Page 1

SIMATIC FS600 Laser Scanner

Laser Scanner for Personal Protection and Measurement Tasks

Instruction Manual

Page 2

600672

Page 3

Warning

The SIMATIC FS600 Laser Scanners are designed to protect operators

working at or in the vicinity of dangerous machinery. They can only fulfill their

protective requirements if they are installed to a suitable machine. It is

therefore vital that you fully understand the information provided in this

instruction manual and in all documents mentioned herein before any installation attempt. For any question please refer to your local SIEMENS dealer.

Important

This instruction manual must accompany the product throughout its working

life. Those persons responsible for the product must ensure that all persons

involved in the installation, commissioning, operation, maintenance and servicing on the product have access to all the information supplied by the

manufacturers of the machine and its safety system.

3

Page 4

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal

safety, as well as to prevent damage to property. The notices referring to your personal

safety are highlighted in the manual by a safety alert symbol, notices referring only to

property damage have no safety alert symbol. These notices shown below are graded

according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not

taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not

taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper

precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper

precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding

information is not taken into account.

If more than one degree of danger is present, the warning notice representing the

highest degree of danger will be used. A notice warning of injury to persons with a

safety alert symbol may also include a warning relating to property damage.

4

Page 5

Qualified Personnel

The device/system may only be set up and used in conjunction with this

documentation. Commissioning and operation of a device/system may only be

performed by qualified personnel. Within the context of the safety notes in this

documentation qualified persons are defined as persons who are authorized to

commission, ground and label devices, systems and circuits in accordance with

established safety practices and standards.

Prescribed Usage

Note the following:

WARNING

This device may only be used for the applications described in the catalog or the technical description and only in connection with devices or components from other manufacturers which have been approved or recommended by Siemens. Correct, reliable

operation of the product requires proper transport, storage, positioning and assembly

as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining

trademarks in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the

hardware and software described. Since variance cannot be precluded entirely, we

cannot guarantee full consistency. However, the information in this publication is

reviewed regularly and any necessary corrections are included in subsequent editions.

5

Page 6

About this Instruction Manual

This instruction manual contains information on the proper use and effective application of the SIMATIC FS600 Laser Scanner.

WARNING

All the information contained herein, in particular the safety notes, need to be carefully

observed.

Notes regarding safety and warnings are marked by this symbol .

Notes regarding important pieces of information are marked by the symbol .

References to the safety of laser devices are identified with the symbol .

This instruction manual must be stored carefully. It must be available for the entire

operating time.

SIEMENS AG is not liable for damages caused by improper use. Knowledge of

this instruction manual is an element of proper use.

Warning

Dangerous electric voltage! Electric voltage can cause electric shock and burns. Before commencement of work you

therefore need to turn the system/device power off.

Important note

Safe device operation can only be guaranteed when certified components are used!

The products described herein were developed to take over safety-related functions as

part of a turn key system or machine. A complete safety-related system is usually

equipped with sensors, evaluation units, status controls and incorporates concepts for

safe switch-off procedures. It is the responsibility of the manufacturer of a system or a

machine to ensure its correct overall operation. SIEMENS AG, its local offices and

associated companies (hereafter referred to as “SIEMENS”) cannot guarantee for all

features of a turn key system or a machine that was not designed by SIEMENS.

Neither does SIEMENS assume liability for recommendations given in or implied in the

following instruction manual. The following instruction manual shall not be construed as

a new guarantee, warranty or liability claim beyond the general terms and conditions of

SIEMENS.

Copyright © SIEMENS AG 2007 All rights reserved

Reprints and reproduction of this instruction manual as well as communication and

utilization of its content is not permitted without express permission. Noncompliance

will entail compensation for damages. All rights reserved, in particular for the grant of

patents or design registrations.

Technical Support:

Telephone:+49 (0) 180 50 50 222

Internet:www.siemens.com/automation/service&support

Subject to change without prior notice.

L

6

Page 7

CONTENTS

1 Approvals and Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1 Approval and Declaration of EC Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Specialized Technical Terms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Guidelines and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Brief Description and Functional Principle of the SIMATIC FS600 Laser

Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Special Features of the SIMATIC FS600 Laser Scanner . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Safety notes and usage in accordance with intended purpose . . . . . . . . . . . . . . . . . . . . . . 17

3.1 General safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Usage requirements and usage in accordance with intended purpose . . . . . . . . . . . . . . 17

3.3 Restrictions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Information Related to Detection Zone Changeover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 General information related to determining detection zone contours . . . . . . . . . . . . . . . 20

3.6 Additional Safety Notes for Stationary Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7 Additional Safety Notes for Mobile Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 Applications for the SIMATIC FS600 Laser Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Stationary Safeguarding of the Danger Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Access guarding by passage monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Safeguarding of danger points based on hand and arm detection . . . . . . . . . . . . . . . . . 25

4.4 Mobile Safeguarding of Automatic Guided Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.5 Protecting Transporter Trolleys against Collisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6 Guarding the sides on AGVs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.7 Other possible applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 Information for Planning and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Attachment and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2 Installing adjacent laser scanners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.2 Adjusting adjacent laser scanners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3 Information on Setting the Dimensions of Detection Zones . . . . . . . . . . . . . . . . . . . . . . 32

5.3.1 Methods of Configuring Detection Zones using the PC . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3.2 Range of the Detection Zone, Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3.3 Range of the Warning Zone, Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3.4 Range of the measurement field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.5 Required Detection Zone Additions Z . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.4 Safeguarding Stationary Danger Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4.1 The Purpose of Safeguarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4.2 Mounting Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4.3 Mounting Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.4.4 Recommendations for Mounting to Prevent Unmonitored Zones . . . . . . . . . . . . . . . . . . 36

5.4.5 Additions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4.6 System Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4.7 Restart Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4.8 Calculating the Detection Zone Dimensions for Safeguarding an Area . . . . . . . . . . . . . 42

5.5 Access protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.5.1 Object of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.5.2 Installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.5.3 Safety-relevant settings, and calculation of the safety distance . . . . . . . . . . . . . . . . . . . 47

5.5.4 Definition of the reference boundary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7

Page 8

5.6 Protecting danger points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.6.1 Object of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.6.2 Installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.6.3 Safety-related settings, and calculation of the safety distance . . . . . . . . . . . . . . . . . . . . 49

5.6.4 Defining the reference boundary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.7 Safeguarding Mobile Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7.1 The Purpose of Safeguarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7.2 Installing adjacent laser scanners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7.3 Mounting Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7.4 Mounting Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7.5 Recommendations for Mounting to Prevent Unmonitored Zones . . . . . . . . . . . . . . . . . . 53

5.7.6 Additions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.7.7 System Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.7.8 Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.7.9 Calculating the Dimensions of the Detection Zone of an AGV Application . . . . . . . . . . . 57

5.7.10 Side guarding configuration on AGVs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6 Details on switching over detection and warning zones . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.1 Sequence of zone pair switchovers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Practical AGV Application (Example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7 Functions of the SIMATIC FS600 Laser Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.1 Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.2 Channels for Zone Pair Changeovers, FP 1 to FP 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.3 Alarm 1 (X1-5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.4 Alarm 2 (X1-15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.5 OSSD 1 (X1-12) and OSSD 2 (X1-11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.6 Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8 Integrating the SIMATIC FS600 Laser Scanner into Machine Controls . . . . . . . . . . . . . . . . 68

8.1 Integrating the SIMATIC FS600 Laser Scanner with External Wiring with Relays

and Quadruple Zone Pair Changeover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.2 Connecting the SIMATIC FS600 Laser Scanner to a Safety Sequence Circuit

with Manual Restart, Relay Monitoring, without Zone Pair Changeover . . . . . . . . . . . . . 71

8.3 Connecting the SIMATIC FS600 Laser Scanner to a PLC with Corresponding

Safety Level (Cat. 3 or higher, EN 954) and Zone Pair Changeover . . . . . . . . . . . . . . . 72

9 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.1 Electrical Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2 Connecting the PC and Control Cables to the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.3 Connector Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.4 Points to Consider When Preparing and Laying the Cables . . . . . . . . . . . . . . . . . . . . . . 74

9.5 Interface Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.1 Hardware and Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.2 Installing “SIMATIC FS600 Parameterization Software LS4soft” and Starting Up

the SIMATIC FS600 Laser Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3 SIMATIC FS600 Laser Scanner status indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.4 Status information of the SIMATIC FS600 Laser Scanner . . . . . . . . . . . . . . . . . . . . . . . 81

10.5 Restart and device swap-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8

Page 9

11 Maintenance and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.1 Test before First Startup by Person Qualified and Authorized to Perform the

Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.2 Extended Shutdown of the SIMATIC FS600 Laser Scanner . . . . . . . . . . . . . . . . . . . . . . 83

11.3 Regular Tests by a Person Qualified and Authorized to Perform the Task . . . . . . . . . . . 84

11.4 Daily Test by with Test Piece Performed by Responsible Operating Personnel . . . . . . . 84

11.4.1 Checklist for Daily Test of Stationary Applications by Responsible Operating

Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11.4.2 Checklist for Daily Test of Mobile Applications by Responsible Operating

Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.5 Checklist for Testing Stationary Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.6 Checklist for Testing Mobile Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.7 Replacing the Optical Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

11.7.1 General information: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

11.7.2 Initial Measurement of the New Optical Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.7.3 Procedure when Using the SIMATIC FS600 Parameterization Software LS4soft

User Software Version 1.09 or later . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

11.8 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.8.1 Cleaning the Optical Window when Dirty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.8.2 Cleaning the Optical Window; Cleaning Diffusing Light Panes . . . . . . . . . . . . . . . . . . . . 96

12 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

13 Delivery Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

13.1 Coding of the Control Cable X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

14 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

14.1 Test Pieces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

14.2 Detection zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

14.3 Detection Zone Additions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

14.4 Warning zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

14.5 Contour Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

14.6 Electrical Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

14.7 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

14.8 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

14.9 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.10 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.11 Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

