Page 1

Ausgabe 2.2

Controller series B

CE1P2379E

15.07.2002

Siemens Building Technologies

HVAC Products

RVA47.320

Cascade Controller for modulating gas-fired Boilers

Basic Documentation

Page 2

2/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products 15.07.2002

Page 3

3/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Contents 15.07.2002

Contents

1 Summary ......................................................................................................... 8

1.1 Brief description............................................................................................... 8

1.2 Features .......................................................................................................... 9

1.3 Range of products ......................................................................................... 11

1.4 Field of use .................................................................................................... 12

1.5 Product liability .............................................................................................. 12

2 Handling ........................................................................................................ 13

2.1 Installation ..................................................................................................... 13

2.1.1 Mounting location .......................................................................................... 13

2.1.2 Regulations for installation ............................................................................13

2.1.3 Mounting procedure....................................................................................... 13

2.1.4 Required cut-out ............................................................................................ 15

2.1.5 Orientation ..................................................................................................... 15

2.2 Electrical installation ...................................................................................... 16

2.2.1 Regulations for installation ............................................................................16

2.2.2 Wiring ............................................................................................................ 16

2.3 Commissioning .............................................................................................. 18

2.3.1 Functional checks.......................................................................................... 18

2.4 Parameter settings for the enduser ............................................................... 20

2.4.1 Overview of enduser parameters ..................................................................21

2.5 Parameter settings for the heating engineer .................................................22

2.5.1 Overview of heating engineer parameters..................................................... 23

2.6 Parameter settings for the OEM .................................................................... 27

2.6.1 Overview of OEM parameters ....................................................................... 28

2.7 Operation.......................................................................................................30

2.7.1 Operating elements ....................................................................................... 30

2.8 Operational faults .......................................................................................... 31

3 Description of the enduser settings ............................................................... 32

User interface ................................................................................................................32

3.1 Heating circuit operating modes .................................................................... 32

3.2 Operating mode of d.h.w. heating .................................................................33

3.3 Nominal room temperature setpoint .............................................................. 34

3.4 Manual operation...........................................................................................35

Setting the clock ............................................................................................................37

3.5 Time of day....................................................................................................37

3.6 Weekday........................................................................................................ 37

3.7 Date (day, month)..........................................................................................38

3.8 Year ............................................................................................................... 38

Time switch program for space heating......................................................................... 39

3.9 Preselecting the weekday.............................................................................. 39

3.10 Switching times.............................................................................................. 40

D.h.w. values .................................................................................................................42

3.11 Nominal d.h.w. temperature setpoint............................................................. 42

Heating circuit values .................................................................................................... 43

3.12 Reduced room temperature setpoint ............................................................. 43

3.13 Frost protection setpoint of the room temperature ........................................44

3.14 Summer / winter changeover temperature of the heating circuit ................... 44

3.15 Heating curve slope....................................................................................... 46

Page 4

4/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Contents 15.07.2002

Actual values..................................................................................................................48

3.16 Actual value of the room temperature............................................................48

3.17 Actual value of outside temperature ..............................................................48

Maintenance ..................................................................................................................49

3.18 Standard time switch program for heating circuit and d.h.w. .........................49

Time switch program for d.h.w. heating .........................................................................50

3.19 Preselecting the weekday ..............................................................................50

3.20 Switching times ..............................................................................................50

Service . ...................................................................................................................52

3.21 Displaying the BMU error code ......................................................................52

3.22 Indication of faults ..........................................................................................53

4 Description of the heating engineer settings..................................................55

Service values................................................................................................................55

4.1 Output test .....................................................................................................55

4.2 Input test ........................................................................................................55

4.3 Display of plant type.......................................................................................56

4.4 Displaying the PPS communication ...............................................................58

Actual values..................................................................................................................60

4.5 Actual boiler temperature values of BMUs (TKx)...........................................60

4.6 Actual value of cascade flow temperature .....................................................60

4.7 Actual value of the cascade return temperature ............................................61

4.8 Actual value of buffer storage tank temperature ............................................63

4.9 Actual value of the d.h.w. temperature (TBWx) .............................................63

4.10 Attenuated outside temperature.....................................................................64

4.11 Composite outside temperature.....................................................................65

Setpoints . ..................................................................................................................66

4.12 Outside temperature source ..........................................................................66

4.13 Boiler temperature setpoint of BMUs .............................................................66

4.14 Setpoint of the cascade flow temperature......................................................67

4.15 D.h.w temperature setpoint............................................................................67

4.16 Nominal room temperature setpoint...............................................................68

4.17 Room temperature setpoint ...........................................................................69

4.18 Flow temperature setpoint .............................................................................69

Heat generation values ..................................................................................................70

4.19 Existing boilers...............................................................................................70

4.20 Display lead boiler..........................................................................................70

4.21 Remaining number of operating hours for changeover of boiler sequence ...71

4.22 Burner operating hours BMU 1 – 4 ................................................................72

4.23 Minimum limitation of the boiler temperature TKmin......................................72

4.24 Nominal output of BMU 1 - 4..........................................................................73

Configuration of plant.....................................................................................................74

4.25 Pump function output Q1 ...............................................................................74

4.26 Use sensor input B70/B4 ...............................................................................74

Heating circuit values.....................................................................................................76

4.27 Parallel displacement of the heating curve ....................................................76

4.28 Room influence ..............................................................................................76

4.29 Switching differential of the room temperature ..............................................77

4.30 Minimum limitation of the flow temperature setpoint......................................78

4.31 Maximum limitation of the flow temperature setpoint.....................................79

4.32 Type of building construction .........................................................................80

4.33 Adaption of the heating curve ........................................................................81

Page 5

5/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Contents 15.07.2002

4.34 Maximum forward shift of optimum start control............................................ 82

4.34.1 Optimum start control .................................................................................... 83

4.34.2 Without room influence.................................................................................. 83

4.34.3 With room influence....................................................................................... 83

4.35 Maximum forward shift of optimum stop control ............................................ 84

4.35.1 Optimum stop control ....................................................................................84

D.h.w. values .................................................................................................................85

4.36 Reduced setpoint of the d.h.w. temperature.................................................. 85

4.37 Release of d.h.w. heating .............................................................................. 85

4.37.1 24-hour operation - Setting 0......................................................................... 86

4.37.2 Operation according to heating program(s) with forward shift - Setting 1 ..... 86

4.37.3 Operation according to the d.h.w. time switch program - Setting 2 ...............87

4.38 Switching program circulating pump.............................................................. 87

4.39 Assignment of d.h.w. heating ........................................................................88

4.40 Number of d.h.w. charging cycles .................................................................88

4.40.1 Once per day with a forward shift of 2.5 hours Setting 0............................... 89

4.40.2 Several times per day with a forward shift of 1 hour Setting 1 ......................89

4.41 Type of d.h.w. demand .................................................................................. 89

4.42 Boost of the flow temperature setpoint for d.h.w. ..........................................90

4.43 D.h.w. priority................................................................................................. 91

4.43.1 Shifting priority............................................................................................... 92

4.44 Demand for heat with reduced d.h.w. setpoint ..............................................94

Cascade settings ...........................................................................................................95

4.45 Changeover of boiler sequence in a cascade ...............................................95

4.46 Exemption from automatic changeover of the boiler sequence..................... 96

4.47 Lead boiler with a fixed changeover of the boiler sequence.......................... 97

4.48 Switch-on delay lag boilers............................................................................ 98

4.49 Restart lock of BMUs..................................................................................... 98

LPB / system ................................................................................................................. 99

4.50 LPB device address....................................................................................... 99

4.51 LPB segment address ................................................................................. 100

4.52 LPB power supply........................................................................................ 100

4.53 Displaying the LPB power supply ................................................................101

4.54 Displaying the LPB communication ............................................................. 101

4.55 Range of action of central changeover........................................................ 102

4.56 Automatic summer / winter changeover ...................................................... 102

4.57 Central standby switch ................................................................................103

4.58 Clock mode.................................................................................................. 103

4.59 Winter- / summertime changeover ..............................................................104

4.60 Summer- / wintertime changeover............................................................... 105

Input H1 . .............................................................................................................. 106

4.61 Input H1 ....................................................................................................... 106

4.61.1 Changeover of operating mode (remote telephone switch) - Setting 0 / 1 107

4.61.2 Minimum setpoint of flow temperature contact H1 ......................................108

4.61.3 Heat generation lock - Setting 3 ................................................................ 108

4.61.4 Demand for heat - Setting 4 ......................................................................109

4.62 Minimum setpoint of flow temperature contact H1 ......................................110

4.63 Maximum value of heat demand signal DC 0...10 V (H1) ...........................111

4.64 Operating action of the contact connected to H1 ........................................111

5 Description of the OEM settings .................................................................. 112

Heat generation values................................................................................................ 112

5.1 Minimum limitation of the boiler temperature setpoint OEM (TKmin

OEM

).....112

Page 6

6/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Contents 15.07.2002

5.2 Maximum limitation of the boiler temperature setpoint ................................112

5.3 Pump overrun time.......................................................................................113

5.4 Minimum limitation of the boiler return temperature.....................................113

5.5 Calibration of actual output range of BMU 1-4.............................................114

Heating circuit values...................................................................................................115

5.6 Gain factor of room influence (KORR) .........................................................115

5.7 Constant for quick setback (KON) ...............................................................116

5.8 Boost of room temperature setpoint.............................................................117

5.9 Frost protection for the plant ........................................................................118

5.10 Overtemperature protection for the pump heating circuit.............................119

5.11 Heat gains....................................................................................................120

5.12 Adaption sensitivity 1 ...................................................................................120

5.13 Adaption sensitivity 2 ...................................................................................121

D.h.w. values ...............................................................................................................123

5.14 Maximum nominal setpoint of d.h.w. temperature .......................................123

5.15 Switching differential of the d.h.w. temperature ...........................................123

5.16 Legionella function .......................................................................................124

5.17 Setpoint of the legionella function ................................................................125

5.18 Protection against discharging of d.h.w. ......................................................125

Cascade settings .........................................................................................................127

5.19 Cascade management strategy ...................................................................127

5.19.1 Type of lead boiler operation .......................................................................128

5.19.2 Running time strategies ...............................................................................129

5.20 Lower limit of output range (Pmin) ...............................................................131

5.21 Upper limit of output range (Pmax) ..............................................................132

5.22 Mandatory time on basic stage ....................................................................132

5.23 Minimum temperature differential at the pressureless header.....................133

Configuration of plant...................................................................................................134

5.24 Continuous display.......................................................................................134

General values.............................................................................................................135

5.25 Software version ..........................................................................................135

5.26 Device operating hours ................................................................................135

6 Functions with no settings............................................................................136

6.1 Chimney sweep ...........................................................................................136

6.2 Generating the boiler temperature setpoint .................................................136

6.3 Automatic 24-hour heating limit ...................................................................137

6.3.1 Without room influence ................................................................................137

6.3.2 With room influence .....................................................................................138

6.4 Quick setback with room sensor ..................................................................139

6.5 D.h.w. push ..................................................................................................140

6.6 Pump kick ....................................................................................................141

6.7 Protection against discharging after d.h.w. heating .....................................141

6.8 Overview of pump operation ........................................................................142

6.9 Frost protection ............................................................................................143

6.9.1 For the boiler................................................................................................143

6.9.2 For the d.h.w. ...............................................................................................143

7 Application examples ...................................................................................144

7.1 Plant types RVA47.320 - no. 27...................................................................145

7.2 Plant types RVA47.320 - no. 28...................................................................146

7.3 Plant types RVA47.320 - no. 29...................................................................147

7.4 Plant types RVA47.320 - no. 30...................................................................148

Page 7

7/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Contents 15.07.2002

7.5 Plant types RVA47.320 - no. 31 .................................................................. 149

7.6 Plant types RVA47.320 - no. 32 .................................................................. 150

7.7 Plant types RVA47.320 - no. 33 .................................................................. 151

7.8 Plant types RVA47.320 - no. 34 .................................................................. 152

7.9 Plant types RVA47.320 - no. 35 .................................................................. 153

7.10 Plant types RVA47.320 - no. 36 .................................................................. 154

7.11 Plant types RVA47.320 - no. 65 .................................................................. 155

7.12 Plant types RVA47.320 - no. 66 .................................................................. 156

7.13 Plant types RVA47.320 - no. 67 .................................................................. 157

7.14 Legend......................................................................................................... 158

8 Dimensions.................................................................................................. 159

9 Technical data .............................................................................................160

Page 8

8/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Summary 15.07.2002

1 Summary

1.1 Brief description

ALBATROS™- RVA47.320 (B-series) is designed for use as a single-boiler controller or

cascade controller with up to 12 heat sources.

It is designed for integration in heat generating equipment / plants with

• a modulating gas burner

• a Boiler Management Unit (BMU)

• d.h.w. heating with charging pump (via RVA47) or changeover valve

(via BMU)

• a primary or heating circuit pump

Heating circuit control uses weather compensation while d.h.w. heating operates

depending on the storage tank temperature and the time program.

When employed in an interconnected system along with the ALBATROS™ controller

RVA43.222 (C-series), it is possible to operate mixed cascades (modulating / multistage) with up to 15 heat sources.

When used in connection with gas-fired heating boilers, the availability of a BMU is

mandatory. Siemens offers different types of BMUs:

- Boiler Mangement Unit LMU5/6x

It is also possible to use BMUs of other manufacture if appropriately equipped. If you

intend to use a non-Siemens burner control in connection with the RVA47.230, please

contact your nearest Siemens representative.

The range of products comprises several units that complement one another in terms of

application and scope of functions. The controllers have communication capability and

can be combined to form heating systems that include up to 40 controllers.

For more detailed information about the generation of LPB systems, refer to "Local

Process Bus (LPB), Basic Documentation, System Engineering”, document no.

CE1P2370E.

