equipment manual Operator Panel OP3 is organized into five parts:

Part Chapters Contents

I 1 - 2 Overview of the Operator Panel and range of

functions in tabular form.

II 3 - 4

5 - 11

12

How to operate the OP3.

Step-by-step instructions on how to operate the

Operator Panel using the standard screens.

Information on how to connect the OP3 to the

SIMATIC S7.

III 13 - 14 – Mechanical and electrical installation,

– Commissioning

IV 15 - 16 – Dimensions and connection elements,

– Test and monitoring functions

V Appendix – Brief descriptions of standard screens,

– System messages,

– Technical data,

– ESD guidelines,

– SIMATIC HMI documentation,

– Glossary of technical terms.

Purpose

Organization of

the manual

ii

Operator Panel OP3

Edition 11/99

The following conventions are used in this manual:

Motor off Text on the display of the OP3 is shown in ”type-

writer” style.

Variable Symbolic names representing variable values on the

display of the OP3 are shown in italic ”typewriter”

style.

System Functions which you can choose are shown in nor-

mal italics.

System → Mode Steps that are performed in succession are linked by

an arrow.

ESC The names of keys are shown in a different type.

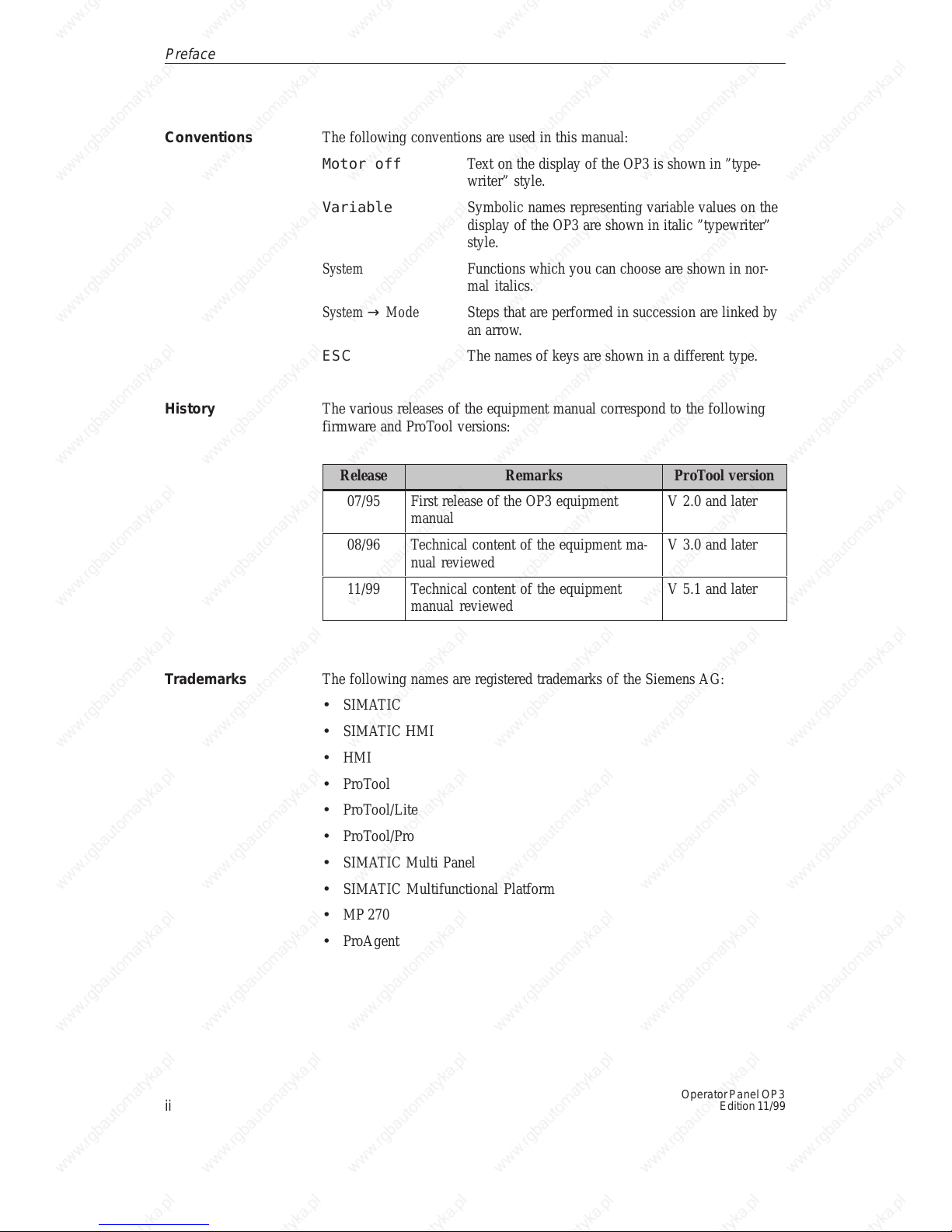

The various releases of the equipment manual correspond to the following

firmware and ProTool versions:

Release Remarks ProTool version

07/95 First release of the OP3 equipment

manual

V 2.0 and later

08/96 Technical content of the equipment ma-

nual reviewed

V 3.0 and later

11/99 Technical content of the equipment

manual reviewed

V 5.1 and later

The following names are registered trademarks of the Siemens AG:

• SIMATIC

• SIMATIC HMI

• HMI

• ProTool

• ProTool/Lite

• ProTool/Pro

• SIMATIC Multi Panel

• SIMATIC Multifunctional Platform

• MP 270

• ProAgent

Conventions

History

Trademarks

Preface

iii

Operator Panel OP3

Edition 11/99

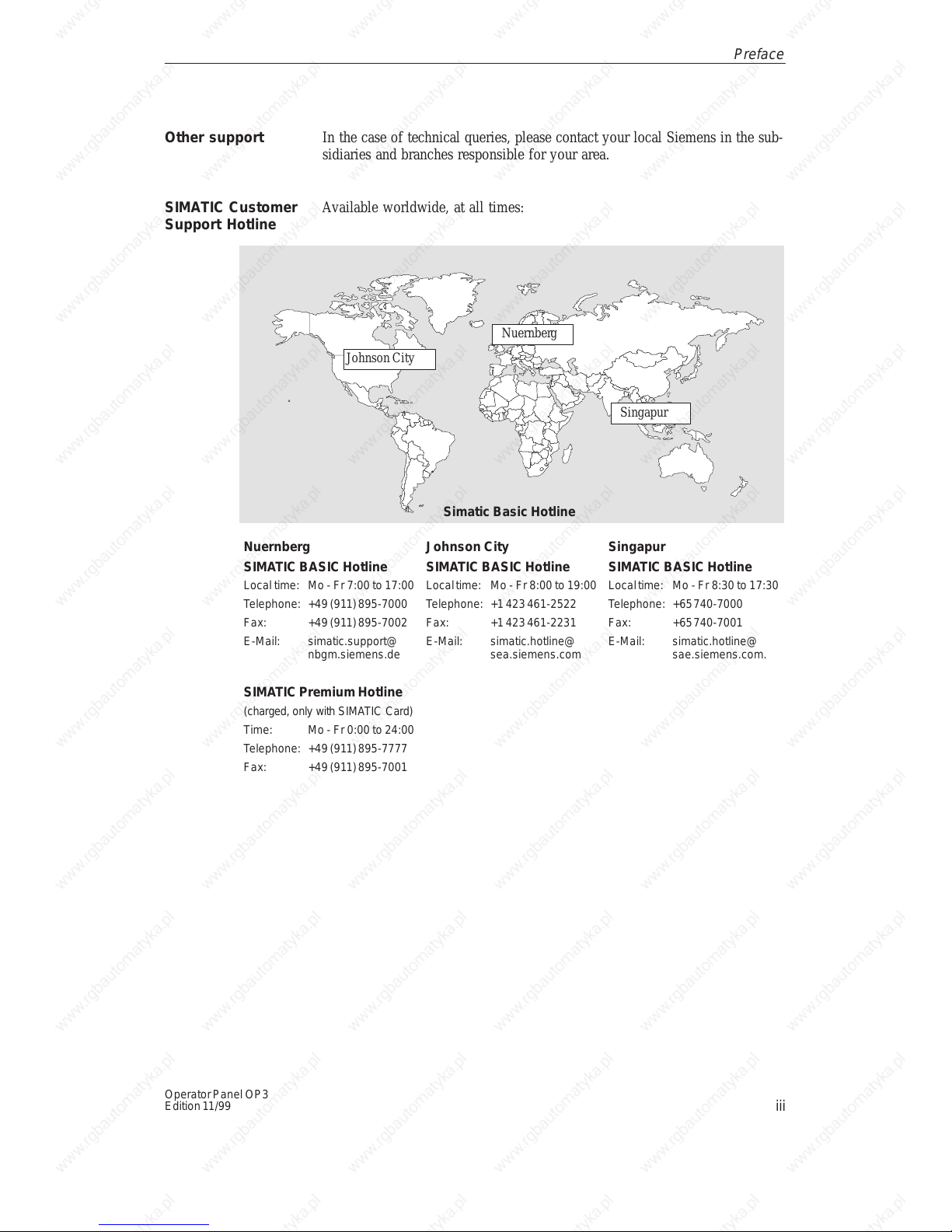

In the case of technical queries, please contact your local Siemens in the sub-

sidiaries and branches responsible for your area.

Available worldwide, at all times:

Johnson City

Nuernberg

Singapur

Simatic Basic Hotline

Nuernberg

SIMA TIC BASIC Hotline

Johnson City

SIMA TIC BASIC Hotline

Singapur

SIMA TIC BASIC Hotline

Local time: Mo - Fr 7:00 to 17:00

T elephone: +49 (911) 895-7000

Fax: +49 (911) 895-7002

E-Mail: simatic.support@

nbgm.siemens.de

Local time: Mo - Fr 8:00 to 19:00

T elephone: +1 423 461-2522

Fax: +1 423 461-2231

E-Mail: simatic.hotline@

sea.siemens.com

Local time: Mo - Fr 8:30 to 17:30

T elephone: +65 740-7000

Fax: +65 740-7001

E-Mail: simatic.hotline@

sae.siemens.com.

SIMA TIC Premium Hotline

(charged, only with SIMATIC Card)

Time: Mo - Fr 0:00 to 24:00

T elephone: +49 (911) 895-7777

Fax: +49 (911) 895-7001

Other support

SIMATIC Customer

Support Hotline

Preface

iv

Operator Panel OP3

Edition 11/99

SIMATIC Customer Support offers comprehensive additional information

concerning SIMATIC products through its Online services as follows:

• Up–to–date general information is provided

– in Internet under http://www.ad.siemens.de/simatic

– via Fax-Polling under 08765-93 02 77 95 00

• Up–to–date product information and downloads for practical use can be

found:

– in Internet unter http://www.ad.siemens.de/support/

html–00/

– via the Bulletin Board System (BBS) in Nürnberg (SIMATIC Custo-

mer Support Mailbox) under +49

(911) 895–7100

In order to contact the mailbox, please use a modem with up to 28.8

kBaud (V.34) capacity. Set the parameters as follows: 8, N, 1, ANSI,

or dial for connection via ISDN (x.75, 64 kBit).

The abbreviations used in this equipment manual have the following

meaning:

EPROM (with UV light) erasable programmable read-only memory

RAM Random access memory (working memory)

AM Alarm Message

CPU Central Processing Unit

EM Event message

ESD Electrostatic Sensitive Device

LCD Liquid Crystal Display

LED Light–Emitting Diode

MPI Multipoint Interface (SIMATIC S7)

PC Personal Computer

PLC Programmable Logic Controller

PU Programming Unit

PPI Point to Point Interface (SIMATIC S7)

SRAM Static Random Access Memory

OP Operator Panel

SIMATIC Customer

Online Services

Abbreviations

Preface

i

Operator Panel OP3

Edition 11/99

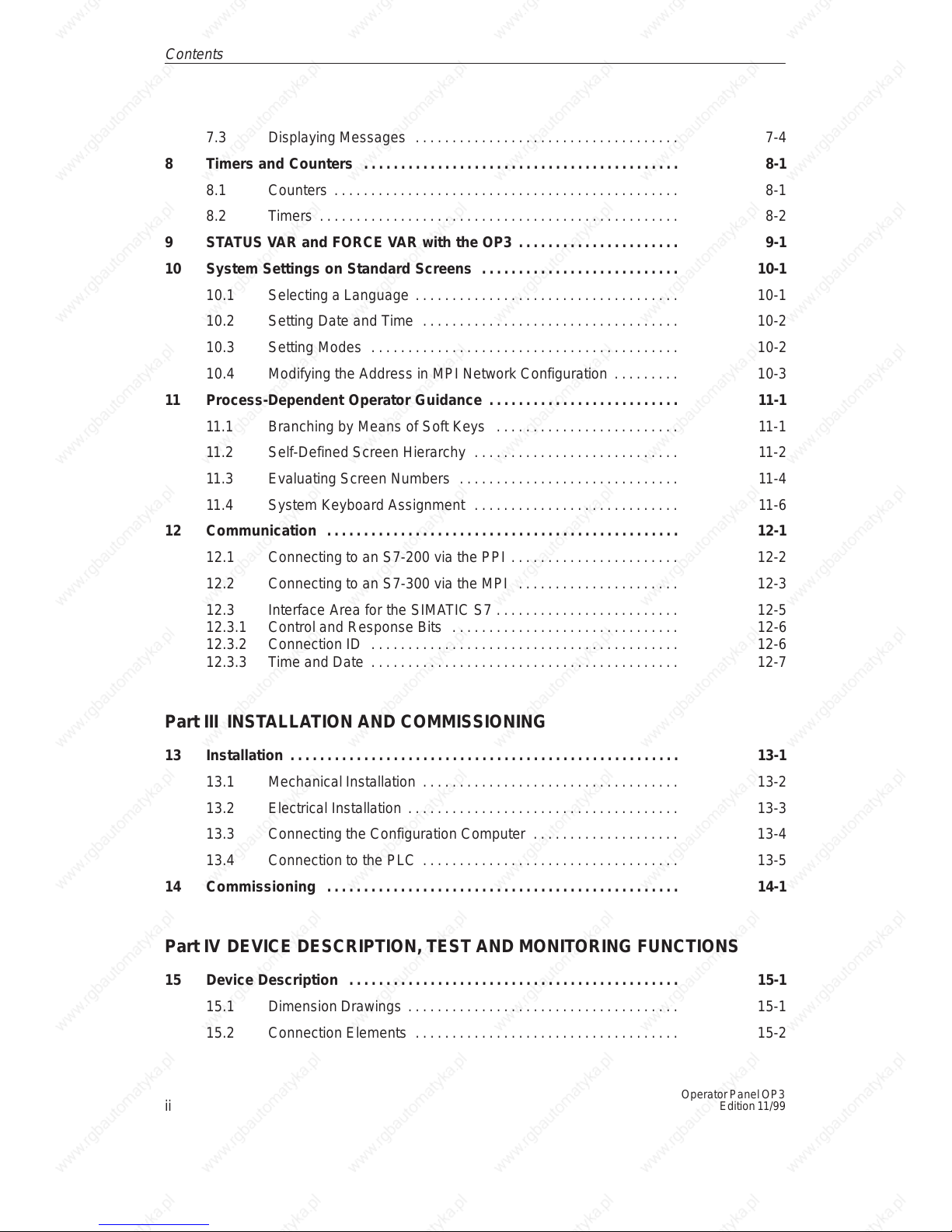

Contents

Part I INTRODUCTION

1 Product Description 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Configuration and Process Control Phases 1-1. . . . . . . . . . . . . . . . .

