Siemens SIMATIC HMI IRD400 Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC HMI

HMI device

IRD400

Operating Instructions

05/2018

A5E36790512

Preface

Overview

1

Safety instructions

2

Installing and connecting the

display unit

3

Operating the display unit

4

Configuring the display unit

5

Maintenance and repairs

6

Technical specifications

7

Appendix

A

-AC

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E36790512-AC

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

05/2018 Subject to change

Preface

Purpose of the operating instructions

Scope

Note

Note:

• You are also going to need this document whenever the system is recommissioned. Keep

•

Knowledge required

Style conventions

Notation

Scope

command

These operating instructions provides information relating to the place of use, transport,

storage, mounting, use and maintenance of the device.

These operating instructions are intended for:

● Commissioning engineers

● Operators

● Maintenance personnel

This document applies to the display unit "SIMATIC HMI IRD400" with the article number

6ES7292-0AA50-1AA0.

Submit all of these documents to a future owner of the device.

General knowledge in the fields of electrical engineering, automation technology and

process communication is prerequisite for comprehension of this documentation.

"Add screen"

"File > Edit" Operational sequences, e.g, menu command, shortcut menu

this and supplementary documentation in a safe place for the entire life cycle of the

device.

• Terminology for the user interface, e.g. dialog name, tab, but-

ton, menu command

• Necessary entries, e.g. limit value, tag value

• Path information

IRD400

Operating Instructions, 05/2018, A5E36790512-AC

3

Preface

Note

A note contains important information about the product described in the document and its

handling, or a specific section of the document to which you should pay particular attention.

Naming conventions

Term

Applies to

Display unit

SIMATIC HMI IRD400

Device

Display unit

Figures

Please observe notes labeled as follows:

Control cabinet

• Installation cabinet

• Enclosure

• Terminal box

• Console

• Switchboard

This document contains illustrations of the described devices. The illustrations may deviate

from the particularities of the delivered device.

IRD400

4 Operating Instructions, 05/2018, A5E36790512-AC

Table of contents

Preface ........................................................................................................................................ 3

1 Overview ...................................................................................................................................... 7

2 Safety instructions ....................................................................................................................... 10

3 Installing and connecting the display unit ........................................................................................ 13

4 Operating the display unit ............................................................................................................. 26

5 Configuring the display unit ........................................................................................................... 29

6 Maintenance and repairs .............................................................................................................. 40

1.1 Product overview ................................................................................................................. 7

1.2 Scope of delivery ................................................................................................................. 7

1.3 Design of the display unit ..................................................................................................... 8

1.4 Accessories ......................................................................................................................... 9

2.1 Industrial Security .............................................................................................................. 12

3.1 Preparing for mounting ...................................................................................................... 13

3.1.1 Checking the package contents ......................................................................................... 13

3.1.2 Permitted mounting positions ............................................................................................. 14

3.1.3 Installation location and clearance ..................................................................................... 16

3.2 Installing the display unit.................................................................................................... 18

3.3 Connecting the display unit ................................................................................................ 19

3.3.1 Connection information ...................................................................................................... 19

3.3.2 Connecting functional ground ............................................................................................ 20

3.3.3 Connecting the Power Supply ............................................................................................ 22

3.3.4 Connecting the PLC .......................................................................................................... 24

3.3.5 Connecting digital inputs/outputs ....................................................................................... 25

3.3.6 Securing the cables ........................................................................................................... 25

5.1 PROFINET modules .......................................................................................................... 29

5.2 Configuring in the TIA Portal .............................................................................................. 30

5.3 Slot 1 - IR-RC module (IR remote control).......................................................................... 33

5.4 Slot 2 - DISPLAY module (7-segment display and LEDs) ................................................... 34

5.5 Slot 3 - Digital port module (8 x DI/DO) .............................................................................. 36

5.6 Slot 4 - IR-P2P module ("IR-P2P" operating mode) ............................................................ 37

5.7 Slot 5 - Control module (operating mode) .......................................................................... 38

6.1 Recycling and disposal ...................................................................................................... 40

IRD400

Operating Instructions, 05/2018, A5E36790512-AC

5

Table of contents

7 Technical specifications ............................................................................................................... 41

A Appendix ................................................................................................................................... 51

Index ......................................................................................................................................... 53

7.1 Certificates and approvals ..................................................................................................41

