Page 1

RVD240

District Heating and Domestic Hot Water Controller

Basic Documentation

Edition 3.0

Controller series D

CE1P2384en

27.05.2004

Siemens Building Technologies

HVAC Products

Page 2

Siemens Building Technologies AG

HVAC Products

Gubelstrasse 22

CH 6301 Zug

Tel. +41 41 724 24 24

Fax +41 41 724 35 22

www.landisstaefa.com

2/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 27.05.2004

© 1999 Siemens Building Technologies AG

Subject to change

Page 3

Contents

1 Summary ....................................................................................................... 13

1.1 Brief description and key features ................................................................. 13

1.2 Type summary............................................................................................... 13

1.3 Equipment combinations ............................................................................... 13

1.3.1 Suitable sensors ............................................................................................ 13

1.3.2 Suitable room units........................................................................................ 14

1.3.3 Suitable valve actuators ................................................................................14

1.3.4 Communication.............................................................................................. 14

1.3.5 Documentation ..............................................................................................14

2 Use ................................................................................................................ 15

2.1 Types of plant ................................................................................................ 15

2.2 Types of houses and buildings ...................................................................... 15

2.3 Types of heating systems.............................................................................. 15

2.4 Heating circuit functions ................................................................................15

2.5 D.h.w. functions ............................................................................................. 16

2.6 Auxiliary functions.......................................................................................... 16

3 Fundamentals................................................................................................ 18

3.1 Key technical features ................................................................................... 18

3.1.1 Function blocks.............................................................................................. 18

3.1.2 Plant types..................................................................................................... 18

3.2 Operating modes ........................................................................................... 22

3.2.1 Heating circuit control .................................................................................... 22

3.2.2 D.h.w. heating................................................................................................ 23

3.2.3 Manual operation........................................................................................... 23

4 Acquisition of measured values..................................................................... 24

4.1 General.......................................................................................................... 24

4.2 Flow temperature heating circuit ...................................................................24

4.2.1 Types of sensors ........................................................................................... 24

4.2.2 Handling faults............................................................................................... 24

4.3 Outside temperature (B9) .............................................................................. 24

4.3.1 Types of sensors ........................................................................................... 24

4.3.2 Handling faults............................................................................................... 24

4.4 Room temperature (A6)................................................................................. 25

4.4.1 Types of sensors ........................................................................................... 25

4.4.2 Handling faults............................................................................................... 25

4.4.3 Room model .................................................................................................. 25

4.5 D.h.w. temperature (B3) ................................................................................ 25

4.5.1 Measured variable ......................................................................................... 25

3/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Contents 27.05.2004

Page 4

4.5.2 Types of sensors............................................................................................25

4.5.3 Handling faults ...............................................................................................26

4.6 D.h.w. storage tank temperature (B31)..........................................................26

4.6.1 Measured variable .........................................................................................26

4.6.2 Types of sensors............................................................................................26

4.6.3 Handling faults ...............................................................................................26

4.7 D.h.w. storage tank or return temperature (B32) ...........................................26

4.7.1 Measured variable .........................................................................................26

4.7.2 Types of sensors............................................................................................26

4.7.3 Handling faults ...............................................................................................27

4.8 Return temperature (B7, B71 and B72) .........................................................27

4.8.1 Measurement .................................................................................................27

4.8.2 Types of sensors............................................................................................27

4.8.3 Handling faults ...............................................................................................27

5 Function block Space heating........................................................................28

5.1 Operating lines...............................................................................................28

5.2 Settings and displays .....................................................................................28

5.3 Heating program ............................................................................................29

6 Function block Clock settings ........................................................................30

6.1 Operating lines...............................................................................................30

6.2 Entries............................................................................................................30

7 Function block End-user d.h.w.......................................................................31

7.1 Operating lines...............................................................................................31

7.2 D.h.w. heating program..................................................................................31

7.3 Adjustment of setpoints..................................................................................31

8 Function block Display of actual sensor values .............................................32

8.1 Operating lines...............................................................................................32

8.2 Displays .........................................................................................................32

9 Function block Holiday settings .....................................................................33

9.1 Operating lines...............................................................................................33

9.2 Holiday program.............................................................................................33

10 Function block Indication of errors .................................................................34

10.1 Operating line.................................................................................................34

10.2 Indication of errors .........................................................................................34

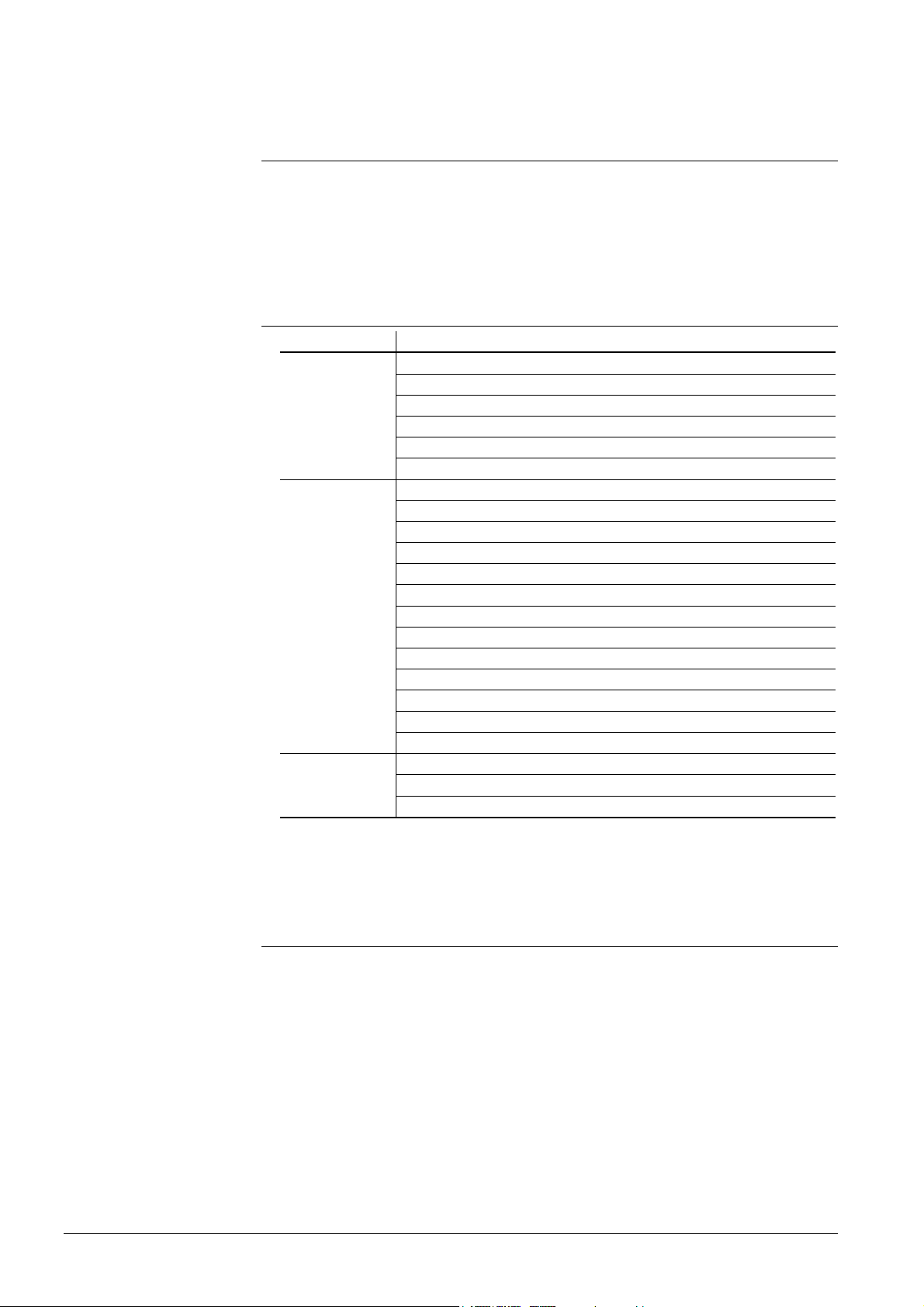

11 Function block Plant configuration .................................................................35

11.1 Operating lines...............................................................................................35

11.2 Parameters to be set......................................................................................35

11.2.1 Plant type .......................................................................................................35

11.2.2 Input B71 / U1 ................................................................................................35

4/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Contents 27.05.2004

Page 5

11.2.3 Circulating pump............................................................................................ 36

11.2.4 Input H5 ......................................................................................................... 36

