Page 1

Edition 1.3

Controller series B

CE1P2374E

19.04.2001

Siemens Building Technologies

Landis & Staefa Division

RVA63.280, RVA53.280

Boiler and Heating Circuit Controllers

Basic Documentation

Page 2

2/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis &Staefa Division 19.04.2001

Page 3

3/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division Summary 19.04.2001

Contents

1 Summary.........................................................................................................8

1.1 Brief description...............................................................................................8

1.2 Features ..........................................................................................................8

1.3 Range of products.........................................................................................10

1.4 Field of use....................................................................................................11

1.5 Product liability ..............................................................................................11

2 Handling ........................................................................................................12

2.1 Installation .....................................................................................................12

2.1.1 Regulations for installation ............................................................................12

2.1.2 Mounting location ..........................................................................................12

2.1.3 Mounting procedure.......................................................................................12

2.1.4 Required cut-out............................................................................................14

2.1.5 Orientation.....................................................................................................14

2.2 Electrical installation......................................................................................15

2.2.1 Regulations for installation ............................................................................15

2.2.2 wiring.............................................................................................................15

2.3 Commissioning..............................................................................................17

2.3.1 Functional checks..........................................................................................17

2.4 Parameter settings for the end-user..............................................................21

2.4.1 Overview of end-user parameters.................................................................22

2.5 Parameter settings for the heating engineer .................................................24

2.5.1 Overview of heating engineer parameters ....................................................25

2.6 Parameter settings for the OEM....................................................................29

2.6.1 Overview of OEM parameters.......................................................................30

2.7 Operation.......................................................................................................32

2.7.1 Operating elements.......................................................................................32

2.8 Operational faults ..........................................................................................34

1 Description of end-user settings....................................................................36

User interface................................................................................................................36

1.1 Operating modes of heating circuit................................................................36

1.2 Operating mode of d.h.w. heating .................................................................38

1.3 Nominal room temperature setpoint..............................................................39

1.3.1 Temperature adjustment via room unit..........................................................40

1.4 Heating circuit selection button .....................................................................41

1.5 Chimney sweep.............................................................................................42

1.6 Manual operation...........................................................................................43

Setting the clock............................................................................................................44

1.7 Time of day....................................................................................................44

1.8 Weekday .......................................................................................................44

1.9 Date (day, month)..........................................................................................45

1.10 Year...............................................................................................................45

Time switch programs 1 and 2 ......................................................................................46

1.11 Pre-selection of weekday: for time switch programs 1 and 2 ........................46

1.12 Switching times of time switch programs 1 and 2.........................................48

Time switch program 3 (d.h.w.) .....................................................................................49

1.13 Preselection of weekday for time switch program 3 (d.h.w.).........................49

1.14 Switching times of time switch program 3 (d.h.w.) ........................................50

D.h.w. values.................................................................................................................51

Page 4

4/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division Summary 19.04.2001

1.15 Nominal setpoint of d.h.w. temperature (TBWw)...........................................51

Heating circuits ..............................................................................................................52

1.16 Reduced setpoint of room temperature (TRRw)............................................52

1.17 Frost protection setpoint of room temperature (TRF)....................................53

1.18 Summer / winter changeover temperature HC1 and HC2 (THG)..................54

1.19 Slope of heating curve (S) .............................................................................56

Display of actual values.................................................................................................58

1.20 Actual value of room temperature (TRx)........................................................58

1.21 Actual value of outside temperature (TAx) ....................................................58

Display of burner data....................................................................................................59

1.22 Burner hours run stage 1 (tBR1)....................................................................59

1.22.1 Counting the hours run ..................................................................................59

1.22.2 Average burner running time .........................................................................59

1.23 Burner hours run stage 2 (tBR2)....................................................................60

1.23.1 Counting the hours run ..................................................................................60

1.24 Number of burner starts stage 1....................................................................60

1.25 Number of burner starts stage 2....................................................................61

Maintenance ..................................................................................................................62

1.26 Standard times...............................................................................................62

Holidays 63

1.27 Holiday period................................................................................................63

1.28 Beginning and end of holiday period .............................................................63

1.29 Indication of BMU error code.........................................................................64

1.30 Indication of faults..........................................................................................65

2 Description of heating engineer settings........................................................67

Service values................................................................................................................67

2.1 Output test.....................................................................................................67

2.2 Input test........................................................................................................68

2.3 Display of plant type ......................................................................................69

Actual values..................................................................................................................70

2.4 Actual value of flow temperature ...................................................................70

2.5 Actual value of boiler temperature.................................................................70

2.6 Actual value of common flow temperature.....................................................70

2.7 Actual value 1 of d.h.w. temperature (TBWx)................................................71

2.8 Actual value 2 of d.h.w. temperature .............................................................71

2.9 Display of maximum flue gas temperature (TGxmax) ...................................71

2.10 Attenuated outside temperature (TAxged).....................................................72

2.11 Composite outside temperature (Taxgem) ....................................................72

2.12 Outside temperature source ..........................................................................73

Setpoints 74

2.13 Display of boiler temperature setpoint ...........................................................74

2.14 Display of common flow temperature setpoint...............................................74

2.15 Display of d.h.w temperature setpoint ...........................................................75

2.16 Display of nominal room temperature setpoint ..............................................76

2.17 Display of room temperature setpoint (TRw).................................................77

2.18 Display of flow temperature setpoint (TVw)...................................................78

2.19 Floor curing data............................................................................................79

Heat generating equipment............................................................................................80

2.20 Type of heat source.......................................................................................80

2.20.1 No heat generation or BMU...........................................................................80

2.20.2 Multi-stage burners........................................................................................80

Page 5

5/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division Summary 19.04.2001

2.21 Minimum limitation of boiler temperature (TKmin).........................................81

2.22 Extra heating for the bathroom......................................................................82

2.22.1 Extra heating for the bathroom......................................................................82

Heating circuit................................................................................................................83

2.23 Parallel displacement of heating curve..........................................................83

2.24 Room influence .............................................................................................84

2.25 Switching differential of room temperature (SDR).........................................85

2.26 Operating mode of room unit.........................................................................86

2.27 Room unit values...........................................................................................87

2.27.1 Examples of room unit assignments .............................................................88

2.28 Minimum limitation of flow temperature setpoint (TVmin)..............................89

2.29 Maximum limitation of flow temperature setpoint (TVmax)............................90

2.30 Maximum forward shift of optimum start control............................................91

2.30.1 Optimum start control....................................................................................91

2.30.2 Without room influence..................................................................................92

2.30.3 With room influence.......................................................................................92

2.31 Maximum forward shift of optimum stop control............................................93

2.31.1 Optimum stop control ....................................................................................93

2.32 Type of building construction.........................................................................94

2.33 Adaption of heating curve..............................................................................95

2.33.1 Adaption ........................................................................................................95

2.34 Locking signal gain........................................................................................97

2.35 Floor curing ...................................................................................................98

2.35.1 Temperature profile.......................................................................................98

2.35.2 Activating the function ................................................................................... 99

2.35.3 Function.........................................................................................................99

2.35.4 Display...........................................................................................................99

2.35.5 Aborting the function .....................................................................................99

D.h.w. 100

2.36 Reduced setpoint of d.h.w. temperature (TBWR) .......................................100

2.37 D.h.w. heating program...............................................................................101

2.37.1 24-hour operation setting 0 ........................................................................101

2.37.2 Operation according to the time switch programs with forward shift (d.h.w.)

Setting 1 ......................................................................................................102

2.37.3 Operation according to the local time switch program 3 (d.h.w.) Setting 2 .102

2.38 Assignment of d.h.w. heating ......................................................................103

2.39 D.h.w. charging ...........................................................................................104

2.39.1 Once per day with a forward shift of 2.5 hours Setting 0.............................104

2.39.2 Several times per day with a forward shift of 1 hour Setting 1 ....................104

2.40 Type of d.h.w. demand................................................................................105

2.41 Boost of flow temperature setpoint for d.h.w. heating (UEBW)...................107

2.42 D.h.w. priority...............................................................................................108

2.42.1 Frost protection for the plant .......................................................................108

2.42.2 Shifting priority.............................................................................................109

2.42.3 Temperature-time integral...........................................................................110

2.43 Controlling element for d.h.w.......................................................................111

LPB / system ...............................................................................................................112

2.44 LPB device address ....................................................................................112

2.45 LPB segment address.................................................................................113

2.46 LPB power supply .......................................................................................114

2.47 Display of LPB power supply.......................................................................115

2.48 Range of action of central changeover........................................................116

2.49 Automatic summer / winter changeover......................................................117

2.50 Central stand-by switch...............................................................................118

Page 6

6/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division Summary 19.04.2001

2.51 Clock mode..................................................................................................119

2.52 Winter- / summertime changeover...............................................................120

2.53 Summer- / wintertime changeover...............................................................120

2.54 Display of PPS communication....................................................................121

Multi-functional inputs..................................................................................................122

2.55 Input H1.......................................................................................................122

2.55.1 Changeover of operating mode ...................................................................123

2.55.2 Minimum flow temperature setpoint TVHw..................................................124

2.55.3 Heat generation lock....................................................................................124

2.55.4 Heat demand DC 0...10 V............................................................................125

2.55.5 Changeover of operating mode ...................................................................125

2.56 Minimum flow temperature setpoint contact H (TVHw) ...............................126

2.57 Maximum value of heat demand signal DC 0...10 V (H1)............................127

2.58 Operating action contact H1 and H2............................................................127

2.59 Input B31/H2................................................................................................128

2.59.1 D.h.w. sensor 2............................................................................................128

2.59.2 Minimum flow temperature setpoint (TVHw)................................................129

2.59.3 Heat generation lock....................................................................................129

2.59.4 Changeover of operating mode ...................................................................129

3 Description of OEM settings ........................................................................130

Heat generating equipment..........................................................................................130

3.1 Minimum limitation of boiler temperature (TKmin

OEM

)..................................130

3.2 Maximum limitation of boiler temperature (TKmax) .....................................130

3.3 Switching differential of the boiler temperature............................................131

3.3.1 Single-stage burner .....................................................................................132

3.3.2 2-stage burner .............................................................................................132

3.4 Minimum limitation of burner running time...................................................133

3.5 Release integral of burner stage 2...............................................................134

3.5.1 Temperature-time integral ...........................................................................134

3.6 Reset integral of burner stage 2 ..................................................................135

3.6.1 Temperature-time integral ...........................................................................135

3.7 Pump overrun time ......................................................................................136

3.8 Operating mode of the boiler .......................................................................137

3.8.1 Extended burner running time .....................................................................137

3.9 Protective boiler start-up..............................................................................138

3.9.1 Impact on 2-position loads...........................................................................138

3.9.2 Impact on modulating loads.........................................................................139

3.9.3 Temperature-time integral ...........................................................................140

3.10 Control of boiler pump .................................................................................141

Heating circuit..............................................................................................................142

3.11 Boost of flow temperature setpoint mixing valve (UEM)..............................142

3.12 Gain factor of room influence (KORR).........................................................143

3.13 Constant for quick setback and optimum start control (KON)......................144

3.13.1 Quick setback without room influence .........................................................144

3.13.2 Optimum start control without influence.......................................................144

3.14 Boost of room temperature setpoint (DTRSA).............................................145

3.14.1 Boost heating...............................................................................................145

3.15 Frost protection for the plant........................................................................146

3.15.1 Frost protection for the plant........................................................................146

3.16 Control mode of actuator .............................................................................147

3.17 Switching differential of actuator..................................................................148

3.17.1 Control of mixing valve actuator ..................................................................148

3.18 Overtemperature protection for the pump heating circuit ............................149

Page 7

7/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division Summary 19.04.2001

3.19 Heat gains (Tf).............................................................................................150

3.20 Adaption sensitivity 1 (ZAF1).......................................................................151

3.21 Adaption sensitivity 2 (ZAF2).......................................................................152

3.22 P-band mixing valve (Xp) ............................................................................153

3.23 Integral action time mixing valve (Tn)..........................................................153

3.24 Actuator running time mixing valve..............................................................153

D.h.w. 154

3.25 Maximum nominal setpoint of d.h.w. temperature (TBWmax) ....................154

3.26 Switching differential of d.h.w. temperature (SDBW) ..................................155

3.26.1 d.h.w. temperature control...........................................................................155

3.26.2 D.h.w. temperature control with 2 sensors ..................................................156

3.27 Legionella function ......................................................................................157

3.28 Setpoint of legionella function .....................................................................158

3.29 Discharge protection during d.h.w. heating.................................................159

Service 160

3.30 Continuous display......................................................................................160

3.31 Software version..........................................................................................160

3.32 Device operating hours ...............................................................................161

4 General control processes ..........................................................................162

4.1 Generation of boiler temperature setpoint...................................................163

4.2 Automatic 24-hour heating limit...................................................................164

4.2.1 Without room influence................................................................................164

4.2.2 With room influence.....................................................................................165

4.3 Quick setback with room sensor .................................................................166

4.4 Overtemperature protection mixing heating circuit......................................167

4.5 Attenuated outside temperature..................................................................168

4.6 Composite outside temperature ..................................................................169

4.7 D.h.w. push .................................................................................................170

4.8 Pump and valve kick ...................................................................................171

4.9 Protection against discharging after d.h.w. heating.....................................171

4.10 Overview of pump operation .......................................................................172

4.11 Frost protection ...........................................................................................173

4.11.1 For the boiler ............................................................................................... 173

4.11.2 For the d.h.w................................................................................................173

4.11.3 For the heating circuit..................................................................................174

5 Application examples ..................................................................................175

5.1 Plant types...................................................................................................175

5.1.1 D.h.w. heating with diverting valve..............................................................176

5.2 Supplementary information on the plant types listed...................................176

5.3 Legend to plant types..................................................................................177

5.4 Electrical connections..................................................................................177

6 Dimensions..................................................................................................178

6.1.1 Panel cut-out ...............................................................................................178

6.1.2 Combination of controllers...........................................................................178

7 Technical data.............................................................................................179

Page 8

8/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

1 Summary

1.1 Brief description

The ALBATROS controllers described in this documentation are designed for

integration in mass-produced heat generating equipment and offer the following control

choices:

• Single- or 2-stage burner, 1 BMU

• D.h.w. charging pump or diverting valve

• 3-position mixing valve and circulating pump

The range of products comprises several units that are complementary in terms of

application and scope of functions. The controllers have communication capability and

can be combined to form extensive heating systems.

