Siemens SIMATIC HMI KTP700 Basic, SIMATIC HMI KTP900 Basic, SIMATIC HMI KTP1200 Basic DP, SIMATIC HMI KTP700 Basic DP, SIMATIC HMI KTP1200 Basic Basic Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC HMI

HMI devices

Basic Panels 2nd Generation

Operating Instructions

10/2016

A5E33293231

Preface

Overview

1

Safety instructions

2

Mounting and connecting

3

Operating the device

4

Configuring the device

5

Commissioning a project

6

Maintenance and care

7

Technical specifications

8

Technical Support

A

Abbreviations

B

-AB

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E33293231-AB

Ⓟ

Copyright © Siemens AG 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

11/2016 Subject to change

Preface

Purpose of the operating instructions

Target group

Chapter

All

Operators

the process control phase.

Commissioning engineers

section "Maintenance and servicing."

Service technicians

"Maintenance and servicing."

Maintenance technicians

maintenance work during the process control phase.

These operating instructions provide information based on the requirements defined by

IEC 62079 for documentation. This information relates to the HMI device, its storage,

transportation, place of use, installation, use and maintenance.

These operating instructions are intended for a variety of target groups. The following table

shows the chapters of these operating instructions that are of particular importance for the

respective target group.

"Safety instructions"

The operator operates and monitors the system during

"Overview"

"Operating the device"

The commissioning engineer integrates the HMI device

into the system and ensures the operating capability of

the HMI device for the process control phase.

Service technicians rectify faults that occur during the

process control phase.

Maintenance technicians carry out servicing and

The information system of WinCC contains additional information. The information system is

integrated as online help in WinCC and contains instructions, examples and reference

information in electronic form.

All chapters.

Depending on the use of the HMI device,

certain chapters may not be of relevance to

the commissioning engineer, e.g. the

All chapters.

Depending on the use of the HMI device,

certain chapters may not be of relevance to

the service technicians, e.g. the section

Maintenance and care

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

3

Preface

Scope

Device designation

SIMATIC HMI

Device type

Interface type

Can be configured with

KTP400 Basic

PROFINET

KTP700 Basic DP

PROFIBUS

KTP900 Basic

PROFINET

KTP1200 Basic

PROFINET

KTP1200 Basic DP

PROFIBUS

1

higher.

Basic knowledge required

These operating instructions are valid for all versions of the SIMATIC HMI Basic Panels. The

following naming conventions apply:

KTP700 Basic PROFINET

Devices are configurable as of WinCC V13. The description in this manual relates to V14 or

Knowledge of automation technology and process communication is necessary to

understand the operating instructions.

An understanding of the use of computers and operating systems is also required.

Touch device with

function keys

WinCC (TIA Portal) as of V13 1

Basic Panels 2nd Generation

4 Operating Instructions, 10/2016, A5E33293231-AB

Preface

Illustrations and text highlighting

Graphical highlighting

Description

in the figures as a representation of

Text highlighting

Scope

commands

<F1>

Keyboard operation

This manual contains figures of the described devices. The figures may deviate from the

supplied device in certain details.

The following graphical highlighting facilitates reading these operating instructions:

If the instructions involve several

tasks, the individual tasks are

highlighted by a red number circle.

A light blue highlight indicates

components and tools that are

required in the course of a task.

KTP700 Basic is sometimes shown

all Basic Panels.

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

The following text highlighting facilitates reading these operating instructions:

"Add screen"

"File > Edit" Operational sequences, for example, menu commands, shortcut menu

• Terms that appear in the user interface, for example, dialog names, tabs,

buttons, menu commands

• Input values, for example, limits, tag values

• Path information

5

Preface

Note

A note contains important information on described products and their handling or on a

section of this documentation.

Names of the software

Names of the hardware

Trademarks

Note information highlighted as follows:

Configuration and runtime software have different names as follows:

● "WinCC (TIA Portal) V13", for example, refers to the configuration software.

The term "WinCC" is used in a general context. The full name is always used when it is

necessary to differentiate between different versions of the configuration software.

● "WinCC Runtime" refers to the runtime software that can run on HMI devices.

These operating instructions describe the new "Basic Panels 2nd Generation" which

replaces the current Basic Panels. The term "Basic Panel" is used synonymously for a

"Basic Panel 2nd Generation" in these instructions.

Names labeled with a ® symbol are registered trademarks of the Siemens AG. Other names

used in this documentation may be trademarks, the use of which by third parties for their

own purposes could violate the rights of the owner.

®

● HMI

● SIMATIC

● SIMATIC HMI

● WinCC

®

®

®

Basic Panels 2nd Generation

6 Operating Instructions, 10/2016, A5E33293231-AB

Table of contents

Preface ................................................................................................................................................... 3

1 Overview............................................................................................................................................... 11

2 Safety instructions ................................................................................................................................. 17

3 Mounting and connecting ...................................................................................................................... 21

4 Operating the device ............................................................................................................................. 39

1.1 Product overview .................................................................................................................... 11

1.2 Design of the PROFINET devices .......................................................................................... 12

1.3 Design of the PROFIBUS devices .......................................................................................... 13

1.4 Scope of delivery .................................................................................................................... 14

1.5 Accessories ............................................................................................................................. 15

2.1 General safety instructions ..................................................................................................... 17

2.2 Notes about usage .................................................................................................................. 19

3.1 Preparations ............................................................................................................................ 21

3.1.1 Checking the package contents .............................................................................................. 21

3.1.2 Checking the operating conditions .......................................................................................... 21

3.1.3 Selecting a mounting position ................................................................................................. 22

3.1.4 Checking clearances............................................................................................................... 23

3.1.5 Making the mounting cutout .................................................................................................... 24

3.2 Mounting the HMI device ........................................................................................................ 25

3.3 Connecting the HMI device ..................................................................................................... 27

3.3.1 Connection sequence ............................................................................................................. 27

3.3.2 Connecting the equipotential bonding circuit .......................................................................... 28

3.3.3 Connecting the power supply ................................................................................................. 29

3.3.4 Connecting a programming device ......................................................................................... 31

3.3.5 Connecting the configuration PC ............................................................................................ 31

3.3.6 Connecting the controller ........................................................................................................ 33

3.3.7 Connecting a USB device ....................................................................................................... 35

3.4 Switching on and testing the HMI device ................................................................................ 36

3.5 Securing the cables ................................................................................................................ 38

4.1 Overview ................................................................................................................................. 39

4.2 General functions of the screen keyboard .............................................................................. 41

4.3 The screen keyboards ............................................................................................................ 42

4.4 Entering data ........................................................................................................................... 46

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

7

Table of contents

5 Configuring the device .......................................................................................................................... 47

6 Commissioning a project ....................................................................................................................... 73

5.1 Opening the settings .............................................................................................................. 47

5.2 Overview of functions ............................................................................................................. 49

5.3 Save to external storage medium – Backup .......................................................................... 50

5.4 Restore from external storage medium – Restore ................................................................. 51

5.5 Load project from external storage medium .......................................................................... 52

5.6 Update operating system from external storage medium ...................................................... 53

5.7 Changing the IP address and device name of a controller .................................................... 54

5.8 Editing communication connections....................................................................................... 55

5.9 Configuring the time server .................................................................................................... 56

5.10 Enter time and date ................................................................................................................ 57

5.11 Activating the acoustic signal ................................................................................................. 58

5.12 Configuring Autostart or wait time .......................................................................................... 59

5.13 Changing the password settings ............................................................................................ 60

5.14 Displaying licensing information for the HMI device .............................................................. 61

5.15 Displaying information about the HMI device ........................................................................ 62

5.16 Change network settings of PROFINET devices ................................................................... 63

5.17 Change network settings of PROFIBUS devices ................................................................... 64

5.18 Assigning transfer parameters ............................................................................................... 65

5.19 Configure Sm@rt Server ........................................................................................................ 66

5.20 Importing a certificate via USB ............................................................................................... 67

5.21 Displaying and deleting certificates ....................................................................................... 68

5.22 Calibrating the touch screen .................................................................................................. 69

5.23 Changing the monitor settings ............................................................................................... 70

5.24 Setting the screen saver ........................................................................................................ 71

6.1 Overview ................................................................................................................................ 73

6.2 Operating modes.................................................................................................................... 74

6.3 Data transmission options ...................................................................................................... 75

6.4 Transfer .................................................................................................................................. 75

6.4.1 Overview ................................................................................................................................ 75

6.4.2 Starting the manual transfer ................................................................................................... 75

6.4.3 Starting the transfer automatically ......................................................................................... 77

6.4.4 Testing a project..................................................................................................................... 78

Basic Panels 2nd Generation

8 Operating Instructions, 10/2016, A5E33293231-AB

Table of contents

7 Maintenance and care ........................................................................................................................... 95

8 Technical specifications ........................................................................................................................ 97

6.5 Backup and restore ................................................................................................................. 80

6.5.1 Overview ................................................................................................................................. 80

6.5.2 Backup and restore using ProSave ........................................................................................ 81

6.5.3 Backup and restore using WinCC ........................................................................................... 82

6.6 Updating the operating system - Basic Panel DP ................................................................... 83

6.6.1 Overview ................................................................................................................................. 83

6.6.2 Resetting the factory settings ................................................................................................. 84

6.6.3 Updating the operating system using ProSave ...................................................................... 84

6.7 Updating the operating system - Basic Panel with PROFINET interface ............................... 85

6.7.1 Overview ................................................................................................................................. 85

6.7.2 Resetting the factory settings ................................................................................................. 86

6.7.3 Updating the operating system using ProSave ...................................................................... 87

6.7.4 Updating the operating system using WinCC ......................................................................... 88

6.7.5 Resetting to factory settings with ProSave ............................................................................. 89

