Siemens simatic hmi op27, simatic hmi op37 Equipment Manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Preface, Contents

Part I Introduction

1

2

Part II Functions

3

11

Part III Installation and

Commissioning

12

15

Part IV Equipment Description

and Maintenance

16

19

Part V Appendices

A

F

Glossary, Index

Release 05/99

OP27, OP37

Operator Panels

Equipment Manual

SIMATIC HMI

6AV3991–1AK01–0AB0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual contains notices which you should observe to ensure your own personal safety, as

well as to protect the product and connected equipment. These notices are highlighted in the

manual by a warning triangle and are marked as follows according to the level of danger:

!

Warning

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

!

Caution

indicates that minor personal injury or property damage can result if proper precautions are not

taken.

Note

draws your attention to particularly important information on the product, handling the product,

or to a particular part of the documentation.

Equipment may be commissioned and operated only by qualified personnel. Qualified personnel within the meaning of the safety notices in this manual are persons who are authorized to

commission, ground and identify equipment, systems and circuits in accordance with safety

engineering standards.

Note the following:

!

Warning

The equipment may be used only for the applications stipulated in the catalog and in the technical description and only in conjunction with other equipment and components recommended

or approved by Siemens.

Startup must not take place until it is established that the machine, which is to accommodate

this component, is in conformity with the guideline 89/392/EEC.

Faultless and safe operation of the product presupposes proper transportation, proper storage,

erection and installation as well as careful operation and maintenance.

The approvals that apply to the device are detailed in the Chapter Technical Data.

SIMATICR, ProTool/LiteR, ProToolR and ProTool/ProR

are registered trademarks of

Siemens AG.

Some of the other designations used in these documents are also registered trademarks; the

owner’s rights may be violated if they are used be third parties for their own purposes.

Editor and Publisher: A&D PT1

W

e have checked the contents of this manual for agreement with

the

hardware and software described. Since deviations cannot be

precluded

entirely

, we cannot guarantee full agreement. However

,

the

data in this manual are reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions for

improvement

are welcomed.

T

echnical data subject to change.

E

Siemens

AG 1999

Disclaimer of Liability

Copyright E

Siemens

AG 1999 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created

by patent grant or registration of

a utility model or design,

are reserved.

Siemens AG,

Bereich Automation & Drives

SIMA

TIC Human Machine Interface

A&D PT1

Postfach 4848,

D-90327 Nuernberg

Siemens Aktiengesellschaft

Order No. 6A

V3991–1AK01–0AB0

Safety

Guidelines

Qualified Personnel

Correct Usage

Approvals

Trademarks

Impressum

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

i

OP27,

OP37 Equipment Manual

Release 05/99

Preface

This

equipment manual provides operation, installation, configuration and sys

-

tem personnel with information concerning functionality

, operation and techni

-

cal design of the Operator Panels OP27 and OP37.

The ”OP27 , OP37 Operator Panel” equipment manual is or

ganized into the

following chapters:

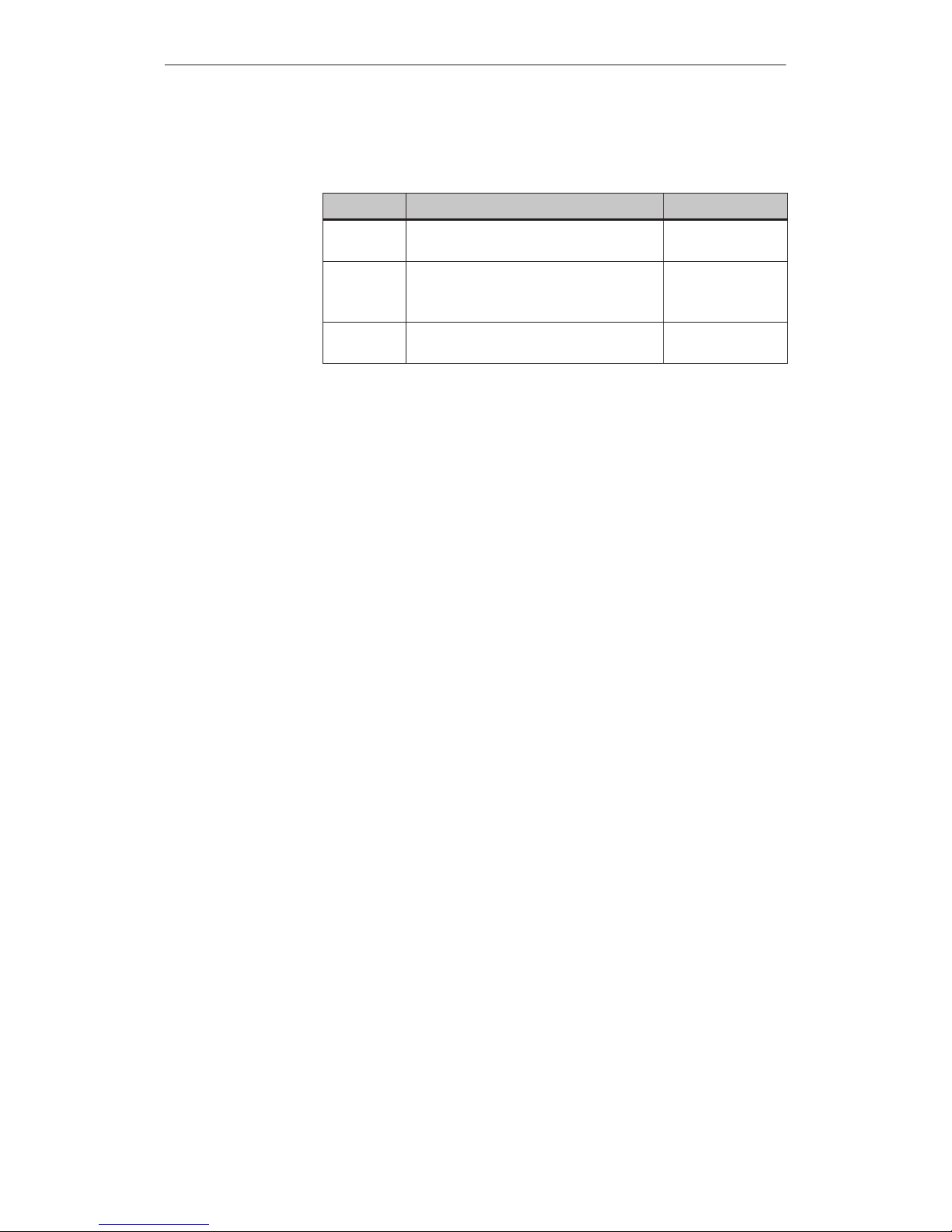

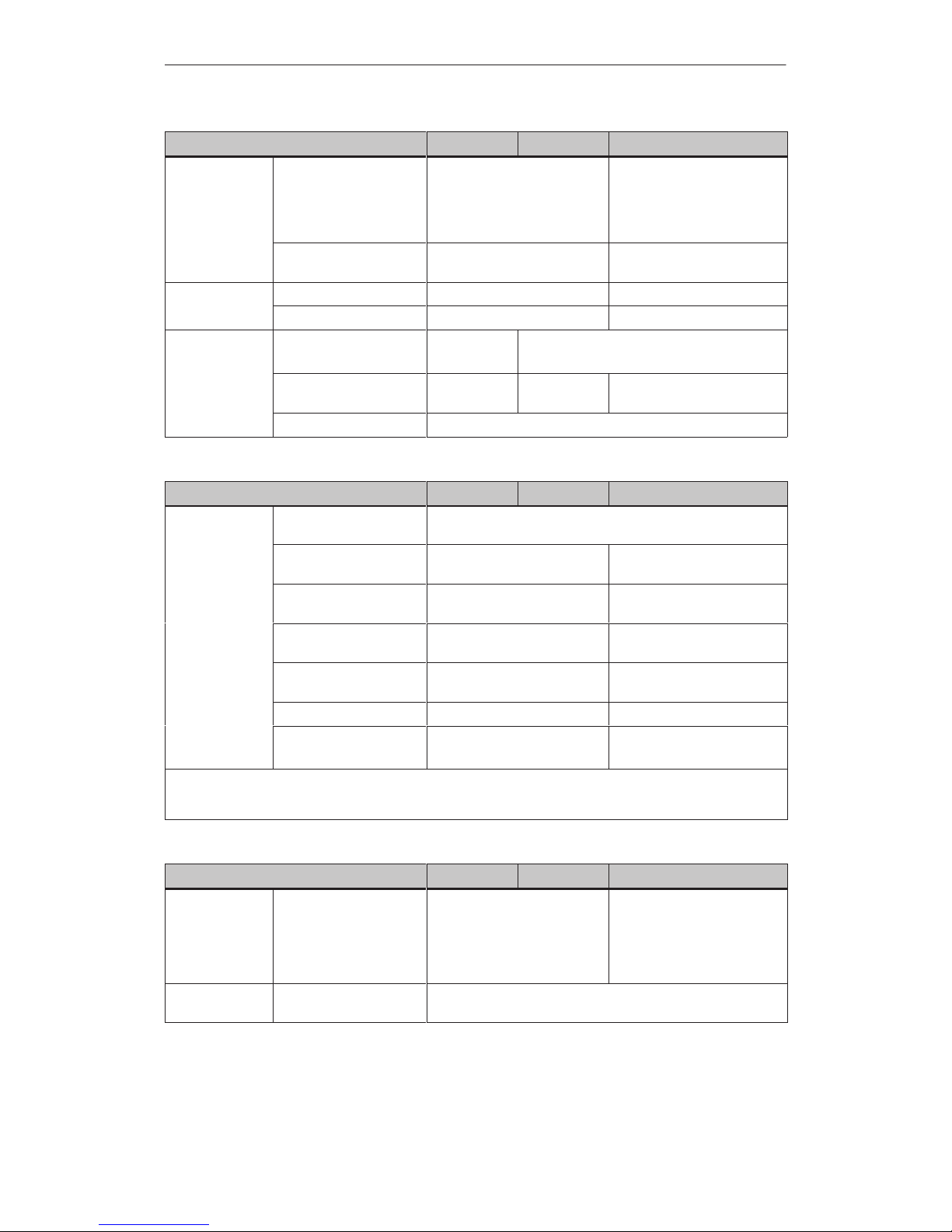

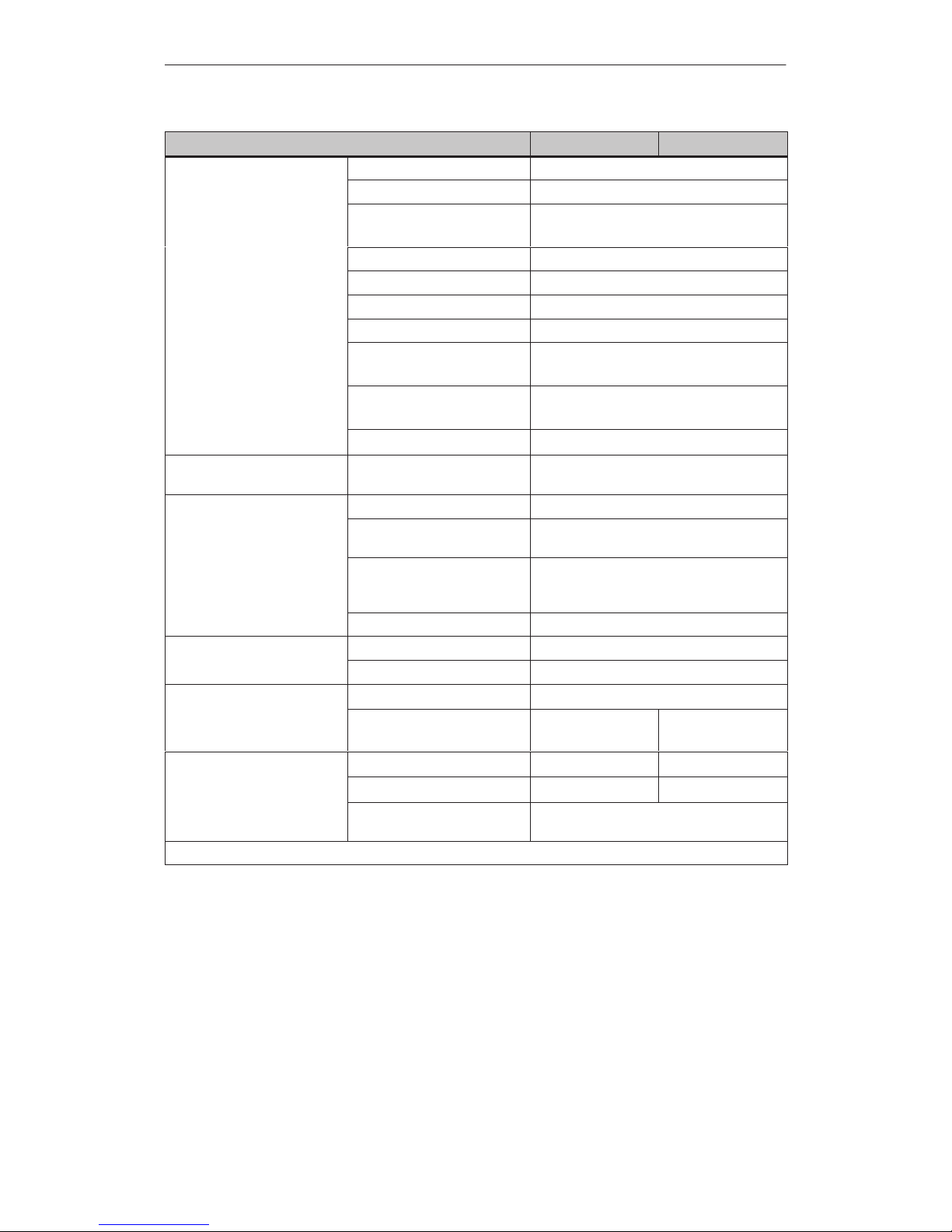

Part Chapters Contents

I

1 - 2

Overview of features and functional scope of the

OP in tabular form.