7.2 Notes about usage .............................................................................................................42

7.3 Electromagnetic compatibility .............................................................................................42

7.4 Ambient conditions .............................................................................................................44

7.4.1 Transportation and storage requirements ...........................................................................44

7.4.2 Operational requirements ...................................................................................................45

7.4.3 Tests for ambient conditions ...............................................................................................46

7.5 Dimensional diagram ..........................................................................................................47

7.6 Technical specifications ......................................................................................................47

7.7 Interface description ...........................................................................................................49

7.7.1 Power supply .....................................................................................................................49

7.7.2 RS 232 interface (X30) .......................................................................................................49

7.7.3 PROFINET .........................................................................................................................50

7.7.4 Digital inputs/outputs ..........................................................................................................50

A.1 Technical support ...............................................................................................................51

A.2 Abbreviations .....................................................................................................................52

IRD400

6 Operating Instructions, 05/2018, A5E36790512-AC

1

1.1

Product overview

1.2

Scope of delivery

The display unit is used to display data which is sent by a controller. Digits or symbols can

be shown in the display. The status of the controller, for example, can be signaled via the

LEDs. In addition, two controllers which are each connected to a IRD400 display unit can

communicate via the display units.

The display ensures legibility up to a distance of 10 m. You can use the integrated dimming

function to adjust the display to the ambient light conditions.

The display unit has an infrared transmitter/receiver module which is tuned to the IR remote

control with the article number 6ES7292-0CA50-0AA0 and can communicate with a display

unit of the same design. The display unit can be used with and without remote control. You

can use the IR remote control to adjust the brightness of the display on the display unit and

transmit signals to the controller via the display unit.

The display unit is configured with STEP 7 (TIA Portal).

IRD400

Operating Instructions, 05/2018, A5E36790512-AC

The scope of delivery of the display unit includes:

● 1 × display unit

● 1 x accessory pack with the following contents:

– 4 mounting clips

– 4 threaded pins for the mounting clips

– 1 mains terminal for the power supply

– 1 plug connector, 12-pin

7

Overview

1.3

Design of the display unit

①

PROFINET ports X1 P1 and X1 P2

⑥

Recesses for a mounting clip

②

⑦

displaying the operating state

③

⑧

LED

④

I/O interface X10, digital inputs/outputs

⑨

Rating plate

⑤

Display with three 7-segment displays

⑩

Connection for functional earthing

1.3 Design of the display unit

Power supply connector X80

Mounting seal

The RS 232 interface X30 is deactivated.

IRD400

8 Operating Instructions, 05/2018, A5E36790512-AC

"Green" and "red" LEDs, for example for

IR transmitter/receiver module with "blue"

Overview

Display and LEDs

PROFINET ports and digital inputs/outputs

1.4

Accessories

1.4 Accessories

The LED contains three 7-segment displays, each with a decimal point.

The response of the three 7-segment displays and LEDs is defined via the configuration.

The display unit communicates with the controller via PROFINET. The response of the digital

inputs/outputs (pins 1...8) of the I/O interface X10 is defined via the configuration of the slots

in HW Config (TIA Portal) and is freely-programmable.

Accessories for the display unit:

● IR remote control

The IR remote control represents the input device for the display unit. The article number

is 6ES7292-0CA50-0AA0.

Accessories can be found on the Internet (https://mall.industry.siemens.com

).

IRD400

Operating Instructions, 05/2018, A5E36790512-AC

9

2

WARNING

Injury or material damage

Safety during commissioning and operation

WARNING

Installation/use as intended

Safety when working in and on electrical systems

You risk the development of danger sources and deactivation of safety functions if you

neglect the safety and handling instructions provided in this document. This can result in

personal injuries or material damage.

Strictly adhere to the safety and handling instructions.

Always adhere to the safety instructions and accident prevention regulations for the

respective application, independent of the safety instructions provided in this document.

It is strictly forbidden to commission the device before compliance with Machinery Directive

2006/42/E has been verified for the machine to be operated with this device.

Verify before commissioning that the provisions of Directive 2006/42/EC are fulfilled.

