Page 1

Preface

RUGGEDCOM WIN5214

Installation Guide

Introduction

Installing the Device

Technical Specifications

Dimension Drawings

Certification

1

2

3

4

5

08/2015

RC1130-EN-04

Page 2

RUGGEDCOM WIN5214

Installation Guide

Copyright © 2015 Siemens Canada Ltd.

All rights reserved. Dissemination or reproduction of this document, or evaluation and communication of its contents, is not authorized

except where expressly permitted. Violations are liable for damages. All rights reserved, particularly for the purposes of patent application or

trademark registration.

This document contains proprietary information, which is protected by copyright. All rights are reserved. No part of this document may be

photocopied, reproduced or translated to another language without the prior written consent of Siemens Canada Ltd..

Disclaimer Of Liability

Siemens has verified the contents of this manual against the hardware and/or software described. However, deviations between the product

and the documentation may exist.

Siemens shall not be liable for any errors or omissions contained herein or for consequential damages in connection with the furnishing,

performance, or use of this material.

The information given in this document is reviewed regularly and any necessary corrections will be included in subsequent editions. We

appreciate any suggested improvements. We reserve the right to make technical improvements without notice.

Registered Trademarks

ROX™, Rugged Operating System On Linux™, CrossBow™ and ELAN™ are trademarks of Siemens Canada Ltd. ROS® is a registered

trademark of Siemens Canada Ltd.

Other designations in this manual might be trademarks whose use by third parties for their own purposes would infringe the rights of the

owner.

Security Information

Siemens provides products and solutions with industrial security functions that support the secure operation of plants, machines, equipment

and/or networks. They are important components in a holistic industrial security concept. With this in mind, Siemens' products and solutions

undergo continuous development. Siemens recommends strongly that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable preventive action (e.g. cell protection concept)

and integrate each component into a holistic, state-of-the-art industrial security concept. Third-party products that may be in use should also

be considered. For more information about industrial security, visit http://www.siemens.com/industrialsecurity.

To stay informed about product updates as they occur, sign up for a product-specific newsletter. For more information, visit http://

support.automation.siemens.com.

Warranty

Siemens warrants this product for a period of five (5) years from the date of purchase, conditional upon the return to factory for maintenance

during the warranty term. This product contains no user-serviceable parts. Attempted service by unauthorized personnel shall render all

warranties null and void. The warranties set forth in this article are exclusive and are in lieu of all other warranties, performance guarantees

and conditions whether written or oral, statutory, express or implied (including all warranties and conditions of merchantability and fitness for

a particular purpose, and all warranties and conditions arising from course of dealing or usage or trade). Correction of nonconformities in the

manner and for the period of time provided above shall constitute the Seller’s sole liability and the Customer’s exclusive remedy for defective

or nonconforming goods or services whether claims of the Customer are based in contract (including fundamental breach), in tort (including

negligence and strict liability) or otherwise.

For warranty details, visit www.siemens.com/ruggedcom or contact a Siemens customer service representative.

Contacting Siemens

Address

Siemens Canada Ltd.

Industry Sector

300 Applewood Crescent

Concord, Ontario

Canada, L4K 5C7

Telephone

Toll-free: 1 888 264 0006

Tel: +1 905 856 5288

Fax: +1 905 856 1995

E-mail

ruggedcom.info.i-ia@siemens.com

Web

www.siemens.com/ruggedcom

ii

Page 3

RUGGEDCOM WIN5214

Installation Guide

Table of Contents

Table of Contents

Preface ................................................................................................................ v

Alerts .................................................................................................................................................. v

Related Documents ............................................................................................................................. v

Accessing Documentation ................................................................................................................... vi

Training .............................................................................................................................................. vi

Customer Support .............................................................................................................................. vi

Chapter 1

Introduction .......................................................................................................... 1

1.1 Feature Highlights ........................................................................................................................ 1

1.2 Configuration Ports and Indicator LEDs ......................................................................................... 2

1.3 Antennas ..................................................................................................................................... 4

Chapter 2

Installing the Device ............................................................................................ 7

2.1 Mounting the Device .................................................................................................................... 8

2.1.1 Mounting the Device to a Pole ........................................................................................... 9

2.1.2 Mounting the Device to a Wall or Tower ............................................................................ 11

2.2 Installing the Antenna ................................................................................................................. 13

2.3 Assembling the PoE Cable ......................................................................................................... 14

2.4 Connecting the WIN1010 Data Adapter ....................................................................................... 17

2.5 Connecting to a RUGGEDCOM RP100 or RP110 ........................................................................ 19

2.6 Installing the Device in Hazardous Locations ............................................................................... 20

2.7 Grounding the Device ................................................................................................................. 21

2.8 Weatherproofing the Device ........................................................................................................ 21

2.9 Configuring the CPE .................................................................................................................. 23

Chapter 3

Technical Specifications ..................................................................................... 25

3.1 Power Consumption ................................................................................................................... 25

3.2 Operating Environment ............................................................................................................... 25

3.3 Mechanical Specifications ........................................................................................................... 25

3.4 IDU to ODU Cable Specifications ................................................................................................ 26

iii

Page 4

Table of Contents

Chapter 4

RUGGEDCOM WIN5214

Installation Guide

Dimension Drawings .......................................................................................... 29

Chapter 5

Certification ........................................................................................................ 31

5.1 Standards Compliance ............................................................................................................... 31

5.2 Agency Approvals ...................................................................................................................... 31

5.3 MIL-STD Ratings ........................................................................................................................ 32

5.4 IEEE 802.16e Mobile WiMAX Compliance ................................................................................... 32

5.5 Environmental Type Tests ........................................................................................................... 32

iv

Page 5

RUGGEDCOM WIN5214

Installation Guide

Preface

This guide describes the RUGGEDCOM WIN5214. It describes the major features of the device, installation,

commissioning and important technical specifications.

It is intended for use by base station installers and operators, and assumes readers have a working knowledge

of WiMAX technologies and procedures. While some safety precautions are reviewed here, it is assumed that

installers are trained in safe installation practices. Users unfamiliar with safe installation procedures, WiMAX

technologies, and service procedures should not rely on this manual for comprehensive guidance.

Alerts

The following types of alerts are used when necessary to highlight important information.

DANGER!

DANGER alerts describe imminently hazardous situations that, if not avoided, will result in death or

serious injury.

Preface

WARNING!

WARNING alerts describe hazardous situations that, if not avoided, may result in serious injury and/or

equipment damage.

CAUTION!

CAUTION alerts describe hazardous situations that, if not avoided, may result in equipment damage.

IMPORTANT!

IMPORTANT alerts provide important information that should be known before performing a procedure

or step, or using a feature.

NOTE

NOTE alerts provide additional information, such as facts, tips and details.

Related Documents

Other documents that may be of interest include:

• RUGGEDCOM CPE User Guide

• RUGGEDCOM RP100 Installation Guide

• RUGGEDCOM RP110 Installation Guide

Alerts v

Page 6

Preface

RUGGEDCOM WIN5214

Installation Guide

Accessing Documentation

The latest Hardware Installation Guides and Software User Guides for most RUGGEDCOM products are

available online at www.siemens.com/ruggedcom.