11.2.5 Control of variable speed pump..................................................................... 36

12 Function block Space heating .......................................................................40

12.1 Operating lines ..............................................................................................40

12.2 Compensating variables ................................................................................40

12.2.1 Outside temperature...................................................................................... 40

12.2.2 Room temperature......................................................................................... 41

12.3 Heating curve ................................................................................................42

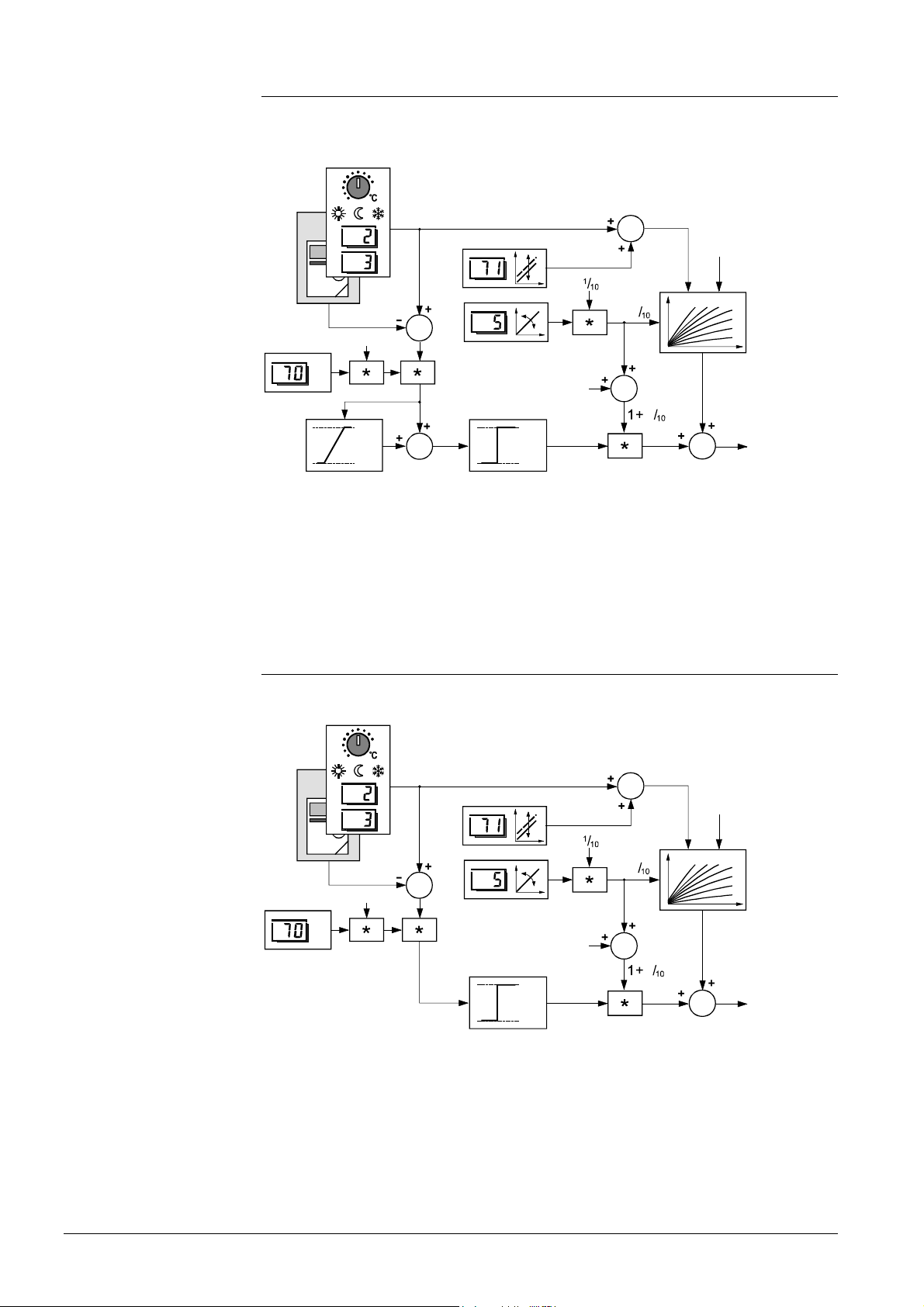

12.4 Generation of setpoint ...................................................................................43

12.4.1 Display of setpoint ......................................................................................... 43

12.4.2 Setpoint of weather-compensated control ..................................................... 43

12.4.3 Setpoint of room-compensated control.......................................................... 44

12.4.4 Setpoint of weather-compensated control with room influence ..................... 44

12.5 Heating circuit control ....................................................................................45

12.5.1 Weather-compensated control ......................................................................45

12.5.2 Room-compensated control ..........................................................................45

12.5.3 Weather-compensated control with room influence ......................................45

12.6 Automatic ECO function ................................................................................46

12.6.1 Fundamentals................................................................................................ 46

12.6.2 Compensating variables and auxiliary variables ...........................................46

12.6.3 Heating limit................................................................................................... 47

12.6.4 Mode of operation of ECO function 1 ............................................................ 47

12.6.5 Mode of operation of ECO function 2 ............................................................ 47

12.7 Pump overrun ................................................................................................47

12.8 Maximum limitation of the room temperature ................................................47

12.9 Optimization................................................................................................... 48

12.9.1 Definition and purpose................................................................................... 48

12.9.2 Fundamentals................................................................................................ 48

12.9.3 Process.......................................................................................................... 49

12.9.4 Room model temperature.............................................................................. 49

12.9.5 Optimum stop control ....................................................................................50

12.9.6 Quick setback ................................................................................................ 50

12.9.7 Optimum start control .................................................................................... 50

12.9.8 Maximum rate of flow temperature increase .................................................51

12.10 Frost protection for the building ..................................................................... 51

12.10.1 General.......................................................................................................... 51

12.10.2 Mode of operation with room sensor ............................................................. 51

12.10.3 Mode of operation without room sensor ........................................................ 51

12.11 Protective functions ....................................................................................... 52

12.11.1 Pump kick ...................................................................................................... 52

12.11.2 Valve kick ......................................................................................................52

5/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Contents 27.05.2004

Page 6

12.11.3 Shutdown of pump .........................................................................................52

12.11.4 Pump and mixing valve overrun.....................................................................52

13 Function block Valve actuator of heat converter............................................54

13.1 Operating lines...............................................................................................54

13.2 Mode of operation ..........................................................................................54

13.3 Control process..............................................................................................54

13.4 Maximum limitation of the flow temperature ..................................................54

13.5 Minimum limitation of the flow temperature ...................................................54

13.6 External heat demand at input H5 .................................................................55

13.7 External heat demand at input U1 .................................................................55

14 Function block Valve actuator heating circuit..................................................56

14.1 Operating lines...............................................................................................56

14.2 Mode of operation ..........................................................................................56

14.3 Control process..............................................................................................56

14.4 Maximum limitation of the flow temperature ..................................................56

14.5 Minimum limitation of the flow temperature ...................................................57

15 Function block D.h.w. heating........................................................................58

15.1 Operating lines...............................................................................................58

15.2 Release of d.h.w. heating ..............................................................................58

15.3 Control of the circulating pump ......................................................................59

15.4 Switching differential of d.h.w. control............................................................59

15.5 Legionella function .........................................................................................59

15.6 Priority of d.h.w. heating ................................................................................59

15.6.1 General ..........................................................................................................59

15.6.2 Absolute priority .............................................................................................60

15.6.3 Shifting priority ...............................................................................................60

15.6.4 No priority.......................................................................................................61

15.7 Pump overrun ................................................................................................61

15.7.1 General ..........................................................................................................61

15.7.2 Intermediate circuit pump...............................................................................61

15.7.3 Storage tank charging pump..........................................................................61

15.8 Frost protection for d.h.w. ..............................................................................62

15.9 Switching d.h.w. heating off ...........................................................................62

16 D.h.w. heating ................................................................................................63

16.1 D.h.w. heating with storage tanks ..................................................................63

16.1.1 General ..........................................................................................................63

16.1.2 Maximum charging time.................................................................................63

16.1.3 Manual storage tank heating..........................................................................63

16.1.4 Forced charging .............................................................................................63

16.1.5 Protection against discharging.......................................................................64

16.1.6 Protection against overtemperatures .............................................................64

6/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Contents 27.05.2004

Page 7

16.1.7 Storage tank with electric immersion heater.................................................. 64

16.2 D.h.w. heating with stratification storage tank ...............................................64

16.2.1 General.......................................................................................................... 64

16.2.2 D.h.w. heating................................................................................................ 65

16.2.3 Feeding the circulating water into the heat exchanger .................................. 65

16.3 Direct d.h.w. heating...................................................................................... 65

16.3.1 General.......................................................................................................... 65

16.3.2 D.h.w. heating................................................................................................ 65

16.3.3 Protection against cooling down.................................................................... 66

16.3.4 Siting the sensors .......................................................................................... 66

16.3.5 Flow switch .................................................................................................... 67

16.3.6 Compensation of heat losses through control ............................................... 67

16.3.7 Cold water sensor.......................................................................................... 68

17 Function block Extra legionella functions ......................................................69

17.1 Operating lines ..............................................................................................69

17.1.1 Legionella function......................................................................................... 69

17.1.2 Setpoint .........................................................................................................69

17.1.3 Time............................................................................................................... 69

17.1.4 Dwelling time ................................................................................................. 69

17.1.5 Operation of circulating pump........................................................................ 70

17.1.6 Maximum limitation of the return temperature ............................................... 70

17.2 Mode of operation.......................................................................................... 70

18 Function block Valve actuator d.h.w.............................................................. 72

18.1 Operating lines ..............................................................................................72

18.2 Mode of operation.......................................................................................... 72

18.3 Control process .............................................................................................72

18.4 Setpoint boost................................................................................................ 72

18.4.1 Charging boost .............................................................................................. 73

18.4.2 Flow temperature boost................................................................................. 73

18.5 Maximum setpoint of the d.h.w. temperature ................................................73

18.6 D.h.w. charging with two storage tank sensors .............................................73

18.7 Adjustable load limit....................................................................................... 73

18.7.1 Adjustment to the time of year....................................................................... 73

18.7.2 Load limit ....................................................................................................... 74

18.7.3 Child-proofing ................................................................................................ 74

19 Function block Assignment of d.h.w. ............................................................. 75

19.1 Operating line ................................................................................................75

19.2 Assignment of d.h.w. heating ........................................................................ 75

20 Function block LPB parameters ....................................................................76

20.1 Operating lines ..............................................................................................76

20.2 LPB parameters............................................................................................. 76

7/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Contents 27.05.2004

Page 8

20.2.1 Addressing the devices..................................................................................76

20.2.2 Source of time of day .....................................................................................76

20.2.3 Bus power supply...........................................................................................77

20.2.4 Outside temperature source ..........................................................................77

21 Locking signals ..............................................................................................78

21.1 Fundamentals ................................................................................................78

21.2 Critical locking signals....................................................................................78

21.3 Uncritical locking signals................................................................................78

21.3.1 General ..........................................................................................................78

21.3.2 Controller-internal uncritical locking signals...................................................79

21.3.3 Uncritical locking signals from the data bus...................................................79

22 Function block Device functions ....................................................................80

22.1 Operating lines...............................................................................................80

22.2 Actuator pulse lock.........................................................................................80

22.3 Frost protection for the plant ..........................................................................80

22.3.1 Principle .........................................................................................................80

22.3.2 Mode of operation with outside sensor ..........................................................80

22.3.3 Mode of operation without outside sensor .....................................................81

22.3.4 Frost protection for the heating circuit flow ....................................................81

22.4 Flow alarm .....................................................................................................81

22.4.1 Heating circuit and d.h.w. circuit with storage tanks ......................................81

22.4.2 Direct d.h.w. heating via heat exchanger.......................................................82

22.5 Winter- / summertime changeover.................................................................83

23 Function block M-bus parameter ...................................................................84

23.1 Operating lines...............................................................................................84

23.2 General ..........................................................................................................84

23.3 Addressing and identification .........................................................................84

23.4 Baud rate .......................................................................................................84

23.5 Load management .........................................................................................84

23.5.1 Load management of d.h.w. ..........................................................................84

23.5.2 Load management of the heating system......................................................84

23.5.3 Resetting the load control signals ..................................................................85

23.5.4 Use on the LPB..............................................................................................85

23.5.5 Resolution of M-bus signals...........................................................................85

24 Function block PPS parameter ......................................................................86

24.1 Operating lines...............................................................................................86

24.2 Suitable devices.............................................................................................86

24.3 Impacts of a room unit on the heating circuits ...............................................86

25 Function block Test and display.....................................................................87

25.1 Operating lines...............................................................................................87

8/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Contents 27.05.2004

Page 9

25.2 Sensor test ....................................................................................................87

25.3 Setpoint test................................................................................................... 87

25.4 Relay test....................................................................................................... 88

25.5 Display of the pump speed ............................................................................88

25.6 Display of the digital inputs............................................................................ 88

25.7 Limitations .....................................................................................................89

25.8 Software version............................................................................................ 90

26 Function block DRT and maximum limitation of the return temperature .......91

26.1 Operating lines ..............................................................................................91

26.2 Maximum limitation of the primary return temperature ..................................91

26.2.1 General.......................................................................................................... 91

26.2.2 Maximum limitation in heating mode ............................................................. 92

26.2.3 Maximum limitation in d.h.w. mode ...............................................................92

26.3 Maximum limitation of the secondary return temperature .............................93

26.4 Maximum limitation of the temperature differential (DRT function) ............... 94

26.4.1 Mode of operation.......................................................................................... 94

26.4.2 Purpose ......................................................................................................... 94

26.5 Integral action time of the limitation functions................................................ 94

27 Function block Various functions................................................................... 95

27.1 Operating lines ..............................................................................................95

27.2 Limitation function at contact H5 ................................................................... 95

27.3 Suppression of hydraulic creep .....................................................................96

27.3.1 Mode of operation.......................................................................................... 96

27.3.2 Mode of operation.......................................................................................... 96

27.4 Raising the reduced room temperature setpoint ...........................................96

28 Function block Operation locking functions ................................................... 98

28.1 Operating lines ..............................................................................................98

28.2 Locking settings on the software side............................................................ 98

28.3 Locking of setting level "Locking functions" on the hardware side ................98

29 Combination with PPS devices...................................................................... 99

29.1 General.......................................................................................................... 99

