Siemens SCALANCE X-200, SCALANCE XF200, X204-2, X204-2TS, X204-2FM Operating Instructions Manual

...

SCALANCE X-200

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC NET

Industrial Ethernet Switches

SCALANCE X-200

Operating Instructions

03/2015

C79000

-G8976-C284-06

Preface

Functions

1

Description of the device

2

Safety notices

3

Installation

4

Connecting up

5

Approvals

6

Technical specifications

7

Dimension drawings

A

Test of mechanical stability

B

Training, Service & Support

C

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

C79000-G8976-C284-06

Ⓟ

03/2015 Subject to change

Copyright © Siemens AG 2012 - 2015.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by

personnel qualified

for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

3

Preface

Components of the product

The following components are supplied with a

SCALANCE X-200

IE switch:

● One device

● One 2-pin plug-in terminal block

● One 4-pin plug-in terminal block

● One DVD (configuration manual, operating instructions, Primary Setup Tool, GSD file,

SNMP OPC profile)

The following components are supplied with a

SCALANCE X-200

IE switch with the

PRO

supplement:

● One device

● Protective caps for the data interfaces

● Protective caps for the connectors of the power supply

● One protective cap for the signaling contact

● One DVD (configuration manual, operating instructions, Primary Setup Tool, GSD file,

SNMP OPC profile)

Unpacking, checking

WARNING

Do not use any parts that show evidence of damage. If you use damaged parts, there is no

guarantee that the device will function according to the specification.

If you use damaged parts, this can lead to the following problems:

• Injury to persons

• Loss of the approvals

• Violation of the EMC regulations

Use only undamaged parts.

1. Make sure that the package is complete.

2. Check all the parts for transport damage.

If the consignment is incomplete or damaged, contact your supplier or your local Siemens

office.

Preface

SCALANCE X-200

4 Operating Instructions, 03/2015, C79000-G8976-C284-06

Purpose of the Operating Instructions

These operating instructions support you when commissioning networks with the devices of

the product line SCALANCE X-200.

Overview of the technical documentation of the IE Switches X-200

The technical documentation of the X-200 product line is divided into hardware and software

and can be found in the following documents:

●

PH SCALANCE X-200 configuration manual

Software description of the X-200 product line

●

SCALANCE X-200 BA Operating Instructions

Hardware description for all product groups and general information.

You will find the documents here:

● On the data medium that ships with some products:

– Product CD / product DVD

– SIMATIC NET Manual Collection

● On the Internet pages of Siemens Industry Online Support

(http://support.automation.siemens.com/WW/view/en/33118791/133300

).

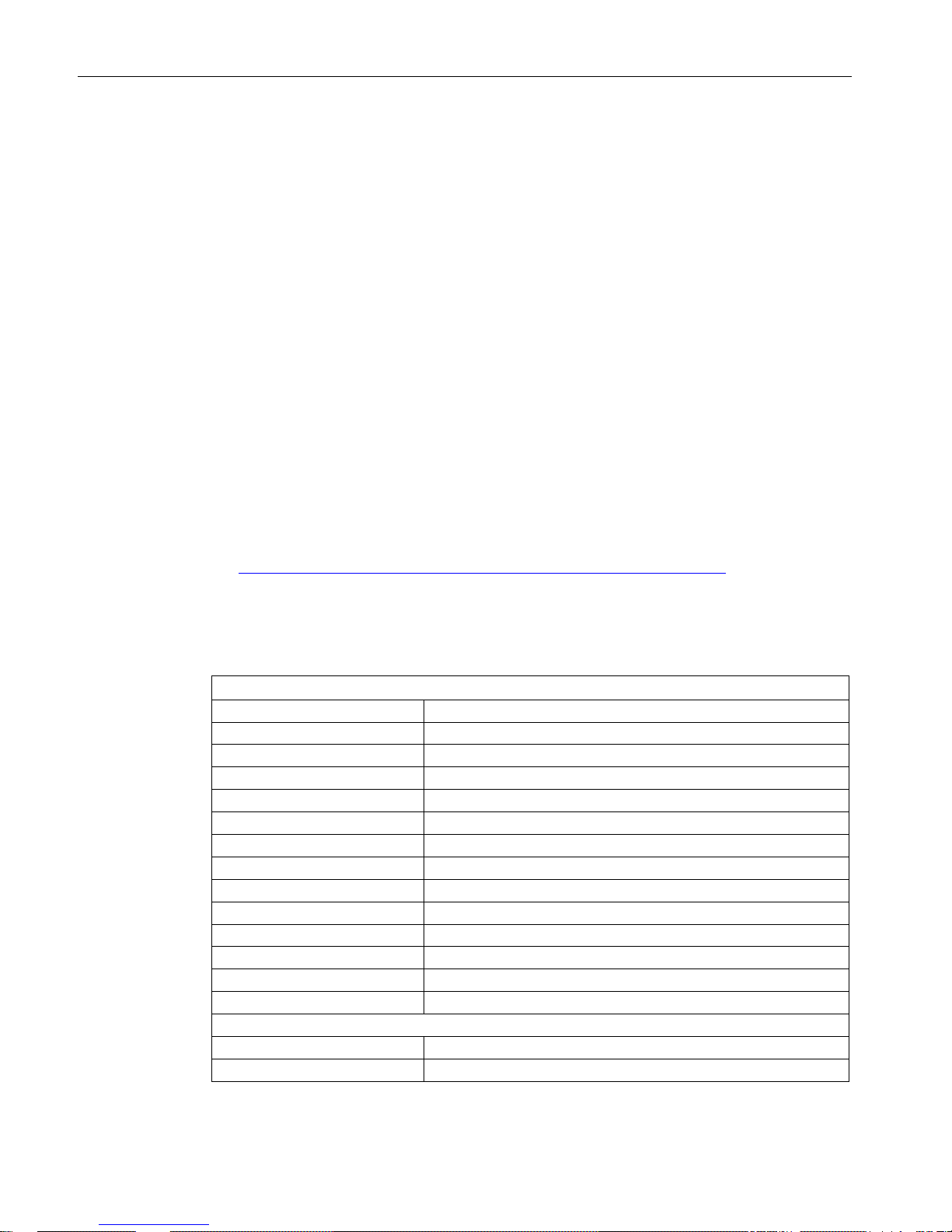

Validity of the Operating Instructions

These operating instructions are valid for the following devices:

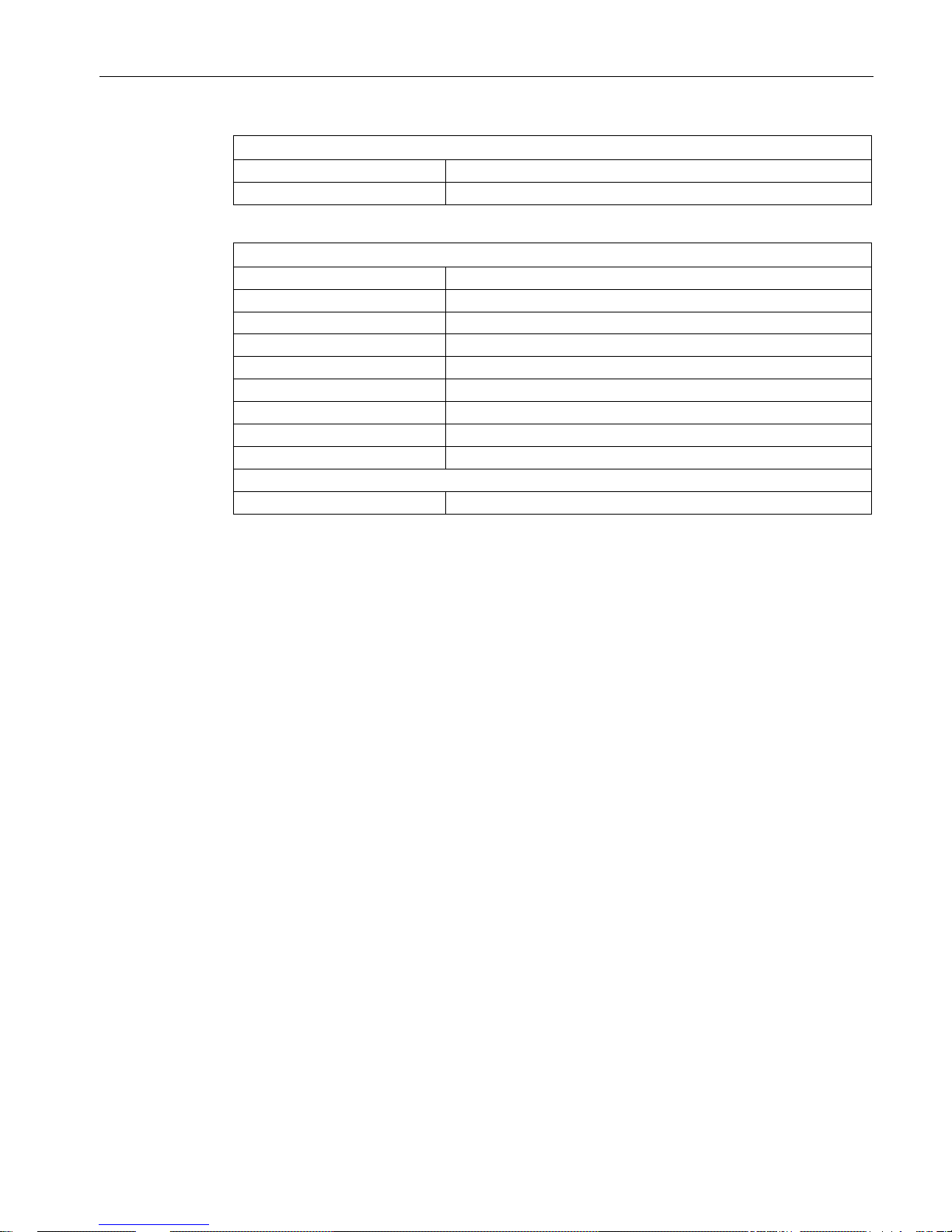

SCALANCE X200 and SCALANCE XF200

Product name:

Order number:

X204-2 6GK5 204-2BB10-2AA3

X204-2TS

6GK5 204-2BB10-2CA2

X204-2FM

6GK5 204-2BB11-2AA3

X204-2LD

6GK5 204-2BC10-2AA3

X204-2LD TS

6GK5 204-2BC10-2CA2

X206-1

6GK5 206-1BB10-2AA3

X206-1LD

6GK5 206-1BC10-2AA3

X208

6GK5 208-0BA10-2AA3

X208PRO

6GK5 208-0HA10-2AA6

X212-2

6GK5 212-2BB00-2AA3

X212-2LD

6GK5 212-2BC00-2AA3

X216

6GK5 216-0BA00-2AA3

X224

6GK5 224-0BA00-2AA3

Flat design:

XF204

6GK5 204-0BA00-2AF2

XF204-2

6GK5 204-2BC00-2AF2

Preface

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

5

SCALANCE X200 and SCALANCE XF200

XF206-1

6GK5 206-1BC00-2AF2

XF208 6GK5 208-0BA00-2AF2

SCALANCE X200IRT and XF200IRT

Product name:

Order number:

X200-4P IRT 6GK5 200-4AH00-2BA3

X201-3P IRT

6GK5 201-3BH00-2BA3

X201-3P IRT PRO

6GK5 201-3JR00-2BA6

X202-2IRT

6GK5 202-2BB00-2BA3

X202-2P IRT

6GK5 202-2BH00-2BA3

X202-2P IRT PRO

6GK5 202-2JR00-2BA6

X204IRT

6GK5 204-0BA00-2BA3

X204IRT PRO

6GK5 204-0JA00-2BA6

Flat design:

XF204IRT

6GK5 204-0BA00-2BF2

Purpose

The SCALANCE X-200 devices are switches for setting up Ethernet networks for industrial

applications.

Restricted area of application according to Hazardous Locations (HazLoc)

The devices are only suitable for use in the following areas:

● In areas according to Class I, Division 2, Groups A, B, C and D and in areas without

explosive atmospheres.

● In areas according to Class I, Zone 2 Groups IIC and in areas without explosive

atmospheres.

Names of the devices in these operating instructions

Unless mentioned otherwise, the descriptions in these operating instructions refer to all

devices of the SCALANCE X-200 product line named above in the section on Validity.

In the remainder of the instructions, these will also be referred to as

IE switches

or also

simply as

X-200

.

Preface

SCALANCE X-200

6 Operating Instructions, 03/2015, C79000-G8976-C284-06

Further documentation

In the system manuals "Industrial Ethernet / PROFINET Industrial Ethernet" and "Industrial

Ethernet / PROFINET passive network components", you will find information on other

SIMATIC NET products that you can operate along with the devices of this product line in an

Industrial Ethernet network.

You will find the system manuals on the Internet pages of Siemens Industry Online Support

under the following entry IDs:

● 27069465 (http://support.automation.siemens.com/WW/view/en/27069465

)

Industrial Ethernet / PROFINET Industrial Ethernet System Manual

● 84922825 (http://support.automation.siemens.com/WW/view/en/84922825)

Industrial Ethernet / PROFINET - Passive network components System Manual

Finding information

To help orientation, there is not only a table of contents but also an Index in the Appendix.

The SIMATIC NET Glossary also provides additional help, see below.

Audience

These operating instructions are intended for persons involved in commissioning networks in

which IE switches are used.

SIMATIC NET Selection Tool

The SIMATIC NET selection tool supports you when selecting Industrial Ethernet switches

and components for Industrial Wireless Communication. You will find current information on

the Product Support pages under the following entry ID:

39134641 (http://support.automation.siemens.com/WW/view/en/39134641

)

Preface

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

7

Where to find Siemens documentation

● Article numbers

You will find the article numbers for the Siemens products of relevance here in the

following catalogs:

– SIMATIC NET - Industrial Communication / Industrial Identification, catalog IK PI

– SIMATIC - Products for Totally Integrated Automation and Micro Automation, catalog

ST 70

You can request the catalogs and additional information from your Siemens

representative. You will also find the product information in the Siemens Industry Mall at

the following address:

(https://mall.industry.siemens.com

)

● Manuals on the Internet

You will find SIMATIC NET manuals on the Internet pages of Siemens Industry Online

Support:

Link to Customer Support (http://support.automation.siemens.com/WW/view/en

)

Enter the entry ID of the relevant manual as the search item. The entry ID is specified in

the references.

As an alternative, you will find the SIMATIC NET documentation on the pages of Product

Support:

10805878 (http://support.automation.siemens.com/WW/view/en/10805878

)

Go to the required product group and make the following settings:

"Entry list" tab, Entry type "Manuals / Operating Instructions"

● Manuals on the data medium

You will often find manuals of SIMATIC NET products on the data medium that ships with

many of the SIMATIC NET products.

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should

also be considered. For more information about industrial security, visit

http://www.siemens.com/industrialsecurity.

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. For more information, visit http://support.automation.siemens.com.

Preface

SCALANCE X-200

8 Operating Instructions, 03/2015, C79000-G8976-C284-06

SIMATIC NET glossary

Explanations of many of the specialist terms used in this documentation can be found in the

SIMATIC NET glossary.

You will find the SIMATIC NET glossary here:

● SIMATIC NET Manual Collection or product DVD

The DVD ships with certain SIMATIC NET products.

● On the Internet under the following entry ID:

50305045 (http://support.automation.siemens.com/WW/view/en/50305045

)

Trademarks

The following and possibly other names not identified by the registered trademark sign ® are

registered trademarks of Siemens AG:

SIMATIC NET, SCALANCE, C-PLUG, OLM

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

9

Table of contents

Preface ...................................................................................................................................................... 3

1 Functions ................................................................................................................................................. 11

2 Description of the device ......................................................................................................................... 15

2.1 Device views ........................................................................................................................... 15

2.2 The LEDs ................................................................................................................................ 17

2.2.1 LED display when the device starts up ................................................................................... 17

2.2.2 Power LED "L" (green/yellow LED) ........................................................................................ 17

2.2.3 Fault LED "F" (yellow/red LED) .............................................................................................. 18

2.2.4 Redundancy manager LED "RM" (green LED) ...................................................................... 18

2.2.5 Standby LED "RM" (yellow LED) ............................................................................................ 19

2.2.6 Port LEDs "P" (green/yellow LEDs) ........................................................................................ 20

2.2.7 Diagnostics LEDs for optical connectors "F" (yellow LED) ..................................................... 20

2.2.8 Show Location ........................................................................................................................ 20

2.3 The SET button ....................................................................................................................... 21

2.4 The C-PLUG ........................................................................................................................... 22

3 Safety notices .......................................................................................................................................... 27

3.1 Safety notices in general ........................................................................................................ 27

3.2 Safety notices for hazardous areas ........................................................................................ 29

3.3 Security recommendations ..................................................................................................... 30

4 Installation ............................................................................................................................................... 33

4.1 Safety notices for installation .................................................................................................. 33

4.2 Installation options .................................................................................................................. 36

4.3 Installation on a DIN rail .......................................................................................................... 37

4.4 Installation on a standard rail .................................................................................................. 38

4.5 Wall mounting ......................................................................................................................... 39

5 Connecting up ......................................................................................................................................... 41

5.1 Safety when connecting up ..................................................................................................... 41

5.2 Power supply .......................................................................................................................... 44

5.2.1 Power supply via terminal block ............................................................................................. 44

5.2.2 Supply for X208PRO .............................................................................................................. 45