14.12 Environment and Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

14.13 Dimensional drawings of the SIMATIC FS600 Laser Scanner . . . . . . . . . . . . . . . . . . . 104

14.14 Dimensional drawings of the mounting system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

15 Diagnostic Codes and Causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9

Page 10

1 Approvals and Certificates

1.1 Approval and Declaration of EC Conformity

EC prototype testing in accordance with

DIN EN 61496 - 1 and

IEC 61496 - 3

TÜV

PRODUCT SERVICE GMBH

IQSE

Ridlerstr. 65

80339 Munich

10

Page 11

1.2 Specialized Technical Terms and Abbreviations

AGV Automatic Guided Vehicle (FTS in German)

AOPD Active Optoelectronic Protective Device

AOPDDR Active Optoelectronic Protective Device responsive to Diffuse

BWS See ESPE

EDM External Device Monitoring

ESPE Electro-Sensitive Protecting Equipment

FTS Automatic Guided Vehicle (see AGV)

N.O. Normal open contact

OSSD Output Signal Switching Device

PC Personal Computer

DZ Detection Zone, German SF

Reset Defined Reset

RS 232 RS 232 interface

RS 422 RS 422 interface

ZP Zone pair (contains 1 x detection zone and 1 x warning zone),

WZ Warning Zone, German WF

Reflection

Monitoring of external control parts (relay monitoring)

Safety-relevant switch output

of SIMATIC FS600 Laser Scanner

German FP

Table 1.2-1: Specialized Technical Terms and Abbreviations

11

Page 12

1.3 Guidelines and Standards

The following guidelines and standards are of critical importance for the implementation

of laser scanners. Guidelines providing particularly relevant information for users of such

systems are marked with an asterisk (

Guideline/Standard Designation

European Guidelines

98 / 37 / EG Machine guideline

73 / 23 / EWG Low voltage guideline

89 / 336 / EWG EMC guideline

A Standards

DIN EN 292 1 and 2 Safety of machinery, basic concepts

DIN EN 1050 Principles of risk assessment

B1 Standards

).

*

*

DIN EN 294 Safety distances

DIN EN 954 -1 Safety-related parts of controls

DIN EN 999 Approach speeds of body parts

B2 Standards

DIN EN 60204 -1 Electrical equipment of machines

DIN EN 60825 -1 Safety of machines with laser components

DIN EN 61496 -1

IEC 61496-3 AOPDs responsive to diffuse reflection

C Standards

DIN EN 775 Industrial robots; safety

DIN EN 1525 Automatic guided vehicles (AGV) and their

DIN EN 12895 Floor conveyor vehicles, electromagnetic

•

Electro-sensitive protecting equipment

(AOPDDR)

systems

compatibility

*

*

*

*

*

*

12

Page 13

Guideline/Standard Designation

National Standards

DIN 15185-2 Warehousing systems using rail-guided aisle

conveyance vehicles

Table 1.3-1: Guidelines and Standards

This list does not claim to be complete. In certain cases, the concrete requirements of

the application will necessitate the application of additional guidelines and standards!

Copies of safety standards can be purchased from the Beuth Publishing Company in

Berlin, Germany.

*

2 System Overview

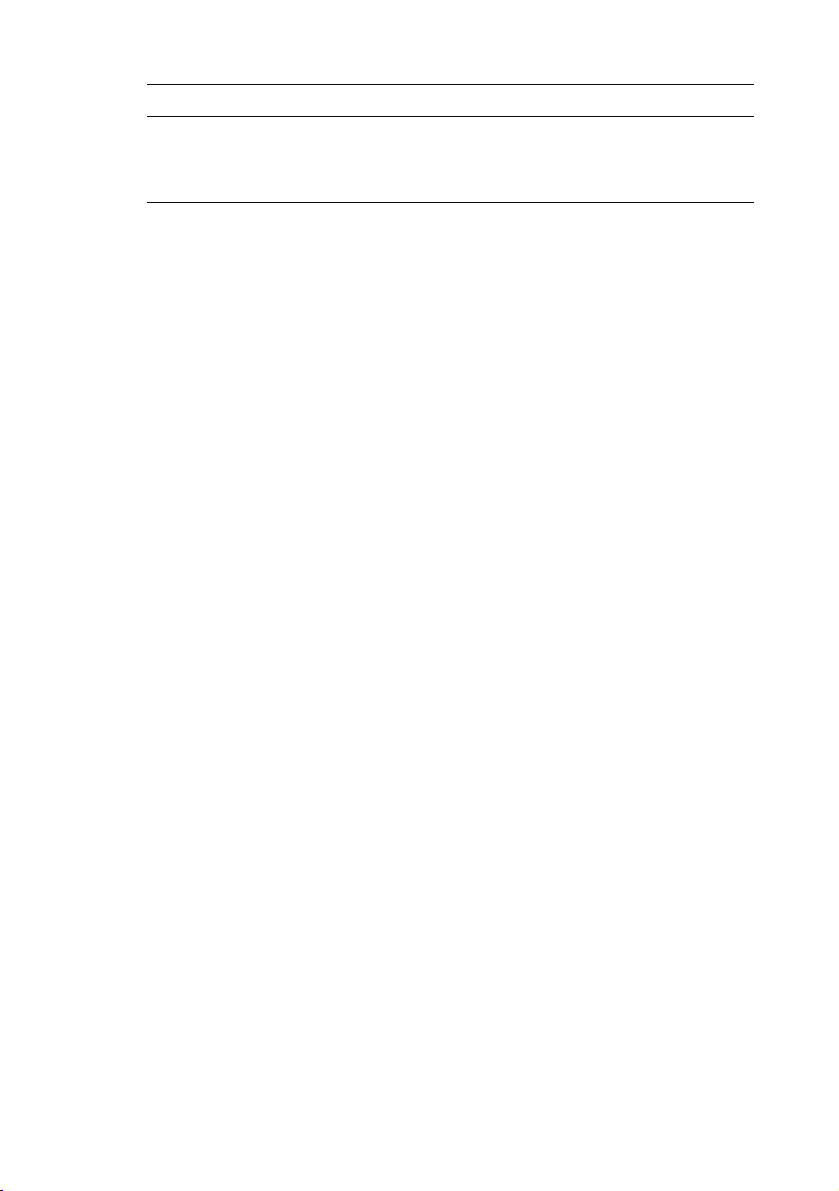

2.1 Brief Description and Functional Principle of the SIMATIC FS600 Laser Scanner

The SIMATIC FS600 Laser Scanner is an optical distance sensor that takes twodimensional measurements. It could also be referred to as an optical area radar device.

The sensor uses a rotating deflecting unit to periodically emit light pulses within a

working range of 190°.

If these pulses strike a person or an obstacle, the reflected light is received and

evaluated by the SIMATIC FS600 Laser Scanner. The scanner calculates the precise

coordinates of the person or object based on the travel time of the reflected light and the

current angle of the deflecting unit. If the person or obstacle is within the bounds of a

previously defined area called a detection zone, a safety-oriented switching function is

performed. This switching function causes the semiconductor outputs to be switched off.

The safety-oriented switching function cannot be reset until the detection zone is clear.

Depending on the operating mode, the reset can be initiated either automatically or

manually.

13

Page 14

DZ = Detection zone, max. 2,15 m / 4 m

WF = Warning zone, max. 15 m

a = Maximum registration of measurement values,

max. 50 m

b = Detection zone programmed

in the SIMATIC FS600

Laser Scanner

(example)

c = Warning zone programmed

in the SIMATIC FS600

Laser Scanner

(example)

d = Configurable detection

zone and warning zone

expansion (-5 °)

d

cb

e = Configurable detection

zone and warning zone

expansion (+5 °)

f = Object in the detection zone

Fig. 2.1-1: The 190° angle range of the SIMATIC FS600 Laser Scanner is divided

into 0.36° angle segments.

A laser diode coupled with transmitter optics produces focused light pulses. These

pulses are projected across the monitored surface by a rotating mirror in such a way that

a light pulse is triggered in each of the angle segments within 40 ms (scanning rate: 25

scans/s).

SF

WF

f

a

e

14

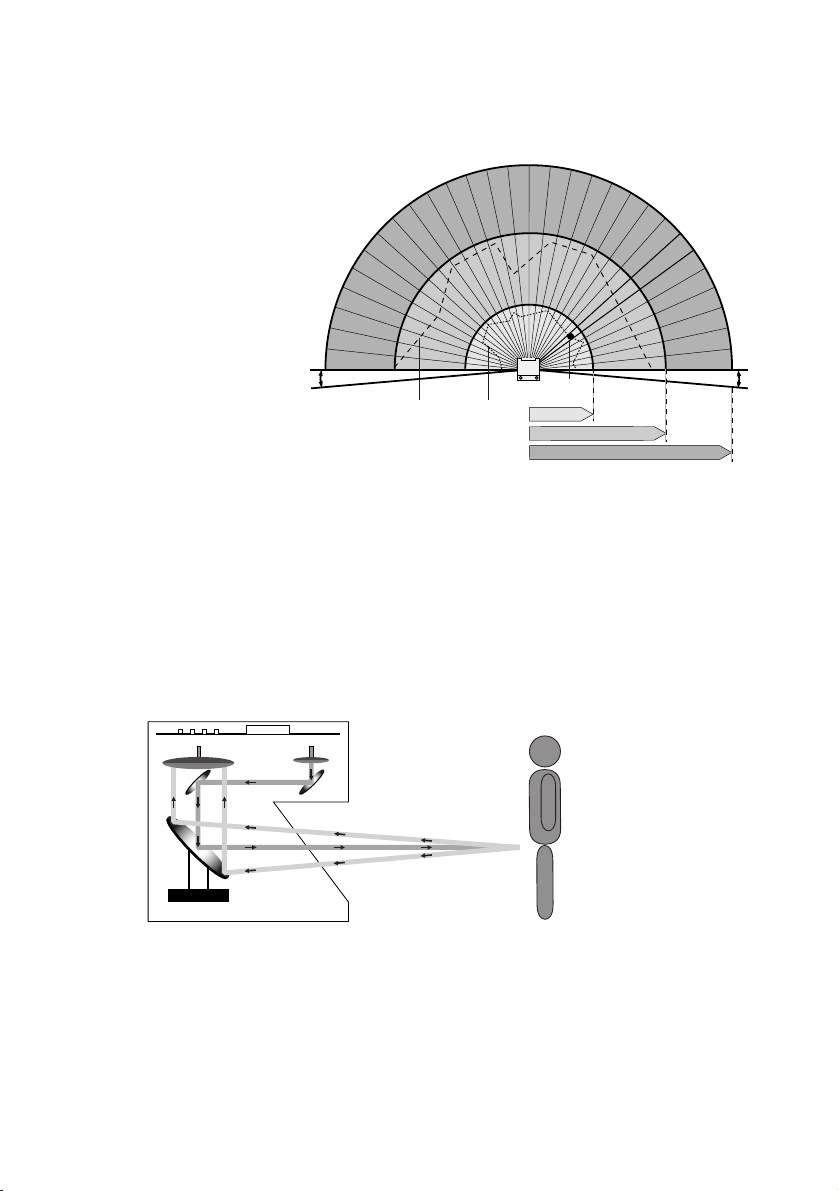

Fig. 2.1-2: Functional principle of the SIMATIC FS600 Laser Scanner

The SIMATIC FS600 Laser Scanner can detect people up to a distance of 4.0 m e.g.

