Siemens SIMATIC ET 200pro User Manual

ET 200pro distributed I/O EtherNet/IP

interface module

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

ET 200pro distributed I/O EtherNet/IP interface module

Manual

03/2016

A5E32861915

Preface

1

Product overview

2

The ET 200pro EtherNet/IP

module

3

Installing, mounting, and

connecting

4

Commissioning

5

General technical

specifications

6

Order number

A

Dimension drawing

B

Address area

C

-AB

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E32861915-AB

Ⓟ

Copyright © Siemens AG 2014 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

03/2016 Subject to change

Table of contents

1 Preface ................................................................................................................................................... 5

2 Product overview .................................................................................................................................... 8

3 The ET 200pro EtherNet/IP module....................................................................................................... 17

4 Installing, mounting, and connecting ...................................................................................................... 51

2.1 What are distributed I/O systems? ............................................................................................ 8

2.2 What is the ET 200pro distributed I/O system? ........................................................................ 9

2.3 Components of the ET200pro distributed I/O system ............................................................. 12

2.4 The ET 200pro EtherNet/IP interface module ........................................................................ 14

2.5 Features and benefits of the ET 200pro EtherNet/IP module................................................. 16

3.1 ET 200pro EtherNet/IP module hardware............................................................................... 17

3.2 Operation ................................................................................................................................ 19

3.3 Parameters for the ET 200pro EtherNet/IP module ................................................................ 22

3.4 Faults ...................................................................................................................................... 23

3.5 Troubleshooting ...................................................................................................................... 26

3.6 Replacing a faulty ET 200pro EtherNet/IP module ................................................................. 28

3.7 Device profile: supported CIP objects ..................................................................................... 29

3.7.1 Identity Object ......................................................................................................................... 29

3.7.2 Assembly Object ..................................................................................................................... 32

3.7.3 Connection Manager Object ................................................................................................... 34

3.7.4 TCP/IP Interface Object .......................................................................................................... 35

3.7.5 EtherNet Link Object ............................................................................................................... 38

3.8 Device profile: vendor-specific objects ................................................................................... 41

3.8.1 Adapter Object ........................................................................................................................ 41

3.8.2 Slot Object .............................................................................................................................. 45

3.9 Technical specifications .......................................................................................................... 49

4.1 Installing .................................................................................................................................. 51

4.2 Mounting ................................................................................................................................. 51

4.3 Connecting .............................................................................................................................. 52

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

3

Table of contents

5 Commissioning ..................................................................................................................................... 53

6 General technical specifications ............................................................................................................ 66

A Order number ....................................................................................................................................... 76

B Dimension drawing ............................................................................................................................... 77

C Address area ........................................................................................................................................ 78

Index .................................................................................................................................................... 79

5.1 Configuring the ET 200pro EtherNet/IP module .................................................................... 53

5.2 Setting the IP address ............................................................................................................ 53

5.3 Grouping electronic modules ................................................................................................. 54

5.4 Commissioning and startup ................................................................................................... 58

5.5 Using QuickConnect .............................................................................................................. 59

5.5.1 QuickConnect overview ......................................................................................................... 59

5.5.2 Guidelines for using QuickConnect on your network ............................................................. 60

5.5.3 Replacing a faulty QuickConnect Adapter ............................................................................. 63

5.5.4 Troubleshooting and optimization .......................................................................................... 64

5.6 Firmware updates .................................................................................................................. 65

6.1 Standards and approvals ....................................................................................................... 66

6.2 Electromagnetic compatibility ................................................................................................ 69

6.3 Shipping and storage conditions ............................................................................................ 70

6.4 Mechanical and climatic environmental conditions ................................................................ 71

6.5 Specifications for insulation tests, protection class, degree of protection, and rated

voltage .................................................................................................................................... 74

ET 200pro distributed I/O EtherNet/IP interface module

4 Manual, 03/2016, A5E32861915-AB

1

Trademarks

Purpose of the manual

Required level of knowledge

Scope of the manual

Certifications, Marks, and Standards

This manual references technologies whose names are trademarked by ODVA, the Open

DeviceNet Vendors Association. The ODVA technologies referenced in this manual include:

EtherNet/IP™

CIP™ (Common Industrial Protocol)

QuickConnect™

For more information on ODVA and its trademarked technologies, visit the ODVA website

(http://www.odva.org).

The information in this manual is intended to enable you to operate the ET 200pro

EtherNet/IP interface module on EtherNet/IP.

You require knowledge of the automation engineering field in order to use the material in this

manual.

This manual is valid for the ET 200pro EtherNet/IP module. Appendix A provides order

information.

This manual contains a description of the components that were valid at the time the manual

was published. Information about new components and new versions of components is

released in Product Information bulletins available on the Siemens Industry Online Support

(https://support.industry.siemens.com/cs/?lc=en-US) website.

The ET 200pro EtherNet/IP module complies with EtherNet/IP Specification CIP Networks

Library Volume 2: EtherNet/IP Adaption of CIP, Edition 1.16.

See the "General technical specifications" chapter for a full description of all applicable

certifications, marks, and standards.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

5

Preface

Relevant manuals

Software

Recycling and disposal

Online product support

The following manuals are included on the disk that shipped with your ET 200pro

EtherNet/IP module:

● ET 200pro EtherNet/IP interface module System Manual (this manual)

● ET 200pro distributed I/O System Operating Instructions

● EIP ET200 Configuration Tool User Reference Guide

The following manual is also relevant to the ET 200pro system. They can be found on the

Siemens Industry Online Support (https://support.industry.siemens.com/cs/?lc=en-US)

website:

● ET 200pro Motor starters Manual

In order to configure the ET 200pro EtherNet/IP module, you require the EIP ET200

Configuration Tool software. This software is located on the companion disk that shipped

with your ET 200pro EtherNet/IP module.

Because it is low in contaminants, the ET 200pro EtherNet/IP module is recyclable. Contact

a certified electronic waste disposal company to recycle and dispose of your old equipment

in an environmentally-friendly manner.

If you have questions about using the ET 200pro EtherNet/IP module that the documentation

does not address, go to the Siemens Industry Online Support

(https://support.industry.siemens.com/cs/?lc=en-US) website and search on "ET 200pro".

ET 200pro distributed I/O EtherNet/IP interface module

6 Manual, 03/2016, A5E32861915-AB

Preface

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should

also be considered. You can find more information about industrial security on the Internet

(http://www.siemens.com/industrialsecurity).

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. You can find more information on the Internet

(http://support.automation.siemens.com).

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

7

2

2.1

What are distributed I/O systems?

When a system is set up, the inputs and outputs from and to the process are often located

centrally in the programmable logic controller.

If there are inputs and outputs at considerable distances from the PLC, there may be long

runs of cabling that are not immediately comprehensible. Additionally, electromagnetic

interference may impair reliability.

Using a distributed I/O system provides the following benefits:

● The controller CPU is located centrally.

● The I/O systems (inputs and outputs) operate locally on a distributed basis.

● The high-performance ET 200pro system ensures that the PLC and I/O systems

communicate smoothly.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

8

Product overview

2.2

What is the ET 200pro distributed I/O system?

