Page 1

SiemensSchmitt

Sensation

Maintenance Protocol

System

Maintenance Protocol System

Customer:

Address:

CT

Fax / E-Mail:

Fax / E-Mail:

Department: Room:

Material-No.: Serial-No.:

Contract-No.: Expire date:

Order-No.: System - ID:

The instructions CT02-023.831.01.20.02 are required for

this protocol

Print No.:

Replaces: CT02-023.832.01.19.02

073931140754198507543015075431060809895108377520088720170887442710017857101300401035125510351301

CT02-023.832.01.20.02

© Siemens

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 10.09

2005

Page 2

Protocol Date: Serial-No.:

1Protocol

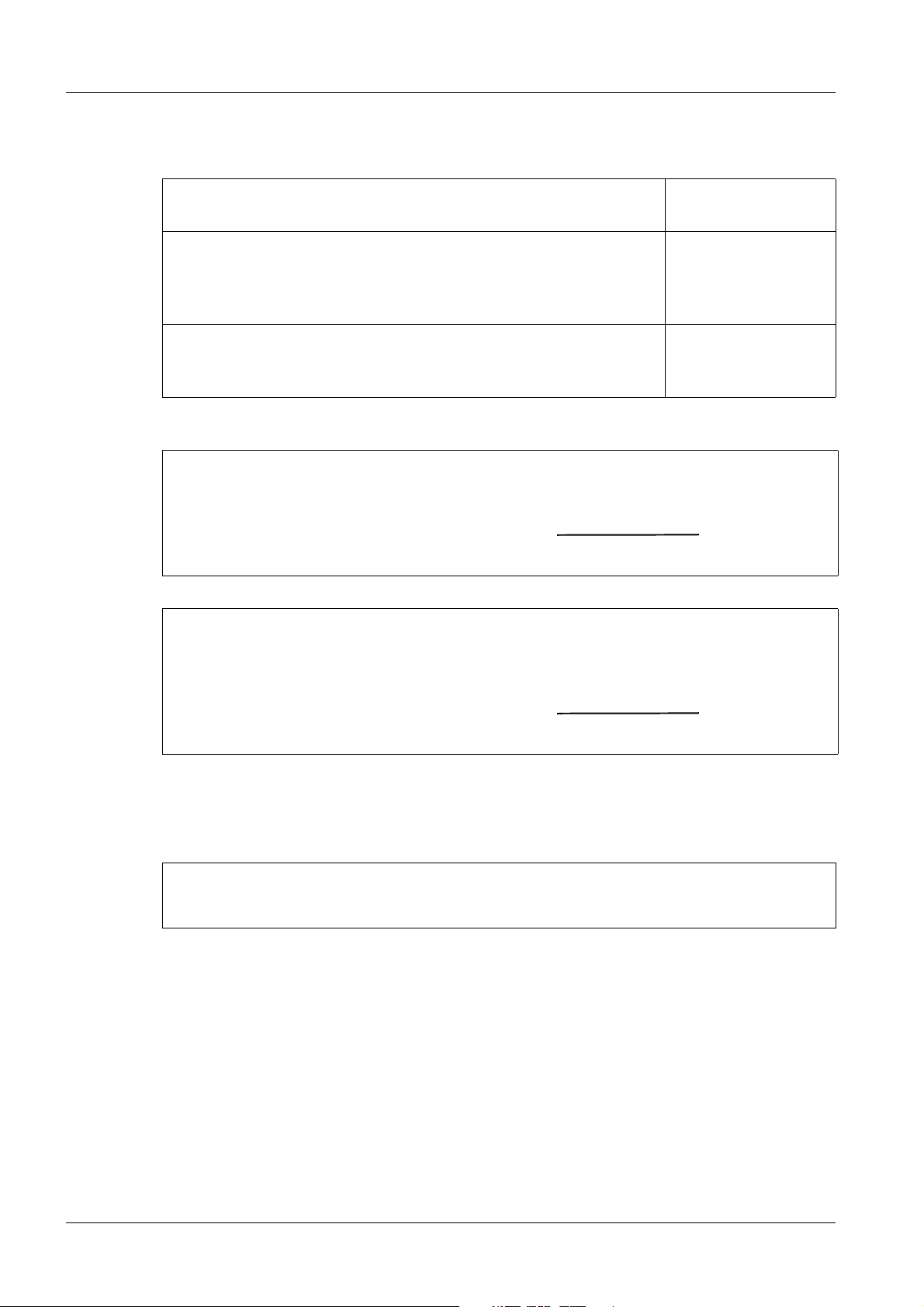

Evaluating the Condition of the System / Component 0

The system / component has no deficiencies. The image quality

test resulted in no differences from required reference values.

The system / component has slight deficiencies that have no affect

on continued operation of the system. However they should be

corrected preventively. The image quality test resulted in no differences from required reference values.

The system / component has serious deficiencies. For safety reasons, continued operation of the system is permitted only after

successfully correcting the deficiencies.

After completing all work steps, an evaluation was performed.

Signature:

Date: Name:

The customer or a representative has taken note of the assessment of the

system condition (only if required in the country).

Signature:

Date: Name:

Remarks

e.g. Additional activities to be performed, customer wishes

Further Processing and Archiving of the Protocol

The protocol is a document and thus must be archived. After completing the test, it must