Only authorized persons are allowed to work in or on electrical equipment. The following

safety regulations for prevention of electrical shock are valid in Germany:

1. Isolation of the system from power

2. Securing the system against restart

3. Verification of isolation from power at all poles

4. Grounding and shorting the system

5. Covering or fencing off adjacent live parts

IRD400

10 Operating Instructions, 05/2018, A5E36790512-AC

Safety instructions

Note

The safety regulations must be

carried out on electrical systems. The safety regulations must be applied in reverse order on

completion of all tasks on the electrical system.

Infrared interference signal

WARNING

Malfunctions with IR interference signal possible

Strong high-frequency radiation

NOTICE

Observe immunity to RF radiation

These safety regulations are based on DIN VDE 0105.

applied in the aforementioned order before any work is

Identify the electrical system in accordance with valid safety regulations when working on

this system.

Observe the valid safety regulations of the respective country.

The display unit receives all infrared signals of their spectrum within their sensing range.

Interference signals can cause unwanted commands to be sent to the controller.

Unintentional reaction of the plant as well as personal injury or property damage can result.

Note:

• Do not operate any infrared signal sources except the permitted remote control in the

entire receiving range of the display unit Only the remote control "IR-RC" with article

number 6ES7292-0CA50-0AA0 is permitted.

• Take appropriate measures to prevent interference by other sources within the spectrum

and reception range of the display unit. Read the information in the technical

specifications.

The device has an increased immunity to RF radiation according to the specifications on

electromagnetic compatibility in the technical specifications.

Radiation exposure in excess of the specified immunity limits can impair device functions,

result in malfunctions and therefore injuries or damages.

Read the information on immunity to RF radiation in the technical specifications.

IRD400

Operating Instructions, 05/2018, A5E36790512-AC

11

Safety instructions

Warranty

ESD

2.1

Industrial Security

Industrial Security

2.1 Industrial Security

Prerequisites for trouble-free and safe operation of the device:

● Proper transportation and storage

● Proper mounting and wiring

● Proper operation and repairs

Non-compliance with these regulations shall render the device warranty void.

An ESD (Electrostatically Sensitive Device) is equipped with electronic components. Due to

their design, electronic components are highly sensitive to overvoltage and electrostatic

discharge. Observer the regulations governing the handling of ESD components.

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity

).

).

IRD400

12 Operating Instructions, 05/2018, A5E36790512-AC

3

3.1

Preparing for mounting

3.1.1

Checking the package contents

Note

Damaged parts

Do not install parts damaged during shipment. In the case of damaged parts, contact your

Siemens representative.

Check the package content for visible signs of transport damage and for completeness.

The package content is described in section Scope of delivery (Page 7).

Keep the provided documentation in a safe place. The documentation is part of the HMI

device and is required for subsequent commissioning.