For more detailed information about the generation of LPB systems, refer to “Local

Process Bus (LPB), Basic Documentation, System Engineering“, document no.

CE1P2370E.

1.2 Features

• Heating controller for mixing and / or pump heating circuits with:

− weather-compensated flow temperature control

− weather-compensated flow temperature control with room influence

• 2 separately controlled heating circuits (mixing or pump heating circuits)

• Quick setback and boost heating

• Automatic 24-hour heating limit

• Automatic summer / winter changeover

• Remote operation via digital room unit

• The building's thermal dynamics are taken into c onsideration

• Automatic adjustment of heating curve to the type of building cons truction and the

heat demand (provided a room unit is connected)

• Adjustable flow temperature boost with mixing heating circuit

• Floor curing function

1)

• Single- or 2-stage burner

• BMU

(Boiler Management Unit)

• Heat generation lock with contact H

• Protective boiler start-up

• Protection against boiler overtemperatures (pump overrun)

• Adjustable minimum and maximum limitation of boiler temperature (boiler flow

temperature)

• Burner cycling protection by observing a minimum burner running time

• Frost protection for the house or building, the plant, d.h.w., the heating circuit, and the

boiler

• Protection for the pump and the mixing valve through periodic control (pump and

valve kick)

• Adjustable minimum and maximum limitation of flow temperature

• Protection against overtemperatures in the pump heating circuit

Systems

Heating circuits

Heat generation

Protection for the plant

Page 9

9/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

• Two 7-day heating programs

− 7-day heating program no. 1 for heating circuit 1

− 7-day heating program no. 2 for heating circuit 2

− Separate 7-day heating program for d.h.w. heating

• Temperature adjustment with the setpoint knob

• Automatic button for efficient operation throughout the year

• Chimney sweep function at the touch of a button

• Manual operation at the touch of a button

• Straightforward selection of operating mode via buttons

• Change of operating mode with contact H

• Output and input tests to assist c ommissioning and a functional test

• Service connection facility for local parameter settings and data logging

• D.h.w. heating with a charging pump or diverting valve

• D.h.w. heating with one or 2 sensors

• Reduced setpoint of d.h.w. temperature

• Selectable d.h.w. program

• Integrated legionella function

• Selectable priority for d.h.w. heating

• Adjustable boost of the d.h.w. charging temperature

• Automatic d.h.w. push

• D.h.w. demand with a sensor or thermostat

• Protection against discharging

• Communicating via Local Process Bus (LPB)

1)

• Communicating via point-to-point interface (PPS)

• Integrity of system architecture with all RVA... controllers

1)

• Can be extended to include up to 40 heating circuits (with central bus power supply)

1)

• Optional remote supervision

• Fault status signals and indications (locally, LPB and PPS)

1)

• Controllers of other manufacture can deliver their heat demand signal via potentialfree H-contact

• Controllers of other manufacture can deliver their heat demand in the form of DC

0…10 signals

• Analysis with service tool

1)

• Logging the number of burner hours run of stages 1 and 2

• Logging the number of burner starts of stages 1 and 2

• Logging the flue gas temperature

• Display of plant diagram no.

1

Not with RVA53.280

Operation

D.h.w.

Systems

1

Logging

Page 10

10/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

1.3 Range of products

The following units and accessories are designed for use with the ALBATROS range:

RVA63.280 Boiler and heating circuit controller

RVA53.280 "

QAA10 Digital room sensor

QAA50 Digital room unit

QAA70 Digital, multi-functional room unit

QAC31 Outside sensor (NTC 600)

QAC21 Outside sensor (Ni 1000)

QAZ21 Immersion sensor with cable

QAD21 Strap-on temperature sensor

Pt1000 Flue gas sensor (third party product)

AGP2S.02M

1

LPB (2 poles) violet

AGP2S.02G Room unit (2 poles ) blue

AGP2S.06A Sensor (6 poles) white

AGP2S.04G Sensor (4 poles) grey

AGP2S.02G Room unit PPS2 (2 poles) blue

AGP2S.04C Sensor (4 poles) yellow

AGP3S.02D Mains(2 poles) black

AGP3S.05D Burner (5 poles) red

AGP3S.03B Pumps (3 poles) brown

AGP3S.03K Actuator (3-poles) green

AGP3S.04F Pumps (4 poles) orange

AGP3S.03K Actuator 2 (3 poles) green

1

Not with RVA53.280

Controllers

Room units

Sensor

Screw type terminal strips

(Rast 5)

Page 11

11/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

1.4 Field of use

• OEMs

• Manufacturers of combi and heating boilers

• Residential and non-residential buildings with own zone heating and d.h.w. heating

facility

• Residential and non-residential buildings with central heating plant

• Standard heating systems, such as:

radiator, convector, underfloor and ceiling heating systems, and radiant panels

• Suited for

– heating plants with 2 heating circuits

– different types of heating systems (creation of extensive systems)

– several heating zones (creation of extensive systems)

• With or without d.h.w. heating

• Heating boilers with single- or 2-stage oil or gas burners

• Gas boilers with BMU

(Boiler Management Unit)

1.5 Product liability

• The products may only be used in building services plant and applications as

described above

• When using the products, all requirements specified in "Technical data" and

"Handling" must be satisfied

• When using the products in a system, all requirements contained in the

documentation “Local Process Bus (LPB), Basic Documentation, System

Engineering“ (document no. CE1P2370E) must be satisfied

• The local regulations (for installation, etc.) must be complied with

Target market

Types of buildings

Types of heating systems

Heat generating

equipment

Page 12

12/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

2 Handling

2.1 Installation

2.1.1 Regulations for installation

.

• Air circulation around the controller must be ensured, allowing the unit to emit the

heat produced by it.

A clearance of at least 10 mm must be provided for the controller's cooling slots

which are situated a the top and bottom of the housing.

The space should not be accessible and no objects should be placed there.

If the controller is enclosed in another closed (insulating) casing, a clearance of up to

100 mm must be observed on all sides

• The controller is designed conforming to the directives for safety class II mounted in

compliance with these regulations

• Power to the controller may be supplied only after it is completely fitted in the cut-out.

If this is not observed, there is a risk of electric shock hazard near the terminals and

through the cooling slots

• The controller may not be exposed to dripping water

• Permissible ambient temperature when mounted and when readyto

operate: 0...50 °C

2.1.2 Mounting location

• In the boiler front

• In the control panel front

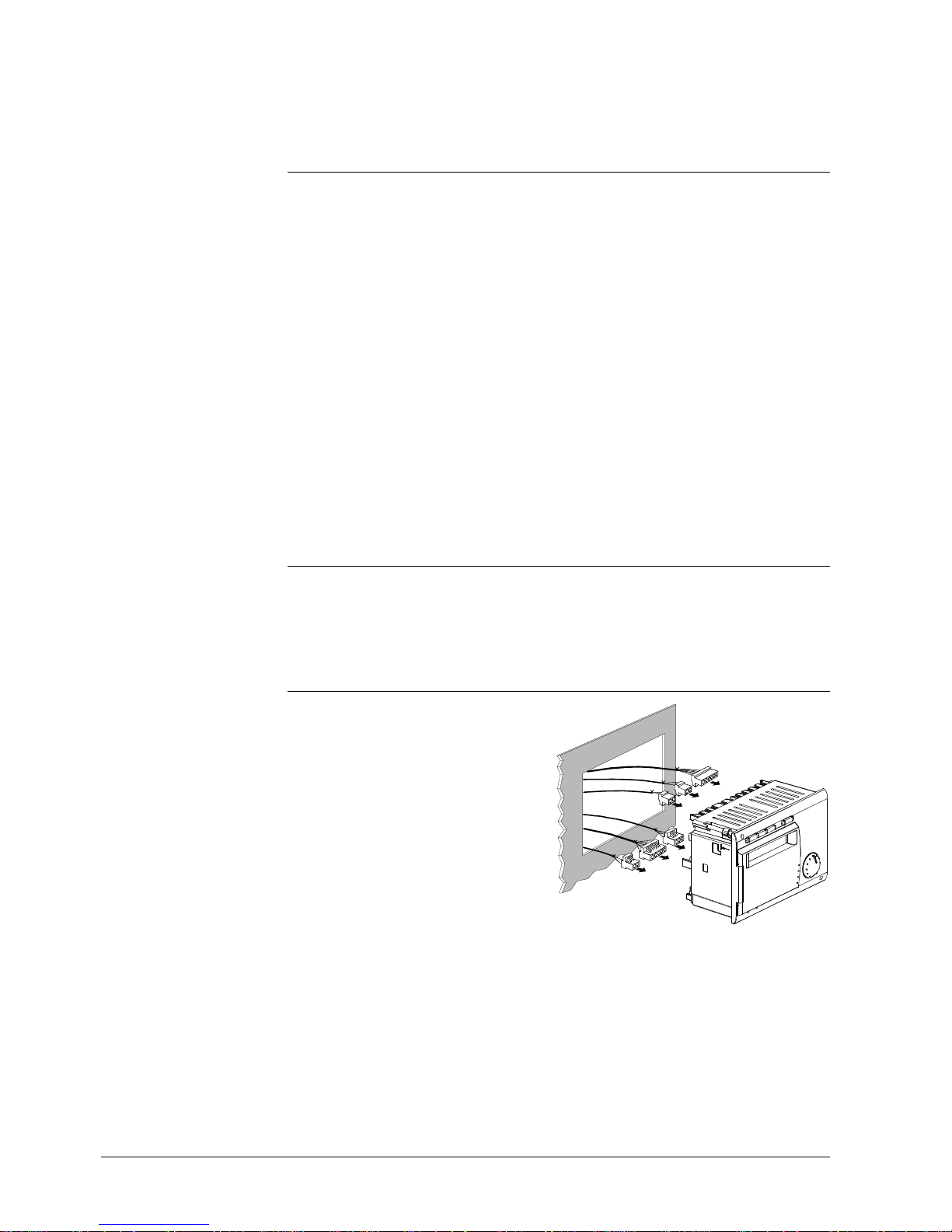

2.1.3 Mounting procedure

• Turn off power supply

• Pull the prefabricated cables through

the cut-out

• Plug the connectors into the

respective sockets at the rear of the

controller

è Note:

The connectors are coded to make

certain they cannot be mixed up.

2373Z05

1. Making the

connections

Page 13

13/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

• Check to ensure the fixing levers are

turned inward

• Check to make certain there is

sufficient space between the front

panel and the fixing levers

2373Z06

• Slide the controller into the panel cutout without applying any force

è Note:

Do not use any tools when inserting

the unit into the cut-out. If it does not

fit, check the size of the cut-out and

the position of the fixing levers.

2373Z07

Tighten the 2 screws on the front of the

controller

è Note:

Tighten the screws only slightly,

applying a torque of maximum

20 Ncm.

When tightening the screws, the

fixing levers automatically assume

their correct positions.

2373Z08

2. Check

3. Fitting

4. Fixing

Page 14

14/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

2.1.4 Required cut-out

The controller's mounting dimensions are 91 x 137 mm

Due to the dimensions of the front, however, the standard spacing is 144 mm

The controller can be fitted in front panels of different thicknesses

The mechanical mounting facility makes

it possible to arrange several controllers

in a row in one cut-out. In that case, it is

merely necessary to have a wider panel

cutout.

Also refer to "Dimensions" in Index.

2373Z09

2.1.5 Orientation

To avoid overtemperatures inside the

controller, the inclination may be no

more than 30° and there must be a

clearance of at least 10 mm above and

below the cooling slots.

This allows the controller to emit the

heat generated during operation.

1

0

m

m

m

a

x

.

3

0

°

2

3

7

1

Z

1

6

1

0

m

m

Dimensions of cut-out

Combination of

controllers

Page 15

15/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

2.2 Electrical installation

2.2.1 Regulations for installation

• Prior to installing the controller, the power supply must be turned off

• The connections for mains and low voltage are separated

• The wiring must be made in compliance with the requirements of safety class II. This

means that sensor and mains cables may not be run in the sameduct

2.2.2 wiring

When using prefabricated cables with connectors, the electrical installation is very

straightforward, owing to coding.