be filed in the corresponding register in the “System Owner Manual“ binder.

Sensation CT02-023.832.01.20.02 Siemens

10.09 H WS CS SD CT

Page 2 of 14

Page 3

Protocol Date: Serial-No.:

Remarks Regarding the Protocol 1.1

The protocol is valid as proof of quality for one check that must be performed on the system

/ component.

The check must be performed in the specified intervals.

The results of the check are entered in this protocol.

The chapter numbers in front of the checkpoints indicate the corresponding chapters in the

particular instructions (see cover page).

The protocol must be completely filled out by the Customer Service Engineer, i.e.:

• All boxes must be filled out. If a box does not apply to the system or if no entry needs to

be made, check the “n.a.“ box.

• Enter the Serial no.: and the date of the check in the header of each page so that each

page can be allocated to a check date.

• The measurement values for the measurements that must be performed during the

check must also be entered in the open spaces / tables provided for them.

• After completing the check, Page 2 of this protocol must be filled out and signed.

Explanation of Abbreviations in the Protocol 0

Abbrev. Explanation Abbrev. Explanation

SI Safety Inspection PMF Preventive Maintenance, Operating

Value Check, Function Check

SIE Electrical Safety Inspection Q System Quality, Image Quality

SIM Mechanical Safety Inspec-

tion

PM Preventive Maintenance QSQ System Quality Check

PMP Periodic Preventive Mainte-

nance

PMA Preventive Maintenance

Adjustments

QIQ Image Quality

SW Software Maintenance

CSE Customer Service Engineer

Siemens CT02-023.832.01.20.02 Sensation

10.09 H WS CS SD CT

Page 3 of 14

Page 4

Protocol Date: Serial-No.:

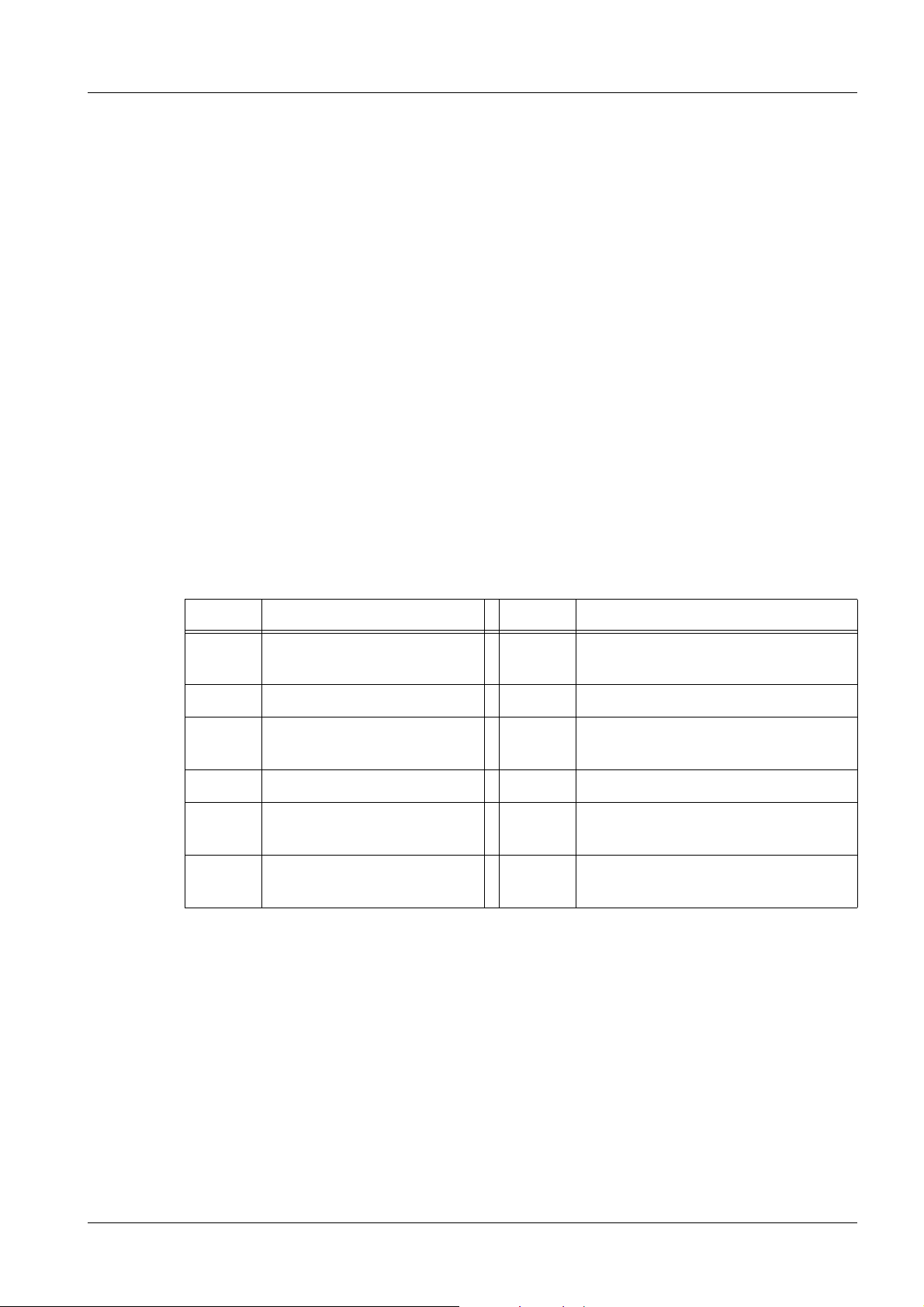

Measuring Equipment and Measuring Instruments Used 1.2

Measuring instruments and measuring devices (phantoms, MR coils etc.) may not be

entered in the table if they have already been entered in the mobile device.