6.7.6 Resetting to factory settings with WinCC................................................................................ 90

6.8 Reset to factory settings via USB ........................................................................................... 91

6.9 Managing WinCC options ....................................................................................................... 92

6.10 Transferring a license key ....................................................................................................... 93

7.1 Maintenance and care ............................................................................................................ 95

7.2 Recycling ................................................................................................................................ 96

8.1 Certificates and approvals ...................................................................................................... 97

8.2 Electromagnetic compatibility ................................................................................................. 99

8.2.1 Emitted interference ................................................................................................................ 99

8.2.2 Immunity to interferences ....................................................................................................... 99

8.3 Mechanical ambient conditions ............................................................................................... 99

8.3.1 Transport and storage conditions ........................................................................................... 99

8.3.2 Operating Conditions .............................................................................................................. 99

8.4 Climatic ambient conditions .................................................................................................. 100

8.4.1 Long-term storage ................................................................................................................. 100

8.4.2 Transport and short-term storage ......................................................................................... 100

8.4.3 Operating Conditions ............................................................................................................ 101

8.4.4 Climate diagram .................................................................................................................... 101

8.5 Information on insulation tests, protection class and degree of protection........................... 102

8.6 Dimension drawings .............................................................................................................. 103

8.6.1 Dimensional drawing of KTP400 Basic................................................................................. 103

8.6.2 Dimensional drawing of KTP700 Basic................................................................................. 104

8.6.3 Dimensional drawing of KTP700 Basic DP .......................................................................... 105

8.6.4 Dimensional drawing of KTP900 Basic................................................................................. 106

8.6.5 Dimension drawings of KTP1200 Basic................................................................................ 107

8.6.6 Dimensional drawing of KTP1200 Basic DP ........................................................................ 108

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

9

Table of contents

A Technical Support ................................................................................................................................ 119

B Abbreviations ....................................................................................................................................... 121

Glossary .............................................................................................................................................. 123

Index ................................................................................................................................................... 129

8.7 Technical specifications ....................................................................................................... 109

8.7.1 Power supply ........................................................................................................................ 109

8.7.2 KTP400 Basic, KTP700 Basic and KTP700 Basic DP ........................................................ 109

8.7.3 KTP900 Basic, KTP1200 Basic and KTP1200 Basic DP .................................................... 111

8.8 Interface description ............................................................................................................. 113

8.8.1 Power supply ........................................................................................................................ 113

8.8.2 PROFIBUS (Sub-D RS422/485) .......................................................................................... 113

8.8.3 PROFINET (LAN)................................................................................................................. 114

8.8.4 USB ...................................................................................................................................... 114

8.9 Scope of functions with WinCC ............................................................................................ 115

A.1 Service and support ............................................................................................................. 119

A.2 System events...................................................................................................................... 120

Basic Panels 2nd Generation

10 Operating Instructions, 10/2016, A5E33293231-AB

1

1.1

Product overview

The beauty of simplicity

New, cost-efficient HMI generation meets the trend for high-quality visualization even in

small machines and plants

Siemens meets the requirements of users for high-quality visualization and operation even in

small and medium-size machines and plants with the second generation of SIMATIC HMI

Basic Panels. While the price of the new devices is based on the current panels, their scope

of performance has been expanded tremendously. The high resolution and a color depth of

up to 65,500 colors are major factors contributing to the increased performance.

Even the connectivity either by PROFINET or PROFIBUS interface plus USB port could be

significantly improved. Configuration and operation of the new panels has become easier in

connection with simplified programming by means of the new WinCC software version in the

TIA Portal.

