Page 1

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Basic Panels

SIMATIC HMI

HMI devices

Basic Panels

Operating Instructions

_________________

Preface

_________________

Overview

_________________

Safety instructions

_________________

Mounting and connecting

_________________

Operating the device

_________________

Configuring the HMI device

_________________

Commissioning a project

_________________

Maintenance and care

_________________

Technical specifications

_________________

Technical Support

_________________

Abbreviations

1

2

3

4

5

6

7

8

A

B

04/2012

A5E02421799-03

Page 2

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the relevant information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E02421799-03

Ⓟ 04/2012 Technical data subject to change

Copyright © Siemens AG 2012.

All rights reserved

Page 3

Preface

Purpose of the operating instructions

These operating instructions provide information based on the requirements defined by

IEC 62079 for documentation. This information relates to the HMI device, its storage,

transportation, place of use, installation, use and maintenance.

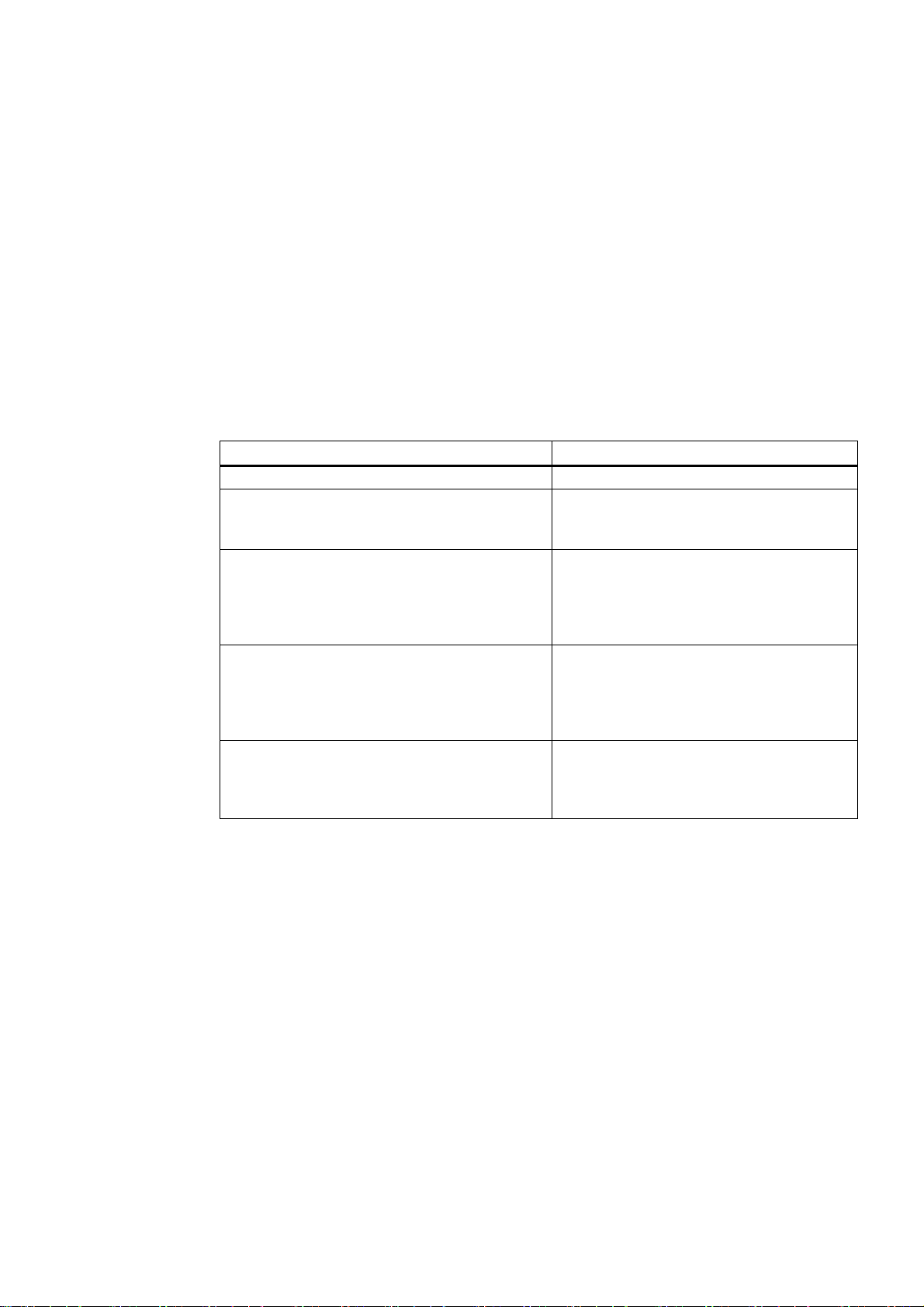

These operating instructions are intended for a variety of target groups. The following table

shows the chapters of these operating instructions that are of particular importance for the

respective target group.

Target group Chapter

All "Safety instructions"

Operators

The operator operates and monitors the system

during the process control phase.

Commissioning engineers

The commissioning engineer integrates the HMI

device into the system and ensures the operating

capability of the HMI device for the process control

phase.

Service technicians

Service technicians rectify faults that occur during

the process control phase.

Maintenance technicians

Maintenance technicians carry out servicing and

maintenance work during the process control

phase.

"Overview"

"Operating a project"

All chapters.

Depending on the use of the HMI device,

certain chapters may not be of relevance to the

commissioning engineer, e.g. the section

"Maintenance and servicing."

All chapters.

Depending on the use of the HMI device,

certain chapters may not be of relevance to the

service technicians, e.g. the section

"Maintenance and servicing."

Maintenance and care

The information system of WinCC flexible and WinCC contains further additional informaiton.

The information system is integrated as online help in WinCC flexible and WinCC and

contains instructions, examples and reference information in electronic form.