29.2 Combination with room unit QAW50... .......................................................... 99

29.2.1 General.......................................................................................................... 99

29.2.2 Overriding the operating mode ...................................................................... 99

29.2.3 Knob for room temperature readjustments.................................................. 100

29.2.4 Controller with operation lock ......................................................................100

29.3 Combination with room unit QAW70 ........................................................... 100

29.3.1 General........................................................................................................ 100

29.3.2 Overriding the operating mode .................................................................... 101

29.3.3 Knob for readjusting the room temperature................................................. 101

29.3.4 Impact of the individual QAW70 operating lines on the RVD240 ................101

9/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Contents 27.05.2004

Page 10

29.3.5 Controller with operation lock.......................................................................102

29.3.6 Entry of holiday periods ...............................................................................102

29.4 Room temperature sensor QAA10...............................................................102

30 Manual operation .........................................................................................103

31 Handling.......................................................................................................104

31.1 Operation .....................................................................................................104

31.1.1 General ........................................................................................................104

31.1.2 Analog operating elements ..........................................................................105

31.1.3 Digital operating elements ...........................................................................105

31.1.4 Controller in "nonoperated state" .................................................................106

31.1.5 Safety concept .............................................................................................106

31.1.6 Setting levels and access rights...................................................................106

31.2 Commissioning ............................................................................................107

31.2.1 Installation instructions.................................................................................107

31.2.2 Operating lines.............................................................................................107

31.3 Installation....................................................................................................107

31.3.1 Mounting location.........................................................................................107

31.3.2 Mounting choices .........................................................................................107

31.3.3 Electrical installation ....................................................................................108

32 Engineering..................................................................................................109

32.1 Connection terminals ...................................................................................109

32.2 Relays ..........................................................................................................110

32.3 PWM output .................................................................................................110

32.4 Lightning protection in M-bus plants ............................................................110

32.5 Connection diagrams ...................................................................................111

32.5.1 Low-voltage side ..........................................................................................111

32.5.2 Mains voltage side .......................................................................................111

33 Mechanical design .......................................................................................112

33.1 Basic design.................................................................................................112

33.2 Dimensions ..................................................................................................112

34 Technical data..............................................................................................113

10/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Contents 27.05.2004

Page 11

Heat source, heat

generation

Pumps

D.h.w. heating

Glossary

In this Basic Documentation, the following key terms are used:

Term Explanation

Heat converter Heat exchanger that, on the primary side, is con-

nected to the district heat network and that, on the

secondary side, delivers the hot water to a common flow. The flow then supplies the hot water to

several consumers that are controlled by zone

controllers, etc.

Heat exchanger Heat exchanger that delivers the heat directly to

the consumers (e.g. space heating, d.h.w. heating, etc.).

Term Explanation

Storage tank charging pump Pump that supplies tap water via the heat ex-

changer into the storage tank where it is made

available as d.h.w.

Intermediate circuit pump Pump that supplies water as a heat carrier. The

water transfers its heat via a coil or storage tank

to the d.h.w. without getting in direct contact with

it.

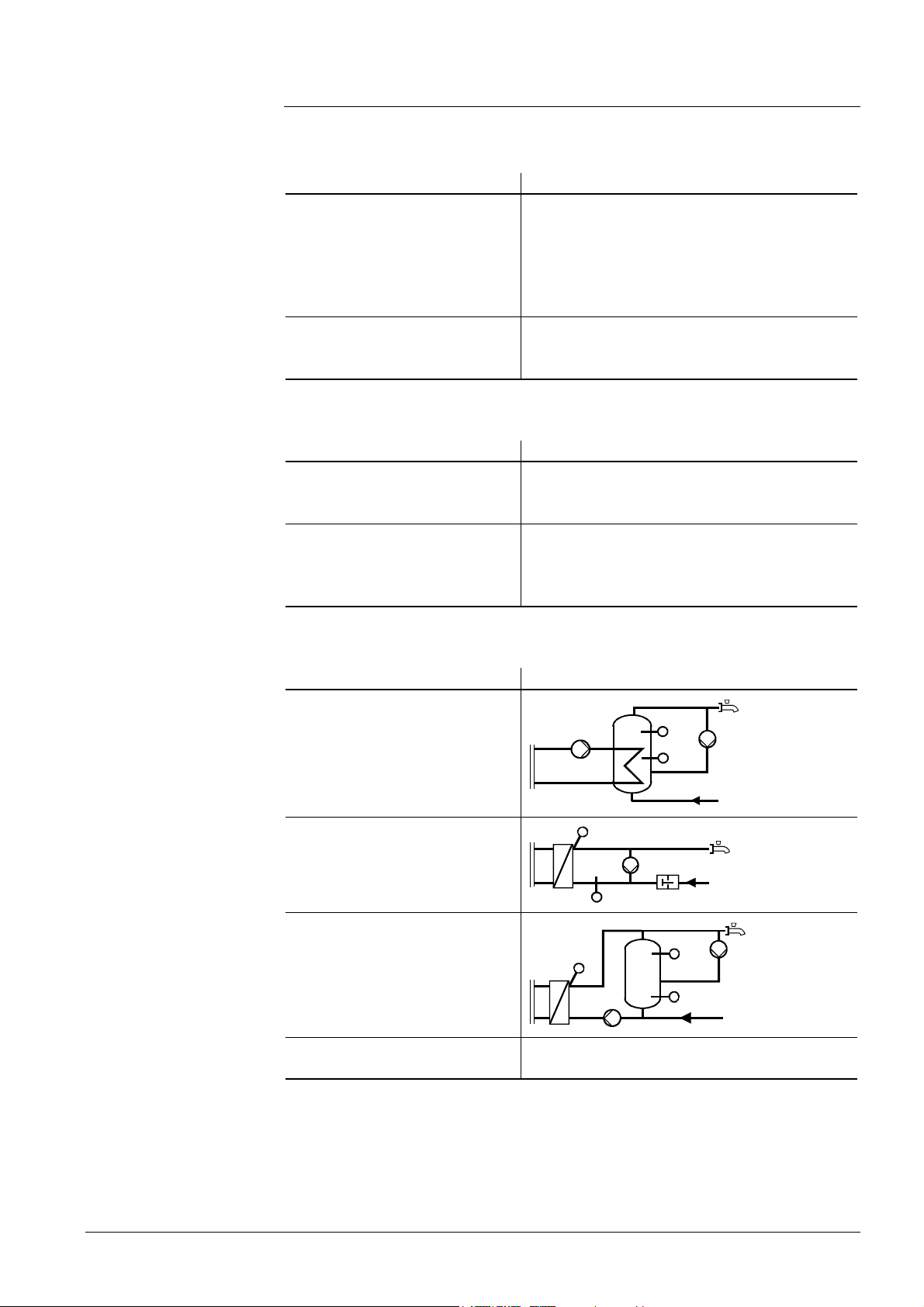

Term Explanation

Coil type storage tank

2383S3 3

Instantaneous d.h.w. heating (via

heat exchanger)

2383S3 4

Stratification storage tank

2383S3 5

Storage tanks Common term used for coil type and stratification

storage tanks.

11/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Glossary 27.05.2004

Page 12

12/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products Glossary 27.05.2004

Page 13

1 Summary

1.1 Brief description and key features

• The RVD240 is a multifunctional heating controller for controlling the flow tempera-

ture of 2 heating circuits and for controlling d.h.w. heating

• The controller’s field of use covers exclusively plants with district heat connections. It

has been designed specifically for small to medium-size residential and nonresidential buildings with 2 heating circuits

• The RVD240 has 4 heating circuit types and 11 d.h.w. plant types preprogrammed.

By combining the different plants, it is possible to configure 14 plant types. The configuration activates all functions and settings required for the respective type of plant

• In terms of control, the RVD240 is designed as a flow temperature controller. Control

can be effected in one of 5 different ways:

− Only weather-compensated control of the heating circuit flow temperatures

− Weather- and room-compensated control of the heating circuit flow temperatures

− Only room-compensated control of the heating circuit flow temperatures

− Demand-dependent control of the common heating circuit flow temperature

• In terms of d.h.w. control, the RVD240 is designed for the following types of applica-

tions:

− D.h.w. heating with coil type storage tanks

− D.h.w. heating with stratification storage tanks

− Direct d.h.w. heating via heat exchanger

− Common or separate heat exchangers for the heating circuit and d.h.w. heating

− Two-stage separation of the d.h.w. from district heating

• The RVD240 is suited for the control of 2-port and 3-port valves and pumps, includ-

ing variable speed pumps

• For the direct adjustment of the nominal room temperature setpoint, there is a setting

knob available. All the other parameters are set digitally based on the operating line

principle

• Key design features: Operating voltage AC 230 V, CE conformity, overall dimensions

to DIN 43700 (96 × 144 mm)

1.2 Type summary

The RVD240 is a compact controller and requires no accessories such as inserts, plugin modules, etc. The controller is supplied complete with base.

1.3 Equipment combinations

1.3.1 Suitable sensors

• For the flow temperatures:

Suitable are all types of temperature sensors that use a sensing element LGNi 1000. The following types are presently available:

− Strap-on temperature sensor QAD22

− Immersion temperature sensors QAE2...

For the control of the d.h.w. flow temperature (B3), it is also possible to use commercially available sensors with Pt 500 sensing elements

• For the return temperatures:

The following types of temperature sensors are presently available:

− Strap-on temperature sensor QAD22

− Immersion temperature sensors QAE2...

13/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 1 Summary 27.05.2004

Page 14

For the control of the primary return temperatures (B7, B71, B72), it is also possible to

use commercially available sensors with Pt 500 sensing elements.

• For the outside temperature:

− Outside sensor QAC22 (sensing element LG-Ni 1000)

− Outside sensor QAC32 (sensing element NTC 575)

• For the room temperature:

PPS-compatible sensors must be used. The following units are available:

− Room temperature sensor QAA10

• For the storage tank temperature:

− Cable temperature sensor QAP21.3

− Immersion temperature sensors QAE2...

1.3.2 Suitable room units

• Room units QAW50...