Important

Use in extensive systems

Page 9

9/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Summary 15.07.2002

1.2 Features

• Heating circuit control with a pump heating circuit

• Remote operation via digital room unit

• Quick setback and boost heating

• Automatic 24-hour heating limit

• Automatic summer / winter changeover

• The building's thermal dynamics are taken into consideration

• Automatic adjustment of the heating curve to the type of building construction and

the heat demand (provided a room unit is connected)

• Overload detection (shifting priority)

• Manual operation

• Cascading with up to 12 modulating heat sources controlled by one controller in

combination with BMUs via LPB

• Cascading with up to 15 modulating heat sources and additional RVA47.320 (from

B-series) via PPS

• Control of mixed cascades (modulating or multistage) with up to 12 heat sources in

combination with RVA43.222 (from C-series) with BMUs via LPB

• Selectable boiler sequence and boiler strategy

• Weather-compensated heating circuit control with or without room influence

• Cascade flow temperature control depending on the heat demand signal from the

heating circuits connected to the system or from controllers outside the system (via

input H1)

• Cascade flow temperature control depending on the temperature demand signal

(DC 0…10 V, input H1)

• Adjustable maximum limitation of temperature demand signals delivered to the

heating boiler

• Performance-related switching on / off of boilers, very accurate flow temperatures

• Supervision of operating conditions at the pressureless header, low return

temperatures

• Protection against boiler overtemperatures (pump overrun)

• Protective boiler startup (acting on the mixing valve)

• Minimum limitation of the boiler return temperature (acting on the mixing valve)

• Adjustable minimum and maximum limitation of boiler temperature (boiler flow

temperature)

• Frost protection for the building, the plant and the boiler

• Frost protection for the d.h.w. storage tank connected directly to the controller

• Pump protection through periodic pump kick

• Overtemperature protection for the pump heating circuit

Heating circuit

Heat generation

Protection for the plant

Page 10

10/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Summary 15.07.2002

• Temperature adjustment with the setpoint knob

• 7-day or 24-hour program for the heating circuit and d.h.w. heating

• Automatic button for efficient operation throughout the year

• D.h.w. button

• Manual operation at the touch of a button

• Output and input tests to aid commissioning and functional checks

• Straightforward selection of operating mode via buttons

• Change of operating mode via a remote switch (via contact H1)

• Heat generation lock or minimum demand for heat with the remote switch (via

contact H1)

• Service connection facility for local parameter settings and data logging

• D.h.w. heating with charging pump or via BMU with diverting valve

• D.h.w. control with temperature sensor or control thermostat

• Selectable priority for d.h.w. heating

• Selectable d.h.w. heating program

• Adjustable boost of the d.h.w. charging temperature

• Reduced setpoint of the d.h.w. temperature

• Protection against discharging of d.h.w.

• Automatic d.h.w. push

• Legionella function

• Communication via the Local Process Bus (LPB)

• Communicating via point-to-point interface (PPS)

• Controllers of other manufacture can deliver their heat demand signal by closing

potential-free contact H1

• Controllers of other manufacture can deliver their analog heat demand by using DC

0...10 V signals

• Input for cascade flow temperature sensor

• Input for cascade return temperature sensor

• Integrity of system architecture with all RVA... controllers

• Can be extended to include 40 heating circuits (with central bus power supply)

• Optional remote supervision

• Error messages (own faults, faults of LPB devices, faults of PPS devices)

• Logging the individual BMU operating hours

• Logging the number of device operating hours

Operation

D.h.w.

Use in extensive

systems

Logging

Page 11

11/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Summary 15.07.2002

1.3 Range of products

The following units and accessories are designed for use with the ALBATROS range:

Type of unit Description Documentation no.

RVA47.320 Cascade controller for modulating gas-fired heating

boilers

CE1P2379E

RVA43.222 Boiler and heating circuit controller (from C-series) CE1P2390E

RVA46.531 Heating circuit controller CE1P2372E

RVA66.540 Heating circuit or primary controller CE1P2378E*

LMU5/6x

Siemens BMUs for heating circuit and d.h.w. control

............. Different types of non-Siemens burner controls for d.h.w. control (e.g.

MCBA)

OCI42

Communication interface RVA-LMU5/6x

RMCI Communication interface RVA-MCBA

QAA10 Digital room sensor

QAA70 Digital, multifunctional room unit

QAA50 Digital room unit

QAC31 Outside sensor NTC 600

QAC21 Outside sensor LG-Ni 1000

QAZ21 Immersion sensor LG-Ni 1000 complete with cable

QAD21 Strap-on sensor LG-Ni 1000

AGP2S.02M LPB (2 poles) violet

AGP2S.02G Room unit (2 poles) blue

AGP2S.06A Sensor (6 poles) white

AGP3S.02D Mains (2 poles) black

AGP3S.03B Pumps (3 poles) brown

Controllers

Burner controls

Room units

Sensor

Screw type terminal strips

(Rast 5)

Page 12

12/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Summary 15.07.2002

1.4 Field of use

• OEMs

• Manufacturers of modulating gas-fired appliances with BMUs

• Residential and non-residential buildings with own heating and d.h.w. heating

facility

• Residential and non-residential buildings with a central heat generating plant

• Standard heating systems, such as:

Standard heating systems, such as radiator, convector, underfloor and ceiling

heating systems, and radiant panels

• With or without d.h.w. heating

• Gas-fired heating boilers with modulating burners.

• Parallel cascading with lead / lag boiler changeover or fixed priority for up to 4

modulating gas-fired boilers (of identical or different capacities) with only one

controller

• Parallel cascading with up to 16 modulating gas-fired boilers (of identical or

different capacities) with additional RVA47.320 (from B-series)

• Mixed cascades with up to 16 modulating and multistage heat sources with

additional RVA47.320 (from B-series) and RVA43.222 (from C-series)

1.5 Product liability

• The products may only be used in building services plant and applications as

described above

• When using the products, all requirements specified in chapters "Handling" and

"Technical data" must be satisfied

• When using the products in a system, all requirements contained in the

documentation ”Local Process Bus (LPB), Basic Documentation, System

Engineering” (document no. CE1P2370E) must be satisfied

• The local regulations for installation must be complied with

Target market

Types of buildings

Types of heating systems

Heat generating

equipment

Page 13

13/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

2 Handling

2.1 Installation

2.1.1 Mounting location

• Boiler control panel

• In the control panel front

2.1.2 Regulations for installation

• A clearance of at least 10 mm must be provided on all sides of the controller,

enabling the unit to emit the amount of heat produced during its operation. The

space should not be accessible and no objects should be placed there.

• The controller is designed for mounting in a boiler control panel. Power to the

controller may be supplied only after it is completely fitted in the cutout. If this is not

observed, there is a risk of electric shock near the terminals and through the

cooling slots.

• If the controller shall be mounted directly on the wall, a housing must be used to

provide protection against electric shock hazard. The housing must have a

sufficient number of cooling slots at the bottom and the top, allowing the controller

to emit the heat it produces.

• The controller has been designed based on the guidelines of safety class 2 and

must therefore be mounted in compliance with these regulations.

• The controller may not be exposed to dripping water.

• Permissible ambient temperature: 0...50 °C

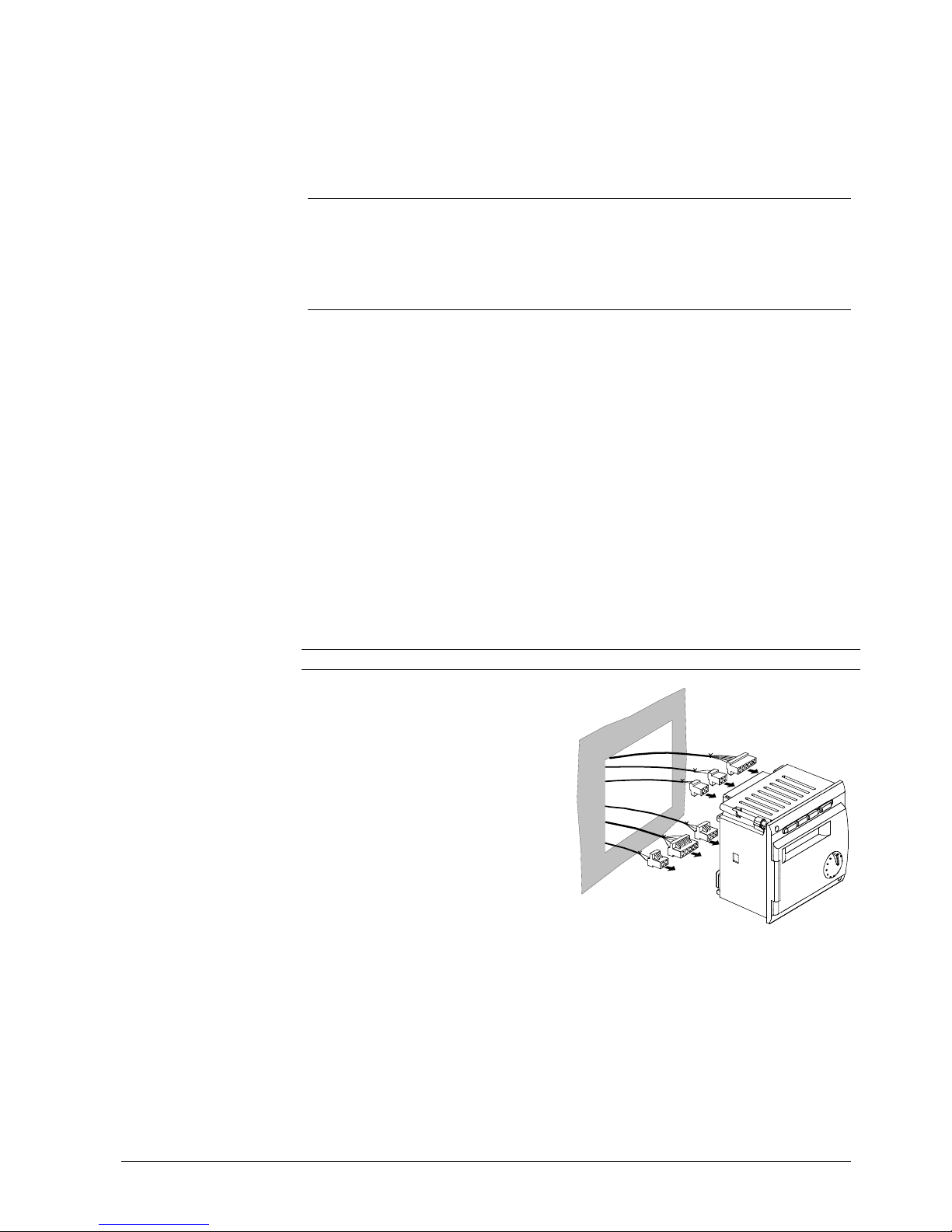

2.1.3 Mounting procedure

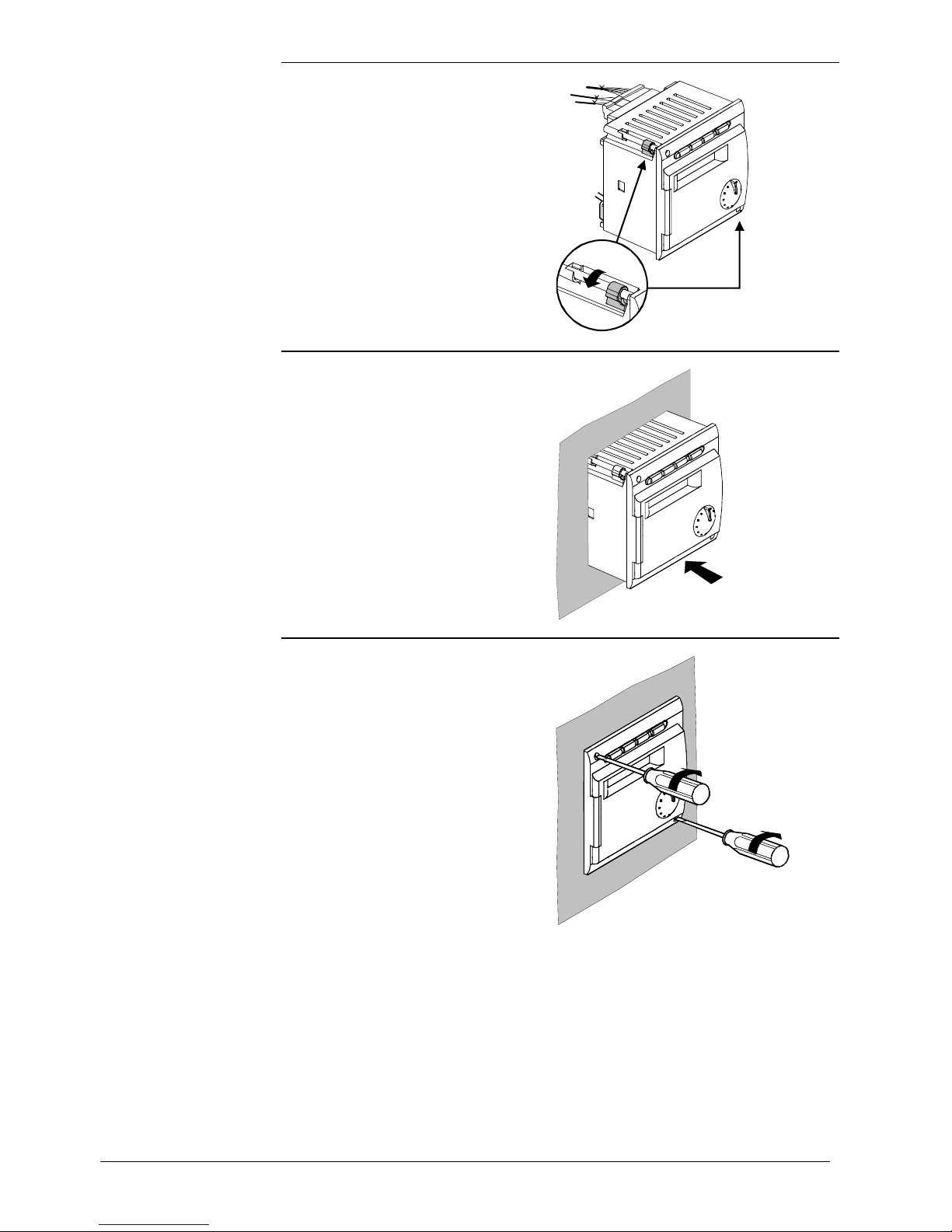

Description Diagram

• Turn off power supply

• Pull the prefabricated cables

through the cut-out

• Plug the connectors into the

respective sockets at the rear of the

controller

Note:

The connectors are coded to make

certain they cannot be mixed up.