2.15 m – even if they are wearing very dark clothing or exhibit a low degree of

reflectance. Dangerous movements are brought to a standstill by two failsafe

semiconductor outputs.

Page 15

Objects (min. 150 x 150 mm) are detected up to a distance of 15 m (corresponds to

the warning zone) and signaled by way of a non-safety-related semiconductor output.

Four programmable zone pairs (each of which consists of one detection zone and one

warning zone) enable the scanner to be optimally adapted to the needs of each

particular application.

The SIMATIC FS600 Laser Scanner can be implemented not only on machines and

systems (stationary safeguarding of danger zones), but also on vehicles (mobile

safeguarding of transport vehicles).

Due to its wide range of measurement and its non-contact, electro-sensitive

measurement principle,

the SIMATIC FS600 Laser Scanner can be effectively used as a protective device for

virtually any application.

2.2 Special Features of the SIMATIC FS600 Laser Scanner

• Four / eight freely programmable detection zones (up to a maximum of 4 m)

• Four / eight freely programmable warning zones (up to a maximum of 15 m)

• Expanded monitoring range of up to 190 °

• ConfigPlug see Chapter 10.5 for easy device swap-out without configuration

expense

• Compact design (W x D x H: 140 mm x 135 mm x 155 mm)

• Low weight (2 kg)

• Low power requirements (300 mA, plus the load at the outputs)

• Two types of interfaces at one Sub-D jack (RS232 and RS422)

• User-friendly software

15

Page 16

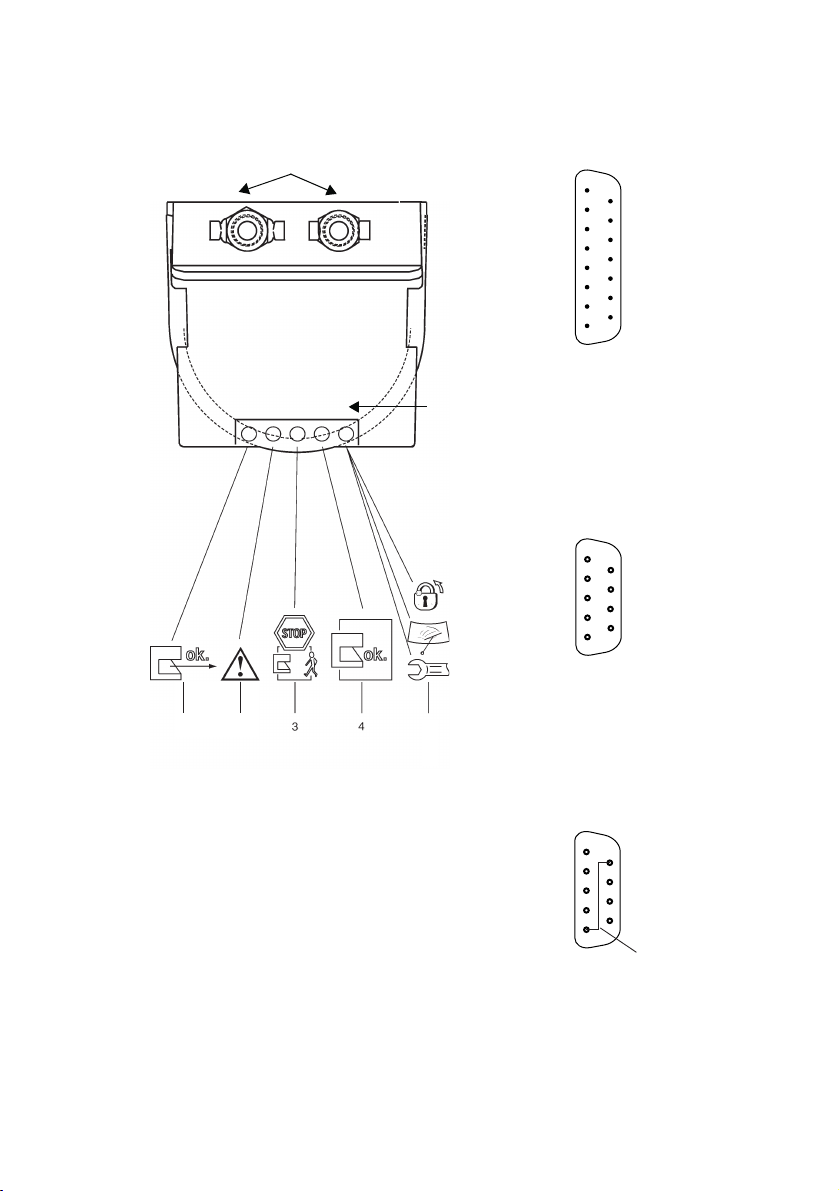

Status displays on the SIMATIC

FS600 Laser Scanner

Protective caps

Assignment of

interface X1

FP 4

8

FP 3

7

FP 2

FP 1

UB

GND

6

5

4

3

2

1

Alarm 1

Restart

LEDs

Assignment of interface

X2 as RS232 port

Alarm 2

15

Reserved

14

Reserved

13

OSSD2

12

OSSD1

11

Reserved

10

Reserved

9

16

1a

2a

1b

2b

2c

5a

5b

5c

1a= Sensor function

1b= Errors on the zone pair control inputs,

Light flashing at 2 Hz

2a= Warning field is occupied

2b= Optical window is dirty,

Light flashing at 2 Hz

2c = Confi gPlug configuration see Chapter 10.5 no t

compatible, Light flashing at 4 Hz

3 = OSSDs are turned off

4 = OSSDs are turned on

5a= Restart inhibit locked,

Continuous light

5b= Optical window is dirty,

Light flashing at 2 Hz

5c = Fault, light flashing at 4 Hz

Reserved

Reserved

GND/shield

TxD

RxD

1

2

3

4

5

RS232 detection

6

Reserved

7

Reserved

8

Reserved

9

Assignment of interface

X2 as RS422 port

Tx +

Tx -

Rx -

Rx +

GND/shield

1

2

3

4

5

RS422 detection

6

Reserved

7

Reserved

8

Reserved

9

Connection

Pin 5 to Pin 6

Page 17

3 Safety notes and usage in accordance with intended purpose

3.1 General safety notes

SIEMENS products are developed and manufactured with careful application of

standard rules of the industry. The protective function of the devices can be negatively

affected, however, if they are used improperly or not in accordance with their intended

purposes. If this occurs, it may not be possibly to safeguard danger areas completely

or at all, which may result in danger to life and limb for persons who are in the general

area of the machines or systems.

CAUTION – LASER RADIATION!

The SIMATIC FS600 Laser Scanner is a laser device belonging to laser class 1. The

valid legal and local regulations for operating laser systems must be complied with.

Avoid positioning the scanner at eye level.

3.2 Usage requirements and usage in accordance with intended purpose

The relevant regulations for machine safety apply for the use of the SIMATIC FS600

Laser Scanner. Responsible authorities (for example professional trade unions, OSHA)

are also available for questions related to safety. In general, the following usage

requirements must be observed:

• If the scanner is enclosed in a protective housing, additional window material, such

as plastic or glass must not be used as it may impair the detection.

• Avoid touching the scanner optical window and the six diffusing light screens.

• The SIMATIC FS600 Laser Scanner is not suitable for use as a protective device:

- if it is possible that dangerous fluids will be spewed out or objects will be

- ejected. for machines with long braking times (max. depth of the detection

zone: 4 m)

For these cases, SIEMENS offers suitable safety interlocking devices (safety

switches) with and without guard locking.

• The SIMATIC FS600 Laser Scanner corresponds to Type 3 in accordance with

IEC 61496-1 and –3A safety category of 3 in accordance with EN 954-can be

achieved with the SIMATIC FS600 Laser Scanner if all other elements in the safety

chain are set up to stop the dangerous motion in accordance with that safety

category.

• The electrical connection of the SIMATIC FS600 Laser Scanner to the control

system must only be made by an electrician.

• The 24-V DC power supply (+20 %, -30 %) must be ensured by a safe network

disconnect in accordance with IEC 742. The same requirements apply to all

connected input and output circuits..

17

Page 18

• The 24-V DC power supply must be fed to the scanner through a separate branch

with a 1.25 Amp delayed action fuse in the control cabinet.

• Guard operation is only permitted with the control cable (X1) of the dummy

connector . This also applies for transport and storage.

• The safety output has a double design. The two OSSDs must always be included

in the shut-off circuit of the machine in such a manner that either of the two is

completely sufficient by itself to turn off the motion that presents a danger.

• The alarm output 1 (Pin 5 on X1) must not be used to switch safety-related signals.

