Page 1

Contents

SIMATIC

ET 200iS Distributed I/O Station

Manual

No. Designation

1 Product information A5E00163808-02 06/2004

2 Product information A5E00207628-02 02/2004

2 Product information A5E00158421-01 06/2004

The following supplements are part of this documentation:

Drawing number

Edition

Preface

Product Overview

Brief Instructions on

Commissioning

Configuration Options

Installation

Wiring

Commissioning and Diagnostics

Maintenance

General Technical Specifications

Terminal Modules

Power Supply Module

Interface Module

Digital Electronics Modules

Analog Electronics Modules

Analog Electronics Modules

with HART

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

This manual has the order number:

6ES7151-2AA00-8BA0

Edition 10/2001

A5E00087831-02

Appendix

Order Numbers

Dimension Drawings

Reaction Times

Address Space of the Inputs

and Outputs

Certifications

Marking

Glossary

Index

16

17

18

19

20

21

22

Page 2

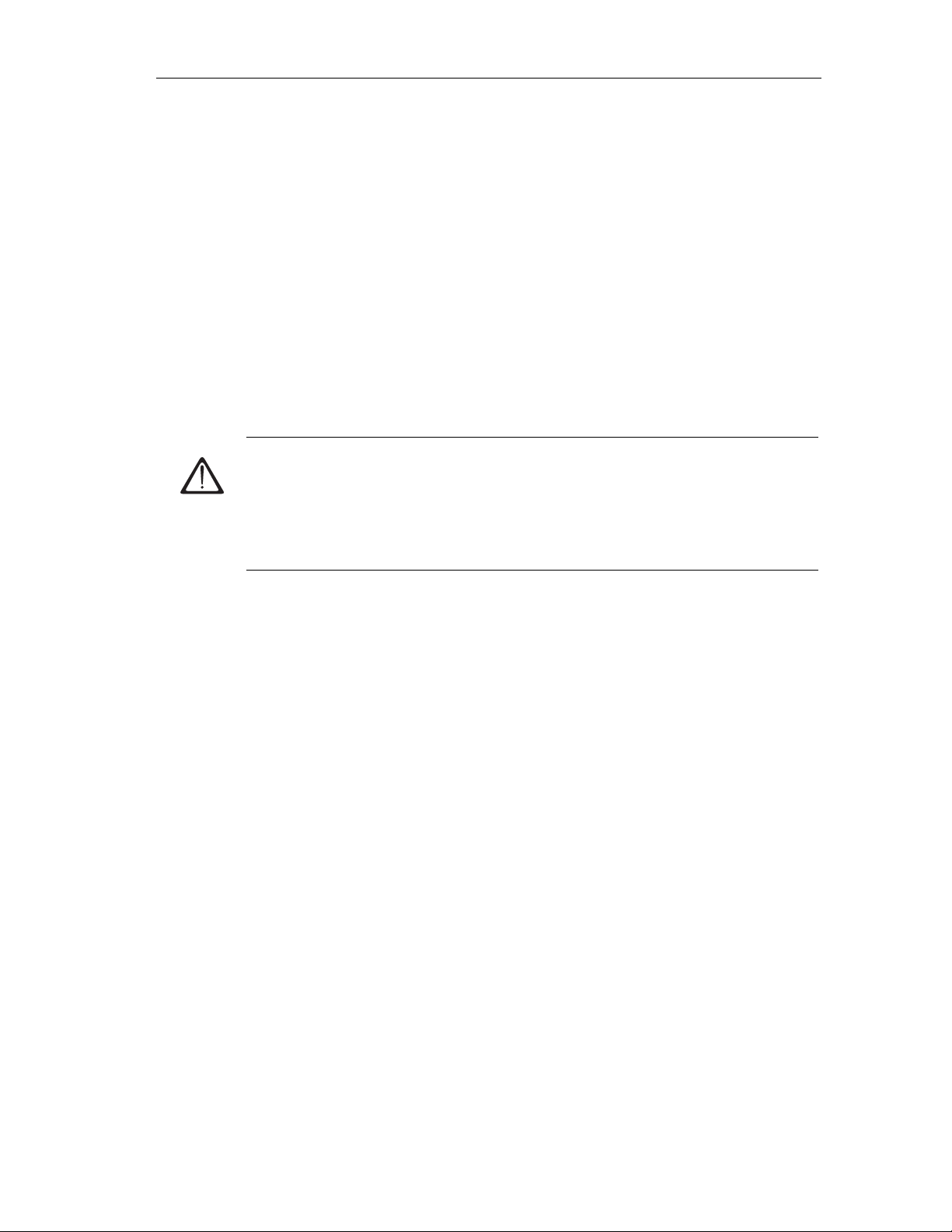

Safety Guidelines

This manual contains notices intended to ensure personal safety, as well as to protect t he products and

connected equipment against damage. These notices are highlighted by the symbols shown below and

graded according to severity by the following texts:

!

!

!

Danger

indicates that death, severe personal injury or substantial property damage will result if proper

precautions are not taken.

Warning

indicates that death, severe personal injury or subst antial property damage can result if proper

precautions are not taken.

Caution

indicates that minor personal injury can result if proper precautions are not taken.

Caution

indicates that property damage can result if proper precautions are not taken.

Notice

draws your attention to particularly important i nformation on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground and to tag circuits, equipment, and

systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

Warning

!

Trademarks

Copyright © Siemens AG 2001 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent g rant or registration of a utility model or design,

are reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschaeftsgebiet Industrie-Automatisierungssysteme

Postfach 4848, D- 90327 Nuernberg

Siemens Aktiengesellschaft A5E00087831

This device and its components may only be used for the applications descri bed in the catal og or the

technical description, and only in connection with devi ces or components from other manufacturers

which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is trans ported, stored, set up, and installed

correctly, and operated and maintained as recommended.

SIMATIC®, SIMATIC HMI® and SIMATIC NET® are registered trademarks of SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to trademarks might

infringe upon the rights of the trademark owners.

Disclaimer of Liability

We have checked the contents of thi s manual for agreement with

the hardware and s oftware described. Since devi ations cannot be

precluded entirely , we cannot guarantee full agre ement. However,

the data in this m anual are reviewed regularl y and any necessary

corrections included in subsequent editions. Suggestions for

improvement are welcomed.

©Siemens AG 2001

Technical data subject to change.

Page 3

Contents

1 1 Preface 1-1

1.1 Preface..............................................................................................................1-1

2 2 Product Overview 2-1

2.1 What are Distributed I/O Stations? ...................................................................2-1

2.2 What Is the ET 200iS Distributed I/O Station?..................................................2-3

2.3 ET 200iS in the Hazardous Area.......................................................................2-9

2.4 Integration in Process Control System............................................................2-13

3 3 Brief Instructions on Commissioning 3-1

3.1 Introduction........................................................................................................3-1

3.2 Requirements....................................................................................................3-1

3.3 Materials and Tools Required to Set Up the Example......................................3-2

3.4 Overview of the Setup.......................................................................................3-3

3.5 Setting Up the Configuration for the Example...................................................3-4

3.5.1 Setting up the ET 200iS ....................................................................................3-4

3.5.2 Setting Up the S7-400.......................................................................................3-4

3.5.3 Installing the Fieldbus Isolating Transformer....................................................3-4

3.6 Wiring the Example Setup.................................................................................3-5

3.7 Insert the interface module and the electronics modules .................................3-8

3.8 Setting the PROFIBUS Address .......................................................................3-8

3.9 Configuring the Example................................................................................... 3-9

3.9.1 Configuring the S7-400 .....................................................................................3-9

3.9.2 Configuration of the ET 200iS.........................................................................3-11

3.9.3 Setting Parameters for the ET 200iS ..............................................................3-13

3.10 Programming the Example..............................................................................3-14

3.11 Putting the Example into Operation ................................................................3-16

3.12 Evaluating the Diagnostics..............................................................................3-16

3.13 Removing and inserting modules....................................................................3-17

3.14 Wire break of the NAMUR encoder connected to the digital input module ....3-18

4 4 Configuration Options 4-1

4.1 System with Scalable Modularit y ......................................................................4-1

4.2 Electronics Modules to Suit your Application.................................................... 4-2

4.3 Which Electronics Modules Match the Terminal Modules? ..............................4-4

4.4 Configuration Options in Zones.........................................................................4-5

4.5 Power Supply of the ET 200iS..........................................................................4-8

4.6 Direct Data Exchange .......................................................................................4-9

4.7 Using the ET 200iS in a Redundant Standard DP Master System.................4-10

4.8 Restricted Number of Connectable Electronics Modules/Maximum

Configuration...................................................................................................4-12

ET 200iS Distributed I/O Station

A5E00087831-02

iii

Page 4

Contents

5 5 Installation 5-1

5.1 Rules for Installation..........................................................................................5-1

5.2 Installing the Terminal Module for the Power Supply Module...........................5-5

5.3 Installing Terminal Modules for the Interface Module and Electronics

Modules.............................................................................................................5-7

5.4 Installing the Bus Termination Module............................................................5-10

5.5 Installing the Shield Contact............................................................................5-12

5.6 Fitting Slot Number Labels and Color Identification Labels............................5-13

5.7 Replacing the Bus Interface Module and Terminal Box on the

Terminal Module..............................................................................................5-16

6 6 Wiring 6-1

6.1 General Rules and Regulations for Wiring........................................................6-1

6.2 Operate the ET 200iS with a Grounded-Neutral Supply...................................6-3

6.3 Electrical Design of the ET 200iS......................................................................6-5

6.4 Lightning and Overvoltage Protection...............................................................6-6

6.4.1 Overview ...........................................................................................................6-6