5.2.3 Supply for IRT-PRO devices ................................................................................................... 45

5.3 Grounding ............................................................................................................................... 48

5.4 Signaling contact ..................................................................................................................... 49

5.5 Attachment to Industrial Ethernet ........................................................................................... 51

5.5.1 Electrical connections ............................................................................................................. 51

Table of contents

SCALANCE X-200

10 Operating Instructions, 03/2015, C79000-G8976-C284-06

5.5.1.1 Electrical attachments to Industrial Ethernet ......................................................................... 51

5.5.1.2 Electrical connectors of the X208PRO .................................................................................. 53

5.5.2 Optical attachments to Industrial Ethernet ............................................................................. 55

5.5.2.1 Multimode fiber-optic cable .................................................................................................... 55

5.5.2.2 Single mode fiber-optic cable ................................................................................................. 56

5.5.2.3 POF and PCF cables ............................................................................................................. 56

5.5.3 Push-pull connector for IRT-PRO devices ............................................................................. 58

6 Approvals ................................................................................................................................................. 59

7 Technical specifications ........................................................................................................................... 67

A Dimension drawings ................................................................................................................................ 77

B Test of mechanical stability ...................................................................................................................... 83

C Training, Service & Support ..................................................................................................................... 85

Index ........................................................................................................................................................ 87

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

11

1

Functions of the X-200 IE Switches

The X-200 IE switches are ideally suited for setting up Industrial Ethernet networks in bus,

star and ring structures with transmission rates of 10/100 Mbps. All X-200 switches operate

in the SIMATIC environment.

Hardware properties:

● X devices have a rugged metal housing and can be installed on a DIN rail, a standard rail

or directly on a wall.

● XF devices have a plastic housing and a flat design. They are suitable for installation on a

DIN rail.

● Redundant power supply, 2 x 24 VDC (exception: IRT-PRO devices)

● Diagnostics LED

● Signaling contact

● SET button for local configuration of the signaling contact

● Slot for C-PLUG

● Reliable plug-in connections thanks to rugged device connectors suitable for industry in

conjunction with PROFINET-compliant FastConnect plugs.

● TS devices meet the railway standard EN 50155

Software properties:

● PROFINET Diagnostics

● Topology support (LLDP)

● CLI - Command Line Interface / Telnet

● WBM - Web Based Management

● Configuration with STEP 7

● SNMP

● Ring redundancy including redundancy manager

● Passive Listening

● FM devices support the Fiber Monitoring Protocol and allow the monitoring of optical line

sections.

Functions

SCALANCE X-200

12 Operating Instructions, 03/2015, C79000-G8976-C284-06

Special features of the X-200IRT IE switches

The IRT variants were designed specifically for setting up Industrial Ethernet networks with

isochronous/clock synchronous real-time communication. In addition to the properties named

above, the IRT switches also provide the following functions:

● IRT communication based on the combination of the switching methods cut through and

store and forward.

● Fast media redundancy thanks to an integrated redundancy manager for Fast Ethernet.

● Standby redundancy

Special features of the PRO variants

The devices with the "PRO" supplement are designed with degree of protection IP65/IP67

for use outside a cabinet.

Frame delay times

The number of IE Switches X-200 connected in a line influences the frame delay.

Note

Frame delay time with X-200 without IRT

When a frame passes through X

-200 IE switches, it is delayed by the Store&Forward

fun

ction of the X-200 IE switches.

•

With a 64 byte frame length by approx. 10 microseconds (at 100 Mbps).

•

With a 1500 byte frame length by approx. 130 microseconds (at 100 Mbps).

This means that the more IE

Switch X-200 devices the frame passes through, the longer the

frame delay.

Note

Frame delay time with X-200 with IRT

The more X

-200IRT IE switches a frame runs through, the higher the frame delay. By using

the "cut through" switching mechanism, the X

-200IRT IE switches are ideal to meet the real-

time requirements of PROFINET.

Cut through is, however, not possible:

•

Between a port set to 10 Mbps and a port set to 100 Mbps.

•

When two packets are to be sent at the same time on one port.

In this case, an X-200 IE switch changes to Store&Forward and the delay increases.