II

3 - 1

1

Step-by–step instructions on how to operate the OP

using the standard screens.

III

12 - 15

–

Mechanical and electrical installation,

– Commissioning

–

OP37 in DOS Mode

IV

16 - 19

Detailed information on the OP and its

maintenance.

V Appendix

A – F

–T

echnical data,

–

Interface assignments,

–

Hardware test,

–

System messages,

– SIMA

TIC HMI documentation,

–

ESD guidelines,

–

Glossary of terms

The following conventions are used throughout this manual:

Motor off Text

which appears in the OP display is presented in

this typewriter font.

Variable

Symbolic names representing variable values on the

screen are presented in this italic typewriter font

Screens

Functions selected by the user are presented in this

standard italic font.

ESC

The labels of buttons are presented in a dif

ferent

font.

Purpose

Organization of the

manual

Conventions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ii

OP27,

OP37 Equipment Manual

Release 05/99

The

various releases of the equipment manual correspond to the following

firmware and versions:

i

Rel

ease

R

emarks

ProTool V

ersion

09/96

First release of the OP37 equipment

manual

V 2.5 and later

11/97

Inclusion of the OP27 and revision

according to the new documentation

concept

V 4.0 and later

05/99

New standard screen for printing

messages; troubleshooting

V 5.0 and later

History

Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iii

OP27,

OP37 Equipment Manual

Release 05/99

In

the case of technical queries, please contact your local Siemens in the sub

sidiaries and branches responsible for your area. Refer to Appendix E of this

equipment manual for a list of addresses.

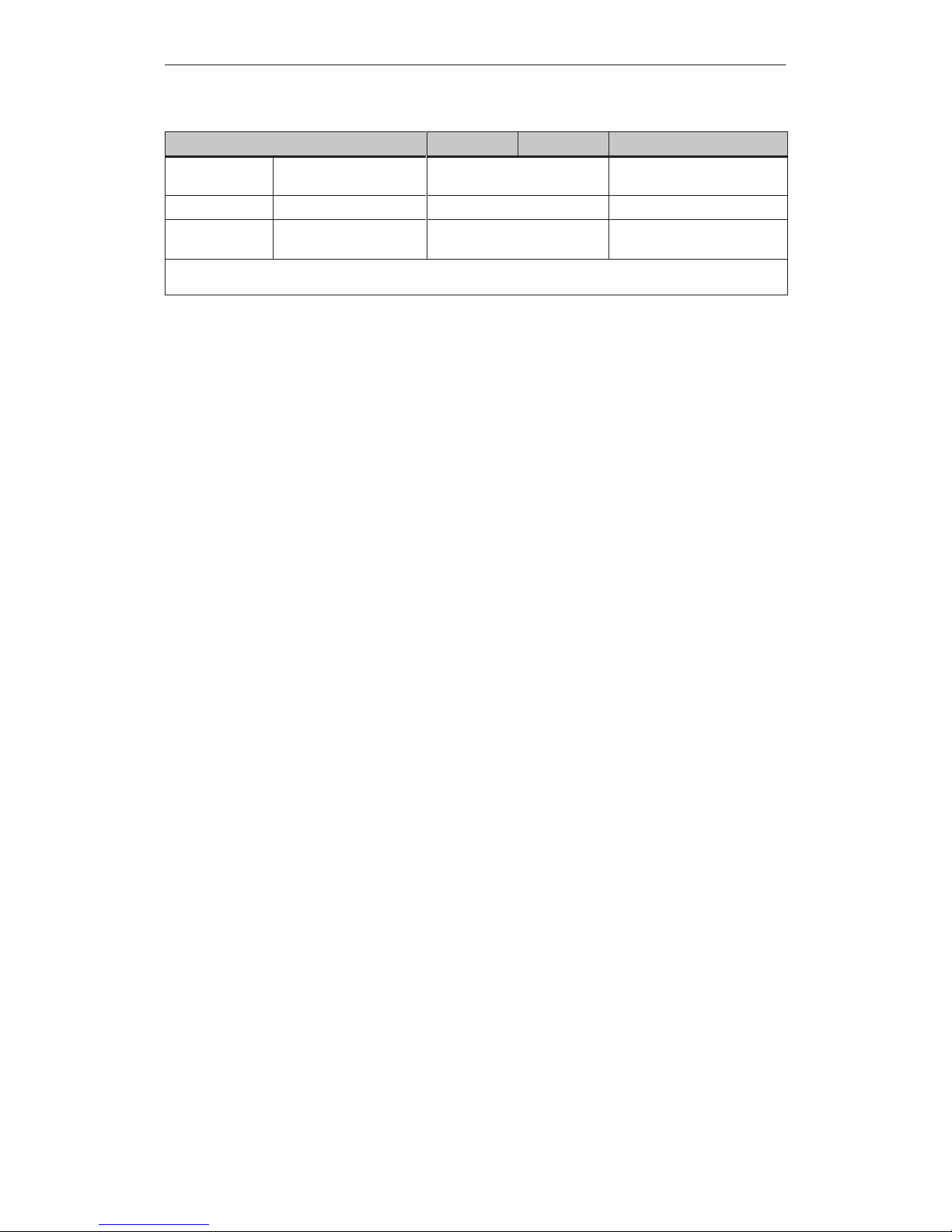

SIMATIC Customer Support Hotline

Available worldwide, at all times:

Johnson City

Nuernberg

Singapur

Simatic

Basic Hotline

Nuernberg

SIMATIC BASIC Hotline

Johnson City

SIMATIC BASIC Hotline

Singapur

SIMATIC BASIC Hotline

Local

time:

Mon - Fri 8:00 to 18:00

T

elephone:

+49 (911) 895-7000

Fax:

+49 (911) 895-7002

E-Mail: simatic.support@

nbgm.siemens.de

Local time:

Mon - Fri 8:00 to 17:00

T

elephone:

+1 423 461-2522

Fax:

+1 423 461-2231

E-Mail: simatic.hotline@

sea.siemens.com

Local time:

Mon - Fri 8:00 to 17:30

T

elephone:

+65 740-7000

Fax:

+65 740-7001

E-Mail: simatic@

singnet.com.sg

SIMATIC

Premium Hotline

(charged,

only with

SIMA

TIC Card)

T

ime:

Mon - Fri 0:00 to 24:00

T

elephone:

+49 (911) 895-7777

Fax:

+49 (911) 895-7001

Other support

Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv

OP27,

OP37 Equipment Manual

Release 05/99

SIMATIC Customer Online Services

SIMATIC

Customer Support offers comprehensive additional information

concerning SIMA

TIC products through its Online services as follows:

Up–to–date

general information is provided

–

in

Internet

under

http://www.ad.siemens.de/simatic

–

via

Fax-Polling

under 08765-93 02 77 95 00

Up–to–date product information and downloads for practical use can be found:

–

in

Internet

unter

http://www.ad.siemens.de/support/

html–00/

–

via the

Bulletin Board System

(BBS) in Nürnber

g (SIMA

TIC Customer

Support Mailbox)

under

+49 (911) 895–7100

In

order to contact the mailbox, please use a modem with up to

28.8

kBaud (V

.34) capacity

. Set the parameters as follows: 8, N, 1,

ANSI, or dial for connection via ISDN (x.75, 64 kBit).

Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

v

OP27,

OP37 Equipment Manual

Release 05/99

The

abbreviations used in this equipment manual

have the following meaning:

AM

Alarm Message

ANSI

American National Standards Institute

AS511

Protocol of the PU interface to SIMA

TIC S5

ASCII

American Standard Code for Information Interchange

AU

Automation Unit

CPI

Control Panel Interface

CPU

Central Processing Unit

DIL

Dual-In-Line (package)

DP

Decentral Periphery

DRAM

Dynamic Random Access Memory

DKM

Direct Key Module

EM

Event Message

ESD

Electrostatic Sensitive Device

JEIDA

Japan Electronic Industry Development Asociation

LCD

Liquid Crystal Display

LED

Light–Emitting Diode

MPI

Multipoint Interface (SIMA

TIC S7)

PC

Personal Computer

PCMCIA

PLC

Personal Computer Memory Card International Association

Programmable Logic Controller

PU

Programming Unit

PPI

Point to Point Interface (SIMA

TIC S7)

SRAM

Static Random Access Memory

STN

Super T

wisted Nematic

TFT

Thin Film T

ransistor

TP T

ouch Panel

TTL Transistor-T

ransistor Logic

Abbreviations

Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

vi

OP27,

OP37 Equipment Manual

Release 05/99

Preface

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

i

OP27, OP37 Equipment Manual

Release 05/99

Contents

Part I: Introduction

1 Product

Description

1-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Visualizing

and Controlling Processes

1-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 The

OPs at a Glance

1-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Functionalty 2-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part II: Functions

3 General Operation 3-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Changing

the Active Window

3-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Integrated

Keyboard

3-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Enter Values 3-8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Entering

Numeric V

alues 3-9.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Entering

Alphanumeric V

alues 3-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Entering

Symbolic V

alues 3-11.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Help Text 3-14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Screens 4-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Screen

Elements

4-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Standard

Screens

4-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Password

Protection

5-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Password

Level and Access Permissions

5-1.

. . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Logging

In and Out on the OP

5-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Password

Management

5-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Messages 6-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Types

of Message

6-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Event

Messages and Alarm Messages

6-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Alarm

Messages

6-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 System

Messages

6-7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Displaying

Messages

6-8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Deleting

Messages

6-11.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Printing

Messages

6-13.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ii

OP27, OP37 Equipment Manual

Release 05/99

6.5 Standard

Screens for Messages

6-15.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 “Edit

Message” Standard Screen

6-15.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 “Output

Messages” Standard Screen

6-17.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.3 “System

Settings” Standard Screen

6-19.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Printing 7-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Recipes 8-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Standard

Screens for Recipes

8-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Creating,

Editing and Saving Data Records

8-8.

. . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Transferring

Data Records

8-13.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Record

Sets

8-15.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Storing and Loading Data 9-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Data T

ypes, Data Media and Storage Principle

9-1.

. . . . . . . . . . . . . . . . . . . . . .

9.2 Clear/Initialize

Storage Medium

9-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Backup/Restore 9-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Status/Force T

ag Using the OP

10-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Status Tag 10-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Force Tag 10-5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 System Settings 11-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Setting

an Operating Mode

11-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Blanking

the Screen

11-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Other

Settings

11-5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part III: Installation and Commissioning

12 Mechanical Installation 12-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Installing

the OP27

12-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 Installing

the OP37

12-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Electrical Installation 13-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Power

Supply and Relay Contacts

13-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.1 Connecting

the Configuration Computer

13-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.2 Connecting

the PLC

13-5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.3 Connecting

a Printer

13-7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 Commissioning 14-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 Initial

Startup

14-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 Recommissioning 14-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 Startup

Behavior

14-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 Testing

a Configuration in OFFLINE Mode

14-7.

. . . . . . . . . . . . . . . . . . . . . . . . . .

14.5 Testing

the Configuration in Conjunction with the PLC

14-8.

. . . . . . . . . . . . . . .

Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iii

OP27, OP37 Equipment Manual

Release 05/99

15 OP37

in DOS Mode

15-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 Specific

OP37 Settings in BIOS Setup

15-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 Changing

Between OP and DOS Modes

15-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Part IV: Equipment Description and Maintenance

16 OP27

Unit Description

16-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 Dimensions 16-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 Operating

and Display Elements

16-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 Connection

Elements

16-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.4 Communication

Options

16-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.5 Labeling

Function Keys

16-5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 OP37

Unit Description

17-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 Dimensions 17-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2 Operating

and Display Elements

17-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.3 Connection

Elements

17-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.4 Communication

Options

17-5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5 Labeling

Function Keys

17-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 Options 18-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.1 AT

Expansion Slot (OP37 only)

18-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2 Direct

Key Module

18-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2.1 Installing

the Direct Key Module

18-5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2.2 Connection

and Adjusting Elements

18-7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3 Control

Panel Interface

18-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3.1 Installing

the Control Panel Interface

18-11.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3.2 Connection

and Adjusting Elements

18-14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 Maintenance/Upkeep 19-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.1 Cleaning

the Screen and Keyboard Overlay

19-1.

. . . . . . . . . . . . . . . . . . . . . . . .

19.2 Replacing

the Backup Battery

19-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.3 Other

Maintenance W

ork on OP27

19-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.3.1 Replacing

the Display on the OP27M

19-5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.3.2 Replacing

the Back-Lighting of the OP27C

19-7.

. . . . . . . . . . . . . . . . . . . . . . . . .

19.4 Other

Maintenance W

ork on OP37

19-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.4.1 Opening

the OP37 Housing

19-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.4.2 Replacing

the Back-Lighting of the OP37

19-12.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

19.4.3 Replacing

the Floppy Disk Drive

19-14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv

OP27, OP37 Equipment Manual

Release 05/99

Part V: Appendix

A Technical

Data

A-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Interface

Assignments

B-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Test Functions C-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 Hardware Test C-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.1 Individual Tests C-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.2 Test

Adapters

C-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D System

Messages

D-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E SIMATIC HMI Documentation E-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F ESD Guidelines F-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INTRODUCTION

1 Product Description

2 Functionality

Part

I

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

-2

OP27,

OP37 Equipment Manual

Release 05/99

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-1

OP27, OP37 Equipment Manual

Release 05/99

Product Description

The

implementation of Operator Panels OP27 and OP37 enables operating

statuses, current process values and faults in respect of a connected PLC to be

graphically represented and the machine or system to be monitored easily oper

-

ated. In order to do this, the OPs are equipped with a lar

ge number of standard

functions. The method of display and operation of the OPs can be customized

using the ProT

ool configuration software to achieve optimum results in respect

of process requirements.

The OPs can be used to

control and monitor the process by means of the menu system. In this way

,

setpoints can be entered, for example, in the form of value input or pressing

configured function keys or to control positioning elements;

display processes, machines and systems on full–graphic and semi–graphic

screens;

visualize event messages, alarm messages and process variables, such as

output fields, bar graphs, trends or status display;

intervene directly in the process by means of the integrated keyboard.