6.4.2 The Lightning Protection Zone Concept ...........................................................6-7

6.4.3 Rules for the Interface between Lightning Protection Zones 0...1..................6-10

6.4.4 Rules for the Interfaces between Lightning Protection Zones 1...2

and higher .......................................................................................................6-12

6.4.5 Example of Protection from Overvoltage for Networked ET 200iS Stations...6-13

6.5 Wiring the ET 200iS........................................................................................6-15

6.5.1 Wiring Rules for the ET 200iS.........................................................................6-15

6.5.2 Wiring Terminal Module TM-E30S44-iS with Scre w Terminals...................... 6-16

6.5.3 Wiring Terminal Module TM-E30C44-iS with Spring Terminals .....................6-17

6.5.4 Wiring Terminal Module TM-PS......................................................................6-18

6.5.5 Wiring Terminal Module TM-IM.......................................................................6-20

6.5.6 Wiring Terminal Module TM-E ........................................................................6-22

6.5.7 Contacting the Cable Shields..........................................................................6-23

6.5.8 Grounding the DIN Rail...................................................................................6-25

6.6 Inserting and Labeling the Power Supply, Interface Module, and

Electronics Modules ........................................................................................6-26

6.7 Setting the PROFIBUS Address .....................................................................6-31

7 7 Commissioning and Diagnostics 7-1

7.1 Overview of Defining the Configuration ............................................................7-1

7.2 Configuration.....................................................................................................7-5

7.3 Parameter Assignment......................................................................................7-7

7.4 Commissioning and Starting up the ET 200iS ................................................7-10

7.5 Reassign Parameters for the ET 200iS during Operation...............................7-14

7.6 Diagnostics Using the Process Image Input Table.........................................7-16

7.7 Status and Error LEDs on the IM 151-2..........................................................7-17

7.8 Diagnostics with STEP 5 and STEP 7 ............................................................7-22

7.8.1 Introduction......................................................................................................7-22

7.8.2 Reading out Diagnostic Information................................................................7-22

7.8.3 Diagnostic Messages of the Electro nic s Modules...........................................7-24

7.8.4 Evaluating Interrupts from the ET 200iS (S7-DP Slave/ DPV1 Slave) ...........7-26

7.8.5 Structure of the Slave Diagnostic Information.................................................7-29

7.8.6 Station Status 1 to 3........................................................................................7-30

7.8.7 Master PROFIBUS Address............................................................................7-32

7.8.8 Vendor ID........................................................................................................7-32

7.8.9 ID-Related Diagnostics ...................................................................................7-33

iv A5E00087831-02

ET 200iS Distributed I/O Station

Page 5

Contents

7.8.10 Module Status .................................................................................................7-34

7.8.11 Channel-Related Diagnostics..........................................................................7-35

7.8.12 Interrupts.........................................................................................................7-38

7.8.13 Diagnostics for Incorrect Module Configuration of the ET 200iS....................7-46

8 8 Maintenance 8-1

8.1 Activities During Operation................................................................................8-1

8.2 Removing and Inserting Elec tr on ics Modules duri ng Oper ati on

(Hot Swapping) .................................................................................................8-2

8.3 Maintenance During Operation......................................................................... 8-5

8.4 Cleaning............................................................................................................8-5

9 9 General Technical Specifications 9-1

9.1 General Technical Specifications......................................................................9-1

9.2 Standards, certificates and approvals...............................................................9-1

9.3 Electromagnetic Compatibility, Transport and Storage Conditions ..................9-3

9.4 Mechanical and climatic environmental conditions...........................................9-6

9.5 Information on Dielectric Strength Tests, Class of Protection, Degree of

Protection and Rated Voltage of the ET 200iS .................................................9-7

10 10 Terminal Modules 10-1

10.1 Overview of the Contents................................................................................10-1

10.2 Terminal Module for the Power Supply Module TM-PS..................................10-2

10.3 Terminal Module for the Interface Module TM-IM...........................................10-4

10.4 Terminal Modules for Electronics Modules TM-E30S44-iS / TM-E30C44-iS .10-6

11 11 Power Supply Module 11-1

11.1 Power Supply Module .....................................................................................11-1

12 12 Interface Module 12-1

12.1 Interface module IM 151-2..............................................................................12-1

12.2 Parameters for the Interface Module ..............................................................12-4

12.3 Parameter Description ....................................................................................12-5

12.3.1 Startup when defined and actual configuration differ......................................12-5

12.3.2 Time stamping / edge evaluation....................................................................12-5

12.3.3 Format of the analog values............................................................................12-7

12.3.4 Interference Frequency Suppression..............................................................12-7

12.3.5 Temperature unit.............................................................................................12-7

12.3.6 Slot Reference Junction/Reference Junction Input.........................................12-7

12.3.7 Identification Data ...........................................................................................12-7

13 13 Digital Electronics Modules 13-1

13.1 Digital Electronics Module 4DI NAMUR..........................................................13-1

13.2 Digital Electronics Module 2DO DC25V/25mA...............................................13-7

13.3 Parameters of the Digital Electronics Modules .............................................13-11

13.4 Parameter Description ..................................................................................13-14

13.4.1 Pulse extension.............................................................................................13-14

13.4.2 Flutter monitoring ..........................................................................................13-15

13.4.3 Identification Data .........................................................................................13-17

13.5 Diagnostics with the Changeover Transducer Type.....................................13-17

ET 200iS Distributed I/O Station

A5E00087831-02

v

Page 6

Contents

14 14 Analog Electronics Modules 14-1

14.1 Analog Value Representation .........................................................................14-1

14.1.1 Overview .........................................................................................................14-1

14.1.2 Analog Value Representation for Measuring Ranges with SIMATIC S7 ........14-3

14.1.3 Analog Value Representation for the Measuring Ranges of the

Analog Input Modules in SIMATIC S7 Format................................................14-4

14.1.4 Analog Value Representation for the Output Ranges of the

Analog Output Modules in SIMATIC S7 Format...........................................14-20

14.1.5 Analog Value Representation for Measuring Ranges with SIMATIC S5......14-21

14.1.6 Analog Value Representation for the Measuring Ranges of the

Analog Input Modules in SIMATIC S5 Format..............................................14-22

14.1.7 Analog Value Representation for the Output Ranges of the

Analog Output Modules in SIMATIC S5 Format...........................................14-38

14.2 Basics of Analog Value Processing ..............................................................14-39

14.2.1 Connecting Thermocouples..........................................................................14-39

14.3 Response of the Analog Modules during Operation and if Faults Occur......14-43

14.4 Analog Electronics Module 2AI I 2WIRE.......................................................14-45

14.5 Analog Electronics Module 2AI I 4WIRE.......................................................14-49

14.6 Analog Electronics Module 2AI RTD.............................................................14-53

14.7 Analog Electronics Module 2AI TC ...............................................................14-57

14.8 Analog Electronics Module 2AO I .................................................................14-61

14.9 Parameters of the Analog El ec tronics Modu les............................................14-65

14.10 Parameter Description ..................................................................................14-69

14.10.1 Reference Junction / Reference Junction Number .......................................14-69

14.10.2 Smoothing .....................................................................................................14-69

14.10.3 Identification Data..........................................................................................14-70

15 15 Analog Electronics Modules with HART 15-1

15.1 Basics of HART...............................................................................................15-1

15.1.1 What is HART?................................................................................................15-1

15.1.2 How Does HART Work? .................................................................................15-2

15.1.3 How Are HART Field Devices Used with the ET 200iS..................................15-3

15.1.4 How Do You Use HART?................................................................................15-4

15.2 Analog Value Representation .........................................................................15-7

15.3 Basics of Analog Value Processing ................................................................15-7

15.4 Response of the Analog Modules with HART during Operation

and if Problems Occur.....................................................................................15-7

15.5 Analog Electronics Module 2AI I 2WIRE HART..............................................15-8

15.6 Analog Electronics Module 2AI I 4WIRE HART............................................15-13

15.7 Analog Electronics Module 2AO I HART ......................................................15-18

15.8 Parameters of the Analog Electronics Modules with HART..........................15-22

15.9 Parameter Description ..................................................................................15-24

15.9.1 Smoothing .....................................................................................................15-24

15.9.2 Identification Data..........................................................................................15-24

15.10 HART Data Records .....................................................................................15-25

16 16 Order Numbers 16-1

16.1 Order Numbers ...............................................................................................16-1

17 17 Dimension Drawings 17-1

17.1 Dimension Drawings .......................................................................................17-1

vi A5E00087831-02

ET 200iS Distributed I/O Station

Page 7

Contents

18 18 Reaction Times 18-1

18.1 Introduction......................................................................................................18-1

18.2 Reaction Times on the DP Master..................................................................18-2

18.3 Reaction Times on the ET 200iS ....................................................................18-2

18.4 Reaction Times with Digital Input Modules.....................................................18-3

18.5 Reaction Times with Digital Output Modules ..................................................18-3

18.6 Reaction Times of Analog Input Modules .......................................................18-4

18.7 Reaction Times of Analog Output Modules ....................................................18-5

19 19 Address Space of the Inputs and Outputs 19-1

19.1 Digital Electronics Modules.............................................................................19-1

19.2 Analog Electronics Modules............................................................................19-2

19.3 Analog Electronics Modules with HART .........................................................19-3

20 20 Certifications 20-1

20.1 EU Prototype Test Certificates........................................................................20-1

20.1.1 ET 200iS Distributed I/O Station.....................................................................20-1

20.1.2 Interface module IM151-2...............................................................................20-5

20.1.3 Power supply PS.............................................................................................20-7

20.1.4 4DI NAMUR.....................................................................................................20-9