Measuring equipment / -instruments Serial No. Date used

Sensation CT02-023.832.01.20.02 Siemens

10.09 H WS CS SD CT

Page 4 of 14

Page 5

Protocol Date: Serial-No.:

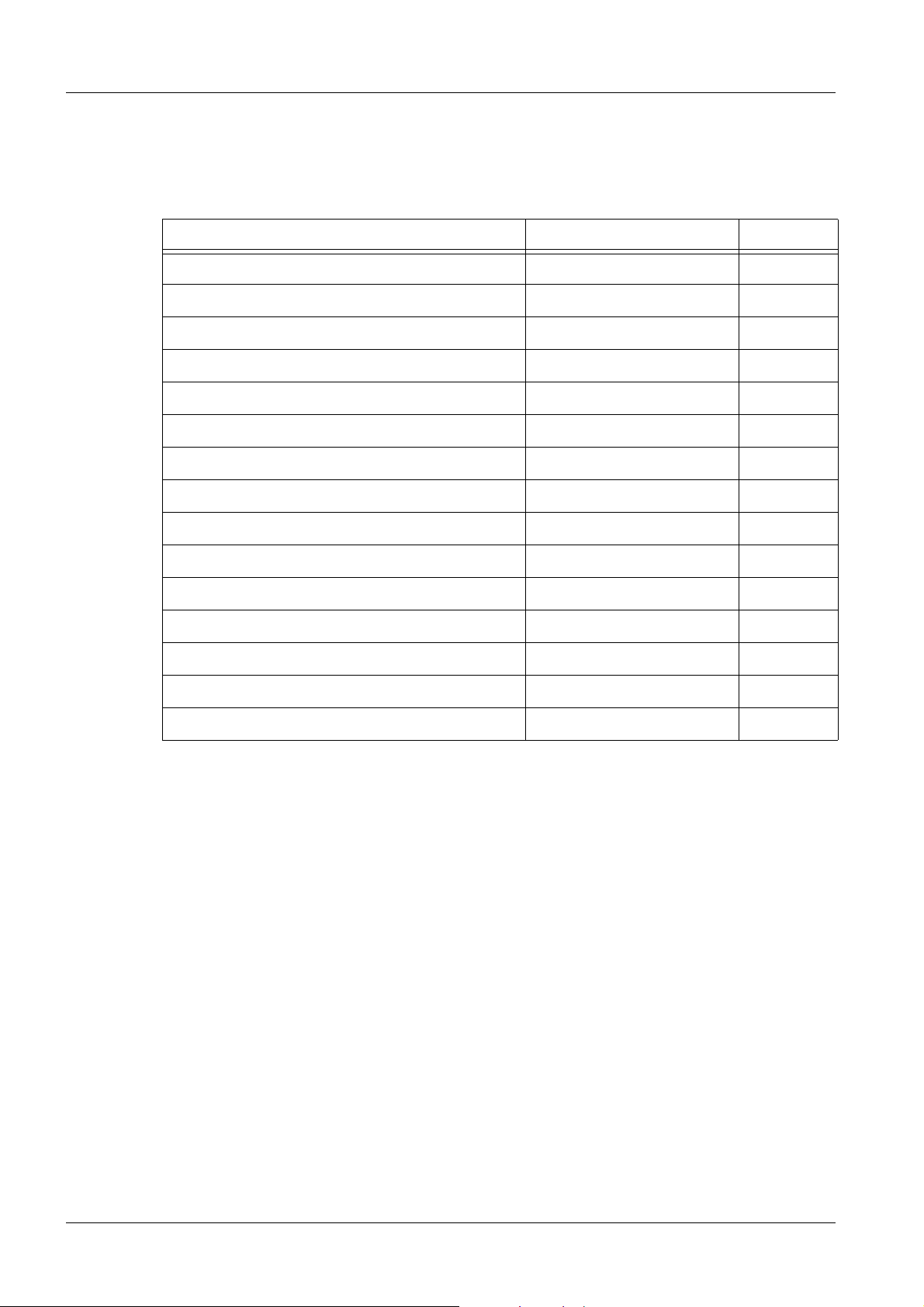

1 General

2 Prerequisites

2.1 Required tools and auxiliary materials

2.2 Evaluating Reports

PM Checking system reports

2.3 Evaluating the logbook

PM Error statistics readout

3 Safety Inspections

3.1 General

3.2 Function Tests

OK not n.a.