1.2 Configuration of OP3 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Functionality 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part II FUNCTIONS OF THE OP3

3 General Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Keyboard 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 SHIFT for Digits and Soft Keys 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Entering Values 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Entering Numerical Values 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Entering Alphanumeric Values 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Entering Symbolic Values 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Using the OP3 with Its Standard Functions 4-1. . . . . . . . . . . . . . . . . . . . . . .

4.1 Operating Levels 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Standard Screens 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Branching in Standard Screens 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Screens 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Screen Entries 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Choosing Screens 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Editing Screens 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Password Protection 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Password Levels and Access 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Logging In and Out on the OP3 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Password Management 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Messages 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Event Messages 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 System Messages 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Operator Panel OP3

Edition 11/99

7.3 Displaying Messages 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Timers and Counters 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Counters 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Timers 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 STATUS VAR and FORCE VAR with the OP3 9-1. . . . . . . . . . . . . . . . . . . . . .

10 System Settings on Standard Screens 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Selecting a Language 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Setting Date and Time 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Setting Modes 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Modifying the Address in MPI Network Configuration 10-3. . . . . . . . .

11 Process-Dependent Operator Guidance 11-1. . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Branching by Means of Soft Keys 11-1. . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Self-Defined Screen Hierarchy 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Evaluating Screen Numbers 11-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 System Keyboard Assignment 11-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Communication 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Connecting to an S7-200 via the PPI 12-2. . . . . . . . . . . . . . . . . . . . . . .

12.2 Connecting to an S7-300 via the MPI 12-3. . . . . . . . . . . . . . . . . . . . . .

12.3 Interface Area for the SIMATIC S7 12-5. . . . . . . . . . . . . . . . . . . . . . . . .

12.3.1 Control and Response Bits 12-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.2 Connection ID 12-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.3 Time and Date 12-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part III INSTALLATION AND COMMISSIONING

13 Installation 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Mechanical Installation 13-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Electrical Installation 13-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 Connecting the Configuration Computer 13-4. . . . . . . . . . . . . . . . . . . .

13.4 Connection to the PLC 13-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 Commissioning 14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part IV DEVICE DESCRIPTION, TEST AND MONITORING FUNCTIONS

15 Device Description 15-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 Dimension Drawings 15-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 Connection Elements 15-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

iii

Operator Panel OP3

Edition 11/99

15.3 Contrast Control 15-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Test and Monitoring Functions 16-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part V APPENDICES

A Brief Description of Standard Screens A-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

B System Messages B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Technical Data C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D ESD Guidelines D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.1 What Does ESD Mean? D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 Important Precautions against Charge D-2. . . . . . . . . . . . . . . . . . . . .

D.3 Handling ESDs D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4 Measuring and Modifying ESDs D-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

D.5 Shipping ESDs D-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E SIMATIC HMI Documentation E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary Glossary-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

iv

Operator Panel OP3

Edition 11/99

Contents

INTRODUCTION

1 Product Description

2 Functionality

Part I

2-2

Operator Panel OP3

Edition 11/99

1-1

Operator Panel OP3

Edition 11/99

Product Description

The device SIMATIC HMI OP3 allows operating states and current process

values of a connected SIMATIC S7 PLC to be visualized. In addition, inputs

can be made on the OP3 and written to the PLC. Functions relating to

machine diagnostics can also be executed on the OP3.

The OP3 is suitable for fitting into switching cabinets and control desks, and

for use as a hand-held device.

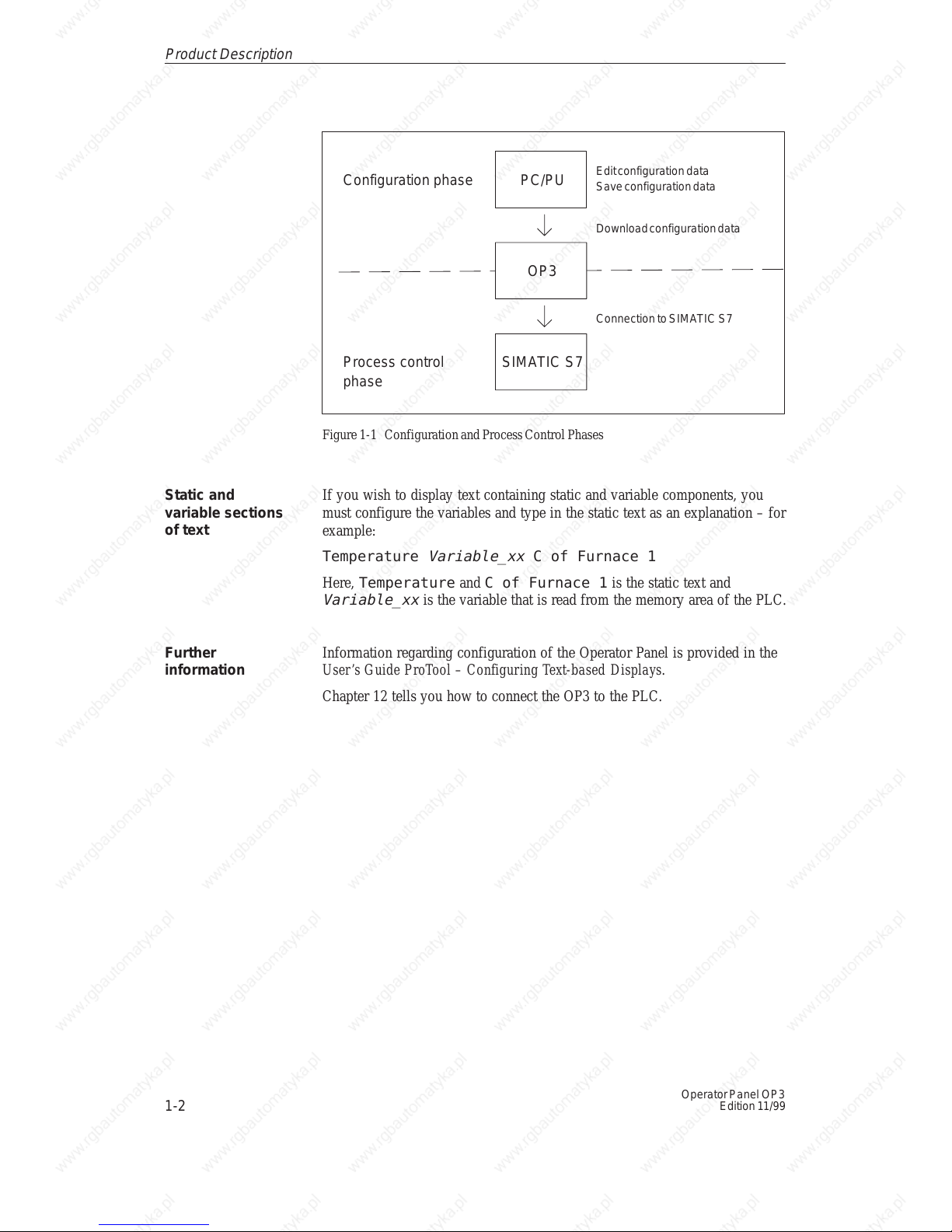

1.1 Configuration and Process Control Phases

Before the OP3 can go into service, it has to be prepared for its job of

visualizing data from the PLC, i.e. it has to be configured. To do so, data

areas used by the OP3 to communicate with the PLC have to be created in

the memory of the PLC.