2379Z11

1. step

Page 14

14/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

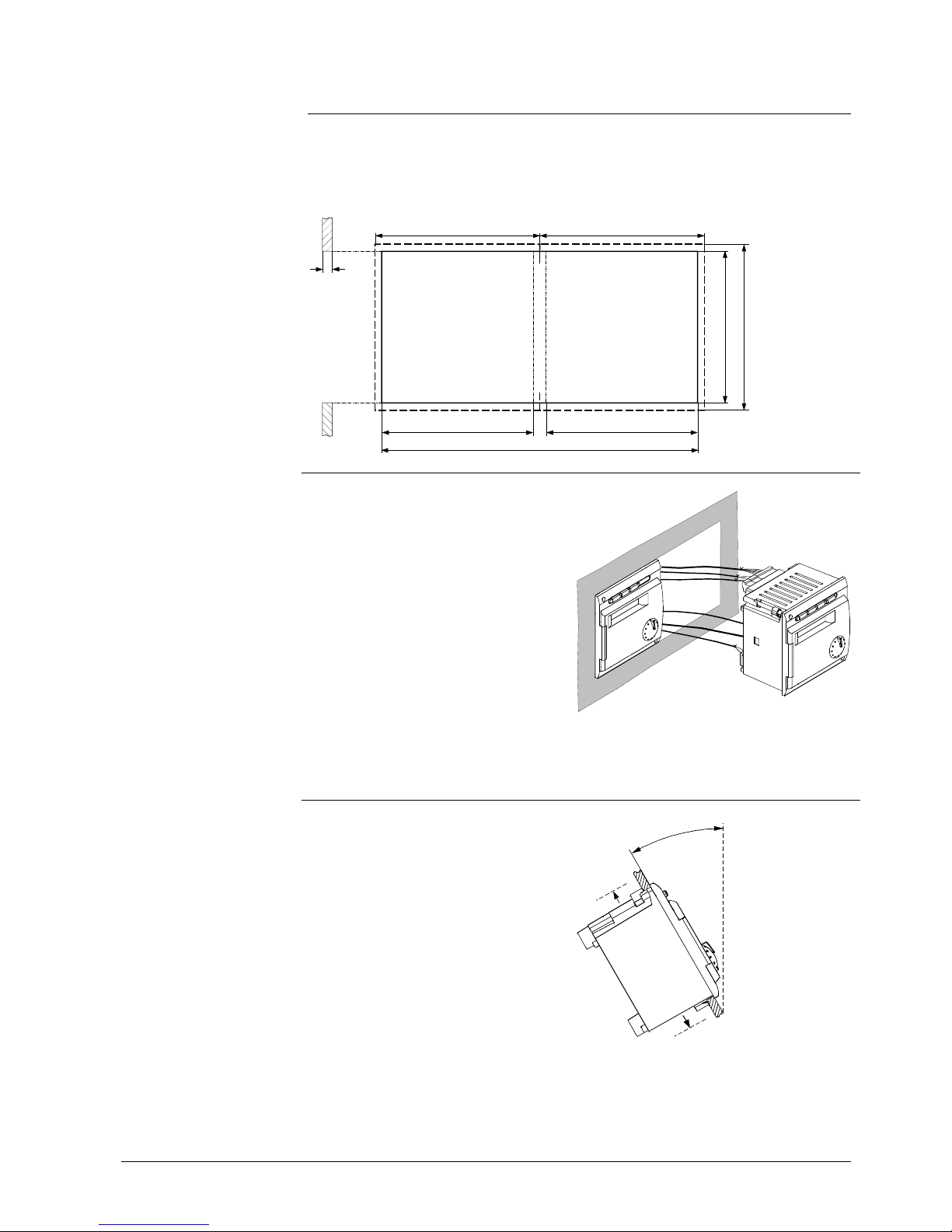

• Check to ensure the fixing levers

are turned inward

• Check to make certain there is

sufficient space between the front

panel and the fixing levers

2379Z12

• Slide the unit into the panel cut-out

without applying any force

Note:

Do not use any tools when inserting

the unit into the cut-out. If it does not

fit, check the size of the cut-out and

the housing.

2379Z13

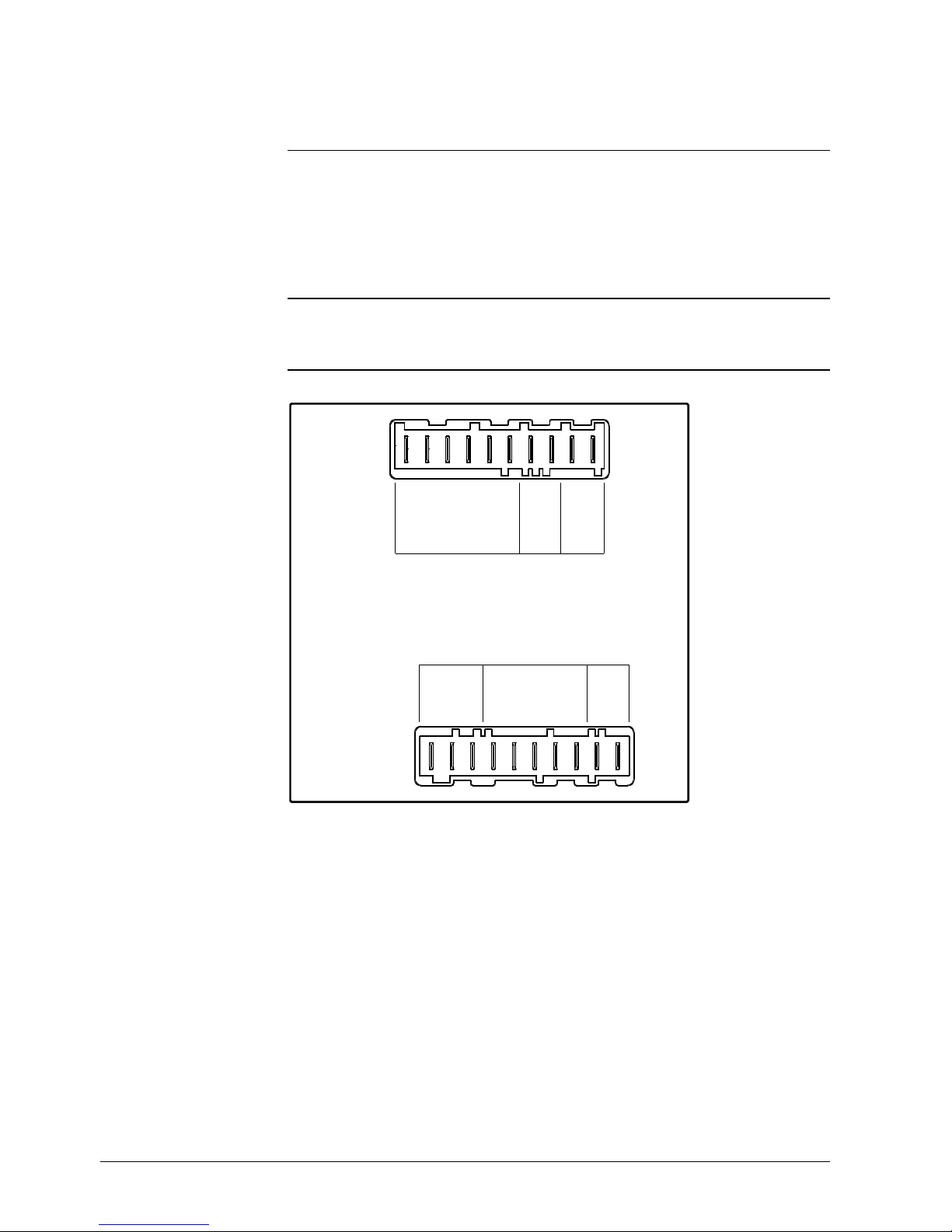

• Secure the fixing levers by

tightening the two screws on the

front of the controller.

Note:

Tighten the screws only slightly .

When tightening the screws, the

fixing levers automatically assume

their correct positions.

2379Z142379Z14

2. step

3. step

4. step

Page 15

15/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

2.1.4 Required cut-out

The controller’s mounting dimensions are 91 x 91 mm.

Due to the dimensions of the front, however, the standard spacing is 96 mm.

The mechanical mounting facility allows the controller to be fitted in front panels having

a thickness of 2 to 10 mm.

The mechanical mounting facility makes

it possible to arrange several controllers

in a row in one cut-out. In that case, it is

merely necessary to have a wider panel

cutout.

2379Z15

2.1.5 Orientation

To avoid overtemperatures inside the

controller, the inclination may be no

more than 30° and there must be a

clearance of at least 10 mm on all sides

of the unit.

This allows the controller to emit the

heat generated during operation.

1

0

m

m

m

a

x

.

3

0

°

2

3

7

1

Z

1

6

1

0

m

m

Dimensions of cut-out

96

2...10

92

+0.8

-0

92

+0.8

-0

96

92

+0.8

-0

2371M02

188

96

Use of several

controllers

Page 16

16/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

2.2 Electrical installation

2.2.1 Regulations for installation

• The connections for mains and low voltage are separated

• The wiring must be made in compliance with the requirements of safety class II.

This means that sensor and mains cables may not be run in the same duct

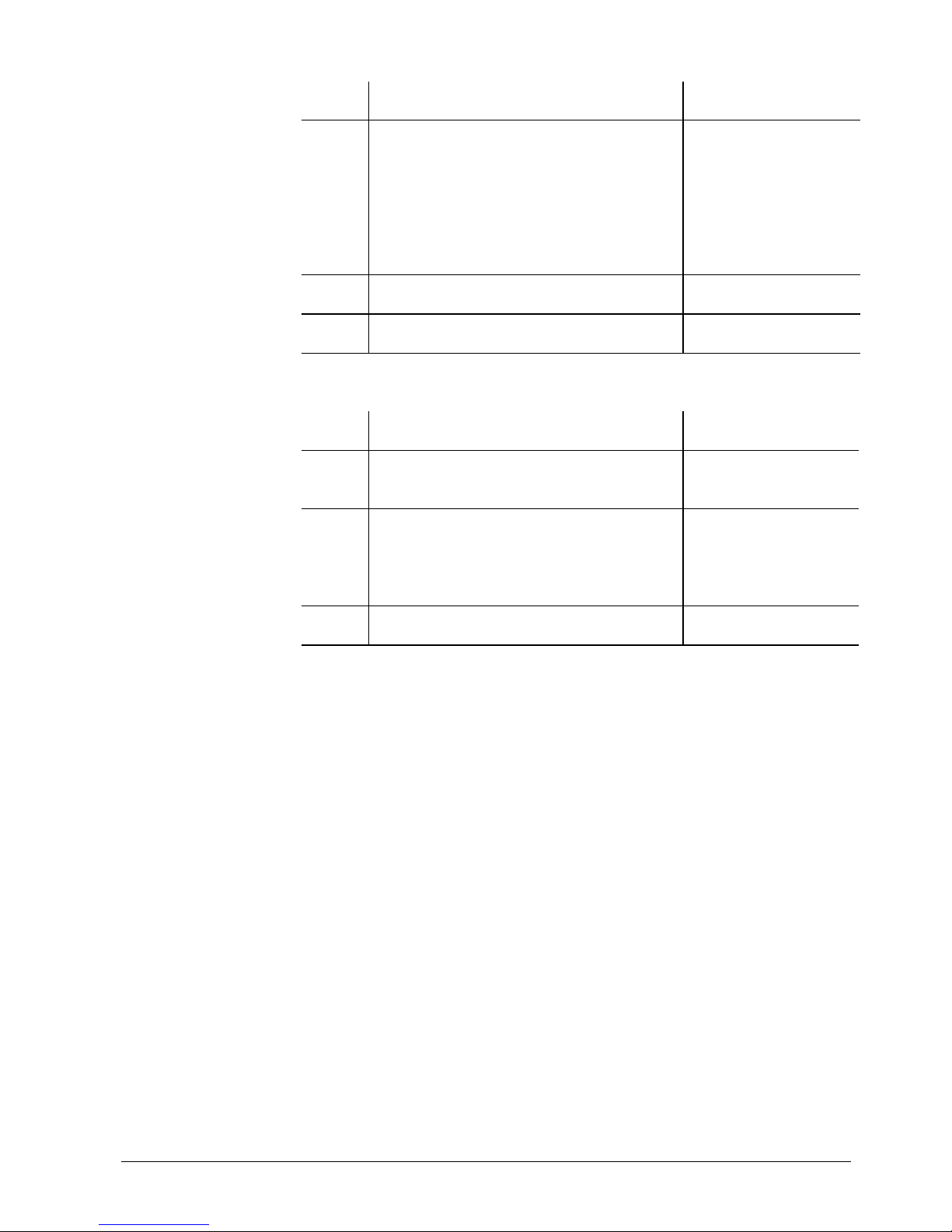

2.2.2 Wiring

When using prefabricated cables with connectors, the electrical installation is very

straightforward, owing to the coding.

Q3

Q1

F1

L

N

M

B10

B9

MDA6MB

DB

654M21M M

32F 432F LN

2379A01

B3

B70/B4

H1

Rear of controller

Connection terminals

Page 17

17/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

Terminal Terminals Connector

H1 input H1 AGP2S.06A (white)

B70/B4 Cascade return temperature sensor B70 or

buffer storage tank temperature sensor B4

B3 D.h.w. temperature sensor or thermostat

M Ground sensors

B10 Cascade flow temperature sensor

(common flow temperature sensor)

B9 Outside sensor

MD Ground PPS (room unit, BMU) AGP2S.02G (blue)

A6 PPS (room unit, BMU)

MB Ground bus (LPB) AGP2S.02M (violet)

DB Data bus (LPB)

Terminal Terminals Connector

Q3 D.h.w. charging pump AGP3S.03B (brown)

Q1 Heating circuit or system pump:

F1 Phase Q1 / Q3

- Not used -

- Not used

- Not used

- Not used

- Not used

L Live AC 230 V (mains connection) AGP3S.02D (black)

N Neutral conductor (mains connection)

Low voltage side

Mains voltage side

Page 18

18/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

2.3 Commissioning

To commission the controller:

1. Make certain that mounting and electrical installation are in compliance with the

relevant requirements.

2. Make all plant-specific settings as described in section "Parameter settings".

3. Reset the attenuated outside temperature (operating line 19).

4. Make the functional checks.

2.3.1 Functional checks

To facilitate commissioning and fault tracing, the controller allows output and input tests

to be made. With these tests, the controller’s inputs and outputs can be checked.