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

11

Overview

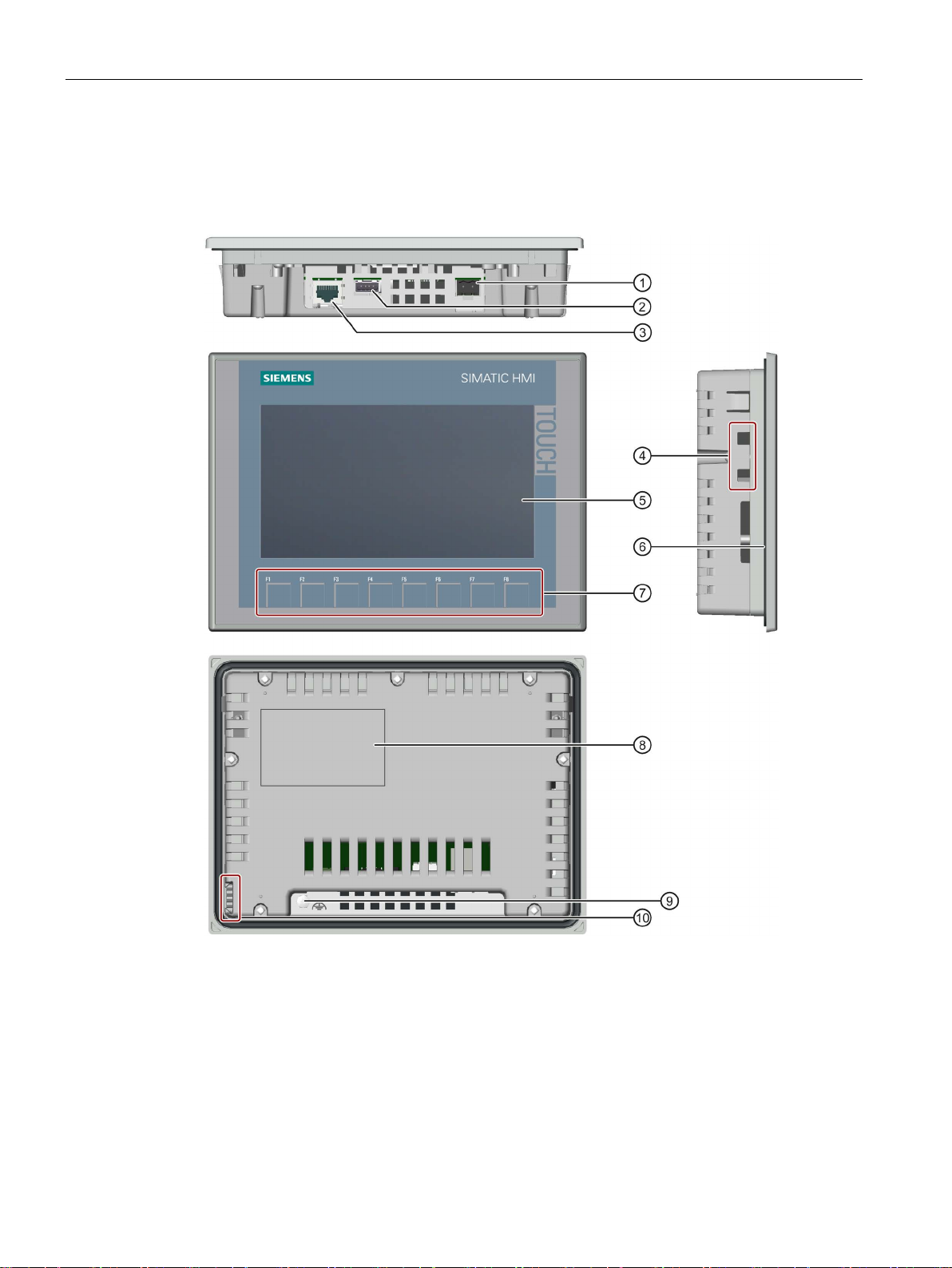

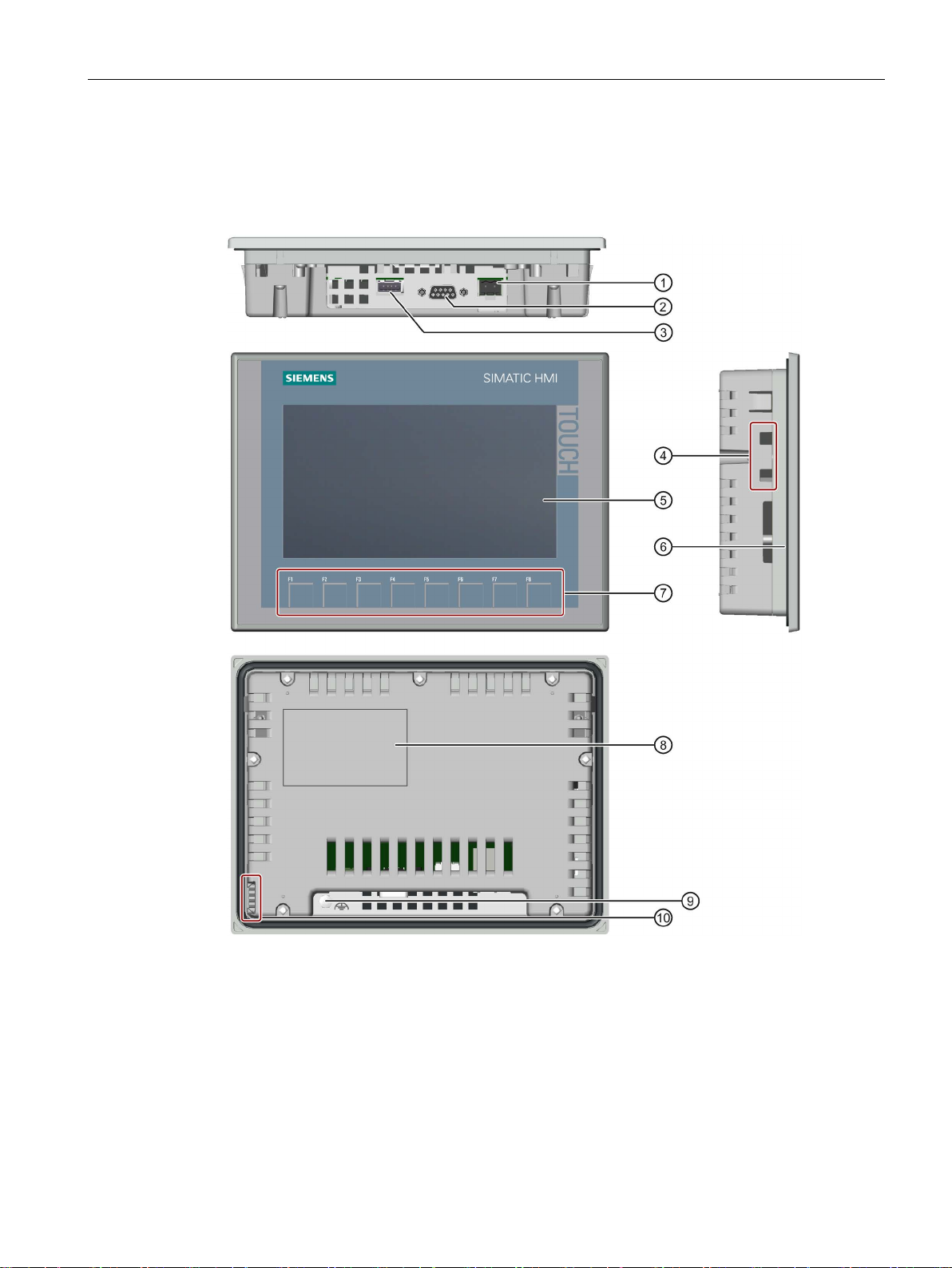

1.2

Design of the PROFINET devices

①

Power supply connection

⑥

Mounting seal

②

USB port

⑦

Function keys

③

PROFINET interface

⑧

Rating plate

④

Recesses for a mounting clip

⑨

Connection for functional ground

⑤

Display/touch screen

⑩

Guide for labeling strips

1.2 Design of the PROFINET devices

The figure below shows the design of the PROFINET devices using KTP700 Basic as an

example.

Basic Panels 2nd Generation

12 Operating Instructions, 10/2016, A5E33293231-AB

Overview

1.3

Design of the PROFIBUS devices

①

Power supply connection

⑥

Mounting seal

②

RS 422/RS 485 port

⑦

Function keys

③

USB port

⑧

Rating plate

④

Recesses for a mounting clip

⑨

Functional earth connection

⑤

Display/touch screen

⑩

Guides for labeling strips

1.3 Design of the PROFIBUS devices

The figure below shows the design of the PROFIBUS devices using KTP700 Basic DP as an

example.

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

13

Overview

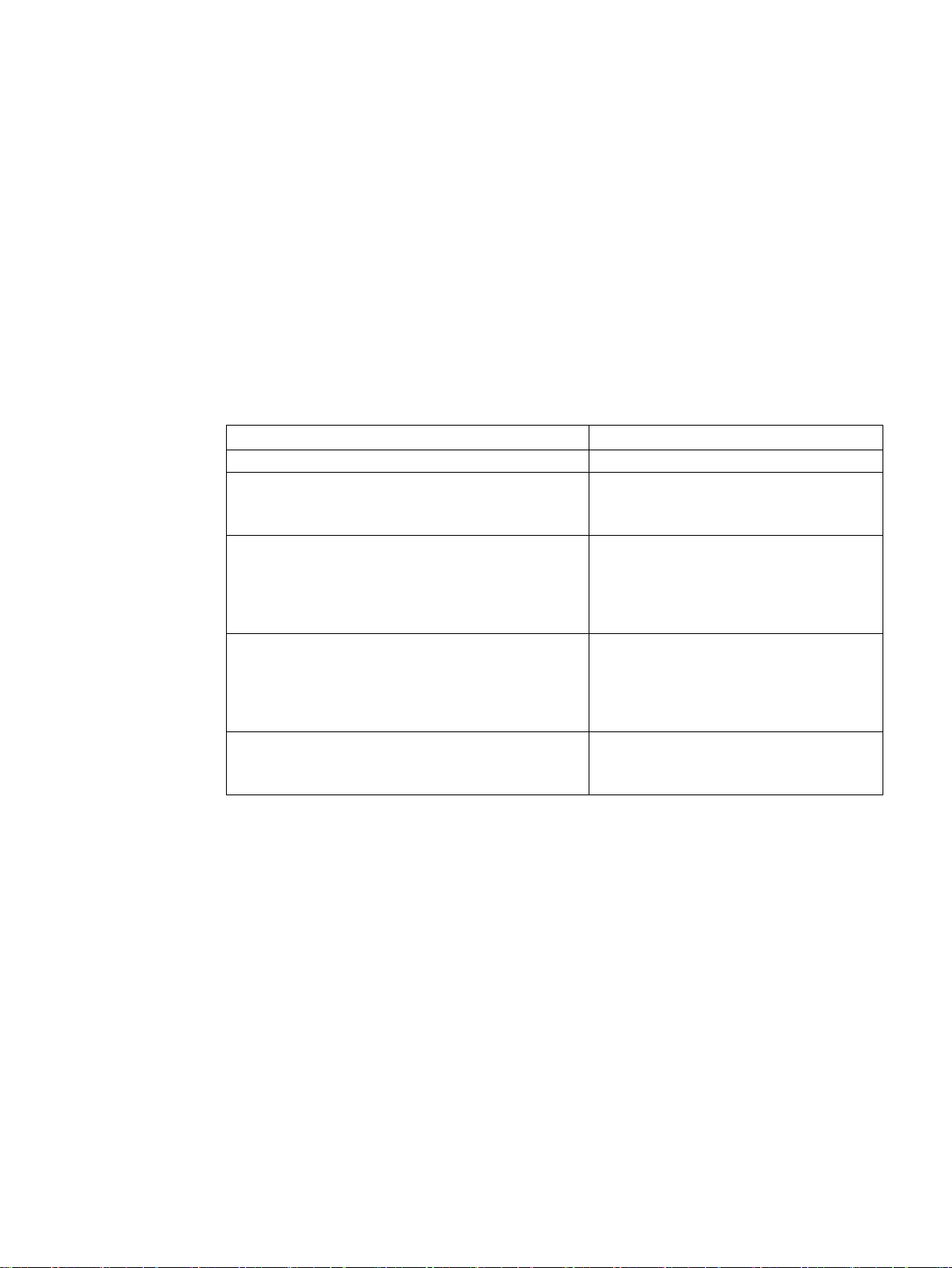

1.4

Scope of delivery

Name

Figure

Quantity

1.4 Scope of delivery

The scope of delivery of the HMI device includes the following components:

HMI device

Quick Installation Guide

Mounting clips with

grub screw

Power supply connector

1

1

According to the quantity required

for mounting, in accessory kit

1, in accessory kit

Basic Panels 2nd Generation

14 Operating Instructions, 10/2016, A5E33293231-AB

Overview

1.5

Accessories

Storage media and I/O devices

Name

Article number

SIMATIC PC USB flash drive

6ES7648-0DC50-0AA0

Converters, adapters and connectors

Name

Purpose

Article number

converter

Basic Panels DP

90 degree elbow adapter

For RS 422/RS 485 port, cable outlet to rear

6AV6671-8XD00-0AX0

straight cable outlet

"IE FC RJ45 Plug 2x2"

Protective films

Name

Purpose

Article number

Protective film 4"

Protective film set for KTP400 Basic

6AV2124-6DJ00-0AX0

KTP700 Basic DP

Protective film 9"

Protective film set for KTP900 Basic

6AV2181-3JJ20-0AX0

KTP1200 Basic DP

Service packages

Name

Article number

Set of 20 mounting clips

6AV6671-8KX00-0AX2

Set of 10 power supply connectors

6AV6671-8XA00-0AX0

1.5 Accessories

Accessories are not included in the HMI device scope of delivery, but can be ordered on the

Internet under Industry Mall (https://mall.industry.siemens.com

).

This section contains the number of accessories available at the time of publication of the

operating instructions.

Industrial USB Hub 4 6AV6671-3AH00-0AX0

RS 422 to RS 232

PROFIBUS connector Recommended PROFIBUS connector with

PROFINET RJ45

connector

Protective film 7" Protective film set for KTP700 Basic and

Protective film 12" Protective film set for KTP1200 Basic and

Connection of third-party controllers to

Required for connection of Basic Panels with

PROFINET interface to PROFINET

6AV6671-8XE00-0AX0

6GK1500-0FC10

6GK1901-1BB10-2AA0

6AV2124-6GJ00-0AX0

6AV2181-3MJ20-0AX0

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

15

Overview

Other accessories

1.5 Accessories

Additional USB accessories can be found on the Internet in the following entry:

FAQ 19188460 (https://support.industry.siemens.com/cs/ww/en/view/19188460

)