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

3

Page 4

Preface

Scope

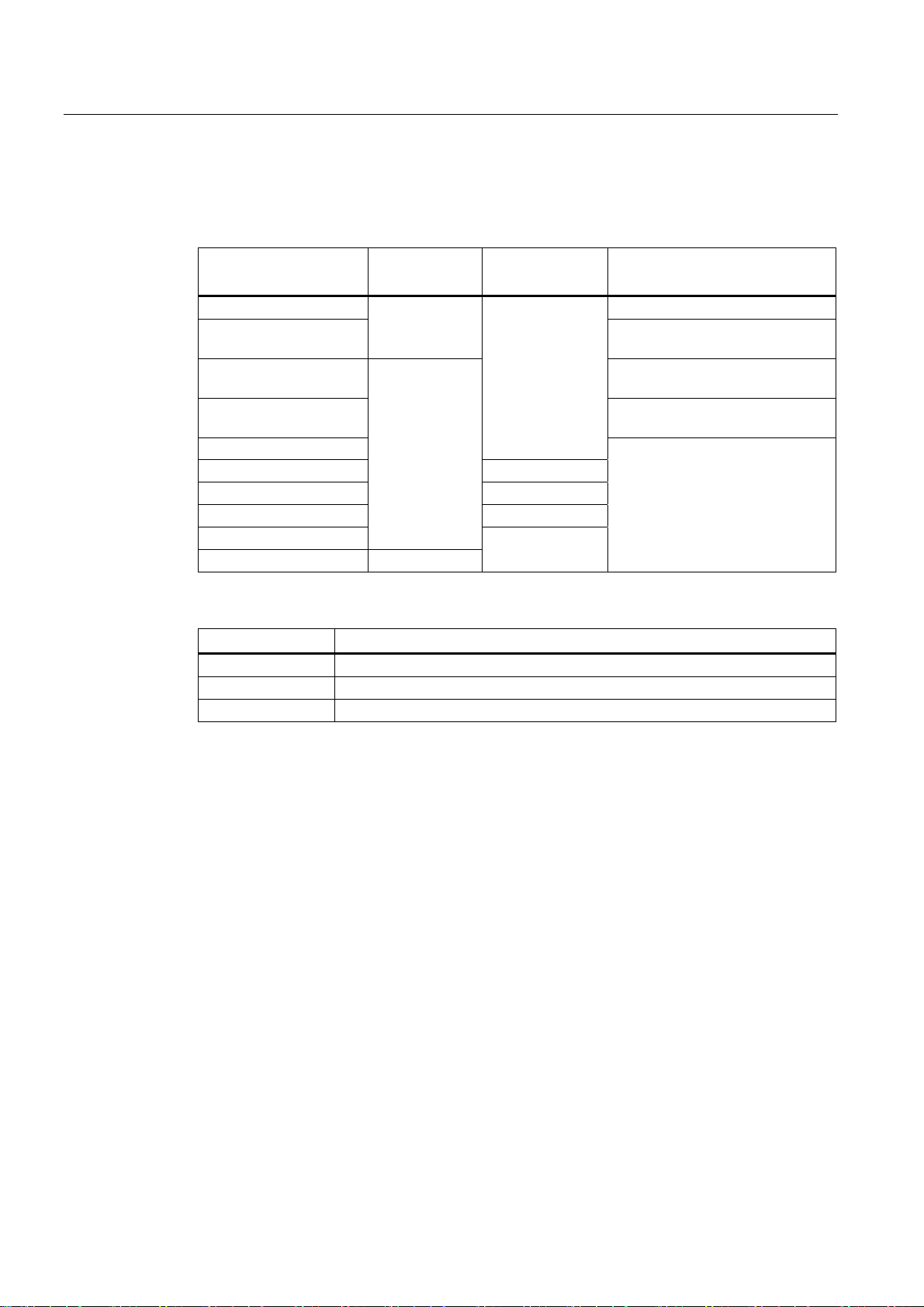

These operating instructions are valid for all SIMATIC HMI Basic Panels. The following

naming conventions apply:

Device designation

SIMATIC HMI

KP300 Basic mono PN WinCC (TIA Portal) as of V11

KP400 Basic color PN

KTP400 Basic mono PN WinCC flexible and WinCC (TIA

KTP400 Basic color PN WinCC (TIA Portal) as of V11 SP2

KTP600 Basic mono PN

KTP600 Basic color DP Basic Panel DP

KTP600 Basic color PN Basic Panel PN

KTP1000 Basic color DP Basic Panel DP

KTP1000 Basic color PN

TP1500 Basic color PN Touch device

Device type Interface type Can be configured with

Keyboard unit

Touch device

with function

keys

Basic Panel PN

WinCC (TIA Portal) as of V11 SP2

Update 2 with HSP Basic 4" color

Portal) as of V11

Update 2 with HSP Basic 4" color

WinCC flexible and WinCC (TIA

Portal) as of V11

Basic Panel PN

In addition, the following collective designations are also used in these operating

instructions:

Designation Covers the HMI devices

KTP400 Basic KTP400 Basic mono PN, KTP400 Basic color PN

KTP600 Basic KTP600 Basic mono PN, KTP600 Basic color DP, KTP600 Basic color PN

KTP1000 KTP1000 Basic color DP, KTP1000 Basic color PN

Basic knowledge required

Knowledge of automation technology and process communication is necessary to

understand the operating instructions.

An understanding of the use of computers and operating systems is also required.

Basic Panels

4 Operating Instructions, 04/2012, A5E02421799-03

Page 5

Preface

Illustrations and text highlighting

This manual contains illustrations of the described devices. The illustrations may deviate

from the supplied device in certain details.

The following graphical highlighting facilitates reading these operating instructions:

Graphical highlighting Description

If the instructions involve several tasks,

the individual tasks are highlighted by a

red number circle.

A light blue highlight indicates

ื 0.2

Nm

.73

components and tools that are required

in the course of a task.

Safety instructions are highlighted by an

orange frame.

KTP600 Basic is sometimes shown in

the illustrations as a representation of all

Basic Panels.

The following text highlighting facilitates reading these operating instructions:

Text highlighting Scope

"Add screen"

"File > Edit" Operational sequences, for example, menu commands, shortcut

<F1> Keyboard operation

• Terms that appear in the user interface, for example, dialog

names, tabs, buttons, menu commands

• Input values, for example, limits, tag values

• Path information

menu commands

Configuration and runtime software have different names as follows:

● "WinCC flexible 2008" or "WinCC (TIA Portal) V11", for example, refers to the

configuration software.

The term "WinCC flexible" or "WinCC" is used in a general context. The full name, for

example, "WinCC flexible 2008", is always used when it is necessary to differentiate

between different versions of the configuration software.

● "WinCC flexible Runtime" or "WinCC Runtime" refers to the runtime software that can run

on HMI devices.

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

5

Page 6

Preface

Note information highlighted as follows:

Note

A note contains important information on described products and their handling or on a

section of this documentation.

Trademarks

Names labeled with a ® symbol are registered trademarks of the Siemens AG. Other names

used in this documentation may be trademarks, the use of which by third parties for their

own purposes could violate the rights of the owner.

®

● HMI

● SIMATIC

● SIMATIC HMI

● WinCC

®

®

®

Basic Panels

6 Operating Instructions, 04/2012, A5E02421799-03

Page 7

Table of contents

Preface ...................................................................................................................................................... 3

1

Overview.................................................................................................................................................. 11

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

2

Safety instructions ................................................................................................................................... 25

2.1

2.2

2.3

Product Overview.........................................................................................................................11

Design of the KP300 Basic mono PN ..........................................................................................12

Design of the KP400 Basic color PN ...........................................................................................13

Design of the KTP400 Basic mono PN........................................................................................15

Design of the KTP400 Basic color PN.........................................................................................16

Design of the KTP600 Basic mono/color PN...............................................................................17

Design of the KTP600 Basic color DP.........................................................................................18

Design of the KTP1000 Basic color PN.......................................................................................19

Design of the KTP1000 Basic color DP.......................................................................................20

Design of the TP1500 Basic color PN .........................................................................................21

Product package ..........................................................................................................................22

Accessories..................................................................................................................................23

Commissioning the HMI device ...................................................................................................24

General safety instructions ..........................................................................................................25

Security information .....................................................................................................................26

Notes about usage.......................................................................................................................26

3

Mounting and connecting......................................................................................................................... 29

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

3.2

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

Preparations.................................................................................................................................29

Checking the package contents...................................................................................................29

Checking the operating conditions...............................................................................................29

Selecting a mounting position......................................................................................................29

Checking clearances....................................................................................................................31

Making the mounting cut-out........................................................................................................31

Labeling the function keys ...........................................................................................................33

Mounting the HMI device .............................................................................................................34

Connecting the HMI device..........................................................................................................36

Connection sequence ..................................................................................................................36

Connecting the equipotential bonding circuit...............................................................................38

Connecting the power supply.......................................................................................................39

Connecting a programming device ..............................................................................................41

Connecting the configuration PC .................................................................................................42

Connecting the PLC.....................................................................................................................45

7

Page 8

Table of contents

3.4 Switching on and testing the HMI device .................................................................................... 48