Functions

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

13

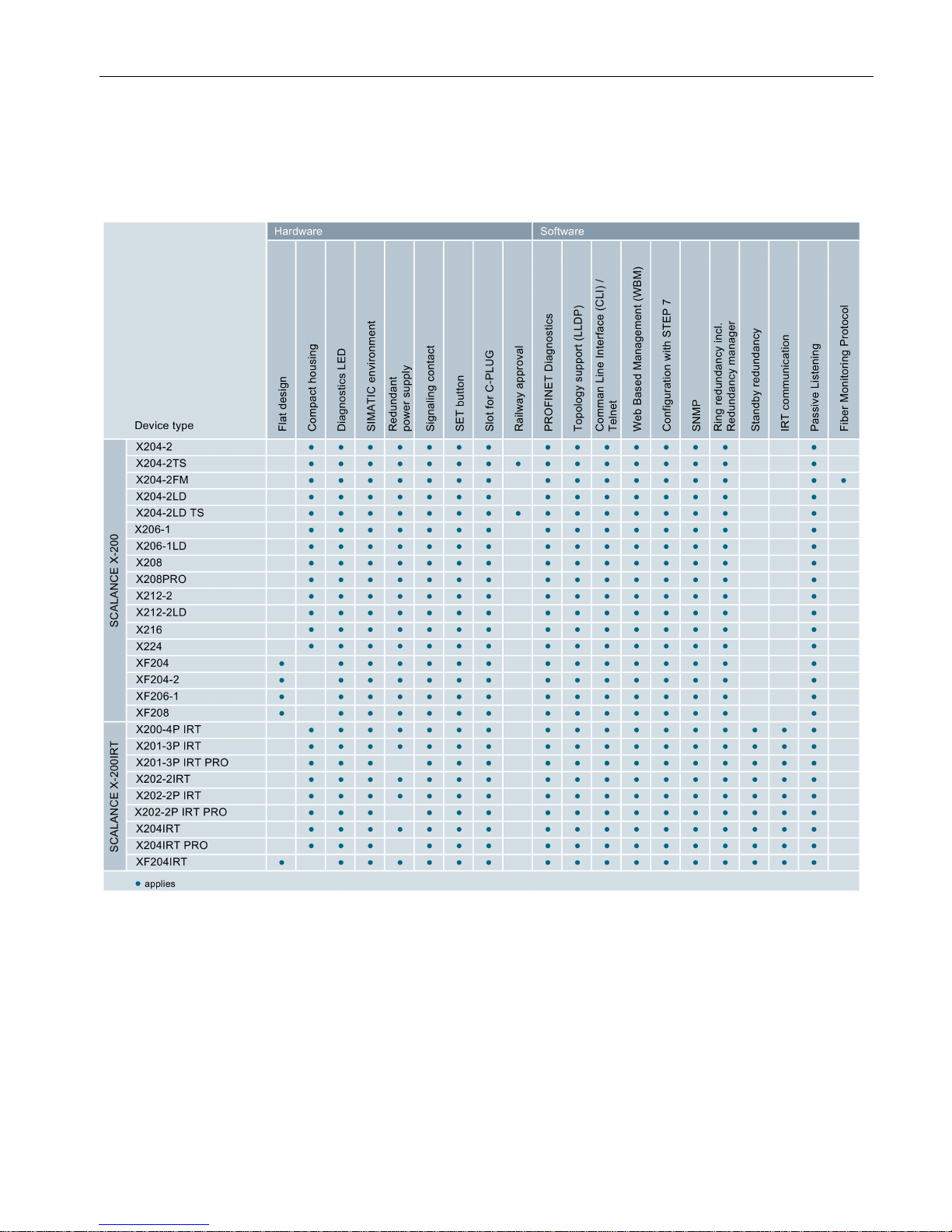

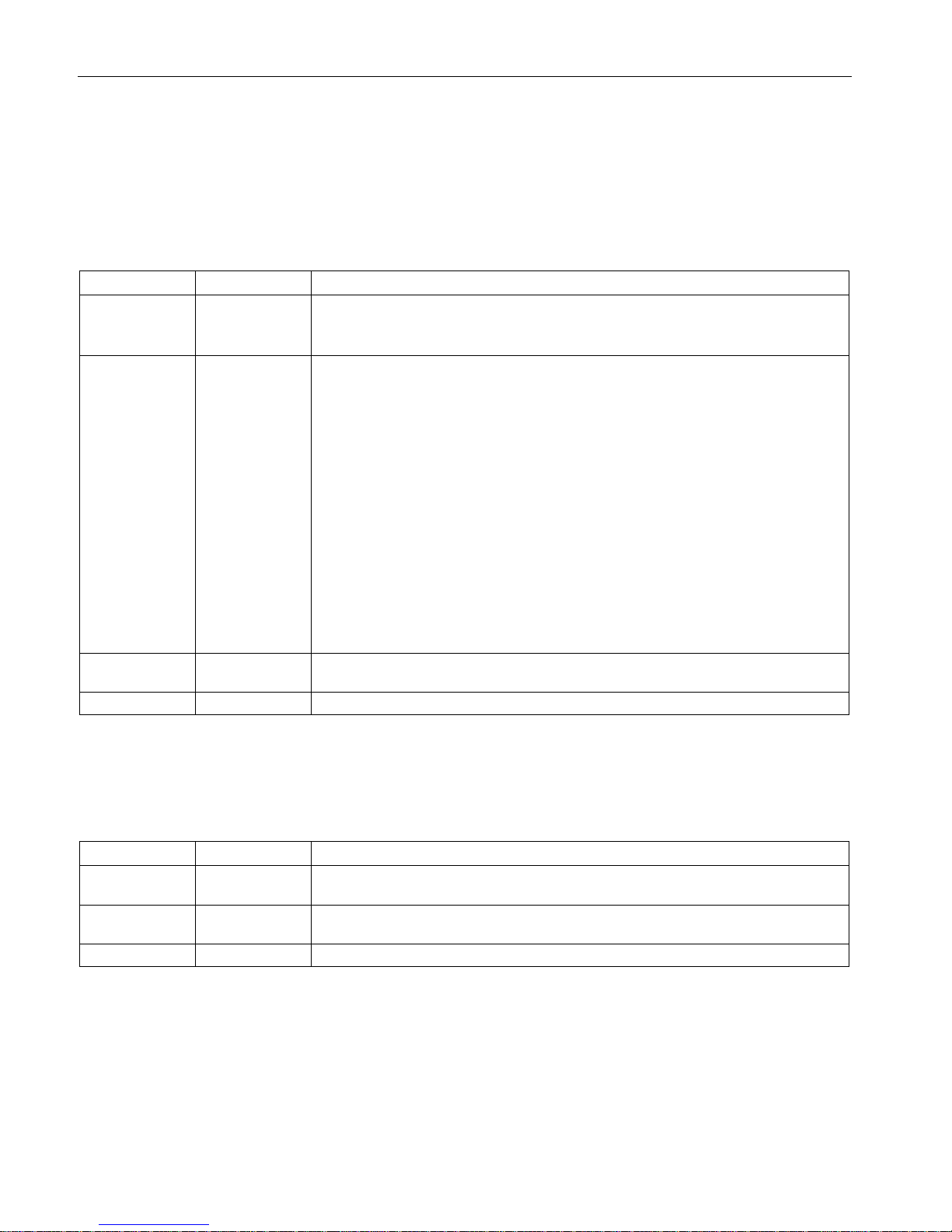

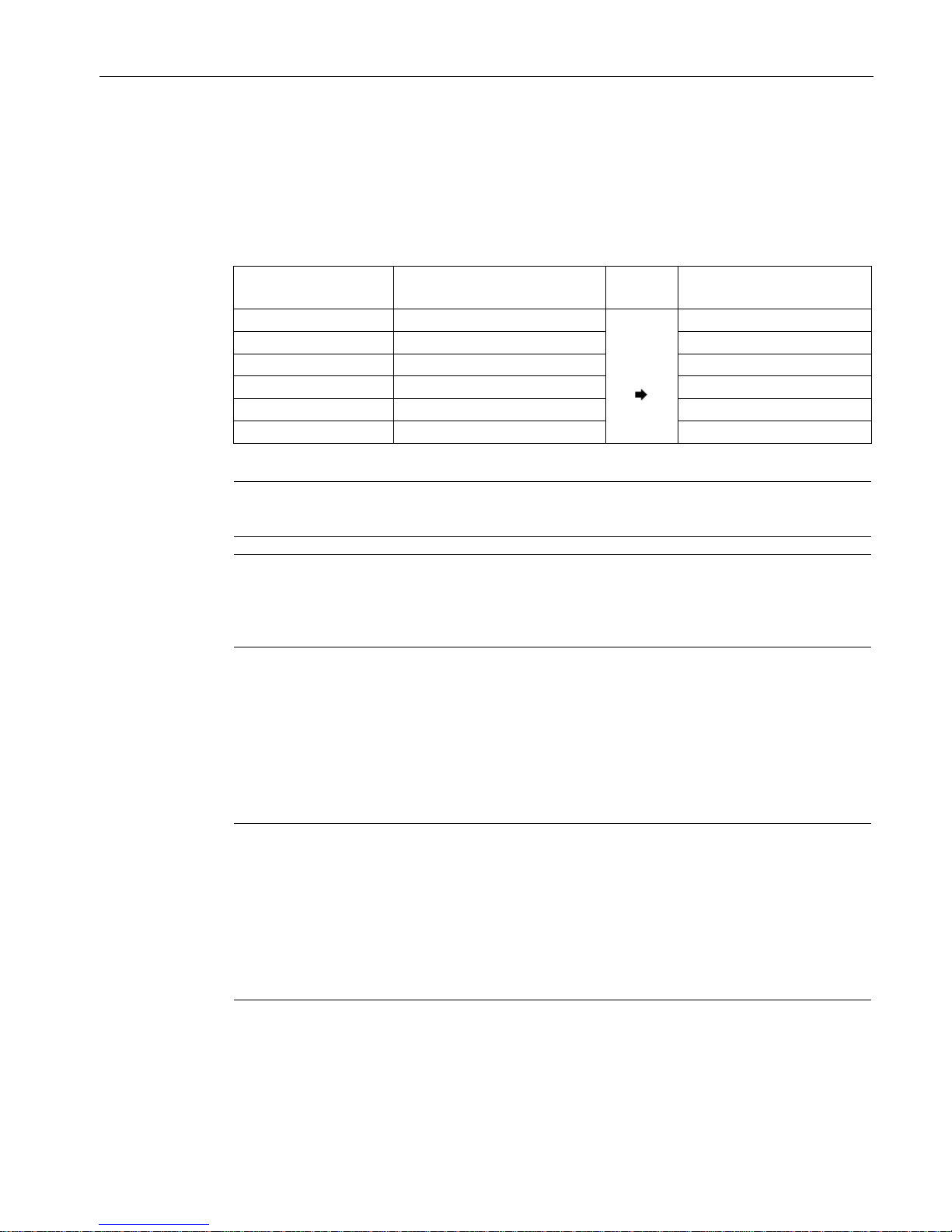

Overview of the functions

The following table shows the hardware and software properties for each product variant of

the X-200 switches in detail:

Number of electrical and optical connectors in the product name

The number before the hyphen in the product name indicates the number of electrical

connectors. The number following the hyphen indicates the number of optical connectors of

the device. For example, the switch X212-2 has twelve electrical and two optical connectors.