Basic Panels 2nd Generation

16 Operating Instructions, 10/2016, A5E33293231-AB

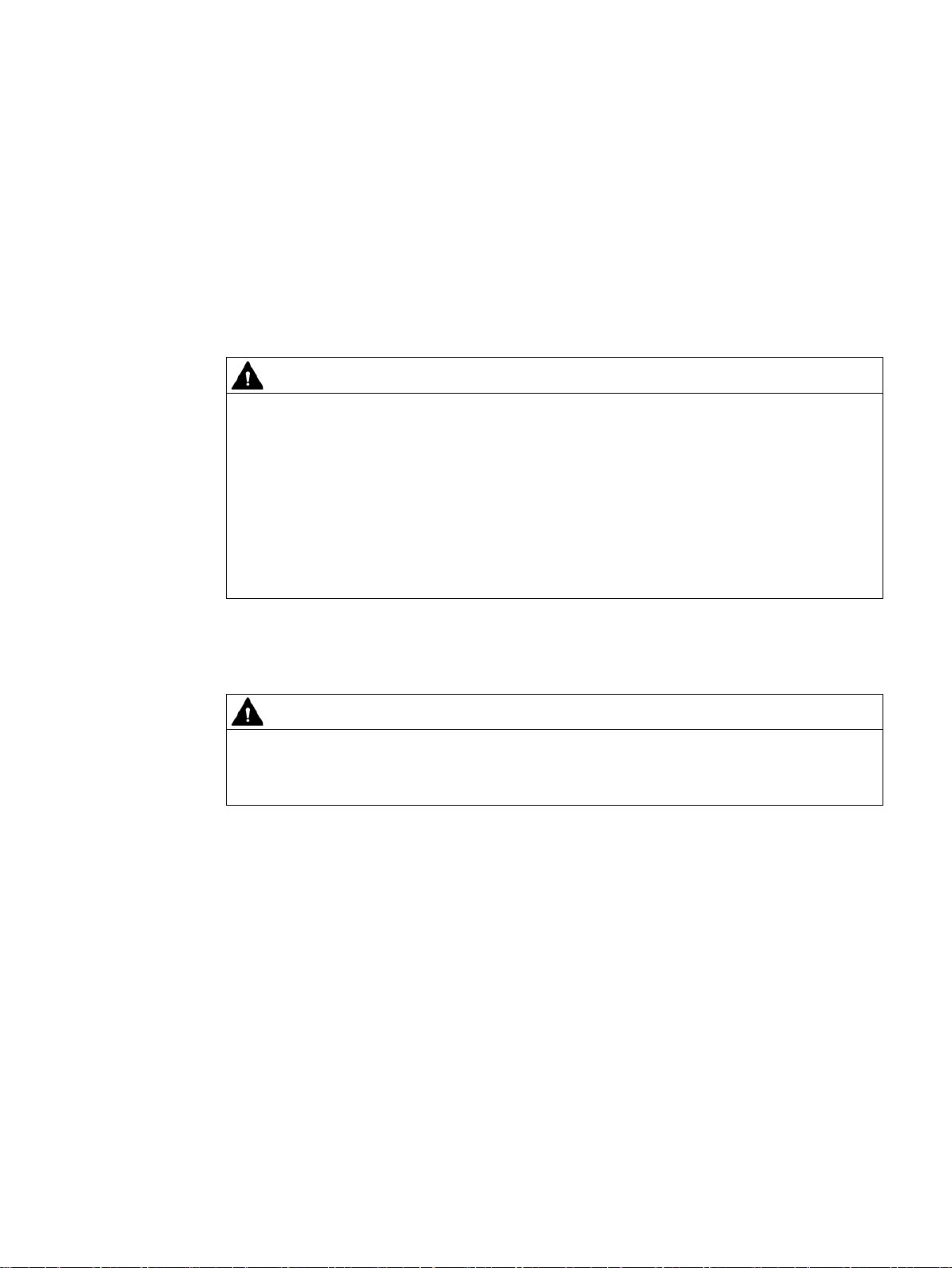

2

2.1

General safety instructions

Working on the control cabinet

WARNING

Open equipment

Dangerous voltage

Installation as intended

WARNING

Installation only in machinery that conforms to the machinery directive

The HMI device is an open equipment. This means the HMI device may only be installed in

cubicles or cabinets that provide front panel access for operating the device.

The cubicle or cabinet in which the HMI device is installed may only be accessed with a key

or tool and only by trained, authorized personnel.

Opening the cabinet will expose high voltage parts. Contact with these parts could be fatal.

Always disconnect the cabinet from the mains before opening it.

You are not permitted to commission the HMI device unless it has been verified that the

machine in which the HMI device is to be installed complies with directive 2006/42/EC.

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

17

Safety instructions

Strong high-frequency radiation

NOTICE

Observe immunity to high-frequency radiation

ESD

Industrial Security

2.1 General safety instructions

The device has an increased immunity to high frequency radiation according to the

specifications on electromagnetic compatibility in the technical specifications.

Radiation exposure in excess of the specified immunity limits can impair device functions

and result in malfunctions and therefore injuries or damage.

Read the information on immunity to high frequency radiation in the technical specifications.

An electrostatically sensitive device is equipped with electronic components. Due to their

design, electronic components are sensitive to overvoltage and thus to the discharge of

static electricity. Note the corresponding regulations when handling ESD.

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity

).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity

).

Basic Panels 2nd Generation

18 Operating Instructions, 10/2016, A5E33293231-AB

Safety instructions

Disclaimer for third-party software updates

Notes on protecting administrator accounts

2.2

Notes about usage

NOTICE

The HMI device is approved for indoor use only.

Industrial applications

Use in residential areas

Note

The HMI device is not intended for use in residential areas. Operation of an HMI device in

residential areas can have a negative influence on radio/TV reception.

2.2 Notes about usage

This product includes third-party software. Siemens AG only provides a warranty for

updates/patches of the third-party software, if these have been distributed as part of a

Siemens software update service contract or officially released by Siemens AG. Otherwise,

updates/patches are undertaken at your own risk. You can find more information about our

Software Update Service offer on the Internet at Software Update Service

http://www.automation.siemens.com/mcms/automation-software/en/software-update-

(

service).

A user with administrator privileges has extensive access and manipulation options in the

system.

Therefore, ensure there are adequate safeguards for protecting the administrator accounts

to prevent unauthorized changes. To do this, use secure passwords and a standard user

account for normal operation. Other measures, such as the use of security policies, should

be applied as needed.

The HMI device may be damaged if it is operated outdoors.

Operate the HMI device indoors only.

The HMI device is designed for industrial applications. It conforms to the following standards:

● Requirements of the emission standard for industrial environments,

EN 61000-6-4: 2007 + A1:2011

● ESD immunity requirements to DIN EN 61000-6-2:2005

If the HMI device is used in a residential area, you must ensure compliance with the limits in

technical standard EN 61000-6-3 regarding the emission of radio frequency interference.

Individual acceptance is required.

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

19

Safety instructions

Use with additional measures

Notes on communication

Note

Communication errors caused by address conflict

Communication errors can occur if several devices in a network share the same bus address

or IP address.

Make sure that your HMI device is assigned a unique address in the network.

Note

Updating tag values following a communication error

If communication between an HMI device and controller is interrupted, all tag values

displayed on the HMI device will be replaced by a hash mark ("#").

When the communication between the HMI device and controller is restored, all tag values

will be u

Ethernet communication with Basic Panels with PROFINET interface

Basic Panels with PROFINET interface support the following types of communication:

•

•

2.2 Notes about usage

The HMI device should not be used at the following locations unless additional measures are

taken:

● In locations with a high degree of ionizing radiation

● In locations with severe operating conditions, for example, due to:

– Corrosive vapors, gases, oils or chemicals

– Strong electrical or magnetic fields of high intensity

● In systems that require special monitoring, for example, in:

– Elevators

– Systems in especially hazardous rooms

pdated immediately. The cycle time for updating the tag values begins again at "0".

PROFINET basic function for commissioning and diagnostics

Standard Ethernet communication

Basic Panels 2nd Generation

20 Operating Instructions, 10/2016, A5E33293231-AB

3

3.1

Preparations

3.1.1

Checking the package contents

Note

Damaged parts

Do not install parts damaged during shipment. In the case of damaged parts, contact your

Siemens representative.

3.1.2

Checking the operating conditions

Check the package content for visible signs of transport damage and for completeness.

The package content is described in section Scope of delivery (Page 14).

Keep the provided documentation in a safe place. The documentation is part of the HMI

device and is required for subsequent commissioning.

Note the information in the following sections of these operating instructions before installing

the HMI device:

● Certificates and approvals (Page 97)

● Electromagnetic compatibility (Page 99)

● Mechanical ambient conditions (Page 99)

● Climatic ambient conditions (Page 100)

● Information on insulation tests, protection class and degree of protection (Page 102)

● Technical specifications (Page 109)