Fields of application

Area of application

Configuration

Terminal modules and electronic modules

2.2 What is the ET 200pro distributed I/O system?

The ET 200pro distributed I/O system is a modular distributed I/O system available in

degrees of protection IP65, IP66, and IP67.

A robust design and degree of protection IP65, IP66, or IP67 make the ET 200pro

EtherNet/IP module particularly suitable for use in rugged industrial environments.

With IP65, IP66 and IP67, the ET 200pro EtherNet/IP module is protected against the

ingress of foreign bodies and water. The module does not require an additional enclosure.

The ET 200pro EtherNet/IP module supports communication with:

● Fieldbus

● Fieldbus Data Link Layer

For more information, see the topic "Standards and approvals".

With the ET 200pro system, you can connect virtually any number of I/O modules in virtually

any combination right next to the interface module. This means that you can adjust the

configuration to suit local requirements.

The ET 200pro EtherNet/IP module is installed on a rack and basically consists of the

following:

● An interface module that transfers data to the EtherNet/IP master

● Up to 16 electronic modules with maximum 1 m total width (without rack)

● Connection modules in various designs for

● Pneumatic interface modules for linking of FESTO valve terminals

You can thus set the focus of your configuration on local requirements.

The convenient handling features of ET 200pro EtherNet/IP module ensure quick

commissioning and easy maintenance.

– ET 200pro EtherNet/IP module

– Supply voltages

– Inputs and outputs

The ET 200pro distributed I/O system consists primarily of various passive connection

modules to which you connect the electronic modules and motor starters.

The ET 200pro EtherNet/IP module enables the ET 200pro distributed I/O system to be

connected to the EtherNet/IP network.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

9

Product overview

Example configuration with electronic modules

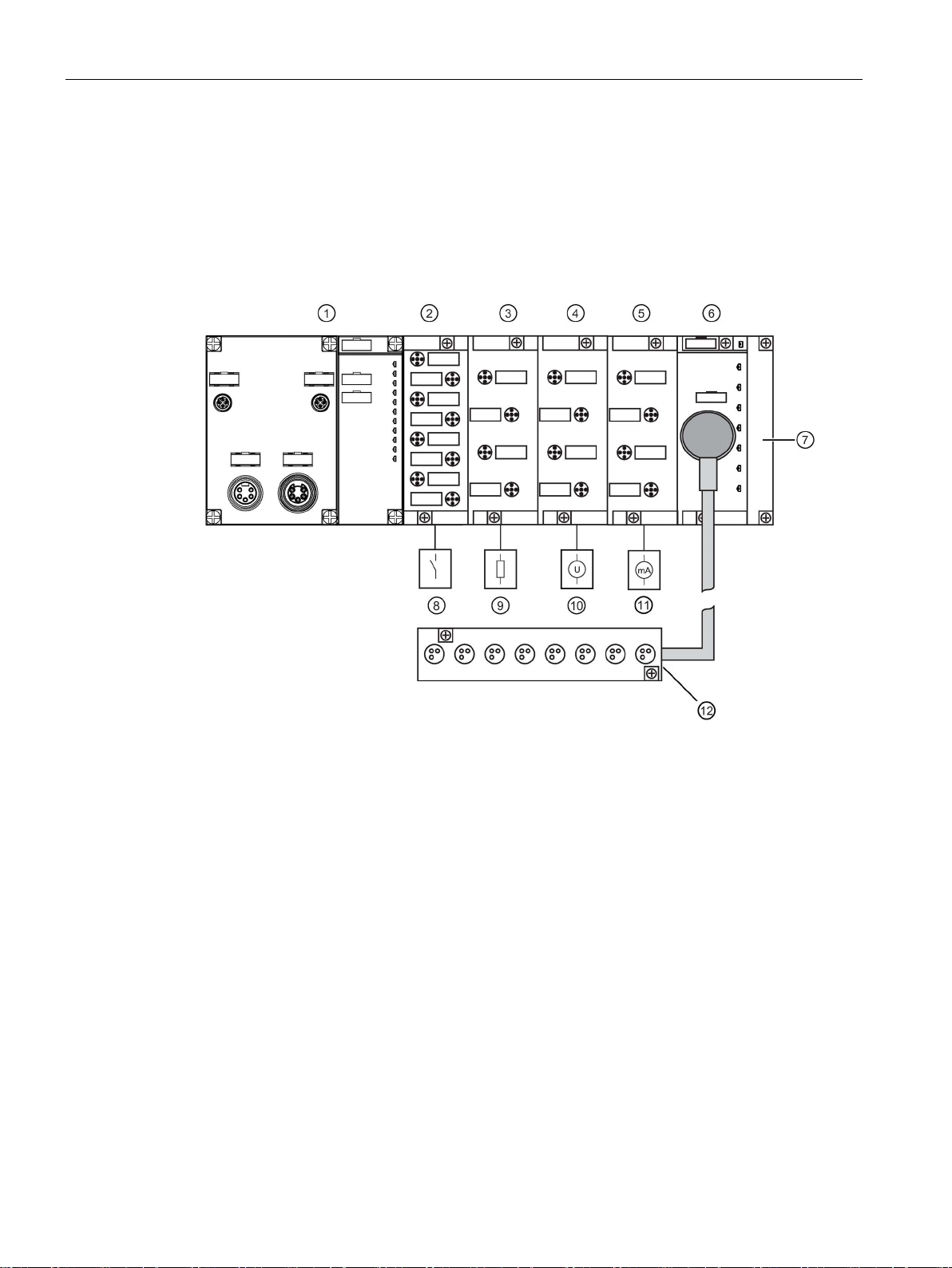

①

ET

②

8 DI DC 24V

③

4 DO DC 24V/2.0A

4 AI U HF

⑤

4 AI I HF

⑥

8 DI DC 24V

⑦

Terminating module

⑧

8 x switches, sensors

⑨

4/8 x load

⑩

4 x voltage measurement

⑪

4 x current measurement for 2

⑫

Actuator/sensor distributor

2.2 What is the ET 200pro distributed I/O system?

The ET 200pro EtherNet/IP module can be equipped up to the maximum configuration with

electronic modules. Between an interface module and a terminating module you can adapt

the electronic modules to your application in whatever configuration you require.

The figure below shows an example configuration of the ET 200pro distributed I/O system.