3.5 Securing the cables..................................................................................................................... 50

4

Operating the device................................................................................................................................ 51

4.1

4.1.1

4.1.2

4.1.3

4.1.4

4.2

4.2.1

4.2.2

4.3

4.3.1

4.3.2

Configuring the HMI device...................................................................................................................... 67

5

5.1

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

5.1.6

5.1.7

5.1.8

5.1.9

5.1.10

5.1.11

5.1.12

5.1.13

Operating touch devices ............................................................................................................. 51

Overview ..................................................................................................................................... 51

General functions of the screen keyboard .................................................................................. 53

Entering data on the KTP400 Basic............................................................................................ 54

Entering data on the KTP600 Basic, KTP1000 Basic , TP1500 Basic ....................................... 57

Operating KP300 Basic............................................................................................................... 59

Overview ..................................................................................................................................... 59

Entering data on the KP300 Basic .............................................................................................. 60

Operating KP400 Basic............................................................................................................... 63

Overview ..................................................................................................................................... 63

Entering data on the KP400 Basic .............................................................................................. 66

Configuring devices with graphical Control Panel ...................................................................... 67

Opening the Control Panel.......................................................................................................... 67

Overview ..................................................................................................................................... 68

Changing MPI/DP settings.......................................................................................................... 69

Changing the network configuration ........................................................................................... 70

Time server configuration............................................................................................................ 71

Changing monitor settings .......................................................................................................... 72

Displaying information about the HMI device.............................................................................. 73

Calibrating the touch screen ....................................................................................................... 74

Displaying licensing information for the HMI device ................................................................... 75

Enabling a data channel.............................................................................................................. 76

Changing password settings....................................................................................................... 78

Setting the Screen Saver ............................................................................................................ 79

Setting acoustic signals............................................................................................................... 79

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

5.2.8

5.2.9

Commissioning a project.......................................................................................................................... 89

6

6.1

6.2

6.3

Basic Panels

Configuring KP300 Basic ............................................................................................................ 80

Opening the Control Panel.......................................................................................................... 80

Overview ..................................................................................................................................... 81

Displaying information about the HMI device.............................................................................. 83

Changing monitor settings .......................................................................................................... 83

Enabling a data channel.............................................................................................................. 84

Changing the network configuration ........................................................................................... 85

Time server configuration............................................................................................................ 86

Changing password settings....................................................................................................... 87

Setting the Screen Saver ............................................................................................................ 88

Overview ..................................................................................................................................... 89

Operating modes......................................................................................................................... 90

Data transmission options........................................................................................................... 91

8 Operating Instructions, 04/2012, A5E02421799-03

Page 9

Table of contents

6.4 Transfer........................................................................................................................................91

6.4.1 Overview......................................................................................................................................91

6.4.2

6.4.3

6.4.4

Starting manual transfer...............................................................................................................91

Starting automatic transfer...........................................................................................................93

Testing a project ..........................................................................................................................95

6.5

6.5.1

6.5.2

6.5.3

6.5.4

6.6

6.6.1

6.6.2

6.6.3

6.6.4

6.7

6.7.1

6.7.2

6.7.3

6.7.4

6.7.5

6.7.6

6.7.7

6.7.8

Maintenance and care ........................................................................................................................... 115

7

7.1

7.2

Backup and restore......................................................................................................................96

Overview ......................................................................................................................................96

Backup and restore using WinCC flexible ...................................................................................97

Backup and restore using ProSave .............................................................................................99

Backup and restore using WinCC..............................................................................................100

OS update - Basic Panel DP......................................................................................................101

Overview ....................................................................................................................................101

Resetting factory settings...........................................................................................................102

Updating the Operating System using WinCC flexible ..............................................................102

Updating the Operating System using ProSave ........................................................................104

OS update - Basic Panel PN......................................................................................................105

Overview ....................................................................................................................................105

Resetting factory settings...........................................................................................................106

Updating the operating system using WinCC flexible................................................................106

Updating the operating system using ProSave..........................................................................108

Updating the operating system using WinCC............................................................................109

Resetting to factory settings with WinCC flexible ......................................................................110

Resetting to factory settings with ProSave ................................................................................112

Resetting to factory settings with WinCC...................................................................................114

Maintenance and care ...............................................................................................................115

Recycling....................................................................................................................................116

8

Technical specifications......................................................................................................................... 117

8.1

8.2

8.2.1

8.2.2

8.3

8.3.1

8.3.2

8.3.3

8.3.4

8.3.5

8.3.6

8.3.7

8.3.8

8.3.9

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

Certificates and approvals .........................................................................................................117

Directives and declarations........................................................................................................118

Electromagnetic compatibility ....................................................................................................118

ESD guideline ............................................................................................................................119

Dimension drawings...................................................................................................................122

Dimension drawing of the KP300 Basic mono PN.....................................................................122

Dimension drawing of the KP400 Basic color PN......................................................................123

Dimension drawing of the KTP400 Basic mono PN ..................................................................124

Dimension drawing of the KTP400 Basic color PN....................................................................125

Dimension drawing of the KTP600 Basic color DP....................................................................126

Dimension drawing of the KTP600 Basic mono/color PN .........................................................127

Dimension drawing of the KTP1000 Basic color DP..................................................................128

Dimension drawing of the KTP1000 Basic color PN..................................................................129

Dimension drawing of the TP1500 Basic color PN....................................................................130

9

Page 10

Table of contents

8.4 Specifications ............................................................................................................................ 131

8.4.1 Power supply............................................................................................................................. 131

8.4.2

8.4.3

8.4.4

8.4.5

8.4.5.1

8.4.5.2

8.4.5.3

KP300 Basic and KP400 Basic................................................................................................. 131

KTP400 Basic and KTP600 Basic ............................................................................................ 133

KTP1000 Basic and TP1500 Basic........................................................................................... 135

Ambient conditions.................................................................................................................... 137

Transport and storage conditions ............................................................................................. 137

Conditions of use ...................................................................................................................... 138

Information on insulation tests, protection class and degree of protection............................... 140

8.5

8.5.1

8.5.2

8.5.3

8.6

A

Technical Support.................................................................................................................................. 147

A.1

A.2

B

Abbreviations......................................................................................................................................... 149

Glossary ................................................................................................................................................ 151

Index...................................................................................................................................................... 157

Interface description.................................................................................................................. 141

Power supply............................................................................................................................. 141

PROFIBUS (Sub-D RS422/485) ............................................................................................... 141

PROFINET (Ethernet)............................................................................................................... 142

Functional scope with WinCC flexible and WinCC ................................................................... 143

Service and support .................................................................................................................. 147

System events........................................................................................................................... 148

Basic Panels

10 Operating Instructions, 04/2012, A5E02421799-03

Page 11

Overview

1.1 Product Overview

Concentrating on the essentials - the new Basic Panels

Today, visualization is part of the standard repertoire for most machines. The cost factor

plays a crucial role in this case, especially for small machines and simple applications. HMI

devices with basic functions are often fully sufficient for simple applications.

This is exactly the demand that we intend to meet – with our new SIMATIC HMI Basic

Panels. By concentrating on the essentials, the Basic Panels offer exactly those basic

features that are demanded – at the right price. A perfect cost-to-performance ratio.

Like all devices in our product catalog, the new Basic Panels offer proven SIMATIC quality

and – regardless of their display dimensions – many software functions as standard: for

example, an alarm system, recipe management, trend functionality and language switching.

Users therefore profit from the advantages of visualization, such as improved process

quality, even with simple applications.