• System tests (of the scanner, machine, control components and switch

components) may only be performed when they do not result in potential hazards

for people.

• Tampering with or making changes to the SIMATIC FS600 Laser Scanner can

result in the loss of the safety function.

• Only expert trained personnel is allowed to perform startup, maintenance,

parameter settings or detection zone configurations. Familiarity with the safety

notes in this Connecting and Operating Instruction and in the operating instructions

for the “SIMATIC FS600 Parameterization Software LS4soft” program constitutes

part of this expert knowledge.

• The password required for configuring safety-relevant parameters must be kept in

a secure location by the safety official. Information about password levels can be

found in the “SIMATIC FS600 Parameterization Software LS4soft” user's manual.

• If the machine is designed for start interlock /manual restart, all detection zones

must be checked before enable - no one is permitted in the danger area.

3.3 Restrictions for Use

• Glass, highly reflective materials such as mirrors (reflectance > 10,000 %), or

objects that do not reflect any light back to the sensor can falsify the measurement

result. More information is available in Chapter 5.3.5.

• Do not expose the SIMATIC FS600 Laser Scanner to flying sparks (for example a

welding flash). Doing so may cause damage to the optical window.

• Vapor, smoke, dust and all particles visible in the air have a significant negative

effect on measurement values and will result in the semiconductor outputs being

turned off.

• Avoid extreme variations in temperature.

18

Page 19

• Make sure that the following types of light sources are not present on the scanning

plane:

- Laser light from one or more other scanners or sensors

- Infrared light

- Fluorescent light

- Stroboscopic light

Please consider as well Chapter 5.2.

• It must not be used with internal combustion engines.

• The SIMATIC FS600 Laser Scanner is conceived for use inside enclosed spaces

and with the operating parameters listed in the technical specifications

(temperature, humidity, shock, vibration, etc.). Please refer to the list of parameters

in Chapter 14.

• Avoid having reflective surfaces (such as glass, mirrors, retro-reflectors, etc.) at

fixed contours in the scanning plane. If this is not possible, an additional detection

zone must be provided.

3.4 Information Related to Detection Zone Changeover

If alternating operation is included in the design, and thus detection zone changeover,

the activation and effect of the detection zone in question must match the alternating

operating mode.

• The new detection zone must be activated before turning off the previous detection

zone. The time at which the changeover is made must be based on a risk analysis.

• Braking paths, response and coast-down times must be taken into consideration

(for example overlapping detection zones).

• A “Start interlock” function is provided.

• If the machine has a restart key, it must not be possible to operate it from inside the

detection zones. All danger areas must be visible from the position of the button.

Before releasing the start/restart interlock, all detection zones must be tested. No

one is permitted inside the danger areas.

• There must be no unmonitored zones inside the danger areas.

• There must be no possibility for direct access to the danger area that shortens the

necessary safety distance (use a protective grid, for example).

• The information on required detection zone additions in Chapter 5 must be

observed.

19

Page 20

3.5 General information related to determining detection zone contours

• Shadow effects (e.g. surfaces or areas located behind stationary objects) must be

considered. As a rule, insufficient safeguarding must be adequately supplemented

by further safety measures such as guard fences, light curtains, and the like!

• Access to the detection zone in the dangerous area is not permitted.

• When setting the dimensions of the detection zone, you must comply with the

formulas cited in Chapters 5.4.8 and 5.7.9 ! Be sure to comply with higher-level

machine standards (e.g. DIN EN 1525) if applicable.

These contain individual specifications, for example, on points of access to the

danger zone and, if applicable, detection zone additions that must be given special

consideration.

They also provide information on how to measure safety distances at machines.

• Detection zones with a radius smaller than 20 cm (at or close to the scanner) are

not admissible. 20 cm is the preset minimum contour.

• When setting the dimensions of the detection zones, please comply with the

maximum angle error stated in the technical specifications (Chapter 14.11).

• Needle-shaped detection zone contours are not permitted, since they do not

ensure any protective effect. For additional information, please refer to the

SIMATIC FS600 Parameterization Software LS4soft user software (Chapter

entitled “Definition of Detection Zones”).

• Due to possible measurement errors, every detection zone has an additions area

in which detection is not guaranteed under all conditions. Please consider as well

Chapter 5.3.5. Read Chapter 5.4.6 and 5.7.7 for information on optimizing system

availability.

• The required safety distances must be taken into account when making detection

zone configurations. Safety distances are calculated according to formulas found in

either the machine-specific C standards or the general B standards IEC 61496-3 in

combination with DIN EN 999 (see Section 2 and 5 of the standard). Tolerance

fields and/or additions

(make sure to consider Chapter 5.4 and 5.7).

• After the detection zones have been set, make a printout of the following

information:

- Detection zone contour with the X and Y coordinates

-Date

- Serial number of the scanner

- Name of the safety official

• When calculating the additions, be sure to consider whether the dust algorithm is

deactivated or activated (see Chapter 5.3.5).

20

Page 21

• When calculating the safety distances, be sure to consider all delay times, such as

the response time of the scanner, response time of the control elements, and

braking times and/or stopping times of the machine/system or AGV! Variations in

delay time caused by factors such as reduced braking power must also be taken

into consideration.

• The effectiveness of the switch-off function must be tested along the defined

contour of the detection zone during the initial startup and subsequent to any

changes made to a machine or system.

• The effectiveness of the switch-off function must be tested for the detection zone

contours along the entire driving route during the initial startup and following any

changes made to an AGV.

• In the event that there is insufficient room available to allow the full dimensions of

a detection zone, for example because of the position of the scanner, additional

safety measures (e.g. safety grids) must be installed.

• Following each definition of and change to the detection zones, the configuration

must be checked to see whether the possibility of people standing in the danger

zone as well as any barriers provided have been considered by an appropriate

layout of the detection zone(s).

3.6 Additional Safety Notes for Stationary Use

• If the danger zone can be accessed from the side, and if the detection zone cannot

be extended sufficiently in this direction, additional safety measures (e.g. safety

fences) must be installed.

• We recommended marking the contour of the detection zone on the floor by

painting a colored line or applying colored adhesive tape.

• Check the mounting regularly (in particular, the angle of inclination) in order to

guarantee the reliability of detection.

21

Page 22

3.7 Additional Safety Notes for Mobile Use

• There are additional requirements for the use of scanners on automatic guided

vehicles (AGV) and transporter trolleys according to DIN EN 1525.

• If possible, expanded detection zones to each side should be provided in order to

safeguard access from the side and directly in front of the vehicle.

• If is it not possible to completely safeguard the contour of the vehicle including its

trailer and the dimensions of its load while making curves, additional protective

devices such as switch strips must be attached to the side of the vehicle.

• There must be a minimum safety distance S

on both sides. A one-sided minimum safety distance is admissible in certain

exceptional cases. The specifications of DIN EN 1525 must be complied with.

• The basic value of the detection zone width for an AGV corresponds to the

maximum vehicle width including the trailer and the dimensions of the load plus the

detection zone additions Z

AGV while making curves must be considered when defining detection zones.

• If the SIMATIC FS600 Laser Scanner is mounted on vehicles, the mounting

(especially the angle of inclination), the vehicles' braking power, and if applicable,

play in the vehicle guidance (the difference between the optimum and actual line of

guidance) must be regularly checked in order to guarantee the reliability of

detection.

. Furthermore, the greatest possible lateral shift of the

S

of 500 mm to the side of the vehicle

AB

22

Page 23

4 Applications for the SIMATIC FS600 Laser Scanner

Due to its continuous coverage of the area, its wide range, and the ability to select

among four / eight zone pairs, the SIMATIC FS600 Laser Scanner is able to handle even

complex applications

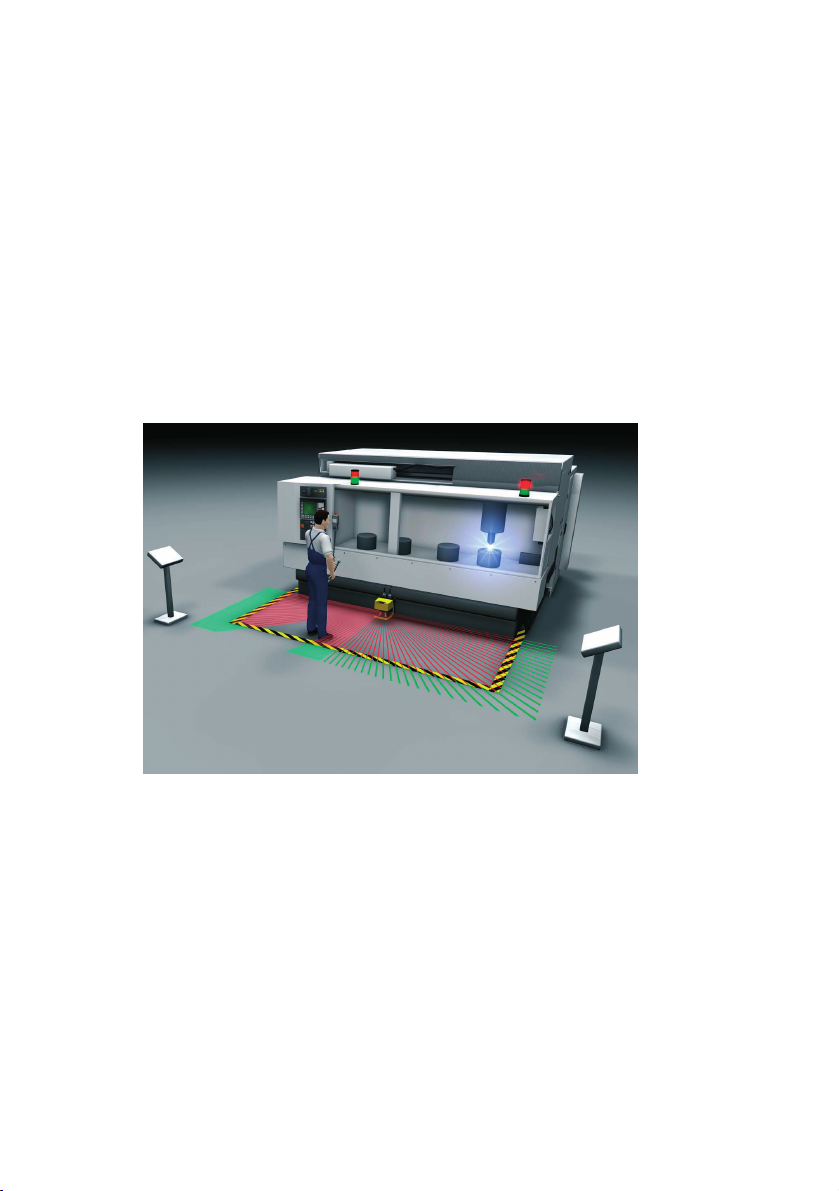

4.1 Stationary Safeguarding of the Danger Area

The SIMATIC FS600 Laser Scanner is used to safeguard dangerous working areas at

machines and systems where both constant and variable demands are placed on the

geometrical shape of the detection zone. The aim is to prevent people from entering the

danger zone or reaching the danger point with their upper and/or lower extremities, at

the same time without impeding the production process.