④

200pro EtherNet/IP interface module (with connection module)

-/4-wire measuring transducer

ET 200pro distributed I/O EtherNet/IP interface module

10 Manual, 03/2016, A5E32861915-AB

Product overview

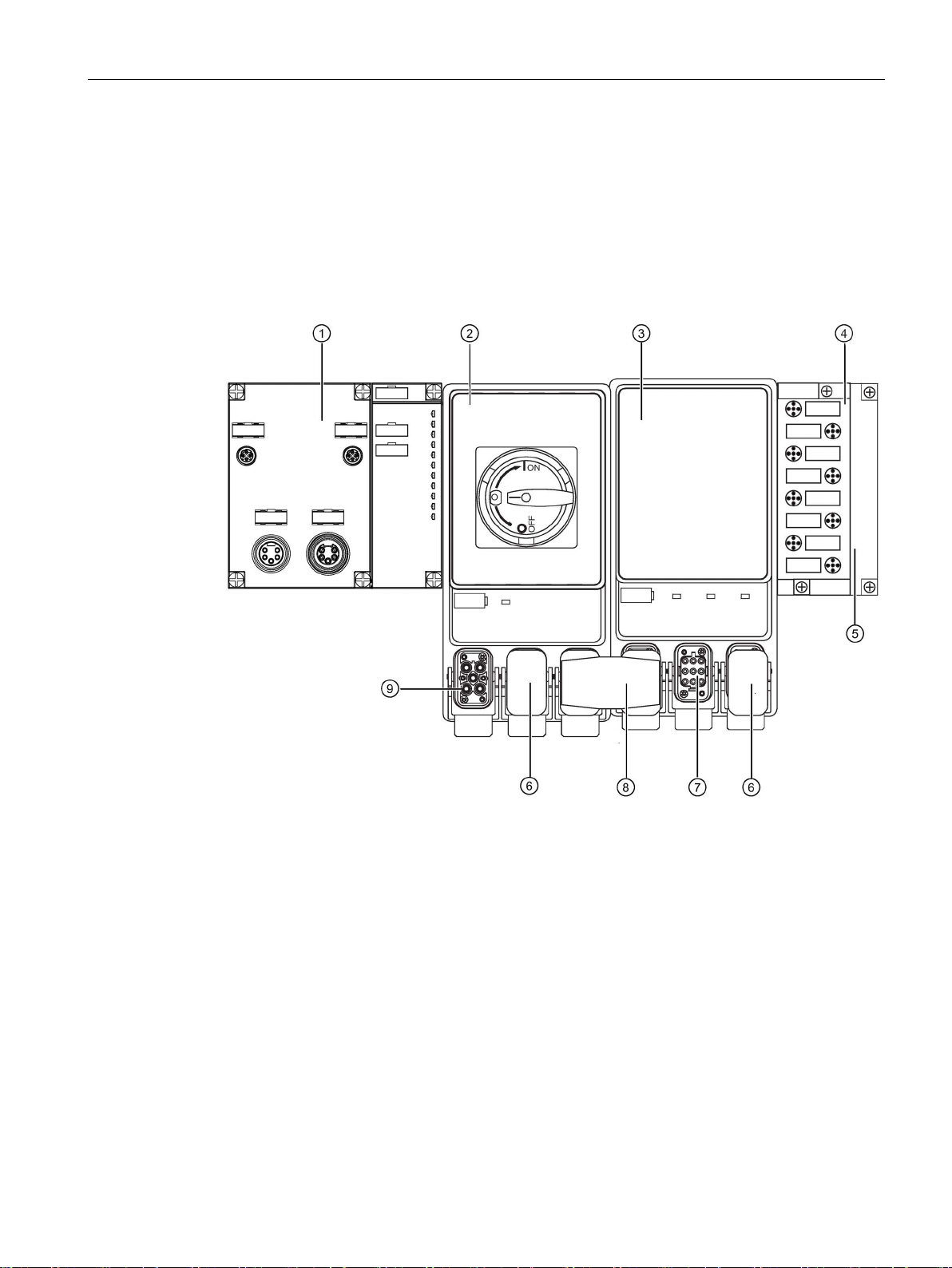

Example configuration with electronic module and motor starter

①

ET

②

Repair switch module

③

DSe; Standard

④

8 DI DC 24

⑤

Terminating module

⑥

Cap

⑦

Motor connection

⑧

Power jumper plug

⑨

Infeed

2.2 What is the ET 200pro distributed I/O system?

Between an interface module and a terminating module you can adapt the electronic

modules, motor starters and frequency converters to your applications in whatever

configuration you require.

The figure below shows an example configuration of the ET 200pro distributed I/O system

with motor starter and repair switch module.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

200pro EtherNet/IP interface module (with connection module)