1

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

11

Page 12

Overview

1.2 Design of the KP300 Basic mono PN

1.2 Design of the KP300 Basic mono PN

① Power supply connector ⑥ Function keys

② PROFINET interface ⑦ Rating plate

③ Display ⑧ Mounting seal

④ Control keys ⑨ Interface name

⑤ Cutouts for a mounting clamp ⑩ Functional earth connection

Basic Panels

12 Operating Instructions, 04/2012, A5E02421799-03

Page 13

Overview

1.3 Design of the KP400 Basic color PN

1.3 Design of the KP400 Basic color PN

① Cutouts for mounting clamps ⑤ Function keys

② Power supply connector ⑥ Control keys

③ PROFINET interface ⑦ Data input keys

④ Display

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

13

Page 14

Overview

1.3 Design of the KP400 Basic color PN

① Rating plate ④ Functional earth connection

② Mounting seal ⑤ Guides for labeling strips

③ Interface name

Basic Panels

14 Operating Instructions, 04/2012, A5E02421799-03

Page 15

Overview

1.4 Design of the KTP400 Basic mono PN

1.4 Design of the KTP400 Basic mono PN

① Power supply connector ⑥ Mounting seal

② Functional earth connection ⑦ Guide for a labeling strip

③ PROFINET interface ⑧ Function keys

④ Cutouts for a mounting clamp ⑨ Rating plate

⑤ Display/touch screen ⑩ Interface name