Rear of controller

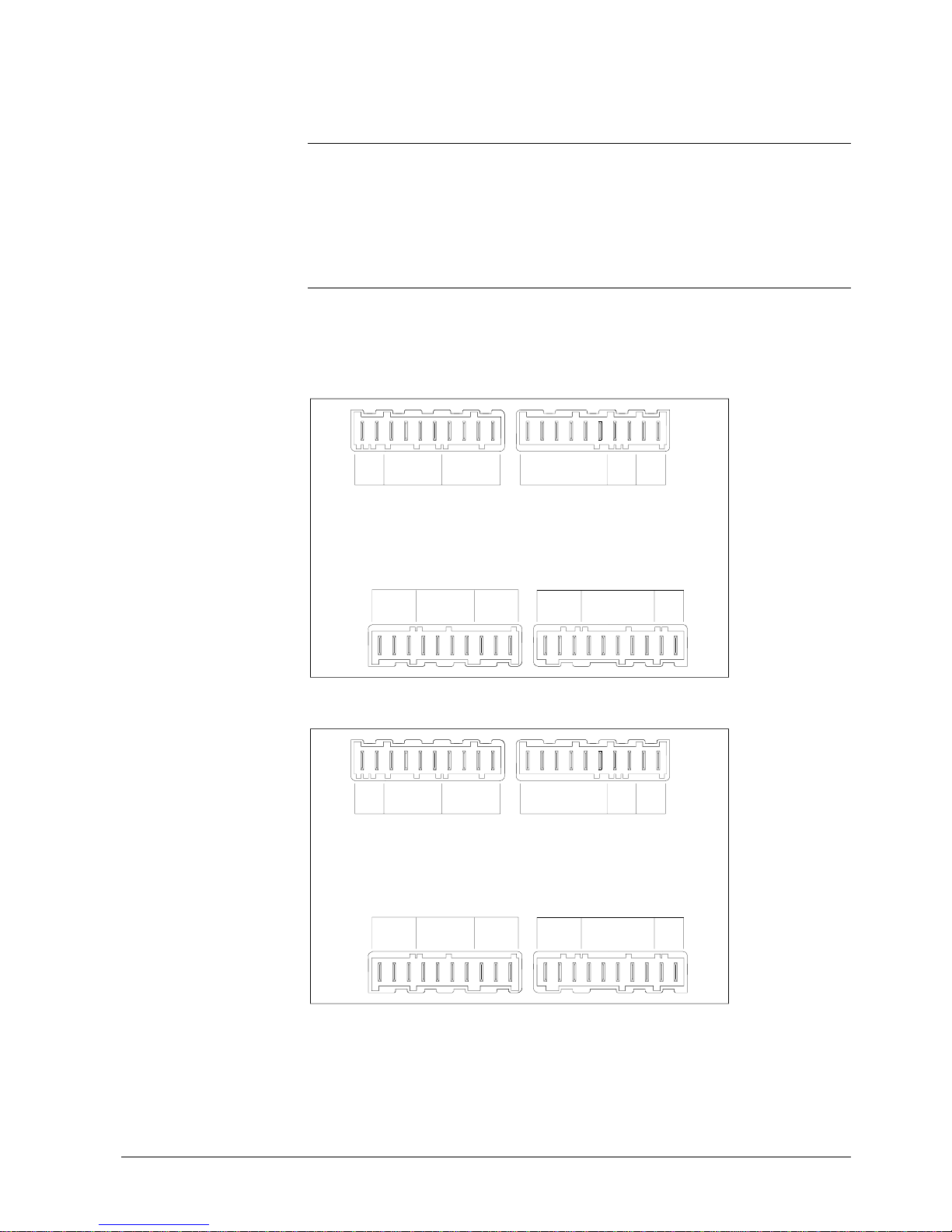

2.2.2.1 Connection terminals of RVA63.280

2374A01

4 654M21M M

FN23F234 LF2F45F23

3M143M1

M

B8MB1

H1B2B3MB9MDA6MBDB

B12

A7

MD

B31/H2

B41

F2NY1

Y2

F6

Q2

L

F4

K4

F5

K5

F1

Q3/Y3

Q6

F3

Y5

Y6

2.2.2.2 Connection terminals of RVA53.280

2374A08

4 654M21M M

FN23F234 LF2F45F23

3M143M1

M

B8MB1

H1B2B3

M

B9MDA6

B12

A7

MD

B31/H2

B41

F2NY1

Y2

F6

Q2

L

F4

K4

F5

K5

F1

Q3/Y3

Q6

F3

Y5

Y6

Note

Page 16

16/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

Terminal Terminals Connector Color

MD Ground room unit bus (PPS) AGP2S.02G blue

A7 Room unit bus HC2 (PPS)

- Not used AGP2S.04C yellow

B12 Flow sensor mixing valve HC2

M Ground sensors

B8 Flue gas sensor

B31/H2 D.h.w. sensor 2 / contact H2 AGP2S.04G grey

B1 Flow sensor mixing valve HC1

M Ground sensors

- Not used

H1 Changeover contact AGP2S.06A white

B2 Boiler sensor

B3 D.h.w. sensor 1 / control thermostat

M Ground sensors

- Not used

B9 Outside sensor

MD Ground PPS (RG1, BMU) AGP2S.02G blue

A6 PPS (RG1, BMU)

MB Ground bus (LPB) AGP2S.02M violet

DB Data bus (LPB)

Terminal Terminals Connector Color

Y6 Mixing valve HC2 CLOSED AGP3S.03K green

Y5 Mixing valve HC2 OPEN

F3 Phases Y5 and Y6

- Not used AGP3S.04F orange

Q6 Circulating pump mixing heating circuit 2

Q2 Circulating pump mixing heating circuit 1

F6 Phase Q2

Y2 Mixing valve CLOSED AGP3S.03K green

Y1 Mixing valve OPEN

F2 Phase Y1and Y2

Q3/Y3 D.h.w.charging pump / d.h.w. diverting

valve

AGP3S.03B brown

- Not used

F1 Phase Q3/Y3

- Not used AGP3S.05D red

K5 Burner stage 2

F5 Phase burner stage 2

K4 Burner stage 1

F4 Phase burner stage 1

L Live AC 230 V (mains connection) AGP3S.02D black

N Neutral (mains connection)

Low voltage side

Mains voltage side

Page 17

17/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

2.3 Commissioning

To commission the controller:

• Make certain that mounting and electrical installation are in compliance with the

relevant requirements

• Make all plant-specific settings as described in section "Parameter settings"

• Reset the attenuated outside temperature

• Make the functional checks

2.3.1 Functional checks

To facilitate commissioning and fault tracing, the controller allows output and input tests

to be made. With these tests, the controller’s inputs and outputs can be checked.

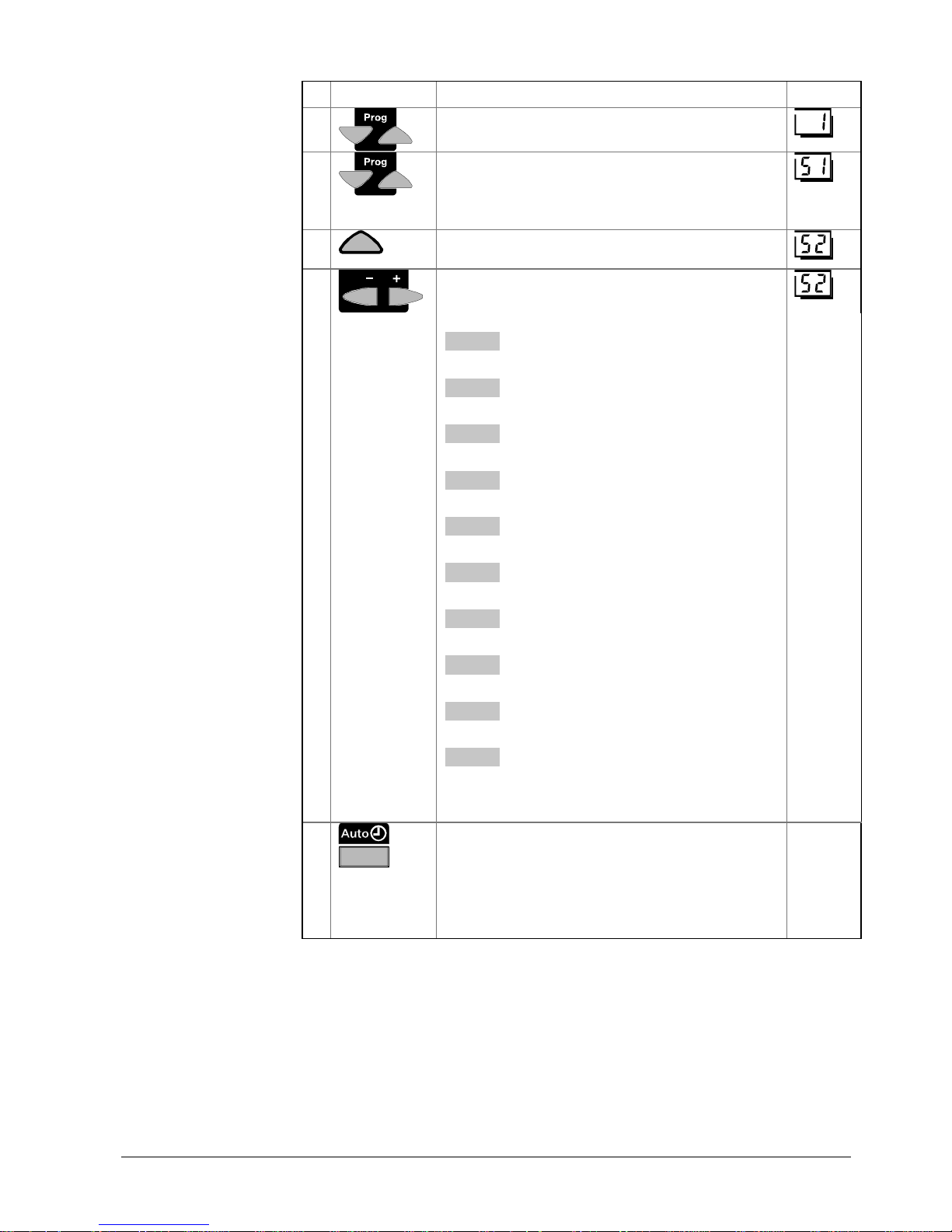

Buttons Explanation Line

1 Press one of the line selection buttons.

This will take you to the programming mode.

2 Press both line selection buttons for at least 3

seconds.

This will take you to the programming mode “Heating

engineer” and, at the same time, to the output test.

3 Press the + or - button repeatedly, which will take you

one test step further:

Test step 0 All outputs are switched according to normal control

operation

Test step 1 All outputs are deactivated

Test step 2 Burner stage 1 (K4) is activated

Test step 3 Burner stages 1 and 2 (K4 + K5) are activated

Test step 4 D.h.w. charging pump / divertingvalve (Q3/ Y3) is

activated

Test step 5 Heating circuit 1 / boiler pump (Q2) is activated

Test step 6 Mixingvalve HC1OPEN (Y1) isactivated

Test step 7 Mixing valve HC1 CLOSED (Y2) is activated

Test step 8 Heating circuit pump HC2 (Q6) is activated

Test step 9 Mixingvalve HC2OPEN (Y5) isactivated

Test step 10 Mixing valve HC2 CLOSED (Y6) is activated

4 By pressing any of the operating mode or line

selection buttons, you leave the programming mode

and thus the output test.

Note:

If no button is pressed for about 8 minutes, the

controller will automatically return to the operating

mode selected last.