20.1.5 2DO DC25V/25mA........................................................................................20-12

20.1.6 2AI I 2WIRE, 2AI I 2WIRE HART..................................................................20-14

20.1.7 2AI I 4WIRE, 2AI I 4WIRE HART..................................................................20-16

20.1.8 2AI RTD.........................................................................................................20-18

20.1.9 2AI TC...........................................................................................................20-20

20.1.10 2AO I, 2AO I HART.......................................................................................20-22

20.2 EU Declarations of Conformity......................................................................20-24

20.2.1 ET 200iS Distributed I/O Station...................................................................20-24

20.2.2 Interface module IM 151-2............................................................................20-24

20.2.3 Power supply PS...........................................................................................20-25

20.2.4 4DI NAMUR...................................................................................................20-25

20.2.5 2DO DC25V/25mA........................................................................................20-26

20.2.6 2AI I 2WIRE, 2AI I 2WIRE HART..................................................................20-26

20.2.7 2AI I 4WIRE, 2AI I 4WIRE HART..................................................................20-27

20.2.8 2AI RTD.........................................................................................................20-27

20.2.9 2AI TC...........................................................................................................20-28

20.2.10 2AO I, 2AO I HART.......................................................................................20-28

21 21 Marking 21-1

21.1 Marking According to Divisions.......................................................................21-1

21.2 Marking According to Zones ...........................................................................21-3

22 22 Glossary 22-1

22.1 Glossary..........................................................................................................22-1

23 Index

ET 200iS Distributed I/O Station

A5E00087831-02

vii

Page 8

Contents

Figures

1-1 SIMATIC Customer Support Hotline.................................................................1-4

2-1 Typical Structure of a PROFIBUS-DP Network................................................2-2

2-2 View of the ET 200iS Distributed I/O Station....................................................2-4

2-3 Identification Codes of the ET 200iS...............................................................2-12

2-4 Integration in the Control System....................................................................2-13

3-1 Overview of the Example Setup........................................................................3-3

3-2 Wiring TM-PS....................................................................................................3-5

3-3 Wiring Fieldbus Isolating Transformer..............................................................3-6

3-4 Wiring the ET 200iS Modules............................................................................3-7

3-5 Setting PROFIBUS Address 3 ..........................................................................3-8

3-6 Configuration of the S7-400............................................................................3-10

3-7 Configuration of the ET 200iS.........................................................................3-12

3-8 Disabling ET 200iS Channels .........................................................................3-13

4-1 Example of an ET 200iS Configuration.............................................................4-2

4-2 Configuration Options for the ET 200iS in Zone 1............................................4-6

4-3 Power Supply Module PS.................................................................................4-9

4-4 Example of Direct Data Exchange..................................................................4-10

4-5 ET 200iS and the Y-Link .................................................................................4- 11

5-1 Enclosure for the ET 200iS in Zone 1...............................................................5-2

5-2 Enclosure for the ET 200iS in Zone 2...............................................................5-3

5-3 Minimum Clearances to the Enclosure .............................................................5-4

5-4 Installing the Terminal Module TM-PS..............................................................5-6

5-5 Installing the Terminal Module TM-IM and TM-E..............................................5-8

5-6 Uninstalling the Terminal Module TM-IM or TM-E from the Right ....................5-9

5-7 Installing the Bus Termination Module............................................................5-11

5-8 Installing the Shield Contact............................................................................5-13

5-9 Fitting Slot Number Labels and Color Identification Labels............................5-15

5-10 Replacing the Bus Interface Module and Terminal Box..................................5-17

6-1 Operating the ET 200iS with a Grounded Reference Potential........................6-4

6-2 Potentials on the ET 200iS................................................................................6-6

6-3 Lightning Protection Zones of a Building ..........................................................6-9

6-4 Example of Wiring Networked ET 200iS Stations...........................................6-13

6-5 Wiring with Spring Terminals ..........................................................................6-18

6-6 Connecting the Power Supply and Grounding Conductor on the TM-PS.......6-20

6-7 Wiring Terminal Module TM-IM.......................................................................6-22

6-8 Wiring Terminal Module TM-E ........................................................................6-23

6-9 Contacting the Cable Shields..........................................................................6-24

6-10 Inserting and Identifying the Power Supp l y Module PS..................................6-27

6-11 Inserting and Labeling the IM 151-2 and Electronics Modules.......................6-28

6-12 Removing Interface and Electronics Modules.................................................6-29

6-13 Replacing and Electronics Module with a Different Type................................6-30

6-14 Setting the PROFIBUS Address .....................................................................6-32

7-1 Basis on Which Configuration Takes Place......................................................7-1

7-2 Starting up the ET 200iS.................................................................................7-12

7-3 Starting up the Time-of-Day Synchronization/Time Stamping........................7-13

7-4 Assignment of the Value Status to the Digital Input........................................7-16

7-5 LED Display on the Interface Module..............................................................7-17

7-6 Status LEDs on the Power Supply Module.....................................................7-19

7-7 Status and Error LEDs on the Digital Electronics Modules.............................7-20

7-8 Error LEDs on the Analog Electronics Modules..............................................7-21

viii A5E00087831-02

ET 200iS Distributed I/O Station

Page 9

Contents

7-9 Interrupts from Analog Input Modules.............................................................7-27

7-10 Structure of the Slave Diagnostic Information.................................................7-29

7-11 Structure of the ID-Related Diagnostic Information for the ET 200iS.............7-33

7-12 Module Status.................................................................................................7-34

7-13 Structure of the Channel-Related Diagnostic Information ..............................7-36

7-14 Structure of the Interrupt Status of the Interrupt Section................................7-39

7-15 Structure of Bytes x+4 to x+7 for Diagnostic Interrupts ..................................7-40

7-16 Structure Starting at Byte x+8 for Diagnostic Interrupts

(Input or OutputModules) ................................................................................7-41

7-17 Example of a Diagnostic Interrupt...................................................................7-42

7-18 Example of a Diagnostic Interrupt (continued)................................................7-43

7-19 Structure Starting at Byte x+4 for Hardware Interrupts (Analog Input)...........7-44

7-20 Structure Starting at Byte x+4 for Remove/Insert Interrupts...........................7-44

7-21 Structure Starting at Byte x+4 for Update Interrupt.........................................7-45

8-1 Automatic Parameter Assignment after Replacing a Module ...........................8-3

9-1 Mark for Australia..............................................................................................9-2

10-1 Block Diagram of the Terminal Module TM-PS...............................................10-3

10-2 Block Diagram of the Terminal Module TM-IM ...............................................10-5

10-3 Block Diagram of the Terminal Module TM-E30S44-iS / E30C44-iS..............10-7

11-1 Block Diagram of the Power Supply Module...................................................11-1

12-1 Block Diagram of the IM 151-2........................................................................12-2

12-2 Example of Time Stamping and Edge Evaluation...........................................12-6

13-1 Block Diagram of the 4DI NAMUR..................................................................13-4

13-2 Block Diagram of the 2DO DC25V/25mA .......................................................13-8

13-3 Output Curve.................................................................................................13-11

13-4 Principle of Pulse Extension..........................................................................13-14

13-5 Principle Behind Flutter Monitoring...............................................................13-16

14-1 Compensation by 2AI RTD ...........................................................................14-40

14-2 Example of Parameter Assignment for Reference Junctions.......................14-41

14-3 Block Diagram of the 2AI I 2WIRE................................................................14-46

14-4 Block Diagram of the 2AI I 4WIRE................................................................14-50

14-5 Block Diagram of the 2AI RTD......................................................................14-54

14-6 Block Diagram of the 2AI TC.........................................................................14-58

14-7 Block Diagram of the 2AO I...........................................................................14-62

14-8 Example of the Influence of Smoothing on the Step Response ...................14-70

15-1 The HART Signal............................................................................................15-2

15-2 Location of the HART Analog Modules in the Distributed System .................15-4

15-3 System Environment for Using HART.............................................................15-5

15-4 Block Diagram of the 2AI I 2WIRE HART.......................................................15-9

15-5 Block Diagram of the 2AI I 4WIRE HART.....................................................15-14

15-6 Block Diagram of the 2AO I HART................................................................15-19

17-1 Terminal Module TM-PS with Power Supply Module PS Inserted..................17-1

17-2 Terminal Module TM-IM with Interface Module IM 151-2 Inserted.................17-2

17-3 Terminal Module TM-E with Electronics Module Inserted ..............................17-2

17-4 Bus Termination Module.................................................................................17-3

18-1 Reaction Times between the DP Master and ET 200iS .................................18-1

18-2 Calculating the Reaction Time........................................................................18-2

18-3 Example of Calculating the ET 200iS Reaction Time.....................................18-3

18-4 Cycle Times of the Analog Input Channel.......................................................18-4

18-5 Cycle Time of the Analog Output Module.......................................................18-5

18-6 Response Time of an Analog Output Channel ...............................................18-6

19-1 Address Space of Digital Input Modules.........................................................19-1

19-2 Address Space of Digital Output Modules ......................................................19-1

ET 200iS Distributed I/O Station

A5E00087831-02

ix

Page 10

Contents

19-3 Address Space of Analog Input Modules........................................................19-2

19-4 Address Space of Analog Output Modules.....................................................19-2

19-5 Address Space of Analog Input Modules with HART .....................................19-3

19-6 Address Space of Analog Output Modules with HART...................................19-3

21-1 Overview.........................................................................................................21-1

Tables

1-1 Qualified Personnel........................................................................................... 1-1

2-1 Components of the ET 200iS............................................................................2-4

2-2 Properties and Uses..........................................................................................2-8