V

11

Product overview

2.3

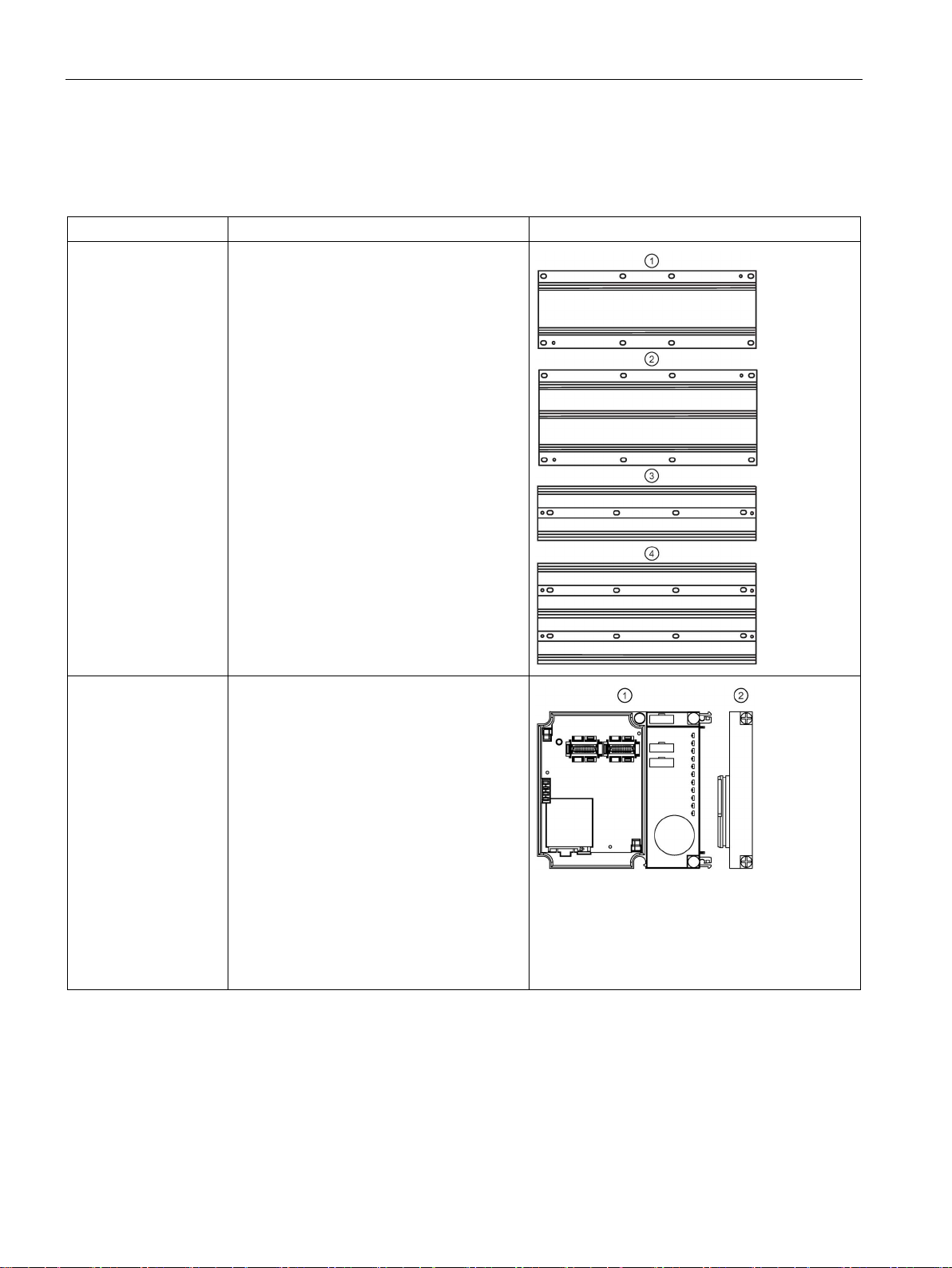

Components of the ET200pro distributed I/O system

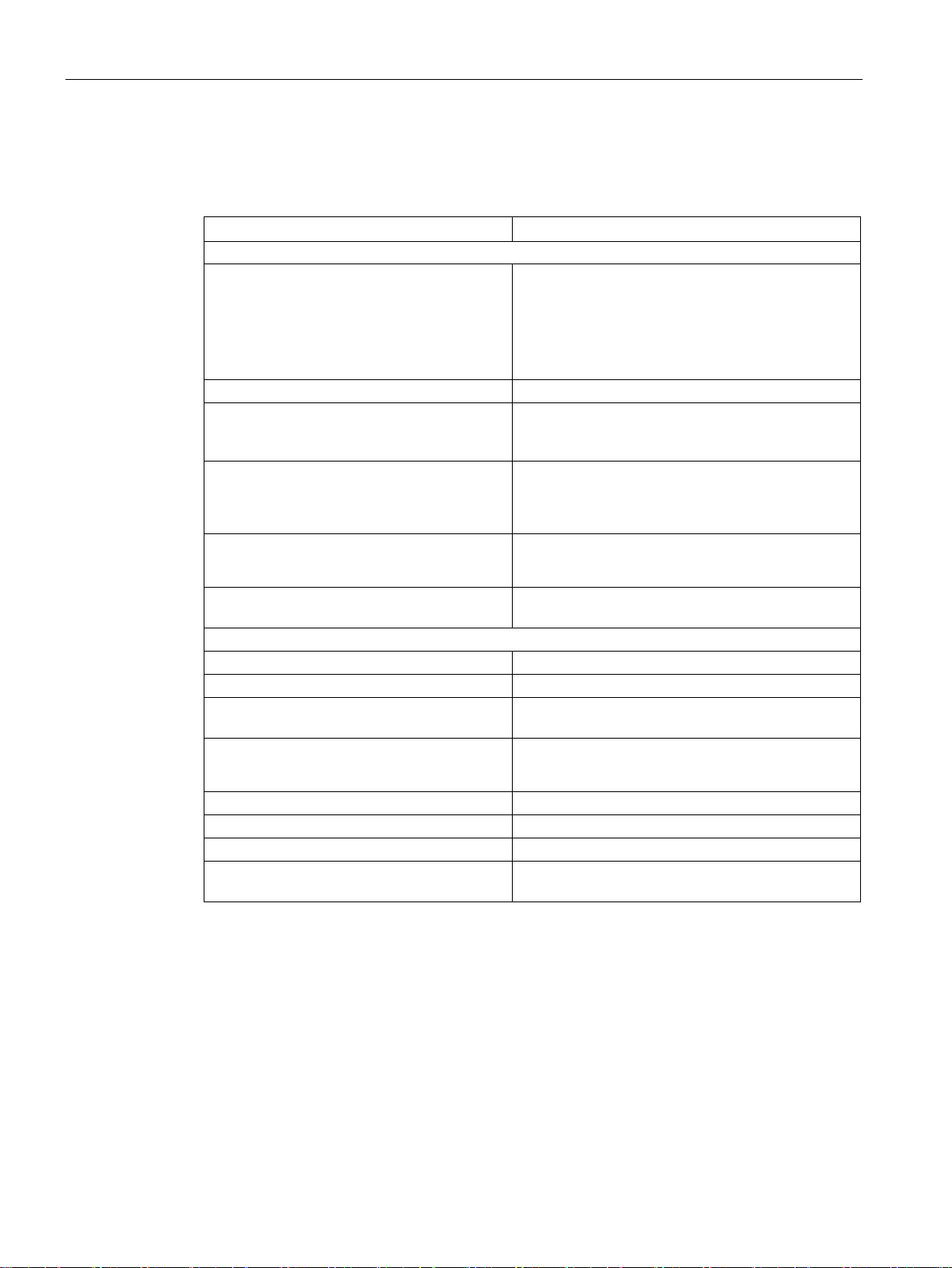

Component

Function

View

2.3 Components of the ET200pro distributed I/O system

The table below lists the most important components of an ET 200pro system.

Rack The ET 200pro is mounted onto the rack.

Four versions with different lengths are available:

Rack, narrow

Rack, wide ②

Rack, compact narrow ③

Rack, compact wide ④

①

Interface module for

EtherNet/IP with bus

module and terminating module

The interface module interconnects

ET 200pro with the EtherNet/IP master and

prepares the data for the electronic modules.

The unit is delivered with the terminating

module

already mounted on the bus module.

• The bus module is the mechanical and

• The terminating module terminates the

The following interface modules are available

for EtherNet/IP:

• ET 200pro EtherNet/IP interface module

②, and the interface module ① is

electrical connection element between

the various ET 200pro modules.

ET 200pro, backplane bus.

(ZNX:EIP200PRO)

ET 200pro distributed I/O EtherNet/IP interface module

12 Manual, 03/2016, A5E32861915-AB

Product overview

Component

Function

View

Power module with bus

2.3 Components of the ET200pro distributed I/O system

Connection module for

the ET 200pro EtherNet/IP interface module

module and outgoing

module

The connection module is mounted on the

interface module. It is used to connect

EtherNet/IP and the electronic, encoder, and

load voltage supplies.

The following connection module is available

for EtherNet/IP:

• CM IM M12, 7/8" (ZNX:ET200PROCM1)

① The power module provides a new poten-

tial group for the 2L+ load voltage supply.

The unit is shipped with the power module

mounted on the bus module.

② The outgoing module enables the 1L+

electronics/encoder supply and the 2L+ load

voltage supply to be tapped.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

13

Product overview

2.4

The ET 200pro EtherNet/IP interface module

ET 200pro EtherNet/IP interface module package

Order number

ET 200pro EtherNet/IP interface module features

Note

Operating with ungrounded reference potential

When the ET

and 1M and FE are not interconnected, any interference currents are discharged

protective ground via an internal RC circuit.

2.4 The ET 200pro EtherNet/IP interface module

The ET 200pro EtherNet/IP interface module package includes the following components:

● Interface module and terminating module (ET 200pro EtherNet/IP)

● Companion disk with EIP ET200 Configuration Tool software, EIP ET200 Configuration

Tool User Reference Guide, and this ET 200pro EtherNet/IP interface module manual

The order number for this package is: ZNX:EIP200PRO.