The OPs are installation units for use directly at the machine location. The

degree of protection is high (front panel IP65), so the devices are suitable for

use in hostile industrial environments.

Installation locations for the units may be as follows:

OP27 OP37

Panels/Consoles Panels/Consoles

–

19” panels/racks

Before commissioning the OPs, they must be prepared for the task of visualiz

-

ing data from the PLC. T

o do this, data areas must be created in the PLC’

s

memory in the configuration; the data areas are used by the OP to communi

-

cate with the PLC.

Use

of OP27 and

OP37

Installation

possibilities

Set up data areas

1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-2

OP27,

OP37 Equipment Manual

Release 05/99

Graphics

and texts to be displayed on the OP must be created beforehand using

a configuration computer (PC or PU) implementing the configuration software

ProT

ool. Before downloading the configuration data to the OP

, connect the

configuration computer to the OP (refer to the configuration phase in Fig

-

ure 1-1).

Once the configuration has been successfully downloaded, disconnect the con

-

figuration computer and then connect the OP to the PLC. The OP now commu

-

nicates with the PLC and reacts to program execution on the PLC in accor

dance with the configured requirements (refer to the process control phase in

Figure 1-1).

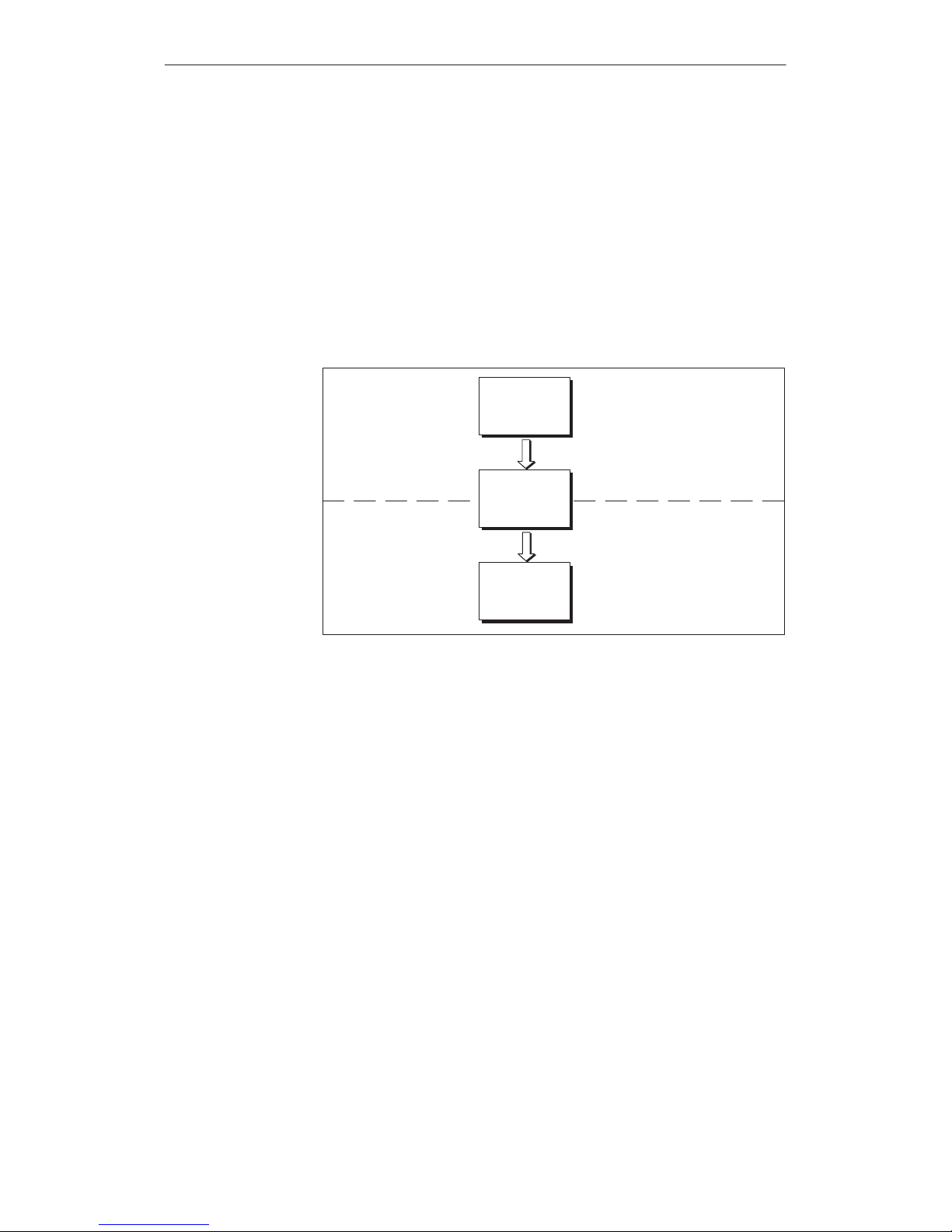

Figure 1-1 outlines the configuration and process control phase.

Figure 1-1 Configuration and process control phase

Information

regarding configuration of the OP is provided in the

User’

s Guide,

ProT

ool Configuring Graphics Displays

. The

Communication User’s Manual

provides information on the connection between the OP and PLC.

Configuration

using

ProT

ool

Further

information

Product Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-3

OP27,

OP37 Equipment Manual

Release 05/99

1.1 Visualizing and Controlling Processes

The

basic functions of the OP27 und OP37 Operator Panels are the visualiza

tion of process statuses and the operation of processes. The following display

and operating functions can be configured:

screens

input/output of process values

bar graphs and trends

text or graphics lists

messages

logging

print

text

help text

recipes

multiple languages

password protection

functions for function keys and soft keys.

Logically related process data from the PLC can be compiled, displayed on a

screen and individual parts of it modified. Screens may contain soft keys,

graphics, texts and values.

The OPs can display machines and systems as

full–graphics scr

eens

. This

makes it easier for the operator to find his way around.

Numeric, alphanumeric or symbolic values can be entered in input fields on the

OP which are then transferred to the PLC. Current values of the PLC are dis

played in output fields in alphanumeric form.

Current process values can be output as numeric values, symbolic text,

symbolic graphs or in the form of bar graphs and trend curves.

Bar graphs

represent a value as a rectangular area. Bar graphs can be used to display

fill levels or quantities, for example.

Trends

display a value continuously. This display mode is useful when displaying

values that vary with time, variations in temperature or pressure, for exam

-

ple.

V

arious graphic elements (bitmaps) or texts can be called into the display

depending on the process status. In this way

, for example, the current setting of

a valve can be visualized on the OP screen by means of symbolic graphics, or

text can be modified according to the situation.

Display and

operating

functions

Screens

Input / Output

Bar graphs and

trend curves

Symbol lists

Product Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-4

OP27,

OP37 Equipment Manual

Release 05/99

Messages

are displayed on the OP in plain text. The message text may also

contain current process values. Incoming messages are stored in a message

buf

fer together with their date and time.

Event messages

provide information and operating notes on current processes or machine

states, for example

Motor running at 3000 revs.