For any questions about the documentation or for assistance finding a specific document, contact a Siemens

sales representative.

Training

Siemens offers a wide range of educational services ranging from in-house training of standard courses on

networking, Ethernet switches and routers, to on-site customized courses tailored to the customer's needs,

experience and application.

Siemens' Educational Services team thrives on providing our customers with the essential practical skills to make

sure users have the right knowledge and expertise to understand the various technologies associated with critical

communications network infrastructure technologies.

Siemens' unique mix of IT/Telecommunications expertise combined with domain knowledge in the utility,

transportation and industrial markets, allows Siemens to provide training specific to the customer's application.

For more information about training services and course availability, visit www.siemens.com/ruggedcom or

contact a Siemens sales representative.

Customer Support

Customer support is available 24 hours, 7 days a week for all Siemens customers. For technical support or

general information, contact Siemens Customer Support through any of the following methods:

Online

Visit http://www.siemens.com/automation/support-request to submit a Support Request (SR) or

check on the status of an existing SR.

Telephone

Call a local hotline center to submit a Support Request (SR). To locate a local hotline center, visit

http://www.automation.siemens.com/mcms/aspa-db/en/automation-technology/Pages/default.aspx.

Mobile App

Install the Industry Online Support app by Siemens AG on any Android, Apple iOS or Windows

mobile device and be able to:

• Access Siemens' extensive library of support documentation, including FAQs and manuals

• Submit SRs or check on the status of an existing SR

• Contact a local Siemens representative from Sales, Technical Support, Training, etc.

• Ask questions or share knowledge with fellow Siemens customers and the support community

vi Accessing Documentation

Page 7

RUGGEDCOM WIN5214

Installation Guide

Introduction

The RUGGEDCOM WIN5214 Outdoor Unit (ODU) Customer Premises Equipment (CPE) device is part of the

RUGGEDCOM WIN family, a line of mobile WiMAX broadband wireless access systems based on the IEEE

802.16e mobile WiMAX standard.

The RUGGEDCOM WIN5214 is a high-performance, self-learning subscriber. It automatically detects the base

station on the best signal available allowing for plug and play installation and maintenance free operation. The

automatic switching and monitoring features guarantee on-going operation in changing conditions, which results

in low maintenance and considerable operating expense savings.

The device is compliant to the IEEE 802.16e standards to effectively meet the unique requirements of the

wireless Metropolitan Area Network (MAN) environment and to deliver broadband access services to a wide

range of customers. Specifically designed for point-to-multipoint broadband wireless access applications,

the RUGGEDCOM WIN5214 provides efficient use of the wireless spectrum, supporting a range of user

environments.

The RUGGEDCOM WIN5214 Outdoor Unit (ODU) Customer Premises Equipment (CPE) device also complies

with the IEEE 802.16-2005 standard for the deployment of point-to-multipoint (PMP) and point-to-point (PTP)

network architectures.

The device is a WiMAX Forum IEEE 802.16e Wave 2 (MIMO) certified subscriber. Each subscriber registers and

establishes a bi-directional data link with the base station.

The following sections provide more information about the device:

• Section 1.1, “Feature Highlights”

• Section 1.2, “Configuration Ports and Indicator LEDs”

• Section 1.3, “Antennas”

Chapter 1

Introduction

Section 1.1

Feature Highlights

Long Range

The device has multiple built-in receivers to improve range and Non-Line-of-Sight (NLoS) performance. The

system has the ability to leverage sub-channelization technology to balance links with high-power base stations.

Robust Design

The device is designed for mission critical applications in harsh environments with very high Mean Time Before

Failure.

Quality of Service

The device gives the user the ability to separate traffic types over the air, and guarantee latency, minimum

bandwidth and jitter according to application needs.

Power Supply Options

When combined with the injector series (RP100 or RP110), the device offers the industry’s leading power supply

options with 12, 24, 48, and 88–300 VDC or 85–264 VAC available for a variety of industrial applications.

Feature Highlights 1

Page 8

Chapter 1

2

1

Introduction

Flexibility

The device supports both IP convergence sublayer for wireless Internet service providers or Ethernet

Convergence Sublayer, ideal for mission critical private networks.

Radio and Modem Features

• Supported Frequency Bands: 5251, 5151, 7251

• Frequency: 1350 MHz to 1525 MHz

• Radio Access Method: IEEE802.16-2005 (16e OFDMA)

• Operation Mode: TDD

• Compatibility: Wave 2 Profile (MIMO)

• Channel Bandwidth: 5MHz, 7MHz, 10MHz

• Frequency Resolution: 0.25 MHz

• Antenna Support: Integrated Dual Slant Antenna

• Antenna Diversity Support: STC/MRC/MIMO

• Output Power (average): 24 dBm

• FFT/Modulation: 1024/512 FFT points; QPSK, 16 QAM, 64 QAM

RUGGEDCOM WIN5214

Installation Guide

• FEC: Convolutional Turbo Code

• Dynamic Range:

▪ RX: -100 dBm: -20 dBm

▪ TX: -30 dBm: +24 dBm

Section 1.2

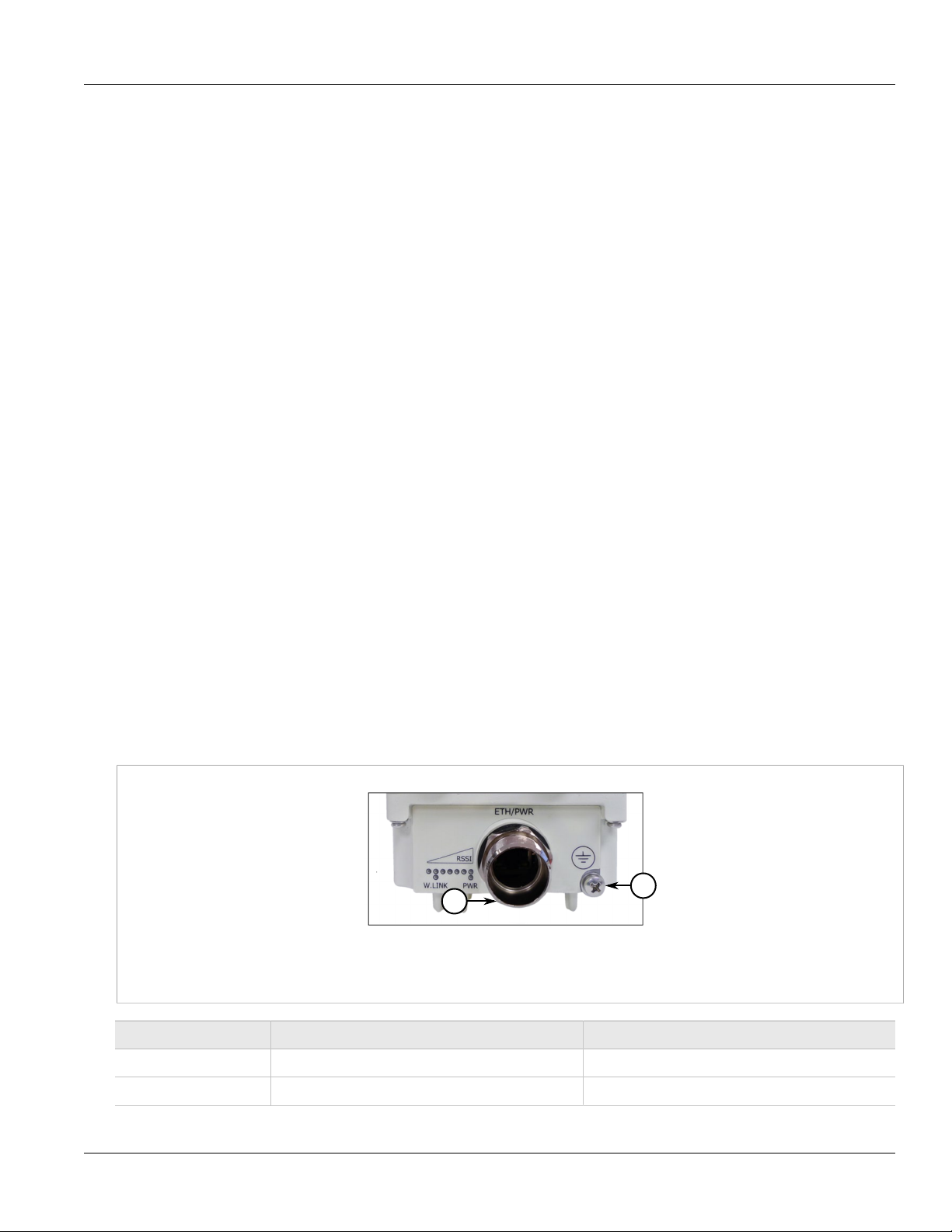

Configuration Ports and Indicator LEDs

Connectors and LED indicators are found on the bottom of the device casing.

Figure 1: RUGGEDCOM WIN5214 Connectors

1. ETH/PWR 2. Ground

Name Description Connector Type

ETH/PWR Data and power from PoE injector RJ-45

Ground Ground Grounding screw

2 Configuration Ports and Indicator LEDs

Page 9

RUGGEDCOM WIN5214

Installation Guide

LED Indicators

The LED indicators display the following information:

• RSSI: displays the Received Signal Strength Indicator (RSSI) level

• W.LNK: displays the wireless link indication

• PWR: displays the power status

The following table displays the LED indicators for the device:

LED Color Description

Chapter 1

Introduction

WLNK is ON Green

WLNK is BLINKING Green

PWR is ON Green CPE power is on.

RSSI: one LED is ON (least

significant)

RSSI: two LEDs are ON Green -85 < RSSI < -90

RSSI: three LEDs are ON Green -80 < RSSI < -85

RSSI: four LEDs are ON Green -75 < RSSI < -80

RSSI: five LEDs are ON Green -70 < RSSI < -75

RSSI: six LEDs are ON Green -65 < RSSI < -70

RSSI: seven LEDs are ON

Green RSSI < -90

Older Hardware

LEDs 1-7: Green

LED 8: Red

Latest Hardware

LEDs 1-6: Green

LED 7: Red

The device is connected with and

receives services from the base

station; network entry is complete.

The link between the CPE and the

base station is down.

-20 < RSSI < -60

RSSI: only the last LED is ON

(most significant)

Red -20 < RSSI (Saturation)

RUGGEDCOM WIN1010 Data Adapter LED Indicators

LEDs on the WIN1010 data adapter indicate the status of the WIN1010 power supply.

Name Color Description

PWR Green Input power is connected

LAN Green LAN link/activity display

WLNK Green Wireless link/activity display

Configuration Ports and Indicator LEDs 3

Page 10

Chapter 1

1

2

3

Introduction

Section 1.3

Antennas

The CPE consists of the following modules:

Module Description

RUGGEDCOM WIN5214

Installation Guide

Base-Band board: Includes the WiMAX 16e MIMO Base-Band SoC and runs the 16e

Power Supply board with DC/DC power supply: Converts 48 VDC input to the voltages feeding the Digital and RF

RF board: Single transmit/dual receive module that modulates the analog

Chassis

Antenna or Antennas: Integrated dual polarization antenna supporting MIMO schemes.

MAC + PHY, user interface, and analog front end interface to the RF

module.

modules.

WiMAX signal input from the Base-Band modem to the high

frequency RF output. Several RF modules exist, each supporting a

different frequency band.

Figure 2: RUGGEDCOM WIN5214 CPE Block Diagram: Integrated Antenna

1. Power Supply 2. RF 3. Base-Band 4. Antennas

Outdoor Grounding System

Verify the antenna or cable system is grounded. The CPE antenna installation must be as per Article 810 of the

NEC.

WARNING!

Fire hazard – risk of serious personal injury and/or damage to equipment. To reduce the risk of fire, use

only 26 AWG or larger telecommunication line cord between indoor and outdoor units.

Specifically, the requirement the grounding conductor be not less than 10 AWG (Cu). The grounding scheme

should either be in accordance with UL 96 and 96A Lightning Protection Components and Installation

Requirements for Lightning Protection Systems, or tested in accordance with UL 50 and UL 497.

4 Antennas

Page 11

RUGGEDCOM WIN5214

Installation Guide

Chapter 1

Introduction

NOTE

The antenna is an integral part of the device.

Antennas 5

Page 12

RUGGEDCOM WIN5214

Installation Guide

Chapter 1

Introduction

Antennas 6

Page 13

RUGGEDCOM WIN5214

Installation Guide

Installing the Device

Installing the Device

This chapter describes how to install the device, including mounting the device, connecting power, connecting the

antenna, and connecting the device to the network.

DANGER!

Electrocution hazard – risk of serious personal injury and/or damage to equipment. Before performing

any maintenance tasks, make sure all power to the device has been disconnected and wait

approximately two minutes for any remaining energy to dissipate.

DANGER!

Electrocution hazard – risk of death or serious injury. When the base station is installed in an outdoor

location, all indoor components (e.g. Ethernet and power supply) should be connected through a

lightning protector.

Lightning protection protects people and equipment located indoors from lightning that may strike the

base station or its outdoor cables. Therefore, install the lightning protector base station indoors, as

close as possible to the point where the cables enter the building. The lightning protector can also be

installed outdoors as long as the cables that lead indoors are well protected from lightning between the

protector and the building entrance.

Chapter 2

WARNING!

Safety hazard – risk of serious personal injury and/or damage to equipment. Installing the

RUGGEDCOM WIN5214 can pose a serious safety hazard. Be sure to take precautions to avoid the

following:

• Exposure to high voltage lines during installation

• Falling when working at heights or with ladders

• Injuries from dropping tools

• Contact with AC wiring (power system connection)

IMPORTANT!

Only certified personnel should be permitted to install equipment.

IMPORTANT!

This product contains no user-serviceable parts. Attempted service by unauthorized personnel shall

render all warranties null and void.

Changes or modifications not expressly approved by Siemens Canada Ltd. could invalidate

specifications, test results, and agency approvals, and void the user's authority to operate the

equipment.

IMPORTANT!

This product should be installed in a restricted access location where access can only be gained by

authorized personnel who have been informed of the restrictions and any precautions that must be

taken. Access must only be possible through the use of a tool, lock and key, or other means of security,

and controlled by the authority responsible for the location.