The ET 200pro EtherNet/IP module is a communications adapter for interfacing with an

ET 200pro distributed I/O system. It provides connectivity between an EtherNet/IP network

and ET 200pro power and I/O modules, and has the following features:

● It prepares the data for electronic modules and motor starters.

● It supplies the backplane bus.

● The maximum address space is 255 bytes for inputs and 255 bytes for outputs.

● The connection between 1M and FE is not applicable in a configuration with ungrounded

reference potential.

● A maximum of 16 modules can be operated with the interface module.

● The maximum width of the station is 1 m.

● The maximum parameter length for the entire station is 237 bytes.

● You can group modules within one byte (packing).

200pro EtherNet/IP module is operated with ungrounded reference potential

to

ET 200pro distributed I/O EtherNet/IP interface module

14 Manual, 03/2016, A5E32861915-AB

Product overview

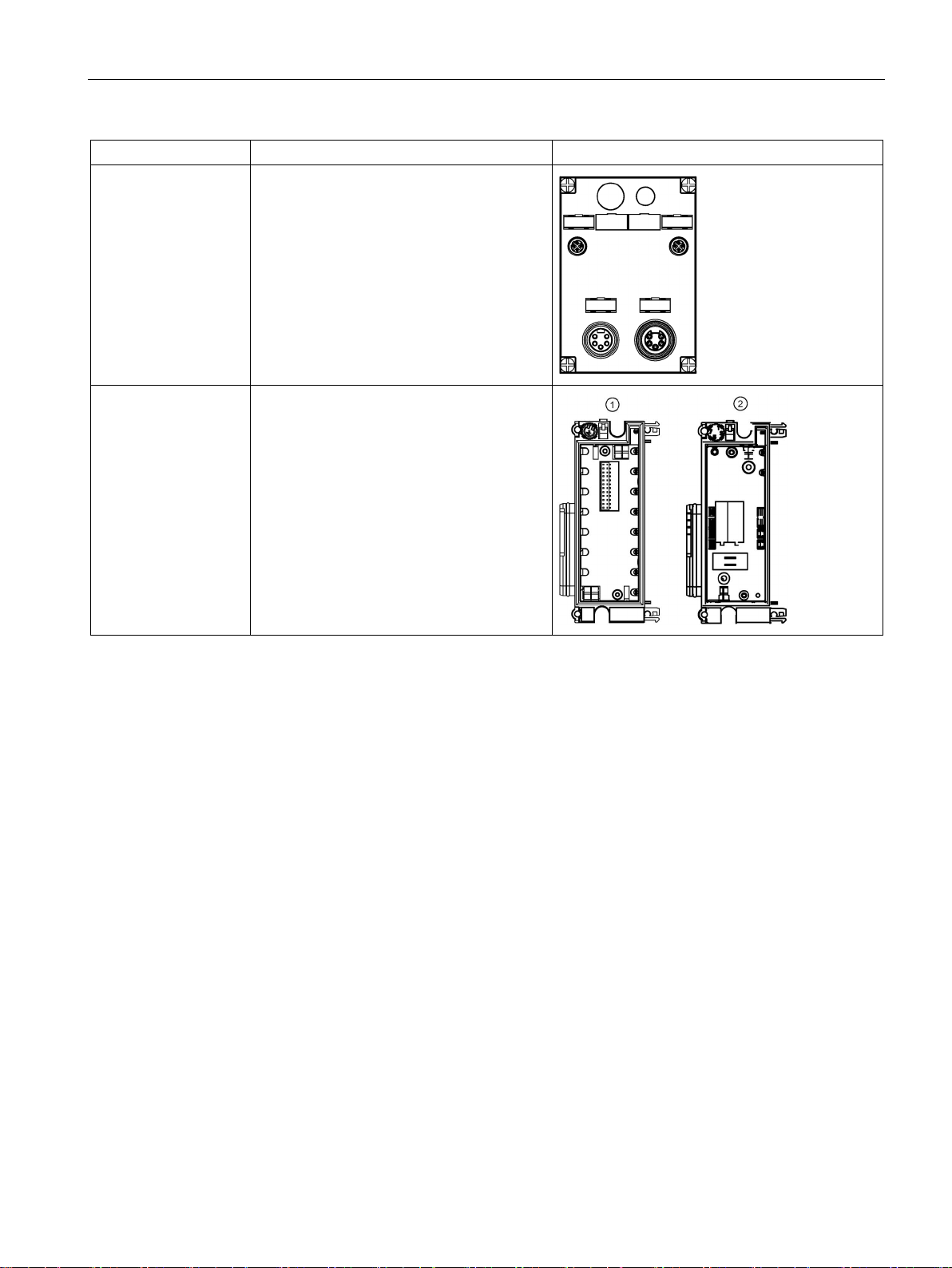

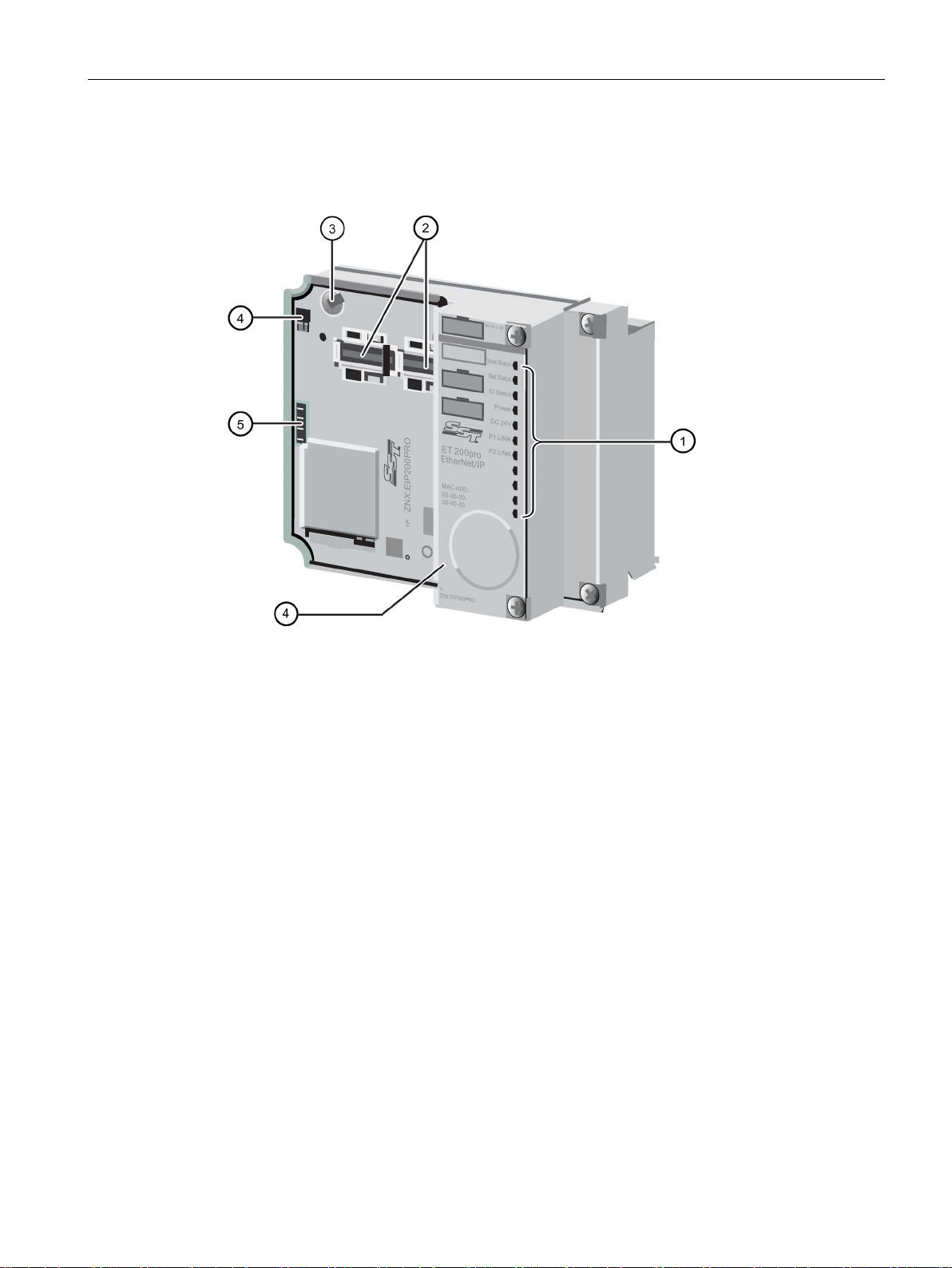

①

Status LEDs

②

Connection module interface

③

Coding element

④

Ground connections

⑤

Power connection

I/O features

2.4 The ET 200pro EtherNet/IP interface module

The following illustration shows the hardware features of the ET 200pro EtherNet/IP module:

The ET 200pro EtherNet/IP module provides the following I/O features:

● Provides support for a subset of ET 200pro modules

● Supports up to 16 modules per ET 200pro EtherNet/IP module

● Supports electronic module parameterization

● Supports electronic module diagnostics

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

15

Product overview

2.5

Features and benefits of the ET 200pro EtherNet/IP module

Features

Benefits

Structure

Extensive range of electronic modules

Broad area of application

tions (10 g vibration resistance)

the machine, high availability

Connection system

Integrated voltage buses

Reduced effort required for wiring

Power bus up to 25 A for motor starters

Minimization of wiring in 400 V range

essary