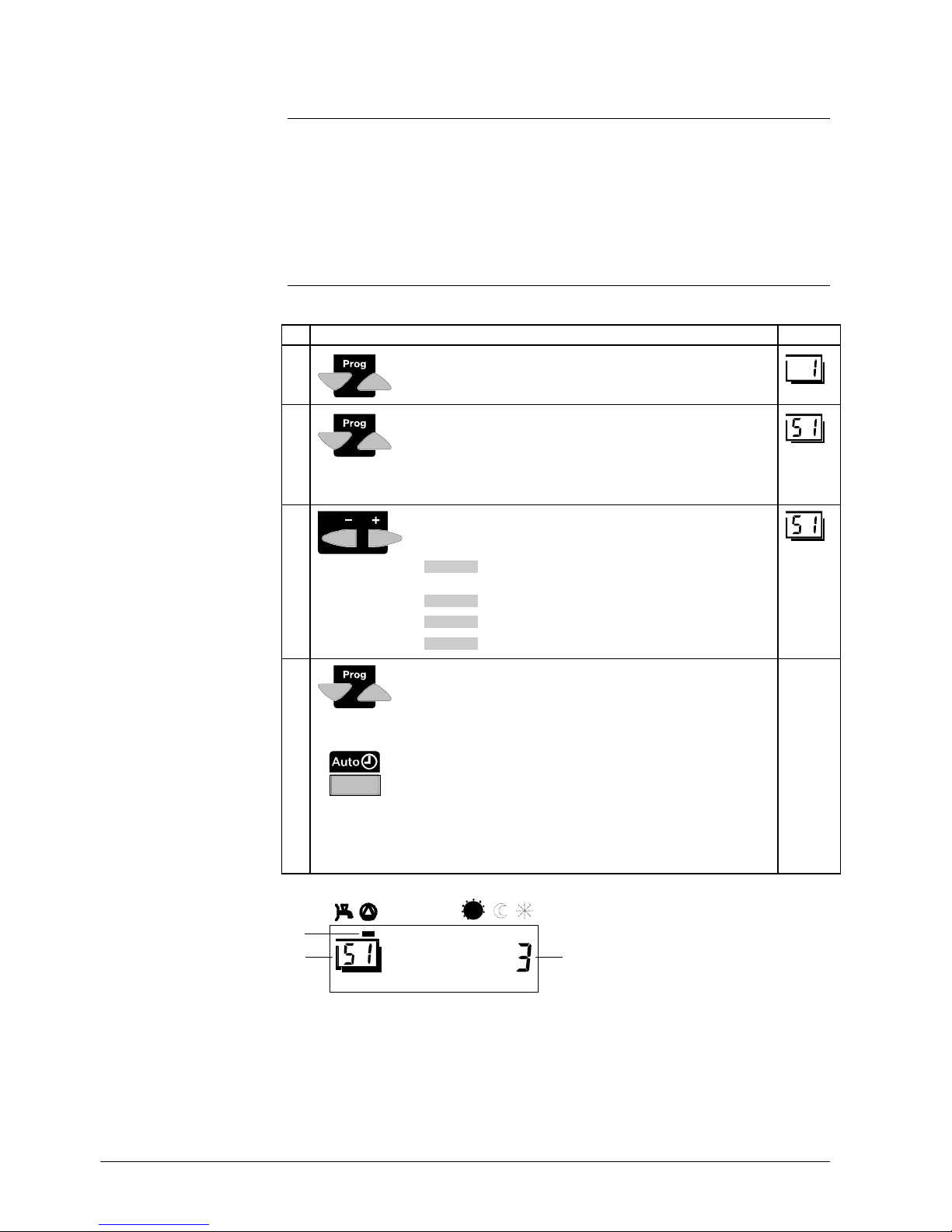

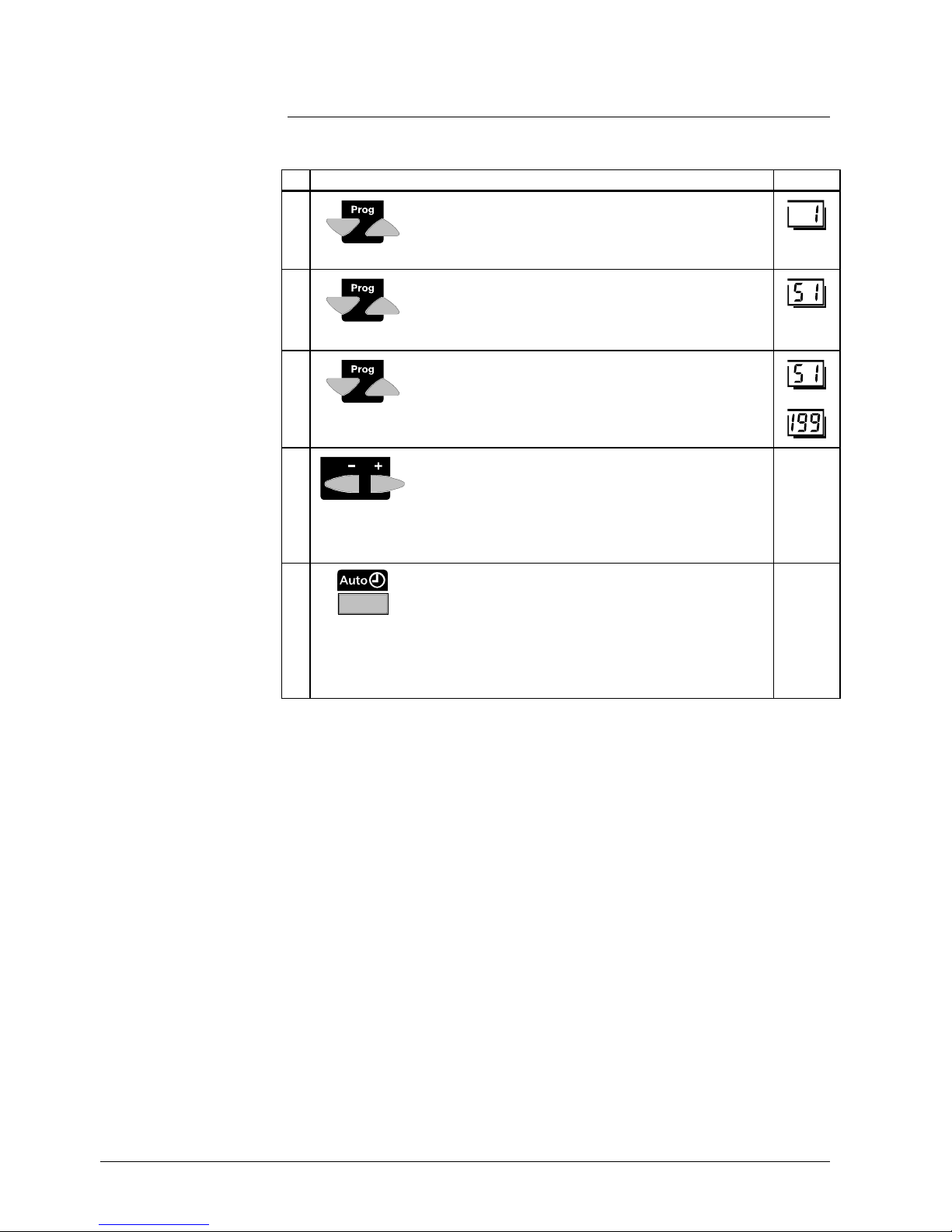

Buttons Explanation Line

1

Press one of the line selection buttons.

This will take you to the programming level "Enduser”.

2

Press both line selection buttons for at least 3 seconds.

This will take you to the programming level “Heating

engineer” and, at the same time, to the relay test (output

test).

3

Press the + or - button repeatedly, which will take you

one test step further:

Test step 0 All outputs are switched according to actual control

operation

Test step 1 All outputs are deactivated

Test step 2 D.h.w. charging pump (Q3) is activated

Test step 3 Heating circuit or system pump activated (Q1).

4

You leave the programming line "Output test” by

pressing either one of the line selection buttons,

or one of the operating mode buttons

Note:

If no button is pressed for about 8 minutes, the

controller will automatically return to the operating mode

selected last.

contin.

display

a) The pointer below the symbol indicates the output activated

b) The number indicates the current test step

c) The framed number indicates the selected setting line

Prerequisites

Output test

(relays)

Display

a)

b)

c)

2379Z02

04

812162024

Page 19

19/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

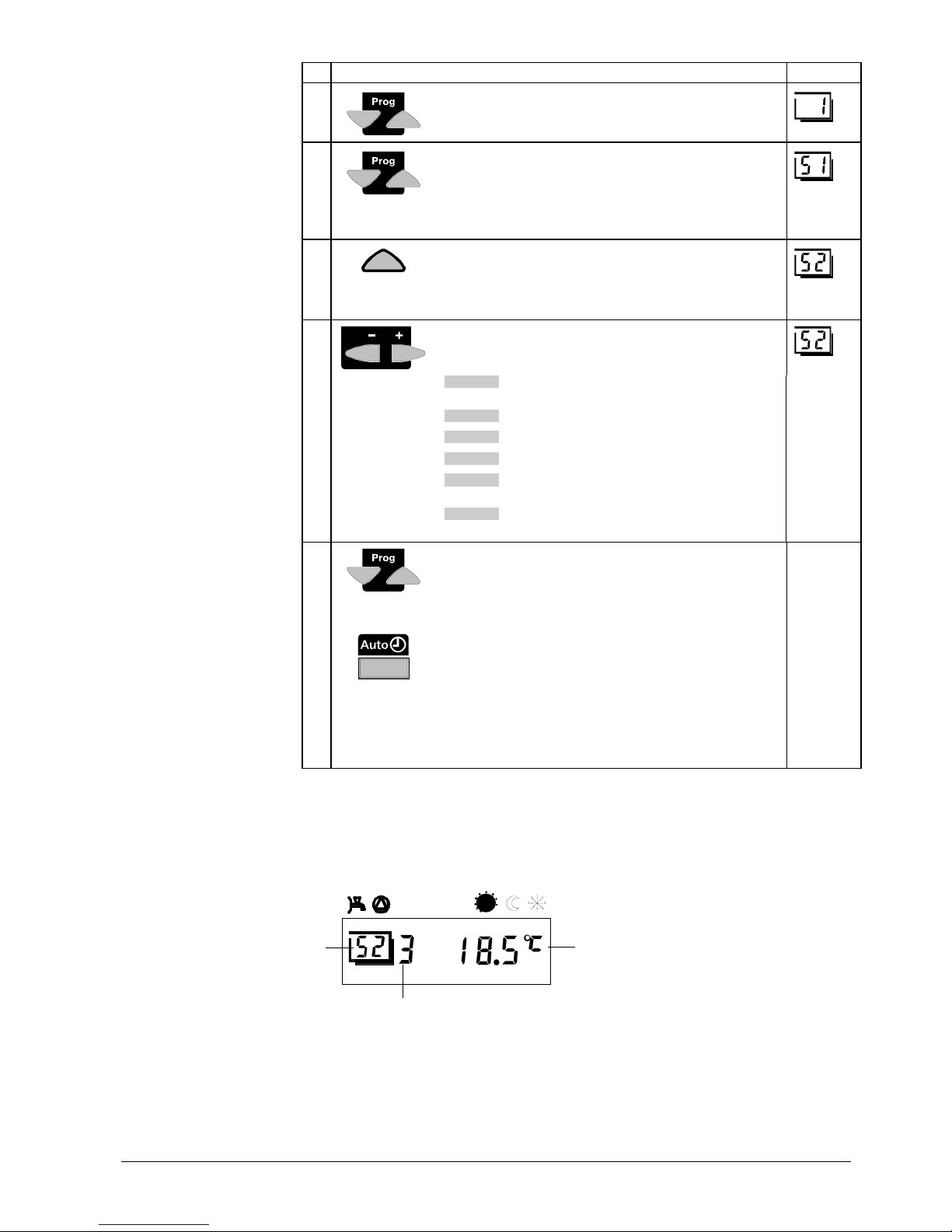

Buttons Explanation Line

1

Press one of the line selection buttons.

This will take you to the programming level "Enduser”.

2

Press both line selection buttons for at least 3

seconds.

This will take you to the programming level "Heating

engineer”.

3

Press line selection button "Up" until you reach line

52.

This will take you to the input test.

4

Press the + or - button repeatedly, which will take you

one test step further:

Test step 0 Display of the function selected on line 97 (B70/B4)

[°C].

Test step 1 Display of d.h.w. temperature (B3).

Test step 2 Display of the cascade flow temperature (B10).

Test step 3 Display of the actual outside temperature (B9)

Test step 4 Display of room temperature acquired with room

unit connected to A6

Test step 5 Display of input H1 according to the function

selected on operating line 170 [°C, - - - , o o o].

5

You leave the programming line "Input test" by

pressing either one of the line selection buttons,

or one of the operating mode or function buttons

Note:

If no button is pressed for about 8 minutes, the

controller will automatically return to the operating

mode selected last.

Contin.

display

The selected sensor values are updated within a maximum of 5 seconds. If no sensor

is present, the connecting line interrupted, or the contact open, the display shows "---”;

in the event of a short-circuit, or if the contact is closed, the LCD displays "ooo”.

a) The framed number indicates the selected setting line

b) Displayed value of the temperature measured

c) The number indicates the selected test step

Input test

(sensors)

Display

a)

c)

b)

2379Z02

04

812162024

Page 20

20/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

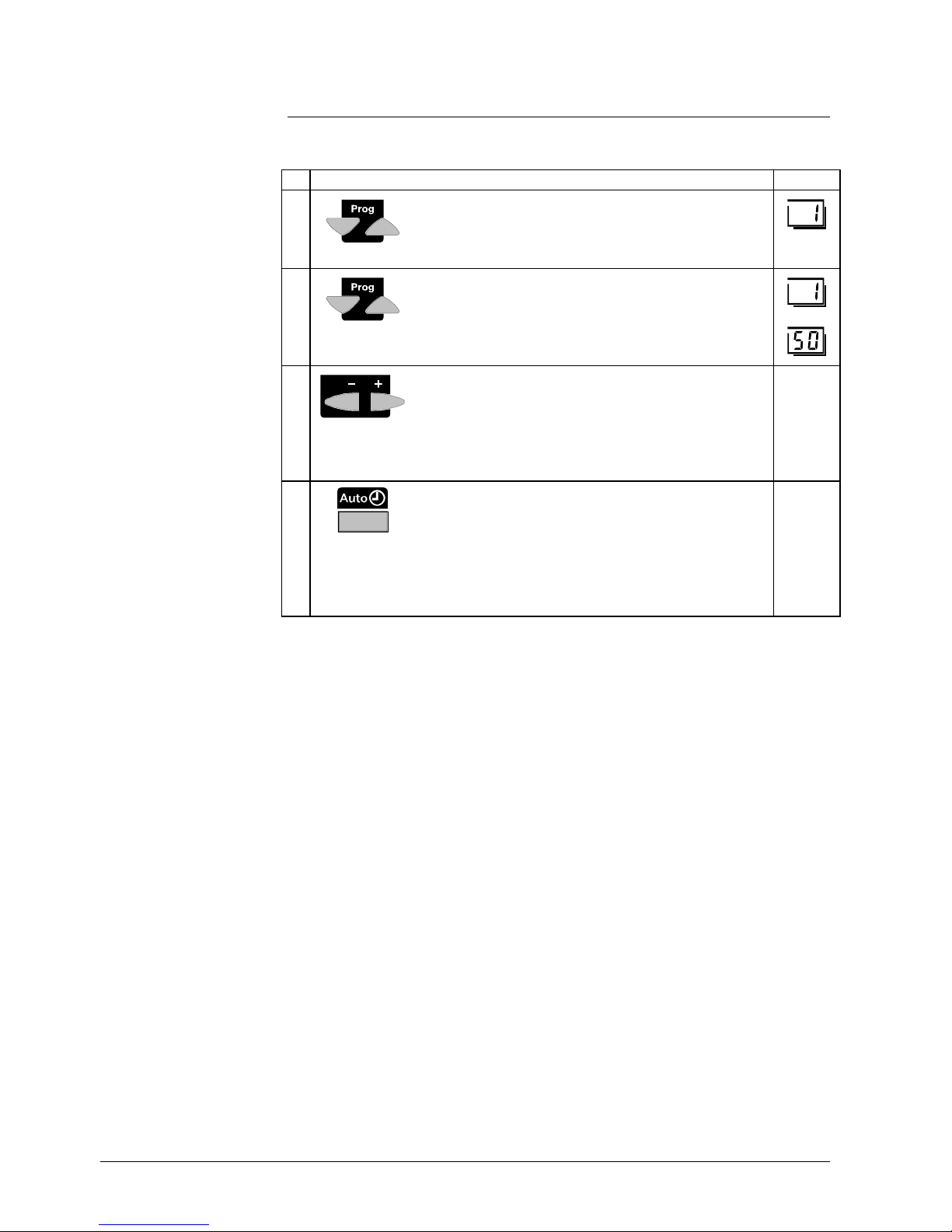

2.4 Parameter settings for the enduser

The following settings can be made to meet the individual needs of the enduser.