Prerequisites

Output test

Page 18

18/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

b)

c)

2374Z03

a)

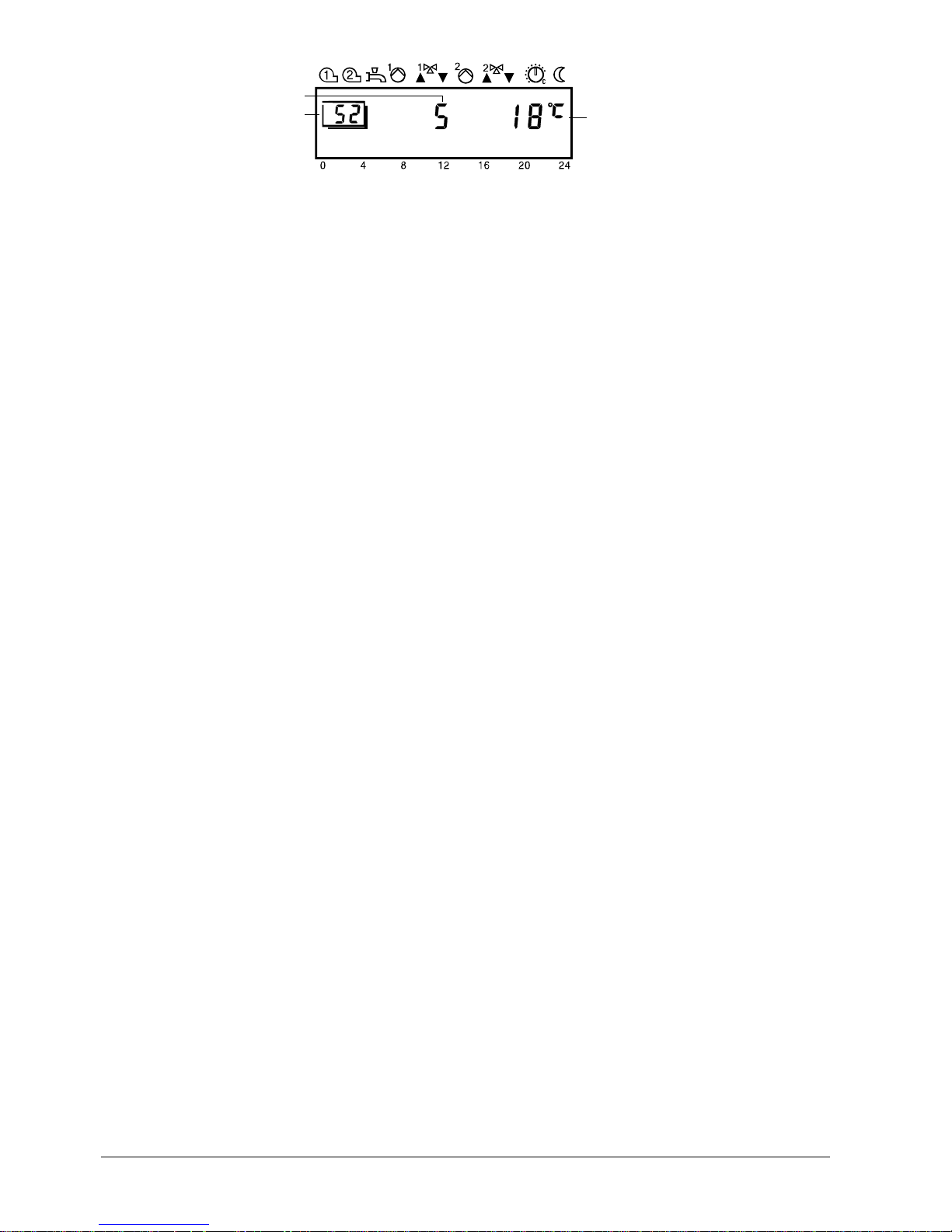

a) The pointerbelow the symbol indicates the output activated

b) The numberindicates the current test step

c) The number indicates the selected setting line

Display

Page 19

19/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

Buttons Explanation Line

1 Press one of the line selection buttons.

This will take you to the programming mode.

2 Press both line selection buttons for at least 3

seconds.

This will take you to the programming mode "Heating

engineer”.

3

-

Press line selection button UP until you reach line 52.

This will take you to the input test.

4 Press the + or - button repeatedly, which will take you

one test step further:

Test step 0 Display of boiler temperature acquired with sensor

B2

Test step 1 Display of d.h.w. temperature acquired with sensor

B3

Test step 2 Display of input B31/H2/B41 according to the

function selected on line 174 [°C or ooo or ---].

Test step 3 Display offlow temperature HC1 acquired with

detector B1

Test step 4 Display offlow temperature HC2 acquired with

detector B12

Test step 5 Display of outside temperature acquired with

sensor B9

Test step 6 Display of room temperature acquired withroom

unit connected to A6

Test step 7 Display of room temperature acquired withroom

unit connected to A7

Test step 8 Display ofthe flue gas temperature acquired with

sensor B8

Test step 9 Display of input H1 according to the function

selected on line 170 [°C / 000 / - - -].

5 By pressing any of the operating mode buttons, you

leave the programming mode and thus the input test.

Note:

If no button is pressed for about 8 minutes, the

controller will automatically return to the operating

mode selected last.

Continuous

display

The selected sensor values are updated within a maximum of 5 seconds.

An open-circuit is displayed as – – –.

A short-circuit is displayed as o o o.

Input test

Note

Page 20

20/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

b)

c)

2374Z04

a)

a) The numberindicates the current test step

b) Displayed value of the temperature measured

c) The number indicates the selected setting line

Display

Page 21

21/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

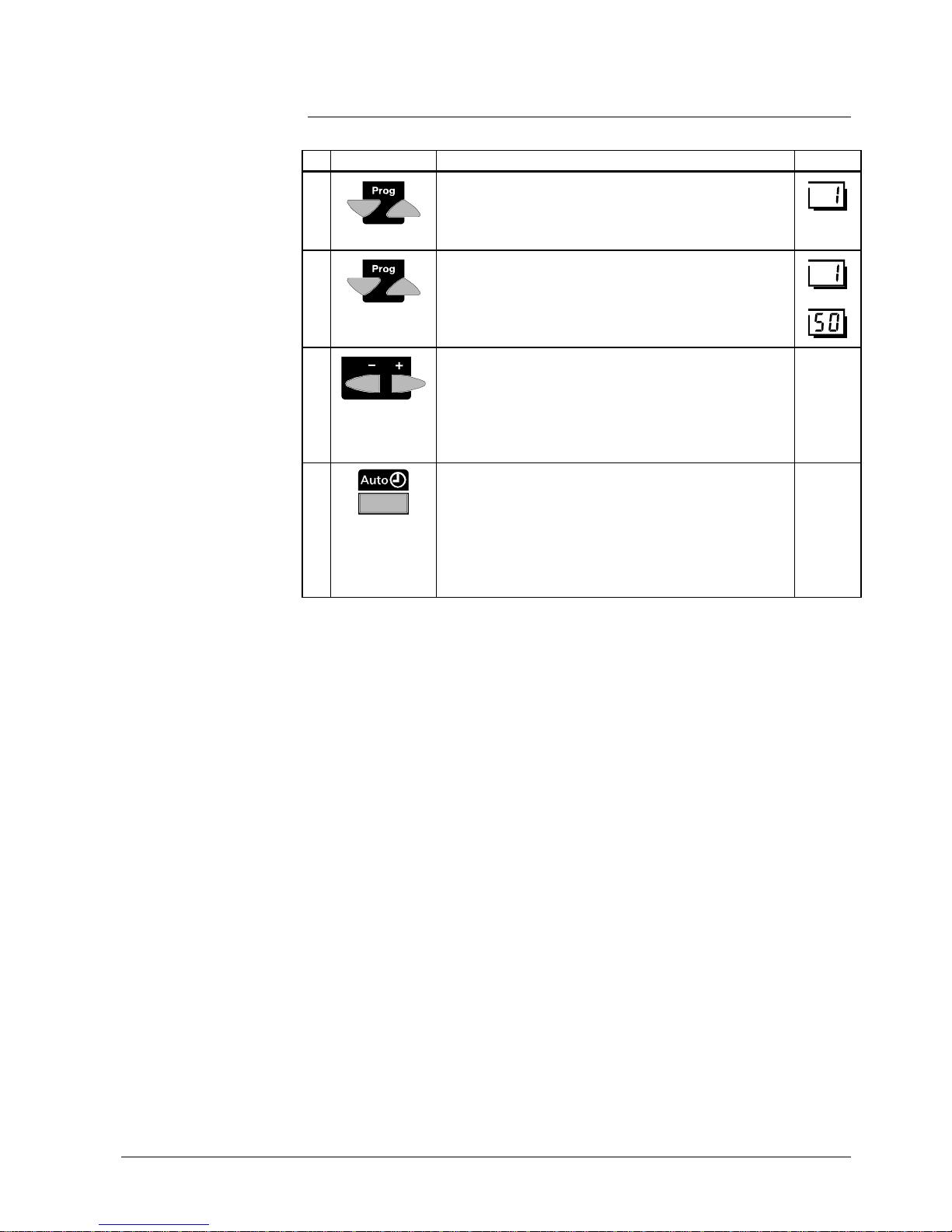

2.4 Parameter settings for the end-user

The following settings can be made to meet the individual needs of the end-user.