Alarm

messages

provide information on critical machine states, for example

Motor speed too high.

Alarm

messages must be acknowledged on account of their ur

gency.

Messages are classified as event messages or alarm messages during configura

-

tion.

All message events can be additionally recorded by being printed out in online

mode on a connected printer

. Messages which have accumulated in the event

and alarm buf

fers can also be printed out.

It is possible to print the current status of a screen by pressing

PRINT SCREEN. It

is possible to configure a function which enables up to 20 screens to be printed

simultaneously.

T

exts identify individual parts of the screen in order to be able to assign the

fields displayed to the process.

Help texts represent additional information and notes for the operator which

can be configured in respect of the screens, input fields and messages. The help

text relating to an alarm message may display information on the cause of a

malfunction and how to clear it.

Complete machine data records can be stored as recipes in the OP

. A recipe

defines the data structure in a configuration. Data is assigned to the configured

structure on the OP

.

The purpose of recipes is to transfer several items of data collectively to the

PLC. In this respect, it is immaterial whether actual recipes, specifications of

quantities, distances to be traversed or temperature variations are involved.

Message texts, texts in screens, help texts and system messages can be stored

in three languages simultaneously in the OP and selected online.

The password protection feature prevents unauthorized operation of the OP

.

Dif

ferent passwords can be assigned to dif

ferent users or user groups, thus

authorizing or prohibiting access to specific control functions by assigning

dif

ferent password levels.

Messages

Recording

Print

Texts

Help texts

Recipe

Multiple languages

Password

protection

Product Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-5

OP27,

OP37 Equipment Manual

Release 05/99

The

OPs are equipped with a range of function keys which can be assigned

operating functions, such as message logging on/of

f, screen selection and print

screen during configuration. The function keys may be assigned globally or

locally

. Globally means that the assignment applies to the whole configuration.

Locally means that the assignment applies only to a single screen. A function

key whose assignment changes from one screen entry to another is known as a

soft key

.

Functions

for

function keys and

soft keys

Product Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-6

OP27,

OP37 Equipment Manual

Release 05/99

1.2 The

OPs at a Glance

The

following unit models are available:

OP27M with STN monochrome display for screens with gray shading

OP27C with STN color display

OP37 with STN color display

OP37 with TFT color display

OP37

OP27

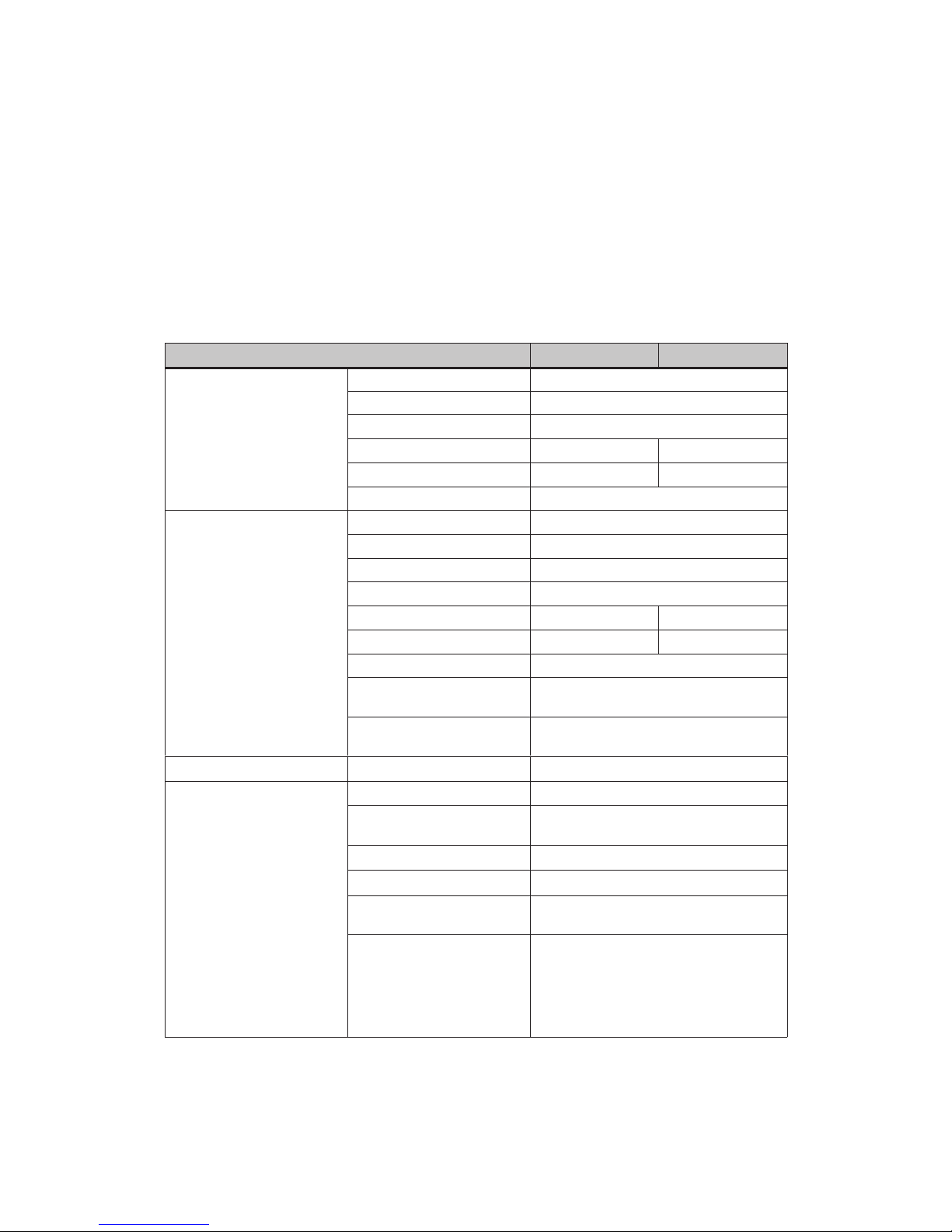

Hardware OP27M OP27C OP37

Display

Monochrome display

Color display

4

–

–

4

Type STN LCD STN LCD

TFT LCD

Resolution (pixels) 320 x 240 640 x 480

Colors 8 gray scales 8

Backlighting 4

Membrane

keyboard

System keys with permanent functions

24

(4 with LEDs)

32

(4 with LEDs)

Function keys with configurable functions (can

also be used as DP direct

keys)

24

(18 with LEDs)

36

(28 with LEDs)

For use as soft keys 14 20

Key labeling

for function keys

System-specific labeling using labeling strips

Product

Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-7

OP27,

OP37 Equipment Manual

Release 05/99

OP37OP27COP27MHardware

Interfaces

Serial communications

port for

connection to PLC,

PC/PU, printer

2 x RS232/TTY

(active/passive)

1 x RS422/RS485

2 x RS232/TTY

(active/passive)

1 x RS422/RS485

1 x TTY (passive) /

RS422/RS485

Parallel interface for

connecting a printer

– 1 x TTL

(Centronics)