Functions

SCALANCE X-200

14 Operating Instructions, 03/2015, C79000-G8976-C284-06

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

15

2

2.1

Device views

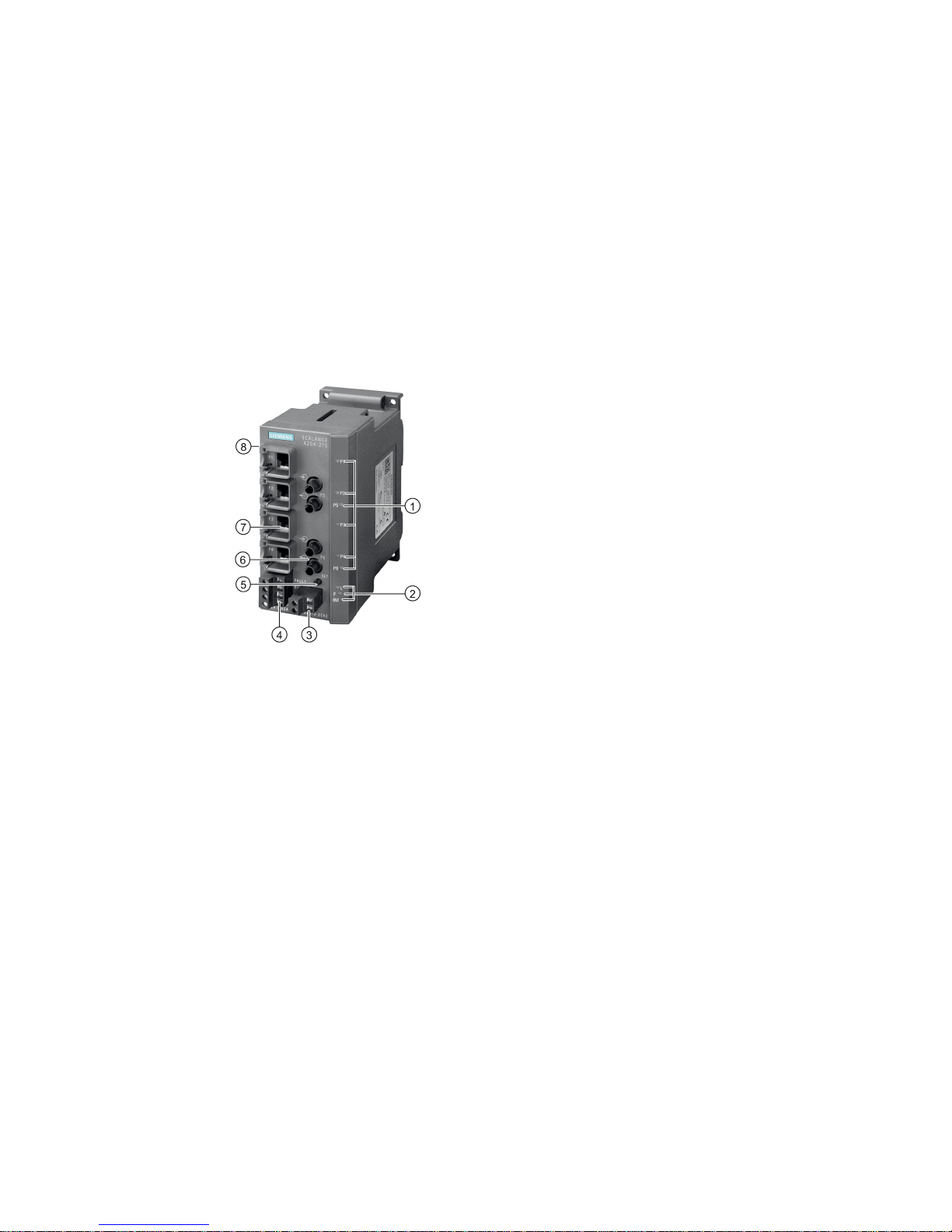

Device view based on the example of an X204-2TS

The following figure describes the individual components of an IE switch X200.

1

LEDs for attachments to Industrial Ethernet

2 LEDs

•

L: Power LED, power supply

•

F: Fault LED

•

RM: Redundancy manager or standby

3

Connector for signaling contact

4

Connector for power supply

5

SET button

6

Optical attachment to Industrial Ethernet

7

Electrical attachment to Industrial Ethernet

8 (on rear of device, not shown in figure:) Slot for C

-

PLUG

Description of the device

2.1 Device views

SCALANCE X-200

16 Operating Instructions, 03/2015, C79000-G8976-C284-06

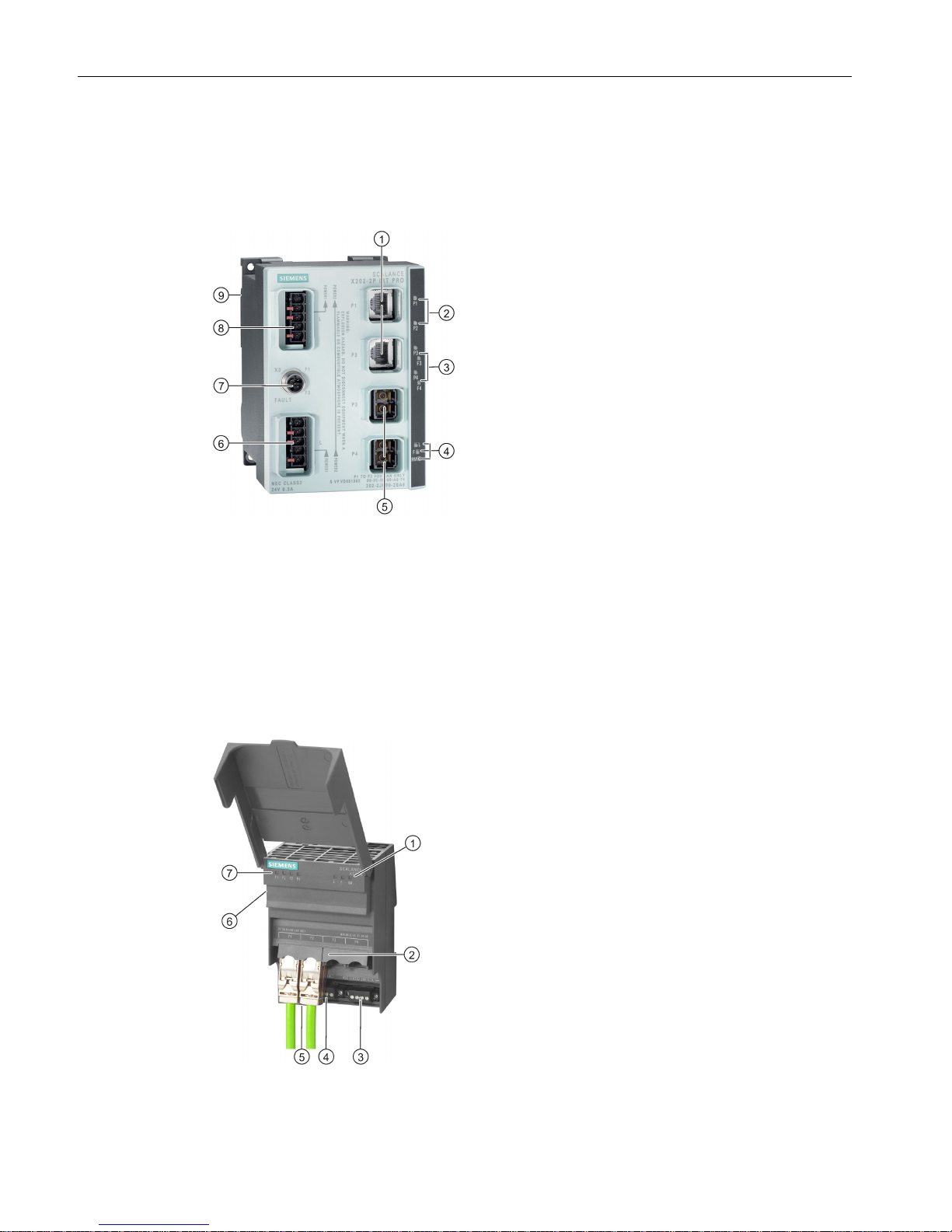

Device view based on the example of an X202-2P IRT PRO

The following figure describes the individual components of a PRO version of an IE switch X-

200.

1

Electrical attachments to Industrial Ethernet

2 LEDs for electrical connectors

3 LEDs for optical connectors with diagnostics

LEDs

4 LEDs

•

L: Power LED, power supply

•

F: Fault LED

•

RM:

– green = redundancy manager

– yellow = standby indicator

5

Optical attachments to Industrial Ethernet

6 Connector for the power supply (supplied with

L1, additionally looped through to L2)

7

Connector for signaling contact

8 Power supply for further devices (looped

through from L1 to L2)

9 (on rear of device, not shown in figure): Slot for

the C-PLUG and SET button

Device view based on the example of an XF204

The following figure describes the individual components of an IE switch X-200, flat design.

1 LEDs

•

L: Power LED, power supply

•

F: Fault LED

•

RM: Redundancy manager

2

Attachments to Industrial Ethernet

3

Connector for power supply

4

Connector for signaling contact

5 (behind the connectors, not shown in figure:)

SET button

6 (on side of device, not shown in figure:) Slot for

C-PLUG

7 LEDs for attachments to Industrial Ethernet

Description of the device

2.2 The LEDs

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

17

2.2

The LEDs

2.2.1

LED display when the device starts up

When the X-200 starts up, the LEDs light up in the following sequence:

● The green power LED lights up immediately after turning on the device.

● The LEDs of the Ethernet connectors light up for approximately 6 seconds.

● When the Ethernet LEDs go off, the red fault LED is lit for approximately 20 seconds.

● Following this, after approximately 2 seconds the correct link status is displayed.

The X-200 is now ready for operation.

2.2.2

Power LED "L" (green/yellow LED)

The power LED shows the status of the power supply on the X-200 IE switch. The power

LED can light up either green or yellow. The meanings of the display are as follows:

LED color

LED status

Meaning

Green

Lit

Both power supplies are connected; in other words, redundant power supply.

Yellow Lit Only one power supply is connected.

- Off No power supply is connected or the voltage is < 14 VDC or with TS devices < 8

VDC.

Note

The following devices do not have a redundant power supply:

•

X201-3P IRT PRO

•

X202-2P IRT PRO

•

X204IRT PRO

Description of the device

2.2 The LEDs

SCALANCE X-200

18 Operating Instructions, 03/2015, C79000-G8976-C284-06

2.2.3

Fault LED "F" (yellow/red LED)

The fault LED indicates a fault/error on the X-200. If the X-200 detects an error, the signaling

contact is opened at the same time assuming that the response of the signaling contact was

not configured differently.

The meanings of the fault LED display are as follows:

LED color

LED status

Meaning

Yellow Lit The LED can only adopt this status with FM devices.