• Room unit QAW70

1.3.3 Suitable valve actuators

All actuators from Siemens with the following features can be used:

• Electric or electrohydraulic actuators with a running time of 10...900 seconds

• 3-position control

• Operating voltage AC 24 V...AC 230 V

1.3.4 Communication

Communication with other devices, controllers, etc., is possible:

• Via LPB, e.g. assignment of d.h.w., reception of radio signal, master / slave assign-

ments for the time switch, reception of outside temperature signal

• Via M-bus, e.g. reading setpoints and actual values, or output control for space heat-

ing

1.3.5 Documentation

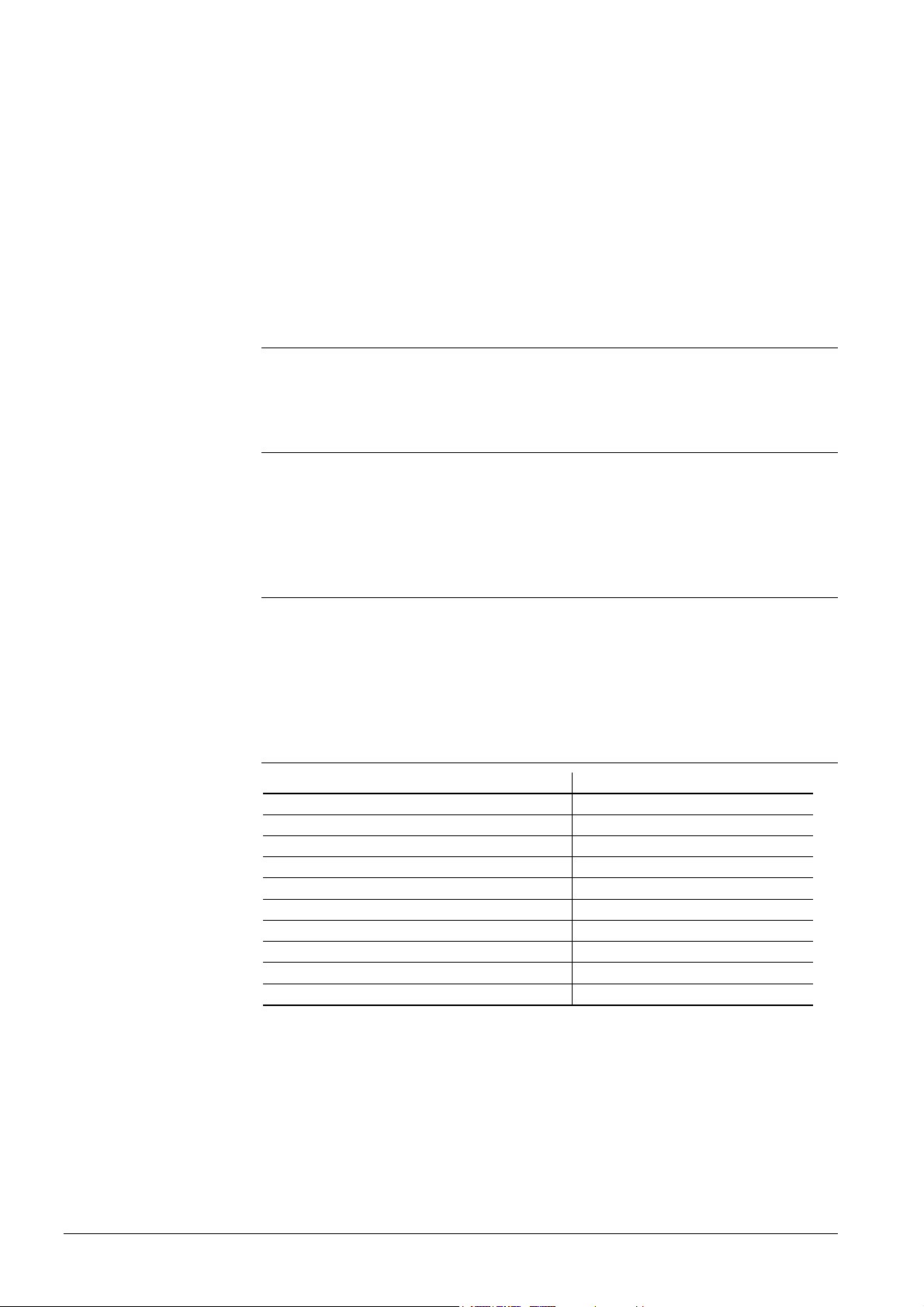

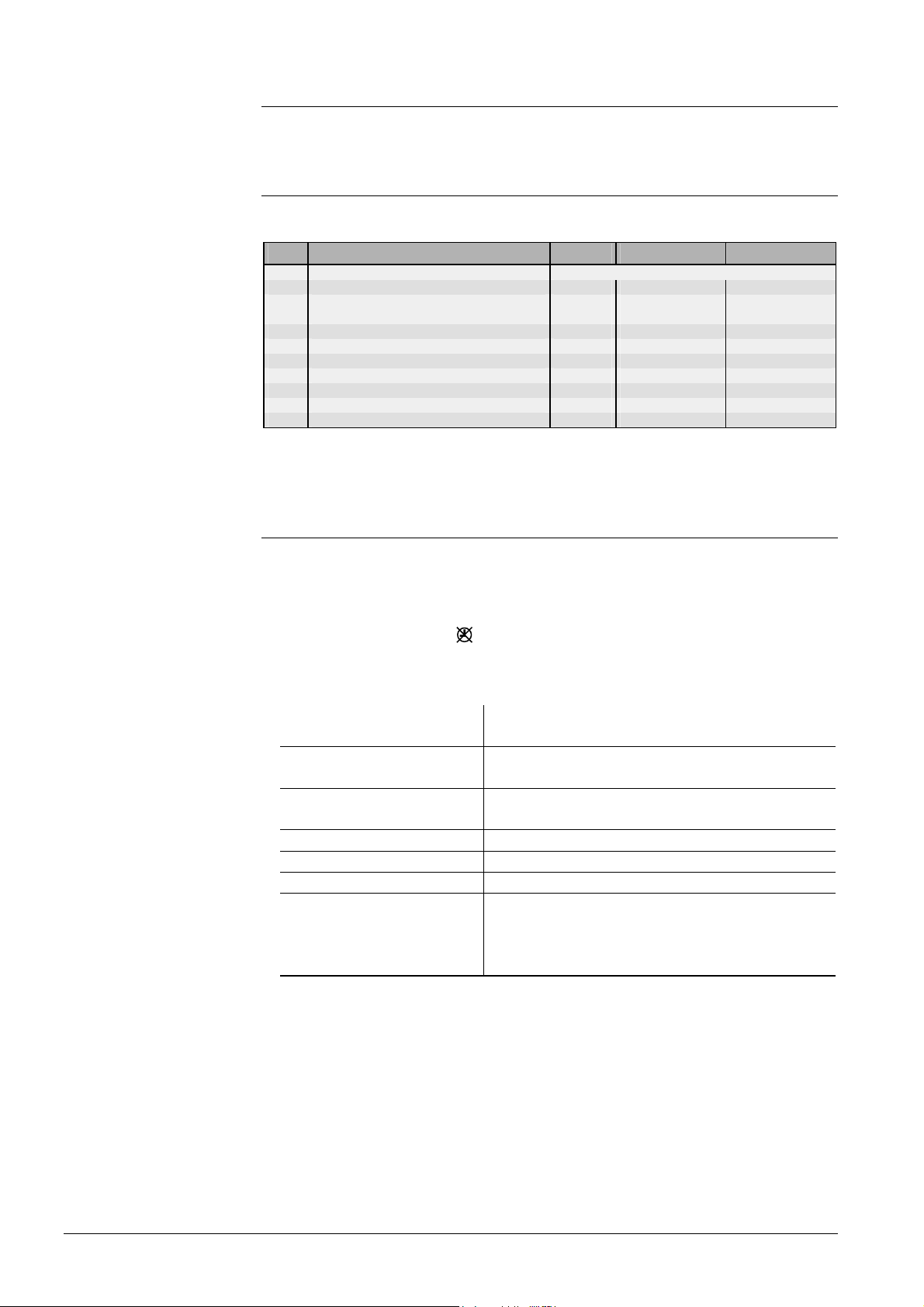

Type of documentation Classification number

Data Sheet RVD240 N2384

Operating Instructions RVD240 B2384

Installation Instructions RVD240 G2384

Data Sheet QAW50... N1635

Data Sheet QAW70 N1637

Installation Instructions QAW70 G1637

Data Sheet QAA10 N1725

Data Sheet "LPB Basic System Data" N2030

Data Sheet "LPB Basic Engineering Data" N2032

Basic Documentation M-Bus P5361

14/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 1 Summary 27.05.2004

Page 15

2 Use

2.1 Types of plant

Basically, the RVD240 is suited for the control of all types of heating plants in houses or

buildings

• that are connected to a district heat network

• that use 2 heating circuits

• in which the flow temperature of the heating circuits is controlled either weather- or

room-compensated

• in which the control of d.h.w. heating can be integrated as an option

2.2 Types of houses and buildings

Basically, the RVD240 is suited for use in all types of houses and buildings in which the

heating is controlled either weather- or room-compensated. It has been designed especially for:

• Single-family homes

• Multifamily houses

• Small to medium-size non-residential buildings

2.3 Types of heating systems

The RVD240 is suited for use with all standard heating systems, such as:

• Radiators

• Convectors

• Underfloor heating systems

• Ceiling heating systems

• Radiant panels

2.4 Heating circuit functions

The RVD240 is used if 1 or several of the following heating circuit functions is / are

required:

• Weather- or room-compensated or weather- and room-compensated flow tempera-

ture control

• Separate flow temperature control of both heating circuits

• Flow temperature control through a modulating seat or slipper valve

• Common or separate heat exchangers for the heating circuits and for d.h.w. heating

• Optimum heating up and setback of the room temperature by learning the switch-on

and switch-off time

• Quick setback with and without room temperature sensor

• ECO function: Demand-dependent switching of the heating system as a function of

the outside temperature

• 7-day program for the heating periods with a maximum of 3 heating periods per day

and varying on times

• Frost protection for the plant and the house or building

• Yearly clock

• Holiday programs

• Independent time programs for space heating and d.h.w.

• Separate time programs for each heating circuit

15/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 2 Use 27.05.2004

Page 16

• Maximum rate of flow temperature increase

• Minimum and maximum limitation of the flow temperature

• Maximum limitation of the room temperature

• Flow alarm

• Heat demand signal can be received

• Differential temperature limitation (DRT function)

• Maximum limitation of the primary return temperature, can be adjusted with 4 vari-

ables

• Limitation of power or volumetric flow by pulses

• Suppression of hydraulic creep in the primary circuit

• Weather-compensated raising of the reduced room temperature setpoint

• Remote operation via room unit

2.5 D.h.w. functions

The RVD240 is used if one or several of the following d.h.w. functions is / are required:

• Common or separate heat exchangers for the heating circuit and for d.h.w. heating

• D.h.w. heating with a coil type storage tank, with charging pump

• Direct d.h.w. heating via heat exchanger

• D.h.w. heating with coil type or stratification storage tanks, with or without mixing

valve in the intermediate circuit

• Continuous d.h.w. heating with mixing valve

• Flow switch with an adjustable load limit, child-proofing and adaptation to the season

• Own time program for the release of d.h.w.

• Optional assignment of the circulating pump to the heating circuit or the d.h.w. circuit

time program

• Protection against cooling down with d.h.w. heating via heat exchanger

• Legionella protection

• Forced d.h.w. charging

• frost protection for d.h.w.

• Selectable priority for d.h.w. heating : Absolute, shifting or parallel

• Manual d.h.w. charging outside the time program

• Maximum limitation of the d.h.w. return temperature

• Flow alarm

2.6 Auxiliary functions

The RVD240 is used if one or several of the following functions is / are required:

• Pump kick, periodic pump run

• Demand-dependent control of the common flow

• Pump overrun

• Valve kick, periodic activation of all actuators on the secondary side

• PWM output, control of a variable speed pump

• Display of parameters, actual values, operating states and fault status signals

• Alarm input

• Analog input DC 0...10 V (display, external heat demand)

• Digital input (heat meter, external heat demand, etc.)

• Flow switch (including child-proofing and adaptation to the season)

• Communication via M-bus

• Communication via LPB (Local Process Bus)

• Service functions

• Pulse lock for actuators

• Sensor test

16/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 2 Use 27.05.2004

Page 17

• Relay test

• Display of setpoint

• Display of all active limitations

• Locking of settings

• Connection of sensors for display only

17/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 2 Use 27.05.2004

Page 18

3 Fundamentals

3.1 Key technical features

The RVD240 offers 2 key technical features:

• The controller has 14 different plant types preprogrammed.