IRD400

Operating Instructions, 05/2018, A5E36790512-AC

13

Installing and connecting the display unit

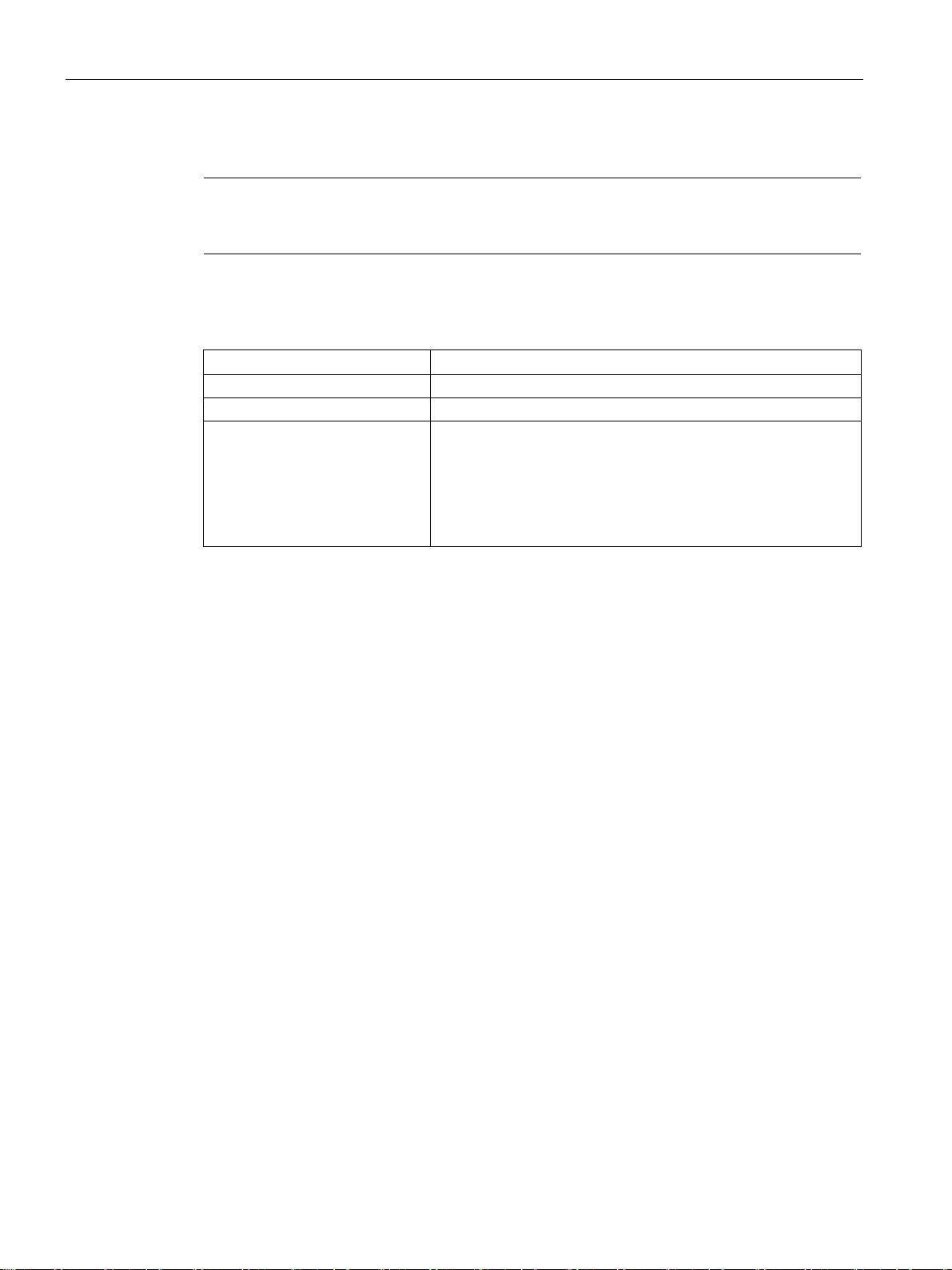

3.1.2

Permitted mounting positions

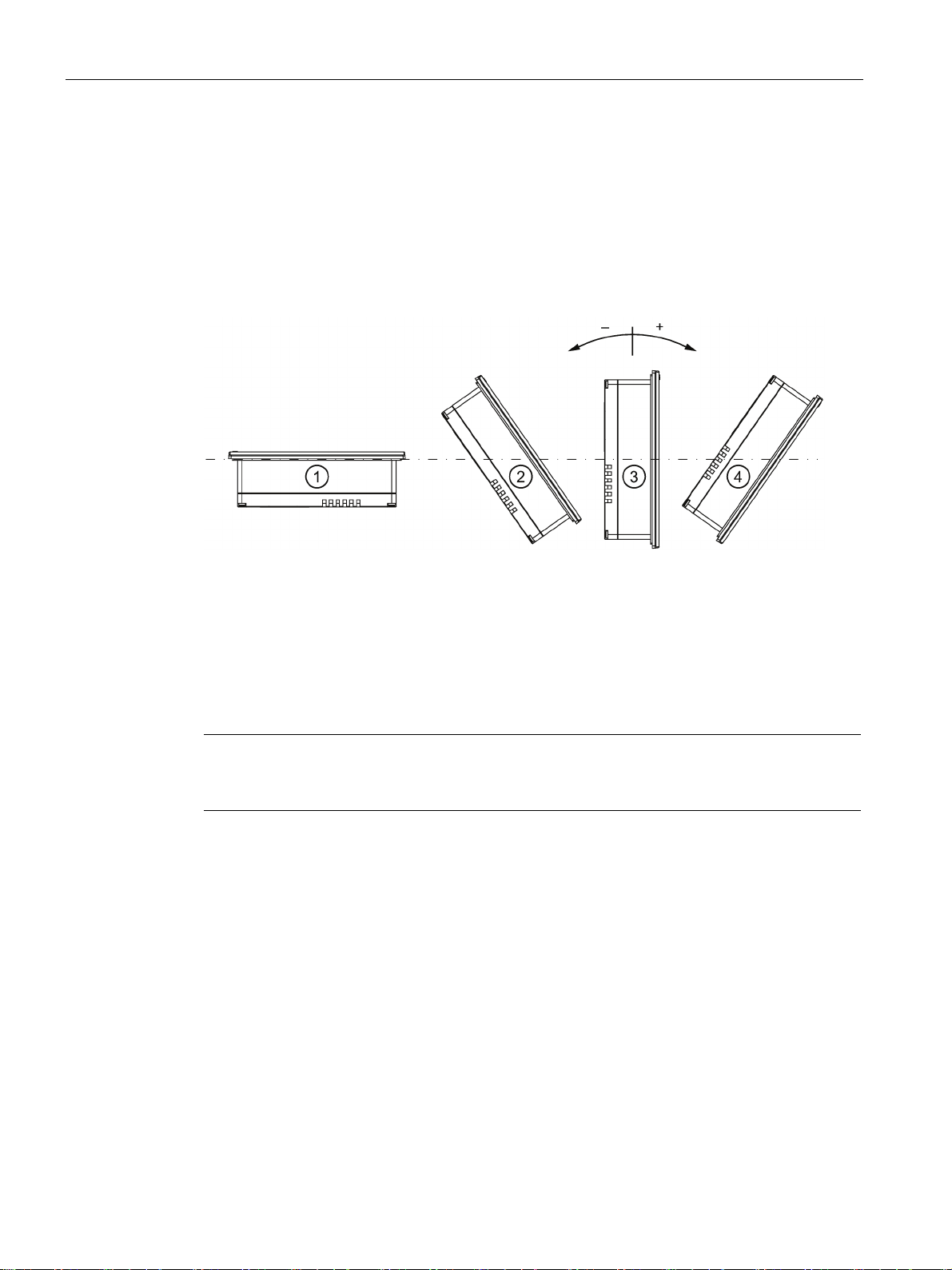

Mounting position

Mounting position

Deviation from the perpendicular axis

Temperature

①

Horizontal

-90°

0 ... 50 °C

②

Inclined

≥ –35°

0 ... 60 °C

③

Vertical

0°

0 ... 60 °C

④

Inclined

≤ 35°

0 ... 60 °C

Note

You risk damage to the display unit if operating it outside the approved ambient temperature

limits. The approvals and warranty for the display unit are rendered void in this case.

3.1 Preparing for mounting

The display unit is approved for operation in horizontal and inclined mounting position in

stationary and mobile control cubicles.

The following lateral installation angles are permitted:

The display unit is quipped with venting slots for heat convection into the control cabinet

where thermal energy is dissipated on the panels of the control cabinet.