7

Page 14

Chapter 2

Installing the Device

IMPORTANT!

Install equipment in accordance with the electrical code relevant to the country of installation, such as:

• the National Electrical Code (NEC), ANSI/NFPA 70

• the Canadian Electrical Code (CEC), Part 1, CSA C22.1

• the National Electrical Safety Code IEEE C2 (when applicable)

Unless marked or otherwise identified, the Standard for the Protection of Electronic Computer/Data

Processing Equipment, ANSI/NFPA 75, also applies.

IMPORTANT!

Outdoor exposed communication lines longer than 40 m (140 ft) must be considered as TNV-1 circuits.

The installer must make sure the power supply and network ports are designed for full compliance with

the standards for TNV-1 telecommunication networks.

The general procedure for installing the device is as follows:

1. Mount the device to a pole or wall.

2. Install and connect the antenna.

3. Assemble the PoE cable.

4. Connect a RUGGEDCOM WIN1010 adapter.

5. Connect a RUGGEDCOM RP100/RP110.

6. If the device is to be installed in a hazardous location, install the Class I, Division II kit.

7. Make sure the device is grounded.

8. Weatherproof the ends of all cables.

9. Configure the device.

These steps, and other related information, are described in the following sections:

• Section 2.1, “Mounting the Device”

• Section 2.2, “Installing the Antenna”

• Section 2.4, “Connecting the WIN1010 Data Adapter ”

• Section 2.5, “Connecting to a RUGGEDCOM RP100 or RP110 ”

• Section 2.6, “Installing the Device in Hazardous Locations”

• Section 2.7, “Grounding the Device”

• Section 2.3, “Assembling the PoE Cable”

• Section 2.8, “Weatherproofing the Device”

• Section 2.9, “Configuring the CPE”

RUGGEDCOM WIN5214

Installation Guide

Section 2.1

Mounting the Device

The RUGGEDCOM WIN5214 is designed for maximum mounting and display flexibility. It can be secured to a

bracket and then mounted to a pole or to a wall or tower.

8 Mounting the Device

Page 15

RUGGEDCOM WIN5214

Installation Guide

Installing the Device

NOTE

For detailed dimensions of the device, refer to Chapter 4, Dimension Drawings.

The following sections describe the various methods of mounting the device, and how to install the mounting

bracket:

• Section 2.1.1, “Mounting the Device to a Pole”

• Section 2.1.2, “Mounting the Device to a Wall or Tower”

The RUGGEDCOM WIN5214 ODU CPE mounting kit allows for pole or wall mounting.

When choosing the mounting location for the unit, consider the available mounting structures and antenna

clearance.

Site Survey

Most wireless networks include many CPEs and BSTs installed in various locations in an overlapping radiocell pattern. It is important to position each CPE at an optimal location considering the assignment of its radio

channels. Therefore, a site survey becomes an essential first step before physically deploying the RUGGEDCOM

WIN5214 solution.

The site survey should include details important to the planning of the CPE deployment in each specific site,

including potential mounting points for CPE and antennas, as well as the routing options for data, power and

antenna cables.

Chapter 2

Recommended Site Requirements

It is highly recommended the RUGGEDCOM WIN5214 be mounted with as few obstructions as possible between

the CPE and the base station. The CPE should be pointed in the direction of the designated server base station.

When choosing the ideal location, it is also important to take into consideration the overall area topology.

Section 2.1.1

Mounting the Device to a Pole

The device can be attached to any pipe or pole with a diameter of 44.5 to 254 mm (1.75 to 10 in).

To mount the device to a pole, do the following:

1. Select a mounting location on the pole.

2. Position the mounting bracket against the pole.

3. Secure the clamping bracket to the mounting bracket using screws, spring washers and nuts. Make sure the

screws are hand tightened.

NOTE

When mounting the device, note the orientation of the clamping bracket in the illustration.

Mounting the Device to a Pole 9

Page 16

Chapter 2

1

8

9

2

10

5

6

7

5

4

6

2

3

Installing the Device

RUGGEDCOM WIN5214

Installation Guide

Figure 3: Mounting the Antenna/Enclosure to a Large Pole

1. Pole 2. Clamping Bracket 3. Mounting Bracket 4. M8-25 Hex Screw 5. M8 Flat Washer 6. M8 Spring Washer 7. M8

Nut 8. M8-70 Hex Screw 9. M8 Spring Washer 10. M8 Flat Washer

10 Mounting the Device to a Pole

Page 17

RUGGEDCOM WIN5214

1

8

9

2

10

5

6

7

5

4

6

2

3

Installation Guide

Installing the Device

Chapter 2

Figure 4: Mounting the Antenna/Enclosure to a Small Pole

1. Pole 2. Clamping Bracket 3. Mounting Bracket 4. M8-25 Hex Screw 5. M8 Flat Washer 6. M8 Spring Washer 7. M8

Nut 8. M8-70 Hex Screw 9. M8 Spring Washer 10. M8 Flat Washer

4. Adjust the position of the device. For more information about aligning the CPE antenna, refer to Section 2.2,

“Installing the Antenna”.

5. Tighten the screws connecting the clamping bracket to the mounting bracket. Make sure the screws are

torqued to 14 N·m (10 lbf-ft).

Section 2.1.2

Mounting the Device to a Wall or Tower

Attach the device to any wall capable of carrying the device's weight. An outer wall on a roof or other high

location to avoid interference from other buildings or trees is preferred.

Mounting the Device to a Wall or Tower 11

Page 18

Chapter 2

5

6

7

1

3

5

64

8

2

9

10

Installing the Device

RUGGEDCOM WIN5214

Installation Guide

Figure 5: Mounting the Device to a Wall or Tower

1. CPE 2. Mounting Kit 3. Wall Holder/Pole Mount 4. M8-25 Hex Screw 5. M8 Flat Washer 6. Spring Washer 7. M8 Nut 8. M5

Flat Washer 9. Screw for Chipboard 10. Wall Plug (Plastic Anchor)

To mount the device to a wall, do the following:

1. Select a mounting location on the wall.

2. Place the mounting bracket on the wall and mark 4 mounting holes.

3. Drill 4 holes and insert a wall plug into each hole.

4. Secure the mounting bracket to the wall with 4 type NS 1/4" × 1/2" HEX screws, 4 spring washers, and 4 flat

washers.

5. Connect the arm bracket to the mounting bracket using a screw, spring washer and washer. Make sure the

screw is hand tightened.

6. Connect the device to the arm bracket using a screw, spring washer and washer. Make sure the screw is

hand tightened.

7. Adjust the position of the device. For more information about how to align the CPE Antenna, refer to

Section 2.2, “Installing the Antenna”.

8. Tighten the screws connecting the arm bracket to the device and mounting bracket. Make sure the screws

are torqued to 24 N·m (17.7 ft. lb.).

12 Mounting the Device to a Wall or Tower

Page 19

RUGGEDCOM WIN5214

Installation Guide

Section 2.2

Installing the Antenna

To install the antenna, do the following:

WARNING!

