Siemens SIMATIC HMI KTP700F Mobile, SIMATIC HMI KTP400F Mobile, SIMATIC HMI KTP700 Mobile, SIMATIC HMI KTP900F Mobile, SIMATIC HMI KTP900 Mobile Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC HMI

HMI devices

Mobile Panels 2nd Generation

Operating Instructions

09/2018

A5E33876626

Preface

Overview

1

Safety instructions

2

Installing system

components

3

Handling the Mobile Panel

4

Parameterizing the Mobile

Panel

5

Configuring the Mobile Panel

6

Commissioning a project

7

Operating a project

8

Fail-safe operation

9

Maintenance and care

10

Technical specifications

11

Technical Support

A

Markings and symbols

B

List of abbreviations

C

-AC

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E33876626-AC

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

09/2018 Subject to change

Preface

Purpose of the operating instructions

Basic knowledge required

Scope of the document

These operating instructions contain information on place of use, transport, storage,

mounting, use and maintenance of the device.

These operating instructions are intended for:

● Users

● Commissioning engineers

● Maintenance personnel

You can find more information such as operating instructions, examples and reference

information in the information system of the TIA Portal or through online support.

General knowledge of automation technology and process communication is needed to

understand the operating instructions. Knowledge of personal computers and the Microsoft

operating systems is required to understand this manual.

The operating instructions apply to the following Mobile Panels 2nd Generation in

combination with the corresponding connection boxes:

● SIMATIC HMI KTP400F Mobile, article number 6AV2125-2DB23-0AX0

● SIMATIC HMI KTP700 Mobile, article number 6AV2125-2GB03-0AX0

● SIMATIC HMI KTP700F Mobile, article number 6AV2125-2GB23-0AX0

● SIMATIC HMI KTP900 Mobile, article number 6AV2125-2JB03-0AX0

● SIMATIC HMI KTP900F Mobile, article number 6AV2125-2JB23-0AX0

The corresponding connection boxes with article numbers and information on compatibility

can be found in the following sections:

● Connection boxes (Page 18)

● Mobile Panel and connection box compatibility (Page 29)

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

3

Preface

Note

This document is part of the Mobile Panel system, connecting cable and connection box, and

is also required for repeat commissioning. Keep all supplie

documentation for the entire service life of the Mobile Panel.

Provide any future owner or user with all the documents for the HMI device.

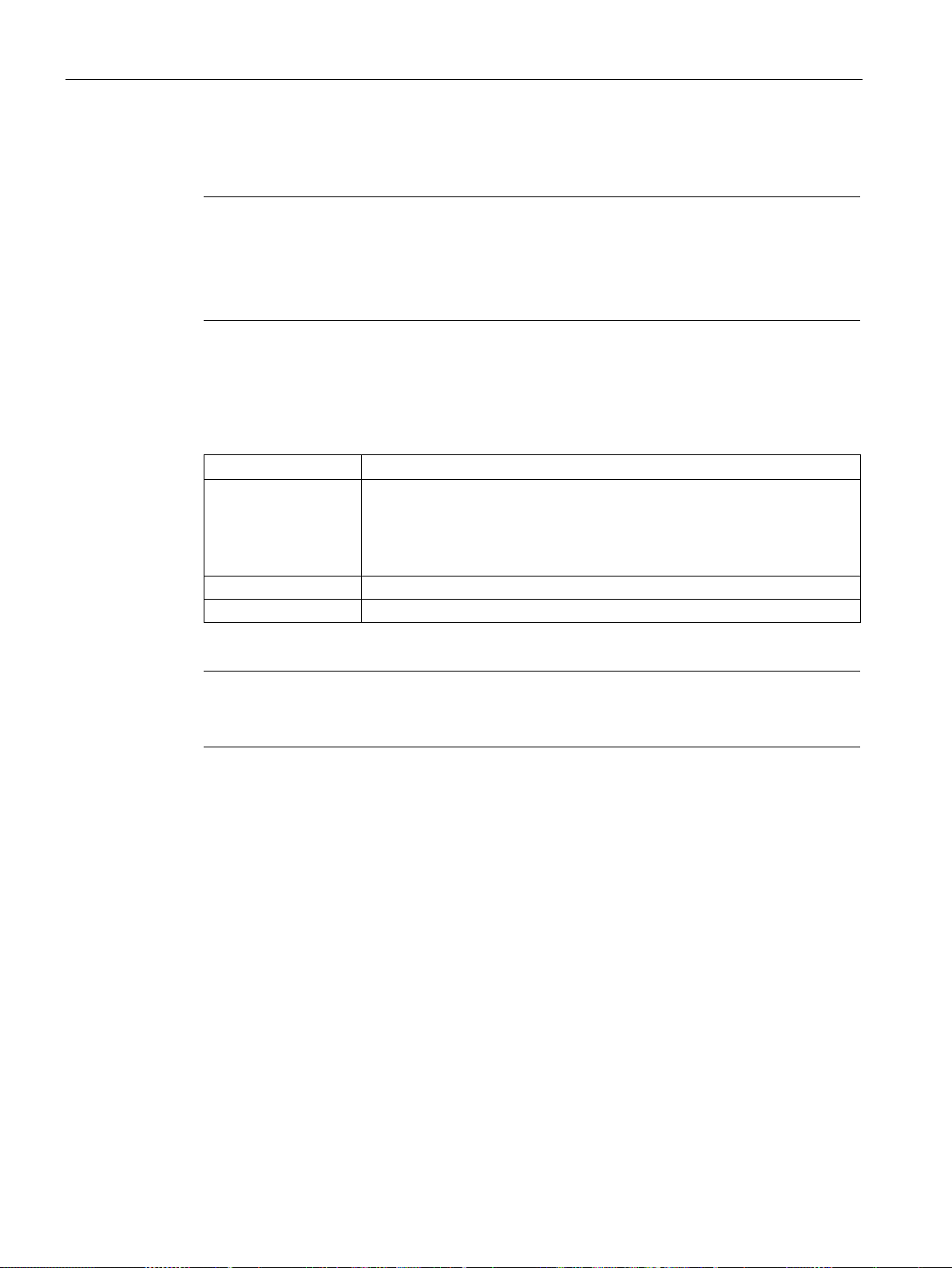

Style conventions

Style Convention

Scope

"File > Edit"

Operational sequences, e.g, menu command, shortcut menu command

<F1>, <Alt+P>

Keyboard operation

Note

A note contains important information abo

handling, or a specific section of the document to which you should pay particular attention.

The document applies in conjunction with the software listed in "Software required

(Page 24)".

d and supplementary

Make sure that every supplement to the documentation that you receive is stored together

with the operating instructions.

"Add screen"

• Terminology that appears in the user interface, for example, dialog

names, tabs, buttons, menu commands

• Necessary entries, for example, limit, tag value

• Path information

Please observe notes labeled as follows:

ut the product described in the document and its

Mobile Panels 2nd Generation

4 Operating Instructions, 09/2018, A5E33876626-AC

Preface

Naming conventions

Term

Applies to

Control cabinet

Mounted cabinet, enclosure, terminal box, panel, control panel

F-system

Fail-safe automation system with fail-safe Mobile Panel

STEP 7

STEP 7 V13 SP1 or higher

Safety optional package

STEP 7 Safety Advanced V13 SP1 or later optional package

Information on standards

Plant System, machining center, one or more machines

Connection box

HMI device

Mobile Panel

Fail-safe Mobile Panel

Safety-related operator

control

Storage medium

WinCC

• Connection box compact

• Connection box standard

• Connection box advanced

• KTP400F Mobile

• KTP700 Mobile

• KTP700F Mobile

• KTP900 Mobile

• KTP900F Mobile

• KTP400F Mobile

• KTP700F Mobile

• KTP900F Mobile

• Emergency stop / stop button

• Enabling button

• SD memory card

• USB flash drive

• WinCC Comfort V13 SP1 or higher

• WinCC Advanced V13 SP1 or higher

You can find detailed information on standards including year of publication and

corresponding supplements in the section "Standards on operating safety (Page 221)".