Subsection 3.1.2 shows the relevant plant diagrams.

• The settings are assigned to different setting levels each of which contains a number

of function blocks with the relevant settings

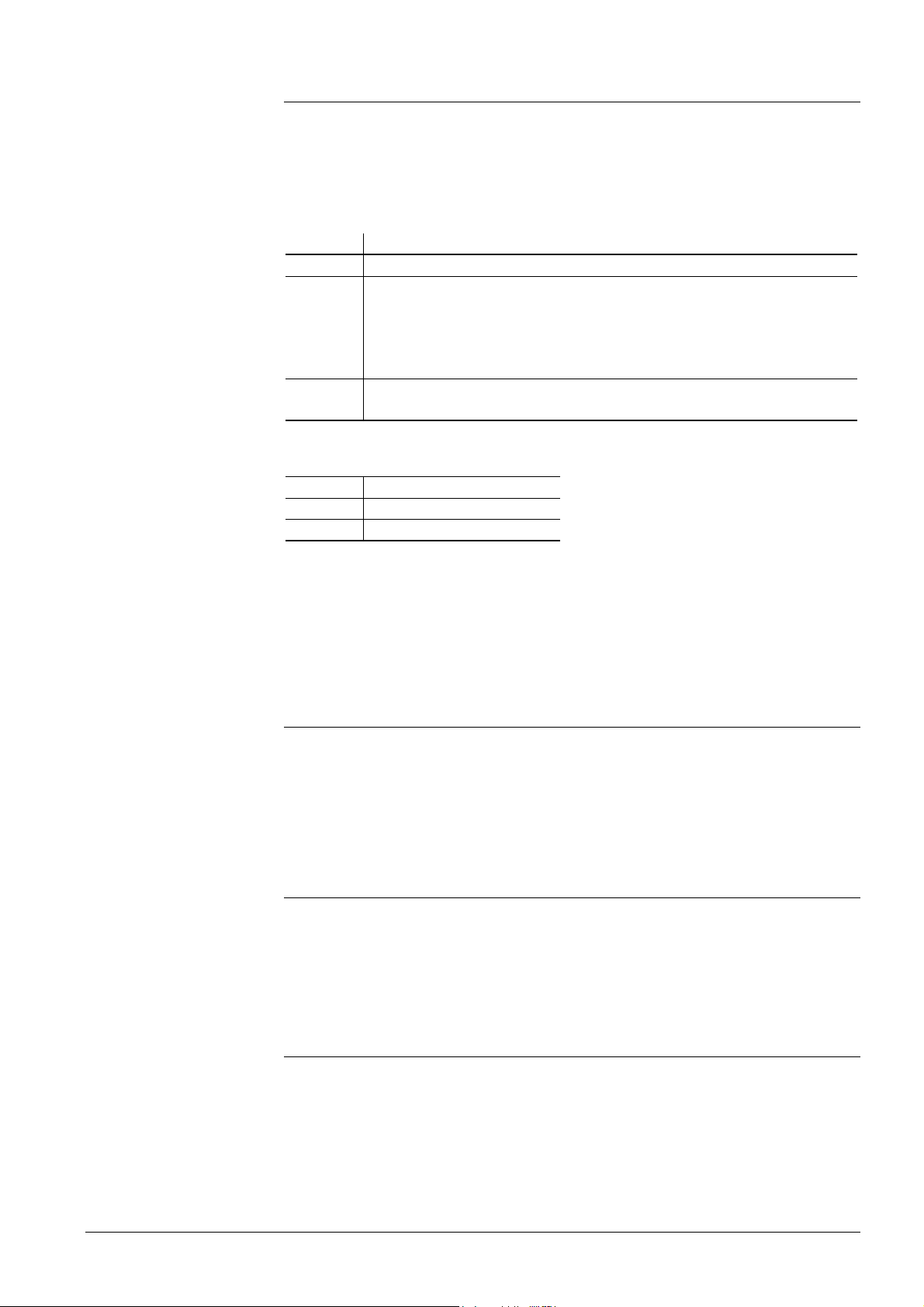

3.1.1 Function blocks

Setting levels Function block

End-user

Heating engineer

Locking functions

Space heating

Clock setting

End-user d.h.w. heating

Display of actual sensor values

Holiday settings

Indication of errors

Plant configuration

Space heating

Actuator heat exchanger

Actuator heating circuit

D.h.w. heating

D.h.w. actuator

Assignment of d.h.w.

Extra legionella functions

LPB parameter

Control functions

M-bus parameter

PPS parameter

Test and display

DRT and limitation of the return temperature

Various functions

Locking functions

For each function block, the required settings are available in the form of operating

lines. On the following pages, a description of the individual functions per block and

line is given.