2-3 Classification of Zones....................................................................................2-10

2-4 Properties and Types of Protection................................................................. 2- 10

3-1 Required Material and Tools.............................................................................3-2

3-2 Changes..........................................................................................................3-14

3-3 Program for the Example................................................................................3-15

4-1 Electronics Modules to Suit your Application....................................................4-3

4-2 Which Electronics Modules Match the Terminal Modules? ..............................4-4

4-3 Rules for Configuration .....................................................................................4-7

4-4 Calculation Table for Current Consumption....................................................4-13

4-5 Example of a Calculation Table for Current Consumption..............................4-14

5-1 Installation Dimensions .....................................................................................5-2

5-2 Fitting Slot Number Labels and Color Identification Labels............................5-14

5-3 Removing Slot Number Labels and Color Identification Labels......................5-15

6-1 Plant Startup after Certain Events.....................................................................6-2

6-2 System Power Supply in the Safe Area............................................................6-2

6-3 24 V DC Supply in the Safe Area......................................................................6-2

6-4 Protection from External Electrical Influences ..................................................6-3

6-5 Components and Protective Measures.............................................................6-3

6-6 Lightning Protection Zones ...............................................................................6-7

6-7 Protection of Cables with Overvoltage Protection Compone nts.....................6-11

6-8 Example of a Lightning-Protected Configuration ............................................6-14

6-9 Wiring Rules for the ET 200iS.........................................................................6-16

7-1 Comparison of DPV1, S7 DP and DPV0 ..........................................................7-3

7-2 Software Requirements.....................................................................................7-4

7-3 Configuration.....................................................................................................7-5

7-4 Including the GSD File in STEP 7 / COM-PROFIBUS......................................7-6

7-5 Setting Parameters with STEP 7 or PCS 7.......................................................7-7

7-6 Setting Parameters with SIMATIC PDM ...........................................................7-8

7-7 Requirements for Commissioning...................................................................7-11

7-8 Commissioning the ET 200iS..........................................................................7-11

7-9 Reassigning Parameters.................................................................................7-15

7-10 Status and Error LEDs on the IM 151-2..........................................................7-18

7-11 Status LEDs on the Power Supply Module.....................................................7-19

7-12 LED Display on the Digital Electronics Modules.............................................7-20

7-13 Error LEDs on the Analog Electronics Modules..............................................7-21

7-14 Reading out Diagnostic Information with STEP 7 and STEP 5 ......................7-22

7-15 Digital Input Modules.......................................................................................7-24

7-16 Digital Output Modules....................................................................................7-25

7-17 Analog Input Modules .....................................................................................7-25

7-18 Analog Output Modules...................................................................................7-25

x A5E00087831-02

ET 200iS Distributed I/O Station

Page 11

Contents

7-19 Structure of Station Status 1 (Byte 0) .............................................................7-30

7-20 Structure of Station Status 2 (Byte 1) .............................................................7-31

7-21 Structure of Station Status 3 (Byte 2) .............................................................7-31

7-22 Structure of the Vendor ID (Byte 4, 5).............................................................7-32

7-23 Types of Error/Fault of the Electronics Modules.............................................7-37

7-24 Diagnostics for Incorrect Module Configuration of the ET 200iS....................7-46

8-1 Permitted Activities in Zone 1............................................................................8-1

8-2 Requirements....................................................................................................8-4

9-1 Pulse-Shaped Disturbances..............................................................................9-4

9-2 Sinusoidal Disturbances....................................................................................9-4

9-3 Emission of Radio Interference.........................................................................9-5

9-4 Transport and Storage Conditions....................................................................9-5

9-5 Climatic Ambient Conditions .............................................................................9-6

9-6 Testing for Mechanical and Climatic Ambient Conditions.................................9-7

9-7 Dielectric Strength.............................................................................................9-7

9-8 Rated Voltage for Operation .............................................................................9-8

10-1 Terminal Modules and Electronics Modules ...................................................10-1

10-2 Terminal Assignment on the Terminal Module TM-PS...................................10-2

10-3 Technical Specifications of the Terminal Module for the

Power Supply Module TM-PS.........................................................................10-3

10-4 Pinning of the PROFIBUS-DP Ex i Socket on the TM-IM...............................10-4

10-5 Technical Specifications of the Terminal Module for the Interface

Module TM-IM.................................................................................................10-5

10-6 Terminal Assignment of the Terminal Module TM-E30S44-iS / E30C44-iS...10-6

10-7 Technical Data of the Terminal Modules for Electronics Modules

TM-E30S44iS/ TME30C44-iS .........................................................................10-7

11-1 Technical Specifications..................................................................................11-2

12-1 Technical Specifications..................................................................................12-2

12-2 Parameters for the Interface Module IM 151-2...............................................12-4

12-3 Identification Data ...........................................................................................12-5

12-4 Identification Data ...........................................................................................12-8

13-1 Terminal Assignment of NAMUR Sensors or Sensors Complying with

DIN 19234.......................................................................................................13-1

13-2 Terminal Assignment of NAMUR Changeover Contacts or Changeover

Contacts Complying with DIN 19234 ..............................................................13-2

13-3 Terminal Assignment of a Single Contact Wired with 10 kΩ

(mechanical NO contact).................................................................................13-2

13-4 Terminal Assignment of a Changeover Contact Wired with 10 kΩ

(mechanical changeover contact) ...................................................................13-3

13-5 Terminal Assignment of a Single Contact Unswitched

( mechanical NO contact with single contact )................................................13-3

13-6 Terminal Assignment of a Changeover Contact Unswitched

(mechanical changeover contact) ...................................................................13-4

13-7 Technical Specifications..................................................................................13-5

13-8 Terminal Assignment of the 2DO DC25V/25mA.............................................13-7

13-9 Technical Specifications..................................................................................13-8

13-10 Parameters for 4 DI NAMUR.........................................................................13-11

13-11 Parameters of the 2DO DC25V/25mA..........................................................13-13

13-12 Identification Data .........................................................................................13-13

13-13 Principle.........................................................................................................13-18

14-1 Measured Values in the Event of Wire Break Dependent on Enabled

Diagnostics (Format S7) .................................................................................14-2

ET 200iS Distributed I/O Station

A5E00087831-02

xi

Page 12

Contents

14-2 Measured Values in the Event of Wire Break Dependent on Enabled

Diagnostics (Format S5) .................................................................................14-2

14-3 Analog Value Representation (SIMATIC S7 Format) .....................................14-3

14-4 Examples.........................................................................................................14-3

14-5 Measured Value Resolution of the Analog Values (SIMATIC S7 Format) .....14-4

14-6 SIMATIC S7 format: Measuring range ± 80 mV .............................................14-5

14-7 SIMATIC S7 Format: Measuring Range 0/4 to 20 mA....................................14-6

14-8 SIMATIC S7 format: Measuring range 600 ohms absolute ............................14-6

14-9 SIMATIC S7 Format: Measuring Range Pt100 Standard in °C ......................14-7

14-10 SIMATIC S7 Format: Measuring Range Pt100 Standard in °F.......................14-7

14-11 SIMATIC S7 Format: Measuring Range Pt100 Climatic in °C........................14-8

14-12 SIMATIC S7 Format: Measuring Range Pt100 Climatic in °F ........................14-8

14-13 SIMATIC S7 Format: Measuring Range Ni100 Standard in °C ......................14-9

14-14 SIMATIC S7 Format: Measuring Range Ni100 Standard in °F.......................14-9

14-15 SIMATIC S7 Format: Measuring Range Ni100 Climatic in °C......................14-10

14-16 SIMATIC S7 Format: Measuring Range Ni100 Climatic in °F ......................14-10

14-17 SIMATIC S7 Format: Measuring Range Type E in °C..................................14-11

14-18 SIMATIC S7 Format: Measuring Range Type E in °F ..................................14-11

14-19 SIMATIC S7 Format: Measuring Range Type N in °C..................................14-12

14-20 SIMATIC S7 Format: Measuring Range Type N in °F..................................14-12

14-21 SIMATIC S7 Format: Measuring Range Type J in °C...................................14-13

14-22 SIMATIC S7 Format: Measuring Range Type J in °F...................................14-13

14-23 SIMATIC S7 Format: Measuring Range Type K in °C..................................14-14

14-24 SIMATIC S7 Format: Measuring Range Type K in °F ..................................14-14

14-25 SIMATIC S7 Format: Measuring Range Type L in °C ..................................14-15

14-26 SIMATIC S7 Format: Measuring Range Type L in °F...................................14-15

14-27 SIMATIC S7 Format: Measuring Range Type S, R in °C .............................14-16

14-28 SIMATIC S7 Format: Measuring Range Type S, R in °F..............................14-16

14-29 SIMATIC S7 Format: Measuring Range Type B in °C..................................14-17

14-30 SIMATIC S7 Format: Measuring Range Type B in °F ..................................14-17

14-31 SIMATIC S7 Format: Measuring Range Type T in °C..................................14-18

14-32 SIMATIC S7 Format: Measuring Range Type T in °F...................................14-18

14-33 SIMATIC S7 Format: Measuring Range Type U in °C..................................14-19

14-34 SIMATIC S7 Format: Measuring Range Type U in °F..................................14-19

14-35 SIMATIC S7 Format: Measuring Range 0/4 to 20 mA..................................14-20

14-36 Analog Value Representation of the Analog Inputs

(SIMATIC S5 Format) ...................................................................................14-21

14-37 Analog Value Representation of the Analog Outputs

(SIMATIC S5 Format) ...................................................................................14-22

14-38 SIMATIC S5 Format: Measuring Range ± 80 m V.........................................14-23