The configuration for the OP3 is created on a configuration computer

(PC/PU) using the ProTool configuration software. When the configuration is

ready, it is transferred to the OP3. During operation, the OP3 communicates

with the PLC to which it is connected and reacts to program execution on the

PLC according to the configured requirements.

The following illustration depicts the configuration and process control

phases:

Using the OP3

Creating data

areas

Configuring with

ProTool

1

1-2

Operator Panel OP3

Edition 11/99

PC/PU

OP3

SIMATIC S7

Edit configuration data

Save configuration data

Download configuration data

Connection to SIMATIC S7

Configuration phase

Process control

phase

Figure 1-1 Configuration and Process Control Phases

If you wish to display text containing static and variable components, you

must configure the variables and type in the static text as an explanation – for

example:

Temperature

Variable_xx

C of Furnace 1

Here, Temperature and C of Furnace 1 is the static text and

Variable_xx

is the variable that is read from the memory area of the PLC.

Information regarding configuration of the Operator Panel is provided in the

User’s Guide ProTool – Configuring Text-based Displays.

Chapter 12 tells you how to connect the OP3 to the PLC.

Static and

variable sections

of text

Further

information

Product Description

1-3

Operator Panel OP3

Edition 11/99

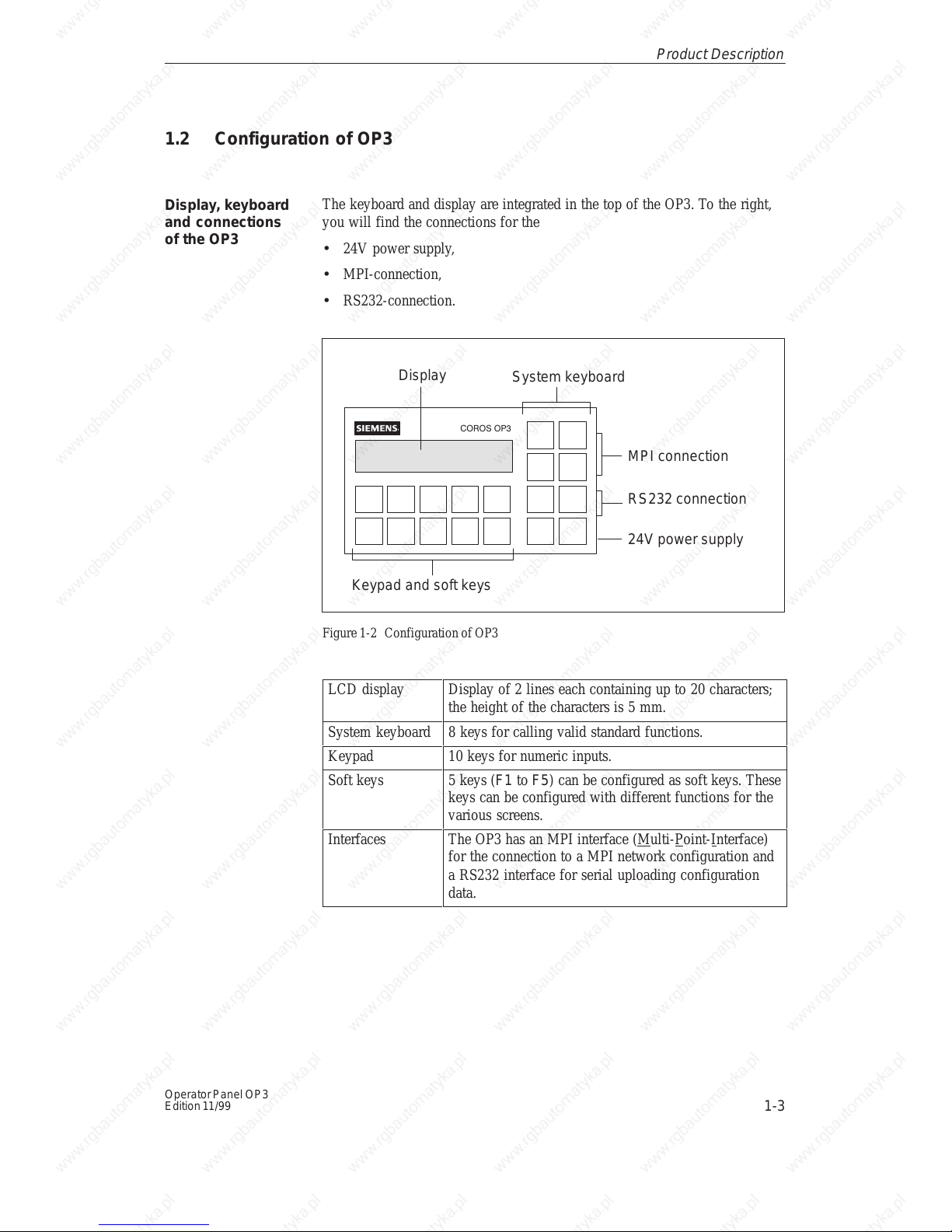

1.2 Configuration of OP3

The keyboard and display are integrated in the top of the OP3. To the right,

you will find the connections for the

• 24V power supply,

• MPI-connection,

• RS232-connection.

COROS OP3

MPI connection

Keypad and soft keys

Display

System keyboard

24V power supply

RS232 connection

Figure 1-2 Configuration of OP3

LCD display Display of 2 lines each containing up to 20 characters;

the height of the characters is 5 mm.

System keyboard 8 keys for calling valid standard functions.

Keypad 10 keys for numeric inputs.

Soft keys 5 keys (F1 to F5) can be configured as soft keys. These

keys can be configured with different functions for the

various screens.

Interfaces The OP3 has an MPI interface (Multi-Point-Interface)

for the connection to a MPI network configuration and

a RS232 interface for serial uploading configuration

data.