Radiation hazard – risk of Radio Frequency (RF) exposure. This base station is compliant with

the requirements set forth in CFR 47, section 1.1307, addressing Radio Frequency (RF) exposure

from radio frequency base stations, as defined in FCC OET Bulletin 65 FCC OET Bulletin 65 [http://

transition.fcc.gov/Bureaus/Engineering_Technology/Documents/bulletins/oet65/oet65.pdf]. The emitted

radiation should be as little as possible. To achieve minimum RF exposure, install the base station

when it is configured not to transmit and set it to operational mode remotely, rather than having a

technician enable transmission on-site. For maintenance of the base station, or other operations which

require RF exposure, the exposure should be minimized in time and according to the regulations set by

the FCC or the regulations relevant to the country of installation.

IMPORTANT!

During antenna installation, observe the following:

• Always install the antenna at least 0.39 m from people and public areas.

• Antenna must be in a fixed position.

• After it is installed, do not change the antenna position.

Installing the Device

Chapter 2

NOTE

The device is compliant with the requirements set forth in CFR 47, section 1.1307, addressing Radio

Frequency (RF) exposure from radio frequency devices as defined in OET Bulletin 65. The emitted

radiation should be as little as possible. To achieve minimum RF exposure, install the device when it

is configured not to transmit and set it to operational mode remotely, rather than enabling transmission

by the installer on-site. For maintenance of the device, or other operations which require RF exposure,

minimize the exposure time according to the regulations set by the FCC or the regulations relevant to

the country of installation.

IMPORTANT!

Make sure the front of the device is always facing the base station. In some conditions, such as when

the line of sight to the base station is impeded, better reception may be achieved using a reflected

signal. In this case, direct the device towards the reflecting object, rather than towards the base station.

In some cases, the device may need to be tilted to make sure the level at which the device receives

transmissions from the base station (and vice versa) is not too high. When only the last RSSI LED is

on, this indicates saturation and the received signal level is too high. This must be avoided, preferably

by tilting the device upwards. As a rule of thumb, if the device is located at a distance of less than 300

meters from the base station, it is recommended to tilt the device upwards by approximately 10° to 15°.

1. Point the front face of the device in the general direction of the designated base station.

2. Verify that power is applied to the device. The PWR LED should be ON.

3. Position the device until the maximum RSSI link quality reading is achieved. A single RSSI LED indicates

the device is at minimum synchronized with the base station. For information about the RSSI LED indicators,

refer to Section 1.2, “Configuration Ports and Indicator LEDs”.

If the device is not synchronized with the base station, make sure all parameters are configured properly.

Installing the Antenna 13

Page 20

Chapter 2

1

2

38 mm

(1.5 in)

1 2

Installing the Device

RUGGEDCOM WIN5214

Installation Guide

If the expected link quality still cannot be achieved, try to improve the reception quality by placing the device

at a higher point or in an alternate location.

4. Make sure the antenna is properly grounded according to local standards.

Section 2.3

Assembling the PoE Cable

The following describes how to assemble the PoE cable using the supplied connector kit. The ODU CPE uses a

shielded male RJ45 connector to provide the data and Power-over-Ethernet (PoE) connection to the device.

The following components and tools are required:

• CPE RJ45 Connector Kit (supplied with the device). Contains an RJ45 connector and loading bar.

• CAT-5e cable of suitable length for your application. For information on cable specifications, refer to

Section 3.4, “IDU to ODU Cable Specifications”.

• Standard cable splicing tools, including a standard crimp tool.

To assemble the RJ45 connector, do the following:

1. Slide the connector components on to the wire.

Figure 6: Assembling the Connector Components

1. Plug Housing 2. Dust Cover

2. Strip the wire jacket 38 mm (1.5 in) from the tip, making sure not to cut the foil or drain wire.

14 Assembling the PoE Cable

Figure 7: Cutting the Jacket

1. Wire Jacket 2. Foil

Page 21

RUGGEDCOM WIN5214

1

2

3

3

1

2

Installation Guide

3. Fold the foil back over the wire jacket.

Figure 8: Folding Back the Foil

1. Foil 2. Twisted-Pair Wires 3. Drain Wire

4. Bend the drain wire back over the jacket.

Installing the Device

Chapter 2

Figure 9: Bending the Drain Wire

1. Foil 2. Drain Wire 3. Twisted-Pair Wires

5. Partially untwist each wire pair, making sure to retain a half twist at the end.

Figure 10: Untwisting the Wire Pairs

6. Arrange the wires according to the following pin-out description:

Assembling the PoE Cable 15

Page 22

Chapter 2

1

2

1

2

2

1

1

3

4

Installing the Device

RUGGEDCOM WIN5214

Installation Guide

Figure 11: CAT-5e PoE Cable Pin-Out

1. Pin 1 2. Pin 8

Pin

Number

1 White/Orange ETH Data TP0+

2 Orange ETH Data TP0-

3 White/Green ETH Data TP1+

4 Blue 48 V TP2+

5 White/Blue 48 V TP2-

6 Green ETH Data TP1-

7 White/Brown RTN (-) TP3+

8 Brown RTN (-) TP3-

Color Description

7. Slide the wires into the loading bar and then pull the loading bar down until its face is 16 mm (0.63 in) from

the wire jacket. If necessary, use pliers to hold the wires while pulling the loading bar.

Figure 12:

1. Loading Bar 2. Wires 3. Pin 1 4. Pin 8

8. Trim the wires until they are flush with the face of the loading bar.

9. Insert the wires and loading bar into the plug body. Make sure:

• the cable is pushed to the front of the plug body

• the spine of the strain relief on the plug body covers the drain wire

10. Bend the strain relief until it is flat against the jacket and foil.

11. Crimp the plug and strain relief using a standard crimping tool.

12. Trim away any excess foil or drain wire extruding from the strain relief.

13. Slide the connector components up to the plug body.

14. Insert the modular plug into the plug housing.

16 Assembling the PoE Cable

Page 23

RUGGEDCOM WIN5214

2

3

1

4

2

3

1

Installation Guide

Figure 13: Assembling the Connector Components

1. PoE Plug 2. Plug Housing 3. Dust Cover

Installing the Device

15. Align the latch with the LATCH slot.

16. Press the plug into the plug housing until it bottoms out.

17. While maintaining inward pressure on the plug or keeping the dust cover engaged, tighten the compression

nut to 0.56 N·m (5 In-lbs).

Chapter 2

Figure 14: Connecting the PoE Cable to the CPE

1. PoE Cable 2. Dust Cover 3. Plug Housing 4. CPE

Section 2.4

Connecting the WIN1010 Data Adapter

The RUGGEDCOM WIN1010 data adapter powers the device and distributes data. The WIN1010 data adapter

unit provides RJ45 input connectors that include 10/100Base-T transceivers for connection to an IEEE802.3

(10/100Base-T) compatible device. The unit receives power from 100 to 240VAC using an IEC-320-C14 industry

standard connector.

CAUTION!

The power supply AC cord should be 3 wires, 18 AWG minimum, with length less than 4.5 m (14.8 ft),

and safety certified according to national rules.

A single output RJ45 connector provides 10/100 Base-T data and power to the outdoor unit over a

Category 5e cable. This cable provides for the bi-directional transfer of data and signaling as well as a

power feed to the outdoor equipment.