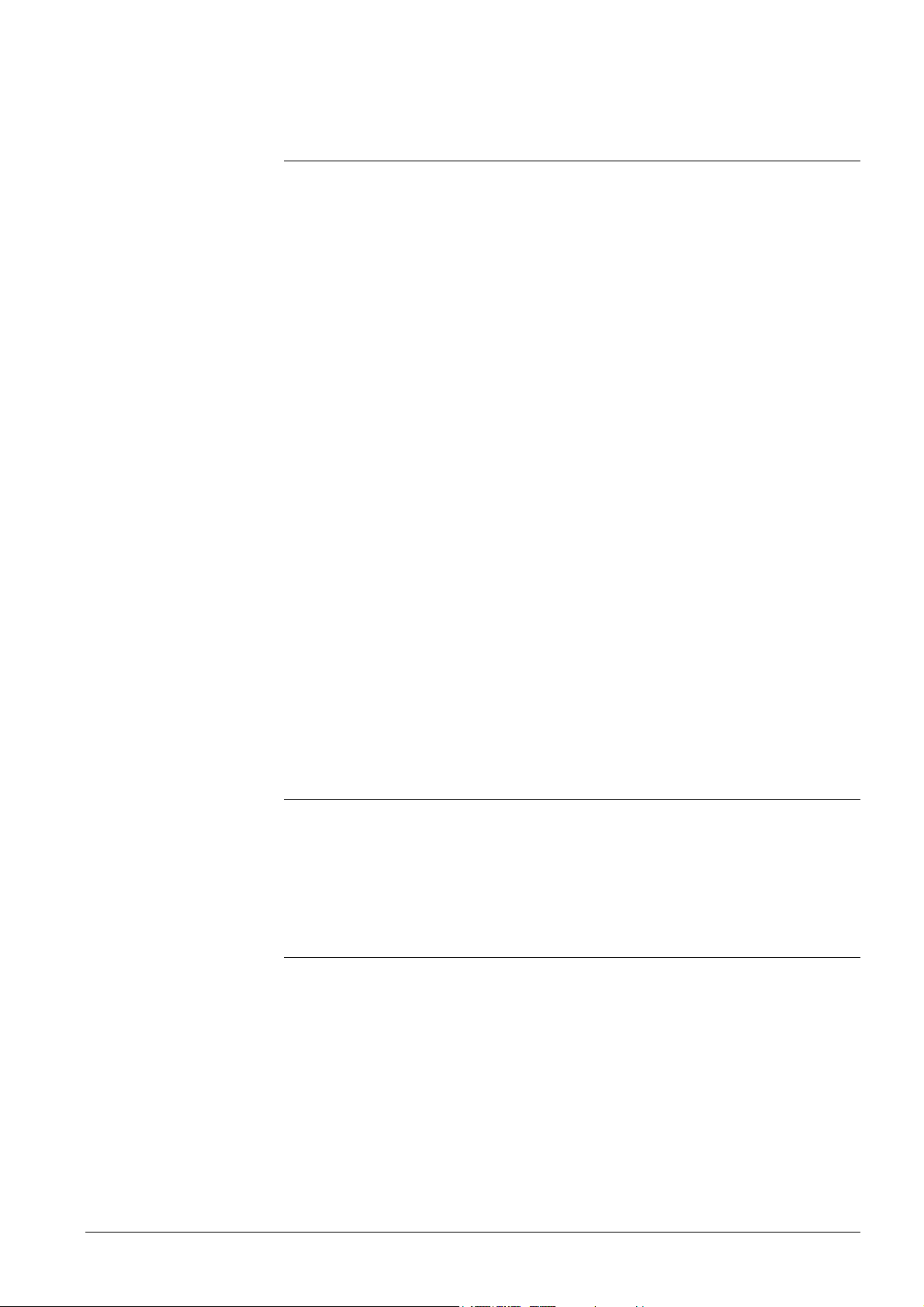

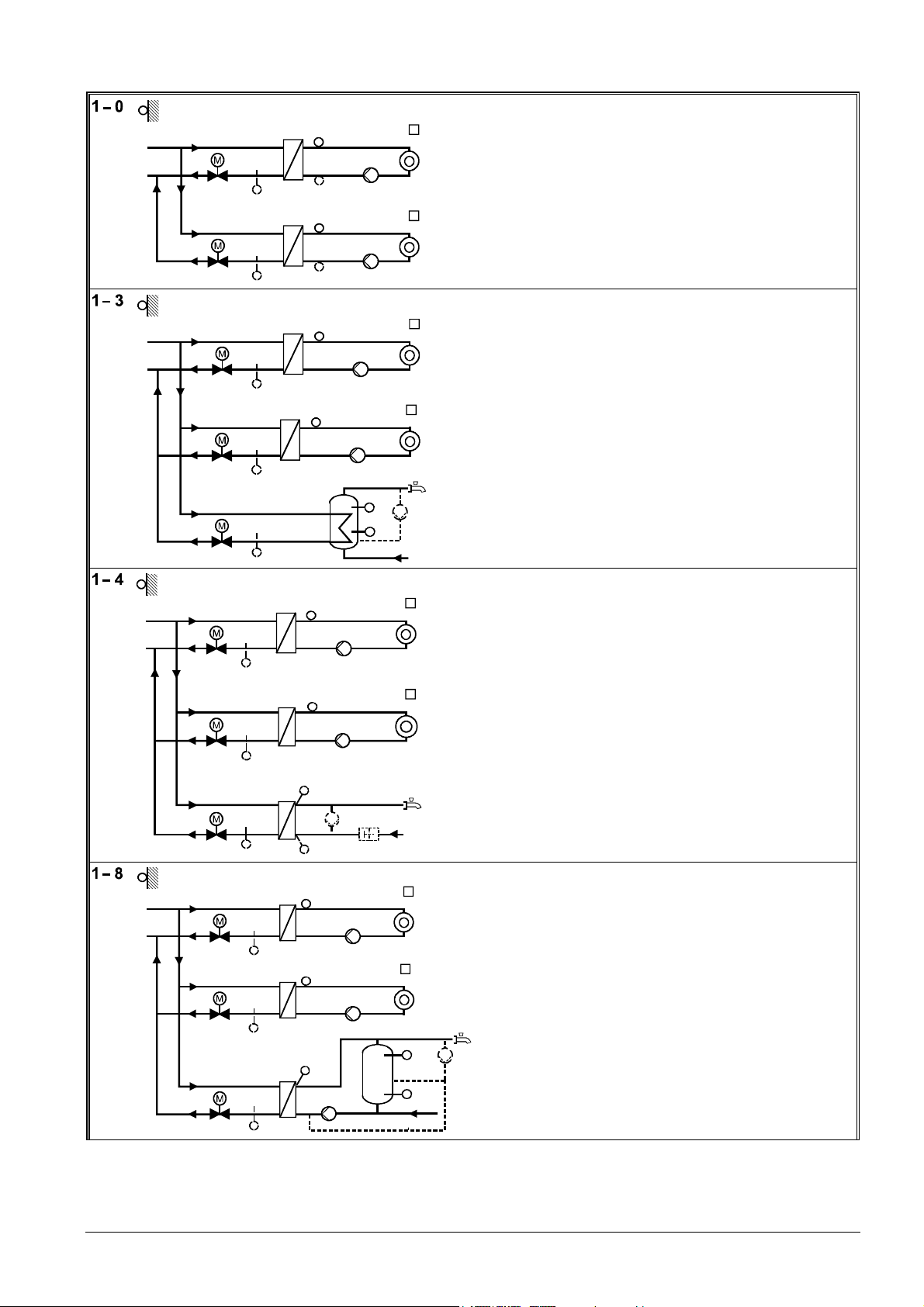

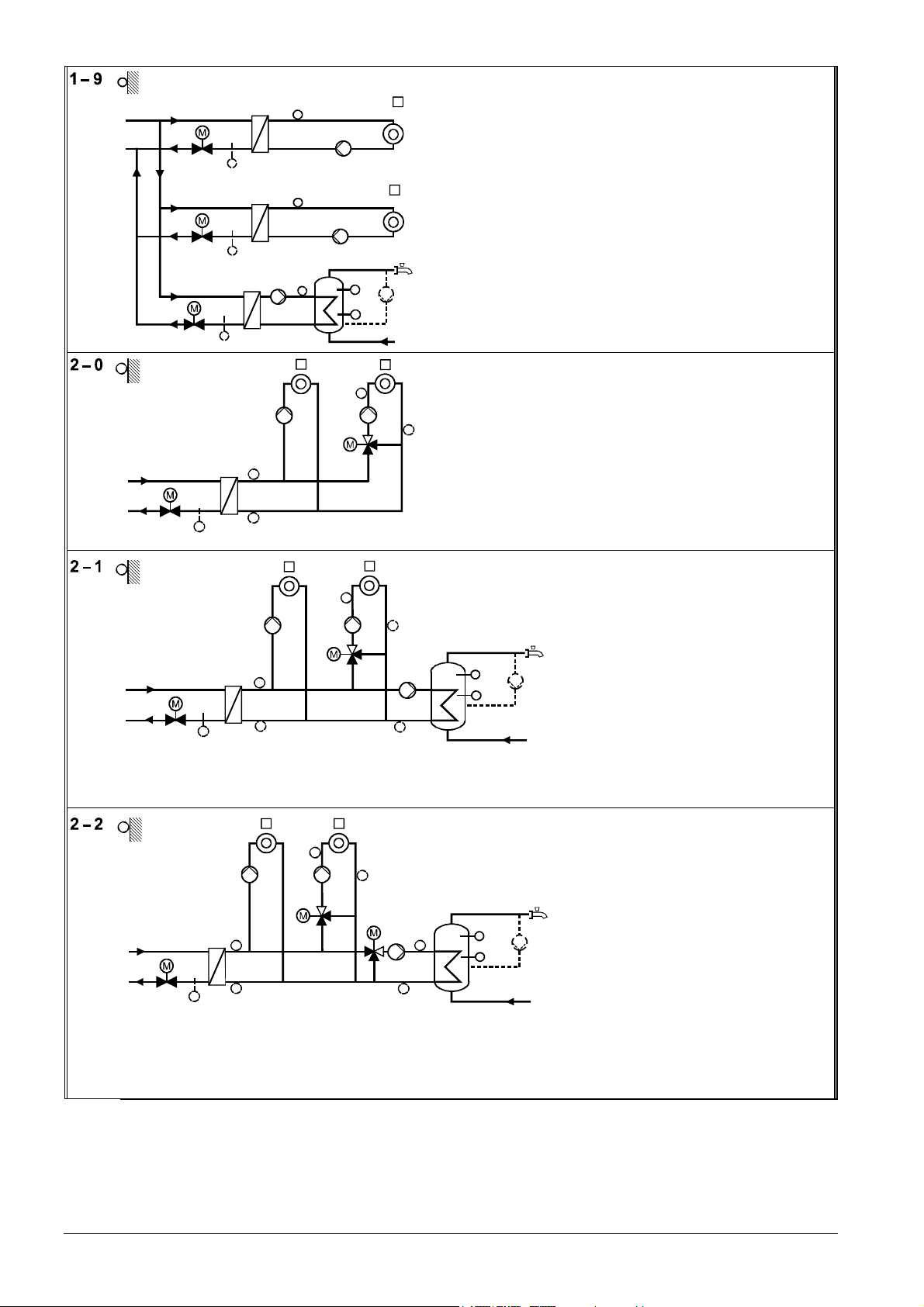

3.1.2 Plant types

The RVD240 has 14 plant types preprogrammed; the functions required for each type

of plant are ready assigned. When commissioning the installation, the relevant plant

type must be selected.

Each plant type is comprised of 2 heating circuits and 1 d.h.w. circuit. When making

use of all possible or practical combinations, the above mentioned total of 14 plant

types are available.

With the number of preprogrammed plant types available, practically all types of heating plants with district heat connection and own d.h.w. heating can be handled and

controlled.

Note on the plant

diagrams

18/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 3 Fundamentals 27.05.2004

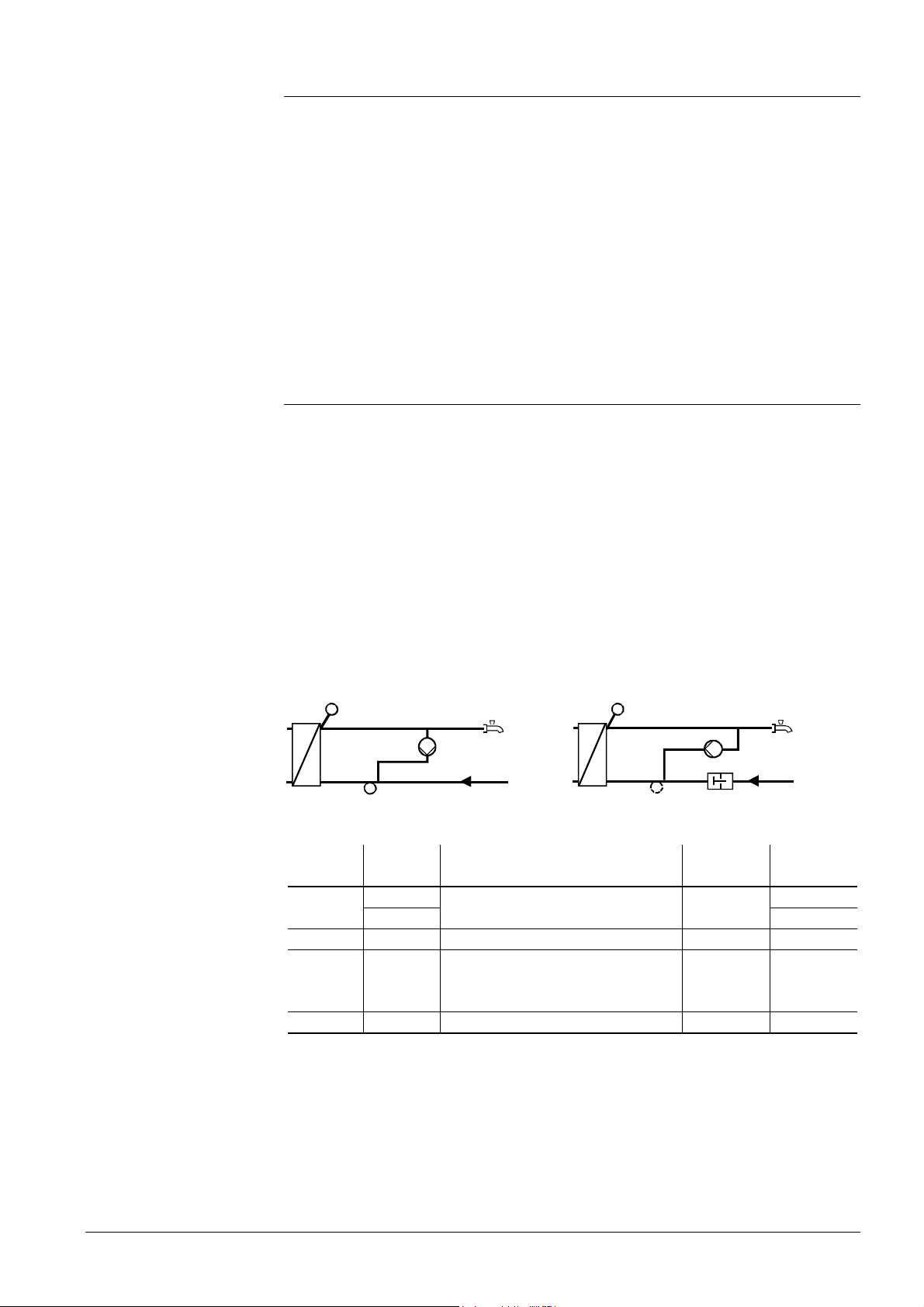

Elements shown in broken lines (sensors B7 and B71, circulating pump and flow

switch) are optional components.

Page 19

Type ref. Diagram Legend

B9

Y1

Y7 B72

B9 A6

Y1

Y7 B72

B1

B7 B71

B12

B3

B1

B7

B12

Q1

Q2

Q1

Q2

B31

B32

A6

A6

A6

Q3

A6 Room units

B1 Flow sensor heating circuit 1

B12 Flow sensor heating circuit 2

B3 Secondary return sensor heating circuit 2

B7 Primary return sensor heating circuit 1*

B71 Secondary return sensor heating circuit 1

B72 Primary return sensor heating circuit 2*

B9 Outside sensor

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Y1 2-port valve primary return heating circuit 2

2384S01

Y7 2-port valve primary return heating circuit 2

A6 Room units

B1 Flow sensor heating circuit 1

B12 Flow sensor heating circuit 2

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Primary return sensor heating circuit 1*

B71 Return sensor d.h.w. circuit

B72 Primary return sensor heating circuit 2*

B9 Outside sensor

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 Circulating pump (optional)

Y1 2-port valve primary return heating circuit 2

Y5 2-port valve d.h.w. primary return

Y7 2-port valve primary return heating circuit 2

B71

B9

Y5

Y1 B7

Y7

B72

B1

Q1

B12

Q2

B3

A6

A6

2384S 02

A6 Room units

B1 Flow sensor heating circuit 1

B12 Flow sensor heating circuit 2

B3 D.h.w. flow sensor

B32 Return sensor d.h.w.