Check the received power or the loss of power on optical connections. If necessary,

replace the parts.

Red Lit The fault LED lighting up can have the following meanings:

• Link down event on a monitored port

• Loss of the power supply

• C-PLUG error

• Device is in PROFINET mode:

– There is no connection to the controller.

– There is a connection to the controller. A configured diagnostics interrupt is

also pending, for example power fail interrupt, C-PLUG interrupt etc.

• Redundancy manager connected through

• Switchover of standby connection

• A defined value was undershot in a monitored optical connection.

• A loop was detected.

• Device startup. The LED lights up for approximately 20 seconds.

Red Flashing Internal error detected. Notify maintenance personnel. If necessary, send the device

in for repair.

-

Off

No error detected.

2.2.4

Redundancy manager LED "RM" (green LED)

The green LED shows the following statuses of the X-200:

LED color

LED status

Meaning

Green Lit The device is operating in the role of redundancy manager. The ring is operating free

of errors. The monitoring is enabled.

Green Flashing The device is operating in the role of redundancy manager. An interruption was de-

tected in the ring. The device has switched through.

-

Off

The device is not operating in the role of redundancy manager.

Description of the device

2.2 The LEDs

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

19

Note

This LED labeled on the device with "RM" has a dual function. The color of the display

changes depending on the function:

•

If the LED is lit green, the redundancy manager function is indicated.

•

If the LED is lit yellow, the standby function is indicated.

In

Web Based Management (WBM), the LED is labeled differently depending on the

function:

•

The redundancy manager function (as shipped) is labeled "RM".

•

The standby function is labeled "SB" in the WBM.

2.2.5

Standby LED "RM" (yellow LED)

You will find the standby LED only on devices with the IRT function.

Note

This LED labeled on the device with "RM" has a dual function. The color of the display

changes depending on the function:

•

If the LED is lit green, the redundancy manager function is indicated.

•

If the LED is lit yellow, the standby function is indicated.

In

Web Based Management (WBM), the LED is labeled differently depending on the

function:

•

The redundancy manager function (as shipped) is labeled "RM".

•

The standby function is labeled "SB" in the WBM.

The yellow LED indicates the following statuses of the X-200IRT:

LED color

LED status

Meaning

Yellow

Lit

The standby function is activated, the switch is in active mode.

Yellow

Flashes slowly

The standby function is activated, the switch is in passive mode.

Yellow

Flashes quickly

Standby partner lost.

-

Off

The standby function is not activated.

Description of the device

2.2 The LEDs

SCALANCE X-200

20 Operating Instructions, 03/2015, C79000-G8976-C284-06

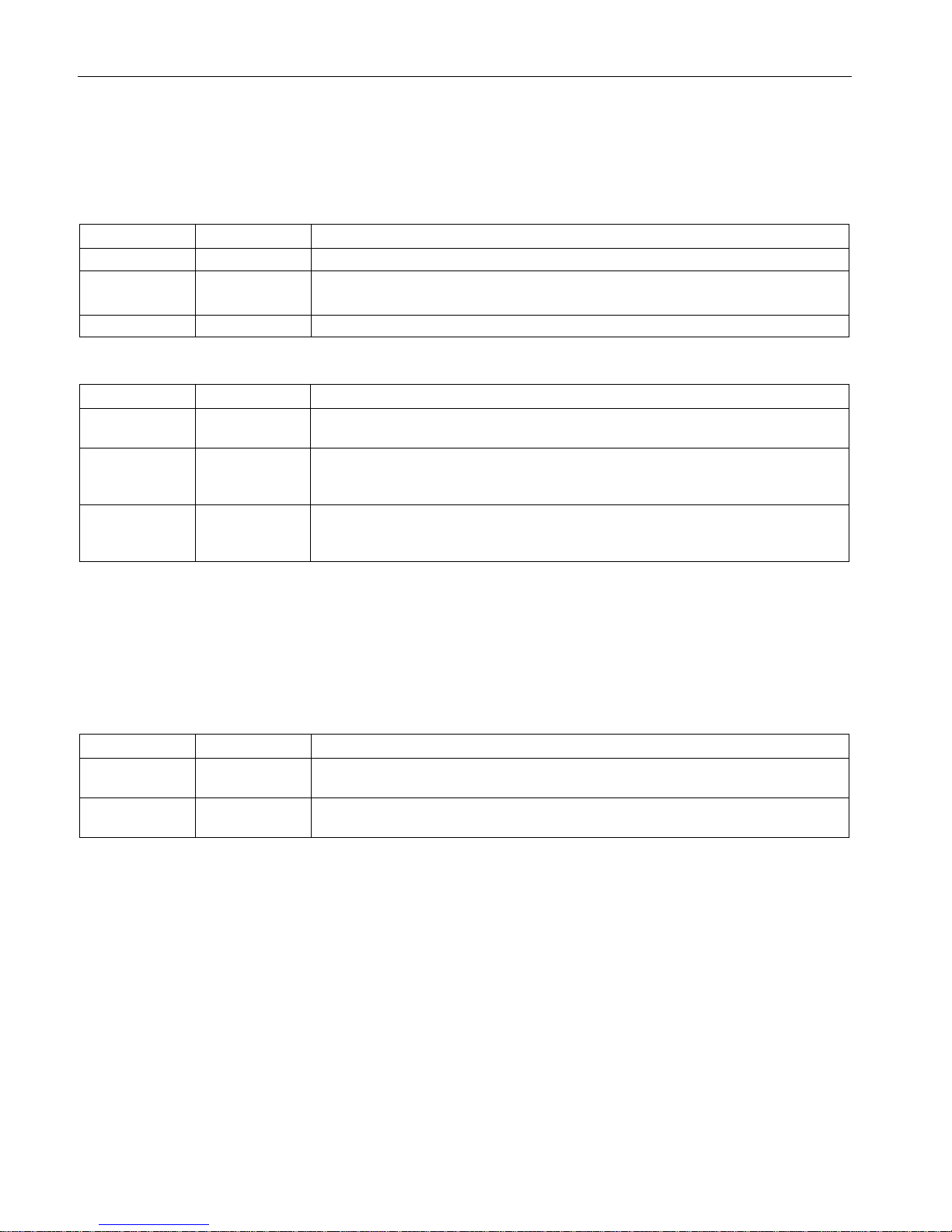

2.2.6

Port LEDs "P" (green/yellow LEDs)

The LEDs of the Ethernet connectors can be lit green or yellow. The meanings of the display

are as follows:

LED color

LED status

Meaning

Green

Lit

Link exists, no data reception

Yellow Lit Link exists, data being received

Device startup. The LED lights up for approximately 6 seconds.

Yellow

Flashing

Setting or display of the fault mask

The following statuses of the port LEDs do not exist on devices with the IRT function:

LED color

LED status

Meaning

Green flashes

once per period

Link exists and port in "blocking" status.

In this status, the port only receives management data (no user data).

Green flashes

three times per

period

Link exists and port is deactivated by the management.

In this status, no data is sent or received via the port.

Green flashes

four times per

period

Port exists and is in the "monitor port" status.

In this status, the data traffic of another port is mirrored to this port.

2.2.7

Diagnostics LEDs for optical connectors "F" (yellow LED)

You will find the diagnostics LEDs only on the devices with the IRT function.

The status of the optical connectors is indicated by an additional yellow LED per connector.

The LEDs signal the following statuses:

LED color

LED status

Meaning

Yellow Lit Check the plug-in connection and the quality of the fiber-optic cable. If necessary,

replace the parts.

- Off Relevant only if the link exists. The existing link power margin is adequate for error-

free operation.

2.2.8

Show Location

Localizing an IE Switches X-200

To identify an IE Switch X-200 locally and with certainty, you can use the "show location"

function on a programming device to select the node over the network and make it flash.

This can be used, for example, when assigning addresses to make sure that the correct

node receives the address. All port LEDs of the addressed node flash green at 2 Hz.

With the Primary Setup Tool (PST) V3.0 or higher, you can trigger this function with "Module

\ Flash".