Standards and supplements will be referenced in the remainder of the document without

citation of the year of publication, for example, "EN 61000-6-4 +A1".

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

5

Preface

Figures

See also

This document contains figures of the devices described. The figures can deviate from the

particularities of the delivered device.

Picture components are marked with black position numbers on a white background

①, ②, ③, etc.

Steps in the figures are identified with white process numbers on a black background

according to the sequence in which they have to be executed: , , , ...

Terms for fail-safe operation (Page 24)

Mobile Panels 2nd Generation

6 Operating Instructions, 09/2018, A5E33876626-AC

Table of contents

Preface ................................................................................................................................................... 3

1 Overview............................................................................................................................................... 13

2 Safety instructions ................................................................................................................................. 31

3 Installing system components ............................................................................................................... 43

1.1 Product overview .................................................................................................................... 13

1.2 Design of the Mobile Panels ................................................................................................... 14

1.3 KTP Mobile connecting cable ................................................................................................. 17

1.4 Connection boxes ................................................................................................................... 18

1.5 Scope of delivery .................................................................................................................... 20

1.6 Accessories ............................................................................................................................. 21

1.6.1 KTP Mobile wall-mounting bracket ......................................................................................... 21

1.6.2 Fail-safe KTP Mobile spare key .............................................................................................. 22

1.6.3 Protective films ........................................................................................................................ 22

1.6.4 Storage media ......................................................................................................................... 22

1.6.5 SIRIUS safety relays ............................................................................................................... 23

1.7 Software required .................................................................................................................... 24

1.8 Terms for fail-safe operation ................................................................................................... 24

1.9 Organizational measures ........................................................................................................ 28

1.10 Mobile Panel and connection box compatibility ...................................................................... 29

2.1 General safety instructions ..................................................................................................... 31

2.2 Security management for HMI devices ................................................................................... 36

2.3 Data protection ........................................................................................................................ 36

2.4 Notes about usage .................................................................................................................. 37

2.5 Risk assessment of the plant .................................................................................................. 38

2.6 Important information on emergency stop / stop button ......................................................... 39

2.7 Important notes for the enabling mechanism ......................................................................... 40

3.1 Checking the delivery.............................................................................................................. 43

3.2 Mounting the connection box compact ................................................................................... 43

3.2.1 Mounting position, mounting cutout and clearance ................................................................ 43

3.2.2 Fastening the connection box compact .................................................................................. 45

3.3 Installing the connection box standard and connection box advanced .................................. 45

3.3.1 Mounting position and clearance ............................................................................................ 45

3.3.2 Fastening the connection box standard and connection box advanced ................................. 46

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

7

Table of contents

4 Handling the Mobile Panel .................................................................................................................... 77

5 Parameterizing the Mobile Panel ........................................................................................................... 87

3.4 Attaching the KTP Mobile wall-mounting bracket .................................................................. 47

3.4.1 Assembling the KTP Mobile wall-mounting bracket ............................................................... 47

3.4.2 Mounting position and clearance ........................................................................................... 48

3.4.3 Fasteneing the KTP Mobile wall-mounting bracket ............................................................... 50

3.5 Connecting the Mobile Panel ................................................................................................. 51

3.5.1 Connection information .......................................................................................................... 51

3.5.2 Inserting the SD memory card ............................................................................................... 51

3.5.3 Connecting the Mobile Panel connecting cable ..................................................................... 53

3.5.4 Connecting a Configuring PC ................................................................................................ 54

3.5.5 Replacing the connecting cable ............................................................................................. 55

3.5.6 Replacing an SD memory card .............................................................................................. 57

3.5.7 Inserting the USB memory stick ............................................................................................. 58

3.6 Connecting the connection box .............................................................................................. 59

3.6.1 Connection information .......................................................................................................... 59

3.6.2 Opening and closing connection box standard and connection box advanced ..................... 60

3.6.3 Equipotential bonding of connection boxes ........................................................................... 62

3.6.4 Connecting the functional grounding and power supply to the connection box .................... 64

3.6.5 Connecting cables for a hardwired F-system ........................................................................ 66

3.6.6 Connecting Ethernet to the connection box ........................................................................... 67

3.6.7 Setting the box ID of the connection box ............................................................................... 70

3.6.8 Secure cables and seal screw glands ................................................................................... 72

3.7 Connecting the KTP Mobile connecting cable to the connection box.................................... 73

3.8 Selecting the connection box ................................................................................................. 75

4.1 Holding the Mobile Panel and attaching it to the wall-mounting bracket ............................... 77

4.2 Keyswitches, function keys and illuminated pushbuttons ...................................................... 79

4.3 Operating the enabling button ................................................................................................ 81

4.4 Pressing the emergency stop / stop button ........................................................................... 83

4.5 Testing Mobile Panel readiness for operation ....................................................................... 85

5.1 Firmware and software .......................................................................................................... 87

5.2 Desktop and Start Center ...................................................................................................... 87

5.3 Operating the desktop, Start Center and Control Panel ........................................................ 88

5.4 Installed programs ................................................................................................................. 88

5.5 Security mode ........................................................................................................................ 89

5.5.1 Overview ................................................................................................................................ 89

5.5.2 Using the HMI device in password-protected security mode ................................................. 89

5.6 Control Panel ......................................................................................................................... 90

5.6.1 Opening the settings .............................................................................................................. 90

5.6.2 Overview of functions ............................................................................................................. 91

5.6.3 Operating the Control Panel .................................................................................................. 93

5.6.4 Display types for the screen keyboard ................................................................................... 93

Mobile Panels 2nd Generation

8 Operating Instructions, 09/2018, A5E33876626-AC

Table of contents

5.7 Configuring operation.............................................................................................................. 96

5.7.1 Changing display brightness ................................................................................................... 96

5.7.2 Configuring the screen keyboard ............................................................................................ 97

5.7.3 Setting the character repeat rate of the screen keyboard ...................................................... 98

5.7.4 Setting the double-click ........................................................................................................... 99

5.7.5 Calibrating the touch screen ................................................................................................. 100

5.7.6 Restarting the HMI device .................................................................................................... 101

5.8 General settings .................................................................................................................... 103

5.8.1 Regional and language settings ........................................................................................... 103

5.8.2 Setting the date and time ...................................................................................................... 104

5.8.3 Entering and deleting a password ........................................................................................ 105

5.8.4 Setting the screen saver ....................................................................................................... 107

5.8.5 Parameterizing Transfer ....................................................................................................... 109

5.8.6 Storage management ........................................................................................................... 111

5.8.6.1 Displaying the memory distribution ....................................................................................... 111

5.8.6.2 Setting the project storage location and start delay .............................................................. 111

5.8.6.3 Activating memory management .......................................................................................... 113

5.8.6.4 Activate/deactivate retentivity of the alarm buffer on the HMI device ................................... 113

5.8.7 Backing up registry information and temporary data ............................................................ 115

5.8.8 Changing the print options .................................................................................................... 116

5.8.9 Displaying general system properties ................................................................................... 117

5.8.10 Displaying information about the Mobile Panel .................................................................... 118

5.8.11 Display firmware ................................................................................................................... 118

5.9 Changing Internet settings ....................................................................................................

119

5.9.1 Changing general settings .................................................................................................... 119

5.9.2 Setting the proxy server ........................................................................................................ 120

5.9.3 Changing Internet security settings ...................................................................................... 121

5.9.4 Activating encryption protocols ............................................................................................. 123

5.9.5 Importing, displaying and deleting certificates ...................................................................... 124

5.10 Enabling PROFINET ............................................................................................................. 126

5.11 Enabling NTP ........................................................................................................................ 127

5.12 Setting the PROFIsafe address ............................................................................................ 129

5.13 Configuring network operation .............................................................................................. 130

5.13.1 Overview ............................................................................................................................... 130

5.13.2 Specifying the computer name of the HMI device ................................................................ 131

5.13.3 Specifying the IP address and name server ......................................................................... 132

5.13.4 Specifying the logon data ..................................................................................................... 133

5.13.5 Configuring e-mail ................................................................................................................. 134

5.13.6 Configuring Telnet for remote control ................................................................................... 136

5.13.7 Configure Sm@rt Server ...................................................................................................... 136

5.13.8 Configure Web Server .......................................................................................................... 140

5.14 Assigning a safety-related operating mode .......................................................................... 142

5.15 Functions for service and commissioning ............................................................................. 144

5.15.1 Saving to external storage medium – backup ....................................................................... 144

5.15.2 Restoring from external storage medium – Restore ............................................................. 147

5.15.3 Update operating system ...................................................................................................... 149

5.15.4 Load project from external storage medium ......................................................................... 152

5.15.5 Using automatic backup........................................................................................................