B7 Primary return sensor heating circuit 1*

B71 Primary return sensor d.h.w. circuit

B72 Primary return sensor heating circuit 2*

B9 Outside sensor

H5 Flow switch (optional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 Circulating pump (optional)

Y1 2-port valve primary return heating circuit 2

Y5 2-port valve d.h.w. primary return

Y7 2-port valve primary return heating circuit 2

Q3

A6

A6

2384S03

A6 Room units

B1 Flow sensor heating circuit 1

B12 Flow sensor heating circuit 2

B3 D.h.w. flow sensor

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Primary return sensor heating circuit 1*

B71 Primary return sensor d.h.w. circuit

B72 Primary return sensor heating circuit 2*

B9 Outside sensor

Q Circulating pump (controlled externally, optional)

Q1 Pump heating circuit 1

B31

b)

Q

B32

a)

2384S04

Q2 Pump heating circuit 2

Q3 Storage tank charging pump

Y1 2-port valve primary return heating circuit 2

Y5 2-port valve d.h.w. primary return

Y7 2-port valve primary return heating circuit 2

* Suppression of hydraulic creep

H5

Q1

B9

Y5

Y1

B71

B7

B32

B1

B12

Y7

B72

Q2

B3

B71

Y5

Q3

19/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 3 Fundamentals 27.05.2004

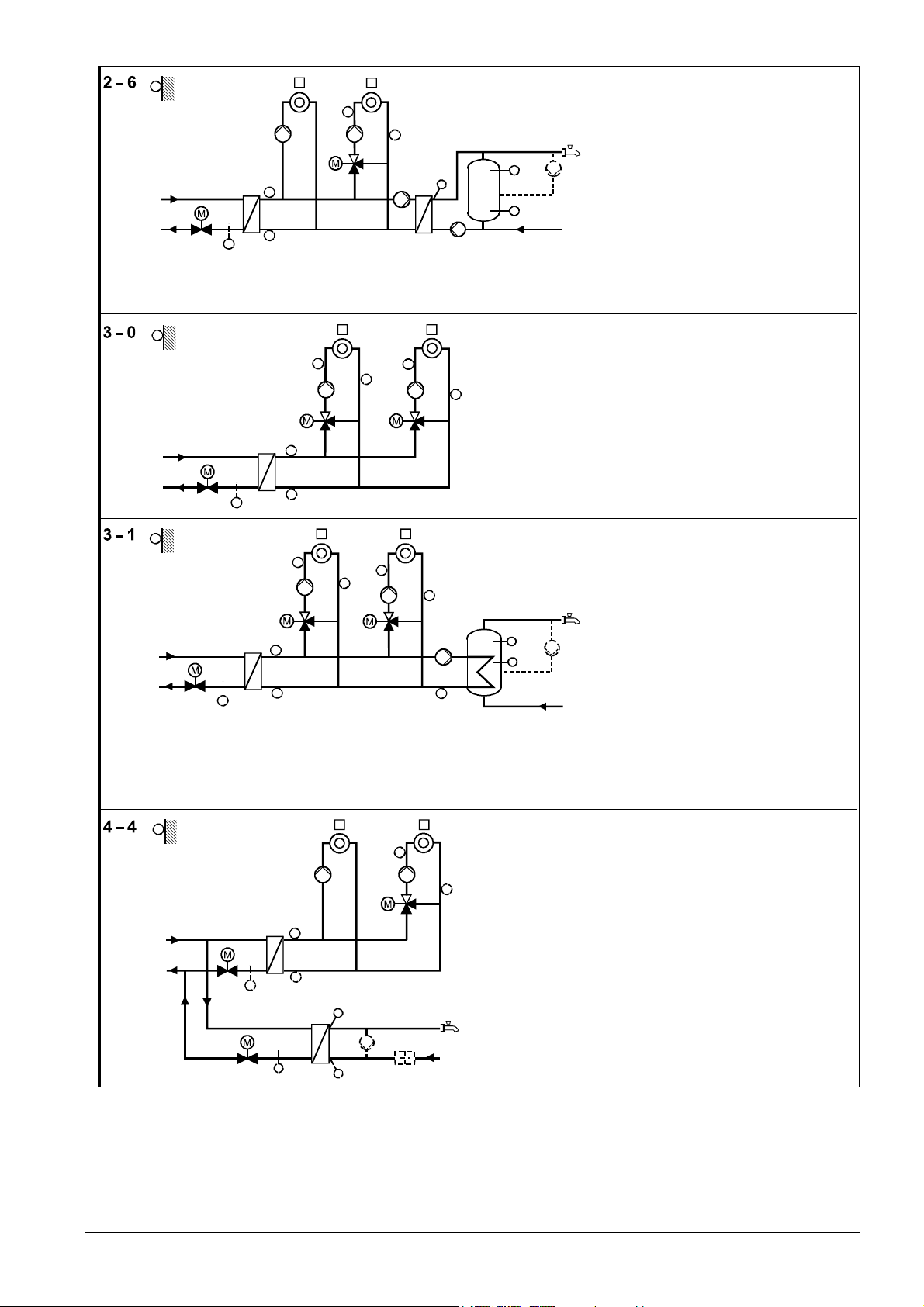

Page 20

B9

B9

Y1

Y1

Y7 B72

Y5

B71

B7

B7

Q1

B1

B71

Q3

B1

B12

B3

A6

Y5

Q1

Q2

B12

Q2

B31

B32

A6

A6

A6

Q

2384S05

B72

A6 Room units

B1 Flow sensor heating circuit 1

B12 Flow sensor heating circuit 2

B3 D.h.w. flow sensor

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Primary return sensor heating circuit 1*

B71 Primary return sensor d.h.w. circuit

B72 Primary return sensor heating circuit 2*

B9 Outside sensor

Q Circulating pump (controlled externally, op-

tional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 D.h.w. intermediate circuit pump

Y1 2-port valve primary return heating circuit 2

Y5 2-port valve d.h.w. primary return

Y7 2-port valve primary return heating circuit 2

A6 Room units

B1 Common flow sensor

B12 Flow sensor heating circuit 2

B7 Common primary return sensor*

B71 Common secondary return sensor

B72 Return sensor heating circuit 2

B9 Outside sensor

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

2384S06

Y1 2-port valve common primary return

Y5 Mixing valve heating circuit 2

A6

B72

B9

Q1

A6

B12

Q2

Y5

Y1

B7

B1

B71

A6

A6

Q3

B71

B12

B9

Q1

Q2

B72

Y7

Y5

B1

B7

Y1

a) Circulating pump feeding water into the heat exchanger’s return

b) Circulating pump feeding water into the storage tank

B71

Q3

B3

B71

B31

B32

B31

B32

A6 Room units

B1 Common flow sensor

2384S07

B12 Flow sensor heating circuit 2

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Common primary return sensor*

B71 Sensor common secondary return or return

sensor d.h.w. circuit (only if Q3 is speed-

K6

2384S08

Q

controlled)

B72 Return sensor heating circuit 2

B9 Outside sensor

K6 Circulating pump (optional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 D.h.w. intermediate circuit pump

Y1 2-port valve common primary return

Y5 Mixing valve heating circuit 2

A6 Room units

B1 Common flow sensor

B12 Flow sensor heating circuit 2

B3 D.h.w. flow sensor

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Common primary return sensor*

B71 Sensor common secondary return or return

sensor d.h.w. circuit (only if Q3 is speed-

controlled)

B72 Return sensor heating circuit 2

B9 Outside sensor

Q Circulating pump (controlled externally, op-

tional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 D.h.w. intermediate circuit pump

Y1 2-port valve common primary return

Y5 Mixing valve d.h.w. circuit

Y7 Mixing valve heating circuit 2

* Suppression of hydraulic creep

20/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 3 Fundamentals 27.05.2004

Page 21

A6

A6

B12

B9

Q1

B1

Q2

Y5

B72

Q3

B3

B31

B32

Y1

B7

B71

Q4

A6A6

B9

B12

Q1

Y5

B72

Y7

Q2

B3

B71

B1

Y1

B9

B7

Y5

B12

Q1

B1

B71

A6

A6

B3

B72

Q2

Y7

B71

Q3

2384S10

B31

B32

B7

Y1

B9

B71

Q1

A6

B12

Q2

B71

A6

B71

Y7

B1

Y1

B7

B71

B3

Q3

Y5

B72

B32

H5

2384S12

A6 Room units

B1 Common flow sensor

2384S09

B12 Flow sensor heating circuit 2

B3 D.h.w. flow sensor

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Common primary return sensor*

K6

B71 Common secondary return sensor

B72 Return sensor heating circuit 2

B9 Outside sensor

K6 Circulating pump (optional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 D.h.w. intermediate circuit pump

Q4 Storage tank charging pump

Y1 2-port valve common primary return

Y5 Mixing valve heating circuit 2

A6 Room units

B1 Common flow sensor

B12 Flow sensor heating circuit 1

B3 Flow sensor heating circuit 2

B7 Common primary return sensor*

B71 Sensor common secondary return or return

sensor heating circuit 2

B72 Return sensor heating circuit 1

B9 Outside sensor

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Y1 2-port valve common primary return

Y5 Mixing valve heating circuit 1

Y7 Mixing valve heating circuit 2

A6 Room units

B1 Common flow sensor

2384S1 1

B12 Flow sensor heating circuit 1

B3 Flow sensor heating circuit 2

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Common primary return sensor*

B71 Sensor common secondary return or return

Q

sensor heating circuit 2 or return sensor

d.h.w. circuit (only if Q3 is speed-controlled)

B72 Return sensor heating circuit 1

B9 Outside sensor

Q Circulating pump (controlled externally, op-

tional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 D.h.w. intermediate circuit pump

Y1 2-port valve common primary return

Y5 Mixing valve heating circuit 1

Y7 Mixing valve heating circuit 2

A6 Room units

B1 Sensor common heating circuit flow

B12 Flow sensor heating circuit 2

B3 Flow sensor d.h.w. circuit

B32 Return sensor d.h.w. circuit

B7 Sensor common primary return heating cir-

cuit*

B71 Sensor common secondary return heating

circuit or return sensor heating circuit 2

B72 Return sensor d.h.w. circuit

B9 Outside sensor

H5 Flow switch (optional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 Circulating pump (optional)

Y1 2-port valve common heating circuit flow

Y5 2-port valve d.h.w. primary return

Y7 Mixing valve heating circuit 2

* Suppression of hydraulic creep

21/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 3 Fundamentals 27.05.2004

Page 22

A6A6

Q3

B3

Y7

B12

Y7

B12

Q2

Q2

a)

B31

B32

b)

B31

B32

B71

Q

2384S13

A6A6

B71

Q

2384S14

B9

Q1

B1

Y1

B7

B71

B3

Y5

B72

B9

Q1

B1

Y1

Y5

a) Circulating pump feeding water into the heat exchanger’s return

b) Circulating pump feeding water into the storage tank

B7

B71

Q3

B72

A6 Room units

B1 Sensor common heating circuit flow

B12 Flow sensor heating circuit 2

B3 Flow sensor d.h.w. circuit

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Sensor common primary return heating circuit*

B71 Sensor common secondary return heating circuit or

return sensor heating circuit 2

B72 Return sensor primary d.h.w. circuit

B9 Outside sensor

Q Circulating pump (controlled externally, optional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 Storage tank charging pump

Y1 2-port valve common heating circuit flow

Y5 2-port valve d.h.w. primary return

Y7 Mixing valve heating circuit 2

A6 Room units

B1 Sensor common heating circuit flow

B12 Flow sensor heating circuit 2

B3 Flow sensor d.h.w. circuit

B31 Storage tank sensor 1

B32 Storage tank sensor 2

B7 Sensor common primary return heating circuit*

B71 Sensor common secondary return heating circuit or

return sensor heating circuit 2

B72 Return sensor primary d.h.w. circuit

B9 Outside sensor

Q Circulating pump (controlled externally, optional)

Q1 Pump heating circuit 1

Q2 Pump heating circuit 2

Q3 D.h.w. intermediate circuit pump

Y1 2-port valve common heating circuit flow

Y5 2-port valve d.h.w. primary return

Y7 Mixing valve heating circuit 2

* Suppression of hydraulic creep

3.2 Operating modes

3.2.1 Heating circuit control

The RVD240 offers the following operating modes:

Automatic operation

• Automatic heating operation, changeover between the nominal room

temperature and the reduced room temperature according to the time

program

• Demand-dependent switching of the heating system as a function of the

outside temperature while giving consideration to the building's thermal

inertia (ECO function)

• Remote operation via room unit (optional)

• Frost protection is ensured

Continuous operation

• Heating mode with no time program

• Heating to the temperature adjusted with the setting knob

• Automatic ECO function inactive

• Frost protection is ensured

Standby

• Heating operation at the frost level

• Frost protection is ensured

22/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 3 Fundamentals 27.05.2004

Page 23

3.2.2 D.h.w. heating

• ON (button is lit): d.h.w. heating takes place independent of the heating

circuit’s operating mode and control (no d.h.w. heating during holiday periods)

• OFF (button dark): no d.h.w. The circulating pump switches off. Frost

protection is ensured

3.2.3 Manual operation

• No control

• All pumps are in operation

• The 2-port valve in the primary circuit can be manually adjusted with set-

ting buttons

For more detailed information, refer to chapter 30 "Manual operation".