The SIMATIC FS600 Laser Scanner can be mounted directly at the machine table or

on the side or in front of the machine.

b

WF2

SF2

SF1

a

WF1

SF1= Detection zone 1, activated a = Emergency stop and

manual restart interlock

SF2= Detection zone 2, deactivated b = SIMATIC FS600 Laser Scanner

WF1= Warning zone 1, activated

WF2= Warning zone 2, deactivated

Fig. 4.1-1: Danger area guarding at stationary machinery with two alternating work

Please comply with the safety notes in Chapter 3 and Chapter 5.4.7. For an example of

how to calculate detection zone measures, please refer to Chapter 5.4.8.

areas

23

Page 24

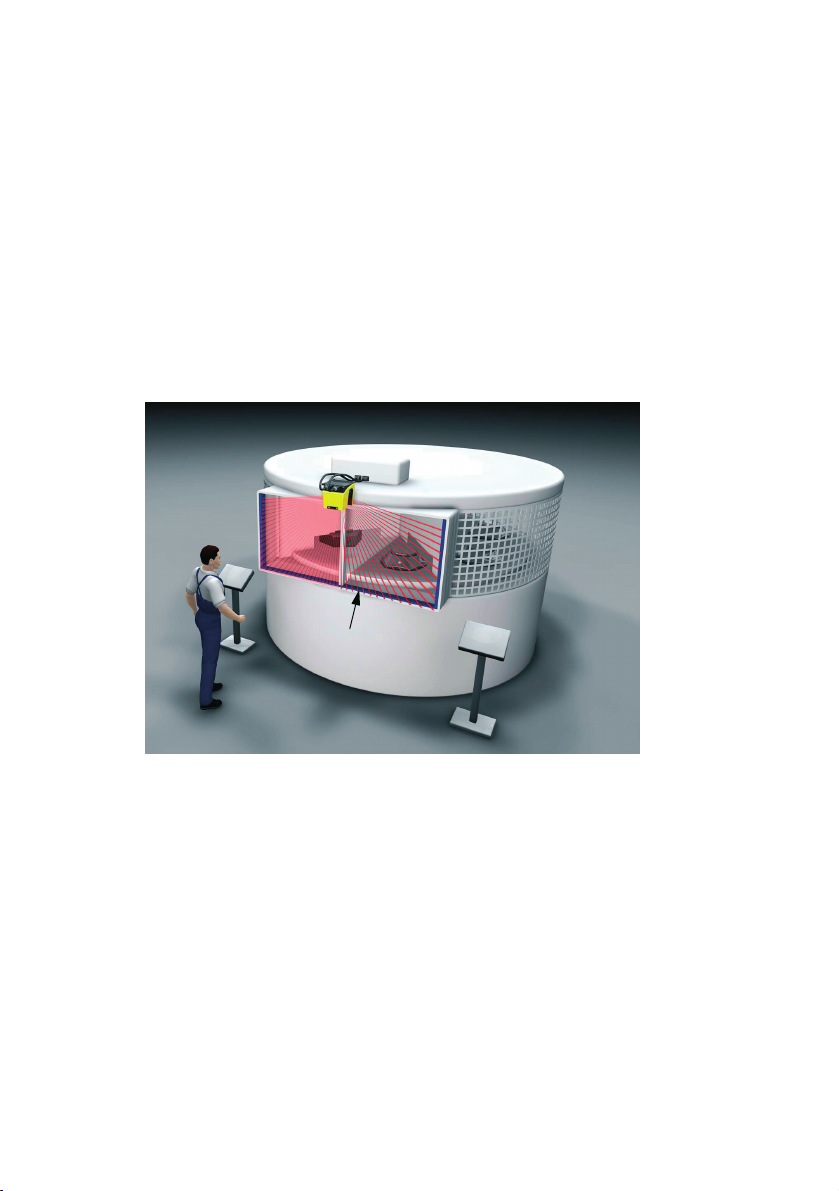

4.2 Access guarding by passage monitoring

Access guarding by passage monitoring (whole body trip control) is a suitable method

when the access to a machine or to a hazardous zone can be precisely defined in

structural terms, and there is no other unprotected access to the area. It is best to mount

the laser scanner above the passage in question, in vertical alignment. In order to secure

the protective equipment, laser scanner and fence against inadvertent misadjustment

and manipulation, the detection zones of the SIMATIC FS660I Laser Scanner must be

defined on the basis of a reference boundary. In this operating mode, the scanner will

use the polled environment as a reference and so check for changes in the layout of the

protective equipment, as well as checking every one of the individual measurements it

carries out with a view to detecting an intrusion. An example of the configuration of the

SIMATIC FS660I Laser Scanner to give access protection by passage monitoring will be

found in Chapter 5.5.

a

c

SF1

b

24

a = SIMATIC FS660I Laser Scanner SF1 =

b=Reference boundary of the detection zone

c=Emergency stop and triggering of the manual restart interlock

Fig. 4.2-1: Access guarding by whole body trip control with system check of a

reference boundary

Detection zone 1, enabled

Page 25

4.3 Safeguarding of danger points based on hand and arm detection

If the machine operator, in close proximity to the danger zone, needs to halt the

hazardous movement of the machine or to coordinate the handling of workpieces or their

removal from the machine, the machine must be provided with protection at the danger

point. To safeguard danger points in this way a protective system needs to be installed.

The SIMATIC FS660I Laser Scanner is certified as a system providing hand and arm

protection, and is able in such a situation to guarantee flexible safety conditions in the

workplace. This may be combined with alternation of the detection zones. In order to

safeguard the protective equipment, laser scanner and side-mounted panels (which

serve as a reference and provide additional access protection) against inadvertent

misadjustment or manipulation, the detection zones of the SIMATIC FS660I Laser

Scanner must be defined on the basis of a reference boundary.

An example of the configuration of the SIMATIC FS660I Laser Scanner for the protection

of danger points based on hand and arm protection may be found in Chapter 5.6.