Connecting the WIN1010 Data Adapter 17

Page 24

Chapter 2

3

2

6

4

7

1

5

Installing the Device

NOTE

The Category 5e Ethernet cable is not included. Refer to Section 3.4, “IDU to ODU Cable

Specifications” for detailed technical specifications.

NOTE

The device should always be connected to a supported Power over Ethernet (PoE) injector.

The WIN5214-AC ODU CPEs are non-standard PoE devices. Do not attempt to use third-party PoE

injectors. The use of any other type of connection or application of the device and/or WIN1010 data

adapter is not permitted.

Route all power supply cords so that people cannot walk on them or place objects on or against them,

which can pinch or damage the cords.

RUGGEDCOM WIN5214

Installation Guide

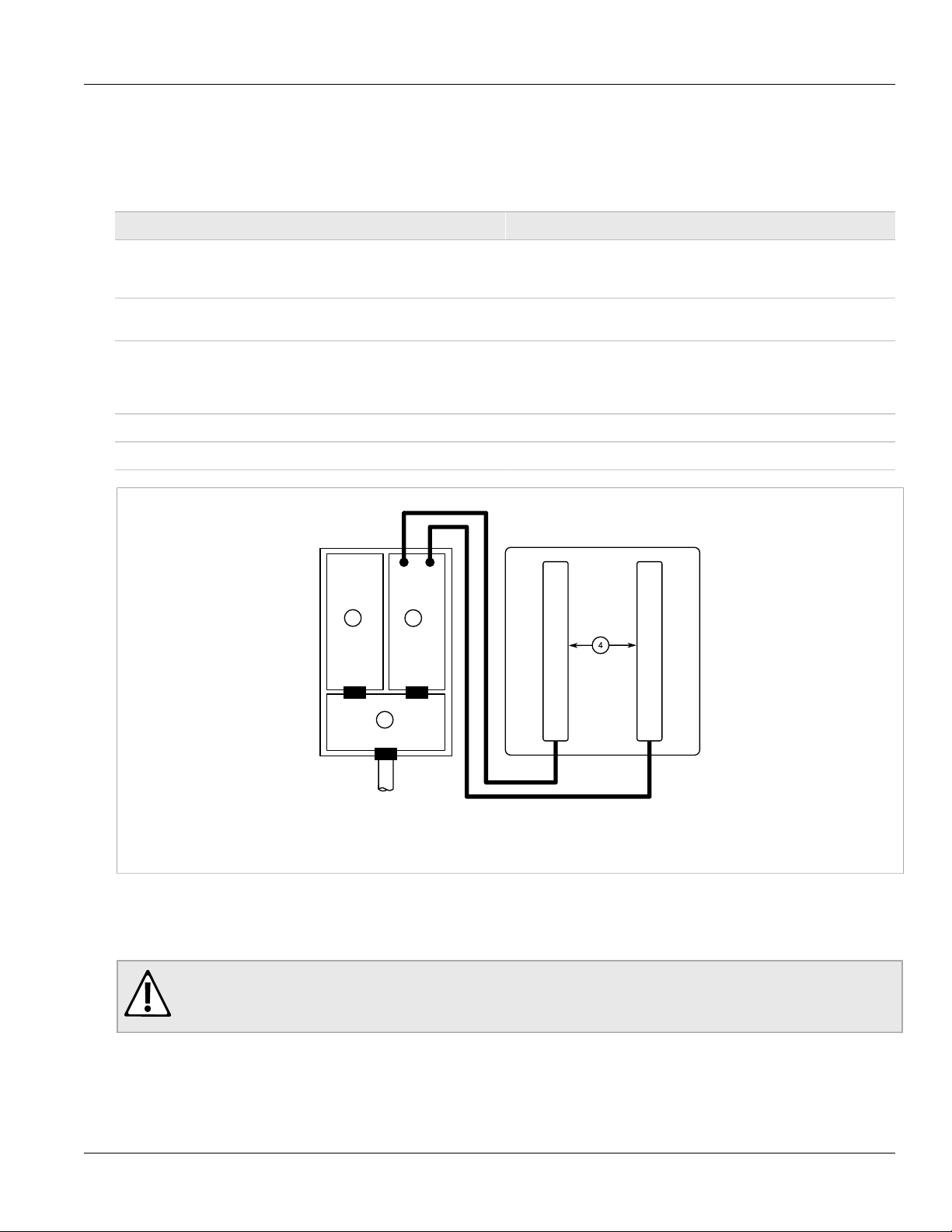

Figure 15: Power over Ethernet Connection Schematic

1. ODU CPE 2. PoE 3. Data Adapter 4. AC Power 5. Ethernet 6. Switch 7. Ethernet

NOTE

Before connecting the WIN1010 data adapter to the 110/220 VAC power source, verify that all system

components are properly installed and all cable connectors are securely positioned in the appropriate

ports.

To connect power to the device, do the following:

1. Connect a Category 5e cable between the device and the WIN1010 data adapter.

2. Connect a Category 5e cable between the WIN1010 data adapter and a 10/100Base-T port of a switch,

router, or PC.

3. Connect the WIN1010 data adapter to the 110/220 VAC power source using the cable.

18 Connecting the WIN1010 Data Adapter

Page 25

RUGGEDCOM WIN5214

1

3

3

3

4

52

6

3

Installation Guide

Section 2.5

Installing the Device

Connecting to a RUGGEDCOM RP100 or RP110

The RUGGEDCOM RP100 and RP110 are optional power injectors that can be ordered to power the

RUGGEDCOM WIN5214. The RUGGEDCOM RP100 and RP110 meet a wider temperature and voltage range

than the WIN1010.

When the CPE is connected to a RUGGEDCOM RP100 or RP110, make sure there is a solid connection

between the lightning protector and the CPE. The following illustration details a typical installation:

NOTE

A shielded cable must be used and connected to local ground at both the RUGGEDCOM WIN5214

and CPE.

NOTE

The lightning protector must meet the necessary requirements of IEC/UL/CSA 60950-1. The clamping

voltage must also be less than 60 V and the protector must not activate when the voltage is less than

56 V. For more information, contact Siemens Customer Support.

IMPORTANT!

Install the lightning protector and the RUGGEDCOM RP100/RP110 as close as possible.

Chapter 2

Figure 16: Typical Outdoor Installation

1. RUGGEDCOM WIN5214 2. Shielded Cable 3. Ground Connection 4. Lightning Protector 5. RUGGEDCOM RP100/RP110

6. Drain Wire (Shielded)

For more information about the RUGGEDCOM RP100 or RP110, refer to either the RUGGEDCOM RP100

Installation Guide or the RUGGEDCOM RP110 Installation Guide.

Connecting to a RUGGEDCOM RP100 or RP110 19

Page 26

Chapter 2

4

1

6

2

2

3

5

Installing the Device

Section 2.6

RUGGEDCOM WIN5214

Installation Guide

Installing the Device in Hazardous Locations

An approved surge suppression unit is required when the base station is installed in a hazardous location.