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

15

Page 16

Overview

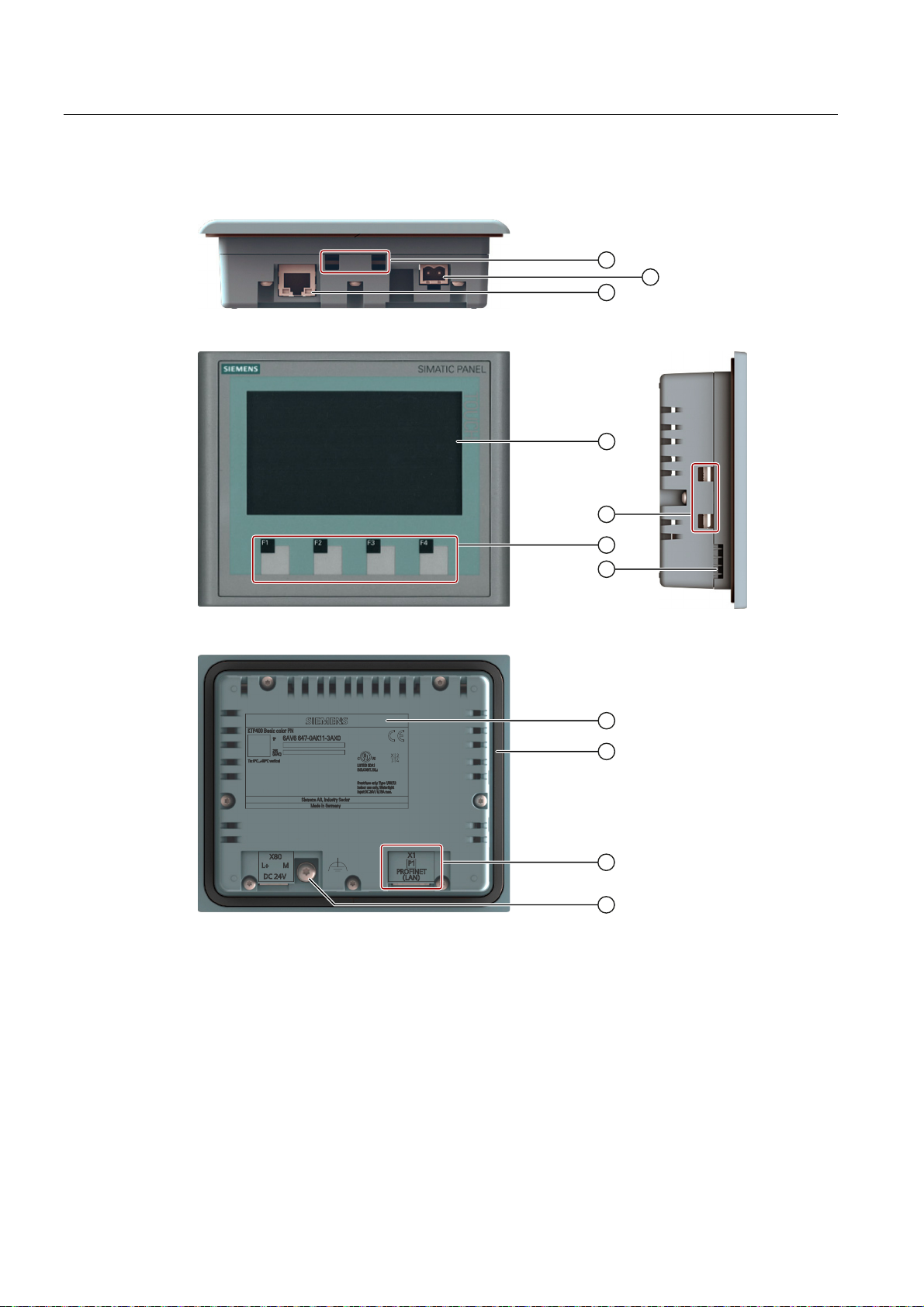

1.5 Design of the KTP400 Basic color PN

1.5 Design of the KTP400 Basic color PN

① Cutouts for mounting clamps ⑥ Guide for a labeling strip

② Power supply connector ⑦ Rating plate

③ PROFINET interface ⑧ Mounting seal

④ Display/touch screen ⑨ Interface name

⑤ Function keys ⑩ Functional earth connection

Basic Panels

16 Operating Instructions, 04/2012, A5E02421799-03

Page 17

Overview

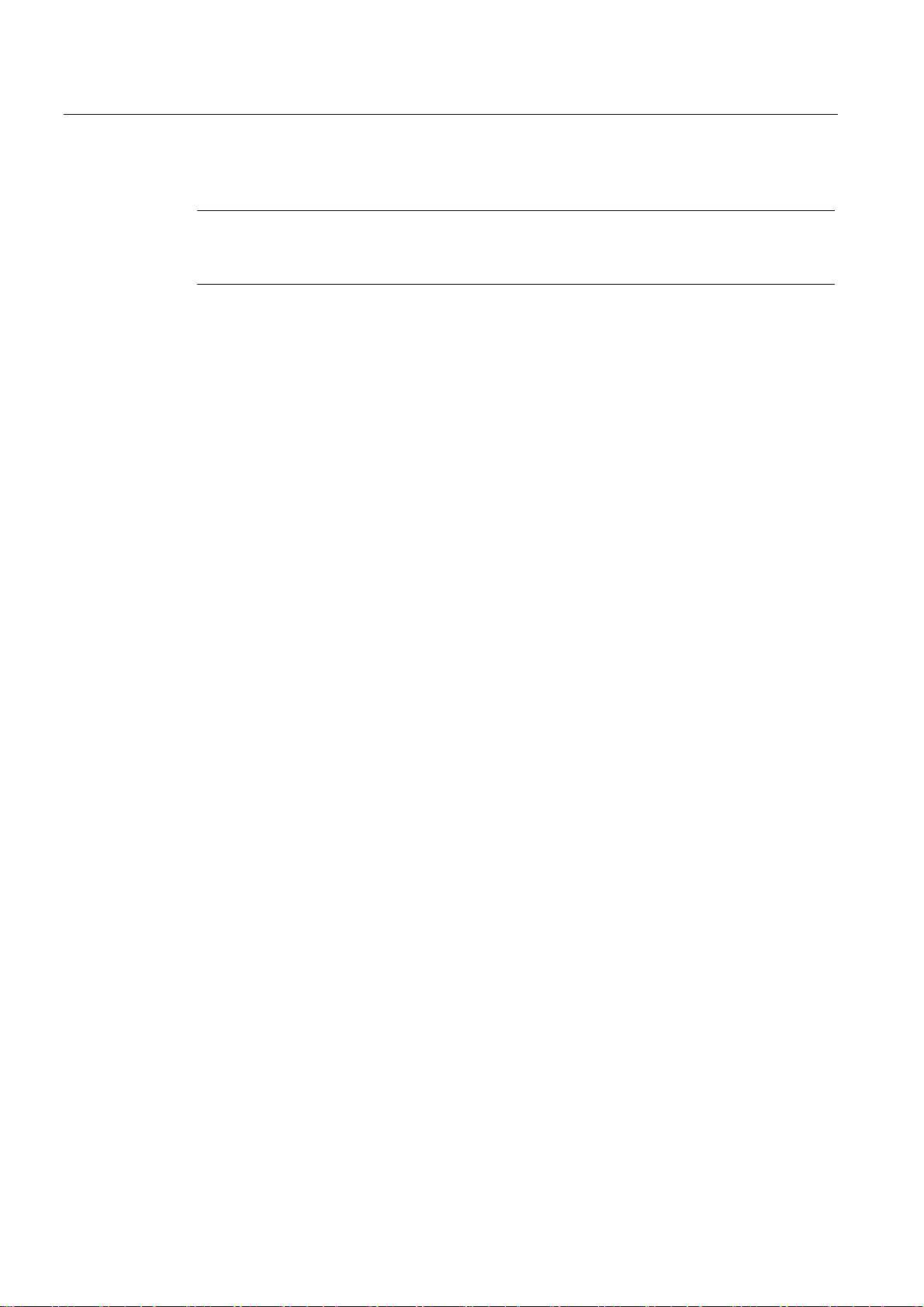

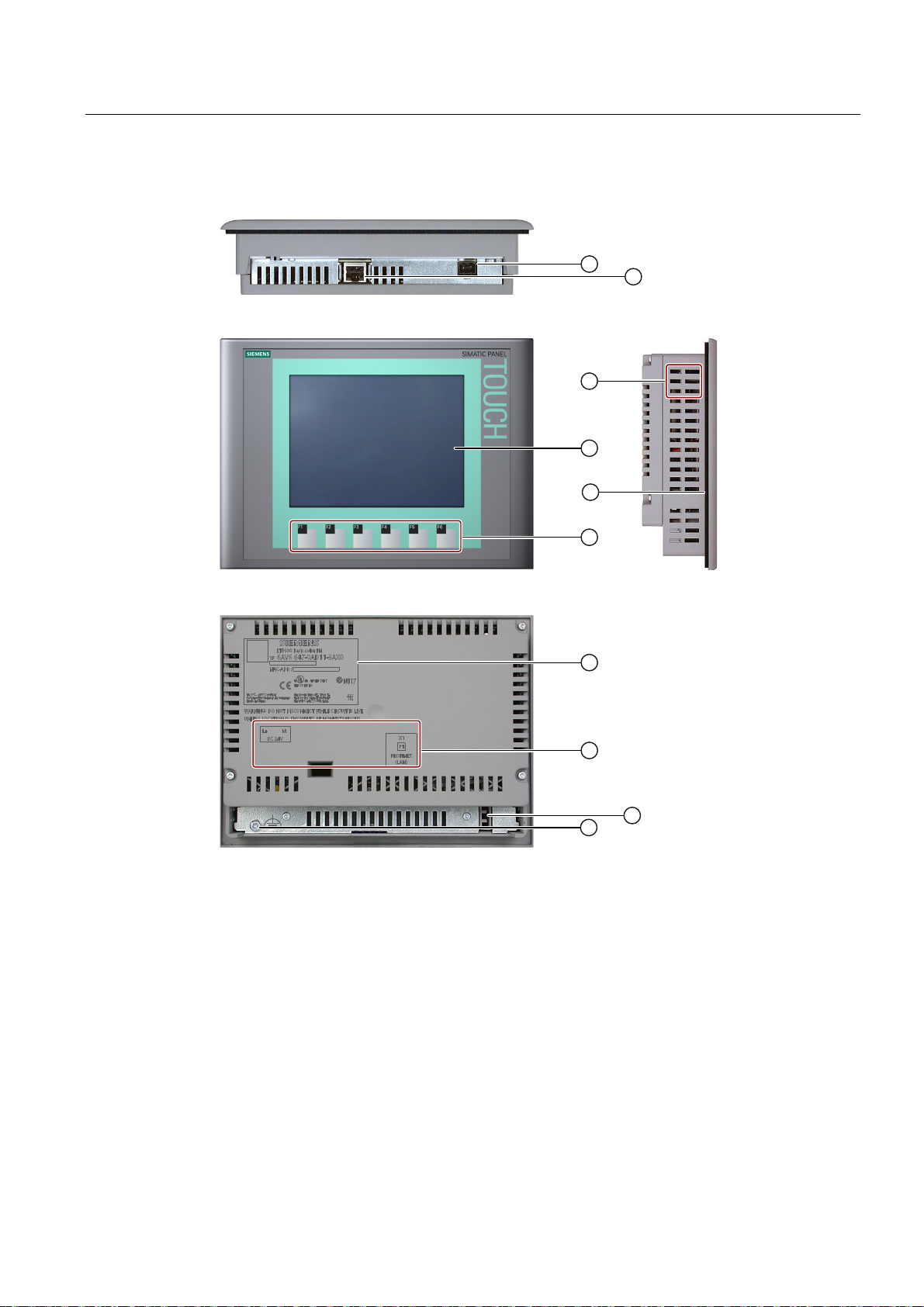

1.6 Design of the KTP600 Basic mono/color PN

1.6 Design of the KTP600 Basic mono/color PN

① Power supply connector ⑥ Function keys

② PROFINET interface ⑦ Rating plate

③ Cutouts for a mounting clamp ⑧ Interface name

④ Display/touch screen ⑨ Guide for a labeling strip

⑤ Mounting seal ⑩ Functional earth connection

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

17

Page 18

Overview

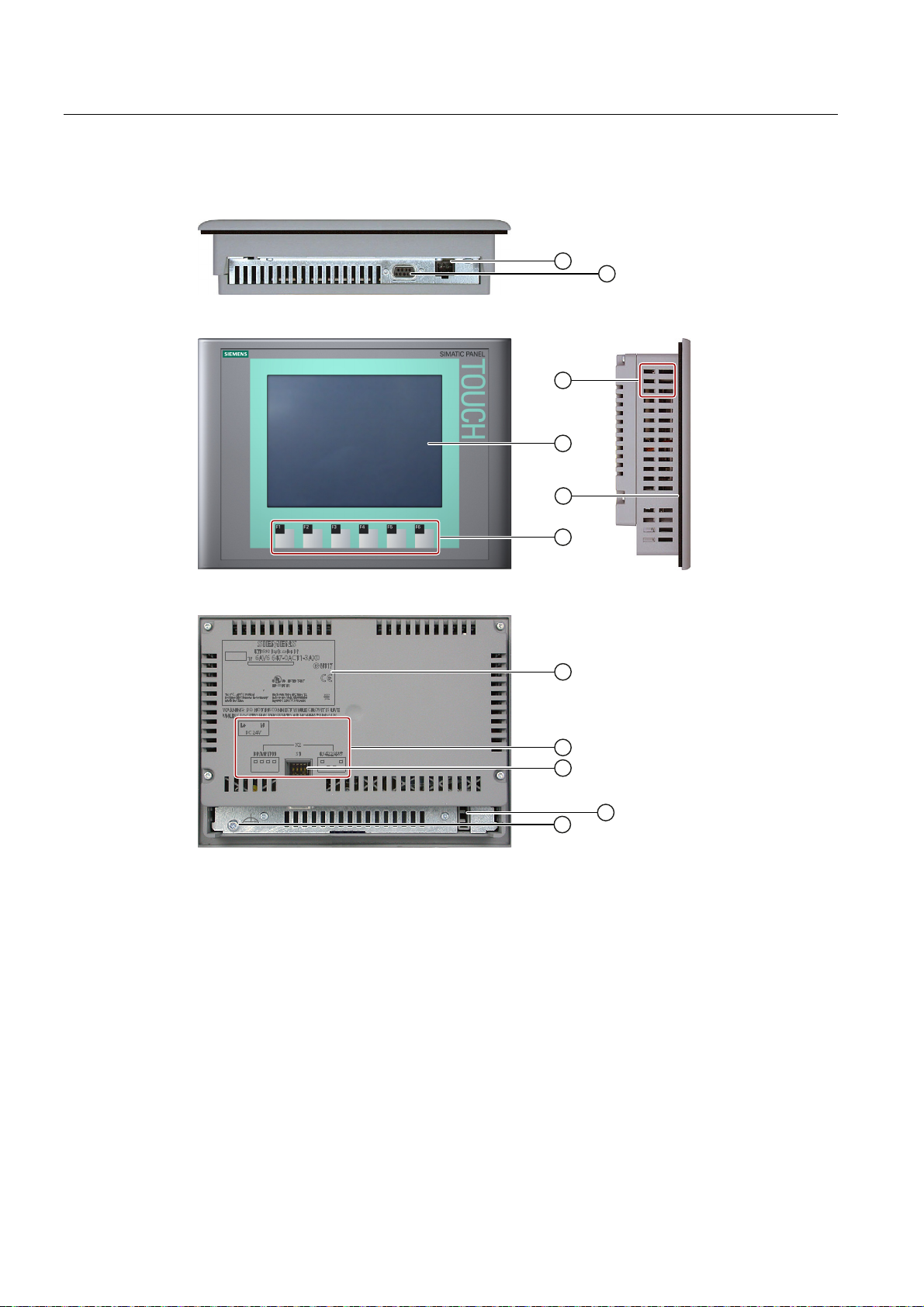

1.7 Design of the KTP600 Basic color DP

1.7 Design of the KTP600 Basic color DP

① Power supply connector ⑦ Rating plate

② RS-422/RS-485 interface ⑧ Interface name

③ Cutouts for a mounting clamp ⑨ DIP switch

④ Display/touch screen ⑩ Guide for a labeling strip