14-39 SIMATIC S5 Format: Measuring Ranges 0 to 20 mA, 4 to 20 mA ...............14-23

14-40 SIMATIC S5 format: Measuring range 600 ohms absolute ..........................14-24

14-41 SIMATIC S5 Format: Measuring Range Pt100 Standard in °C ....................14-25

14-42 SIMATIC S5 Format: Measuring Range Pt100 Standard in °F.....................14-25

14-43 SIMATIC S5 Format: Measuring Range Pt100 Climatic in °C......................14-26

14-44 SIMATIC S5 Format: Measuring Range Pt100 Climatic in °F ......................14-26

14-45 SIMATIC S5 Format: Measuring Range Ni100 Standard in °C ....................14-27

14-46 SIMATIC S5 Format: Measuring Range Ni100 Standard in °F.....................14-27

14-47 SIMATIC S5 Format: Measuring Range Ni100 Climatic in °C......................14-28

14-48 SIMATIC S5 Format: Measuring Range Ni100 Climatic in °F ......................14-28

14-49 SIMATIC S5 Format: Measuring Range Type E in °C..................................14-29

14-50 SIMATIC S5 Format: Measuring Range Type E in °F ..................................14-29

14-51 SIMATIC S5 Format: Measuring Range Type N in °C..................................14-30

xii A5E00087831-02

ET 200iS Distributed I/O Station

Page 13

Contents

14-52 SIMATIC S5 Format: Measuring Range Type N in °F..................................14-30

14-53 SIMATIC S5 Format: Measuring Range Type J in °C ..................................14-31

14-54 SIMATIC S5 Format: Measuring Range Type J in °F...................................14-31

14-55 SIMATIC S5 Format: Measuring Range Type K in °C..................................14-32

14-56 SIMATIC S5 Format: Measuring Range Type K in °F ..................................14-32

14-57 SIMATIC S5 Format: Measuring Range Type L in °C ..................................14-33

14-58 SIMATIC S5 Format: Measuring Range Type L in °F...................................14-33

14-59 SIMATIC S5 Format: Measuring Range Type R, S in °C .............................14-34

14-60 SIMATIC S5 Format: Measuring Range Type R, S in °F..............................14-34

14-61 SIMATIC S5 Format: Measuring Range Type B in °C..................................14-35

14-62 SIMATIC S5 Format: Measuring Range Type B in °F ..................................14-35

14-63 SIMATIC S5 Format: Measuring Range Type T in °C..................................14-36

14-64 SIMATIC S5 Format: Measuring Range Type T in °F ..................................14-36

14-65 SIMATIC S5 Format: Measuring Range Type U in °C..................................14-37

14-66 SIMATIC S5 Format: Measuring Range Type U in °F..................................14-37

14-67 SIMATIC S5 Format: Measuring Ranges 0 to 20 mA, 4 to 20 mA ...............14-38

14-68 Compensation of the Reference Junction Temperature...............................14-39

14-69 Reference Junction Parameters ...................................................................14-41

14-70 Relevant Parameters for the Interface Module IM 151-2..............................14-42

14-71 Relevant Parameters for 2AI RTD and 2AI TC.............................................14-42

14-72 Dependence of the Input and Output Values on the Operating State

of the PLC (CPU of the DP master) and the Power Supply Voltage L+.......14-43

14-73 Response of the Analog Modules Depending on the Location

of the Analog Input Value in the Value Range..............................................14-44

14-74 Response of the Analog Modules Depending on the Location

of the Analog Output Value in the Value Range...........................................14-44

14-75 Terminal Assignment of the 2AI I 2WIRE .....................................................14-45

14-76 Technical Specifications................................................................................14-46

14-77 Terminal Assignment of the 2AI I 4WIRE .....................................................14-49

14-78 Technical Specifications................................................................................14-50

14-79 Terminal Assignment of the 2AI RTD ...........................................................14-53

14-80 Technical Specifications................................................................................14-54

14-81 Terminal Assignment of the 2AI TC..............................................................14-57

14-82 Technical Specifications................................................................................14-58

14-83 Terminal Assignment of the 2AO I................................................................14-61

14-84 Technical Specifications................................................................................14-63

14-85 Parameters of 2AI I 2WIRE, 2AI I 4WIRE.....................................................14-65

14-86 Parameters of 2AI RTD, 2AI TC ...................................................................14-66

14-87 Parameters of 2AO I .....................................................................................14-68

14-88 Identification Data .........................................................................................14-69

15-1 Examples of HART Parameters......................................................................15-3

15-2 Properties of the ET 200iS HART Analog Modules........................................15-6

15-3 Terminal Assignment of the 2AI I 2WIRE HART.............................................15-8

15-4 Technical Specifications................................................................................15-10

15-5 Terminal Assignment of the 2AI I 4WIRE HART...........................................15-13

15-6 Technical Specifications................................................................................15-15

15-7 Terminal Assignment of the 2AO I HART .....................................................15-18

15-8 Technical Specifications................................................................................15-20

15-9 Parameter 2AI I 2WIRE HART; 2AI I 4WIRE HART.....................................15-22

15-10 Parameters of 2AO I HART...........................................................................15-23

15-11 Identification Data .........................................................................................15-24

15-12 HART Data Records .....................................................................................15-25

16-1 Interface Module .............................................................................................16-1

ET 200iS Distributed I/O Station

A5E00087831-02

xiii

Page 14

Contents

16-2 Terminal Modules............................................................................................16-1

16-3 Power Supply Module.....................................................................................16-2

16-4 Digital Electronics Modules.............................................................................16-2

16-5 Analog Electronics Modules............................................................................16-2

16-6 Analog Electronics Modules with HART .........................................................16-2

16-7 ET 200iS Accessories.....................................................................................16-3

16-8 Network Components for the ET 200iS ..........................................................16-4

16-9 Manuals on STEP 7 and SIMATIC S7............................................................16-5

16-10 Manual on the ET 200 in SIMATIC S5............................................................16-6

16-11 Book on PROFIBUS-DP with SIMATIC S7 and STEP 7 ................................16-6

21-1 Device group I.................................................................................................21-3

21-2 Device group II................................................................................................21-4

21-3 Classification of Zones....................................................................................21-4

21-4 Types of Protection.........................................................................................21-5

21-5 Explosion Groups............................................................................................21-6

21-6 Temperature Classes......................................................................................21-7

21-7 Classification of Gases and Vapors in Explosion Groups and

Temperature Classes......................................................................................21-7

xiv A5E00087831-02

ET 200iS Distributed I/O Station

Page 15

1Preface

1.1 Preface

Purpose of the Manual

With the information in this manual, you will be able to operate the ET 200iS

distributed I/O station as a DP slave on PROFIBUS DP Ex i over a fieldbus

isolating transformer.

Basic Knowledge Required

To understand the manual, you require general experience in the field of

automation engineering.

The following qualifications are also required:

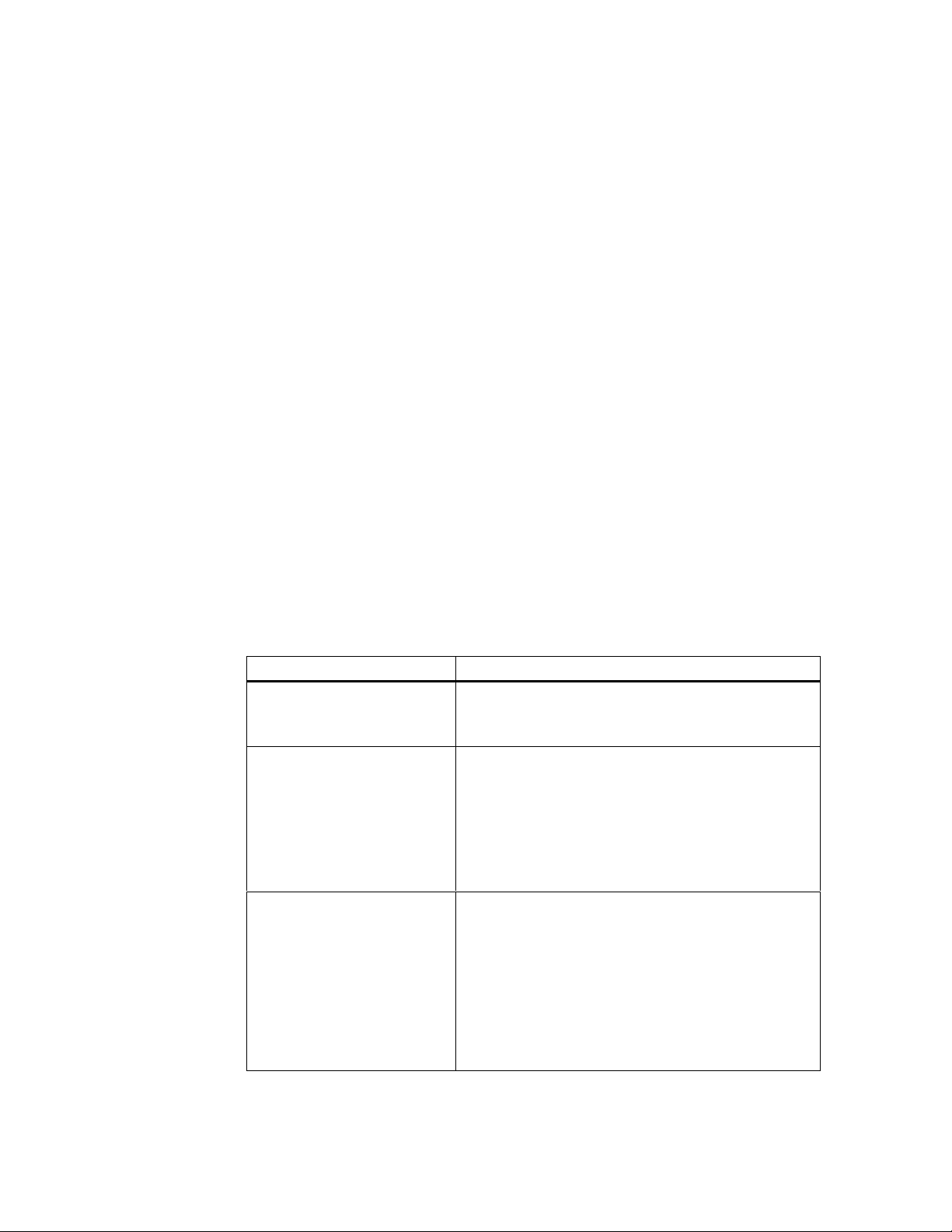

Table 1-1 Qualified Personnel

Activities Qualifications

Setting up the ET 200iS • Basic technical training

Wiring the ET 200iS • Basic practical training in electro-engineering

Commissioning the ET 200iS • Knowledge of all electrical and functional parameters