The WIN5214 is certified for installation in Class I, Division II Groups A, B, C and D hazardous locations when

installed using the Class I, Division II kit (P/N MKIT0090). The Class I, Division II kit contains the following items:

• Lambda power supply unit (model DPP50-48)

• L-COM passive PoE injector (model BT-CAT5-P1)

• DC power cable

• AC open-ended power cable

WARNING!

EXPLOSION HAZARD

• Substitution of components may impair suitability for Class I, Division II

• Do not disconnect equipment unless power has been switched off or the area is known to be nonhazardous

• Use only Lambda DPP50-48 Power Supply in conjunction with the unit

RISQUE D’EXPLOSION

• La substitution decomposants peut rendre ce matériel inacceptable pour les emplacements de

Classe I, Division II

• Avant de déconnecter l’equipment, couper le courant ou s’assurer que l’emplacement est désigné

non dangereux

• Utilisez l’unité uniquement avec une batterie de la marque Lamba DPP50-48

To install the base station in a hazardous location, do the following:

1. Connect the DC power cable between the Lambda Power Supply Unit (PSU) and the L-COM passive PoE

injector.

Figure 17: Connecting the CPE in a Hazardous Location

1. Ethernet Switch 2. CAT-5e Cable 3. L-COM Passive PoE Injector 4. RUGGEDCOM WIN5214 5. DC Power Cable

6. Lambda PSU

20 Installing the Device in Hazardous Locations

Page 27

RUGGEDCOM WIN5214

Installation Guide

2. Using a CAT-5e cable, connect the PoE injector to the CPE.

3. Using a CAT-5e cable, connect the Ethernet switch to the PoE injector.

Installing the Device

CAUTION!

The AC power cable must consist of 3 wires, be minimum 18 AWG, be less than 4.5 m (14.7 ft)

long, and be safety certified according to national rules.

4. Connect the AC open-ended power cable to the Lambda PSU.

Section 2.7

Grounding the Device

When connecting the ground cable to the device, make sure to use a 10 AWG grounding cable and torque the

screw to 15 N·m (11 ft. lb.).

DANGER!

Electrocution hazard – risk of death or serious injury. The system must be properly grounded to protect

against power surges and accumulated static electricity. It is the installer’s responsibility to install this

base station in accordance with the local electrical codes.

Chapter 2

Section 2.8

Weatherproofing the Device

Most outdoor CPE, antenna or cable problems are caused by coaxial cable connections loosened by vibration,

allowing moisture to penetrate the connector interface. Siemens strongly recommends weatherproofing all

outdoor cable connections to prevent the ingress of water and help secure connections.

Since PoE cables also carry DC current, the need for proper weatherproofing cannot be overstated.

Use electrical tape and a heavy-duty weather, abrasion and UV-resistant rubber splicing or self-amalgamating

tape to seal connections.

IMPORTANT!

The warranty is void if the base station is assembled without waterproof sealing or if the sealing is

removed from the connections.

IMPORTANT!

PVC tape, silicon seal and glue are not recommended for weatherproofing, as these materials are

difficult to apply accurately and are difficult to remove.

IMPORTANT!

This method of weatherproofing must be completed on all external connections. If surge arrestors are

used, all associated connections and arrestors must be completely wrapped with splicing tape or selfamalgamating tape.

Rubber mastic or duct sealing putty must also be used to complete the weatherproofing where needed.

To weatherproof an outdoor cable connection, do the following for both ends of the cable:

1. Make sure the connector and cable are free of any foreign substances, such as oil, grease or dirt.

Grounding the Device 21

Page 28

Chapter 2

Installing the Device

RUGGEDCOM WIN5214

Installation Guide

2. Make sure the connection is secure and the cable extends below the connector to provide a path for water to

flow away from the base station.

3. Starting as close to the base station as possible, stretch and wind rubber splicing or self-amalgamating tape

around the connector and cable. Make sure there are no gaps. Continue wrapping until the tape is 25 mm (1

in) down the cable.

Figure 18: Wrapping the Connector with Rubber Splicing or Self-Amalgamating Tape

NOTE

Where available, use 3M™ Scotch® Super 88 electrical tape.

4. To protect the rubber splicing or self-amalgamating tape from UV damage, stretch and wind two layers of

electrical tape around the connector and cable the same way it was done in Step 3.

Figure 19: Wrapping the Connector with Electrical Tape

5. Work rubber mastic or duct sealing putty between the connector and the body of the radio or antenna. Make

sure the putty fills any gaps not covered by the tape.

22 Weatherproofing the Device

Page 29

RUGGEDCOM WIN5214

Installation Guide

Figure 20: Sealing Gaps with Putty

Section 2.9

Installing the Device

Chapter 2

Configuring the CPE

Once the CPE is installed and connected to the network, it must be configured. The RUGGEDCOM WIN5214

features a Web-based User Interface (UI) for all configuration management. For more information about

configuring the base station, refer to the RUGGEDCOM WIN CPE User Guide associated with the device and the

installed software release.

Configuring the CPE 23

Page 30

RUGGEDCOM WIN5214

Installation Guide

Installing the Device

Chapter 2

Configuring the CPE 24

Page 31

RUGGEDCOM WIN5214

Installation Guide

Technical Specifications

The following sections provide important technical specifications related to the device:

• Section 3.1, “Power Consumption”

• Section 3.2, “Operating Environment”

• Section 3.3, “Mechanical Specifications”

• Section 3.4, “IDU to ODU Cable Specifications”

Section 3.1

Power Consumption

Typical power consumption: 12 W

Technical Specifications

Chapter 3

Section 3.2

Operating Environment

Parameter Range Comments

Ambient Operating Temperature -40 to 75 °C

Ambient Relative Humidity 5% to 95% Non-condensing

Ambient Storage Temperature -40 to 75 °C

Section 3.3

(-40 to 167 °F)

(-40 to 167 °F)

Mechanical Specifications

Parameter Value

Dimensions Refer to Chapter 4, Dimension Drawings

Weight 1.5 kg (3.3 lb)

Enclosure Aluminum

Ingress Protection IP67

Power Consumption 25

Page 32

Chapter 3

Technical Specifications

Section 3.4

IDU to ODU Cable Specifications

Special 4×2×24 AWG FTP Cat. 5e Outdoor Double Jacket Data Cable UL (1581 VW 1)

IDU to ODU Cable

Applications: Outdoor installations, fixed or portable installations, digital distribution frames in

transmission stations, outdoor installations in harsh environments.

RUGGEDCOM WIN5214

Installation Guide

General Construction: Custom made cable designed specially for wireless systems, meeting the requirements of

Conductor Size: 0.52 mm

Outer Jacket Material: UV resistant FR-PVC

Outer Diameter: 7.9 mm nominal

Weight: 68.0 kg/km

Cat. 5e per ANSI/TIA/EIA-568-B.2 and IEC 61156-5. The cable contains 4 twisted pairs,

cabled, foil-tape shielded and jacketed with two special black UV resistant, flame retardant

PVC compounds for direct outdoor use in harsh electrical environments. The diameter of the

inner core complies with RJ45 connecting hardware allowing direct connection to equipment

without patch cords.