Display, keyboard

and connections

of the OP3

Product Description

1-4

Operator Panel OP3

Edition 11/99

Product Description

2-1

Operator Panel OP3

Edition 11/99

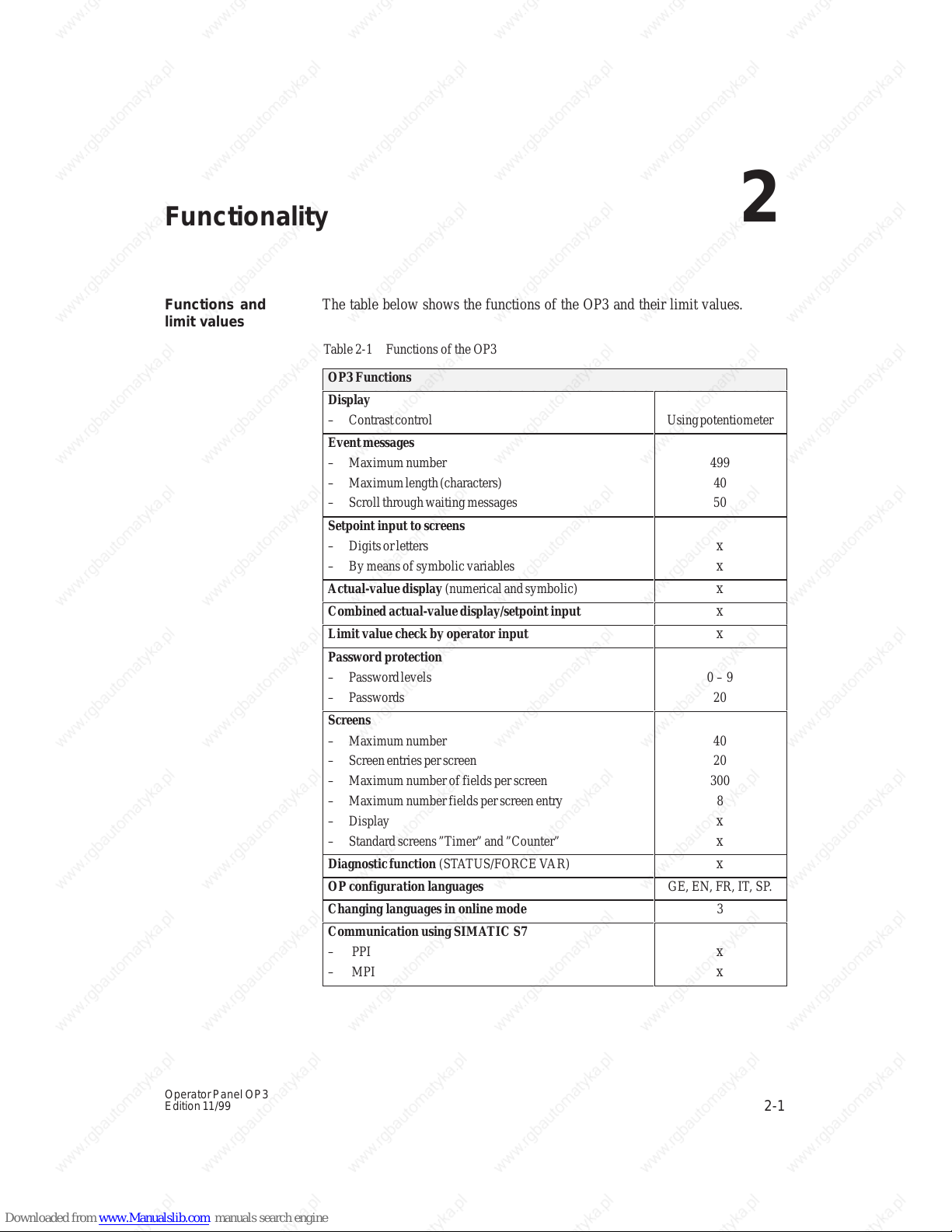

Functionality

The table below shows the functions of the OP3 and their limit values.

T able 2-1 Functions of the OP3

OP3 Functions

ББББББББББББББ

Á

Display

– Contrast control

БББББ

Á

Using potentiometer

ББББББББББББББ

Á

ББББББББББББББ

Á

Event messages

– Maximum number

– Maximum length (characters)

– Scroll through waiting messages

БББББ

Á

БББББ

Á

499

40

50

ББББББББББББББ

Á

ББББББББББББББ

Á

Setpoint input to screens

– Digits or letters

– By means of symbolic variables

БББББ

Á

БББББ

Á

x

x

Actual-value display (numerical and symbolic)

x

Combined actual-value display/setpoint input

x

Limit value check by operator input

x

ББББББББББББББ

Á

ББББББББББББББ

Á

Password protection

– Password levels

– Passwords

БББББ

Á

БББББ

Á

0 – 9

20

ББББББББББББББ

Á

ББББББББББББББ

Á

ББББББББББББББ

Á

ББББББББББББББ

Á

ББББББББББББББ

Á

ББББББББББББББ

Á

Screens

– Maximum number

– Screen entries per screen

– Maximum number of fields per screen

– Maximum number fields per screen entry

– Display

– Standard screens ”Timer” and ”Counter”

БББББ

Á

БББББ

Á

БББББ

Á

БББББ

Á

БББББ

Á

БББББ

Á

40

20

300

8

x

x

Diagnostic function (ST ATUS/FORCE VAR)

x

OP configuration languages

GE, EN, FR, IT , SP.