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

21

Mounting and connecting

3.1.3

Selecting a mounting position

NOTICE

Damage due to overheating

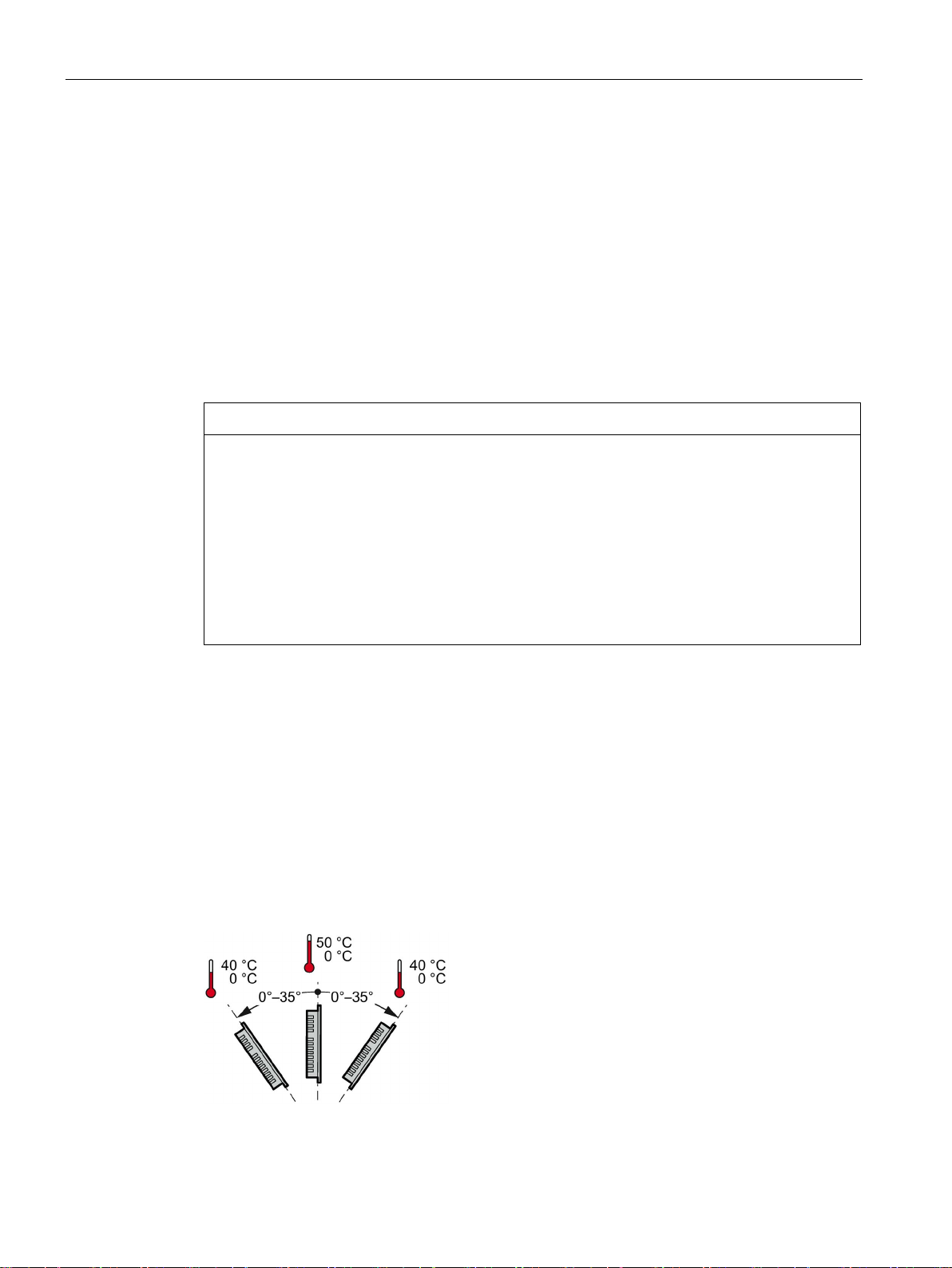

Mounting position

Mounting in horizontal format

3.1 Preparations

The device is suitable for installation in:

● Mounting cabinets

● Control cabinets

● Switchboards

● Consoles

In the following, all of these mounting options are referred to by the general term "cabinet".

The device is self-ventilated and approved for inclined mounting at angles up to +/-35° from

the vertical in stationary cabinets.

Inclined installation reduces the convection by the device and therefore the maximum

permitted ambient temperature for operation.

If there is sufficient forced ventilation, the device can also be operated in the inclined

mounting position up to the maximum permitted ambient temperature for vertical

installation. The device may otherwise be damaged and its certifications and warranty will

be rendered null and void.

The ambient temperature ranges listed in this section apply to the temperature inside the

cabinet.

Select one of the approved mounting positions for your device. The approved mounting

positions are described in the following sections.

Ambient temperature in the cabinet with horizontal mounting:

● Vertical mounting (0° inclined): Maximum +50 °C

● Inclined mounting (inclined up to 35°): Maximum +40 °C

Basic Panels 2nd Generation

22 Operating Instructions, 10/2016, A5E33293231-AB

Mounting and connecting

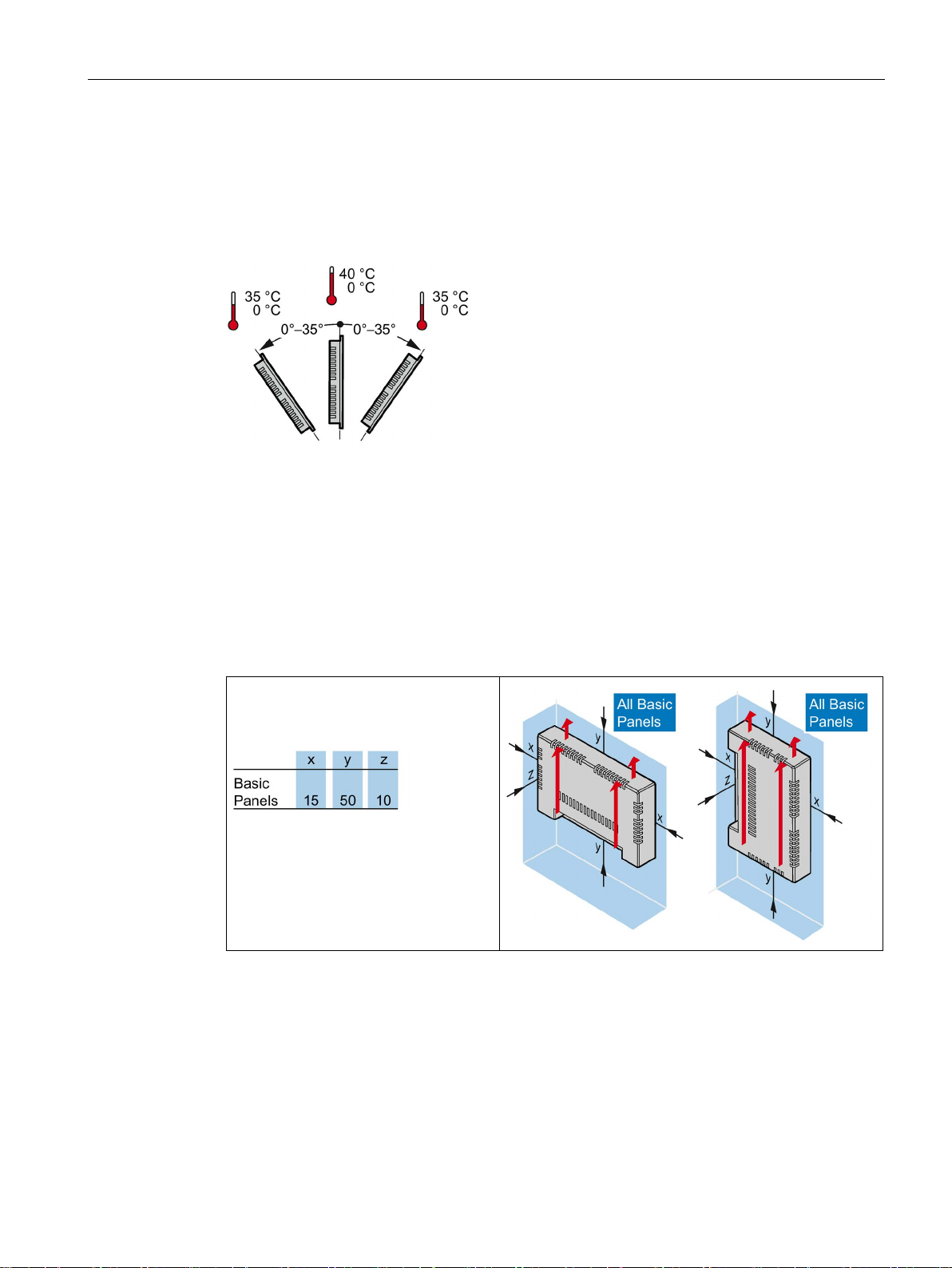

Mounting in vertical format

See also

3.1.4

Checking clearances

3.1 Preparations

Ambient temperature in the cabinet with vertical mounting:

● Vertical mounting (0° inclined): Maximum +40 °C

● Inclined mounting (inclined up to 35°): Maximum +35 °C

Operating Conditions (Page 101)

The following clearances are required around the HMI device to ensure sufficient selfventilation:

Required clearance around the

HMI devices.

All dimensions in mm

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

23

Mounting and connecting

3.1.5

Making the mounting cutout

Note

Stability of the mounting cutout

The material in the area of the mounting

lasting and safe mounting of the HMI device.

To achieve the degrees of protection described below, it must be ensured that deformation