Processor

Type 80486 Pentium

Clock rate (MHz) 33 100

Memory

Flash EPROM for firmware and user data (MB)

1 2

DRAM main memory

(MB)

2 4 8

Buffered SRAM (KB) 128

Hardware OP27M OP27C OP37

Special features

Hardware clock (battery–

backed)

4

Relay output for temperature monitoring

– 4

Use of an external

MF2 keyboard

– 4

1)

Use of an external PS2

keyboard

– 4

1)

Use of an external PS2

mouse

– 4

2)

DOS mode – 4

Module slot for PCMCIA/

JEIDA cards

1 2

(Slot A and Slot B)

3)

1)

Can only be used for BIOS setup and in DOS mode

2)

Can only be used in DOS mode

3)

Slot A can only be used for DOS mode, Slot B for OP and DOS modes

Options OP27M OP27C OP37

Direct key

module

Digital outputs, triggered

optionally by means of

direct keys

configurable outputs

8

8

12

16

Control Panel

Interface

4)

Digital inputs/outputs 16 or 32

Product

Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-8

OP27,

OP37 Equipment Manual

Release 05/99

OP37OP27COP27MOptions

Floppy disk

drive

Storage capacity – 1.44 MB

Hard disk

5)

Storage capacity – 2 GB

AT extension

slot

5)

Plug-in 2/3 length, 16-bit

AT cards

– 2

4)

Can only be used in conjunction with SIMA

TIC S7 PLC

5)

Can only be used in DOS mode

Product

Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-1

OP27,

OP37 Equipment Manual

Release 05/99

Functionalty

The

following table presents an overview of the functions of operator panels OP27 and OP37. The values

specified are the maximum values that can be managed by the respective OP

. The values are limited by

the size of the working memory

.