⑤ Mounting seal ⑪ Functional earth connection

⑥ Function keys

Basic Panels

18 Operating Instructions, 04/2012, A5E02421799-03

Page 19

Overview

1.8 Design of the KTP1000 Basic color PN

1.8 Design of the KTP1000 Basic color PN

① Power supply connector ⑦ Rating plate

② PROFINET interface ⑧ Interface name

③ Cutouts for a mounting clamp ⑨ Fixing element

④ Display/touch screen ⑩ Functional earth connection

⑤ Mounting seal ⑪ Guide for labeling strips

⑥ Function keys

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

19

Page 20

Overview

1.9 Design of the KTP1000 Basic color DP

1.9 Design of the KTP1000 Basic color DP

① Power supply connector ⑦ Rating plate

② RS-422/RS-485 interface ⑧ DIP switch

③ Cutouts for a mounting clamp ⑨ Interface name

④ Display/touch screen ⑩ Fixing element

⑤ Mounting seal ⑪ Functional earth connection

⑥ Function keys ⑫ Guides for labeling strips

Basic Panels

20 Operating Instructions, 04/2012, A5E02421799-03

Page 21

Overview

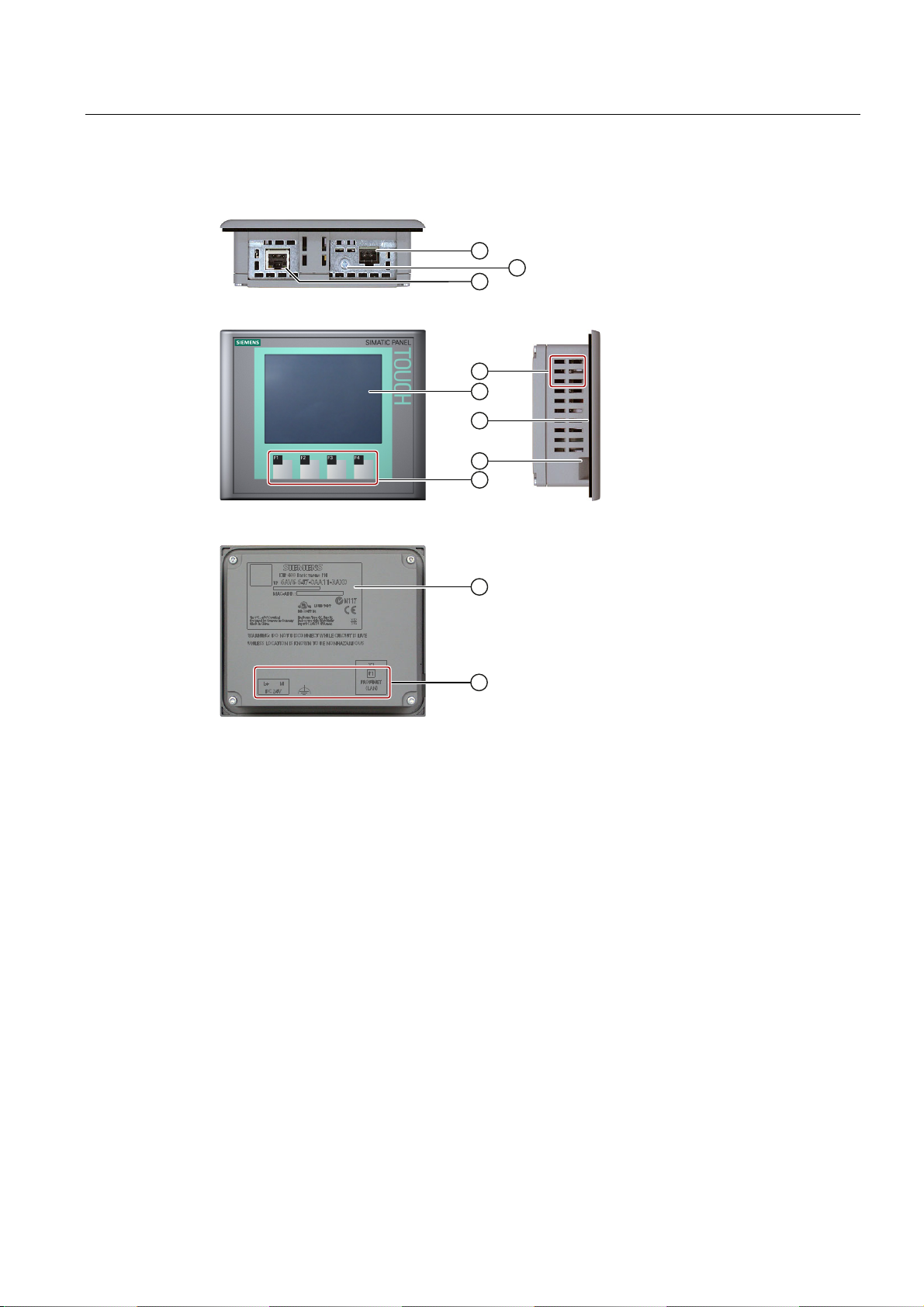

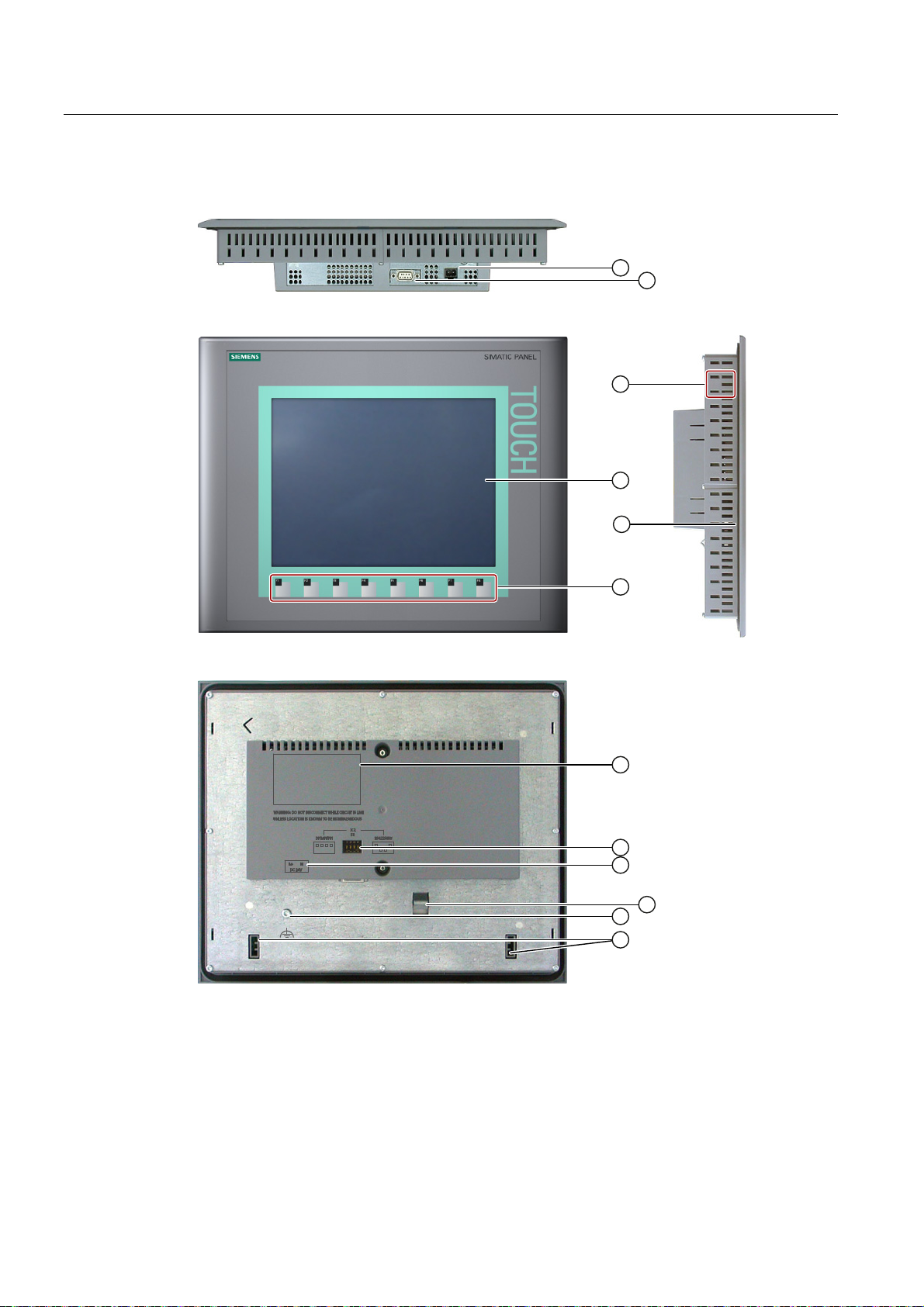

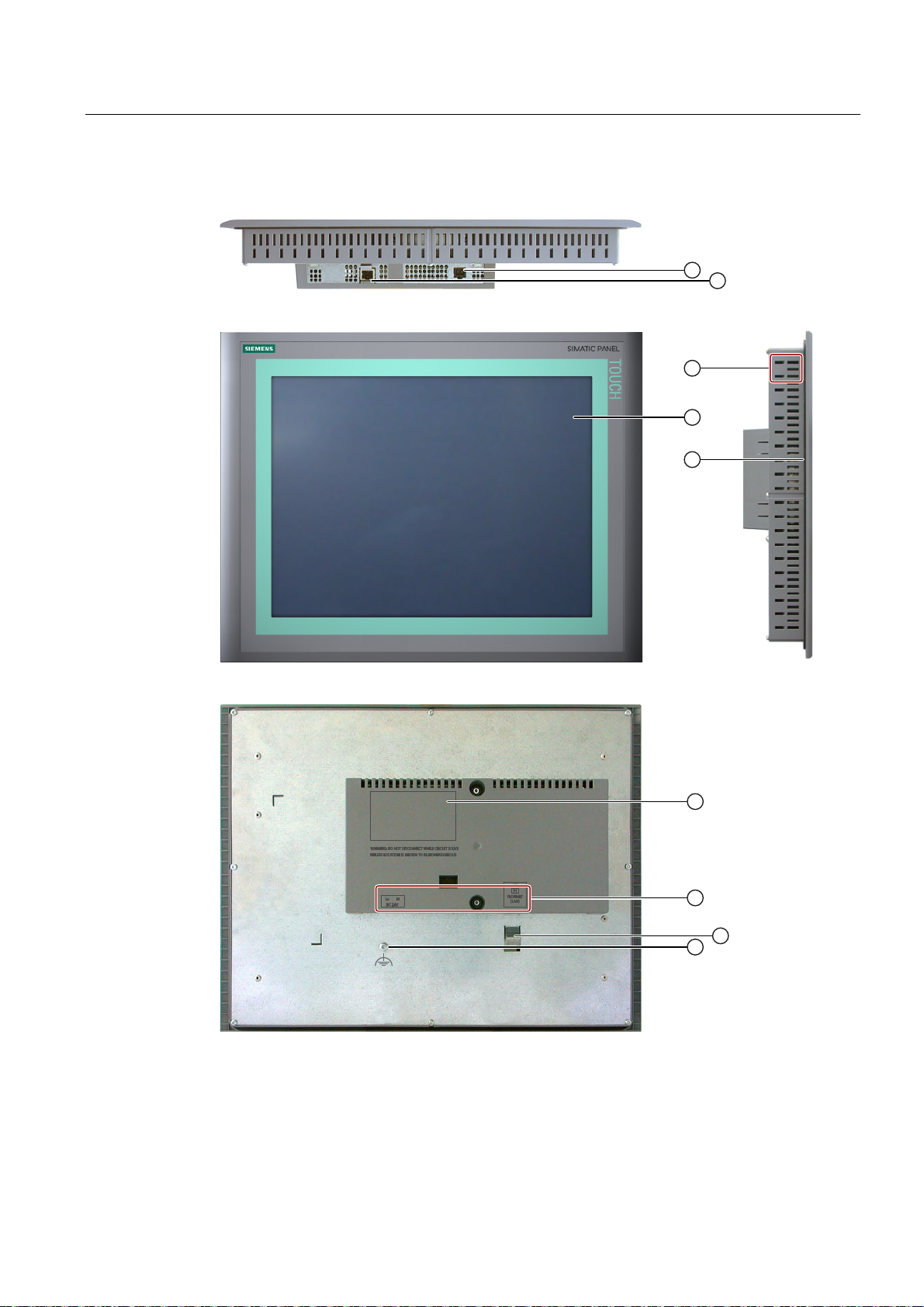

1.10 Design of the TP1500 Basic color PN

1.10 Design of the TP1500 Basic color PN

① Power supply connector ⑥ Rating plate

② PROFINET interface ⑦ Interface name