Buttons Explanation Line

1

Press one of the line selection buttons.

This will take you directly to the programming level

"Enduser”.

2

Press the line selection buttons to select the required

line.

The parameter list on the next pages contains all

available lines.

• • •

3

Press the + or - button to set the required value.

The setting will be stored as soon as you leave the

programming mode or change to another line.

The parameter list on the next 2 pages contains all

settings that can be made.

4

By pressing any of the operating mode buttons, you

leave the programming level "Enduser”.

Note:

If no button is pressed for about 8 minutes, the

controller will automatically return to the operating

mode selected last.

Contin.

display

Description

Setting

Page 21

21/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

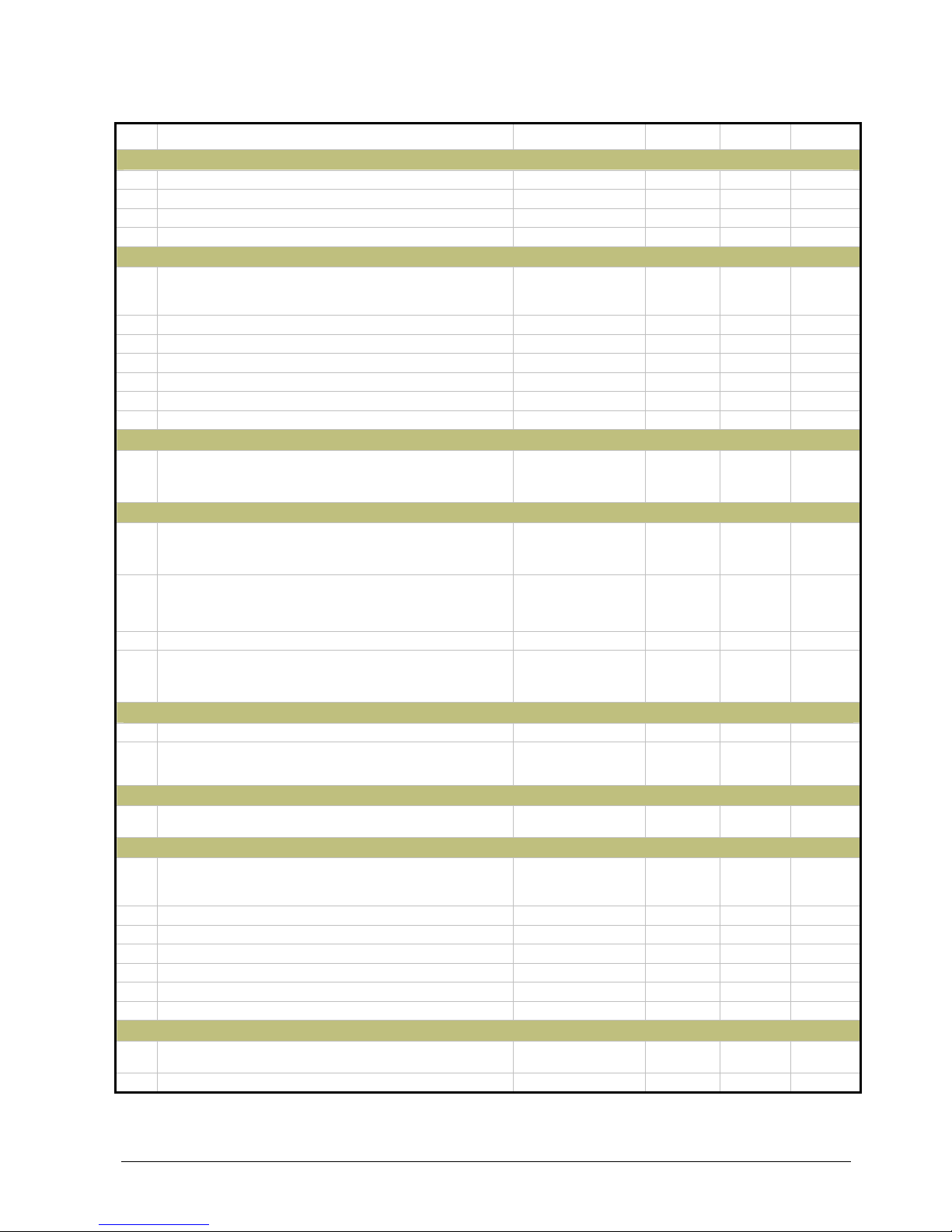

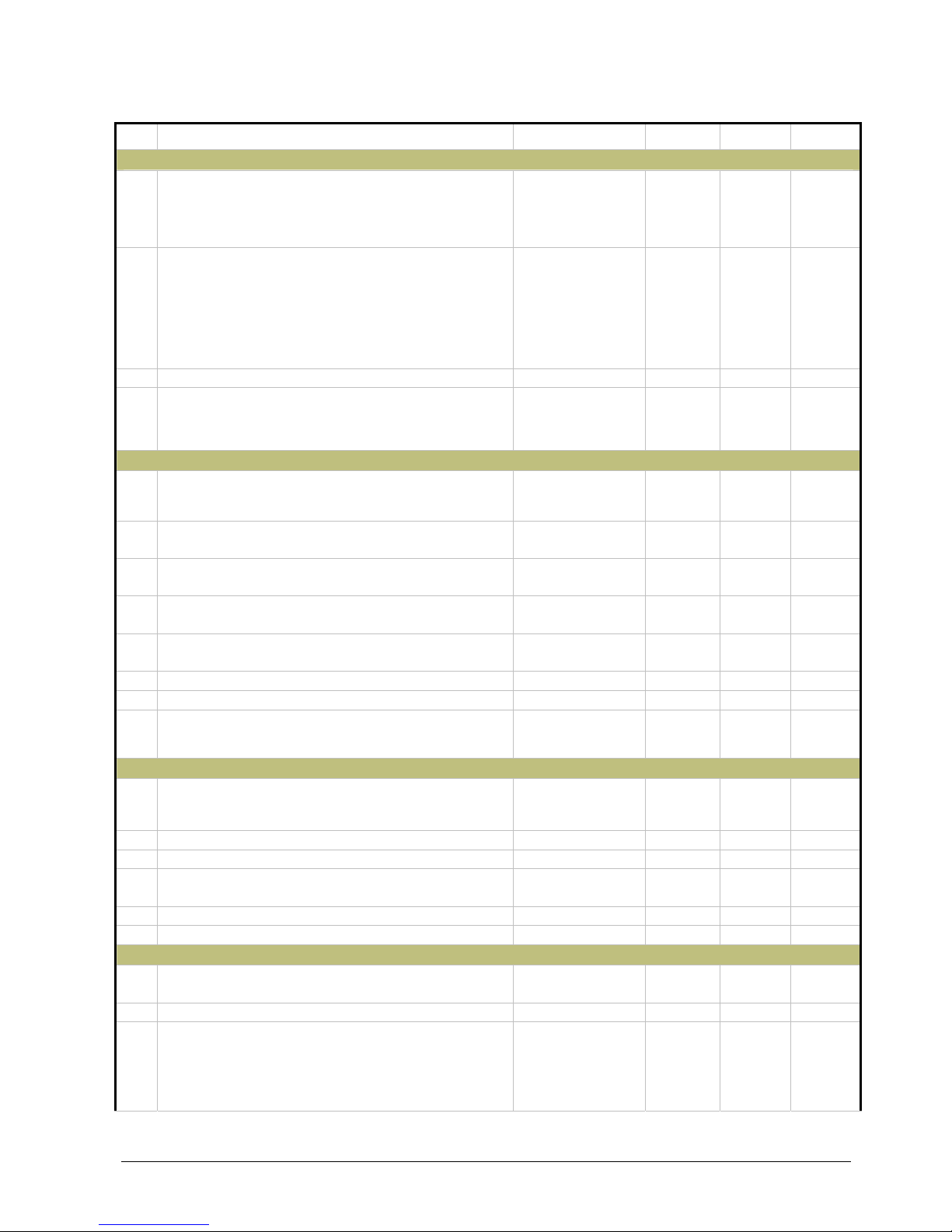

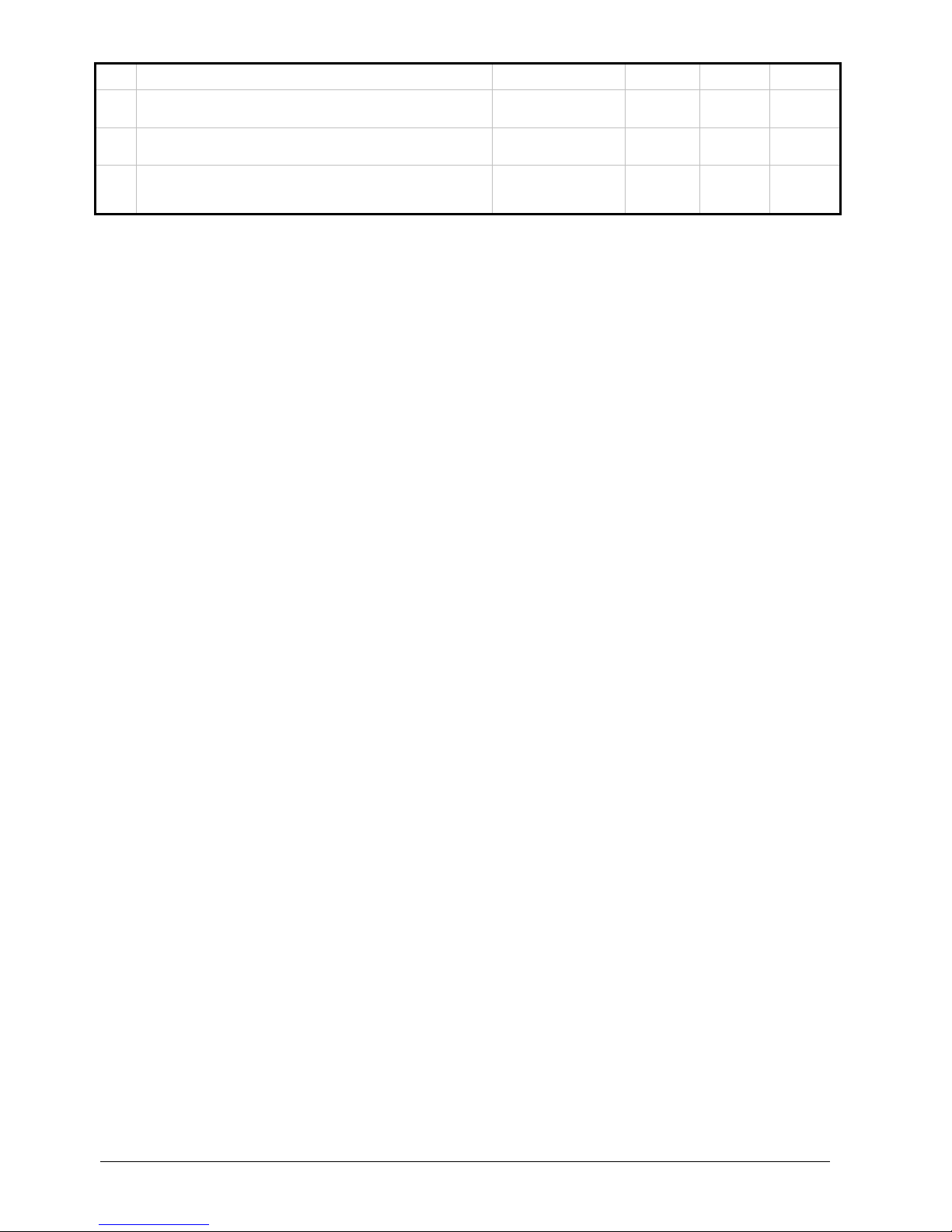

2.4.1 Overview of enduser parameters

Line Function Range Unit Resolution Factory

setting

Setting the clock

1 Time of day 0...23:59 h / min 1 min 2 weekday 1...7 Weekday 1 day 3 Date (day, month) 01.01...31.12 dd.MM 1 4 Year 1999...2099 jjjj 1 -

Time switch program for heating circuit

5 Weekday-preselection heating circuit

1-7 7-day block

1...7 Individual days

1-7 / 1...7 Weekday 1 day -

6 Switch-on time 1. 3rd period heating circuit 00:00...23:59 h / min 10 min 06:00

7 Switch-off time 1. 3rd period heating circuit 00:00...23:59 h / min 10 min 22:00

8 Switch-on time 2. 3rd period heating circuit 00:00...23:59 h / min 10 min - -:- 9 Switch-off time 2. 3rd period heating circuit 00:00...23:59 h / min 10 min - -:- 10 Switch-on time 3. 3rd period heating circuit 00:00...23:59 h / min 10 min - -:- 11 Switch-off time 3. 3rd period heating circuit 00:00...23:59 h / min 10 min - -:- -

D.h.w. values

13 Nominal setpoint of the d.h.w. temperature (TBWw)

TBWR Line 120

TBWmax Line 40 (OEM)

TBWR...TBWmax °C 1 55

Heating circuit values

14 Reduced room temperature setpoint (TRRw)

TRF Line 15

TRN Setpoint knob

TRF...TRN °C 0,5 16

15 Frost protection setpoint of the room temperature

(TRFw)

TRR Line 14

4...TRR °C 0,5 10

16 summer / winter changeover temperature 8...30 °C 0,5 17

17 heating curve slope

-:- - Inactive

2,5...40 Active

-:- - / 2,5...40 - 0,5 15

Actual values

18 Actual value of the room temperature (TRx) 0...50 °C 0,5 19

Actual value of the outside temperature (TAx)

To set the attenuated outside temperature to Tax, press the + / buttons simultaneously for 3 seconds.