155

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

9

Table of contents

6 Configuring the Mobile Panel ............................................................................................................... 165

7 Commissioning a project ...................................................................................................................... 189

8 Operating a project .............................................................................................................................. 203

5.15.6 Editing IP addresses and communication connections ....................................................... 159

5.15.6.1 Overview .............................................................................................................................. 159

5.15.6.2 Assigning IP address and device name ............................................................................... 160

5.15.6.3 Configuring a communication connection ............................................................................ 162

6.1 Configuration in WinCC ....................................................................................................... 167

6.1.1 Adding a controller to the project ......................................................................................... 167

6.1.2 Adding the Mobile Panel to the project ................................................................................ 169

6.1.3 Configuring a fail-safe Mobile Panel .................................................................................... 170

6.2 Configuring F-FBs in STEP 7 ............................................................................................... 174

6.3 Configuring plant areas in WinCC........................................................................................ 179

6.3.1 Overview .............................................................................................................................. 179

6.3.2 Configuring connection point detection ................................................................................ 179

6.3.3 Configuring zones and start screens ................................................................................... 181

6.4 Additional configuration options in WinCC ........................................................................... 182

6.4.1 Configuring function and direct keys .................................................................................... 182

6.4.2 Setting the transfer mode ..................................................................................................... 183

6.4.3 Changing the operating mode .............................................................................................. 183

6.5 Controlling and evaluating operator controls and display elements .................................... 184

6.5.1 Overview .............................................................................................................................. 184

6.5.2 Evaluating operator controls as direct keys ......................................................................... 184

6.5.3 Controlling the LEDs of the function keys by means of system functions ........................... 187

6.5.4 Controlling and evaluating the illuminated pushbutton by means of system functions ....... 187

6.5.5 Evaluating the key-operated switch by means of system functions .................................... 188

7.1 Overview .............................................................................................................................. 189

7.2 Using existing projects ......................................................................................................... 190

7.3 Data Transmission Options .................................................................................................. 190

7.4 Transferring a project with WinCC ....................................................................................... 191

7.4.1 Configuring data channel and setting transfer mode ........................................................... 191

7.4.2 Starting the transfer ............................................................................................................. 191

7.4.3 Testing a project................................................................................................................... 193

7.5 Backup and restore .............................................................................................................. 194

7.5.1 Backup and restore with a PC ............................................................................................. 194

7.5.2 Backup and restore with an external storage medium......................................................... 194

7.5.3 Backup and restore via ProSave ......................................................................................... 194

7.6 Updating the operating system using ProSave .................................................................... 196

7.7 Reset to factory settings with ProSave ................................................................................ 198

7.8 Managing WinCC options .................................................................................................... 200

7.9 Transferring a license key .................................................................................................... 201

8.1 Overview .............................................................................................................................. 203

8.2 Function keys ....................................................................................................................... 204

Mobile Panels 2nd Generation

10 Operating Instructions, 09/2018, A5E33876626-AC

Table of contents

9 Fail-safe operation .............................................................................................................................. 209

10 Maintenance and care ......................................................................................................................... 215

11 Technical specifications ...................................................................................................................... 219

8.3 Direct keys ............................................................................................................................ 205

8.4 Setting the project language ................................................................................................. 205

8.5 Entering and modifying the value, date and time ................................................................. 206

8.6 Displaying infotext ................................................................................................................. 207

8.7 Closing the project ................................................................................................................ 208

9.1 Connecting the connecting cable .......................................................................................... 209

9.2 Unplugging the connecting cable .......................................................................................... 211

9.3 Safety-related dialogs ........................................................................................................... 212

9.3.1 "End PROFIsafe communication" dialog .............................................................................. 212

9.3.2 "Confirm communication error" dialog .................................................................................. 213

9.3.3 "Fatal Error" dialog ................................................................................................................ 213

10.1 General information on maintenance and servicing ............................................................. 215

10.2 Replacing the Mobile Panel .................................................................................................. 215

10.3 Servicing the Mobile Panel ................................................................................................... 216

10.4 Cleaning the Mobile Panel .................................................................................................... 217

10.5 Spare parts and repairs ........................................................................................................ 218

10.6 Recycling and disposal ......................................................................................................... 218

11.1 Software license agreements ............................................................................................... 219

11.2 Certificates and approvals .................................................................................................... 219

11.3 Standards on operating safety .............................................................................................. 221

11.4 Electromagnetic compatibility ............................................................................................... 221

11.5 Mechanical ambient conditions ............................................................................................. 223

11.5.1 Storage conditions ................................................................................................................ 223

11.5.2 Operating Conditions ............................................................................................................ 223

11.6 Climatic ambient conditions .................................................................................................. 224

11.6.1 Long-term storage ................................................................................................................. 224

11.6.2 Transport and short-term storage ......................................................................................... 224

11.6.3 Operating Conditions ............................................................................................................ 224

11.7 Dimension drawings .............................................................................................................. 225

11.7.1 KTP400F Mobile dimension drawing .................................................................................... 225

11.7.2 KTP700 Mobile dimension drawing ...................................................................................... 226

11.7.3 KTP700F Mobile dimension drawing .................................................................................... 227

11.7.4 KTP900 Mobile dimension drawing ...................................................................................... 228

11.7.5 KTP900F Mobile dimension drawing .................................................................................... 229

11.7.6 Connection box compact dimension drawing ....................................................................... 230

11.7.7 Dimension drawing for connection box standard and connection box advanced ................ 231

11.7.8 KTP Mobile wall-mounting bracket dimension drawing ........................................................ 232

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

11

Table of contents

A Technical Support ................................................................................................................................ 267

B Markings and symbols ......................................................................................................................... 271

C List of abbreviations ............................................................................................................................. 273

Glossary .............................................................................................................................................. 275

Index ................................................................................................................................................... 281

11.8 Technical specifications ....................................................................................................... 233

11.8.1 Mobile Panel ........................................................................................................................ 233

11.8.2 Connecting cable ................................................................................................................. 235

11.8.3 Connection boxes ................................................................................................................ 236

11.8.4 Power consumption specifications ....................................................................................... 238

11.8.5 Reaction times and safety characteristics for fail-safe operation ........................................ 239

11.8.6 Specification of cables to be used ....................................................................................... 242

11.9 Interface description for Mobile Panel ................................................................................. 243

11.9.1 Internal interface X1P1 ........................................................................................................ 243

11.9.2 Internal interface X80 ........................................................................................................... 243

11.9.3 External interface X61 .......................................................................................................... 243

11.10 Connection box compact interfaces ..................................................................................... 244

11.10.1 Position of the interfaces ...................................................................................................... 244

11.10.2 Interface X1 .......................................................................................................................... 244

11.10.3 Plug-in terminal strip X10 ..................................................................................................... 245

11.10.4 Wiring of safety-related operator controls ............................................................................ 246

11.11 Interfaces of the connection box standard and connection box advanced .......................... 248

11.11.1 Position of the interfaces ...................................................................................................... 248

11.11.2 Fast connector X1 and X2 ................................................................................................... 249

11.11.3 Plug-in terminal strip X10 ..................................................................................................... 249

11.11.4 Wiring of safety-related operator controls ............................................................................ 250

11.12 Communication with controllers ........................................................................................... 253

11.13 Scope of functions with WinCC ............................................................................................