of the material cannot occur due to the force of the mounting clips

Degrees of protection

Mounting compatibility

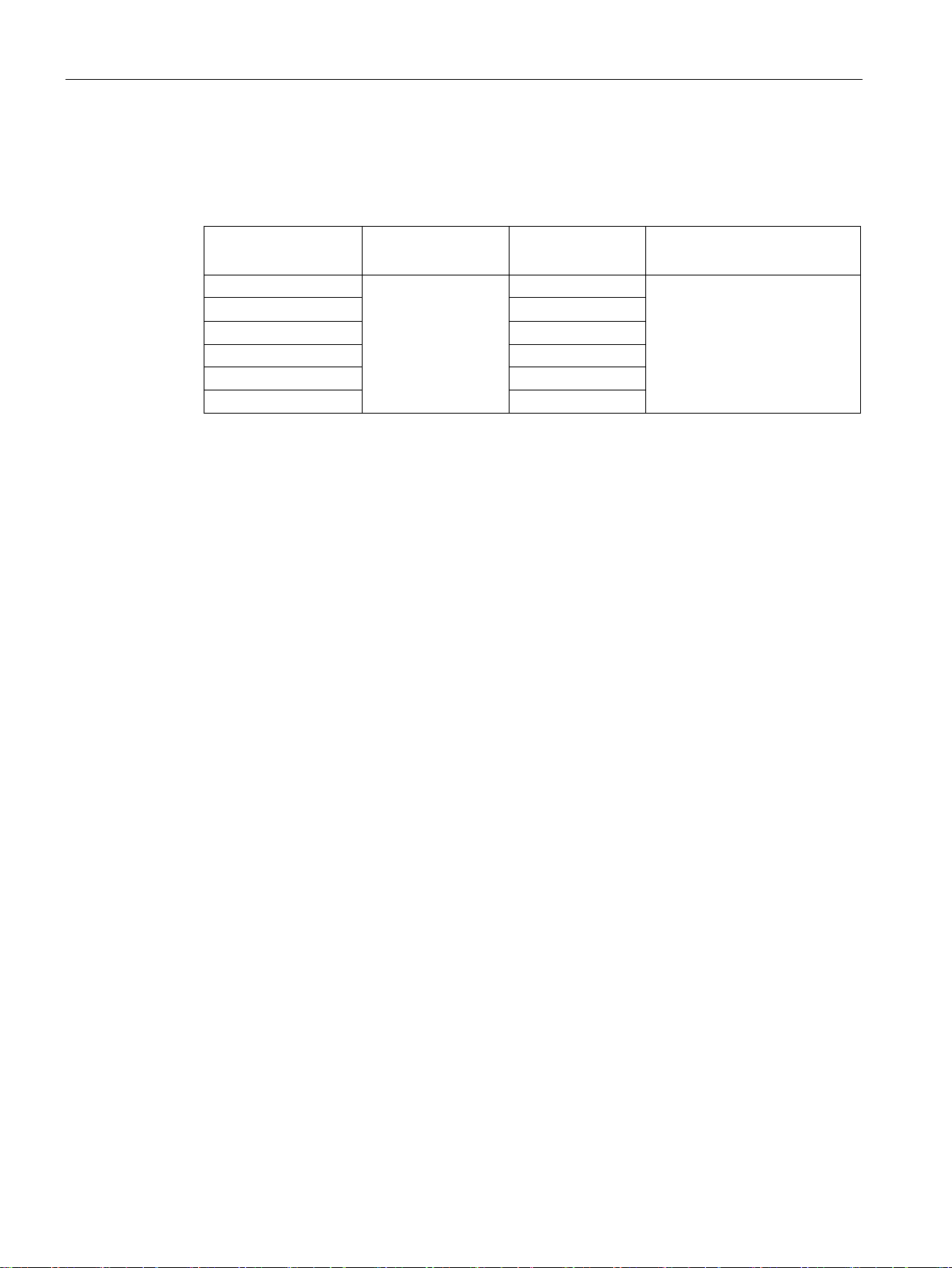

Mounting cutout Basic Panel

Compatible with the mounting cutouts of the HMI device

KTP400 Basic

KTP400 Basic color PN

KTP700 Basic, KTP700 Basic DP

KTP600 Basic color PN; TP700 Comfort

KTP900 Basic

TP900 Comfort

KTP1200 Basic, KTP1200 Basic DP

TP1200 Comfort

3.1 Preparations

cutout must provide sufficient strength to guarantee

or operation of the device.

The degrees of protection of the HMI device can only be guaranteed if the following

requirements are met:

● Material thickness at the mounting cutout for a protection rating of IP65 or Front face only

Type 4X/Type 12 (indoor use only): 2 mm to 6 mm.

● Permitted deviation from plane at the mounting cutout: ≤ 0.5 mm

This condition must be met for the mounted HMI device.

● Permitted surface roughness in the area of the mounting seal: ≤ 120 µm (R

The mounting cutouts of the Basic panels are compatible with the mounting cutouts of the

following SIMATIC HMI devices:

120)