-50...+50 °C 0,5 -

Maintenance

23 Standard time program for heating circuit and d.h.w.

To activate, press the + and - buttons simultaneously for 3 seconds

0/1 - 1 0

Time switch program for d.h.w. heating

29 preselection of weekday

1-7 7-day block

1...7 Individual days

1-7 / 1...7 Weekday 1 day -

30 Switch-on time 1. 3rd period d.h.w. 00:00...23:59 h / min 10 min 06:00

31 Switch-off time 1. 3rd period d.h.w. 00:00...23:59 h / min 10 min 22:00

32 Switch-on time 2. 3rd period d.h.w. 00:00...23:59 h / min 10 min - -:- 33 Switch-off time 2. 3rd period d.h.w. 00:00...23:59 h / min 10 min - -:- 34 Switch-on time 3. 3rd period d.h.w. 00:00...23:59 h / min 10 min - -:- 35 Switch-off time 3. 3rd period d.h.w. 00:00...23:59 h / min 10 min - -:- -

Service

49 Indication of BMU error code

1...4 = BMU number, 1...255 = error code

1...4 / 0...255 - 1 -

50 indication of faults 0..255 / 00.01–14.16 - 1 -

Page 22

22/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

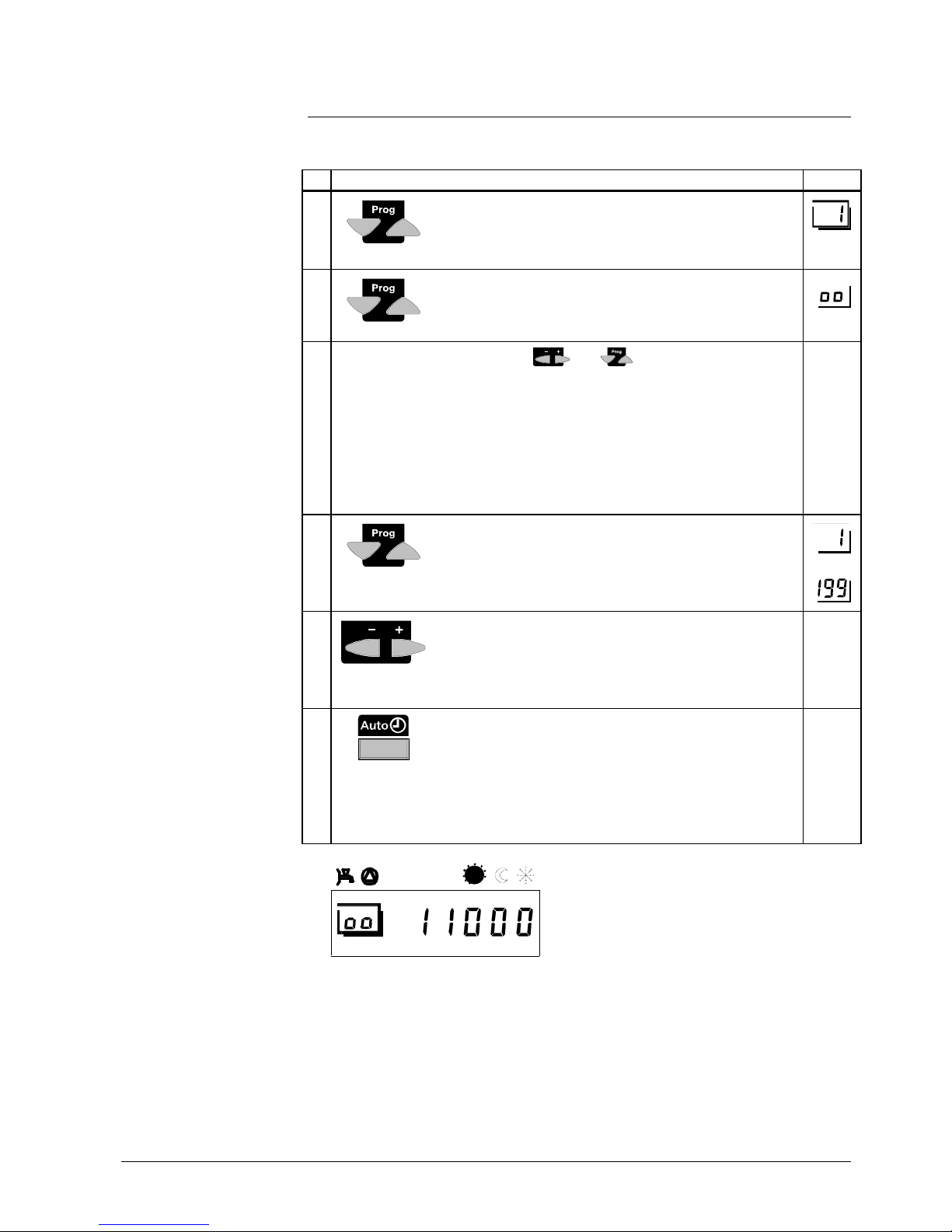

2.5 Parameter settings for the heating engineer

Configuration and parameter settings to be made by the heating engineer.

Buttons Explanation Line

1

Press one of the line selection buttons.

This will take you first to the programming level

"Enduser”.

2

Press both line selection buttons for at least 3 seconds.

This will take you to the programming level "Heating

engineer”.

3

Press the line selection buttons to select the required

line.

The parameter list on the next 2 pages contains all

available lines.

• • •

4

Press the + or - button to set the required value.

The setting will be stored as soon as you leave the

programming mode or change to another line.

The parameter list on the next 2 pages contains all

settings that can be made.

5

You leave the programming level "Heating engineer" by

pressing one of the operating mode buttons.

Note:

If no button is pressed for about 8 minutes, the

controller will automatically return to the operating

mode selected last.

Contin.

display

Description

Setting

Page 23

23/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

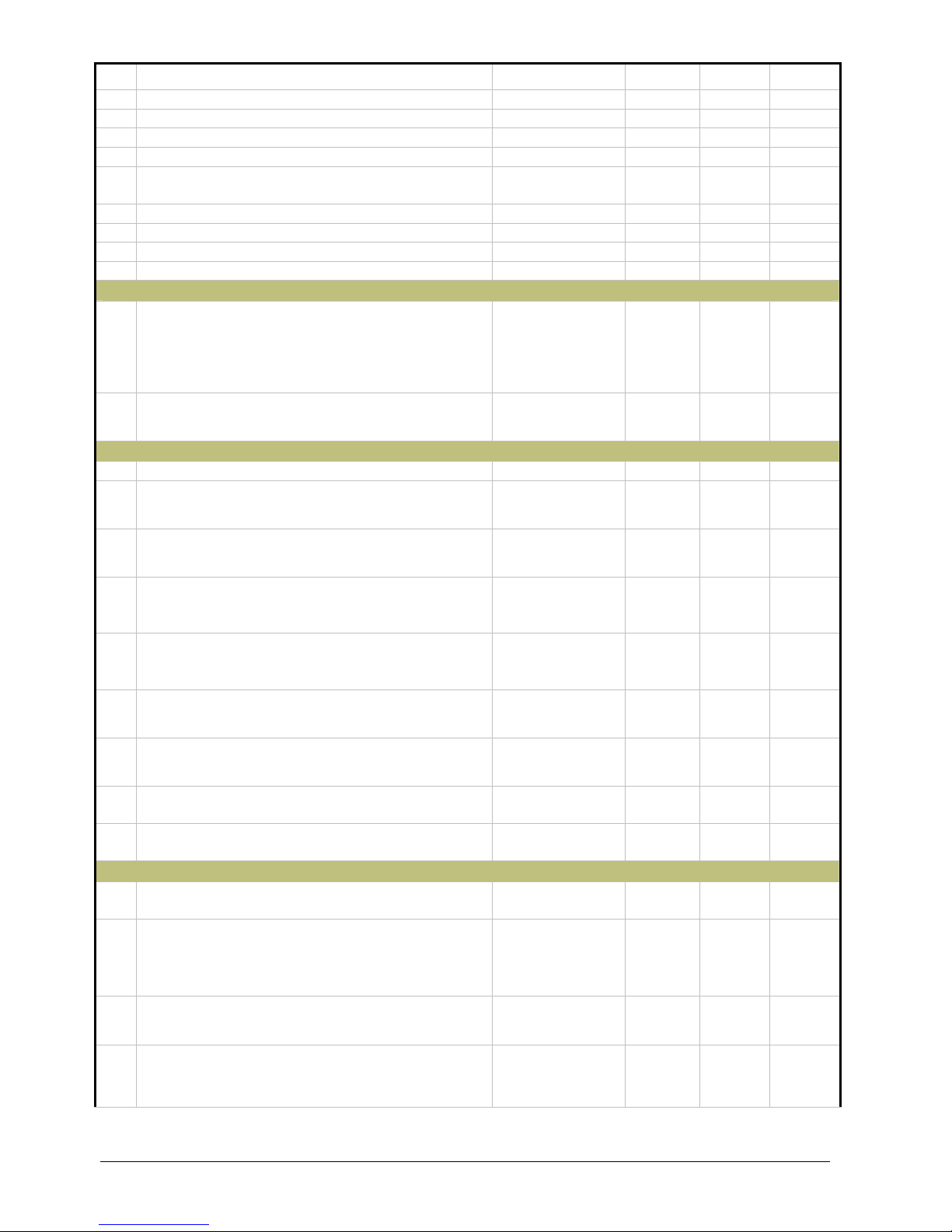

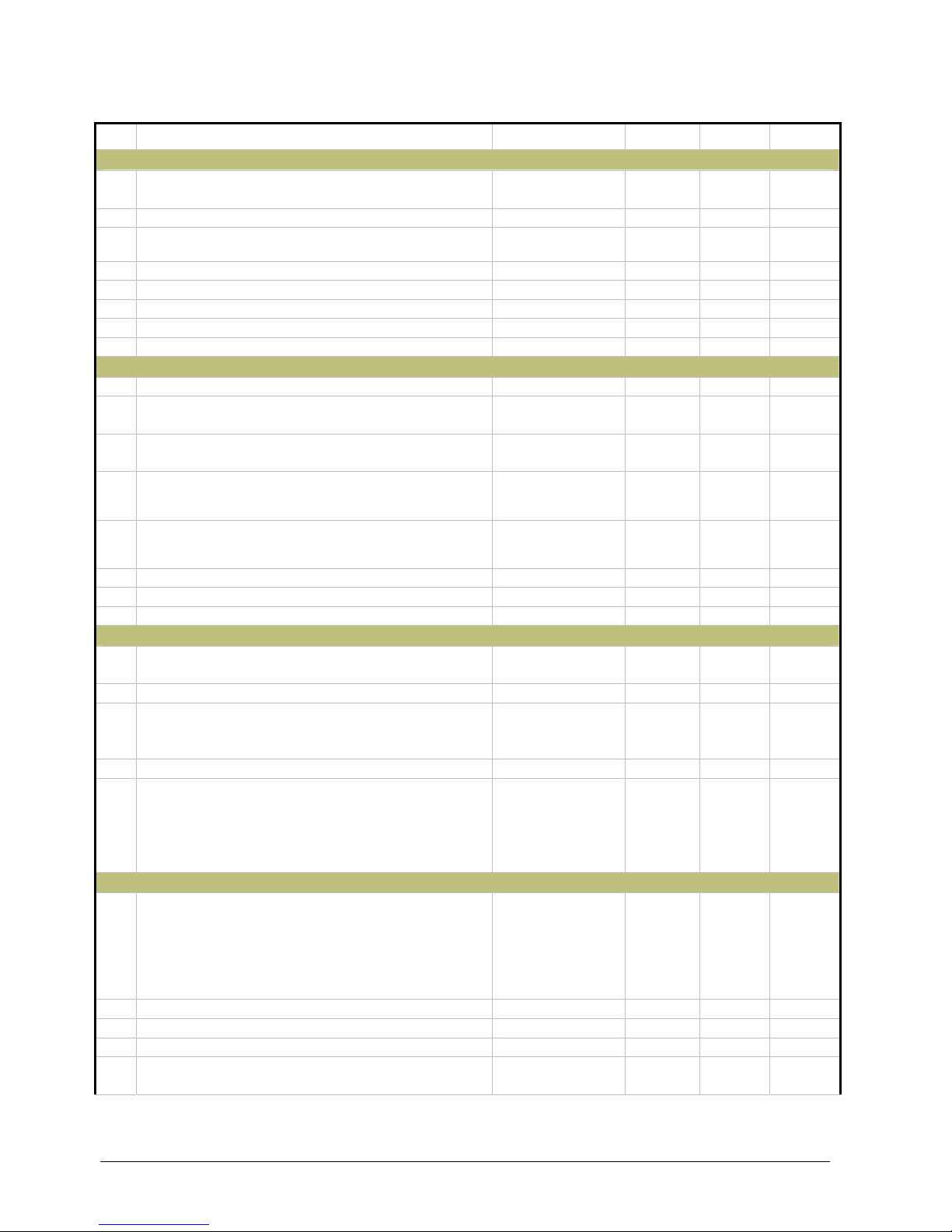

2.5.1 Overview of heating engineer parameters

Line Function Range Unit Resolution Factory

setting

Service values

51 Output test (relay test)

0 Control mode according to the operational status

1 All outputs are deactivated

2 D.h.w. charging pump ON Q3

3 Heating circuit / system pump ON Q1

0...3 - 1 0

52 Input test (sensor test)

0 Cascade return temperature sensor B70/B4

or buffer storage tank temperature sensor

1 D.h.w. temperature sensor B3

2 Cascade flow temperature sensor B10

3 outside temperature sensor B9

4 Room temperature sensor (room unit) A6

5 input H1 H1

0...5 - 1 0

53 Display of plant type 27...36 / 65...67 - 1 54 displaying the PPS communication

- - - No communication

1...12 PPS device address

0...255 identification code

--- / 1..12 / 0..255 - 1 -

Actual values

55 Actual value of boiler temperature of BMUs (TKx) 1)

1...4 = BMU number, 0...140 = actual value of boiler temperature

(interrogate with + / - buttons)