23/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 3 Fundamentals 27.05.2004

Page 24

4 Acquisition of measured values

4.1 General

In the event of a faulty sensor, the RVD240 always attempts to maintain the required

comfort level, if necessary at the expense of certain heat losses. But this will not cause

any damage.

In the case of severe faults, which do not allow the RVD240 to perform its control functions, an error message will be generated. The controller displays this as Er (Error).

4.2 Flow temperature heating circuit

4.2.1 Types of sensors

Suitable are all types of temperature sensors that use a sensing element LG-Ni 1000.

The following types are presently available:

• Strap-on temperature sensor QAD22

• Immersion temperature sensors QAE2...

4.2.2 Handling faults

A flow temperature sensor with a short-circuit or open-circuit always triggers an error

message, irrespective of the type of plant. If that occurs, the heating circuit pump will be

activated and the primary mixing valve driven to the fully closed position in the case of

a mixing circuit, and the heating circuit pump will be deactivated in the case of a pump

circuit.

In all cases, a fault status signal will be generated. This means:

• The controller’s LCD displays Er

• When querying the flow temperature on the QAW70 room unit (if present), its display

shows --- if there is a short-circuit or open-circuit

Note

4.3 Outside temperature (B9)

4.3.1 Types of sensors

The following types of sensors can be used:

• Outside sensor QAC22 with a sensing element LG-Ni 1000

• Outside sensor QAC32 with a sensing element NTC 575, for connection to terminal

B9

The controller automatically identifies the type of sensor used.

The range of use is –50...+50 °C.

The outside temperature can also be acquired via LPB (refer to subsection 20.2.4).

4.3.2 Handling faults

If there is a short-circuit or open-circuit in the measuring circuit of outside sensor

QAC22 or QAC32, the controller will respond as follows:

• Plants with a room temperature sensor:

The controller switches over to room-compensated control

• Plants without a room temperature sensor:

The controller operates with a fixed outside temperature of 0 °C

24/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 4 Acquisition of measured values 27.05.2004

Page 25

An error message will be generated only when there is no actual room temperature

value available. This is the case when no room unit is used or when the room temperature measuring circuit is faulty.

The error message means:

• The controller’s LCD displays Er

• When querying the outside temperature on the QAW70 room unit (if present), its

display shows --- if there is a short-circuit or open-circuit

4.4 Room temperature (A6)

4.4.1 Types of sensors

The room temperature is acquired via PPS (point-to-point interface); only a unit with an

appropriate output signal can be connected to it. The following types of units can be

used:

• Room unit QAW50...

• Room unit QAW70

• Room temperature sensor QAA10

Its sensing range is 0...32 °C

If a room unit or room sensor is used in both heating circuits, one of the 2 devices must

be addressable. This means:

• The first room unit can be a QAA10, QAW50, QAW50.03 or QAW70

• The second room unit must then be a QAW50.03 or QAW70, addressed with 2

4.4.2 Handling faults

A short-circuit in the measuring circuit leads to an error message.

An open-circuit in the measuring circuit does not lead to an error message since it is

not possible to have a room unit connected.

If the room unit detects a fault in the room temperature measurement (short-circuit or

open-circuit), an appropriate signal will be passed to the RVD240.

4.4.3 Room model

The RVD240 uses a room model for each heating circuit that is ready integrated in the

controller. It simulates the room temperature based on the progression of the outside

temperature and the type of building construction, using a defined attenuation. In plants

with no room temperature measurement, the room model ensures optimum start control.

4.5 D.h.w. temperature (B3)

4.5.1 Measured variable

With all types of d.h.w. plants, the temperature of the d.h.w. flow is acquired at input

B3.

4.5.2 Types of sensors

The following types of sensors can be used:

• All types of sensors from HVAC Products with a sensing element LG-Ni 1000. Suited

for d.h.w. applications is the immersion temperature sensor QAE2... . Its range of

use is 0...130 °C

25/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 4 Acquisition of measured values 27.05.2004

Page 26

• Commercially available sensors using a sensing element Pt 500. Its range of use is

0...180 °C

The controller automatically identifies the type of sensor used.

4.5.3 Handling faults

If there is a malfunction (short-circuit or open-circuit), an error message will be delivered.

In the event of fault, the plant responds as follows, depending on the type of d.h.w.

actuating device used:

• The d.h.w. intermediate circuit pump will be deactivated

• The mixing valve will be fully closed

• If pump charging is in progress, it will be stopped by deactivating the storage tank

charging pump

When querying the d.h.w. temperature on the QAW70 room unit (if present), its display

shows --- in both cases, if there is a short-circuit or open-circuit.

4.6 D.h.w. storage tank temperature (B31)

4.6.1 Measured variable

The storage tank temperature is always acquired at input B31. Depending on the type

of plant, it is possible to use a second storage tank sensor (B32).

4.6.2 Types of sensors

The type of sensor is the QAE22... immersion sensor with a sensing element LGNi 1000.

Thermostats cannot be used.

4.6.3 Handling faults

In the event of a short-circuit or open-circuit, the controller first attempts to use the second sensor. If no second sensor is available, an error message will be delivered

4.7 D.h.w. storage tank or return temperature

(B32)

4.7.1 Measured variable

Depending on the type of plant, input B32 is used for acquiring the

• secondary return temperature in the d.h.w. circuit (plant types x–4)

• storage tank temperature (other plant types)

4.7.2 Types of sensors

The type of sensor is the QAE22... immersion sensor with a sensing element LGNi 1000.

Thermostats cannot be used.

26/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 4 Acquisition of measured values 27.05.2004

Page 27

4.7.3 Handling faults

• When used as a storage tank temperature sensor:

In the event of a short-circuit or open-circuit, the controller first attempts to use the

second sensor. If no second sensor is available, an error message will be delivered

• When used as a secondary return temperature sensor:

If there is a short-circuit in the measuring circuit, an appropriate error message will

be delivered

4.8 Return temperature (B7, B71 and B72)

4.8.1 Measurement

Depending on the type of plant, the return temperature (both primary and secondary) is

fed to input B7, B71 or B72.

With plant types no. 2–x and 3–x, the primary return temperature at input B7 is passed

on via LPB; with plant types no. 0–x, it is input B72.

4.8.2 Types of sensors

The following types of sensors can be used:

• All types of sensors from HVAC Products with a sensing element LG-Ni 1000. Suited

for d.h.w. applications is the immersion temperature sensor QAE2... . Its sensing

range is 0...130 °C

• Commercially available immersion temperature sensors with a sensing element

Pt 500

The sensing range of all types is 0...180 °C.

The controller automatically identifies the type of sensor used.

Primary return temperature sensor

Secondary return temperature sensor

4.8.3 Handling faults

In the event of a faulty primary return temperature sensor (short-circuit or open-circuit),

an error message will be delivered when the maximum limitation of the primary return

temperature or the differential temperature limitation function has been activated.

• In that case, the controller’s LCD shows Er

• If maximum limitation of the secondary return temperature is activated (by making an

entry on operating line 177; lowering to the primary limit value), no error message

will be delivered on purpose

In the event of a faulty secondary return temperature sensor (short-circuit or opencircuit), an error message will be delivered when the maximum limitation of the primary

and secondary return temperature or the differential temperature limitation function has

been activated.

In that case, the controller’s LCD shows Er.

27/126

Siemens Building Technologies Basic documentation RVD240 CE1P2384en

HVAC Products 4 Acquisition of measured values 27.05.2004

Page 28

5 Function block Space heating

This function block contains settings and readouts that are intended for the end-user.

5.1 Operating lines

The buttons for selecting the operating lines and for changing settings are described in

section 31.1 "Operation ".

Line Function, parameter Unit Factory setting Range

1 Current room temperature setpoint Display function

2 Reduced room temperature setpoint °C 14 variable

3 Setpoint for frost protection / holiday mode °C 8 8...variable

5 Heating curve slope 15 2.5...40

6 Weekday for entering the heating program Current weekday 1…7, 1-7

7 Start of heating period 1 hh:min 06:00 --:-- / 00:00…24:00

8 End of heating period 1 hh:min 22:00 --:-- / 00:00…24:00

9 Start of heating period 2 hh:min --:-- --:-- / 00:00…24:00

10 End of heating period 2 hh:min --:-- --:-- / 00:00…24:00

11 Start of heating period 3 hh:min --:-- --:-- / 00:00…24:00

12 End of heating period 3 hh:min --:-- --:-- / 00:00…24:00

Notes on settings and explanations on every function block are given in the descriptions of the individual functions.

5.2 Settings and displays

• The nominal room temperature setpoint is adjusted with the setpoint knob. Its scale

is calibrated in °C room temperature. The room temperature will be maintained at the

adjusted setpoint:

− In automatic operation during the heating periods

− In continuous operation always

• On operating line 1, the LCD shows the current room temperature setpoint of each

heating circuit Depending on the operating mode and the operating state, the room

temperature setpoint can be:

Operating mode and operating state

Heating to the nominal setpoint

Heating to the reduced setpoint

Continuous operation Adjustment made with the setpoint knob

Quick setback Reduced setpoint (setting operating line 2)

Frost protection Setpoint for frost protection (setting operating line 3)

OFF by ECO • During heating periods: adjustment made with

• The reduced room temperature setpoint of each heating circuit is to be set sepa-

rately on operating line 2; at the top, the setting range is limited by the nominal set-

point; at the bottom, by the setpoint for frost protection. This is the setpoint main-

tained outside the heating periods

• The setpoint for frost protection of each heating circuit is to be set separately on

operating line 3; the setting range is from 8 °C (fixed value) to the adjusted reduced

setpoint. Hence, this frost protection acts as frost protection for the house or building.

At the same time, this setting represents the setpoint for the holiday mode. A holiday

program can be entered either on the controller or on the QAW70 room unit. For

Displayed setpoint

Adjustment made with the setting knob (incl. the

readjustment made on the room unit)

Reduced setpoint (setting operating line 2)

the setting knob (incl. the readjustment made on

the room unit)

• Outside heating periods: Reduced setpoint

28/126