OK

3.2.1 Measuring the patient leakage current (DIN VDE 751-1)

SI Patient leakage current checked

3.2.2 Checking the protective ground conductor resistance

3.2.3 Checking the function of the door contact switch

SI Door contact switch checked

3.2.4 System: Checking the radiation preparation indicator

SI Radiation preparation indicators checked

3.2.5 System: Checking the radiation indicator

SI Radiation indicators checked

3.2.6 System: Checking the radiation monitor (108%)

SI Radiation switch-off checked

Measured value:

3.2.7 System: Checking the emergency STOP circuit

SI Emergency STOP circuit checked

3.2.8 Gantry: Checking the tube cooling hoses

SI Tube cooling hoses checked

3.2.9 PHS: Checking the safety switches

SI Safety limit switches checked

3.2.10 PHS: Checking the spindle brake

SI Function of spindle brake checked

3.2.11 PHS: Checking the motor brake

SI Function of motor brake checked

Siemens CT02-023.832.01.20.02 Sensation

10.09 H WS CS SD CT

Page 5 of 14

Page 6

Protocol Date: Serial-No.:

3.2.12 PHS: Checking the patient positioning aids

SI Patient positioning aids checked

3.2.13 PDC: Protection functionality test

SI Circuit breaker checked

Maintenance of this section was performed by:

Signature:

Date: Name:

3.3 Next steps

3.3.1 Labels

3.3.2 Concluding test

Q Condition of the CT system checked

Maintenance of this section was performed by:

OK not n.a.

OK

Signature:

Date: Name:

4 Preventive maintenance (part 1)

4.1 General

4.1.1 Preparations

4.1.2 Required tools and auxiliary materials

4.2 Patient handling system

4.2.1 Lubricating the spindle nut

PM Spindle nut lubricated

4.2.2 Lubricating the linear guides on the lower part of scissor mechanism

PM Lower part of the scissor mechanism: Linear guides lubricated

4.2.3 Lubricating the linear guides of the upper part of scissor mechanism

PM Upper part of the scissor: Linear guides lubricated

4.2.4 Lubricating the guide rails of the tabletop

PM Tabletop: Guide rails lubricated

4.2.5 Lubricating the guide rails of the top support

PM Top support: Guide rails lubricated

4.2.6 Checking the movement of the tabletop

PM Movement force for horizontal tabletop travel checked

Sensation CT02-023.832.01.20.02 Siemens

10.09 H WS CS SD CT

Page 6 of 14

Page 7

Protocol Date: Serial-No.:

4.2.7 Checking the movement of the top support

PM Movement force for horizontal top support travel checked.

4.2.8 Checking the compression spring on the patient table

PM Compression spring checked

4.2.9 Cleaning the motor brake of the couch lift motor

PM Vertical motor brake cleaned

Maintenance of this section was performed by:

Signature:

Date: Name:

4.3 Next steps

4.3.1 Concluding test

Q Condition of the CT system checked

OK not n.a.

OK

Maintenance of this section was performed by:

Signature:

Date: Name:

5 Preventive maintenance (part 2)

5.1 General

5.1.1 Preparations

5.1.2 Required tools and auxiliary materials

5.2 Care Vision (Option)

5.2.1 Checking the weight compensation of the support arm

SI Weight compensation of the support arm checked

Siemens CT02-023.832.01.20.02 Sensation

10.09 H WS CS SD CT

Page 7 of 14

Page 8

Protocol Date: Serial-No.:

5.3 Sliding gantry (optional)

PM Check the toothed belt

PM Cleaning the energy chain (every 3 years)

PM Check the switching elements (front and rear)

PM Check the blind covering (optional)

PM Check the protective conductor connection

Maintenance of this section was performed by:

Signature:

Date: Name:

5.4 Gantry

5.4.1 Functional check of the fans in the generator electronic box

SI Function of E-box fans checked

5.4.2 Functional check of the HV transformer fans

SI Function of HV transformer fans checked

OK not n.a.