IRD400

14 Operating Instructions, 05/2018, A5E36790512-AC

Installing and connecting the display unit

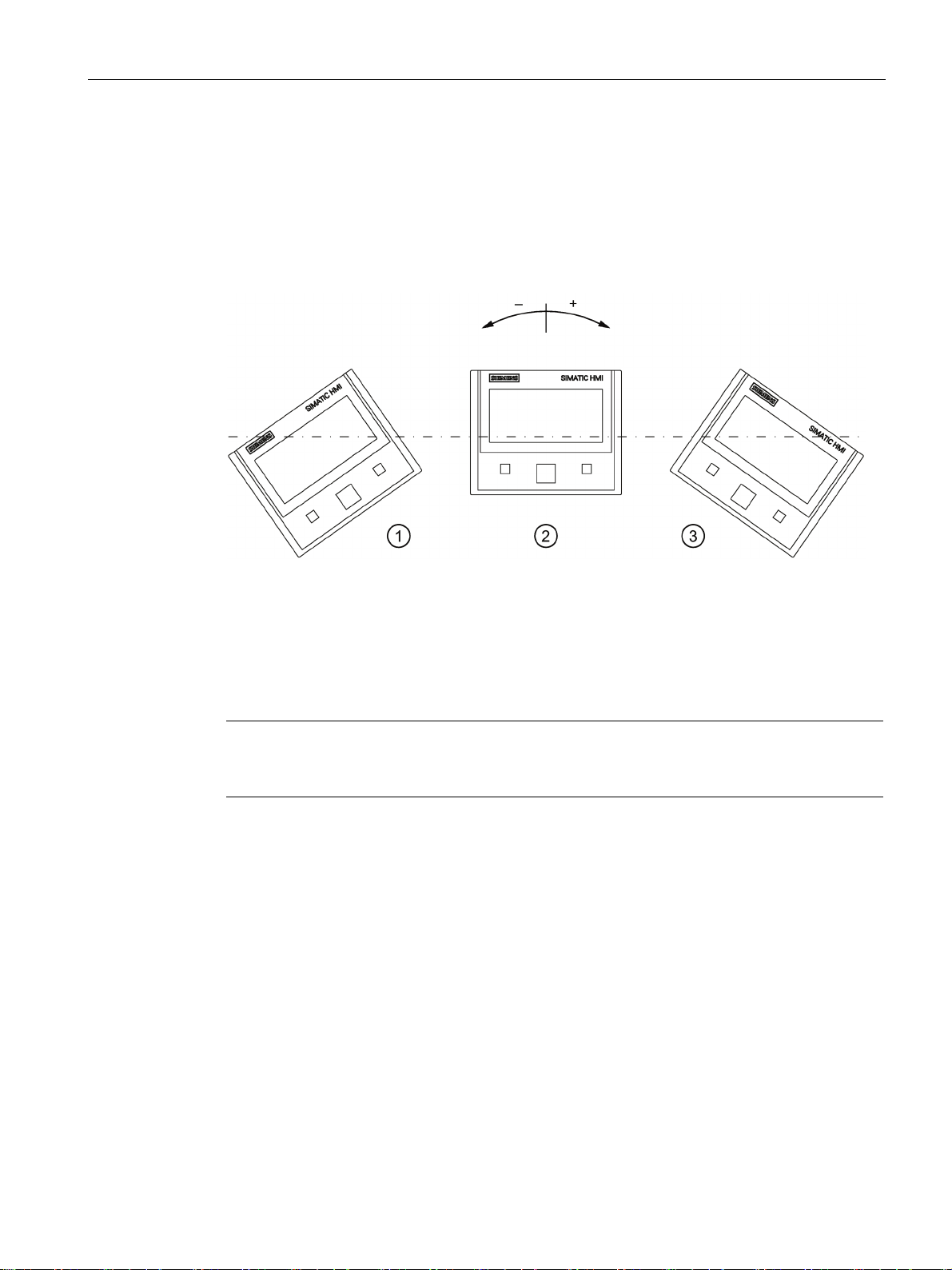

Mobile operation

Position

Deviation from the perpendicular axis

①

Tilted

≥ –35°

②

Vertical

0°

③ Tilted

≤ 35°

Note

Please note that the vertical position

period of time.

3.1 Preparing for mounting

If you operate the device in a mobile system, for example in an electrical monorail system,

then in addition to the lateral installation angle, the permitted tilt of the front of the device

must be taken into consideration.

The following angles of inclination are permitted for a short time for the display unit during

movement:

Inclinations may occur, for example, if the display unit is mounted to a conveying device that

services several levels of the plant.