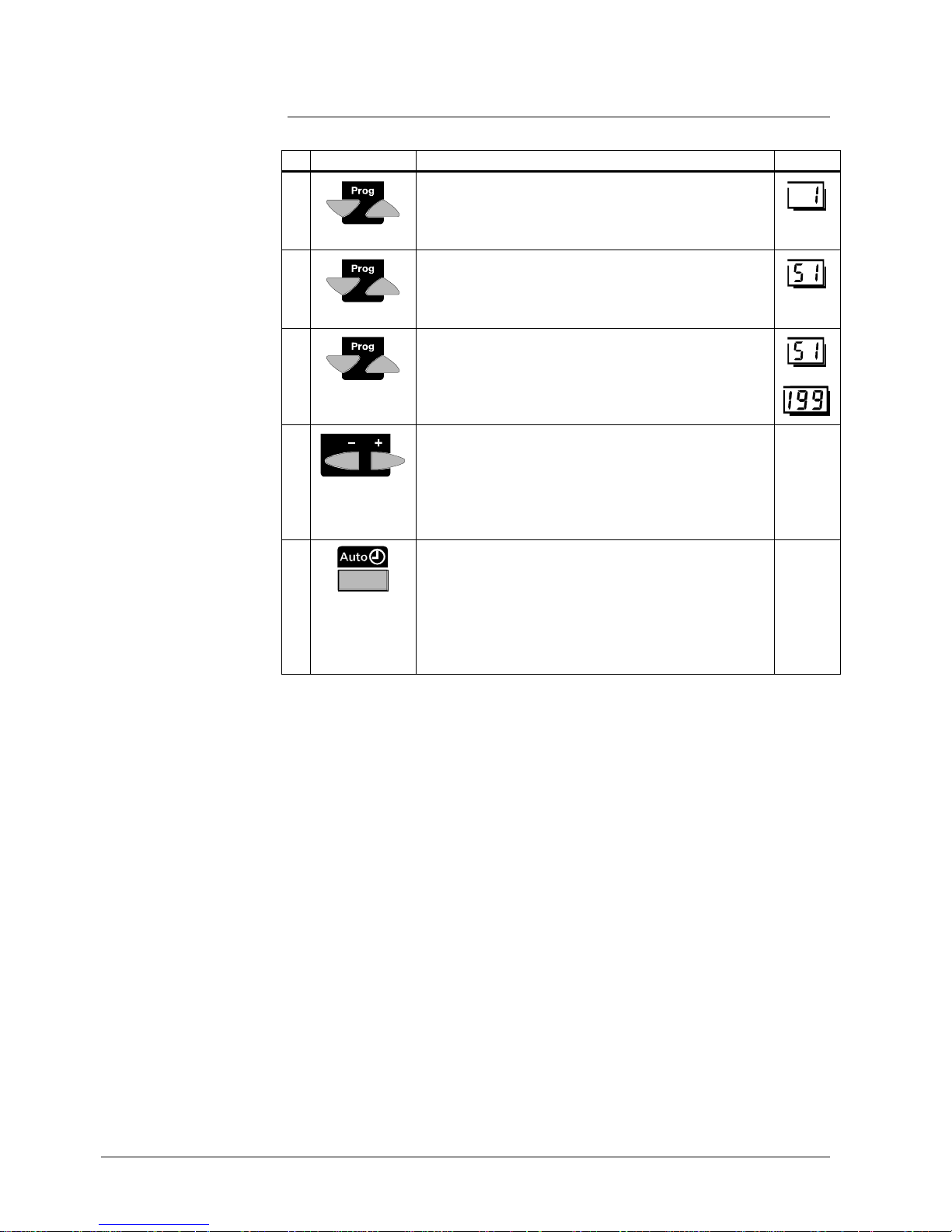

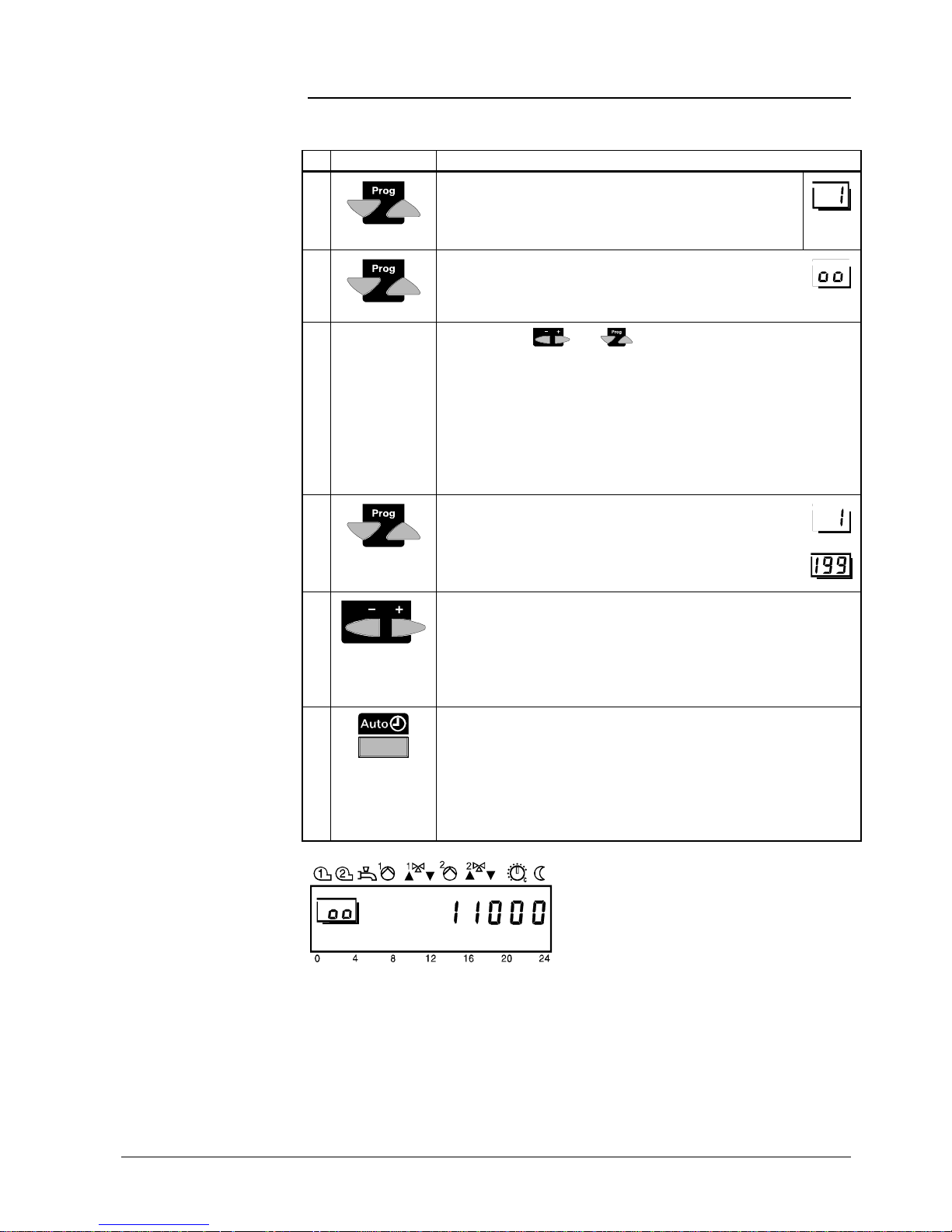

Buttons Explanation Line

1

Press one of the line selection buttons UP/DOWN.

This will take you directly to the programming mode

"End-user”.

2

Press the line selection buttons to select the required

line.

The parameter list on the next 2 pages contains all

available lines.

•••

3

Press the + or - button to set the required value.

The setting will be stored as soon as you leave the

programming mode or change to another line.

The parameter list on the next 2 pages contains all

settings that can be made.

4

By pressing any of the operating mode buttons, you

leave the programming mode "End-user”.

è Note:

If no button is pressed for about 8 minutes, the

controller will automatically return to the operating

mode selected last.