IP65, IP66, and IP67 connection modules

A change in connection method is not necessary

Automatic coding of the I/O modules

Quick and reliable module replacement

Large label plate

Adequate space for clear identification

accordance with EN 954-1

2.5 Features and benefits of the ET 200pro EtherNet/IP module

The following table lists the features and benefits of the ET 200pro EtherNet/IP module:

Finely-graduated modular design:

• 4/8/16 channel electronic modules

• Power modules

• Integrated motor starters

Communication capacity, system-integrated

motor starter: direct and reversing starter to

7.5 kW

Permanent wiring due to the separation of the

connection module and electronic components

Individual connection of power modules to

common potential

Robust structure for rough industrial condi-

M8, M12, and M23 connections A change in terminal connection method is not nec-

• Function-oriented, cost-optimized station design

• Considerable reduction in outlay for configuration

and documentation

• Space savings due to arbitrary arrangement of

the modules

PLC inputs and outputs, terminal blocks, circuit

breakers and contactors in a plug-in module save

space and the effort involved in wiring

• Prewiring possible

• Module replacement during operation of the

ET 200pro EtherNet/IP module ("hot swapping")

• Individual formation of potential groups

• Simple load interruption

High operating reliability when mounted directly on

• 2- and 3-wire connection, or

• 2-, 3- and 4-wire connection

With motor starters up to safety category 4 in

Optimal selection on grounds of space and cost

Saves money on costly safety equipment

ET 200pro distributed I/O EtherNet/IP interface module

16 Manual, 03/2016, A5E32861915-AB

3

3.1

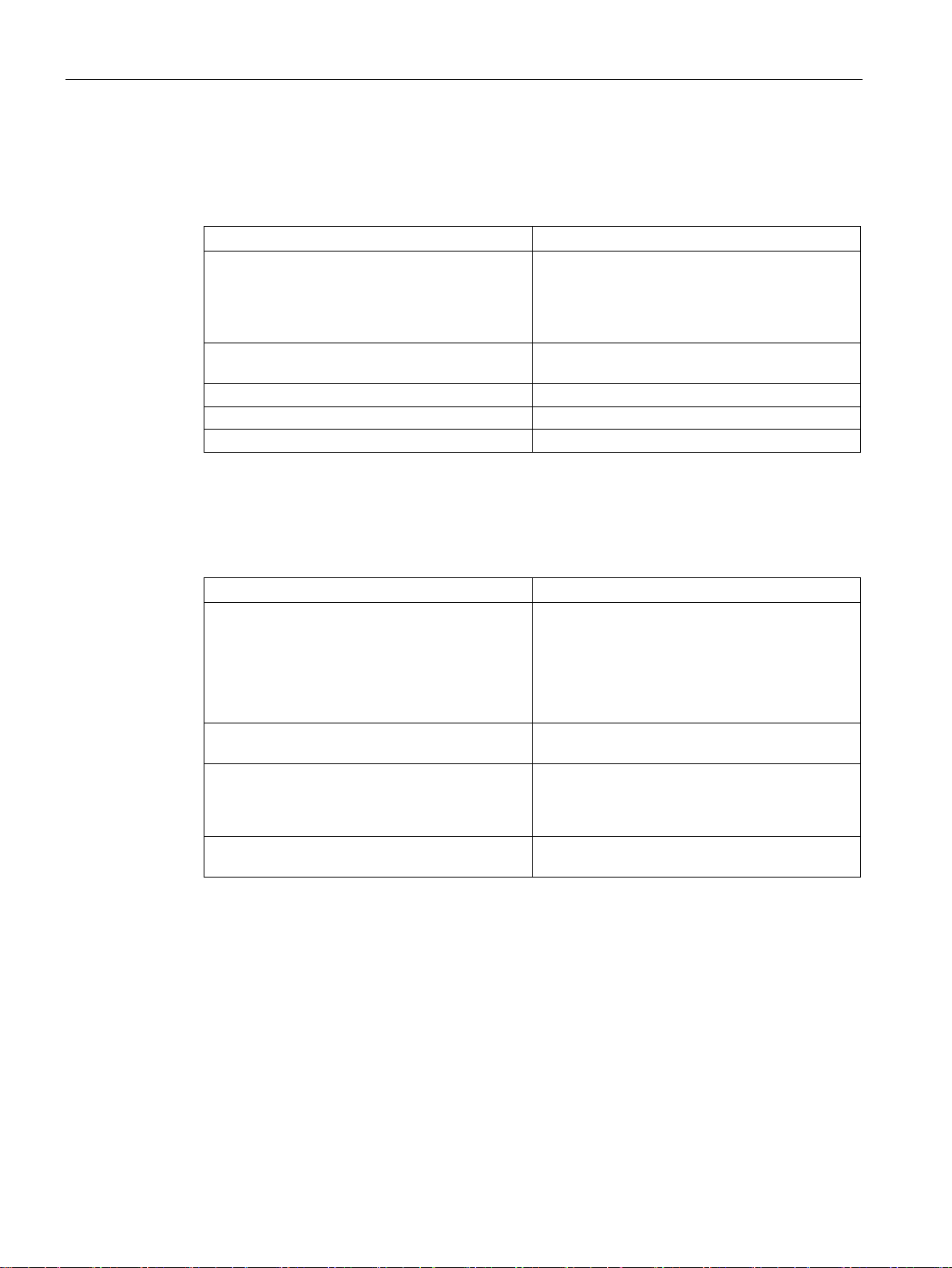

ET 200pro EtherNet/IP module hardware

Hardware configuration

LED status indicators

LED status indicator: Module Status LED

State

Description

Invalid parameter data.

commissioning due to configuration

Red

Unrecoverable fault detected: hardware failure.