② for mobile use may only be exceeded for a short

IRD400

Operating Instructions, 05/2018, A5E36790512-AC

15

Installing and connecting the display unit

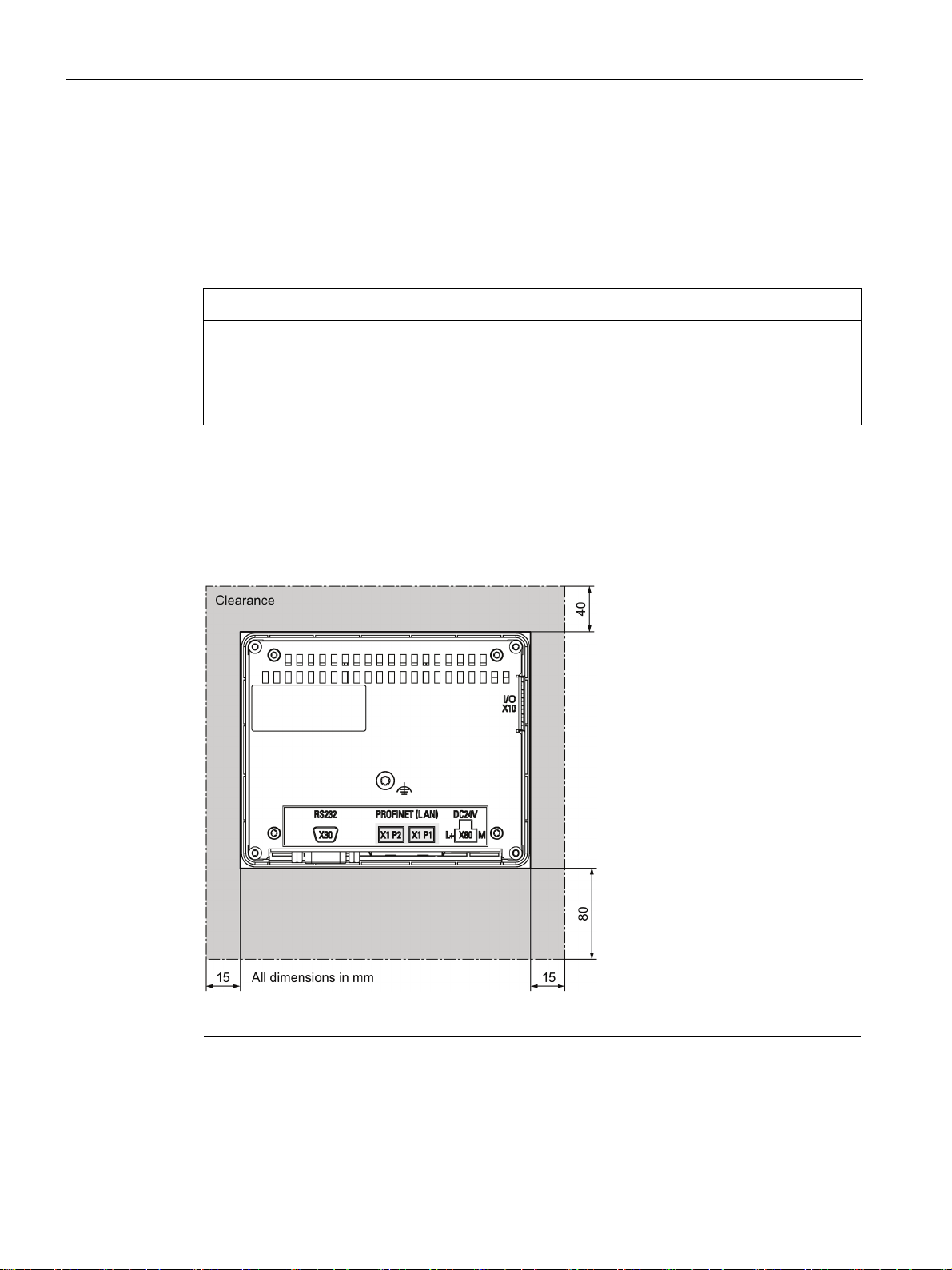

3.1.3

Installation location and clearance

Selecting installation location

NOTICE

Installation location

Observe the permissible ambient conditions when selecting the installation location.

Clearance

Note

Additional clearance for connectors and cables

Take into consideration additional clearance due to the type of connector used and the

permissible bending radii of the connecting cables.

3.1 Preparing for mounting

The display unit is designed for installation in a control cabinets. The display unit is installed

in landscape format.

Non-compliance with permissible ambient conditions at the installation location may lead to

malfunctions.

When selecting the mounting location for the display unit, ensure that sufficient heat

convection is possible. Avoid installation of heat generating equipment directly underneath

the display unit.

The following clearance is required for ventilation of the display unit:

10 mm clearance at the rear side of the device.