z

Basic Panels 2nd Generation

24 Operating Instructions, 10/2016, A5E33293231-AB

Mounting and connecting

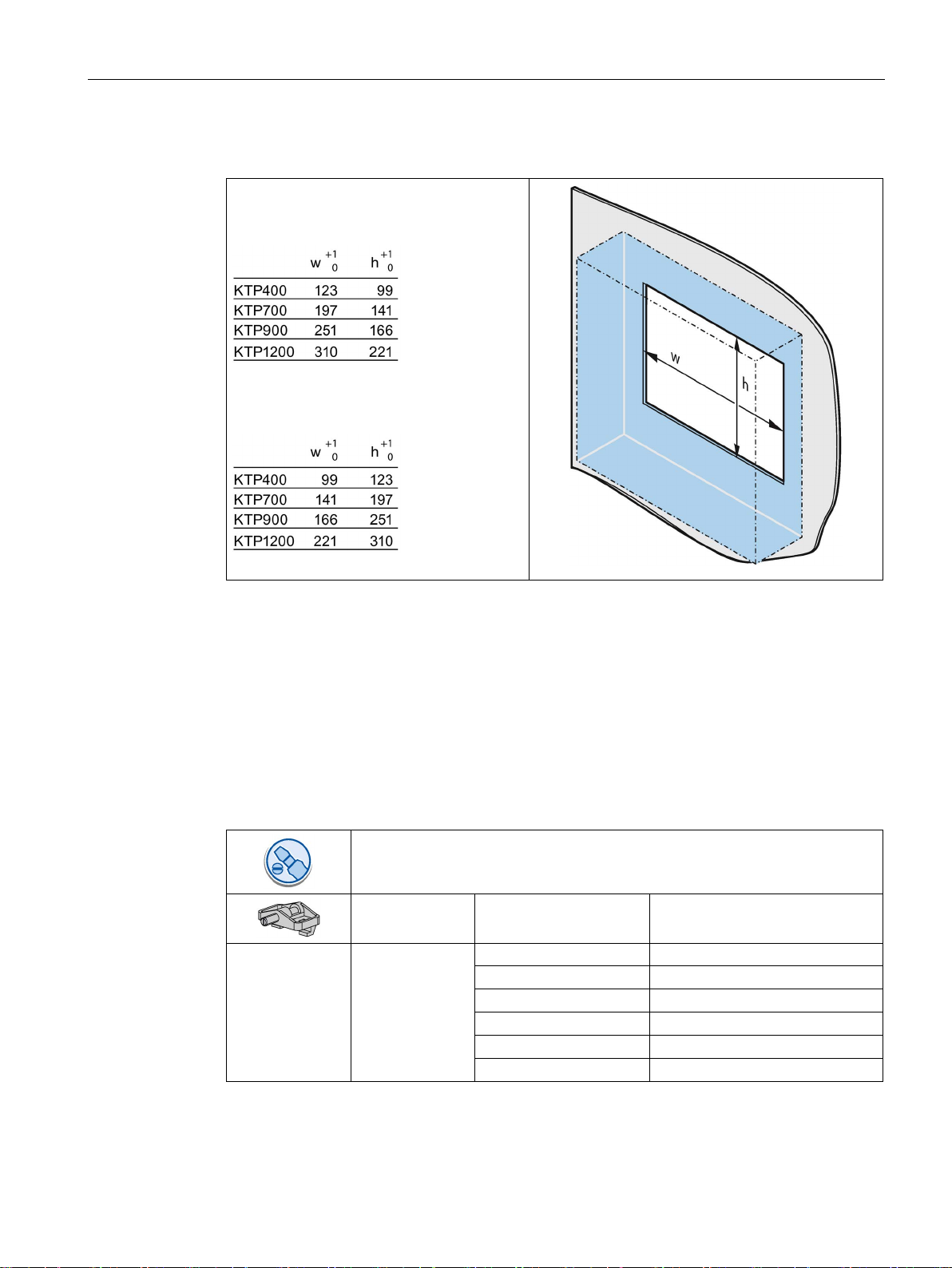

Dimensions of the mounting cutout

All dimensions in mm

See also

3.2

Mounting the HMI device

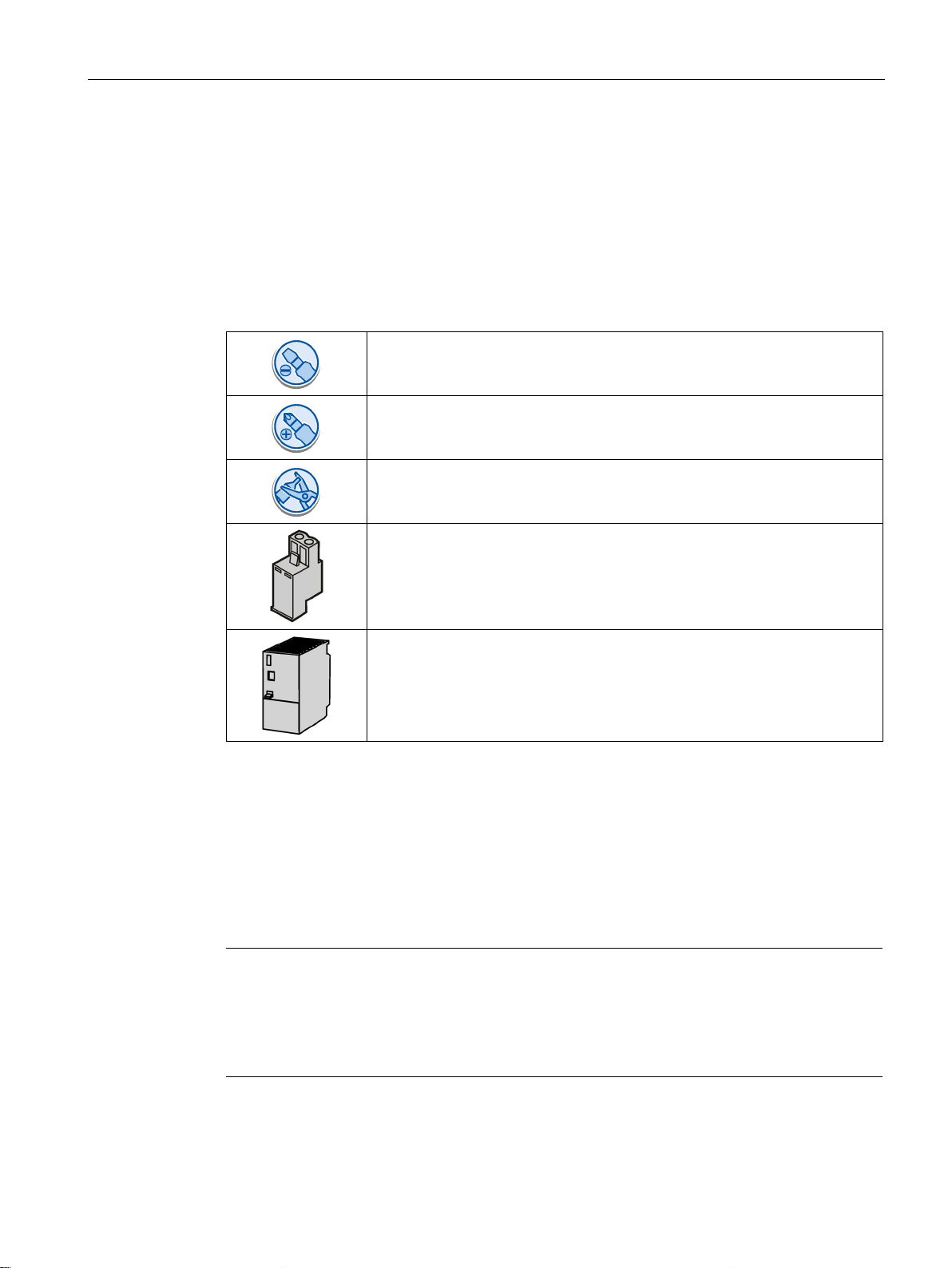

Required tools and accessories

KTP400 Basic

4

KTP700 Basic

7

KTP700 Basic DP

7

KTP900 Basic

10

KTP1200 Basic

12

KTP1200 Basic DP

12

3.2 Mounting the HMI device

Dimensions of the mounting cutout for the

Basic HMI devices in horizontal mounting

position:

Dimensions of the mounting cutout for the

Basic HMI devices in vertical mounting

position:

Accessories (Page 15)

Slotted screwdriver, size 2

Mounting clips for HMI device Required quantity

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

25

Mounting and connecting

Inserting the HMI device

1.

2.

Securing the HMI device with mounting clips

1.

2.

3.

4.

3.2 Mounting the HMI device

Slide the labeling strip

into the device using

the guide, if available.

Insert the HMI device

into the mounting

cutout from the front.

Make sure that

protruding labeling

strips are not caught

between the mounting

cutout and HMI device.

If mounting clips and grub screws are

available separately in the accessory

kit, insert a grub screw into the

mounting clip bore hole and turn it

several times.

Place the first mounting clip into the

corresponding cutout.

Fasten the mounting clip with a size 2

screwdriver. The maximum permitted

torque is 0.2 Nm.

Repeat steps 1 to 3 for all mounting

clips required to secure your HMI

device.

Basic Panels 2nd Generation

26 Operating Instructions, 10/2016, A5E33293231-AB

Mounting and connecting

3.3

Connecting the HMI device

3.3.1

Connection sequence

Required tools and accessories

Procedure

Note

Strain relief

Contacts can be broken or wires

relief.

Provide adequate strain relief for all cables.

See also

3.3 Connecting the HMI device

Before you start connecting the HMI device, have the following tools and accessories at

hand:

Slotted screwdriver, size 2

Phillips screwdriver, size 3

Crimp pliers

Power supply connector

24 V DC with sufficient amperage.

See Technical specifications (Page 109)

Keep to the following sequence of tasks when connecting the HMI device:

1. Connecting the equipotential bonding circuit (Page 28)

2. Connecting the power supply (Page 29)

3. Connecting the configuration PC (Page 31)

4. Connecting the controller (Page 33)

Securing the cables (Page 38)