Changing languages in online mode

3

ББББББББББББББ

Á

Communication using SIMA TIC S7

– PPI

– MPI

БББББ

Á

x

x

Functions and

limit values

2

2-2

Operator Panel OP3

Edition 11/99

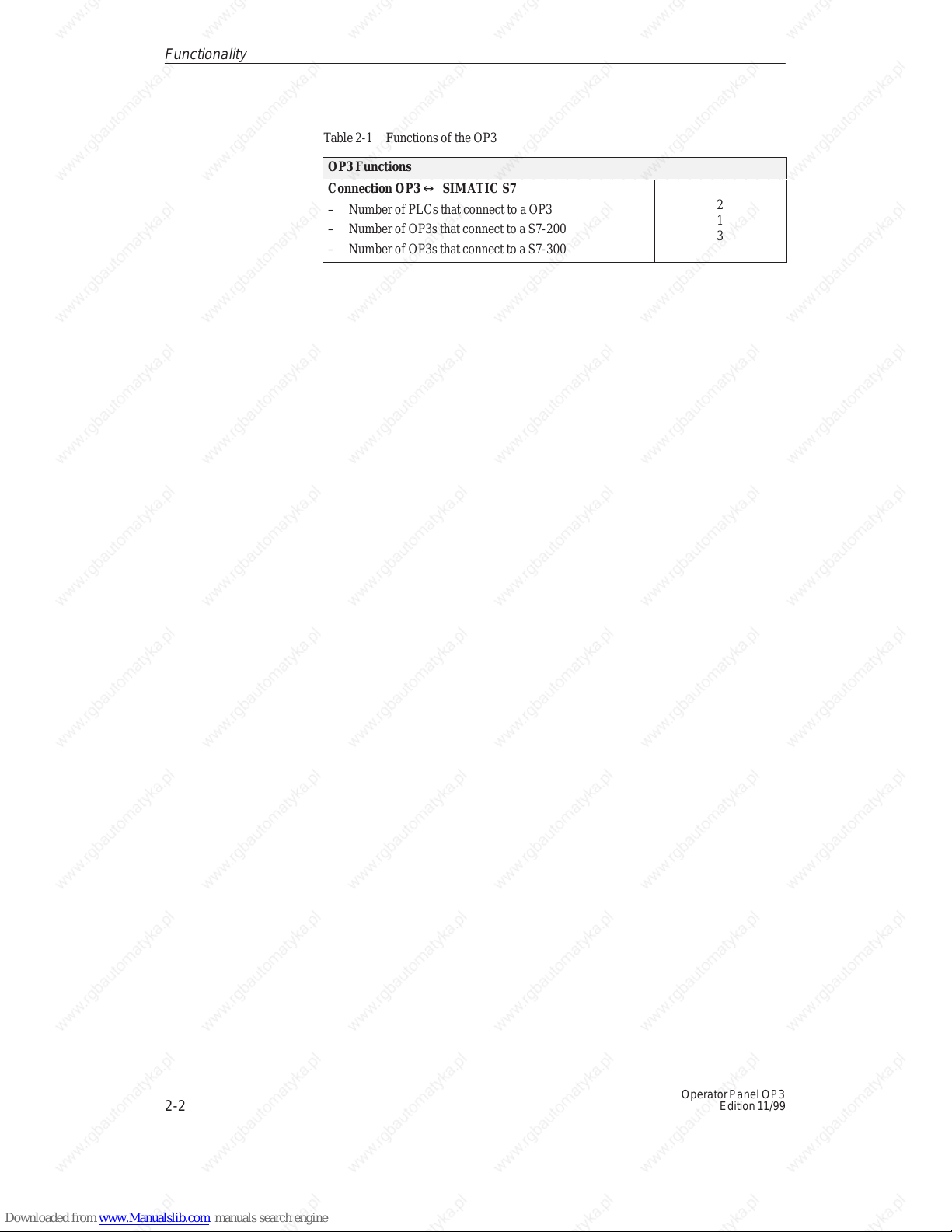

T able 2-1 Functions of the OP3

OP3 Functions

ББББББББББББББ

Á

ББББББББББББББ

Á

ББББББББББББББ

Á

Connection OP3 ↔ SIMA TIC S7

– Number of PLCs that connect to a OP3

– Number of OP3s that connect to a S7-200

– Number of OP3s that connect to a S7-300

БББББ

Á

БББББ

Á

БББББ

Á

2

1

3

Functionalit

y

FUNCTIONS OF THE OP3

3 General Operation

4 Using the OP3 with Its Standard Functions

5 Screens

6 Password Protection

7 Messages

8 Timers and Counters

9 STATUS VAR and FORCE VAR Functions with the OP3

10 System Settings on Standard Screens

11 Process-Dependent Operator Guidance

12 Communication

Part II

2-2

Operator Panel OP3

Edition 11/99

3-1

Operator Panel OP3

Edition 11/99

General Operation

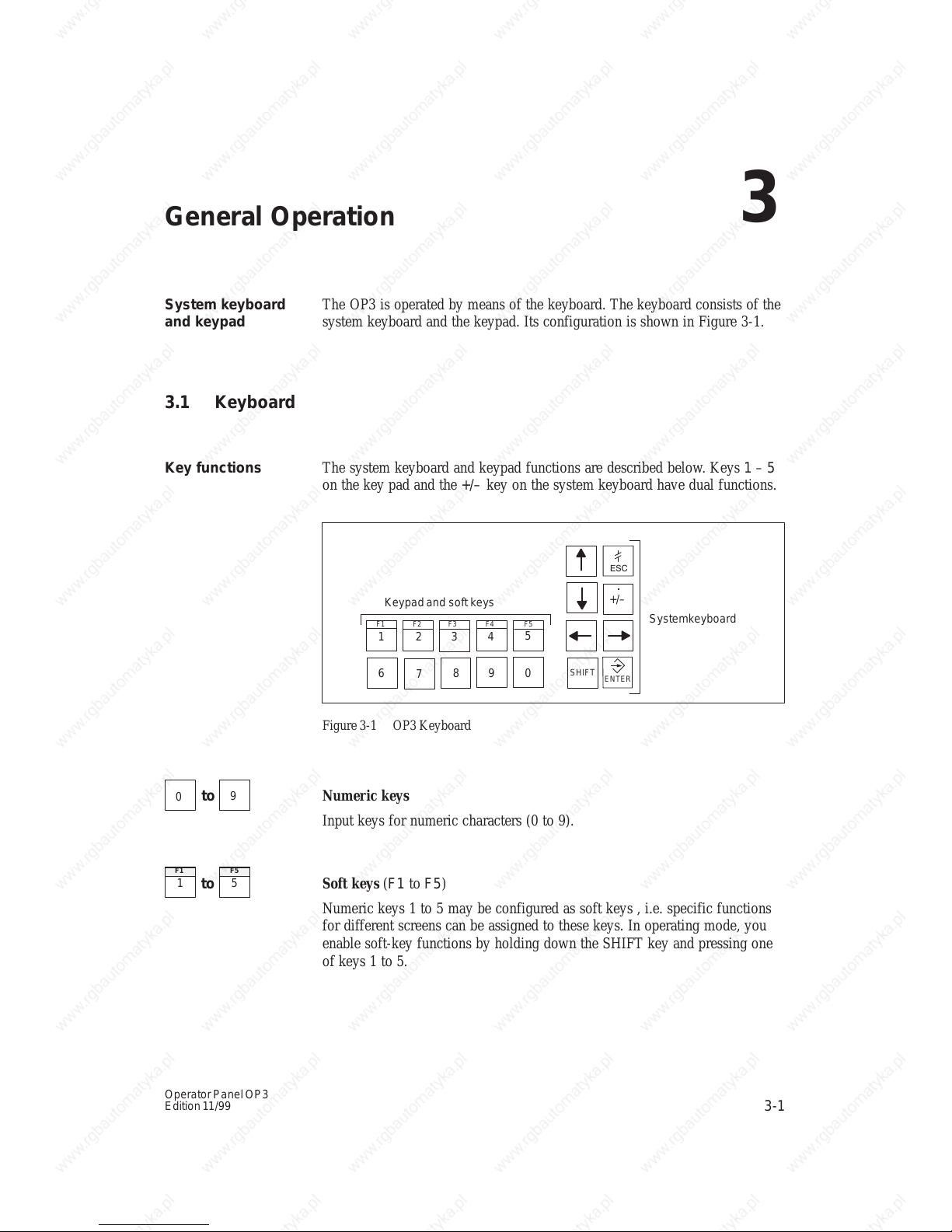

The OP3 is operated by means of the keyboard. The keyboard consists of the

system keyboard and the keypad. Its configuration is shown in Figure 3-1.

3.1 Keyboard

The system keyboard and keypad functions are described below. Keys 1 – 5

on the key pad and the +/– key on the system keyboard have dual functions.

0

1 2

3

4

5

6

7

8

9

SHIFT

ENTER

+/–

ESC

Keypad and soft keys

Systemkeyboard

.

F1 F2 F3 F4 F5

Figure 3-1 OP3 Keyboard

0

to

9

Numeric keys

Input keys for numeric characters (0 to 9).

1

F1

to

5

F5

Soft keys (F1 to F5)

Numeric keys 1 to 5 may be configured as soft keys , i.e. specific functions

for different screens can be assigned to these keys. In operating mode, you

enable soft-key functions by holding down the SHIFT key and pressing one

of keys 1 to 5.

System keyboard

and keypad

Key functions

3

3-2

Operator Panel OP3

Edition 11/99

SHIFT

SHIFT key

Switch to the second function of the dual-assignment keys.

To do this, the SHIFT key is pressed si m ult ane ously wi th the other ke y

concerned - for example:

Decimal point : Press

SHIFT

+

+/–

.

Soft-key function: Press

SHIFT

+

3

F3

+/–

.

Sign key

Change of sign from ”Plus” to ”Minus” and vice versa.

Second function (with pressed SHIFT key):

input of a decimal point.

ENTER

ENTER key

With this key you confirm and terminate your input.

With ENTER you also change from message level to screen level.

ESC

ESCAPE key

Undo:

Undoes entries in fields provided they have not been confirmed with

ENTER.

Branch back:

Branches back from a screen to the configured cross-jump destination (by

default, the last position called), or go from the start screen to message level.

Reset when scrolling through messages:

Cancels scrolling through waiting messages to reset the display to the

currently waiting message.

Hide a system message.

Arrow keys

Move the cursor. Depending on the operating situation, the cursor is moved

one character, field, entry or display to the left, right, up or down.