1

• Knowledge of safety regulations regarding the

workplace

• Knowledge of the relevant electrotechnical safety

regulations

• Knowledge of methods of installing explosion-proof

electrical equipment

• Knowledge of safety regulations regarding the

workplace

and properties of the ET 200iS

• Knowledge of the functions and commissioning of

PROFIBUS-DP

• Knowledge of the connected encoders, actuators,

and HART field devices

• Knowledge of the safety regulations regarding the

workplace, particularly regarding procedures in

hazardous areas

ET 200iS Distributed I/O Station

A5E00087831-02

1-1

Page 16

Preface

Scope of the Manual

This manual is valid for the distributed I/O station ET 200iS.

Approbations, Standards, and Approvals

Approbations

The distributed I/O station ET 200iS complies with the following directives:

• EU directive 73/23/EEC on low voltages

• EU directive 89/336/EEC on electromagnetic compatibility

• EU directive 94/9/EC on correct usage in hazardous plants

Standards and Approvals

The distributed I/O station ET 200iS

• is based on the standard IEC 61158/ EN 50170, Volume 2, PROFIBUS.

• meets the requirements and criteria of IEC 61131-2 and the requirements for

the CE mark.

• is approved for FM (applied for), CENELEC.

For more detailed information on the standards and approvals, refer to General

Technical Specifications.

Where this Documentation Fits In

In addition to this manual, you also require the manual for the DP master you are

using ( see Appendix Order Numbers).

In the Appendix Order Numbers, you will find a list with further sources of

information on SIMATIC S7 and the ET 200 distributed I/O system.

A description of the parameter assignment and configuration frame is not included

in this manual. You will find a description on the Internet at

http://www.ad.siemens.de/simatic-cs

Guide to the Manual

This manual describes the hardware of the ET 200iS distributed I/O station. It

consists of introductory chapters and reference chapters (technical specifications).

The manual deals with the following top ic s:

• Installing and wiring the ET 200iS distributed I/O station

• Commissioning and diagnostics of the ET 200iS distributed I/O station

• Components of the ET 200iS distributed I/O station

• Order Numbers

1-2 A5E00087831-02

ET 200iS Distributed I/O Station

Page 17

Further Support

If you have questions about using the products described in the manual and you

cannot find the answers here, please contact your local Siemens representative.

http://www.ad.siemens.de/partner

Training Centers

Courses are available to help you become familiar with the distributed I/O. Please

contact your regional or the central training center.

Phone: +49 (911) 895–3200

http://www.sitrain.com

SIMATIC Documentation on the Internet

You can obtain documentation free of charge on the Internet at:

http://www.ad.siemens.de/support

Preface

Here, you can use the Knowledge Manager to locate the documentation you

require quickly. If you have questions or suggestions regarding the documentation,

a "Documentation" conference is available in the Internet Forum.

ET 200iS Distributed I/O Station

A5E00087831-02

1-3

Page 18

Preface

SIMATIC Customer Support Hotline

Open round the clock, worldwide:

Figure 1-1 SIMATIC Customer Support Hotline

Worldwide (Nuremberg)

Technical Support

(FreeContact)

Local time: Mo.-Fr. 7:00 to 17:00

Phone: +49 (180) 5050 222

Fax: +49 (180) 5050 223

E-mail:

techsupport@ad.siemens.de

GMT: +1:00

Europe / Africa (Nuremberg)

Authorization

Local time: Mo.-Fr. 7:00 to 17:00

Phone: +49 (911) 895-7200

Fax: +49 (911) 895-7201

E-mail:

authorization@nbgm.siemens.de

GMT: +1:00

English and German are spoken on all hotlines. On the authorization hotline, French, Italian and Spanish

are also spoken.

Worldwide (Nuremberg)

Technical Support

(charged, only with SIMATIC

Card)

Local time: Mo.-Fr. 0:00 to 24:00

Phone: +49 (911) 895-7777

Fax: +49 (911) 895-7001

GMT: +1:00

America (Johnson City)

Technical Support and

Authorization

Local time: Mo.-Fr. 8:00 to 19:00

Phone: +1 423 262-2522

Fax: +1 423 262-2289

E-mail:

simatic.hotline@sea.siemens.

com

GMT: –5:00

Asia / Australia (Singapore)

Technical Support and

Authorization

Local time: Mo.-Fr. 8:30 to 17:30

Phone: +65 740-7000

Fax: +65 740-7001

E-mail:

simatic.hotline@sea.siemens.

com.sg

GMT: +8:00

1-4 A5E00087831-02

ET 200iS Distributed I/O Station

Page 19

Service & Support on the Internet

In addition to our documentation services, you can also make use of all our

knowledge on the Internet.

http://www.ad.siemens.de/support

Here, you will find:

• Current product information (Updates), FAQs (Frequently Asked Questions),

Downloads, Tips and Tricks.

• The Newsletter keeps you constantly up to date with the latest information on

the products you use.

• The Knowledge Manager will find the documents you need.

• In the Forum, users and specialists exchange information and experience.

• You can find your local contact for Automation & Drives in our contacts

database.

• Information on local service, repair, spares and much more is available to you

under the rubric Service.

Preface

ET 200iS Distributed I/O Station

A5E00087831-02

1-5

Page 20

Preface

1-6 A5E00087831-02

ET 200iS Distributed I/O Station

Page 21

2Product Overview

2.1 What are Distributed I/O Stations?

Distributed I/O Stations - Area of Application

When designing a system, the inputs and outputs from and to the process are often

installed in the programmable controller.

When the inputs/outputs are at a distance from the programmable controller, the

wiring involved can be extensive and confusing; electromagnetic interference can

also reduce the reliability.

In such systems, it is often advisable to use distributed I/O stations:

• the control CPU is located centrally

• the I/O devices are distributed on site

• PROFIBUS-DP allows high data transmission rates so that the control CPU and

I/O devices communicate both quickly and reliably.

• less installation effort since less cables are required.

2

What is PROFIBUS -DP?

PROFIBUS-DP is an open bus system complying with the IEC 61158/EN 50170,

Volume 2, PROFIBUS standard with the "DP" protocol (DP stands for distributed

(peripheral) I/O).

Physically, PROFIBUS-DP is an electrical network based on a shielded twisted pair

or an optical network using fiber optic cable.

The "DP" protocol allows fast, cyclic data exchange between the control CPU and

the distributed I/O devices.

What is PROFIBUS-DP Ex i

In contrast to PROFIBUS-DP, PROFIBUS-DP Ex i is intrinsically save (type of

protection intrinsically safe i). The intrinsic safety is assured by the use of a fieldbus

isolating transformer that acts like a safety barrier.

ET 200iS Distributed I/O Station

A5E00087831-02

2-1

Page 22

Product Overview

What are DP Masters and DP Slaves?

The link between the control CPU and the distributed I/O devices is the DP master.

The DP master exchanges data over PROFIBUS-DP with the distributed I/O

devices and monitors PROFIBUS-DP.

The distributed I/O devices (= DP slaves) prepare the data of the encoders and

actuators locally so that they can be transferred to the control CPU over

PROFIBUS-DP.

Which Devices Can Be Connected to PROFIBUS-DP?