1...4 / 0...140 °C 1 -

56 Actual value of cascade flow temperature

Input B10

0...140 °C 1 -

57 Actual value of cascade return temperature

Input B70

0...140 °C 1 -

58 actual value of buffer storage tank temperature

Input B4

0...140 °C 1 -

59 Actual value of the d.h.w. temperature (TBWx)

1)

(Input B3 or value from BMU)

0...140 °C 1 -

60

Attenuated outside temperature

(Taxged)

-50.0...+50.0 °C 0.5 -

61

Composite outside temperature

(TAxgem)

-50.0...+50.0 °C 0.5 -

62 outside temperature source

--.-- No signal

00.01 Segment / device address

--.-- / 00.01...14.16 - - -

Setpoints

65 Setpoint of the boiler temperature of BMUs (TKx) 1)

1...4 = BMU number, 0...140 = actual value of boiler temperature

(interrogate with + / - buttons)

1...4 / 0...140 °C 1 -

66 Setpoint of the cascade flow temperature 0...140 °C 1 69 Setpoint of d.h.w. temperature (TBWw) 0...140 °C 1 70 Nominal room temperature setpoint

Nominal setpoint plus readjustment made on the room unit

0.0...35.0 °C 0,5 -

71 Setpoint of room temperature (TRRw) 0.0...35.0 °C 0,5 72 Flow temperature setpoint (TVw) 0...140 °C 1 -

Heat generation values

75

Display of the available cascade boilers

(--- = none)

--- / 00.1...16.3 - 01.1 -

76 display lead boiler --- / 00.1...16.3 - 01.1 77

Remaining number of operating hours for changeover

of boiler

sequence

Only if a value is selected on line 130, otherwise the LCD displays - -

-

0...990 h 1 -

Page 24

24/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

Line Function Range Unit Resolution Factory

setting

80 Burner hours run BMU 1

1)

0...65535 h 1 0

81 Burner hours run BMU 2

1)

0...65535 h 1 0

82 Burner hours run BMU 3

1)

0...65535 h 1 0

83 Burner hours run BMU 4

1)

0...65535 h 1 0

90 Minimum limitation of the boiler temperature (TKmin) 1) TKmin

OEM

...TKmax

(max 95°C)

°C 1 8

91 Nominal output BMU 1

1)

0...255 kW 1 20

92 Nominal output BMU 2

1)

0...255 kW 1 20

93 Nominal output BMU 3

1)

0...255 kW 1 20

94 Nominal output BMU 4

1)

0...255 kW 1 20

Configuration of plant

95

pump function output Q1

1 Heating circuit pump or no pump

2 System pump for heating circuits only

3 System pump for heating circuits and d.h.w. storage tank

4 d.h.w. circulating pump

5 Pump H1

1...5 - 1

97

use sensor input B70/B4

1 Cascade return temperature (B70)

2 Buffer storage tank temperature sensor (B4)

1...2 - 1 1

Space heating

100 parallel displacement of the heating curve -4.5...+4.5 K (°C) 0,5 0,0

101 room influence

0 Inactive

1 Active

0 / 1 - 1 1

102 Switching differential of the room temperature (SDR)

- - . - Inactive

0,5...4,0 Active

- - . - / 0.5...4.0 K (°C) 0,5 - - . -

103 Minimum limitation of the flow temperature setpoint

(TVmin)

TVmax Line 104

8...Tvmax °C 1 8

104 Maximum limitation of the flow temperature setpoint

(TVmax)

Tvmin Line 103

TVmin...95 °C 1 80

105 type of building construction

0 Heavy

1 Light

0 / 1 - 1 1

106 adaption of the heating curve

0 Inactive

1 Active

0 / 1 - 1 1

107 Maximum forward shift of optimum start control

0 No forward shift

00:00...06:00 hh:mm 10 min 00:00

108 Maximum forward shift of optimum stop control

0 No forward shift

00:00...06:00 hh:mm 10 min 00:00

D.h.w.

120 Reduced setpoint of d.h.w. temperature (TBWR)

TBWw Line 13

8...TBWw °C 1 40

121 release of d.h.w. heating

0 24 h/day

1 According to the heating circuit time switch program)s) with

forward shift

2 According to d.h.w. time switch program (lines 29...35)

0...2 - 1 1

122 switching program circulating pump

0 According to heating circuit time switch program

1 According to release of d.h.w. heating

0...1 - 1 1

123 Assignment of d.h.w. heating

0 For local consumer only

1 For all consumers in the same segment

2 For all consumers in the system

0...2 - 1 2

Page 25

25/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

Line Function Range Unit Resolution Factory

setting

124 D.h.w. charging

0 Once per day (forward shift 2.5 h)

1 Several times per day (forward shift 1h)

0 / 1 - 1 1

125 Type of d.h.w. demand

0 Sensor

1 Control thermostat

0 / 1 - 1 0

126 Flow temperature boost for d.h.w. 0...30 K 1 16

127 d.h.w. priority

0 MK + PK absolute

1 MK + PK shifting

2 None (parallel)

3 MK shifting, PK absolute

0...3 1 1 1

129 demand for heat with reduced d.h.w. setpoint

0 No (application with buffer storage tank)

1 Yes

0 / 1 - 1 1

Boiler cascade

130 changeover of boiler sequence in cascades

--- No automatic changeover (fixed boiler sequence)

10...990 Changeover according to the selected number of hours

--- / 10...990 - / hours 10 500

131 Exclusion with autom. changeover of boiler

sequence

0 None

1 First boiler

2 Last boiler

3 First and last boiler

0...3 - 1 0

132 Lead boiler with the fixed sequence 00.1...16.3 - 01.1 133 Switch-on delay lag boilers 2...120 min 1 5

134 Restart lock of BMUs 0...1800 s 10 300

LPB / system

140 LPB device address

0 Standalone

1...16 Device number

0...16 - 1 1

141 LPB segment address

0 Central segment (heat generation)

1...14 Segment (heat consumers)

0...14 - 1 0

142 LPB power supply

0 Off (central bus power supply)

1 AUTOMATIC (controller - bus power supply)

0 / 1 - 1 1

143 Displaying the LPB power supply ON / OFF - - 144 displaying the LPB communication ON / OFF - - 145

Range of action of central changeover

0 In the segment

1 In the system (if segment address = 0)

0 / 1 - 1 1

146 Automatic summer / winter changeover

0 Effect on local heating circuit only

1 Central changeover of all heating circuits

0 / 1 - 1 0

147 Central standby switch

0 OFF (Inactive)

1 ON (all units on standby)

0 / 1 - 1 0

148 clock mode

0 Autonomous clock

1 System time without remote adjustment

2 system time with remote adjustment

3 System clock (master)

0...3 - 1 3

149 Winter- / summertime changeover 01.01...31.12 tt.MM 1 25.03

150 Summer- / wintertime changeover 01.01...31.12 tt.MM 1 25.10

input H1

170 input H1

0 Changeover of operating mode (HC standby / d.h.w. off)

1 Changeover of operating mode (HC standby)

2 Minimum setpoint of flow temperature (setting on line 171)

3 Heat generation lock

4 Heat demand DC 0...10 V

0...4 - 1 0

Page 26

26/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

Line Function Range Unit Resolution Factory

setting

171 minimum setpoint of flow temperature contact H1

If activated at input H1 (setting 2)

8...TKmax °C 1 70

172 Maximum value of heat demand

If activated at input H1 (setting 4)

5...130 °C 1 100

173 operating action of the contact H1

0 N.C. contact

1 N.O.

0 / 1 - 1 1

1)

If a BMU is connected via LPB, this setting will not be active.

The respective setting must be made directly on the BMU.

Page 27

27/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

2.6 Parameter settings for the OEM

Boiler-specific settings and protective functions for the boiler manufacturer.

Buttons Explanation Line

1

Press one of the line selection buttons.

This will take you first to the programming level

"Enduser”.

2

9 s

Press both line selection buttons for at least 9 seconds.

A special display for entering the code will appear.

3

CODE

Press buttons

and to enter the required

combination of the access code.

If the combination of buttons is correct, you reach the

programming mode ”OEM”.

Wrong code:

If the code has been entered incorrectly, the display will

change to the "Parameter settings for the heating

engineer”.

4

Press the line selection buttons to select the required

line.

The parameter list on the next 2 pages contains all

available lines.

• • •

5

Press the + or - button to set the required value.

The setting will be stored as soon as you leave the

programming mode or change to another line.

The following parameter list contains all available lines.

6

You leave the programming level "OEM" by pressing any

of the operating mode buttons.

Note:

If no button is pressed for about 8 minutes, the controller

will automatically return to the operating mode selected

last.

Contin.

display

2379Z02

04

812162024

Whether correct or incorrect, each push of a button represents irrevocably a digit of the

code.

As a confirmation, the respective digit changes to 1.

Description

Setting

Example

Page 28

28/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

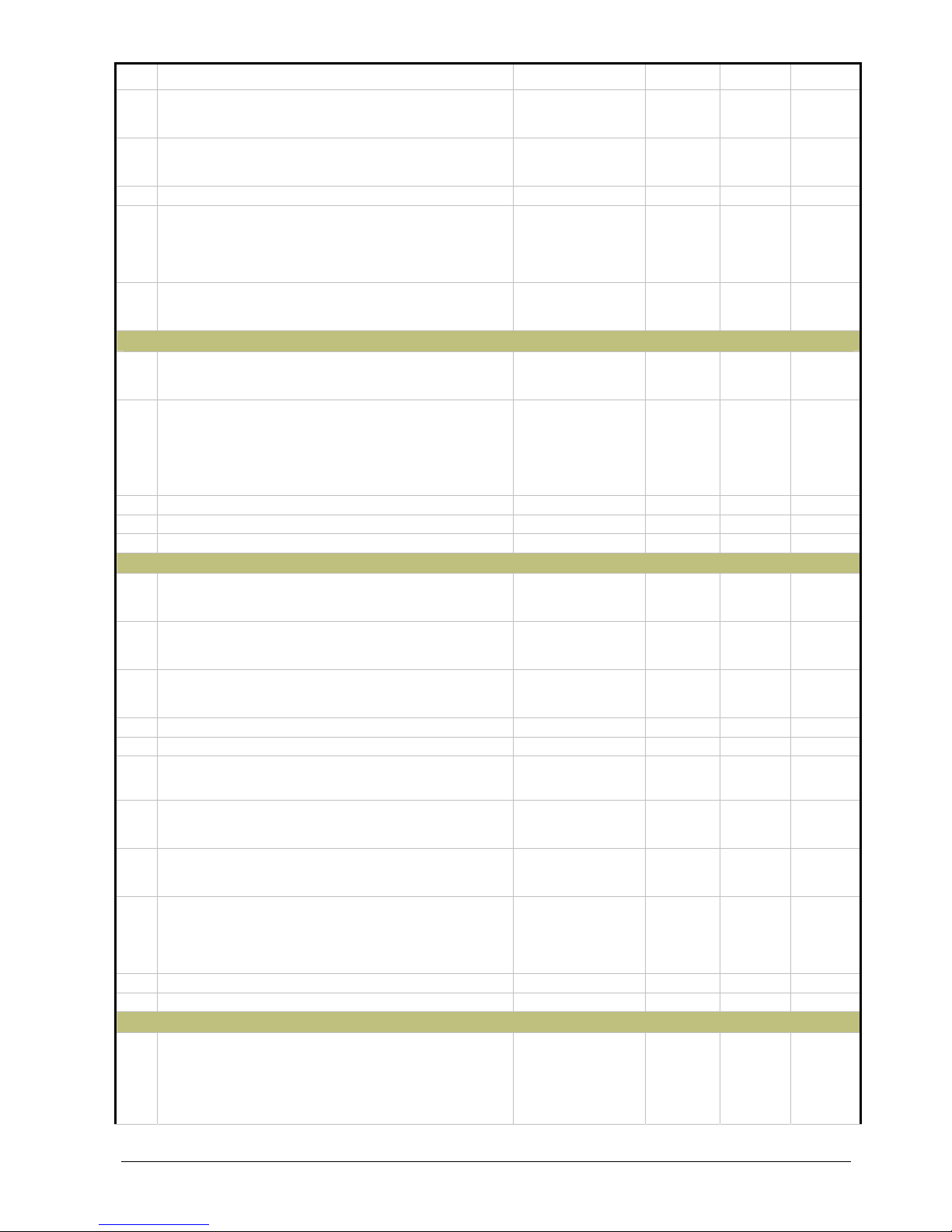

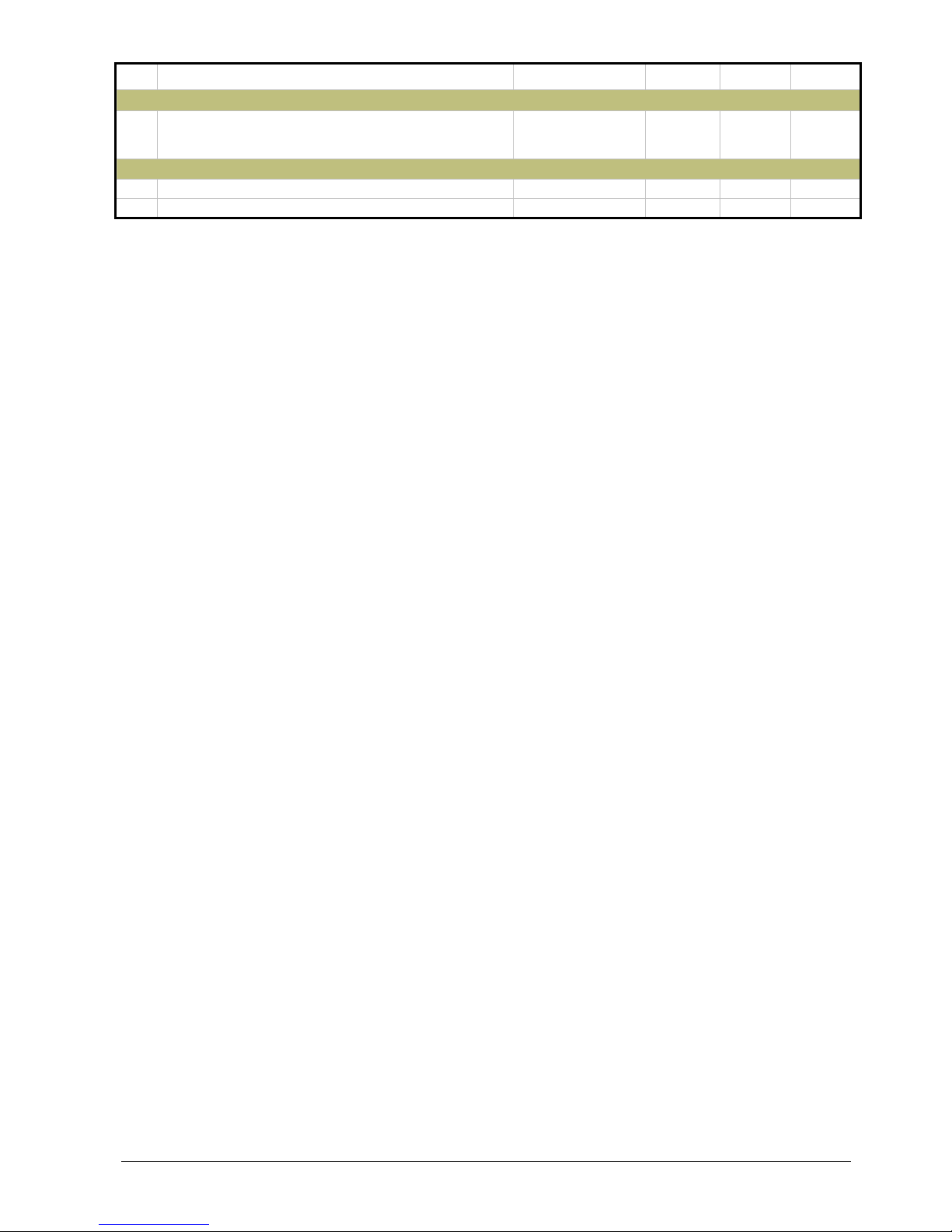

2.6.1 Overview of OEM parameters

Line Function Range Unit Resolution Factory

setting

Heat source OEM

1

Minimum limitation of the boiler temperature:OEM

1)