IRD400

16 Operating Instructions, 05/2018, A5E36790512-AC

Installing and connecting the display unit

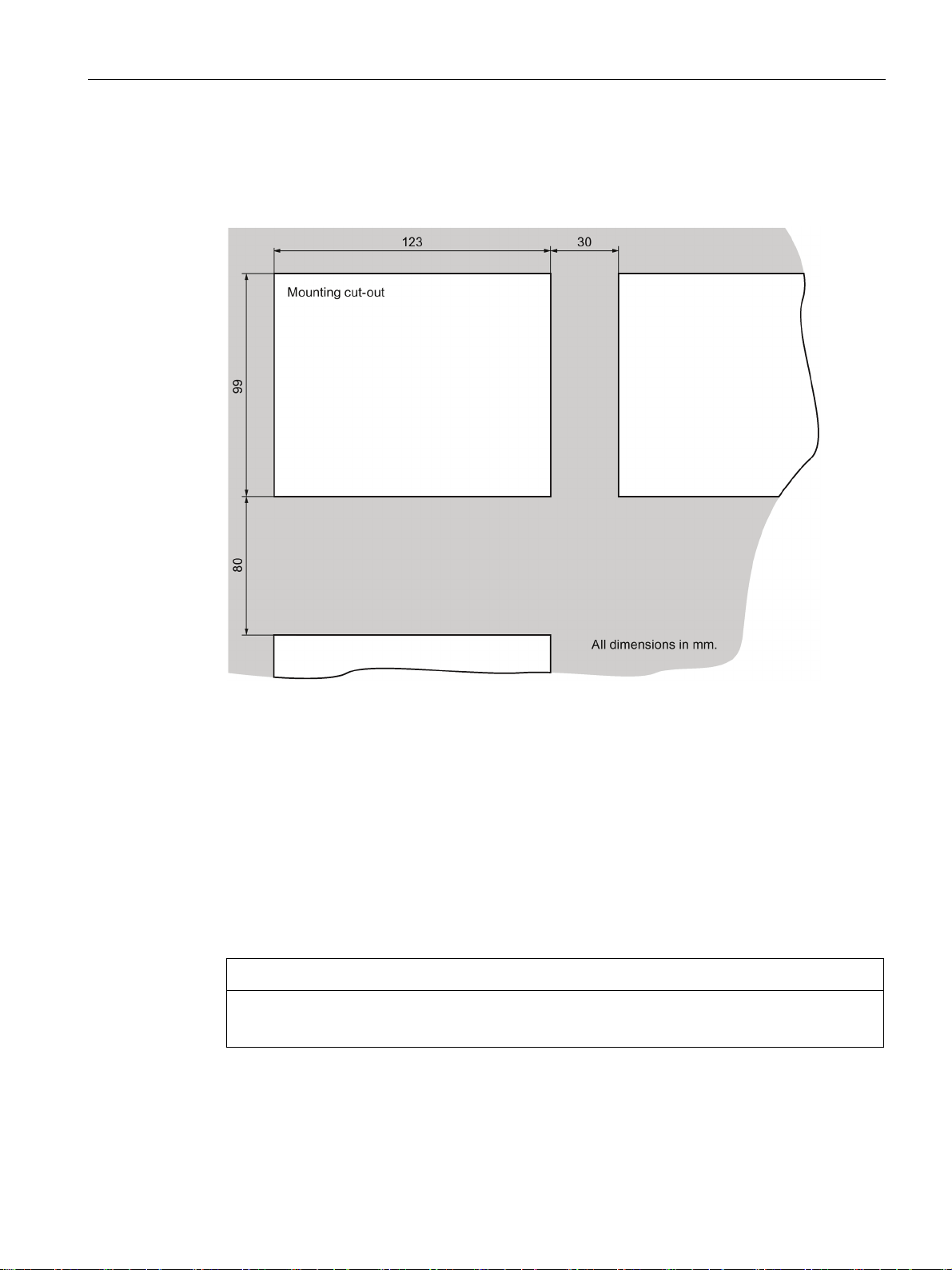

Dimensions of the mounting cut-out

Configuration of the mounting cut-out

NOTICE

Operation in the scope of UL508

3.1 Preparing for mounting

The following figure shows the dimensions of the mounting cut-out and the clearances to be

observed when mounting several devices in a horizontal or vertical arrangement.

The following conditions must be met to ensure the degree of protection:

● The material at the mounting cut-out must be resistant to distortion.

● Material thickness at the mounting cut-out for IP65 degree of protection, or for

enclosure type 4X/type 12 (indoor use only): 2 mm bis 6 mm

● Permitted deviation from plane at the mounting cutout: ≤ 0.5 mm

This condition must be fulfilled for the mounted HMI device.

● Permitted surface roughness in the area of the mounting seal: ≤ 120 µm (R

For use on a flat surface of a Type 1 (indoor use only) Enclosure.

120)

z

IRD400

Operating Instructions, 05/2018, A5E36790512-AC

17

Loading...

Loading...