General Operation

3-3

Operator Panel OP3

Edition 11/99

In combination with SHIFT:

SHIFT

+ : Scroll up in font.

SHIFT

+ : Scroll down in font.

SHIFT

+ : Next position in an input field.

SHIFT

+ : Previous position in an input field.

The numeric and arrow keys have a auto repeat function. If you keep a key

pressed, your input is continually repeated after a short delay until you

release the key.

If several keys are pressed in quick succession, some operator inputs may be

lost. Operator inputs not accepted by the OP3 are indicated by an acoustic

signal.

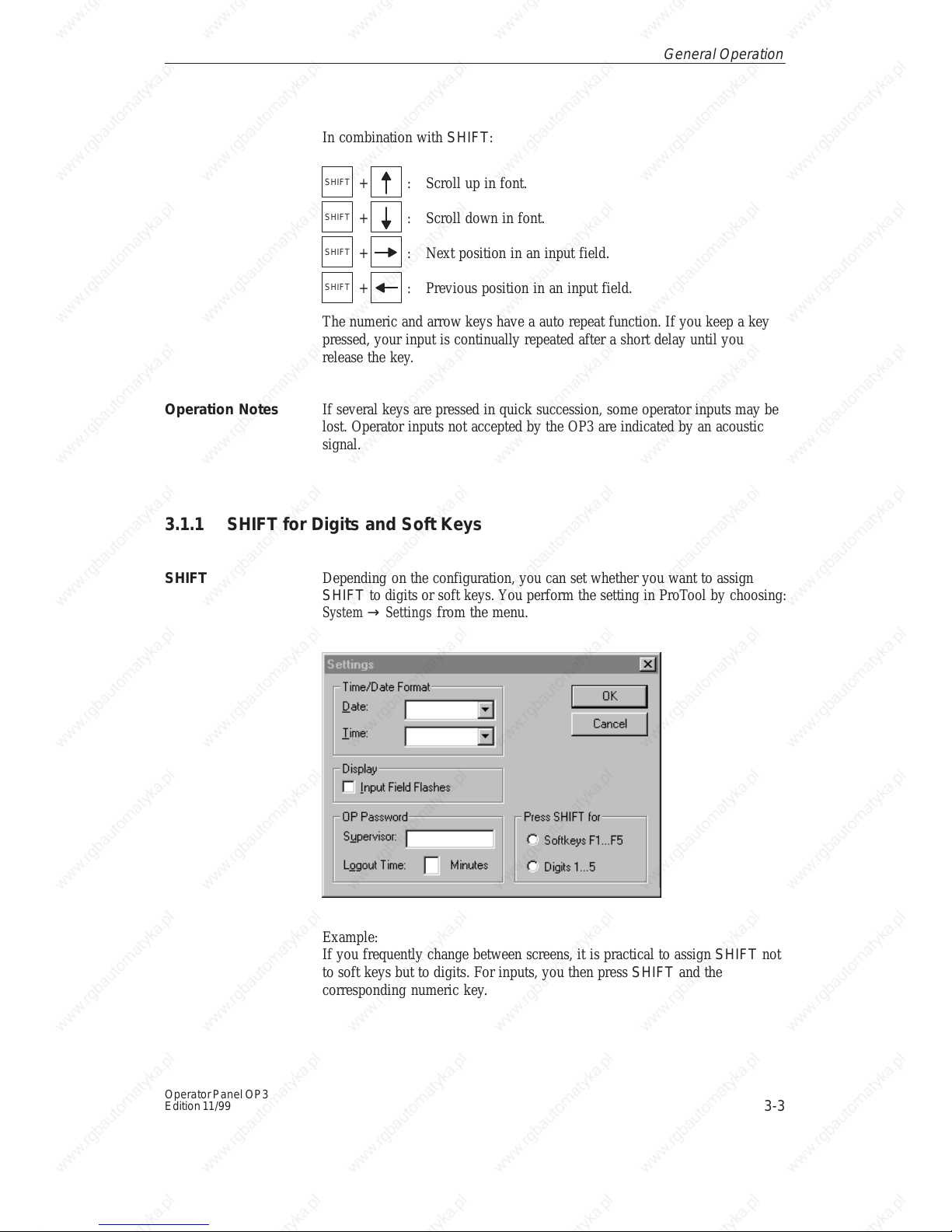

3.1.1 SHIFT for Digits and Soft Keys

Depending on the configuration, you can set whether you want to assign

SHIFT to digits or soft keys. You perform the setting in ProTool by choosing:

System → Settings from the menu.

Example:

If you frequently change between screens, it is practical to assign SHIFT not

to soft keys but to digits. For inputs, you then press SHIFT and the

corresponding numeric key.

Operation Notes

SHIFT

General Operation

3-4

Operator Panel OP3

Edition 11/99

3.2 Entering Values

In input fields, values can be entered on the OP3 and transferred to the PLC.

1. Branch, as described in section 4.3, initially to the screen you require and

then to the corresponding screen entry.

2. Using the arrow keys, select the input field you require within the screen

entry.

3. Then enter your value. Depending on how the field has been configured,

values may be input as

• numerical values (refer to section 3.2.1),

• alphanumeric values (refer to section 3.2.2),

• symbolic values (refer to section 3.2.3).

4. Confirm your input with ENTER.

You can cancel any incorrect input by pressing ESCAPE . The original

value is then automatically reinserted in the field. Then enter the correct

value.

5. Exit the screen entry by pressing ESCAPE.

General procedure

General Operation

3-5

Operator Panel OP3

Edition 11/99

3.2.1 Entering Numerical Values

In fields that allow the operator to enter a numerical value, you enter the

numerical value character by character on the keypad.

You enter a decimal point by pressing the SHIFT key and the sign key

simultaneously.

If there is a value in the field already, it is cleared completely from the field

when the first character is entered. Once input has started, you cannot exit

from the input field until the input has been entered or canceled.

In numerical fields (not in hexadecimal format), input is usually

right-justified. Digits that have already been entered are moved to the left

(pocket calculator format).

Exception:

Input fields for setpoints in bit pattern format – for instance, when calling the

PU functions STATUS/FORCE VAR – are changed to left-justified. When

input begins, the old value does not disappear from the display completely

but its bit pattern is overwritten one character at a time. You move the cursor

in this type of field by simultaneously pressing the SHIFT key and an arrow

key (← or →).

You can configure limit values for numerical input fields. In this type of

field, a limit value check takes place. Entered values are applied only if they

are within the configured limits. If a value outside these limits is entered, a

system message is displayed and, after it has been canceled, the old value is

displayed again.

If a numerical field has been configured with a certain number of decimal

places and if, after you confirmed your input, too many have been entered,

the extra ones are ignored; if too few have been entered, the field is fitted

with zeros.

Entering values

with a decimal

point

Changing

numerical values

Right-justified

input

Limit value check

Decimal places

General Operation

3-6

Operator Panel OP3

Edition 11/99

3.2.2 Entering Alphanumeric Values

In an input of alphanumeric values, digits and letters are mixed.

For the numerical components of the input, proceed as described in section

3.2.1. If, however, you wish to enter a letter at the current cursor position,

you must enable the alphanumeric character set.

To enter the string 18OCT61, for example, proceed as follows:

1. Enter 1 and 8 by means of the keypad.

2. Press the SHIFT key and hold it down.

The extended character set becomes available.

3. Scroll with the UP or DOWN arrow key through the extended character

set.