A wide variety of devices can be attached to PROFIBUS-DP as DP masters or DP

slaves providing they operate in compliance with the IEC 61158/ EN 50170 ,

Volume 2, PROFIBUS standard. These include the devices of the following product

families:

• SIMATIC S5

• SIMATIC S7/C7

• SIMATIC programming devices/PCs

• SIMATIC HMI (operator control and monitoring devices OP, OS, TD)

• Distributed I/O devices

• Devices from other vendors

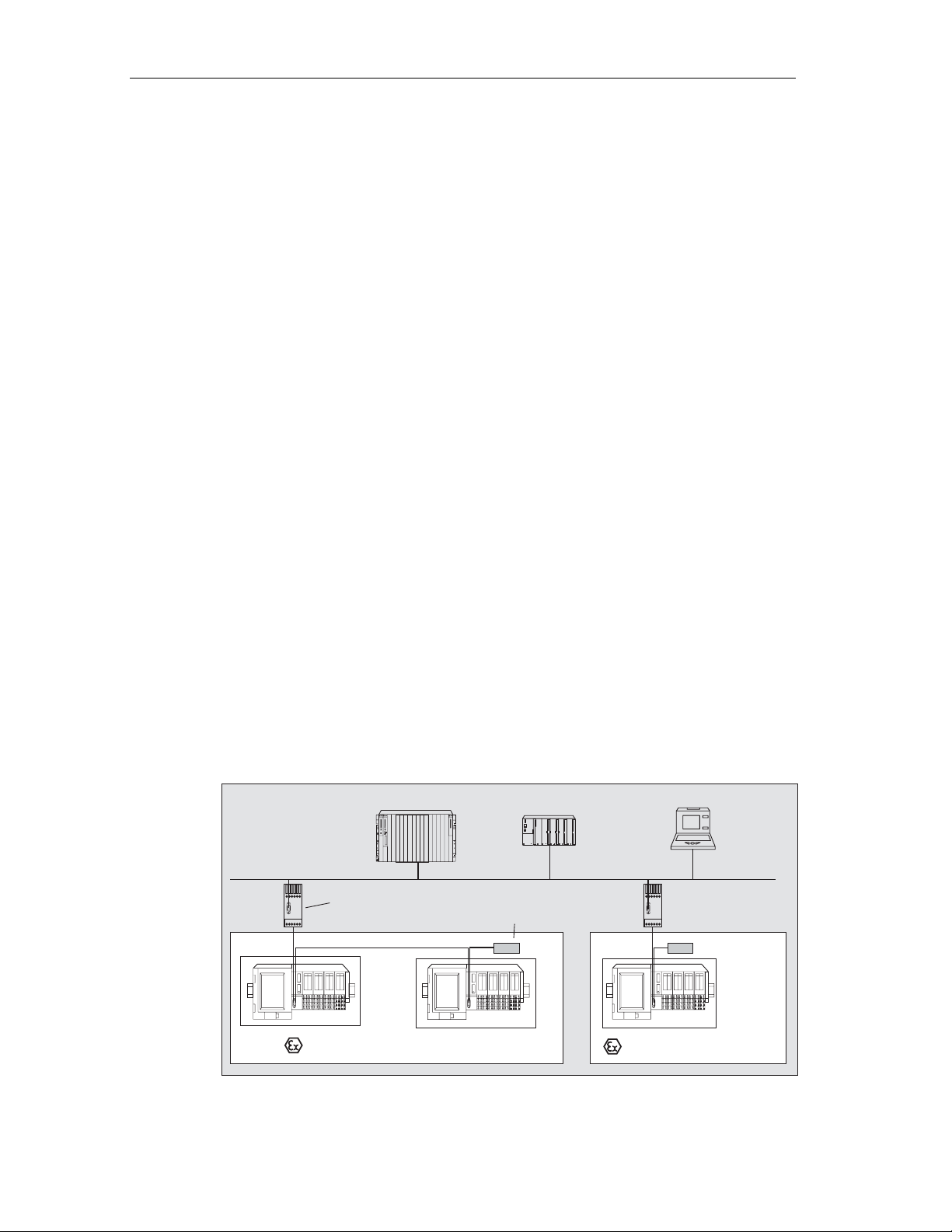

Structure of a PROFIBUS-DP Network

The schematic below illustrates the typical structure of a PROFIBUS-DP network.

The DP master is integrated in the relevant device, for example the S7-400 as a

PROFIBUS-DP interface. The ET 200iS distributed I/O stations are connected to

the DP master over PROFIBUS-DP Ex i and PROFIBUS DP.

S7-400

PROFIBUS-DP

Fieldbus isolating transformer

PROFIBUS-DP Ex i

S7-300

Terminating resistor

PG/PC

ET 200iS

Hazardous area: zone 1

Figure 2-1 Typical Structure of a PROFIBUS-DP Network

Hazardous area: zone 2

ET 200iS Distributed I/O Station

ET 200iS

2-2 A5E00087831-02

Page 23

2.2 What Is the ET 200iS Distributed I/O Station?

Definition

The ET 200iS distributed I/O station is a highly modular and intrinsically safe DP

slave with degree of protections IP 30.

Areas of Application

The ET 200iS distributed I/O station can be used in hazardous areas in zone 1.

The inputs and outputs of the ET 200iS to the actuators/sensors are intrinsically

safe (EEx ia IIC T4 or EEx ib IIC T4).

Of course, the ET 200iS can also be used in zone 2 or in the safe area.

Directly beside the interface module that transfers the data to the DP master, you

can insert almost any combination of I/O modules belonging to the ET 200iS. This

allows you to tailor the station exactly to your needs locally.

Every ET 200iS consists of a power supply module, an interface module, and a

maximum of 32 electronics modules (for example digital electronics modules).

Product Overview

Terminal and Electronics Modules

In principle, the ET 200iS distributed I/O station consists of various passive

terminal modules onto which you plug the electronics modules.

The ET 200iS is connected to the PROFIBUS-DP Ex 1 using a connector on the

terminal module TM-IM. Every ET 200iS is a DP slave on PROFIBUS-DP Ex i.

ET 200iS Distributed I/O Station

A5E00087831-02

2-3

Page 24

Product Overview

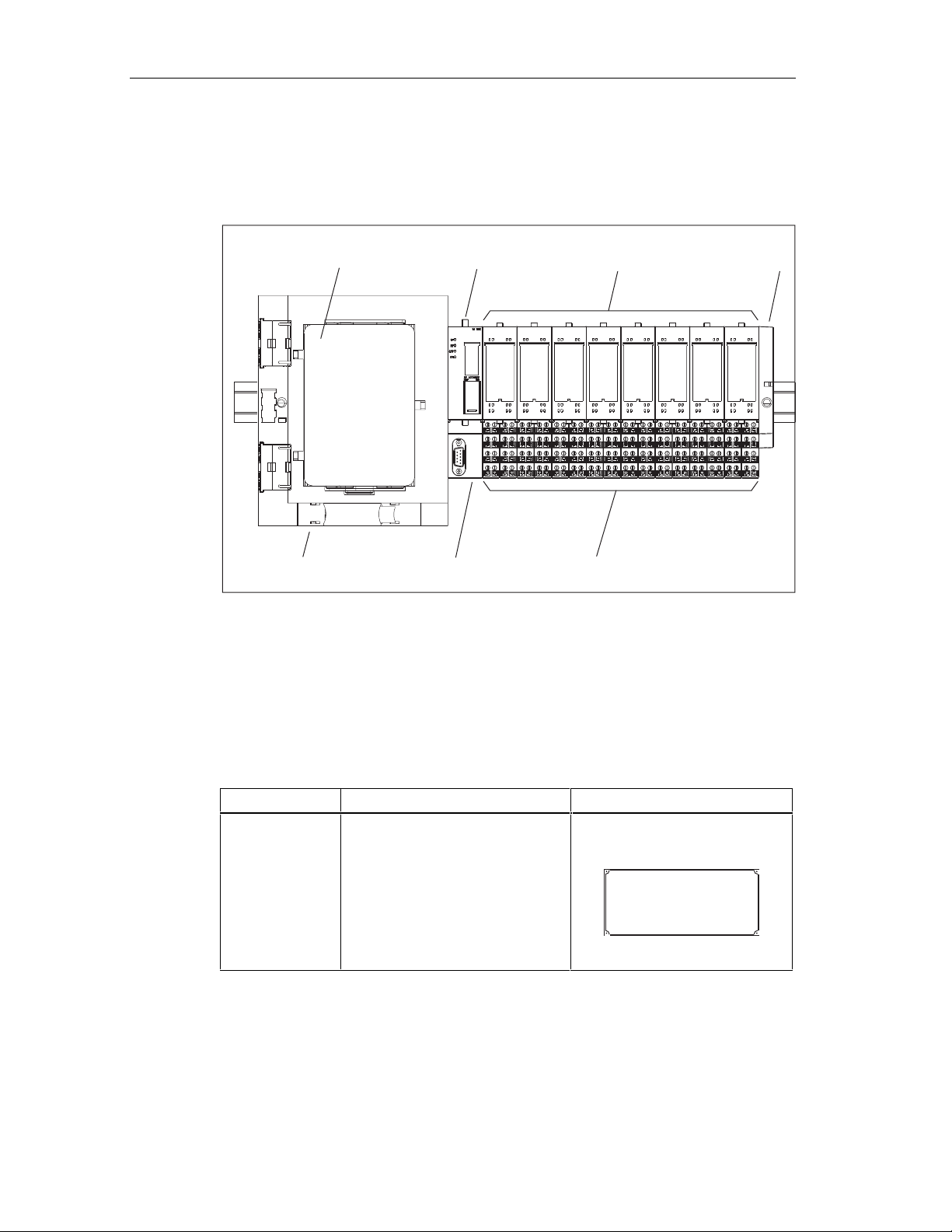

Layout

The following figure shows an example of an ET 200iS configuration.

Power supply

module PS

Terminal module

TM-PS

Figure 2-2 View of the ET 200iS Distributed I/O Station

Components of the ET 200iS

Interface

module IM 151-2

Terminal module

TM-IM

Electronics

module

Terminal modules

TM-E

Bus termination

module

The table below provides you with an overview of the most important components

of the ET 200iS.