a

SF2

SF1

b

a = SIMATIC FS660I Laser

Scanner

SF1= Detection zone 1, enabled SF2 = Detection zone 2, disabled

c=Emergency stop and manual triggering of restart interlock, acknowledgement for

switchove

Fig. 4.3-1: Safeguarding of danger points based on hand and arm detection with

r

alternation of detection zones

c

b=

Reference boundarys of the detection zones

25

Page 26

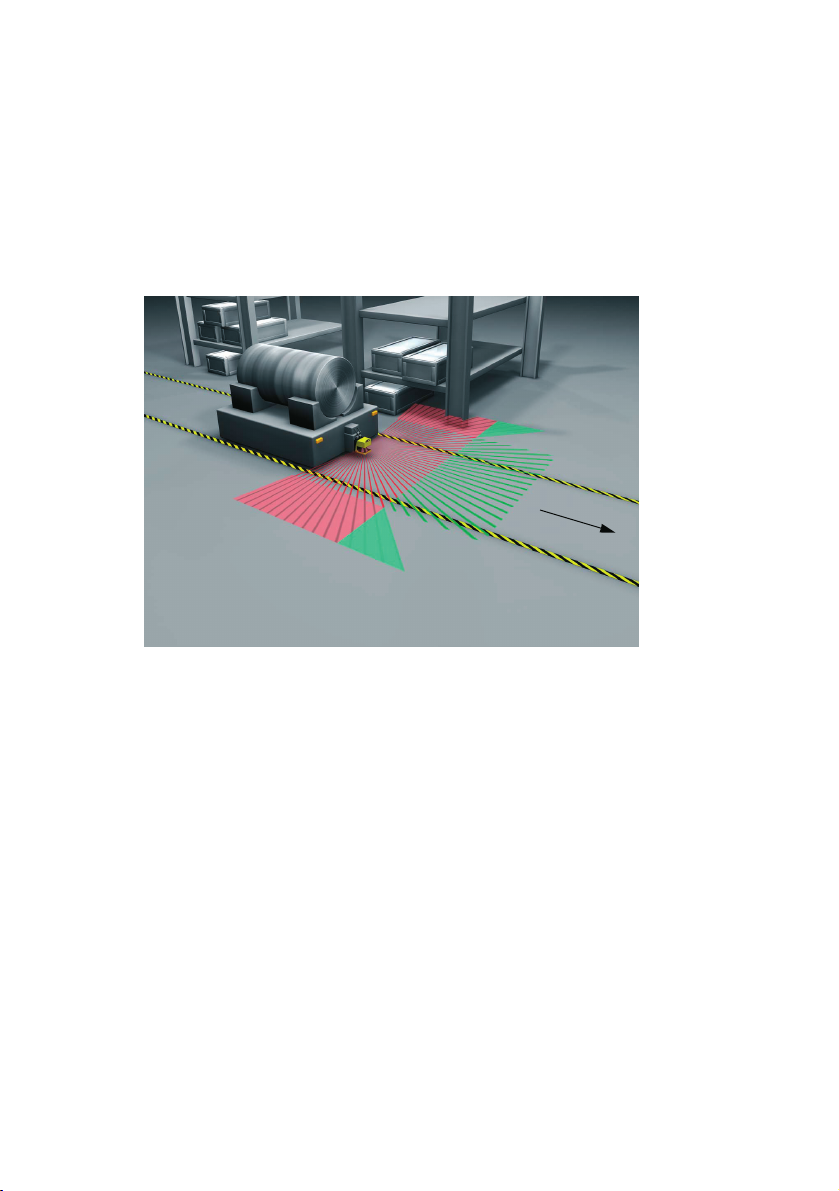

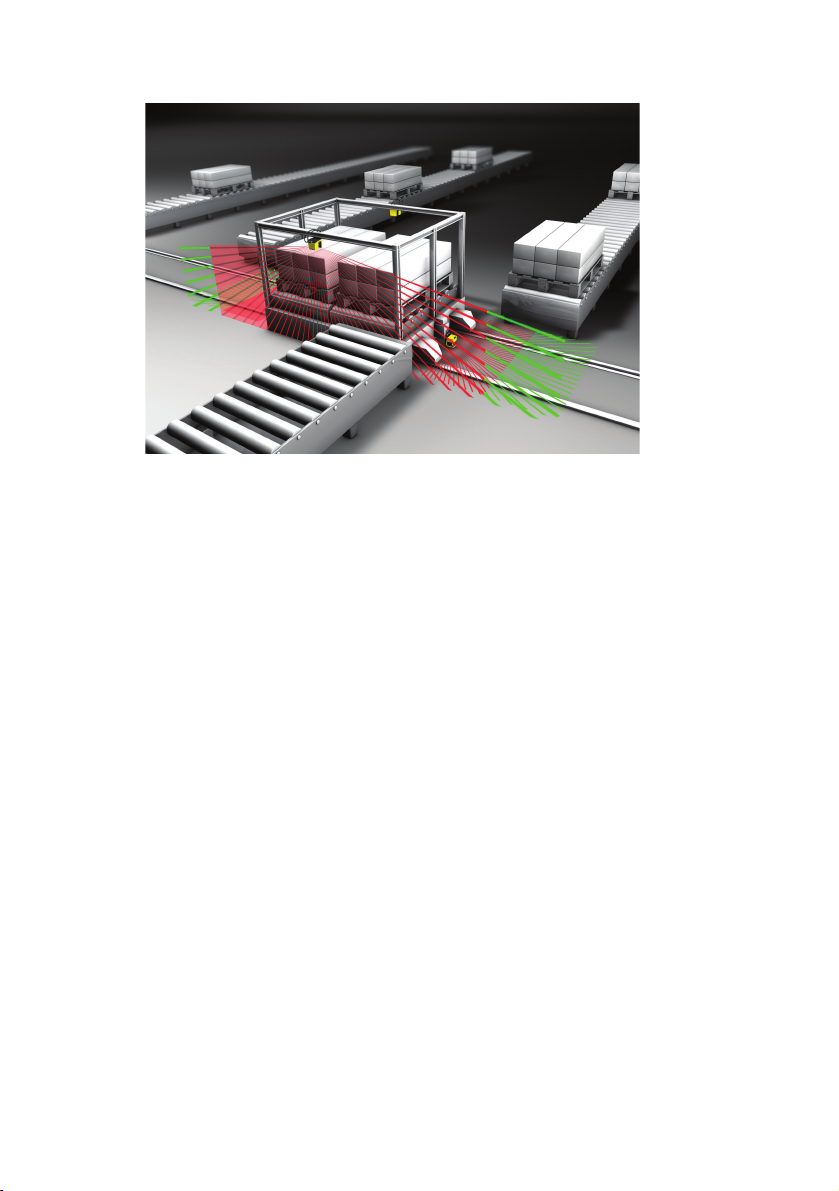

4.4 Mobile Safeguarding of Automatic Guided Vehicles

For this application, the SIMATIC FS600 Laser Scanner is installed on automatic guided

vehicles in order to monitor the vehicle path. The aim is to detect people or objects in the

path of the vehicle and to automatically bring the vehicle to a halt. Safety systems

available up to now, such as bumpers or safety bars, have allowed only very low driving

speeds to be maintained. In contrast, using the SIMATIC FS600 Laser Scanner as a

non-contact “advance bumper” results in the creation of a substantially larger safety

zone.

The vehicles can move faster, and down times are reduced to the necessary minimum.

SF3

SF1

WF1

SF4

a

SF1= Detection zone 1 for slow speed SF3= Detection zone 3 for a route

WF1= Detection zone 2 for high speed SF4= Detection zone 4 for a route

a = Traveling straight ahead

Fig. 4.4-1: Safeguarding an automatic guided vehicle

Please comply with the safety notes in Chapter 3. For an example of how to calculate

detection zone measures, please refer to Chapter 5.7.9.

curving to the left

curving to the right

4.5 Protecting Transporter Trolleys against Collisions

Transporter trolleys are generally guided along a system of rails or grooves in the floor.

Hence the vehicle paths are usually just slightly wider than the trolleys themselves. This

represents an increased hazard for people, since it is impossible to get out of the way of

the trolley. For this reason, transporter trolley are used in enclosed areas equipped with

suitable access safeguarding.

26

Page 27

SF1

SF2

SF1= Detection zone 1 for slow speed SF2= Detection zone 2 for high

speed

Fig. 4.5-1: Safeguarding a transporter trolley

Please comply with the safety notes in Chapter 3 and Chapter 5.7.8.

In these cases, the SIMATIC FS600 Laser Scanner is used to detect people or objects

in the vehicle path and then automatically bring the vehicle to a halt. Select “Manual

restart” mode.

The demands placed on the geometrical shape of the detection zone are determined by

the vehicle width, speed, stopping distance and response time. Here as well, factors

such as additions in the direction of travel for tolerances in the measurement value and

reduced braking power due to wear and tear must be taken into consideration.

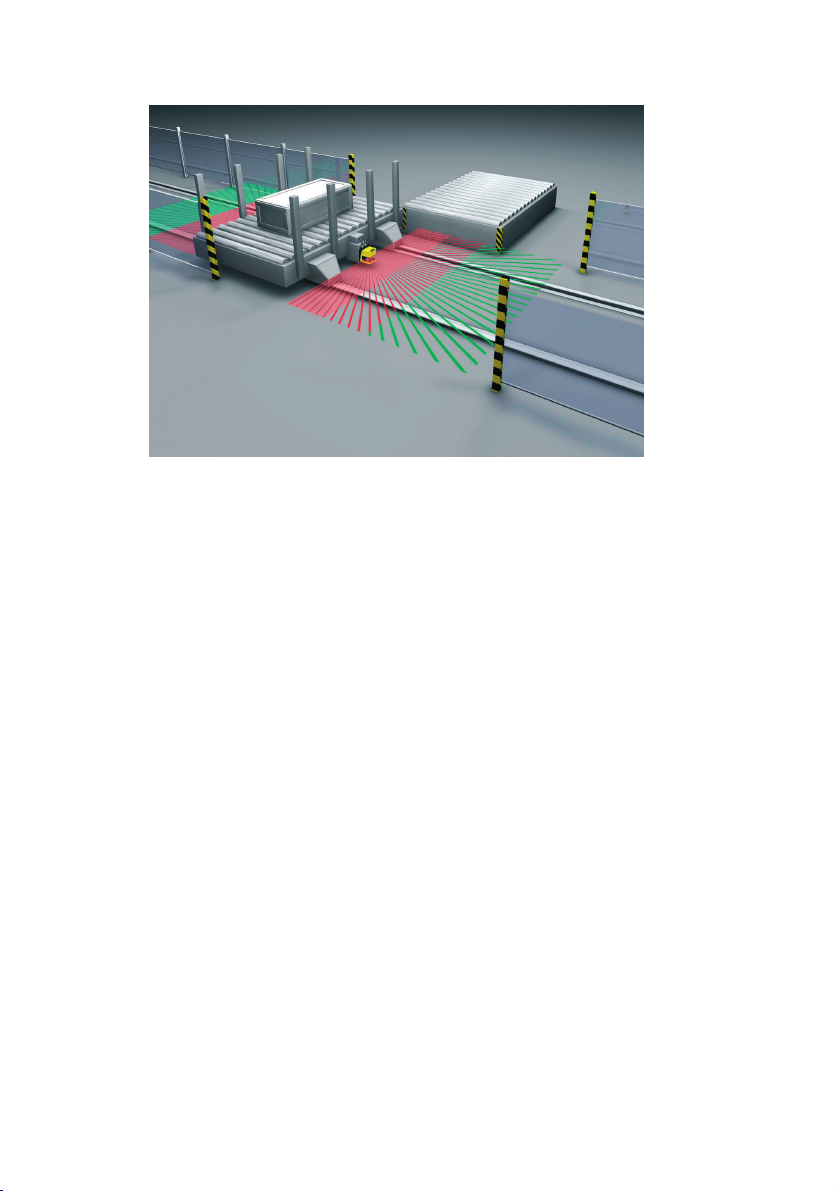

4.6 Guarding the sides on AGVs

In addition to the danger area guarding of the path of an AGV application, in some cases

it is also necessary to set up a side guarding. This side guarding detects people in the

space between vehicle and conveyor, or detects people that stand on the conveyor edge

in the vehicle area. Furthermore, the side guarding also enables the correct position of

the load to be monitored, so that a transport with overhanging load is not initiated.

27

Page 28

Fig. 4.6-1: Bild 6.3-1 Guarding the sides on AGVs

Please observe the safety notes in Chapter 3. An example for the side guarding

configuration on AGVs can be found inChapter 5.7.9 and 5.7.10.