254

11.14 Mobile Panel 2nd Generation F-FBs ................................................................................... 258

11.14.1 Using F-FBs ......................................................................................................................... 258

11.14.2 F_FB_KTP_Mobile ............................................................................................................... 260

11.14.3 F_FB_KTP_RNG .................................................................................................................. 263

A.1 Troubleshooting ................................................................................................................... 267

A.2 Service and support ............................................................................................................. 268

A.3 Parameterization of the connection box standard and connection box advanced .............. 269

A.4 System events...................................................................................................................... 269

B.1 Safety-relevant symbols ....................................................................................................... 271

Mobile Panels 2nd Generation

12 Operating Instructions, 09/2018, A5E33876626-AC

1

1.1

Product overview

The second generation of SIMATIC HMI Mobile Panels offers direct mobile operation and

monitoring of the production process. The Mobile Panels 2nd Generation system consists of

a Mobile Panel, connection box and connecting cable.

The Mobile Panels 2nd Generation is available with display sizes 4", 7" and 9" widescreen.

The figure below shows a fail-safe Mobile Panel with a 7" widescreen display connected to a

connection box advanced.

Depending on the application, either non-fail-safe or fail-safe Mobile Panels can be used.

With a fail-safe Mobile Panel, you run the plant in fail-safe mode. You meet the requirements

of Safety Integrity Level 3 and Performance Level PL e with a fail-safe Mobile Panel. An

emergency stop / stop switch and an enabling button are integrated in a fail-safe Mobile

Panel 2nd Generation. You can hardwire the safety-related operator controls or evaluate

them in a PROFIsafe-based F-system with a fail-safe controller.

The 7" and 9" devices come equipped with a keyswitch as additional option for protecting the

HMI device from unauthorized access.

You can choose from three connection boxes each with a different range of functions. The

connection box compact is designed for installation in control cabinets. The connection box

standard and connection box advanced are approved for external mounting directly on the

machine.

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

13

Overview

1.2

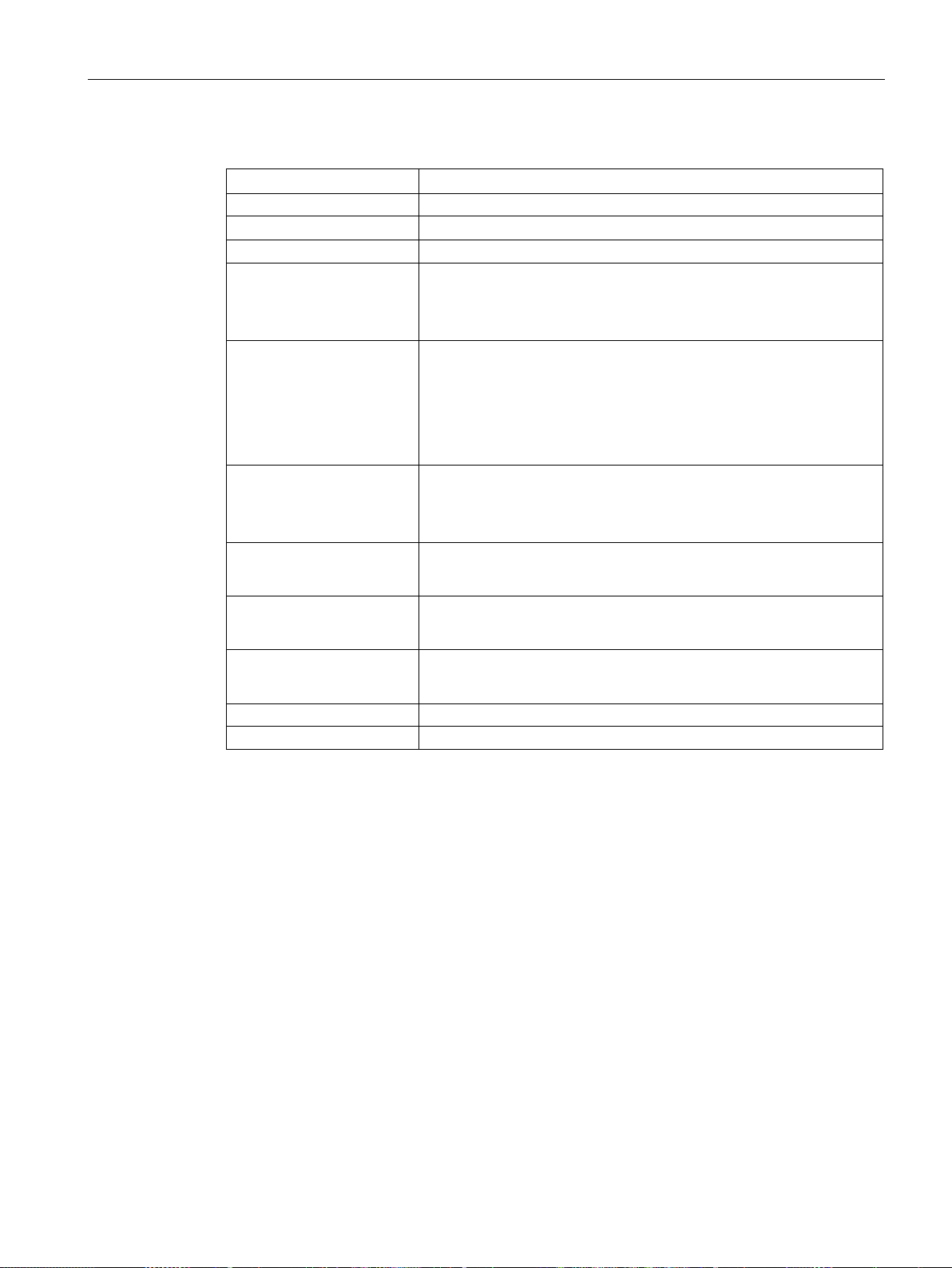

Design of the Mobile Panels

SIMATIC HMI

Number of

function keys

Illuminated

pushbutton

Emergency stop / stop button,

acknowledgment button

Keyswitch

KTP400F Mobile

4 2 Yes

No

KTP700F Mobile

8 2 Yes

Yes

KTP900 Mobile

10 2 No

No

KTP900F Mobile

10 2 Yes

Yes

Note

System components

To operate a Mobile Panel, you need:

•

•

•

•

You can find the ordering information for the system components on the Internet

(

1.2 Design of the Mobile Panels

The device is designed for industrial use:

● High fall resistance

● High protection class

● High impact resistance

● High chemical resistance to operating and cleaning agents

(http://support.automation.siemens.com/WW/view/en/39718396

).

The enclosure type protects the emergency stop / stop button. Two protective bumpers to

prevent damage to the emergency stop / stop button during a fall of the HMI device.

All Mobile Panels can be configured with the WinCC software. WinCC is a component of the

"Totally Integrated Automation Portal" engineering framework.

The Mobile Panels 2nd Generation are available in the following device versions:

KTP700 Mobile 8 2 No No

An HMI device

A connecting cable (Page 17)

At least one connection box (Page 18)

For hardwired F-systems: A safety relay (Page 23) or suitable F-DI modules.

https://mall.industry.siemens.com/mall/en/de/Catalog/Products/10165537).

Mobile Panels 2nd Generation

14 Operating Instructions, 09/2018, A5E33876626-AC

Overview

Front and side views

①

Keyswitch, only for KTP700F Mobile and KTP900F Mobile

②

Enabling button, for fail-safe Mobile Panel

③

Emergency stop / stop switch for fail-safe Mobile Panel

④

Drop protection for emergency stop / stop switch for fail-safe Mobile Panel

⑤

Cover of the USB port

⑥

Handle

⑦

Function key blocks

⑧

Display with touch screen

⑨

Illuminated pushbutton

1.2 Design of the Mobile Panels

The figures below show an example of the design of the fail-safe HMI device, KTP900F

Mobile. The other HMI devices of the type KTP Mobile are constructed similarly.