You can operate your ET 200pro EtherNet/IP module in automatic configuration mode, or

you can use the EIP ET200 Configuration Tool software to operate in user configured mode.

The software and associated User Reference Guide can be found on the companion disk

that shipped with your module, or downloaded from the Siemens Industry Online Support

(https://support.automation.siemens.com/cs/?lc=en-US) website.

The ET 200pro EtherNet/IP module has three bi-color LEDs that provide diagnostic

information about the current state of the device and provide an indication of any faults. The

LEDs conform to the behaviors defined in the ODVA EtherNet/IP Adaptation of CIP Adapter

Specification for the Module Status and Network Status LEDs, and in this manual for I/O

Status LEDs.

The bi-color Module Status LED indicates the current state of the ET 200pro EtherNet/IP

module, as described in the following table:

Off No power applied to device.

Flashing green Device has not been configured.

Green Device has initialized successfully and no errors

Flashing red Recoverable fault.

were detected.

Device needs

error:

• Invalid parameter data

• Invalid slot configuration data.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

17

The ET 200pro EtherNet/IP module

LED status indicator: Network Status LED

State

Description

Green

Connected.

Red

Duplicate IP address detected.

LED status indicator: I/O Status LED

State

Description

mal operation, RUN mode).

I/O is active.

3.1 ET 200pro EtherNet/IP module hardware

The bi-color Network Status LED indicates the current state of the ET 200pro EtherNet/IP

communications link, as described in the following table:

Off

Flashing green No connection - an IP address is configured, but

Flashing red One or more CIP connections have timed out.

The bi-color I/O Status LED provides diagnostic information about the current state of the I/O

under the control of the ET 200pro EtherNet/IP module, as described in the following table:

Off

Green Device online with connections established (nor-

• Device is powered off, or is powered on but

does not have an IP address.

• May be waiting for IP address if in

DHCP/BOOTP mode.

no CIP connections are established.

• All outputs and inputs are inactive.

• Configuration errors prevent enabling of in-

puts/outputs.

• No connection.

• Device not powered.

Flashing green

Flashing red One or more outputs or inputs are faulted when

ET 200pro distributed I/O EtherNet/IP interface module

• Device online with connections established

(normal operation, IDLE mode).

• Firmware update in progress.

18 Manual, 03/2016, A5E32861915-AB

The ET 200pro EtherNet/IP module

3.2

Operation

Automatic Configuration mode

Note

Motor starters require User

3.2 Operation

The ET 200pro EtherNet/IP interface module is capable of operating out of the box in

Automatic Configuration mode without any special configuration software. Automatic

Configuration mode is the default mode.

However, to take full advantage of advanced diagnostics and features, you can operate in

User-configured mode by using the EIP ET200 Configuration Tool software.

You can access the Configuration Tool software and associated User Reference Guide in

one of two places:

● on the companion disk that shipped with your ET 200pro EtherNet/IP interface module

● on the Siemens Industry Online Support website

(https://support.automation.siemens.com/cs/?lc=en-US)

When operating in Automatic Configuration mode, the ET 200pro EtherNet/IP module

configures its I/O sizes, I/O module parameterization data, and configuration data according

to the combination of ET 200pro modules present at power-up or reset. In Automatic

Configuration mode:

● Electronic module parameter data cannot be specified. The modules use the default

parameters. You must make certain that the default parameters for the modules satisfy

your application requirements.

● I/O configuration cannot be verified. The ET 200pro EtherNet/IP module verifies the

configuration by examining I/O sizes.

Note that the ET 200pro EtherNet/IP module is unable to differentiate modules of similar

configuration types (for example, a 2 A discrete output module as compared to a 0.5 A

discrete output module):

● The I/O data format is defined by the combination of modules installed.

● I/O module grouping is enabled.

● The I/O status byte is enabled.

-configured mode.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

19

The ET 200pro EtherNet/IP module

User-configured mode

Changes to configuration data

Setting the IP address

I/O status byte

3.2 Operation

When operating in User-configured mode, the ET 200pro EtherNet/IP module I/O sizes, I/O

module parameterization data, and I/O configuration data are stored in nonvolatile memory

and accessed via the Slot Object. In User-configured mode:

● You can modify electronic module parameter data, allowing access to more advanced

configuration options and diagnostics.

● I/O configuration is verified. Mismatching I/O configurations result in an error.

Note that the ET 200pro EtherNet/IP module is unable to differentiate modules of similar

configuration types (for example, a 2 A discrete output module as compared to a 0.5 A

discrete output module).

● You can set Slot Object instance attributes (as long as there are no open I/O

connections).

● You define the I/O data format by the combination of modules you configure.

● I/O module grouping is available, but you must define it by your configuration selections.

Changes to user configuration data take effect immediately after download without resetting

the device.

Changes to user configuration data are stored in nonvolatile memory immediately (before the

explicit message response is sent).

DHCP is the factory default. When the ET 200pro EtherNet/IP module is using DHCP, you

can set IP addresses by using Microsoft Windows and Linux DHCP/BOOTP servers. There

are several free servers for Microsoft Windows available for download from the Internet. Use

discretion when downloading software from the Internet.

After you set the IP address with DHCP, you can use the EIP ET200 Configuration Tool to

set a permanent IP address and turn off DHCP. See the "EIP ET200 Configuration Tool User

Reference Guide" for detailed instructions.

The Adapter Object IO_StatusEnable attribute allows you to enable or disable the generation

of an additional I/O status byte to detect faults in the ET 200pro EtherNet/IP. If the

IO_StatusEnable attribute is TRUE (1), an additional status byte is placed at the beginning of

the input data packet, prior to any electronic module data. In the event of a fault, the status

byte is set to 1, and the I/O status LED flashes red while I/O is active.

If the IO_StatusEnable attribute is FALSE (0), the input data packet contains only electronic

module data as configured.

ET 200pro distributed I/O EtherNet/IP interface module

20 Manual, 03/2016, A5E32861915-AB

The ET 200pro EtherNet/IP module

Module grouping

Reset behavior

Note

When network power is removed (or if an I/O

their configured "substitute" value according to how the parameter is set for each I/O

module. The "default" substitute value, which is in effect in Automatic Configuration mode, is

to turn off or to zero out

details. To set a non

3.2 Operation

The ET 200pro EtherNet/IP module supports grouping electronic module data to enable

more efficient data transfer and use of address space. Electronic module data is always

grouped in Automatic Configuration mode. See the topic "Configuring the ET 200pro

EtherNet/IP module" for details about grouping module data.