4.7 Other possible applications

• Object and contour measurement

• Logistics (counting, measuring, controlling)

• Projection control (e.g. in fully automatic parking ramps or lots)

• Safeguarding or monitoring enclosed spaces

• and many more

28

Page 29

5 Information for Planning and Mounting

It is essential that the following key points be complied with so that the SIMATIC FS600

Laser Scanner can provide optimum performance:

• The SIMATIC FS600 Laser Scanner must be placed so that areas of access to the

danger zone being monitored are completely covered by the detection zone.

• The mounting position of the scanner should provide protection from humidity, dirt

and extreme temperatures below 0° C or over 50° C.

• The mounting position must be selected in such a way as to minimize the possibility

of mechanical damage. Additional protective cover panels or safety bars must be

installed at exposed positions.

• Reinforcements, cover panels, mounting niches, and other machine elements may

not in any way impair the field of view of the scanner.

• If there are areas of shadow caused by fixed obstacles that were defined as part of

the detection zone boundary, these should be safeguarded (e.g. by safety grids) in

order to prevent people standing in them from being able to suddenly enter the

detection zone. This point must be taken into account in the hazard analysis of the

machine or system.

• Be sure that there are no retro-reflectors or highly reflective surfaces made of metal

or ceramic in the area of the detection zone and at the height of the scanning plane.

Such objects can cause measurement errors.

• In order to ensure a consistent detection height at every point of the detection zone,

the scanner – and hence the scanning plane – must be placed parallel to reference

section.

• If the “Restart interlock” function is included, the restart button must ne located

outsidethe detection zone in a place that is visible from the entire danger area .

• If the scanner is used without a start interlock or startup test with automatic start/

restart, a startup warning (visual or acoustic) must be provided.

• The scanner must not be used as an aid for climbing. If there is is any risk, a

suitable diagonal protection (45°) should be set up.

Please comply with the safety notes in Chapter 3, Chapter 5.4.7 and 5.7.8.

29

Page 30

5.1 Attachment and Dimensions

For attaching the SIMATIC FS600 Laser Scanner, four drill holes are located at the back

of the unit. Any laser scanner installation point is possible with mounting. The SIMATIC

FS600 Laser Scanner can, for example, also be mounted on the head or inclined facing

down.

The mounting set 3RG7838-1AA is available as an accessory offering following

advantages:

• Speeds up the mounting process by providing screws that are accessible from the

front.

• Allows vertical inclinations of up to 9°, either up or down, infinitely adjustable within

this range.

• Allows lateral tilting of up to approx. 9° to either side from the midpoint setting,

infinitely adjustable within this range.

• Enables quick replacement of the scanner without requiring realignment.

For information on which parts and dimensions are required for mounting, please refer

to Chapter 14.13 and 14.14.

5.2 Installing adjacent laser scanners

The SIMATIC FS600 Laser Scanner has been developed in a way that prevents several

laser scanners from interfering with one other as much as possible.

WARNING

An increase in the response time can, however, be caused by the installation of several

adjacent laser scanners. If

in the following sections or the specific adjustment (section 5.2.2) are implemented,

then the SIMATIC FS600 Laser Scanner response time set and shown in the

configuration and diagnosis software (SIMATIC FS600 Parameterization

Software LS4soft) is extended by 40 ms.

be taken into account when calculating the safety distance!

none

of the constructive measures (section 5.2.1) described

This extension in the response time MUST

5.2.1 Constructive measures

The direct external light irradiation from laser scanners of the same kind (905 nm laser

light wavelength) in a line and at the same installation height can be prevented with

shielding plates at scan level. Shielding, as high as the scanner front screen and flush

with the front housing edge, is sufficient. The same also applies with installation in

vertical alignment and overlapping of the scan levels

30

.

Page 31

b

a

c

d

a = SIMATIC FS600 Laser b = Machine (view from above)

Scanner

c = Detection zones d = Shield plate, flush with the housing

Fig. 5.2-1: Shielding to prevent direct irradiation

5.2.2 Adjusting adjacent laser scanners

In order to prevent faulty deactivation and scanners interfering with each other as much

as possible, when using several laser scanners you must install these as shown in the

following examples. Installation on the basis of the 3RG7838-1AA installation system

makes precise adjustment significantly easier.

Installation with height offset or a crossed alignment also prevents interference from

beam reflections onto surrounding objects. When safeguarding danger zones, please

also ensure that it is not possible to crawl under the protective field, so that gaps do not

occur with access guarding..

a

c

100 mm

Fig. 5.2-2: Installation with height offset (parallel alignment)

31

Page 32

Fig. 5.2-3: Installation without height offset (crossed alignment)

Fig. 5.2-4: Opposing installation without height offset (crossed alignment)

5.3 Information on Setting the Dimensions of Detection Zones

The hazards caused by machines and systems place a wide range of demands on

safety distances and detection zones which must be appropriately defined.

5.3.1 Methods of Configuring Detection Zones using the PC

With its SIMATIC FS600 Parameterization Software LS4soft configuration and

diagnostic software, the SIMATIC FS600 Laser Scanner offers various methods for

setting the configurations of detection zones.

Numerical input

A separate dialogue within the user program “SIMATIC FS600 Parameterization

Software LS4soft” allows the right, left and front edges of the detection zone to be set

using numerical values in mm.

Graphic input

A separate dialogue within the user program “SIMATIC FS600 Parameterization

Software LS4soft” allows the basic contours of the detection zone to be entered. The

contours can be adapted infinitely to the desired size of the detection zone. The following

shapes are available:

•circle

• rectangle

• polygon

100 mm

100 mm

32

Page 33

In addition, the contours can be infinitely varied by:

• changing

• limiting and

• deleting

partial segments as desired

5.3.2 Range of the Detection Zone, Resolution

The maximum range of the detection zone S

object with a diameter of 70 mm and a reflectance factor of 1.8 % (e.g. black corduroy).

The reference point of the measurement is the axis of the rotating mirror on the scanner

64 mm behind the front edge of the scanner.

5.3.3 Range of the Warning Zone, Resolution

A maximum range of 10 meters is available for an object with a diameter of 100 mm. The

maximum available range for an object with a diameter of 150 mm is

15 m. Both of these figures assume a reflectance factor of 20 %.

Resolution in mm

1000

500

200

100

150

a

80

60

40

20

b

4 m (including the additions) for an

MAX

c

10

8

6

4

2

1

0

0,2 0,5

2

1

46

15

10

20

100

50

Distance in m

a = Detection zone

b = Warning zone

c = Measurement field

Fig. 5.3-1: Detecting objects in the detection zone and in the warning zone. The

reference point of the distance measurement is the axis of the rotating

mirror.

33

Page 34

5.3.4 Range of the measurement field

The maximum distance for contour measurement at a reflectance factor of 80% (white

gipsum) is 50 m.

Remission in %

Reflectors

White gypsum

Writing paper

Gray carton

Black corduroy

a = Detection zone

b = Measurement field

a

Fig. 5.3-2: Detection of objects depending on the reflectance factor. The reference

point of the distance measurement is the axis of the rotating mirror.

5.3.5 Required Detection Zone Additions Z

The SIMATIC FS600 Laser Scanner is equipped with a selectable dust algorithm to

ensure optimum freedom from interference.

The following detection zone additions must be taken into account:

Addition ZSM if dust

83 mm

suppression is deactivated

Addition Z

suppression

is activated

SM

if dust

83 mm (for a detection zone size < 3.5 m)

100 mm (for a detection zone size > 3.5 m)

Activation and deactivation of the function is performed by SIMATIC FS600

Parameterization Software LS4soft.

b

15

Distance in m

34

Page 35

If retro-reflectors or very shiny surfaces, such as polished or enameled metals or

ceramics, may possibly be present in the scanning plane, the following table applies:

Addition Z

reflectors or very shiny,

surface-treated materials

(e.g. metals and ceramics)

are present in the scanning

plane

Z = ZSM + Z

REFL

REFL

if retro-

0 mm

for reflectors more than 1.2 m behind the detection

zone line

110 mm

for reflectors up to 1.2 m behind the detection zone

line

Z = Required detection zone addition, in mm

Z

= Measurement error of the scanner, in mm

SM

= Addition for considering reflectors, in mm

Z

REFL

5.4 Safeguarding Stationary Danger Zones

Please comply with the safety notes in Chapter 3.

5.4.1 The Purpose of Safeguarding

is for protection:

• to protect people when entering a danger zone

• to protect people from reaching a danger point with their extremities

• to protect objects from the danger of collision due to variable machine or part

movements.

5.4.2 Mounting Position

The SIMATIC FS600 Laser Scanner can be mounted either in a stationary position (e.g.

on a wall or a machine) or on moving parts (e.g. machine table).

The qualified installer must ensure that the mounting position of the SIMATIC FS600

Laser Scanner allows the danger zone to be monitored completely.

If a restart button is being used, make certain that the entire detection zone area can be

viewed by the person pressing the button. It must not be possible to activate the button

from the danger area.

Refer to the safety notes in Chapter 3.6 with regard to lateral access into the danger

zone.

35

Page 36

5.4.3 Mounting Height

According to DIN EN 999, the lowest admissible height of the scanning plane for people,

as measured from the base level, is calculated according to the following formula:

H

= 15 * (d - 50 mm)

MIN

= Lowest admissible scanning plane from the base level

H

MIN

d = Resolution of the scanner in mm (object size = 70 mm throughout the

detection zone).

The admissible height range of the SIMATIC FS600 Laser Scanner scanning plane lies

between 0 mm (Presettings leg detection) and 1000 mm above the base level. If the

application requires a scanning plane higher than 300 mm, or if children have access to

the area, the analysis of the danger zone must consider the hazard caused by persons

crawling below the scanning plane.

5.4.4 Recommendations for Mounting to Prevent Unmonitored Zones

Unmonitored zones can result if the scanner is mounted onto a protruding attachment

or if the contour of the machine/system is varied in depth.

36

Page 37

5.4.4.1 Recessed installation (undercut) under the machine table

The undercut must be at least as deep as the zone not monitored by the detection zone

lateral to and in front of the scanner. The minimum depth Z

possible to recess the scanner, this is allowed up to a maximum of 40 mm; the depth of

the undercut is reduced by the depth value of the recess. If the mounting system is being

used, the necessary dimensions of the undercut depth must be increased accordingly

(see Chapter 14.13 and 14.14). The height of the undercut must be limited to prevent

people from being able to step beneath it.