The position of the emergency stop/stop button makes it easily accessible. Due to its profiled

design, the emergency stop/stop button is easily accessible. Two bumpers protect the

emergency stop / stop button against impact damage, for example, if it falls. The bumpers

are dimensioned so that the emergency stop / stop button can be activated during an impact.

The operator controls are described in the section "Handling the Mobile Panel (Page 77)".

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

15

Overview

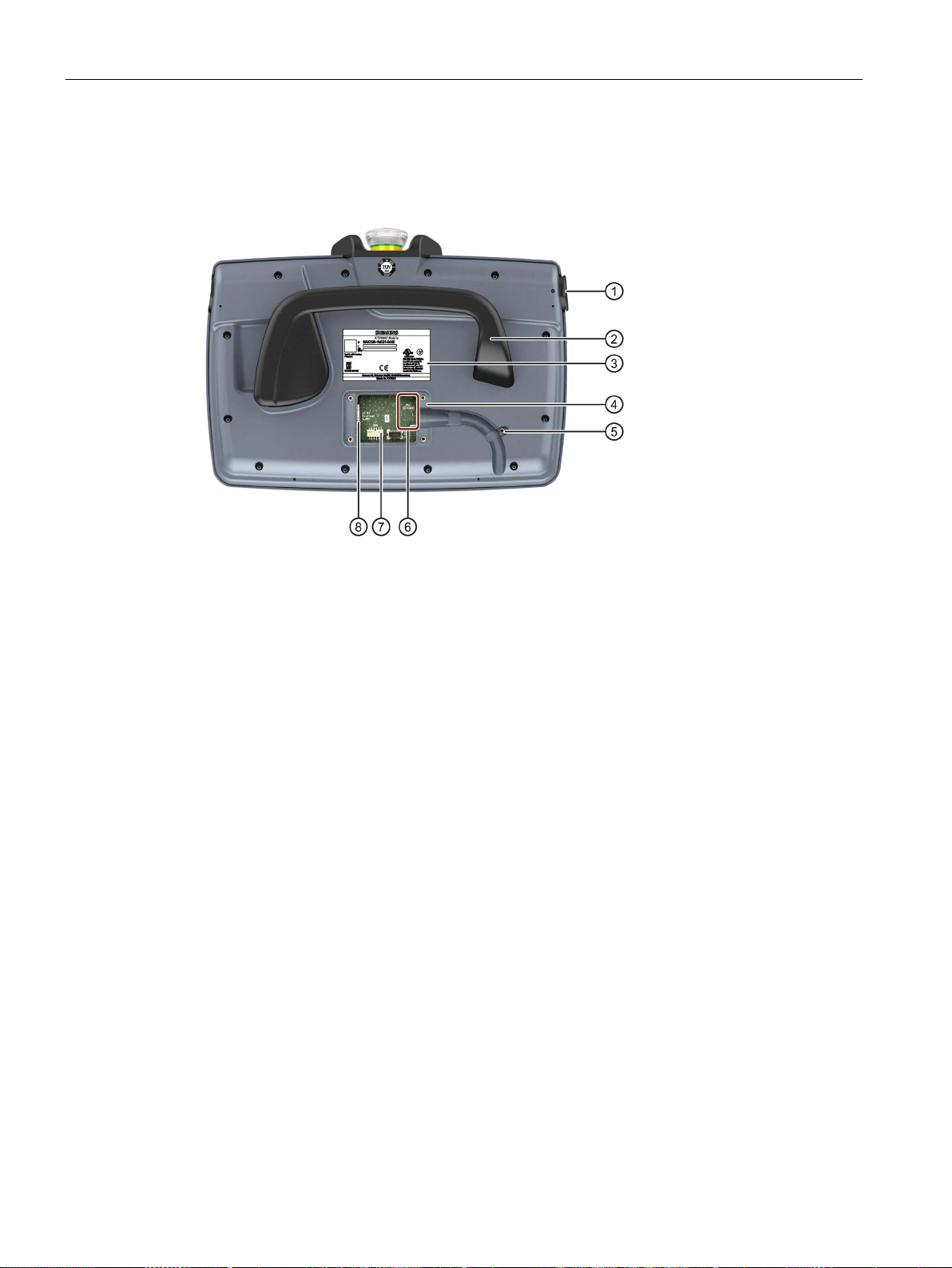

Rear view and interfaces

①

⑤

not for KTP400F Mobile

②

Handle

⑥

Slot for an SD memory card, not for KTP400F Mobile

③

Nameplate

⑦

12-pin connector for the connecting cable

④

Terminal compartment

⑧

RJ45 socket PROFINET (LAN)

1.2 Design of the Mobile Panels

The figure below shows an example of the design of the fail-safe HMI device, KTP900F

Mobile. The other HMI devices of the type KTP Mobile are constructed similarly.

USB port with cover

Threaded sleeve for mounting screw of the cable retainer,

Mobile Panels 2nd Generation

16 Operating Instructions, 09/2018, A5E33876626-AC

Overview

1.3

KTP Mobile connecting cable

①

RJ45 connector

②

Plug connector, 12-pin

③

Retainer, not required for KTP400F Mobile.

④

Label with order number, length specification and product version

⑤

Seal

⑥

Terminal compartment cover

⑦

Connector for the connection box

Product name and length

Article number

KTP Mobile 2 m connecting cable

6AV2181-5AF02-0AX0

KTP Mobile 5 m connecting cable

6AV2181-5AF05-0AX0

KTP Mobile 8 m connecting cable

6AV2181-5AF08-0AX0

KTP Mobile 10 m connecting cable

6AV2181-5AF10-0AX0

KTP Mobile 15 m connecting cable

6AV2181-5AF15-0AX0

KTP Mobile 20 m connecting cable

6AV2181-5AF20-0AX0

KTP Mobile 25m connecting cable

6AV2181-5AF25-0AX0

1.3 KTP Mobile connecting cable

You connect the Mobile Panel to the connection box using the rugged connecting cable. The

tensile and flexural strength of the connecting cable is geared toward the actual usage

conditions.

Functions of the connecting cable:

● Power supply of the Mobile Panel

● Ethernet connection between Mobile Panel and connection box

● Transmission of the signals for emergency stop / stop button and enabling button

● Transmission of the box ID

The KTP Mobile connecting cable is available in the following lengths:

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

17

Overview

1.4

Connection boxes

Connection box compact

①

positioning mark on the connection box when connecting.

②

Connection socket for the connecting cable

③

Cover of the connection socket

④

Safety strap

1.4 Connection boxes

The connection boxes are available in the following versions:

● Connection box compact, article number 6AV2125-2AE03-0AX0

● Connection box standard, article number 6AV2125-2AE13-0AX0

● Connection box advanced, article number 6AV2125-2AE23-0AX0

The figure below shows the connection box compact.

Positioning mark

There is also a red positioning mark on the connecting cable. Align this mark with the