Continuou

s display

Description

Setting

Page 22

22/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

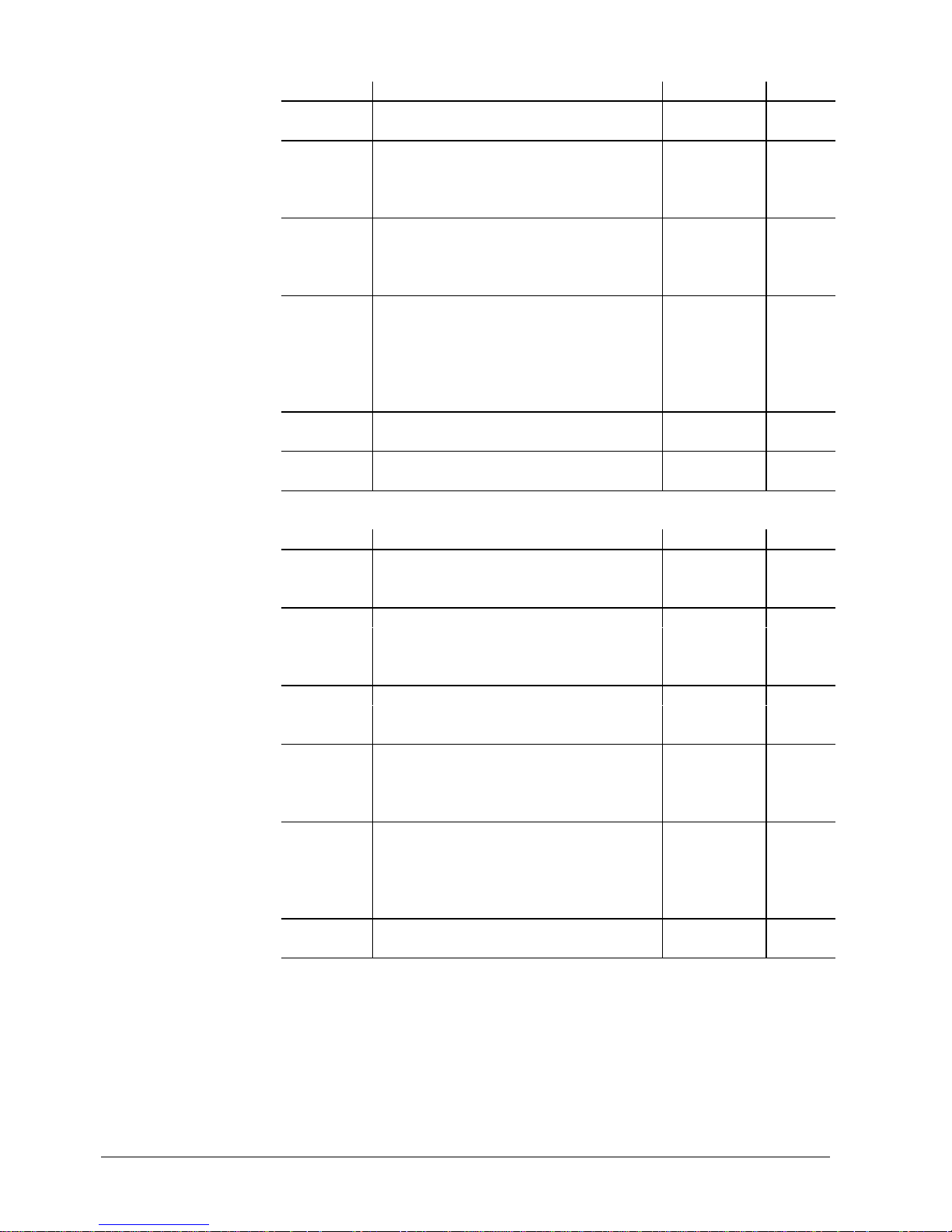

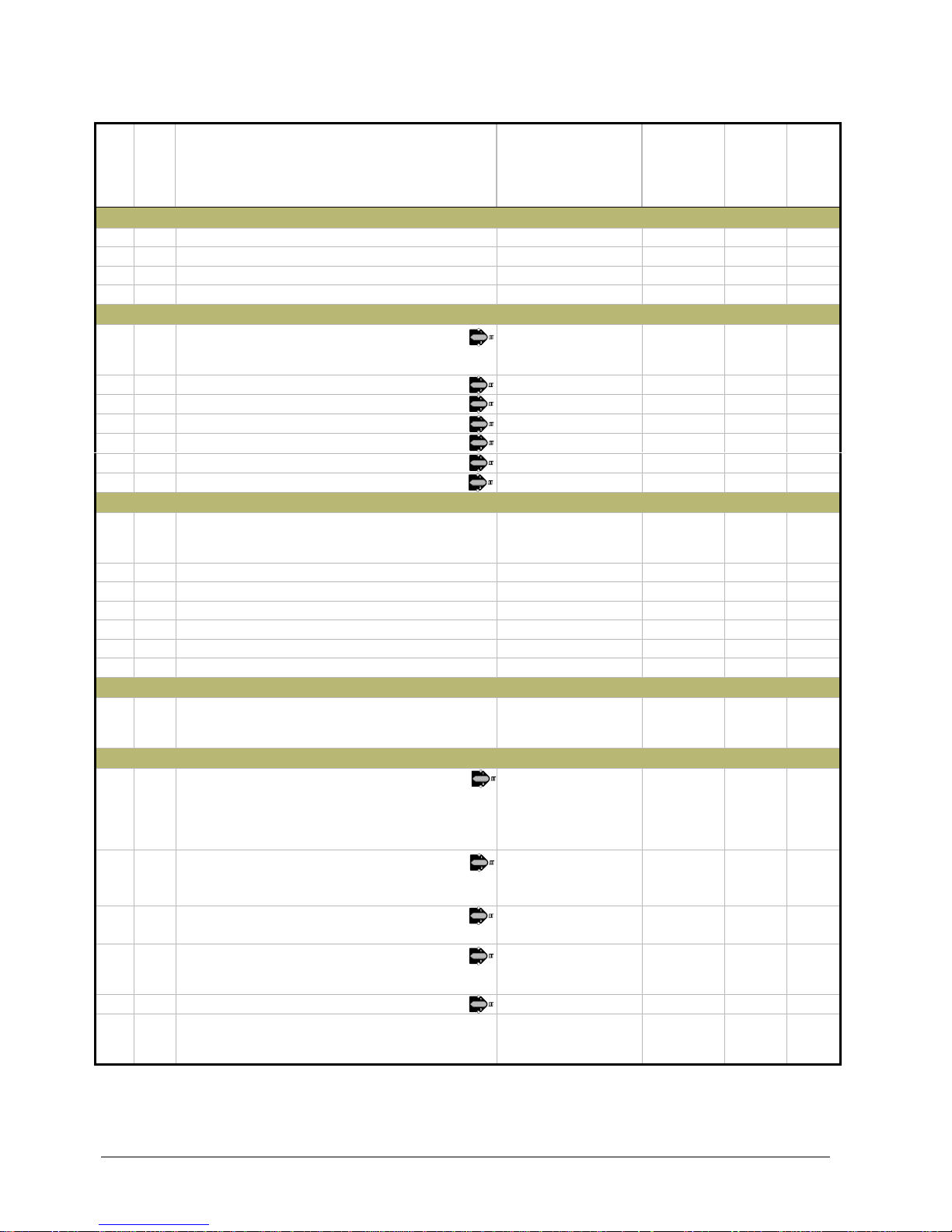

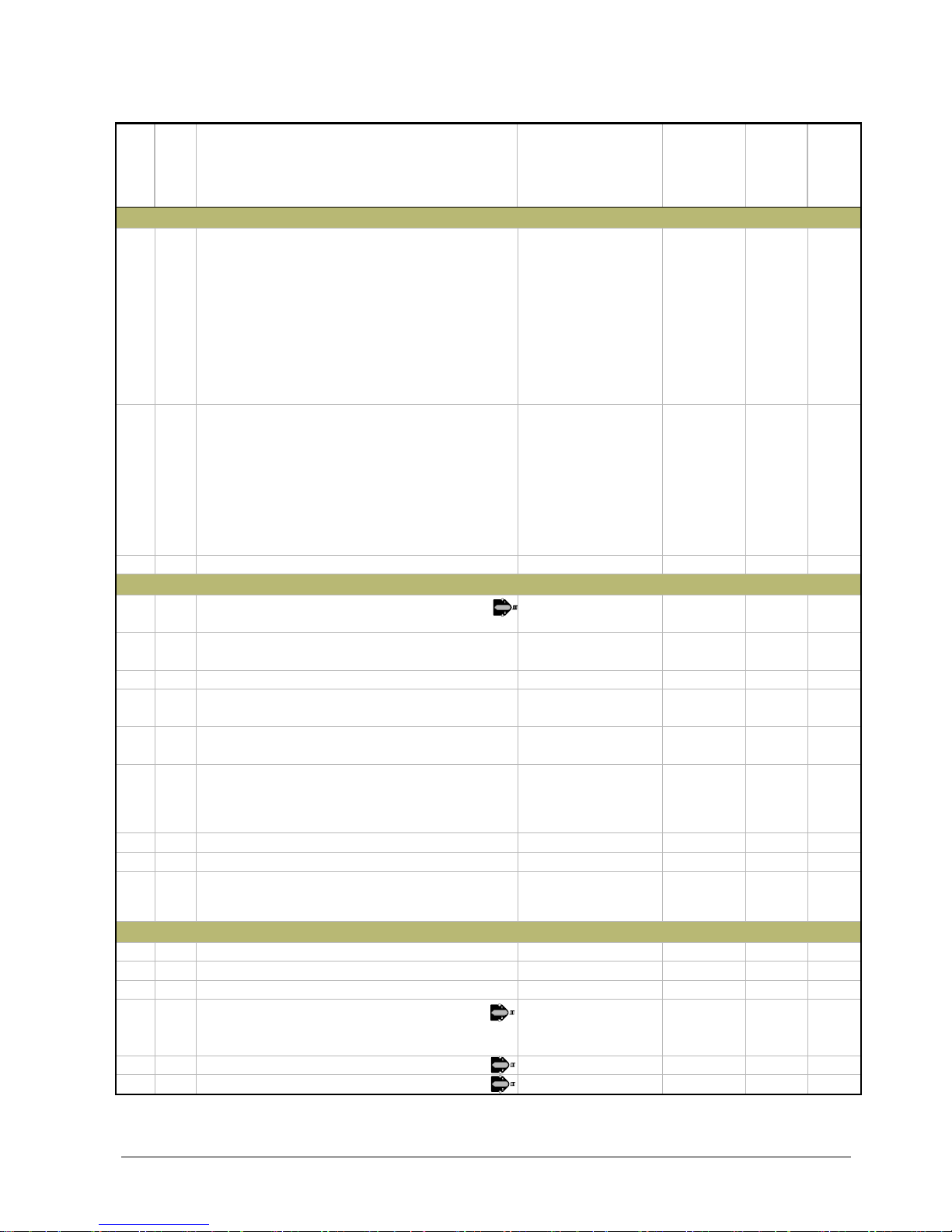

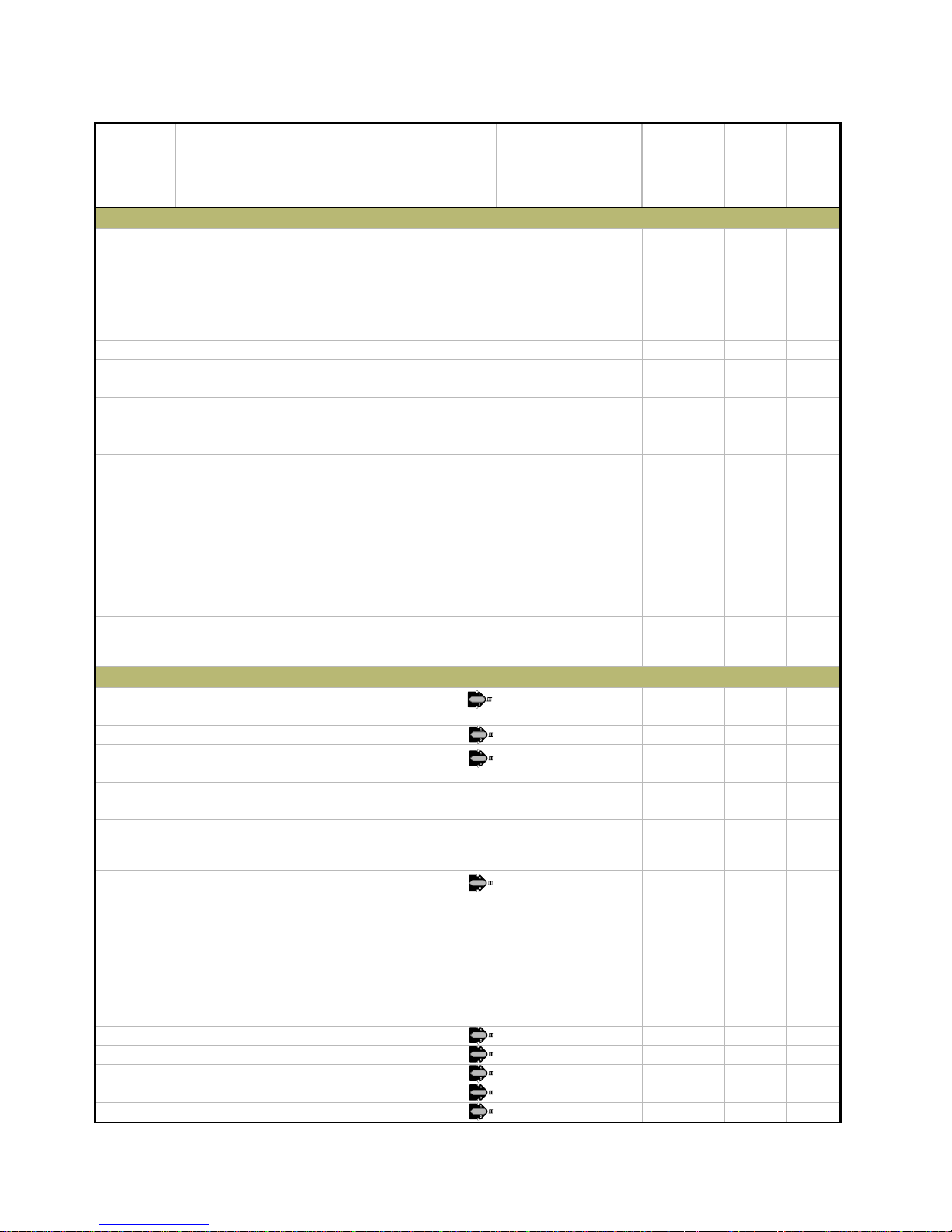

2.4.1 Overview of end-user parameters

RVA63.280

RVA53.280

Function

Range

Unit

Resolution

Factory setting

Setting the clock

1 1 Time of day 0...23:59 h / min 1 min 00:00

2 2 Weekday 1...7 Day 1 day 1

3 3 Date (day, month) 01.01...31.12 tt.MM 1 4 4 Year 1999...2099 jjjj 1 -

Time switch program 1

5 5 Pre-selection of weekday

1-7 7-day block

1...7 Individual days

1-7 / 1...7 Day 1 day -

66

Switch-on time 1. Period

- -:- -...24:00 h / min 10 min 06:00

77

Switch-off time 1. Period

- -:- -...24:00 h / min 10 min 22:00

88

Switch-on time 2. Period

- -:- -...24:00 h / min 10 min - -:- -

99

Switch-off time 2. Period

- -:- -...24:00 h / min 10 min - -:- -

10 10

Switch-on time 3. Period

- -:- -...24:00 h / min 10 min - -:- -

11 11

Switch-off time 3. Period

- -:- -...24:00 h / min 10 min - -:- -

Time switch program 3 (d.h.w.)

19 19 Pre-selection of weekday

1-7 7-day block

1...7 Individual days

1-7 / 1...7 Day 1 day -

20 20 Switch-on time 1. Period - -:- -...24:00 h / min 10 min 06:00

21 21 Switch-off time 1. Period - -:- -...24:00 h / min 10 min 22:00

22 22 Switch-on time 2. Period - -:- -...24:00 h / min 10 min - -:- 23 23 Switch-off time 2. Period - -:- -...24:00 h / min 10 min - -:- 24 24 Switch-on time 3. Period - -:- -...24:00 h / min 10 min - -:- 25 25 Switch-off time 3. Period - -:- -...24:00 h / min 10 min - -:- -

D.h.w.

26 26 Nominal setpoint of d.h.w. temperature (TBWw)

TBWRw Line 120

TBWmax Line 50 (OEM)

TBWR...TBWmax °C 1 55

Heating circuit

27 27 Reduced setpoint of room temperature

(TRRw)

TRF Frost protection setpoint of room temperature,

line 28

TRN Setpoint knob heating circuit 1 or 2

TRF...TRN °C 0,5 16

28 28 Frost protection setpoint of room temperature

(TRFw)

TRRw Line 27

4...TRRw °C 0,5 10

29 29 Summer / winter c hangeover temperature

(THG)

8...30 °C 0,5 17

30 30 Slope of heating curve (S)

- : - - Inactive(only HC2)

2.5...40 Active

- : - - / 2,5...40 - 0,5 15

33 33 Actual value of room temperature (TRx) 0...50 °C 0,5 34 34 Actual value of outside temperature (TAx)

To reset the attenuated outside temperature to TAx, press the

+ and- buttons simultaneously for 3 seconds.

-50...+50 °C 0,5 -

Page 23

23/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

RVA63.280

RVA53.280

Function

Range

Unit

Resolution

Factory setting

Heat generating equipment

35 35 Burner hours run stage 1 or BMU (tBR1) 0...65535 h 1 0

36 36 Burner hours run stage 2 (tBR2) 0... 65535 h 1 0

37 37 Number of burner starts stage 1 0... 65535 - 1 0

38 38 Number of burner starts stage 2 0... 65535 - 1 0

Standard values

39 39 Standard times for switching programs 1, 2, 3

(lines 6...11 and 20...25)

To activate, press the + and - buttonssimultaneously for 3

seconds

----

Holidays

40 40 Holiday period 1...8 - 1 1

41 41 Beginning of holiday period

- -.-- No holiday period programmed

Month, day

To reset the selected holiday period, press the + and - buttons

simultaneously for 3 seconds.

--.--

01.01...31.12

tt.MM 1 -

42 42 End of holiday period

- -.-- No holiday period programmed

Month, day

To reset the selected holiday period, press the + and - buttons

simultaneously for 3 seconds.

--.--

01.01...31.12

tt.MM 1 -

Service

49 49 Indication of BMU error code

0...255 Error code

0...255 - 1 -

50 50 Indication of faults 0...255 - 1 -

Page 24

24/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

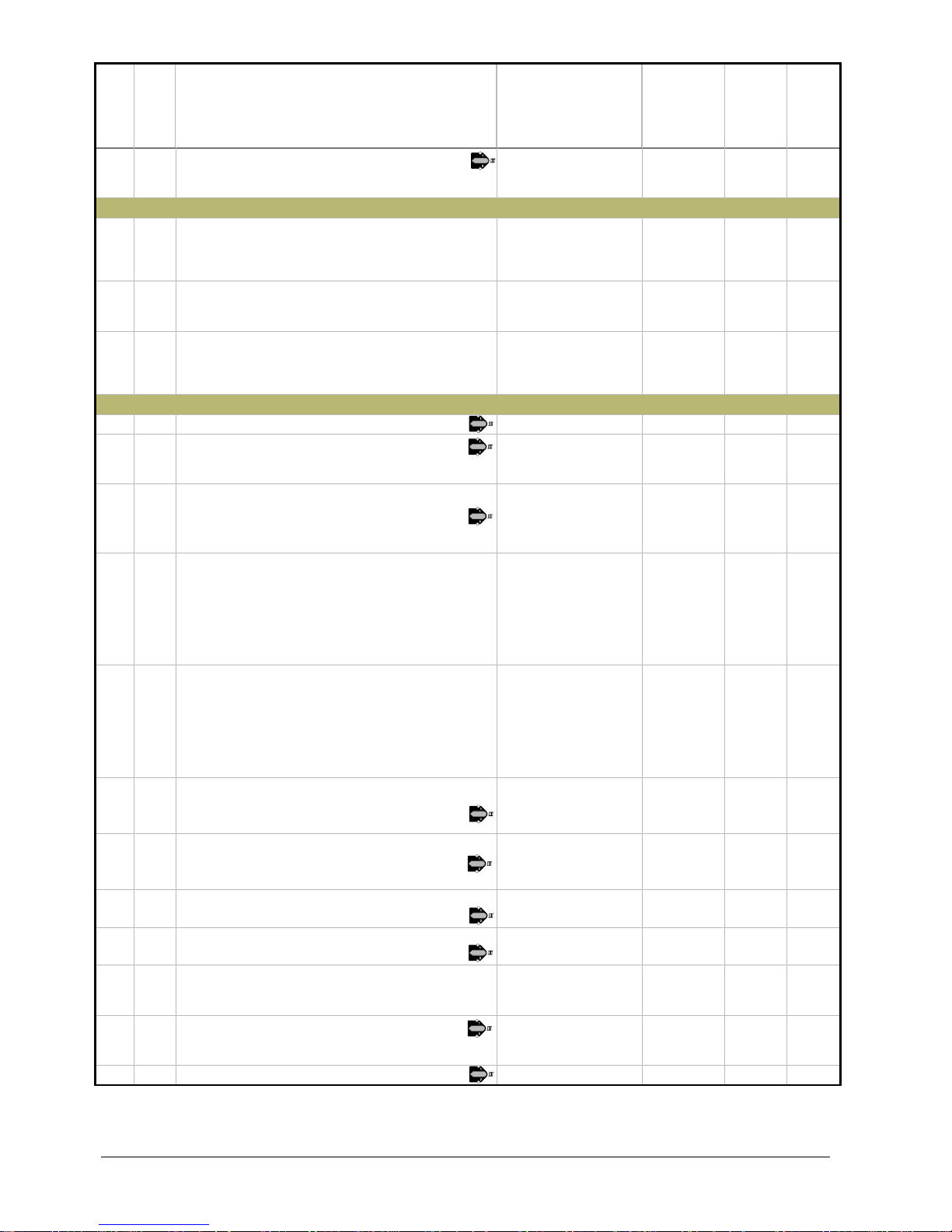

2.5 Parameter settings for the heating engineer

Configuration and parameter settings to be made by the heating engineer.

Buttons Explanation Line

1

Press one of the line selection buttons UP/DOWN.

This will take you directly to the programming mode

"End-user”.

2

Press both line selection buttons for at least 3 seconds.

This will take you directly to the programming mode

"Heating engineer”.

3

Press the line selection buttons to select the required

line.

The parameter list on the next 2 pages contains all

available lines.

•••

4

Press the + or - button to set the required value.

The setting will be stored as soon as you leave the

programming mode or change to another line.

The parameter list on the next 2 pages contains all

settings that can be made.

5

By pressing any of the operating mode buttons you

leave the programming mode "Heating engineer”.

è Note:

If no button is pressed for about 8 minutes, the

controller will automatically return to the operating

mode selected last.