OK

5.4.3 Functional check of the C-box fans (only Sensation 10 / 16 / Cardiac)

SI Function of C-box fan checked

5.4.4 Functional check of the DMS fans

SI Function of DMS fans checked

5.4.5 Cleaning the slip ring compartment

PM Slip ring compartment and assembly cleaned

5.4.6 Cleaning/checking the power brush block

PM Power brush block cleaned

PM Power carbon brushes checked

Startup Date: . .

Date of Last Replacement

: DD MMM YYYY

5.4.7 Checking/replacing the voltage and control data brushes

PM Voltage and control data brushes checked

PM Control data brushes replaced

Startup Date: . .

Date of Last Replacement

Sensation CT02-023.832.01.20.02 Siemens

10.09 H WS CS SD CT

: DD MMM YYYY

Page 8 of 14

Page 9

Protocol Date: Serial-No.:

5.4.8 Replacing the stator ring brush (only Sensation 10 / 16 / Cardiac)

PM Stator ring brush replaced

Startup Date: . .

OK not n.a.

OK

Date of Last Replacement

: DD MMM YYYY

5.4.9 Lubricating the rack and pinion gear of the UHR assembly (only Sensation 64, Cardiac 64)

PM Rack and pinion gear lubricated (only Sensation 64, Cardiac 64, not

UHR-Plus)

5.4.10 Cleaning/checking the detector window

PM Detector window cleaned/checked

Startup Date: . .

Date of Last Replacement

: DD MMM YYYY

5.4.11 Lubricating the main bearing

PM Main bearing lubricated

5.4.12 Replacing the filter in the dehumidifier

PM Filter in Dehumidifier replaced

Startup Date: . .

Date of Last Replacement

: DD MMM YYYY

Maintenance of this section was performed by:

Signature:

Date: Name:

5.5 Power distribution cabinet

5.5.1 Replacing the air filter

PM Air filter in PDC replaced

Startup Date: . .

Date of Last Replacement

: DD MMM YYYY

Siemens CT02-023.832.01.20.02 Sensation

10.09 H WS CS SD CT

Page 9 of 14

Page 10

Protocol Date: Serial-No.:

5.5.2 Checking/replacing the varistors and discharger

PM Varitors / discharger checked/replaced

Startup Date: . .

OK not n.a.

OK

Date of Last Replacement

: DD MMM YYYY

Maintenance of this section was performed by:

Signature:

Date: Name:

5.6 Water cooling system

5.6.1 Checking the water pressure

PM Water pressure checked

Measured value:

5.6.2 Cleaning the filter in the water-air cooling system

PM Filter cleaned

Maintenance of this section was performed by:

Signature:

Date: Name:

5.7 Imaging system

5.7.1 Cleaning the ICS, IRS and IES

PM Air inlets of ICS, and IES cleaned

PM Air inlets of IRS and air filters are cleaned

PM IRS air filter replaced

Startup Date: . .

Date of Last Replacement

Maintenance of this section was performed by:

Date: Name:

: DD MMM YYYY

Signature:

Sensation CT02-023.832.01.20.02 Siemens

10.09 H WS CS SD CT

Page 10 of 14

Page 11

Protocol Date: Serial-No.:

5.8 SRS Check

5.8.1 Work Steps for Som/7 VA11 and Som/5 VB30/VB38

5.8.1.1 Checking the status of the SRS installation (check only!)

PM Checking the status of the SRS installation

5.8.1.2 Checking the System Management Configuration

PM Checking the System Management Configuration

5.8.2 Work Steps for Som/5 VB20/VB28

5.8.2.1 Checking the status of the SRS network connection (check only!)

PM Checking the status of the SRS network connection

5.8.2.2 Checking the System Management Configuration

PM Checking the System Management Configuration

5.9 Next steps

5.9.1 Concluding test

Q Condition of the CT system checked

OK not n.a.