Mobile Panels 2nd Generation

18 Operating Instructions, 09/2018, A5E33876626-AC

Overview

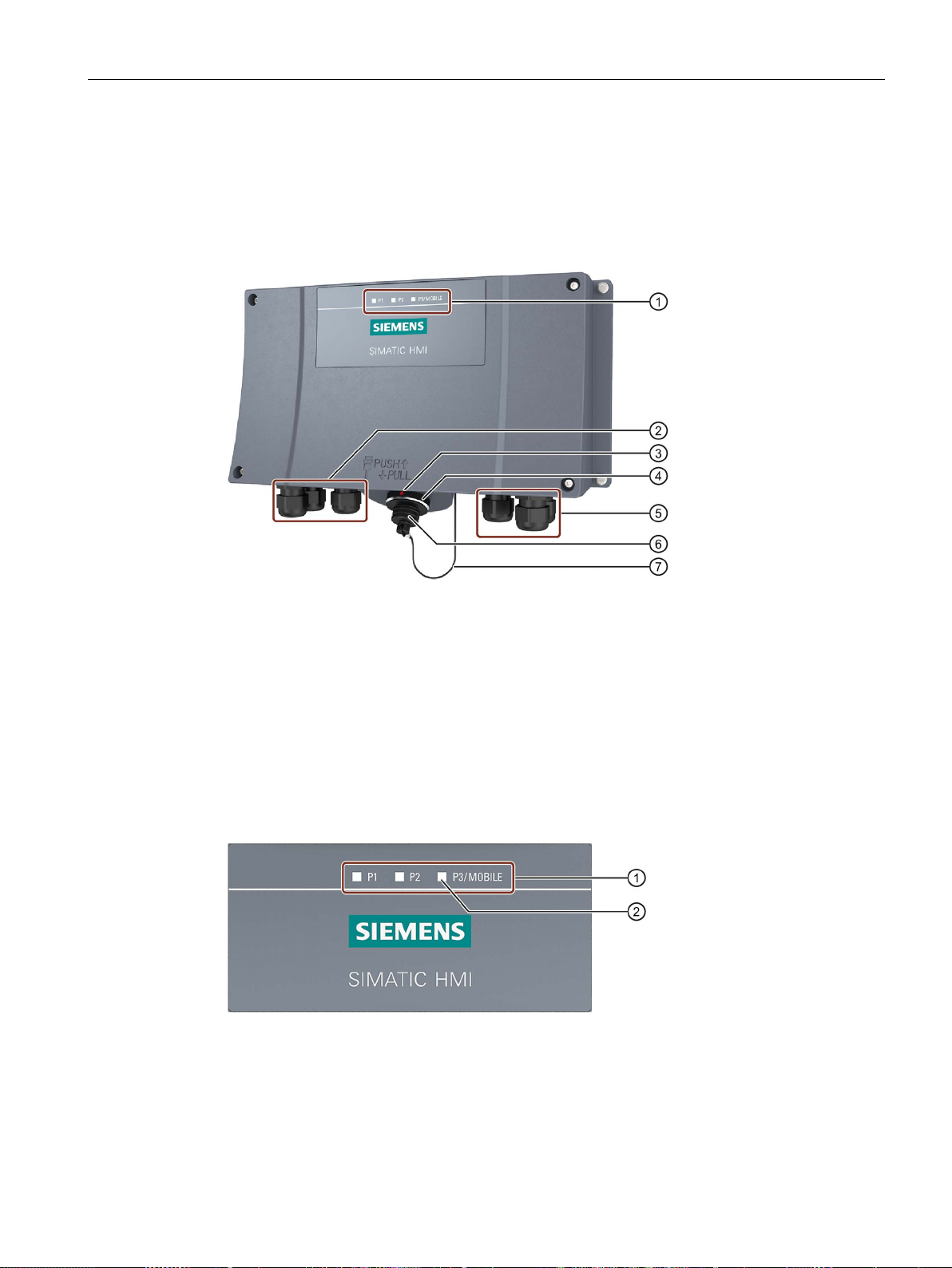

Connection box standard and connection box advanced

①

LED display

②

Screw glands for the data cables

③

positioning mark on the connection box when connecting.

④

Connection socket for the connecting cable

⑤

Screw glands for power supply cables and F-signal cables

⑥

Cover of the connection socket

⑦

Safety strap

①

②

LED

1.4 Connection boxes

The figure below shows the connection box standard or the connection box advanced. The

connection box advanced also features:

● Real-time Ethernet

● F-signal transmission

Positioning mark

There is also a red positioning mark on the connecting cable. Align this mark with the

There are three LEDs on the front of the connection box that indicate the status of

communication.

LED display of the three Ethernet ports:

• P1: Fast Connector X1

• P2: Fast Connector X2

• P3: Connection socket for the Mobile Panel

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

19

Overview

See also

1.5

Scope of delivery

Mobile Panel 2nd Generation:

Connection box compact:

Connection box standard and connection box advanced:

Connecting cable:

1.5 Scope of delivery

Basic functions of the LEDs:

● LED lit green: Link established, no data transmission

● LED flashes green or amber: Link established, data transfer in progress

You can find information about other possible LED states in the following document:

Operating instructions "SCALANCE X-200"

(https://support.industry.siemens.com/cs/ww/en/view/102051962

)

Connecting the connection box (Page 59)

This section describes the system components in the scope of delivery that you need for

operating a Mobile Panel 2nd Generation.

● 1 Mobile Panel or fail-safe Mobile Panel

● 1 DVD with documentation and product information

● 1 "Mobile Panels 2nd Generation" Quick Install Guide

The scope of delivery may contain additional documents.

● 1 Connection box compact

● 1 DVD with documentation and product information

● 1 Accessory kit with mounting clips

● 1 Installation instruction

The scope of delivery may contain additional documents.

● 1 Connection box

● 1 DVD with documentation and product information

● 1 Installation instruction

The scope of delivery may contain additional documents.

● 1 Connecting cable with terminal compartment cover with four screws

● 1 Cable retainer with screw

Mobile Panels 2nd Generation

20 Operating Instructions, 09/2018, A5E33876626-AC

Overview

1.6

Accessories

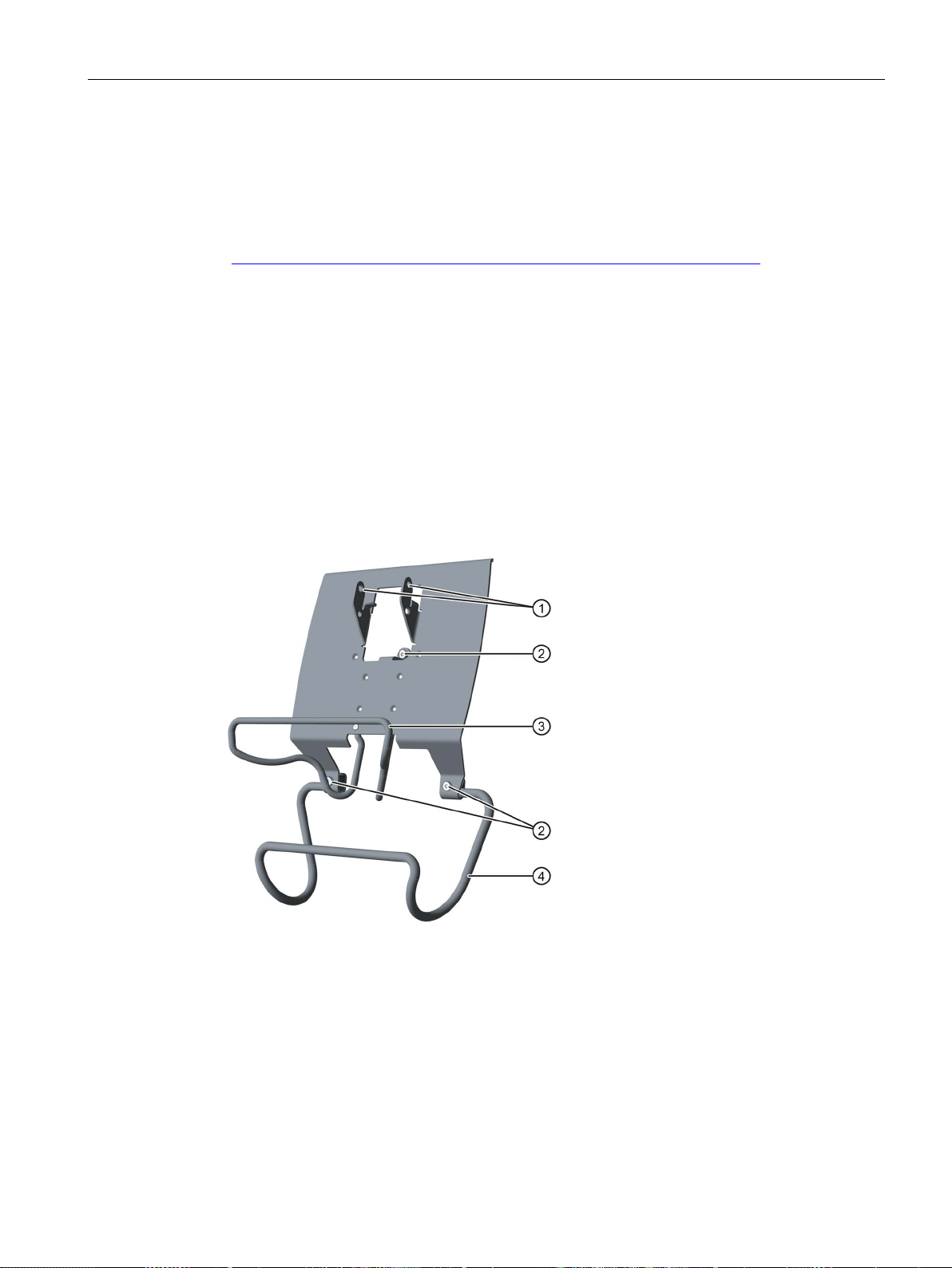

1.6.1

KTP Mobile wall-mounting bracket

①

Hooks for the handle on the Mobile Panel

②

Screw flange

③

Safety bar for the Mobile Panel

④

Holding bracket for the connecting cable

1.6 Accessories

Accessories are not included in the scope of delivery but can be ordered from the following

address:

HMI accessories

(https://mall.industry.siemens.com/mall/en/WW/Catalog/Products/10144445

In the Industry Mall you can find the following accessories for the HMI devices of type KTP

Mobile, for example:

● KTP Mobile wall-mounting bracket

● KTP Mobile spare key

● Memory card

● Protective film

The wall-mounting bracket holds the Mobile Panel securely in place during stationary

operation.

)

The assembly of the KTP Mobile wall-mounting bracket is described in the section

"Assembling the KTP Mobile wall-mounting bracket (Page 47)".

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

21

Overview

1.6.2

Fail-safe KTP Mobile spare key

1.6.3

Protective films

1.6.4

Storage media

1.6 Accessories

The KTP Mobile spare key is part of the keyswitch for the fail-safe Mobile Panel 2nd

Generation. See section "Keyswitches, function keys and illuminated pushbuttons

(Page 79)".

The protective film prevents the touch screen from getting scratched and dirty during

operation. One set of protective film contains 10 protective films.

● Protective film 4" touch devices, type 13

● Protective film 7" touch devices, type 13

● Protective film 9" touch devices, type 13

You can use the storage media to back up Mobile Panel data and copy data to the Mobile

Panel. Use the following storage media:

● SIMATIC HMI Memory Card

Siemens AG has approved the use of SD memory cards in the Mobile Panel.

● USB flash drive

The USB flash drive must be suitable for industrial applications. The storage medium is

inserted in the port on the left of the device.

Mobile Panels 2nd Generation

22 Operating Instructions, 09/2018, A5E33876626-AC

Overview

1.6.5

SIRIUS safety relays

Note

Evaluation of the safety-related operator controls via F-DI modules

Instead of a SIRIUS safety relay, F

The F

SIL/performance level and category. Depending on the safety integrity level SIL/performance

level and category required, the following functions are, for example, to be used for the F

modules:

•

•

•

•

The plant operator/system engineer is resp

hardwired F

DI modules.

See also

1.6 Accessories

If you are using a fail-safe Mobile Panel in a hardwired F system, you must use a safety

relay.

The Mobile Panels 2nd Generation have been tested with the following safety relays and

approved:

● SIRIUS safety relay, standard, relay output

article number 3SK1111-1AB30

● SIRIUS safety relay, standard, electronic output

article number 3SK1112-1BB40

● SIRIUS safety relay, advanced, relay output

article number 3SK1121-1AB40

● SIRIUS safety relay, advanced, electronic output

article number 3SK1122-1AB40

You can find the complete portfolio of the SIRIUS 3SK safety relays on the Internet

(http://www.siemens.com/product?3SK

).

-DI modules used must be appropriate for the required safety integrity level

Short- and cross-circuit monitoring

Discrepancy monitoring

Short-circuit detection

Cross-circuit detection

-system with evaluation of the safety-related operator controls via one or more F-

FAQs Mobile Panels 2nd Generation

(https://support.industry.siemens.com/cs/ww/en/ps/14746/faq

-DI modules can be used for the evaluation.

-DI

onsible for checking the proper functioning of the

)

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

23

Overview

1.7

Software required

Configuration software

KTP700 Mobile, KTP700F Mobile, KTP900 Mobile, KTP900F Mobile

KTP400F Mobile

See also

1.8

Terms for fail-safe operation

1.7 Software required

You need one of the following software products to configure the HMI devices:

● WinCC Comfort V13 SP1 Update 4 or higher

● WinCC Advanced V13 SP1 Update 4 or higher

To operate a fail-safe Mobile Panel in a PROFIsafe-based F-system, you need the optional

package STEP 7 Safety Advanced V13 SP1 or higher.

You need one of the following software products to configure the KTP400F Mobile:

● WinCC Comfort V13 SP1 Update 6 or higher

● WinCC Advanced V13 SP1 Update 6 or higher

You also need the HSP0168 HMI KTP400F Mobile V1.0 or higher.

To operate a KTP400F Mobile in a PROFIsafe-based F-system, you need the optional

package STEP 7 Safety Advanced V13 SP1 or higher.

Configuring a fail-safe Mobile Panel (Page 170)

This section defines terms relating to fail-safe operation with a fail-safe HMI device.

You can find additional information on the topic of "Safety" in the following document:

"SIMATIC Safety - Configuring and Programming" programming and operating manual

(http://support.automation.siemens.com/WW/view/en/54110126

)

Mobile Panels 2nd Generation

24 Operating Instructions, 09/2018, A5E33876626-AC

Overview

Fail-safe automation system, F system

Safe operating state

1.8 Terms for fail-safe operation

A fail-safe automation system is required in a plant with high safety requirements.

An F-system is characterized by the following features:

● Safety-related shutdown response of the system after the triggering of a stop or

emergency stop via a safety-related operator control.

● The confirmation of machine movements entailing danger via an enabling mechanism.

The following F-systems iIn conjunction with a fail-safe Mobile Panel are distinguished in this

document:

● Hardwired F-system: The safety-related operator controls are wired to a safety relay. If

one of the safety-related operator controls is activated, the safety relay triggers the safe

state or confirms a machine movement entailing danger in the F-system via the enabing

button.

● PROFIsafe-based F-system: The signals of the safety-related operator controls are

transmitted to the F-system via PROFIsafe.

Safety-related devices with fail-safe controllers communicate with PROFIsafe via

PROFINET to enable these devices to be used in fail-safe automation systems up to

SIL3. PROFIsafe implements safety-related communication with a special user data

format and a special protocol. PROFIsafe is specified for PROFINET in the standard IEC

61784-3.

If an unexpected event occurs during plant operation that poses a risk to persons or

equipment, the plant must respond with a defined safety shutdown. Protection of personnel

against physical injury can only be ensured if intervention in manufacturing processes, for

example during retrofitting or troubleshooting, is safe and secure.

Based on the risk analysis, the safety shutdown and therefore the shutdown response of the

plant must therefore be configured to ensure that the plant or plant area can be switched to a

safe operating state in the event of a risk.

In addition to the qualitative risk analysis required, the machine operator also has an

obligation to make a quantitative assessment of potential hazards. On this basis, the

operator must then establish what risks could arise during plant or plant area operation and

whether the relevant safety functions are sufficiently effective for the hazard in question.

The safe operating state is assigned to the fail-safe controller by a safety program. The plant

constructor is responsible for the required configuration which should be described in the

plant documentation.

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

25

Overview

Safety-related operator controls

Fail-safe operation

Emergency stop, stop

1.8 Terms for fail-safe operation

A fail-safe Mobile Panel comes equipped with the two safety-related operator controls

"Emergency stop / stop button" and "Acknowledgment button". All other operator controls are

not safety-related operator controls.

In a hardwired or PROFIsafe-based F-system, you operate the plant or a plant section in failsafe mode. In fail-safe mode, the safety-related operator controls emergency stop/stop

button and enabling buttons are active.