Continuou

s display

Description

Setting

Page 25

25/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

2.5.1 Overview of heating engineer parameters

RVA63.280

RVA53.280

Function

Range

Unit

Resolution

Factory setting

Service values

51 51 Output test

0 Control mode according to the operating state

1 Alloutputs OFF

2 Burnerstage 1 ON K4

3 Burnerstages 1 and 2 ON K4 / K5

4 D.h.w. chargingpump ON Q3/Y3

D.h.w. diverting valve OPEN Q3 / Y3

5 Heating circuit pump 1 Q2

6 Mixing valve 1 open Y1

7 Mixing valve 1 close Y2

8 Heating circuit pump 2 Q6

9 Mixing valve 2 open Y5

10 Mixing valve 2 close Y6

0...10 - 1 0

52 52 Input test

0 Boiler sensor B2

1 D.h.w. sensor 1 B3

2 Display of input B31/H2 B31

3 Flow sensor HC1 B1

4 Flow sensor HC2 B12

5 Outside sensor B9

6 Room sensor 1 RG1, A6

7 Room sensor 2 RG2, A7

8 Flue gassensor B8

9 Display of input H1 H1

0...9 - 1 0

53 53 Display of plant type 1...127 - 1 -

Actual values

55 55 Actual value of flow temperature (TVx)

Input B1/B12

0...140 °C 1 -

56 56 Actual value of boiler temperature (TKx)

Input B2/B4

0...140 °C 1 -

57 - Actual value of common flow temperature 0...140 °C 1 61 61 Actual value 1 of d.h.w. temperature (TBWx)

(Higher temperature)

0...140 °C 1 -

62 62 Actual value 2 of d.h.w. temperature (TBWx)

(Lower temperature)

0...140 °C 1 -

63 63 Display of maximum flue gas temperature

(TGxmax)

To make a reset to the current value, press the + and –

buttons simultaneously for 3 seconds

0...350 °C 1 -

65 65 Attenuated outside temperature(TAxged) -50...+50 °C 0.5 66 66

Composite outside temperature

(Taxgem) -50...+50 °C 0.5 -

67 -

Outside temperature source

- - . - - Nosignal

00.01...14.16 Address

- -:- / 00.01...14.16

-1-

Setpoints

68 68 Display of boiler temperature setpoint 0...140 °C 1 69 - Display of common flow temperature setpoint 0...140 °C 1 70 70 Display of d.h.w temperature setpoint 0...140 °C 1 71 71 Display of nominal room temperature

setpoint

Nominal setpoint incl. room unit readjustment

0...35 °C 0,5 -

73 73 Display of room temperature setpoint (TRw) 0...35 °C 0,5 75 75 Display of flow temperature setpoint 0...140 °C 1 -

Page 26

26/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

RVA63.280

RVA53.280

Function

Range

Unit

Resolution

Factory setting

77 - Floor curing data

Day

Flow temperature setpoint

0...32

0...95

°C

1-

Heat generating equipment

80 80 Type of heat source

0 No heatgeneration or PPS-BMU

1 Single-stage burner

2 2-stage burner

0...2 - 1 2

81 81 Minimum limitation of boiler temperature (TKmin)

Tkmin

OEM

Line 1 OEM

Tkmax Line2OEM

TKmin

OEM

...TKmax °C 1 40

82 82 Extra heating for the bathroom

(HK2 ist pump heating circuits)

0Inactive

1Active

0/1 - 1 0

Heating circuit

100 100 Parallel displacement of heating curve -4,5...+4,5 °C (K) 0,5 0,0

101 101 Room influence

0Inactive

1Active

0/1 - 1 1

102 102 Switching differential of the room temperature

(SDR)

--.- Inactive

0.5...4.0 Active

- -:-...4,0 °C (K) 0,5 - -:-

103 103 Operating mode of room unit

0 Parallel action: Roomunit 1 on heating circuit 1

Room unit 2 on heating circuit 2

1 Crossed action: Room unit 1 on heating circuit 2

Room unit 2 on heating circuit 1

2 Serial action: Room unit 1 on heating circuits1

and 2

0...2 - 1 0

104 104 Room unit values

0 Parallel action: Roomunit 1 on heating circuit 1

Room unit 2 on heating circuit 2

1 Crossed action: Room unit 1 on heating circuit 2

Room unit 2 on heating circuit 1

2 Serial action: Room unit 1 on heating circuits1

and 2

0...2 - 1 0

105 105 Minimum limitation of flow temperature setpoint

(TVmin)

TVmax Line 107

8...TVmax °C 1 8

107 107 Maximum limitation of flow temperature setpoint

(TVmax)

Tvmin Line 105

TVmin...95 °C 1 80

109 109 Maximum forward shift of optimum start control

0 forwardshift/OFF

00:00...06:00 hh:mm 10 min 00:00

110 110 Maximum forward shift of optimum stop control

0 Noforwardingshift

00:00...06:00 hh:mm 10 min 00:00

113 113 Type of building construction

0Heavy

1 Light

0/1 - 1 1

114 114 Adaption of heating curve

0Inactive

1Active

0/1 - 1 1

115 115 Gain of locking signal 0...200 % 1 100

Page 27

27/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

RVA63.280

RVA53.280

Function

Range

Unit

Resolution

Factory setting

116 - Floor curing

0Off

1 Functional heating

2 Floor curing

3 Functional and floor curing heating

0...3 - 1 0

D.h.w.

120 120 Reduced setpoint of d.h.w. temperature (TBWR)

TBWw Line 26

8...TBWw °C 1 40

121 121 D.h.w. heating program

0 24 h/day

1 Heating program with forward shift

2 Timeswitchprogram3

0...2 - 1 1

123 - Assignment of d.h.w. heating

0 Local heating circuit

1 All heatingcircuits in the segment

2 All heatingcircuits in the system

0...2 - 1 2

124 124 D.h.w. charging

0 Once perday with a forward shift of 2.5 hours

1 Severaltimesperdaywitha1hforwardshift

0/1 - 1 1

125 125 Type of d.h.w. demand

0Sensor

1 Control thermostat

0/1 - 1 0

126 126 Boost of the flow temperature setpoint for d.h.w.

heating (UEBW)

0...30 °C (K) 1 16

127 127 D.h.w. priority

0 Absolute (mixing and pump heating circuit)

1 Shifting (mixing and pump heating circuit)

2 None (parallel)

3 Mixing heating circuit (shifted)

Pump heating circuit (absolut)

0...3 - 1 1

128 128 Controlling element for d.h.w.

0 Charging pump

1 Diverting valve

0/1 - 1 0

LPB / system

140 - LPB device address

0 Standalone

1...16 Deviceaddress (system)

0...16 - 1 0

141 - LPB segment address

0 Heat source segment

1...14 Heat consumption segments

0...14 - 1 0

142 - LPB power supply

0 Off (centralbus power supply

1) Auto (buspower supply via controller)

0/1 - 1 1

143 - Display of LPB power supply On / OFF - 145 - Range of action of central changeover

0 In the segment

1 In thesystem (if segment address = 0)

0/1 - 1 1

146 - Automatic summer / winter changeover

0 Local changeover

1 Central changeover of all heating circuits

0/1 - 1 0

147 - Central stand-by switch

1)

0Off

1ON

0/1 - 1 0

148 - Clock mode

0 Autonomous clock

1 System time without adjustment

2 (System time with adjustment)

3 System clock (master)

0...3 - 1 0

Page 28

28/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

RVA63.280

RVA53.280

Function

Range

Unit

Resolution

Factory setting

150 150 Winter- / summertime changeover 01.01...31.12 tt.MM 1 25.03

151 151 Summer- / wintertime changeover 01.01...31.12 tt.MM 1 25.10

155 155 Display of PPS communication (A6)

0 0 0 Short-circuit

- - - No communication

0...255 OK communication

000/---/0...255 - 1 -

156 156 Display of PPS communication room unit 2 (A7)

000 Short-circuit

- - - No communication, no room unit

0...255 Room unit number, communication OK

0...255 - 1 0

Multifunktional inputs (H1) (H2/B31)

170 170 Input H1

0 Changeover of operating mode of all HC and

d.h.w.

1 Changeover of operating mode of all HC

2 Min. flow temperature setpoint(TVHw)

3 Heat generation lock

1 Demand for heat DC 0...10 V

5 Changeover of operating mode HC1

6 Changeover of operating mode HC2

0...6 - 1 0

171 171 Minimum flow temperature setpoint contact H

(TVHw)

...TKmax Line 2 OEM

8...TKmax °C 1 70

172 172 Maximum value of heat demand signal (DC 0...10

V) H1

5...130 °C 1 100

173 173 Operating action contacts H1 and H2

0N.C.

1N.O.

0/1 - 1 1

174 174 Input B31/H2

0 D.h.w. sensor 2

1 Min. flow setpoint (TVHw)

2 Heat generation lock

1 Changeover of operating mode HC1

4 Changeover of operating mode HC2

0...4 - 1 0

1)

This line is active only if the unit is addressed as the heat generation master. Also refer

to "LPB device address" in Index.

Page 29

29/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

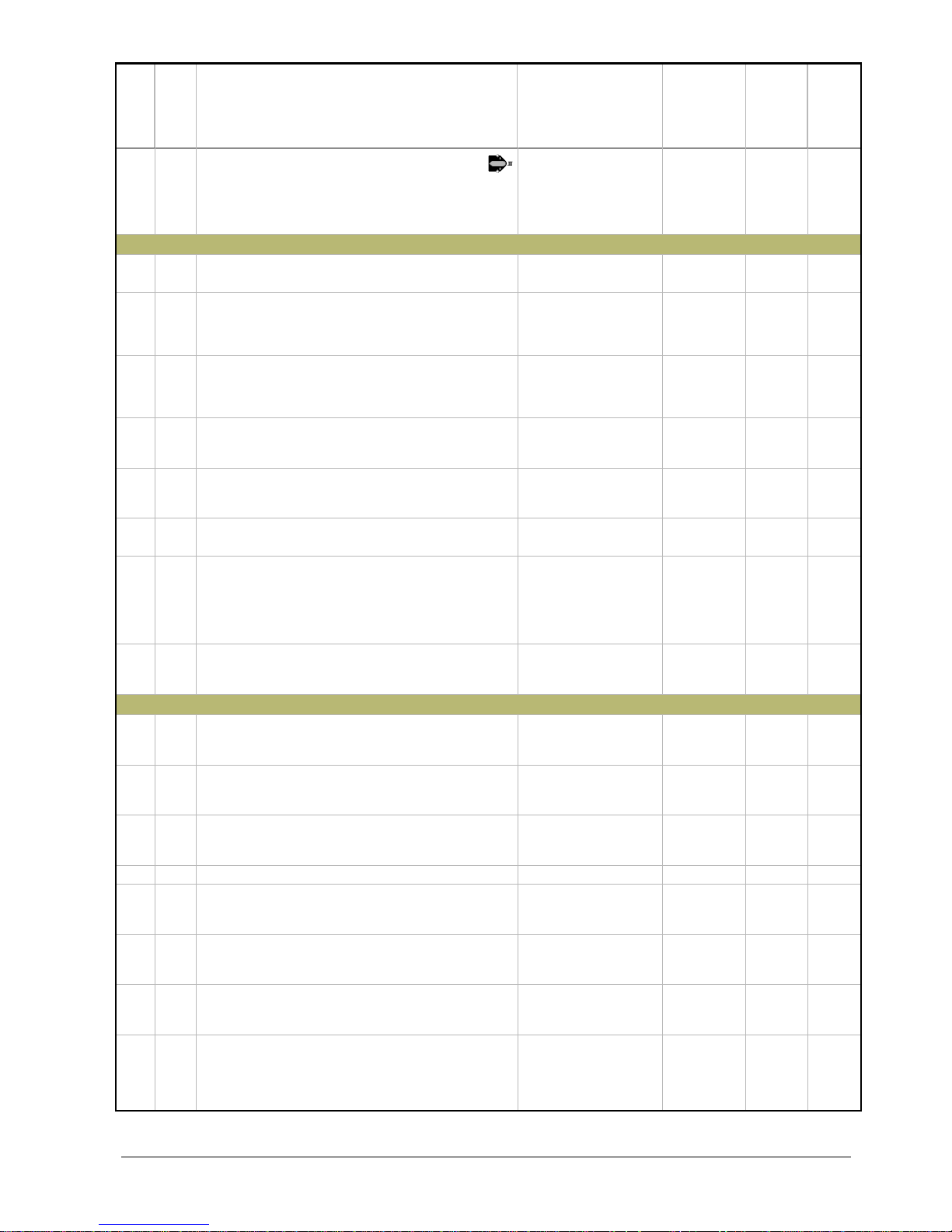

2.6 Parameter settings for the OEM

Boiler-specific settings and protective functions for the boiler manufacturer.

Buttons Explanation Line

1

Press one of the line selection buttons UP/DOWN.

This will take you directly to the programming mode

"End-user”.

2

9s

Press both line selection buttons for at least 9 seconds.

A special display for entering the code will appear.

3

CODE

Press buttons

and to enter the required

combination of the access code.

If the combination of buttons is correct, you reach the

programming mode “OEM”.

è Wrong code:

If the code has been entered incorrectly, the display will

change to the "Parameter settings for the heating

engineer”.

4

Press the line selection buttons to select the required

line.

The parameter list on the next 2 pages contains all

available lines.

•••

5

Press the + or - button to set the required value.

The setting will be stored as soon as you leave the

programming mode or change to another line.

The parameter list on the next 2 pages contains all

settings that can be made.