③ Cutouts for a mounting clamp ⑧ Fixing element

④ Display/touch screen ⑨ Functional earth connection

⑤ Mounting seal

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

21

Page 22

Overview

1.11 Product package

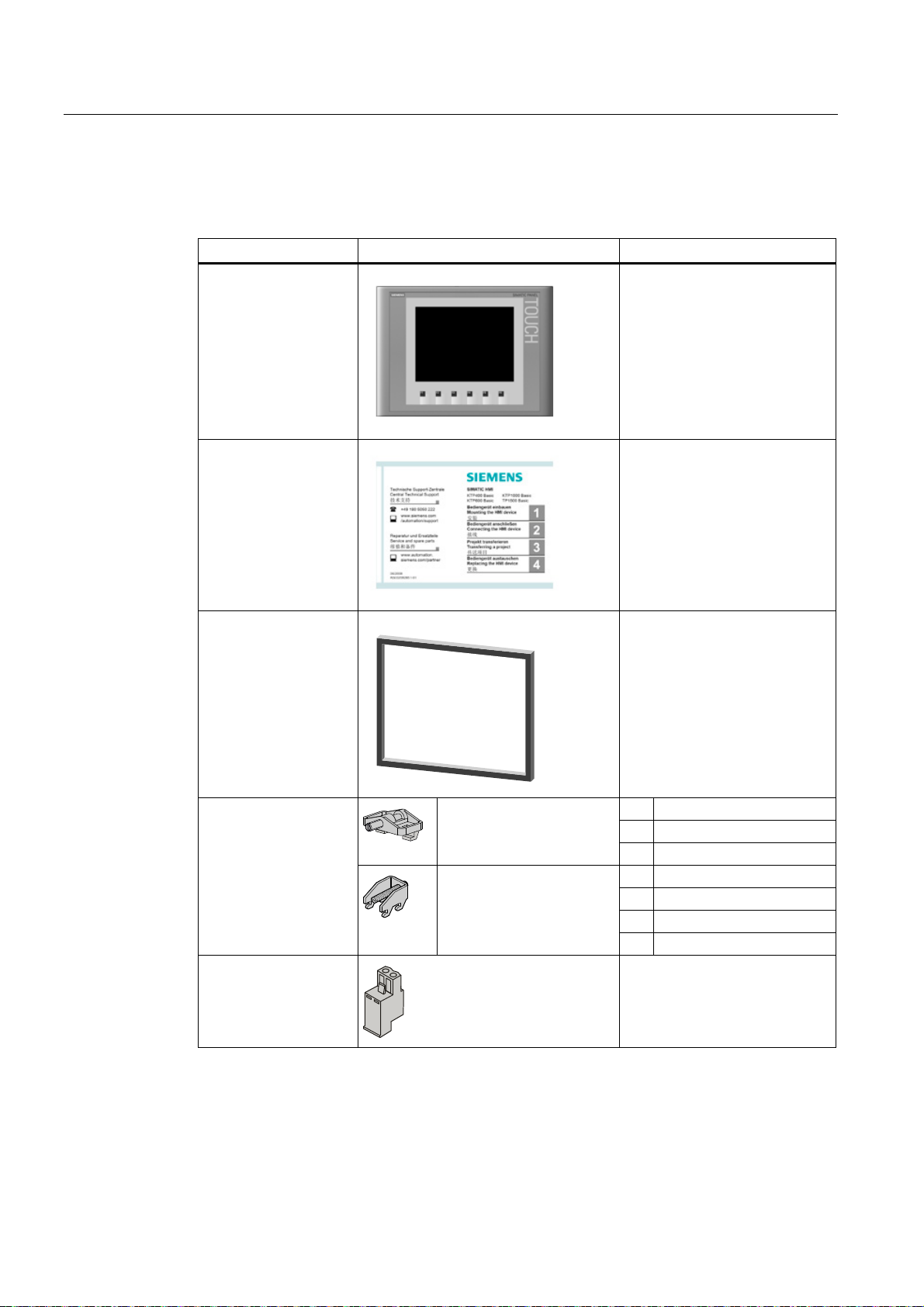

1.11 Product package

The following components are included in the product package of the HMI device.

Name Figure Quantity

HMI device

1

Quick Installation Guide

Mounting seal

Mounting clamps with

grub screw

Power supply terminal

Plastic mounting clamps

Aluminum mounting

clamps

1

1

Included with KTP 600 Basic and

already installed with all other

HMI devices.

4 KP300 Basic

7 KP400 Basic

5 KTP400 Basic color PN

5 KTP400 Basic mono PN

6 KTP600 Basic

12 KTP1000 Basic

14 TP1500 Basic

1

Basic Panels

22 Operating Instructions, 04/2012, A5E02421799-03

Page 23

Overview

1.12 Accessories

1.12 Accessories

Accessories are not included in the product package of the HMI device, but can ordered on

the Internet under Industry Mall (http://mall.automation.siemens.com

This section contains the number of accessories available at the time of publication of the

operating instructions.

).

Converters, adapters and connectors

Name Purpose Order no.

RS 422 to RS 232

converter

PC/PPI cable Converts RS 422/RS 485 signals to RS 232