● For a hardwired F-system: Fail-safe mode runs via a fixed connection with a safety relay.

● In a PROFIsafe-based F-system: The HMI device in fail-safe mode detects the signals of

the "emergency stop / stop button" and "enabling button" safety-related operator controls;

communication with the F-system is performed via PROFIsafe.

When configuring the safety functions with the STEP 7 Safety Advanced optional

package, fail-safe operation according to SIL 3 or Performance Level e and Category 4 is

possible with an HMI device of the type KTPx00F Mobile.

The safety-related operator controls can be configured as fail-safe inputs in the safety

program.

The operator presses the emergency stop / stop button to activate either an emergency stop

or a stop.

● The emergency stop is an emergency action that is intended to stop a process or

movement entailing danger. All machines that are assigned to the trigger are immediately

brought to a safe state via the emergency stop.

● The emergency stop / stop button of the HMI device brings about a safety-related stop of

the plant or machine in accordance with EN 60204-1, Section 9.2.5.3.

Whether the emergency stop / stop button causes an "emergency stop" or "stop" function

must be decided upon and configured on the basis of the risk assessment.

Mobile Panels 2nd Generation

26 Operating Instructions, 09/2018, A5E33876626-AC

Overview

Safety-related operating mode

stop button

emergency stop

button

emergency stop

button

Emergency stop / stop bypass

PROFIsafe communication, logon and logoff in the safety program

Mobile Panel logon

1.8 Terms for fail-safe operation

In fail-safe mode, you can use the HMI device in combination with a connection box in one of

the following operating modes:

● Stop button evaluated by safety relay

This operating mode is intended for a hardwired F-system. The signals of the safetyrelated operator controls are wired to a safety relay. If you press the

emergency stop / stop button, the plant typically responds with a stop.

The emergency stop / stop button does not light up.

In this operating mode, the emergency stop / stop button is called the

● E-stop button evaluated by safety relay

This operating mode is intended for a hardwired F-system. The signals of the safetyrelated operator controls are wired to a safety relay. When you press the emergency stop

/ stop button, the plant responds with an emergency stop.

The emergency stop / stop button lights up when active.

In this operating mode, the emergency stop / stop button is called the

.

● E-stop button evaluated by PROFIsafe

This operating mode is intended for a PROFIsafe-based F-system. If you press the

emergency stop / stop button, an emergency stop is triggered in the plant.

The emergency stop / stop button lights up when active, that is, if the HMI device has

been registered in the safety program.

In this operating mode, the emergency stop / stop button is called the

.

.

The emergency stop / stop bypass is a function of the connection box advanced for

hardwired F-systems.

The function ensures that no stop or emergency stop will be triggered in the plant when

reconnecting the Mobile Panel to another connection box.

The following applies in a PROFIsafe-based F-system for the logon and logoff of the fail-safe

Mobile Panel to a safety program:

If you have connected the fail-safe HMI device with a connection box and started the HMI

project, the HMI device is automatically logged onto the safety program. After logon, the failsafe HMI device is integrated into PROFIsafe communication and the emergency stop button

and enabling button become active.

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

27

Overview

Mobile Panel logoff

Connection point recognition

1.9

Organizational measures

Measures

1.9 Organizational measures

Before disconnecting the fail-safe HMI device from a connection box, you must log off the

HMI device using an appropriate operator control of the safety program or close the current

project. Logoff must be confirmed in a dialog. When you log off, the HMI device is removed

from PROFIsafe communication. After logging off, the emergency stop button and enabling

button are no longer active. You can therefore disconnect the HMI device from the

connection box.

For the HMI devices KTP700F Mobile and KTP900F Mobile: If you logged off the HMI device

without closing the project from the safety program, the project remains active on the HMI

device for the duration of the backup time and you can plug the HMI device into another

connection box. After plugging into another connection box and automatic logon to the safety

program, you can continue working with the current project in fail-safe mode.

If you disconnect the fail-safe Mobile Panel without logging off the connection box, a

PROFIsafe communication error occurs and the plant goes into safe operating mode

according to the configured shutdown behavior.

The connection point recognition is a function that you can configure for connection boxes.

Once you have configured connection point recognition, you can determine the plant area in

which an HMI device is connected and the connection box used for this. This provides the

following functions, for example:

● Display of screens on the HMI device for specific plant areas

● Emergency stop / stop for specific plant areas

If you are using a fail-safe Mobile Panel in a fail-safe system, you must consider the

following organizational measures:

● Install stationary emergency stop or emergency off buttons in the plant that are effective

independent of the Mobile Panel.

● Perform a risk assessment of the plant.

● If the overall plant is not to be monitored from a single location, configure plant areas.

● Select the same operating mode for all connection boxes in a contiguous plant area.

● Create a safety program.

● Run an acceptance test on the fail-safe automation system.

Mobile Panels 2nd Generation

28 Operating Instructions, 09/2018, A5E33876626-AC

Overview

F-systems

Connection box

PROFIsafe-

based F-system

Hardwired F-system, no

emergency stop/stop bypass

Hardwired F-system with

emergency stop/stop bypass

compact

Yes

Yes

No

advanced

Yes

No

Yes

safety relay

safety relay

1.10

Mobile Panel and connection box compatibility

Ccompatibility of Mobile Panels 2nd Generation – connection box PN Basic and PN Plus

1.10 Mobile Panel and connection box compatibility

The table below shows the F-systems that can be configured or installed for a given

connection box. Requirement is that you are using a fail-safe Mobile Panel.

standard Yes Yes No

Safety-related

operating mode

E-stop button

evaluated by

PROFIsafe

Stop button evaluated by

safety relay

E-stop button evaluated by

Stop button evaluated by

safety relay

E-stop button evaluated by

This section addresses the following compatibility:

● Ccompatibility of Mobile Panels 2nd Generation to connection box PN Basic and PN Plus

● Ccompatibility of Mobile Panels 1st Generation to connection boxes compact, standard

und advanced

The Mobile Panels 2nd Generation are not compatible with the connection box DP Basic and

connection box DP Plus.

The 2nd Generation Mobile Panels are compatible with the following connection boxes:

● Connection box PN Basic, article number 6AV6671-5AE01-0AX0

● Connection box PN Plus, article number 6AV6671-5AE11-0AX0

Mobile Panels 2nd Generation

Operating Instructions, 09/2018, A5E33876626-AC

Restrictions:

● Only one hardwired F-system with a stop function and enabling function is permitted.

● PROFINET communication is possible with the connection boxes PN Basic and PN Plus,

a PROFIsafe -based F-system is not feasible.

● Note the reduced maximum permissible amperage for the acknowledgment button circuit

in the technical specifications, section "Connection boxes (Page 236)".

29

Overview

Compatibility of Mobile Panels 1st Generation – connection boxes of the Mobile Panel 2nd

Generation

1.10 Mobile Panel and connection box compatibility

You can use the connection box compact, the connection box standard and the connection

box advanced with the following predecessor devices:

● Mobile Panel 177 PN

Article numbers 6AV6645-0BA01-0AX0, 6AV6645-0BB01-0AX0, 6AV6645-0BC01-0AX0

● Mobile Panel 277 8"

Article numbers 6AV6645-0CA01-0AX0, 6AV6645-0CB01-0AX0, 6AV6645-0CC01-0AX0

● Mobile Panel 277 10"

Article number 6AV6645-0BE02-0AX0

Restrictions:

● Only one hardwired system F-system with a stop function and enabling function is

permitted with a Mobile Panel 1st Generation.

● PROFIsafe communication is not possible with predecessor devices, therefore a

PROFIsafe -based F-system is not feasible.

● The "Mobile Panel inserted" signal is not available on the connection boxes of the Mobile

Panel 2nd Generation.

● The "Control" signal is not available on the connection boxes of the Mobile Panel 2nd

Generation.

Mobile Panels 2nd Generation

30 Operating Instructions, 09/2018, A5E33876626-AC

Loading...

Loading...