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

can be torn off if cables are not provided adequate strain

27

Mounting and connecting

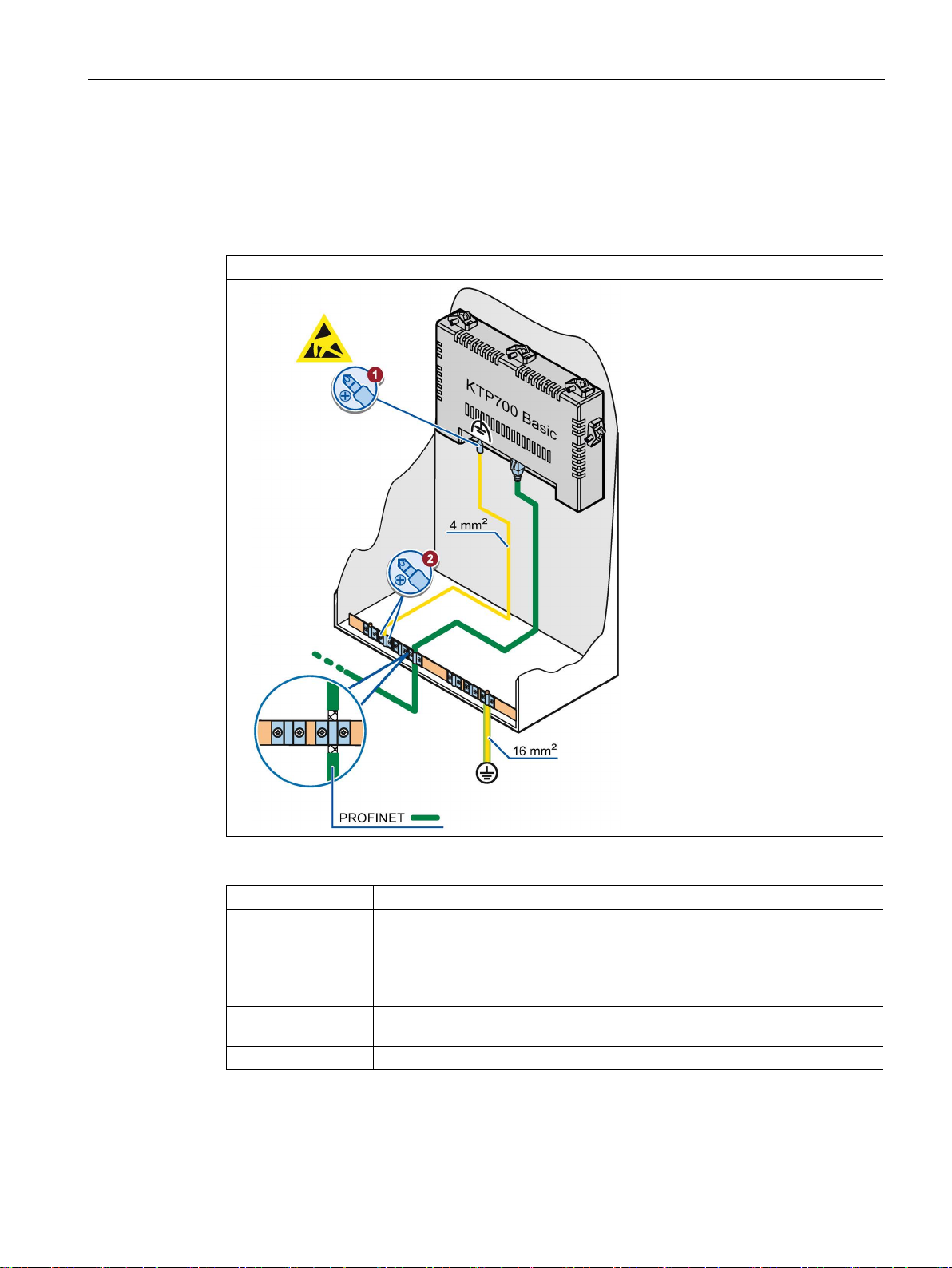

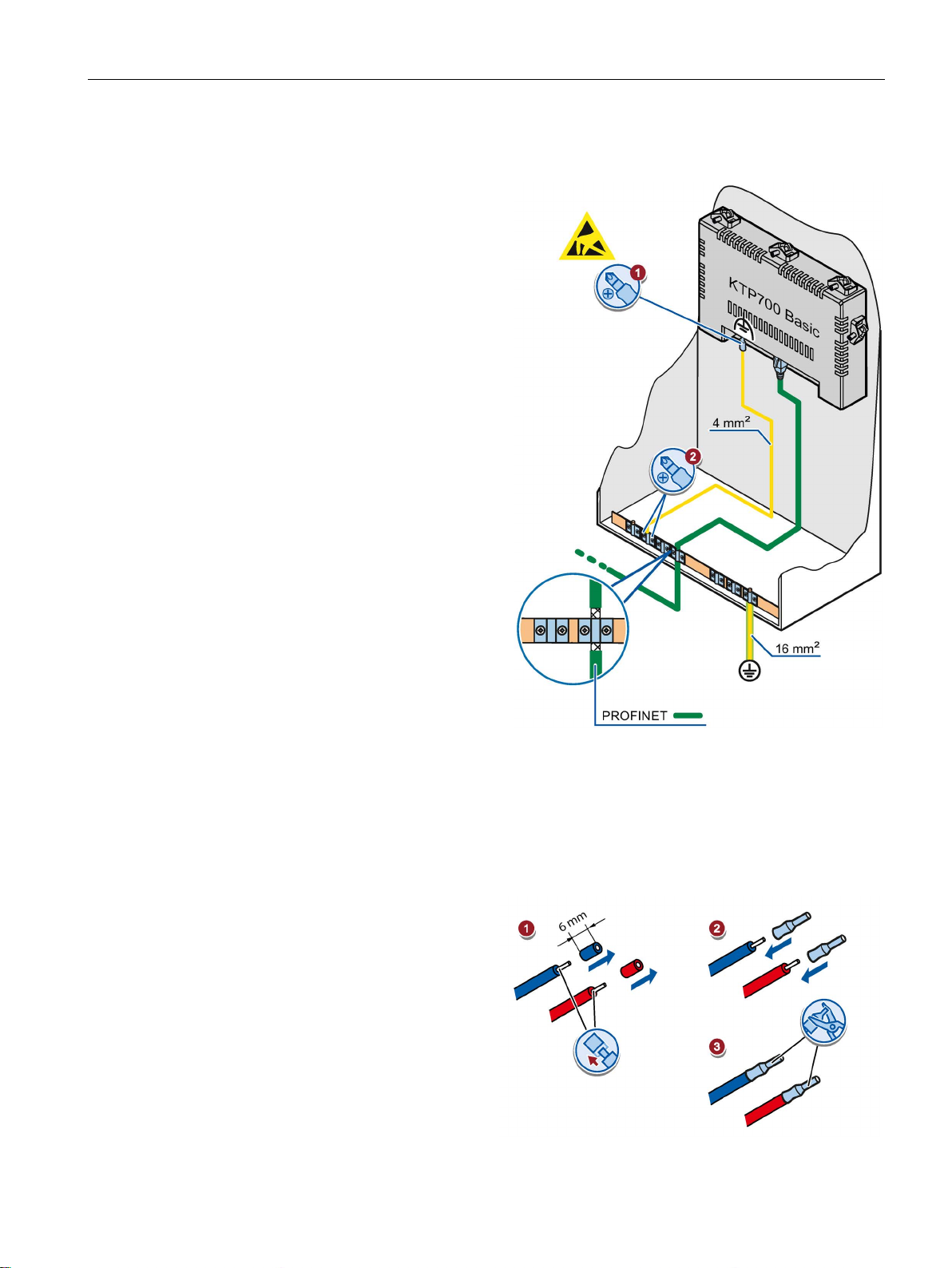

3.3.2

Connecting the equipotential bonding circuit

Differences in electrical potential

General requirements for equipotential bonding

Note

Equipotential bonding conductor

Cable shielding is not suitable for equipotential bonding. Always use the prescribed

equipotential bonding conductors. The cross

must not be less than 16

installing MPI and PROFIBUS DP networks. The interface modules may otherwise be

damaged or destroyed.

3.3 Connecting the HMI device

Differences in electrical potential can develop between spatially separated system

components. Such electrical potential differences can lead to high equalizing currents on the

data cables and therefore to the destruction of their interfaces. Equalizing currents can

develop if the cable shielding is terminated at both ends and grounded to different system

parts.

Differences in potential may develop when a system is connected to different mains

supplies.

Differences in potential must be reduced by means of equipotential bonding conductors to

ensure trouble-free operation of the relevant components of the electronic system. The

following must therefore be observed when installing the equipotential bonding circuit:

● The effectiveness of equipotential bonding increases as the impedance of the

equipotential bonding conductor decreases or as its cross-section increases.

● If two system parts are interconnected by means of shielded data cables and their

shielding is bonded at both ends to the grounding/protective conductor, the impedance of

the additionally installed equipotential bonding conductor must not exceed 10% of the

shielding impedance.

● The cross-section of an equipotential bonding conductor must be capable of handling the

maximum equalizing current. The best practical results for equipotential bonding between

two cabinets have been achieved with a minimum conductor cross-section of 16 mm².

● Use equipotential bonding conductors made of copper or galvanized steel. Establish a

large surface contact between the equipotential bonding conductors and the

grounding/protective conductor and protect them from corrosion.

● Clamp the shielding of the data cable from the HMI device flush at the equipotential rail

using suitable cable clamps. The equipotential rail should be very close to the HMI

device.

● Route the equipotential bonding conductor and data cables in parallel and with minimum

clearance between them.

-section of the equipotential bonding conductor

mm². Always use cables with an adequate cross-section when

Basic Panels 2nd Generation

28 Operating Instructions, 10/2016, A5E33293231-AB

Mounting and connecting

Procedure

1.

2.

3.3.3

Connecting the power supply

Stripping the cable

Use power supply cables with a

maximum cross

1. Strip the ends of two power supply

2.

3.

3.3 Connecting the HMI device

Interconnect the functional earth

connection of the HMI device with

an equipotential bonding conductor,

cross-section 4 mm

Connect the equipotential bonding

conductor to the equipotential

bonding rail.

2

.

cables to a length of 6 mm.

Attach cable sleeves to the bare

cable ends.

Basic Panels 2nd Generation

Operating Instructions, 10/2016, A5E33293231-AB

Install the end sleeves on the

cable ends using the crimp pliers.

-section of 1.5 mm2.

29

Mounting and connecting

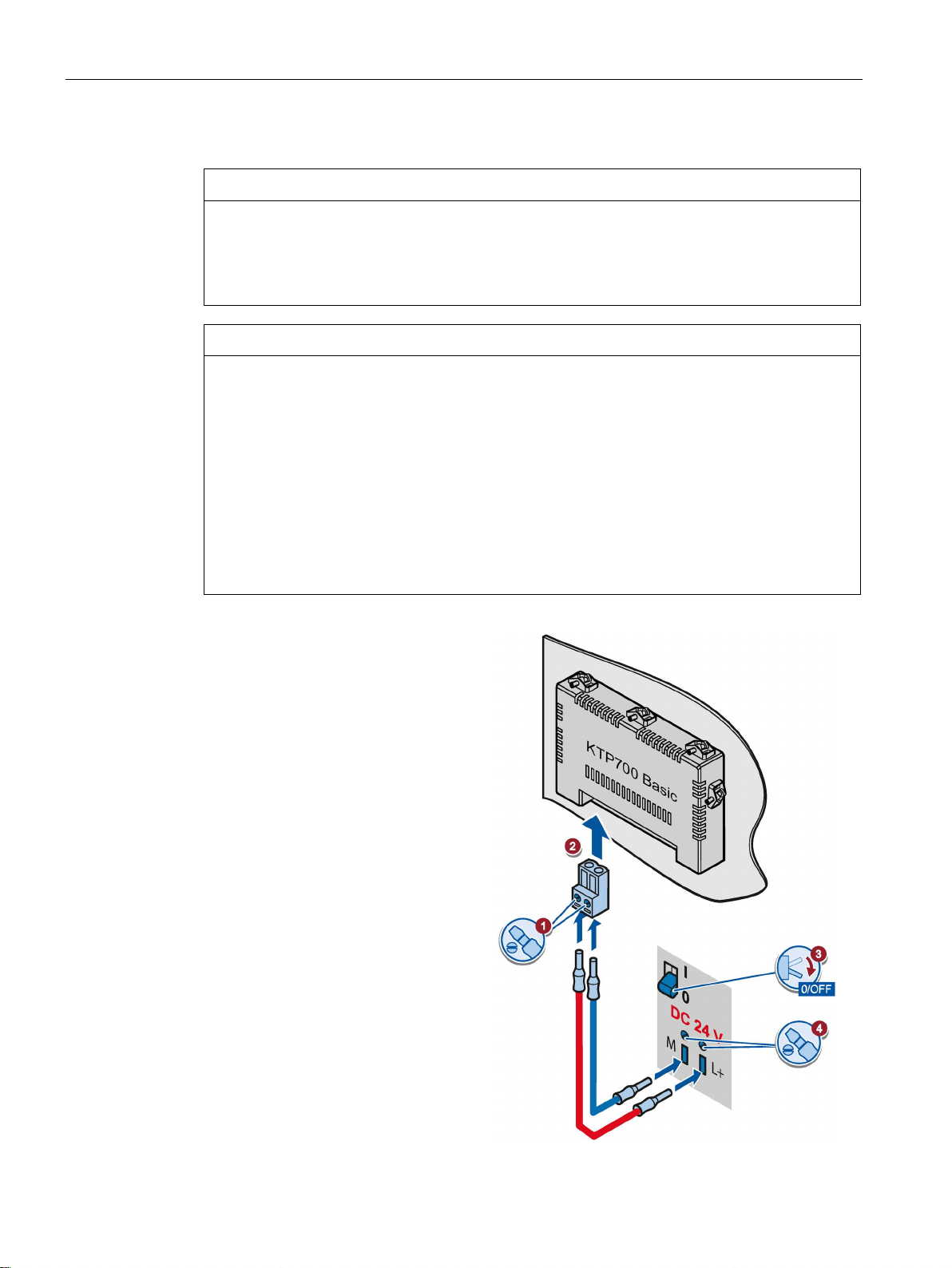

Procedure

NOTICE

24 V DC only

NOTICE

Safe electrical isolation

1.

2.

3.

4.

3.3 Connecting the HMI device

An incorrectly dimensioned power supply can destroy the HMI device.

Use a 24 V DC power supply with adequate amperage; see Technical specifications

(Page 109).

For the 24 V DC supply, use only power supply units with safe electrical isolation in

accordance with IEC 60364-4-41 or HD 384.04.41 (VDE 0100, Part 410), e.g. conforming

to the SELV/PELV standard.

The supply voltage must be within the specified voltage range. Otherwise, malfunctions at

the HMI device cannot be ruled out.

Applies to non-isolated system configurations:

Connect the GND 24 V connection from the 24 V power supply output to equipotential

bonding for uniform reference potential. You should always select a central point of

termination.

Connect the two power supply

cables to the power supply

connector as shown. Secure the

power supply cables with a slotted

screwdriver.

Connect the power supply

connector to the HMI device.

Check the correct polarity of the

cables using the interface marking

on the back of the HMI device.

Switch off the power supply.

Insert the two remaining cable

ends into the power supply

terminals and secure them with

the slotted screwdriver.

Ensure correct polarity.

Basic Panels 2nd Generation

30 Operating Instructions, 10/2016, A5E33293231-AB

Loading...

Loading...