4. Select O and move right one position using the RIGHT arrow key.

The charact er you sel ect ed is applie d by movi ng the cursor.

5. Select C and move right one position using the RIGHT arrow key.

6. Select T and move right one position using the RIGHT arrow key.

7. Release the SHIFT key. The extended character set is de-activated.

8. Enter the remaining figures 6 and 1 by means of the keypad and confirm

your input by pressing the ENTER key.

3.2.3 Entering Symbolic Values

In the case of a symbolic input of a value, text is displayed or typed instead

of the value. If a field has to be filled in using a symbolic entry for a value,

then apply the text from a list box. To do this, proceed as follows:

1. Press SHIFT in the input fi eld and hold it down.

The list box with its configured symbolic inputs is activated.

2. With the cursor keys, select the text you require.

3. Release SHIFT.

4. Confirm your selection by pressing ENTER.

Mixed input of

digits and letters

Example

Text instead of a

value

General Operation

4-1

Operator Panel OP3

Edition 11/99

Using the OP3 with Its Standard Functions

The configuration software ProTool, includes a configuration which contains

standard screens. You can choose all the functions required for operating the

OP3 by using these standard screens. The different functions are described in

this manual with reference to the standard screens.

The English-language standard screens, which are loaded from the firmware

of the OP3, remain active, once you have switched on the operating voltage,

until a configuration is loaded (refer to section 4.2).

4.1 Operating Levels

In OP3 operation, you have to distinguish between two distinct operating

levels, between which you can switch:

• Message level

At the message level, current messages are displayed.

• Screen level

At the screen level, functions are chosen, serviced and executed.

The message level is the highest level on the OP3. At message level, waiting

event messages and system messages are displayed. After the OP3 starts up,

it changes to message level and displays the standby message.

The screen level is reached by pressing the ENTER key. The first screen to

be called is the start screen. From the start screen you branch, depending on

the configuration, to other screens. On the screens, you view the actual

process values, and you can enter values and initiate functions by means of

soft keys.

The linking of individual screens is referred to as a screen hierarchy. As you

go further down the screen hierarchy, you go stage by stage right back to the

start screen by pressing the ESCAPE key. From here you can return to the

message level by pressing the ESCAPE key. You can also return directly to

the message level from a screen, depending on the configuration.

Using the standard

screens

Message level and

screen level

Screen hierarchy

4

4-2

Operator Panel OP3

Edition 11/99

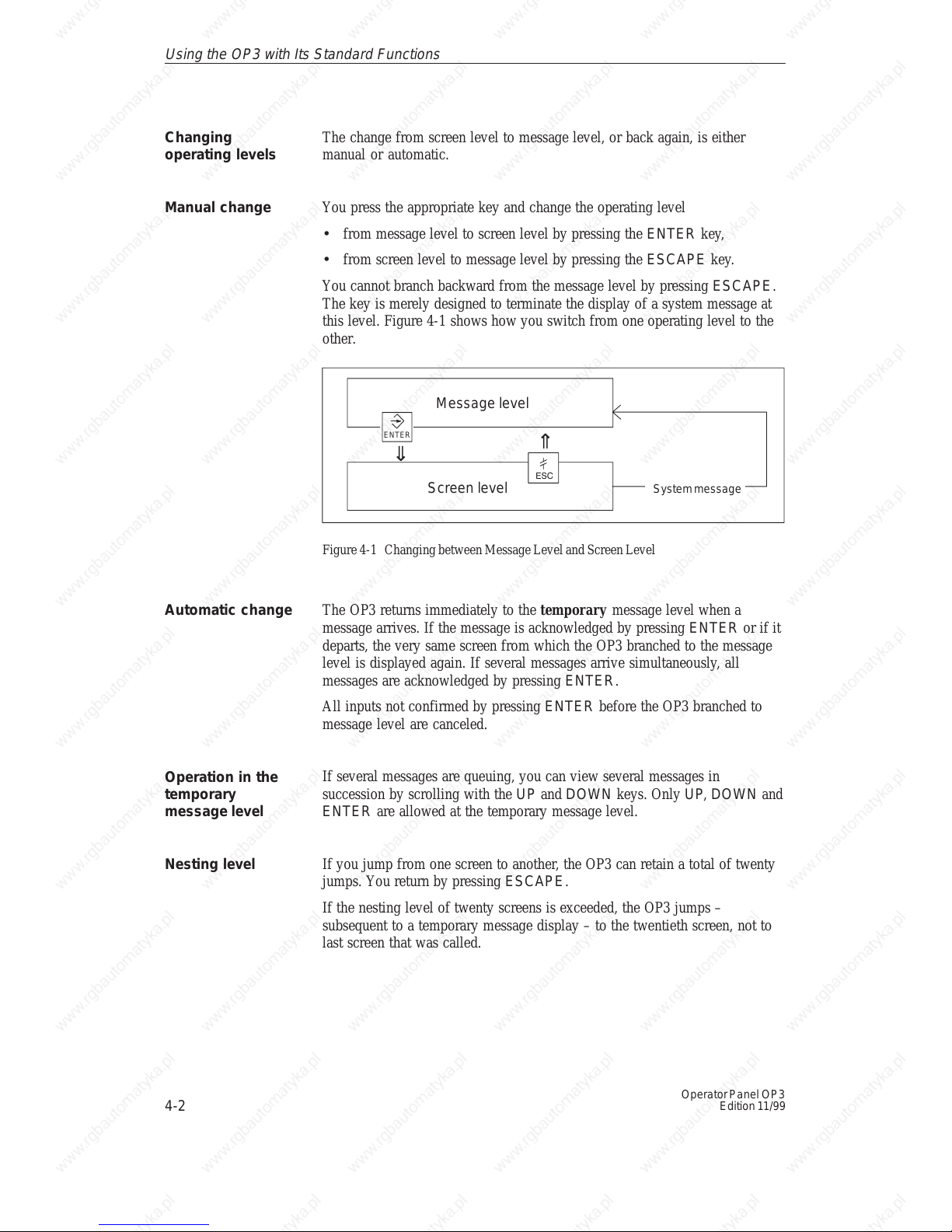

The change from screen level to message level, or back again, is either

manual or automatic.

You press the appropriate key and change the operating level

• from message level to screen level by pressing the ENTER key,

• from screen level to message level by pressing the ESCAPE key.

You cannot branch backward from the message level by pressing ESCAPE .

The key is merely designed to terminate the display of a system message at

this level. Figure 4-1 shows how you switch from one operating level to the

other.

Message level

Screen level

⇓

⇑

ESC

System message

ENTER

Figure 4-1 Changing between Message Level and Screen Level

The OP3 returns immediately to the temporary message level when a

message arrives. If the message is acknowledged by pressing ENTER or if it

departs, the very same screen from which the OP3 branched to the message

level is displayed again. If several messages arrive simultaneously, all

messages are acknowledged by pressing ENTER.

All inputs not confirmed by pressing ENTER before the OP3 branched to

message level are canceled.

If several messages are queuing, you can view several messages in

succession by scrolling with the UP and DOWN keys. Only UP, DOWN and

ENTER are allowed at the temporary message level.

If you jump from one screen to another, the OP3 can retain a total of twenty

jumps. You return by pressing ESCAPE.

If the nesting level of twenty screens is exceeded, the OP3 jumps –

subsequent to a temporary message display – to the twentieth screen, not to

last screen that was called.

Changing

operating levels

Manual change

Automatic change

Operation in the

temporary

message level

Nesting level

Using the OP3 with Its Standard Functions

Loading...

Loading...