IDU to ODU Cable Design and Materials

Conductor Material: Bare copper

Conductor Size: 24 AWG

Insulation Material: Solid PO

Insulation O.D.: 1.07 mm

Color Code: Per TIA/EIA 568-B

Overall Foil Shield: Yes

Overall Shield Material: Aluminum/Polyester Foil

Overall Foil Design: 100% Coverage

Overall Drain-wire Material: Tinned Copper

Overall Drain-wire Size: 24 AWG

Overall Drain-wire Construction: Stranded

Inner Jacket Material: UV resistant FR-PVC

Inner Jacket Diameter: 6.1 mm

Total Number of Wires: 8

IDU to ODU Cable Standards

Flammability Rating: IEC 60332, UL1581 VW-1

Standards: IEC 61156, TIA/EIA-568

IDU to ODU Cable Performance

Frequency Range: 1-100 MHz

26 IDU to ODU Cable Specifications

Page 33

RUGGEDCOM WIN5214

Installation Guide

Impedance: 100 Ω

DC Resistance: 93 Ω/km nominal

Max. DC Resistance 95 Ω/km @ 20 °C

Capacitance Unbalance: 1.6 pF/m maximum

Velocity of Propagation: 68% nominal

Propagation Delay Skew: 35 ns/100 m maximum

Dielectric Strength: 700 V/minute

Dielectric Strength to Shield: 700 V/minute

Minimum Bend Radius: 70 mm

Operating Temperature Range: -40 to 70 °C

Technical Specifications

Chapter 3

IDU to ODU Cable Specifications 27

Page 34

RUGGEDCOM WIN5214

Installation Guide

Technical Specifications

Chapter 3

IDU to ODU Cable Specifications 28

Page 35

RUGGEDCOM WIN5214

312.4

44.5

69.6

59.5

176.4

154

11

304.8

304.8

Installation Guide

Dimension Drawings

Dimension Drawings

Chapter 4

NOTE

All dimensions are in millimeters, unless otherwise stated.

Figure 21: Overall Dimensions

29

Page 36

RUGGEDCOM WIN5214

Installation Guide

Dimension Drawings

Chapter 4

30

Page 37

RUGGEDCOM WIN5214

Installation Guide

Certification

The RUGGEDCOM WIN5214 ODU CPE has been thoroughly tested to guarantee its conformance with

recognized standards and has received approval from recognized regulatory agencies.

• Section 5.1, “Standards Compliance”

• Section 5.2, “Agency Approvals”

• Section 5.3, “MIL-STD Ratings”

• Section 5.4, “IEEE 802.16e Mobile WiMAX Compliance”

• Section 5.5, “Environmental Type Tests”

Section 5.1

Standards Compliance

Chapter 5

Certification

The RUGGEDCOM WIN5214 complies with the following standards:

• FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference on his own expense.

• Industry Canada Compliance

CAN ICES-3 (A) / NMB-3 (A)

• Other

EN 50155 (Railway)

Section 5.2

Agency Approvals

The RUGGEDCOM WIN5214 has received approval from various agencies.

Agency Standards Comments

CSA CSA C22 Approved

CE EN 60950-1 Approved

TUV UL 60950-1 Approved

CE ETSI EN 301489-1/4,

ETSI EN 302 326-1/2/3

Standards Compliance 31

Approved

Page 38

Chapter 5

Certification

RUGGEDCOM WIN5214

Installation Guide

Agency Standards Comments

ETSI ETS 300 019 Approved

UL/CSA Class I Div II, UL 1604,

CSA 22.2 No213-M1987

ATEX Zone 2 EN60079-0, EN60079-15 Approved

Section 5.3

Approved

MIL-STD Ratings

Test Description Test Levels

IEC 60068-2-11

MIL-STD-810E

Section 5.4

SALT FOG 5% NaCI 35° 48h

IEEE 802.16e Mobile WiMAX Compliance

The IEEE802.16-2005 specifications describe a Point-to-Multipoint (PMP) broadband wireless access standard

for systems. This standard includes descriptions for both the Media Access Control (MAC) and the physical

(PHY) layers.

The device is compliant to the IEEE802.16-2005 WiMAX forum Wave 2 profile.

NOTE

The RUGGEDCOM WIN1010 WIN product family is designed to comply with a specific revision of the

IEEE 802.16e standards, which are subject to amendment.

Section 5.5

Environmental Type Tests

Test Description Test Levels

IEC-60068-2-1 LOW TEMP -40 °C

IEC-60068-2-2 HIGH TEMP 60 °C

IEC-60068-2-14 TEMP CHANGE -10 to 45 °C

IEC 60068-2-30 HUMIDITY (Cycling) 30°C 90-100%

IEC 60068-2-18 WATER: Rain (intensity) 0.01m3/min, 90kPa, 30min

Duration: 16h

Duration: 16h

0.5 °C/min

Duration: 2 cycles

Duration: 2 cycles

32 MIL-STD Ratings

Page 39

RUGGEDCOM WIN5214

Installation Guide

Chapter 5

Certification

Test Description Test Levels

IEC 529 (IP65/IP67)

IEC-60068-2-64

Class 4M5

RANDOM

VIBRATION (4M5)

ASD - 0.04 m²/s3³

12 -12 dB /oct

Freq. Range 5-10, 10-50, 50-100 Hz

3 Axes

Duration: 30min each axes

IEC-60068-2-29

Class 4M5

SHOCK (4M5) Spectrum: Half sine

Duration: 11 ms

Accelerator: 50 m/s²

100 shocks in each direction

IEC-60068-2-1 LOW TEMP -40 °C

Duration: 72h

IEC-60068-2-2 HIGH TEMP 70 °C

Duration: 72h

IEC-60068-2-14 TEMP CHANGE -40 -30 °C

1 °C/min

Duration: 5 cycles

IEC 60068-2-30 HUMIDITY (Cycling) 40°C, 90-100%

Duration: 2 cycles

IEC 60068-2-18 WATER: Rain 0.01 m³/min, 90 kPa

Duration: 15 min.

IEC-60068-2-64 RANDOM

VIBRATION

ASD - 1 m²/s³

-3 dB /oct

Freq. Range: 5-20 Hz

20-200

3 Axes

Duration: 30min each axes

IEC-60068-2-29 SHOCK Spectrum: Half sine

Duration: 6 ms

Accelerator: 180 m/s²

100 shocks in each direction

IEC-60068-2-32

Nebs: GR63

FREE FALL Height: 1m

One fall on 3 faces, 3 edges and 4 corners

IEC-60068-2-1 LOW TEMP -25 °C

Duration: 72h

IEC-60068-2-2 HIGH TEMP 55 °C

Duration: 72h

IEC 60068-2-30 HUMIDITY (Cycling) 30°C, 90-100%

Duration: 2 cycles

IEC-60068-2-6 SINE

VIBRATION

Velocity: 5 mm/s

Displacement: 1.5 mm

Environmental Type Tests 33

Page 40

Chapter 5

Certification

RUGGEDCOM WIN5214

Installation Guide

Test Description Test Levels

Acceleration: 2 m/s²

Frequency Range: 5-62, 62-200 Hz

3 Axes

Duration: 3x5 sweep

34 Environmental Type Tests

Loading...

Loading...