Machine (side view) Machine (view from above)

is 135 mm. If it is

UMIN

S

b

a

f

Z

UMIN

e

g

S

b

c

a

c

Z

UMIN

T

S

Z

d

S

a = SIMATIC FS600 Laser Scanner S = Safety distance

b=Machine S

c = unmonitored zone ST= detection zone

= Entire width of the

B

d = Detection zone Z = detection zone additions

e = Height of the undercut Z

f = Mounting surface

= depth of the undercut

UMIN

g = Scanning plane

Fig. 5.4-1: Recessed scanner installation with undercut

The additional safeguarding required for the particular application must be taken into

account.

Please note that the undercut must cover any unmonitored zones.

B

37

Page 38

5.4.4.2 Recessed installation within the machine contour

Furthermore, the scanner can be recessed into the contours of a machine. The recess

can have a depth of up to 40 mm without the mounting system 3RG7838-1AA,

or up to 65 mm with the mounting system 3RG7838-1AA. This is in reference to

detection zones that cover an angle range of 180°. If it is not possible to comply with

these values, or if unmonitored zones result due to the shape or movement of the

machine, additional safety measures must be taken.

The effectiveness of the detection zones can be optimized by changing the depth at

which the scanner is installed, or by adjusting the angle range (e.g. from 180° to 190°).

For information on how to configure the scanner in this way, please refer to the

“SIMATIC FS600 Parameterization Software LS4soft” user's manual included with

delivery.

b

h

c

f

a

g

e

d

f

Z

a = SIMATIC FS600 Laser Scanner f = Lateral access safe

b = Machine guarding, if needed

c = Lateral Access protection g = detection zone

d = Maximum recessing (40 mm) h = Front machine edge

e = Installation niche Z = Detection zone addition

Fig. 5.4-2: Recessed installation within the machine contour

If it is not possible to mount the SIMATIC FS600 Laser Scanner directly onto the

machine, it can also be positioned lateral to or across from the machine.

38

Page 39

5.4.4.3 External mounting lateral to or across from the machine

c

d

b

a = SIMATIC FS600 Laser Scanner

b = Machine

c = Distance, max. 35 mm

a

d = Detection zone

Fig. 5.4-3: Lateral external scanner mounting without an undercut

If the machine contour runs parallel to the 90° beam of the laterally placed SIMATIC

FS600 Laser Scanner, the distance between the detection zone boundary and the

machine may not exceed 35 mm.

Z

UMIN

c

d

a = SIMATIC FS600 Laser Scanner

a

b=Machine

c = Minimum distance from the environment

b

d = Detection zone

Z = Required detection zone additions

= Minimum depth of the undercut

Z

Z

UMIN

Fig. 5.4-4: Mounting the scanner across from the machine with an undercut

39

Page 40

5.4.5 Additions

The axis of the rotating mirror (midpoint of the scanner) is of critical importance when

configuring the detection zones. This axis is assigned a value of 64 mm from the front

edge of the scanner when calculating detection zones.

Add

83 mm

or

100 mm

Chapter 5.3.5 .

Add an addition Z

REFL

area.

Please note that safety additions must principally be added to the safety distance

throughout the entire detection zone.

In other words, additions may not be added to just one side or only to certain sections.

Please consult the operating instructions provided by the machine or system

manufacturer.

5.4.6 System Availability

There must be a buffer distance of 83 mm between the surrounding contour and the

detection zone contour (including the additions). This distance increases the up-time of

the machine or system since it prevents the surrounding contour from being detected as

relevant for generating a switch-off signal. If there is an undercut across from the

scanner that is impossible for a person to step beneath (see Fig. 5.4-4), the depth of the

undercut can be calculated according to the following formula:

Z

= Z +83 mm - d

UMIN

Z

= Depth of the undercut, in mm

UMIN

Z = Required detection zone additions, in mm

d = Resolution of the scanner (d = 70 mm)

This is possible since it is absolutely certain that a person will be detectedin front of the

undercut .

Furthermore, the dust algorithm of the SIMATIC FS600 Laser Scanner can be

implemented if floating particles may be present in the area. This algorithm, which can

be activated in the user program “SIMATIC FS600 Parameterization Software LS4soft”,

prevents the machine or system from being switched off unintentionally. Please note

Chapter 5.3.5.

If the danger zone analysis allows a multiple evaluation, detection errors caused by

floating particles can be decreased. The number of evaluations that is decisive for the

response time of the scanner (T

can be set in the user program “SIMATIC FS600 Parameterization Software LS4soft”.

In the event of an error event that lasts only briefly (for example the effect of extraneous

light) the scanner performs a one-time reboot. If automatic startup and restart are

activated, the scanner turns the OSSDs back on after this brief error event, and after the

detection zone has been free for about 25 seconds. This one-time reboot results in an

additional increase in availability. This function does not have any effect if detection zone

activation is faulty. If startup test, startup interlock and / or manual restart are included,

they will not be removed.

for the maximum radial measurement error ZSM as described in

as described in Chapter 5.3.5 if reflectors could be present in the

), and thus also requires a larger detection zone,

SCAN

40

Page 41

SAFETY NOTES

Automatic startup / restart must only be used in cases where there is absolutely no

possibility that the effective detection zone could be entered or bypassed in some other

way. Depending on the hazard assessment, visual and / or acoustic startup warnings

should be provided.

If parameters are set for the function “Manual restart”, the required enable from the

startup/restart button affects all detection zones and is independent of any detection

zone changeover. If the current detection zone is manually enabled, this enable also

applies even if the system switches to another detection zone and this detection zone

becomes free! If startup/restart interlock is in effect in the current detection zone, it is

also in effect for the other detection zone to which the system switches even if this

detection zone is free.

5.4.7 Restart Interlock

The SIMATIC FS600 Laser Scanner is equipped with a restart interlock function. You

can select or deselect this function as needed to connected restarting of the machine to

a manual approval. It affects all detection zones and does not depend on any detection

zone changeovers. For information on how to configure the scanner appropriately,

please refer to SIMATIC FS600 Parameterization Software LS4soft (Section: “Safetyrelevant parameters” folder)

The restart button must be mounted so that

• the entire danger zone (or detection zone area ) can be viewed from the operating

position.

• it is not possible to directly step or reach into the danger zone or danger point from

the operating position.

The button refer to the areas to be enabled in a easily understandable manner.

Please comply with the safety notes in Chapter 3 and 5.4.6.

41

Page 42

5.4.8 Calculating the Detection Zone Dimensions for Safeguarding an Area

According to

IEC 61496-3

and

DIN EN 999

, the following formulas apply for calculating

the safety distance and the minimum depth of the detection zone when the direction of

approach runs parallel to the detection zone:

S=(K x T) + C C

C = 1200 mm – 0.4 H H

= 850 mm

MIN

= 15 (d – 50 mm)

MIN

H

= 1000 mm

MAX

S = Safety distance, minimum distance from the danger zone to the point of

detection, to the plane of detection, or to the detection zone, in mm

K = Approach speed of a person or a person’s body parts

(1600 mm/s), in mm/s

T = Lag time of the entire system (response time and braking time until

standstill), in s

C = Safety-related constant to consider entry into the danger zone before the

protective device is triggered, in mm

= Minimum value of the safety-related constant (850 mm), in mm

C

MIN

H = Height of the scanning plane from the reference point, in mm

H

= Minimum height of the scanning plane from the reference plane,

H

MIN

MAX

in mm

= Minimum height of the scanning plane from the reference plane,

in mm

d = Resolution of the scanner (70 mm throughout the detection zone), in mm

42

Page 43

5.4.8.1 Additions and Minimum Depth of Detection Zone

The sum of the system-specific and application-specific detection zone additions (see

Chapter 5.3.5) is calculated according to the following formula:

Z

= ZSM + Z

TOT

Z

= Sum of the system-specific and application-specific detection zone

Z

Z

Z

TOT

SM

REFL

AU

additions, in mm

= Scanner measurement error, in mm

= Addition of the reflectors taken into account, in mm

= Addition for application-specific undercut, in mm

REFL

+ Z

AU

The depth of the detection zone, with reference to the direct distance between the

danger zone and the detection point or line, is calculated according to the following

formula:

ST =

(K x (T

SCAN

+ T

MACH

+ ( T

LAG

x L

))) + C + Z

LAG

TOT

S

T

=Depth of detection zone, distance from danger area to detection point or

line, including system and application-specific additions, in mm

K =Approach speed of a person or a person’s body parts

(1600 mm/s), in mm/s

T

SCAN

T

MACH

T

LAG

L

LAG

C = Safety-related constant, in mm

5.4.8.2 Maximum range of detection zone

S

MAX

S

BDIFF

S

MAX

=Response time of the scanner, in s

=Response time of the machine or system, in s

=Lag time of the entire system, in s

=Factor for increase in lag time

22

2222222

S

S

+=

T

BDIFF

= G

BDIFF

+ S + Z

=Maximum range of the detection zone considering the diagonals,

in mm

S

T

S

BDIFF

=Depth of the detection zone, in mm

=Largest width of the detection zone between the axis of the rotating mirror

and the outer edge of the detection zone, in mm

G

BDIFF

=Largest width of the danger zone between the axis of the rotating mirror

and the boundary of the danger zone, in mm

S = Safety distance, minimum distance from the danger zone to the point of

detection, to the plane of detection, or to the detection zone, in mm

Z =Required detection zone additions, in mm

43

Page 44

S

T

Z

Z

UMIN

c

d

a

b

c

AU

Z

e

S

S

B

G

BDIFF

S

BDIFF

Z

S

MAX

S

44

a = SIMATIC FS600 Laser Scanner

b = Dangerous machine/danger zone

c = Safety fence to prevent stepping behind

d = Axis of the rotating mirror