OK

Maintenance of this section was performed by:

Signature:

Date: Name:

6 Preventive parts replacement

6.1 General

6.1.1 Preparations

6.1.2 Required tools and auxiliary materials

6.2 Uninterrupted power supply

6.2.1 Prerequisites

6.2.2 Replacing the standard UPS

PM UPS replaced

Startup Date: . .

Date of Last Replacement

: DD MMM YYYY

Maintenance of this section was performed by:

Signature:

Date: Name:

Siemens CT02-023.832.01.20.02 Sensation

10.09 H WS CS SD CT

Page 11 of 14

Page 12

Protocol Date: Serial-No.:

6.3 DMS cover Sensation 10 / 16 / Sensation Cardiac

6.3.1 Prerequisites

6.3.2 Check the correct attachment of the lead sheet metal.

PM DMS cover replaced

Startup Date: . .

OK not n.a.

OK

Date of Last Replacement

Maintenance of this section was performed by:

Date: Name:

6.4 Next steps

6.4.1 Concluding test

Q Condition of the CT system checked

Maintenance of this section was performed by:

Date: Name:

: DD MMM YYYY

Signature:

Signature:

7 Image quality - constancy

Q Image quality check completed

Maintenance of this section was performed by:

Signature:

Date: Name:

8 Final steps

8.1 Installing the unit covers

SIM Covers and protective conductor cables are installed

Sensation CT02-023.832.01.20.02 Siemens

10.09 H WS CS SD CT

Page 12 of 14

Page 13

Protocol Date: Serial-No.:

OK not n.a.

8.2 Checking the protective system conductor

8.3 General notes when measuring at the monitors

8.3.1 Measuring point 18” monitor

8.3.2 Measuring point 19” monitor

8.4 SOMATOM Sensation 10 / 16 / Cardiac / 40 / 64 / Cardiac 64 / Open

SIE PDC Cabinet: Protective conductor resistance ≤ 100 mΩ

Measured value:

SIE Gantry: Protective conductor resistance ≤ 300 mΩ

Measured value:

SIE Patient table (PHS): Protective conductor resistance ≤ 300 mΩ

Measured value:

OK

SIE ICS Tower PC: Protective conductor resistance ≤ 300 mΩ

Measured value:

SIE IRS Cabinet: Protective conductor resistance ≤ 300 mΩ

Measured value:

SIE IES Tower PC: Protective conductor resistance ≤ 300 mΩ

Measured value:

SIE ICS Monitor: Protective conductor resistance ≤ 300 mΩ

Measured value:

SIE IES Monitor: Protective conductor resistance ≤ 300 mΩ

Measured value:

SIE WCS Cabinet: Protective conductor resistance (mains connected

directly) ≤ 100 mΩ Protective conductor resistance (connected via PDC)

≤ 300 mΩ

Measured value:

SIE UPS IES: Protective conductor resistance ≤ 100 mΩ

Measured value:

Siemens CT02-023.832.01.20.02 Sensation

10.09 H WS CS SD CT

Page 13 of 14

Page 14

Protocol Date: Serial-No.:

SIE IES Tower PC: Protective conductor resistance ≤ 300 mΩ

Measured value:

8.5 CARE Vision CT option

SIE Overhead support: Protective conductor resistance ≤ 300 mΩ

Measured value:

SIE Monitor trolley: Protective conductor resistance ≤ 300 mΩ

Measured value:

SIE Monitor: Protective conductor resistance ≤ 300 mΩ

Measured value:

8.6 Cleaning the monitors

SIM Monitors cleaned

OK not n.a.

OK

8.7 Testing the system application

Q Condition of the CT system checked

Maintenance of this section was performed by:

Signature:

Date: Name:

9 Changes to previous Version

Sensation CT02-023.832.01.20.02 Siemens

10.09 H WS CS SD CT

Page 14 of 14

Loading...

Loading...