When the ET 200pro EtherNet/IP module is reset, the outputs are deactivated during the

short period that the reset is in progress. The unit can be reset in the following ways:

● by cycling of primary device 24 VDC power of the primary device

● by using the reset function in the EIP ET200 Configuration Tool.

● by sending an explicit EtherNet/IP Reset service message to instance 1 of the Identity

Object with service data of 0, 1, or 2. If service data 1 is sent, on reset the module returns

to factory default state and any user configuration is lost. If service data 2 is sent, the

module returns to the factory default state, but the IP address is maintained.

connection times out or is lost), outputs go to

puts. Consult the documentation for your specific I/O module for

-default substitute value, you must use User-configured mode.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

21

The ET 200pro EtherNet/IP module

3.3

Parameters for the ET 200pro EtherNet/IP module

Parameter assignment

Parameter

Value range

Default

Operation for ref. <> actual conf.

enable disable

disable

Submodule status

enable disable

enable

Channel-related diagnostics

enable disable

enable

Option handling

not currently supported

Parameter description

Operation for ref. <> actual conf.

Identifier-related diagnostics

Submodule status

Channel-related diagnostics

3.3 Parameters for the ET 200pro EtherNet/IP module

Parameters for the ET 200pro EtherNet/IP module are set by using the EIP ET200

Configuration Tool software. After loading new parameters into the interface module, the

parameters take effect immediately.

The following table describes the parameters of the ET 200pro EtherNet/IP interface module

as they appear in the Configuration Tool:

Identifier-related diagnostics enable disable enable

If this parameter is enabled and:

● you hot-swap an electronic module, this will not cause a failure of the ET 200pro station.

● the preset and actual configurations do not match, ET 200pro can still exchange data with

the PLC.

If this parameter is disabled and:

● you hot-swap an electronic module, this will cause a failure of the ET 200pro station.

● the preset and actual configurations do not match, ET 200pro cannot exchange data with

the PLC.

This parameter has no effect for the ET 200pro EtherNet/IP module. All of the diagnostic

data is always available through the Adapter Object.

This parameter has no effect for the ET 200pro EtherNet/IP module. All of the diagnostic

data is always available through the Adapter Object.

ET 200pro distributed I/O EtherNet/IP interface module

22 Manual, 03/2016, A5E32861915-AB

This parameter has no effect for the ET 200pro EtherNet/IP module. All of the diagnostic

data is always available through the Adapter Object.

The ET 200pro EtherNet/IP module

Option handling

3.4

Faults

Configuration faults

Electronic module faults

3.4 Faults

This parameter is not currently supported.

Faults in the electronic module configuration and parameterization data are handled slightly

differently depending on when they are detected.

Regardless of the detection time, the following occur:

● The Adapter Object AdapterStatus attribute indicates the appropriate code.

● The Identity Object Status attribute indicates a minor recoverable fault.

When the fault is detected at power-up or as a result of a hot swap when no I/O connections

are open:

● An attempt to open I/O connections results in a Device State Conflict error.

A fault detected as a result of a hot-swap when one or more I/O connections are open result

in the following behavior:

● If the IO_StatusEnable attribute is TRUE, a fault is indicated in the I/O Status byte at the

beginning of the input data packet.

● Output data from the scanner is ignored.

● Any attempt to allocate I/O connections is rejected by the device.

You can recover from the configuration fault by:

● installing or removing I/O modules to make the actual configuration match the

user-defined configuration; and/or

● changing the configuration data to match the actual configuration.

The I/O configuration is reapplied immediately after a configuration download from the

EIP ET200 Configuration Tool, and at module startup.

When an I/O connection is active, faults in electronic modules are reported as follows:

● If the IO_StatusEnable attribute is TRUE, a fault is indicated in the I/O Status byte at the

beginning of the input data packet.

● The appropriate Slot Object instance SlotStatus attribute and Channel<n>Status

attribute(s) indicate the nature of the fault.

● The I/O status LED state is flashing red when I/O is active.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

23

The ET 200pro EtherNet/IP module

Module hot swap

WARNING

Changing the coding

3.4 Faults

The ET 200pro distributed I/O system supports removing and inserting one electronic

module (one gap) while the device is active on the network without removing power.

The ET 200pro remains in RUN state when the electronic module is removed.

The ET 200pro station fails if you remove more than one electronic module.

Hot-swapping electronic modules in RUN state is supported only if the "Operation in setpoint

<> actual configuration" parameter is enabled for the ET 200pro EtherNet/IP module.

To perform the hot-swap, you will need a size 2 cross-tip (or Phillips) screwdriver and

pointed pliers.

To replace an electronic module, follow these steps:

1. Using the screwdriver, remove the two screws from the front of the connection module

from the right side top and bottom.

2. Remove the connection module next to the electronic module from the bus module.

3. While pressing the interlock button on the top of the electronic module, pull the

connection module upwards and out of the electronic module.

4. Remove one half of the coding key from the new electronic module (top left).

5. Insert the connection module into the electronic module (same type).

6. Insert the connection module with the electronic module into the bus module and screw it

down.

To change from one type of electronic module to another, follow these steps:

1. Using the screwdriver, remove the two screws from the front of the connection module

from the right side top and bottom.

2. Remove the connection module next to the electronic module from the bus module.

3. While pressing the interlock button on the top of the electronic module, pull the

connection module upwards and out of the electronic module.

4. Use the pointed pliers to remove one half of the coding key from the connection module

(top right).

5. Insert the appropriate connection module into the replacement electronic module.

6. Insert the connection module with the electronic module into the bus module and screw it

down.

7. Change the configuration using the EIP ET200 Configuration Tool and download it to the

EtherNet/IP master device.

ET 200pro distributed I/O EtherNet/IP interface module

24 Manual, 03/2016, A5E32861915-AB

If you change the coding, this may result in a mismatch between the ET 200pro EtherNet/IP

module and the connection module, which could result in dangerous plant conditions.

The ET 200pro EtherNet/IP module

CAUTION

Communication faults

3.4 Faults

In order to prevent damage to your ET 200pro, always deactivate the outputs before you

remove any connection modules.

If you are unable to communicate with the ET 200pro EtherNet/IP module, ensure that you

have completed the following :

● Check that the appropriate link LED, P1 or P2, is green. If it is off, check the cabling to the

network switch. The link LED must be on before proceeding to the next step.

● If the Network Status LED is off, the IP address is not set. If the module is using DHCP

(factory default), check that the DHCP server is set up and running correctly. The

Network Status LED must be flashing green before proceeding to the next step.

● Perform a List Identity from the EIP ET200 Configuration Tool.

● Ensure that the IP address is unique on the network.

● Ensure that the IP address of the communication partner is on the same IP subnet.

ET 200pro distributed I/O EtherNet/IP interface module

Manual, 03/2016, A5E32861915-AB

25

Loading...

Loading...