Description of the device

2.3 The SET button

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

21

2.3

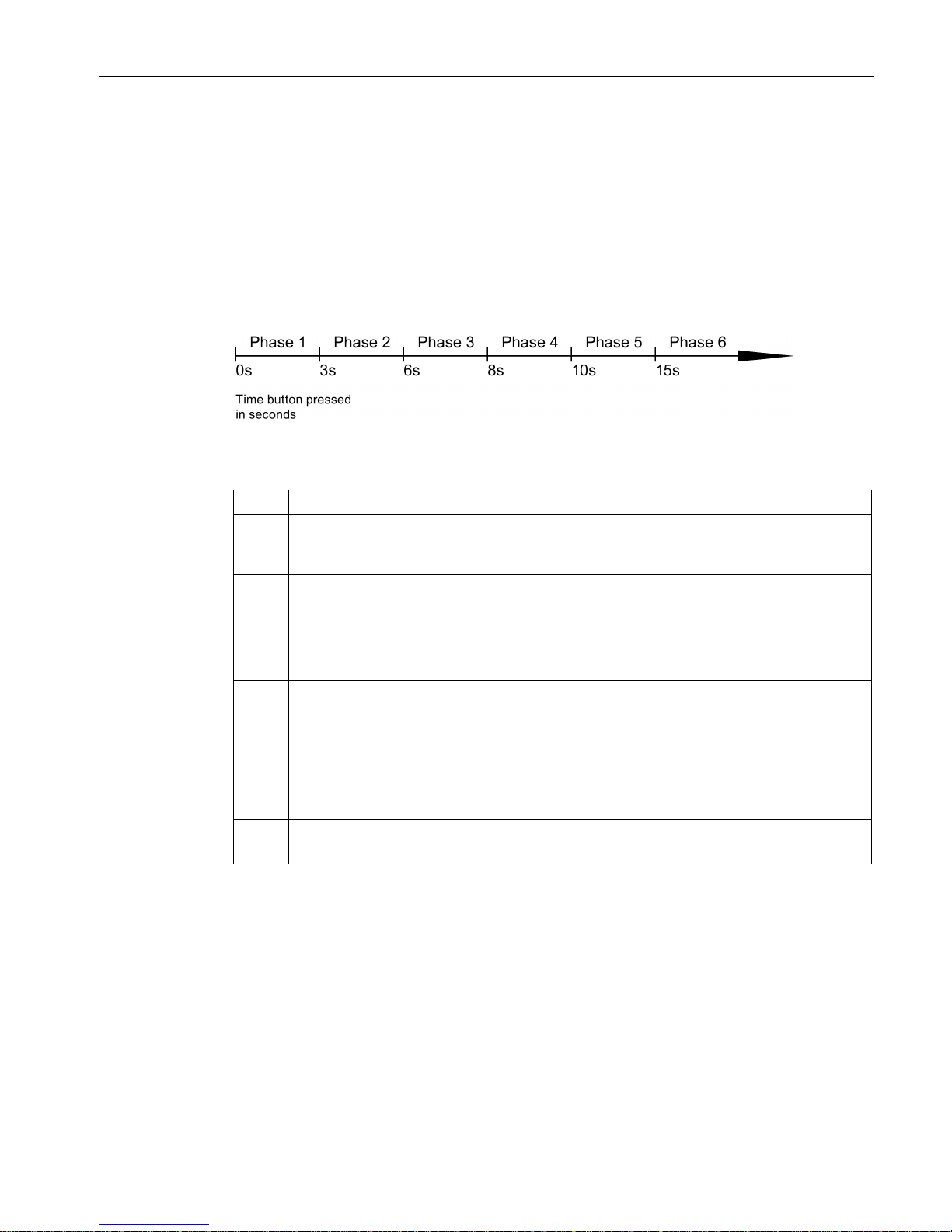

The SET button

Function of the SET button

With the SET button, you can change various settings of the device. The changed settings

remain after cycling power to the device.

Different settings are made depending on how long you hold down the SET button, as

described in the following table:

Figure 2-1 Phases for changing settings using the SET button

Phase

Description

1 The currently set fault mask is displayed. If no fault mask has been set, all ports flash one

after the other.

If you release the button in phase 1, this has no effect.

2 The LEDs of the ports at which there is currently a link flash at 2.5 Hz.

If you release the button in phase 2, this has no effect.

3 The LEDs of the ports at which there is currently a link and the LEDs of the connected pow-

er supply are lit permanently.

If you release the button in phase 3, the fault mask corresponding to the lit LEDs is adopted.

4 The RM LED flashes.

If you release the button in phase 4, the redundancy manager is deactivated. The redundancy function remains enabled. The device changes to "Automatic Redundancy Detect"

mode.

5 The RM LED is lit permanently.

If you release the button in phase 5, the redundancy function is activated and the device is

configured as HRP manager.

6 All LEDs flash.

The device is reset to the factory defaults.

Description of the device

2.4 The C-PLUG

SCALANCE X-200

22 Operating Instructions, 03/2015, C79000-G8976-C284-06

2.4

The C-PLUG

Area of application

The C-PLUG is an exchangeable medium for storage of the configuration and project

engineering data of the basic device. This means that the configuration data remains

available if the basic device is replaced.

How it works

Power is supplied by the basic device. The C-PLUG retains all data permanently when the

power is turned off.

If an empty C-PLUG (factory settings) is inserted, all configuration data of an IE

Switch X-200 is saved to it when the device starts up. Changes to the configuration during

operation are also saved on the C-PLUG without any operator intervention being necessary.

If a C-PLUG is inserted, the configuration stored internally on the basic device is no longer

changed. Al changes made to the configuration during ongoing operation are only stored on

the C-PLUG.

A basic device with an inserted C-PLUG automatically uses the configuration data of the

C-PLUG when it starts up. This is, however, only possible when the data was written by a

compatible device type.

This allows fast and simple replacement of the basic device. If a device is replaced, the CPLUG is taken from the failed component and inserted in the replacement device. The first

time it is started up, the replacement device has the same configuration as the failed device

except for the MAC address set by the vendor.