90 degree elbow

adapter

USB/PPI cable Converts RS 422/RS 485 signals to USB

PROFIBUS connector Recommended PROFIBUS connector with

PROFINET RJ45

connector "IE FC RJ45

Plug 2x2"

1

If the connection is lost during the operating system update, set a lower bit rate. If you use a higher

bit rate, you must use the PC/PPI cable release 3 or higher. The release code is printed on the

cable ("E version 3," for example, corresponds to release 3).

Connection of third-party controllers to Basic

Panels DP

signals. Is required for updating the operating

system with reset to factory settings

be used for the transfer.

For RS422/RS485 interface, cable outlet to rear 6AV6671-8XD00-0AX0

signals. Is required for updating the operating

system with reset to factory settings. Can also

be used for the transfer.

straight cable outlet

Required for connection of Basic Panels PN to

PROFINET

1

. Can also

6AV6671-8XE00-0AX0

6ES7 901-3CB30-0XA0

6ES7 901-3DB30-0XA0

6GK1500-0FC10

6GK1901-1BB10-2AA0

Clamping frame

Basic Panels

Operating Instructions, 04/2012, A5E02421799-03

Name Purpose Order no.

Clamping frame

for 10"/12" Touch

For reinforcement of the mounting cutout for

KTP1000 Basic when material is not thick

enough

6AV6 671-8XS00-0AX0

23

Loading...

Loading...