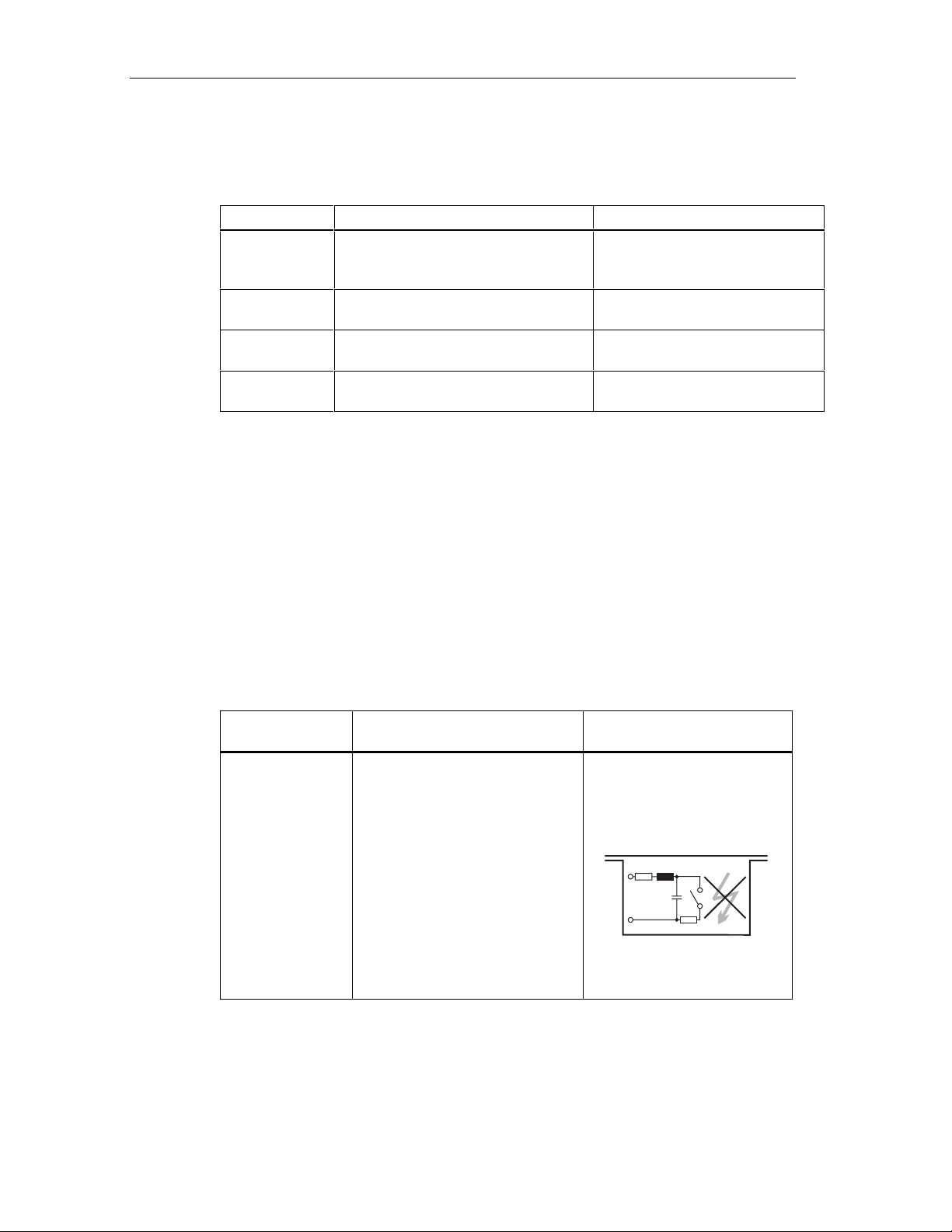

Table 2-1 Components of the ET 200iS

Component Function Appearance

Enclosure ... is an additional measure to

further increase safety avoiding the

production of high temperatures,

sparks and electric arcs.

• Zone 1: Enclosure with degree

of protection EEx e

• Zone 2: Enclosure with at least

degree of protection IP54

ET 200iS Distributed I/O Station

2-4 A5E00087831-02

Page 25

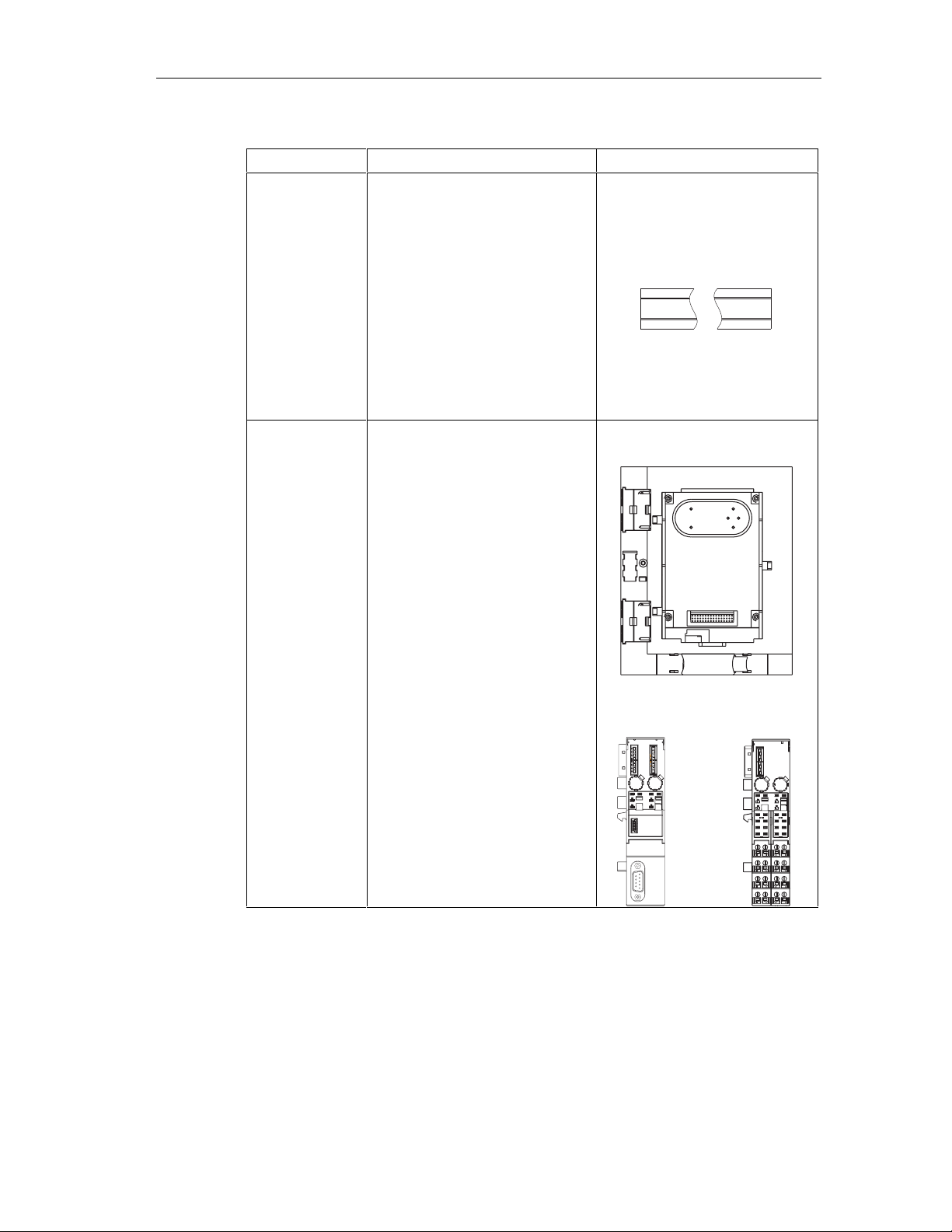

Product Overview

Component Function Appearance

DIN rail ( 35 x 15

mm, tin-plated or

hot-galvanized in

compliance with

DIN 50022)

Terminal module ...carries the wiring and

... is the rack of the ET 200iS. You

install the ET 200iS on the DIN rail.

accommodates the power supply

module, interface module, and the

electronics modules. The following

types of terminal modules are

available:

• for the power supply module

TM-PS

• for the interface module TM-IM

• for the electronics modules TM-

E

Terminal module TM-PS

ET 200iS Distributed I/O Station

A5E00087831-02

Terminal module

TM-IM

Terminal module

TM-E

2-5

Page 26

Product Overview

Component Function Appearance

Power supply

module

Interface module ... is plugged onto the terminal

... is plugged onto the terminal

module

TM-PS. The power supply module

supplies the electronics and

encoders with voltage.

module

TM-IM. The interface module

connects the ET 200iS with the DP

master and conditions the data for

the inserted electronics modules.

Electronics

module

... is plugged onto the terminal

module

TM-E and decides which function

is performed:

• Digital electronics modules for

NAMUR encoders, digital

output

• Analog electronics modules

with current and resistance

measurement, thermoresistors

and thermocouples

• Analog electronics modules

with HART, analog output

ET 200iS Distributed I/O Station

2-6 A5E00087831-02

Page 27

Product Overview

Component Function Appearance

Bus termination

module

...completes the ET 200iS.

Fieldbus isolating

transformer

Shield contact ...used to contact cable shields.

...converts PROFIBUS-DP to

PROFIBUS-DP Ex i

Label sheet (DIN

A4, perforated,

foil)

ET 200iS Distributed I/O Station

A5E00087831-02

...for machine labeling or printing;

80 strips per sheet

2-7

Page 28

Product Overview

Component Function Appearance

Slot number

labels

Color labels ...allow customer and country-

...for identifying the slots on the

terminal module

specific identification of the

terminals on the terminal module

1

2

31

32

PROFIBUS cable

with bus

connector

...interconnects the nodes of a

PROFIBUS-DP Ex i system or

connects the fieldbus isolating

transformer with the ET 200iS.

Bus terminating

...terminates PROFIBUS-DP Ex i

resistor

Properties and Uses of the ET 200iS

Table 2-2 Properties and Uses

Features Uses

Scalable modular design with 2 or 4-channel

electronics modules

Wide range of electronics modules Extensive area of application

Permanent wiring by separating mechanical

and electronic components

Integrated powerbus Reduced wiring effort

Screw or spring terminals Use of most suitable terminating technique

The design

• Station design optimized to contain costs

• Reduced configuration and

documentation effort