Description of the device

2.4 The C-PLUG

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

23

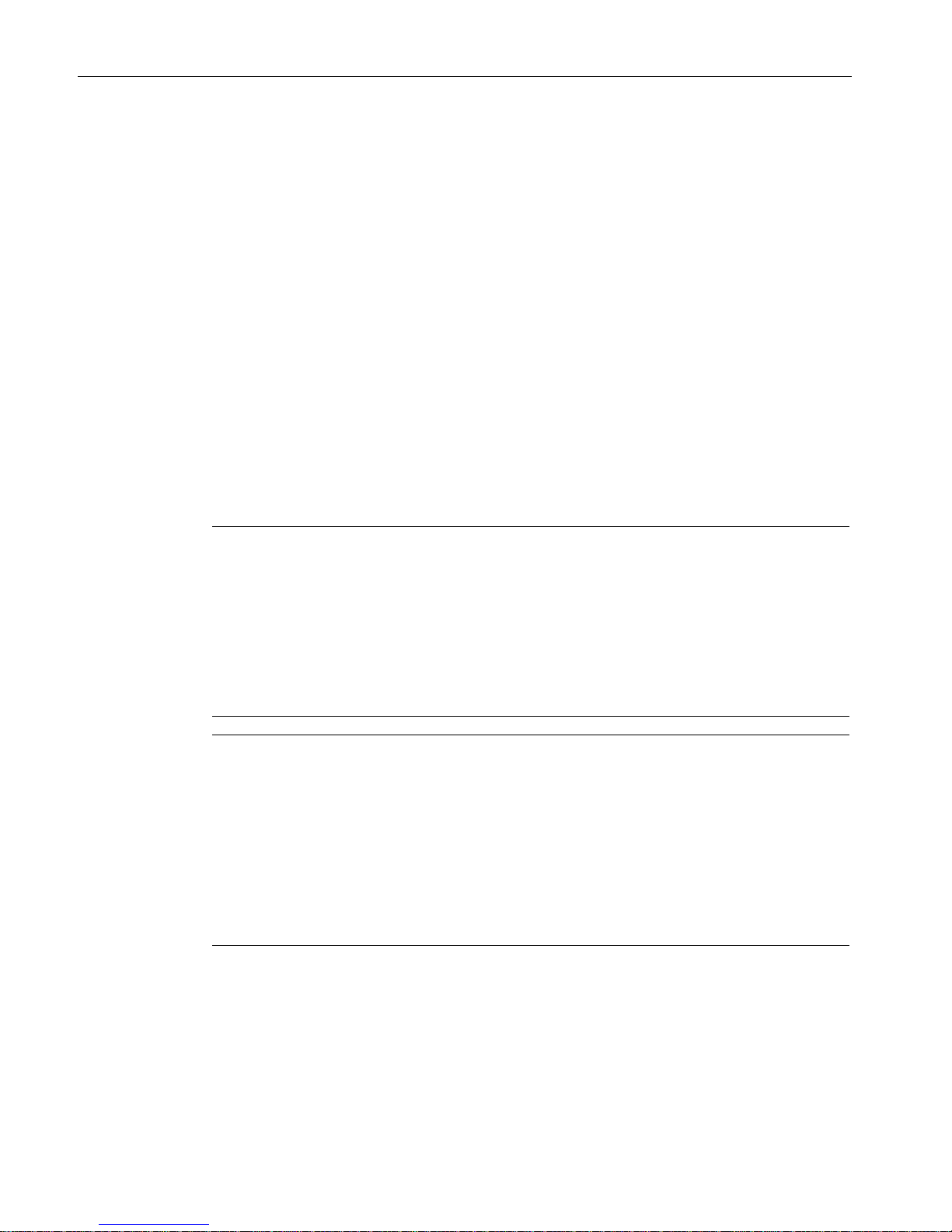

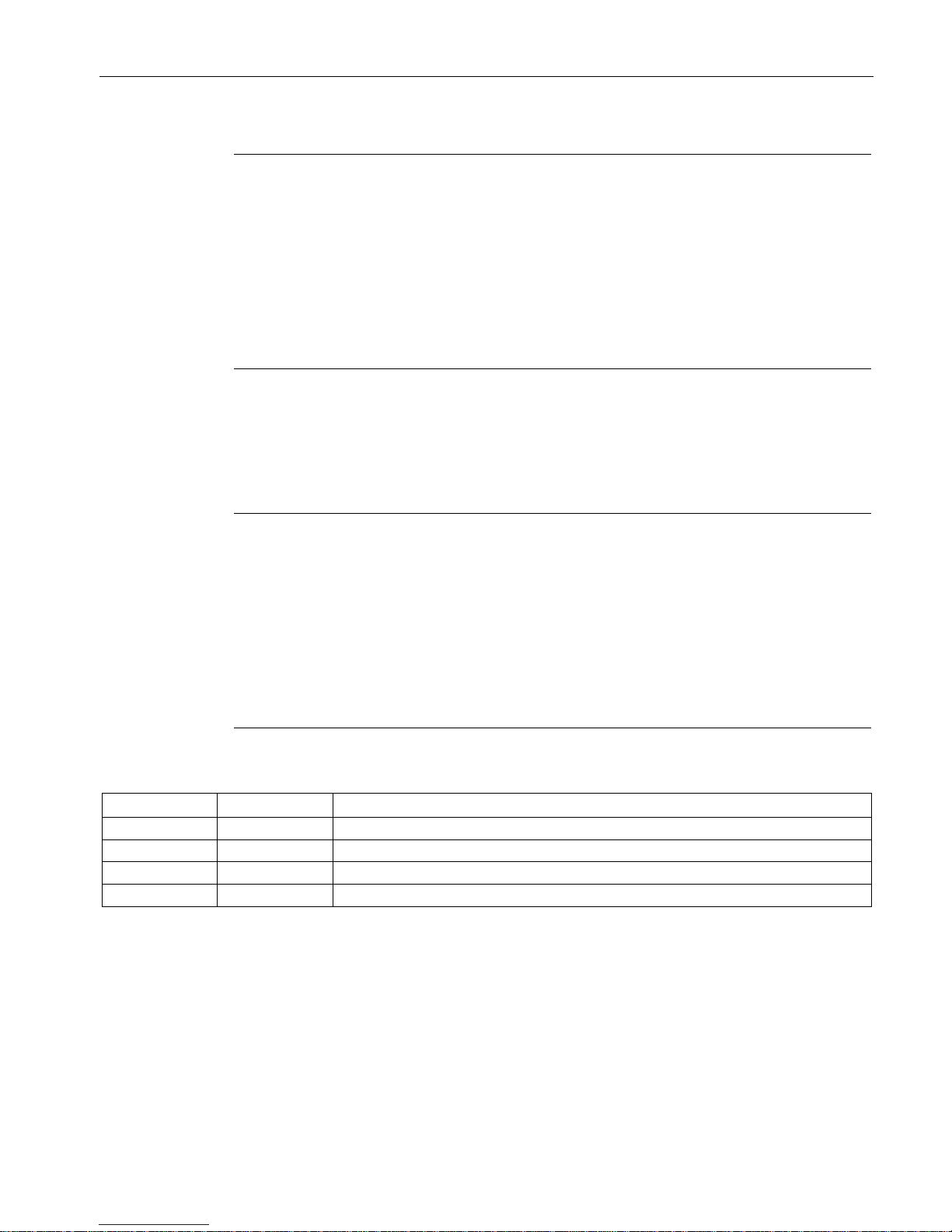

Compatible devices

As a general rule, the data on the C-PLUG is only compatible with devices having an

identical order number and the same device name.

The device combinations shown in the following table are exceptions. With these devices,

the exchange of the C-PLUG is possible in one direction.

Device type

C-PLUG created by device with

order number

Compatible with device with

order number

X204-2

6GK5 204-2BB00-2AA3

6GK5 204-2BB10-2AA3

X204-2LD 6GK5 204-2BC00-2AA3 6GK5 204-2BC10-2AA3

X206-1

6GK5 206-1BB00-2AA3

6GK5 206-1BB10-2AA3

X206-1LD

6GK5 206-1BC00-2AA3

6GK5 206-1BC10-2AA3

X208

6GK5 208-0BA00-2AA3

6GK5 208-0BA10-2AA3

X208PRO

6GK5 208-0HA00-2AA6

6GK5 208-0HA10-2AA6

Note

Combinations other than those shown in the table are not compatible with each other.

Note

If you insert a C

-PLUG in a compatible device, the system name of the original device is

entered both in the system name as well as in the PROFINET IO device name of the

compatible device.

Using a previously written C-PLUG

If you want to insert a C-PLUG that has already been used and written to into a new

differently configured X-200 IE switch, you will first need to delete the existing data on the CPLUG. You will find information about this in the configuration manual of the SCALANCE X200 in the section on the WBM menu items.

Note

The X

-200 IE switches normally start up with the configuration of the C-

PLUG, assuming this

was written to by a compatible device type. If the C

-PLUG was written to by an incompatible

device type, the basic device will not start up fully and signals an error. The WBM menu

"System C

-PLUG" is displayed automatically. Here, use the "Modify C-PLUG" function to

specify whether or not the device operates

with a C-PLUG.

If you operate a device with a C

-PLUG, the C-PLUG can either be initialized with the factory

settings or with the settings stored internally on the device.

Description of the device

2.4 The C-PLUG

SCALANCE X-200

24 Operating Instructions, 03/2015, C79000-G8976-C284-06

Diagnostics

The following events are signaled by the diagnostics mechanisms of the X-200, such as

LEDs, WBM etc.:

● Inserting a C-PLUG that contains the configuration of an incompatible device type.

● The accidental removal of a C-PLUG

● General malfunctions of the C-PLUG.

The C-PLUG does not ship with the product

The C-PLUG is not supplied with the X-200 IE switch. It is an optional accessory available

under the following order number: 6GK1 900-0AB00.

Inserting in the slot

NOTICE

•

Insert and remove the C-PLUG only when power is off.

•

In a device with a varnished printed circuit board, you may only use a C-PLUG with a

varnished board.

Figure 2-2 C-PLUG and slot

Description of the device

2.4 The C-PLUG

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

25

The slot for the C-PLUG is located as follows:

● On the IE Switch X-200 on the back of the device.

● On the IE Switch XF-200 on the left hand side of the device.

Follow the steps below to insert the C-PLUG:

1. Remove the screw cover.

2. Insert the C-PLUG in the slot.

3. Close the slot with the screw cover.

Removing the C-PLUG

It is only necessary to remove the C-PLUG if the IE Switch X-200 develops a fault.

You can lever the C-PLUG out of the slot carefully using flat pliers, tweezers, or a small

screwdriver.

If no C-PLUG is inserted in the device, when the device restarts, an error message is output

in Web Based Management and in the Command Line Interface. In this case, you will need

to set the device to operation without C-PLUG. For further information, refer to the section

"System C-PLUG" in the section on the WBM menu in the configuration manual.

Description of the device

2.4 The C-PLUG

SCALANCE X-200

26 Operating Instructions, 03/2015, C79000-G8976-C284-06

SCALANCE X-200

Operating Instructions, 03/2015, C79000-G8976-C284-06

27

3

3.1

Safety notices in general

Note the following safety notices. These relate to the entire working life of the device.

WARNING

Do not use any parts that show evidence of damage

If you use damaged parts, there is no guarantee that the device will function according to

the specification.

If you use damaged parts, this can lead to the following problems:

• Injury to persons

• Loss of the approvals

• Violation of the EMC regulations

• Damage to the device and other components

Use only undamaged parts.

Installation guidelines

The product meets the requirements if you adhere to the installation and safety notices

contained in this documentation and in the following documentation when installing and

operating the product.

Current documentation on the Internet

The current descriptions of the currently available products can be found on the Product

Support pages under the entry IDs below:

● Configuration manual SIMATIC NET PH SCALANCE X-200

63203259 (http://support.automation.siemens.com/WW/view/en/63203259

)

● System manual SIMATIC NET Industrial Ethernet Network Manual

27069465 (http://support.automation.siemens.com/WW/view/en/27069465

)

● Configuration manual EMC Installation Guidelines

60612658 (http://support.automation.siemens.com/WW/view/en/60612658

)

Electrostatic discharge

To protect the product process from electrostatic discharge, personnel must first discharge

any electrostatic charge from their body before touching the product.

Loading...

Loading...