(TKminOEM)

8...95 °C 1 8

2 Maximum limitation of the boiler temperature (TKmax) 8...120 °C 1 80

8 Pump overrun time

(after burner OFF)

0...20 min 1 5

22 Minimum limitation of boiler return temperature 8...95 °C 1 8

25 Calibration of actual output value BMU 1

1)

-100...100 - 1 0

26 Calibration of actual output value BMU 2

1)

-100...100 - 1 0

27 Calibration of actual output value BMU 3

1)

-100...100 - 1 0

28 Calibration of actual output value BMU 4

1)

-100...100 - 1 0

Space heating OEM

30 Gain factor of room influence (KORR) 0...20 - 1 4

31 Constant for quick setback (KON)

(without room sensor)

0...20 - 1 2

32 Boost of room temperature setpoint

(with boost heating)

0...20 K (°C) 1 5

33

Frost protection for the plant

0 Inactive

1 Active

0 / 1 - 1 1

34 overtemperature protection for the pump heating circuit

0 Inactive

1 Active

0 / 1 - 1 1

35 Heat gains (Tf) -2...+4 °C 0,1 0

36 adaption sensitivity 1 1...15 - 1 15

37 adaption sensitivity 2 1...15 - 1 15

D.h.w. OEM

40 Maximum nominal setpoint of the d.h.w. temperature

(TBWmax)

8...80 °C 1 60

41 Switching differential of the d.h.w. temperature 0...20 K (°C) 1 5

42 Legionella function

0 = OFF

1 = ON

0 / 1 - 1 1

43 setpoint of the legionella function 8...95 °C 1 65

44

Protection against discharging during d.h.w. heating

0 = no protection against discharging

1 = always protection against discharging

2 = protection against discharging only when heat generation is

locked

0...2 - 1 2

Cascade settings OEM

50 cascade management strategy

1 autonomous 1

2 autonomous 2

3 autonomous 3

4 linked 1

5 linked 2

6 linked 3

1...6 - 1 2

51 Lower limit of output range (Pmin) 0...Pmax % 1 40

52 Upper limit of output range (Pmax) Pmin...100 % 1 90

56 Mandatory time on basic stage when boilers are added 10...1200 s 10 60

60 Minimum temperature differential at the pressureless

header

0...20 K (°C) 1 4

Page 29

29/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

Line Function Range Unit Resolution Factory

setting

Configuration of plant

90 continuous display

0 Weekday / time of day

1 Actual value of cascade flow temperature

0 / 1 - 1 0

Service values OEM

91 software version 00.0...99.9 - 1 92 device operating hours 0...500000 h 1 -

1)

If a BMU is connected via LPB, this setting will not be active.

The respective setting is to be made directly on the BMU.

Page 30

30/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

2.7 Operation

Operating instructions are inserted at the rear of the unit's front cover.

2379Z01

2.7.1 Operating elements

O

p

erating element

F

unction

Room temperature setpoint knob

Adjustment of room temperature setpoint

Setting buttons

Parameter settings

Line selection buttons

Selection of parameters / switching of lines

Display

Readout of actual values and settings

Operating mode buttons

Operating mode changes to:

Automatic operation

continuous operation

Standby

D.h.w. heating ON / OFF

Function button with LED for

manual operation

Manual operation ON / OFF

Connection facility for PC tool

Diagnostics and service

a) Symbols for indicating the operational status with the black bars (level pointers)

When the ECO function is active, the current level pointer flashes.

b) Display during normal control mode or when making settings

c) Programming line when making settings.

d) Time bar for normal control mode or when making settings.

Introduction

Display

a)

b)

c)

2379Z02B

d)

04

812162024

Page 31

31/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Handling 15.07.2002

2.8 Operational faults

2.8.1 No display on the controller:

• Is the heating plant's main switch turned on?

• Are the fuses in order?

• Check the wiring

2.8.2 Controller displays the wrong time of day:

• Set the correct time of day on the controller (operating line 1).

• Set the correct time of day on the clock master (if present).

2.8.3 One of the BMUs does not switch on

• Does the BMU really have to operate? (Check cascade lead strategy, delayed

switching on?)

• Press BMU's lockout reset button.

• Check the electromechanical control thermostat (TR) and the manual reset safety

limit thermostat (STB)

• Check wiring and fuse of the BMU.

• Check communication link to the BMU (operating line 54)

• Check wiring of the cascade temperature sensors (sensor test, operating line 52).

2.8.4 One of the pumps does not run

• Is the right type of plant displayed (operating line 53)?

• Is the pump correctly defined? (Operating line 95)

• Check wiring and fuse of the pump (relay test, operating line 51)

• Check wiring of the sensors (sensor test, operating line 52)

2.8.5 D.h.w. is not being heated:

• Has the button for d.h.w. heating been pressed?

• Check setpoint of the d.h.w. temperature

• Check if d.h.w. heating is released

• Check wiring and fuse of the charging pump (relay test, operating line 51)

• Check wiring of the d.h.w. temperature sensor (sensor test, operating line 52)

• Check setting of the electromechanical control thermostat (TR) installed on the

boiler. It must be above the TKmax setting

2.8.6 The room temperature does not agree with the

required temperature level:

• Does the room temperature setpoint agree with the required temperature level?

(Knob on the controller or on the room unit)

• Is the required operating mode indicated?

• Are weekday, time of day and the displayed heating program correct?

(Operating lines 1...11)

• Has the heating curve slope been correctly set? (Operating line 17)

• Check wiring of outside sensor (operating line 52)

• Has the ”Setting knob for the nominal room temperature setpoint” with the ”Parallel

displacement of the heating curve” (operating line 100) been calibrated based on

the effective room temperature?

2.8.7 Error message; display shows "ER"

• Select operating line 50 which gives you the error code and error address. There,

you see the error code and the address of the error. Refer to section "Indication of

errors" for a list of the possible error codes and their descriptions.

Page 32

32/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Description of the enduser settings 15.07.2002

3 Description of the enduser settings

User interface

3.1 Heating circuit operating modes

• Straightforward selection of heating circuit operating modes

The control provides 3 different heating circuit operating modes that can be directly

selected as required.

Select the required operating mode by pressing the respective operating mode button.

It is located on the controller front for direct access by the user.

Operating

mode

Designation Effect of selected operating mode

Automatic

operation

• Heating according to the time program

(operating lines 5 to 11)

• Temperature setpoints according to the heating

program

• Protective functions active

• Changeover on the room unit active

• Automatic summer / winter changeover and

automatic 24-hour heating limit active (ECO

functions)

continuous

operation

• Heating mode with no time program

• Temperature adjustment with the setpoint knob

• Protective functions active

• Changeover on room unit inactive

• Automatic summer / winter changeover and

automatic 24-hour heating limit inactive (ECO

functions)

Standby

• Heating OFF

• Temperature according to frost protection

• Protective functions active

• Changeover on room unit inactive

Benefit

Description

Setting

Page 33

33/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Description of the enduser settings 15.07.2002

The selected operating mode is indicated by illuminated buttons. A number of functions

can cause the displayed selection to change. The following table shows the possible

statuses. The following table shows the possible statuses:

Function Effect on button and meaning

Heat generation lock

Line 170 = 3

• Selected HC operating mode button flashes when

contact H1 is closed

• D.h.w. operating mode button flashes when

switched on

Changeover of operating

mode

Line 170 = 0

• Selected HC operating mode button

flashes

when contact H1 is closed

• D.h.w. operating mode button flashes when

switched on

Changeover of operating

mode

Line 170 = 1

• HC operating mode

flashes

• D.h.w. operating mode button will not be affected

Minimum setpoint of flow

temperature

Line 170 = 2

• Selected HC operating mode button flashes when

contact H1 is closed.

• D.h.w. operating mode button will not be affected

Central standby switch

Line 147 = 1

• HC operating mode

flashes

• D.h.w. operating mode button will not be affected

Function Effect on button and meaning

Occupancy button

• HC operating mode

flashes when occupancy

button is active.

• D.h.w. operating mode button will not be affected

Holiday function

• HC operating mode

flashes when holiday

function is active

• D.h.w. operating mode button flashes when

switched on

Changeover of the operating mode on the room unit is active only if the controller is in

automatic mode

.

The room temperature is transmitted to the controller via PPS, independent of the

selected operating mode.

3.2 Operating mode of d.h.w. heating

• Selection of d.h.w. heating mode independent of heating operation

• Selection is made directly on the user interface

D.h.w. heating can be switched on and off independent of the other operating modes.

D.h.w. heating is selected by pressing the respective button on the controller's user

interface.

Illuminated buttons

Settings on the controller

Settings on the room unit

Effect of room unit

Benefit

Description

Setting

Page 34

34/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Description of the enduser settings 15.07.2002

By pressing the respective button, d.h.w. heating is switched on or off.

• D.h.w. heating OFF - button dark.

D.h.w. is not being heated. Frost protection remains active, however, and prevents

the storage tank temperature from falling below a certain level

• D.h.w. heating ON - button illuminated.

The d.h.w. is heated according to the settings made

The following settings affect d.h.w. heating:

• Time switch program d.h.w. heating (lines 29...35)

• Nominal d.h.w. temperature setpoint (line 13)

• Reduced d.h.w. temperature setpoint (line 120)

• Release of d.h.w. heating at the nominal setpoint (line 121)

• Assignment of d.h.w. heating (line 123)

• D.h.w. heating (line 124)

• Type of d.h.w. demand (line 125)

The d.h.w. values that can be adjusted on the controller apply to both d.h.w. heating by

the controller and d.h.w. heating by a BMU supplied by Landis & Staefa. Some BMUs

of other manufacture also support this function.

3.3 Nominal room temperature setpoint

• Straightforward setting of the required nominal room temperature setpoint

The heating system uses 3 different setpoints that can be adjusted:

• The nominal room temperature setpoint described here

• The reduced room temperature setpoint (setting on line 14)

• The frost protection setpoint of the room temperature (setting on operating line 15)

The nominal room temperature setpoint is preadjusted with the setpoint knob. It is

located on the controller front for direct access by the user.

Setting range Unit Factory setting

8...26 °C 20

0 2 4 6 8 10 12 14 16 18 20 22 24 26

°C

2379Z17

Room temperature setpoint setting ranges

14 Setting "Reduced room temperature setpoint”

15 Setting "Frost protection setpoint of the room temperature”

When the nominal room temperature setpoint is active, the rooms will be heated

according to the adjustment made with the setpoint knob.

Effect in the various operating modes:

Effect

Important settings

Note

Benefit

Description

Setting

Effect of temperature

setting

Page 35

35/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Description of the enduser settings 15.07.2002

Operating

mode

Effect of knob adjustment

Adjustment

acts on the heating periods

Adjustment acts continuously

Adjustment has no effect

The adjustment made with the setpoint knob has priority over the reduced room

temperature setpoint entered (line 14). Especially in a situation when the adjustment

made with the knob is lower.

During the heating periods, the nominal room temperature setpoint is maintained. The

heating periods are in accordance with the settings made on lines 6 to 11.

0 2 4 6 8 10 12 14 16 18 20 22 24

h

Mo

...

So

2373Z11

When using a room unit without setpoint readjustment (QAA50), the setpoint knob on

the controller acts as described above.

When using a room unit featuring setpoint readjustment (QAA70), the setpoint knob on

the controller is inactive. In that case, the nominal setpoint adjusted on the room unit

applies.

A connected room unit is active only when operating mode

is selected on the

controller.

3.4 Manual operation

• Partly manual heating operation

In operating mode “Manual operation”, the plant components on the consumer side

must be manually adjusted and monitored. The control functions of the unit are only

used for controlling the BMUs.

The BMUs are released and use their boiler temperature sensor to control the

temperature at the level of the maximum limitation of the BMU setpoint (TKmax.)

Factory setting 80 °C. The actual boiler temperatures are displayed on setting line 55.

Activation:

Manual operation is activated by pressing this button. It is accessible

only when the cover of the controller is open

Deactivation:

• By pressing one of the operating mode buttons

• By pressing again the manual operation button

When deactivating the function, the controller will automatically return to the operating

mode previously selected.

As soon as manual operation is selected, all relays will switch to the following statuses:

Note

Example

Room unit

Benefit

Description

Common flow temperature

Setting

Note

Effect

Page 36

36/166

Siemens Building Technologies Basic Documentation RVA47.320 CE1P2379E

HVAC Products Description of the enduser settings 15.07.2002

Output

Terminals Status

BMU PPS All boilers released, fixed