6

By pressing any of the operating mode buttons you leave

the programming mode “OEM”.

è Note:

If no button is pressed for about 8 minutes, thecontroller

will automatically return to the operating mode selected

last.

continuo

us

display

2374Z10

Whether correct or incorrect, each push of a button will be adopted asa digit of the

code. As a confirmation, the respective digit changes to 1.

Description

Setting

Example

Page 30

30/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

2.6.1 Overview of OEM parameters

RVA63.280

RVA53.280

Function

Range

Unit

Resolution

Factory setting

Heat generating equipment

1 1 Min. limitation of boiler temperature OEM

(TKmin

OEM

)

Tkmin Line 81

8...TKmin °C 1 40

2 2 Maximum limitation of boiler temperature

(TKmax)

Tkmin Line 81

TKmin...120 °C 1 80

3 3 Switching differential of the boiler temperature 0...20 °C (K) 1 8

4 4 Min. limitation of burner running time 0...10 min 1 4

5 5 Release limit (integral) of burner stage 2 0...500 °C (K) min 1 50

6 6 Reset limit (integral) of burner stage 2 0...500 °C (K) min 1 10

8 8 Pump overrun time

(after burner OFF)

0...20 min 1 5

9 9 Operating mode of boiler

0 Continuous mode: Ohneverlängerter

burner running time

1 Automatic mode: Ohne verlängerter

burner running time

2 Automatic mode: Mit verlängerter

burner running time

0...2 - 1 1

10 10 Protective boiler start-up

0No

1Yes

0/1 - 1 1

12 12 Control of boiler pump

0 Mixed temperature requisition

1 Parallel to burner operation

0/1 - 1 0

Heating circuit

30 30 Boost of flow temperature setpoint mixing

valve (UEM)

0...50 °C (K) 1 10

31 31 Gain factor of room influence (KORR) 0...20 - 1 4

32 32 Constant for quick setback and optimum start

control (KON)

0...20 - 1 2

33 33 Boost of room temperature setpoint (DTRSA)

(with boost heating)

0...20 °C (K) 1 5

34 34 Frost protection for the plant

0Inactive

1Active

0/1 - 1 1

35 35 Control mode of actuator (Y1 / Y5)

0 2-position (Y1) / (Y5)

1 3-position (Y1,Y2 / Y5,Y6)

0/1 - 1 1

36 36 Switching differential of actuator

For 2-position mixing valve

0...20 °C (K) 1 2

37 37 Overtemperature protection for the pump heating

circuit

0Inactive

1Active

0/1 - 1 1

38 38 Heat gains (Tf) -2...+4 °C 0,1 0

39 39 Adaption sensitivity 1 (ZAF1) 1...15 - 1 15

40 40 Adaption sensitivity 2 (ZAF2) 1...15 - 1 15

41 41 P-band mixing valve (Xp) 1...100 °C (K) 1 32

42 42 Integral action time mixing valve (Tn) 10...873 s 1 120

Page 31

31/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

RVA63.280

RVA53.280

Function

Range

Unit

Resolution

Factory setting

43 43 Actuator running time mixing valve 30...873 s 1 120

D.h.w.

50 50 Maximum nominal setpoint of d.h.w. temperature

(TBWmax)

8...80 °C 1 60

51 51 Switching differential of d.h.w. temperature

(SDBW)

0...20 °C (K) 1 5

52 52 Legionella function

0Inactive

1Active

0/1 - 1 1

53 53 Setpoint of legionella function 8...95 °C 1 65

54 54 Discharge protection during d.h.w. heating

0No

1 Continuously

2Partly

0...2 - 1 2

Service

90 90 Continuous display

0 Weekday / time of day

1 Actual value of boiler temperature

0/1 - 1 0

91 91 Software version 00.0...99.0 - 1 92 92 Device operating hours 0...500000 h 1 0

Page 32

32/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

2.7 Operation

Operating Instructions are inserted at the rear of the unit's front cover.

2.7.1 Operating elements

BUS

ECO

2

2374Z01

8

1

11

3

4

76 5

10

9

Operating element

Function

Room temperature setpoint knob

HC1

Adjustment of room temperature setpoint

for heating circuit 1

Room temperature setpoint knob

HC2

Adjustment of room temperature setpoint

for heating circuit 2

Setting buttons

Parameter settings

Line selection buttons

Parameter settings

Heating circuit selection button

Pre-selection of heating circuit when

making settings

Function button with LED for

manual operation

Activation of manual operation

Function button with LED for

chimney sweep

Activation of chimney sweep function

Operating mode buttons heating

circuit

Operating mode changes to:

Automatic operation

Continuous operation

Stand-by

Operating mode button d.h.w.

D.h.w. heating ON / OFF

Display

Display of actual values and settings

Connection facility for PC tool

Diagnostics and service

Introduction

Page 33

33/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

a)

b)

c)

BUS

ECO

2374Z02

d)

a) Symbols - indication of operating state with the black pointers

b) Display during normal control mode or when making settings

c) Programming line when making settings

d) Heating program of current day

Display

Page 34

34/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

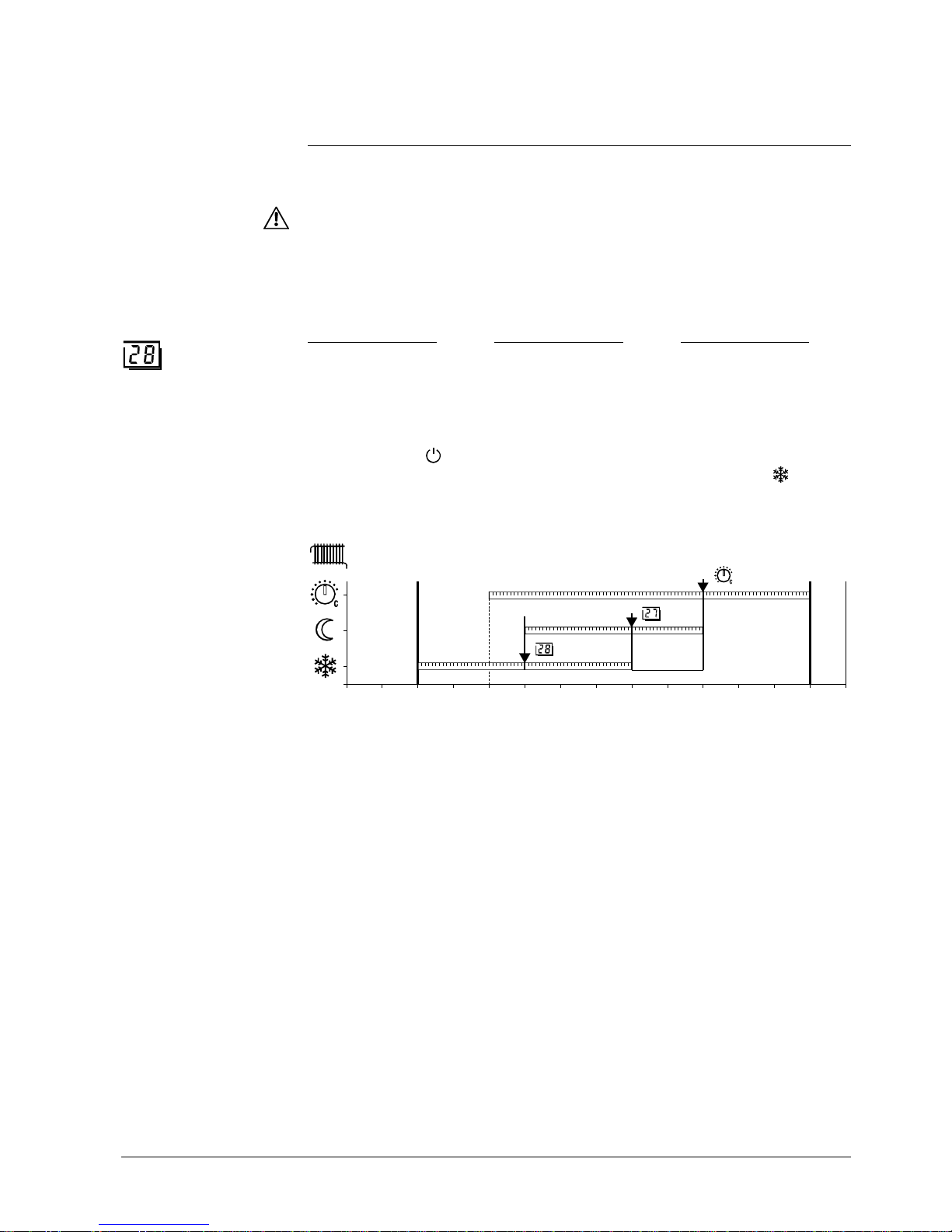

2.8 Operational faults

2.8.1.1 No display on the controller:

• Is the heating plant's main switch turned on?

• Are the fuses in order?

• Check wiring

2.8.1.2 Heating control does not function. There is no display of the time of

day, or the time displayed is incorrect

• Check fuses of the plant

• Make a reset: Isolate controller from the mains supply for about 5 seconds (e.g. turn

off the boiler's main switch for 5 seconds)

• Set the correct time of day on the controller (operating l ine 1).

• Check the time of day on the clock time master if the controller is used in a system

2.8.1.3 Controlling element does not open / close or does not operate

correctly.

• Manual lever of controlling element may not be engaged

• Wiring to the controlling element interrupted (output test)

• Check wiring of the sensors (input test)

• Quick setback or automatic 24-hour heating limit is active

• Check the settings, especially the selection of the double function

2.8.1.4 Heating circuit pump does not run

• Is the right type of plant displayed (setting line 53)?

• Check wiring and fuse (output test)

• Check wiring of the sensors (input test)

• Check the settings, especially the selection of the double function

2.8.1.5 Burner does not switch on

• Press burner's reset button

• Check the fuses

• Wiring to the controlling element interrupted (output test)

• Check the electromechanical control thermostat (TR) and the manual reset safety

limit thermostat (STB)

• Quick setback or automatic 24-hour heating limit is active

• Check wiring of the boiler temperature sensor (input test)

2.8.1.6 Pump does not run

• Check wiring and fuse (output test)

• Check wiring of the sensors (input test)

2.8.1.7 D.h.w. is not being heated

• Has the button for d.h.w. heating been activated?

• Check setting of the electromechanical control thermostat (TR) installed on the

boiler. It must be above the TKmax setting

• Check setpoint of the d.h.w. temperature

• Check actual value of the d.h.w. temperature

Page 35

35/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

• Check if d.h.w. heating is released

• Check wiring and fuse of the charging pump (input test)

• Check wiring of the d.h.w. temperature sensor (output test)

2.8.1.8 The room temperature does not agree with the required temperature

level:

• Check the room temperature setpoints

• Is the required operating mode indicated?

• Is automatic operation overridden by the room unit?

• Are weekday, time of day and the displayed heating program correct?

• Has the heating curve slope been correctly set?

• Check wiring of outside sensor

2.8.1.9 Heating plant does not function properly

• Check all parameters based on the setting instructions "Heating engineer" and the

operating instructions "End-user". especially the preselection of the double function

• Make the input test

• Make the output test

• Check the electromechanical control thermostat (TR) and the manual reset safety

limit thermostat (STB)

2.8.1.10 Frost protection for the plant does not function at all, or does not

function correctly

• Check correct functioning of the burner

• Check correct functioning of the pumps

• Frost protection for the plant in the case of pump heating circuits with active room

temperature limitation

2.8.1.11 Quick setback or boost heating does not function

• Check settings made on the heating engineer's level

• Fühler an A6,A7 kontrollieren (Eingangtest).

• Check the sensor connected to A6, A7 (input test)

2.8.1.12 Fault status signal; display shows "ER"

• For cause of error, refer to section "Parameter settings for end-user" on line 50

Page 36

36/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001

1 Description of end-user settings

User interface

1.1 Operating modes of heating circuit

Straightforward and direct selection of heating circuit operating modes.

The control provides 3 different heating circuit operating modes that can be directly

selected as required.

Select the required operating mode by pressing the respective operating mode button.

It is located on the controller front for direct access by the user.

The setting can be made separately for both heating circuits with the heating circuit

selection button.

The d.h.w. operating mode will not be affected by the selected heating circuit operating

mode, with the exception of the holiday function and when the remote telephone switch

is activated

Operating

mode

Designation Effect of selected operating mode

Automatic

operation

• Heating according to the time program

(lines 5 to 11)

• Temperature setpoints according to the heating

program

• Protective functions active

• Changeover on the room unit active

• Automatic summer / winter changeover (ECO

functions) and automatic 24-hour heating limit

active

Continuous

operation

• Heating mode with no time program

• Temperature adjustment with the setpoint knob

• Protective functions active

• Changeover on room unit inactive

• Automatic summer / winter changeover (ECO

functions)

inactive

Stand-by • Heating OFF

• Temperature according to frost protection

• Protective functions active

• Changeover on room unit inactive

• Automatic summer / winter changeover (ECO

functions) and automatic 24-hour heating limit

active

Benefit

Description

Setting

Note

Effect

Page 37

37/184

Siemens Building Technologies Basic Dokumentation RVA63.280, RVA53.280 CE1P2374E

Landis & Staefa Division 19.04.2001