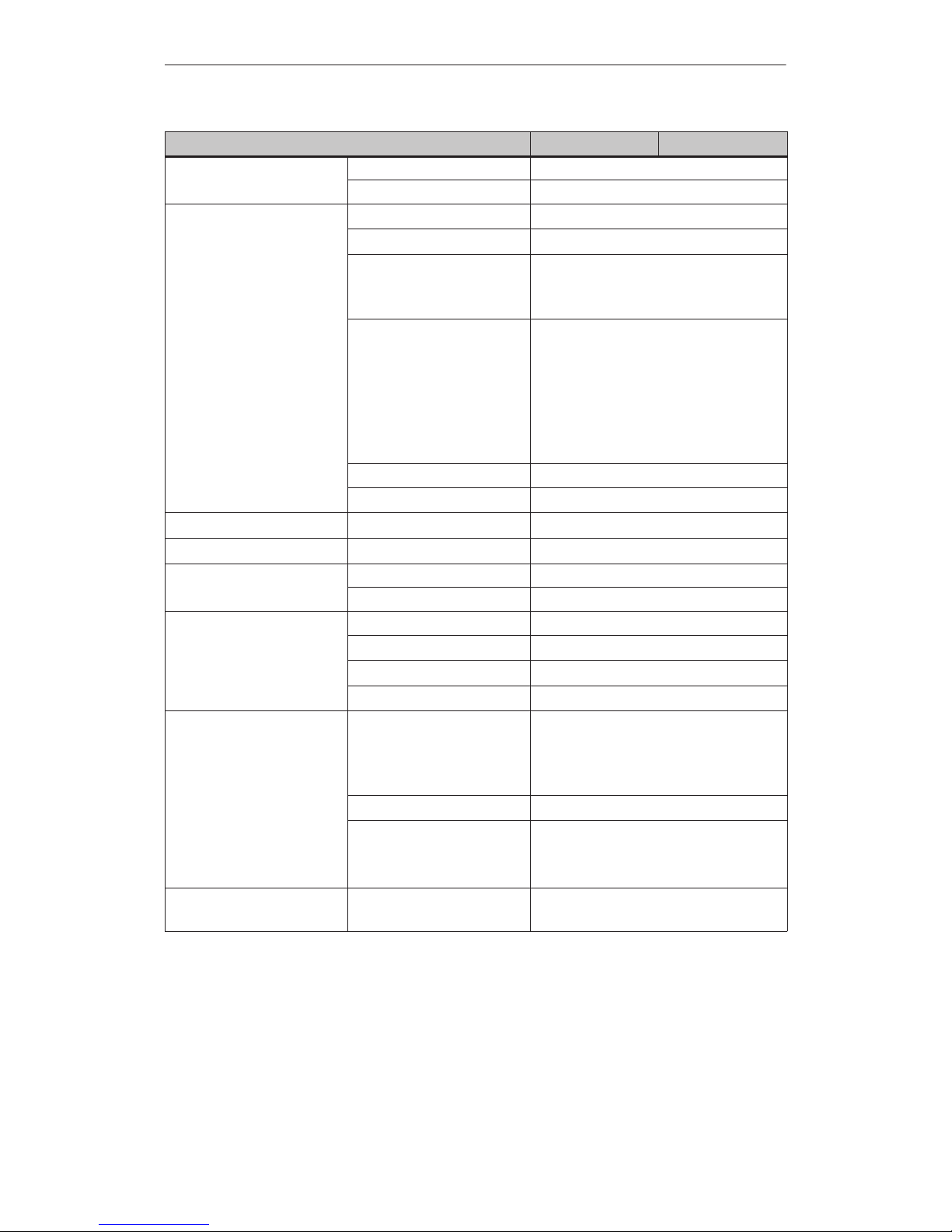

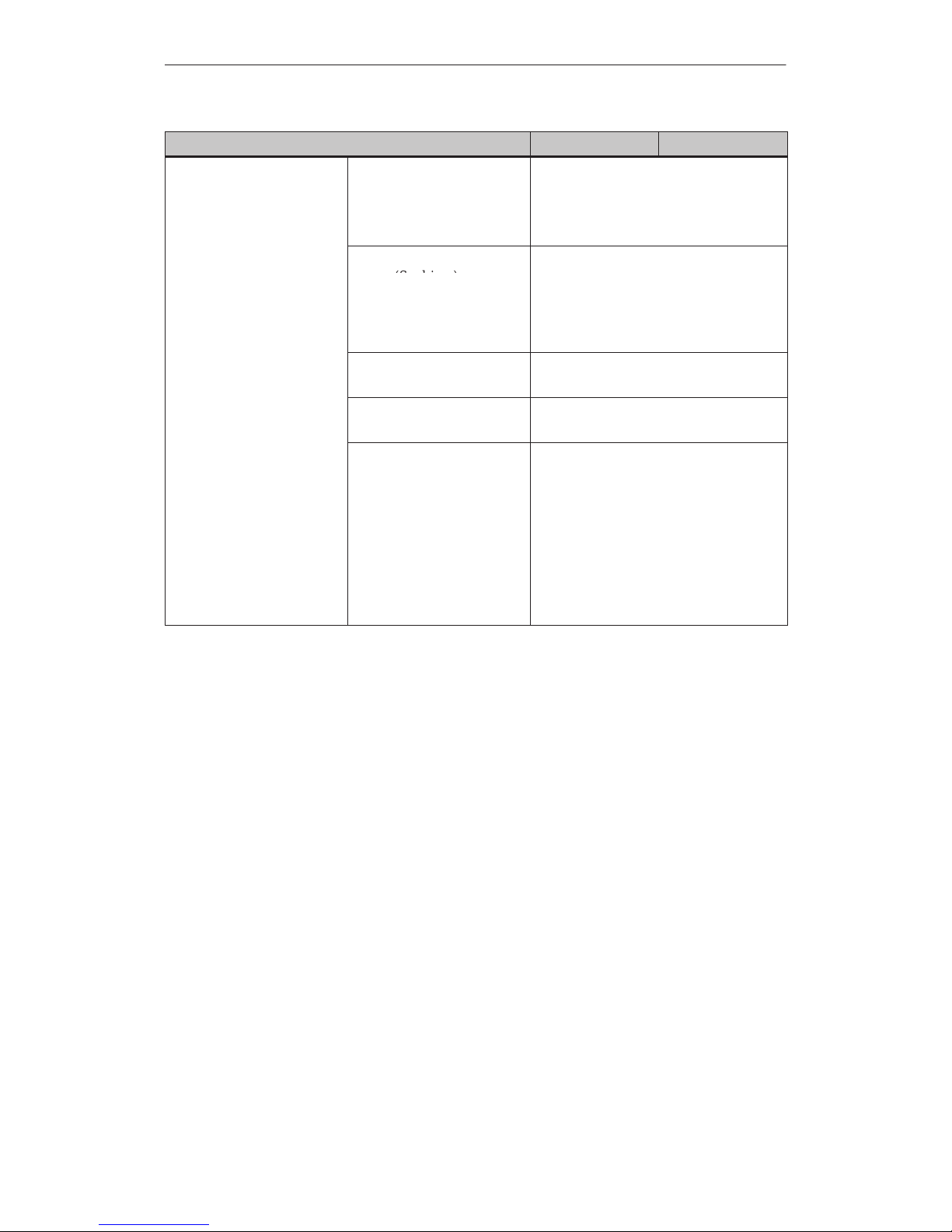

Functions OP27 OP37

Event messages

Number 2000

Display in message line/message window

View all pending messages in message page

Length message text per line 35 characters 70 characters

Lines per message 2 1

Process values in message text 8

Alarm

messages

Number 2000

Display in message line/message window

Display type First value/last value, selectable

View all pending messages in message page

Length message text per line 35 characters 70 characters

Lines per message 2 1

Process values in message text 8

Acknowledge individual alarm

messages

4

Acknowledge several alarm

messages simultaneously

16 acknowledgment groups

Message

logging

Output to printer

4

Message

ar

chive

Capacity 512 message events

View buffered event/alarm

messages

4

Delete

4

Buffer overflow warning

4

Automatic printout on buffer

overflow

4

Message events queued

simultaneously (max.)

Event

messages

or

Alarm messages

500

250

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-2

OP27,

OP37 Equipment Manual

Release 05/99

OP37OP27Functions

Message

acquisition

Time of occurrence Date and time

Message events Arrive, depart, acknowledge

Screens

View

4

Printout

4

Static screen elements Pixel graphics

Text

Character graphics

Input/output elements Numeric/alphanumeric input fields

Numeric/alphanumeric output fields

Combined input/output fields

Symbolic text input fields

Symbolic text/graphics output fields

Bar graphs

Trends

Operator prompting Icons for soft key functions

Fixed window

4

Limit

value monitoring

Inputs/outputs

4

Conversion functions

Inputs/outputs

4

T

ext attributes

Display Flashing, inverse, underscore

Printer (messages) Bold, italic, underscore

Help

text

Lines/characters 7/35

For messages

4

For input fields

4

For screens

4

Print

functions

Hardcopy of screen contents

(screen dump)

character mode (ASCII)

graphics mode

4

4

Direct message logging

4

Print screen lists in

character mode

(ASCII)

graphics mode

4

4

Password

pr

otection Number of passwords

Password levels

50

10 (0...9)

Functionalty

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-3

OP27,

OP37 Equipment Manual

Release 05/99

OP37OP27Functions

Recipes

Number 255

Data records per recipe 500

Entries per data record 500

3000 (SIMATIC S7)

Save (create) data records PLC/OP ! data medium

Load data records Data medium ! OP/PLC

Delete data records On data medium

Modify (edit) data records On data medium

Transfer current values PLC ! OP

OP ! PLC

Transfer data records Data medium ! OP

OP ! Data medium

Record sets

4

Backup Backup/Restore for memory

card

4

Online

language change

Number of languages 3

Loadable character sets per

language

3

Language–independent character set (incl. character–graphic

characters)

1

Character size in pixels 8 x 8 to 64 x 64

PU

functions

SIMATIC S5 4

(Status/Contr

ol T

ag)

SIMATIC S7 4

Display

Blank screen

4

Contrast

4 4

(C-STN display only)

DP direct keys

1)

Number of input

24 36

Number of outputs (LEDs)

18 28

Inputs/outputs with Control

Panel Interface upgradeable by

16 or 32

1)

= Configuration, refer to Communication User’

s Manual

Functionalty

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-4

OP27,

OP37 Equipment Manual

Release 05/99

OP37OP27Functions

Communication SIMATIC S5

– AS511 4

–FAP 4

– PROFIBUS-DP 4

SIMATIC S7/M7

– PPI

(S7 driver)

4

–

MPI (S7 driver)

–

-

4

–

PROFIBUS-DP

(S7 driver)

4

SIMATIC 500/505

– NITP 4

Block driver

– Free

Serial

4

Loadable NATIVE drivers

(optional)

– AEG/Modicon

(Modbus)

4

–

Allen Bradley (DF1)

4

–

Mitsubishi (FX)

4

– Omron 4

–T

elemecanique

(Adjust, Uni-T

elway)

4

Functionalty

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FUNCTIONS

3 General Operation

4 Screens

5 Password Protection

6 Messages

7 Printing

8 Recipes

9 Storing and Loading Data

10 Status/Control Tag with the OP

11 System Settings

Part

II

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-2

OP27,

OP37 Equipment Manual

Release 05/99

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-1

OP27, OP37 Equipment Manual

Release 05/99

General Operation

It

is possible to observe the operating status of the machine or system being

monitored using the OP screen and directly intervene in the process running

via the OP keyboard.

A screen occupies the entire display

. An example of screen partitioning is illus

-

trated in Figure 3-1.

Main

area

Fixed window

ESC

Icons for soft-key

functions

System messages

Event and alarm messages

Message indicators

Help window

Figure 3-1 Screen partitioning on the OP (example OP37)

The

fixed window can be used to display important process magnitudes or date

and time, since the contents are not af

fected by the screen currently open.

The main area comprises the entire display. It is superimposed by all other

areas (fixed window

, message window etc.). The main area contains the current

contents of the screen that is currently open.

Icons are used as symbols of specific screen functions. Icons are located above

or next to soft key function keys in order to describe the functionality of the

key

. The configured function is triggered after pressing the function key

.

Operating concept

Screen partitioning

Fixed window

Main area

Icons

3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...